Patents

Literature

150results about How to "Repair crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shape memory intrinsic type self-repairing material as well as preparation method and application thereof

ActiveCN105802195AThe synthesis method is simpleImprove repair efficiencySelf-healing materialChemistry

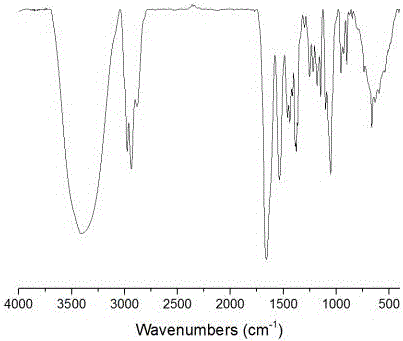

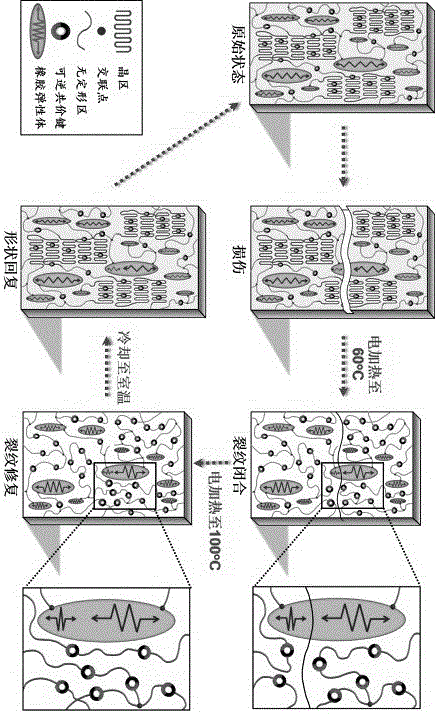

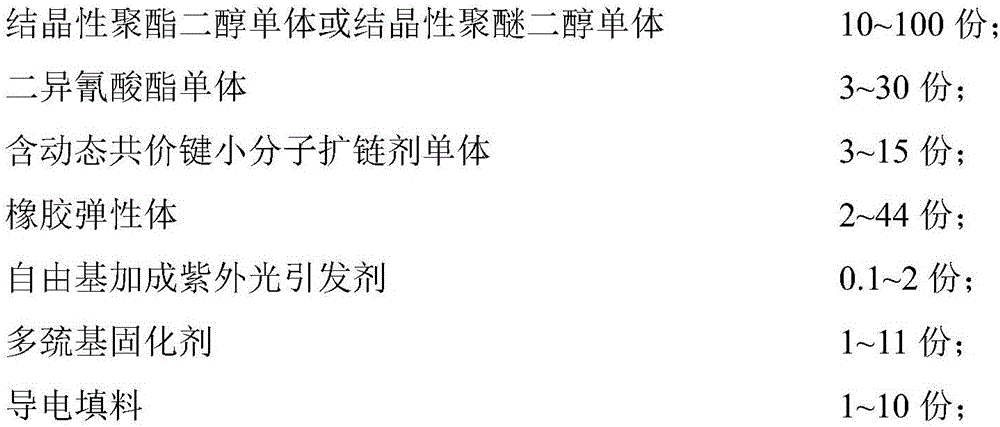

The invention provides a shape memory intrinsic type self-repairing material which is prepared from the following components: a crystal polyether or polyester diol monomer, a diisocyanate monomer, a monomer containing a dynamic covalent bond micromolecule chain extender, a rubber elastic body, a free radical polymeric ultraviolet light initiator, a multi-sulfydryl curing agent and conductive packing. If the shape memory intrinsic type self-repairing material is suffered from mechanical damage, a conductive path consisting of internal conductive packing is damaged, the resistance of the material is increased, under the action of external current, temperature rise can be resulted from the Joule heating effect of the material self, a reversible shape memory effect of the material can be excited, cracks of the material can be shrunk and closed, meanwhile after macroscopic cracking closure, the dynamic covalent bonds inside the material can recombine the material as molecular chains of a fracture surface are diffused with one another and subjected to reversible chemical reaction, at the moment, paths of the conductive packing in the material can be recovered, the resistance of the material can be reduced to an original level, the Joule heating effect can be eliminated, the temperature can be reduced to the room temperature, and the self-repairing process has the characteristics of reversibility and repeatability.

Owner:SUN YAT SEN UNIV

Soft magnetism composite powder and preparation method thereof

InactiveCN103177838ACoated evenlyImprove antioxidant capacityInorganic material magnetismSelf-healingPolyethylene glycol

The invention discloses soft magnetism composite powder and a preparation method of the soft magnetism composite powder. The soft magnetism composite powder is the composite powder which has two layers of inorganic insulation coating structures, the inner core of the composite powder is magnetic particles of FeSiAl or FeSi, SiO2 in a network state is coated on the outer layer of the magnetic particles, and nanocrystalline B2O3 is coated outside the SiO2. The preparation method of the soft magnetism composite powder comprises the following steps: (1) preparing magnetism SiO2 core-shell structural powder; (2) uniformly mixing the magnetism SiO2 core-shell structural powder prepared in the step (1), borate N-butyl, absolute ethanol, polyethylene glycol and deionized water, dropwise adding acetic acid, adjusting the potential hydrogen (pH) value of the mixed solution to be 5-6, stirring the mixed solution for 1-5 hours at the temperature of 40 DEG C-80 DEG C till a complete reaction is achieved, and drying the mixed solution at the temperature 40 DEG C-100 DEG C till the weight is constant; and (3) calcining the dried powder at the temperature of 400 DEG C-500 DEG C for 1-2 hours under the protective atmosphere. The soft magnetism composite powder prepared through the method has a good physical performance and a good magnetic performance. Due to the fact that a B2O3 film is coated outside the SiO2 shell layer, the magnetic powder is enabled to have a crack self-healing capability under the condition of high temperature, the electrical resistivity of a magnetic powder core is improved, and the eddy-current loss of materials is reduced.

Owner:CENT SOUTH UNIV

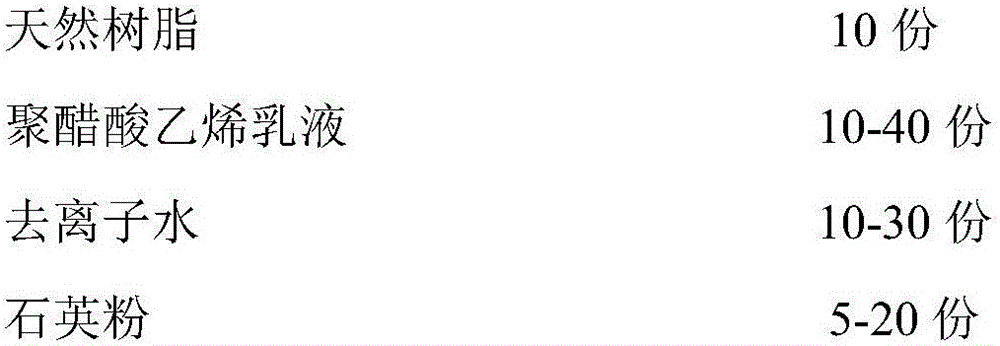

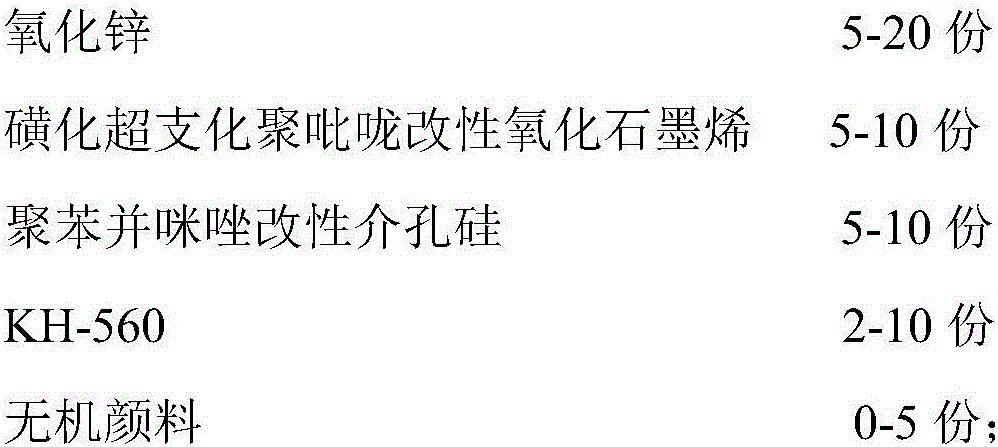

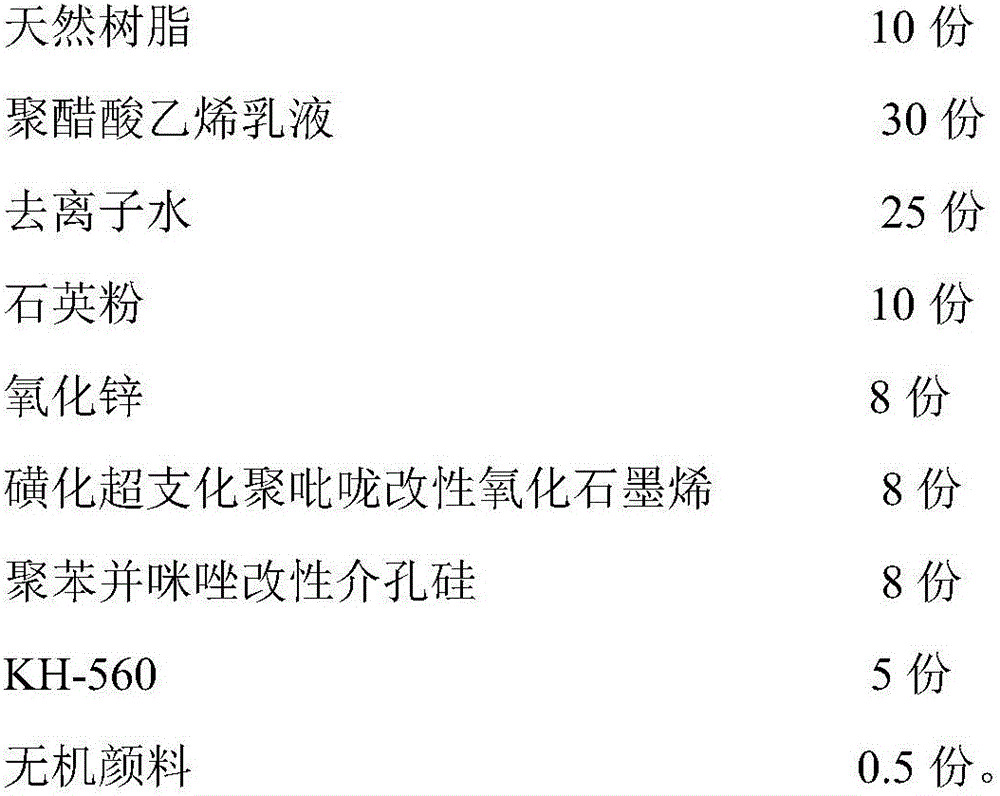

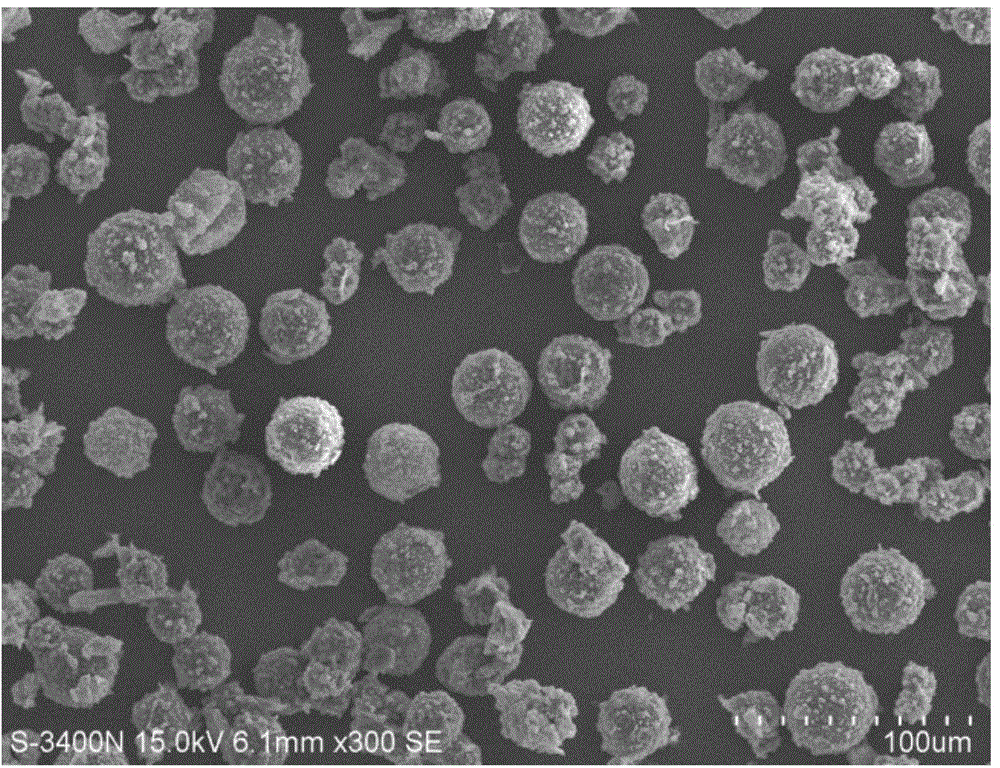

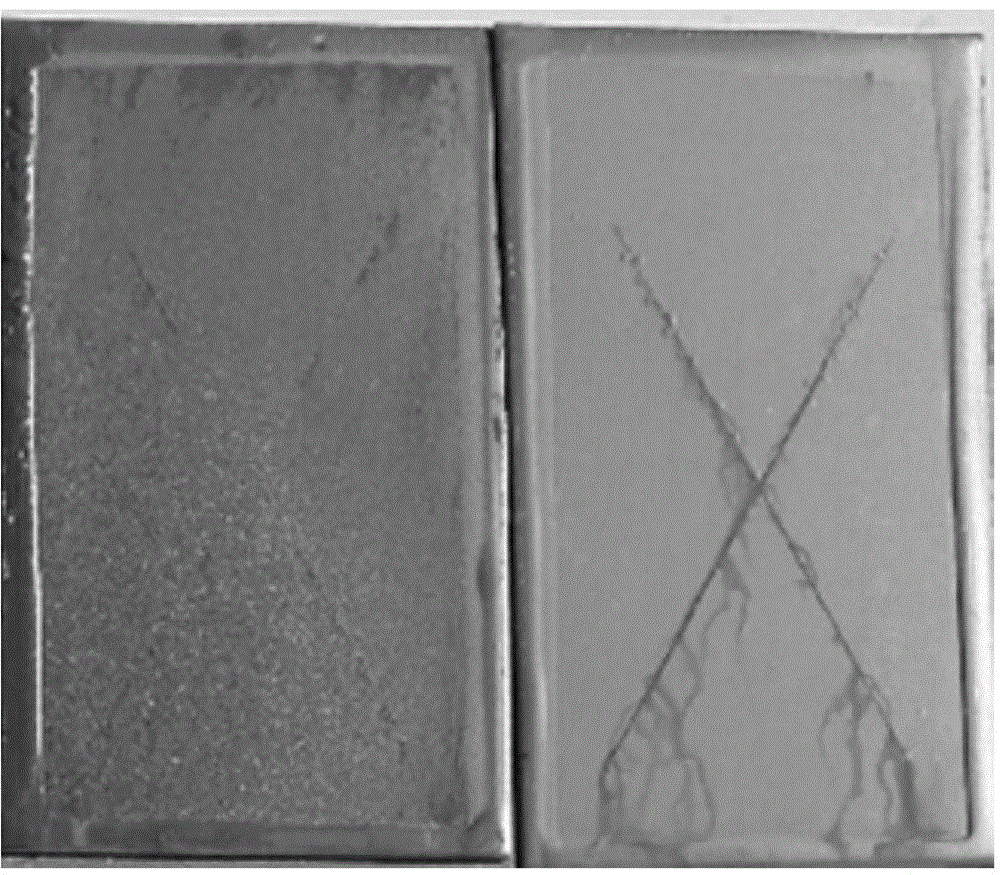

Exterior wall coating material capable of finishing working through one-time painting

ActiveCN105754431AGood stabilityGood alkali resistanceNatural resin coatingsRosin coatingsEmulsionOxide

The invention discloses an exterior wall coating material capable of finishing working through one-time painting.The exterior wall coating material is prepared from natural resin, polyvinyl acetate emulsion, deionized water, quartz powder, zinc oxide, sulfonated hyperbranched polypyrrolone modified graphene oxide, polybenzimidazole modified meso-porous silicon, KH-560 and inorganic pigment.The exterior wall coating material capable of finishing working through one-time painting has the better adhesive capacity, aging resistance, covering power, washing resistance, scratching resistance, stain resistance, self-cleaning performance, fastness, acid resistance and alkali resistance, longer service life and the like compared with existing water-based exterior wall coating materials.

Owner:JIANGXI LONGZHENG SCI & TECH DEV

Curing method for saline soil

InactiveCN101275394AIncrease spawn rateReduce damageIn situ pavingsOrganic fertilisersChemistryCOMPONENT II

A saline soil solidifying method is disclosed, whose basal principle uses the reaction of salinity producing katogene and added firming agent to generate a dilatability outcome yield, which allows the dilatability destroy to take place ahead, the dilatability structure becomes dense from loose by pressing dense, finally the gel component cements the saline soil. The used firming agent includes component i (aluminiferous component), component ii (calcium containing component), component iii (cementing component, with a slower generating velocity), and the doped amount is 1-30% of the mass of the saline soil. The usage mode of the firming agent includes stirring component i, component ii and the saline soil and waiting for 1-30d, doping in component iii after pressing, which can be used as road bed, pavement, or producing saline soil brick; simultaneously adding component i, component ii and component iii in the saline soil, pressing after waiting for 1-20d, which can be used as road bed, pavement, or producing saline soil brick; and also being capable of taking component i, component ii and component iii as firming agent of deep layer padding process and the like for deep consolidation of salination land base.

Owner:BEIHANG UNIV

Microcapsule type additive for corrosion-resistant coating and preparation method thereof

ActiveCN104927468AImprove corrosion resistanceExtended service lifeAnti-corrosive paintsMicroballoon preparationMelamine formaldehyde resinRust converter

The invention discloses a microcapsule type additive for corrosion-resistant coating and a preparation method thereof. The microcapsule type additive is prepared by the following components by weight percent, 40wt-80wt% of water, 5wt%-35wt% of air-drying type film-forming substance, 0.01wt%-10wt% of anti-rusting agent, 5wt%-30wt% of capsule-wall resin and 0.05wt%-2wt% of emulsifying agent; the mixture of the air-drying film-forming substance and the anti-rusting agent is wrapped in the capsule-wall resin which is urea resin, melamine-formaldehyde resin or modified polymer of the urea resin and melamine-formaldehyde resin or mixture of two or more than two substances. The additive disclosed by the invention has the advantages that the additive is added into the corrosion-resistant coating, the corrosion resistance of the prepared coating can be further improved, especially when the paint film is damaged due to action of external force, the added additive can release a restoration agent and the anti-rusting agent to restore the damage and inhibit the corrosion expansion by self, so that the service life of the paint film is prolonged.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

