Patents

Literature

31 results about "Iron boride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron boride refers to various inorganic compounds with the formula FeₓBy. Two main iron borides are FeB and Fe₂B. Some iron borides possess useful properties such as magnetism, electrical conductivity, corrosion resistance and extreme hardness. Some iron borides have found use as hardening coatings for iron. Iron borides have properties of ceramics such as high hardness, and properties of metal properties, such as thermal conductivity and electrical conductivity. Boride coatings on iron are superior mechanical, frictional, and anti-corrosive. Iron monoboride (FeB) is a grey powder that is insoluble in water. FeB is harder than Fe₂B, but is more brittle and more easily fractured upon impact.

Powder material for boiler tube high temperature resistance and wear resistance protecting and preparation method thereof

InactiveCN103878363AHigh hardnessImprove wear resistanceMetallic material coating processesSurface engineeringWear resistant

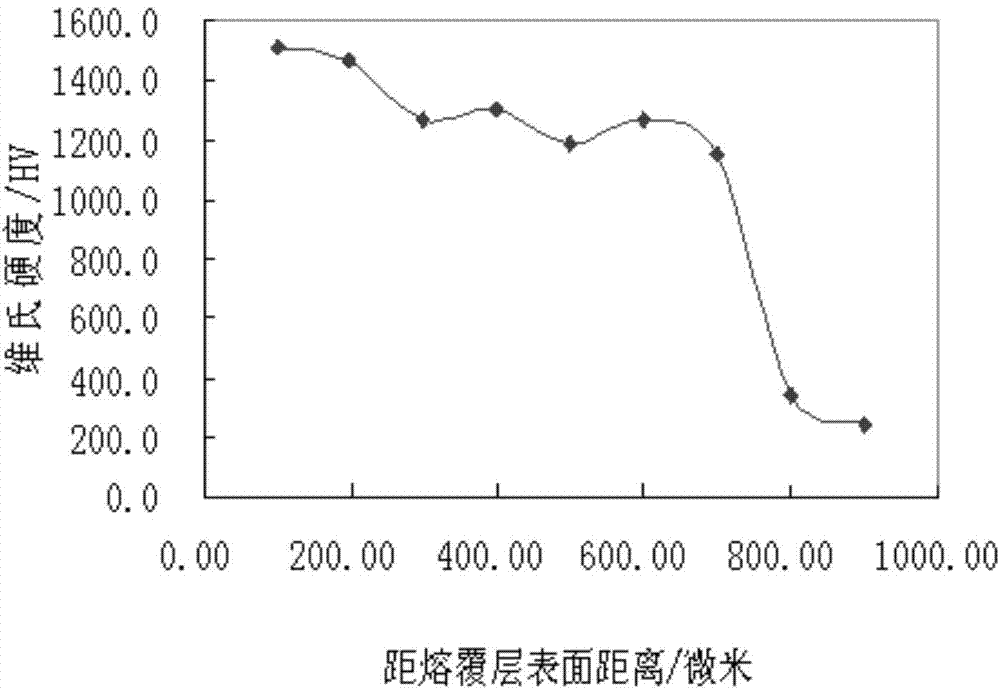

The invention relates to powder material for boiler tube high temperature resistance and wear resistance protecting and a preparation method thereof, and belongs to the technical field of surface engineering. The power material comprises the following components, by weight percentage, 10-20% of titanium-nickel alloy powder, 1.5-3.5% of graphite powder, 0.5-1% of silica powder, 8-25% of nickel-chromium alloy powder Ni80Cr20, 5-10% of iron boride powder and the balance of tri-chromium dicarbide powder. The preparation method comprises the following steps that power material is prepared, mix powder is formed, liquid-containing binders are prepared, sizing agents are prepared from the mix powder, prilling is completed through spray drying, and finished product powder is prepared from screening the prilling powder and is used for preparing a cladding layer. The metal cladding layer with high wear resistant duplex ceramic is formed through laser cladding, and the hardness ranges from 1100 HV to 1600 HV, so that the powder material for boiler tube high temperature resistance and wear resistance protecting and the preparation method thereof has the advantages that efficiency of the laser cladding is higher, loss of powder spattering is low, grain of the cladding layer is tiny, wear resistance of the cladding layer is high and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

