Patents

Literature

84 results about "Selenium hydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen selenide is an inorganic compound with the formula H2Se. This hydrogen chalcogenide is the simplest and most commonly encountered hydride of selenium. H2Se is a colorless, flammable gas under standard conditions. It is the most toxic selenium compound with an exposure limit of 0.05 ppm over an 8-hour period.

Thin-film solar cells

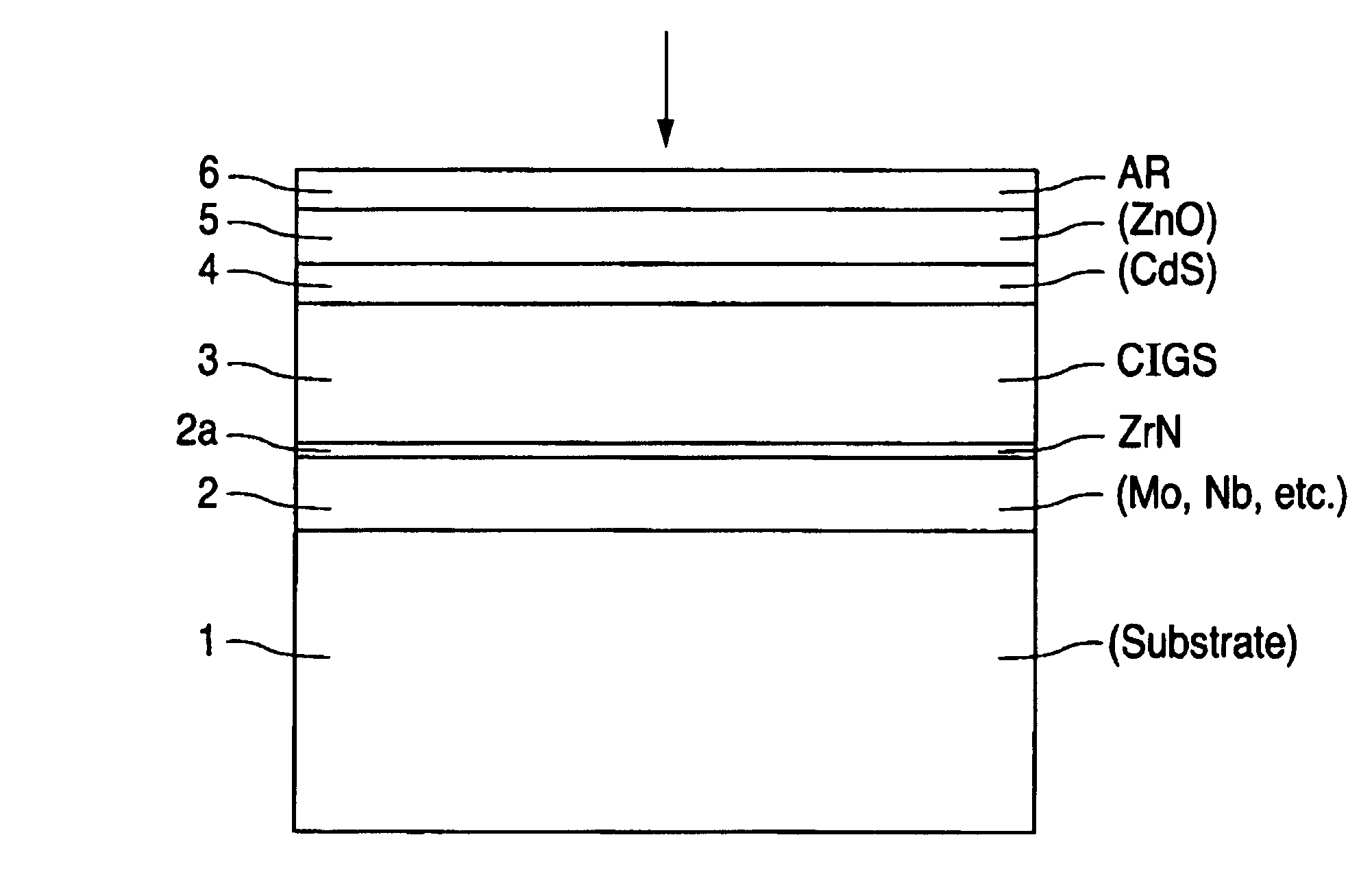

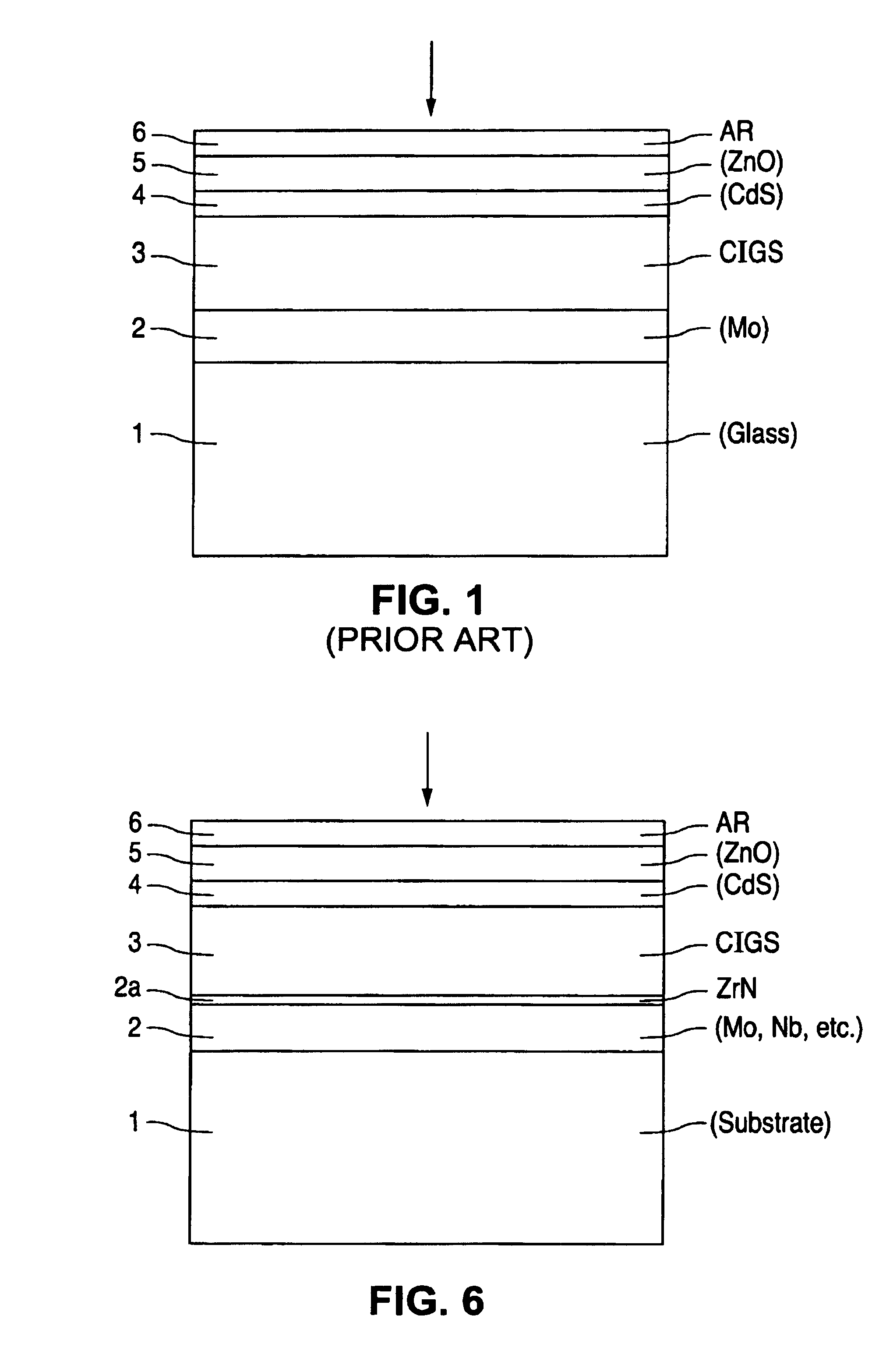

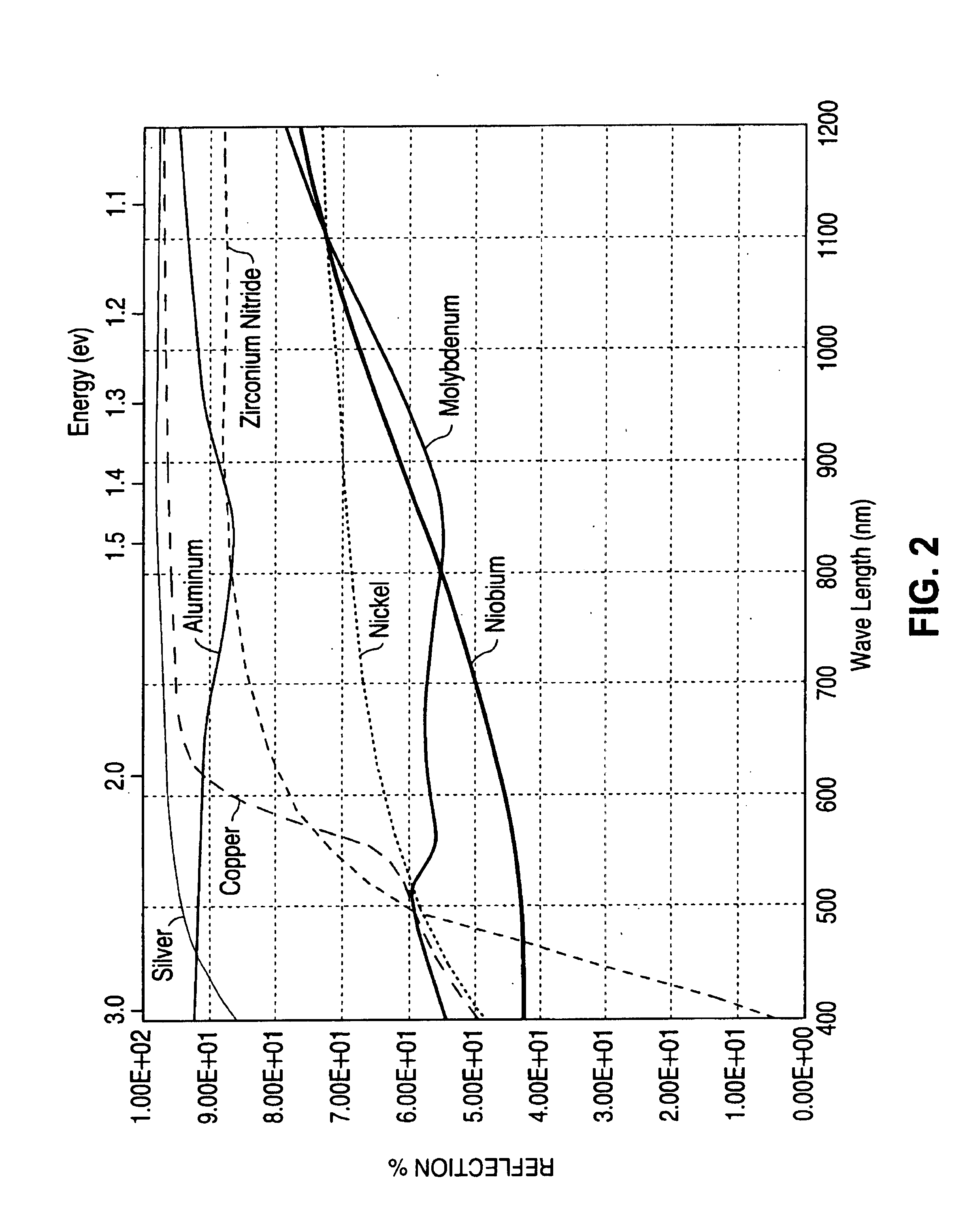

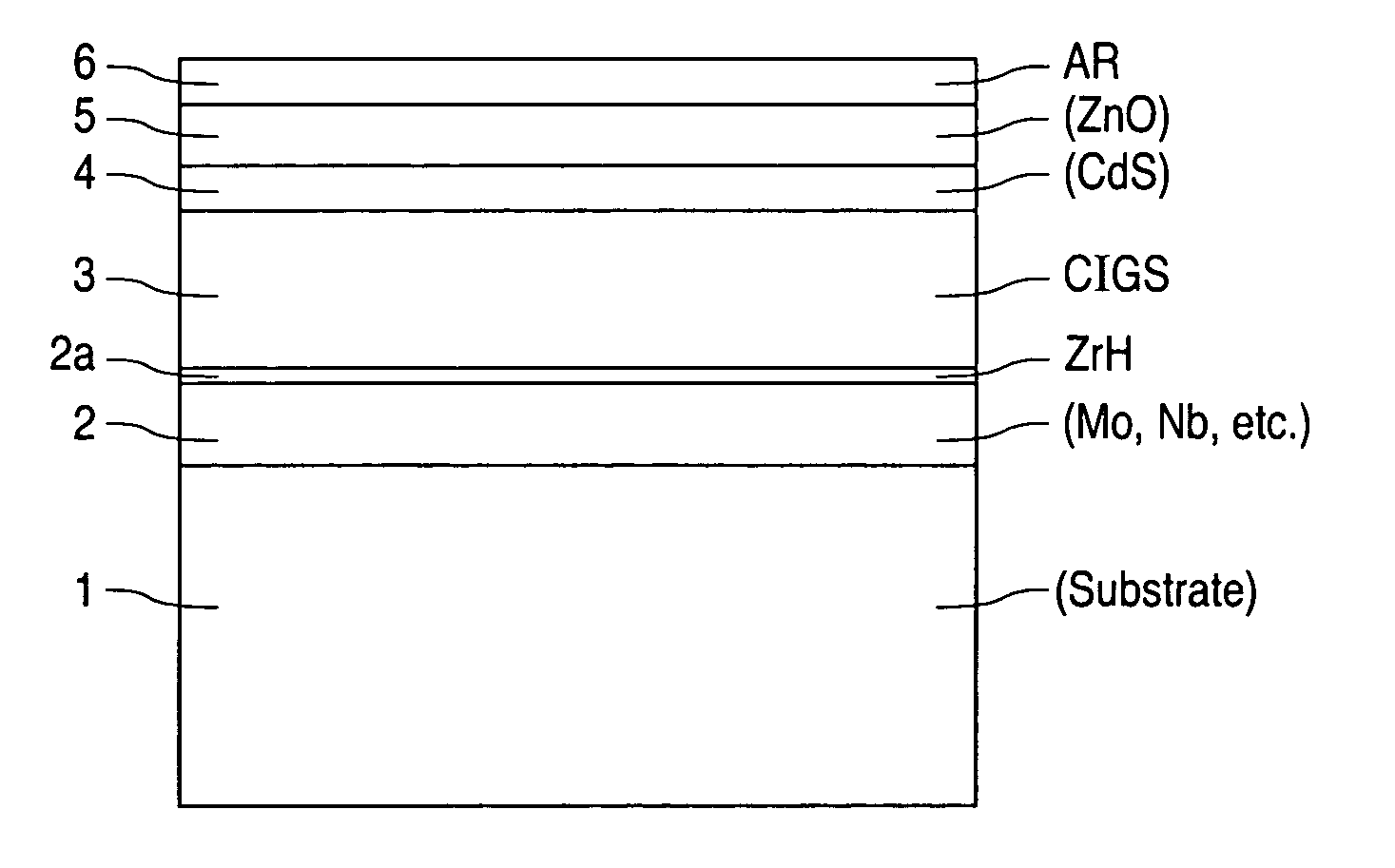

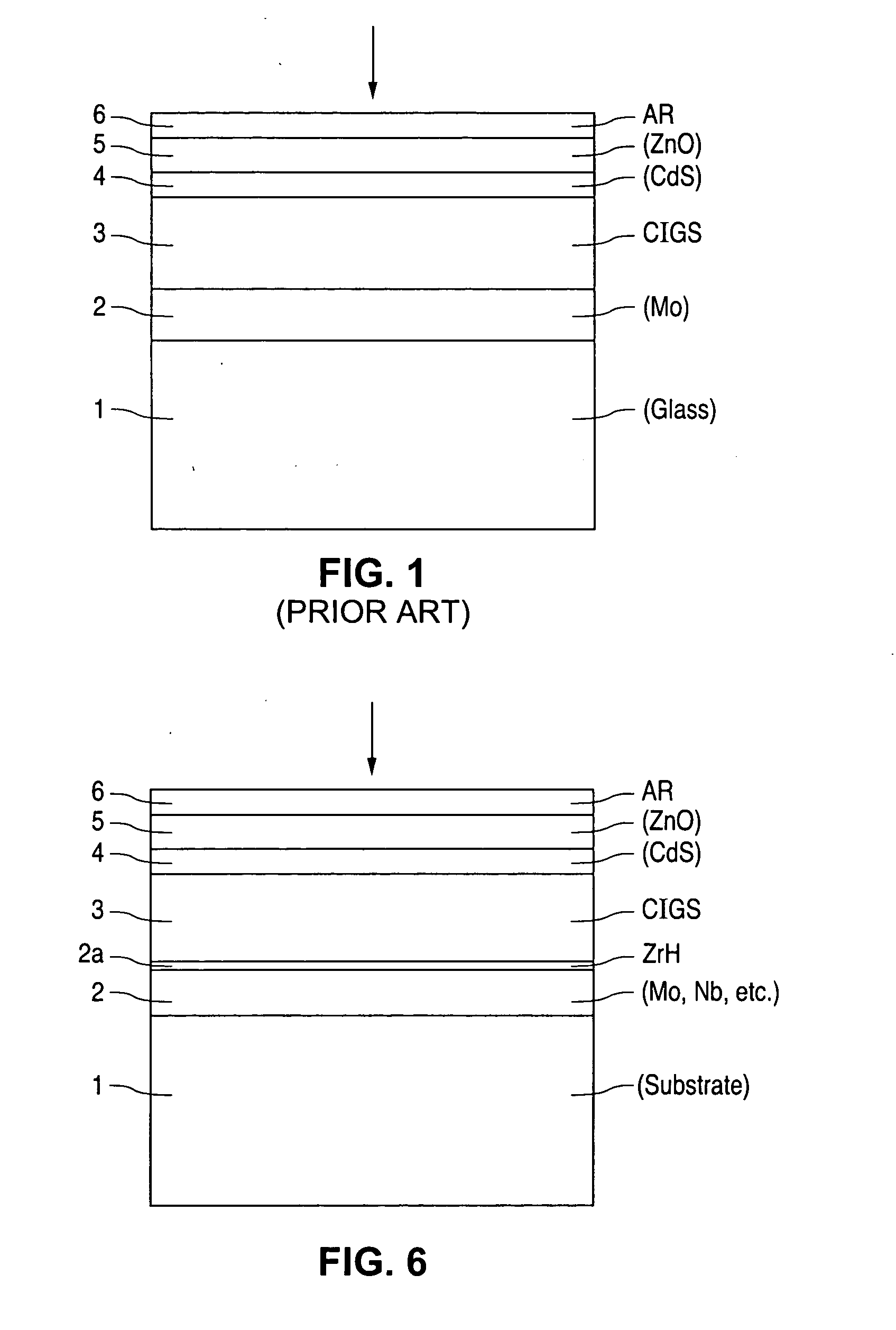

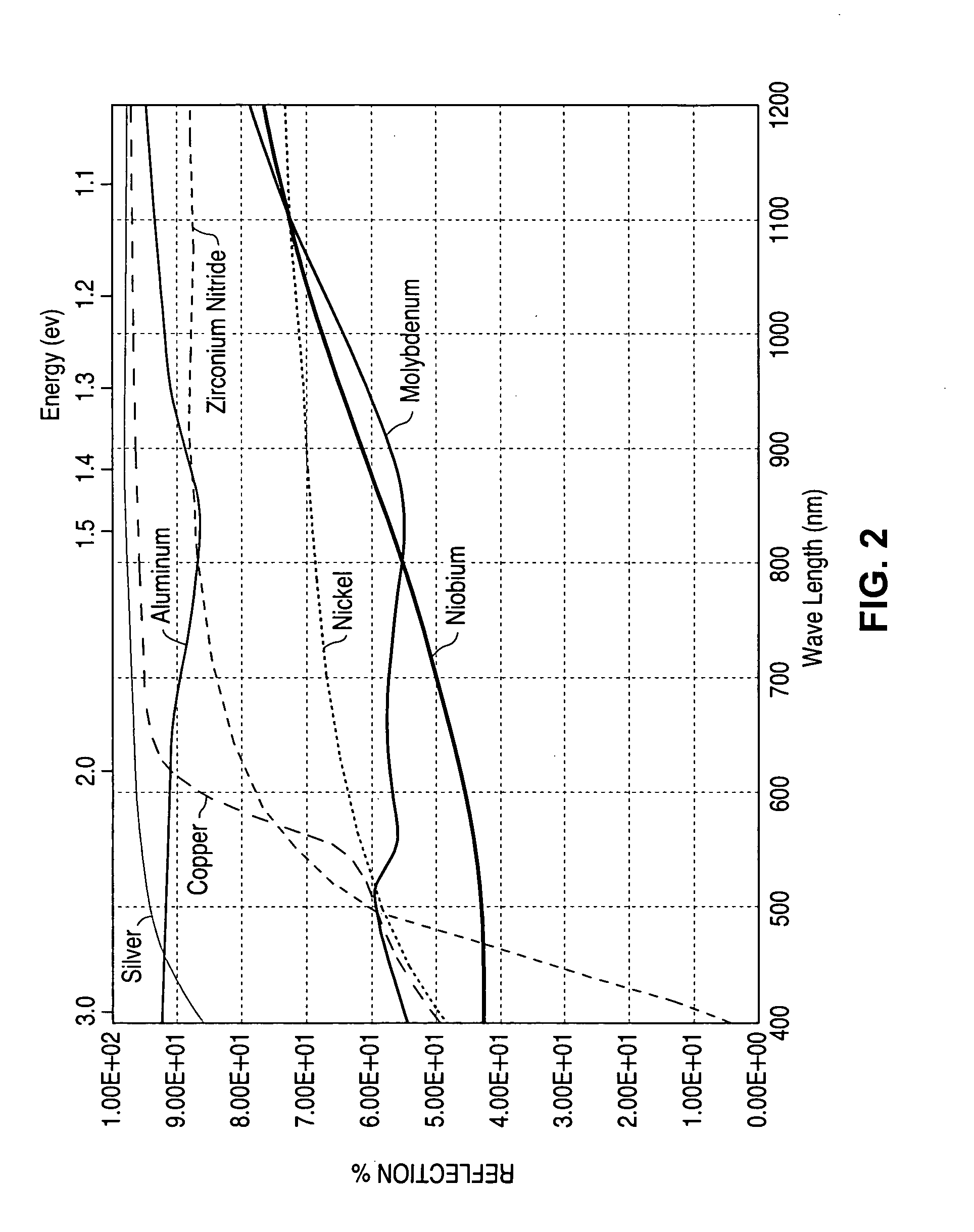

InactiveUS6974976B2Increase reflectionInhibition formationFinal product manufactureVacuum evaporation coatingIndiumElectrical battery

