Patents

Literature

121results about How to "Reduced opening size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

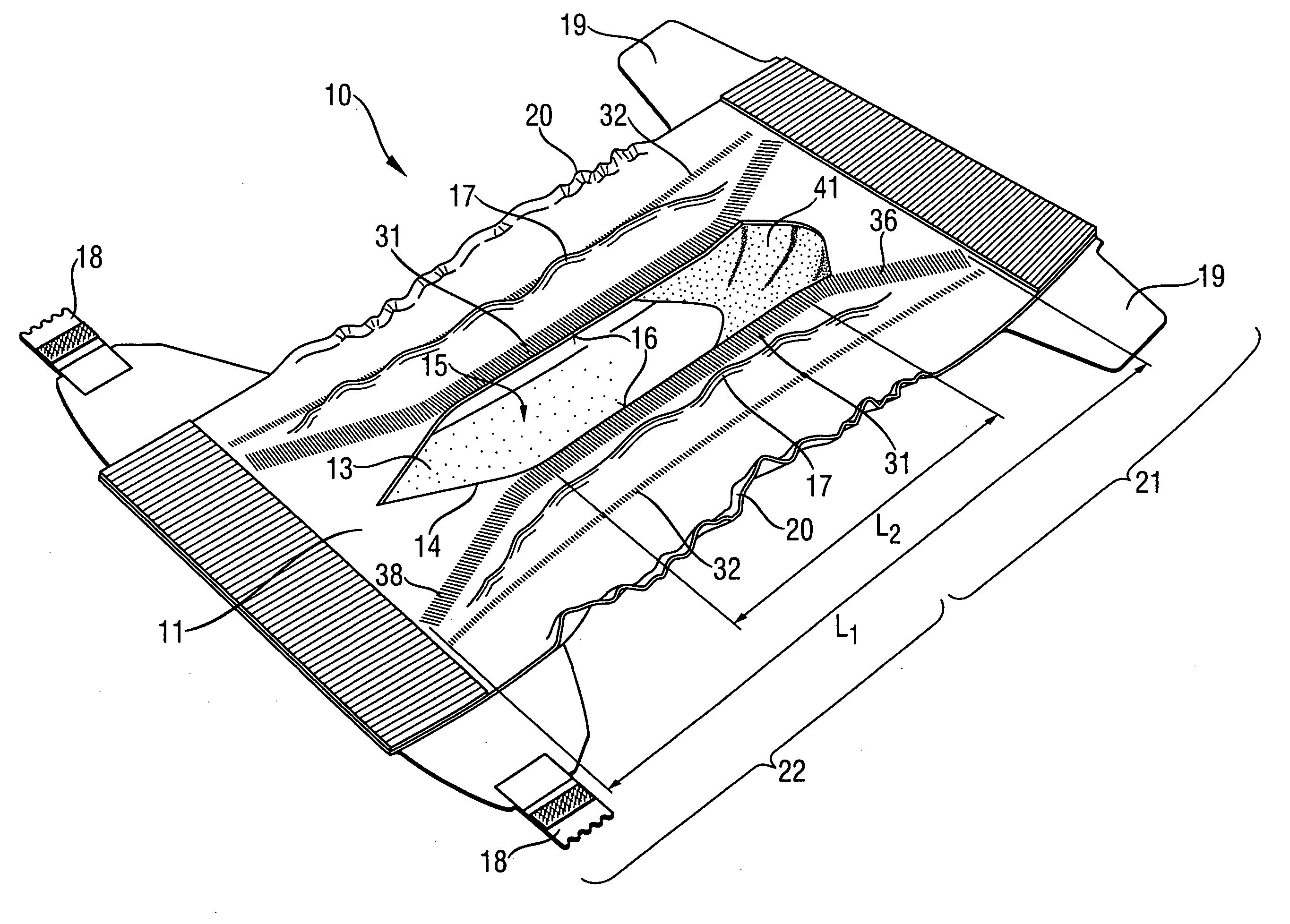

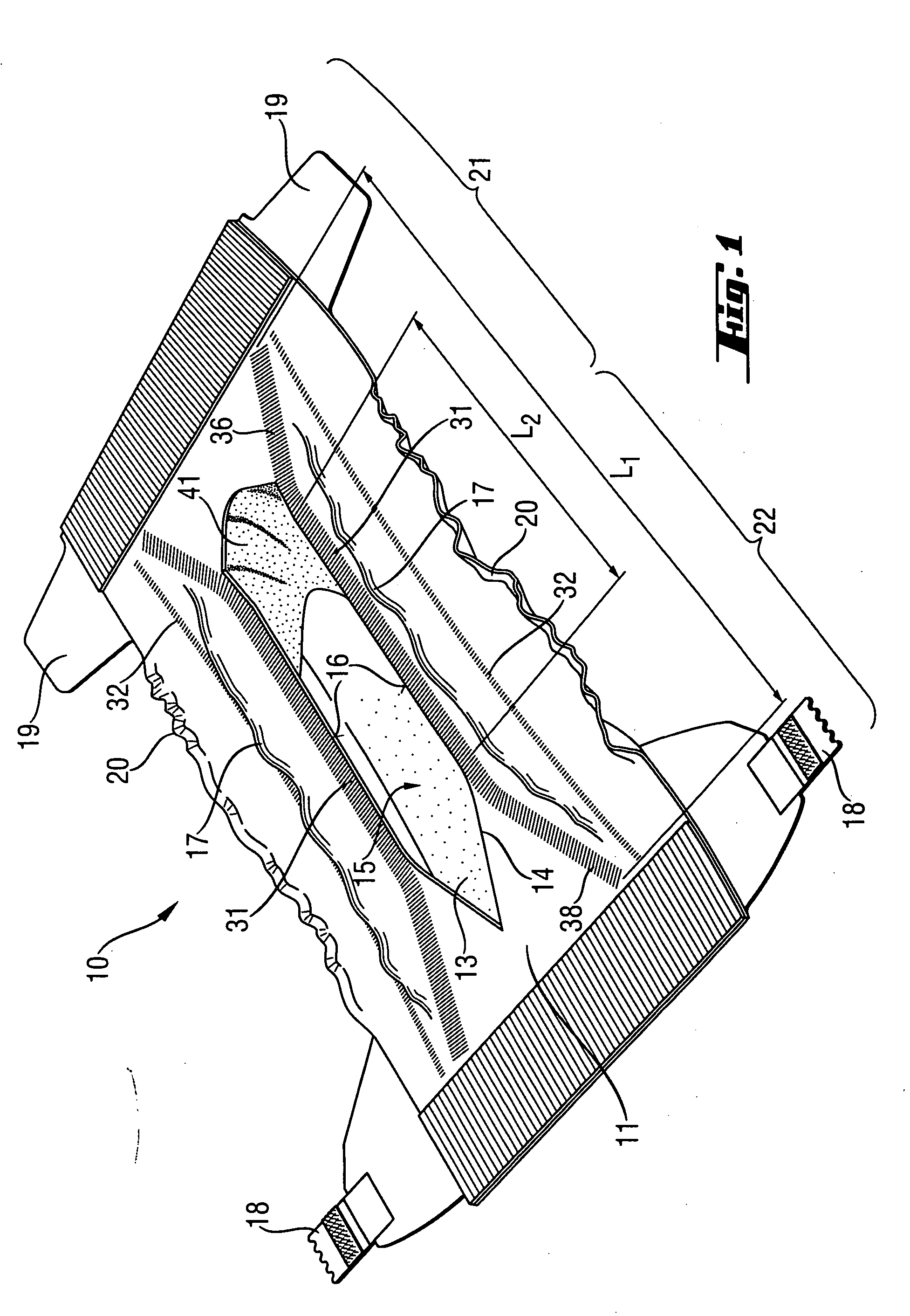

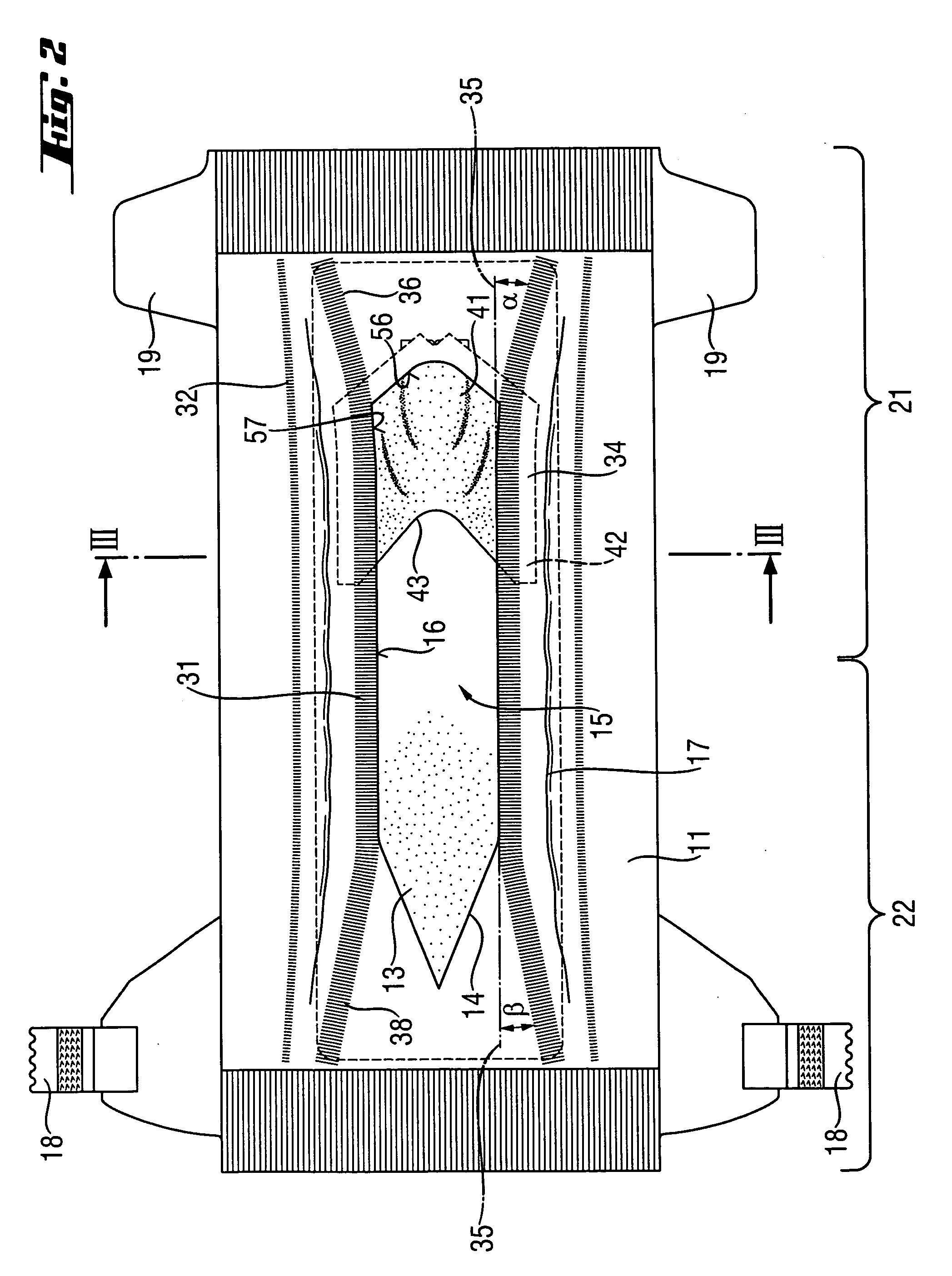

