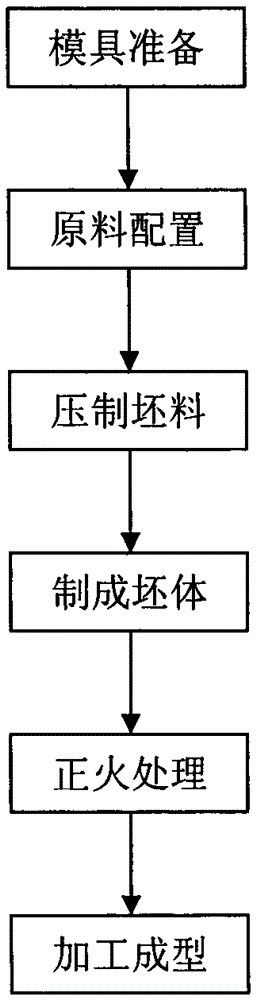

A kind of alloy screw rod material and the production technology of screw rod thereof

A production process and screw technology, which is applied in the field of alloy screw materials and the production process of the screw, can solve problems such as cracks not being well resolved, short service life, alloy layer falling off, etc., and achieve high fracture toughness and wear resistance Excellent performance and good bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

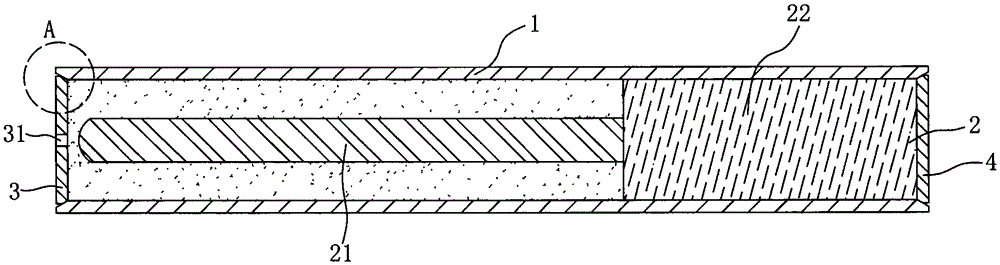

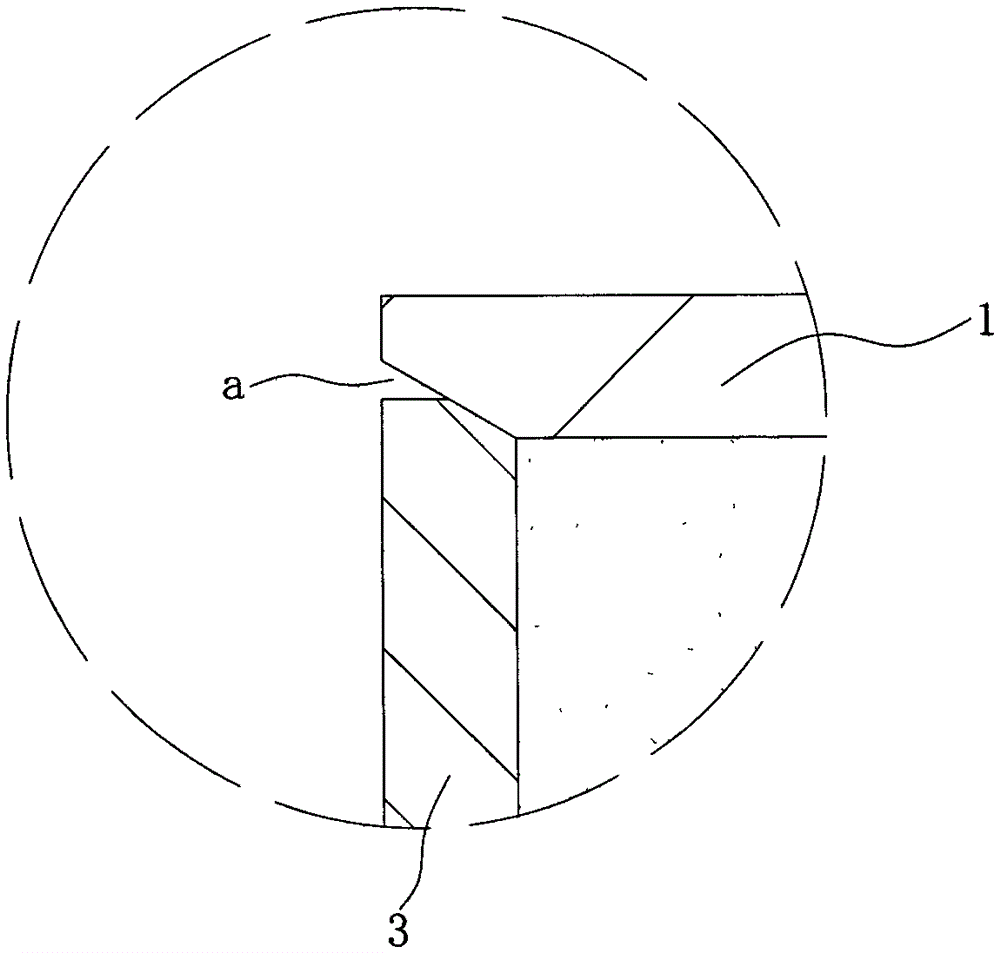

[0034] First, according to the length of the alloy screw to be produced, a pipe with a carbon content of less than 0.25% and a wall thickness of 5 mm in diameter is selected as the pipe sleeve 1 of the mold, preferably low-carbon steel, and the inner hole of the pipe is processed, and the inner surface of the pipe sleeve 1 Form 60 ° chamfering at two ports, then, process a non-porous plug 4 and a holed plug 3 with a diameter of 1.5mm through hole 31 in the center, both of which are 3mm in height, and are formed at one end with 60 ° chamfering and chamfering, the other end of the plug with holes 3 and the plug without holes 4 also forms a vertical surface, the height of the vertical surface is 1mm, the next step is to make a core rod 21 and a core handle 22 The mandrel 2, the front end of the mandrel 21 is arc-shaped, to avoid the radial contraction of the mandrel 21 when pressing the pre-sintered blank, to ensure the yield rate of the alloy screw, the lengths of the mandrel 21 an...

specific Embodiment 2

