Patents

Literature

40 results about "Negative glow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

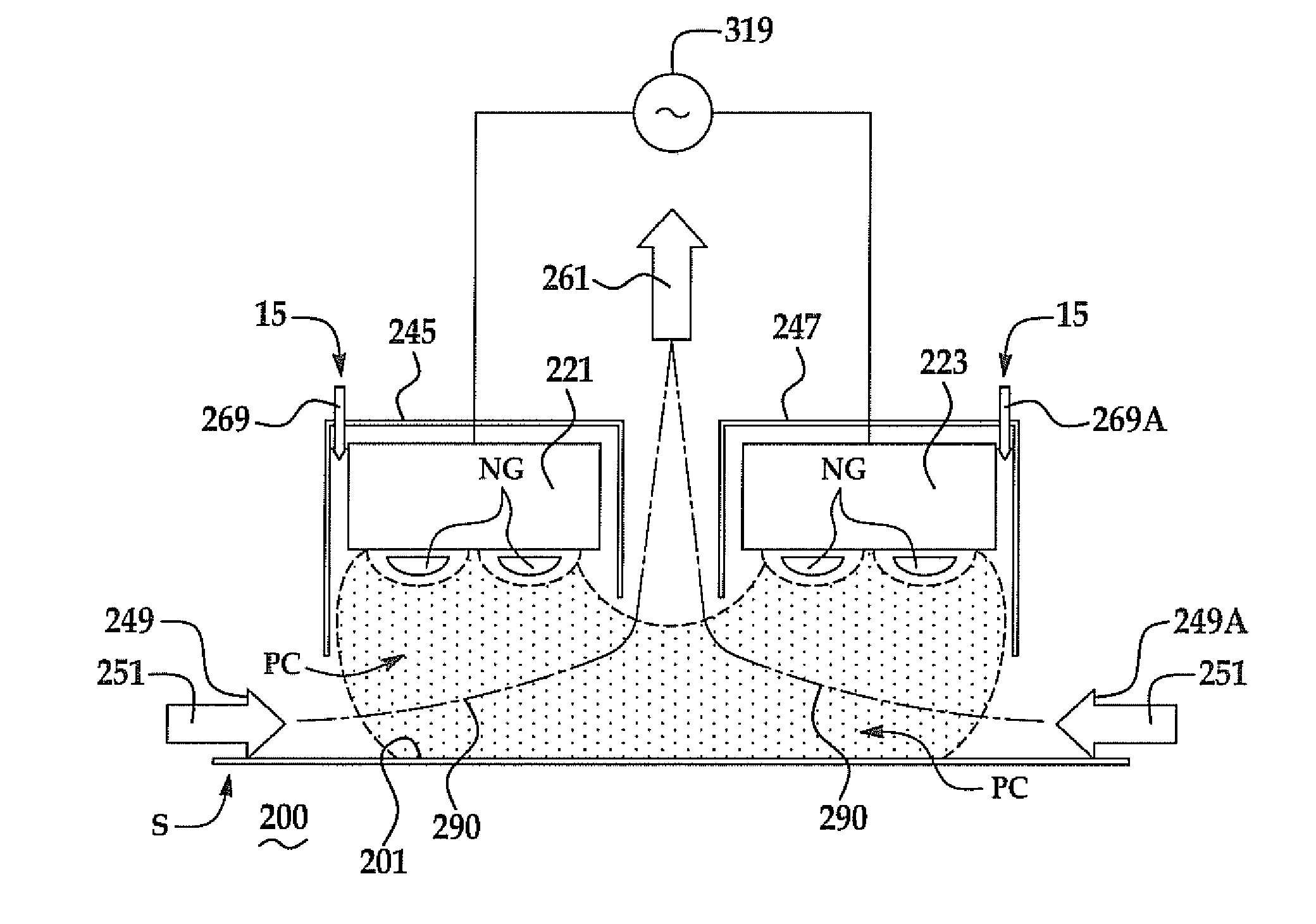

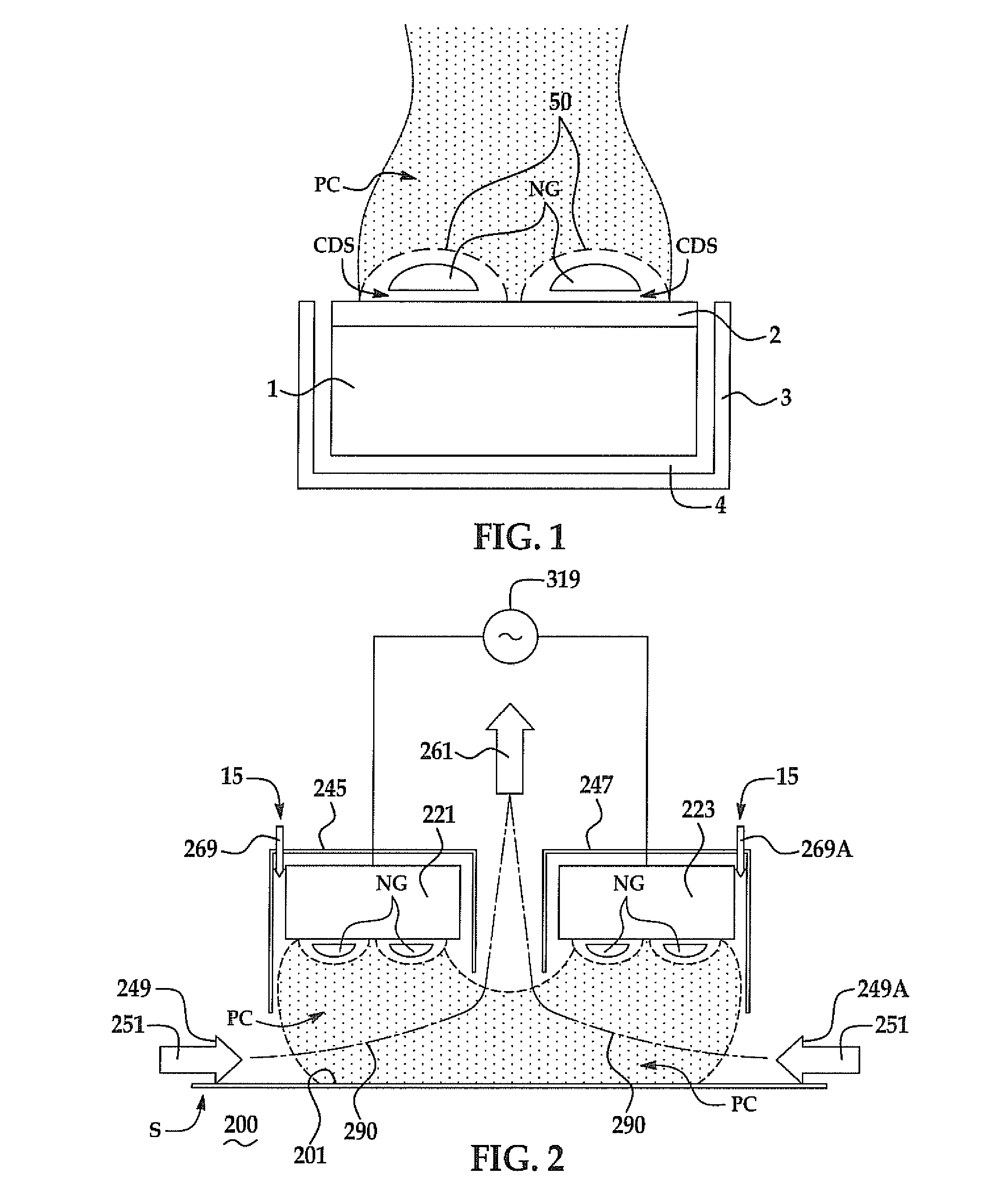

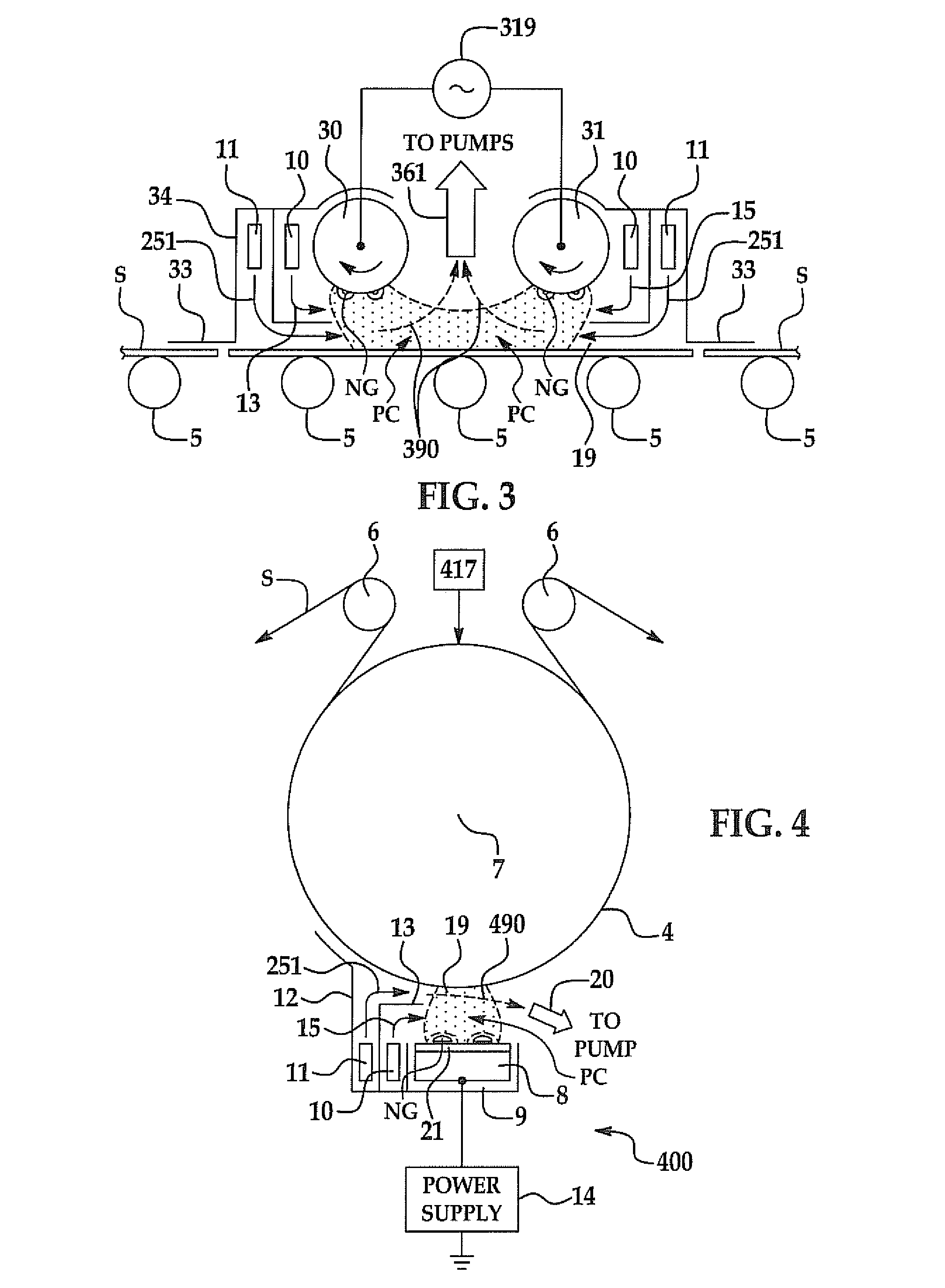

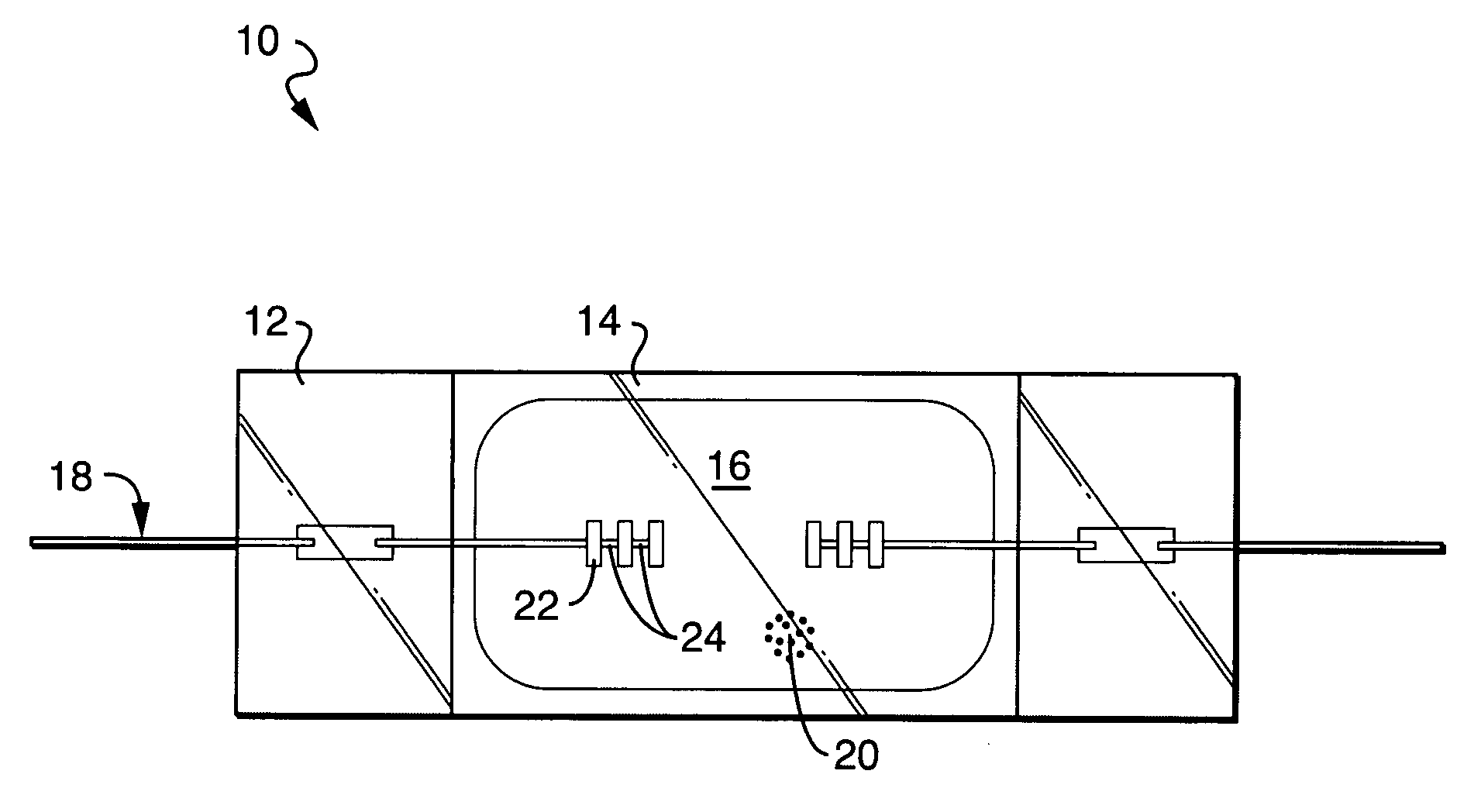

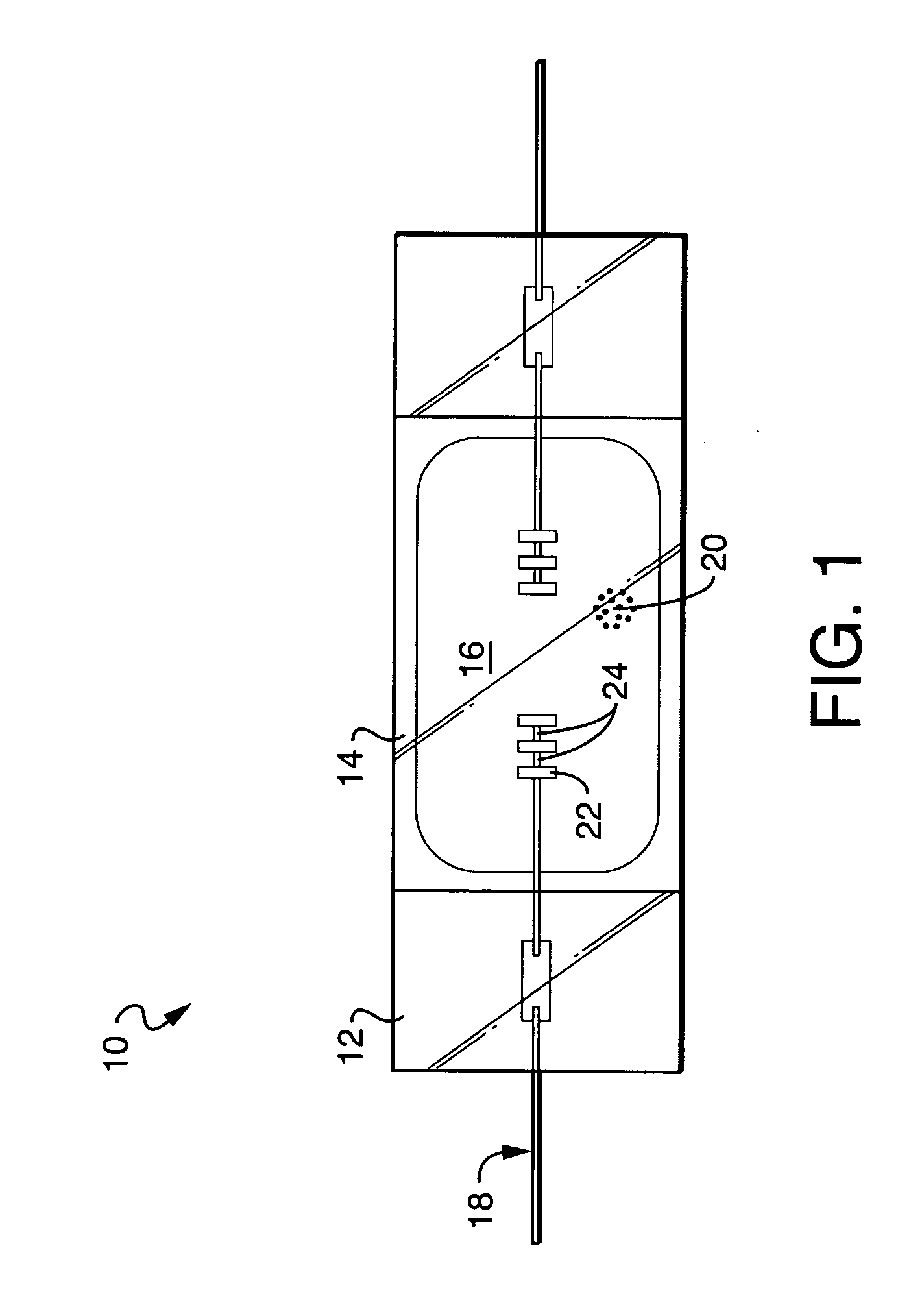

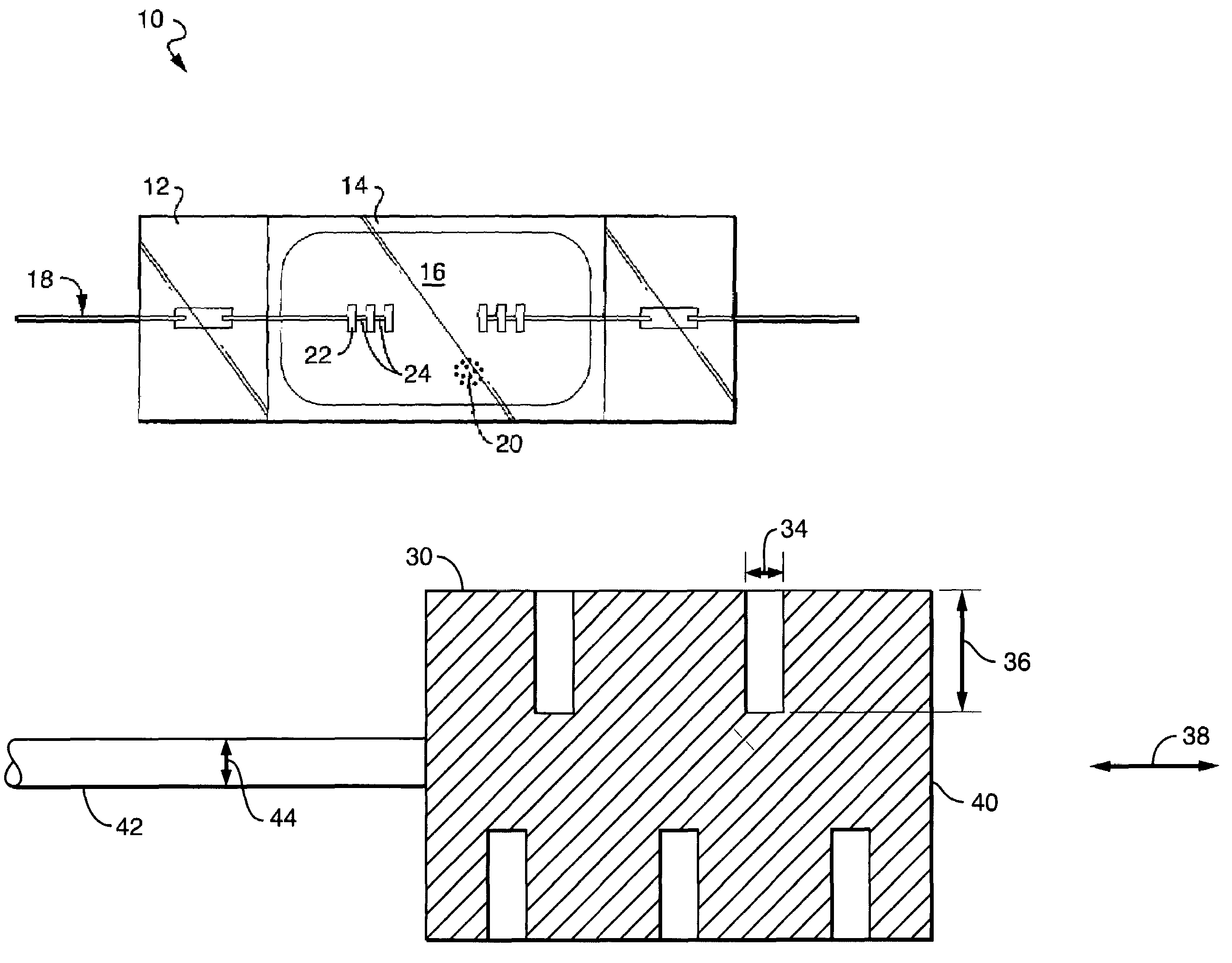

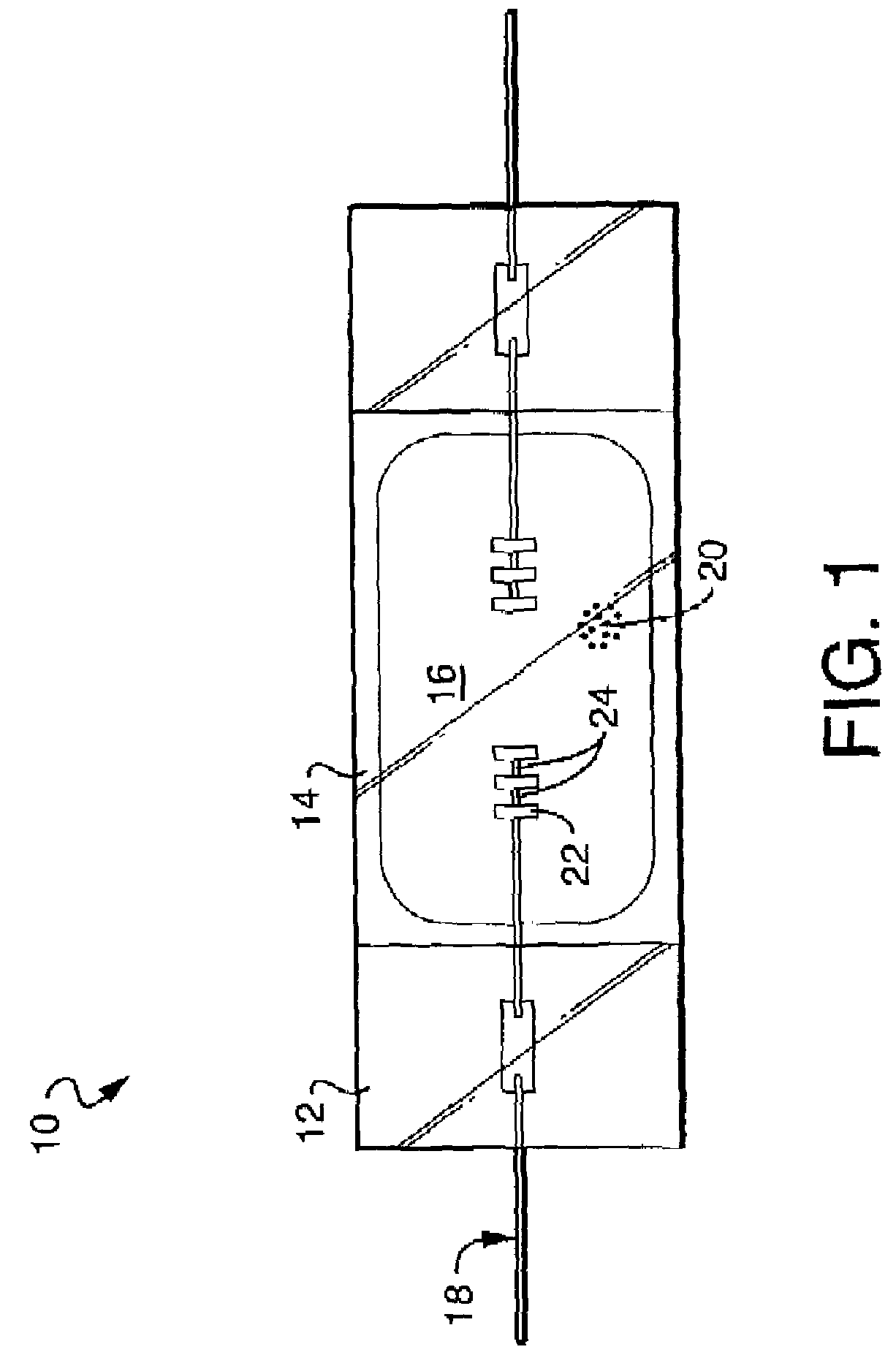

Plasma enhanced chemical vapor deposition apparatus

InactiveUS20120164353A1Long PECVD coating runBuildup is minimizedElectric discharge tubesSemiconductor/solid-state device manufacturingNegative glowPlasma-enhanced chemical vapor deposition

PECVD apparatus for depositing material onto a moving substrate is provided comprising a process chamber, a precursor gas inlet to the process chamber, a pumped outlet, and a plasma source disposed within the process chamber. The plasma source produces one or more negative glow regions and one or more positive columns. At least one positive column is disposed toward the substrate. The plasma source and precursor gas inlet are disposed relative to each other and the substrate such that the precursor gas is injected into the positive column adjacent the substrate. Apparatus is provided to channel the precursor gas into the positive column away from the negative glow region.

