A kind of preparation method of superfine ferric boride

A technology of iron boride and boric acid solution, applied in the direction of boron/boride, metal boride, etc., can solve the problems of large particle size, low activity and small BET of iron boride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

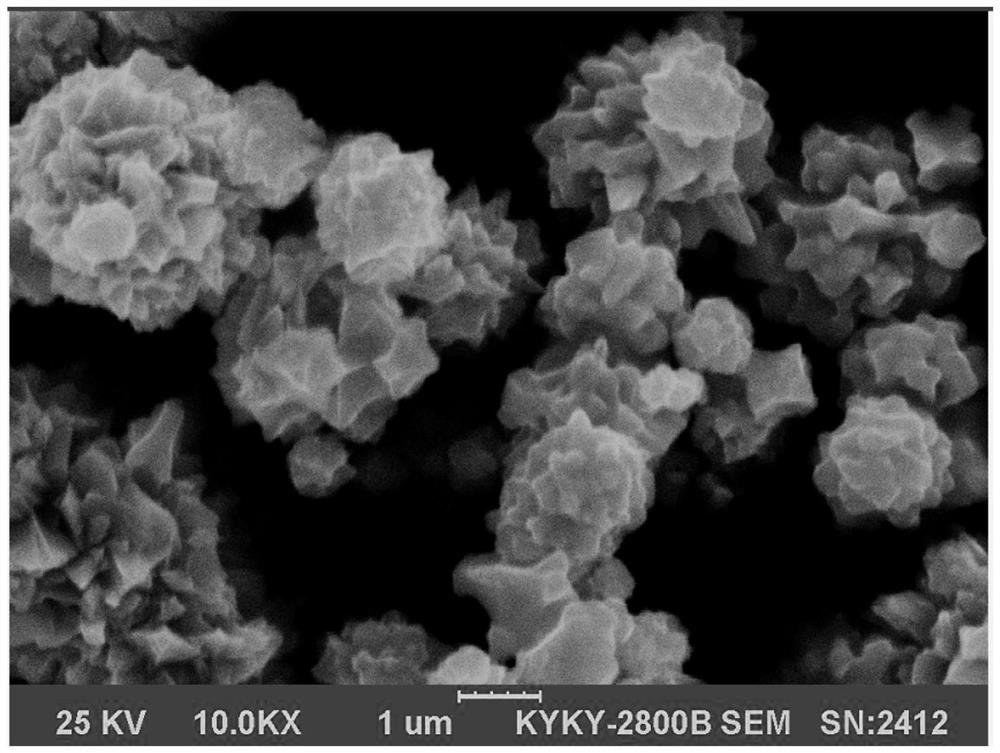

Embodiment 1

[0036] A kind of preparation method of superfine ferric boride, it is the following steps:

[0037] (1) after ferrous gluconate solution and boric acid solution are mixed, spray drying, obtain spray-dried material, the mol ratio of ferrous gluconate solution and boric acid is 1:1.01;

[0038] (2) Sintering the spray-dried material in a methane atmosphere, the sintering time is 10h, and the sintering temperature is 1200°C to react to obtain the reduced material;

[0039] (3) continue to feed carbon dioxide into the reducing material, and react at a temperature of 700°C for 4 hours to obtain a sintered material;

[0040] (4) The sintered material is subjected to jet crushing, screening and vacuum packaging to obtain superfine iron boride.

[0041] The concentration of described step (1) ferrous gluconate solution is 1.5mol / L, and the concentration of boric acid solution is 1mol / L, and spray drying adopts centrifugal spray drier, and the rotating speed of centrifugal atomizing w...