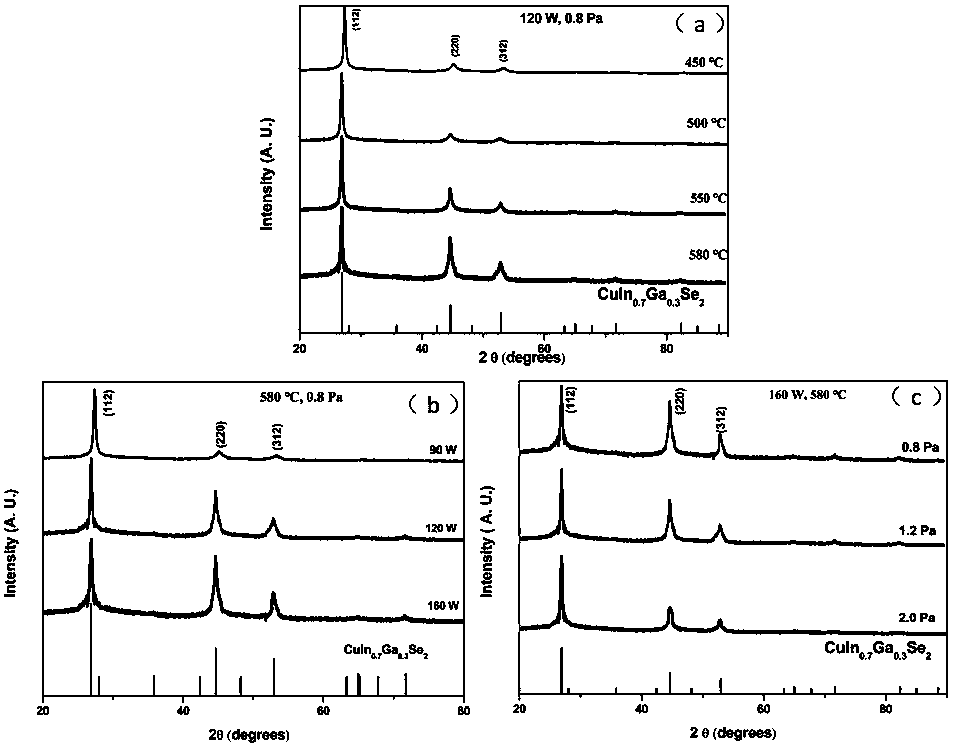

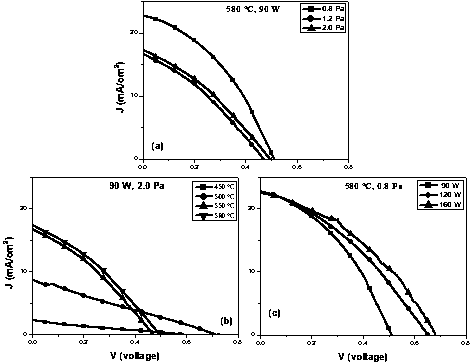

A method of manufacturing improved thin-film solar cells entirely by sputtering includes a high efficiency back contact / reflecting multi-layer containing at least one barrier layer consisting of a transition metal nitride. A copper indium gallium diselenide (Cu(InXGa1−X)Se2) absorber layer (X ranging from 1 to approximately 0.7) is co-sputtered from specially prepared electrically conductive targets using dual cylindrical rotary magnetron technology. The band gap of the absorber layer can be graded by varying the gallium content, and by replacing the gallium partially or totally with aluminum. Alternately the absorber layer is reactively sputtered from metal alloy targets in the presence of hydrogen selenide gas. RF sputtering is used to deposit a non-cadmium containing window layer of ZnS. The top transparent electrode is reactively sputtered aluminum doped ZnO. A unique modular vacuum roll-to-roll sputtering machine is described. The machine is adapted to incorporate dual cylindrical rotary magnetron technology to manufacture the improved solar cell material in a single pass.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

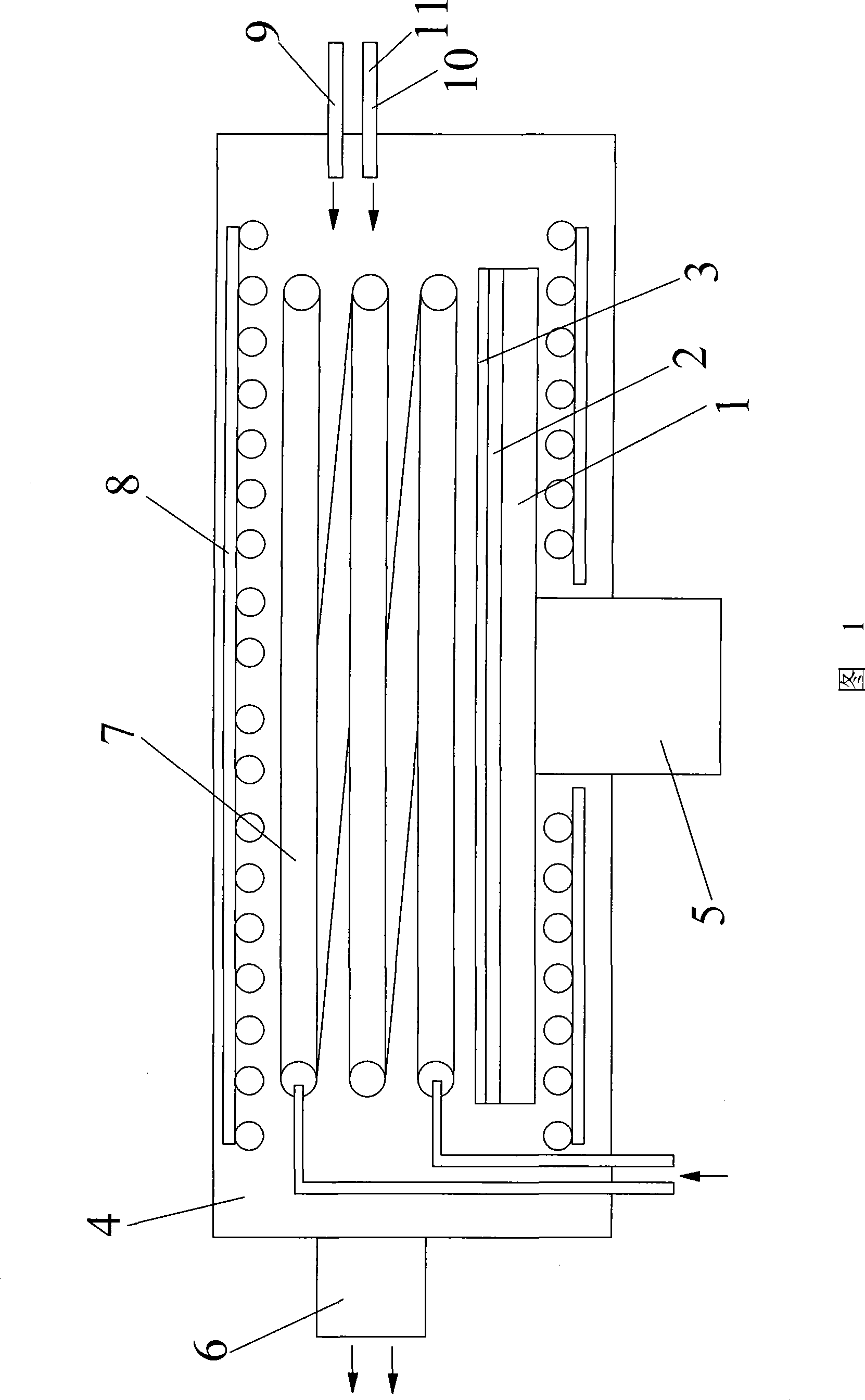

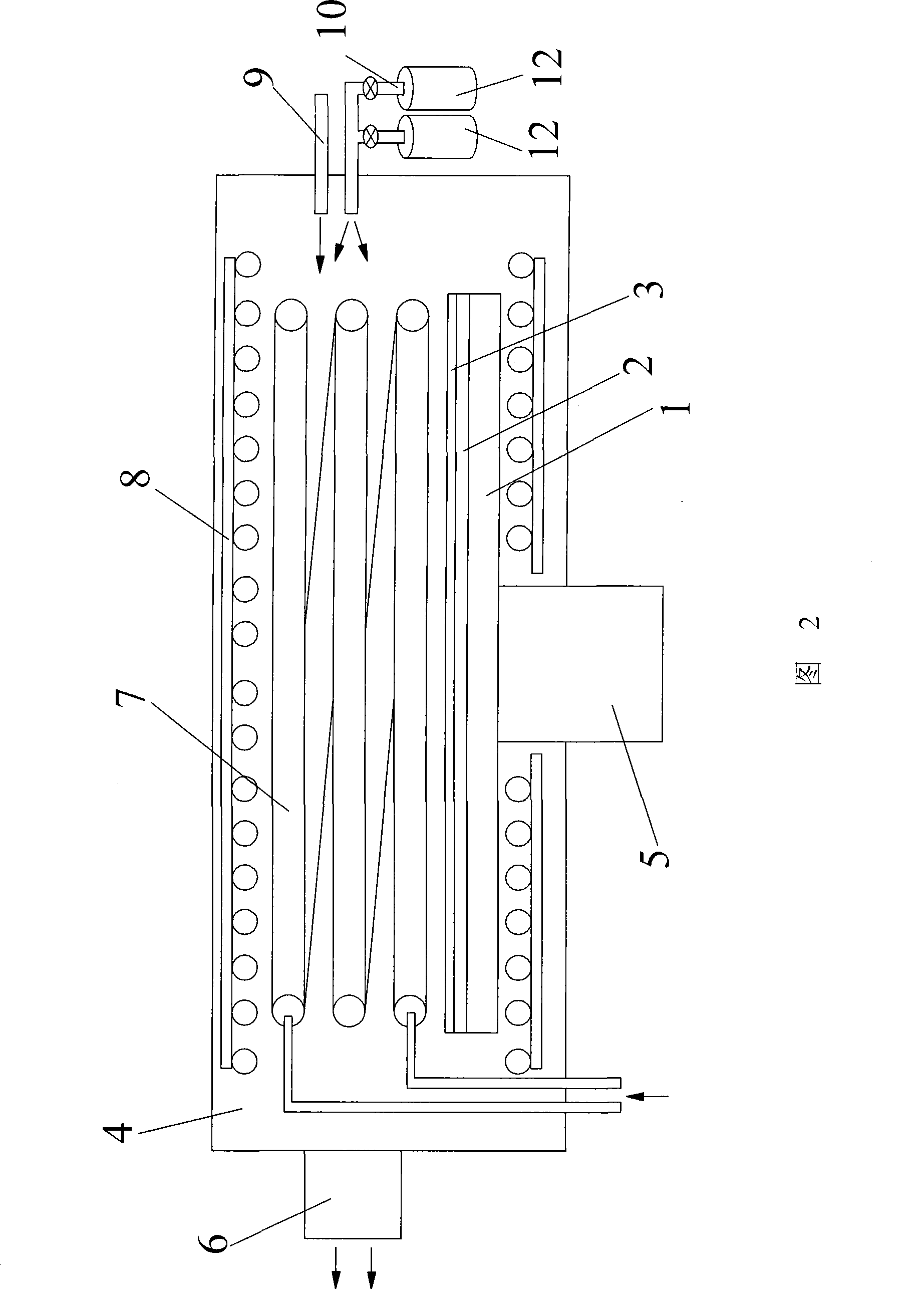

Manufacturing apparatus and method for large-scale production of thin-film solar cells

ActiveUS20050109392A1Cheap productionLow costPV power plantsFinal product manufactureIndiumElectrical battery

A method of manufacturing improved thin-film solar cells entirely by sputtering includes a high efficiency back contact / reflecting multi-layer containing at least one barrier layer consisting of a transition metal nitride. A copper indium gallium diselenide (Cu(InXGa1-x)Se2) absorber layer (X ranging from 1 to approximately 0.7) is co-sputtered from specially prepared electrically conductive targets using dual cylindrical rotary magnetron technology. The band gap of the absorber layer can be graded by varying the gallium content, and by replacing the gallium partially or totally with aluminum. Alternately the absorber layer is reactively sputtered from metal alloy targets in the presence of hydrogen selenide gas. RF sputtering is used to deposit a non-cadmium containing window layer of ZnS. The top transparent electrode is reactively sputtered aluminum doped ZnO. A unique modular vacuum roll-to-roll sputtering machine is described. The machine is adapted to incorporate dual cylindrical rotary magnetron technology to manufacture the improved solar cell material in a single pass.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

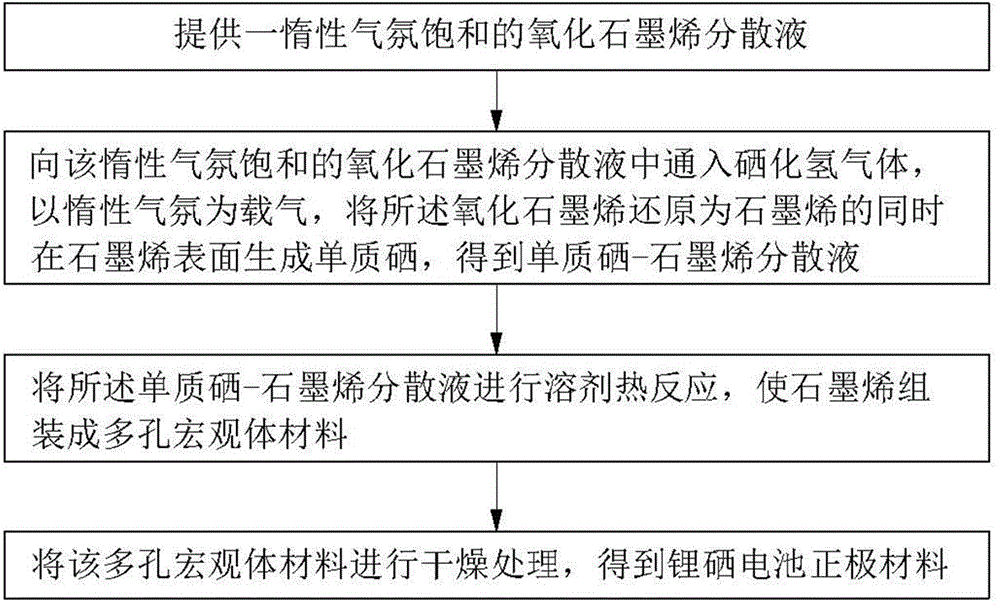

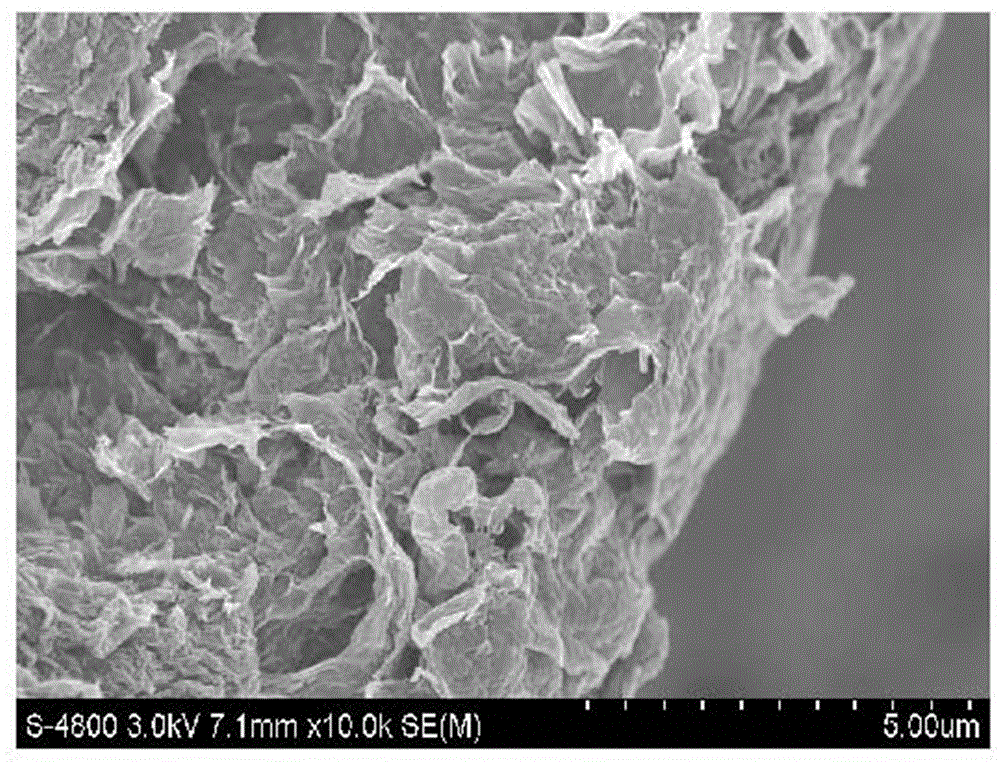

Lithium-selenium battery positive electrode material, preparation method thereof and lithium-selenium battery

ActiveCN104393304AImprove electrochemical performanceComposite method is simpleElectrode carriers/collectorsLi-accumulatorsLithiumSolvent

The invention provides a preparation method of a lithium-selenium battery. The preparation method comprises the steps of providing an oxidized graphene dispersing liquid with saturated inert atmosphere; feeding hydrogen selenide gas to the oxidized graphene dispersing liquid with saturated inert atmosphere, reducing the oxidized graphene to graphene by taking the insert atmosphere as carrier gas, and meanwhile, generating elemental selenium on the surface of the graphene to obtain an elemental selenium-graphene dispersing liquid; performing solvent thermal treatment on the selenium-loaded graphene dispersing liquid to obtain graphene-based gel; and drying the graphene-based gel. The invention further provides a lithium-selenium battery positive electrode material and a lithium-selenium battery using the positive electrode material.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Preparation for copper-indium-galliun-selenium-sulfur or copper-indium-galliun-selenium or copper-indium-galliun-sulfur film solar cell absorption layer

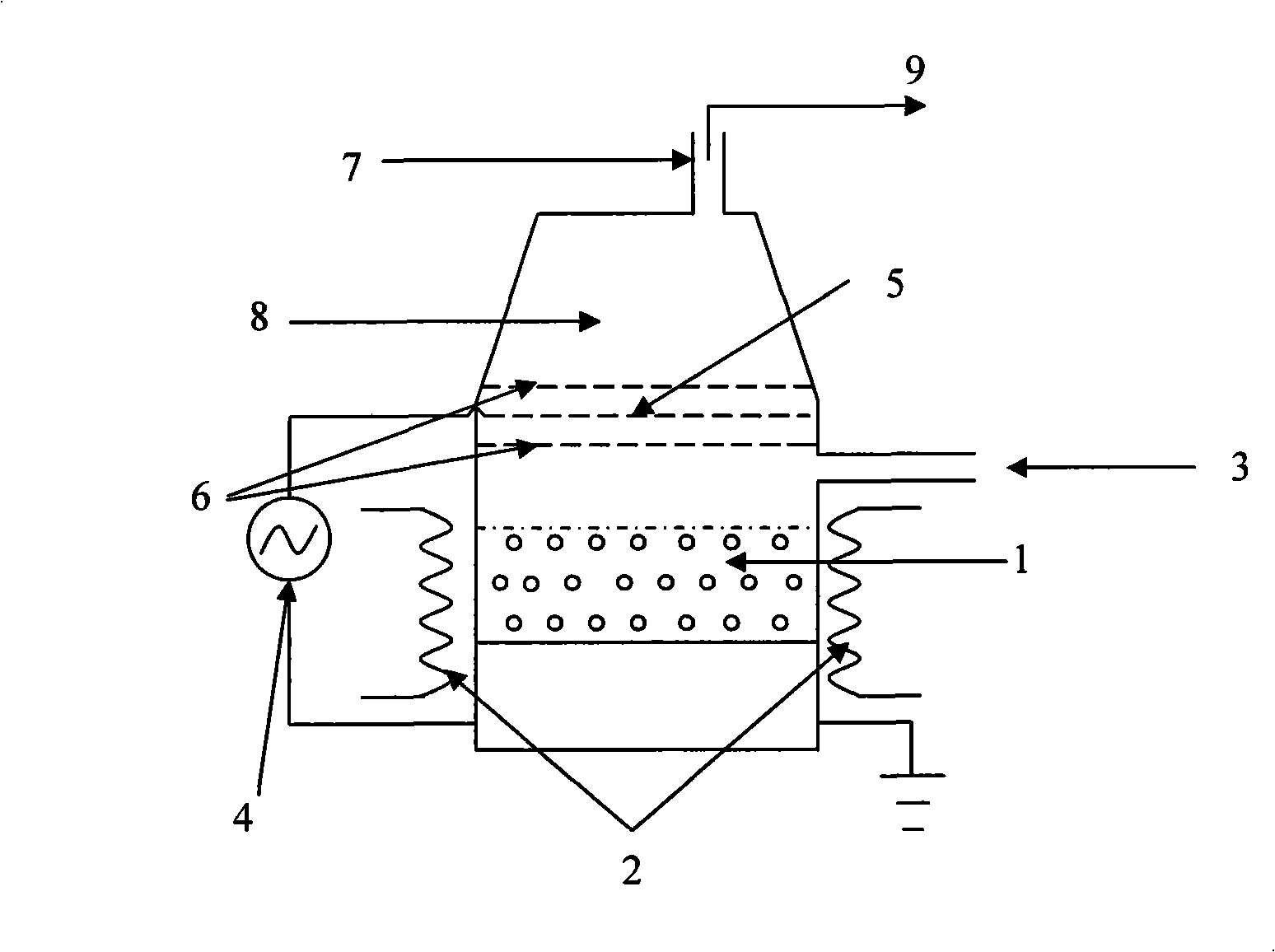

InactiveCN101383389AReduce usageIncreased process safetyFinal product manufactureVacuum evaporation coatingIndiumPlasma generator

The invention discloses a preparation method for a CIGSeS, CIGSe or CIGS thin-film solar cell absorption layer. After a base conductive film and a metal precursor film are prepared in sequence, a selenylation and / or sulfurization reaction source is excited into free or ionized selenium molecules and / or sulfur molecules in vacuum due to high temperature and plasma discharge, and then selenylation and / or sulfurization reaction is carried out on the metal precursor film. The invention also discloses coating equipment of a CIGSeS, CIGSe or CIGS thin-film solar cell absorption layer which comprises a reaction vessel and a vacuum pump arranged outside the reaction vessel and communicated with the reaction vessel, wherein a rotating axle with an upper end extended into inside the reaction vessel is arranged under the reaction vessel, a plasma generator and a heating device are also arranged in the reaction vessel, and the reaction vessel is also provided with a shielding gas input device and a selenylation and / or sulfurization reaction source device in a communicating way. The invention can keep higher conversion efficiency of the original method, also avoids the use of highly toxic gas such as hydrogen selenide or hydrogen sulphide, enhances the security of coating processing, and also improves the use efficiency of the selenium source and / or the sulfur source.

