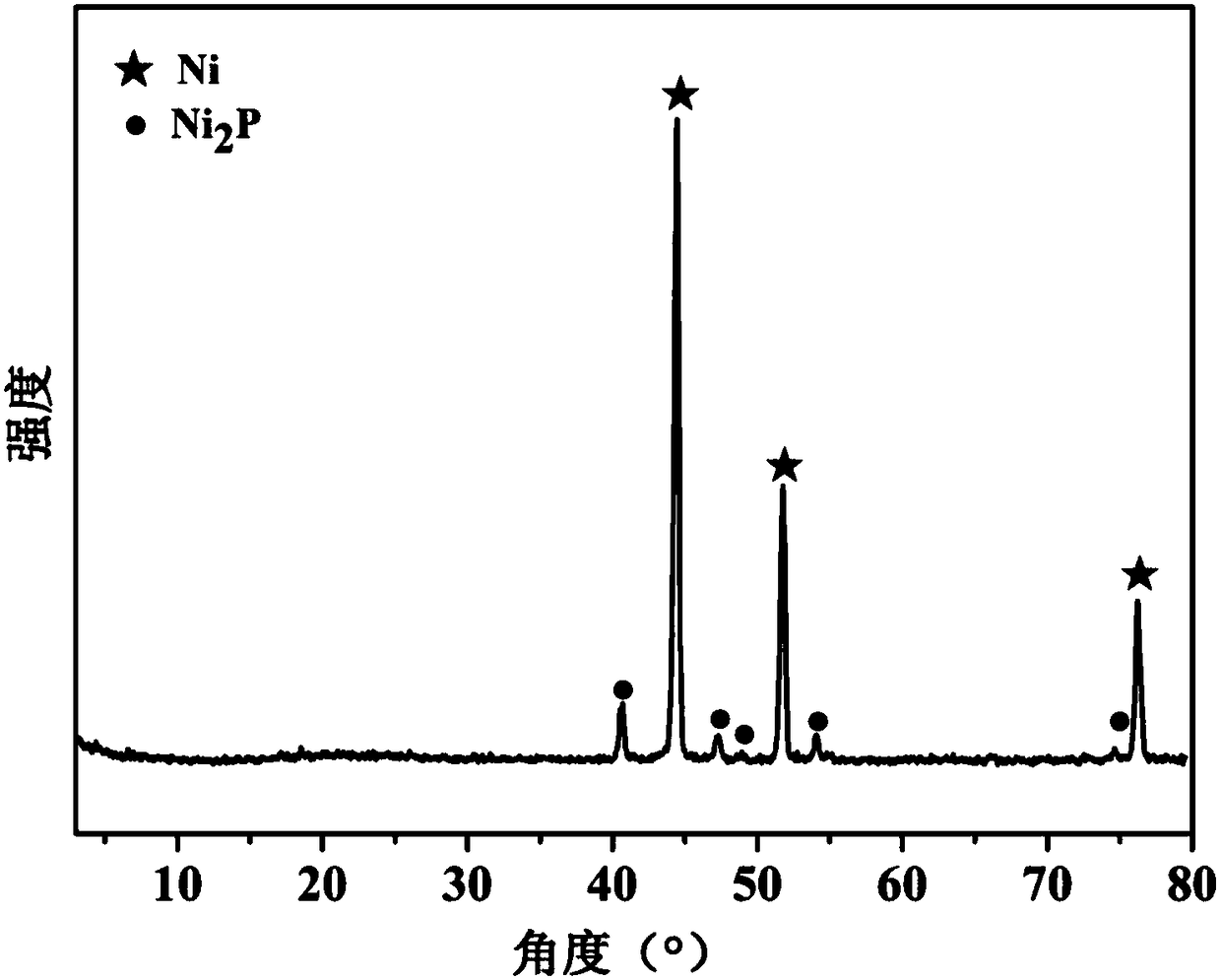

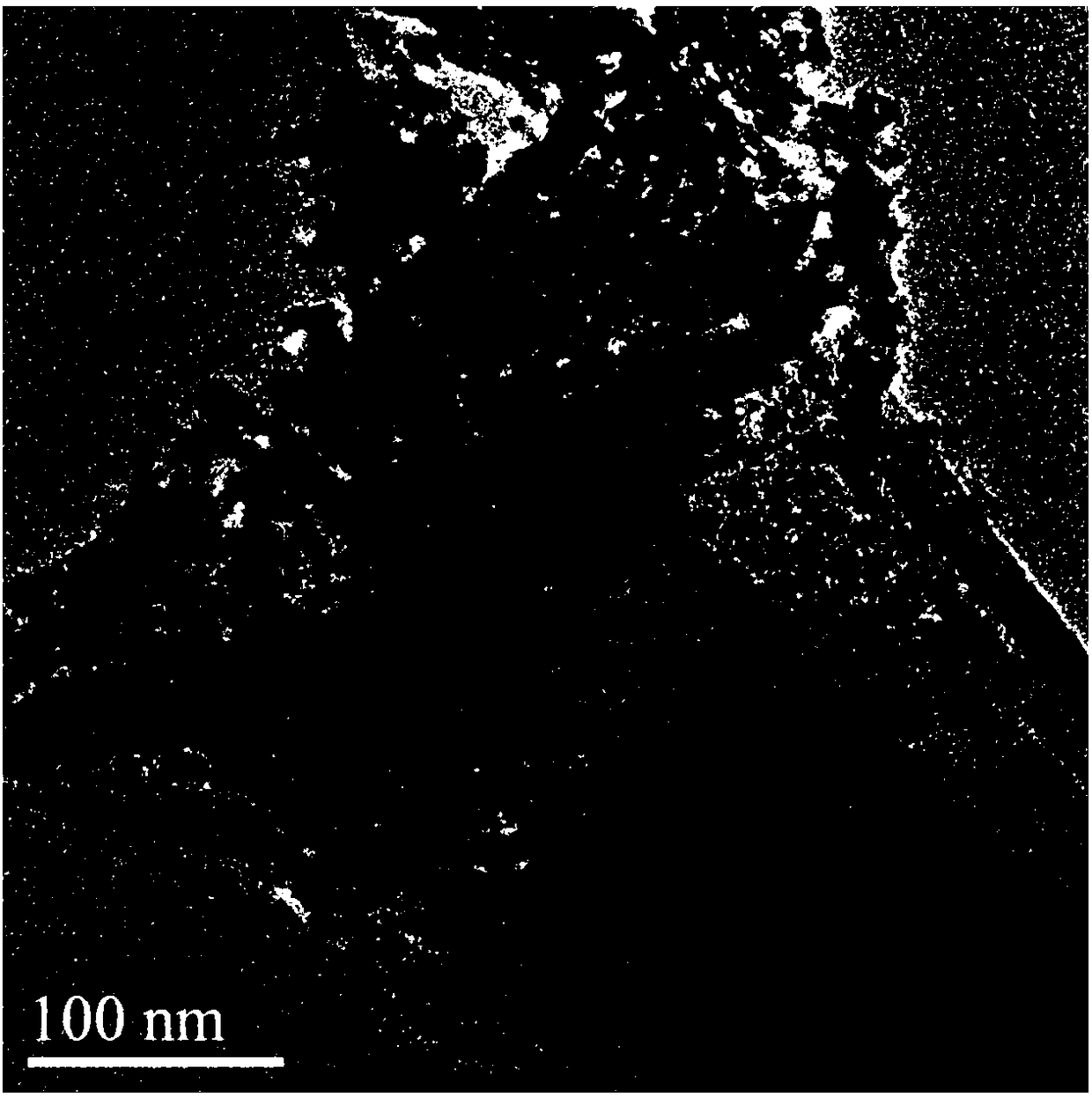

Three-dimensional multi-level structure type high-dispersion nickel-based electro-catalytic material and preparation method thereof

An electrocatalytic material and highly dispersed technology, which can be used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of preventing particle agglomeration, reducing overpotential, and excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Pretreatment of foamed nickel: Cut commercially available nickel foam into 1cm×2cm size, immerse in 20mL of acetone, ultrasonically treat for 15min, remove surface oil, wash 3 times with water, 5min each time, wash off acetone; use 2mol / L Soak in HCl for 5 minutes to remove the oxide film on the surface of nickel foam, and then wash it with water for 3 times, each time for 2 minutes, to remove the Cl - , dried under vacuum conditions for later use.

[0031] A. Use 80mL deionized water to prepare an aluminum nitrate solution with a concentration of 0.03mol / L, transfer it to a 100mL polytetrafluoroethylene liner, immerse the pretreated foam nickel sheet vertically into the above solution, and ultrasonically treat it for 30min; then Add 0.05mol urea and 0.02mol ammonium fluoride in sequence, ultrasonically treat for 2 minutes, seal the polytetrafluoroethylene liner and put it into the autoclave, react at 180°C for 12 hours, after cooling to room temperature, wash with deio...

Embodiment 2

[0035] Commercially available nickel foam is pretreated according to Example 1.