Owner:GENERAL PLASMA

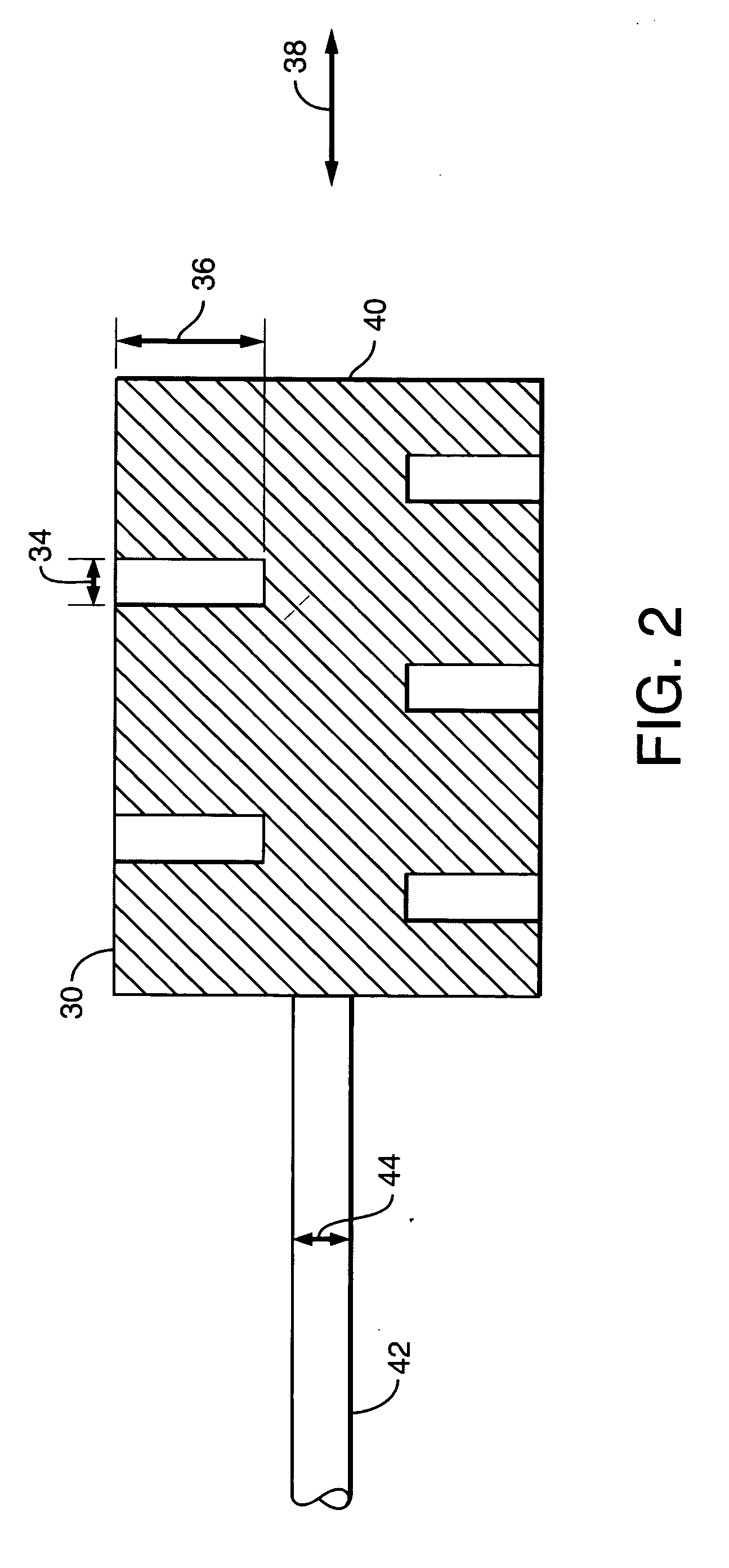

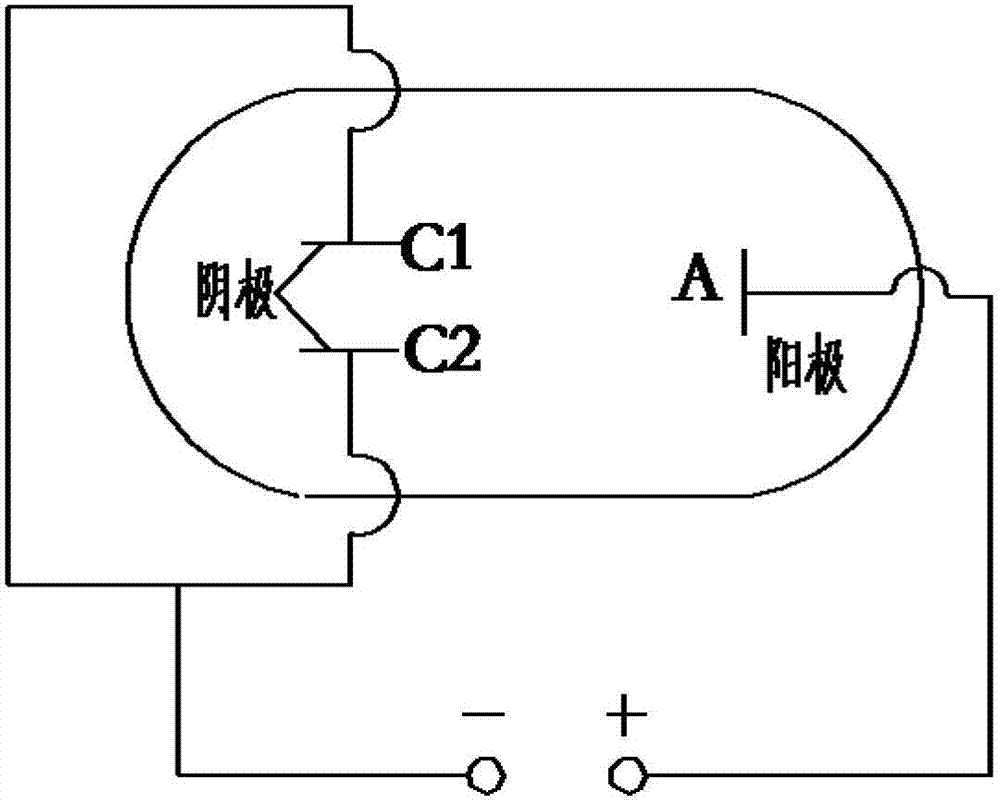

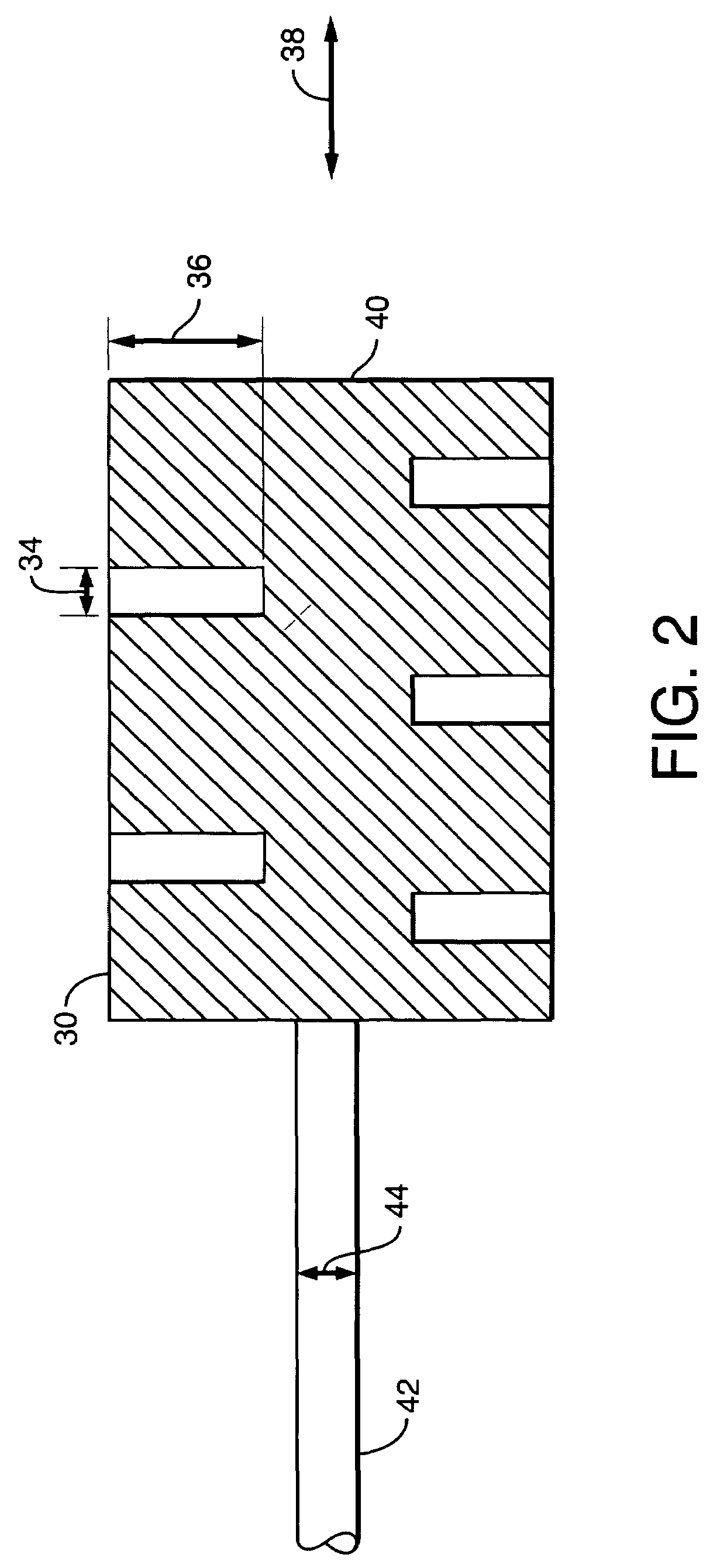

Slotted electrode for high intensity discharge lamp

InactiveUS20060208635A1Reduce evaporationEasy maintenanceElectrode assembly support/mounting/spacing/insulationSolid cathode detailsMean free pathGas composition

Operation of an HID lamp may be improved by forming a glow generating recess on an exterior side the electrode. The lamp may be of standard construction with a light transmissive lamp envelope having a wall defining an enclosed volume. At least one electrode assembly is extended in a sealed fashion from the exterior of the lamp through the lamp envelope wall to be exposed at an inner end of the electrode assembly to the enclosed volume. A metal halide lamp fill is enclosed with an inert fill gas. The inner end of the electrode is formed with a recess having a least spanning dimension S and a recess depth of D where S is greater the electron ionization mean free path but less than twice the cathode fall plus negative glow distances, throughout the glow discharge phase of starting, for the chosen fill gas composition and pressure (cold).

Owner:OSRAM SYLVANIA INC

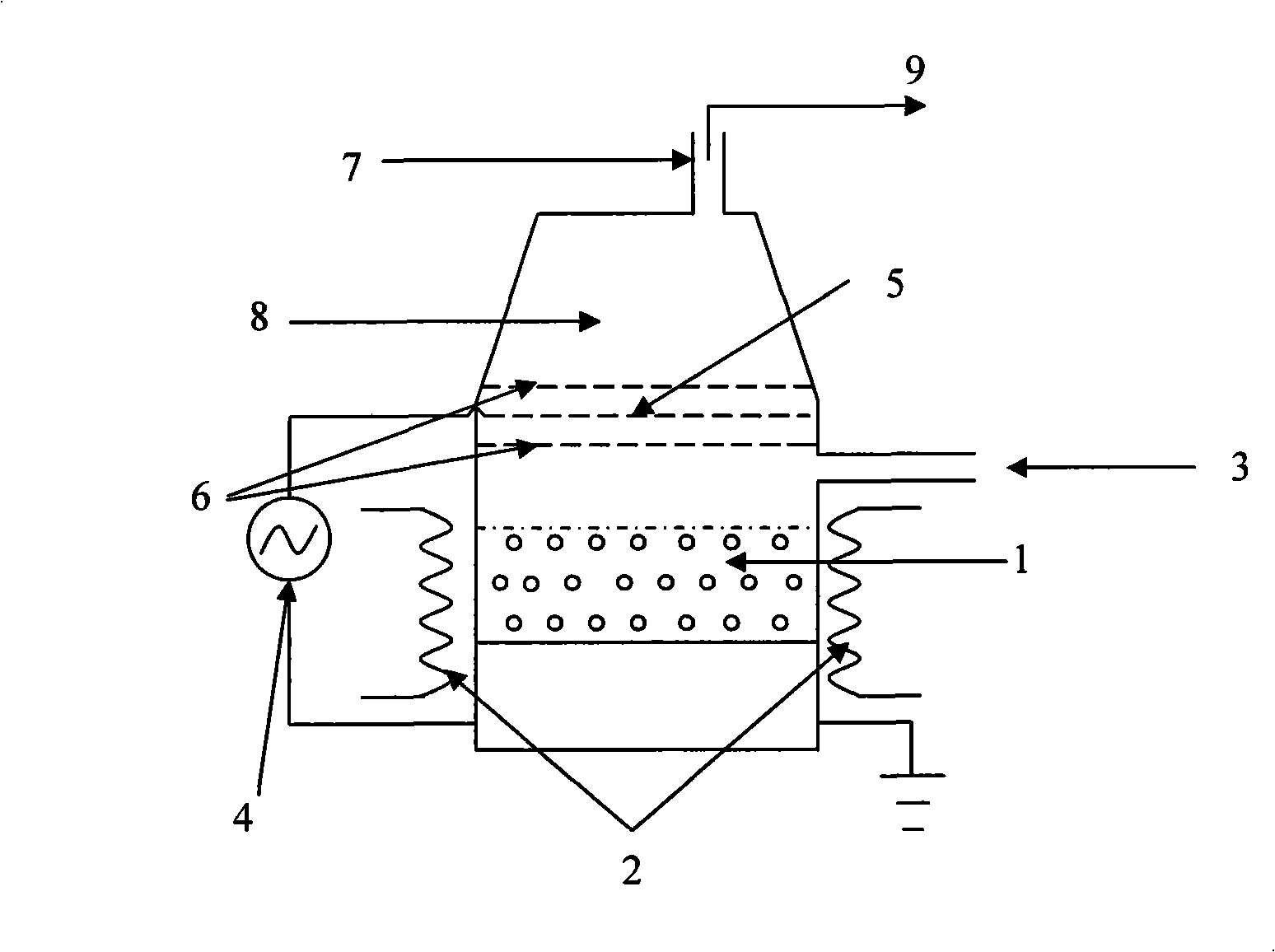

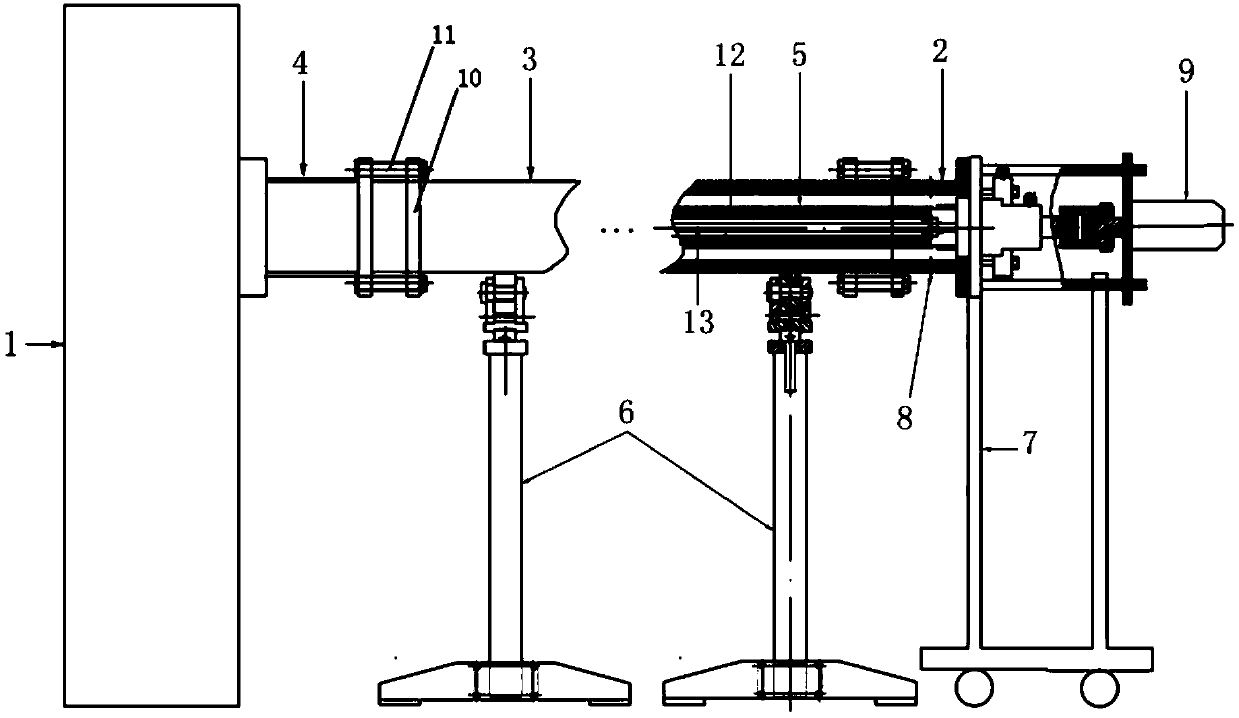

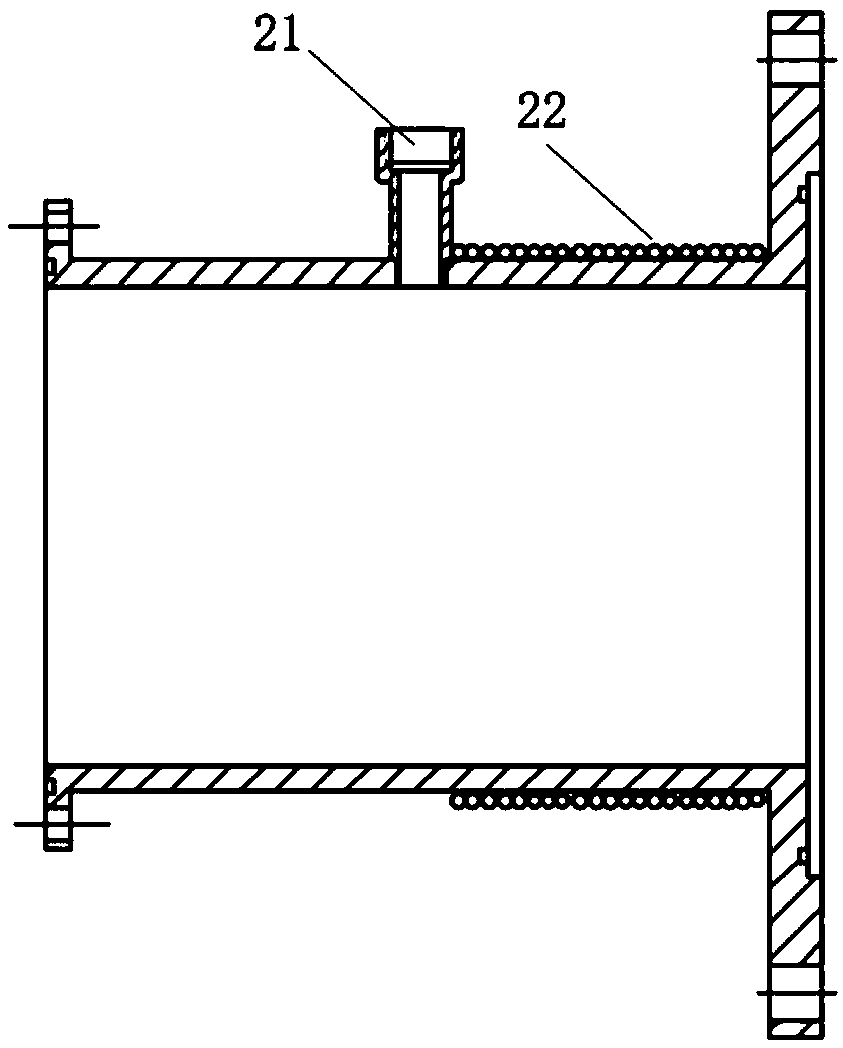

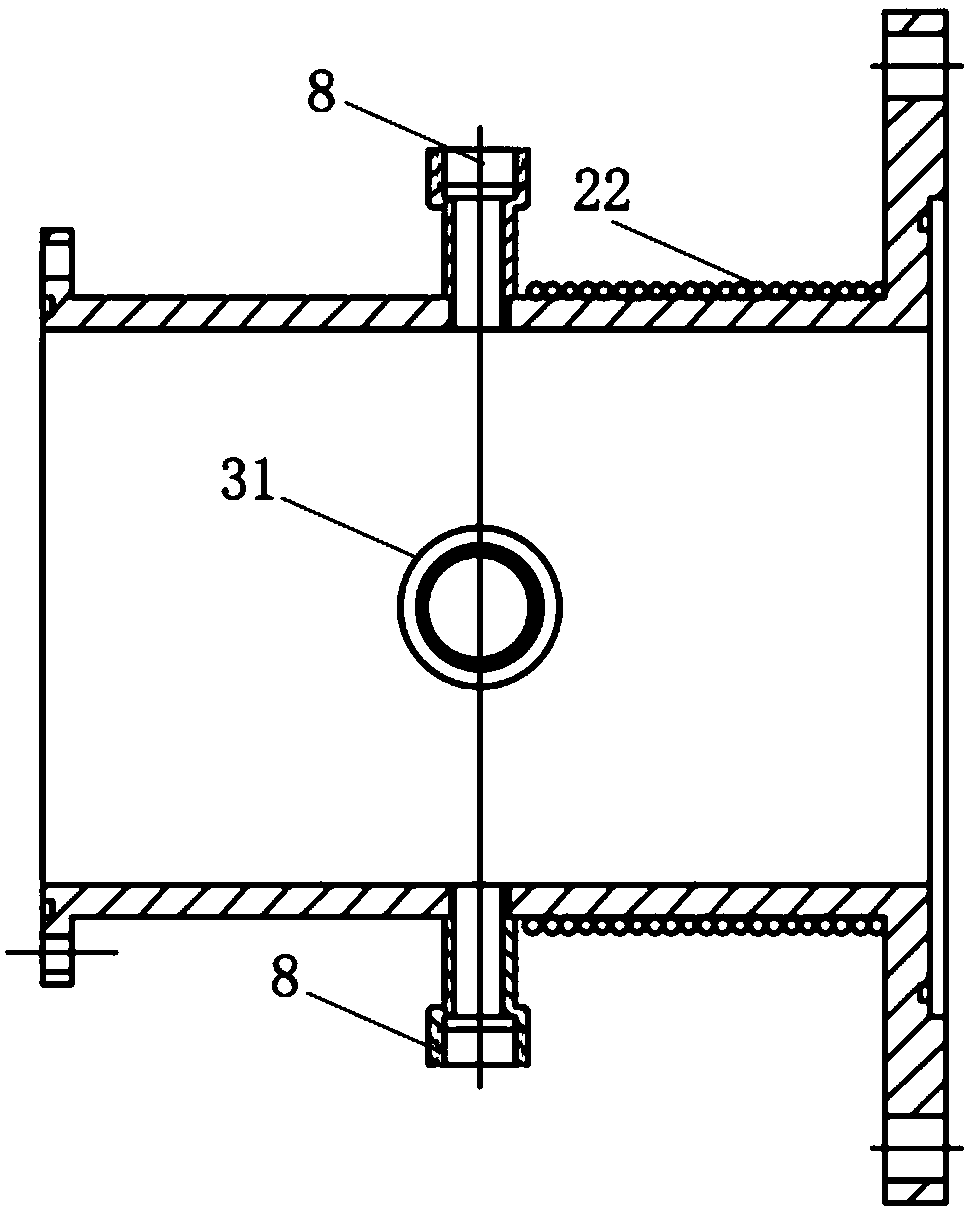

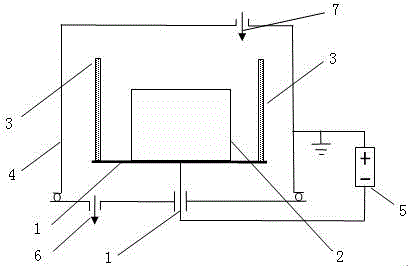

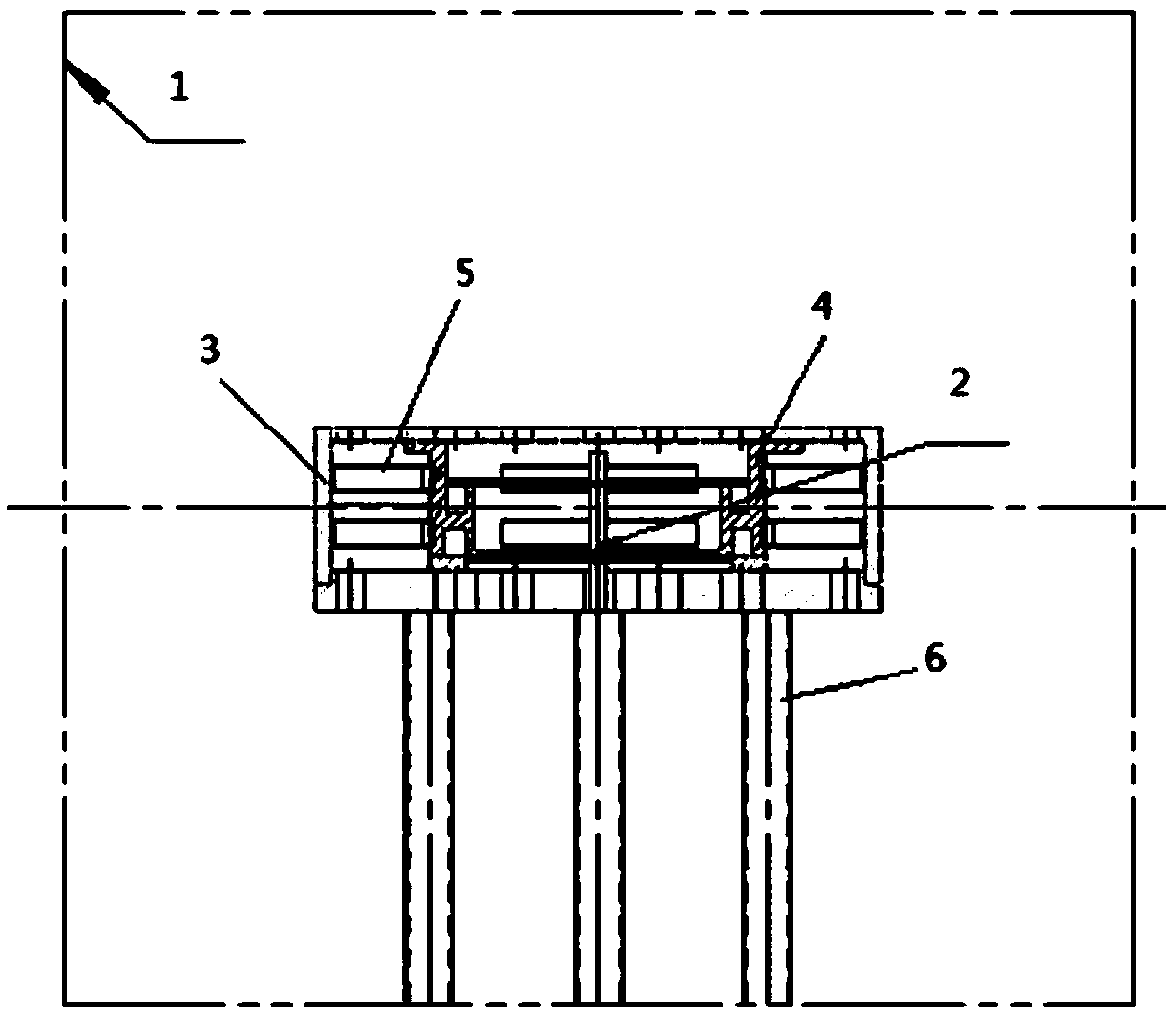

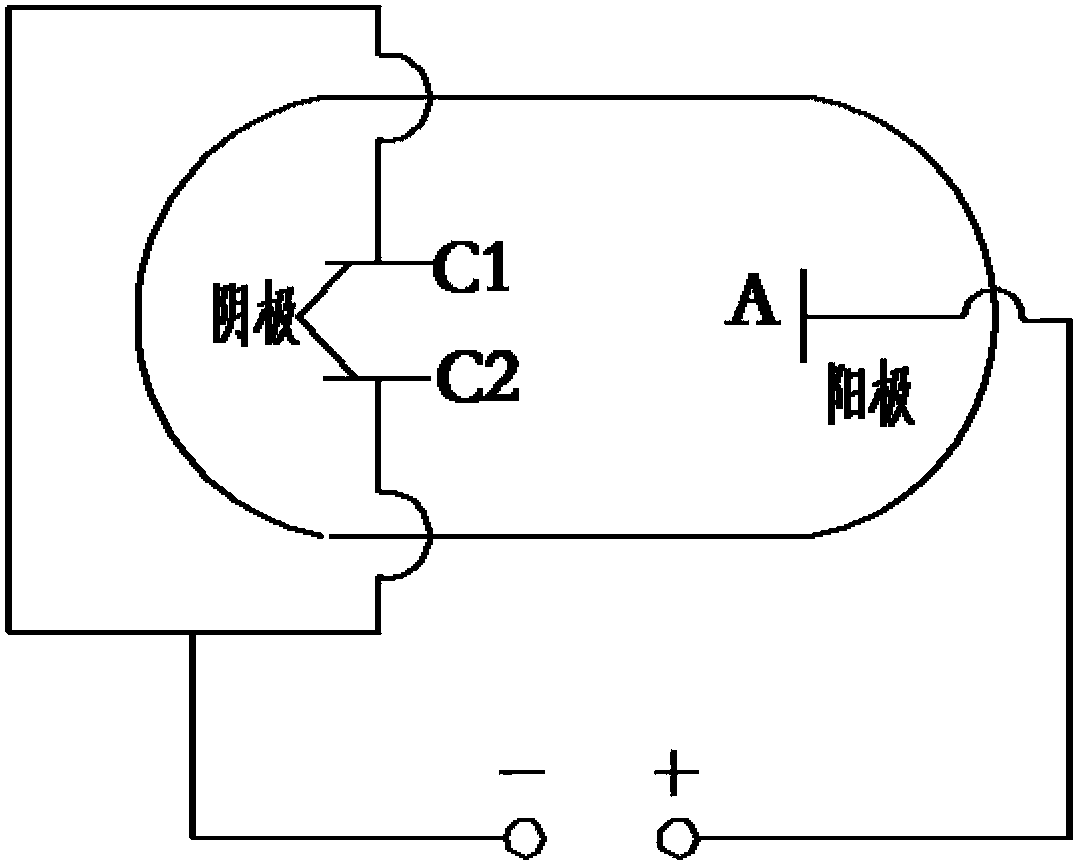

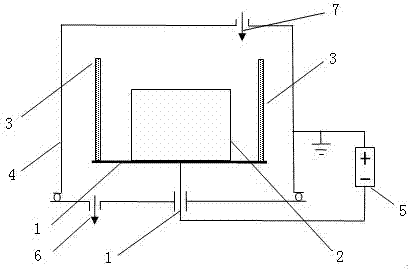

Preparing method of high active selenium source for selenylation, apparatus and applications

