Method for preparing polyacrylonitrile-based porous hollow carbon fibers by coaxial electrospinning

A coaxial electrospinning and hollow carbon fiber technology, which is applied in fiber processing, rayon manufacturing, hollow filament manufacturing, etc., can solve the problem of increasing the specific surface area of carbon fiber, so as to improve the adsorption capacity, improve the use efficiency, and increase the specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

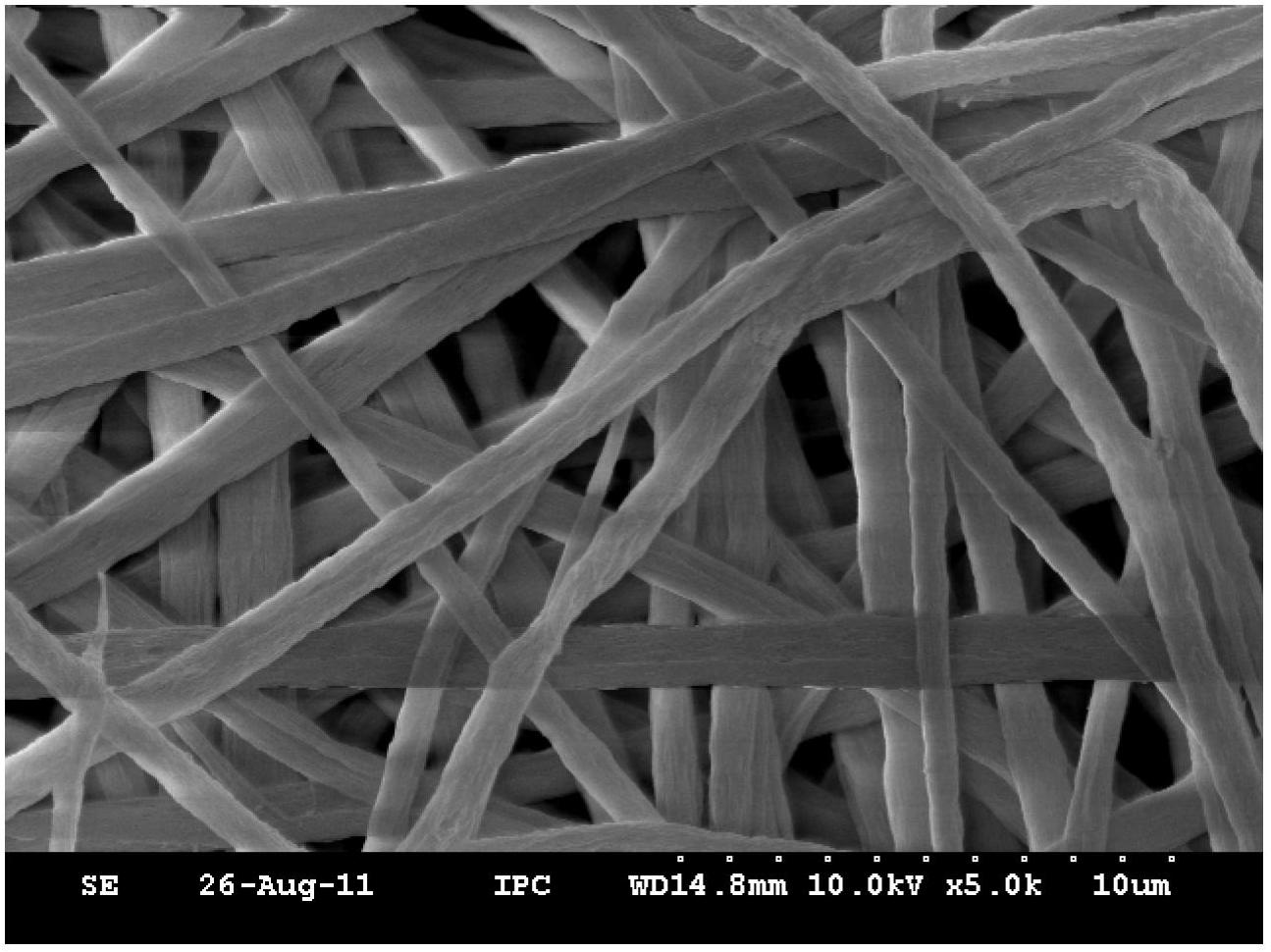

[0046] A method for coaxial electrospinning to prepare PAN-based porous hollow carbon fibers, comprising the following steps:

[0047] (1) At 25°C, 3.6g PAN and 0.4g polyvinylpyrrolidone (PVP) were stirred and dissolved in dimethylformamide solvent at a speed of 15rpm, and stirred until all the solids were dissolved, and the solution was a colorless transparent liquid. The total mass fraction is 20wt% PAN / PVP solution (PAN:PVP=9:1 wt / wt), which is used as the outer layer solution. Use pure simethicone as the inner layer solution.