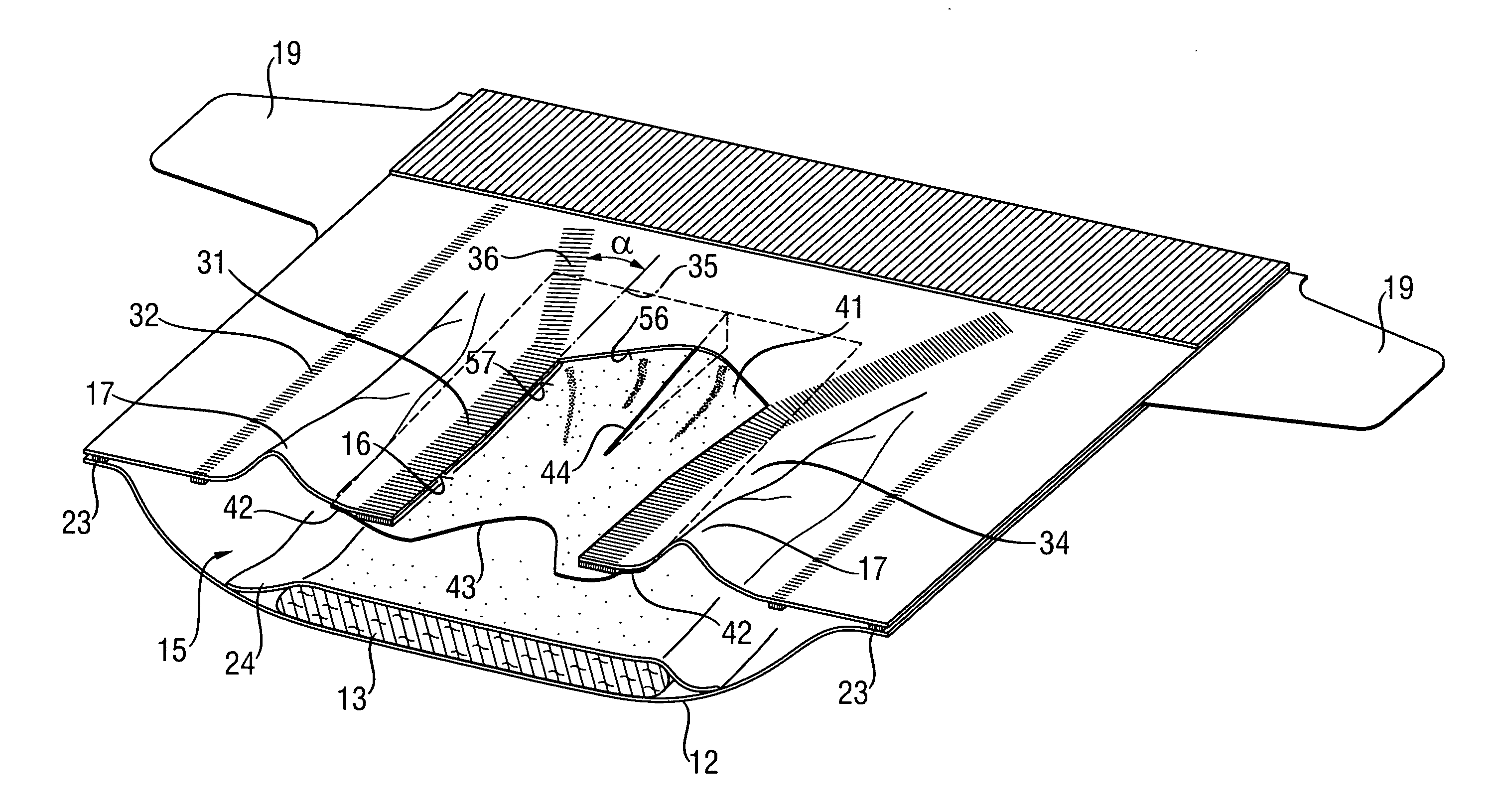

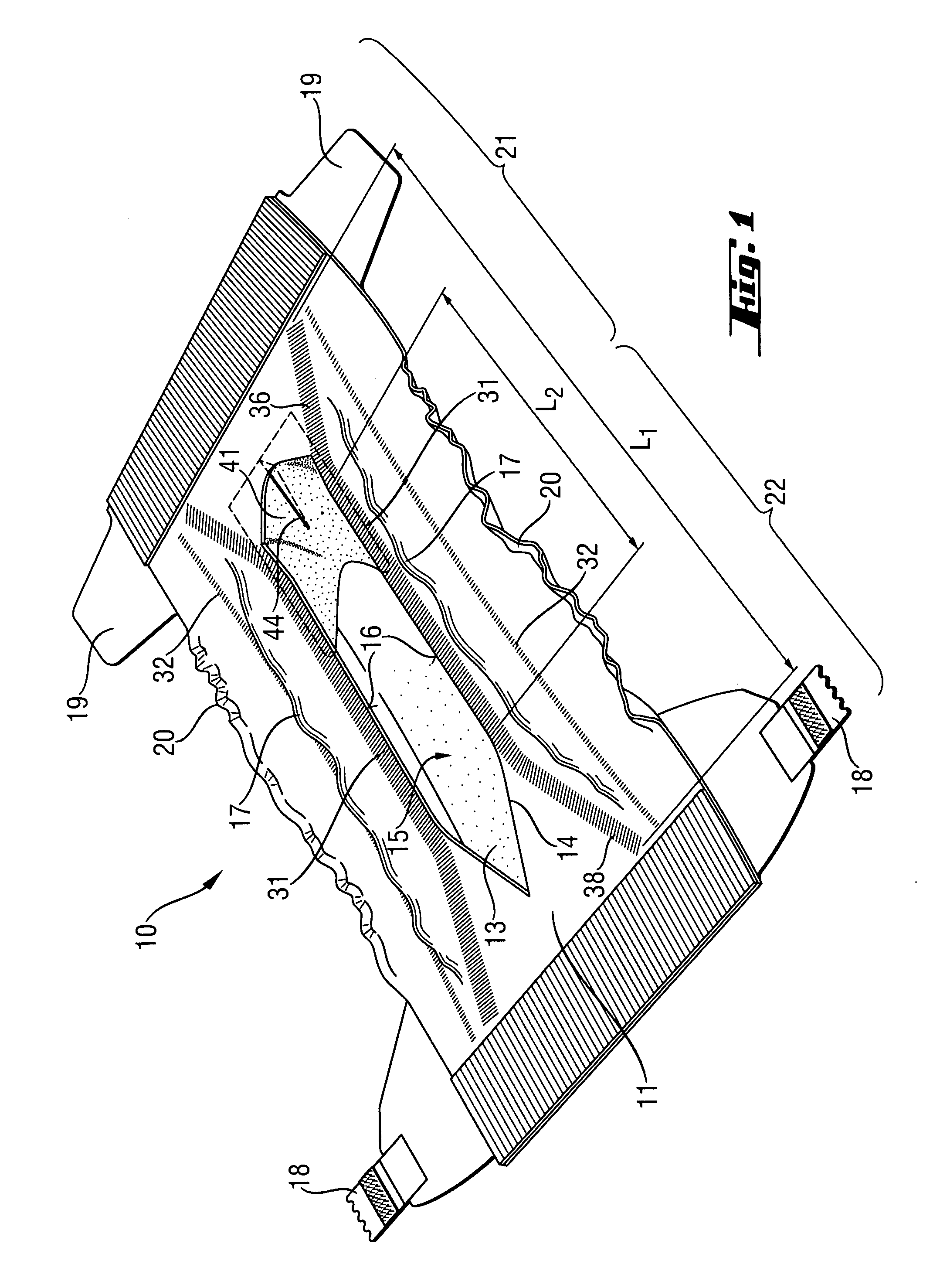

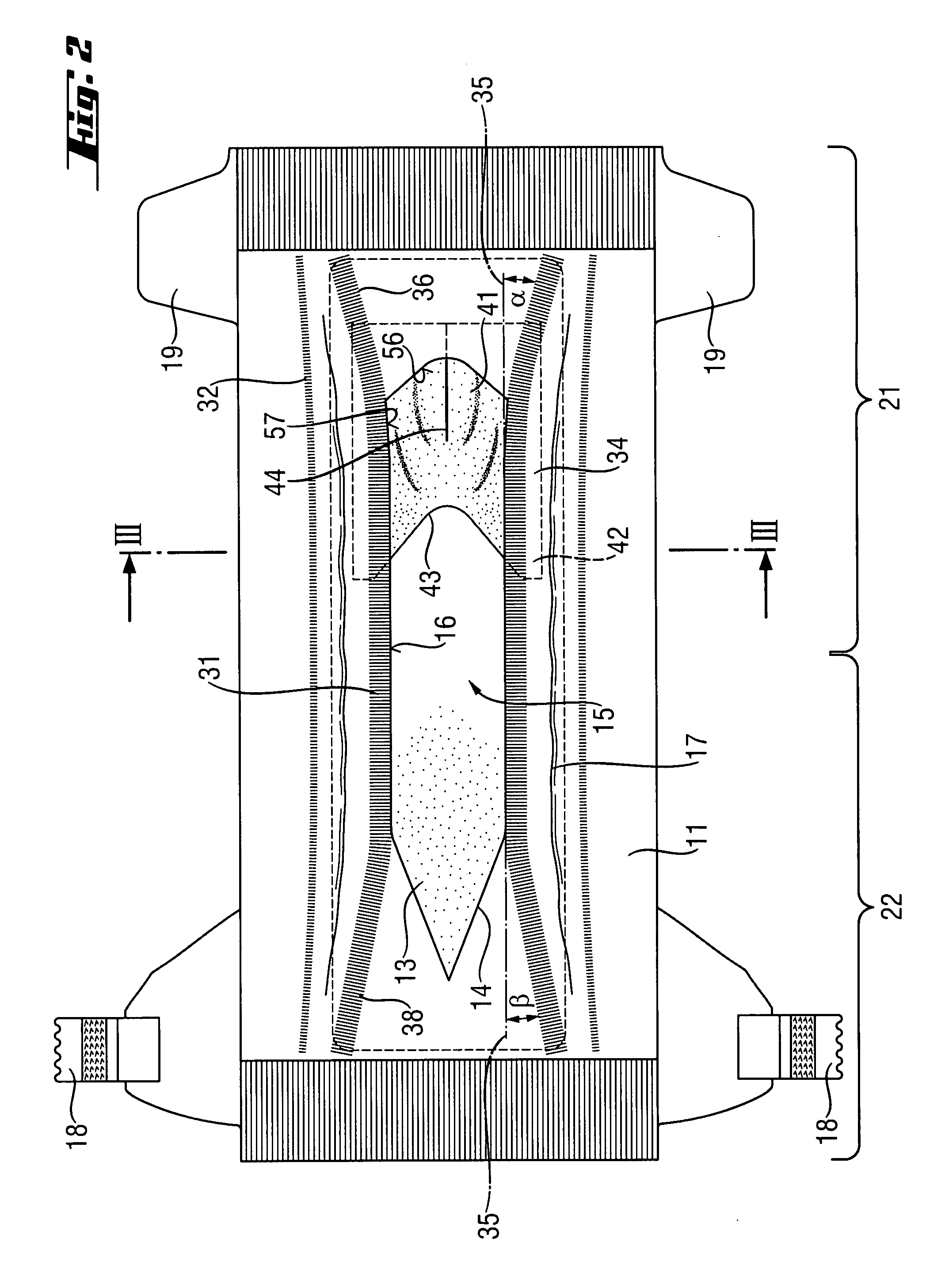

Absorbent article with urine-permeable coversheet

This invention is directed to an absorbent article, preferably a diaper or training pants, having a backsheet, an absorbent core and a topsheet, provided with at least one opening adapted to receive fecal material, comprising also a genital coversheet, which in use covers the genitals, and which is positioned in, under or above part of the opening, such that a void space can be created between the genital coversheet and the absorbent core and such that a void space is present between the topsheet and the absorbent core.