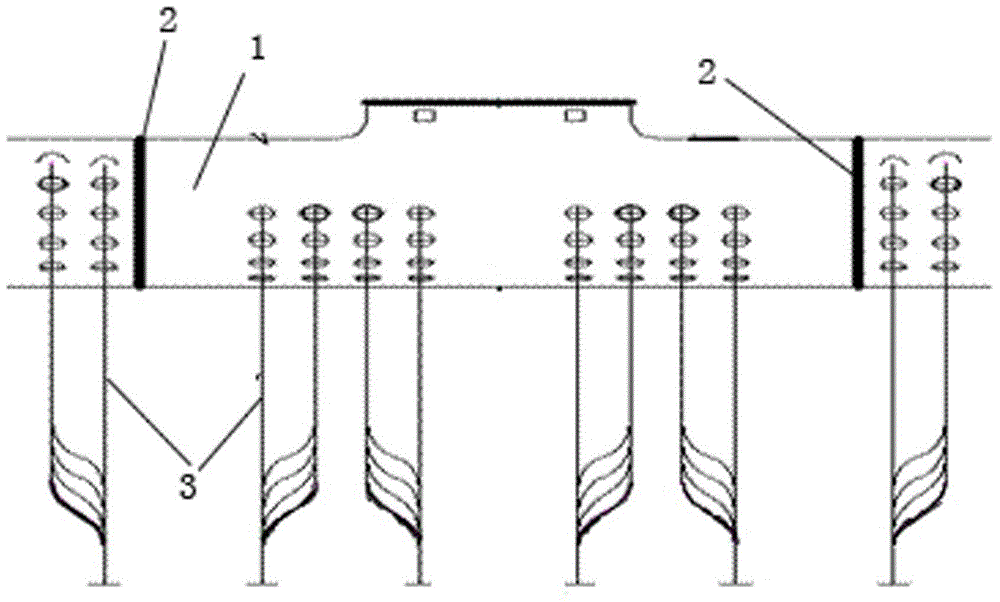

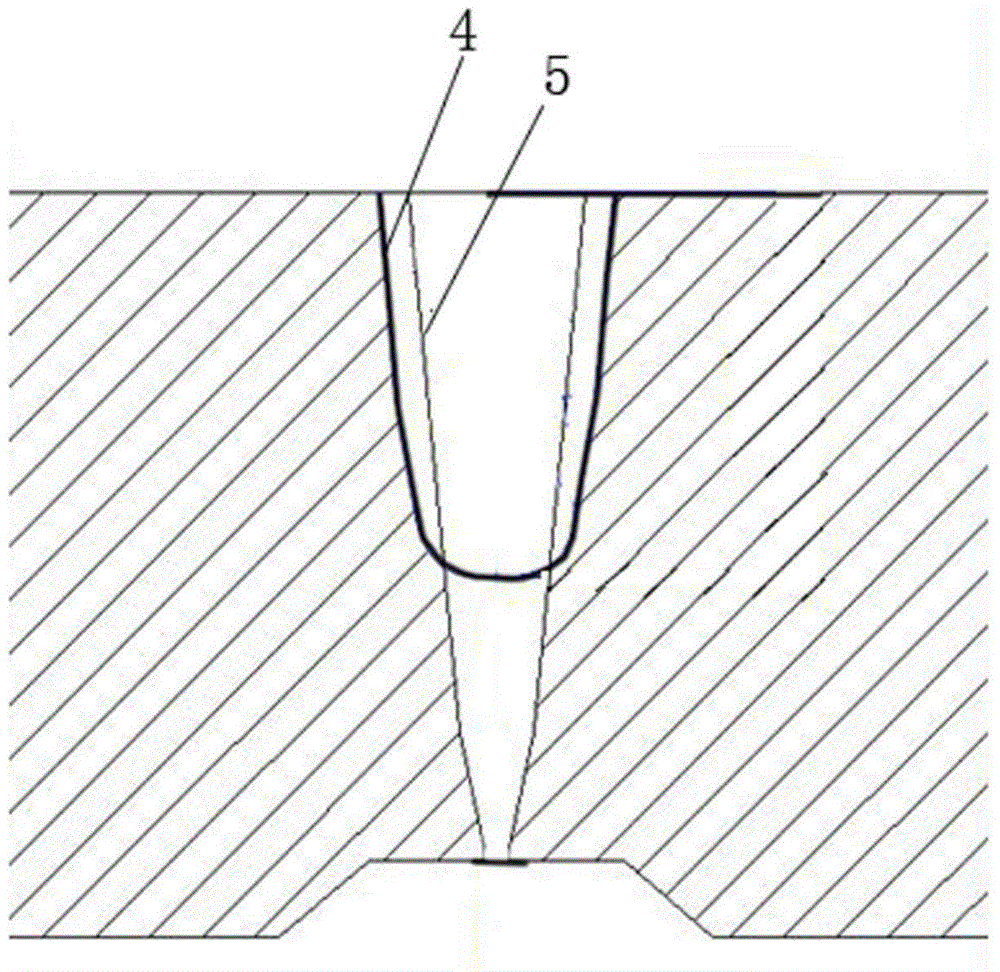

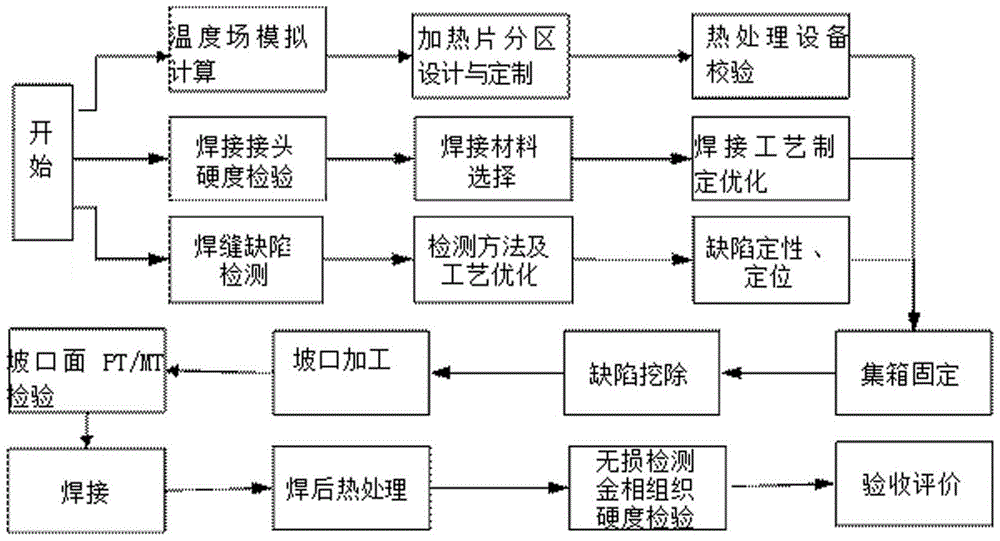

Method for repairing internal cracks of weld joint of container device

The invention discloses a method for repairing internal cracks of a weld joint of a container device. The method comprises the steps of S1, detecting the weld joint of the container device so as to determine the positioning depth of the cracks in the weld joint; S2, removing the weld joint in which the cracks are determined according to the positioning depth of the cracks in the weld joint, so as to form a weld joint groove for removing the cracks in the weld joint; S3, filling and welding the weld joint groove; S4, thermally processing the repaired weld joints subjected to filling and welding. With the adoption of the method for repairing the internal cracks of the weld joint of the container device, the cracks of various types in the weld joint can be effectively repaired, and the completeness of the performances of the container device can be maintained.

Owner:CHINA SHENHUA ENERGY CO LTD +2

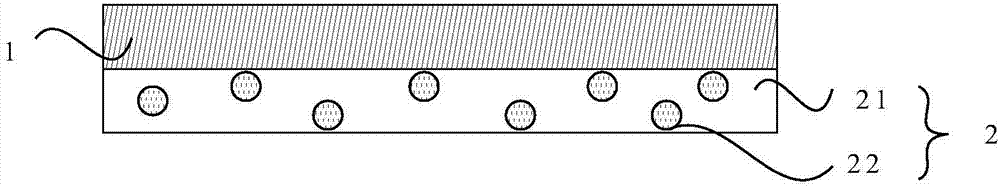

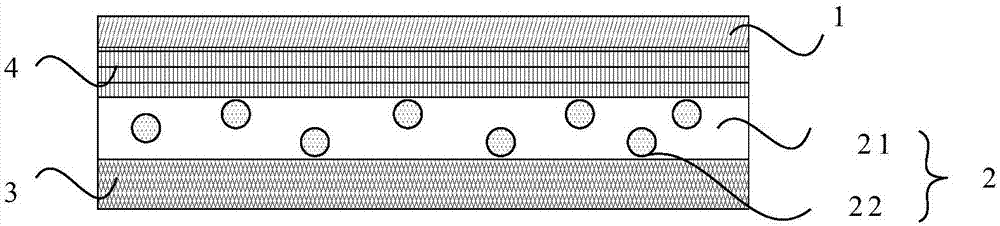

Packaging structure and an organic light emitting display device

PendingCN107369781ARepair crackImprove qualitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The invention relates to the technical field of display, and discloses a packaging structure and an organic light emitting display device which are used to repair cracks generated in a packaging layer, improve the packaging effect and improve the quality of the organic light emitting display device. The packaging structure includes a self-repairing functional layer and a heating layer for heating the self-repairing functional layer. The self-repairing functional layer at least includes a self-repairing material.

Owner:BOE TECH GRP CO LTD

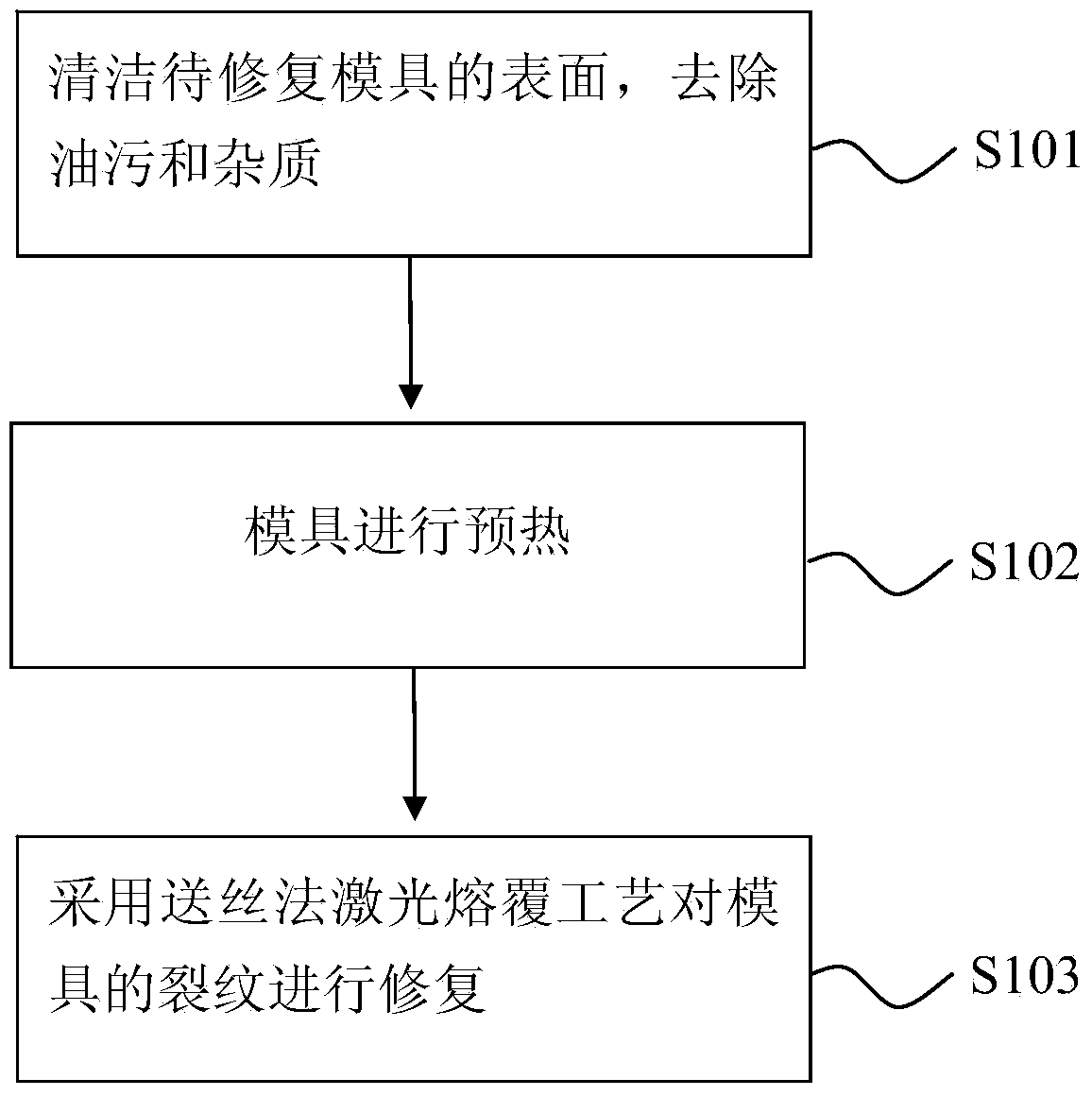

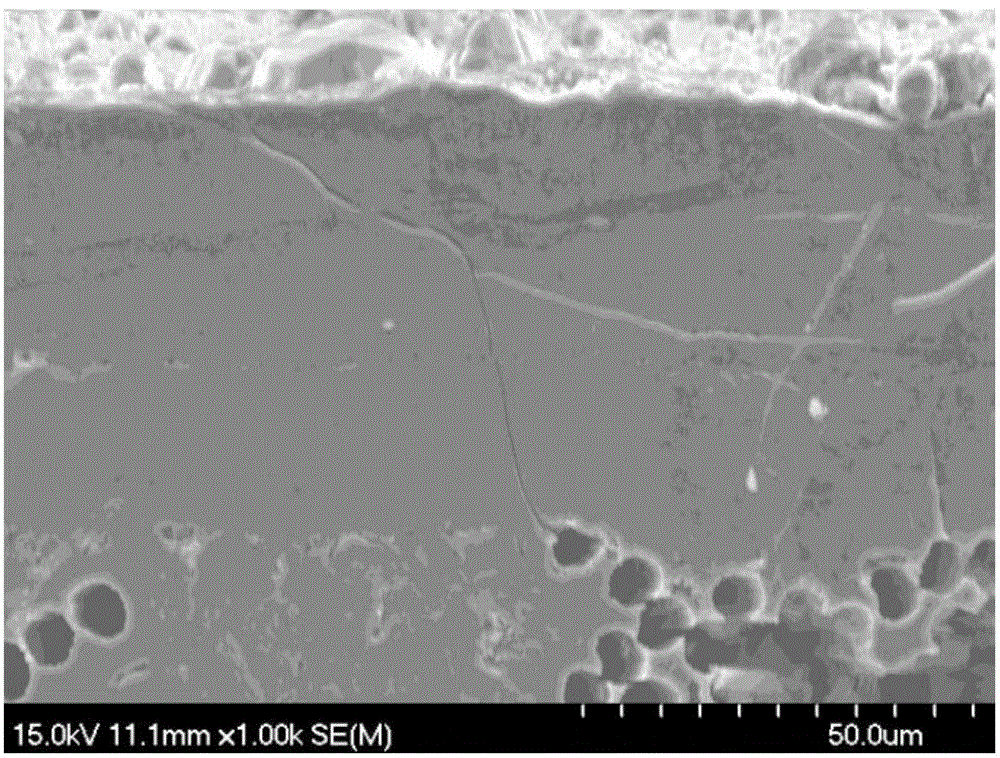

Method for adopting laser fuse wires for repairing mold

The invention discloses a method for adopting laser fuse wires for repairing a mold, crack defects of the mold are repaired, and the mold is made of 5CrNiMo steel or 5CrMnMo steel. The method includes the steps that (a), the surface of the mold to be repaired is cleaned to remove oil stains and impurities; (b), the mold is preheated; (c), by the adoption of a wire feeding method laser cladding technology, cracks of the mold are repaired. Through the steps, cladding layers obtained on the cracks of the mold are compact and even in texture and free of pores, inclusion and other defects. The repairing method is simple in technology, low in cost, capable of effectively repairing the cracks of the mold and suitable for industrial production.

Owner:昆山纯柏精密五金有限公司

Production process for manufacturing high-strength recycled aggregates from construction waste

InactiveCN108658489AReduce contentHigh strengthGas current separationSolid waste managementSlurryHigh intensity

The invention discloses a production process for manufacturing high-strength recycled aggregates from construction waste. By multistage screening, impurities in the construction waste are removed specifically to effectively reduce the content of the impurities in the construction waste, and high-strength clean recycled aggregates can be obtained. By chemical slurry infiltration and cement wrapping, owing to specific properties of added chemical substances, crack repairing and pore filling of the recycled aggregates are realized while interface adhesiveness is improved, and performances and quality of the recycled aggregates are remarkably improved. In conclusion, the production process has advantages of multistage screening, reasonability in arrangement and high strength and performances of products.

Owner:赵素军

Method for repairing heat damage crackles of ceramic based composite material

The invention relates to a method for repairing heat damage crackles of a ceramic based composite material. According to the method, a whole SiC coating on the surface of a sample with heat damage crackles is directly and thoroughly abraded, and then the SiC coating is re-deposited. A deposition surface is smooth, closed pores of a C / SiC composite material for abrading the whole SiC coating are opened, which is beneficial for ensuring that the subsequent deposition of a matrix and a coating becomes more compact and the density gradient is reduced; and the crackles formed in the SiC matrix can be effectively repaired, so that the oxidation resistance of a sample in a high-temperature environment is improved more efficiently. By adopting the method, density defects and heat damages of C / SiC are effectively repaired, micro-crackles generated in a preparation process of C / SiC can be reduced, the density gradient and porosity of C / SiC from surface to inside are reduced, the crackles generated by the heat damages are gradually repaired, the oxidation resistance recovers and is relatively improved, and the bending strength is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