[0040] First of all, according to the length of the alloy screw to be produced, a pipe with a carbon content of less than 0.25% and a wall thickness of 6.5mm in diameter is selected as the pipe sleeve 1 of the mold, preferably low carbon steel, and the inner hole of the pipe is processed, and placed in the pipe sleeve 1 Form 60 ° of chamfers at the two ports of the side, and then, process a non-porous plug 4 and a plug 3 with holes provided with a through hole 31 with a diameter of 2 mm in the center. 60 ° chamfering and chamfering, the other end of the plug with holes 3 and the plug without holes 4 also forms a vertical surface, the height of the vertical surface is 1mm, the next step is to make a core rod 21 and a core handle 22 The mandrel 2, the front end of the mandrel 21 is arc-shaped, to avoid the radial contraction of the mandrel 21 when pressing the pre-sintered blank, to ensure the yield rate of the alloy screw, the lengths of the mandrel 21 and the mandrel 22 are res...

specific Embodiment 3

[0046] First of all, according to the length of the alloy screw to be produced, a pipe with a carbon content of less than 0.25% and a wall thickness of 5.4 mm in diameter is selected as the pipe sleeve 1 of the mold, preferably low carbon steel, and the inner hole of the pipe is processed, and placed in the pipe sleeve 1 A 60° chamfer is formed at the two ports on the side, and then, a non-porous plug 4 and a holed plug 3 with a through hole 31 of diameter 3.5 mm in the center are processed. Form the chamfer matched with the 60° chamfering inclined surface, the other end of the plug with hole 3 and the plug without hole 4 is also formed with a vertical surface, the height of the vertical surface is 1mm, the next step is to make a core rod 21 and a core The mandrel 2 of the handle 22, the front end of the mandrel 21 is arc-shaped, to avoid the radial contraction of the mandrel 21 when pressing the pre-sintered billet, to ensure the yield rate of the alloy screw, the length of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com