Owner:苏州富能技术有限公司

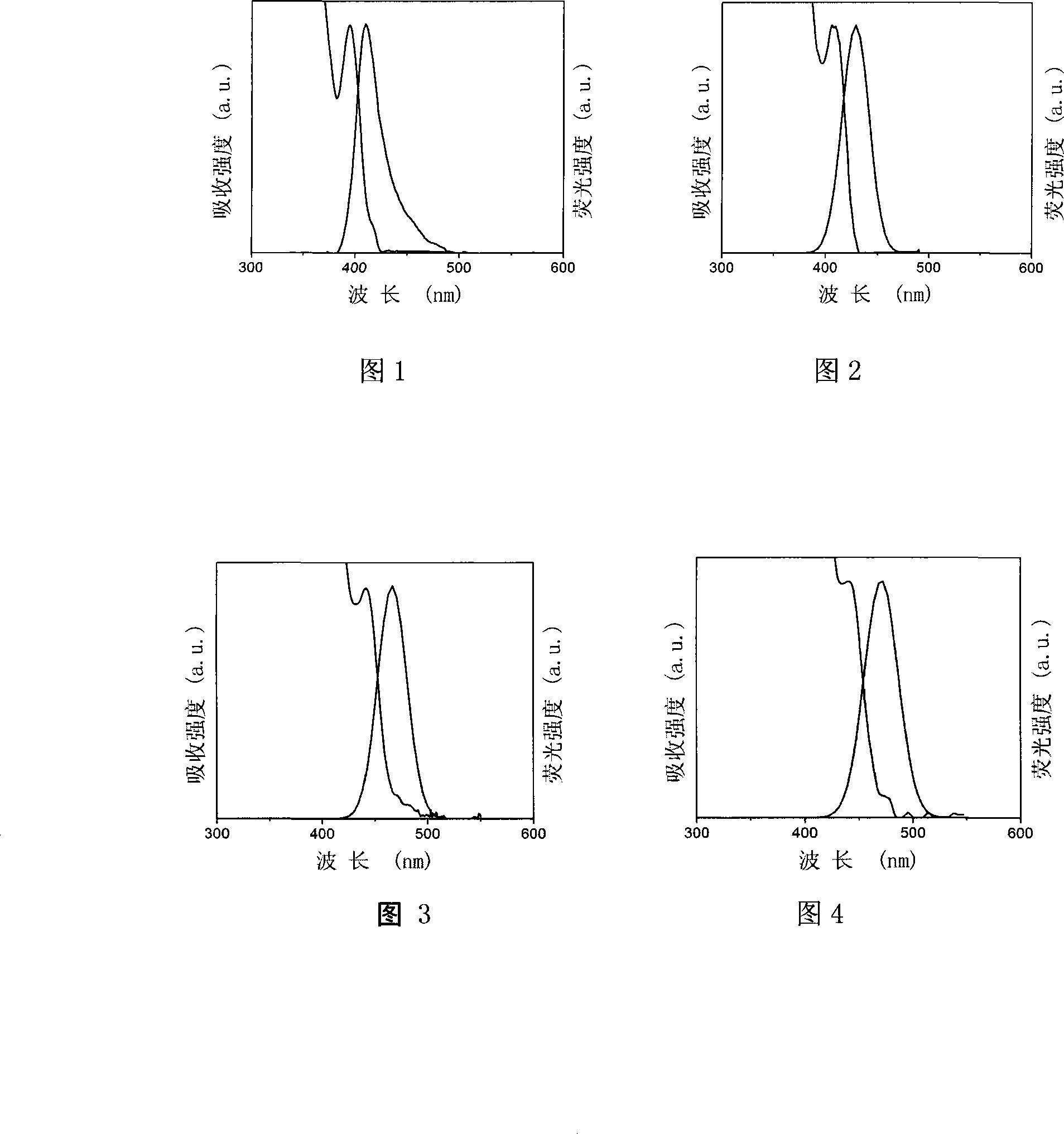

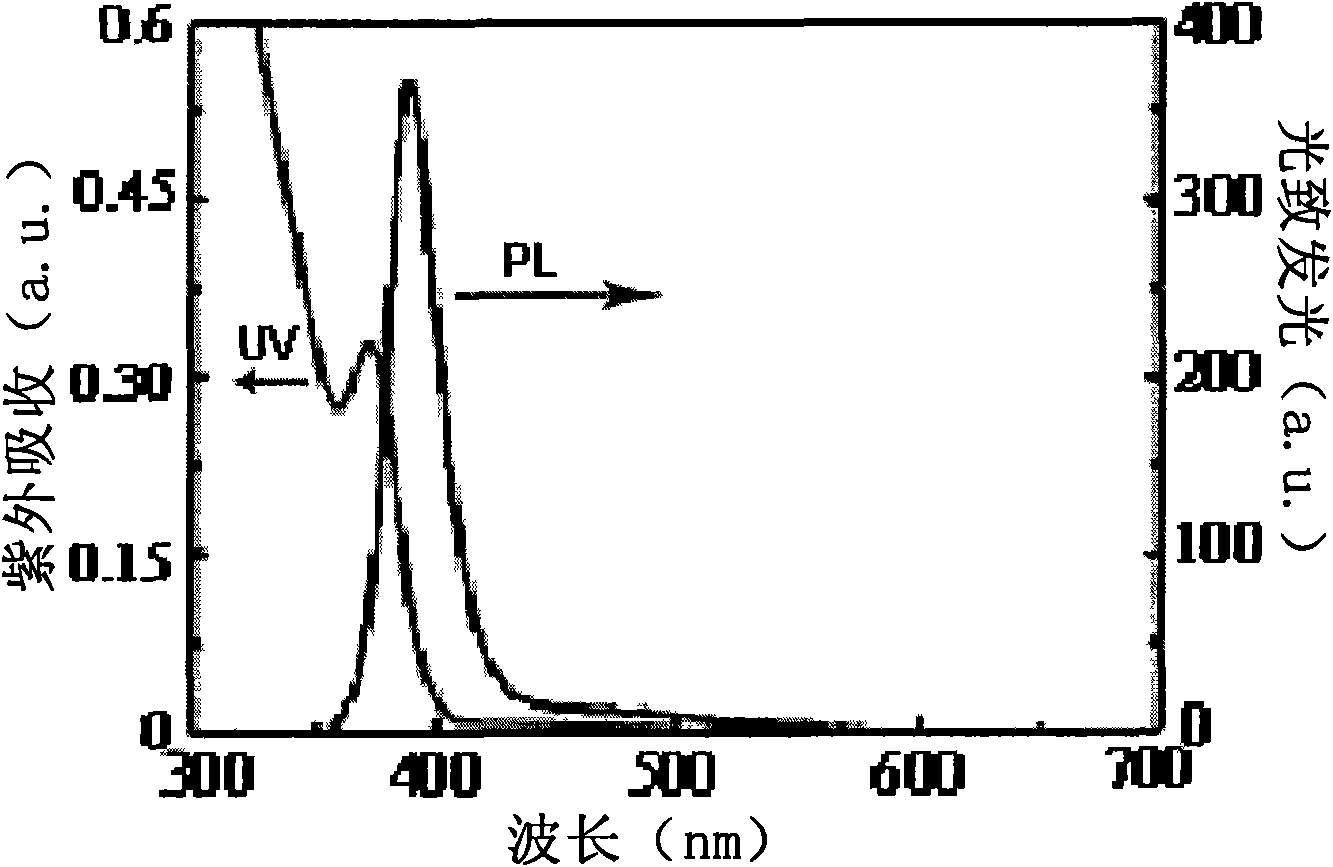

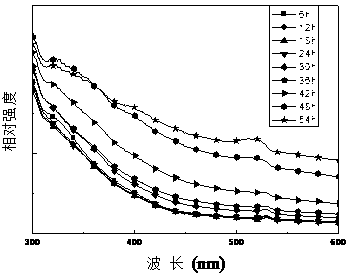

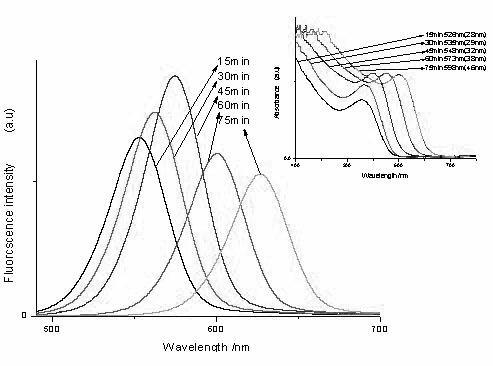

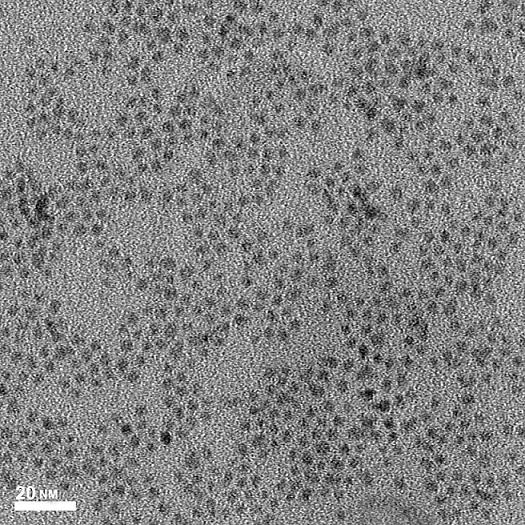

Microwave assistant method for quickly synthesizing quanta point of zinc selenide fluorescence

InactiveCN1687303AGood water solubilityImprove stabilityLuminescent compositionsZinc selenidePotassium borohydride

The present invention relates to a method for microwave-aided quickly synthesizing zinc selenide fluorescence quantum point. Said method uses water as solvent, and adopts the following steps: mixing zinc salt or zinc oxide and water-soluble mercaptocompound, injecting soduim hydrogen selenide or potassium hydrogen selenide produced by adopting sodium borohydride or potassium borohydride and zinc powder and making them produce reaction to obtain zinc solenide ZnSe precursor solution, then placing said solution in a closed teflon tank and making reaction in a temperature-controllable and pressure-controllable microwave reactor so as to quickly synthesize ZnSe fluorescence quantum point.

Owner:SHANGHAI JIAO TONG UNIV

Hydrothermal production method for water-soluble ZnCdSe quantum dot

InactiveCN101220275AIncrease temperatureIncrease pressureLuminescent compositionsFluorescenceNitrogen gas

A hydrothermal preparation method of a water-soluble ZnCdSe ternary quantum dot belongs to the nano technical field; the invention chooses zinc chloride or zinc Oxide as zinc source, sodium hydrogen selenide formed by selenium powder and sodium borohydride as selenium source, glutathione as stabilizer, leading the ZnSe precursor solution to be prepared under the protection of the nitrogen. The ZnSe precursor solution reacts in the hydrothermal environment to obtain the ZnSe quantum dot. The cadmium chloride or the cadmium Oxide chosen as cadmium source, and the glutathione chosen as the stabilizer are mixed together with the prepared ZnSe quantum dot to obtain the ZnCdSe precursor solution. The water-soluble ZnCdSe quantum dot is obtained by leading the ZnCdSe precursor solution to react in the hydrothermal environment. Due to the mild reaction condition, convenient operation and the simple equipment, the invention leads the water-soluble ZnCdSe quantum dot to be suitable for the industrial production with the better dispersion, better uniformity of the particle size and high fluorescent quantum efficiency. .

Owner:SHANGHAI JIAO TONG UNIV

Preparing method of high active selenium source for selenylation, apparatus and applications

ActiveCN101284654AEasy transportationEasy to saveFinal product manufactureChemical industryNegative glowMixed gas

The invention discloses a method for generating a highly active selenium source used for selenizing treatment, and a device and application thereof. The method comprises the steps of heating and vaporizing solid selenium to generate selenium gas; adding hydrogen or a mixture of hydrogen and argon to the selenium gas generated by the last step; and subjecting the mixture of gases in the last step to glow discharge decomposition and synthesis to obtain hydrogen selenide and highly active selenium gas. The device for generating the selenium source comprises an airtight reaction tank, a solid selenium source in the reaction tank, a positive and a negative glow discharge electrodes, a hydrogen selenide reaction cavity, as well as a heating device and an excitation power supply outside the reaction tank. A gas inlet is further arranged on the lateral wall of the reaction tank; a gas outlet is arranged on the top of the reaction tank. The method not only retains the advantages of the solid selenium, namely low cost, non-toxicity and easiness to transport and store, prepares the hydrogen selenide and the highly active selenium ambience with the characteristics of the hydrogen selenide and the highly active selenium, but also saves a large amount of selenide materials, reduces the cost and has important practical value.

Owner:NANKAI UNIV

Preparation method of aqueous phase non-toxic white light quantum with multilayer core-shell structure

InactiveCN102618289AGood water solubilityImprove stabilityGas discharge lamp usageLuminescent compositionsPropanoic acidThio-

The invention relates to a preparation method of an aqueous phase non-toxic white light quantum with a multilayer core-shell structure. The preparation method comprises the following specific steps: (a) preparing a shell layer material Zn+mercaptopropionic acid (MPA)+thioacetamide (TAA): taking Zn(NO3)2 and adding the Zn(NO3)2 into a conical flask filled with deionized water, taking the MPA by using a miniature liquid-transferring gun; adding the TAA into the solution; fully stirring the solution and then adjusting the pH value of the mixed solution by using NaOH; and fully stirring the solution for later use; (b) adding the deionixed water, manganese chloride and the MPA in a three-necked bottle, adjusting the pH value and then introducing nitrogen gas and removing air in the three-necked bottle by using high-purity nitrogen gas; injecting sodium hydrogen selenide by using an injector and then allowing the manganese chloride and the sodium hydrogen selenide to be fully acted to form a selenide-rich MnSe quantum dot; then injecting zinc nitrate and growing for one hour; injecting the shell layer material in the step (a) and growing; then adding a copper chloride solution and growing; adding the shell layer material; and finally, regrowing to obtain the required white light quantum dot. The white light quantum dot synchronized by the preparation method is better in water solubility and stability and has broad application prospect.

Owner:SOUTHEAST UNIV

Method for preparing CdSe and ZnSe quantum dot nanometer granules

InactiveCN101332979AReduce manufacturing costGuaranteed decentralizationTenebresent compositionsBinary selenium/tellurium compoundsFluorescenceStearic acid

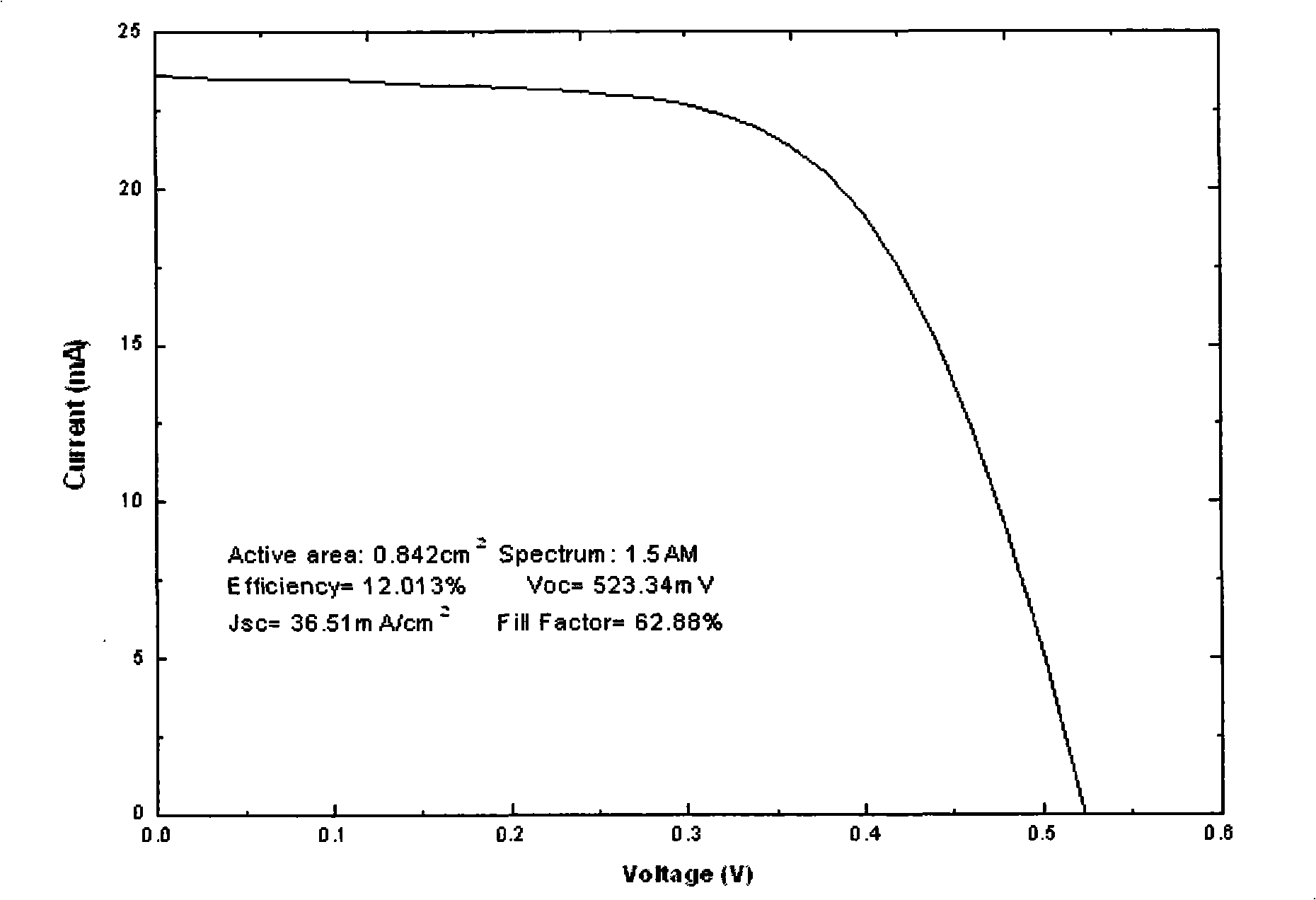

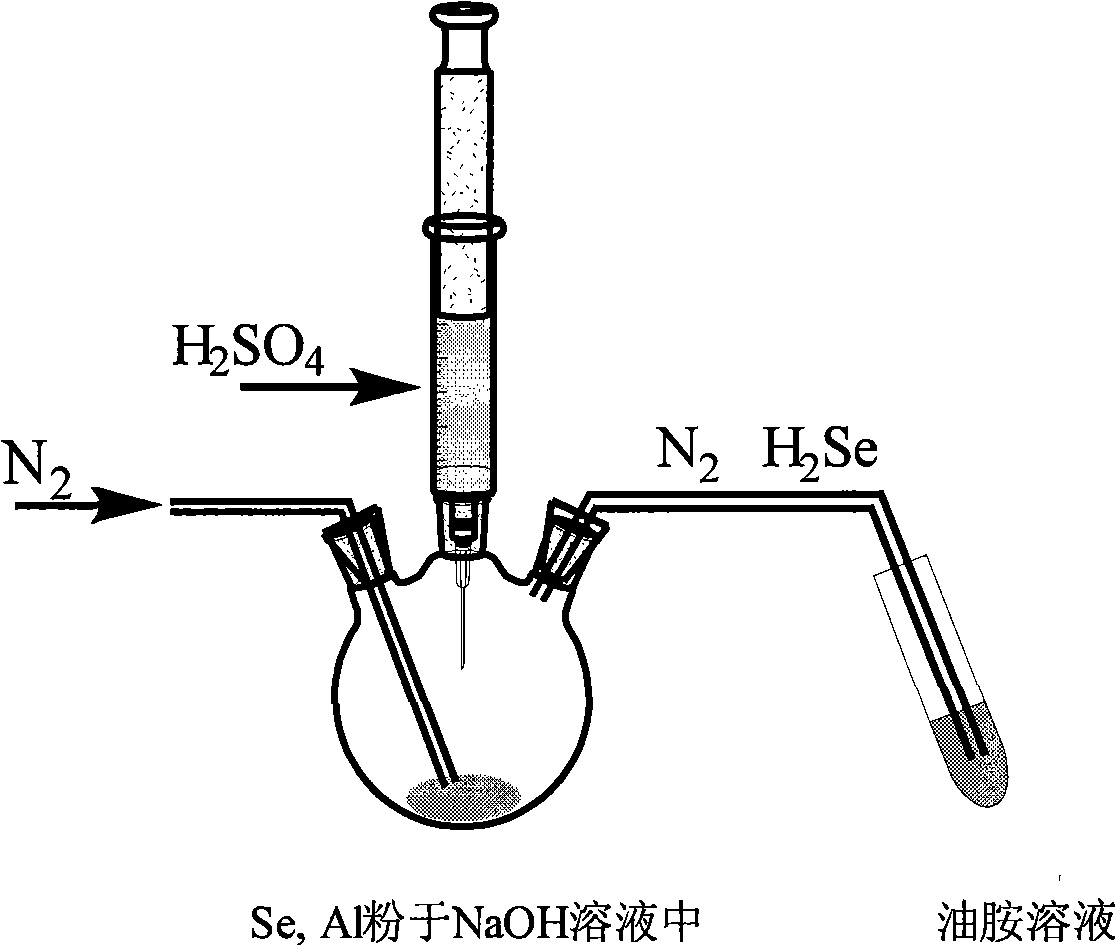

The invention discloses a method for preparing CdSe and ZnSe quantum dots nanometer particles. Aluminum powder and strong base solution are adopted for the reduction of selenium powder and sulphuric acid is added to generate hydrogen selenide, the hydrogen selenide is brought out by the flow of high purity nitrogen and dissolved in oil amine to obtain oil amine-hydrogen selenide composite; the oil amine-hydrogen selenide composite which is taken as a new selenium precursor, together with cadmium stearate and orzinc stearate, is used for preparing the CdSe and ZnSe quantum dots nanometer particles at high temperature; the prepared quantum dots nanometer particles have controllable spectrum and excellent performance and can be applied to the fields such as biological fluorescence label, optoelectronic materials, etc. Furthermore, the method for preparing quantum dots nanometer particles can avoid the adoption of trioctylphosphineoxide (TOP) which has strong toxicity and high price, and is low in cost and suitable for industrial production.