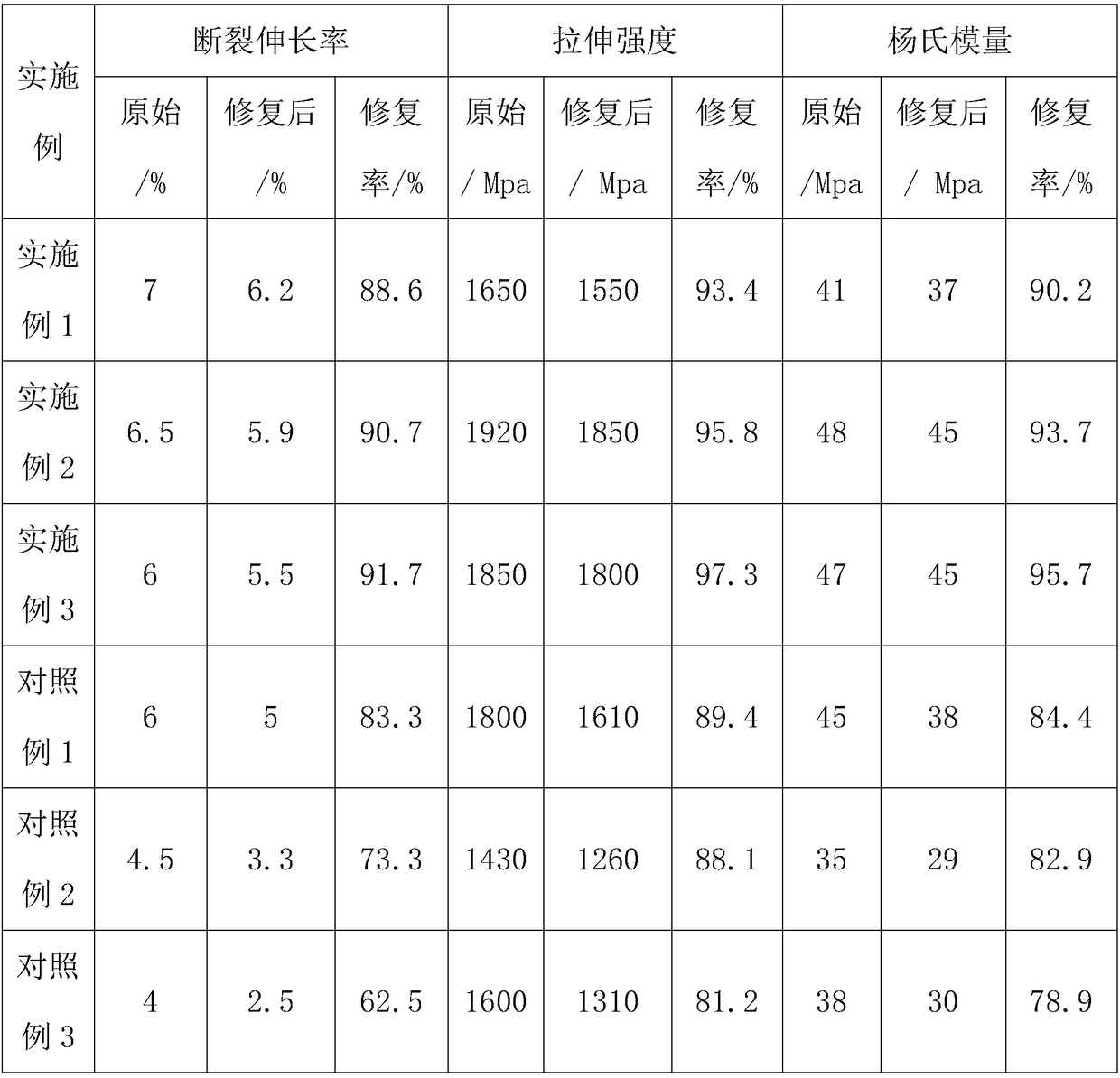

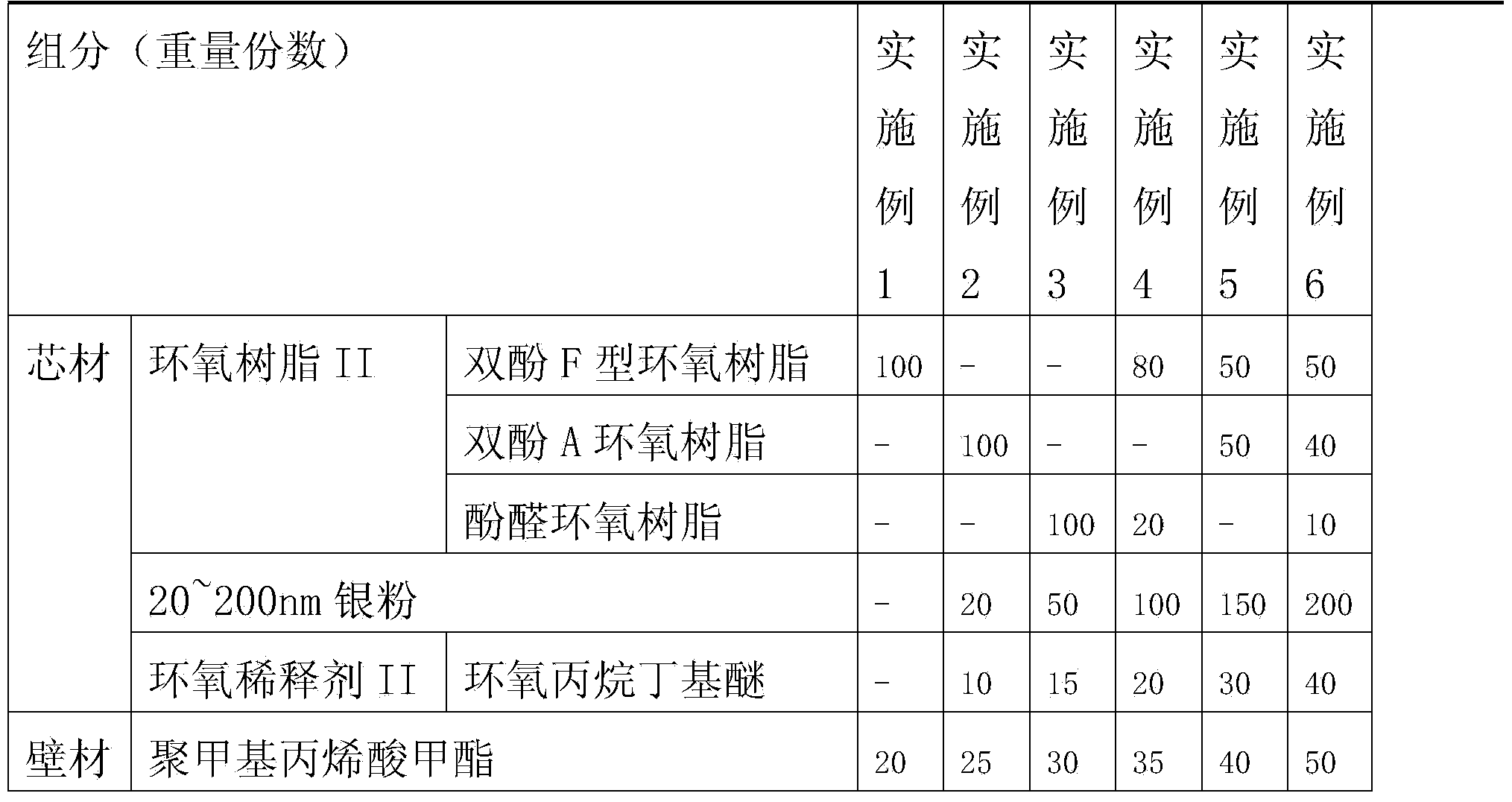

Reparative conductive adhesive and preparation method thereof

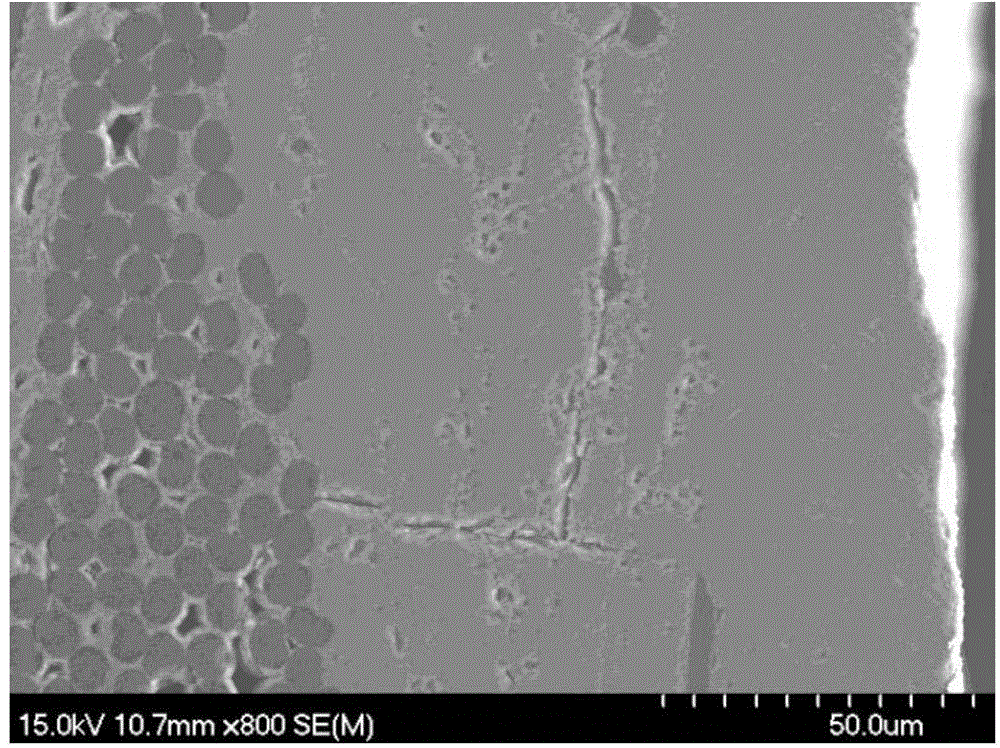

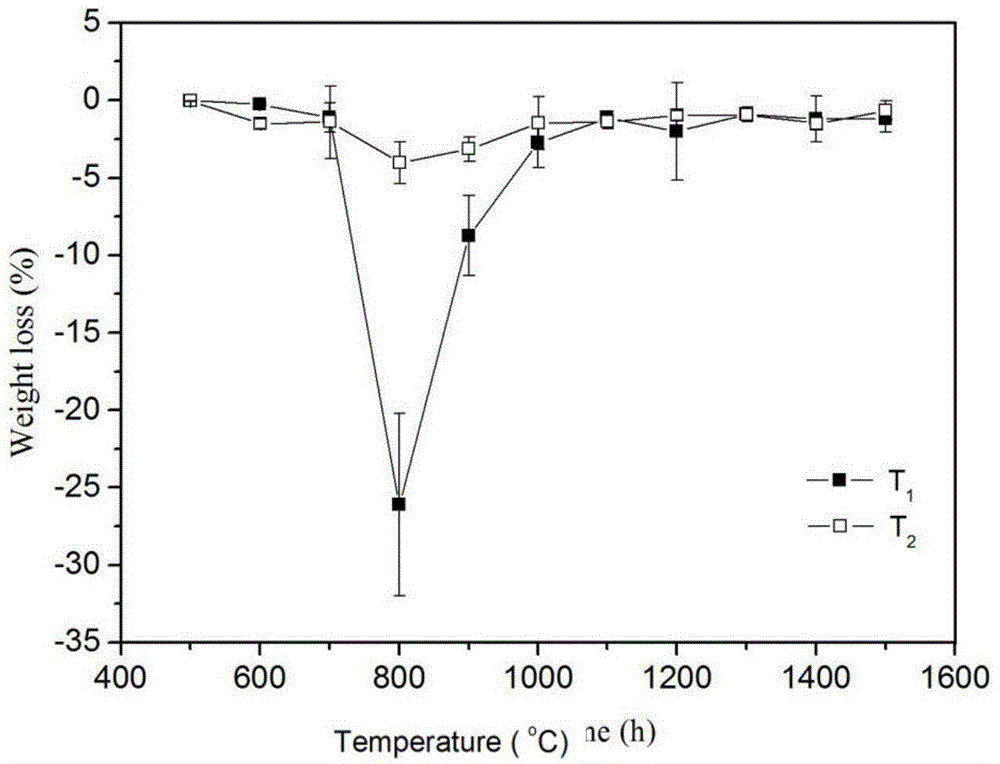

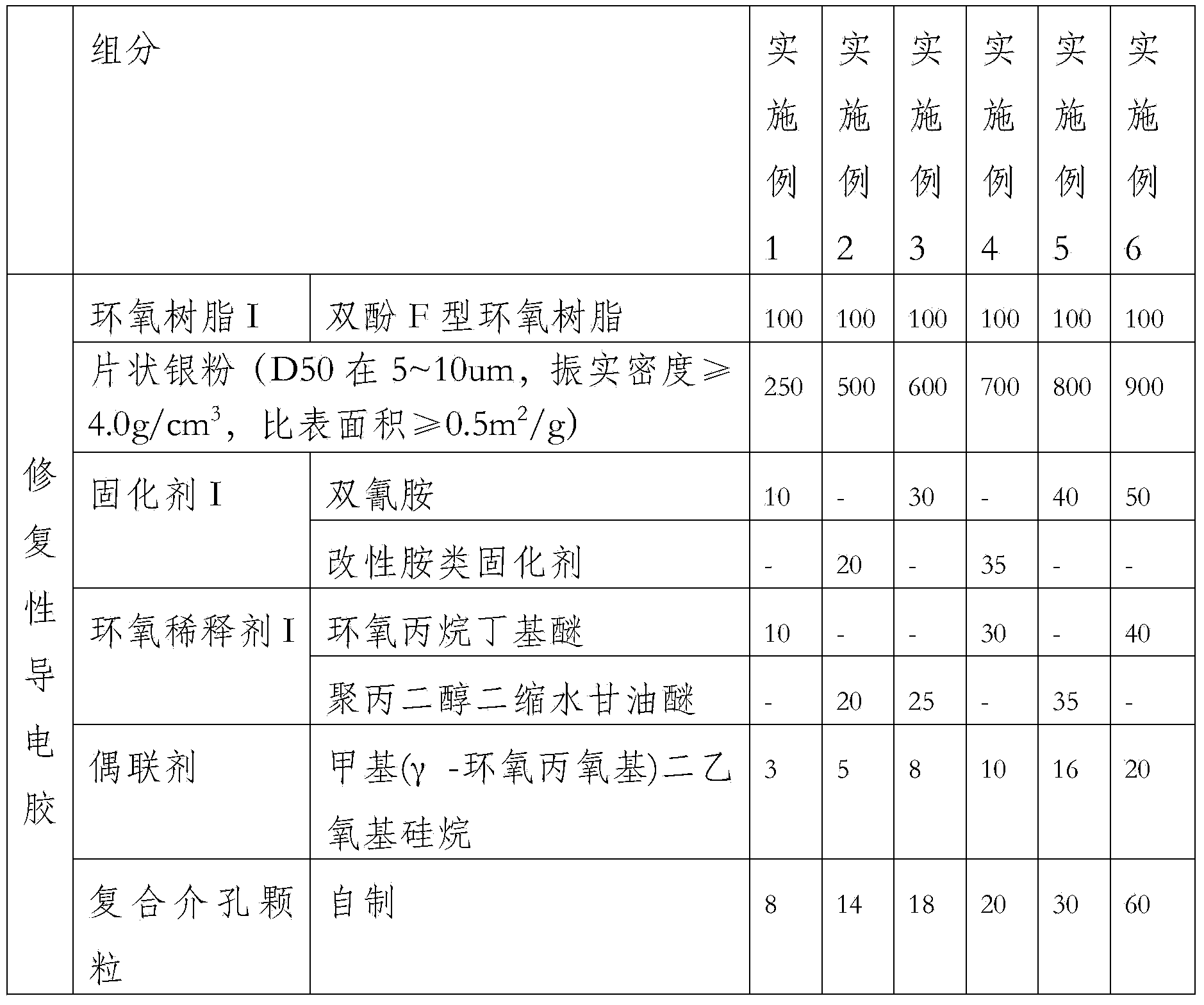

ActiveCN103642422ASimple processControllable parametersNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyStress concentration

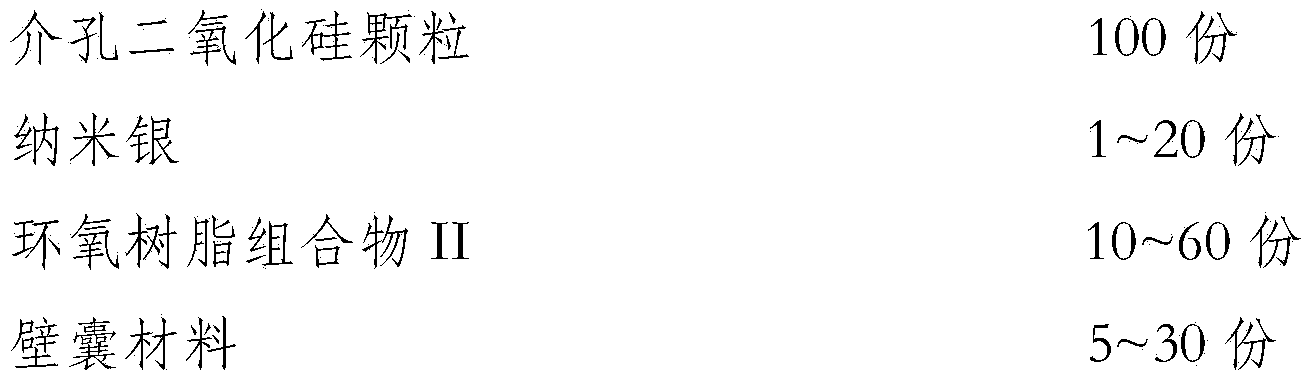

The invention relates to a reparative conductive adhesive. The reparative conductive adhesive consists of the following components in parts by weight: 100 parts of epoxy resin I, 250-900 parts of sheet silver powder, 10-50 parts of a curing agent I, 0-40 parts of an epoxy diluent I, 3-20 parts of a coupling agent and 8-60 parts of composite mesoporous particles, wherein a curing temperature of an epoxy resin composition I consisting of the curing agent I, the epoxy resin I and the epoxy diluent I is 60 DEG C-80 DEG C; the composite mesoporous particles adopt mesoporous silicon dioxide loaded with nano sliver as a carrier, a wall capsule material layer is arranged on the outer surface of the carrier, an epoxy resin composition II is contained in a mesopore, the curing temperature of the epoxy resin composition II is not lower than 150 DEG C, an epoxy diluent II in the epoxy resin composition II is not dissolved or difficultly dissolved in water with a boiling point not lower than 150 DEG C. The invention further relates to a preparation method of the reparative conductive adhesive. The conductive adhesive is high in repair efficiency and can avoid generating stress concentration at repaired cracks.

Owner:JIANGSU RUIDE NEW ENERGY TECH

Sealant for self-repair and leak prevention of storage battery, and preparation method thereof

InactiveCN103540284ARepair crackExtended service lifeOther chemical processesEpoxy resin adhesivesEpoxySealant

The invention discloses a sealant for self-repair and leak prevention of a storage battery, and a preparation method thereof. The sealant comprises the following components in parts by weight: 55-75 parts of epoxy resin, 12-20 parts of a curing agent, 5-15 parts of grafting treated microcapsules and 4-10 parts of a catalyst, wherein the grafting treated microcapsules are microcapsules which are grafted by using a coupling agent previously and the weight of the coupling agent accounts for 3-5% of that of the microcapsule; the wall material of the microcapsules is urea resin and the capsule core of the microcapsule is a repairing agent dicyclopentadiene; the particle size distribution range of the microcapsule is from 220 to 250 microns; the wall thickness of the microcapsule is 3-7 microns. According to the invention, the self-repair material of the microcapsule having a certain particle size distribution range and a certain wall thickness and the catalyst are simultaneously added to the epoxy resin sealant; therefore, the cracks of the storage battery generated in the use process can be effectively repaired, the liquid leak phenomenon at the sealed position of the post terminal of the storage battery is reduced and the service life of the storage battery can be prolonged. The method is simple and practicable, and very easy to popularize.

Owner:KINGFA SCI & TECH CO LTD

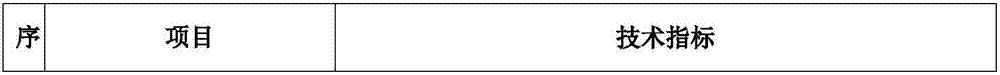

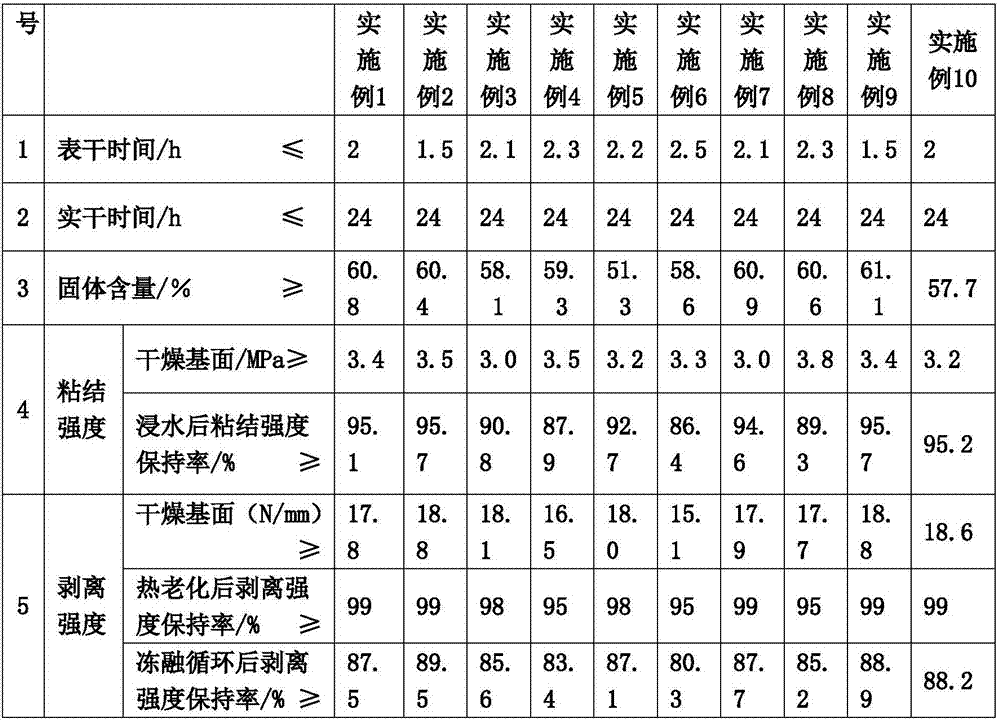

Concrete bottom coating of concrete work protection polyurea material

InactiveCN106867300AEasy to useImprove performanceFilling pastesPolyurea/polyurethane coatingsHigh humidityAntioxidant

The invention discloses a concrete bottom coating of a concrete work protection polyurea material. The concrete bottom coating comprises an A ingredient material and a B ingredient material, wherein the A ingredient material is prepared from 70 to 134 parts of isocyanate, 80 to 150 parts of polylol, 2 to 20 parts of coupling agents and 50 to 150 parts of solvents through being metered in parts by weight; the B ingredient material is prepared from 25 to 75 parts of chain expanding agents, 1 to 5 parts of antioxidants and 50 to 140 parts of solvents through being metered in parts by weight. The defects that the attachment force of the existing bottom coating is greatly reduced or lost in the long-time water soaking or high-humidity state, and a polyurea material bulges and falls off are overcome. The concrete bottom coating has the advantages that the use is convenient; the performance is excellent.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

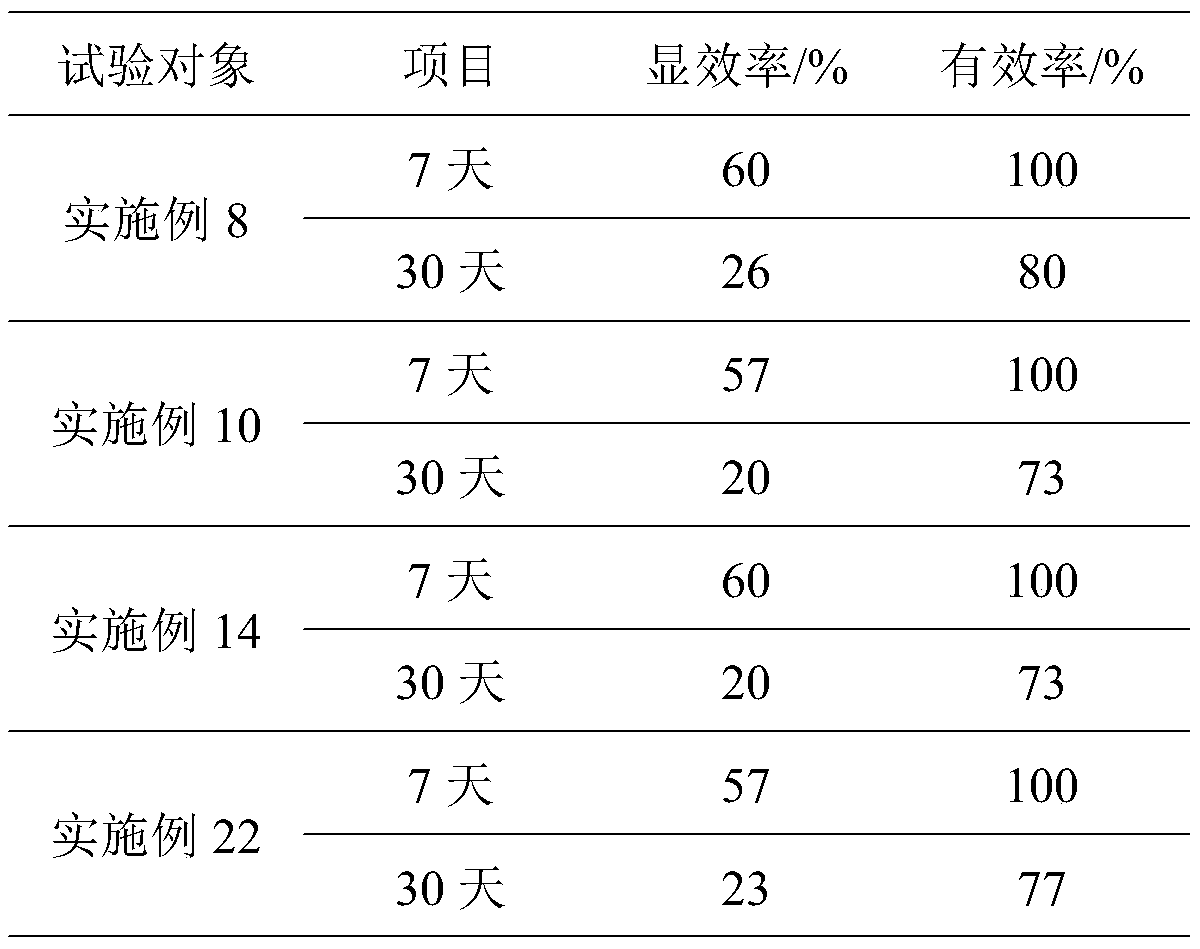

Chinese medicine composition for treating ischemic necrosis of femoral head

InactiveCN101607015AShort course of treatmentQuick resultsPowder deliveryAnthropod material medical ingredientsHeracleum hemsleyanumMyrrh

The invention relates to a Chinese medicine composition for treating ischemic necrosis of femoral head, which solves the problems that the western medicine only releases pain, the Chinese medicine has long treatment period and slow effect, and the operation treatment has large risk and high cost as well as easy recrudescence. The Chinese medicine composition is prepared by the following raw materials according to the weight proportion: 10-100g of angelica, 20-50g of corydalis tuber, 20-60g of heracleum hemsleyanum michaux, 20-40g of frankincense, 20-40g of myrrh, 10-50g of angelica dahurica, 20-50g of cinnamon, 30-100g of rhizoma drynariae, 20-60g of radix dipsaci from Sichuan of China, 20-50g of rhizoma cibotii, 40-100g of lopseed, 20-50g of dragon's blood and 10-50g of eupolyphage sece steleophaga. The Chinese medicine composition has short treatment period and rapid effect, can eliminate the ischemic necrosis of femoral head and the inflammatory pain of rachitis, can eliminate mechanical pain of cervical vertebra and lumbar intervertebral disc protrusion, can repair fiber ring scission, builds the health, improves the microcirculation without side and toxic effects, and promotes the sequestrum absorption of the ischemic necrosis of femoral head and the regeneration of the bone trabecula, thereby achieving the purpose of addressing both the symptoms and root causes.

