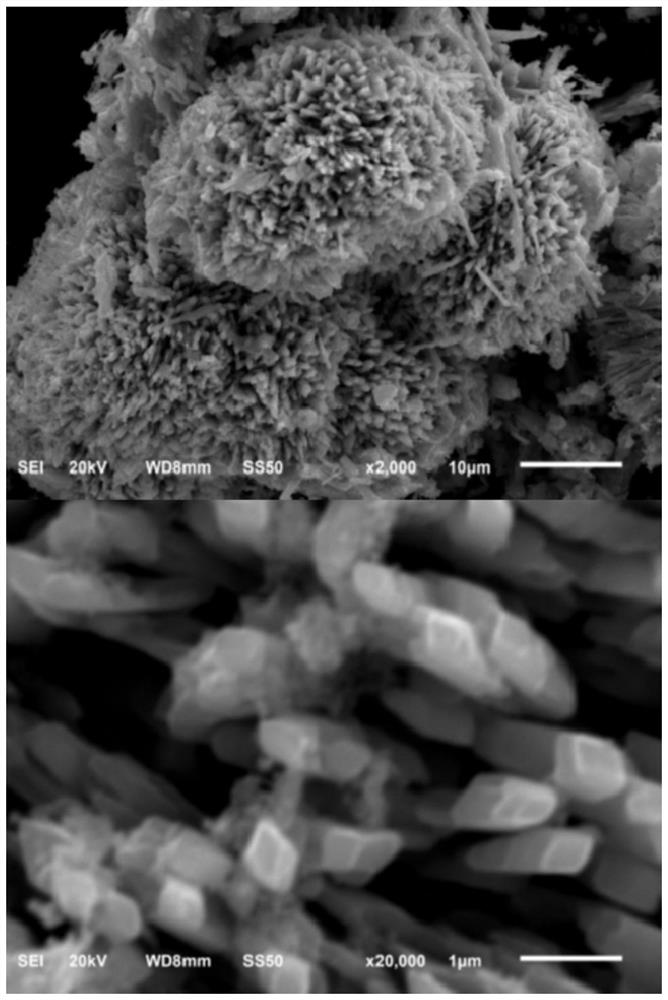

A kind of sea urchin-shaped copper-based catalyst and its preparation method and application

A copper-based catalyst and sea urchin-shaped technology, which is applied in the field of sea urchin-shaped copper-based catalysts and their preparation, can solve problems affecting the reaction of hydrogen and oxygen, fuel cell efficiency reduction, fuel cell electrode poisoning, etc., and achieve a simple and easy preparation method, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 19.9gCu(NO 3 ) 2 and 5.9g of 50% Mn(NO 3 ) 2 The aqueous solution was mixed, and then 7.5ml of distilled water was added to the mixed solution and stirred until Cu(NO 3 ) 2 Dissolve completely to obtain copper-manganese mixed solution.

[0029] (2) Add 112.5gH to the copper-manganese mixture 2 0, 5.6gCTAB, 135.1g absolute ethanol, after stirring at room temperature for 15 minutes (stirring speed is 80-100r / min).

[0030] (3) Slowly add 29.7 g of ammonia water dropwise to the reaction mixture obtained in step (2). After the ammonia water is added dropwise, the mixture is stirred (250-350 r / min) at room temperature for 2 hours.

[0031] (4) The reaction mixture obtained in step (3) was transferred to a hydrothermal synthesis kettle for hydrothermal treatment, and the hydrothermal treatment was performed at 120° C. for 24 hours.

[0032] (5) After the hydrothermal treatment is completed, the solid is obtained by suction filtration, and the solid is washed ...

Embodiment 2-5 and comparative example 1-4

[0037] The difference between embodiment 2-5, comparative example 1-4 and embodiment 1 is that the amount of copper nitrate and manganese nitrate added in step (1) is different, resulting in different contents of Cu and Mn in the catalyst obtained finally, See Table 1 below for details.

[0038] Table 1

[0039]

[0040] in conclusion:

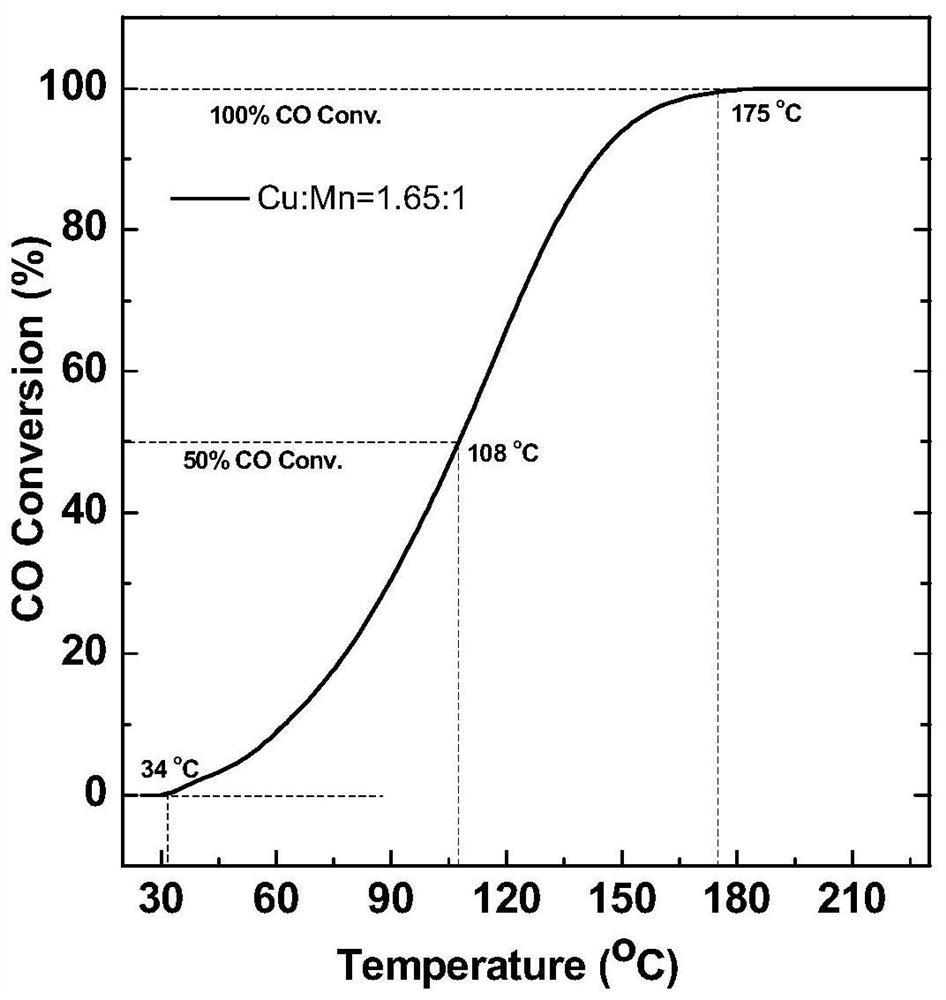

[0041] (1) See Comparative Examples 1-4, when the molar ratio of copper nitrate and manganese nitrate is not in the range of 0.5-1.65:1, the final copper-based catalyst is not sea urchin-like, and the CO oxidation temperature is 43-51 ℃, 50% CO removal temperature is 130-142 ℃, 100% CO removal temperature is 190-219 ℃, both of which are significantly higher than the relevant temperatures of Examples 1-5. In summary, we can conclude that the copper-based catalyst has The urchin-like structure helps to catalyze the conversion of O 2 CO, which is the oxidizing agent, is completely combusted.

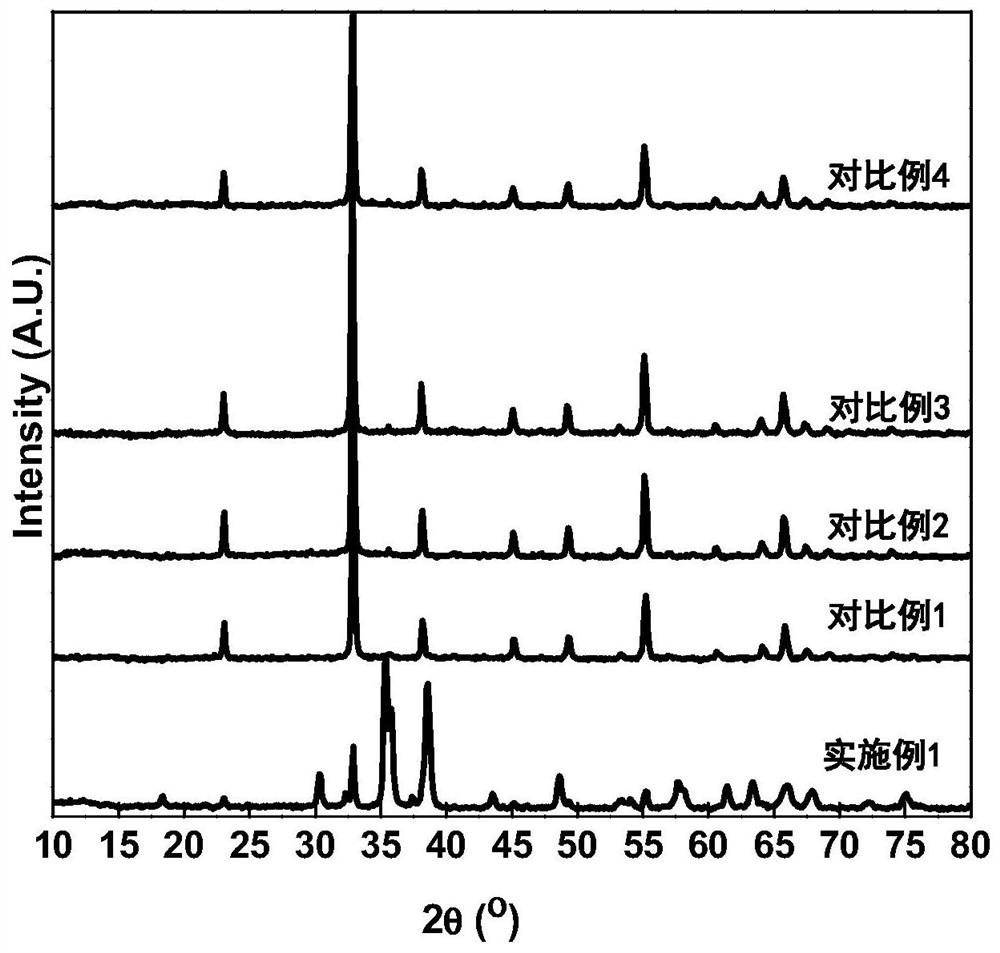

[0042] (2) image 3 It is the X-ray diffracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com