Owner:HUNAN UNIV

Preparation method of ZnSe/ZnS core-shell quantum dots

InactiveCN102517025AOvercoming complexityOvercome operabilityLuminescent compositionsPotassium borohydrideUltraviolet lights

The invention discloses a preparation method of ZnSe / ZnS core-shell quantum dots through illumination assisted room-temperature synthesis. The method comprises the steps of: A. preparing a potassium hydrogen selenide solution by reducing selenium powder with potassium borohydride; B. weighing zinc acetate crystals, which is then dissolved in deionized water to a constant volume, thus obtaining a zinc acetate solution; C. adding quantitative thioglycolic acid into the zinc acetate solution; D. adjusting the solution to a specific pH value with a sodium hydroxide solution; E. after introducing an inert gas for deoxygenation, adding the potassium hydrogen selenide solution; F. placing the stock solution or a diluted solution of the mixed solution under an ultraviolet light for radiation for a certain period of time, and conducting detection with fluorescence spectrum analysis; and G. adding isopropyl alcohol for purification, then carrying out drying by a freeze drier so as to obtain ZnSe / ZnS core-shell quantum dot solid powder, which is dissolved in a PBS solution or deionized water before using, thus obtaining a ZnSe / ZnS core-shell quantum dot solution. The method of the invention has the advantages of simple process, easily controllable technological parameters, as well as cheap raw materials. The synthesized ZnSe / ZnS core-shell quantum dots are free of heavy metal ions, and can be used for biological labeling and imaging.

Owner:WUHAN UNIV

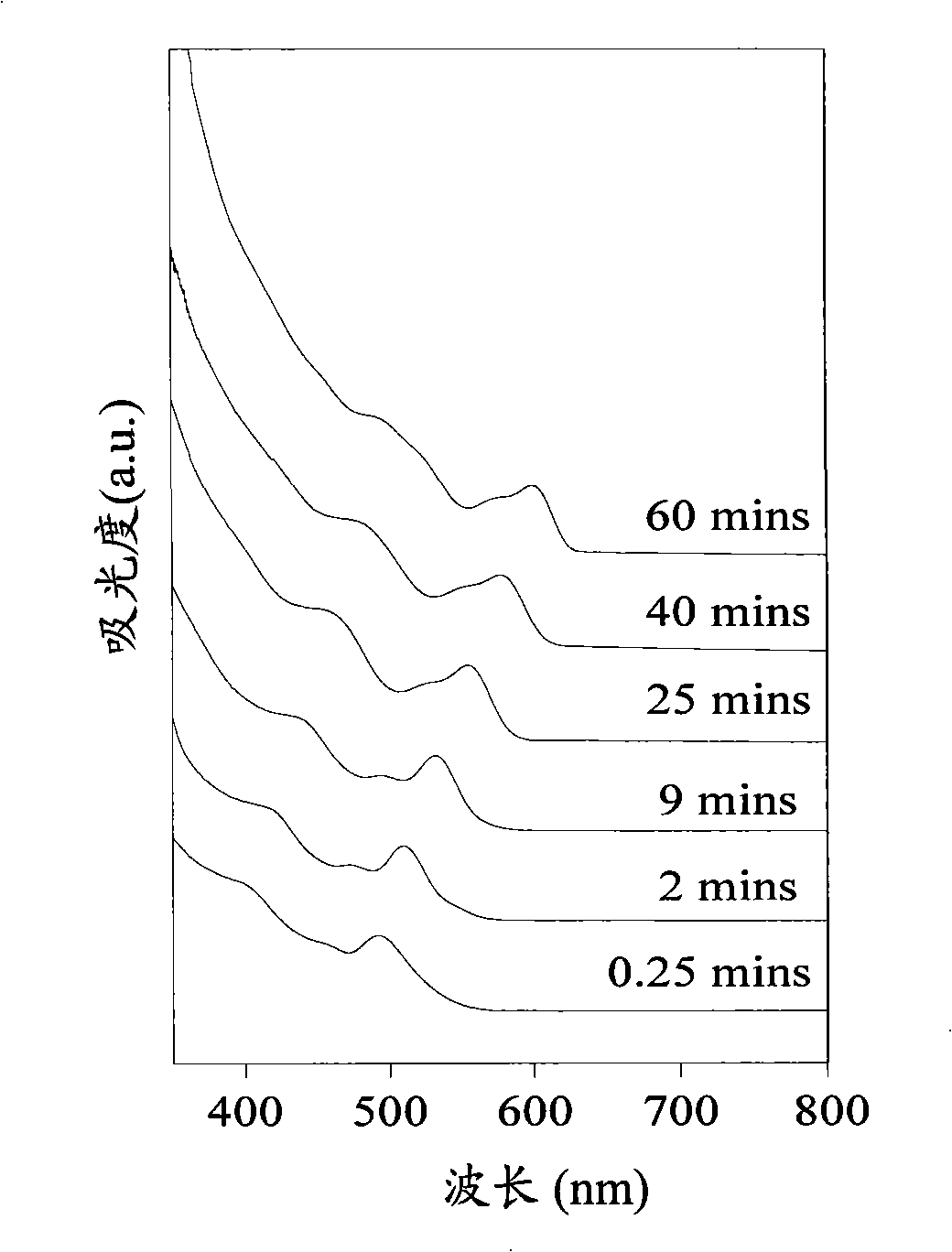

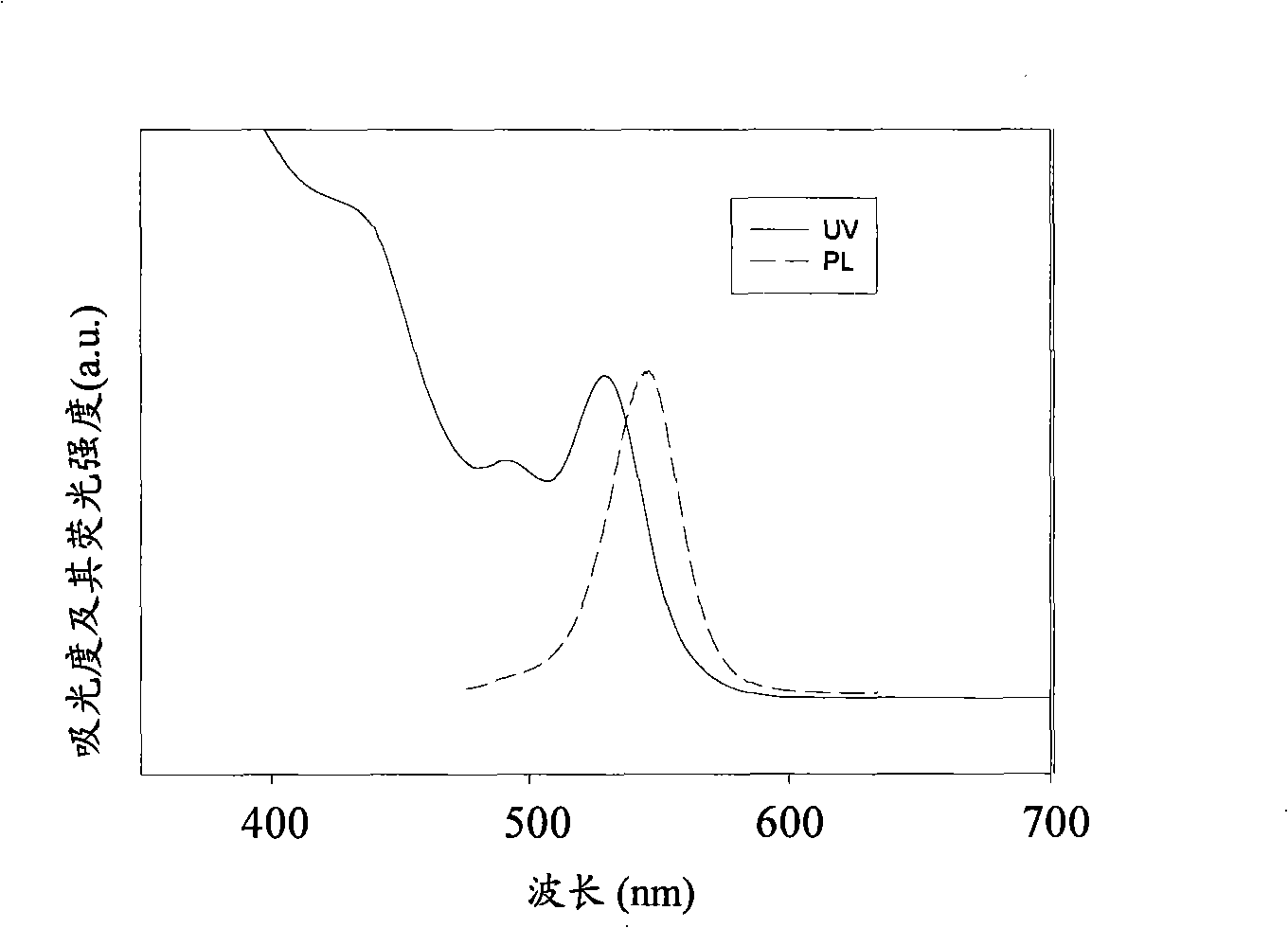

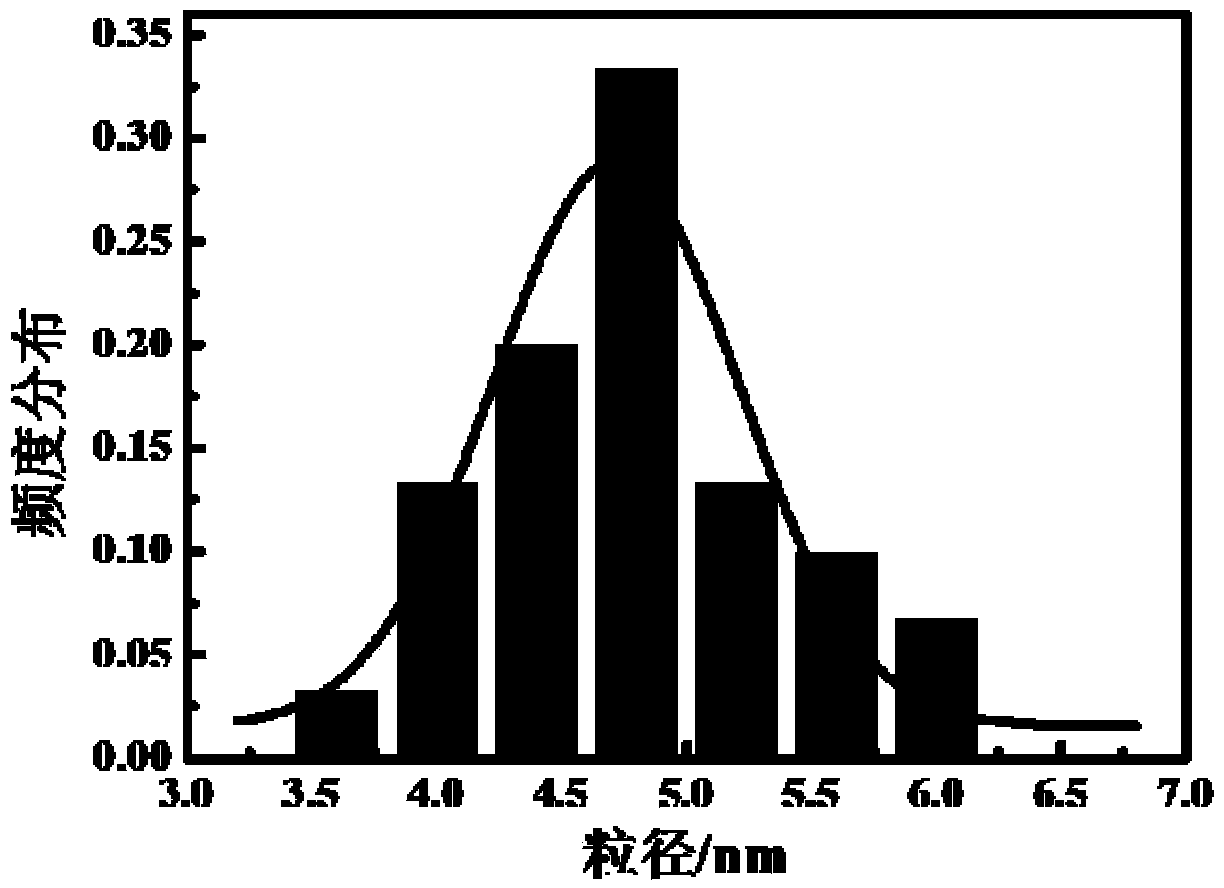

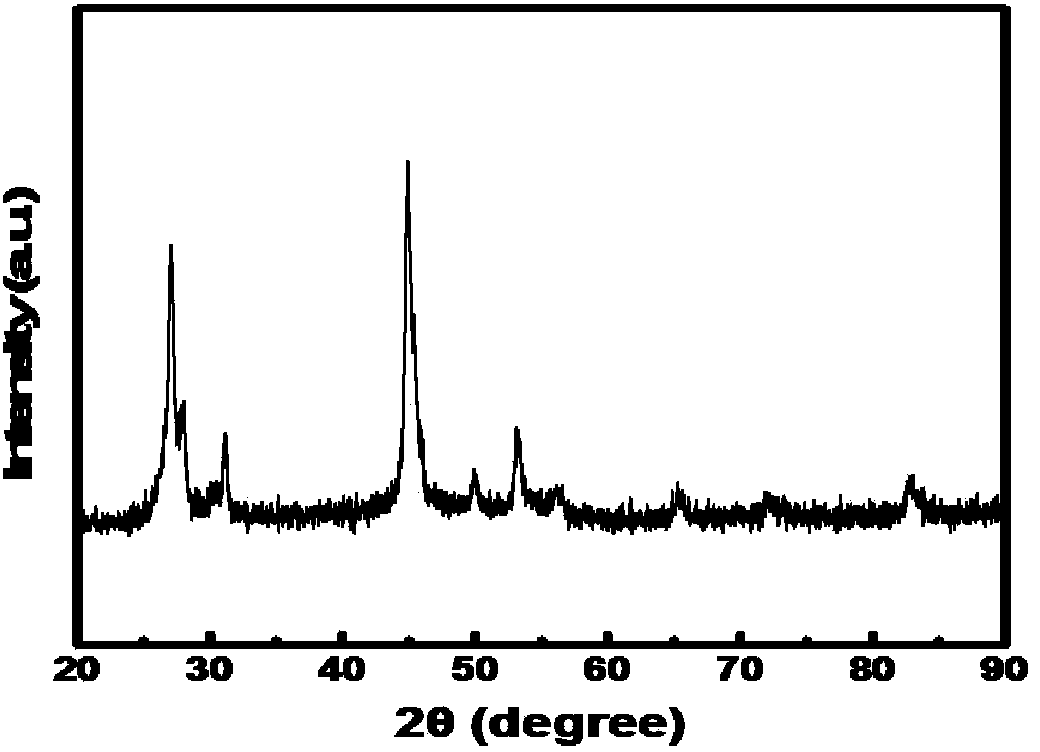

Copper selenide fluorescent quantum dot and preparation method and application thereof

InactiveCN103803511ASimple methodMild conditionsLight-sensitive devicesLuminescent compositionsQuantum yieldSensitized cell

The invention relates to a copper selenide fluorescent quantum dot and a preparation method and application thereof. The copper selenide fluorescent quantum dot is characterized in that the quantum dot is one of Cu2Se, CuSe and Cu(2-x)Se or a combination thereof; the particle size of the quantum dot is 2-10nm, the quantum yield is 10-60%, and the half-peak width of the photoluminescence spectrum is 30-150nm. The preparation method comprises the following steps: with an aqueous solution with copper salt dissolved in as an aqueous phase and an organic solvent with a long-chain ligand dissolved in as an oil phase, stirring in an inertia protective gas, and heating in an oil bath to form a precursor solution; pouring an aqueous solution of sodium hydrogen selenide into the hot precursor solution, and heating for reaction; sampling at different time to obtain organic-phase quantum dot solutions with different emission fluorescence; precipitating the upper-layer organic-phase quantum dot solution; centrifuging and dispersing, and repeating to remove unreacted raw materials to obtain the copper selenide fluorescent quantum dot. The quantum dot does not contain heavy metal elements such as cadmium and the like to realize low toxicity, has the advantages of high quantum yield, uniform particle size, relatively narrow fluorescence emission spectrum and adjustable light color along with excitation wavelength, and can be used for preparing quantum dot solar sensitized cells and LED (light-emitting diode) devices.

Owner:NANJING TECH UNIV

Microwave preparation method of water soluble ZnSe quantum dots

InactiveCN101831711ASimple and fast operationShorten the timePolycrystalline material growthFrom normal temperature solutionsSolubilityZinc hydroxide

The invention discloses a microwave preparation method of water soluble ZnSe quantum dots, which comprises the following steps: (1) mixing solution of sodium hydrogen selenide with solution serving as a zinc source to obtain solution of ZnSe precursor; and (2) heating the solution of the ZnSe precursor by microwaves to obtain water soluble ZnSe quantum dots, wherein the microwave heating conditions include a microwave power of 50 to 300W, a heating time period of 1 to 30 minutes and a heating temperature of 70 to 120 DEG C and the solution serving as the zinc source may be solution of a zinc salt, zinc oxide or zinc hydroxide. The obtained high fluorescent quantum product has high yield, stability and water solubility and can be widely used for making fluorescent labels for biological detection and analysis.