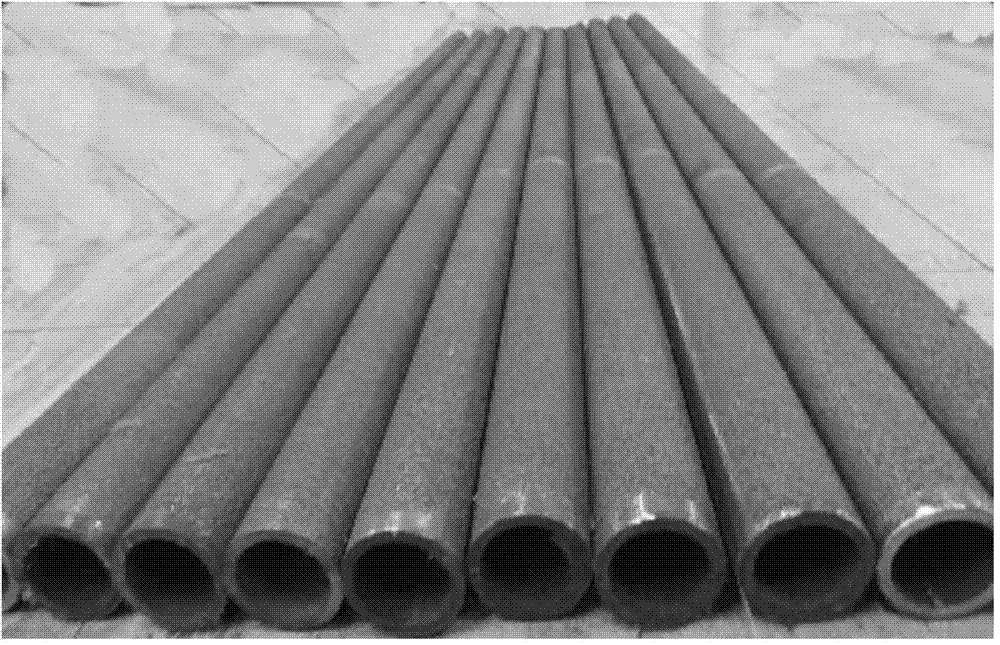

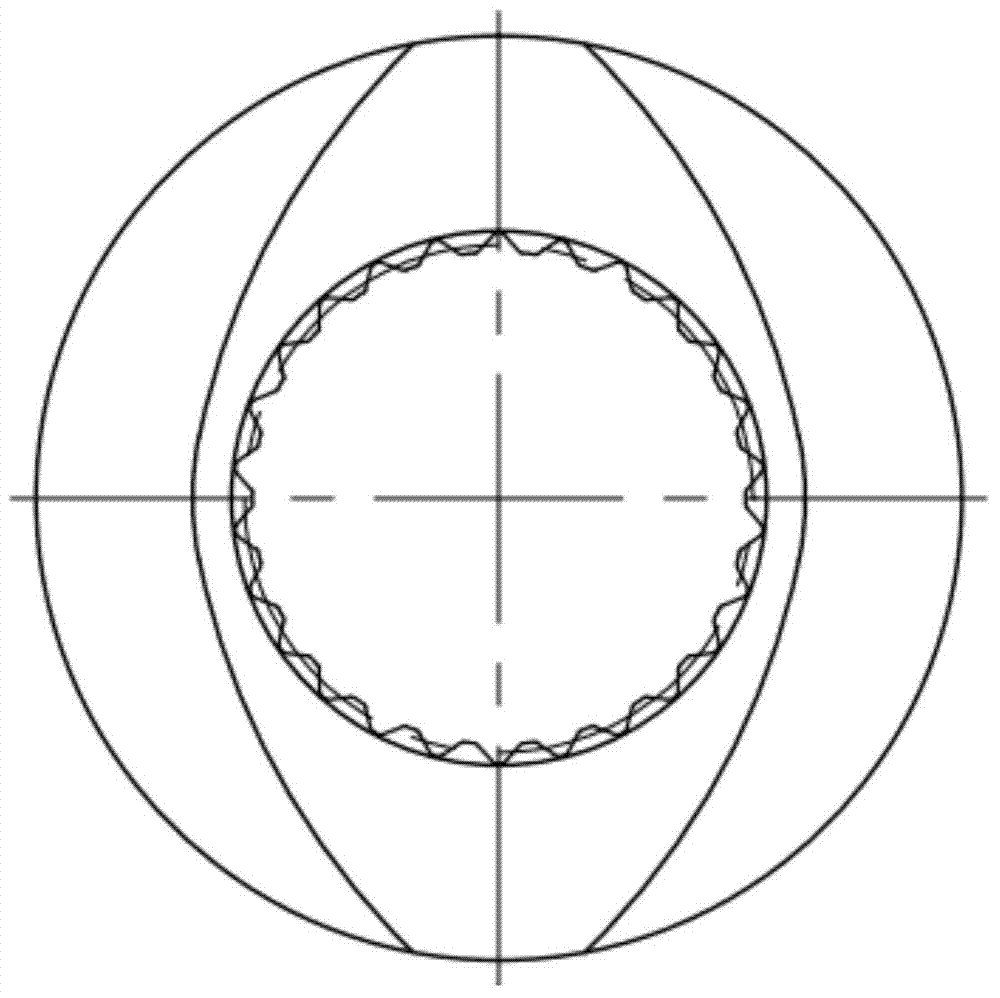

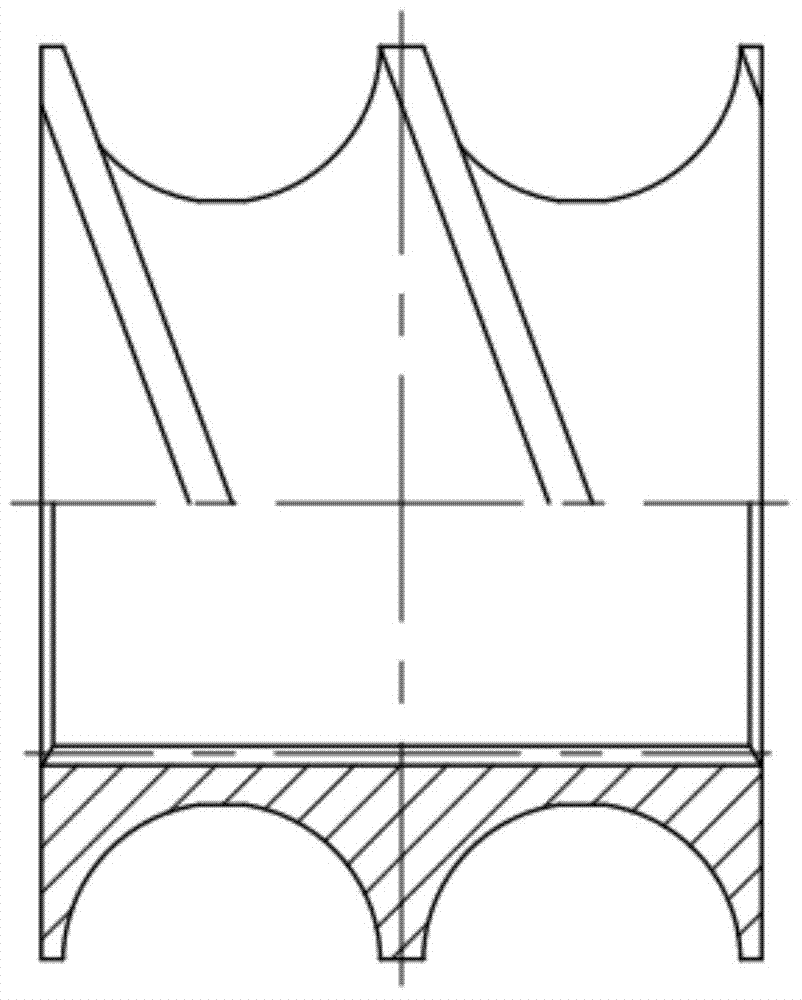

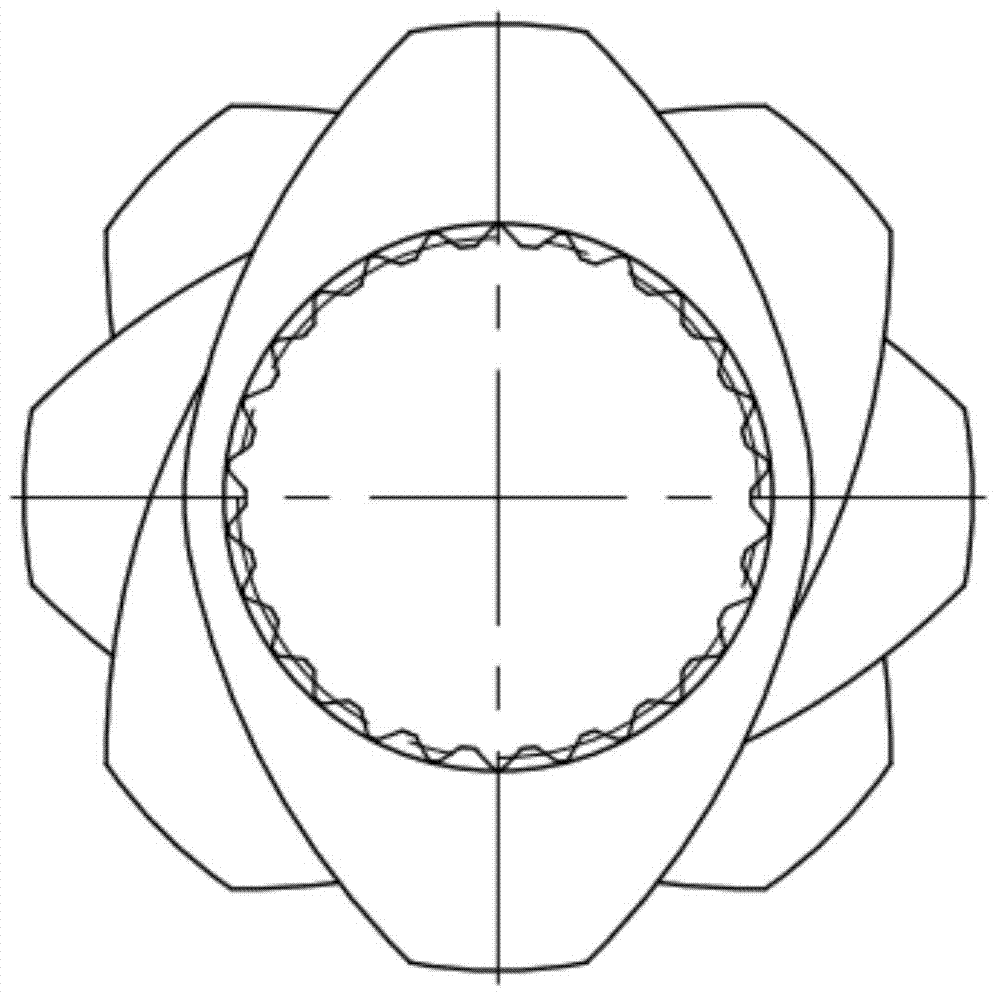

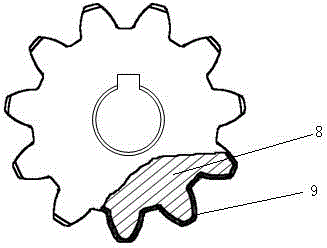

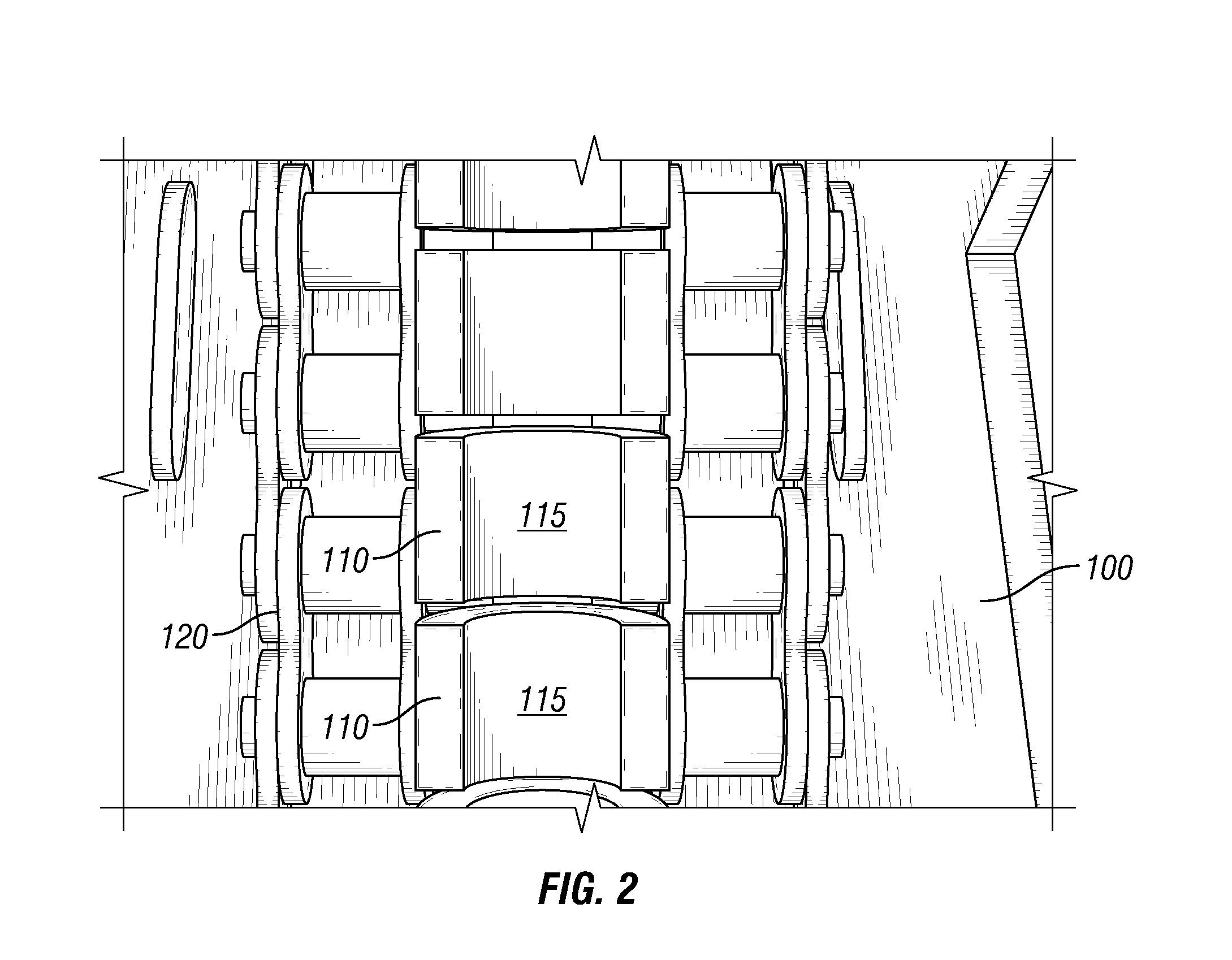

High-wear-resistance iron boride alloy screw element for double-screw machine, and manufacturing method of iron boride alloy screw element

The invention discloses a high-wear-resistance iron boride alloy screw element for a double-screw machine. The iron boride alloy screw element comprises a body and an iron boride alloy layer; the iron boride alloy layer is evenly concentrically molten on the surface layer of the body, the overall thickness of the iron boride alloy layer is 50-150mum; the body is made of high-chromium high-carbon die steel which is Cr12MoV. The high-wear-resistance iron boride alloy screw element for the double-screw machine, disclosed by the invention, is used in industries of plastics, LED (Light-emitting Diode)s, cables, food, feeds, construction materials and the like, and the iron boride alloy screw element has a high wear resistance property, and is capable of greatly lowering the manufacture cost and application cost and greatly improving the production efficiency.

Owner:章鹏

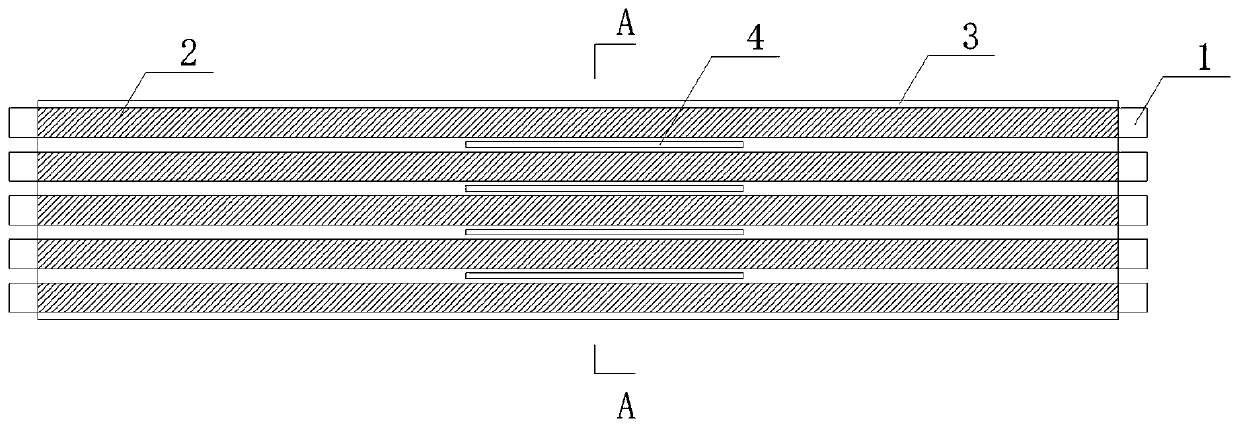

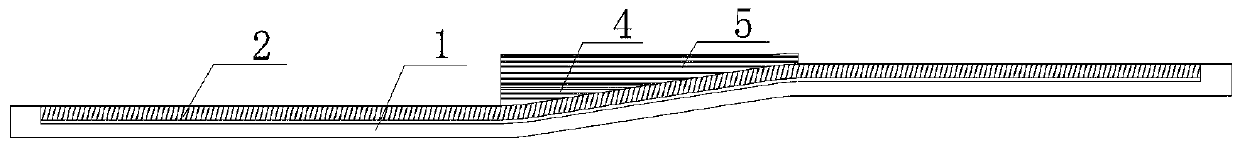

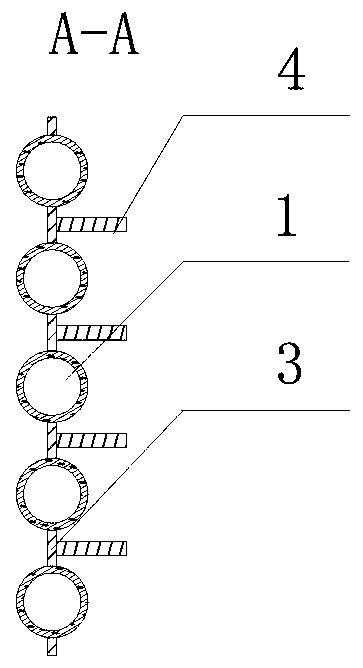

Zirconium boride-silicon carbide laminated composite ultrahigh-temperature ceramic material and preparation method thereof

InactiveCN102179977AImprove fracture toughnessImprove mechanical propertiesCeramic layered productsIron borideUltrahigh temperature ceramics

The invention discloses a zirconium boride-silicon carbide laminated composite ultrahigh-temperature ceramic material and a preparation method thereof, relating to a ultrahigh-temperature ceramic material and a preparation method thereof, wherein the material can be used for solving the problem that the existing boride ultrahigh-temperature ceramic matrix composite material has poor toughness. The zirconium boride-silicon carbide laminated composite ultrahigh-temperature ceramic material is prepared by laminating residual compressive stress layers and residual tensile stress layers alternatively. The preparation method comprises the following steps: 1. weighing raw materials; 2. preparing residual compressive stress layer powder and residual tensile stress layer powder; 3. preparing a laminated mixture; 4. carrying out sintering and heat insulation on the laminated mixture to obtain the zirconium boride-silicon carbide laminated composite ultrahigh-temperature ceramic material. The fracture toughness value of the zirconium boride-silicon carbide laminated composite ultrahigh-temperature ceramic material can reach up to 10.4MPaml / 2. In the invention, the preparation process is simple, the cost is low, and the fracture toughness is improved without influencing the strength of the material.

Owner:HARBIN INST OF TECH

Modified lithium nickel cobalt manganate material

InactiveCN106129398AAdvanced technologyImprove discharge capacityCell electrodesSecondary cellsFiberCarbon fibers

The invention discloses a modified lithium nickel cobalt manganate material. The modified lithium nickel cobalt manganate material comprises the following raw materials: 800-1,000 parts of lithium nickel cobalt manganate, 10-18 parts of nano graphene, 3-5 parts of microcrystalline silicon powder, 5-8 parts of nanocarbon particles, 5-6 parts of carbon fibers, 2-5 parts of iron boride, 4-5 parts of antimony pentoxide, 3-5 parts of silver hexafluorophosphate, 2-4 parts of tetrahydroxy sodium cuprate, 2-4 parts of maleic anhydride grafted compatilizer, 5-6 parts of ethylene diamine tetraacetic acid, 4-5 parts of titanate coupling agent, 5-6 parts of modified copper powder, 4-5 parts of conductive copper powder, 5-8 parts of nanometer aluminum powder and 10-25 parts of deionized water. The modified lithium nickel cobalt manganate material has the advantages of advanced technology, wide raw material resource, low cost, high discharge capacity, long service life and the like; meanwhile, the material has no toxins and environmental pollution; and therefore, the consistency of the industrialization and the cruising power of the power batteries are ensured.