Owner:徐国厚

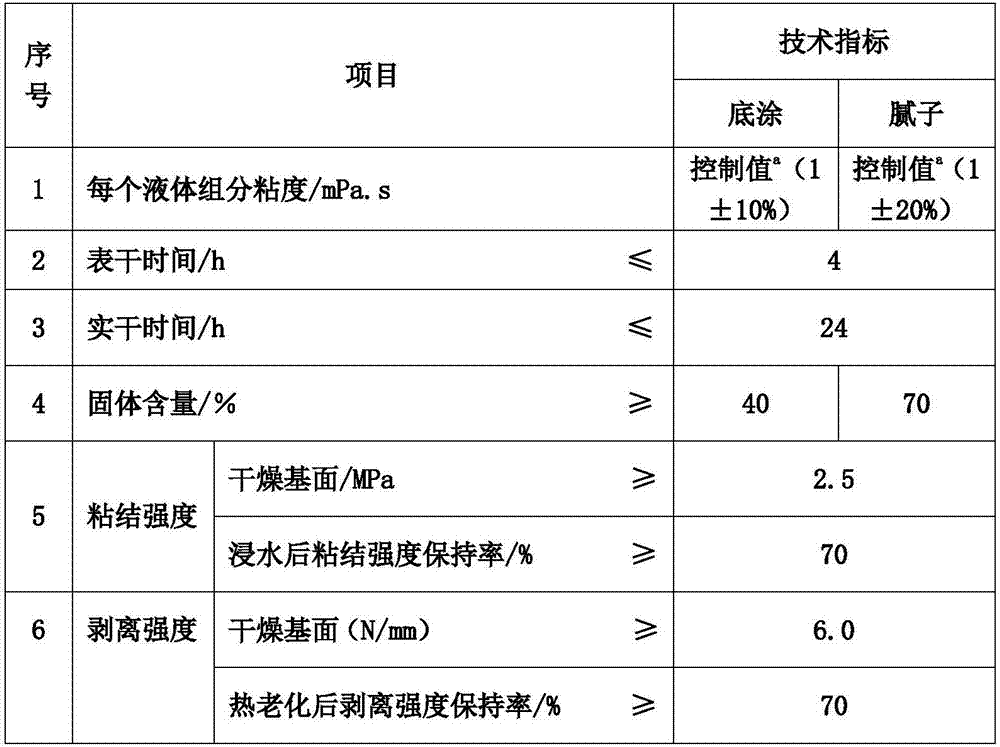

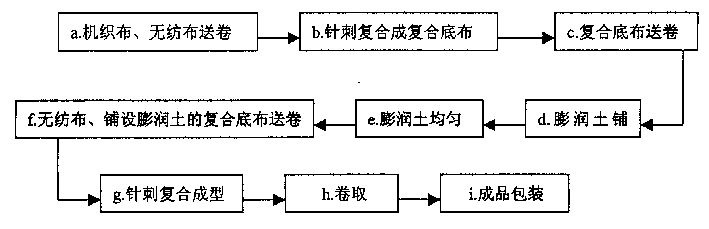

Method for fabricating composite geomaterial in wide size

Owner:SHANGHAI NEW TECHTEXTILES

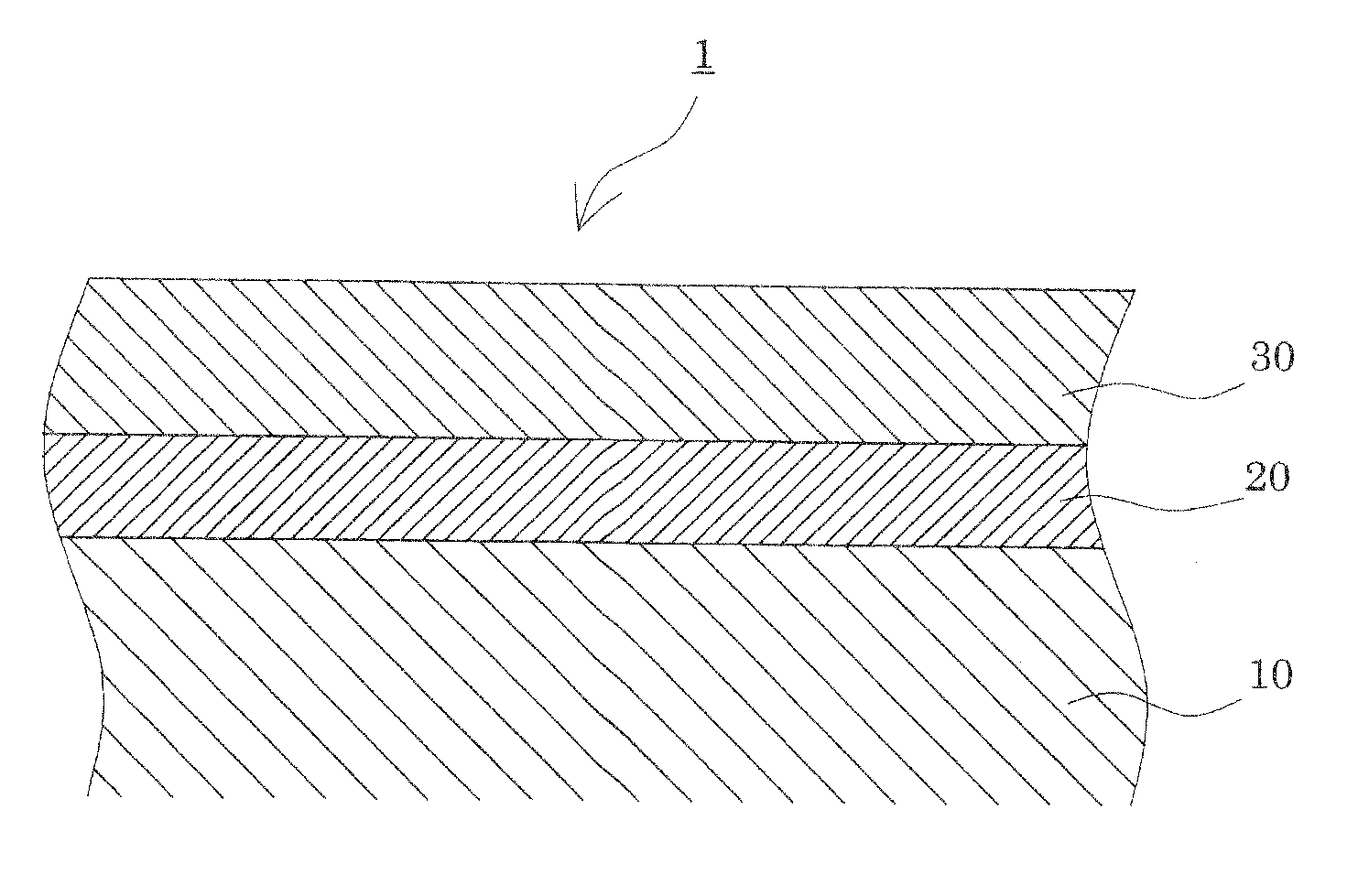

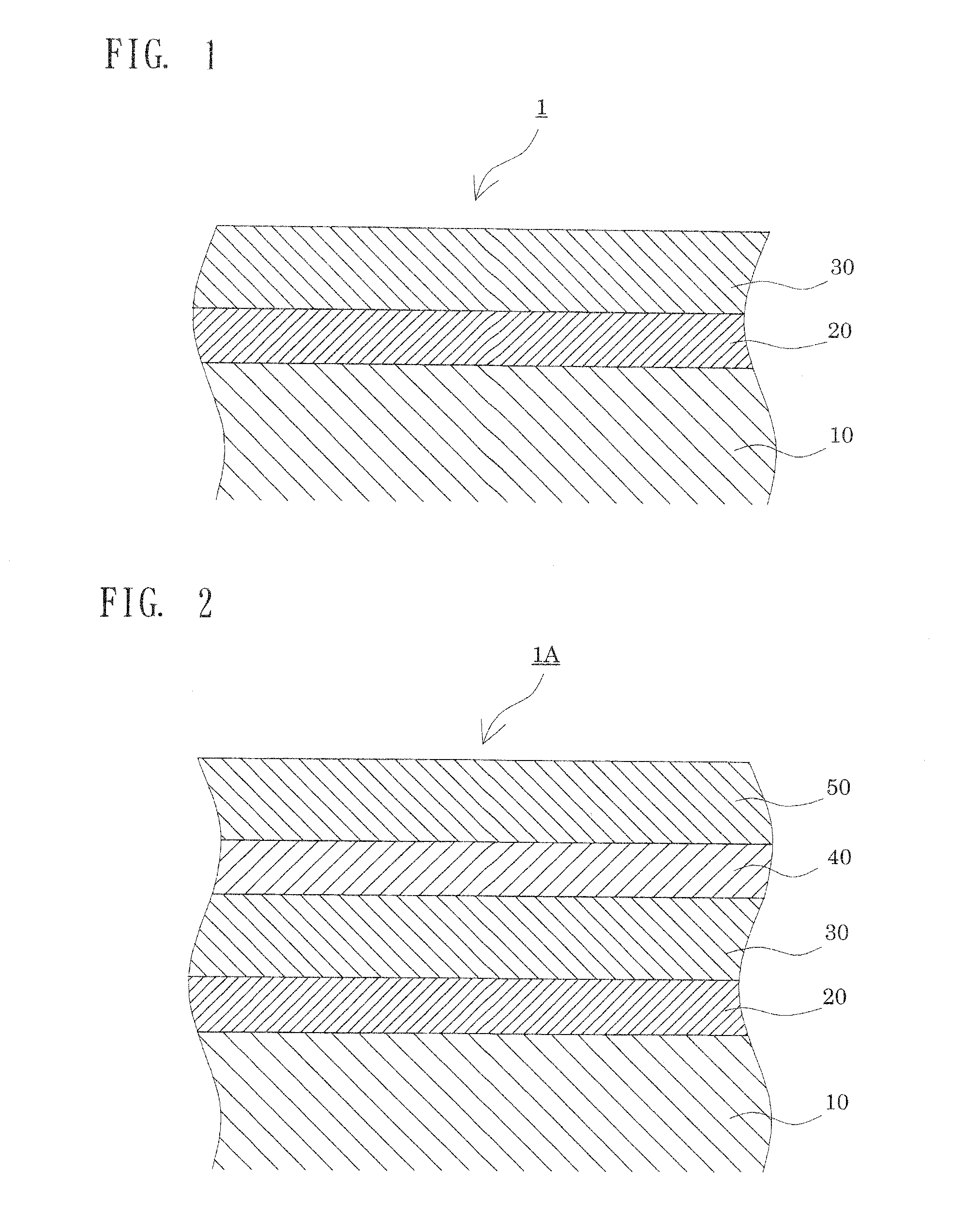

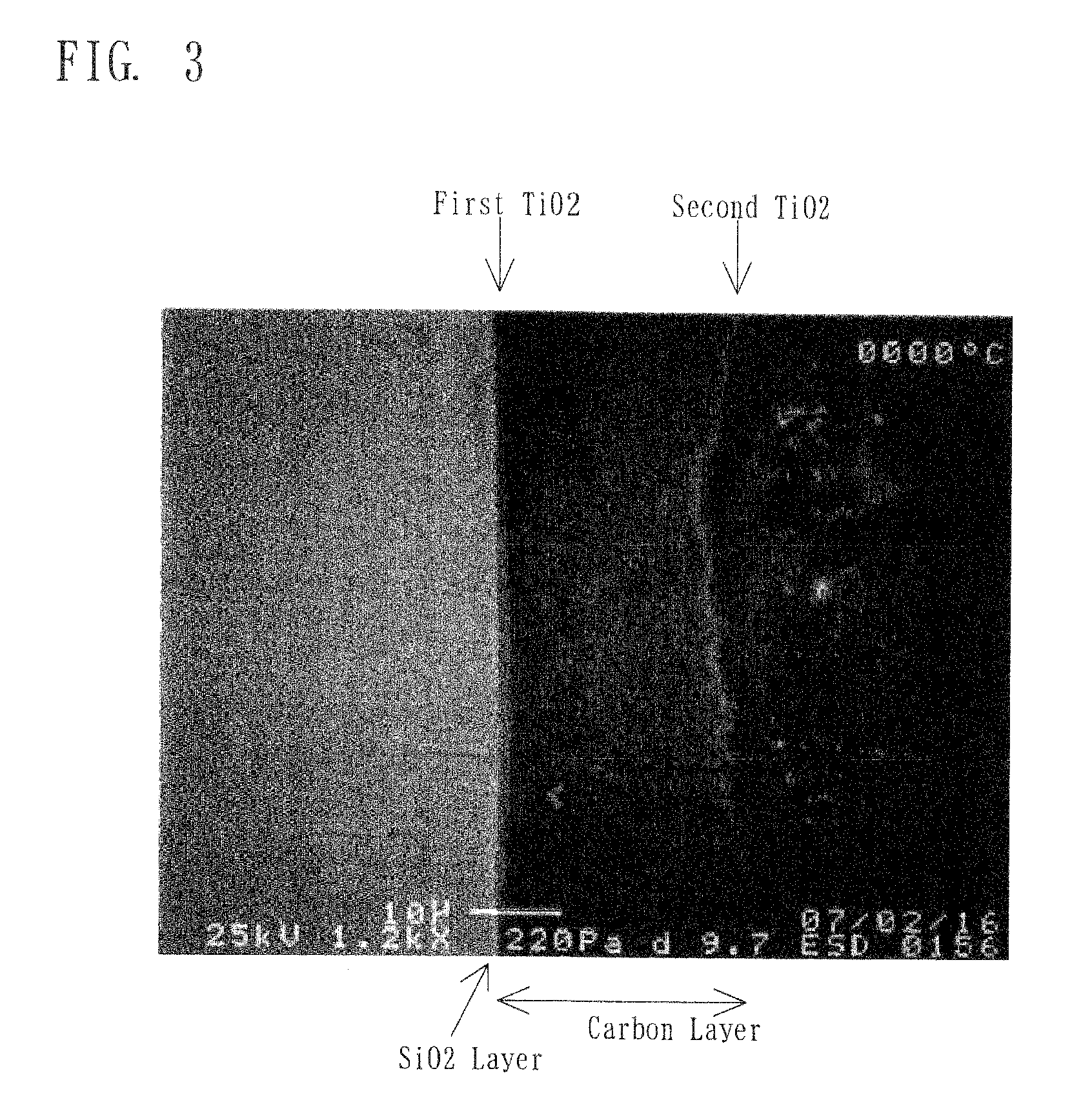

Sulfidation Corrosion Preventing Method, Sulfidation Corrosion-Resistant High Temperature Member and Heat Exchanger Tube Repairing Method

InactiveUS20100233483A1Excellent sulfidation corrosion resistanceIncreased durabilityLaminationPretreated surfacesCarbon layerTitanium metal

A sulfidation corrosion preventing method for protecting a substrate from sulfidation corrosion, a sulfidation corrosion-resistant high temperature member having excellent sulfidation corrosion resistance, and a method for repairing a heat exchanger tube having cracks are disclosed. A silicon oxide layer is formed on a surface of a substrate; a titanium-containing coating fluid containing a titanium metal or a titanium compound is coated on the silicon oxide layer, heated and oxidized to form a first titanium oxide layer; a carbon layer is formed on a surface of the first titanium oxide layer; and a titanium-containing coating fluid is coated on the carbon layer, heated and oxidized to form a second titanium oxide layer. The substrate is protected or repaired with the silicon oxide layer, the first titanium oxide layer, the carbon layer, and the second titanium oxide layer.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