Owner:THE PROCTER & GAMBLE COMPANY

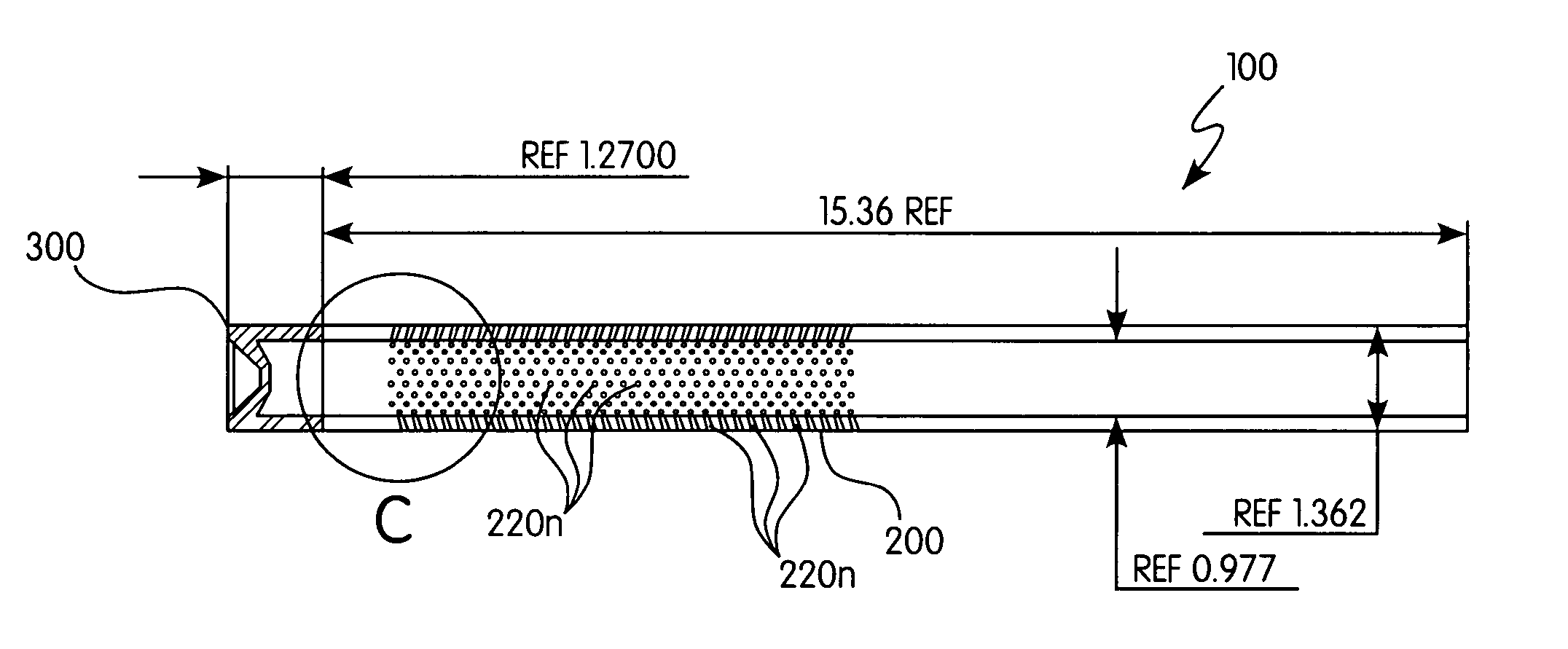

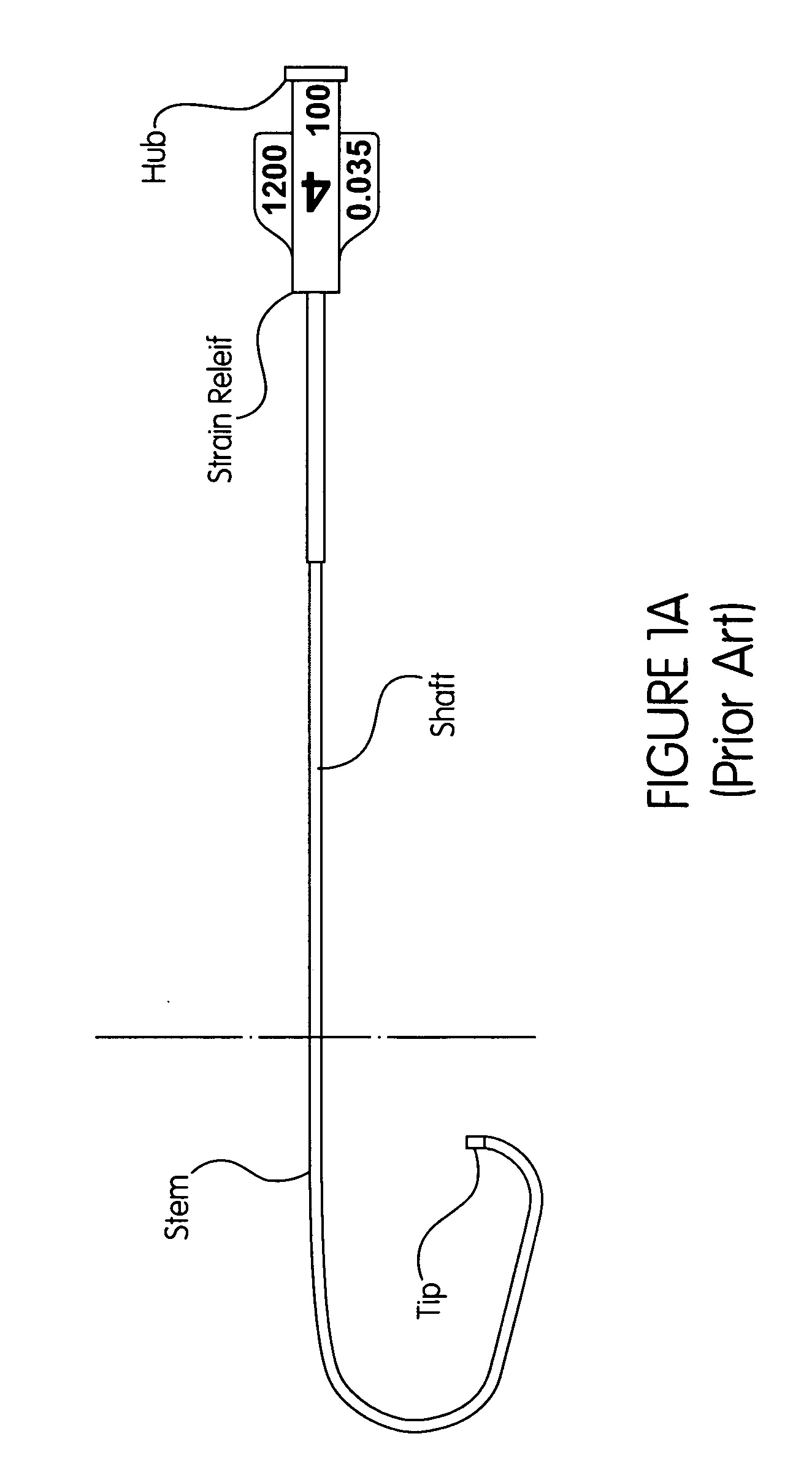

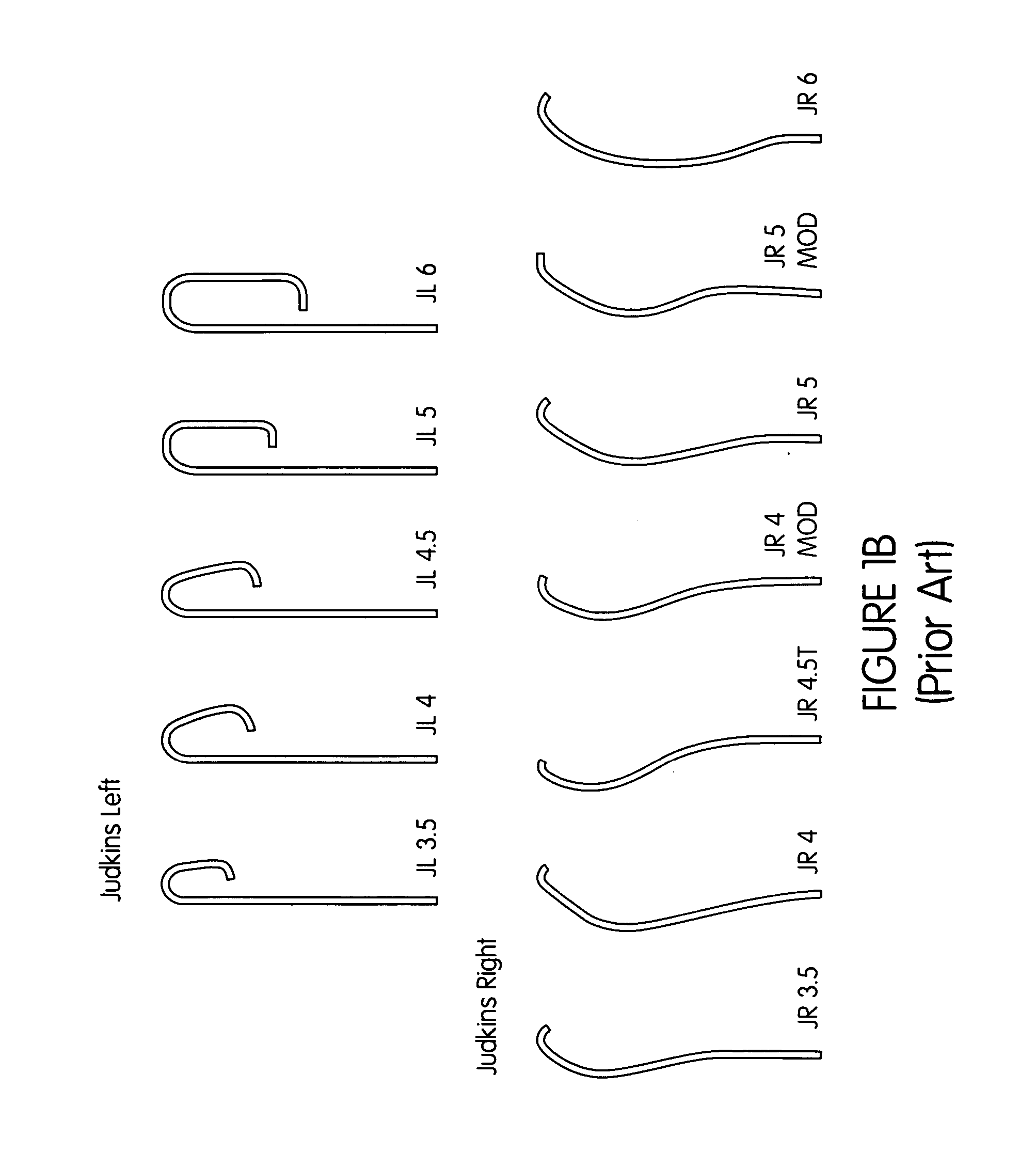

Catheter for diagnostic imaging and therapeutic procedures

InactiveUS20070073271A1Reduced opening sizePreventing both recoil and whippingCatheterIntravenous devicesTreatments proceduresCatheter

A catheter for use in introducing fluid into a vessel or other bodily structure. The catheter comprises a stem and a restrictor. The stem has approximate a distal end thereof a porous section that defines microholes distributed thereabout, which are inclined by a predetermined angle in the proximal direction. Affixed to the stem, the restrictor includes a conically-shaped valve with an apex thereof defining an opening and pointing in the proximal direction. The opening generally decreases in size as the conically-shaped valve flattens out distally as the pressure of the fluid within the tip increases. The forces of the fluid flowing out of the opening of the restrictor and out of the microholes of the stem substantially balance thereby substantially eliminating both recoil and whipping of the catheter, thus enabling its position to remain exceptionally stable while the fluid is finely dispersed therefrom in a cloud-like form.