Owner:陈新堂

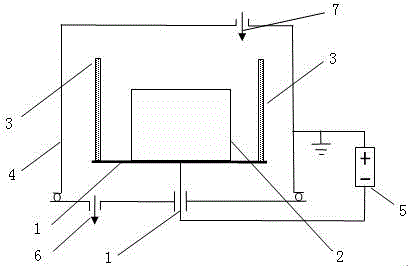

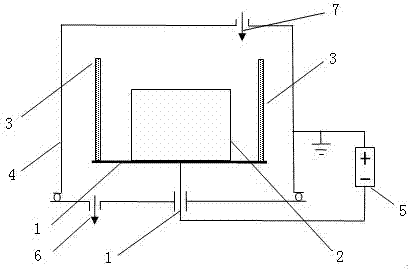

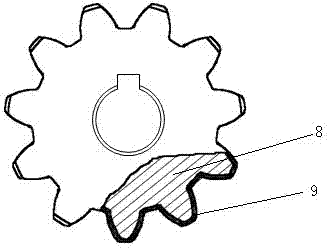

Titanium alloy gear with ferroboron diffusion layer on surface and co-diffusion method thereof

InactiveCN103147037AImprove surface propertiesHigh surface hardnessPortable liftingSolid state diffusion coatingRoom temperatureIron boride

The invention relates to a titanium alloy gear with a ferroboron diffusion layer on the surface and a co-diffusion method thereof. The method comprises the step of: by taking a titanium alloy gear as a workpiece and taking iron boride as a source, placing the titanium alloy gear and the iron boride on a negative disk to form a workpiece-source integral structure, wherein the negative electrode of a direct current power supply is connected to the negative disk, and the positive electrode of the direct current power supply is connected to a vacuum container; vacuumizing and introducing argon, applying a direct-current voltage to generate hollow negative glow discharge, migrating, adsorbing and spreading the sputtered boron, iron ion, atoms and particles into the gear to form an alloy layer, preserving the heat, slowly cooling to room temperature, thereby obtaining the titanium alloy gear with the ferroboron diffusion layer. The method disclosed by the invention is advanced in process and low in cost; and the prepared gear is strong in seizure resistance, good in wear resistance and long in service life.

Owner:TAIYUAN UNIV OF TECH

A kind of alloy screw rod material and the production technology of screw rod thereof

Owner:东莞杰宇机械有限公司

Metal material containing vanadium carbide coating as well as preparation method and application thereof

InactiveCN109136830AWon't break and peelHigh hardnessSolid state diffusion coatingCase hardeningAlloy

The invention provides a metal material containing a vanadium carbide coating which comprises a base metal, a vanadium carbide coating and a boronizing layer located between the base metal and the vanadium carbide coating, wherein the vanadium carbide coating has the thickness of 5-15 [mu]m, the boronizing layer is single-phase iron boride, the boronizing layer has the thickness of 30-200 [mu]m, and the base metal is steel with the carbon content being 0.3% or more than 0.3%. The invention further provides a preparation method of the metal material containing the vanadium carbide coating. Thesurface hardened layer of an alloy prepared with the method provided by the invention has an outmost surface layer being the vanadium carbide coating which is extremely high in tensile strength and high in wear resistance, a subsurface hardened layer is relatively thick and the hardness of the subsurface hardened layer is much higher than that of a base material; the surface hardened layer structure enables the outermost surface layer of the vanadium carbide coating to withstand greater compressive stress without being damaged or peeled off, thereby exerting the performance characteristics ofthe vanadium carbide coating, effectively solving the problem of surface strain of heavy load pull-down deep forming molds or mechanical parts, and greatly prolonging the service life of the heavy load pull-down deep forming molds or the mechanical parts.

Owner:CHANGSHA TOPWELLWEAR METAL MATERIAL SCI

Processing technology of novel PVC material

The invention provides a processing technology of a novel PVC material. The novel PVC material is mainly prepared from PVC resin, carbon fibers, polytetrafluoroethylene, chloroprene rubber, butadienerubber, nitrile butadiene rubber, polycarbonate, titanium dioxide, iron boride, chromium carbide, high manganese steel, tungsten carbide, aluminum oxide, lanthanum oxide, calcium oxide, boron nitride,silicon nitride, molybdenum disilicide, silicon carbide, octyl epoxy stearate and polyurethane. The material is reasonable in design and reasonable in matching of all material components in parts byweight, by adding various different metal compounds, oxides and carbides, the wear resistance and the fire resistance of the material can be improved, and after the material is processed into a product, the characteristics of the product can be promoted, and the wear resistance and the fire resistance of the product can be improved.

Owner:苏师大半导体材料与设备研究院(邳州)有限公司

Novel anticorrosive paint

InactiveCN106366808AImprove friction resistanceImprove corrosion resistanceAnti-corrosive paintsSodium bicarbonateChemical reaction

The invention discloses novel anticorrosive paint. The novel anticorrosive paint is prepared from 18-20 parts of silver powder, 10-18 parts of copper powder, 15-18 parts of iron powder, 20-28 parts of glass powder, 10-15 parts of magnesium powder, 20-25 parts of microcrystalline silicon powder, 15-18 parts of nano carbon particles, 5-6 parts of dibromomethane, 3-5 parts of sodium bicarbonate, 30-45 parts of crylic acid emulsion, 30-35 parts of organic silicone oil, 12-15 parts of iron boride, 20-25 parts of dolomite powder, 15-20 parts of kaolin, 18-20 parts of bentonite, 8-10 parts of alumina silicate fibers, 8-10 parts of glass beads, 10-12 parts of polyvinyl alcohol, 6-8 parts of hydroxyethyl cellulose, 6-8 parts of aluminum-magnesium silicate and 120-150 parts of deionized water. According to the novel anticorrosive paint, the abrasion resistance and corrosion resistance of a coating are improved, the advantages of being high in strength, large in specific area, high in chemical reaction activity and high in fillibility are achieved, the coating and a bottom material are in contact more tightly, the lubricating effect is good, and the abrasion resistance of the coating can be improved. The novel anticorrosive paint has electrochemical inertness, is attached to the surface of a zinc sheet and the surface of an aluminum sheet, therefore, the novel anticorrosive paint is beneficial for a zinc-aluminum cathodic protection reaction, and the anti-corrosion time can be prolonged.

Owner:黄惠娟

Modified PVC material

The invention discloses a modified PVC material. The modified PVC material is prepared from the following raw materials in parts by weight: 50 to 60 parts of nano silver powder modified PVC, 10 to 15parts of calcium sulfate, 10 to 15 parts of calcium oxalate, 12 to 18 parts of carbon fibers, 8 to 10 parts of polytetrafluoroethylene, 8 to 12 parts of chloroprene, 15 to 20 parts of polybutadiene rubber, 4 to 8 parts of nitrile butadiene, 4 to 8 parts of silica gel, 10 to 15 parts of polycarbonate, 4 to 8 parts of tetrabutyl titanate, 10 to 12 parts of titanium dioxide, 4 to 8 parts of iron boride, and 7 to 12 parts of calcium silicon. The modified PVC prepared in the invention has high aging resistance, heat resistance and mechanical performance, and can enlarge the application range of themodified PVC.

Owner:宿迁市正祥新材料股份有限公司

High-hardness wear-resistant grinding wheel and preparation method for same

InactiveCN105818005AHigh hardnessImprove cutting effectAbrasion apparatusGrinding devicesWear resistantPolyethylene glycol

The invention discloses a high-hardness wear-resistant grinding wheel and a manufacturing method thereof, which are prepared from the following raw materials in parts by weight: aluminum oxide, silicon carbide, iron boride, zirconium nitride, polyethylene glycol, and limestone , zinc oxide, polyvinyl chloride, diatomaceous earth, oleic acid, and white carbon black, the preparation method of which is as follows: first, pour aluminum oxide, silicon carbide, iron boride, zirconium nitride, and polyethylene glycol into the mixture Then add limestone, zinc oxide, polyvinyl chloride to the mixer and stir, and finally add diatomaceous earth, oleic acid, white carbon black and stir; then put the mixture into the reaction kettle to heat and keep it warm for modification. After tableting, it can be cooled and formed. The grinding wheel of the invention has the excellent characteristics of high hardness, wear resistance and long service life, and the preparation method is scientific and reasonable, and is suitable for large-scale industrial promotion.