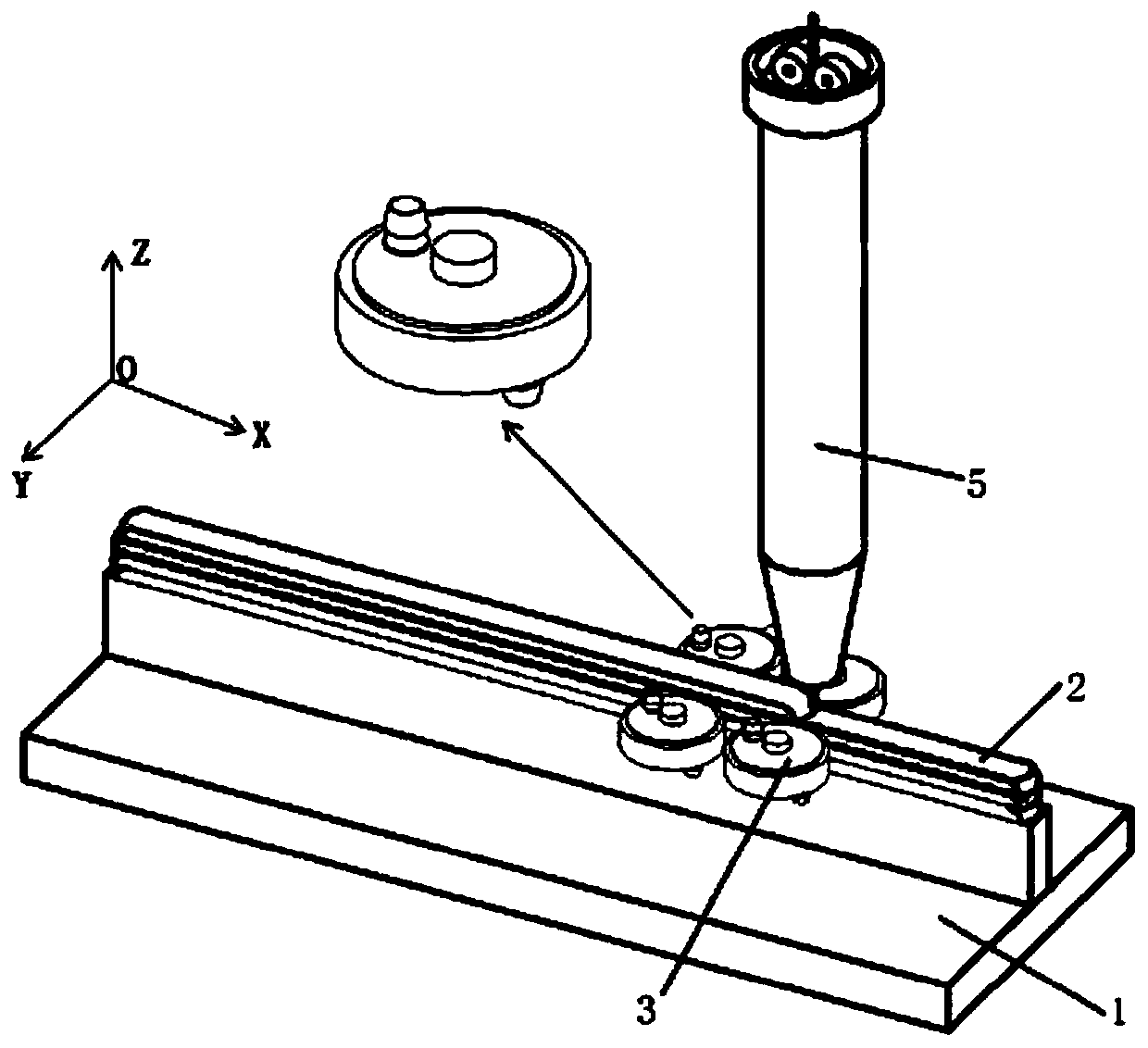

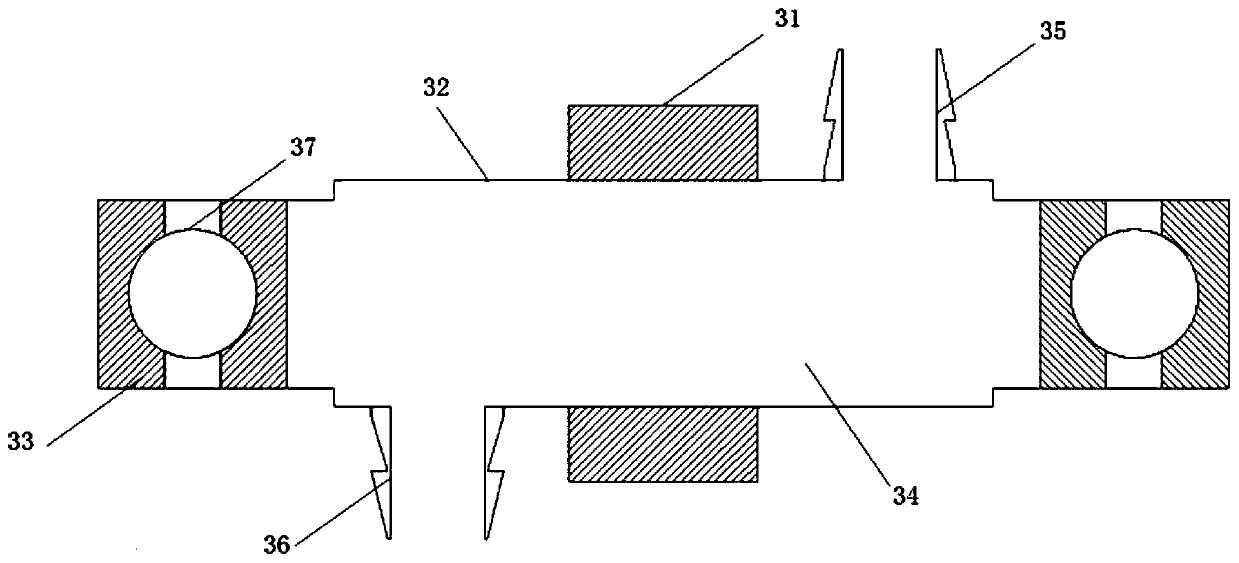

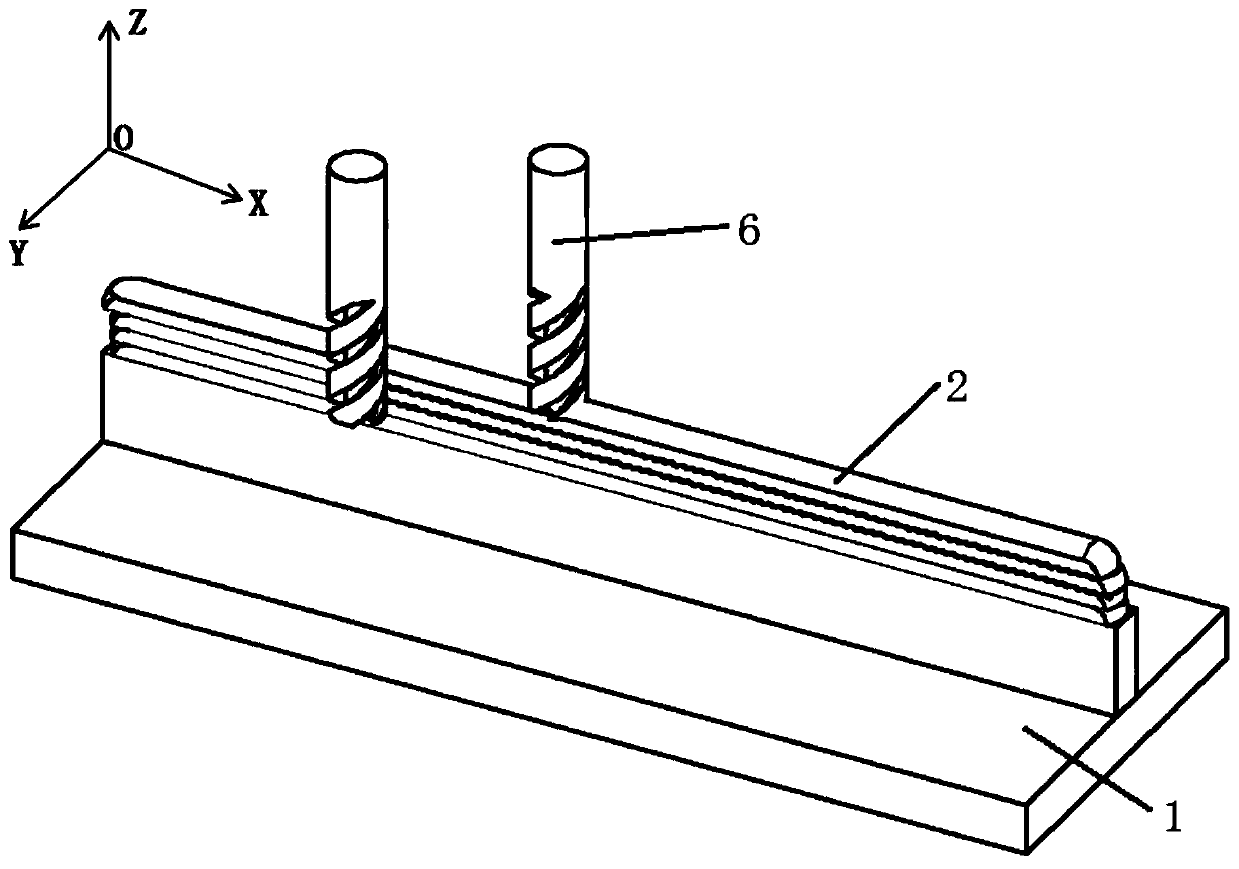

Wire arc additive manufacturing method of Al-Mg-Si alloy

ActiveCN109807562ARepair defects such as pores and cracksAvoid overheatingCrystalliteMachining process

The invention discloses a wire arc additive manufacturing method of Al-Mg-Si alloy. The wire arc additive manufacturing method of Al-Mg-Si alloy comprises the following steps that firstly, cooling rolling is used for assisting in arc additive forming; secondly, milling is carried out on the side face and the top face of an additional material body; thirdly, a friction stir machining device is usedfor carrying out friction stir machining on the additional material body, meanwhile, in the friction stir machining process, a cooling rolling device is used for exerting cooling rolling on the sidewall of the additional material body; fourthly, finish milling is carried out on the upper surface of the additional material body for preparing of arc additive forming of the next step; fifthly, theabove steps are circularly and repeatedly executed until the final forming of the part is finished. Dendritic growth and grain refining in the Al-Mg-Si alloy additive forming process can be completelybroken, defects of air holes, cracks and the like can be effectively overcome, meanwhile, in the wire arc additive manufacturing and the modification process thereof, cooling is applied, the problemsof additional material body overheating and microstructure coarsening caused by overheating can be solved, and the mechanical property, particularly, plasticity and fatigue properties, of the addition material body can be greatly improved.

Owner:NORTHEASTERN UNIV

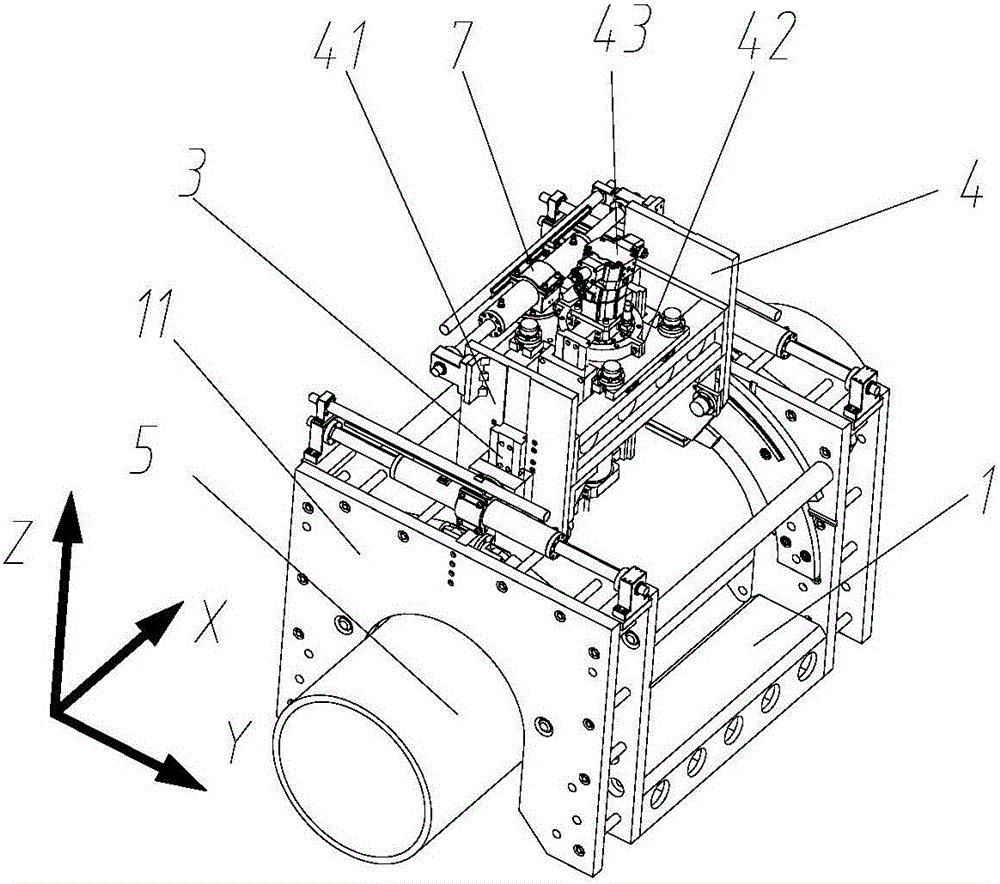

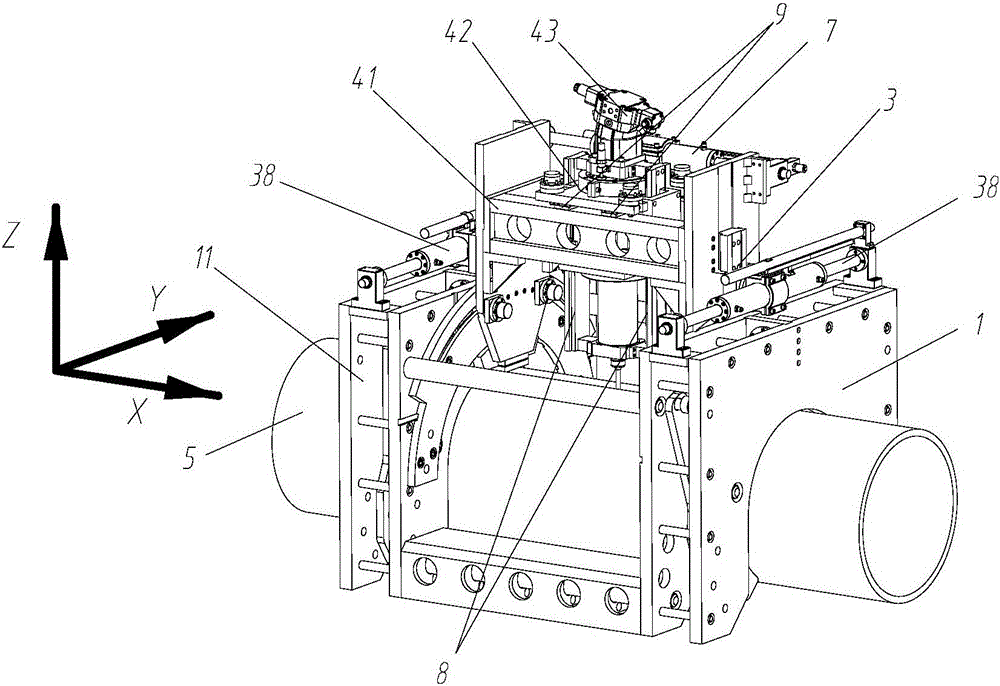

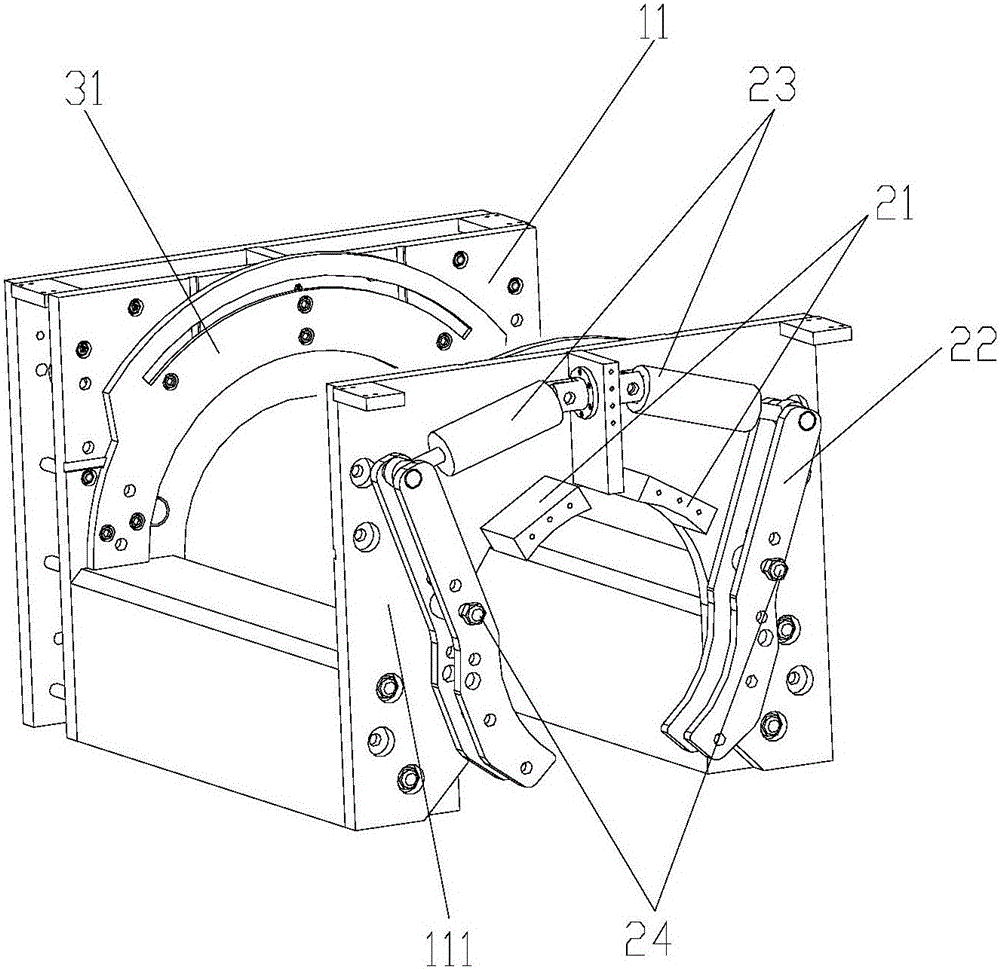

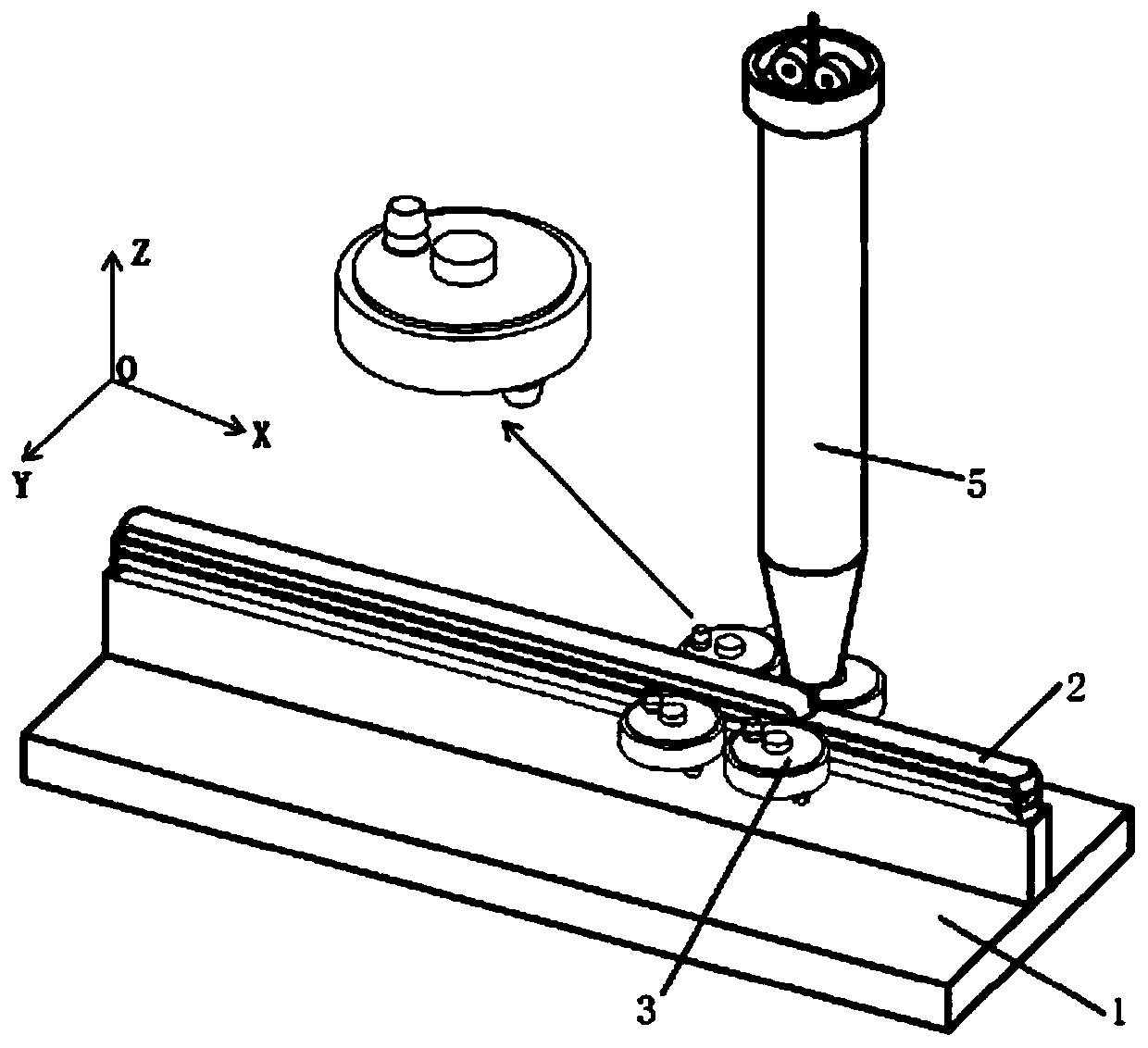

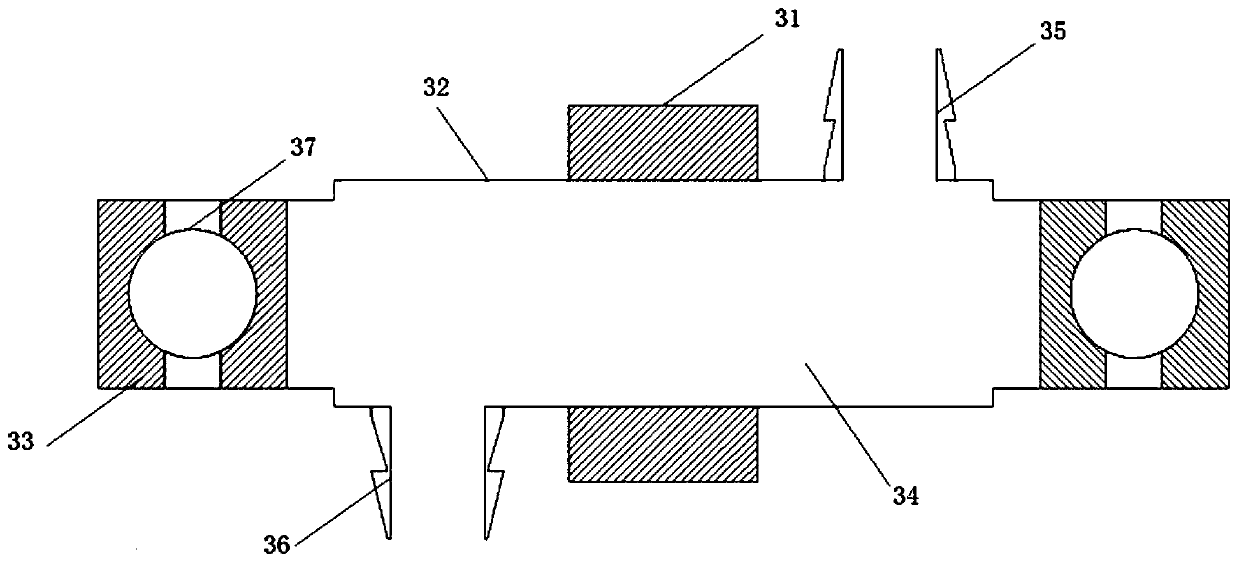

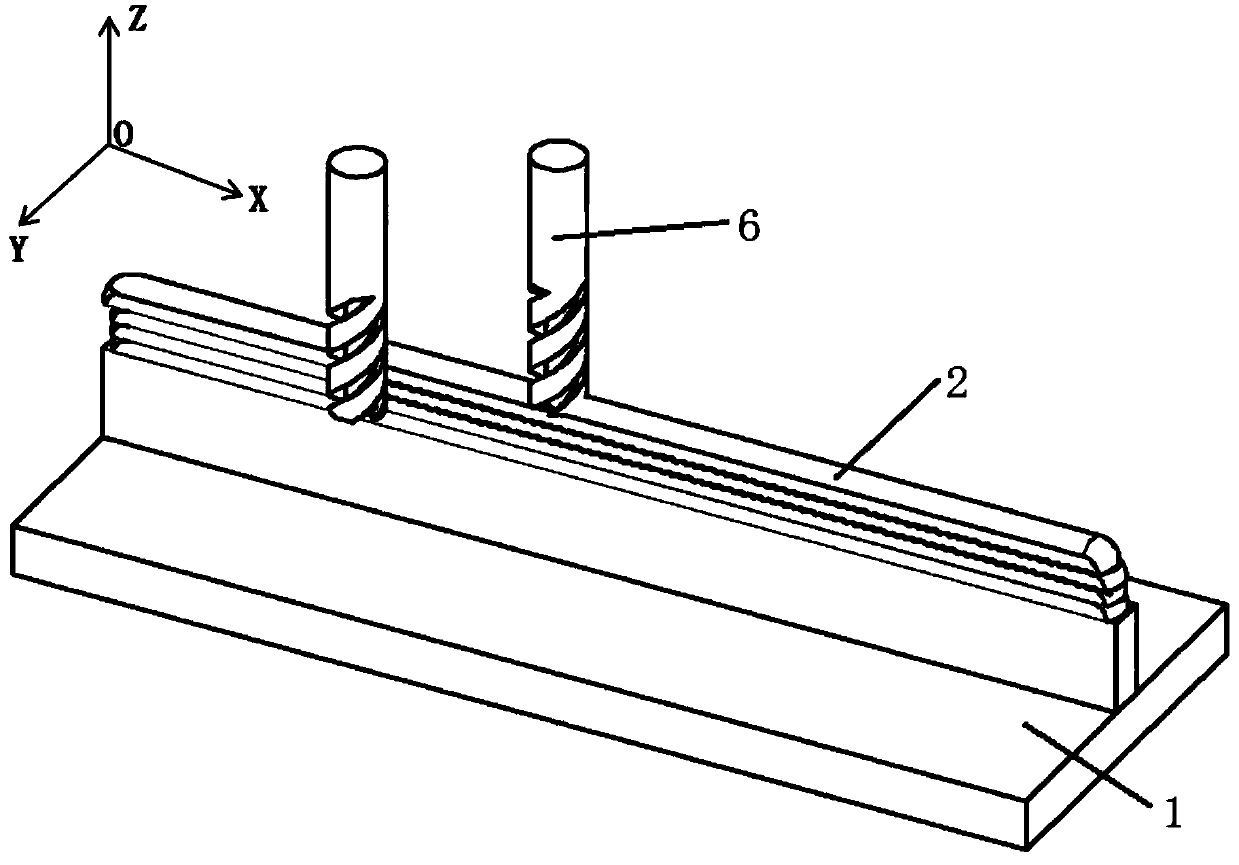

Crossbeam fixing type all-hydraulic driving digital-control friction stitch welding machine with large operating space

ActiveCN106077943AIncrease distanceLarge operating spaceNon-electric welding apparatusHydraulic motorHydraulic cylinder

The invention discloses a crossbeam fixing type all-hydraulic driving digital-control friction stitch welding machine with a large operating space. The crossbeam fixing type all-hydraulic driving digital-control friction stitch welding machine comprises a machine frame, a clamping mechanism, a circumferential moving mechanism and a welding device, wherein the clamping mechanism, the circumferential moving mechanism and the welding device are connected to the machine frame; the welding device comprises a welding bracket, a main shaft mounting frame and a main shaft; the welding bracket comprises a left side plate II and a right side plate II which are symmetrical; the two side plates II are fixedly connected together through a front crossbeam and a rear crossbeam; a framework structure is formed by the two crossbeams, the left side plate II, and the right side plate II; the main shaft mounting frame is in sliding connection to the welding bracket; the main shaft is mounted in the main shaft mounting frame, and comprises a main shaft dual-action hydraulic cylinder and a welding shaft; the main shaft dual-action hydraulic cylinder comprises a cylinder barrel fixed to the main shaft mounting frame; a barrel-shaped piston is arranged in the cylinder barrel of the main shaft dual-action hydraulic cylinder; the welding shaft is arranged in the piston in a supporting manner; the upper end of the welding shaft is connected with a hydraulic motor through a coupling; the hydraulic motor is fixed on the upper end of the piston; and a stopper rod is fixedly connected to the lower end of the welding shaft. The crossbeam fixing type all-hydraulic driving digital-control friction stitch welding machine disclosed by the invention is large in operating space and large in working range.

