Metal ceramic for machine tool guide rail and preparation technology

A technology of cermets and guide rails, applied in the field of cermets, can solve the problems of easy deformation of machine tool guide rails, influence of machine tool machining accuracy, poor stability, etc., and achieve enhanced anti-deformation ability, improved fluidity, and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A cermet used for machine tool guide rails, the raw materials of which include in parts by weight: 50 parts of molybdenum, 25 parts of tungsten carbide, 2.5 parts of carbon nitride, 0.7 parts of iron boride, 2.5 parts of nickel, 0.4 parts of carbon, carbonyl iron powder 50 parts, iron 40 parts, vanadium 4 parts, vanadium iron powder 2.5 parts, chromium 1.9 parts, titanium nitride 2 parts and tungsten 6 parts.

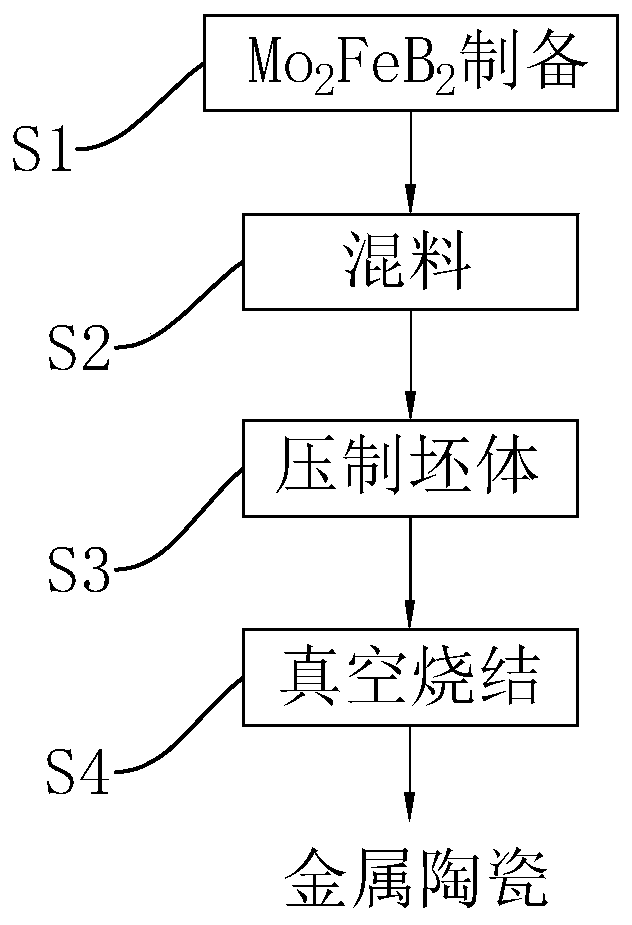

[0039] refer to figure 1 , a preparation process of cermet for machine tool guide rail, comprising the following steps:

[0040] S1: Mo 2 FeB 2preparation. The molybdenum powder with a particle size of 4 μm, the iron boride powder with a particle size of 45 μm, and the carbonyl iron powder with a particle size of 3 μm are put into a rolling ball mill according to the above-mentioned limited parts in this embodiment and mixed for 2h, and the ball-to-material ratio is 7:1, The speed limit of the ball mill is 260r / min. Among them, the purity of molybdenum powde...

Embodiment 7

[0049] The difference between Example 7 and Example 1 is that the raw materials in parts by weight include: 50 parts by weight of molybdenum, 25 parts of tungsten carbide, 2.5 parts of carbon nitride, 0.7 parts of iron boride, 2.5 parts of nickel, 0.4 parts of carbon, carbonyl iron 50 parts of powder, 40 parts of iron, and 4 parts of vanadium.

Embodiment 8

[0050] The difference between Example 8 and Example 1 is that the raw materials in parts by weight include: 50 parts of molybdenum, 25 parts of tungsten carbide, 2.5 parts of carbon nitride, 0.7 parts of iron boride, 2.5 parts of nickel, 0.4 parts of carbon, carbonyl iron 50 parts of powder, 40 parts of iron, 4 parts of vanadium and 2.5 parts of ferrovanadium powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com