Iron boride modified cement mortar with high mechanical properties and preparation method thereof

A technology of cement mortar and iron boride, applied in the direction of boron/boride, metal boride, nanotechnology, etc., can solve the problems of high brittleness, single function, low tensile strength, etc. chemical reaction and mechanical properties improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A preparation method of ferric boride modified cement mortar with high mechanical properties mainly comprises the following steps:

[0043] (1) Preparation of iron boride aqueous solution:

[0044] S1. Weigh 1-3g of scrap iron powder and add it to 60-100mL of 3mol / L dilute nitric acid or 37% concentrated hydrochloric acid for 4-8 hours;

[0045] S2. Take the supernatant obtained in step S1, and add a potassium hydroxide solution with a concentration of 3-6mol / L until the mixed solution is neutral;

[0046] S3. Adding a sodium borohydride solution with a concentration of 2 mol / L to the neutral solution in step S2 until the solution no longer produces precipitation;

[0047] S4. Centrifuge the mixture obtained in step S3 at a speed of 3000r / min, and then repeatedly wash the centrifuged sediment with distilled water and absolute ethanol several times;

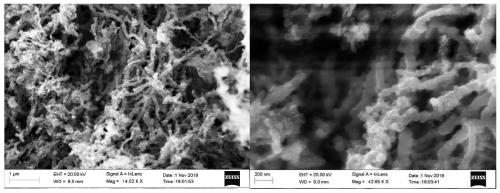

[0048] S5, drying the precipitate obtained in step S4 in an oven at 70° C. for 12 hours to obtain long-chain nano-iron ...

Embodiment 1

[0056] Weigh 1g of scrap iron powder and add it to 60mL of dilute nitric acid with a concentration of 3mol / L to soak for 8 hours, take the supernatant obtained above, add a potassium hydroxide solution with a concentration of 6mol / L until the mixed solution is neutral, and then pour Add a sodium borohydride solution with a concentration of 2 mol / L to the solution until the solution no longer produces precipitation, centrifuge the mixture obtained above at a speed of 3000r / min, and then use distilled water and absolute ethanol to separate the centrifuged precipitates repeatedly. After washing several times, the obtained precipitate was dried in an oven at 70° C. for 12 hours to obtain long-chain nano-iron boride powder for use.