Owner:TIANJIN UNIV

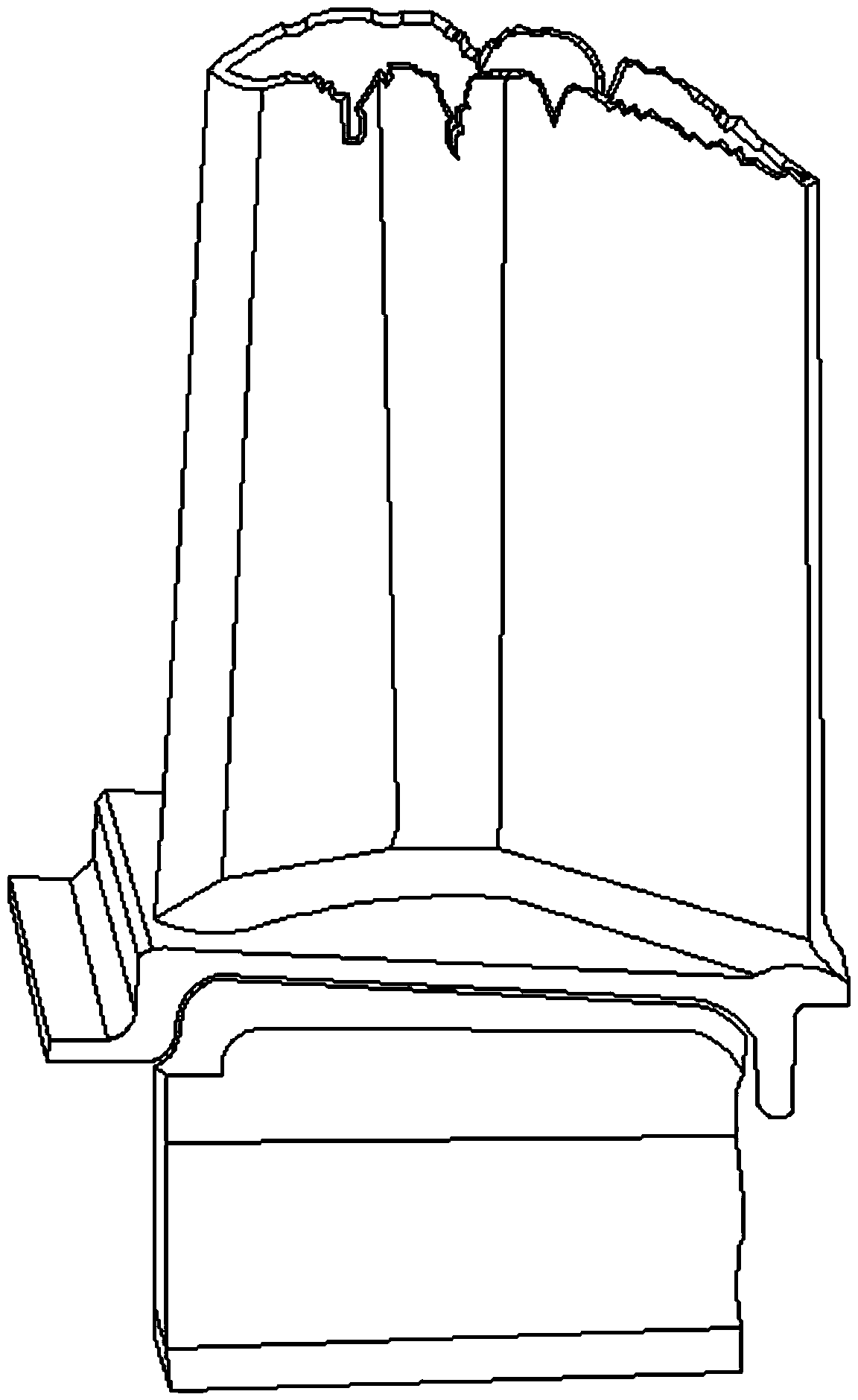

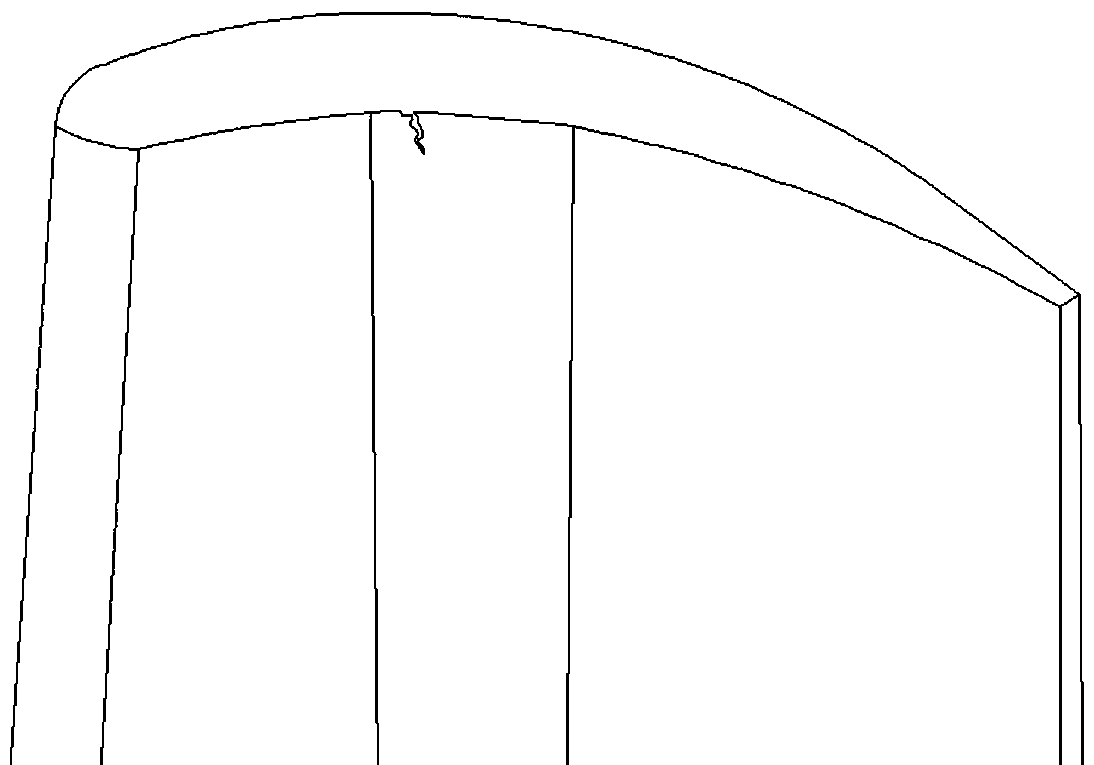

Integral repair method for longitudinal intensive damage of blade crown of aero-engine turbine rotor blade

InactiveCN110202158AReduce the difficulty of operationAvoid crack regenerationAdditive manufacturing apparatusIncreasing energy efficiencyRepair materialNondestructive testing

The invention discloses an integral repair method for the longitudinal intensive damage of a blade crown of an aero-engine turbine rotor blade. The integral repair method for the longitudinal intensive damage of the blade crown of the aero-engine turbine rotor blade comprises the following steps of firstly mechanically grinding the blade, integrally removing a damaged blade crown, adopting laser for repairing cracks under a casting cover plate, and fixing a blade tip cover plate onto the blade crown of the blade; then adopting an integral type laser solid forming technology for integrally forming the blade crown, manually processing a formed blade crown surface, and recovering a runner type surface; and finally, carrying out nondestructive testing on the repaired turbine blade, and puttinginto use after the blade meets a criterion. According to the integral repair method for the longitudinal intensive damage of the blade crown of the aero-engine turbine rotor blade provided by the invention, the integral repairing method is adopted, so that not only is degradation material removed thoroughly, but also the one-by-one repair process is avoided, and the workload is reduced; and meanwhile, through using a special repair material, a combination property of the crown material is improved.

Owner:PLA NO 5719 FACTORY

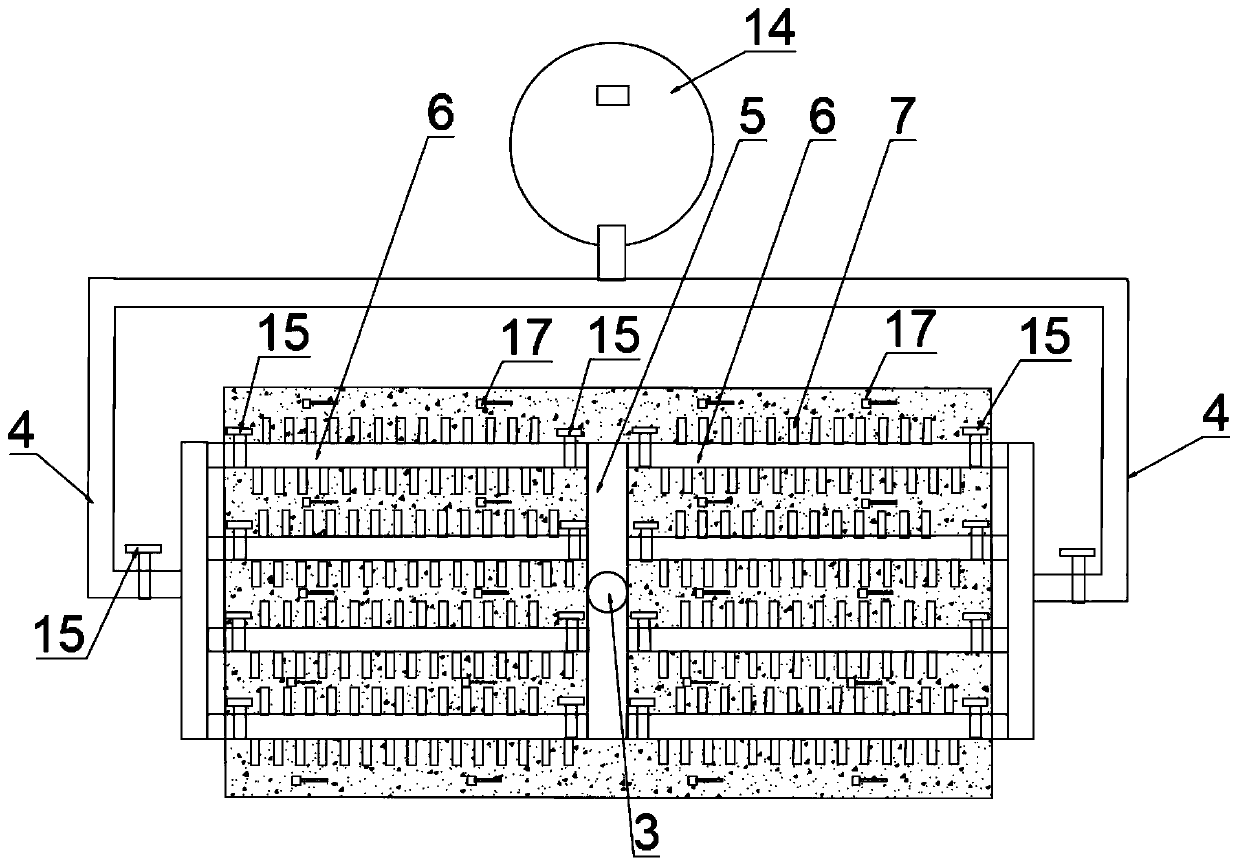

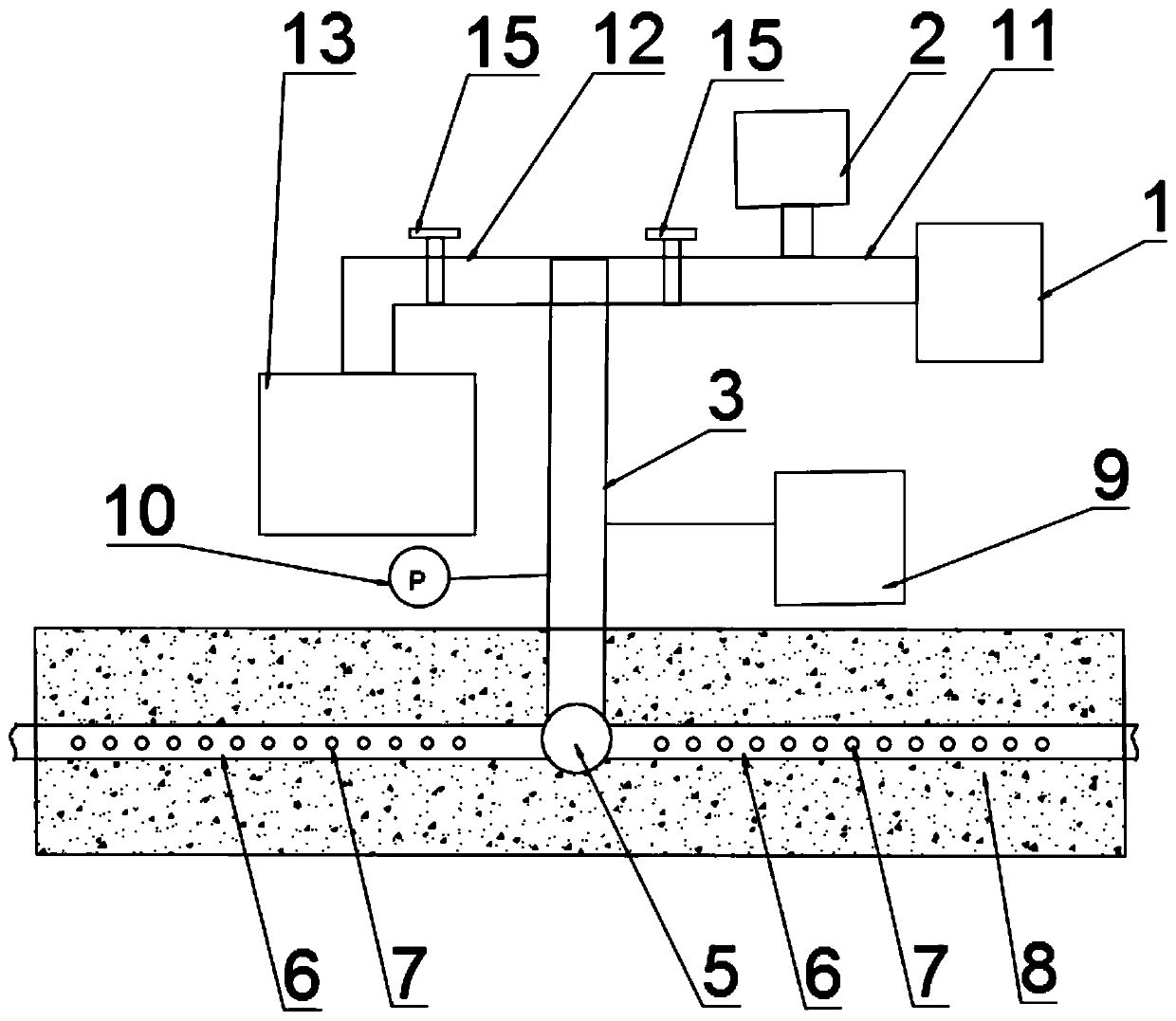

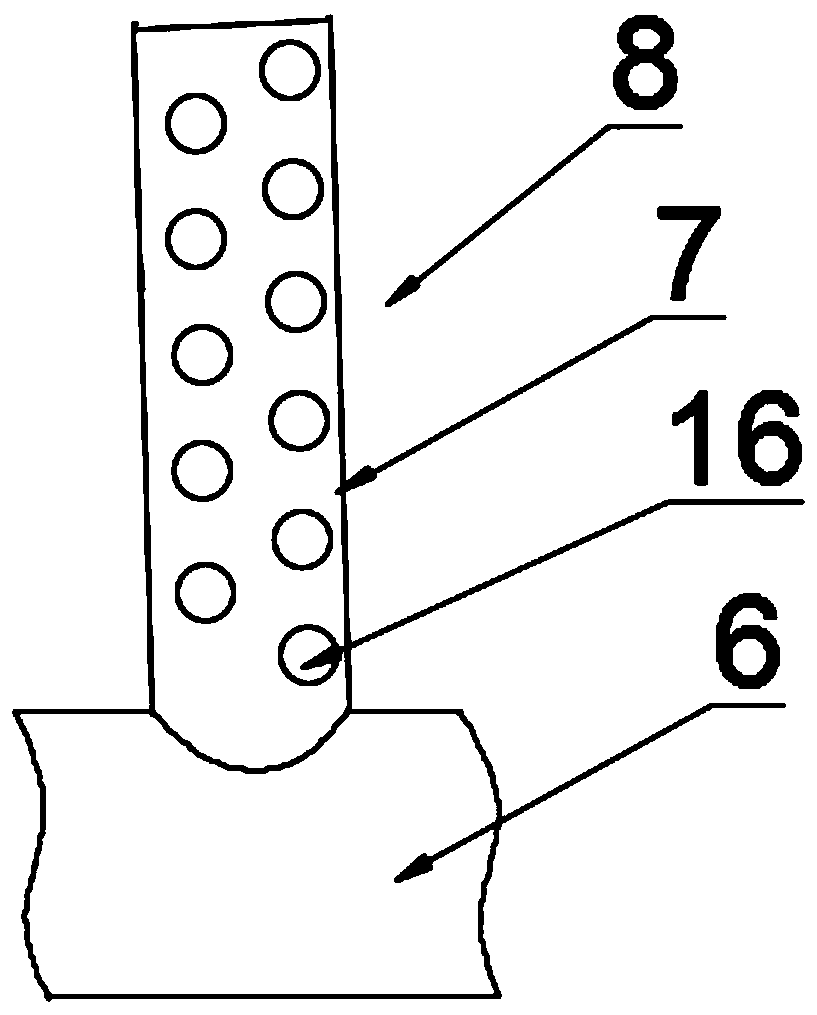

Cooling, moisturizing and grouting integrated device and method for mass concrete

The invention relates to a cooling, moisturizing and grouting integrated device and method for mass concrete. The device comprises an air refrigerator, an atomizer and a cold air pipeline. The cold air pipeline comprises an air inlet pipe, an air outlet pipe and a cold air buried pipe pre-buried in concrete. The cold air buried pipe comprises a cold air main pipe, cold air branch pipes and cold air branch pipes. A pressurizing device and a pressure gauge are arranged on the air inlet pipe, and the air inlet pipe is connected with the low-temperature atomization channel and the superfine cementpaste grouting channel through a three-way pipe; the air outlet pipe is connected with the recovery tank; the two sides of the pipeline of each cold air branch pipe are connected with a plurality ofcold air branch pipes, and a plurality of vent holes are formed in the cold air branch pipes. According to the integrated device, the interior of concrete can be subjected to cooling and moisturizingmaintenance at the same time, the internal stress is greatly reduced, temperature shrinkage and drying shrinkage are reduced, and cracks are reduced; and grouting treatment can be performed to repaircracks in concrete.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