Owner:DIAMOND GRINDING WHEEL CO LTD IN ANHUI TOBE

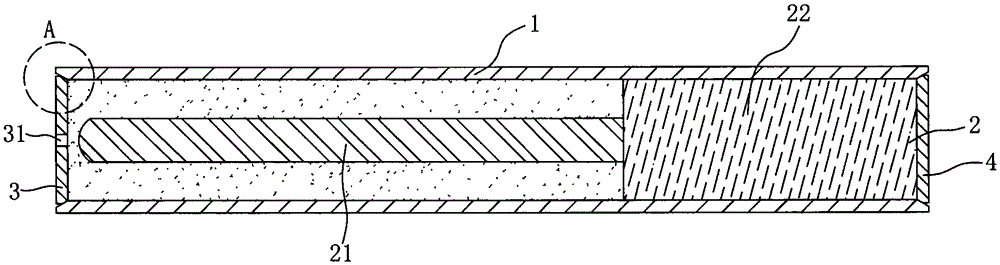

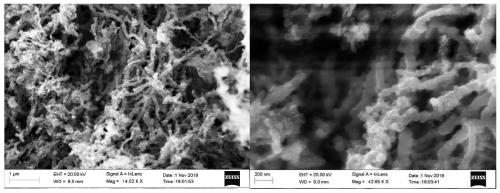

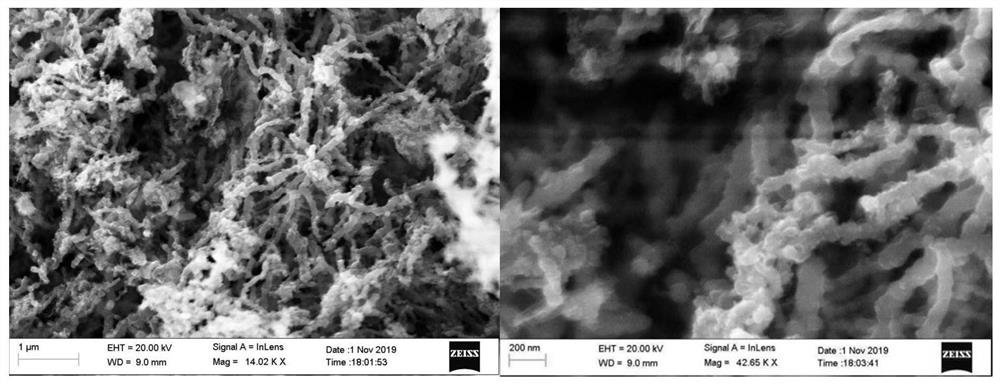

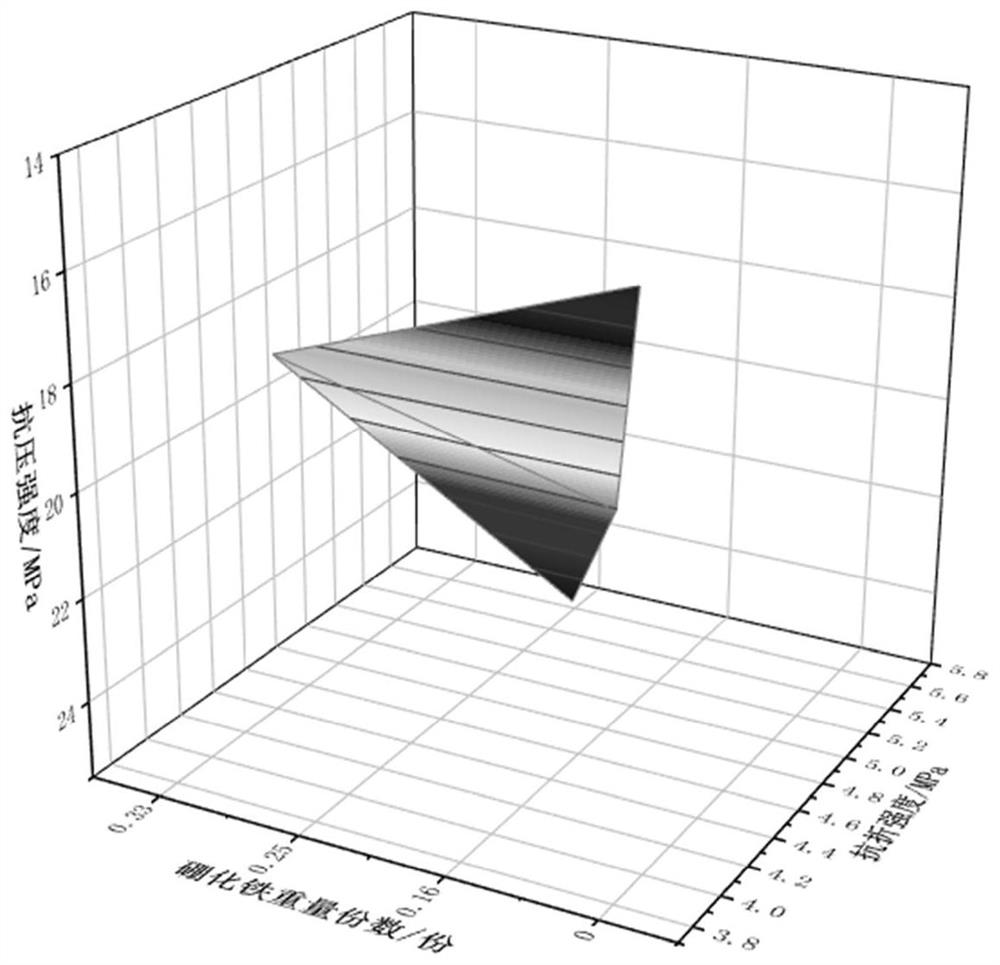

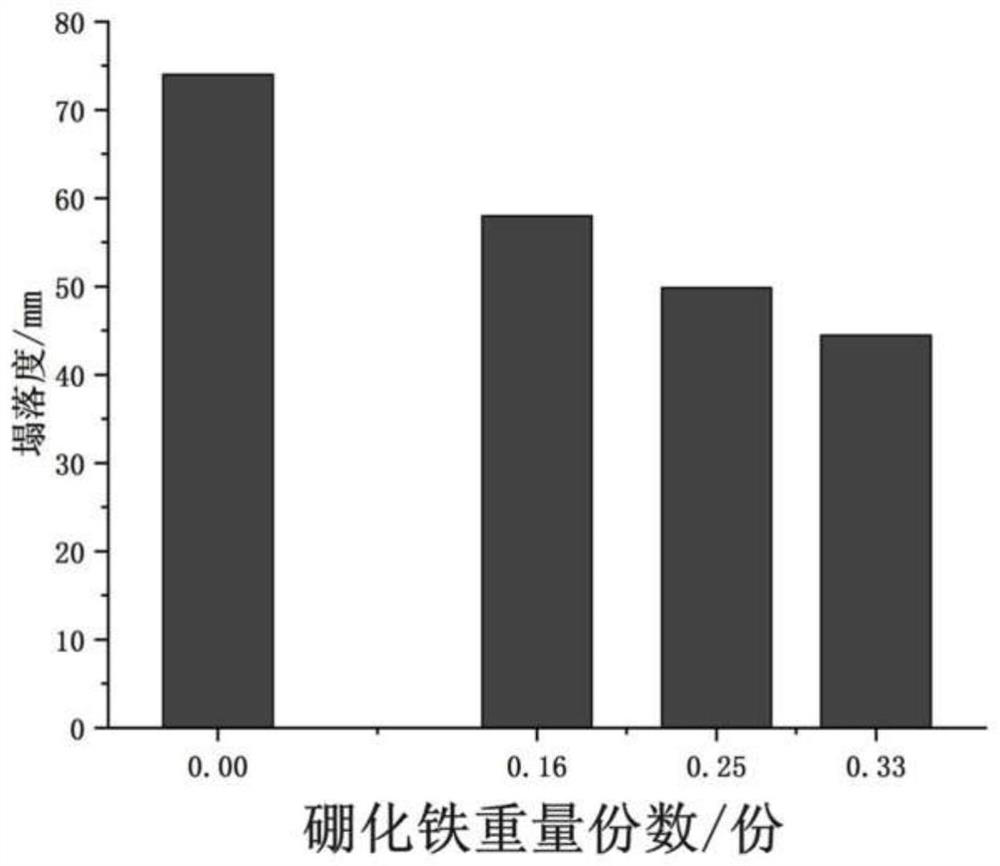

Iron boride modified cement mortar with high mechanical properties and preparation method thereof

ActiveCN111393106AEvenly dispersedPromotes hydrationNanotechnologyMetal boridesPortland cementIron boride

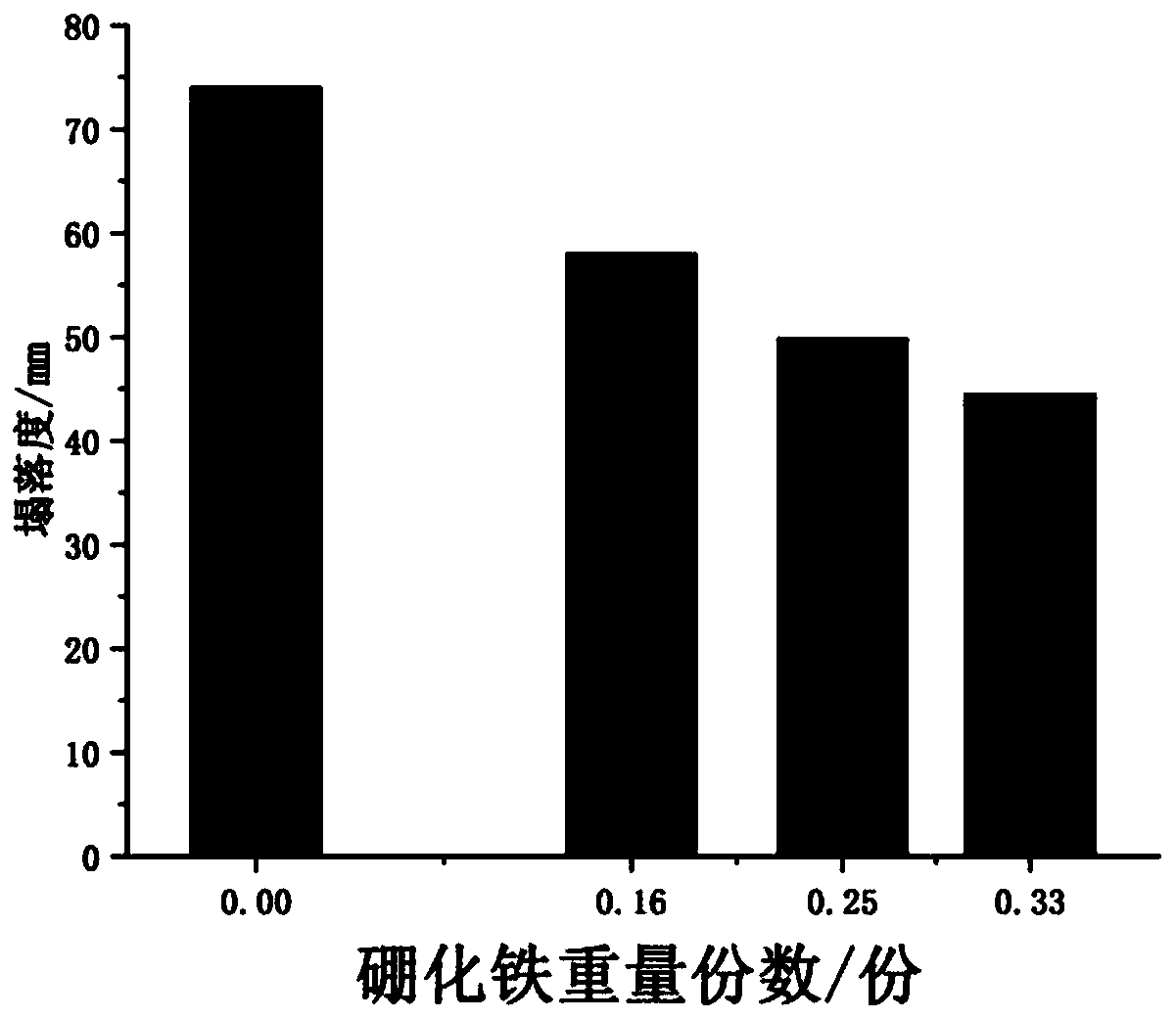

The invention discloses iron boride modified cement mortar with high mechanical properties and a preparation method of the iron boride modified cement mortar. The iron boride modified cement mortar isprepared from the following components in parts by weight: 310 to 350 parts of Portland cement, 1380 to 1420 parts of graded sand, 230 to 270 parts of water and 0.16 to 0.33 part of an iron boride raw material. The preparation method of the iron boride modified cement mortar comprises the following steps: firstly, preparing an iron boride aqueous solution, then taking the iron boride aqueous solution as a composite modifier, uniformly dispersing the iron boride aqueous solution into the cement mortar, and carrying out stirring, vibrating, molding and curing processes to prepare the iron boride modified cement mortar. According to the iron boride modified cement mortar prepared by the invention, the mechanical property is greatly improved, and the raw materials are extracted from construction wastes, so that the environment can be protected, and resources are saved.

Owner:湖北华茂新型建材有限公司

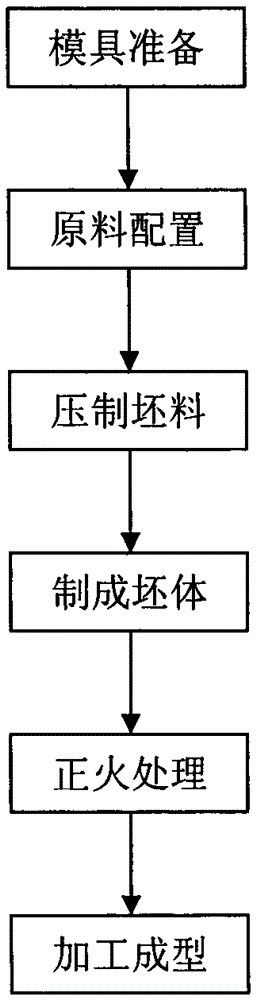

Screw rod assembly for injection molding machine and screw rod production process

The invention discloses a screw rod assembly for an injection molding machine and a screw rod production process. The screw rod production process comprises the following steps of S1, mixing of a material, wherein the material comprises, by weight, 15-30 parts of molybdenum carbide, 10-30 parts of tungsten carbide, 3-17 parts of chromium carbide, 5-20 parts of nickel, 2-10 parts of manganese, 40-60 parts of iron, 0.1-0.7 part of copper, 5-20 parts of iron boride, 0.2-0.4 part of silicon, 2-10 parts of modified phenolic resin adhesives and 5-20 parts of aluminum; and S2, mold manufacturing, specifically, selecting a pipe with the corresponding length according to the length of an alloy screw rod to be manufactured and manufacturing the pipe into a mold. The screw rod manufactured by addingthe molybdenum carbide and the like to the material is more resistant to wear and corrosion and longer in service life. Through two or three times of normalizing treatment, grains in the screw rod arerefined, carbides are distributed more uniformly, the hardness is improved, the machinability is improved, internal stress of the material is removed, deformation and cracking are prevented, and accordingly, the service life of the screw rod is prolonged.

Owner:东莞市华研新材料科技有限公司

Technology for producing spheroidal graphite cast iron for engineering machinery

The invention discloses a technology for producing spheroidal graphite cast iron for engineering machinery and belongs to the field of metallurgy. The technology comprises the following steps of feeding raw materials into a cupola furnace for smelting according to a proportion, adding 0.015 percent of boron alloy into a tapping ladle, flushing molten iron into a casting ladle from the cupola furnace to form iron boride, and forming a borided layer on the surface of the cast iron to improve the abrasion resistance of the cast iron; and then sequentially performing balling treatment and inoculation treatment on the molten iron casting ladle through a wire-feeding machine controlled by a PLC (programmable logic control) system, wherein components of a balling agent and an inoculation agent are uniform, so that the stability of the molten iron component is guaranteed; the PLC system can calculate the content of elements, such as P, S and Ti in the balling agent and the inoculation agent, which greatly affect the performance on the site at the same time to guarantee precision quantification of performance elements in the spheroidal graphite cast iron, so that the plasticity and the toughness of the cast iron are further improved; therefore, the usability of the produced spheroidal graphite cast iron for the engineering machinery is guaranteed.

Owner:XUZHOU NIUTOUSHAN CASTING IND

Manufacturing process of composite ultra-hard grinding wheel

The invention discloses a manufacturing process of a composite ultra-hard grinding wheel, and belongs to the technical field of grinding wheel manufacturing. The grinding wheel is prepared from the following raw materials in parts by weight of 15-30 parts of black silicon carbide, 30-60 parts of aluminum oxide, 1-5 parts of pyrite baking slag, 4-16 parts of zirconium nitride, 2-6 parts of limestone, 3-5 parts of iron boride, 1-3 parts of alumina hollow spheres, 30-50 parts of brown fused alumina, 1-3 parts of feldspar, 1-2 parts of coupling agents, 15-25 parts of phenolic resin and 7-14 partsof epoxy resin. According to the manufacturing process, the pyrite drying slag and the alumina hollow spheres are designed, a certain amount of pyrite drying slag and aluminum oxide hollow spheres areadded into a mixture, the main components of the pyrite drying slag are sulfuric acid slag and iron oxide baking slag, due to combined action of the mixed sulfuric acid slag and the aluminum oxide hollow spheres, when the grinding wheel is rubbed with a workpiece to be processed at a high speed, heat dissipation is fast, the durability of the grinding wheel is greatly improved, the service life of the grinding wheel is prolonged, and the mixed iron oxide baking slag can remarkably increase the strength of the grinding wheel.

