Powder material for boiler tube high temperature resistance and wear resistance protecting and preparation method thereof

A powder material, high temperature wear resistance technology, applied in the field of surface engineering, can solve the problems of high powder splash loss rate, high microcrack density, low cladding efficiency, etc., to achieve low preparation cost, low dilution rate, prolonged high temperature wear resistance, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

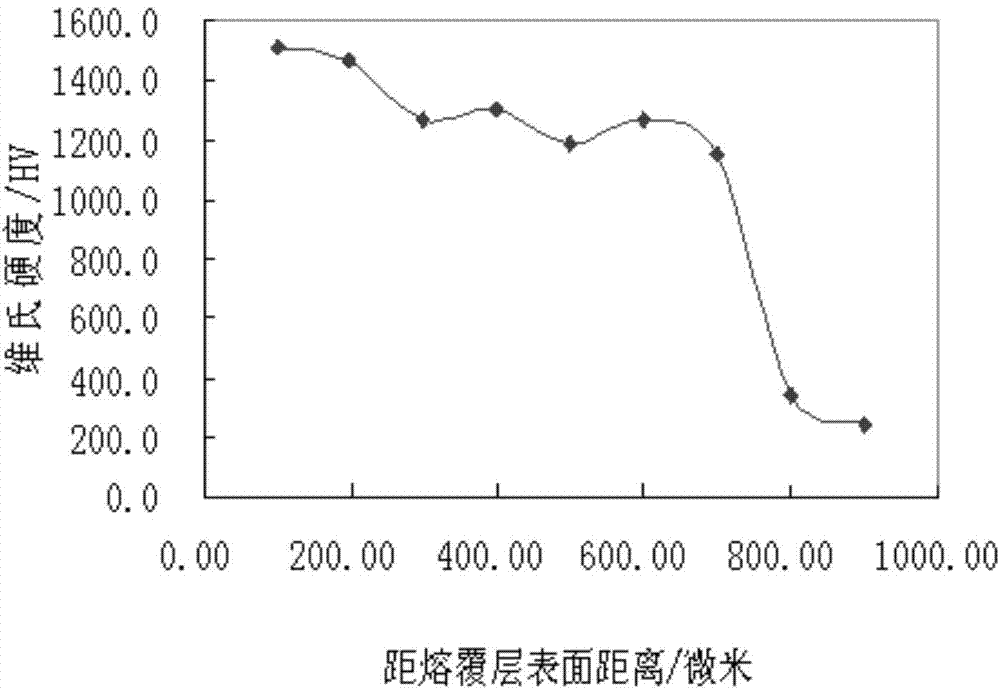

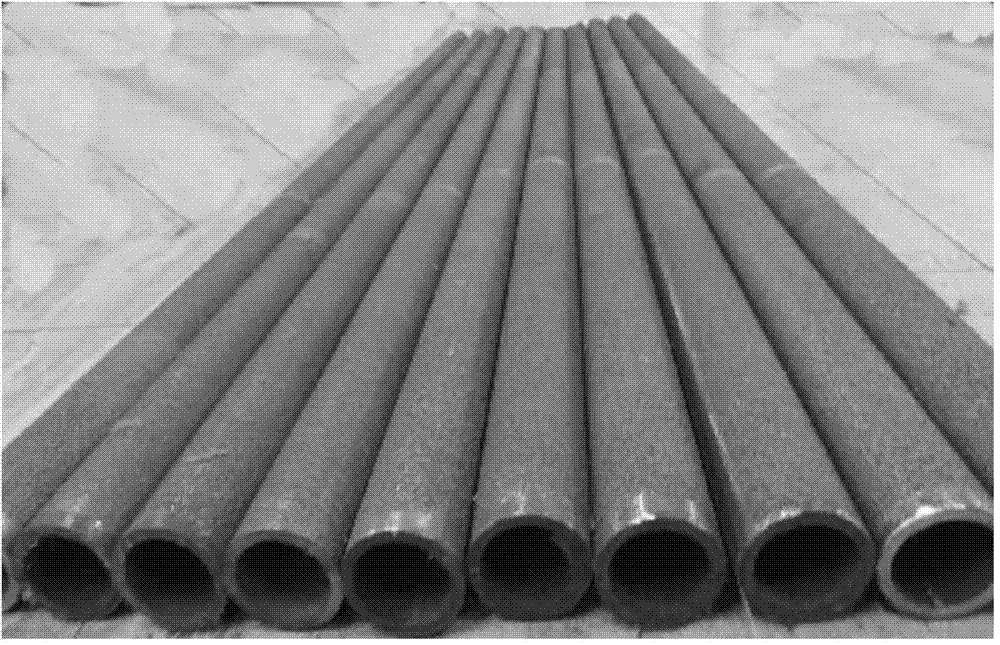

[0035] Example: Preparation of wear-resistant cladding layer on the outer surface of the suspension pipe of the economizer

[0036] 1. Preparation of finished powder

[0037] 1. Preparation of powder raw materials

[0038] The content (weight percent) scope of described powder raw material is as follows:

[0039] The components of the mixed powder material and the content of each component (percentage by weight) are: titanium-nickel alloy powder (particle size -200+400 mesh, purity ≥99.5%): 15%; graphite carbon powder: (particle size -300+600 mesh, Purity ≥ 99.5%): 2.625%; silicon powder: (particle size -200+350 mesh, purity ≥ 99.5%): 1%; nickel-chromium alloy powder (Ni80Cr20): (particle size -200+400 mesh, purity ≥ 99.5%) : 12%; iron boride powder: (particle size -200+400 mesh, purity ≥ 99.5%): 8%; trichromium carbide powder (Cr 3 C 2 , particle size -200+400 mesh, purity ≥ 99.5%): balance.

[0040] Among them, the content of each component in titanium-nickel alloy powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com