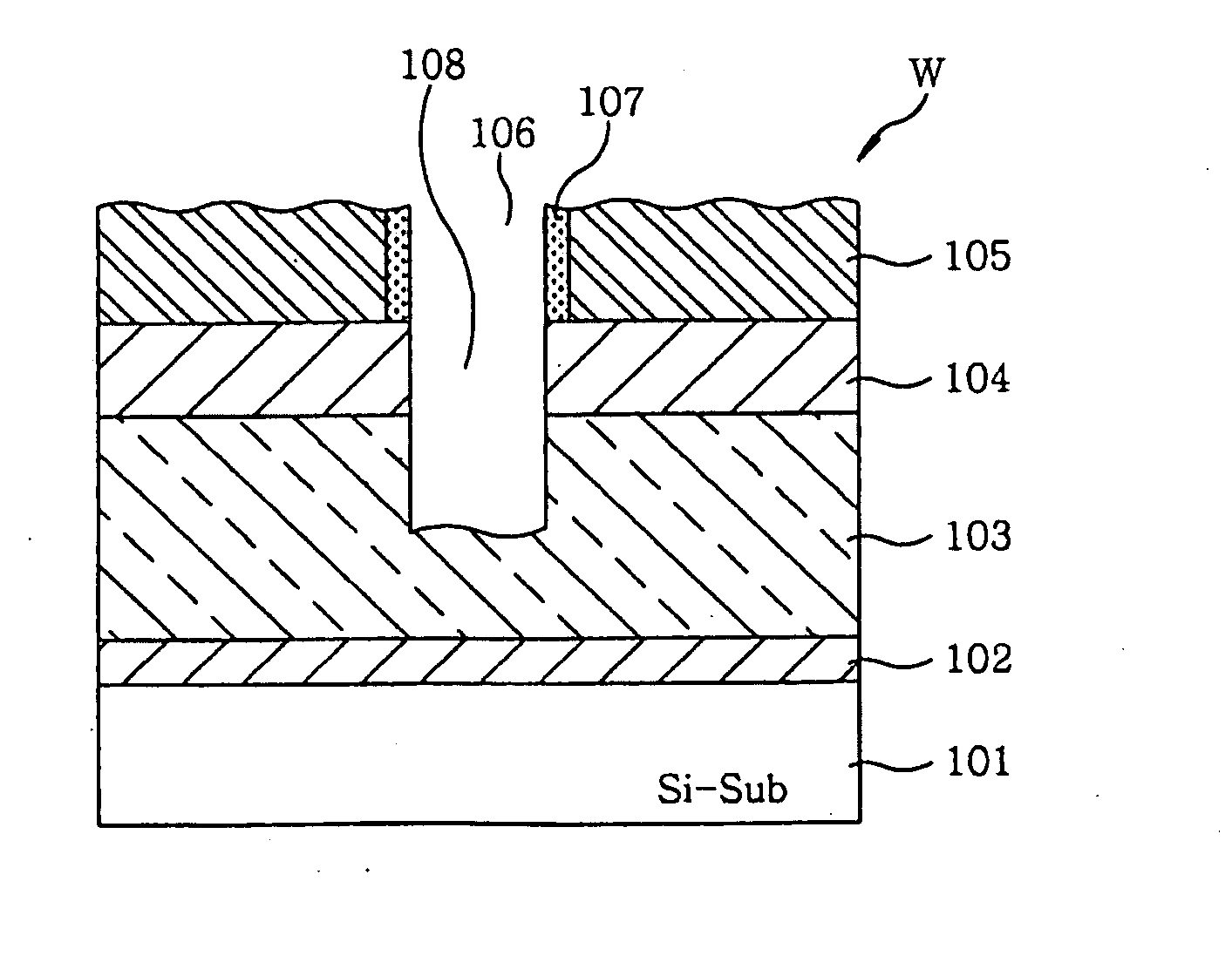

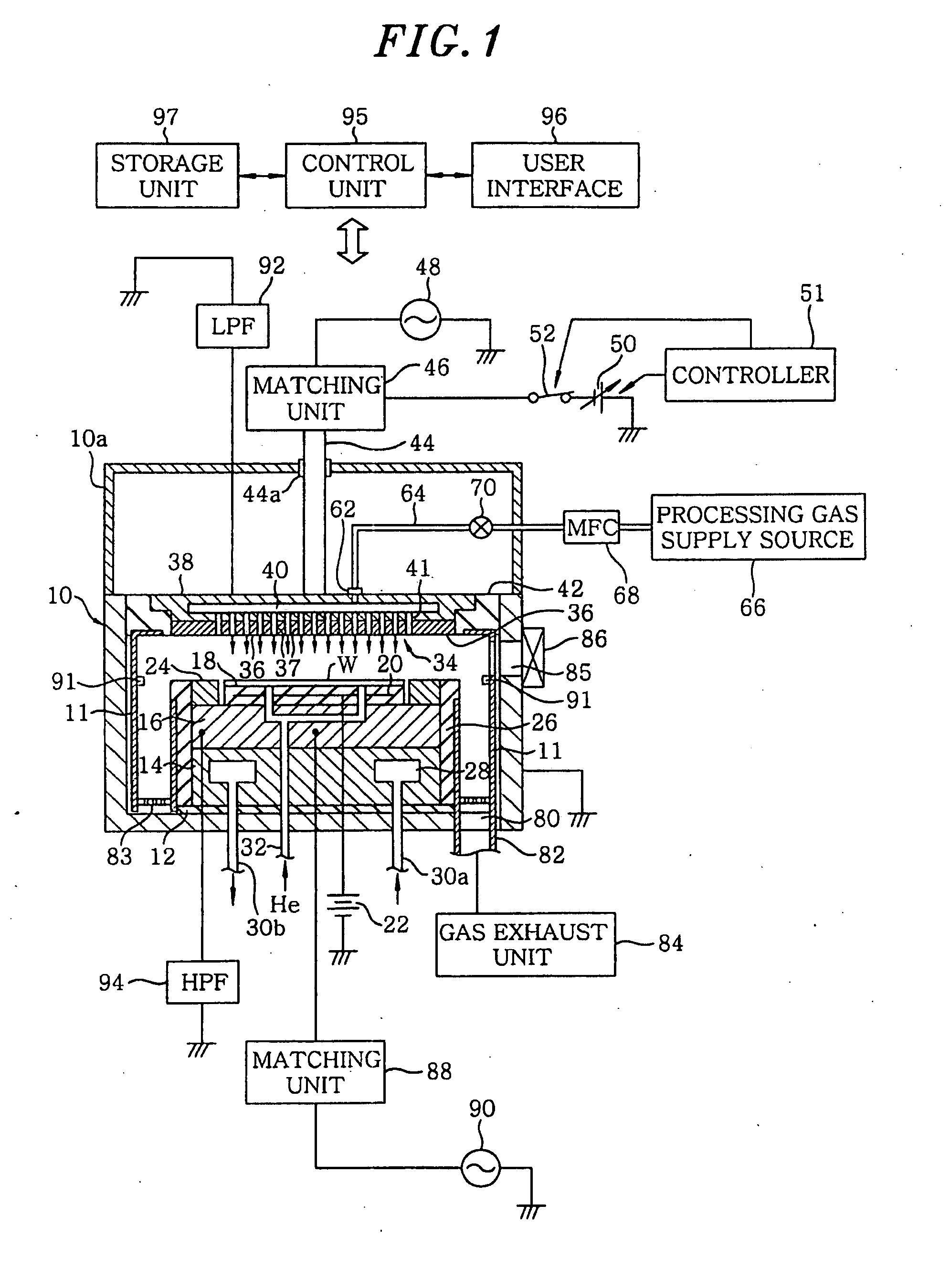

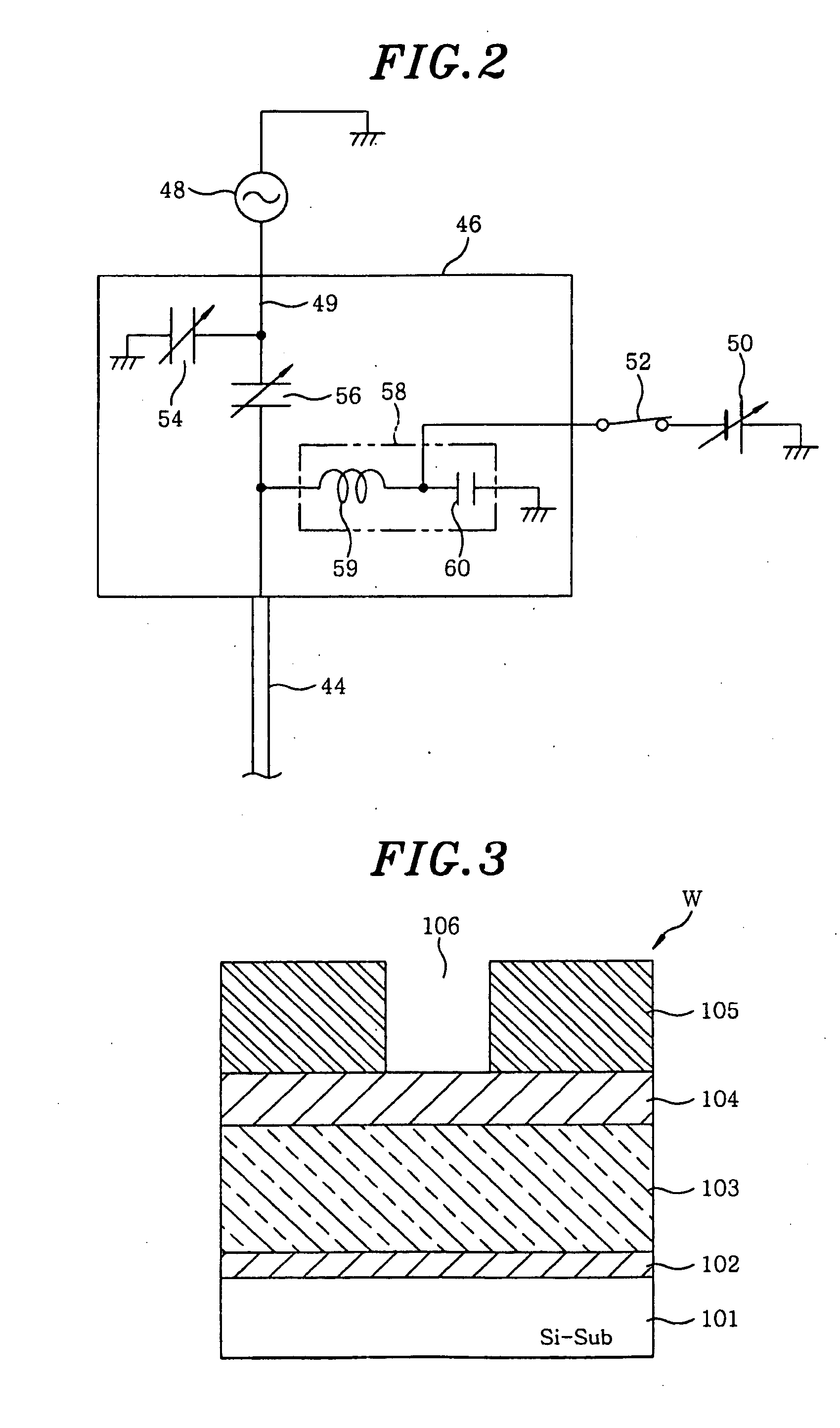

Plasma etching method, plasma etching apparatus and storage medium

InactiveUS20090029557A1Reduced opening sizeImprove surface conditionElectric discharge tubesSemiconductor/solid-state device manufacturingResistHigh frequency power

A plasma etching method plasma-etches an etching target film by using a photoresist film as a mask. The plasma etching method includes loading a target object to be processed into a processing chamber where an upper and a lower electrode are provided to face each other, the target object having the etching target film and the photoresist film in which an opening is formed; introducing into the processing chamber a processing gas containing CF4 gas, CH2F2 gas and CxFy gas, wherein x / y≧0.5; and generating a plasma of the processing gas by applying a high frequency power to at least one of the upper and the lower electrode. The method further includes, by the plasma, etching the etching target film introduced through the opening formed in the photoresist film while reducing the opening size the opening.

Owner:TOKYO ELECTRON LTD

Emulsified asphalt cold paving material

The invention discloses an emulsified asphalt cold paving material and belongs to the technical field of road engineering. The emulsified asphalt cold paving material is made by stirring and mixing linseed oil with a gelatin liquid according to a volume ratio of (1:20)-(1:30); further stirring and mixing with a sodium sulfate solution which is 5-8 times the volume of the gelatin liquid; cooling; further adding a formaldehyde solution which is 1-2 times the volume of the linseed oil; adjusting the pH value; leaving to stand to cure, filtering, and drying so as to obtain modified microcapsules;crushing steel slag, and screening so as to obtain steel slag powder; performing a stirring reaction on the steel slag powder with hydrochloric acid in a mass ratio of (1:30)-(1:50), filtering, and drying so as to obtain modified steel slag powder; by stirring and mixing asphalt, an emulsifier, aggregate, coated sodium peroxide, carbomer, the modified capsules, the modified steel slag powder and water, thereby obtaining the emulsified asphalt cold paving material. The emulsified asphalt cold paving material disclosed by the technical scheme of the invention has the characteristics of excellentmechanical properties, water resistance and flowability.

Owner:CHANGZHOU SIYU ENVIRONMENTAL PROTECTION MATERIAL SCI & TECH

Whitening tooth patch containing photocatalyst and preparation process of whitening tooth patch

InactiveCN110302065AGood biocompatibilityAchieve whitening effectCosmetic preparationsToilet preparationsPeroxideTooth hypersensitivity

The invention relates to a whitening tooth patch containing a photocatalyst and a preparation process of the whitening tooth patch, belongs to the technical field of oral care products, and aims to solve the problems that existing tooth patches use peroxide, easily cause tooth hypersensitivity and is uneven in whitening effect, poor in durability and inconvenient to use, and the packages of the tooth patches are not environmentally friendly. The whitening tooth patch comprises nano titanium dioxide, bioactive glass, acrylate / polyoxyethylene-20 octadecanol ether methyl acrylate copolymer, gel and a moisturizing agent. The whitening tooth patch has the advantages that the nano titanium dioxide is used as the photocatalyst to play a whitening role; the bioactive glass improves tooth color brightness, and the nano titanium dioxide can be attached to the surface of the teeth along with the bioactive glass to generate a continuous whitening effect; the nano titanium dioxide and the bioactiveglass are evenly dispersed in the gel substrate to achieve an even whitening effect; the whitening tooth patch is prepared into a roll shape and can be cut at will during use, the whitening tooth patch is packaged through a self-sealing zipper bag, packaging cost is lowered, and environment protection is achieved.

Owner:四川涑爽医疗用品股份有限公司

Functional crystallization master batch and preparation method thereof and waterproof material

InactiveCN102863170AImprove self-healing performanceImprove anti-re-pressure penetration functionNanotechnologyCalcium carbonateMethyl cellulose

The invention provides a functional crystallization master batch, a preparation method thereof and a waterproof material and belongs to the field of inorganic materials. The functional crystallization master batch is composed of a nanoscale calcium carbonate aluminum oxide composite powder body and chelated titanate. The preparation method includes preparing and mixing calcium carbonate powders and the nanoscale calcium carbonate aluminum oxide composite powder body. The waterproof material is composed of, by weight, 6-8% of the functional crystallization master batch, 4-6% of methyl cellulose thickening agents, 2-4% of anhydrous citric acids retarders, 25-35% of finely grinding quartz sands, and the balance cements. The functional crystallization master batch has excellent crystallization performance and usage performance, the preparation method is simple, low in production cost, safe in operation and suitable for industrial production, and the waterproof material has excellent impermeability pressure, compression strength and rupture strength.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

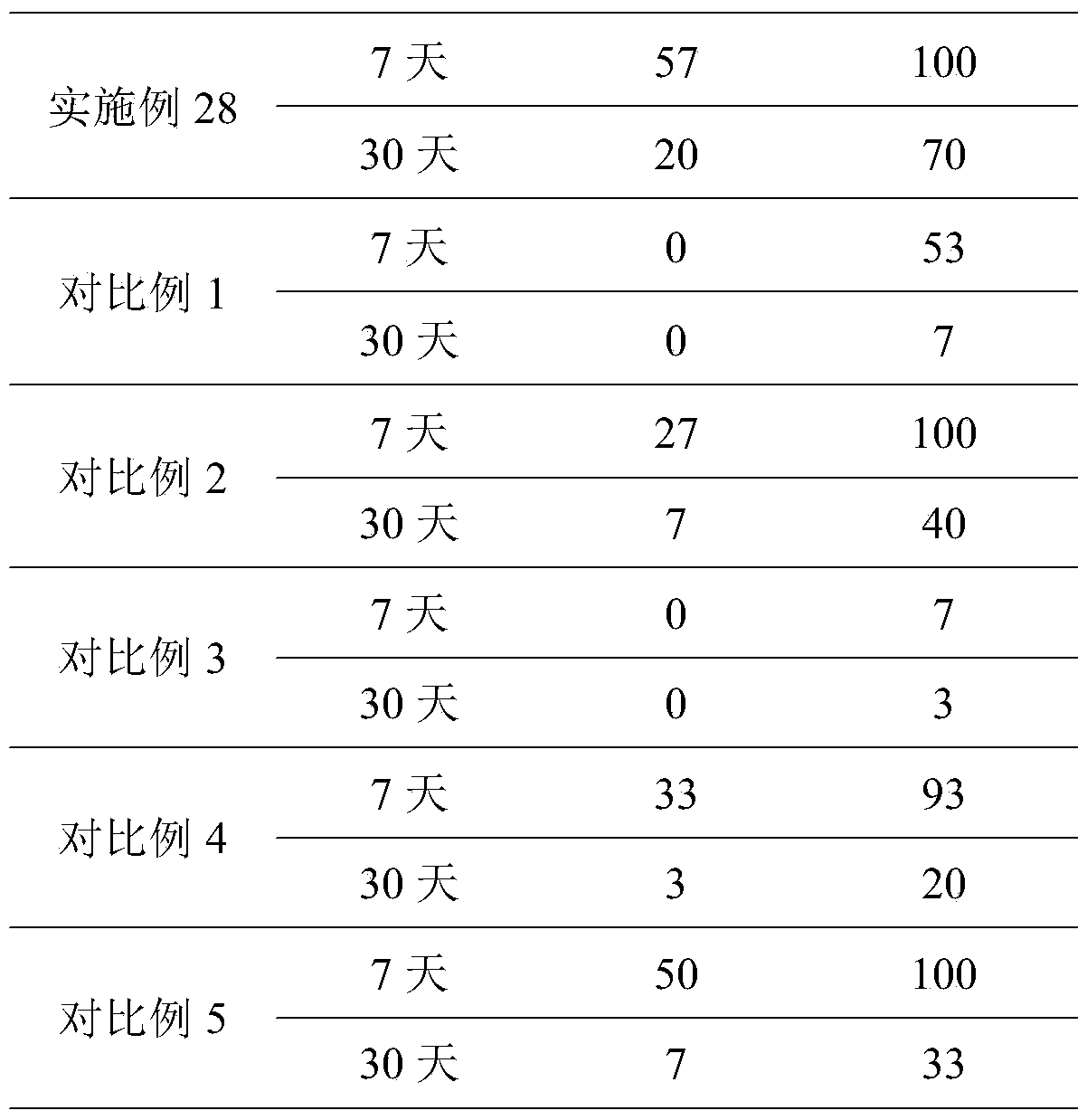

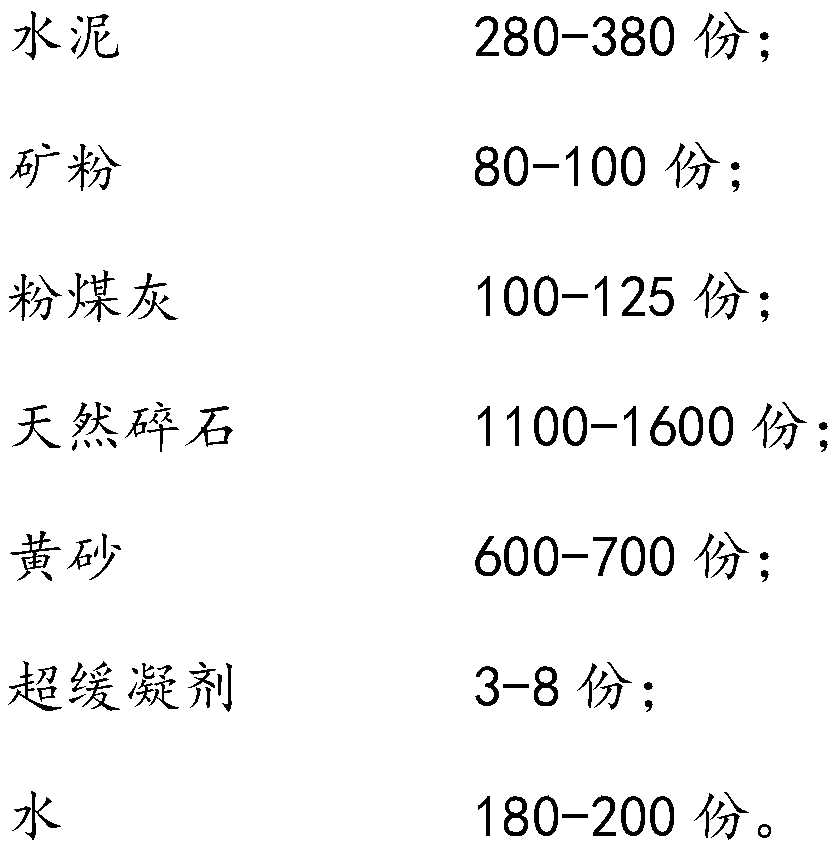

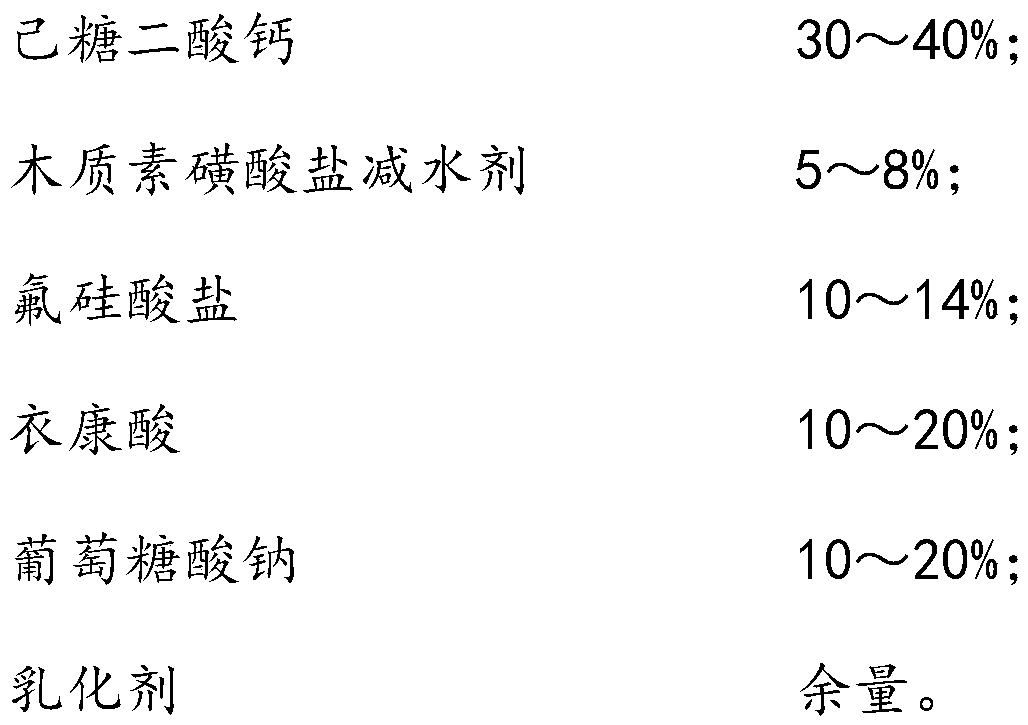

Super retarded concrete

The invention discloses super retarded concrete, and relates to the technical field of concrete, and the super retarded concrete comprises the following raw materials in parts by weight: 280-380 partsof cement, 80-100 parts of mineral powder, 100-125 parts of fly ash, 1100-1600 parts of natural macadam, 600-700 parts of yellow sand, 3-8 parts of an ultra-retarding agent and 180-200 parts of water. The preparation method has the advantages that the initial setting time of the concrete is prolonged, and the strength of the concrete is improved.