Owner:郑州博尔德磨料磨具有限公司

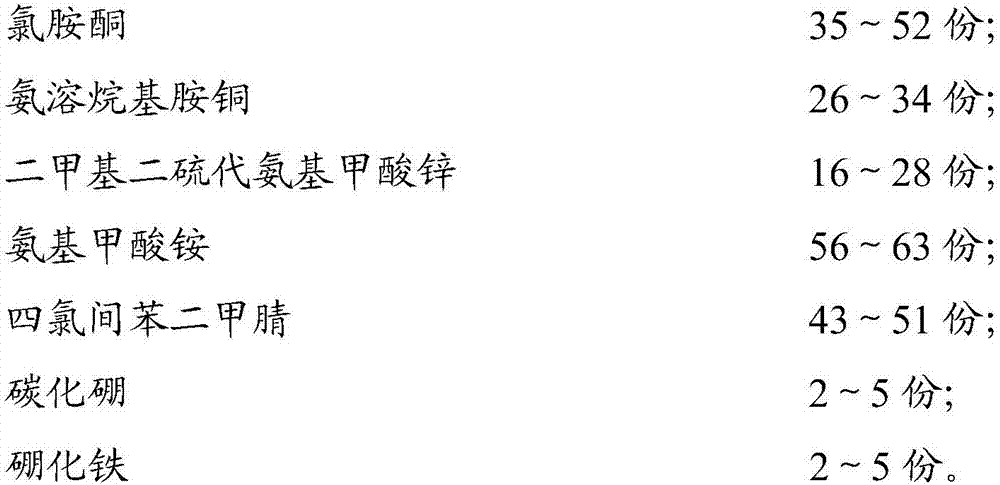

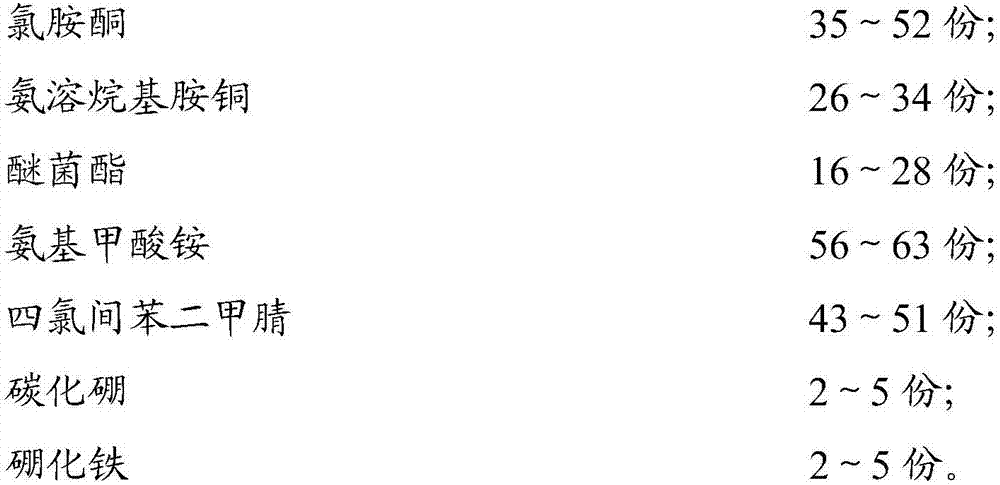

Preservative for wood transportation

InactiveCN106863516AImprove anti-corrosion performanceWith anti-corrosion abilityWood treatment detailsWood impregnation detailsPreservativeBoron carbide

The invention provides a preservative for wood transportation. The preservative for wood transportation comprises the following raw materials in parts by weight: 35 to 52 parts of ketamine, 26 to 34 parts of ammoniacal copper quats, 16-28 parts of zinc dimethyldithiocarbamate or kresoxim-methyl, 56-63 parts of ammonium carbamate, 43 to 51 parts of 2,4,5,6-tetrachloro-3-benzenedicarbonitrile, 2-5 parts of boron carbide and 2 to 5 parts of iron boride. The preservative activity of the preservative for wood transportation is ensured through the adoption of the ammoniacal copper quats; the capability of resisting damage by worms or vermin is ensured through the adoption of the ammonium carbamate; mildew resistance, and stability of the preservative under the condition of illumination and rainwater is ensured through the adoption of the 2,4,5,6-tetrachloro-3-benzenedicarbonitrile; the oxidation resistance and the stability of the preservative for wood transportation can be improved through the adoption of the boron carbide and the iron boride.