Owner:苏州市长三角系统生物交叉科学研究院有限公司

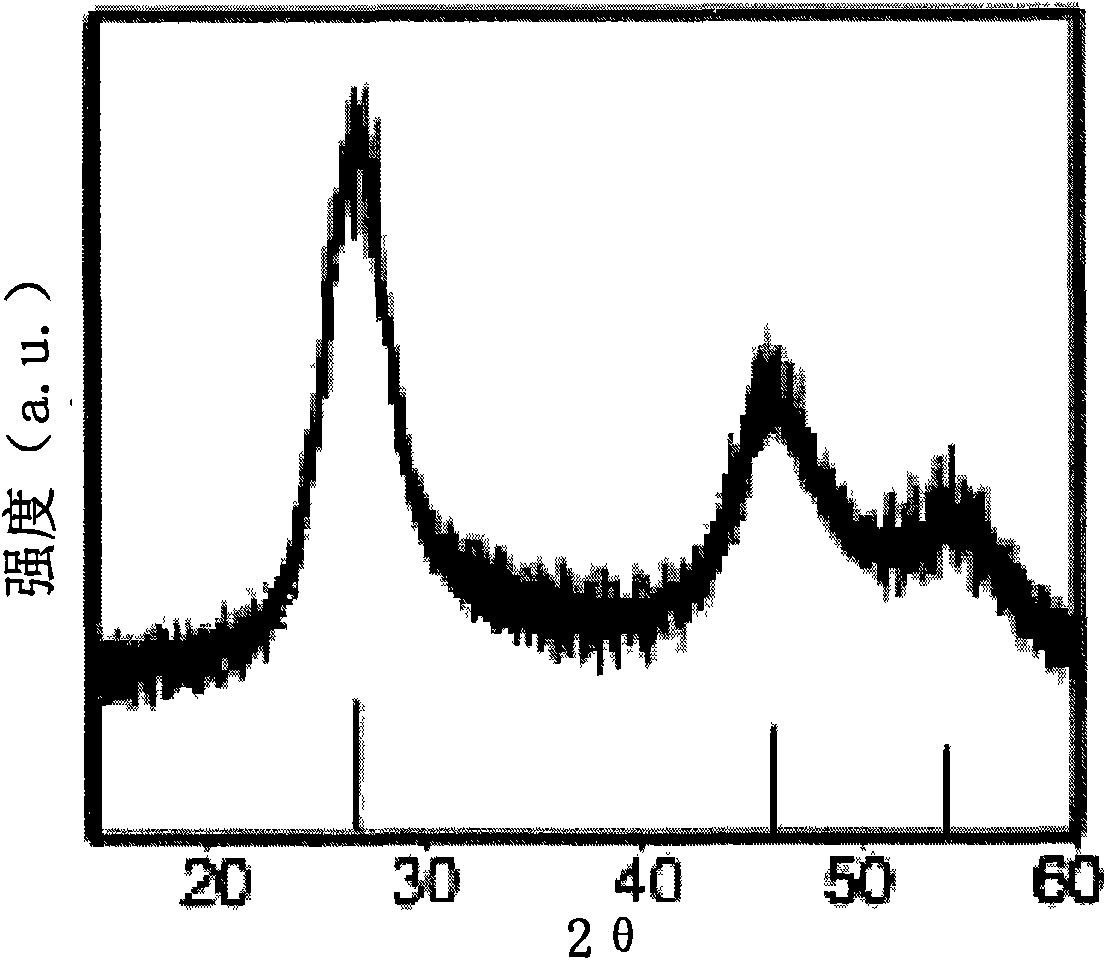

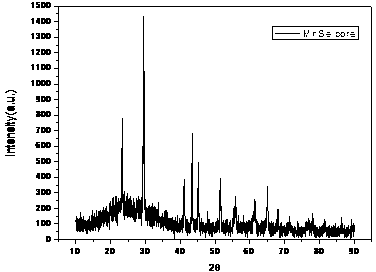

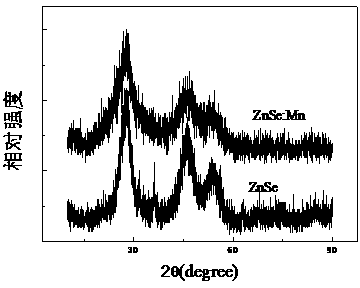

Nucleation water-phase preparation method of ZnSe:Mn quantum dots

InactiveCN103320134AGood dispersionImprove stabilityLuminescent compositionsMANGANESE ACETATEFluorescence

The invention relates to a nucleation water-phase preparation method of ZnSe:Mn quantum dots, belonging to the technical field of composite nano microcrystal materials. The inner core of the product is MnSe quantum dots, and the outer layer is ZnSe quantum dots. The preparation method comprises the following steps: reacting sodium borohydride (NaBH4) and selenium powder to prepare sodium hydrogen selenide (NaHSe), injecting the sodium hydrogen selenide into a manganese acetate / 3-mercaptopropionic acid solution of which the pH value is regulated by sodium hydroxide so as to react to generate a MnSe quantum dot solution, and adding a zinc acetate / 3-mercaptopropionic acid solution of which the pH value is regulated by sodium hydroxide into the MnSe quantum dot solution to form ZnSe:Mn quantum dots. The product obtained by the method provided by the invention has the advantages of uniform dispersion, high stability and less aggregation, and can be used in the fields of biological fluorescence labeling, drug isolation and some photoelectric devices.

Owner:SHANGHAI UNIV

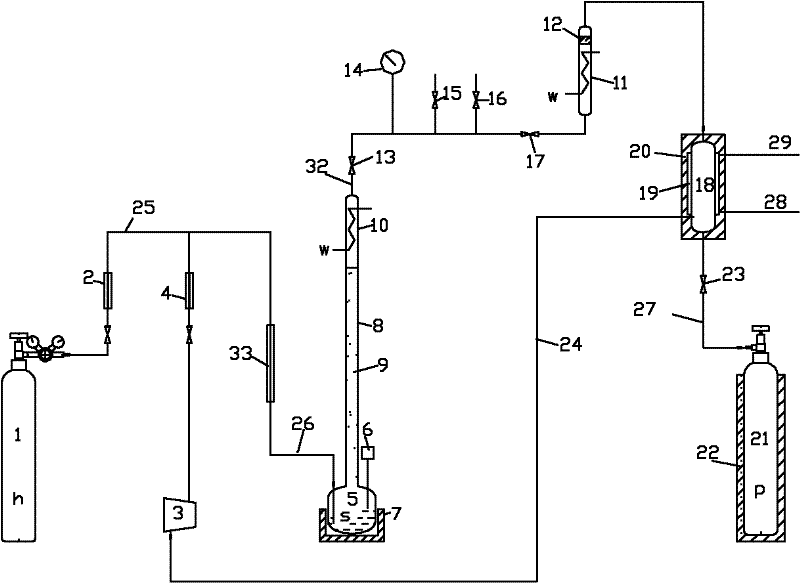

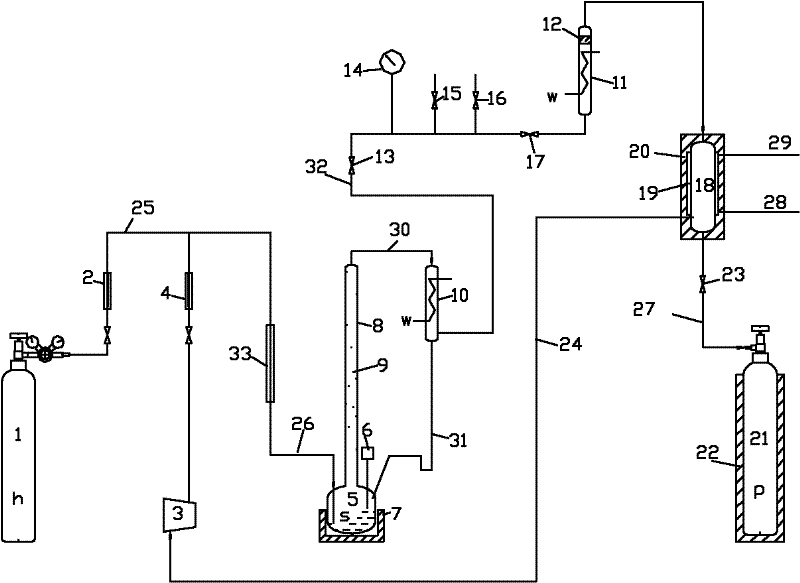

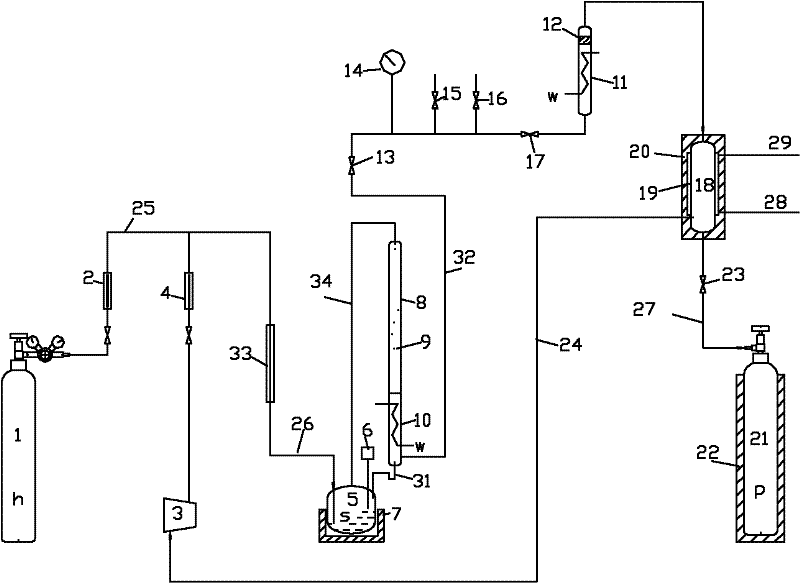

Hydrogen selenide preparation device and method

InactiveCN102674268ALarge surface areaIncrease the chance of meeting and respondingBinary selenium/tellurium compoundsHydrogenStream flow

Disclosed are a hydrogen selenide preparation device and a method. According to the method, the hydrogen selenide is directly synthesized by hydrogen and selenium(Se), a hydrogen inlet pipeline (26) is fed into a selenium liquefaction and vaporization device (5), a primary synthetic reaction between the hydrogen and the selenium is started, synthesized an H2Se / Se / H2 mixing gas-liquid stream is fed into a filling tower-type synthesis reactor (8) and subjected to a continuous synthetic reaction, the Se in a selenium condensation separator (10) is condensed into liquid, then is separated and flows back to the synthesis reactor or the selenium liquefaction and vaporization device for continuing reacting, an H2Se / H2 mixing gas stream flows into a hydrogen selenide condensation separator (18), non-condensable gas hydrogen in the hydrogen selenide condensation separator is separated and conveyed back to the hydrogen inlet pipeline (26), the non-condensable gas hydrogen and the hydrogen are combined for supplying hydrogen, and finally, the H2Se is condensed and collected in the hydrogen selenide condensation separator.

Owner:DALIAN LIFANG CHEM TECH

Method for preparing photocatalytic material from heavy metal ions in biological adsorption solution

ActiveCN104084221ARealize the effect of "three birds with one stone"Increase added valuePhysical/chemical process catalystsWater/sewage treatment by irradiationIndustrial waste waterSodium selenide

The invention provides a method for preparing a photocatalytic material from heavy metal ions in a biological adsorption solution. Based on a biological adsorption technology, the heavy metal ions in industrial wastewater are adsorbed and enriched onto biomass powder particles, then the biomass powder loaded with the heavy metal ions is subjected to a contact reaction with reagents (sodium sulfide, sodium hydrosulfide, thiourea, hydrogen sulphide or sodium selenide, sodium hydrogen selenide, selenourea, hydrogen selenide and the like ) which can provide an S<2-> or Se<2-> source, so that the heavy metal ions adsorbed on the biomass powder particles are in-situ converted into corresponding metal sulfides (selenides). The method realizes a new way of high-valued utilization of various industrial wastewater containing low-concentration valuable metal ions, reaches purposes of economically and efficiently removing the low-concentration metal ions in the industrial wastewater in virtue of biological adsorption, has the highlight advantages of being fast to adsorb, low in cost, short in powder making flow, large in yield, and easy to scale.

Owner:UNIV OF SCI & TECH BEIJING

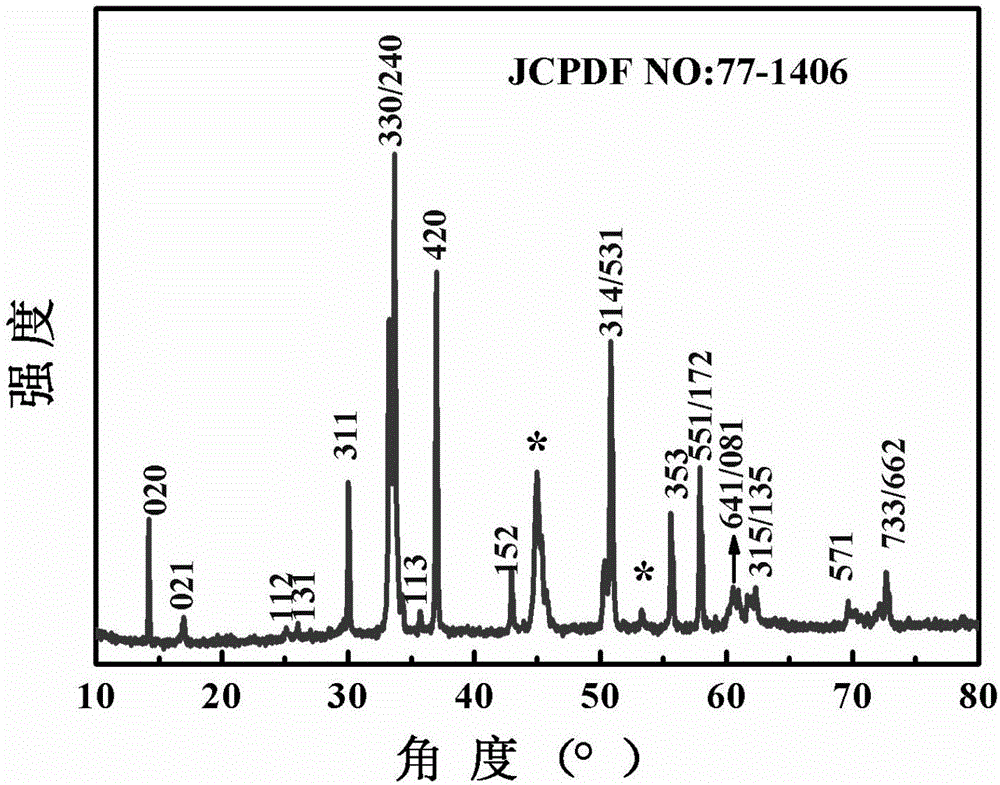

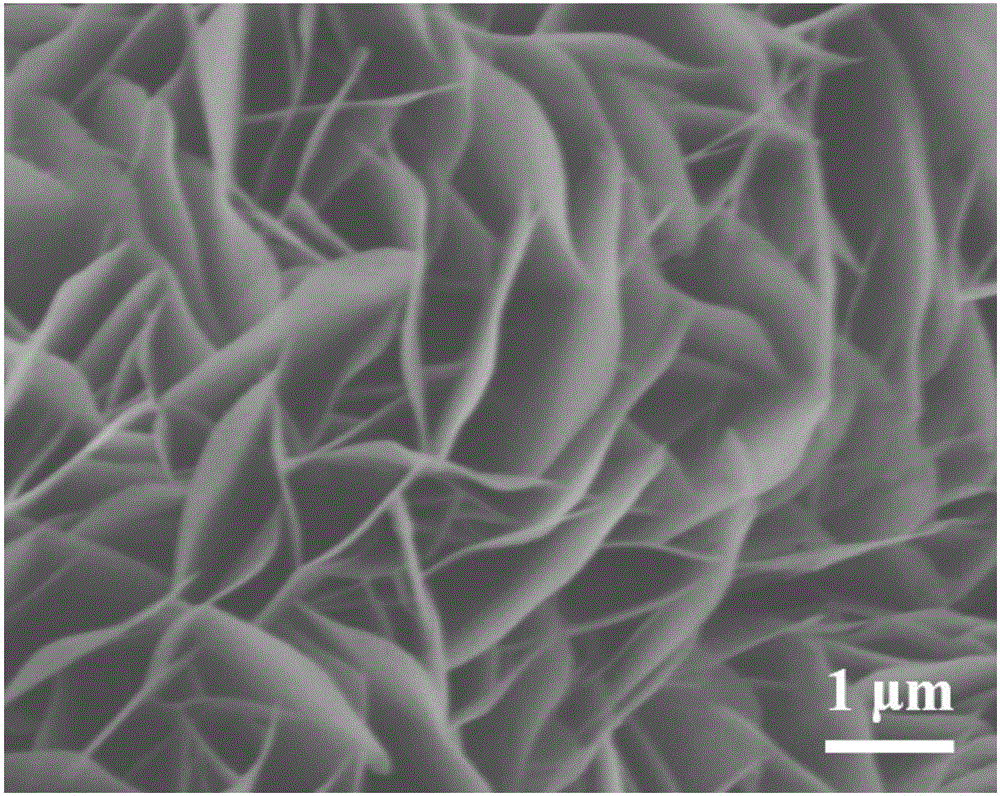

Monocrystal porous V2Se9 nanosheet array electro-catalysis material and preparation method thereof

InactiveCN106835190AHigh catalytic activityImprove stabilityElectrode shape/formsSingle crystalAmmonium metavanadate

The invention discloses a monocrystal porous V2Se9 nanosheet array electro-catalysis material. A V2Se9 nanosheet array grows on a conductive substrate, and V2Se9 is of a monocrystal porous structure. A preparation method of the monocrystal porous V2Se9 nanosheet array electro-catalysis material comprises the following steps: preparing ammonium metavanadate solution with the concentration of 1-4 mol / L, adjusting pH to be 1-3, transferring the solution to a reaction still, putting a conductive substrate in the reaction still, sealing the reaction still, carrying out first-time hydrothermal reaction, growing an ammonium metavanadate nanosheet array on the surface of the conductive substrate, taking out the conductive substrate, washing the surface of the conductive substrate with deionized water, and drying the conductive substrate; calcining the treated conductive substrate in the first step in a muffle furnace to obtain a porous V2O5 nanosheet array; rapidly transferring prepared sodium hydrogen selenide solution to the reaction still, obliquely placing the obtained conductive substrate in the reaction still, sealing the reaction still, then, putting the reaction still in a blasting drying oven, and carrying out second-time hydrothermal reaction; and preparing the V2Se9 nanosheet array. The monocrystal porous V2Se9 nanosheet array electro-catalysis material reduces the hydrogen production cost and has the catalytic activity equivalent to that of platinum.

Owner:CHONGQING UNIV

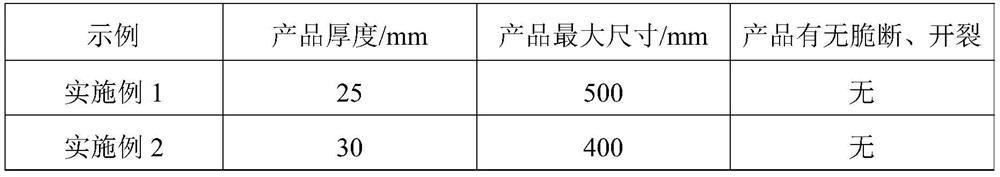

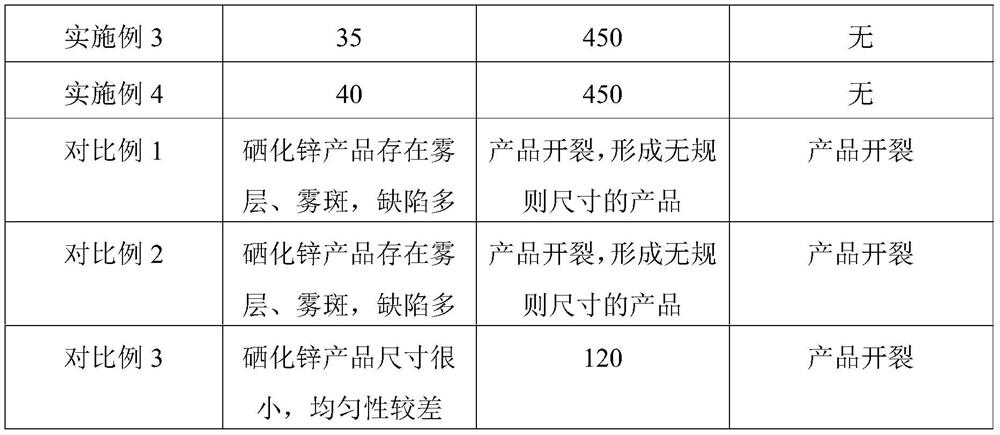

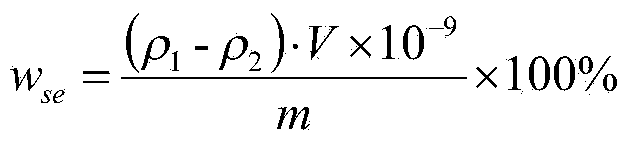

Growth method of zinc selenide

ActiveCN112095150AGood optical performanceSolve the size problemPolycrystalline material growthSingle crystal growth detailsZinc selenideChemical vapor deposition

The invention provides a growth method of zinc selenide, which comprises the following steps: a. Putting zinc into a crucible in a chemical vapor deposition furnace, replacing air in the deposition furnace with argon, and vacuumizing until the vacuum degree is 3000Pa-10000Pa; b, heating a deposition chamber in the chemical vapor deposition furnace to a deposition temperature of 700 DEG C to 800 DEG C, and heating the crucible to an evaporation temperature of 650 DEG C to 700 DEG C; c, respectively introducing gas into the crucible and the deposition chamber to carry out a vapor deposition reaction of zinc selenide, introducing argon into the crucible, and introducing argon and hydrogen selenide into the deposition chamber to make the deposition rate of zinc selenide be 50-150 [mu]m / h; andd, after the reaction is finished, maintaining the same pressure and gas flow as those in the deposition process, continuously heating the deposition chamber to 50 DEG C to 170 DEG C, keeping the temperature constant for the first time, cooling to 500 DEG C to 650 DEG C, keeping the temperature constant again, and cooling the reaction product to room temperature to obtain the zinc selenide product. The growth method of zinc selenide provided by the invention can be used for producing the polycrystalline zinc selenide material with large size, thickened size and high optical performance.

Owner:安徽中飞科技有限公司

Method for measuring content of selenium in molybdenum and molybdenum product

ActiveCN103645165ASimple and fast operationImprove efficiencyPreparing sample for investigationFluorescence/phosphorescenceAtomic fluorescence spectrometryDetection limit

The invention discloses a method for measuring the content of selenium in molybdenum and a molybdenum product. The method comprises the following steps: sampling, preparing a sample solution and a sample blank solution, preparing a working curve solution, drawing a working curve, measuring the content of the selenium in the sample solution, and calculating. According to the method for measuring the content of the selenium in the molybdenum and the molybdenum product, provided by the invention, the problem that an existing hydride generation-atomic fluorescence spectrometry can not be applied to the measurement of the content of the selenium in the molybdenum and the molybdenum product because the selenium hydride of the molybdenum is difficult to form is solved. The method provided by the invention is simple and convenient to operate, high in efficiency and high in sensitivity; and the detection limit is 0.13ng / mL, the recovery rate is 90.23 percent-105.1 percent, and the measurement range of the content of the selenium is 0.0001-0.0050 percent.

