An ultra-thin stone facing heat preservation system and its manufacturing method

A thermal insulation system and stone technology, applied in covering/lining, building, building structure, etc., can solve the problems of no fire prevention function, easy aging, increase the difficulty of construction, etc., and achieve the effect of protecting cutting rigidity and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

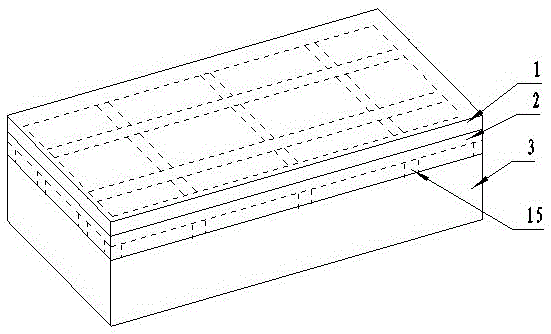

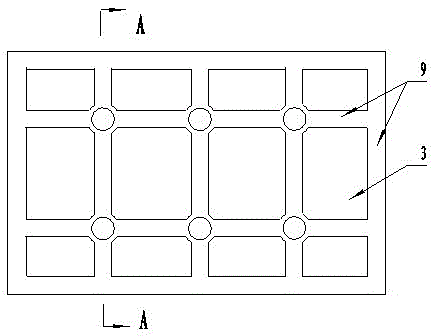

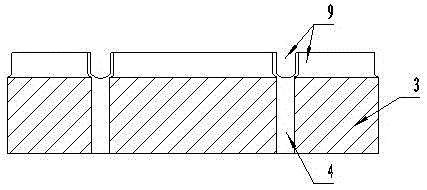

[0025] Such as figure 1 , 2 , 3, the present invention consists of a plurality of ultra-thin stone facing insulation boards, wherein the ultra-thin stone facing insulation boards include a stone facing layer 1, a special-shaped insulation board 3 and are arranged on the stone facing layer 1 and the special-shaped insulation board 3 between the backplane adhesive layer 2. The stone facing layer 1 is facing materials such as stone and ceramic tiles, and the special-shaped insulation board 3 is an organic heat-insulating material such as polystyrene board. The bonding layer 2, the stone veneer layer 1 and the special-shaped insulation board 3 are bonded and pressed together through the backboard adhesive layer 2. The bonding material used for the backboard bonding layer 2 is polymer cement mortar or fine stone concrete. The thickness of the stone veneer laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com