[0036] A. Use 80mL deionized water to prepare an aluminum nitrate solution with a concentration of 0.03mol / L, transfer it to a 100mL polytetrafluoroethylene liner, and handle well Immerse the foamed nickel sheet vertically into the above solution, ultrasonic treatment for 30min; then add 0.08mol urea, 0.02mol ammonium fluoride in turn, ultrasonic treatment for 2min, seal the polytetrafluoroethylene liner and put it into the autoclave, and react at 150℃ for 12h , after cooling to room temperature, washed with deionized water and ethanol three times, and dried to obtain in-situ grown nickel-based hydrotalcite NiAl-LDH / NF.

[0037] B. Place the obtained NiAl-LDH / NF in a three-necked flask of 150mL deionized water; prepare H with a concentration of 0.5mol / L 3 BO 3 solution, and added dropwise into a three-necked flask until the pH of the solution reached 4.5, and then reacted at 90° C. for 12 hour...

Embodiment 3

[0040] Commercially available nickel foam is pretreated according to Example 1.

[0041] A. Use 80mL deionized water to prepare an aluminum nitrate solution with a concentration of 0.03mol / L, transfer it to a 100mL polytetrafluoroethylene liner, immerse the pretreated foam nickel sheet vertically into the above solution, and ultrasonically treat it for 30min; then Add 0.08mol urea and 0.025mol ammonium fluoride in sequence, ultrasonically treat for 2min, seal the polytetrafluoroethylene liner and put it into the autoclave, react at 120°C for 12h, after cooling to room temperature, wash with deionized water and ethanol respectively 3 times, drying to obtain in-situ growth of nickel-based hydrotalcite NiAl-LDH / NF.

[0042] B. Place the obtained NiAl-LDH / NF in a three-necked flask of 150mL deionized water; prepare NaH with a concentration of 0.8mol / L 2 PO 4 solution, and added dropwise into a three-necked flask until the pH of the solution reached 3.5, and then reacted at 90° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com