Owner:FUJIAN AGRI & FORESTRY UNIV

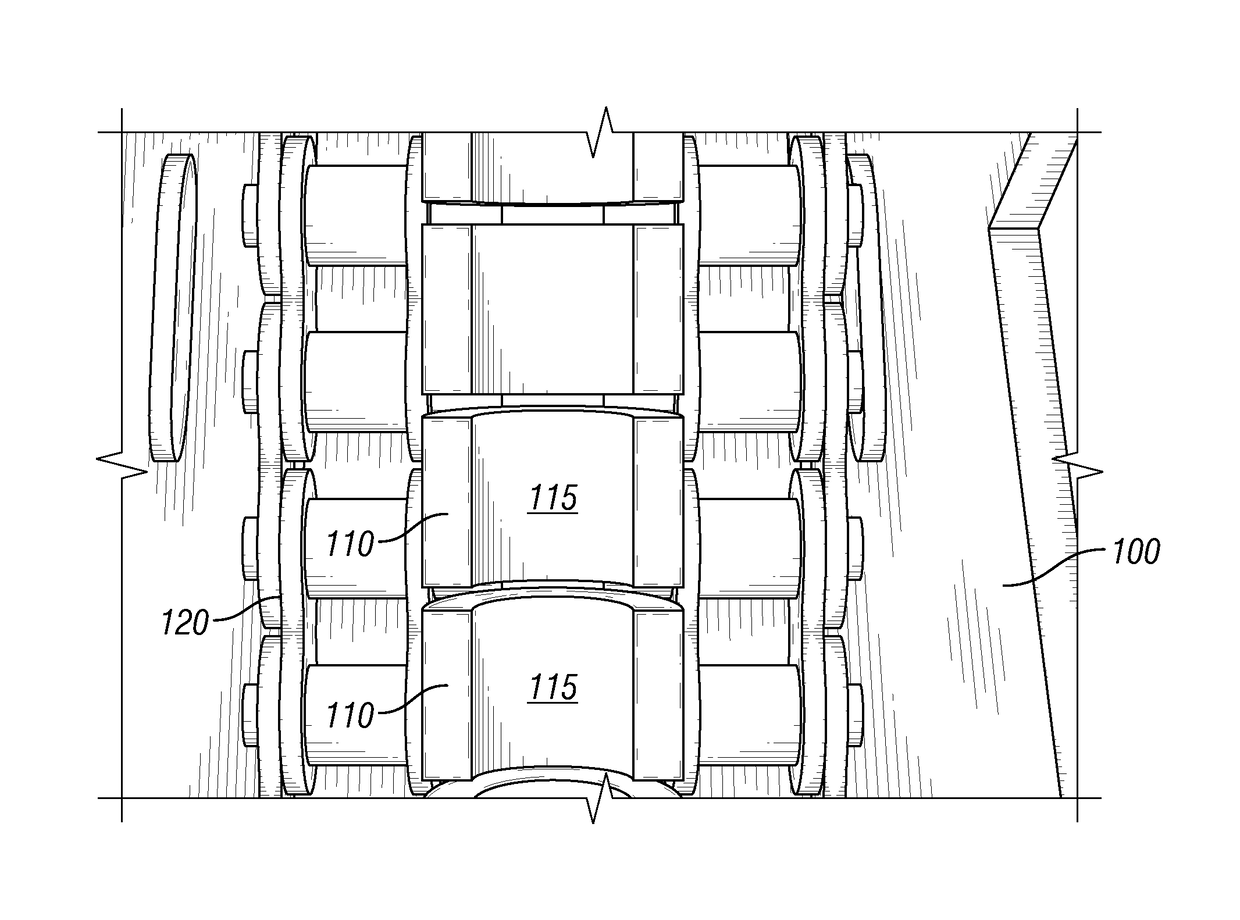

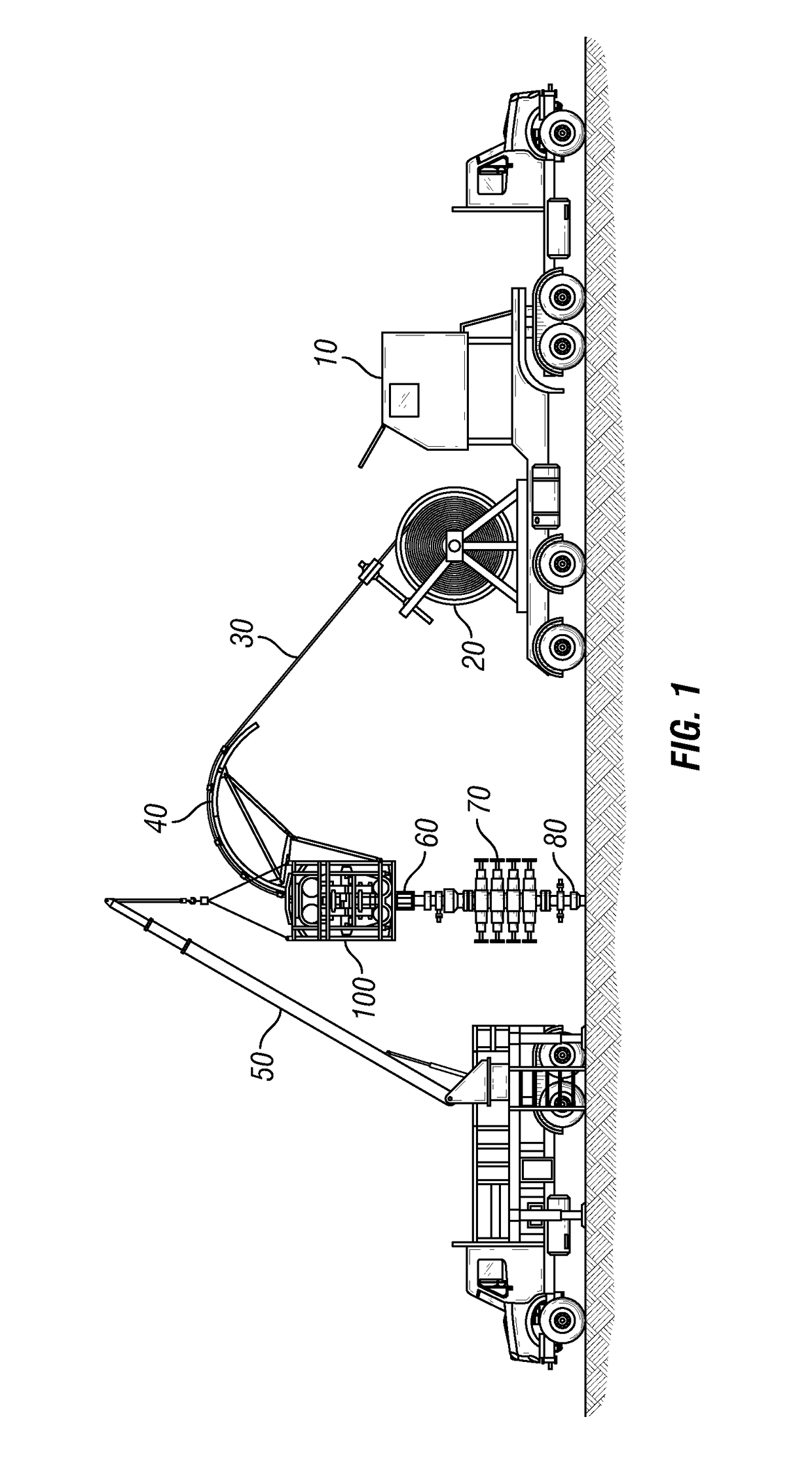

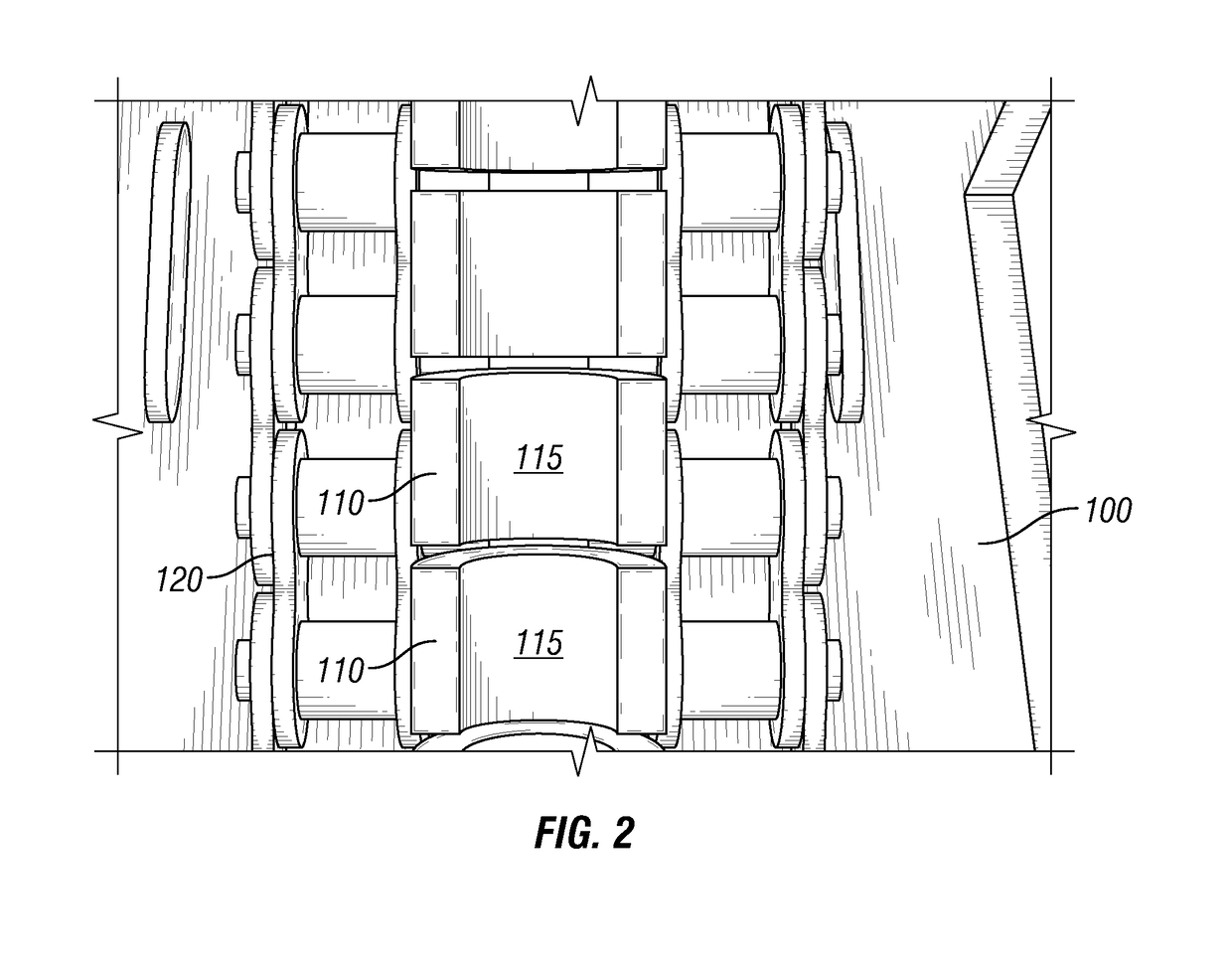

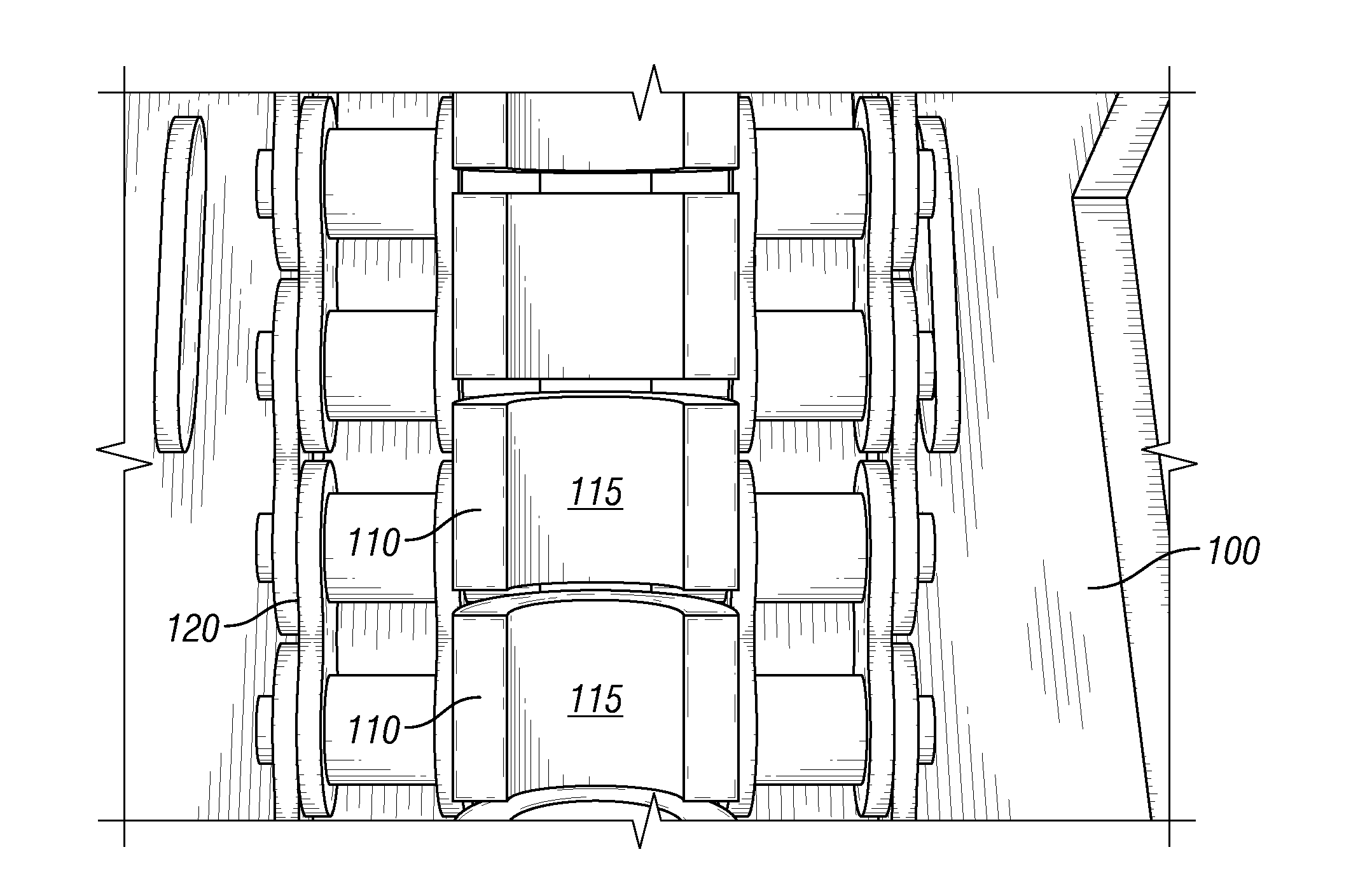

Method for increasing the roughness of injector gripper blocks for coiled tubing operations

ActiveUS9770805B2Increase roughnessReduce roughnessMolten spray coatingDrilling rodsChromium carbideCoiled tubing

Owner:BAKER HUGHES INC

Method for Increasing the Roughness of Injector Gripper Blocks for Coiled Tubing Operations

ActiveUS20160097244A1Increase roughnessReduce roughnessMolten spray coatingDrilling rodsChromium carbideCoiled tubing

A method of increasing a roughness of coiled tubing injector blocks that includes providing a pair of gripper blocks each having a gripper surface configured to grip coiled tubing within an injector head and increasing a first roughness on the gripping surfaces to a second roughness. A coating may be applied to the gripping surfaces to increase the roughness. The coating may be chromium carbide, molybdenum boride, iron boride, titanium boride, or a transitional metal boride. The gripping surfaces may be treated to increase the roughness to a second roughness. The gripping surfaces may be blasted by abrasives or shot peened to increase the roughness. The second roughness may be greater than 20 μm. A system to inject coiled tubing into a wellbore may include an injector head, coiled tubing, and at least two gripper blocks having a gripping surface with a roughness of at least 20 μm.

Owner:BAKER HUGHES INC

Laser-cladding high temperature resistance abrasionproof structure for special-shaped water cooling wall tube bundle

The invention discloses a laser-cladding high temperature resistance abrasionproof structure for a special-shaped water cooling wall tube bundle. The laser-cladding high temperature resistance abrasionproof structure comprises water cooling wall tubes, fins and a guide plate. An abrasionproof layer formed by laser cladding of a ceramic-metal composite material TiB2-Ni-Cr-Mo-Fe-Nb-B-Si-C is arranged on the firing surface of each water cooling wall tube. The ceramic-metal composite material comprises, by weight, 10%-20% of titanium-nickel alloy powder, 1.5%-3.5% of graphite carbon powder, 0.5%-1% of silica powder, 8%-25% of nickel-chromium alloy powder, 5%-10% of iron boride powder and the balance Cr3C2 powder. The two ends of each fin are welded between the surfaces, where no abrasionprooflayer is arranged, of every two adjacent water cooling wall tubes separately so that the multiple water cooling wall tubes can form the water cooling wall tube bundle. The guide plate is arranged at abent area of the water cooling wall tube bundle in the mode of being perpendicular to the corresponding fins. By means of the laser-cladding high temperature resistance abrasionproof structure for the special-shaped water cooling wall tube bundle, the high temperature and abrasion resistance of the surfaces of the water cooling wall tubes is improved remarkably, the problem that side abrasion ofthe bent position of the special-shaped water cooling wall tube bundle with the bent area is serious is solved thoroughly, and the overall service life of the water cooling wall tube bundle is prolonged.

Owner:北京华电德高科技有限责任公司

Timber preservative

The invention relates to the technical field of preservatives and particularly relates to a timber preservative. The timber preservative contains the following components in parts by mass: 30-50 partsof ketamine, 20-30 parts of ammonia-soluble alkylamine copper, 15-28 parts of zinc dimethyl dithiocarbamate, 50-63 parts of ammonium carbamate, 40-55 parts of tetrachloroisophthalonitrile, 1-5 partsof boron carbide and 2-6 parts of iron boride. The prepared preservative has the properties of high efficiency, durability, safety and the like in the field of timber.

Owner:庄法英

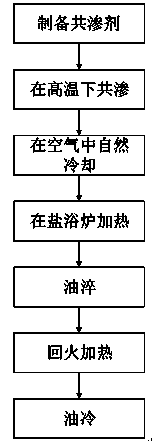

Rare earth boronizing process for roller

InactiveCN103436893AHigh surface hardnessImprove toughnessSolid state diffusion coatingHeating oilTempering

The invention relates to a rare earth boronizing process for a roller. The process comprises the following steps: a co-cementation agent is prepared; the steel roller is co-cemented with the co-cementation agent at high temperature; natural cooling is performed in air; heating, oil-quenching, tempering heating and oil cooling are performed on the steel roller in a salt-bath furnace. By adopting the rare earth boronizing process, the surface hardness of the steel roller can be effectively improved, a co-cementation layer containing two iron boride and iron boride can be formed, the two iron boride and iron boride are wedged into a matrix in a needle-shaped manner, the co-cementation layer and the central part are combined tightly, so that the toughness and crack resistance are enhanced, a small amount of rare earth compound appears in the tissue, the heat resistance property and fatigue resistance fatigue property of the roller are enchanted, and the service life the roller is prolonged obviously.

Owner:XUZHOU UNIV OF TECH +1

Titanium alloy gear with ferroboron diffusion layer on surface and co-diffusion method thereof

InactiveCN103147037BImprove surface propertiesHigh surface hardnessPortable liftingSolid state diffusion coatingRoom temperatureIron boride

The invention relates to a titanium alloy gear with a ferroboron diffusion layer on the surface and a co-diffusion method thereof. The method comprises the step of: by taking a titanium alloy gear as a workpiece and taking iron boride as a source, placing the titanium alloy gear and the iron boride on a negative disk to form a workpiece-source integral structure, wherein the negative electrode of a direct current power supply is connected to the negative disk, and the positive electrode of the direct current power supply is connected to a vacuum container; vacuumizing and introducing argon, applying a direct-current voltage to generate hollow negative glow discharge, migrating, adsorbing and spreading the sputtered boron, iron ion, atoms and particles into the gear to form an alloy layer, preserving the heat, slowly cooling to room temperature, thereby obtaining the titanium alloy gear with the ferroboron diffusion layer. The method disclosed by the invention is advanced in process and low in cost; and the prepared gear is strong in seizure resistance, good in wear resistance and long in service life.