Owner:JINDUICHENG MOLYBDENUM CO LTD

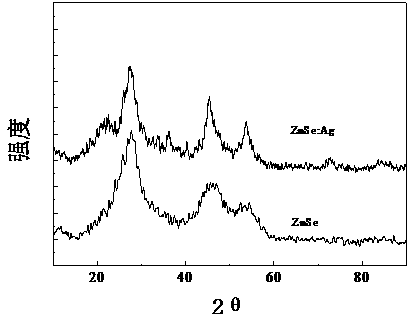

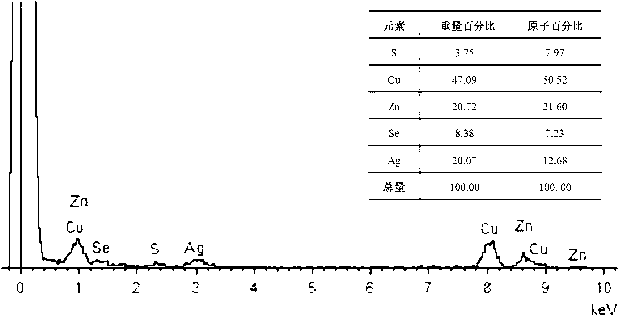

Water-phase preparation method of ZnSe:Ag quantum dots

The invention relates to a water-phase preparation method of ZnSe:Ag quantum dots, belonging to the technical field of composite nano microcrystal materials. The preparation method comprises the following steps: reacting sodium borohydride (NaBH4) and selenium powder to prepare sodium hydrogen selenide (NaHSe), and injecting the sodium hydrogen selenide into a zinc nitrate / 3-mercaptopropionic acid solution of which the pH value is regulated by sodium hydroxide so as to react, thereby obtaining a light-brown transparent ZnSe:Ag quantum dot solution. The product obtained by the method provided by the invention has the advantages of uniform dispersion, high stability and less aggregation, and can be used in the fields of biological fluorescence labeling, drug isolation and some photoelectric devices.

Owner:SHANGHAI UNIV

Preparation method of znse quantum dot labeled bovine serum albumin fluorescent probe

InactiveCN102295932ARich sourcesLow priceFluorescence/phosphorescenceLuminescent compositionsPotassium borohydrideFluorescence

The invention discloses a method for preparing a ZnSe quantum dot marked bovine serum albumin fluorescent probe, which comprises the following steps of: A, preparing KH4Se solution by reducing selenium powder through potassium borohydride; B, respectively weighing the potassium borohydride and the selenium powder, placing the potassium borohydride and the selenium powder into a test tube with a plug, adding high purity water into the test tube, and plugging the test tube with the plug to obtain colorless clear liquid, i.e. potassium selenium hydride; C, weighing zinc acetate crystals and reduced glutathione and dissolving the zinc acetate crystals and the reduced glutathione in oxygen-free high purity water; D, under the condition of stirring and continuously filling high purity argon, adding the potassium selenium hydride and regulating a pH value by utilizing sodium hydroxide solution until raw materials are mixed; E, separately charging the mixture into polyfluortetraethylene digestion tanks and heating the polyfluortetraethylene digestion tanks, wherein a molar ratio of KH4Se to Zn(Ac)2.2H2O to the reduced glutathione is (1 / 15-1 / 10):1:(1.6-1.8); and F, taking ZnSe quantum dots and bovine serum albumin, adding ethyl [3-(dimethylamino)propyl] carbodiimide hydrochloride and oscillating at constant temperature to obtain the quantum dot marked bovine serum albumin fluorescent probe. The method has simple process, is easy to control. The ZnSe quantum dot marked bovine serum albumin fluorescent probe has good biocompatibility and detection performance and can be well used for fluorescence detection.

Owner:WUHAN UNIV

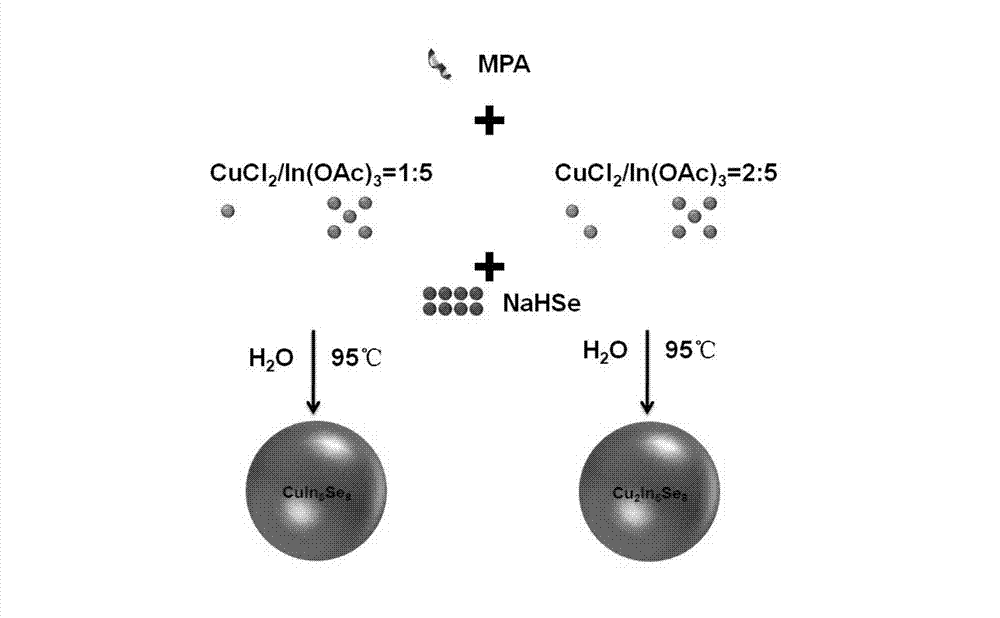

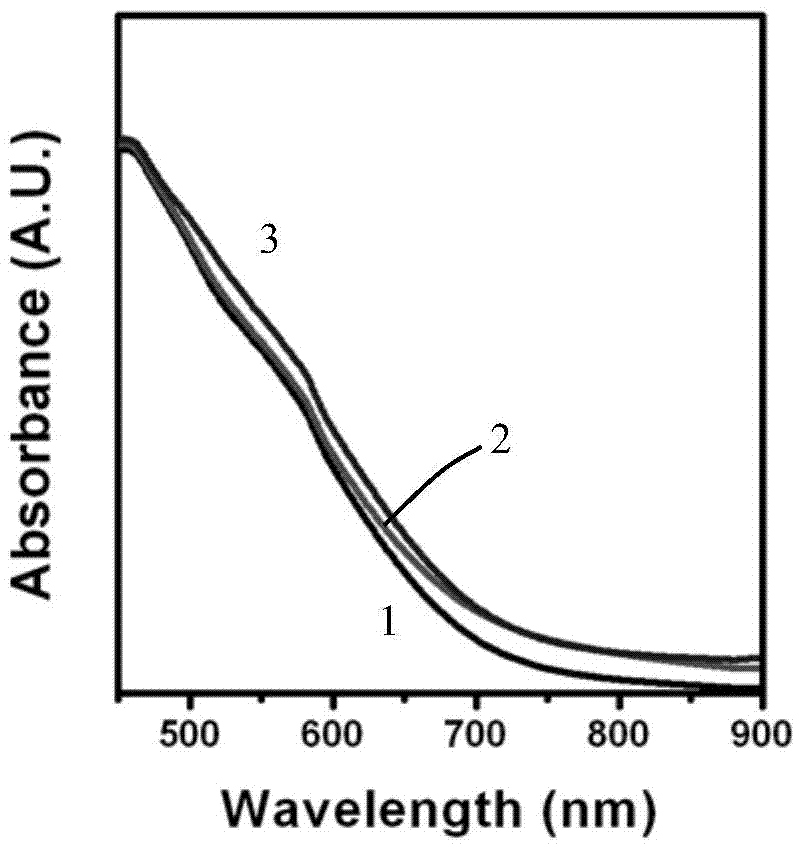

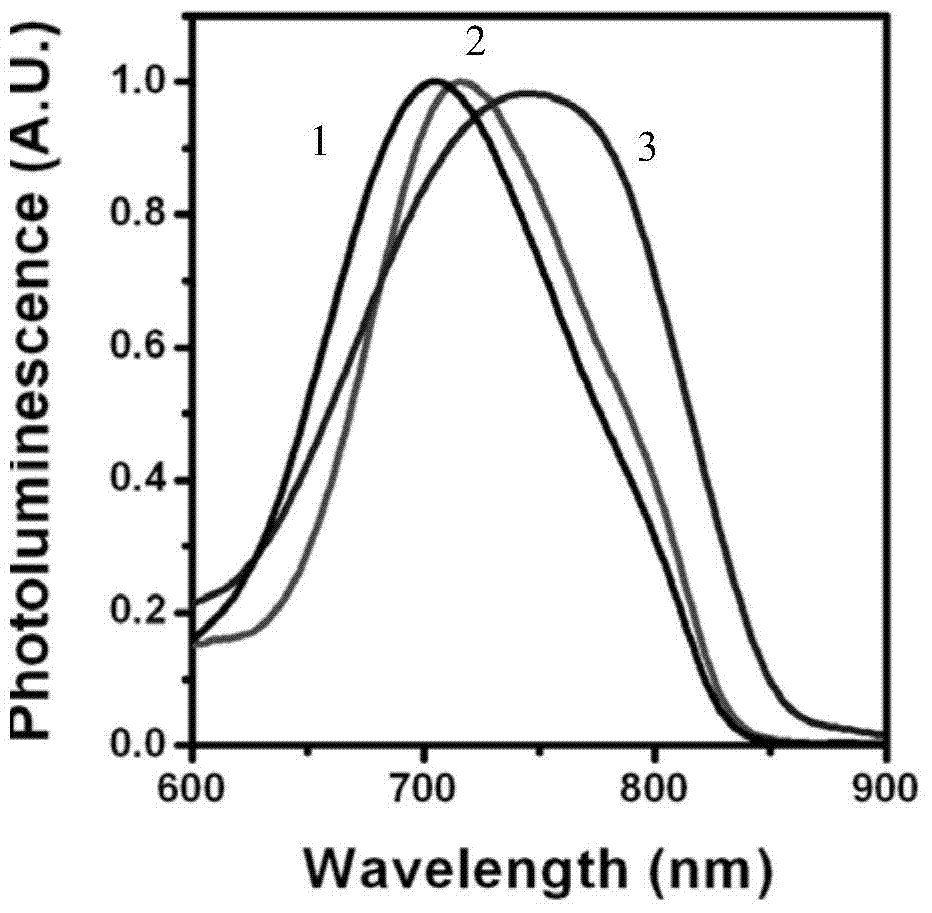

Near-infrared copper-indium-selenium quantum dot and preparation method thereof

InactiveCN104513663ASimple methodThe reaction conditions are mild and controllableLuminescent compositionsIndiumFluorescence

The invention discloses a near-infrared copper-indium-selenium quantum dot and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving cupric chloride or copper acetate, indium acetate, sodium hydrogen selenide and 3-mercaptopropionic acid according to the molar ratio of 1:2.5-5:4-8:24-26, so as to obtain a mixed solution, wherein the concentration of cupric chloride or copper acetate is 0.7-0.9 mmol / L; and (2) adjusting the pH value of the mixed solution obtained in the step (1) to 8-9, then heating the mixed solution at 93-98 DEG C for reaction for 60-90 min, and cooling to room temperature, so as to obtain the near-infrared copper-indium-selenium quantum dot. The prepared quantum dot has the advantages of being nontoxic, simple in method, mild and controllable in reaction conditions, short in reaction time, good in reappearance and the like. The prepared quantum dot is widely applicable to cell and tissue imaging as a fluorescent marker, and also is applicable to in vivo imaging research.