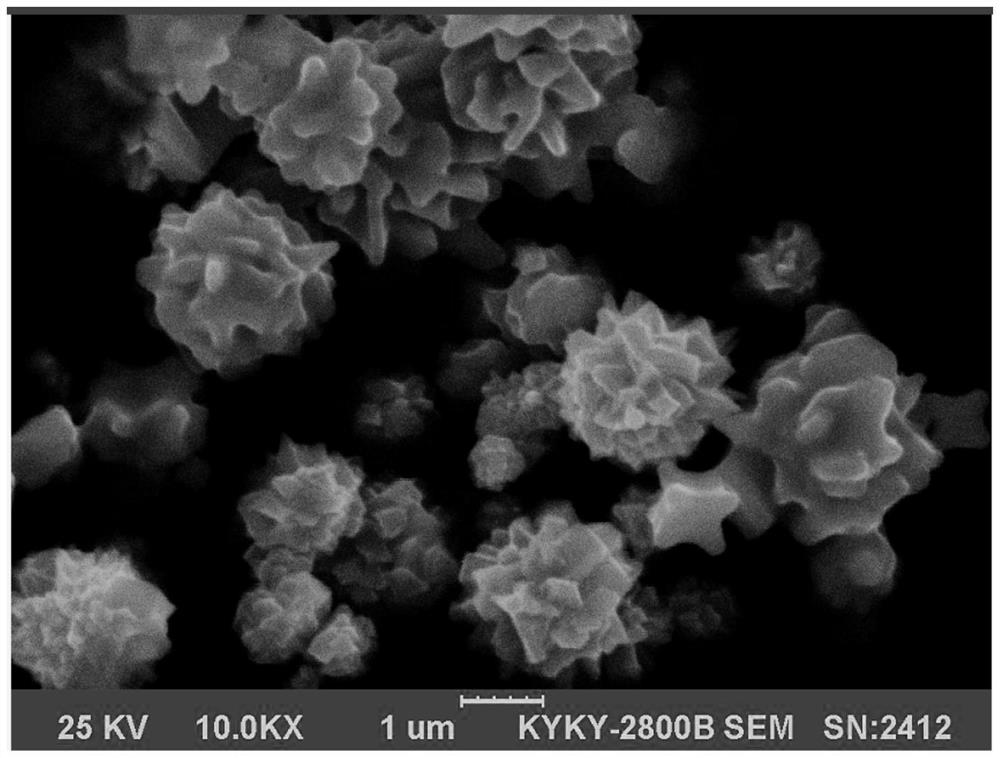

Embodiment 2

[0049] A kind of preparation method of superfine ferric boride, it is the following steps:

[0050](1) after ferrous gluconate solution and boric acid solution are mixed, spray drying, obtain spray-dried material, the mol ratio of ferrous gluconate solution and boric acid is 1:1.02;

[0051] (2) Sintering the spray-dried material in a methane atmosphere, the sintering time is 10h, and the sintering temperature is 1200°C to react to obtain the reduced material;

[0052] (3) Continue to feed carbon dioxide into the reducing material, and react at a temperature of 850° C. for 2 hours to obtain a sintered material;

[0053] (4) The sintered material is subjected to jet crushing, screening and vacuum packaging to obtain superfine iron boride.

[0054] The concentration of described step (1) ferrous gluconate solution is 3mol / L, and the concentration of boric acid solution is 2mol / L, and spray drying adopts centrifugal spray drier, and the rotating speed of centrifugal atomization ...

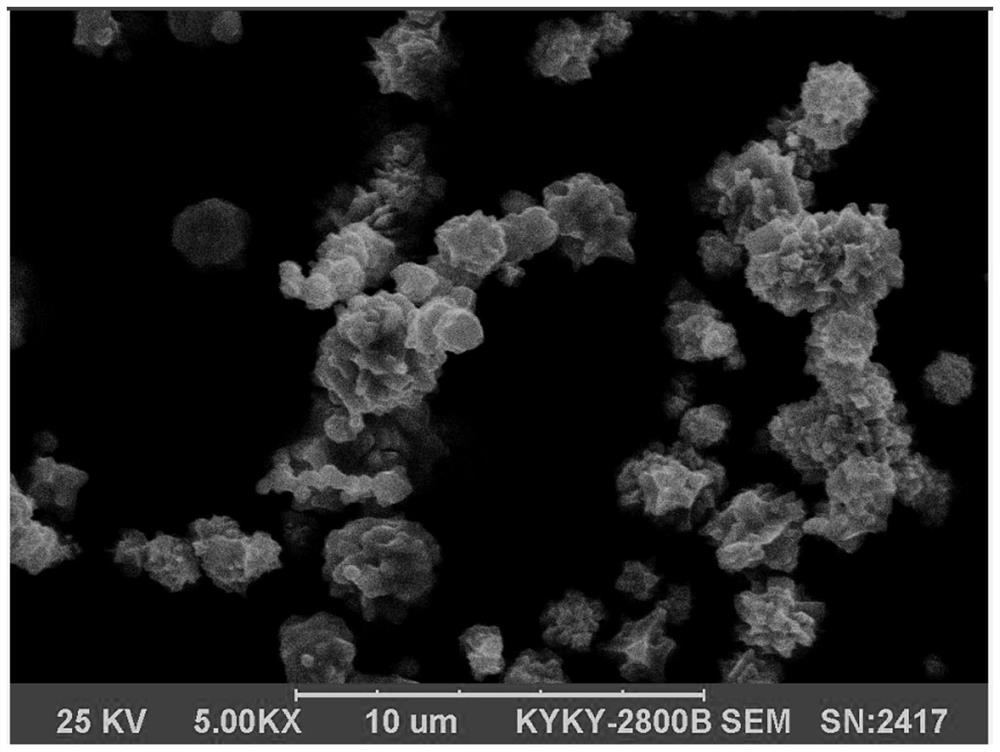

Embodiment 3

[0062] A kind of preparation method of superfine ferric boride, it is the following steps:

[0063] (1) after ferrous gluconate solution and boric acid solution are mixed, spray drying, obtain spray-dried material, the mol ratio of ferrous gluconate solution and boric acid is 1:1.015;

[0064] (2) Sintering the spray-dried material in a methane atmosphere, the sintering time is 8h, and the sintering temperature is 1000°C to react to obtain the reduced material;

[0065] (3) Continue to feed carbon dioxide into the reducing material, and react at a temperature of 780° C. for 3 hours to obtain a sintered material;

[0066] (4) The sintered material is subjected to jet crushing, screening and vacuum packaging to obtain superfine iron boride.

[0067] The concentration of described step (1) ferrous gluconate solution is 2mol / L, and the concentration of boric acid solution is 1.2mol / L, and spray drying adopts centrifugal spray drier, and the rotating speed of centrifugal atomizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com