Owner:TAIYUAN UNIV OF TECH

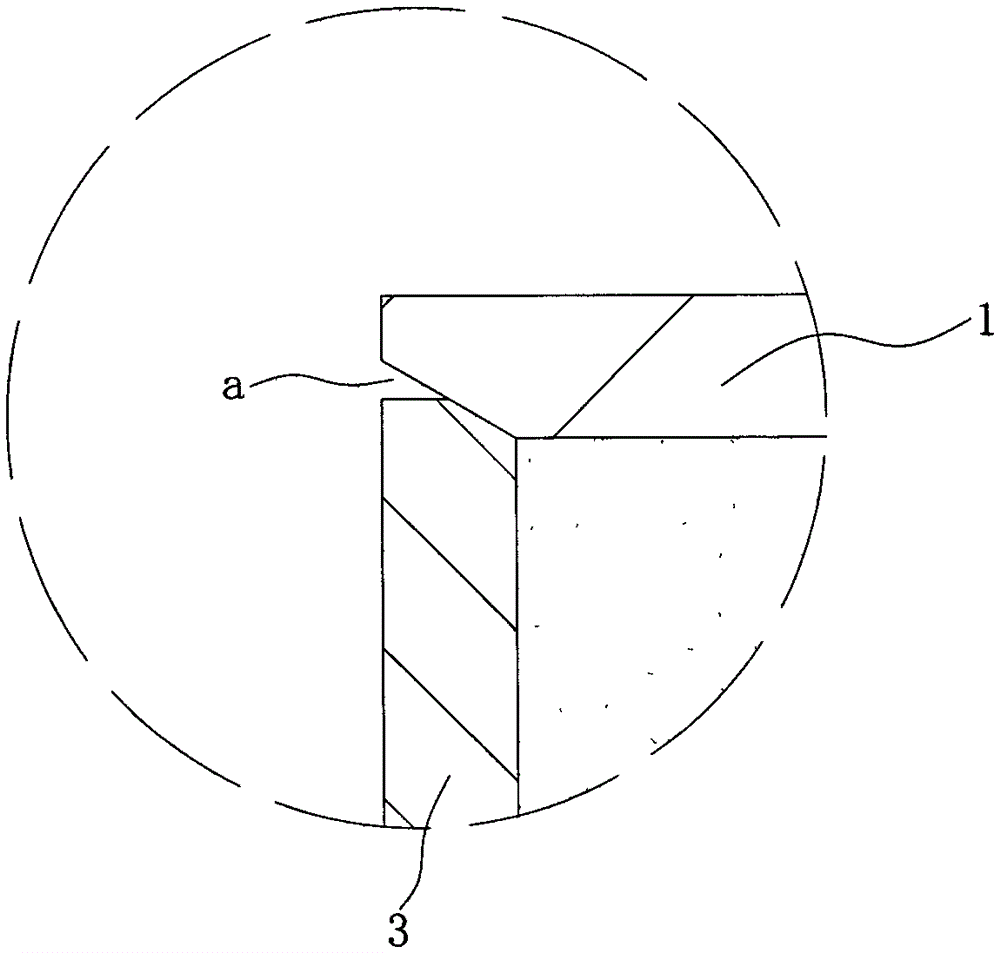

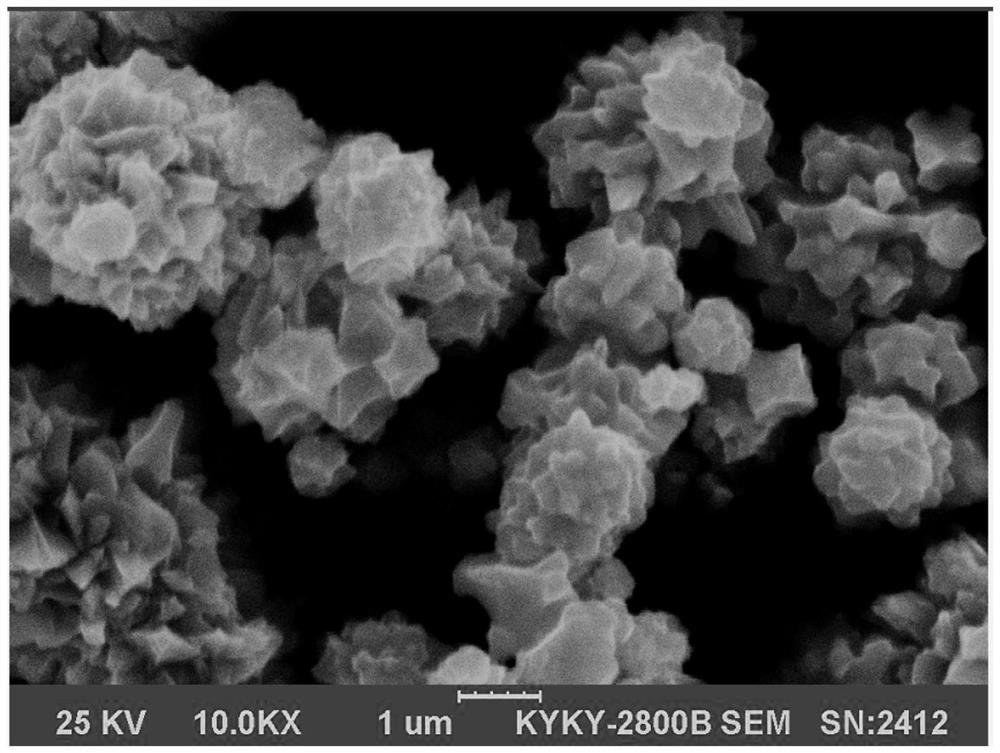

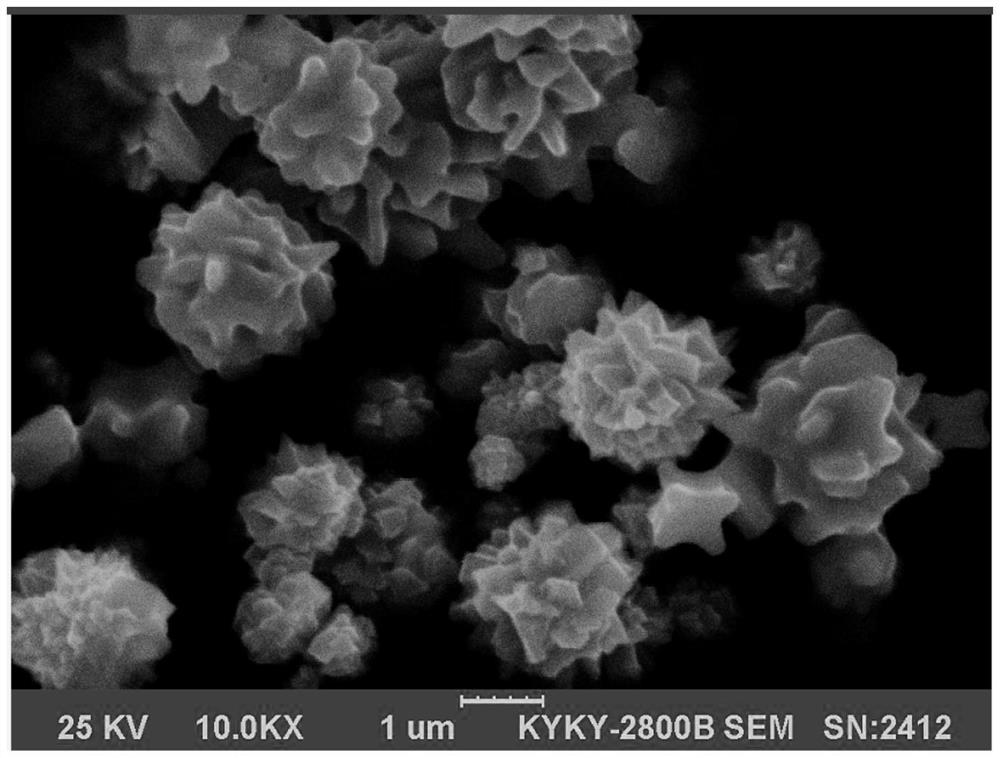

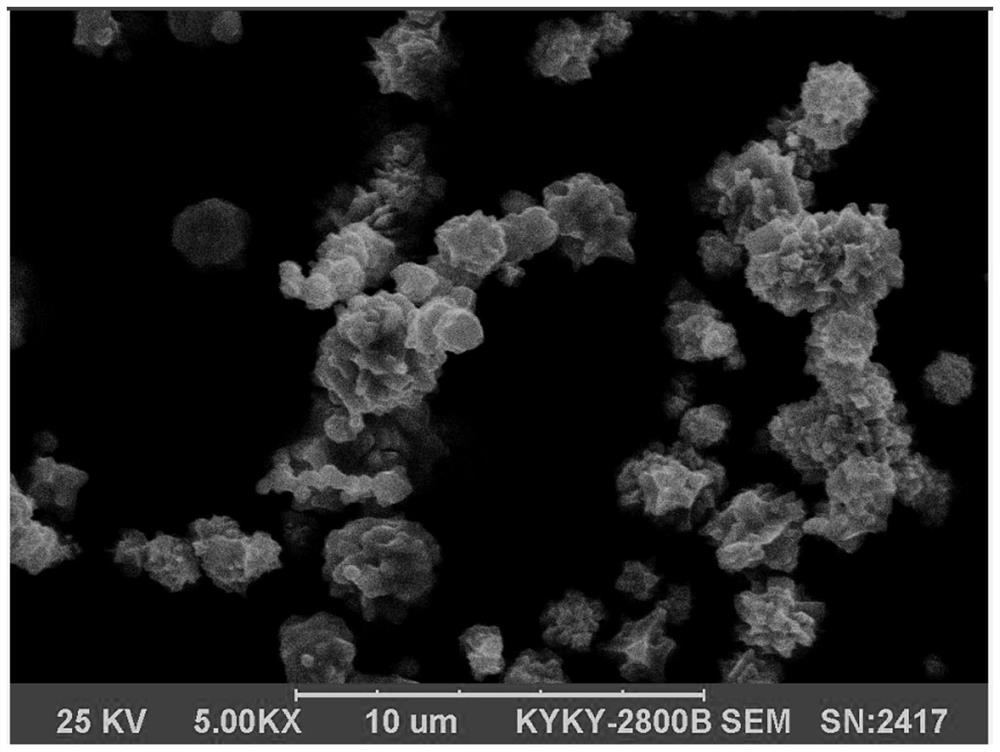

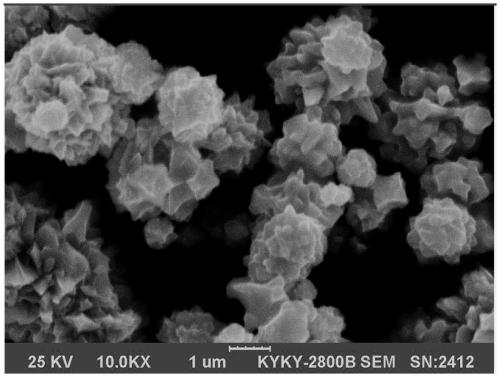

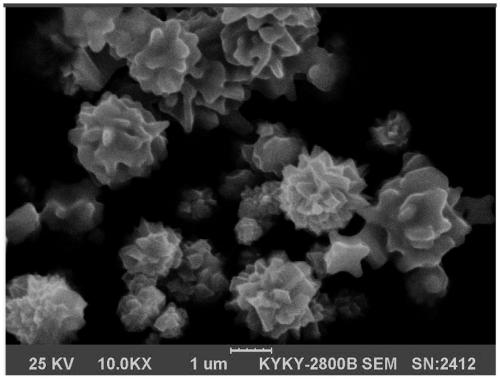

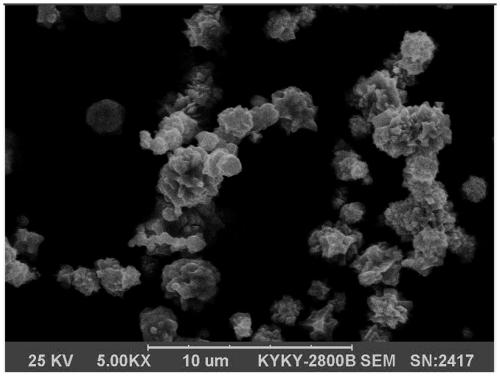

A kind of preparation method of superfine ferric boride

The invention discloses a preparation method of ultrafine iron boride. After ferrous gluconate solution and boric acid solution are mixed, spray drying, obtain spray-dried material, the mol ratio of ferrous gluconate solution and boric acid is 1:1.01-1.02; The spray-dried material is sintered in methane atmosphere, and the sintering time is 5‑10h, the sintering temperature is 800‑1200°C to react to obtain the reduced material; continue to pass the reduced material into carbon dioxide, and react at a temperature of 700‑850°C for 2‑4h to obtain the sintered material; the sintered material is crushed and sieved by airflow and vacuum packaging to obtain ultrafine ferric boride. The invention can prepare superfine iron boride with small particle size, large BET and high purity.

Owner:蒋央芳

Preparation method of ultrafine iron boride

The invention discloses a preparation method of ultrafine iron boride. A ferrous gluconate solution is mixed with a boric acid solution, and spray drying is carried out to obtain a spray-dried material, and the molar ratio of the ferrous gluconate solution to boric acid is 1: 1.01-1.02; the spray-dried material is sintered in a methane atmosphere for 5-10 hours at the sintering temperature of 800-1200 DEG C for reaction to obtain a reduced material; carbon dioxide is continuously introduced into the reducedmaterial, and reacting for 2-4 hours at the temperature of 700-850 DEG C is carried outto obtain a sintered material; and jet milling, screening and vacuum packaging are carried out on the sintered material to obtain the ultrafine iron boride. The ultrafine iron boride can be prepared,the particle size is small, BET is large, and the purity is high.