ActiveCN101284654AEasy transportationEasy to saveFinal product manufactureChemical industryNegative glowMixed gas

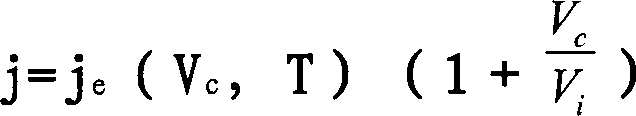

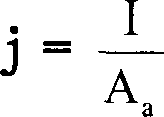

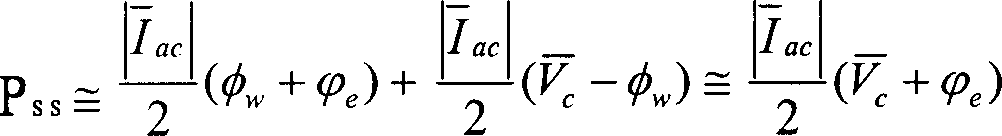

The invention discloses a method for generating a highly active selenium source used for selenizing treatment, and a device and application thereof. The method comprises the steps of heating and vaporizing solid selenium to generate selenium gas; adding hydrogen or a mixture of hydrogen and argon to the selenium gas generated by the last step; and subjecting the mixture of gases in the last step to glow discharge decomposition and synthesis to obtain hydrogen selenide and highly active selenium gas. The device for generating the selenium source comprises an airtight reaction tank, a solid selenium source in the reaction tank, a positive and a negative glow discharge electrodes, a hydrogen selenide reaction cavity, as well as a heating device and an excitation power supply outside the reaction tank. A gas inlet is further arranged on the lateral wall of the reaction tank; a gas outlet is arranged on the top of the reaction tank. The method not only retains the advantages of the solid selenium, namely low cost, non-toxicity and easiness to transport and store, prepares the hydrogen selenide and the highly active selenium ambience with the characteristics of the hydrogen selenide and the highly active selenium, but also saves a large amount of selenide materials, reduces the cost and has important practical value.

Owner:NANKAI UNIV

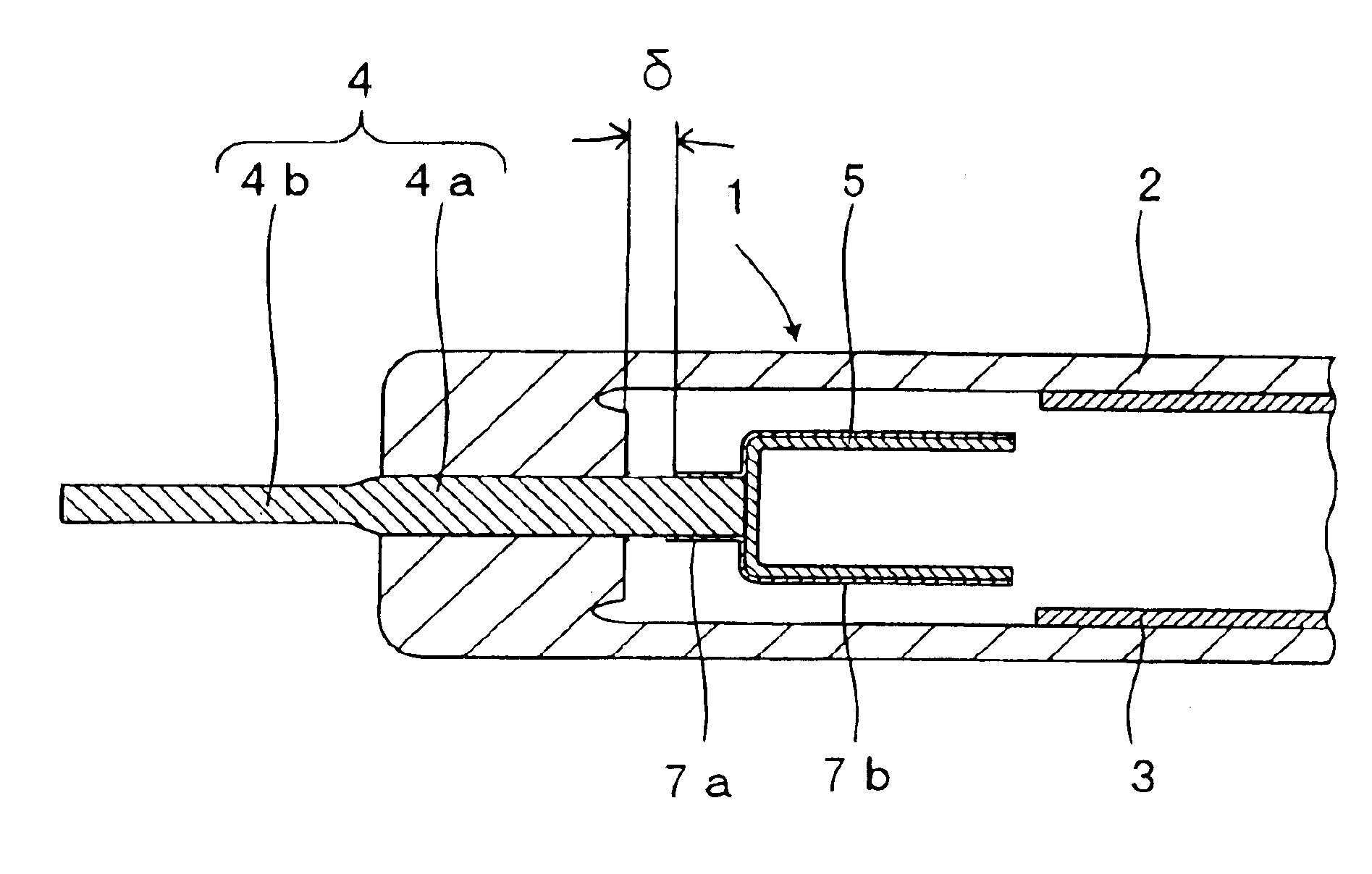

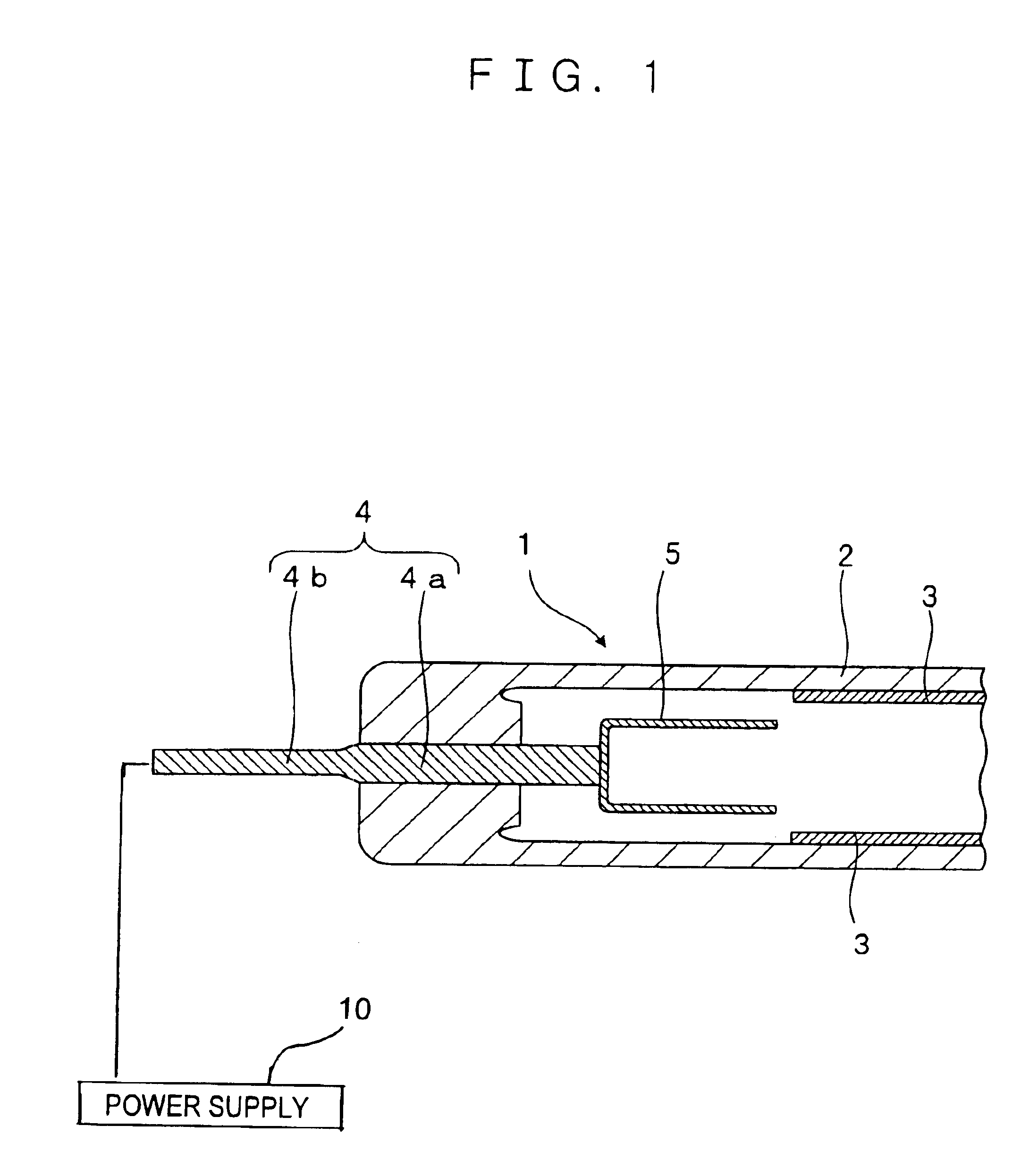

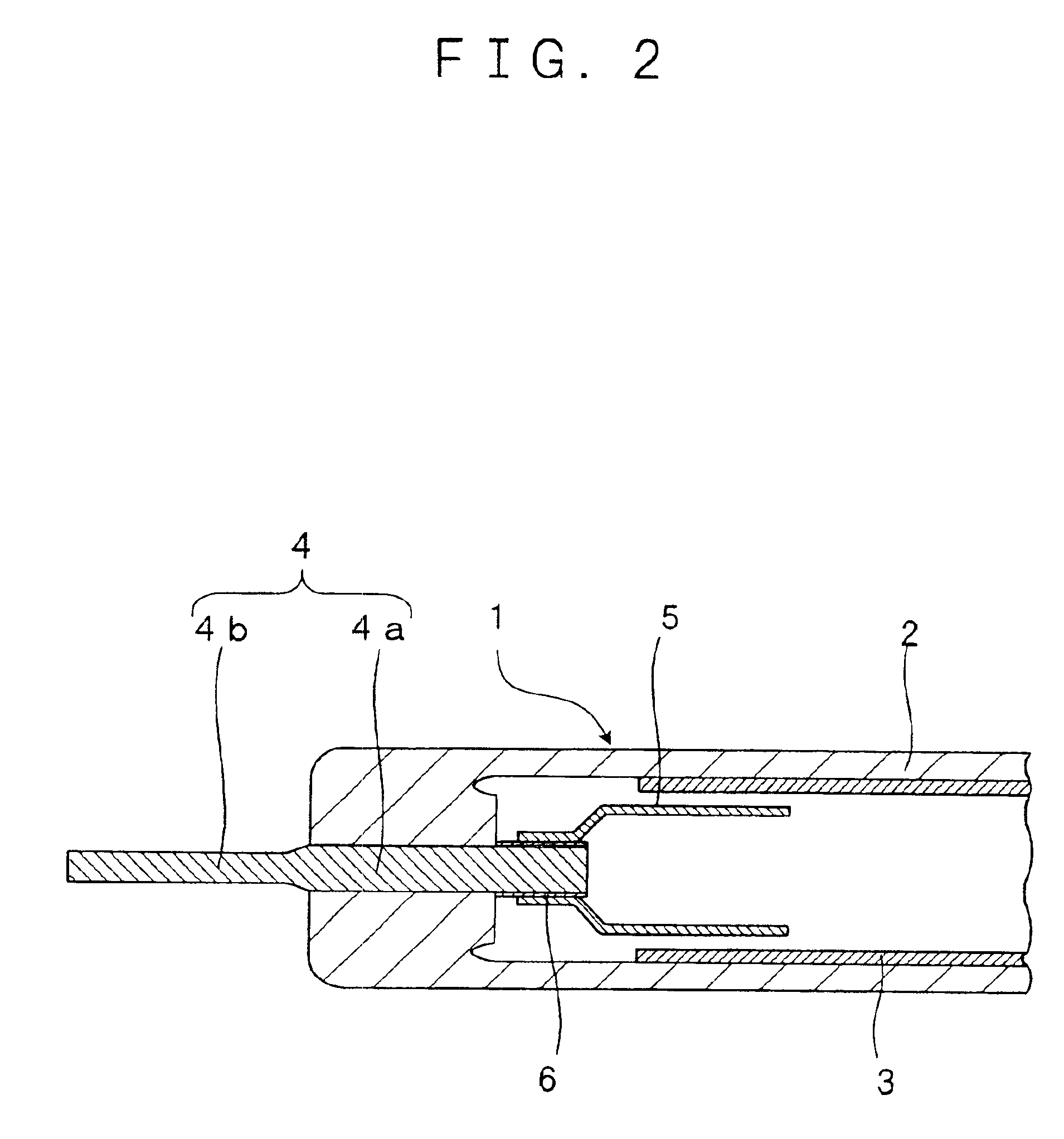

Cold-cathode discharge lamp and lamp device having reduced sputtering on internal lead-in wire

InactiveUS6853139B2Suppress sputteringLong life-timeDischarge tube luminescnet screensLamp detailsSputteringGas-discharge lamp

The present invention has an object to provide a cold-cathode discharge lamp which can suppress sputtering on a lead-in wire and reduce consumption of mercury so as to achieve a longer lifetime without increasing an amount of applied mercury. The cold-cathode discharge lamp of the present invention is characterized in that a lead-in wire connected to a cylindrical electrode in a lighting tube is made of a material same as a material that forms the cylindrical electrode. It is possible to suppress concentration negative glow discharge shifted to the lead-in wire and to allow the electrode to be covered with even negative glow discharge. Thus, it is possible to reduce mercury consumed by excessive sputtering on the outer surface of the internal lead-in wire and to achieve a longer lifetime of the cold-cathode discharge lamp.