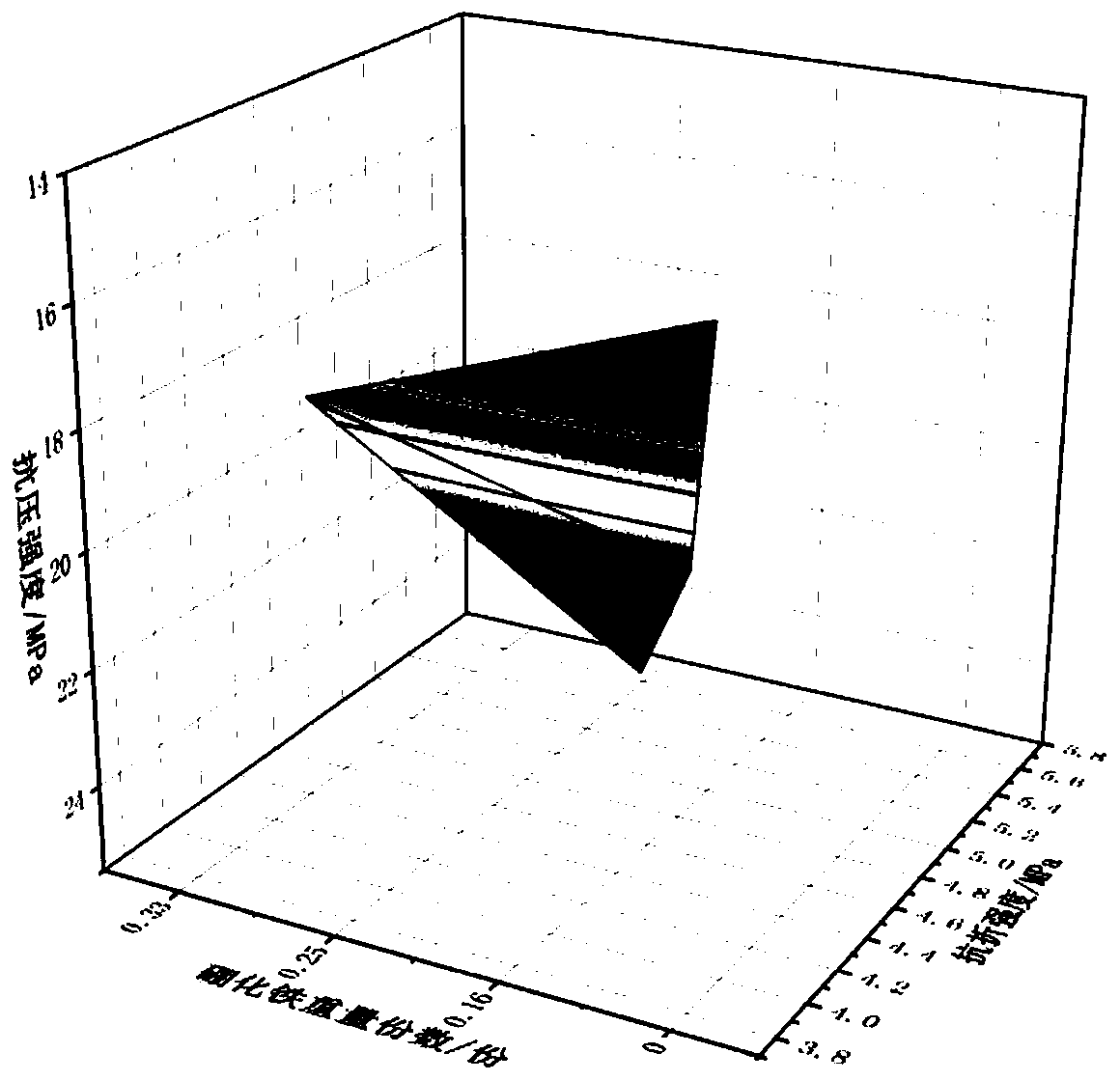

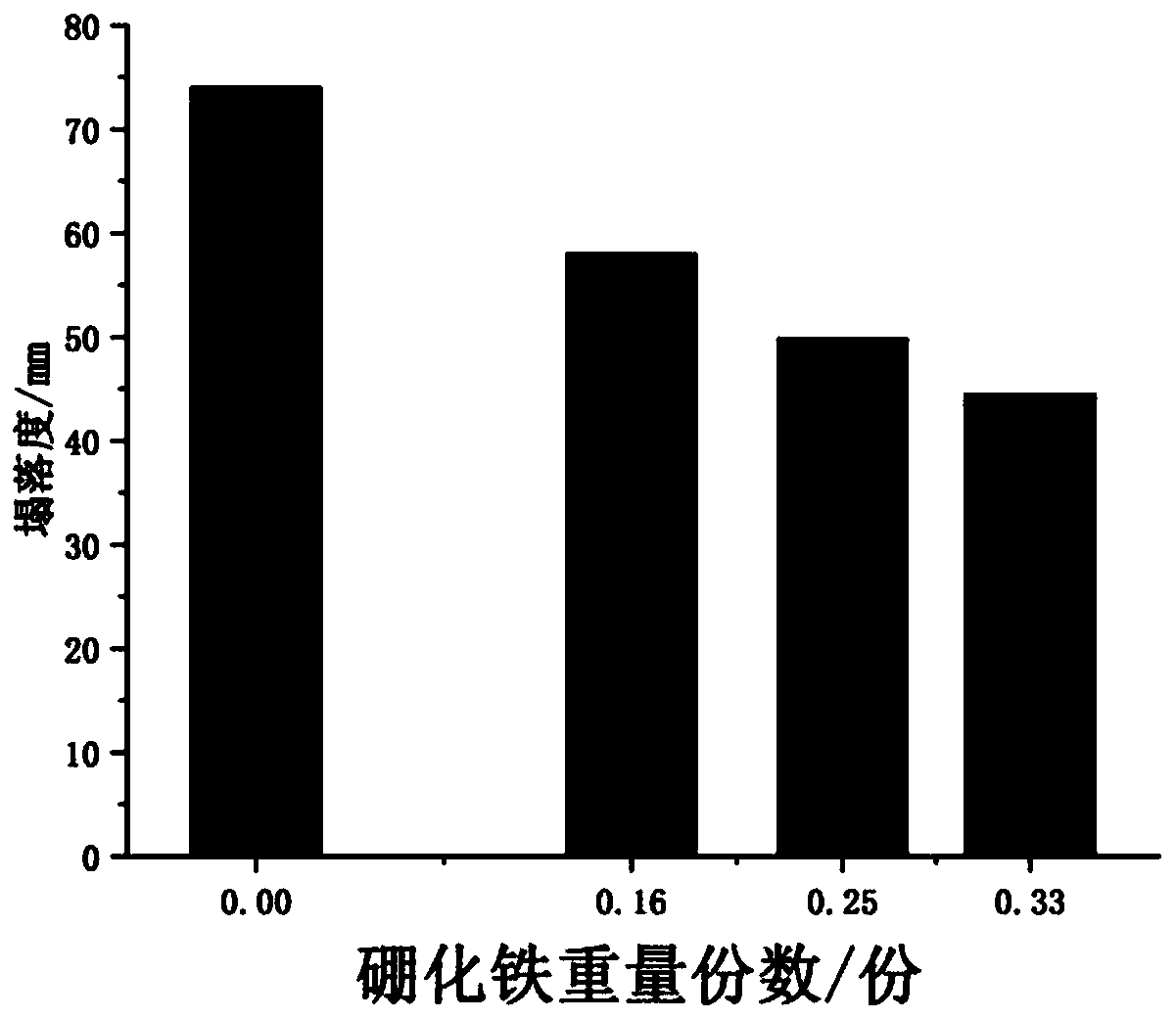

[0057] First, take 0.16 parts of nano-iron boride and slowly add it to 12.5 parts of water to mix, and stir magnetically until there is no suspended nano-iron boride powder on the surface of the water, and then put the initially stirred dispersion solut...

Embodiment 2

[0059] Weigh 3g of scrap iron powder and add it to 100mL of dilute nitric acid with a concentration of 3mol / L and soak for 4 hours, take the supernatant obtained above, add a potassium hydroxide solution with a concentration of 3mol / L until the mixed solution is neutral, and then pour Add a sodium borohydride solution with a concentration of 2 mol / L to the solution until the solution no longer produces precipitation, centrifuge the mixture obtained above at a speed of 3000r / min, and then use distilled water and absolute ethanol to separate the centrifuged precipitates repeatedly. After washing several times, the obtained precipitate was dried in an oven at 70° C. for 12 hours to obtain long-chain nano-iron boride powder for use.

[0060] First, take 0.25 parts of nano-iron boride and slowly add it to 12.5 parts of water to mix, and stir magnetically until there is no suspended nano-iron boride powder on the surface of the water, and then put the initially stirred dispersion sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com