Owner:蒋央芳

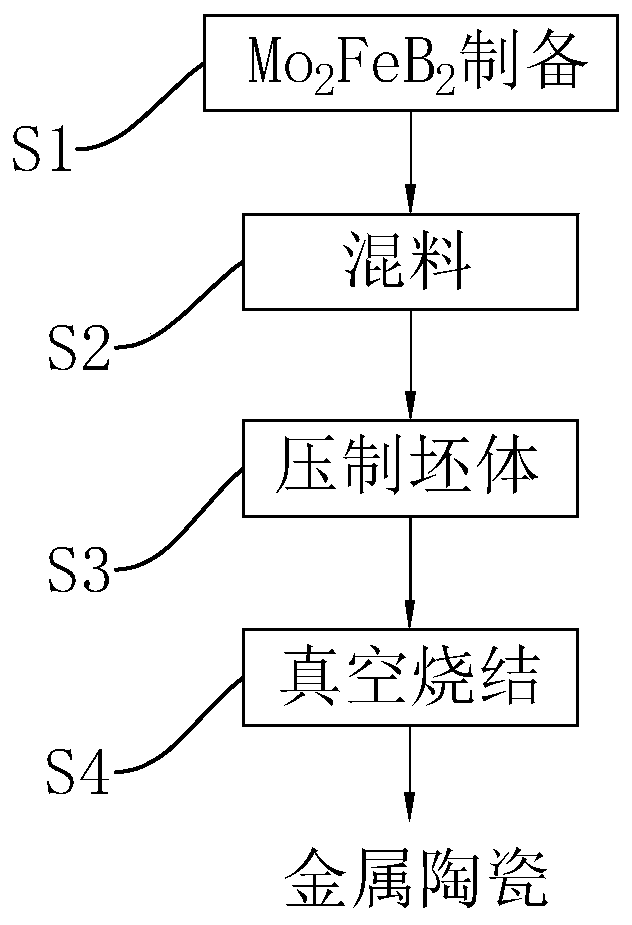

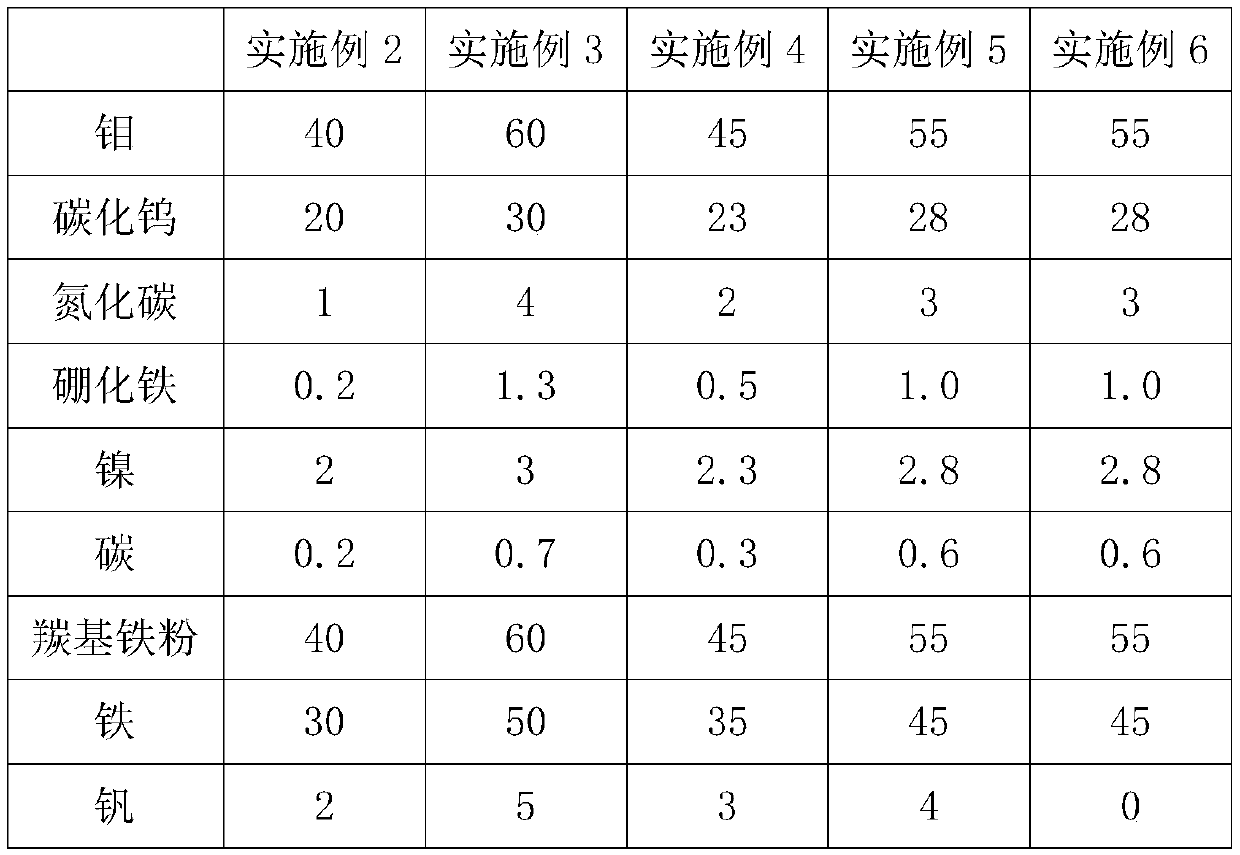

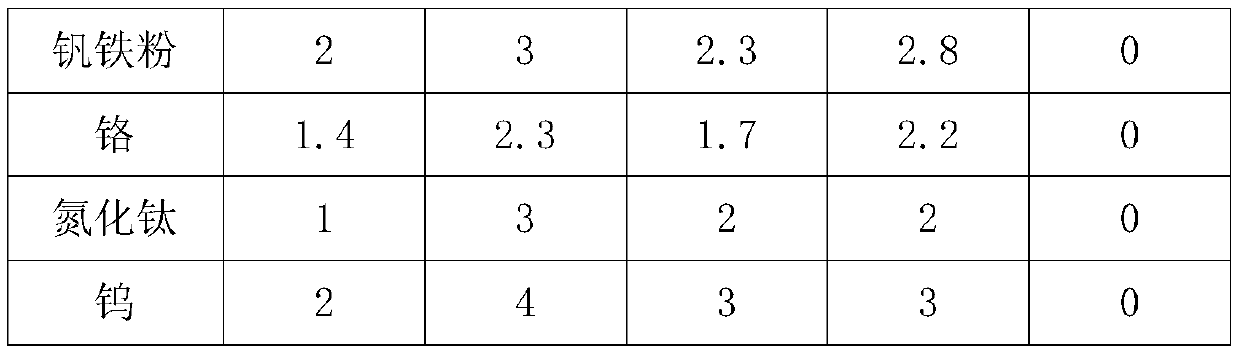

Metal ceramic for machine tool guide rail and preparation technology

InactiveCN111041321AImprove flexural strengthImprove deformation resistanceTurbinesOther manufacturing equipments/toolsTitanium nitrideIron boride

The invention relates to the technical field of metal ceramic, and discloses metal ceramic for a machine tool guide rail. A raw material of the metal ceramic comprises, by weight, 40-60 parts of molybdenum, 20-30 parts of tungsten carbide, 1-4 parts of carbon nitride, 0.2-1.3 parts of iron boride, 2-3 parts of nickel, 0.2-0.7 part of carbon, 40-60 parts of carbonyl iron powder and 30-50 parts of iron. A preparation technology of the metal ceramic comprises the following steps that S1, Mo2FeB2 preparation is conducted; S2, material mixing is conducted, specifically, the obtained Mo2FeB2 powderin the step S1 is smashed with the particle size being 30-40 micrometers, then, the smashed Mo2FeB2 powder is mixed with tungsten carbide powder, carbon nitride powder, nickel powder, carbon powder, iron powder, vanadium powder, ferrovanadium powder, chromium powder, titanium nitride powder and tungsten powder through common ball milling, absolute ethyl alcohol serves as a medium, ball milling lasts for 20-30 h, and after ball milling is completed, drying is conducted; S3, blank body pressing is conducted; and S4, vacuum sintering is conducted, and the metal ceramic for the machine tool guiderail is obtained. The metal ceramic high in bending strength and good in abrasion resistance can be obtained.

Owner:浙江恒大数控装备有限公司

Method for preparing zirconium boride-tungsten titanium carbide self-lubricating composite ceramic material

The invention relates to a method for preparing a zirconium boride-tungsten titanium carbide self-lubricating composite ceramic material. The material is prepared by adding (W, Ti) C solid solution and ZrO2 powder into a ZrB2 matrix, taking MgO as a sintering aid and performing hot pressing sintering on the materials under the vacuum environment. Matrix phase ZrB2 and enhanced phase (W, Ti) C form a good framework structure by introducing (W, Ti) C solid solution; and the ZrO2 is added so as to improve the toughness of the composite ceramic material by means of the phase change characteristic. The sintering temperature of the ZrB2 is reduced by adding the MgO sintering aid, so that a material with higher compactness is obtained. Self-lubricating function of the zirconium boride-tungsten titanium carbide self-lubricating composite ceramic material can be realized by using the chemical reaction of the composite material under the action of high temperature friction. The method has the characteristics of high hardness, high bending strength, high fracture toughness and the like and is suitable for preparing metal cutting tools, modules, nozzles and the like.

Owner:SHANDONG UNIV

A kind of ferric boride modified cement mortar with high mechanical properties and preparation method thereof

ActiveCN111393106BEvenly dispersedPromotes hydrationNanotechnologyMetal boridesPortland cementIron boride

The invention discloses a ferric boride modified cement mortar with high mechanical properties and a preparation method thereof. The ferric boride modified cement mortar is composed of the following components and parts by weight: Portland cement 310-350 parts, graded sand 1380-1420 parts, 230-270 parts of water, 0.16-0.33 parts of ferric boride raw material; the preparation method of ferric boride modified cement mortar is as follows: firstly prepare ferric boride aqueous solution, and then use ferric boride aqueous solution as composite modification The agent is evenly dispersed in the cement mortar, and the iron boride modified cement mortar is obtained through the process of stirring, vibrating, forming and curing. The ferric boride modified cement mortar prepared by the invention not only greatly improves the mechanical properties, but also extracts raw materials from construction waste, which can protect the environment and save resources.

Owner:湖北华茂新型建材有限公司

Micro-smoke environment-friendly carbon steel flux-cored wire

PendingCN114101966AReduce burning lossImprove deposition performanceWelding/cutting media/materialsSoldering mediaIron borideMaterials science

The invention belongs to the technical field of carbon steel flux-cored wires, and relates to a micro-smoke environment-friendly carbon steel flux-cored wire. The welding wire powder is prepared from, by weight, 30%-35% of rutile, 11%-13% of wollastonite, 11%-13% of low-carbon ferromanganese, 1%-5% of silicate, 0.3%-1.2% of iron boride powder, 3%-8% of zirconite, 3%-6% of nickel, 0.5%-2% of ferrotitanium and the balance iron powder. According to the method, part of raw materials are melted and atomized to form a composite material, then the composite material is mixed with other materials to prepare welding wire powder, and more than 80% of low-melting-point harmful impurities (such as S, P and compounds thereof) are removed in the powder preparation process. And the burning loss of alloy elements is reduced, and the deposition performance of weld metal is facilitated. According to the welding wire prepared through the method, the droplet transition period of the welding wire can be prolonged, the metallurgical reaction behavior is intensified, combustion of powder is more sufficient, the smoke dust generation amount is reduced, and environmental pollution and harm to the body of a welder are reduced.

Owner:FARINA JINAN WELDTEC & MACHINERY

A screw production process for screw components for injection molding machines

The invention discloses a screw production process for a screw assembly of an injection molding machine, comprising the following steps: S1, ingredients: molybdenum carbide: 15-30 parts, tungsten carbide: 10-30 parts, chromium carbide Cr: 3 ~17 parts, nickel Ni: 5~20 parts, manganese Mn: 2~10 parts, iron Fe: 40~60 parts, copper Cu: 0.1~0.7 parts, iron boride FeB: 5~20 parts, silicon Si: 0.2 ~0.4 parts, modified phenolic resin adhesive 2~10 parts, aluminum: 5~20 parts; S2, mold making: according to the length of the alloy screw to be produced, it is necessary to select a pipe with a corresponding length to make a mold. In the present invention, the screw made of molybdenum carbide in the ingredients is more wear-resistant and corrosion-resistant, and has a longer service life. During the normalizing treatment, the normalizing treatment is adopted 2 to 3 times, so that the grains in the screw are refined and Uniform carbide distribution and increase hardness, improve processing performance, remove internal stress of materials, prevent deformation and cracking, thereby increasing the service life of the screw.

Owner:东莞市华研新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com