Owner:PANASONIC CORP

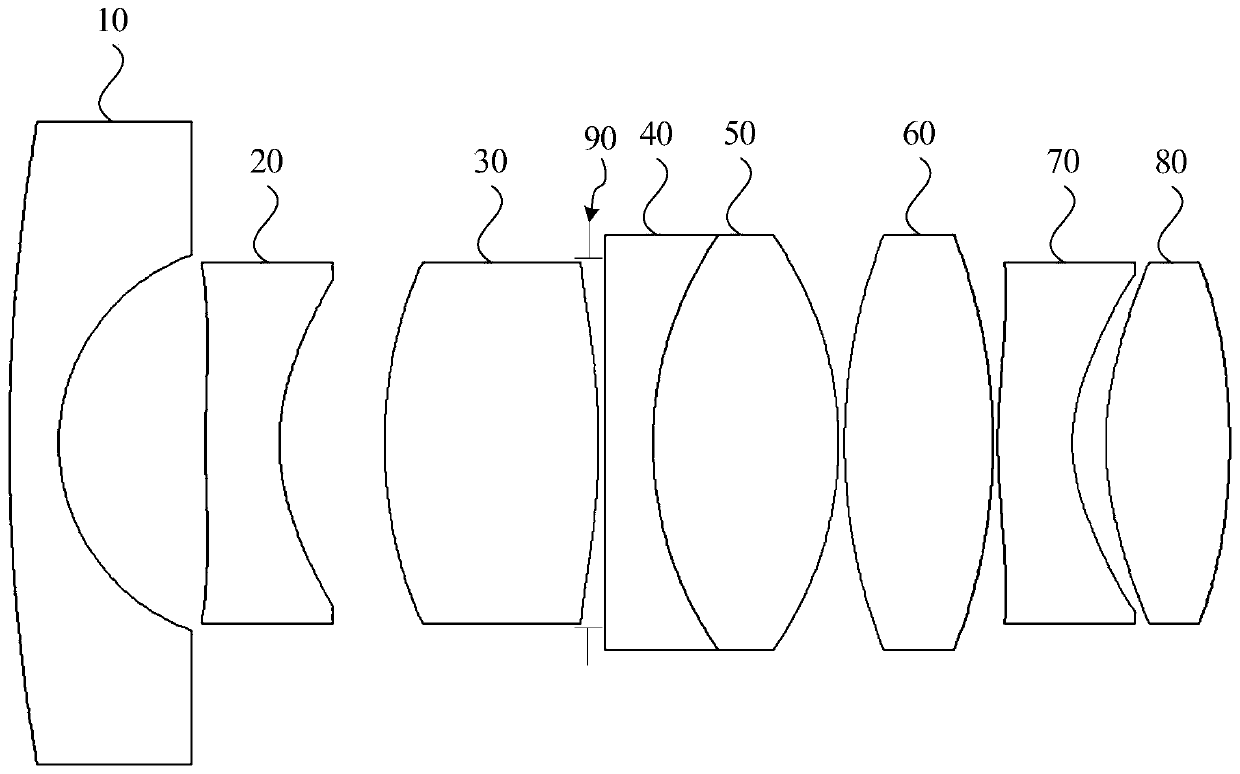

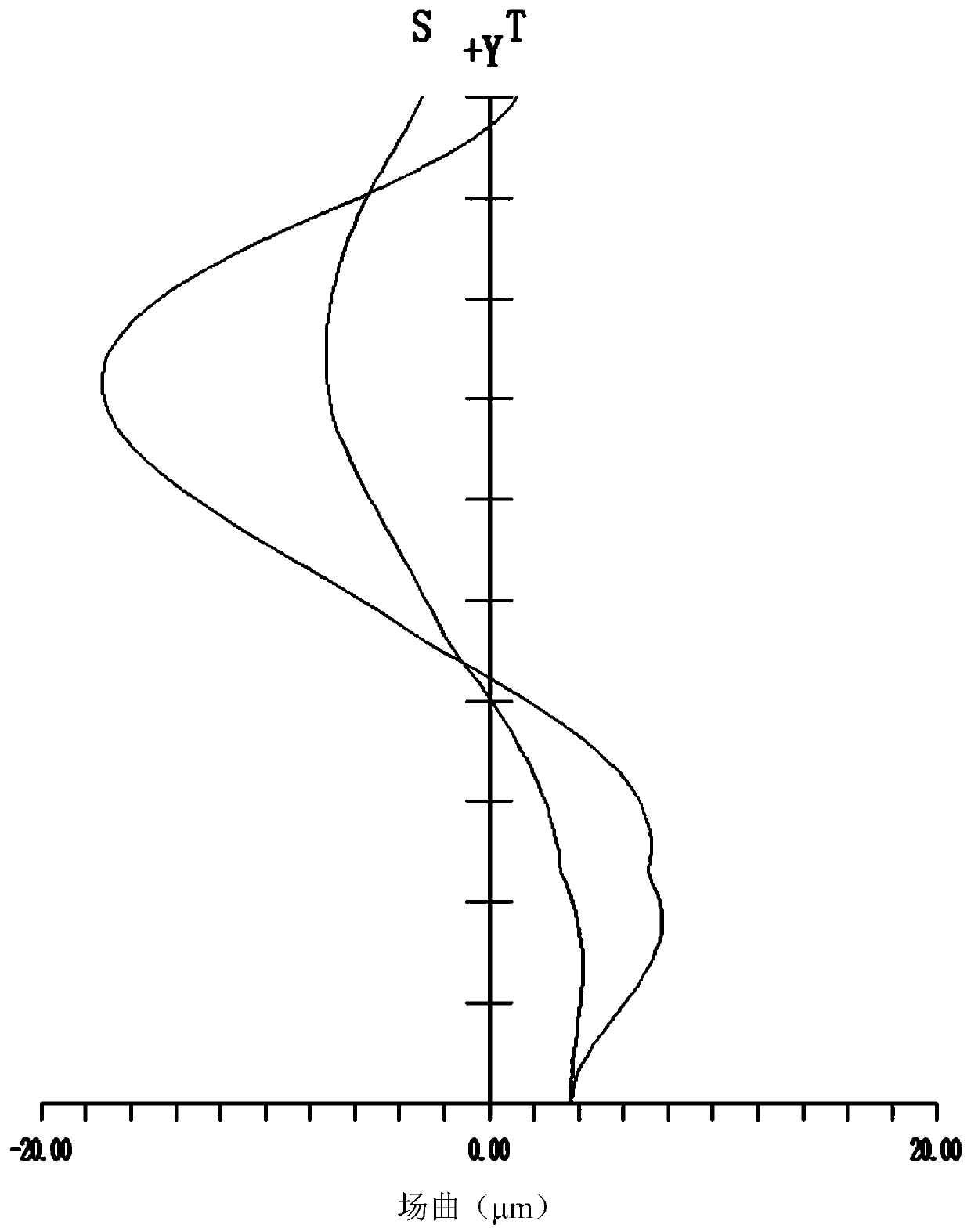

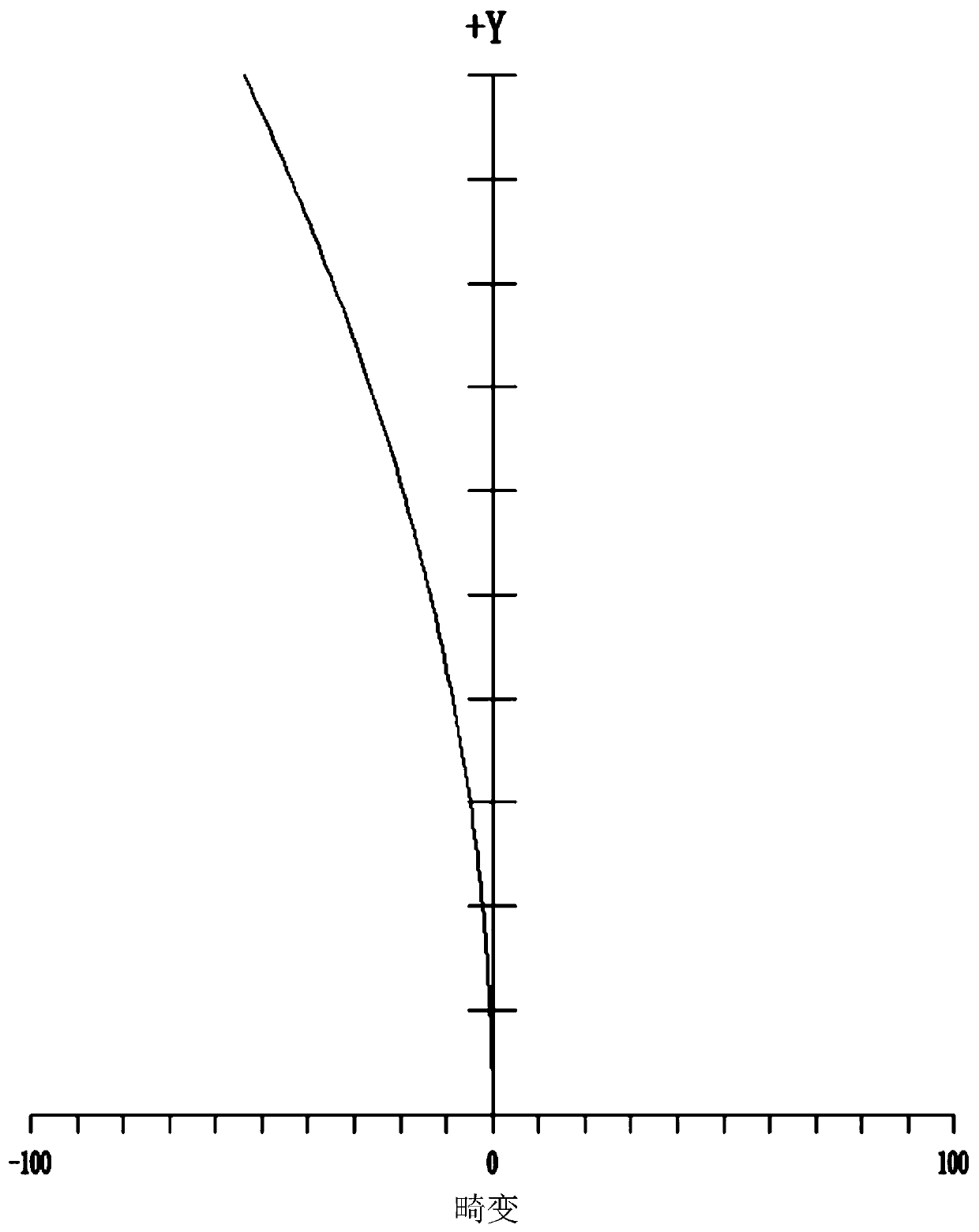

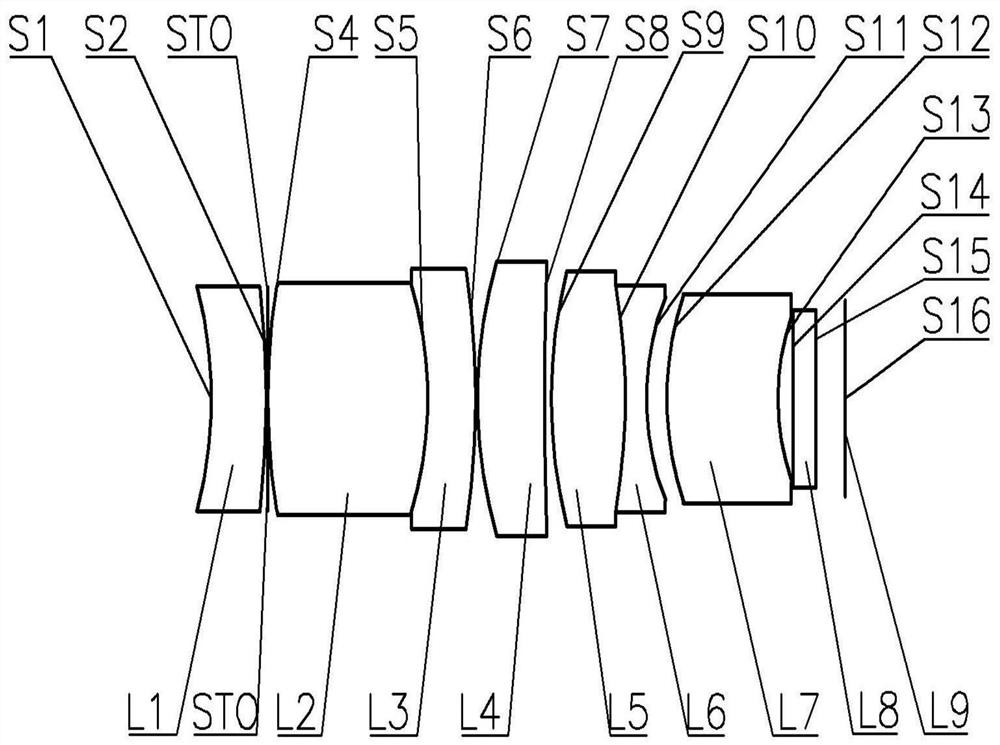

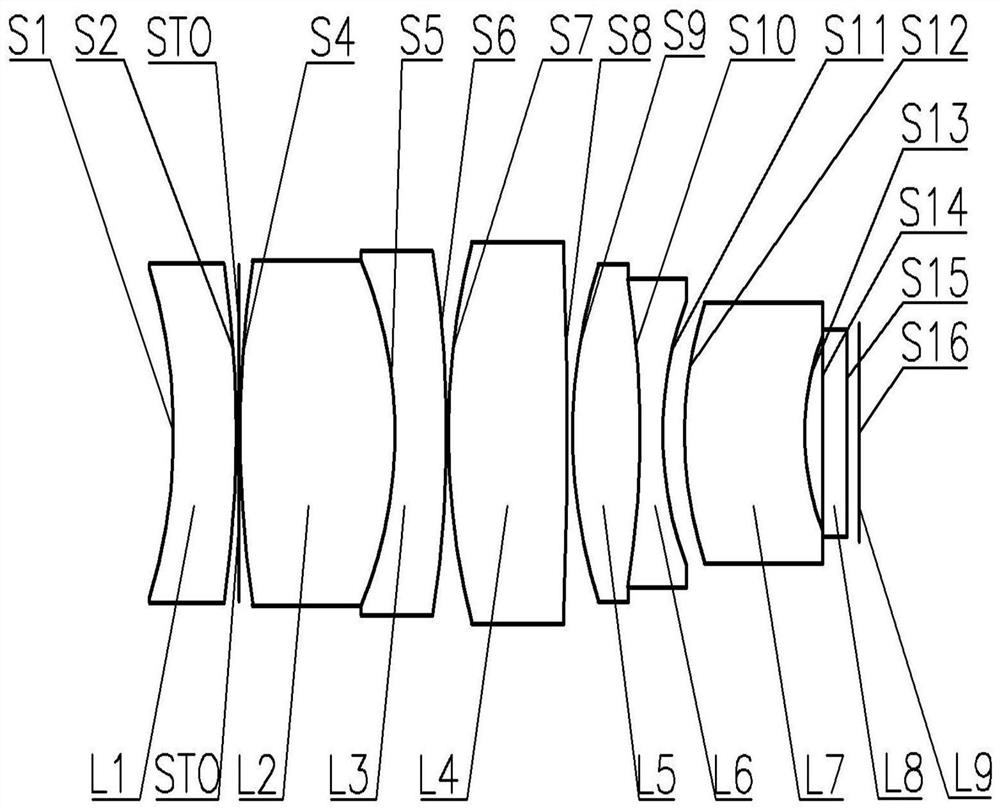

Prime lens

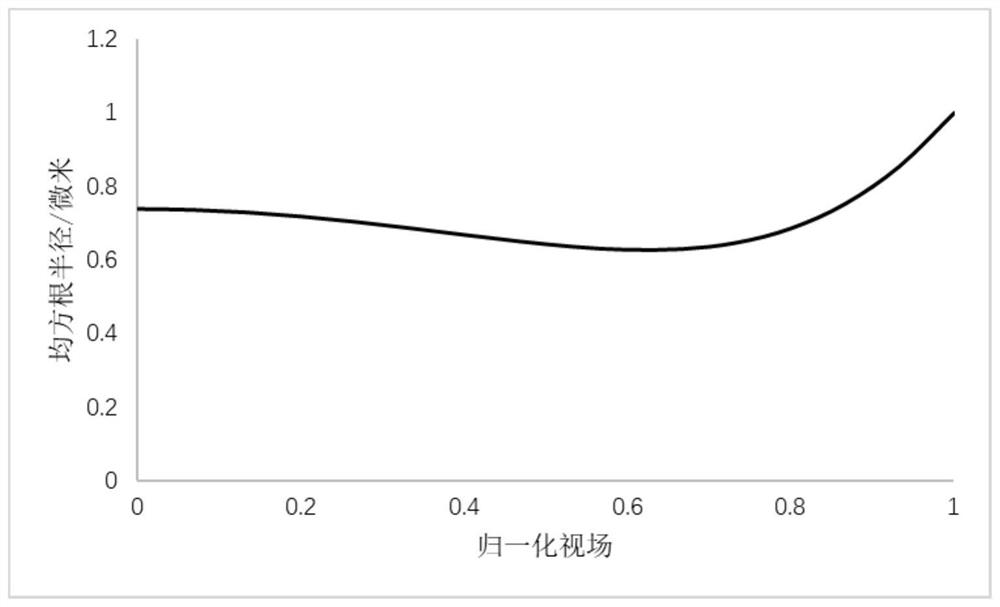

The embodiment of the invention discloses a prime lens. The prime lens includes a first lens with negative light focal power, a second lens with negative light focal power, a third lens with positivelight focal power, a diaphragm, a fourth lens with negative light focal power, a fifth lens with positive light focal power, a sixth lens with positive light focal power, a seventh lens with negativelight focal power, and an eighth lens with positive light focal power, which are arranged successively along an optical axis from an object side to an image side, wherein the fourth lens and the fifthlens form an adhesive lens; the first lens, the fourth lens, the fifth lens, and the sixth lens are spherical lens; and the second lens, the third lens, the seventh lens, and the eighth lens are non-spherical lens. The technical scheme of the embodiment of the invention can be applicable to the field of security and defense. The lens has the characteristics of day and night confocal function, excessive large amount of light and an ultra-wide angle, especially suitable for use under a low illumination condition.

Owner:DONGGUAN YUTONG OPTICAL TECH

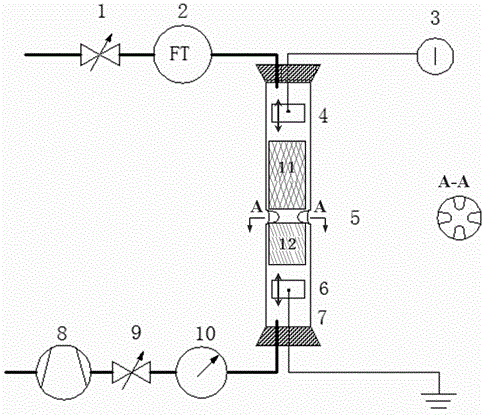

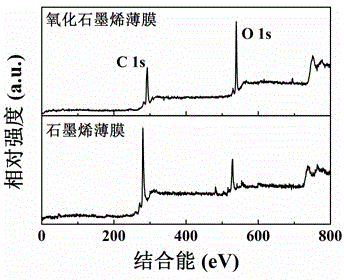

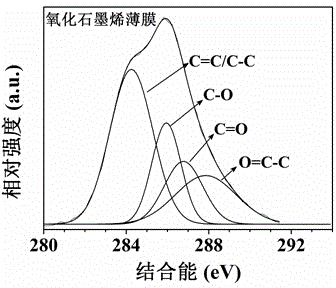

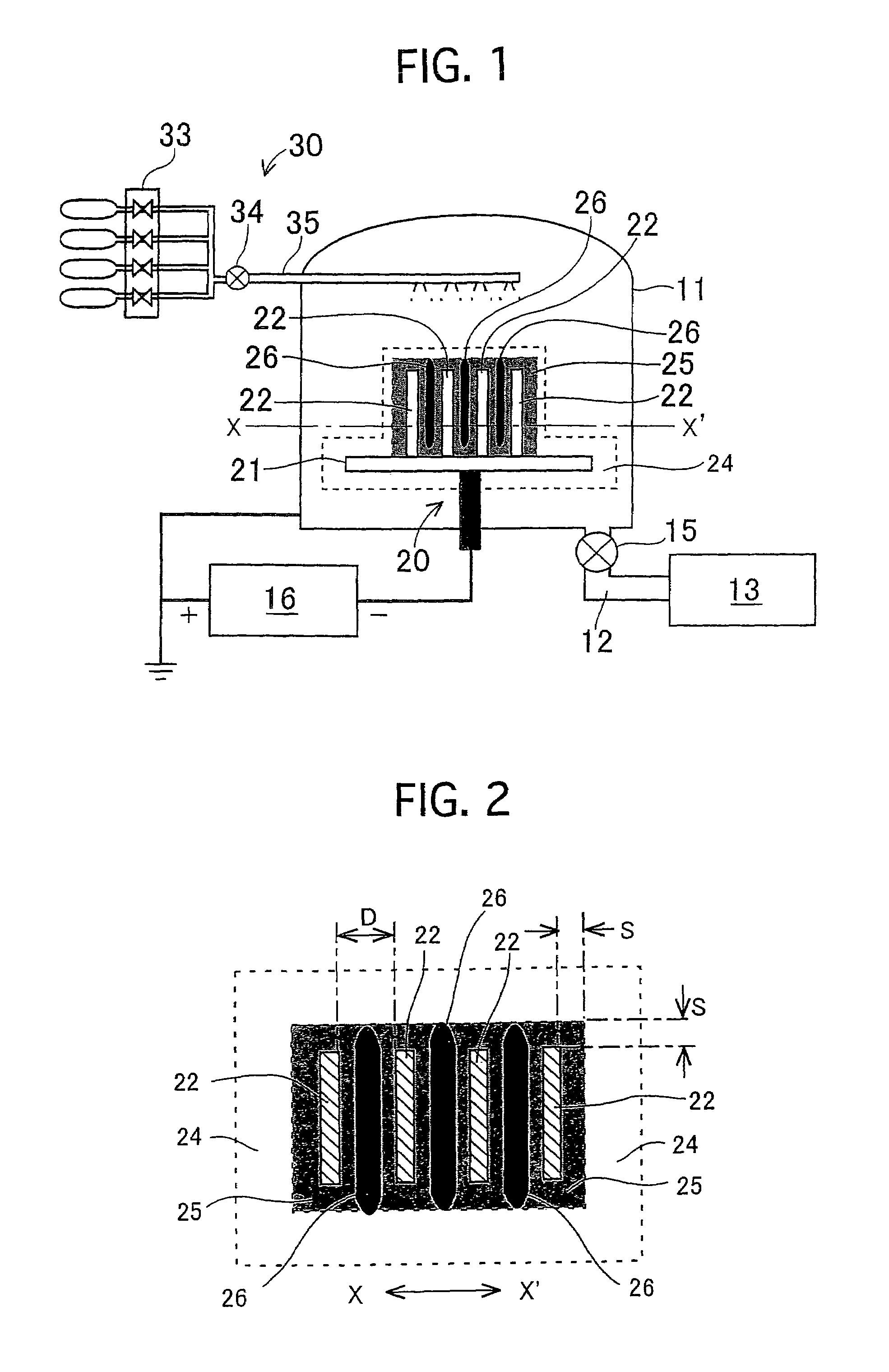

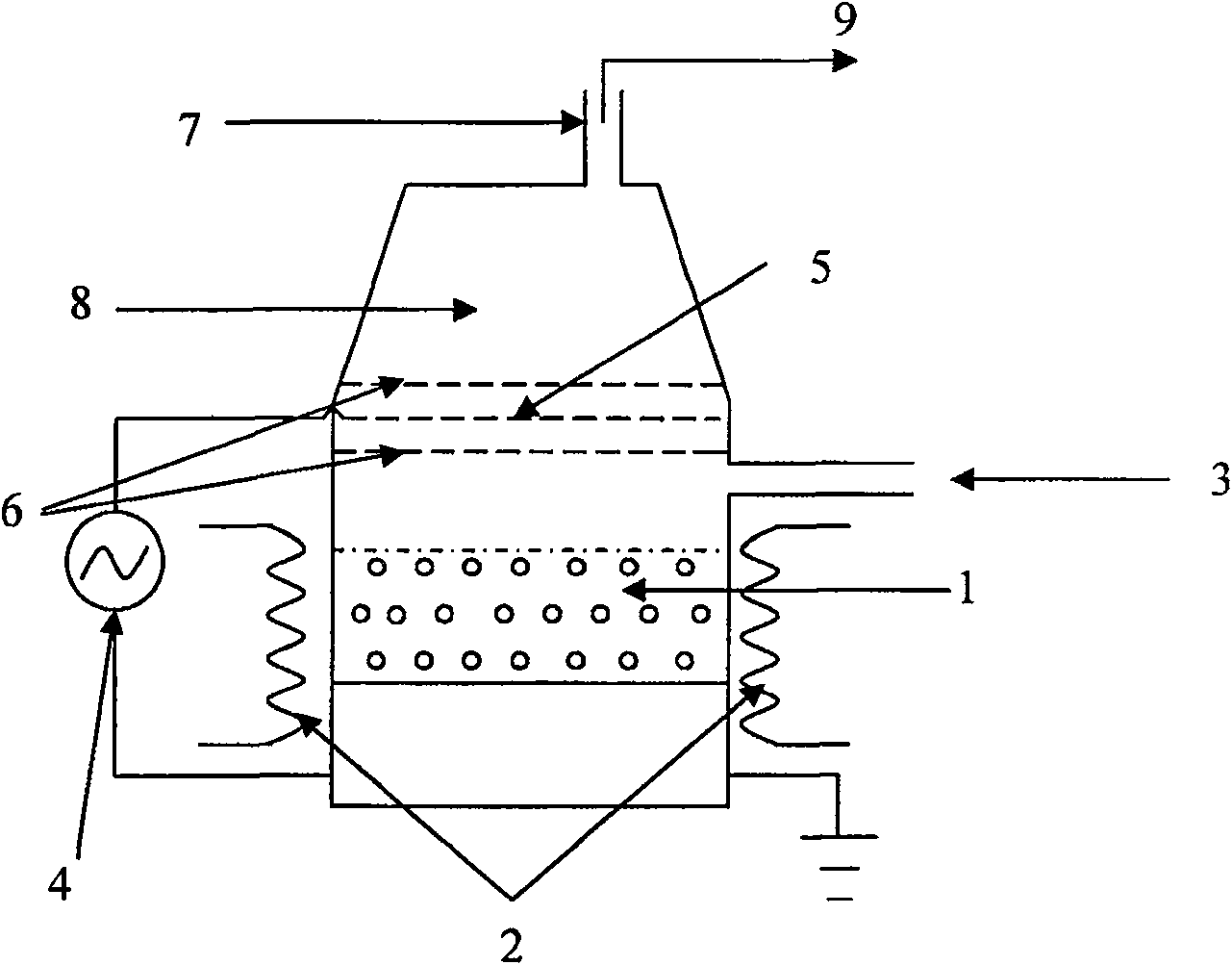

Device and method for preparing graphene film on basis of plasma

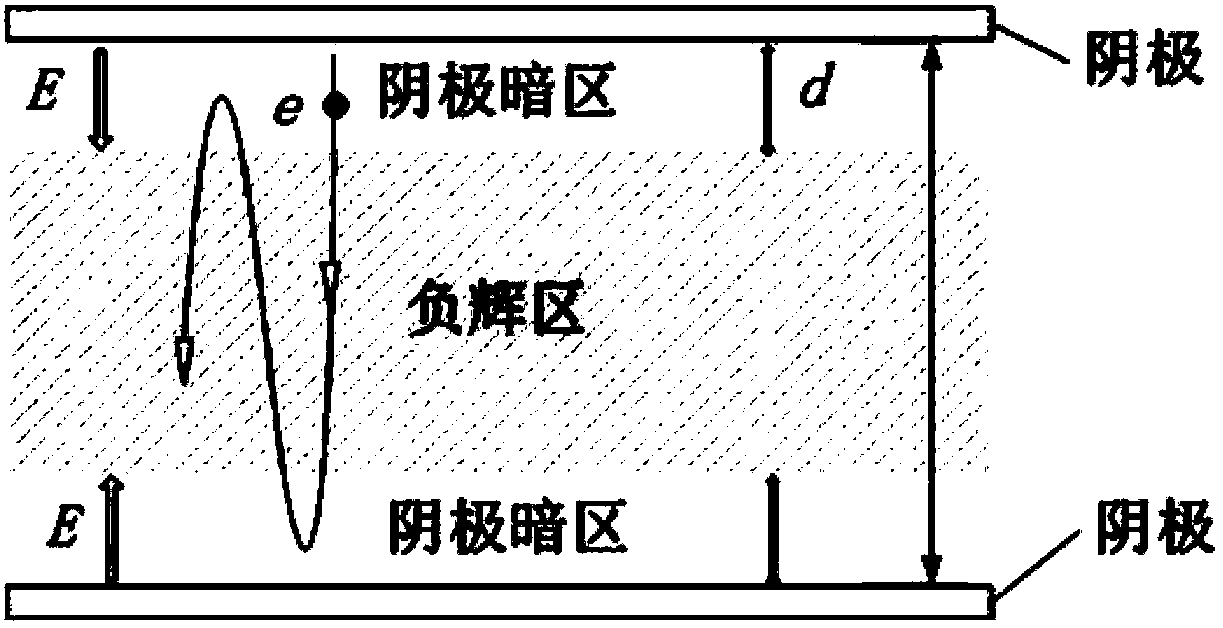

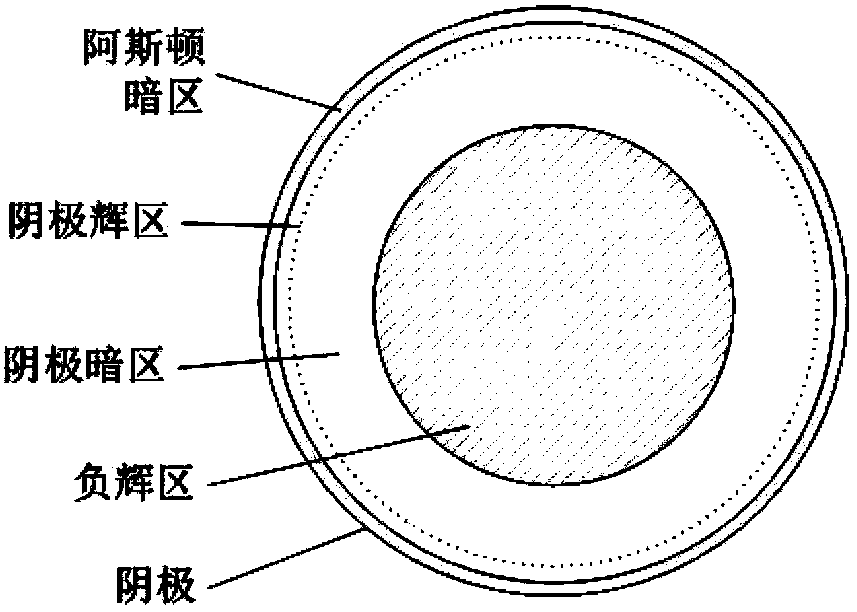

The invention discloses a device and a method for preparing a graphene film on basis of plasma. According to the device, a sample support frame is horizontally arranged in the middle of a quartz tube, a negative electrode is arranged at the upper part of the quartz tube, a positive electrode is arranged at the lower part of the quartz tube, sealing rubber plugs are arranged at the upper and lower ends of the quartz tube, a negative glow zone is arranged between the negative electrode and the sample support frame, a Faraday dark space is arranged between the positive electrode and the sample support frame, a gas regulating valve is connected with the upper part of the quartz tube through a mass flowmeter and the sealing rubber plug at the upper end, a high-voltage negative power supply is connected with a negative electrode through the sealing rubber plug at the upper end, a vacuum pump is connected with the lower part of the quartz tube through a vacuum regulating valve, a vacuometer and the sealing rubber plug at the lower end, and the positive electrode is grounded through the sealing rubber plug at the lower end. The graphene film prepared in the invention is high in degree of graphitization and has excellent properties; in addition, compared with the traditional chemical reduction method and thermal reduction method, the preparation method disclosed by the invention has the advantages of short time consumption, high reduction efficiency, no need of a reducing agent or heating source and the like and has a potential for large-scale industrial application.