[0048](2) At 25°C, input the prepared PAN / PVP solution and simethicone oil into the outer layer and inner layer of the coaxial needle at a flow rate of 1.85ml / h and 1ml / h respectively, and connect the coaxial needle To an 18 kV high-voltage electrostatic generator, use tin foil to receive the fiber, and the receiving distance is 15 cm, to obtain the PAN-based skin-core composite fiber. The average diameter of the fibers was 1702 nm.

[0049] (3) ...

Embodiment 2

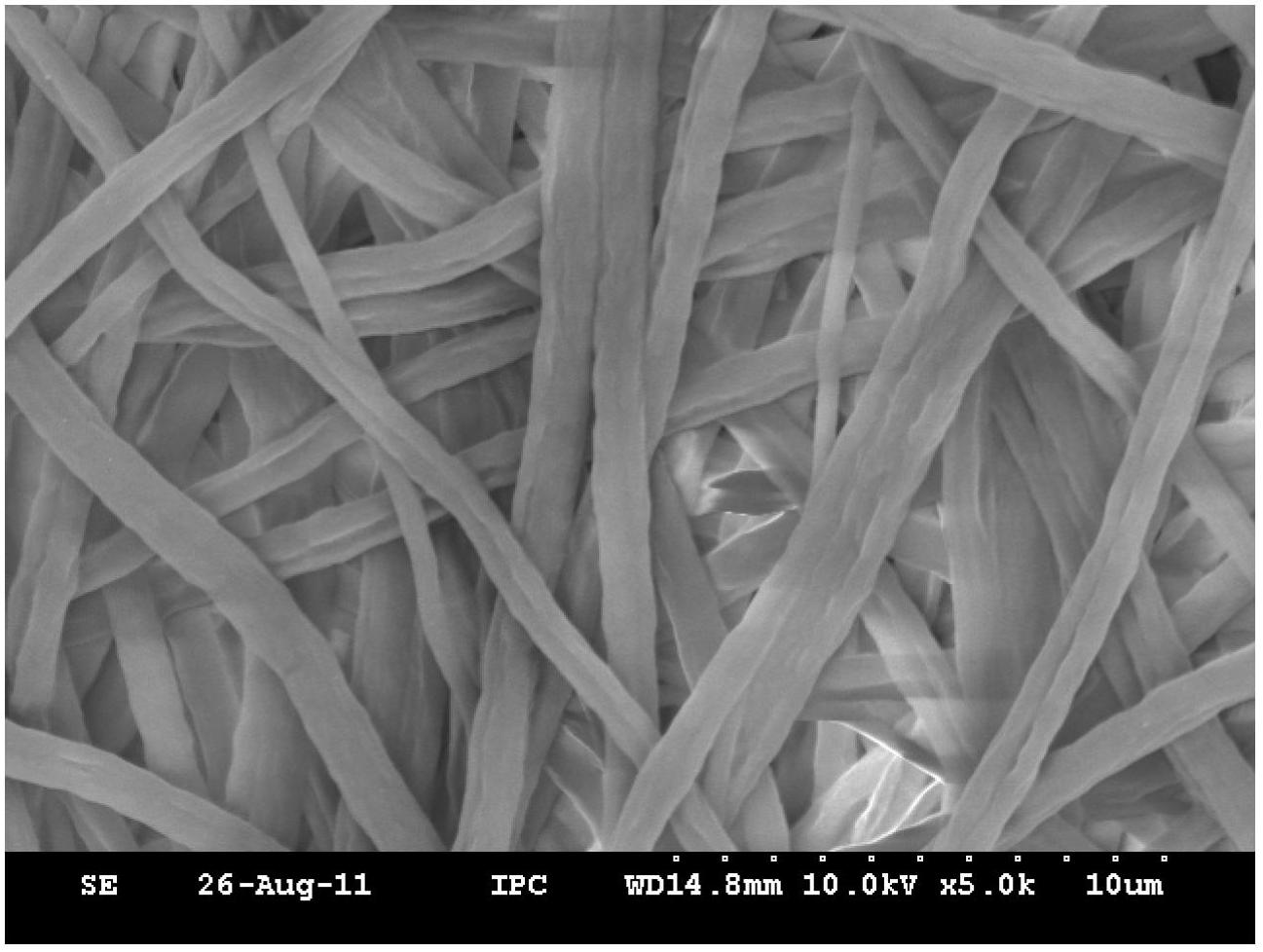

[0053] A method for coaxial electrospinning to prepare PAN-based porous hollow carbon fibers, comprising the following steps:

[0054] (1) At 25°C, 2.8g PAN and 1.2g polyvinylpyrrolidone (PVP) were stirred and dissolved in dimethylformamide solvent at a speed of 15rpm, and stirred until all the solids were dissolved, and the solution was a colorless transparent liquid. A PAN / PVP solution with a total mass fraction of 20wt% (PAN:PVP=7:3wt / wt), which is used as the outer layer solution. Use pure simethicone as the inner layer solution.

[0055] (2) At 25°C, input the configured PAN / PVP solution and simethicone oil into the outer layer and inner layer of the coaxial needle at a flow rate of 1.85ml / h and 1ml / h respectively, and connect the coaxial needle To a 17 kV high-voltage electrostatic generator, use tin foil to receive the fiber, and the receiving distance is 15 cm, to obtain the PAN-based skin-core composite fiber. The average diameter of the fibers was 360 nm.