Owner:SHENZHEN INST OF ADVANCED TECH

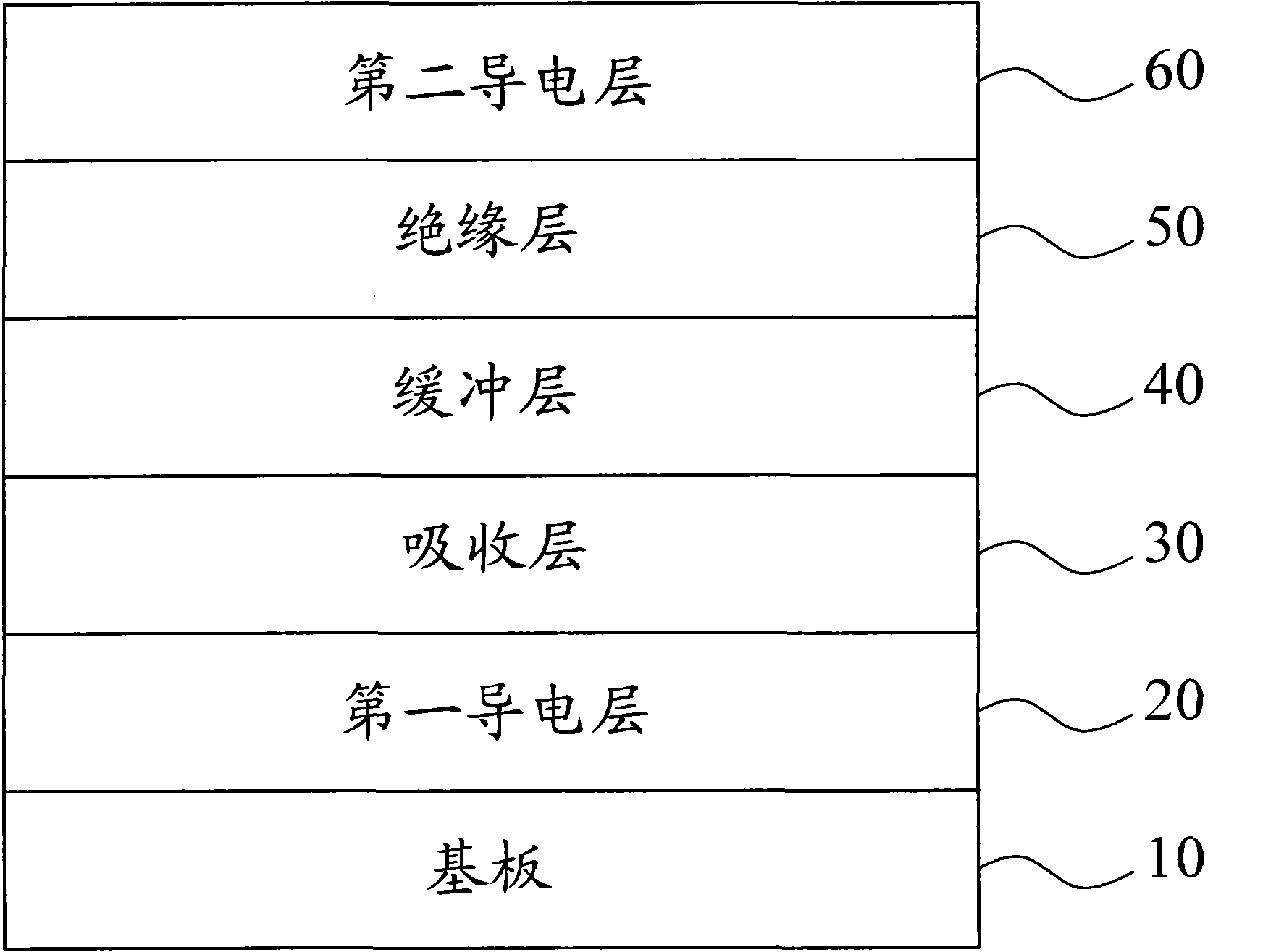

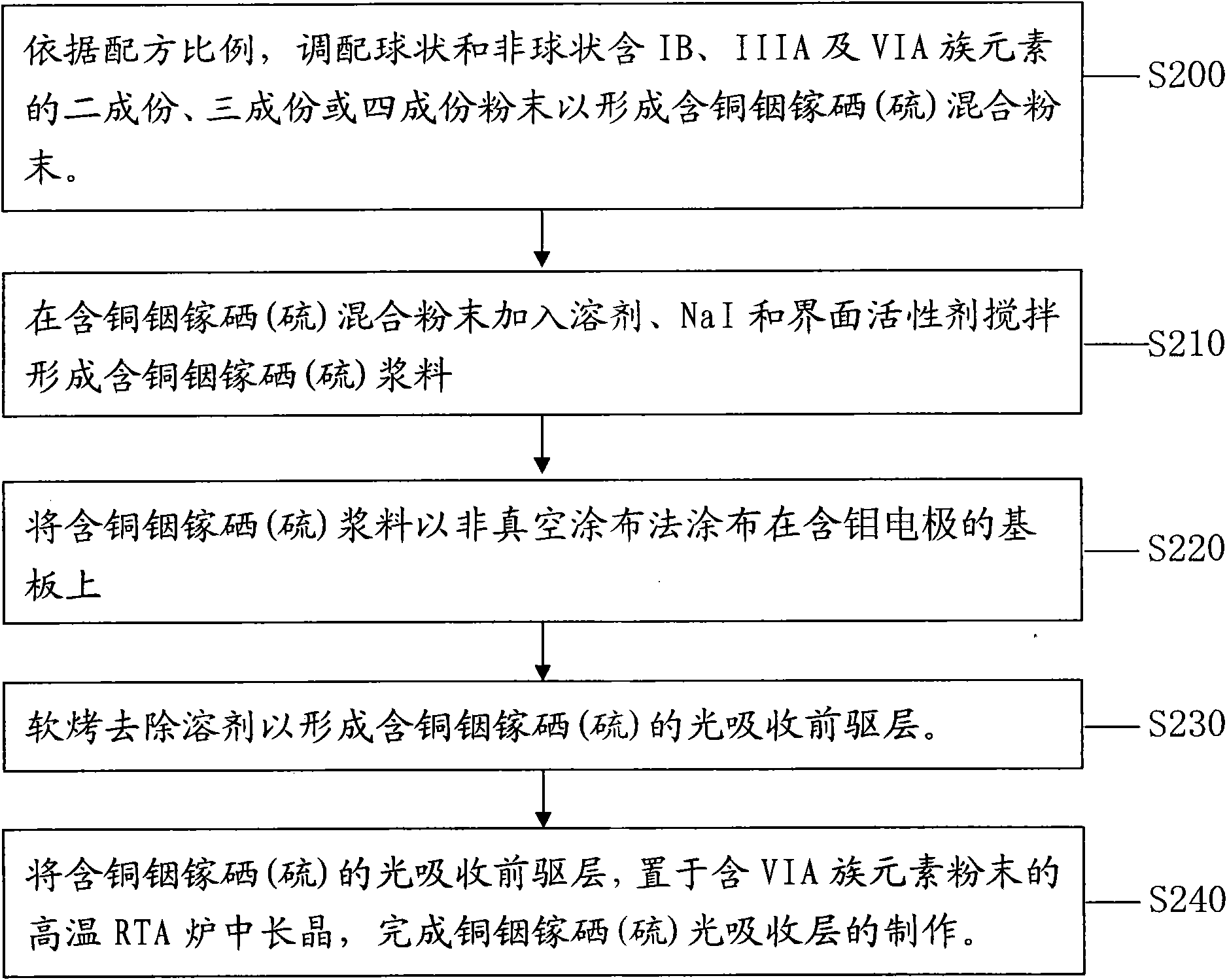

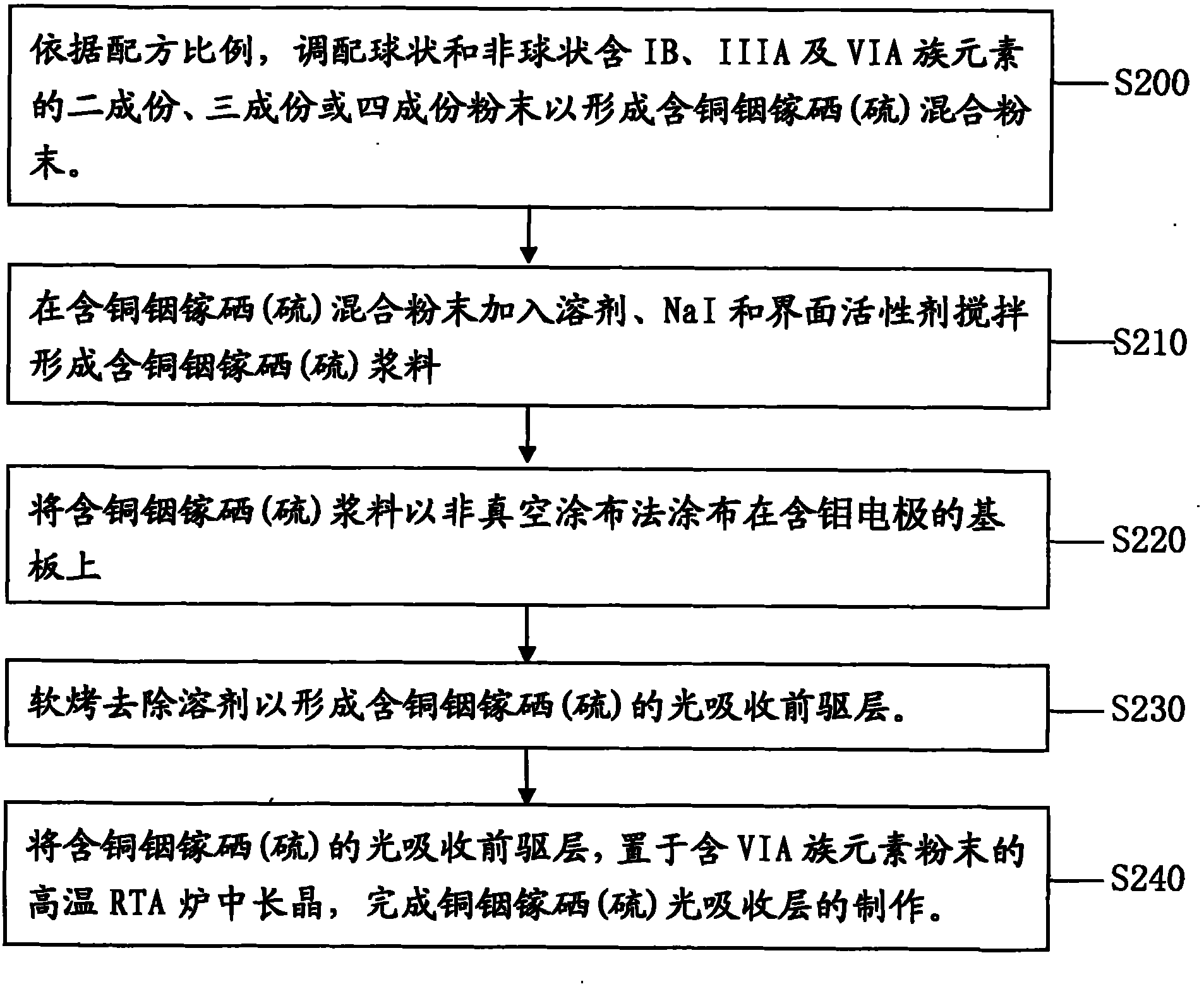

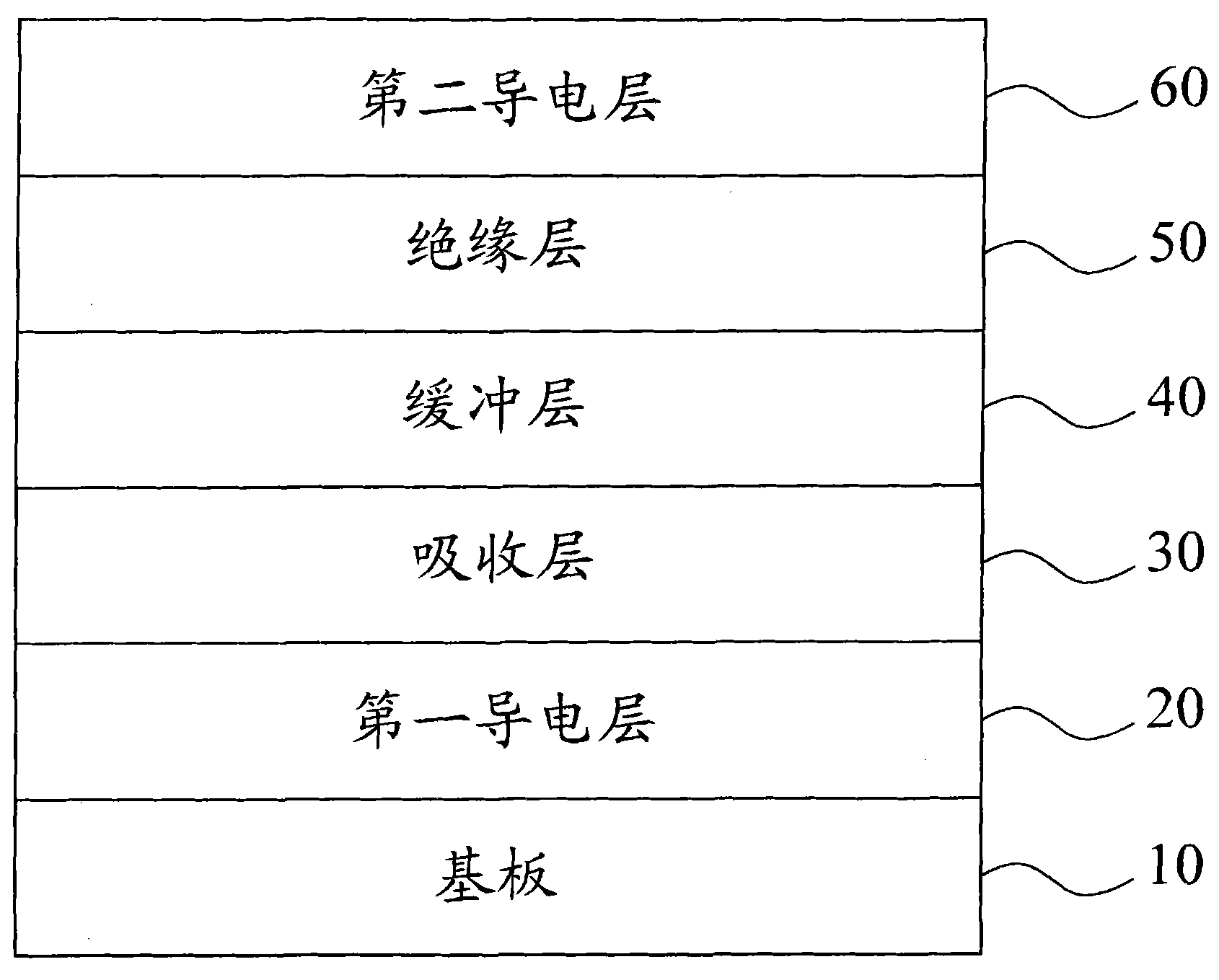

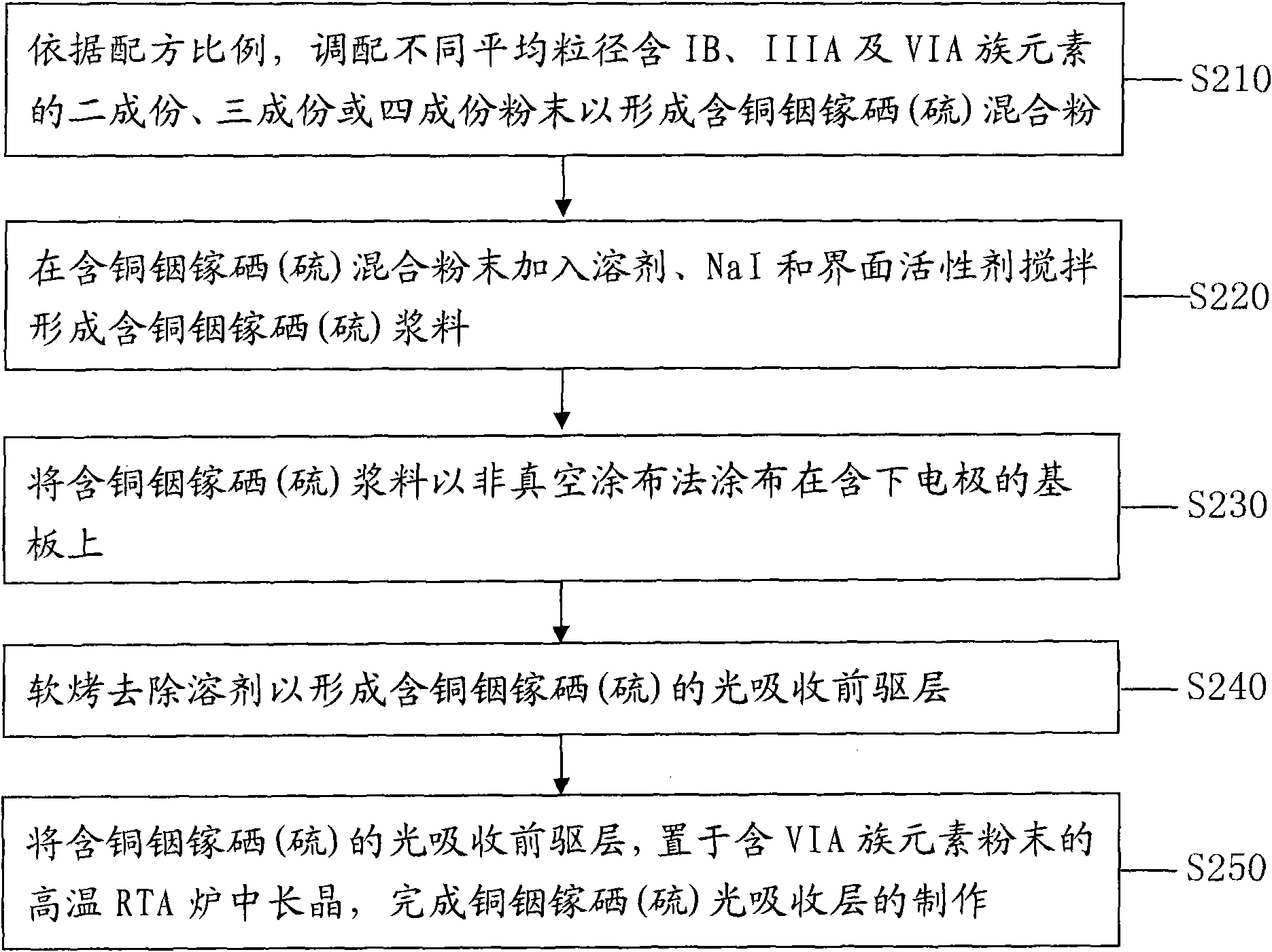

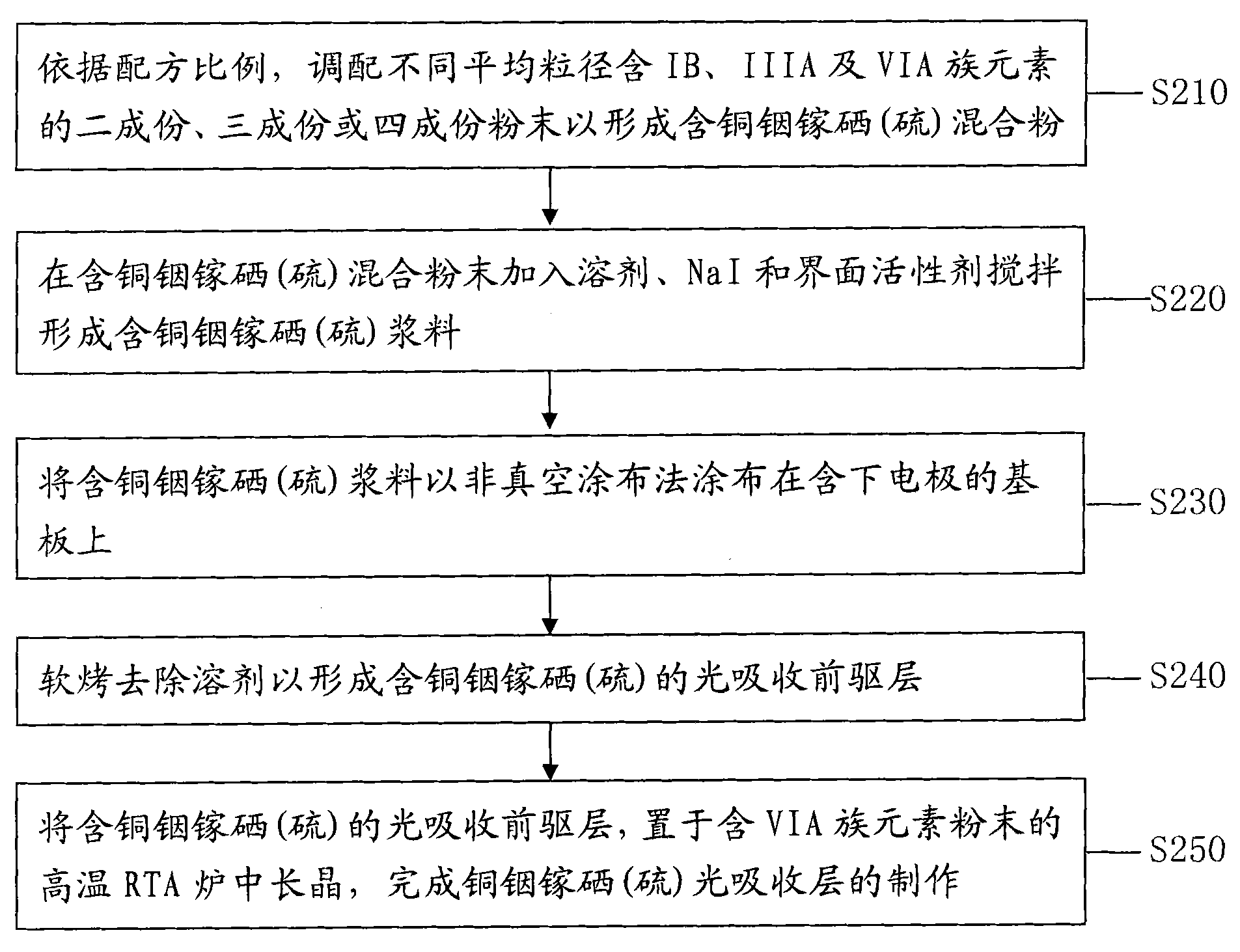

Method for preparing copper-indium-gallium-selenium(sulfur) light absorption layer by adopting non-vacuum process

InactiveCN101818375AReduce porositySignificant progressPolycrystalline material growthFrom solid stateIndiumActive agent

The invention relates to a method for preparing a copper-indium-gallium-selenium(sulfur) light absorption layer by adopting a non-vacuum process. The method comprises the following steps of: in a formula ratio, blending spherical and non-spherical two component powder, three component powder or four component powder containing IB, IIIA and VIA group elements to obtain copper-indium-gallium-selenium(sulfur)-containing mixed powder, wherein the average grain size of the powder is less than 500 nanometers; adding a solvent, NaI and an interface active agent into the copper-indium-gallium-selenium(sulfur)-containing mixed powder, stirring the mixture to obtain copper-indium-gallium-selenium(sulfur)-containing pulp; coating the pulp on a molybdenum electrode-containing substrate by a non-vacuum coating method, obtaining a copper-indium-gallium-selenium(sulfur)-containing light absorption precursor layer by soft-baking; and putting the copper-indium-gallium-selenium(sulfur)-containing light absorption precursor layer in a high-temperature RTA furnace containing VIA group element powder for growing crystals, and obtaining the copper-indium-gallium-selenium(sulfur) light absorption layer. In the method, because the spherical nanometer particles and at least one kind of non-spherical nanometer particles are mixed, the pore problems occurring in the film-forming process are solved; in addition, a selenization method is not adopted, so that the dangerous hydrogen selenide is avoided using.

Owner:昆山正富机械工业有限公司

Preparation method for cadmium selenide-bismuth tungstate compound photocatalyst

The invention discloses a preparation method for a cadmium selenide-bismuth tungstate compound photocatalyst. The method comprises the following steps: (1) dissolving cadmium hydrate and 3-thiohydracrylic acid at mole ratio of 1:(1.5-1.7) into deionized water, thereby forming a mixed solution; regulating pH of the solution to 7-8; adding a selenium hydride precursor into the mixed solution and reacting for 30-35 minutes at 160-170 DEG C, thereby acquiring a cadmium selenide quantum dot; (2) dissolving the cadmium selenide quantum dot and bismuth tungstate into the deionized water, refluxing for 20-25 hours at 80-90 DEG C and centrifugally drying, thereby acquiring the cadmium selenide-bismuth tungstate compound photocatalyst. The cadmium selenide-bismuth tungstate compound photocatalyst acquired according to the invention has high catalytic activity and high stability.

Owner:张家港市金港镇宏业海绵复合厂

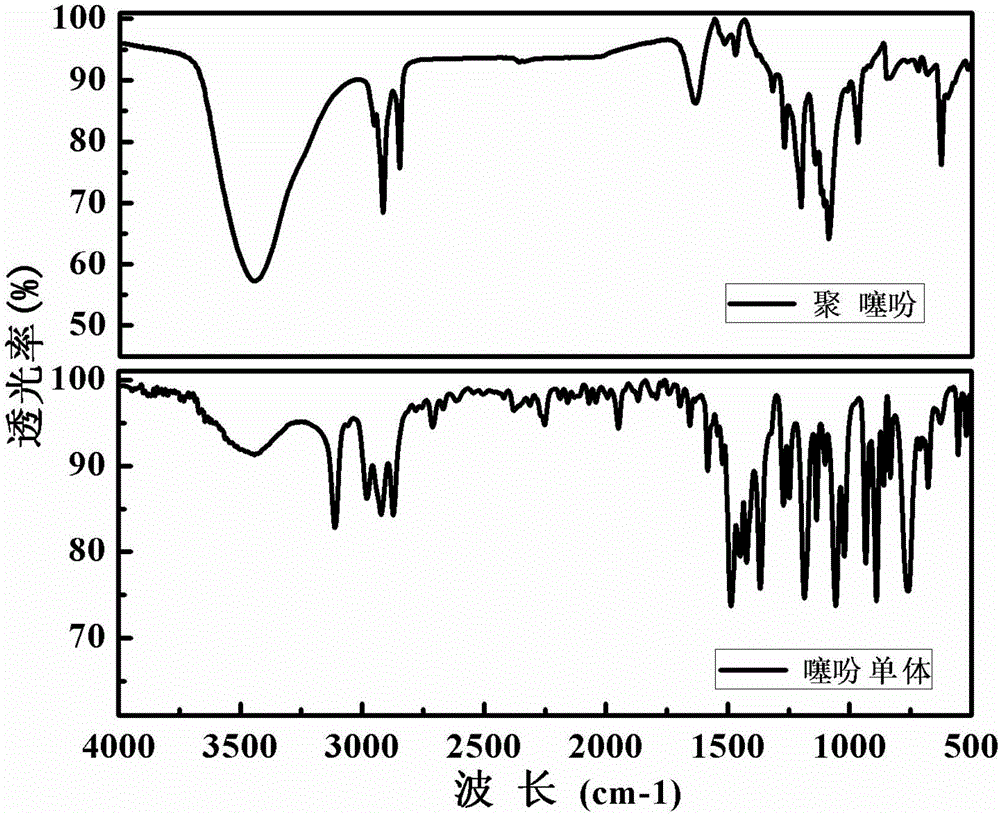

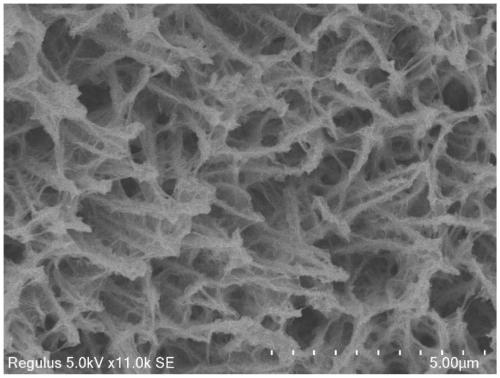

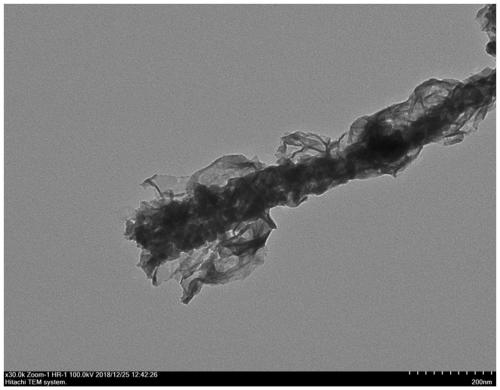

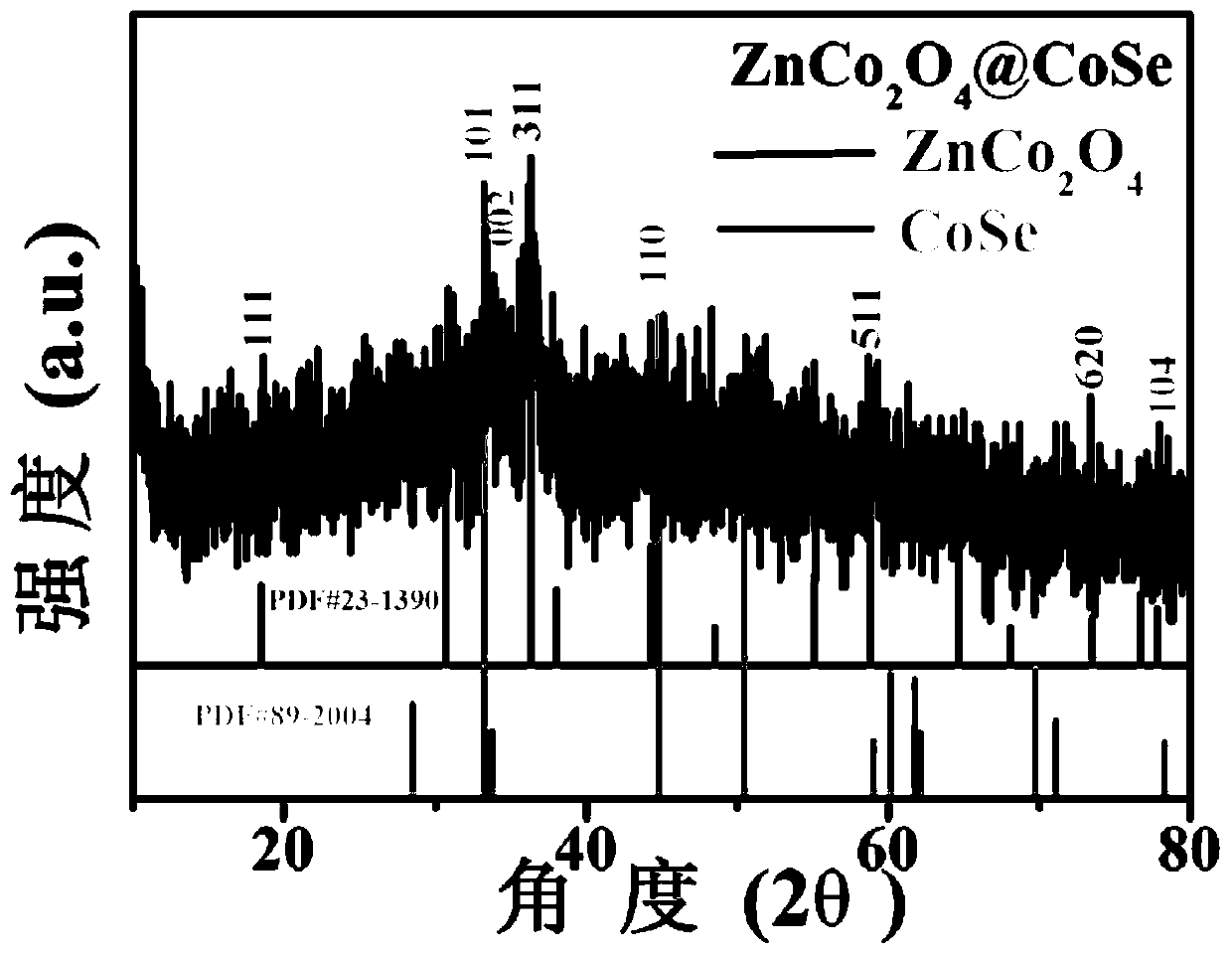

Three-dimensional nickel cobaltate@cobalt selenide (II) nanoneedle array composite material as well as preparation method and application thereof

ActiveCN110152692AImprove electrocatalytic activityStable electrocatalytic activityPhysical/chemical process catalystsElectrodesHydrolysisCobalt

The invention discloses a three-dimensional nickel cobaltate@cobalt selenide (II) nanoneedle array composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: performing a hydrothermal reaction on a ZnCo2O4 nanoneedle array, sodium hydrogen selenide and a cobalt source in water to prepare the three-dimensional ZnCo2O4@CoSe nanoneedle array composite material. The three-dimensional nickel cobaltate@cobalt (II) nanoneedle array composite material provided by the invention has excellent electrocatalytic activity and cycle stability, and can be applied to electrocatalytic hydrolysis of an electrode material; and the preparation method has simple operation, low costs, mild conditions, greenness and environmental protection.