Owner:ZHEJIANG UNIV

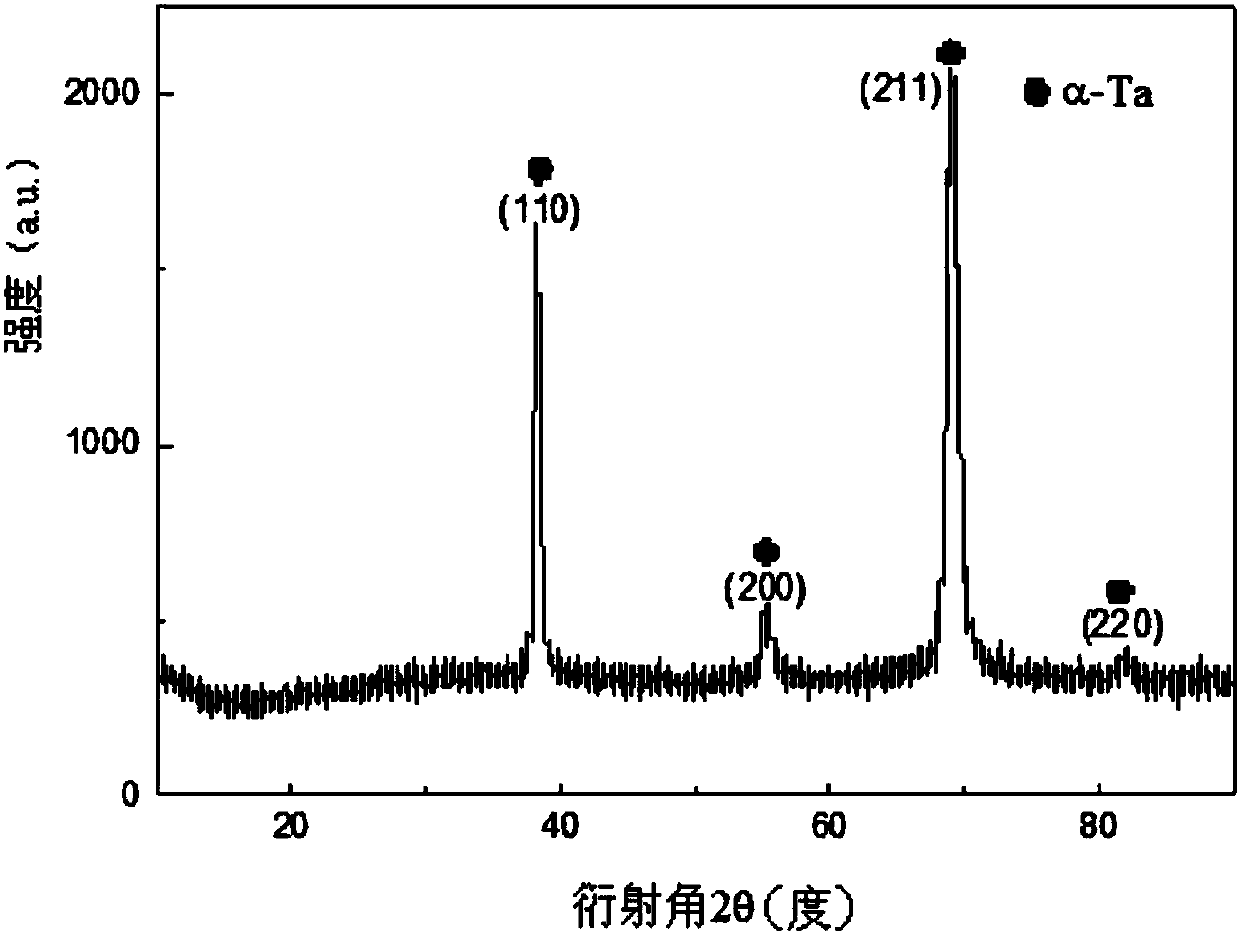

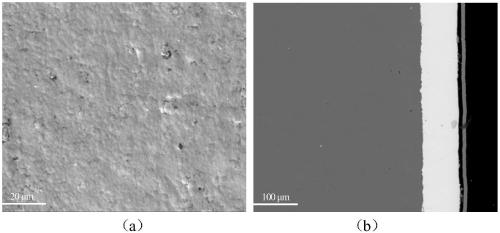

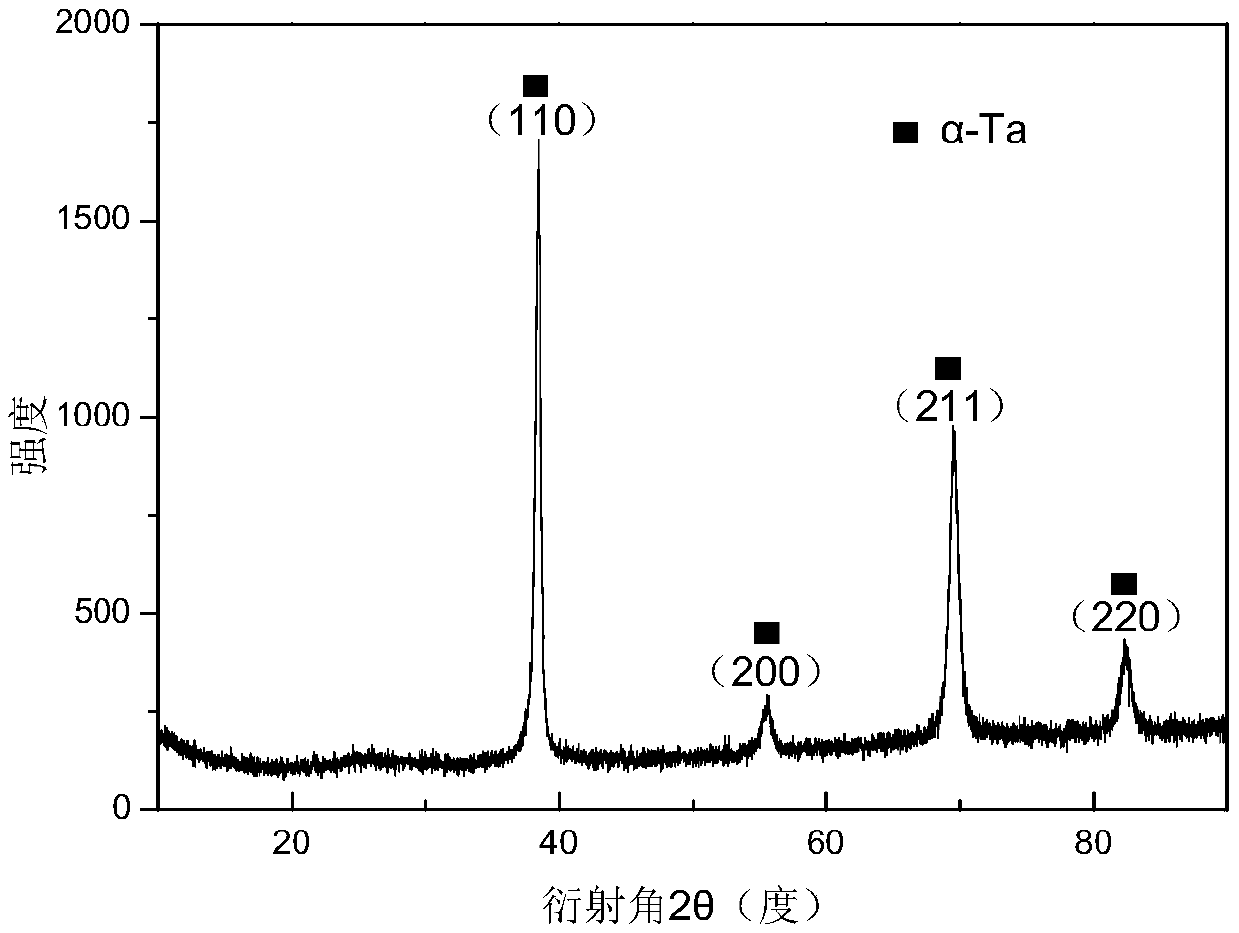

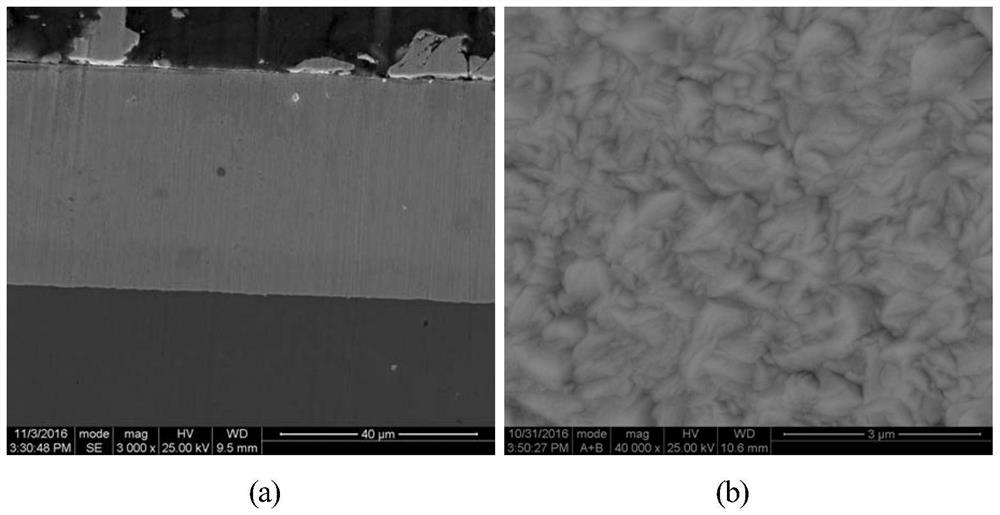

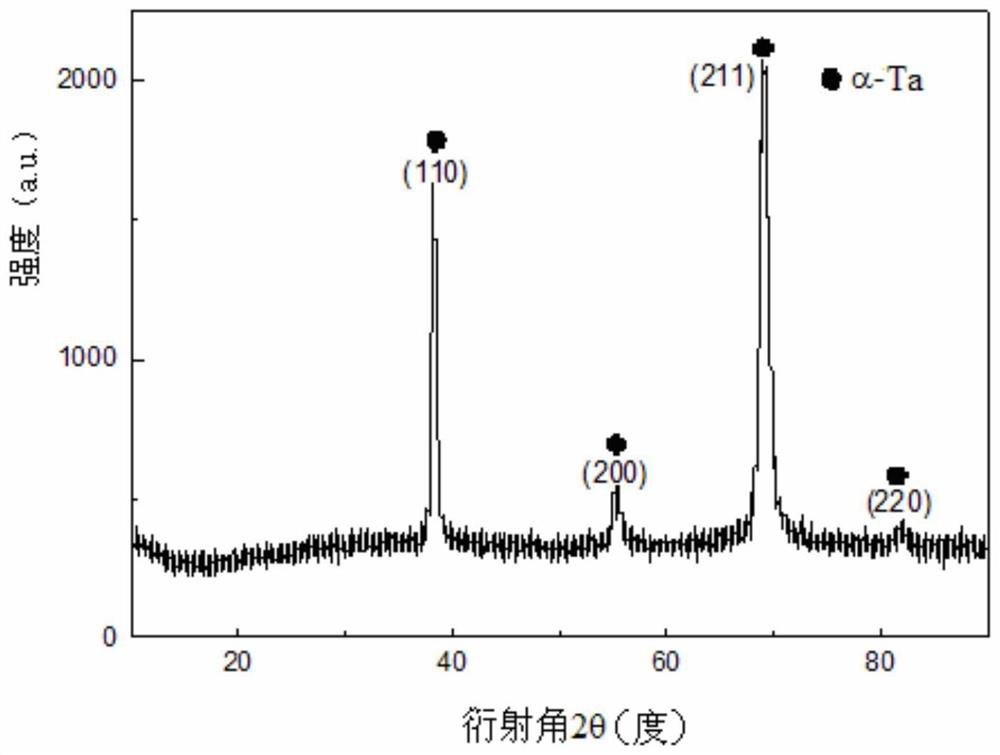

Preparation method of body-centered cubic Ta coating

ActiveCN108103463AImprove thermal shock resistanceAvoid pollutionVacuum evaporation coatingSputtering coatingPulse power supplyBinding force

The invention relates to the field of material science, in particular to a preparation method of a body-centered cubic Ta coating. With adoption of a negative glow region magnetron sputtering method,a substrate part is placed in a negative glow region between an anode and a cathode, heating temperature of the substrate is 200-400 DEG C, a direct-current power supply or a pulsed power supply is used, pure Ta is taken as a target, Ar is taken as working gas, and sputtering power density is 3-15 W / cm<2>. With adoption of the method, the body-centered cubic lattice alpha-Ta coating can be deposited, and binding force and thermal shock resistance are remarkably better than those of an excellent conventional magnetron sputtered Ta coating. The Ta coating prepared with the method binds well withthe substrate when the thickness of the Ta coating reaches about 100 mu m, while the Ta coating prepared with the conventional magnetron sputtering method peels off when the thickness reaches 15 mu m. The thermal shock resistance of the Ta coating prepared with the method and having thickness of 100 mu m is 7 times higher than that of the Ta coating prepared with the conventional magnetron sputtering method and having thickness of 10 mu m.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

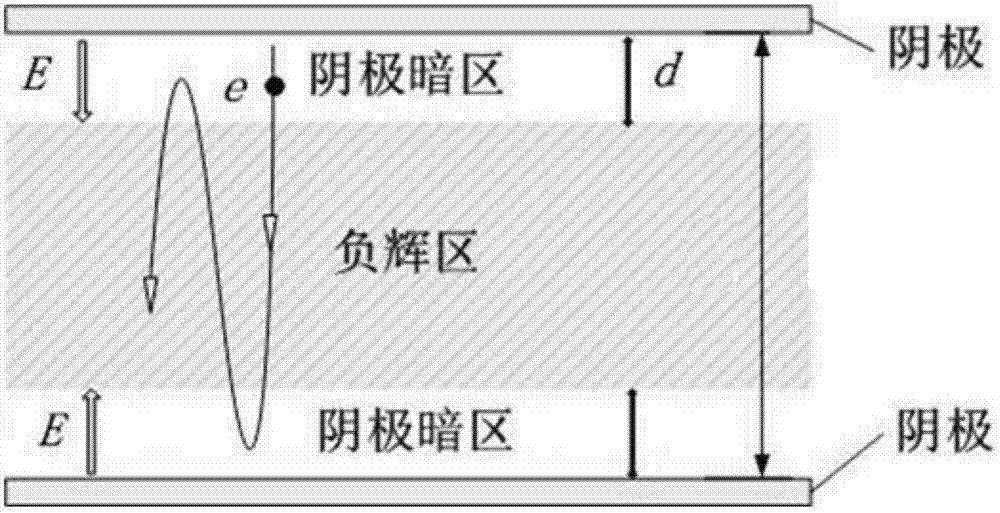

Device for rapidly depositing diamond-like carbon film

InactiveCN103114276AImprove discharge stabilityImprove effectivenessChemical vapor deposition coatingRadio frequencyMaterials science

The invention discloses a method and equipment for rapidly preparing a diamond-like carbon film. The plasma is bounded in a specific area by employing a radio frequency hollow cathode effect and is merged in a negative glow area, so that the gas ionization rate is doubled; meanwhile, the electrons are bounded between electrodes in the radio frequency glow discharge process and move back and forth in the discharge space, and the frequency of colliding with gas molecule is increased, so that the ionization capacity is obviously improved; and therefore, the density and energy of plasma are improved, the deposition rate and quality of the film are improved, the production efficiency is obviously improved, the product cost is reduced, and industrial production is easily realized.

Owner:UNIV OF SCI & TECH BEIJING

Slotted electrode for high intensity discharge lamp

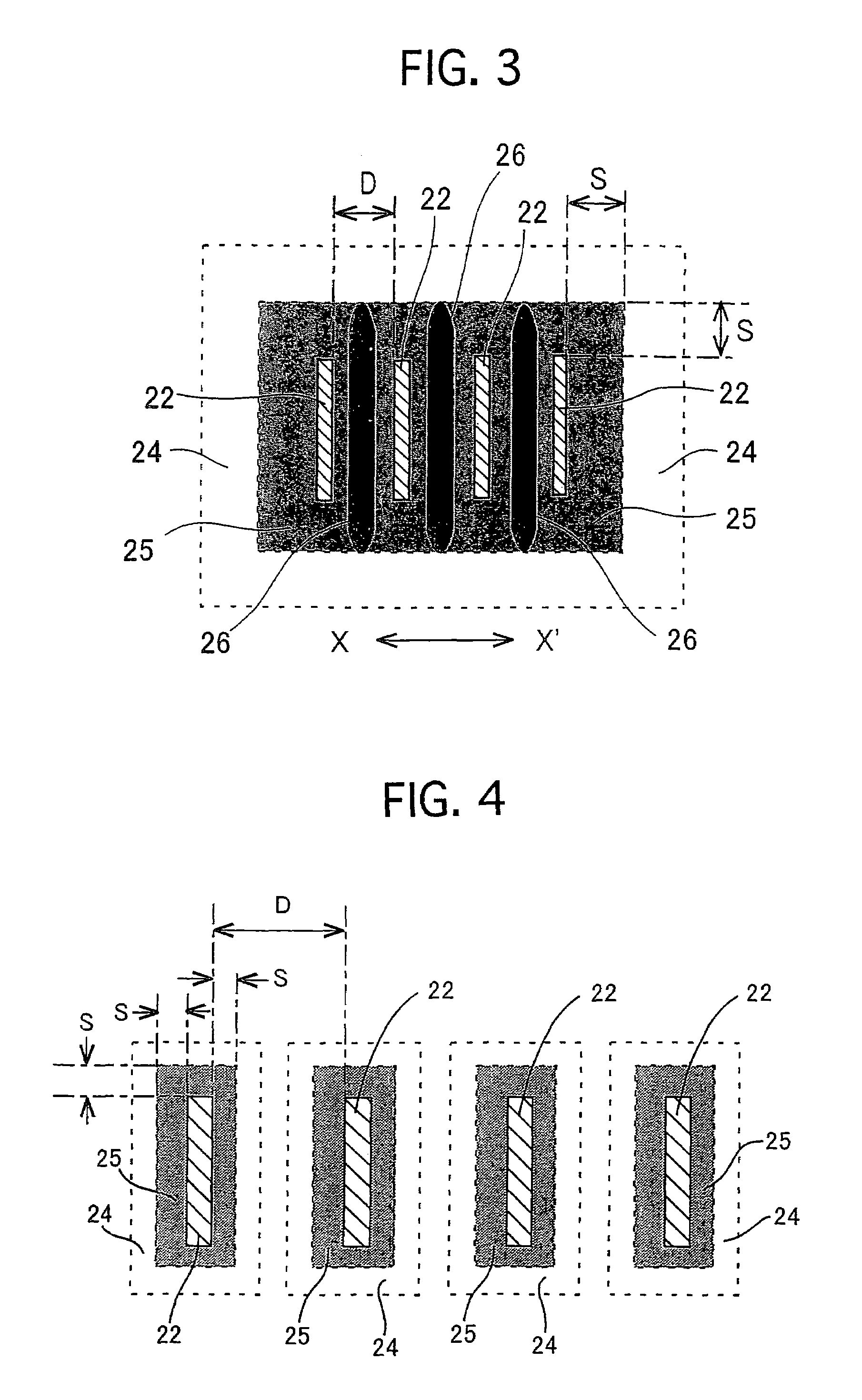

InactiveUS7176632B2Reduce evaporationEasy maintenanceElectrode assembly support/mounting/spacing/insulationSolid cathode detailsMean free pathGas composition

Operation of an HID lamp may be improved by forming a glow generating recess on an exterior side the electrode. The lamp may be of standard construction with a light transmissive lamp envelope having a wall defining an enclosed volume. At least one electrode assembly is extended in a sealed fashion from the exterior of the lamp through the lamp envelope wall to be exposed at an inner end of the electrode assembly to the enclosed volume. A metal halide lamp fill is enclosed with an inert fill gas. The inner end of the electrode is formed with a recess having a least spanning dimension S and a recess depth of D where S is greater the electron ionization mean free path but less than twice the cathode fall plus negative glow distances, throughout the glow discharge phase of starting, for the chosen fill gas composition and pressure (cold).

Owner:OSRAM SYLVANIA INC

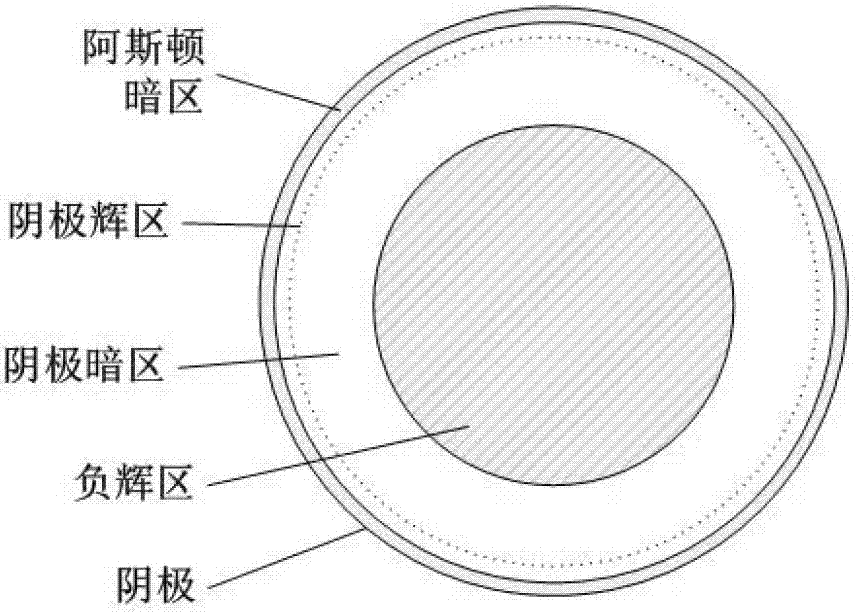

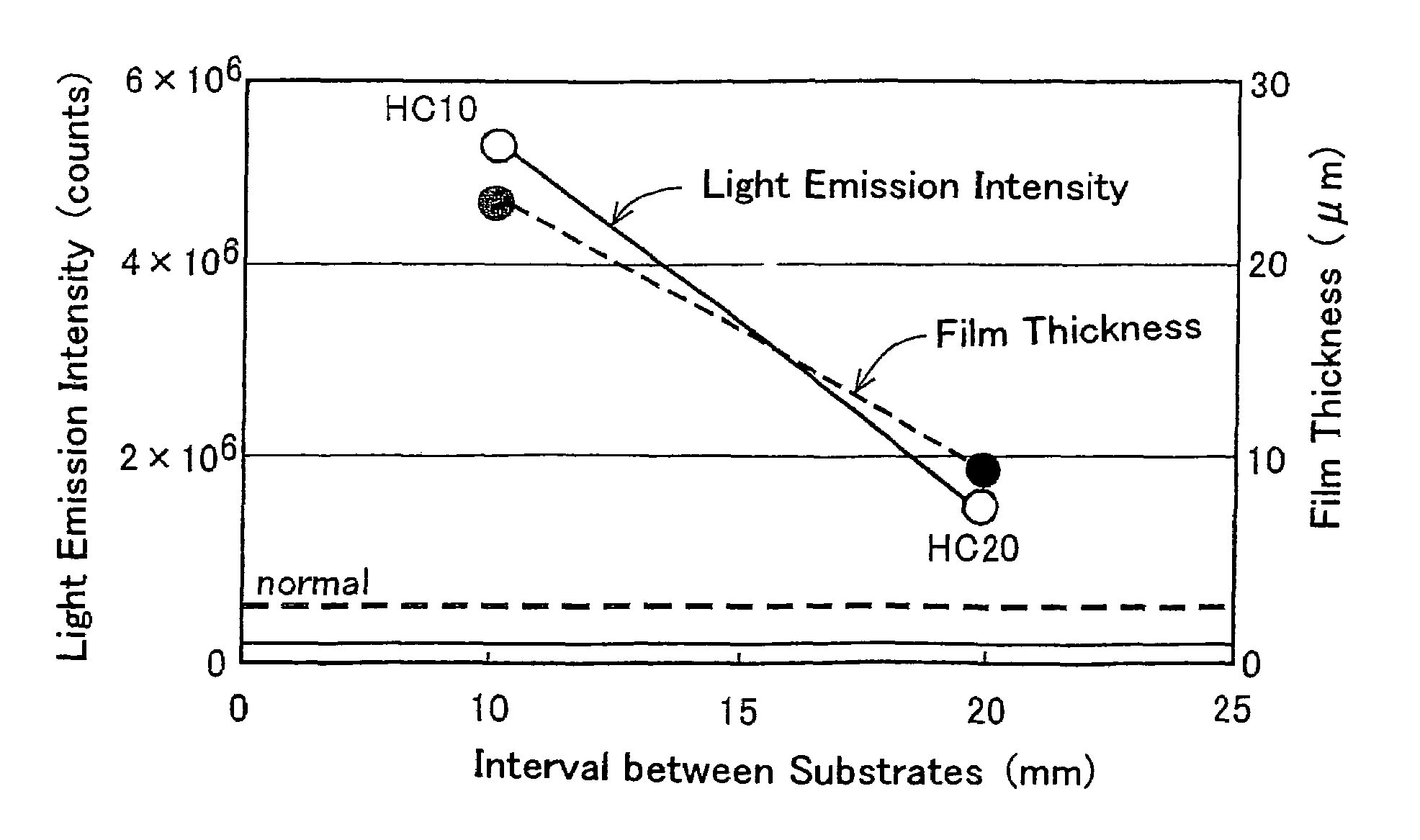

Amorphous carbon, amorphous-carbon coated member, and process for forming amorphous carbon film

InactiveUS7455824B2Damage to coatingAvoid damageLayered productsSemiconductor/solid-state device manufacturingHydrogenMetallurgy

To provide a soft amorphous carbon exhibiting a low elastic modulus, an amorphous-carbon coated member provided with a coated film comprising the amorphous carbon, and a process for forming an amorphous carbon film. The amorphous carbon comprises carbon as a major component and hydrogen in an amount of from more than 30 atomic % to 60 atomic % or less, and exhibits an elastic modulus of from 40 or more to 150 GPa or less. Moreover, the amorphous-carbon coated member comprises a conductive substrate, and a coated film fixed on at least a part of a surface of the substrate and composed of the amorphous carbon. In addition, in a process for forming the amorphous-carbon coated film, an amorphous carbon film is formed on a surface of conductive substrates by a plasma CVD method. Not only a plurality of the substrates are disposed on a substrate holder, which is disposed in a film-forming furnace and is connected with a negative electrode, in such a state that they face to each other, but also a processing gas pressure and a plasma power source are operated so as to overlap negative glows of the neighboring two substrates.

Owner:TOYOTA CENT RES & DEV LAB INC

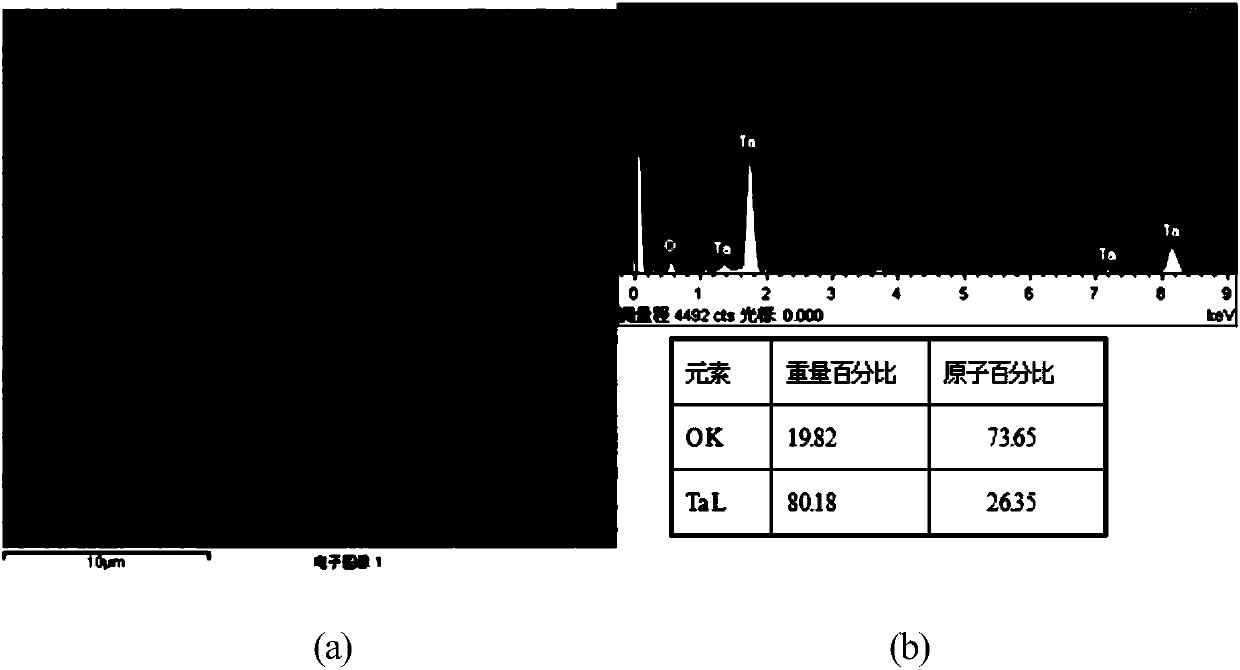

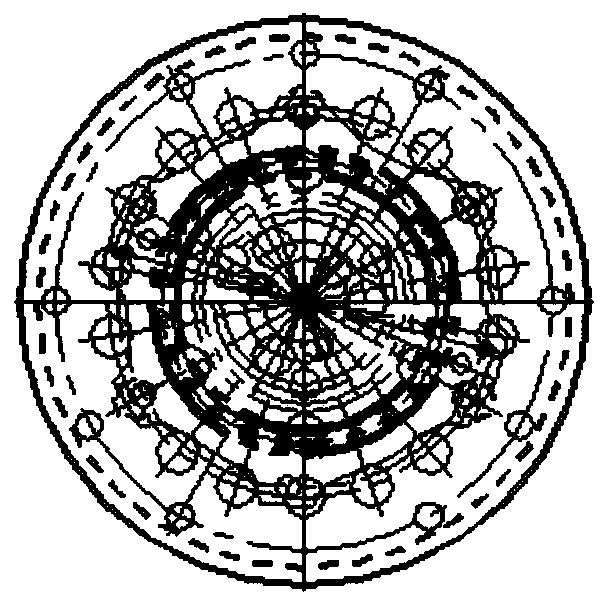

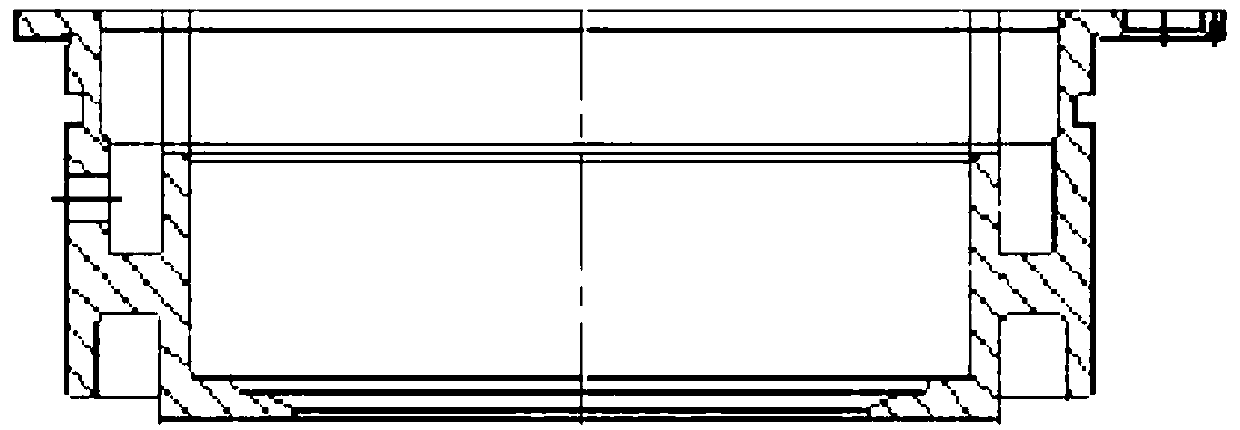

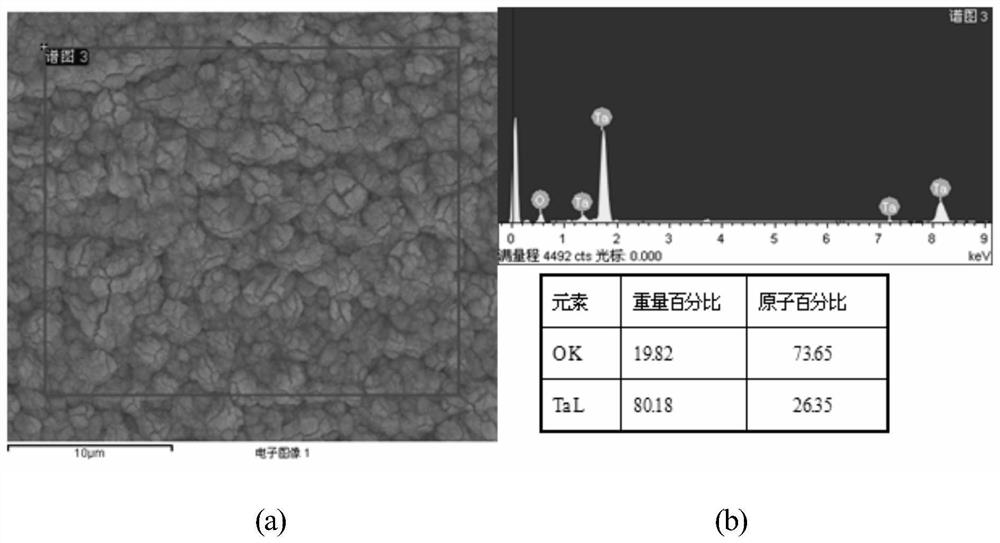

Magnetron sputtering device for inner cavity of pipe with large length-diameter ratio and method for preparing alpha-Ta coating