[0056]...

Embodiment 3

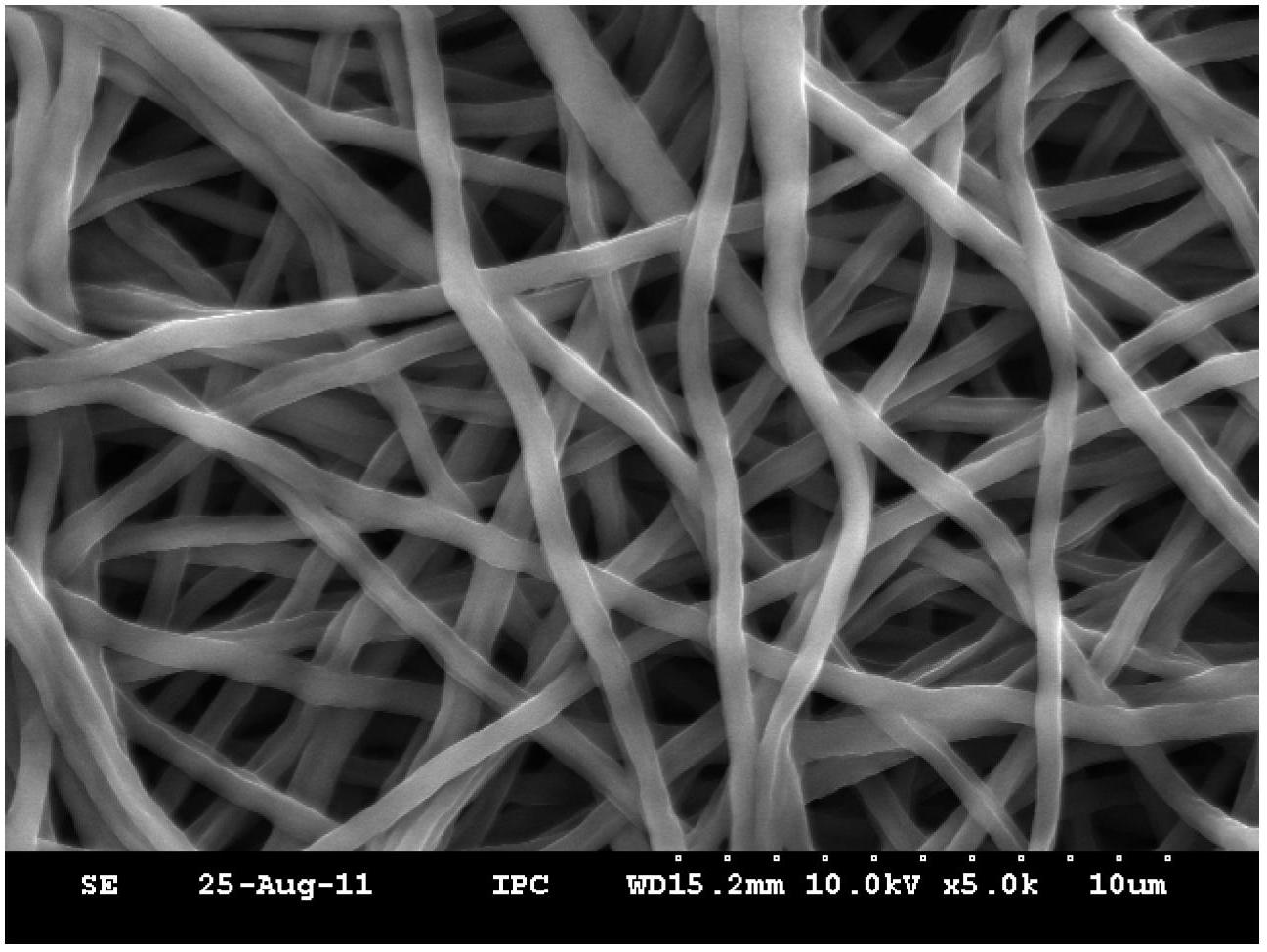

[0060] A method for coaxial electrospinning to prepare PAN-based porous hollow carbon fibers, comprising the following steps:

[0061] (1) At 25°C, 2.0g PAN and 2.0g polyvinylpyrrolidone (PVP) were stirred and dissolved in dimethylformamide solvent at a speed of 15rpm, and stirred until all the solids were dissolved, and the solution was a colorless transparent liquid. A PAN / PVP solution with a total mass fraction of 20wt% (PAN:PVP=5:5wt / wt), which is used as the outer layer solution. Use pure simethicone as the inner layer solution.

[0062] (2) At 25°C, input the configured PAN / PVP solution and simethicone oil into the outer layer and inner layer of the coaxial needle at a flow rate of 1.85ml / h and 1ml / h respectively, and connect the coaxial needle To a high-voltage electrostatic generator of 16.5 kV, use tin foil to receive the fiber, and the receiving distance is 15 cm to obtain the PAN-based skin-core composite fiber. The average diameter of the fibers was 210 nm.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com