Owner:四川信敏绿色新建筑材料科技有限公司

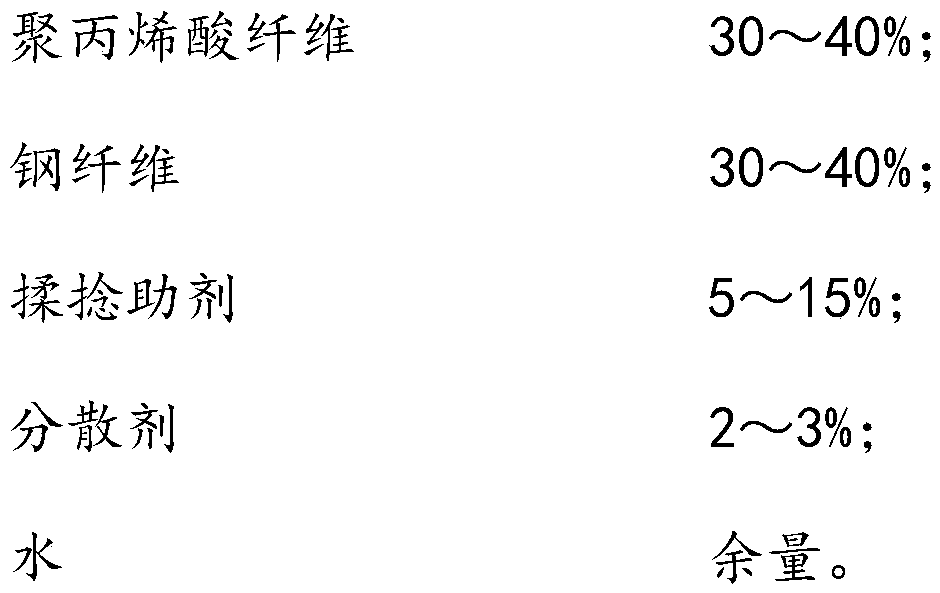

Self-repairing reinforcing material for optical cable, and preparation method thereof

ActiveCN109270646AImprove mechanical propertiesImprove heat resistanceFibre mechanical structuresEpoxyOligomer

The invention discloses a self-repairing reinforcing material for an optical cable. The self-repairing reinforcing material comprises a base material and a resin layer on the surface of the base material. The resin layer comprises the following raw materials in parts by weight: 80-100 parts of epoxy resin, 10-20 parts of an amide oligomer, 30-40 parts of self-repairing polyurethane, and 1-2 partsof a catalyst, wherein the amide oligomer is obtained by reacting dimer acid with diethylenetriamine. The invention further discloses a preparation method of the self-repairing reinforcing material for the optical cable. According to the self-repairing reinforcing material and the preparation method, the substrate and the resin layer are compounded, the resin layer adopts the epoxy resin as a mainmaterial, the self-repairing polyurethane is combined to improve the toughness and the self-repairing property of the reinforcing material, and the addition of the amide oligomer and the catalyst promotes the self-repairing reaction of the polyurethane, and the self-repairing effect is greatly improved.

Owner:安徽牡东通讯光缆有限公司

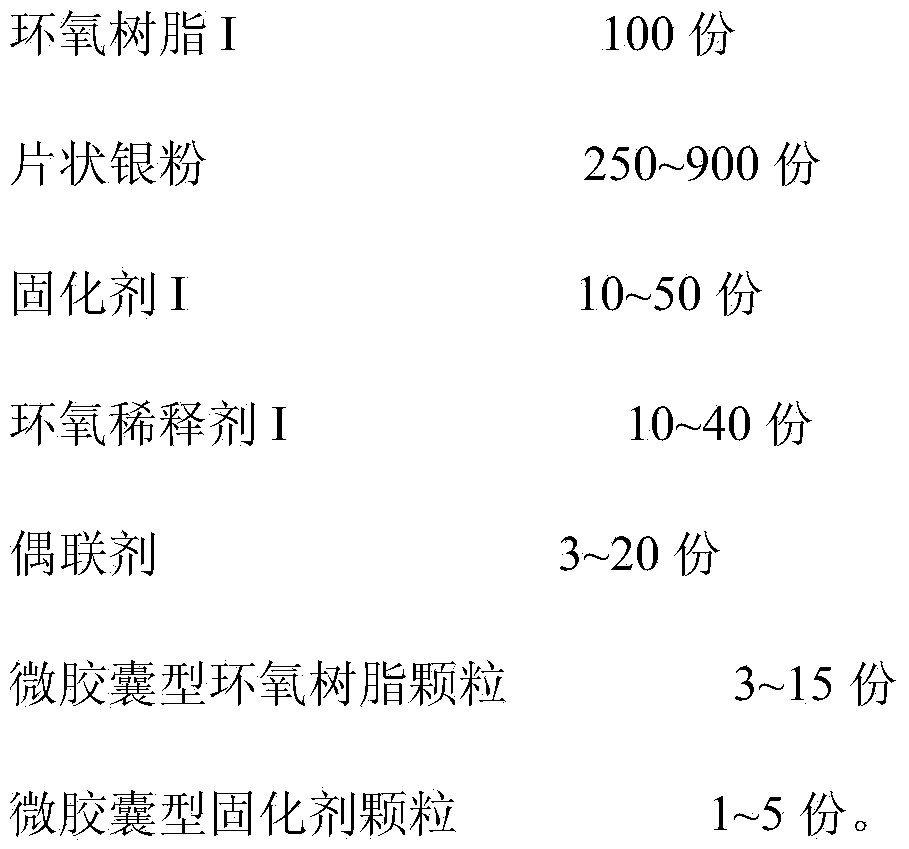

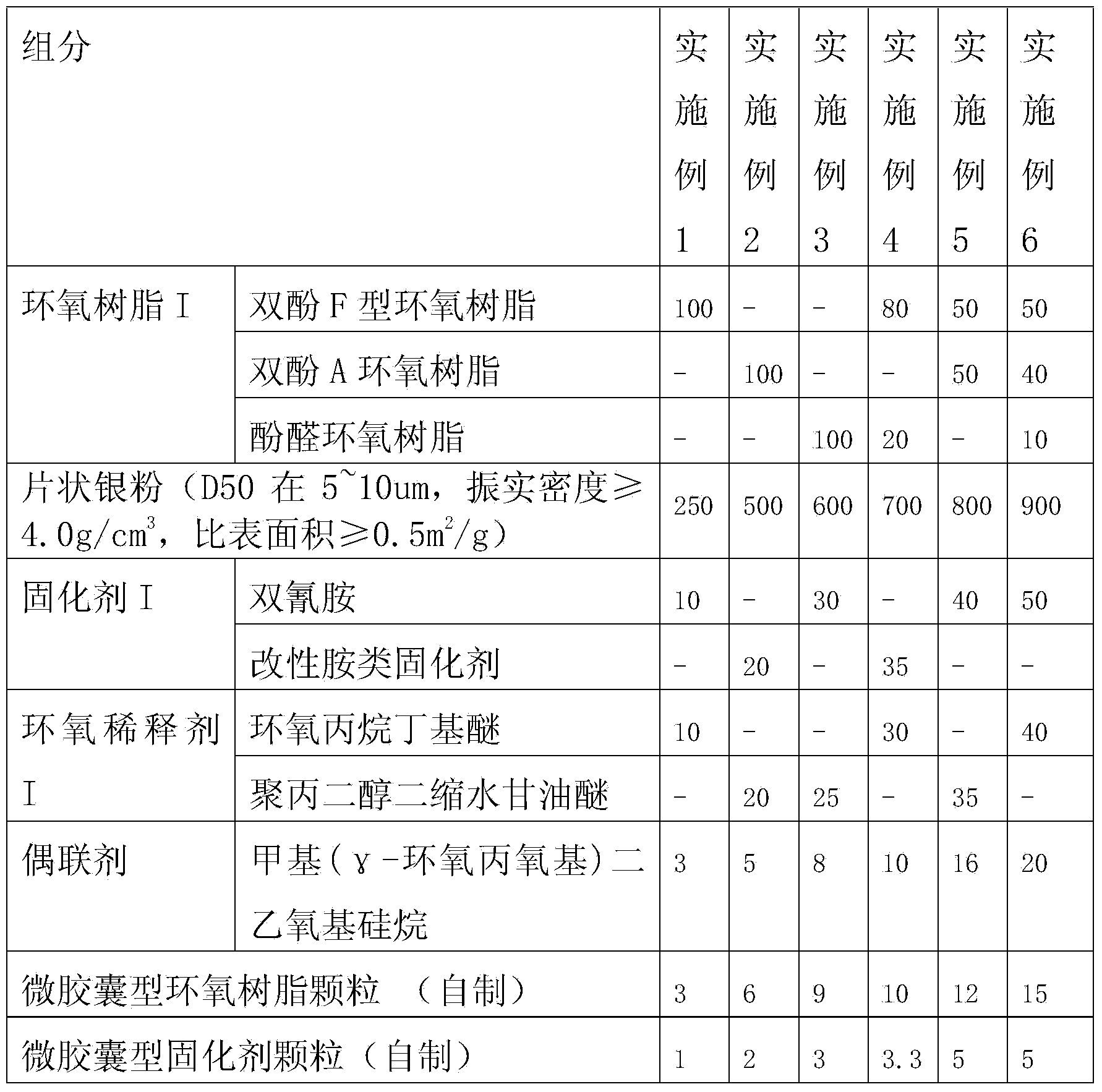

Double-microcapsule-component conductive adhesive

ActiveCN103666317AExtended service lifeRepair crackEpoxynovolac adhesivesMicroballoon preparationEpoxyAdhesive

The invention relates to a double-microcapsule-component conductive adhesive which comprises the following components in parts by weight: 100 parts of epoxy resin I, 250-900 parts of flaky silver powder, 10-50 parts of curing agent I, 10-40 parts of epoxy diluter I, 3-20 parts of coupling agent, 3-15 parts of microcapsule type epoxy resin granule and 1-5 parts of microcapsule type curing agent granule. After cracking, the conductive adhesive can be restored, thereby having long service life. Epoxy resin II, curing agent II and the like for curing cracks are respectively stored in the double microcapsule components and are separated from each other, so that the components can not be subjected to curing reaction before cracking, thus ensuring that the curing agent II and the epoxy resin II can not be tackified with time, ensuring that the double microcapsule components have permanent restoration effect, and reducing the requirements for conductive adhesive coated substrates. Besides, the main body component epoxy resin I of the conductive adhesive dose not need to be excessive, thus ensuring that the cured conductive adhesive has favorable mechanical property.

Owner:JIANGSU RUIDE NEW ENERGY TECH

Al-Zn-Mg-Cu alloy wire and arc additive manufacturing method

The invention provides an Al-Zn-Mg-Cu alloy wire and arc additive manufacturing method. The manufacturing method comprises the following steps of (1) conducting arc additive forming through cooling and rolling assistance; (2) conducting milling on the side face and the top face of an additive material body; (3) conducting friction stir processing on the additive material body through friction stirprocessing equipment and conducting cooling and rolling on the sidewalls of the additive material body through a cooling and rolling device during friction stir processing; (4) conducting finish milling on the upper surface of the additive material body to make preparation for the next step of arc additive forming; and (5) cyclically repeating the above steps until final forming of a part is completed. Through the Al-Zn-Mg-Cu alloy wire and arc additive manufacturing method, dendritic growth and grain refinement in the Al-Zn-Mg-Cu alloy additive forming process can be completely abolished, and the deficiencies such as pores and cracks are effectively repaired; meanwhile, during the wire and arc additive manufacturing and modifying process, microstructure roughening caused by overheat of the additive material body is prevented through cooling, and the mechanical performance, especially plasticity and fatigue performance, of the additive material body is greatly improved.

Owner:NORTHEASTERN UNIV

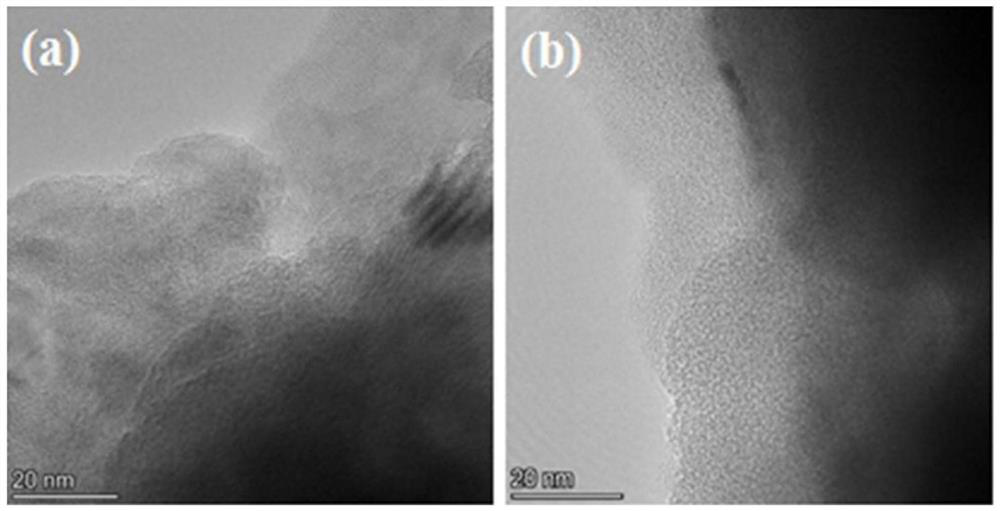

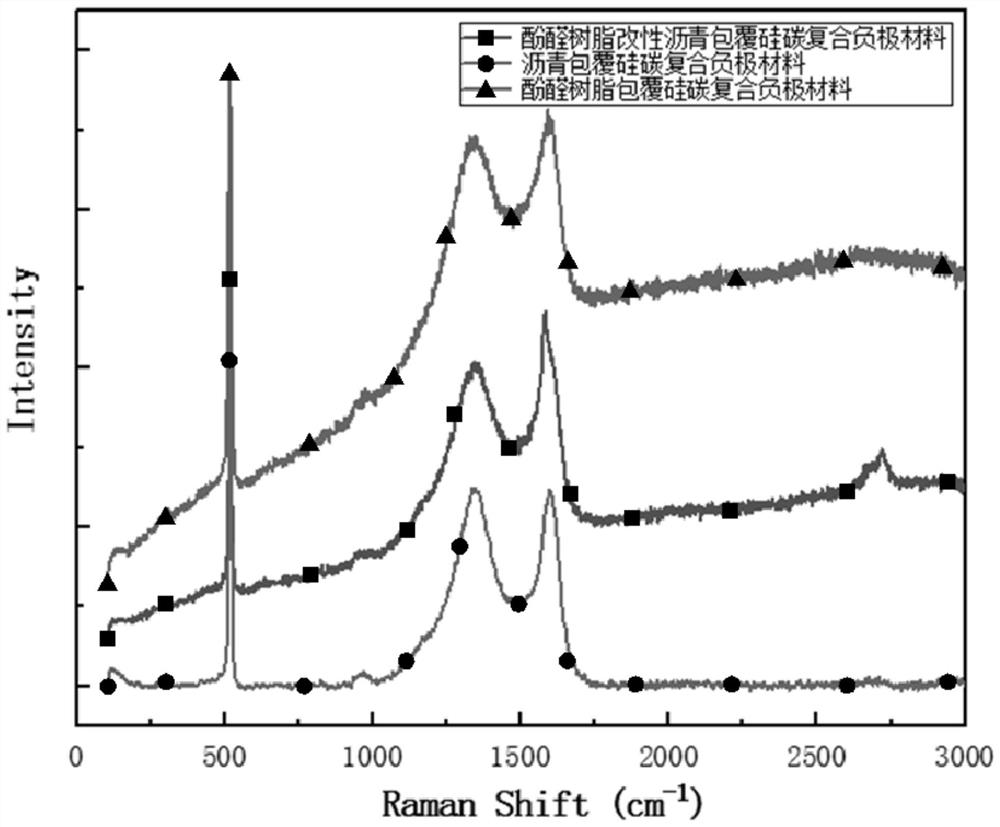

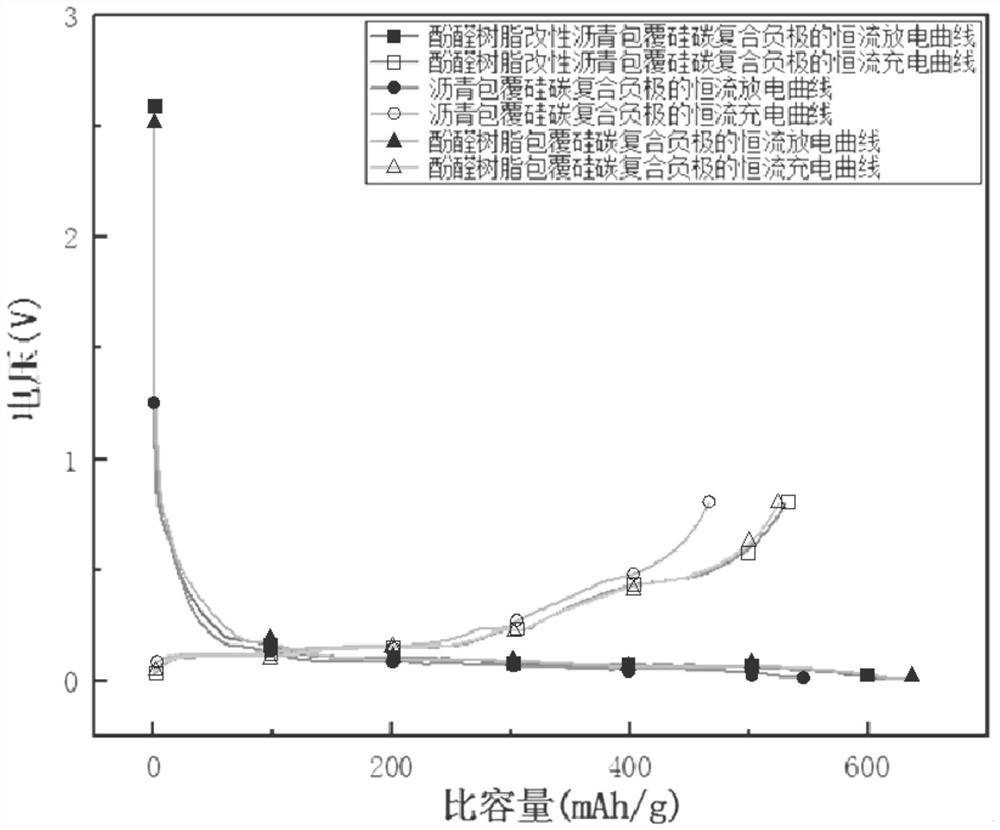

Modification method for coating silicon-carbon composite negative electrode material interface with modified asphalt

PendingCN112768644AHigh carbon residue rateHigh first rateSecondary cellsNegative electrodesCarbon compositesBattery capacity

The invention relates to the technical field of lithium battery materials, and in particular relates to a modification method for coating a silicon-carbon composite negative electrode material interface with modified asphalt. The asphalt-coated silicon-carbon composite negative electrode material is subjected to interface modification by utilizing specially selected phenolic resin, so that the silicon-carbon composite negative electrode material with high rate performance and high first rate is prepared. And a compact nano carbon coating layer with low pore defect degree is formed, so that the defects such as cracks and holes on the surfaces of nano silicon and graphite can be effectively repaired, irreversible consumption of a large number of active lithium ions in the charging and discharging process of a battery is avoided, and irreversible reduction of the battery capacity is remarkably reduced. Therefore, the asphalt-coated silicon-carbon composite negative electrode material is subjected to interface modification by utilizing the mutual synergistic effect of the phenolic resin and the asphalt, the capacity diving condition during high-current charging and discharging of the battery is obviously delayed, and the rate capability and coulombic efficiency of the material are improved.

Owner:西安英纳吉科技有限公司

Special wheat fertilizer for hilly area soil testing and fertilizer recommendation

The present invention discloses a special wheat fertilizer for hilly area soil testing and fertilizer recommendation. The special wheat fertilizer for hilly area soil testing and fertilizer recommendation is prepared from the following raw materials in parts by weight: 24-26 parts of ammonium dihydrogen phosphate, 80-90 parts of waste tea residues, 15-18 parts of ammonium chloride, 280-300 parts of vermicompost, 36-40 parts of crushed eggshells, 50-60 parts of pyrite ash, 8-12 parts of dolomite powder, 10-12 parts of sodium silicate, 28-32 parts of a modified tapioca starch solution, and a proper amount of water; The special wheat fertilizer provided by the present invention is prepared according to soil fertility performance of hilly areas such as Shucheng county, Caitang village and the like as well as fertilizer requirement and fertilizer absorption property of wheat; an organic nutrient body is formed by scientifically proportioning nutrients, so that balanced nutrient supply can be ensured; disease resistance of roots, stems and leaves of wheat can be improved because of addition of amino acid chelate nutrients, and soil fertility condition of hilly areas is modified because of addition of a plurality of waste material organic matters, thereby providing technical support for improving wheat yield and quality.

Owner:SHUCHENG WENHE PLANTING SPECIALIZED COOP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com