ActiveCN109735812AIncrease flexibilityImprove coating uniformityVacuum evaporation coatingSputtering coatingSputteringLeg length

The invention discloses a magnetron sputtering device for an inner cavity of a pipe with a large length-diameter ratio and a method for preparing an alpha-Ta coating, and belongs to the technical field of a magnetron sputtering coating. The device uses a large length-diameter ratio cavity of the pipe as a vacuum cavity, one end of the large length-diameter ratio cavity is connected with a vacuum unit through a vacuum end adapter, the other end of the large length-diameter ratio cavity is connected with a cylindrical magnetron target through a target material adapter, the cylindrical magnetrontarget is arranged in the large length-diameter ratio cavity, and after magnetron sputtering parameters are adjusted, the surface of the inner wall of the pipe is in a negative glow region of glow discharge. According to the device and the method, the 100% alpha-Ta coating can be deposited, and the ablation resistance of the coating is obviously superior to that of a conventional electroplating chromium coating, so that a chrome plating process which is used on a large scale at the present stage and causes severe environment pollution can be replaced. The device and the method are used for preparing the protective coating of the inner cavity of the pipe with the large length-diameter ratio.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Preparation method of low-temperature sputtering alpha-Ta coating of inner cavity with large length-diameter ratio and application thereof

ActiveCN109735811AIncrease flexibilityImprove coating uniformityVacuum evaporation coatingSputtering coatingVolumetric Mass DensityPulse power supply

The invention discloses a preparation method of a magnetron sputtering alpha-Ta coating of an inner cavity with a large length-diameter ratio and an application thereof, and belongs to the technical field of the magnetron sputtering coating. According to the method, the large length-diameter ratio inner cavity is used as a vacuum cavity, a cylindrical magnetron target is used as a deposition source, and extends into the inner cavity for deposition, wherein the diameter difference between the outer wall of a target material and the large length-diameter ratio inner cavity is controlled to be between 50 mm-65 mm, and after magnetron sputtering parameters are adjusted, the surface of the inner wall of a pipe is in a negative glow region of glow discharge. The pipe of the large length-diameterratio is heated to 150-250 DEG C. The used power supply is a direct-current power supply or a pulsed power supply, the target material is pure tantalum, working gas is Ar, and the sputtering power density is 2.5W / cm<2>-10W / cm<2>. According to the method, the 100% alpha-Ta coating can be deposited, the bonding force and the ablation resistance of the coating are obviously superior to those of a conventional electroplating chromium coating, so that the method can be used for replacing a chrome plating process which is used on a large scale at the present stage and causes severe environment pollution.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

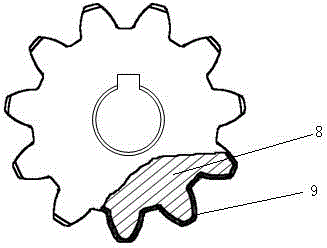

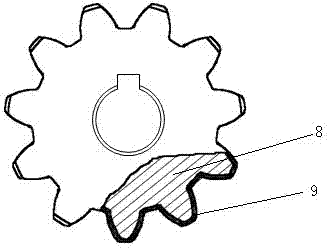

Titanium alloy gear with ferroboron diffusion layer on surface and co-diffusion method thereof

InactiveCN103147037AImprove surface propertiesHigh surface hardnessPortable liftingSolid state diffusion coatingRoom temperatureIron boride

The invention relates to a titanium alloy gear with a ferroboron diffusion layer on the surface and a co-diffusion method thereof. The method comprises the step of: by taking a titanium alloy gear as a workpiece and taking iron boride as a source, placing the titanium alloy gear and the iron boride on a negative disk to form a workpiece-source integral structure, wherein the negative electrode of a direct current power supply is connected to the negative disk, and the positive electrode of the direct current power supply is connected to a vacuum container; vacuumizing and introducing argon, applying a direct-current voltage to generate hollow negative glow discharge, migrating, adsorbing and spreading the sputtered boron, iron ion, atoms and particles into the gear to form an alloy layer, preserving the heat, slowly cooling to room temperature, thereby obtaining the titanium alloy gear with the ferroboron diffusion layer. The method disclosed by the invention is advanced in process and low in cost; and the prepared gear is strong in seizure resistance, good in wear resistance and long in service life.

Owner:TAIYUAN UNIV OF TECH

Slotted electrode for high intensity discharge lamp

InactiveCN1835183AImprove maintenance abilityReduce the temperatureGas discharge lamp detailsMean free pathGas composition

Operation of an HID lamp may be improved by forming a glow generating recess on an exterior side the electrode. The lamp may be of standard construction with a light transmissive lamp envelope having a wall defining an enclosed volume. At least one electrode assembly is extended in a sealed fashion from the exterior of the lamp through the lamp envelope wall to be exposed at an inner end of the electrode assembly to the enclosed volume. A metal halide lamp fill is enclosed with an inert fill gas. The inner end of the electrode is formed with a recess having a least spanning dimension S and a recess depth of D where S is greater the electron ionization mean free path but less than twice the cathode fall plus negative glow distances, throughout the glow discharge phase of starting, for the chosen fill gas composition and pressure (cold).

Owner:OSRAM SYLVANIA INC

Preparing method of high active selenium source for selenylation, apparatus and applications

ActiveCN100581995CLow costImprove photoelectric conversion efficiencyFinal product manufactureChemical industryNegative glowMixed gas

The invention discloses a method for generating a highly active selenium source used for selenizing treatment, as well as a device and the application thereof. The method comprises the steps as follows: heating and vaporizing solid selenium to generate selenium gas; adding hydrogen or a mixture of hydrogen and argon to the selenium gas generated by the last step; and subjecting the mixture of gases in the last step to glow discharge decomposition and synthesis to obtain hydrogen selenide and highly active selenium gas. The device for generating the selenium source comprises an airtight reaction tank, a solid selenium source in the reaction tank, positive and negative glow discharge electrodes, a hydrogen selenide reaction cavity, as well as a heating device and an excitation power supply outside the reaction tank. A gas inlet is further arranged on the lateral wall of the reaction tank; and a gas outlet is arranged on the top of the reaction tank. The method not only retains the advantages of the solid selenium, namely low cost, non-toxicity and easiness in transport and store, and prepares the hydrogen selenide and the highly active selenium ambience with the characteristics of the hydrogen selenide and the highly active selenium, but also saves a large amount of selenide materials, reduces the cost and has important practical value.

Owner:NANKAI UNIV

High-temperature nitriding ultrafine deformation control method of thin-walled dual-shell titanium alloy bushing

The invention belongs to the technical field of metal heat treatment, and relates to a high-temperature nitriding ultrafine deformation control method of a thin-walled dual-shell titanium alloy bushing. According to the high-temperature nitriding ultrafine deformation control method of the thin-walled dual-shell titanium alloy bushing, a titanium alloy ion nitriding furnace with an auxiliary heatsource is used, isoelectric potential local negative glow area space is built with the aid of an auxiliary cathode cylinder-shaped tool, and a hollow cathode effect between double shells is eradicatedcompletely by adopting mechanical shielding; and by a way of overlapping geometric centers of parts, the tool and an effective working area in the ion nitriding furnace, step-type temperature rise, heat preservation and temperature reduction with 300 DEG C-450 DEG C and 500 DEG C-650 DEG C are adopted when ion nitriding is carried out, temperature preservation time is 2-4 hours after the temperature is reached, the rate of heating up and cooling is controlled at 0.5-4 DEG C / min, high temperature annealing with 850 DEG C-950 DEG C is carried out before the nitriding is carried out, a glow heating system is started when the temperature is raised to 300 DEG C-400 DEG C, and nitriding is carried out for 6-20 hours at 750 DEG C-880 DEG C. By comprehensive application of the means, the high-temperature ion nitriding deformation ultrafine control over titanium alloy bushing parts with thin-walled dual-shell complex structures is achieved, and the deformation amount is less than or equal to 0.020mm.

Owner:HARBIN DONGAN ENGINE GRP

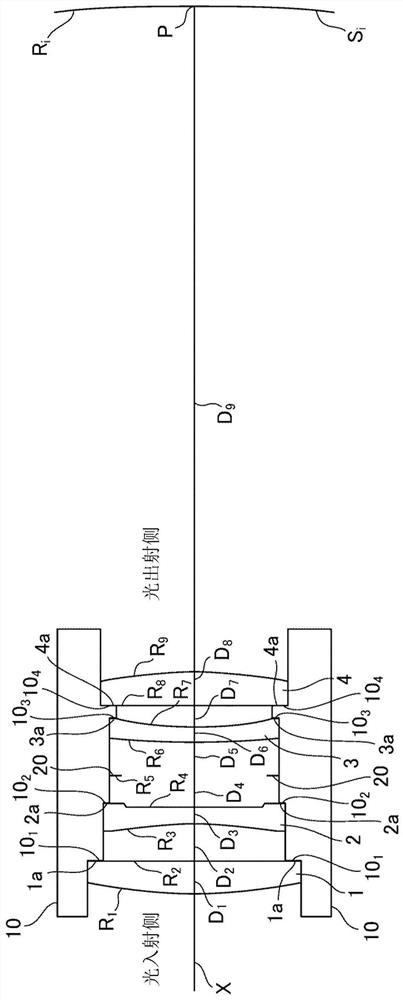

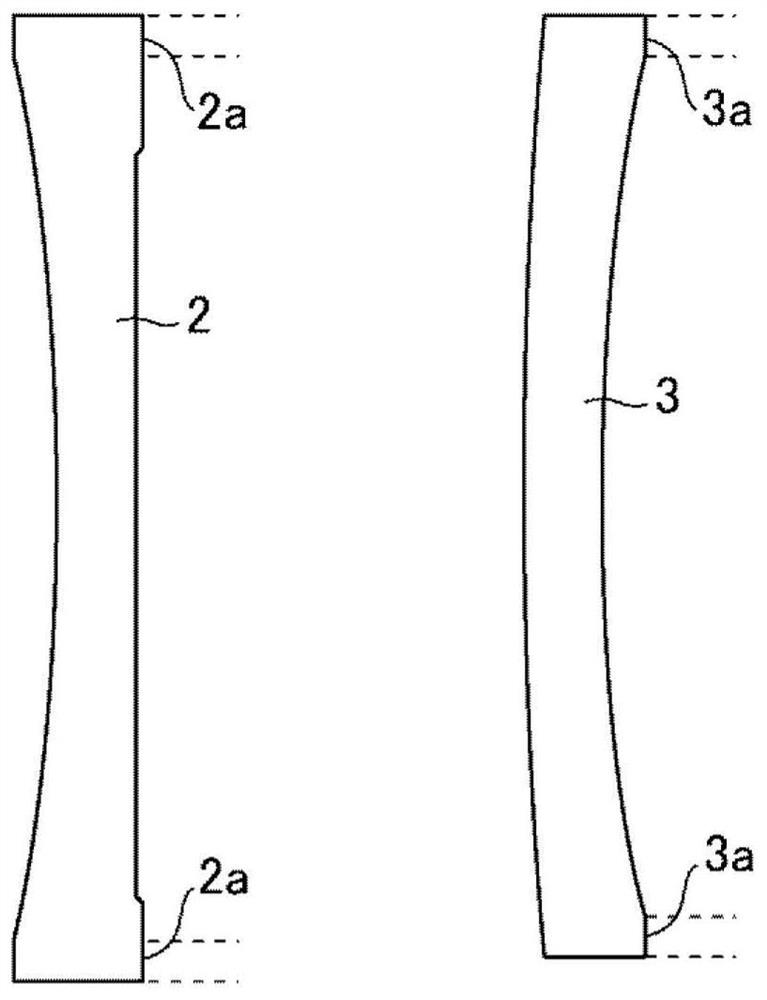

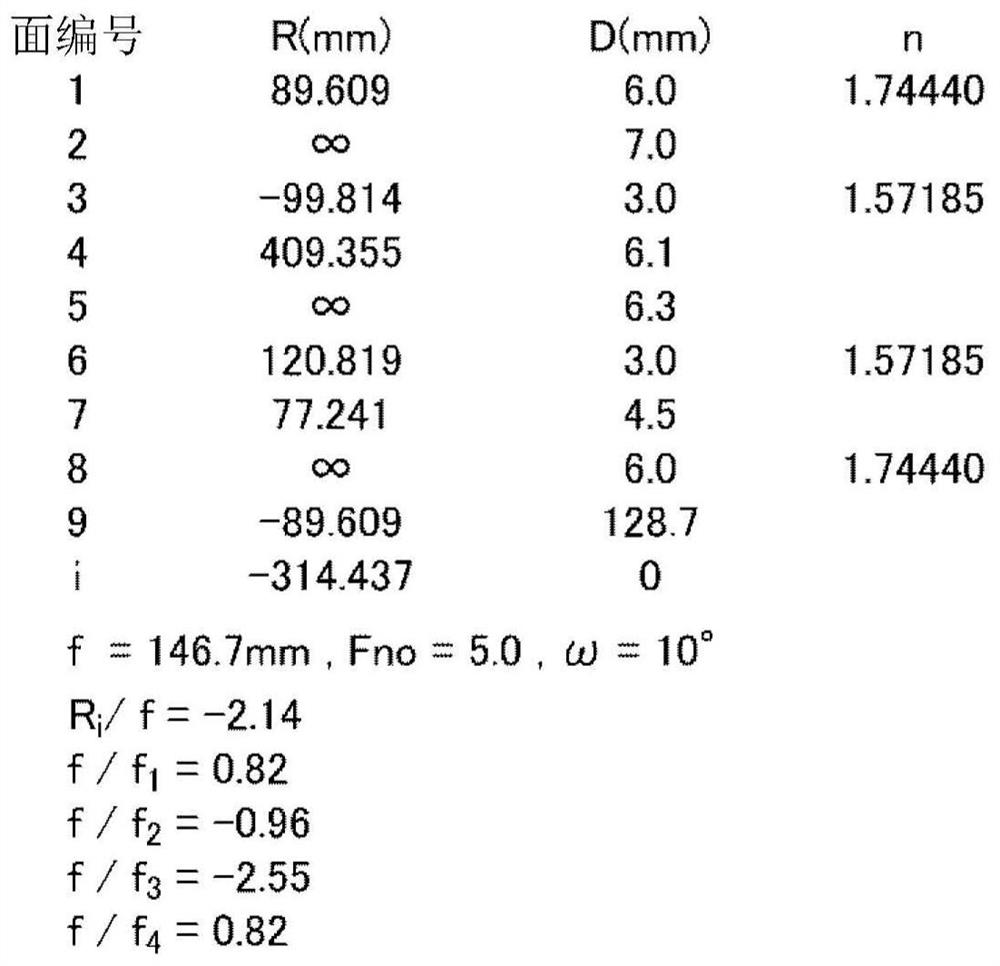

Lens barrel

The lens barrel has: a plano-convex lens (1), the surface of the light incident side of the plano-convex lens (1) is a convex surface, and the surface of the light exit side is a plane; (1) the outgoing light is incident on the biconcave lens (2); the meniscus lens (3), which has a negative refractive power, and the light exiting from the biconcave lens (2) is incident on the meniscus lens (3); A plano-convex lens (4), the surface of the light incident side of the plano-convex lens (4) is a plane, the surface of the light exit side is a convex surface, and the light emitted from the meniscus lens (3) is incident on the plano-convex lens (4); and A lens barrel (10), which holds a plano-convex lens (1), a biconcave lens (2), a meniscus lens (3) and a plano-convex lens (4).

Owner:MITSUBISHI ELECTRIC CORP

PLD (pulsed laser deposition) system provided with hollow cathode plasma and preparation method of thin film

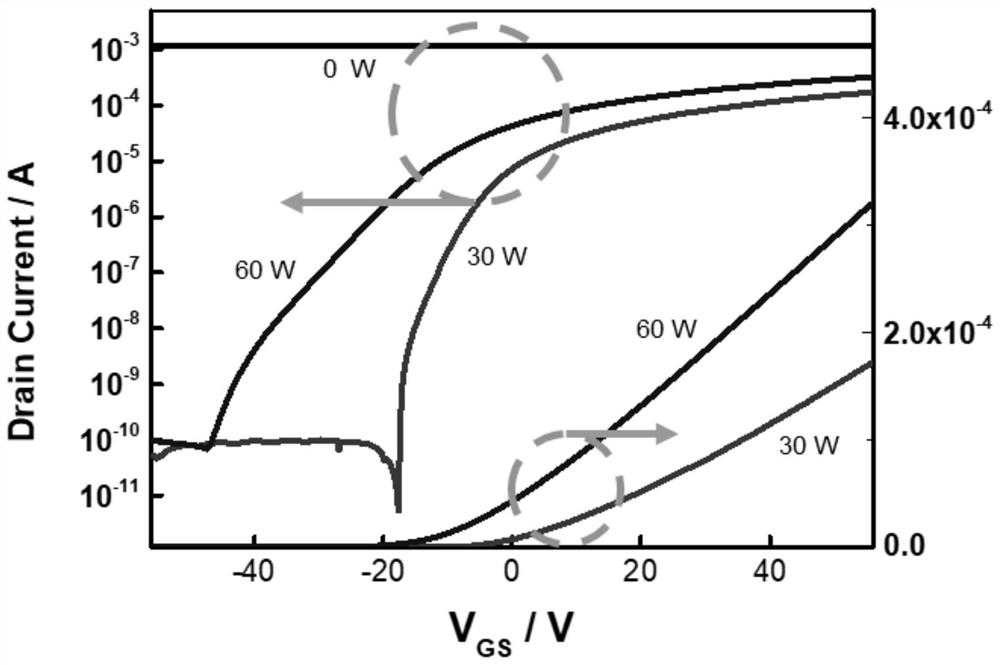

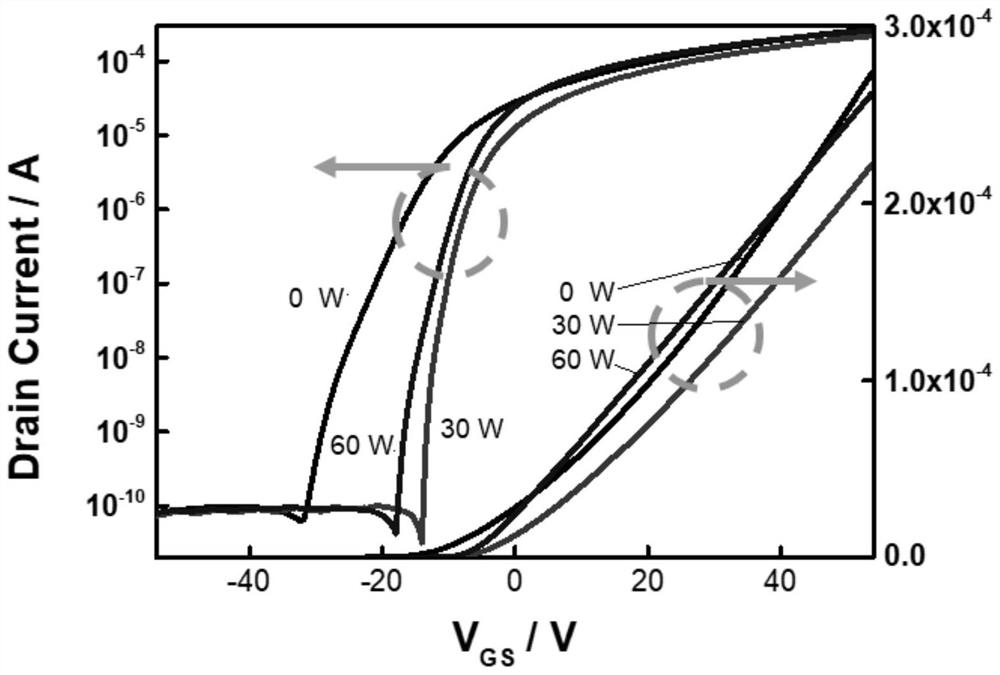

ActiveCN114059022AIncrease concentrationIncrease the number of collisionsVacuum evaporation coatingSputtering coatingOxygen plasmaThin membrane

The invention discloses a PLD system provided with hollow cathode plasma and a preparation method of a thin film. The system is provided with a plasma discharge system in a vacuum cavity of an existing PLD system; and only the middle part of a gas path stainless steel pipe in the existing PLD system is replaced by an aluminum oxide insulating ceramic pipe, one end of the pipe is connected with a power supply, and the other end of the pipe is connected with a gas circuit, so a discharge device is formed. According to the device, negative glow regions of oxygen plasmas can be overlapped, the collision frequency of electrons and gas atoms is increased, ionization effect is remarkably improved, the concentration of the oxygen plasmas in a pulse laser deposition cavity is effectively improved, the content of oxygen vacancies in an ITO thin film is reduced, the problem that the threshold voltage of an amorphous ITO thin film transistor is slightly negative is solved, the subthreshold swing and mobility of the device are optimized to a certain extent, and the performance of the thin film transistor is improved.

Owner:XI AN JIAOTONG UNIV +1

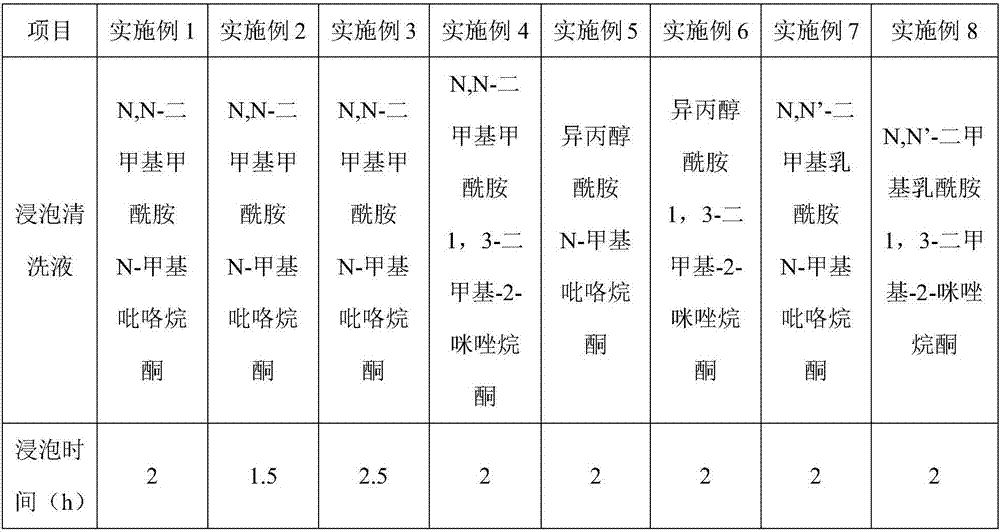

Negative photoresist regeneration method for part of mask aligner during yellow-light process

InactiveCN106959590AEnsure the effect of regenerationUse impactPhotosensitive material processingSolventPhotoresist

The invention relates to the technical field of photoelectricity, in particular to a negative photoresist regeneration method for a part of a mask aligner during the yellow-light process. According to the negative photoresist regeneration method for the part of the mask aligner during the yellow-light process, negative photoresist of the part of the mask aligner during the yellow-light process is cleaned and removed for regeneration and use by combining a conventional ketone organic solvent and an amide solvent which are low in toxicity and even almost have no toxicity, the ketone organic solvent and the amide solvent are combined according to a scientific and reasonable proportion, the dissolving capacity and the evaporation rate of a compound solvent are greatly improved, the cleaning effect is good, a cleaning liquid is low in cost, and the method is friendly to an environment; and meanwhile, the amide solvent and the ketone organic solvent both have reducibility, thus, corrosion and aging of a surface of the part can be prevented very well, the part can be prevented from being corroded and aged very well, the regeneration and usage effect of the part is ensured, and the application of the part cannot be affected. By using an immersion cleaning liquid and the regeneration method, the regeneration frequency of the negative photoresist of the part of the mark aligner during the yellow-light process can reach 100 times.