Owner:ANHUI NORMAL UNIV

Method for preparing GIGS solar cell by applying one-step sputtering method

InactiveCN108389934AImprove conversion efficiencyImprove stabilityFinal product manufacturePhotovoltaic energy generationHydrogenEvaporation

The invention provides a method for preparing a GIGS solar cell by applying a one-step magnetron sputtering method. According to the invention, soda-lime glass is taken as a substrate, Mo / CIGS / CdS / i-ZnO:Al / Ni:Al target materials are sequentially adopted, and a CIGS solar cell with the film thickness being about 1-2 microns through using direct current sputtering and radio frequency sputtering, wherein the Mo target adopts direct current sputtering, the CIGS / CdS / i-ZnO / ZnO:Al sequentially adopt radio frequency sputtering, and the Ni:Al adopts direct current sputtering. Content control for each element is realized through adjusting various parameters in the sputtering process, and a CIGS solar cell with the conversion efficiency reaching 5.77% at most can be obtained. The magnetron sputteringmethod provided by the invention is different from the traditional quaternary co-evaporation, sputtering and post-selenization method, so that there is no need of using a toxic hydrogen selenide gasto prepare a CIGS absorption layer by applying the post-selenization method, but the absorption layer is directly prepared by adopting the selenium-rich CIGS target material, thereby enabling the production process to be simpler to operate, green, environment-friendly and easy to control. In addition, the commercial production can be enabled to be equivalent to laboratory production in productionefficiency, and the method has wide commercial application prospects.

Owner:SOUTHWEST PETROLEUM UNIV

System for enhancing selenium reaction activity by hydrogenating selenium source of flexible CIGS solar cell

ActiveCN110739370AReduce clustersHigh reactivityFinal product manufactureVacuum evaporation coatingProcess engineeringSolar battery

The invention discloses a system for enhancing selenium reaction activity by hydrogenating a selenium source of a flexible CIGS solar cell. The system comprises a selenium source, a hydrogen storage tank, an automatic gas mixing device and a mixed gas output pipeline, wherein the automatic gas mixing device comprises a selenium steam control valve, a hydrogen control valve and a gas conveying pipeline, a selenium steam outlet of the selenium source is connected with an inlet of the selenium steam control valve, a hydrogen outlet of the hydrogen storage tank is connected with an inlet of the hydrogen control valve, an outlet of the selenium steam control valve is connected with a selenium steam inlet of the gas conveying pipeline, an outlet of the hydrogen control valve is connected with ahydrogen inlet of the gas conveying pipeline, an outlet of the gas conveying pipeline is connected with an inlet of the mixed gas output pipeline, and the selenium steam control valve is linked with the hydrogen control valve. The system is advantaged in that automatic and uniform mixing of a selenium steam and hydrogen can be realized, the cluster Se can be effectively opened, a small amount of hydrogen selenide is generated, the reaction activity is increased, and defects of the film are reduced.

Owner:ZHEJIANG SHANGYUE OPTOELECTRONICS TECH +1

Method for preparing copper-indium-gallium-selenium(sulfur) light absorption layer by adopting non-vacuum process

InactiveCN101820025AImprove compactnessSignificant progressFinal product manufactureSemiconductor devicesCooking & bakingIndium

The invention relates to a method for preparing a copper-indium-gallium-selenium(sulfur) light absorption layer by adopting a non-vacuum process. The method comprises the following steps of: in a formula ratio, blending two component powder, three component powder or four component powder which is of different particle size and contains IB, IIIA and VIA group elements to obtain copper-indium-gallium-selenium(sulfur)-containing mixed powder, wherein the average particle size of the small-size particles is less than 30 percent of the average particle size of the small-size particles; adding a solvent into the copper-indium-gallium-selenium(sulfur)-containing mixed powder; coating the copper-indium-gallium-selenium(sulfur)-containing pulp on a lower electrode-containing substrate by a non-vacuum coating method, obtaining a copper-indium-gallium-selenium(sulfur)-containing light absorption precursor layer by soft-baking; and putting the copper-indium-gallium-selenium(sulfur)-containing light absorption precursor layer in a high-temperature RTA furnace containing VIA group element powder for growing crystals, and obtaining the copper-indium-gallium-selenium(sulfur) light absorption layer. The method can improve the compactness of the coated film, and because a selenization method is not adopted, the use of the dangerous hydrogen selenide is avoided.

Owner:昆山正富机械工业有限公司

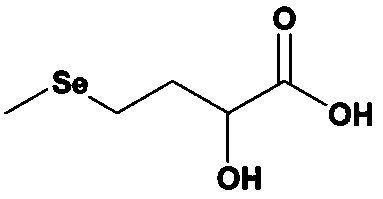

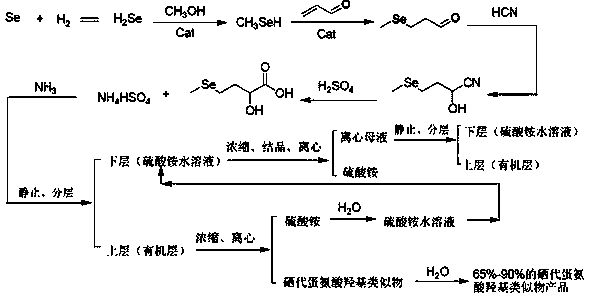

Preparation method of selenomethionine hydroxy analogue

InactiveCN109232342ASimple processHigh yieldOrganic chemistryAccessory food factorsChemical synthesisMethionine hydroxy analog

The invention belongs to the field of amino acid feed, food and medicines, and particularly relates to a method for preparing selenomethionine hydroxy analogue by virtue of a chemical synthesis methylseleno propanal method. The method comprises the following steps: preparing hydrogen selenide by virtue of selenium powder and hydrogen, enabling the hydrogen selenide to react with methanol, preparing methyl-hydroselenide, preparing methylseleno propanal from the methyl-hydroselenide and acraldehyde as well as relevant compounds, enabling a methylseleno propanal and hydrocyanic acid gas mixure toreact and synthesize DL-2-hydroxyl-4-methylseleno butyronitrile, performing acidolysis on DL-2-hydroxyl-4-methylseleno butyronitrile, separating and purifying, thus obtaining the selenomethionine hydroxy analogue and a byproduct ammonium sulfate. The selenomethionine hydroxy analogue has various excellent biological activities not possessed by a methionine hydroxy analogue, as well as organic trace element selenium necessary for the supplement of animal bodies, and has a para-insulin effect for supporting an oral preparation and can be used for treating diabetes, and can be applied to the fields such as medicines, nutrition healthcare and agriculture by the institute of environment and science.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

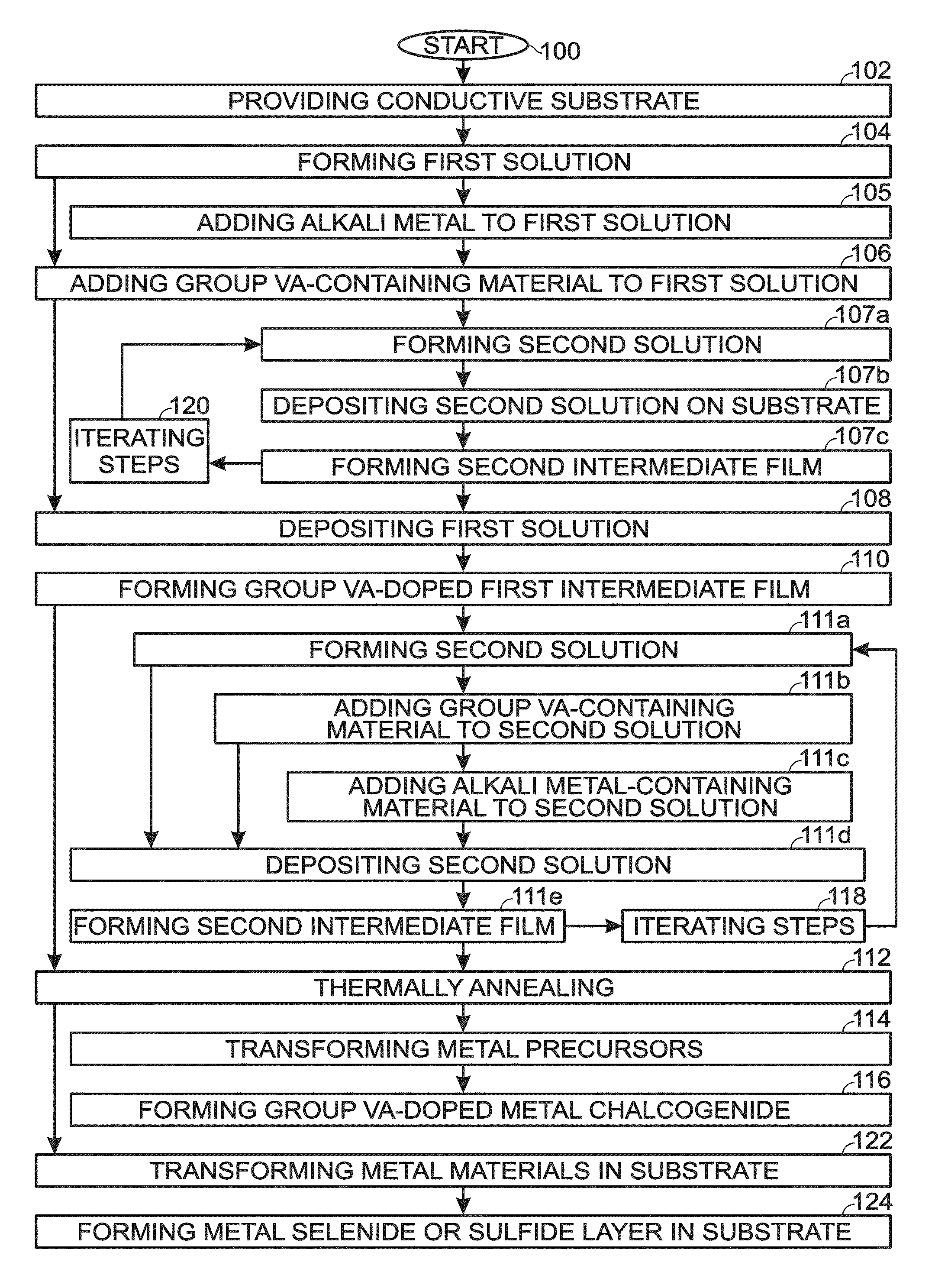

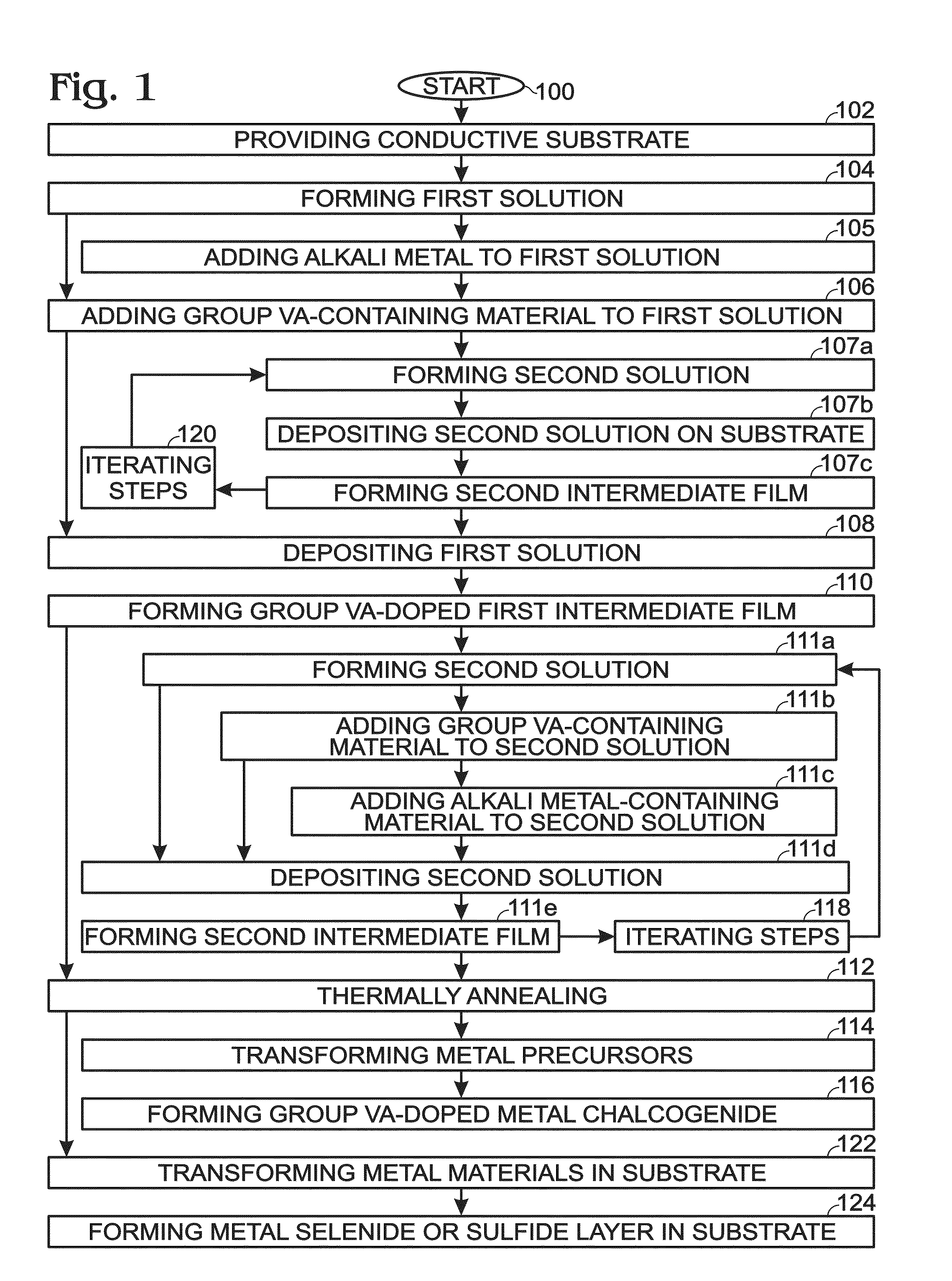

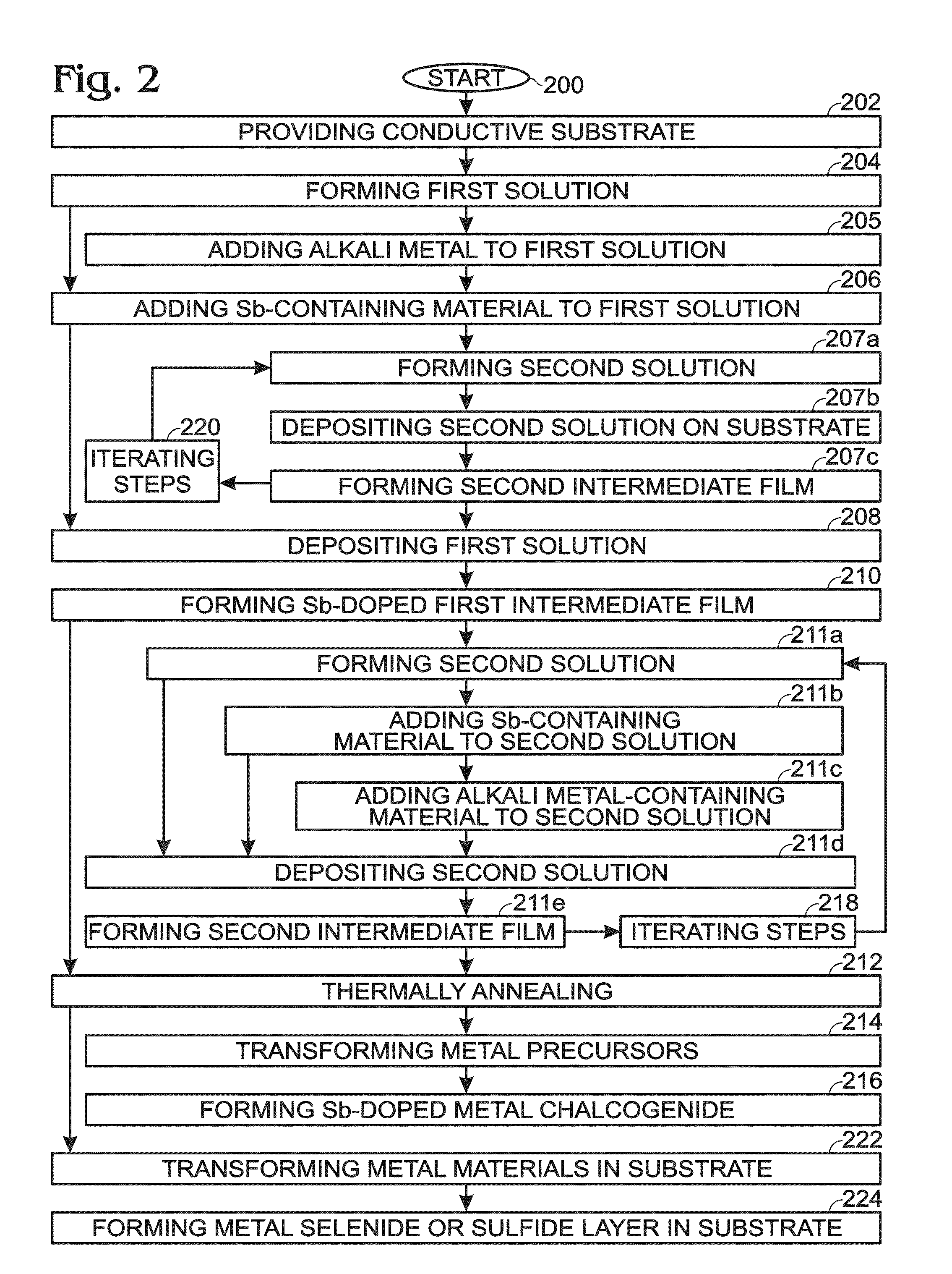

Group VA-doped solution-processed metal chalcogenides

InactiveUS8685779B1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationHydrogenMetal chalcogenides

A method is provided for forming a Group VA-doped solution-processed metal chalcogenide. The method forms a first solution including a first material group, dissolved in solvent. A Group VA-containing material is added to the first solution. The Group VA-containing material may include arsenic (As), antimony (Sb), bismuth (Bi), or combinations thereof. The first solution is deposited on a conductive substrate, and a Group VA-doped first intermediate film is formed comprising metal precursors from corresponding members of the first material group. Thermal annealing is performed in an environment of selenium (Se), Se and hydrogen (H2), hydrogen selenide (H2Se), sulfur (S), S and H2, hydrogen sulfide (H2S), or combinations thereof. As a result, the metal precursors in the Group VA-doped first intermediate film are transformed, forming a Group VA-doped metal chalcogenide layer. In one aspect, an antimony-doped Cu—In—Ga—Se chalcogenide (CIGS) is formed.

Owner:SHARP KK

Preparation method of II-VI family water-soluble selenide semiconductor quantum dots

The invention provides a preparation method of II-VI family water-soluble selenide semiconductor quantum dots, which comprises the following specific steps: adding a stabilizer into solution containing soluble cadmium salt, soluble zinc salt or soluble mercury salt, then regulating the pH value of the solution to be be alkaline, then introducing hydrogen selenide gas under inert atmosphere, and reacting till the solution is pale yellow and transparent, thereby preparing solution of a precursor, wherein the molar ratio of the soluble cadmium salt, the soluble zinc salt or the soluble mercury salt to the stabilizer is 1: 3-1: 2. High-temperature and high-pressure fast growth is performed on the solution of the precursor, thereby preparing the II-VI family water-soluble selenide semiconductor quantum dots. For the preparation method, the operation is simple, the cost is low, the toxicity is small, and the prepared II-VI family water-soluble selenide semiconductor quantum dots can be directly used for biological fluorescent marking, clinical diagnosis and other experiments.

Owner:EAST CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com