A kind of high heat resistant zinc selenide material and its preparation method

A technology of zinc selenide and high heat resistance, applied in the field of nanomaterials, can solve problems such as limiting the application of zinc selenide materials, and achieve the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

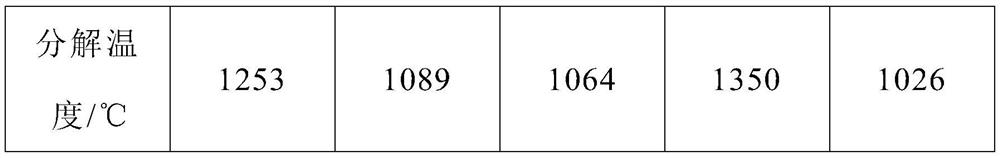

Embodiment 1

[0028] A high heat-resistant zinc selenide material, in parts by weight, mainly comprising: 30 parts of zinc nitrate, 25 parts of selenium powder, 20 parts of sodium borohydride, 5 parts of hydrazine hydrate, 5 parts of calcium hydroxide, 10 parts of modified Chitosan and 4 parts ethyl orthosilicate.

[0029] A preparation method of a high heat-resistant zinc selenide material, the preparation method of the high heat-resistant zinc selenide material mainly comprises the following preparation steps:

[0030] (1) Mix the chitosan solution with the silk fibroin solution in a mass ratio of 4:6, freeze for 12 hours at a temperature of -80°C, freeze-dry it for 48 hours at a temperature of -50°C, and pulverize to obtain modified chitosan;

[0031] (2) Mix selenium powder and sodium borohydride in a beaker at a mass ratio of 5:4, add 8 times the mass of selenium powder to the beaker, and stir the reaction at a temperature of 60 ° C and a rotating speed of 300 r / min. 6h, filtered to ...

Embodiment 2

[0037] A high heat-resistant zinc selenide material, in parts by weight, mainly comprising: 30 parts of zinc nitrate, 25 parts of selenium powder, 20 parts of sodium borohydride, 5 parts of hydrazine hydrate, 5 parts of calcium hydroxide, and 10 parts of chitosan sugar and 4 parts ethyl orthosilicate.

[0038] A preparation method of a high heat-resistant zinc selenide material, the preparation method of the high heat-resistant zinc selenide material mainly comprises the following preparation steps:

[0039] (1) Mix selenium powder and sodium borohydride in a beaker at a mass ratio of 5:4, add 8 times the mass of selenium powder to the beaker, and stir the reaction at a temperature of 60 ° C and a rotating speed of 300 r / min. 6h, filtered to obtain a filter cake, and the filter cake was dried at a temperature of 85 ° C for 3 hours to obtain sodium selenide;

[0040](2) chitosan and zinc nitrate are mixed in the flask by mass ratio 1:3, and to the water of 50 times the mass of...

Embodiment 3

[0043] A high heat-resistant zinc selenide material, in parts by weight, mainly comprising: 30 parts of zinc nitrate, 25 parts of selenium powder, 20 parts of sodium borohydride, 5 parts of hydrazine hydrate, 10 parts of modified chitosan and 4 parts of Ethyl orthosilicate.

[0044] A preparation method of a high heat-resistant zinc selenide material, the preparation method of the high heat-resistant zinc selenide material mainly comprises the following preparation steps:

[0045] (1) Mix the chitosan solution with the silk fibroin solution in a mass ratio of 4:6, freeze for 12 hours at a temperature of -80°C, freeze-dry it for 48 hours at a temperature of -50°C, and pulverize to obtain modified chitosan;

[0046] (2) Mix selenium powder and sodium borohydride in a beaker at a mass ratio of 5:4, add 8 times the mass of selenium powder to the beaker, and stir the reaction at a temperature of 60 ° C and a rotating speed of 300 r / min. 6h, filtered to obtain a filter cake, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com