Owner:安徽高芯众科半导体有限公司

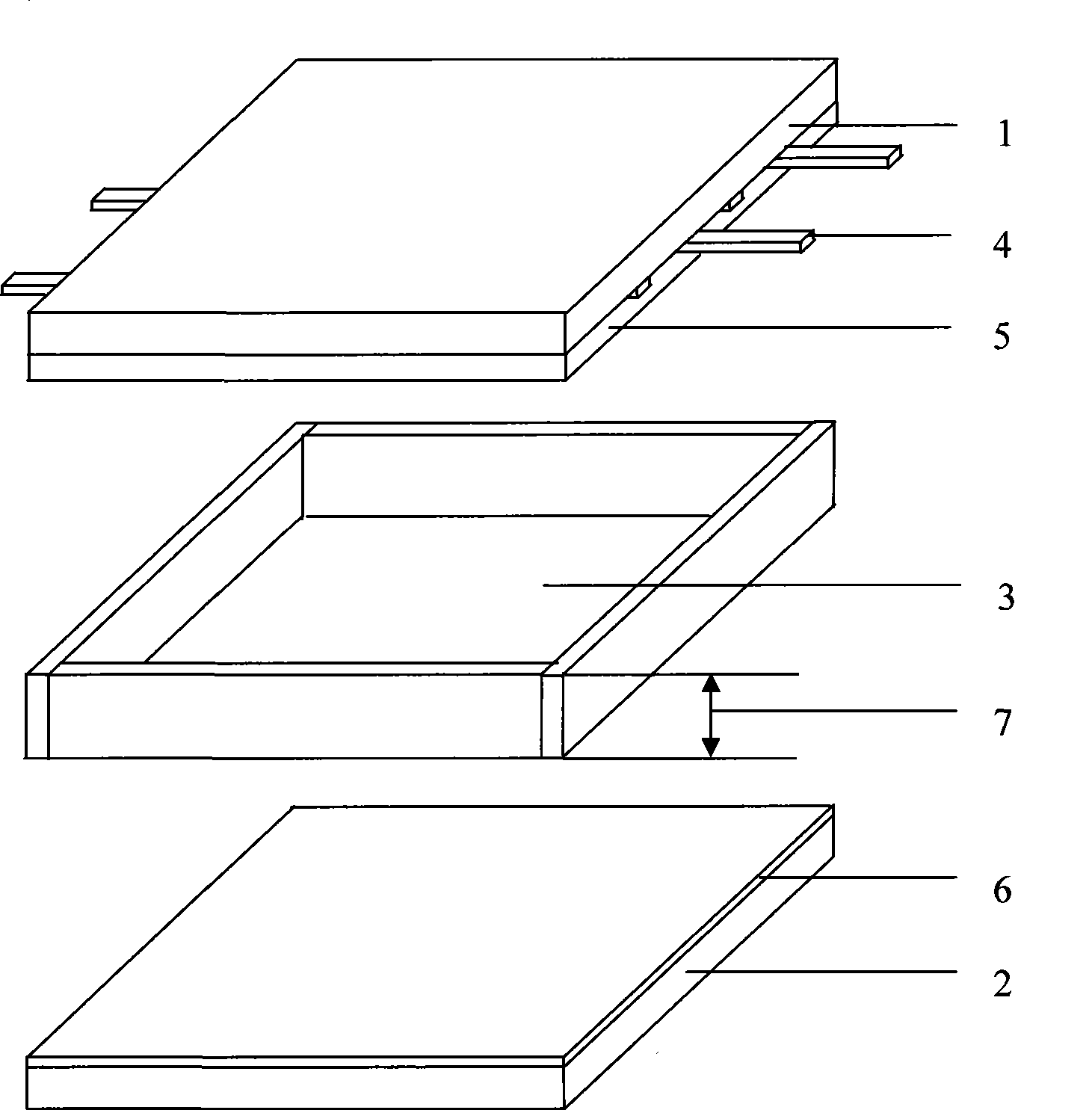

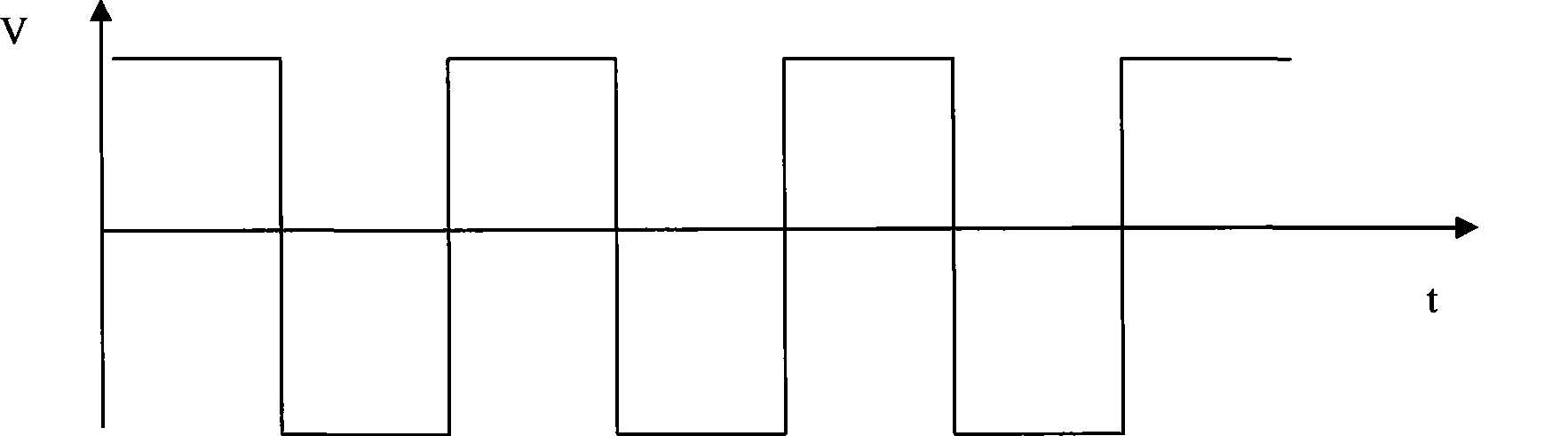

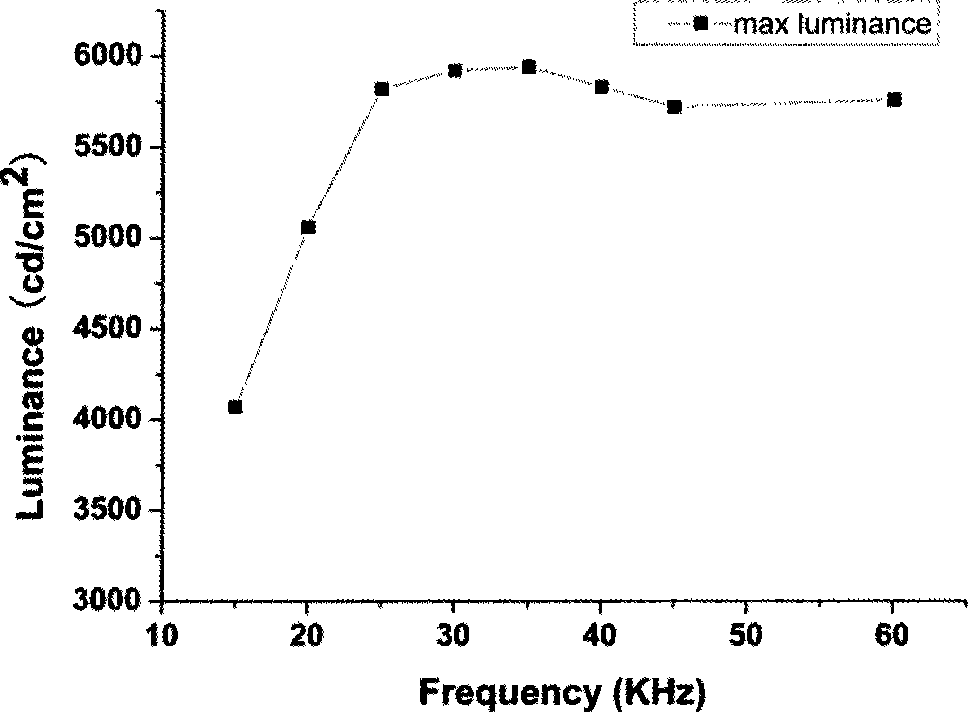

Plasma flat-plate light source

InactiveCN101477940AEffective absorptionImprove luminous efficiencyGas plasma lampsTectorial membraneElectric discharge

A plasma flat light source relates to the technical field of plasma flat light sources, in particular to the technical field of a low-frequency drive pattern of a plasma flat light source. The plasma flat light source comprises a front base plate, a rear base plate and an electric discharge cavity, wherein, the electric discharge cavity is arranged between the front base plate and the rear base plate; a plurality of parallel poles are arranged between the front base plate and the electric discharge cavity in parallel and at equal intervals; protective films are arranged among the parallel poles and the electric discharge cavity; and a phosphor powder mixed layer is arranged between the rear base plate and the electric discharge cavity. The plasma flat light source provides the low-frequency drive pattern aiming at the negative glow discharging pattern in the working mode of the prior plasma flat light source, ensures that the plasma flat light source produces the positive column discharging working pattern, and simultaneously improves the luminous efficiency and the luminous brightness.

Owner:SOUTHEAST UNIV

Device for rapidly depositing diamond-like carbon film

InactiveCN103114276BImprove discharge stabilityImprove effectivenessChemical vapor deposition coatingParticle physicsRadio frequency

The invention is a method and equipment for rapidly preparing a diamond-like film. The radio frequency hollow cathode effect is used to confine the plasma in a specific area, the negative glow area merges, and the gas ionization rate doubles. At the same time, during the radio frequency glow discharge process, electrons are bound between the electrodes and move back and forth in the discharge space, which increases the number of collisions with gas molecules, significantly improves the ionization ability and thus increases the density and energy of the plasma, thereby improving the deposition of thin films. Speed and film quality, and significantly improve production efficiency, reduce product costs, easy to achieve industrial production.

Owner:UNIV OF SCI & TECH BEIJING

A Method for Rapid Plasma Formation in a Liquid Cathode Glow Discharge Atomizer

ActiveCN103712973BSimple and fast operationAnalysis by electrical excitationPeristaltic pumpElectric discharge

The invention discloses a method for fast forming a plasma in a liquid cathode glow discharge atomizer. The method comprises the steps of: controlling the initial flow velocity of a peristaltic pump at 1.5-3.5mL.min<1>, and the interval between a metal anode and a glass capillary tube to be 3mm; when the voltage applied between the metal anode and the glass capillary tube is direct-current high voltage of 950-1050V, regulating the flow velocity of a peristaltic pump at 4.2-8.5mL.min<1>, or increasing the flow velocity to be 4.2-8.5mL.min<1> through a fast pump button in the peristaltic pump; after the current is stable, restoring the flow velocity of a peristaltic pump to be the initial flow velocity. The method for fast forming plasma in the liquid cathode glow discharge atomizer has the advantages of being safe, fast, simple and convenient to operate, and the like, can be widely popularized and applied, and is applicable to plasma in a liquid cathode glow discharge emission spectrometer or similar devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

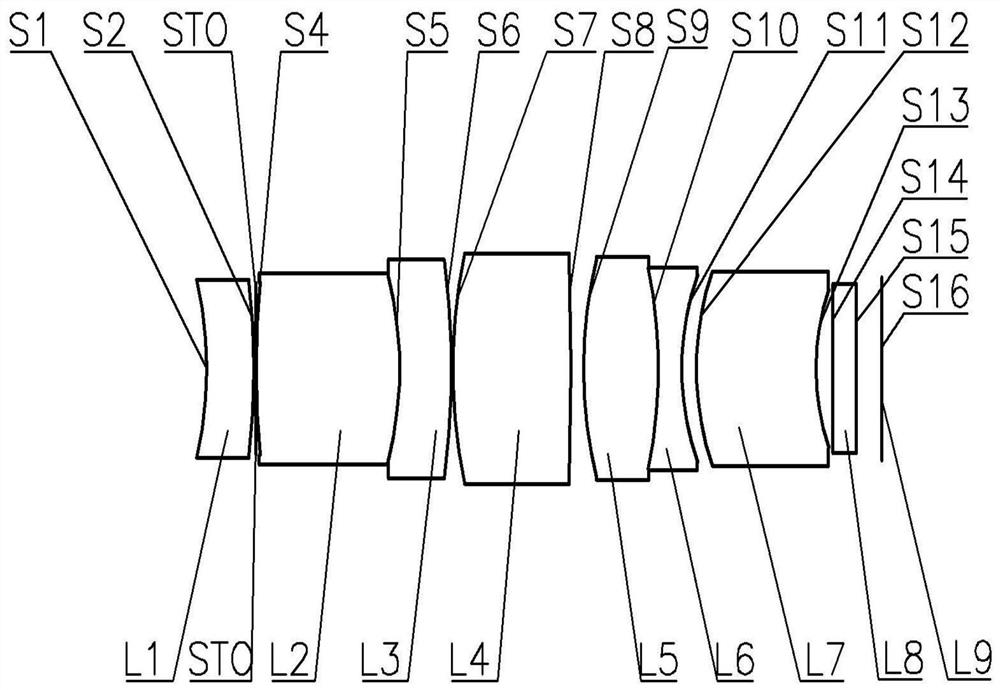

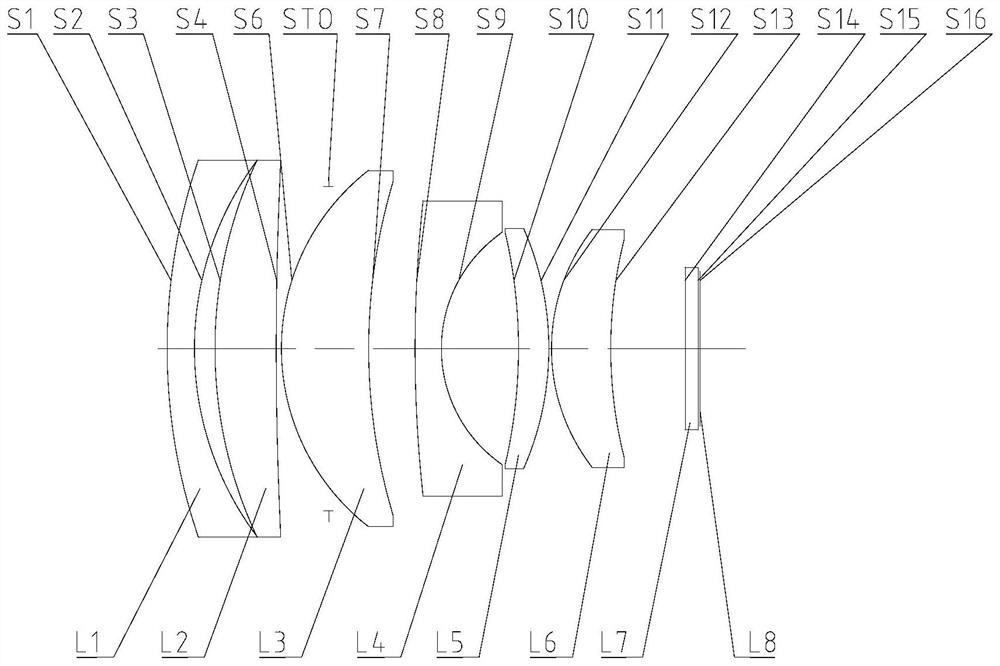

Optical lens

The present application discloses an optical lens. The optical lens may include: a first lens, a second lens, a third lens, a fourth lens, a fifth lens, and a sixth lens in order from the object side to the image side along the optical axis. and seventh lens. Wherein, the first lens, the third lens and the sixth lens can all have negative refractive power; the second lens, the fourth lens, the fifth lens and the seventh lens can all have positive refractive power; The object side of the three lenses can be concave, and the image side can be convex; the object side and the image side of the second lens and the fifth lens can be convex; the object side and the image side of the sixth lens can be concave; and The object side of the seventh lens can be convex, and the image side can be concave.

Owner:NINGBO SUNNY AUTOMOTIVE OPTECH

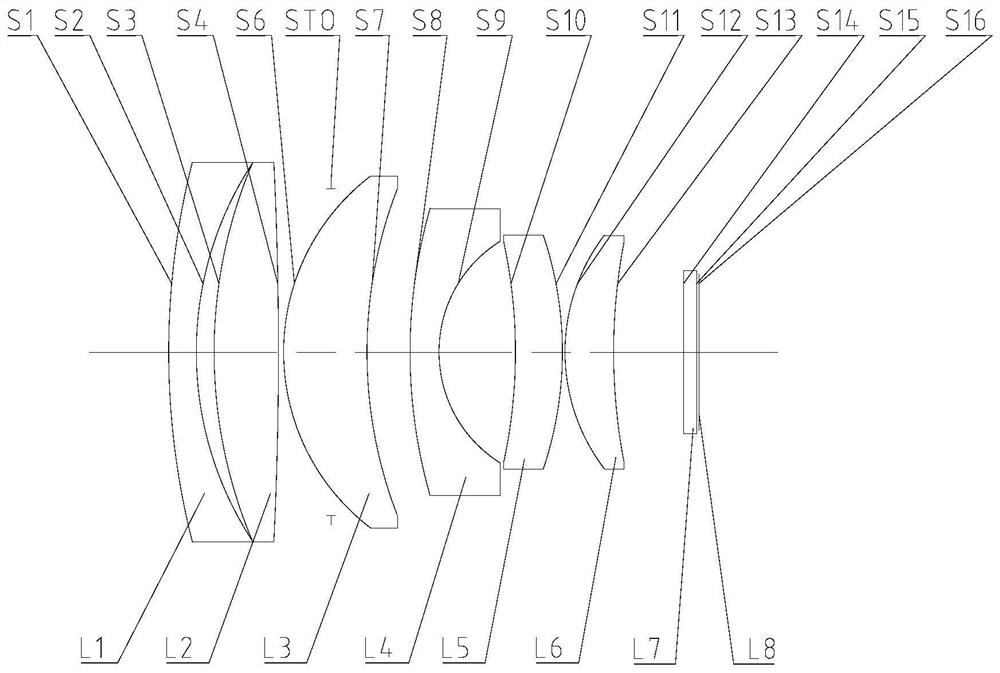

optical lens

The present application discloses an optical lens, and the optical lens may sequentially include: a first lens, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens along the optical axis from the object side to the image side . Wherein, the first lens can have negative refractive power; the second lens, the third lens, the fifth lens and the sixth lens can have positive refractive power; and the fourth lens can have negative refractive power, and its object side is a convex surface, The image side is concave. According to the optical lens of the present application, effects such as miniaturization, small aperture, low cost, and high relative illuminance can be realized.

Owner:NINGBO SUNNY AUTOMOTIVE OPTECH

A kind of preparation method of body centered cubic tantalum coating

ActiveCN108103463BImprove thermal shock resistanceAvoid pollutionVacuum evaporation coatingSputtering coatingSputteringPulse power supply

The invention relates to the field of material science, in particular to a method for preparing a body-centered cubic tantalum coating. Negative glow area magnetron sputtering method is adopted, the substrate parts are placed in the negative glow area between the anode and the cathode, the heating temperature of the substrate is between 200 and 400°C, and the power supply used is a DC power supply or a pulse power supply. The target material is pure tantalum, the working gas is Ar, and the sputtering power density is 3W / cm 2 ~15W / cm 2 between. The invention can deposit a body-centered cubic lattice α-Ta coating, and its binding force and thermal shock resistance are significantly better than the excellent conventional magnetron sputtering tantalum coating. When the thickness of the tantalum coating prepared by the present invention reaches about 100 μm, it is well combined with the substrate, while the tantalum coating prepared by the conventional magnetron sputtering method will peel off when the thickness reaches 15 μm. The thermal shock resistance of the tantalum coating with a thickness of 100 μm prepared by the invention is 7 times higher than that of the tantalum coating with a thickness of 10 μm prepared by a conventional magnetron sputtering method.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Titanium alloy gear with ferroboron diffusion layer on surface and co-diffusion method thereof

InactiveCN103147037BImprove surface propertiesHigh surface hardnessPortable liftingSolid state diffusion coatingRoom temperatureIron boride

The invention relates to a titanium alloy gear with a ferroboron diffusion layer on the surface and a co-diffusion method thereof. The method comprises the step of: by taking a titanium alloy gear as a workpiece and taking iron boride as a source, placing the titanium alloy gear and the iron boride on a negative disk to form a workpiece-source integral structure, wherein the negative electrode of a direct current power supply is connected to the negative disk, and the positive electrode of the direct current power supply is connected to a vacuum container; vacuumizing and introducing argon, applying a direct-current voltage to generate hollow negative glow discharge, migrating, adsorbing and spreading the sputtered boron, iron ion, atoms and particles into the gear to form an alloy layer, preserving the heat, slowly cooling to room temperature, thereby obtaining the titanium alloy gear with the ferroboron diffusion layer. The method disclosed by the invention is advanced in process and low in cost; and the prepared gear is strong in seizure resistance, good in wear resistance and long in service life.

