Preparation method of ultrafine iron boride

A technology of iron boride and boric acid solution, which is applied in the direction of boron/boride, metal boride, etc., can solve the problems of small BET, large particle size of iron boride, and low activity, and achieve large BET, high purity, and environmental protection pressure small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

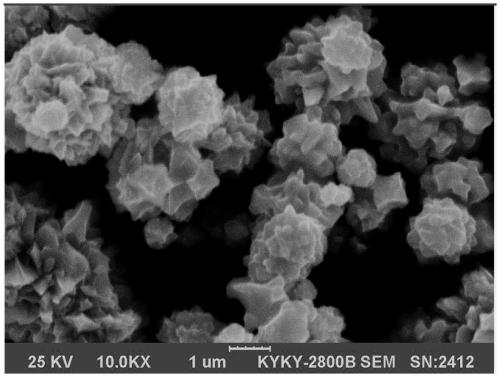

[0036] A kind of preparation method of superfine ferric boride, it is the following steps:

[0037] (1) after ferrous gluconate solution and boric acid solution are mixed, spray drying, obtain spray-dried material, the mol ratio of ferrous gluconate solution and boric acid is 1:1.01;

[0038] (2) Sintering the spray-dried material in a methane atmosphere, the sintering time is 10h, and the sintering temperature is 1200°C to react to obtain the reduced material;

[0039] (3) continue to feed carbon dioxide into the reducing material, and react at a temperature of 700°C for 4 hours to obtain a sintered material;

[0040] (4) The sintered material is subjected to jet crushing, screening and vacuum packaging to obtain superfine iron boride.

[0041] The concentration of described step (1) ferrous gluconate solution is 1.5mol / L, and the concentration of boric acid solution is 1mol / L, and spray drying adopts centrifugal spray drier, and the rotating speed of centrifugal atomization...

Embodiment 2

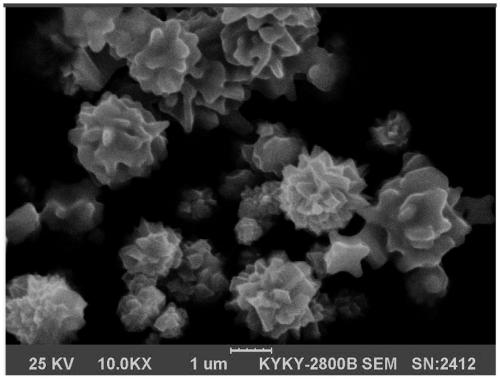

[0049] A kind of preparation method of superfine ferric boride, it is the following steps:

[0050](1) after ferrous gluconate solution and boric acid solution are mixed, spray drying, obtain spray-dried material, the mol ratio of ferrous gluconate solution and boric acid is 1:1.02;

[0051] (2) Sintering the spray-dried material in a methane atmosphere, the sintering time is 10h, and the sintering temperature is 1200°C to react to obtain the reduced material;

[0052] (3) Continue to feed carbon dioxide into the reducing material, and react at a temperature of 850° C. for 2 hours to obtain a sintered material;

[0053] (4) The sintered material is subjected to jet crushing, screening and vacuum packaging to obtain superfine iron boride.

[0054] The concentration of described step (1) ferrous gluconate solution is 3mol / L, and the concentration of boric acid solution is 2mol / L, and spray drying adopts centrifugal spray drier, and the rotating speed of centrifugal atomization ...

Embodiment 3

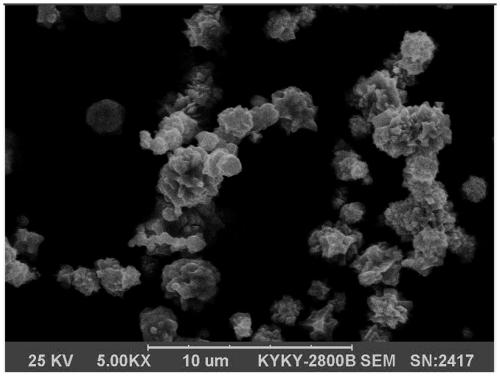

[0062] A kind of preparation method of superfine ferric boride, it is the following steps:

[0063] (1) after ferrous gluconate solution and boric acid solution are mixed, spray drying, obtain spray-dried material, the mol ratio of ferrous gluconate solution and boric acid is 1:1.015;

[0064] (2) Sintering the spray-dried material in a methane atmosphere, the sintering time is 8h, and the sintering temperature is 1000°C to react to obtain the reduced material;

[0065] (3) Continue to feed carbon dioxide into the reducing material, and react at a temperature of 780° C. for 3 hours to obtain a sintered material;

[0066] (4) The sintered material is subjected to jet crushing, screening and vacuum packaging to obtain superfine iron boride.

[0067] The concentration of described step (1) ferrous gluconate solution is 2mol / L, and the concentration of boric acid solution is 1.2mol / L, and spray drying adopts centrifugal spray drier, and the rotating speed of centrifugal atomizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com