Owner:TAIYUAN UNIV OF TECH

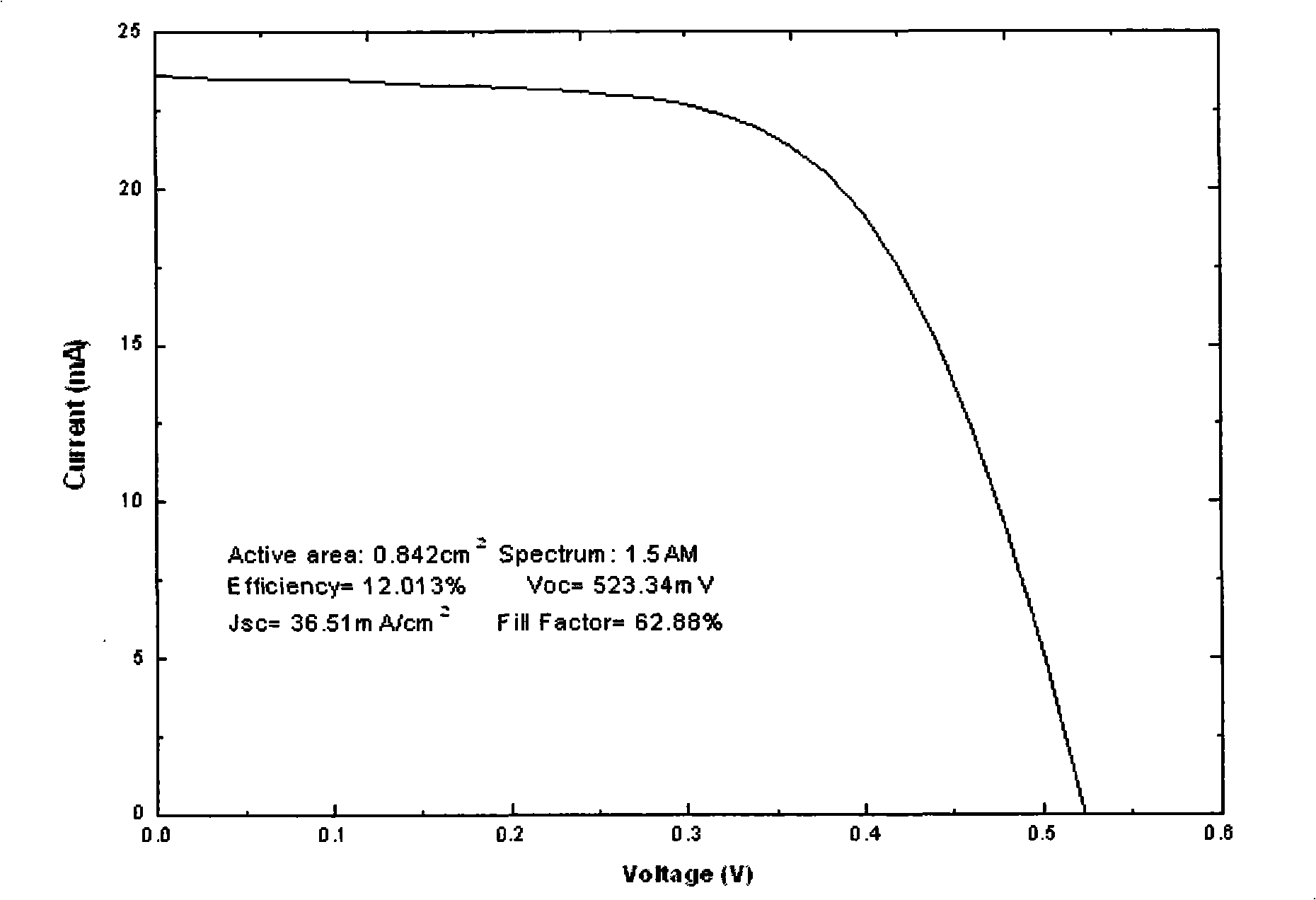

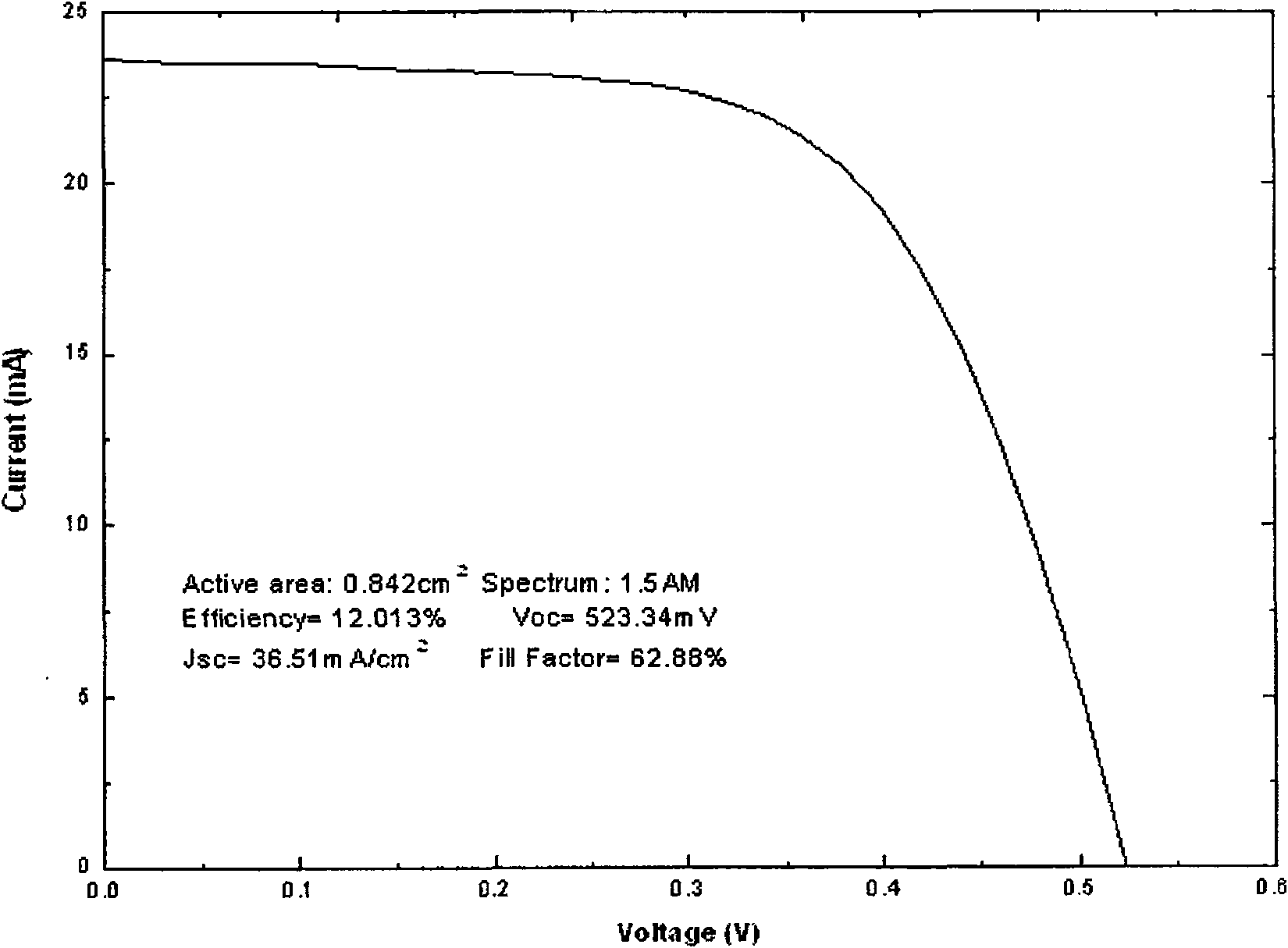

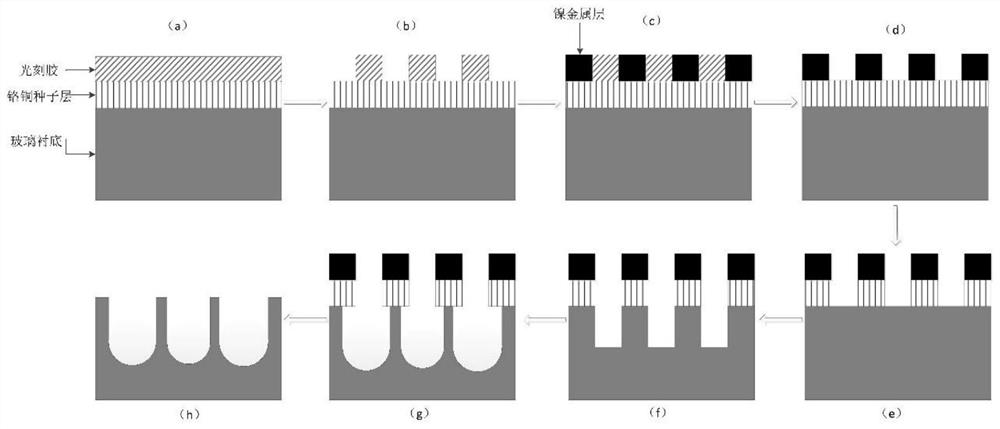

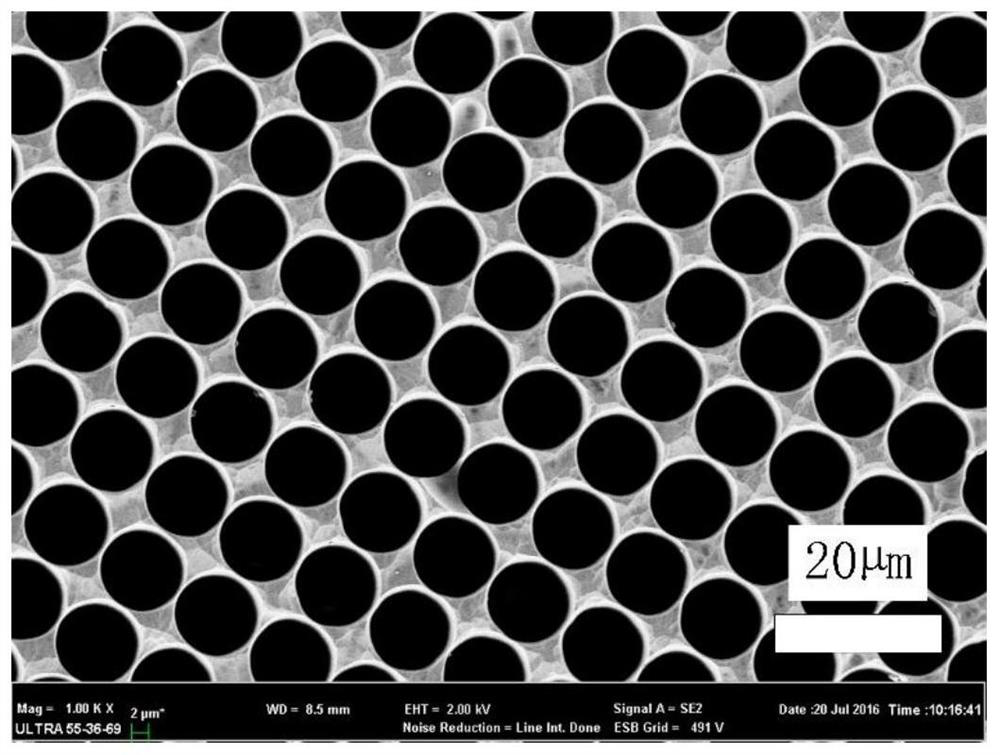

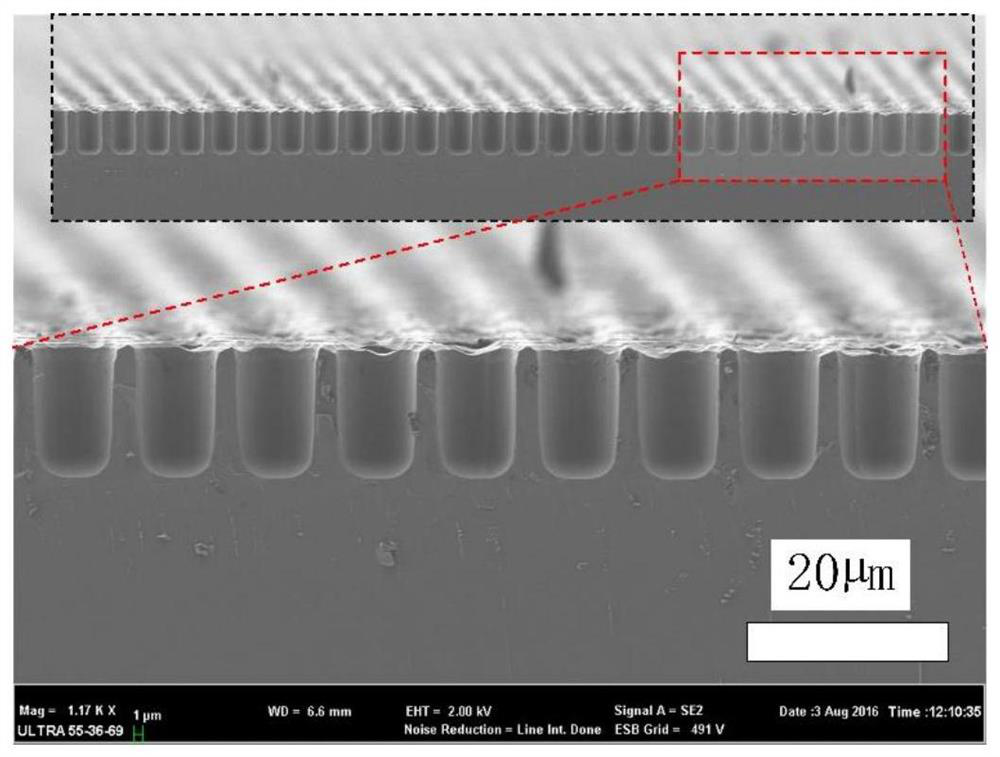

Preparation method of high-aspect-ratio light trapping structure for surface of silicon thin film battery

PendingCN112968077AIncrease contact rateAvoid depositionFinal product manufacturePhotovoltaic energy generationLight energySilicon thin film

The invention provides a preparation method of a high-aspect-ratio light trapping structure for the surface of a silicon thin film battery. The preparation method is characterized in that the process flow of the high-depth and wide-pit array structure on the surface of a glass substrate by using a negative photoetching plate comprises the following steps of: (a) sputtering a metal seed layer, and spin-coating photoresist; (b) carrying out photoetching and developing; (c) electroplating nickel metal (Ni); (d) removing photoresist; (e) etching a seed layer; (f) performing reactive ion etching on the glass substrate; (g) etching the glass substrate with hydrofluoric acid (HF); and (h) removing the metal layer. According to the preparation method, the pit array with the high aspect ratio can be prepared on the surface of the glass, and the reflection can be reduced and the optical path can be prolonged. The preparation method can be used for a surface pit array structure, and by adopting the efficient surface light trapping structure, light energy loss on the surface of the cell can be reduced, light energy escape in the cell can be reduced, meanwhile, the light path of light in a cell absorption layer can be prolonged, and therefore the efficiency of the silicon thin film solar cell is improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

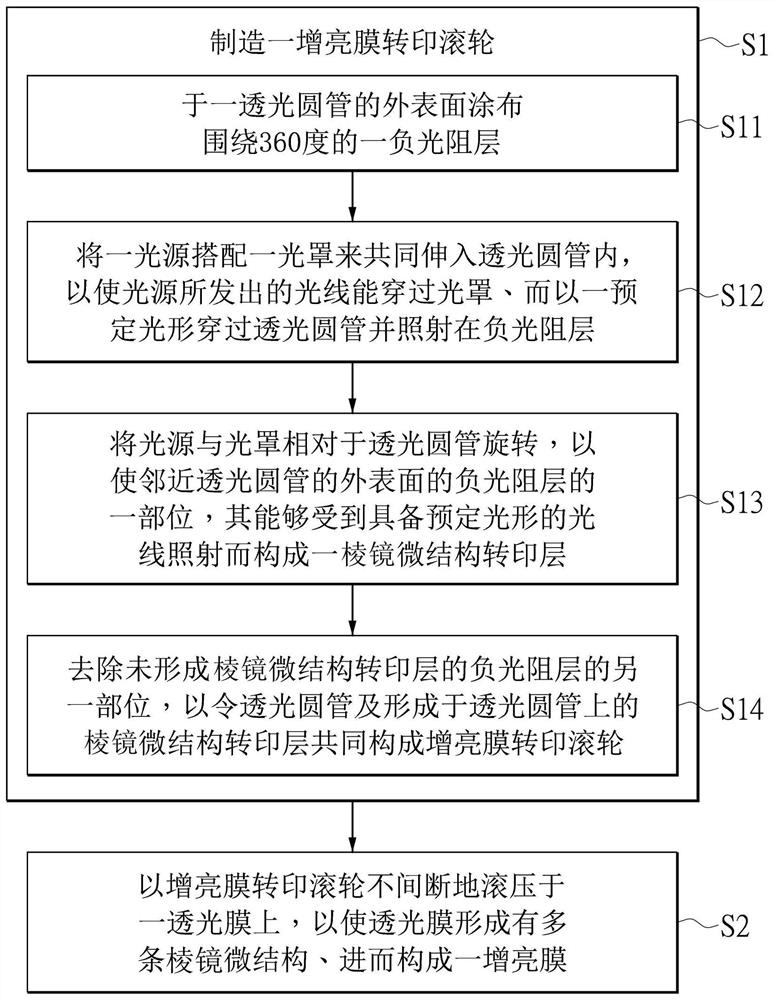

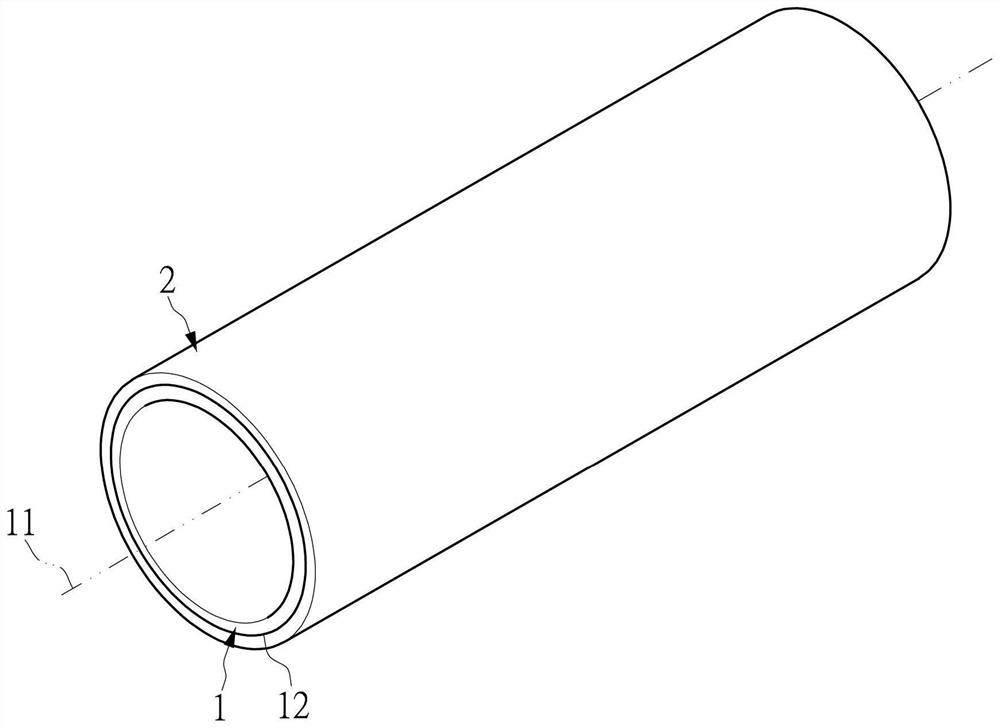

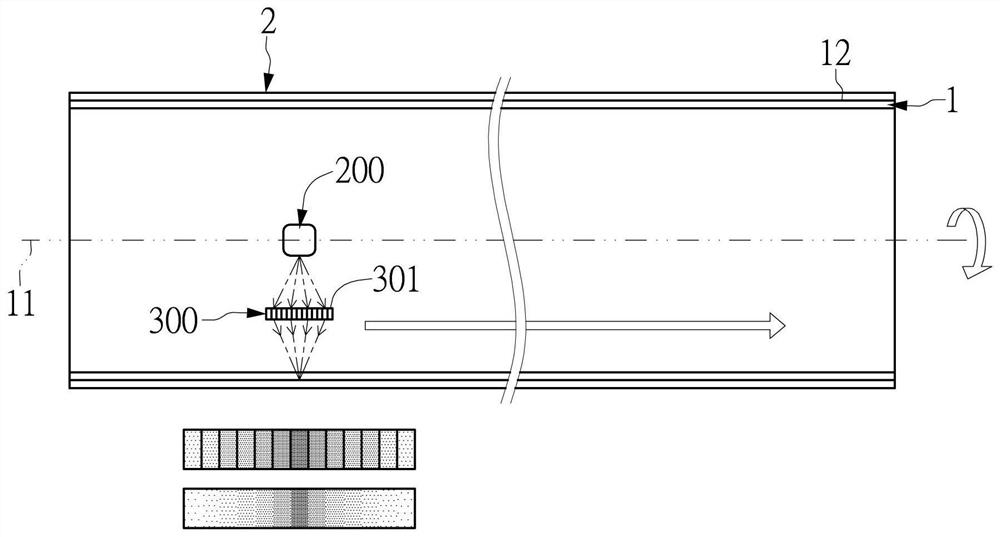

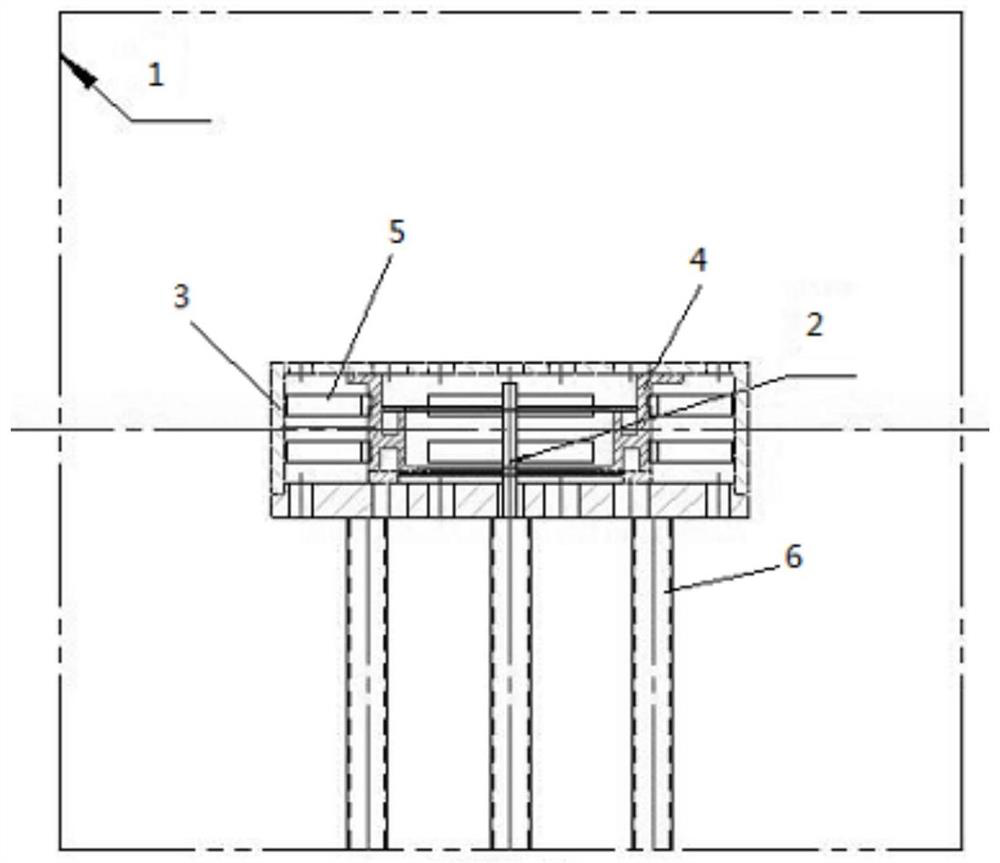

Transfer printing type manufacturing method of brightness enhancement film and brightness enhancement film

PendingCN113917583AAvoid time costReduce manufacturing costDiffusing elementsPhotoresistNegative glow

The invention discloses a transfer printing type manufacturing method of a brightness enhancement film and the brightness enhancement film. The transfer printing type manufacturing method of the brightness enhancement film comprises the following steps: manufacturing a brightness enhancement film transfer printing roller; and rolling a light-transmitting film by using the brightness enhancement film transfer printing roller to form a brightness enhancement film. The manufacturing process of the brightness enhancement film transfer roller comprises the following steps of coating a negative photoresist layer on the outer surface of a light-transmitting round tube; matching a light source with a light cover to jointly extend into the light-transmitting round tube, and enabling the light-transmitting round tube to penetrate through the light-transmitting round tube in a preset light shape and irradiate the negative light resistance layer; rotating the light source and the light cover relative to the light-transmitting circular tube, so that one part of the negative light resistance layer on the outer surface of the light-transmitting circular tube can be irradiated by light with a preset light shape to form a prism microstructure transfer printing layer; and removing the other part of the negative photoresist layer on which the prism microstructure transfer printing layer is not formed to form the brightness enhancement film transfer printing roller. According to the brightness enhancement film provided by the invention, the manufacturing time and the manufacturing cost of the brightness enhancement film can be greatly reduced through the transfer printing type manufacturing method of the brightness enhancement film.

Owner:K LASER TECH

A method for controlling ultra-precision deformation of thin-walled double-shell titanium alloy bushing during high temperature nitriding

The invention belongs to the technical field of metal heat treatment, and relates to a high-temperature nitriding ultra-precision deformation control method of a thin-walled double-shell titanium alloy bushing. The invention uses a titanium alloy ion nitriding furnace with an auxiliary heat source, constructs an equipotential local negative glow area space with the help of an auxiliary cathode cylindrical tooling, and adopts mechanical shielding to prevent the hollow cathode effect between the shells of the double shells. , the tooling and the effective working area in the ion nitriding furnace overlap the geometric centers. During the ion nitriding, the temperature is raised in steps of 300-450°C, 500-650°C, heat preservation and cooling, and the heat preservation time is 2-4 hours. The cooling rate is controlled at 0.5-4°C / min, high-temperature annealing at 850-950°C before nitriding, the glow heating system is started when the temperature is raised to 300-400°C, and nitriding is carried out at 750-880°C for 6-20 hours. Through the comprehensive application of the above means, the present invention realizes the ultra-precise control of the high-temperature ion nitriding deformation of the thin-walled double-shell complex structure titanium alloy bushing parts, and the deformation amount does not exceed 0.020mm.

Owner:HARBIN DONGAN ENGINE GRP

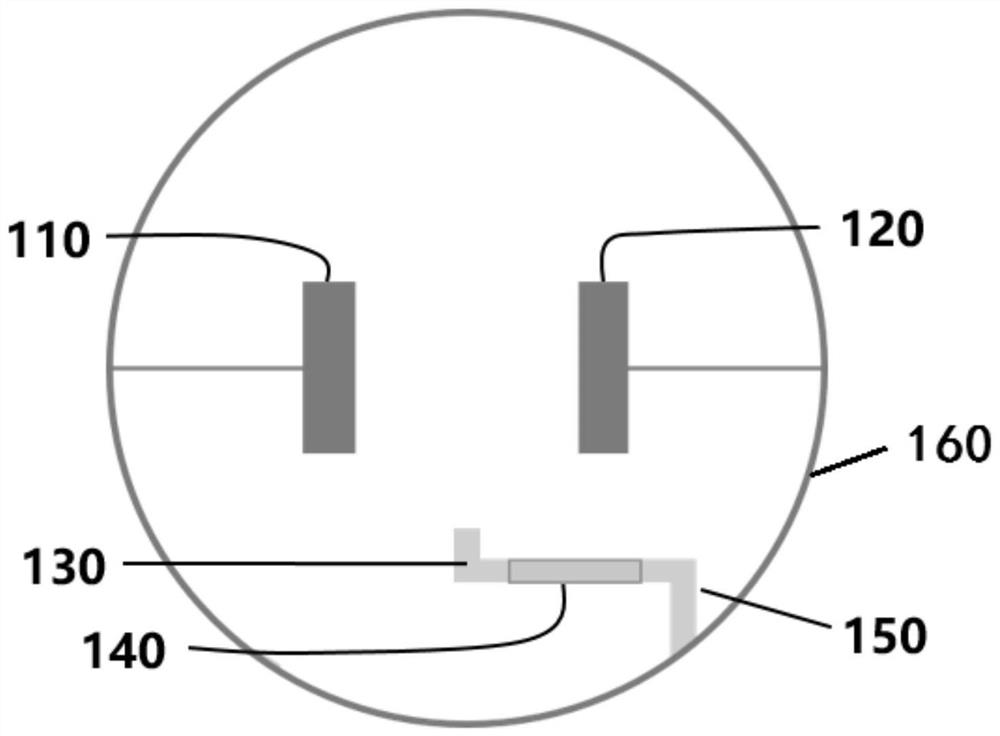

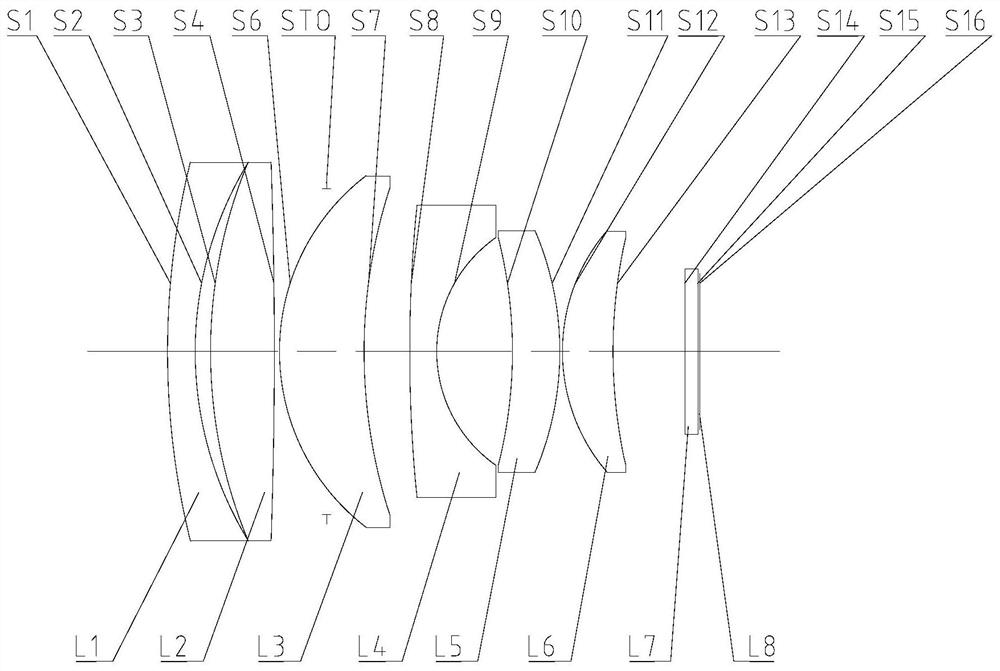

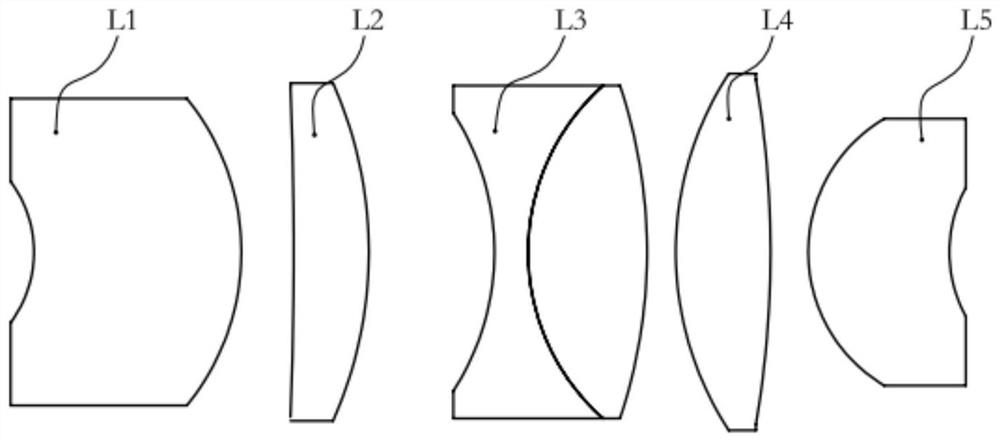

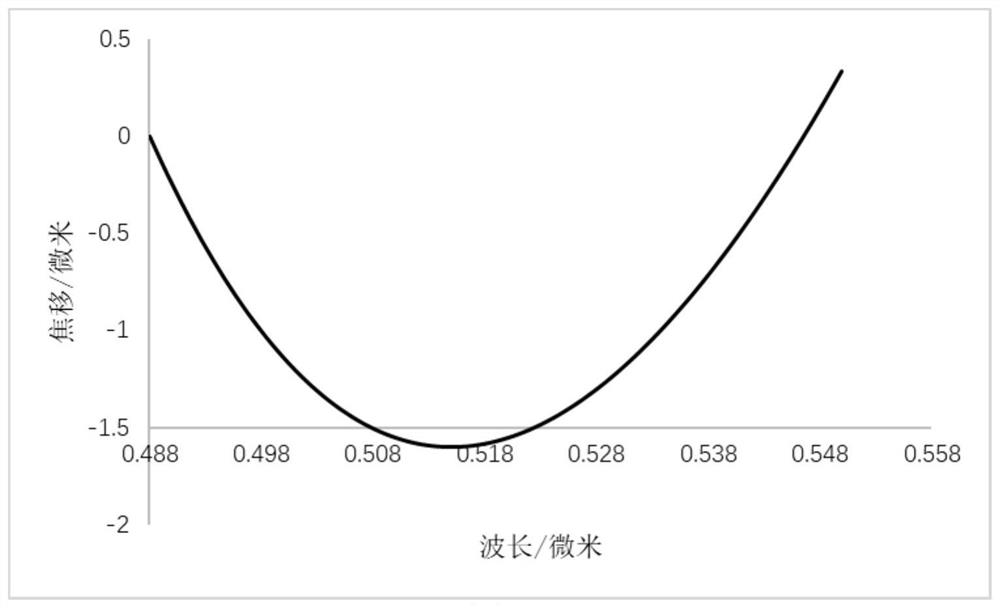

A coupling objective lens for confocal microendoscope

The invention provides a coupling objective lens for a confocal microendoscope, comprising a first lens with a negative refractive power, a second lens with a positive refractive power, a third lens with a negative refractive power, and a lens with a positive refractive power. The fourth lens and the fifth lens with positive refractive power are sequentially arranged along the optical axis from the object side to the image side. The coupling objective lens strictly controls the incident and exit angles of the light through the cooperation between the lenses, achromatizes the excitation light and the fluorescence signal, and makes the numerical aperture match the numerical aperture of the fiber bundle while ensuring a large working distance.

Owner:JINGWEI SHIDA MEDICAL TECH WUHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com