Owner:MEDRAD INC.

Analyte Meter Protectors and Methods

ActiveUS20080234559A1Easily attachableEasily removableAnalysis using chemical indicatorsEnzymologyAnalyte

Owner:ABBOTT DIABETES CARE INC

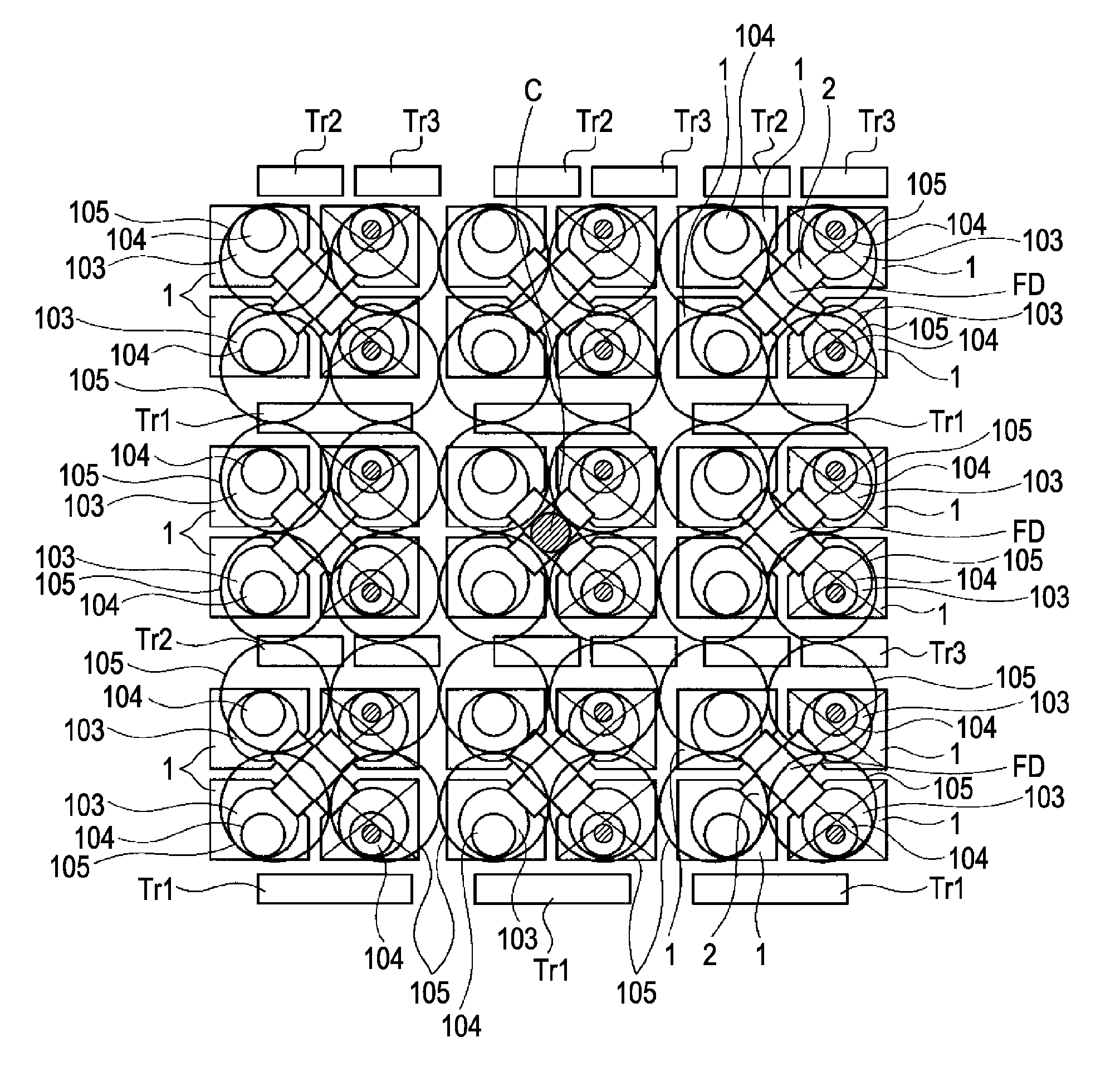

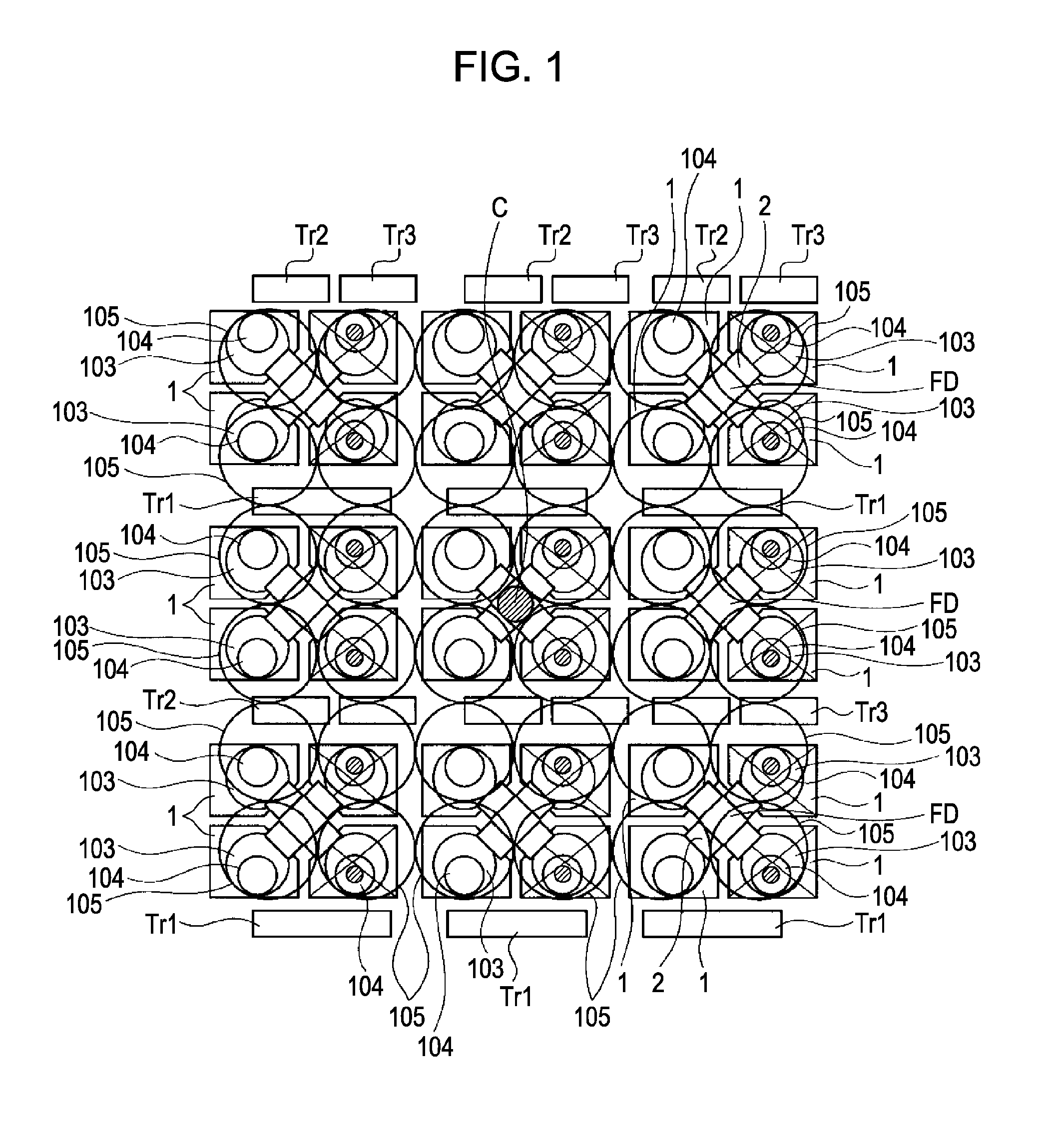

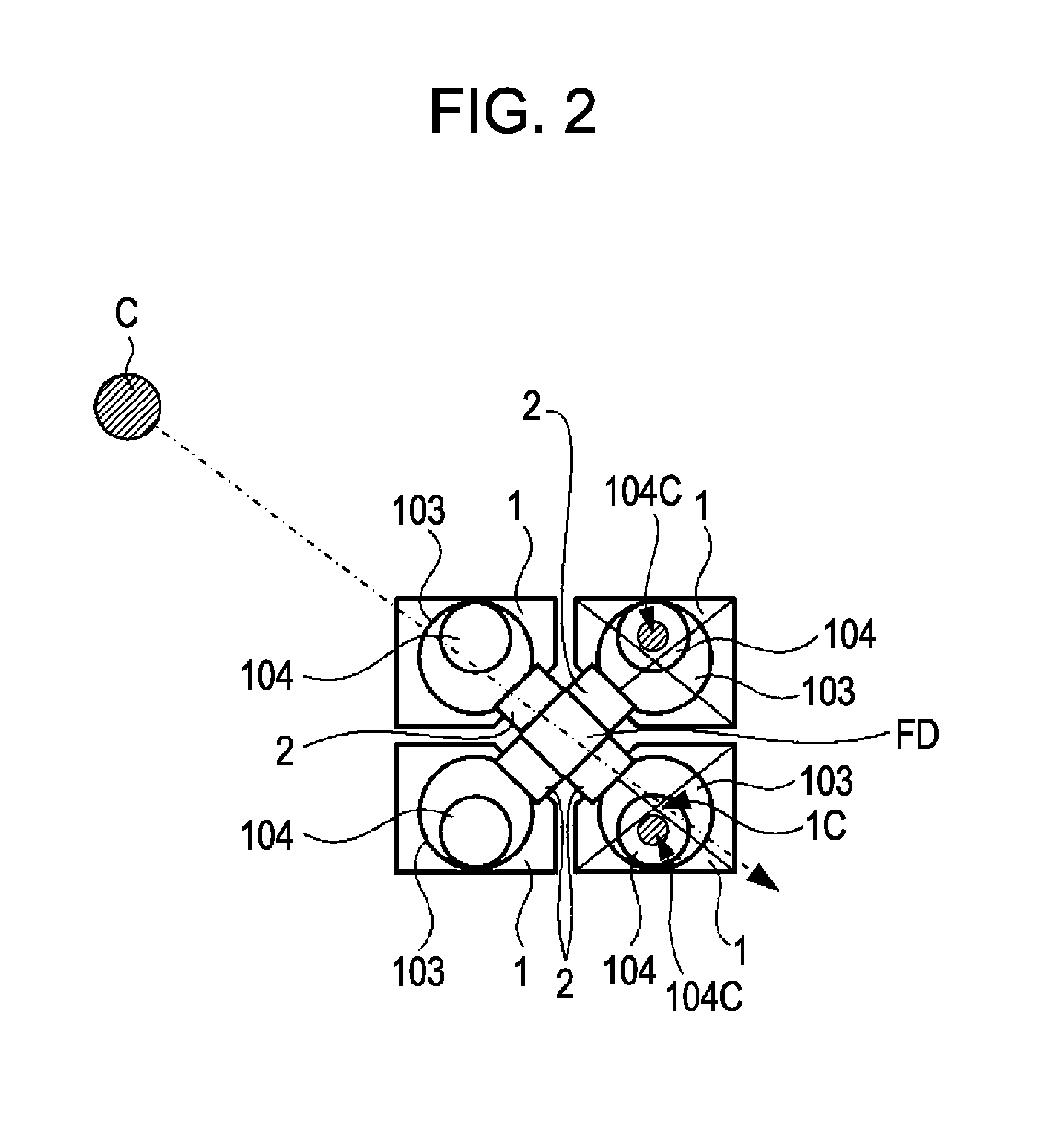

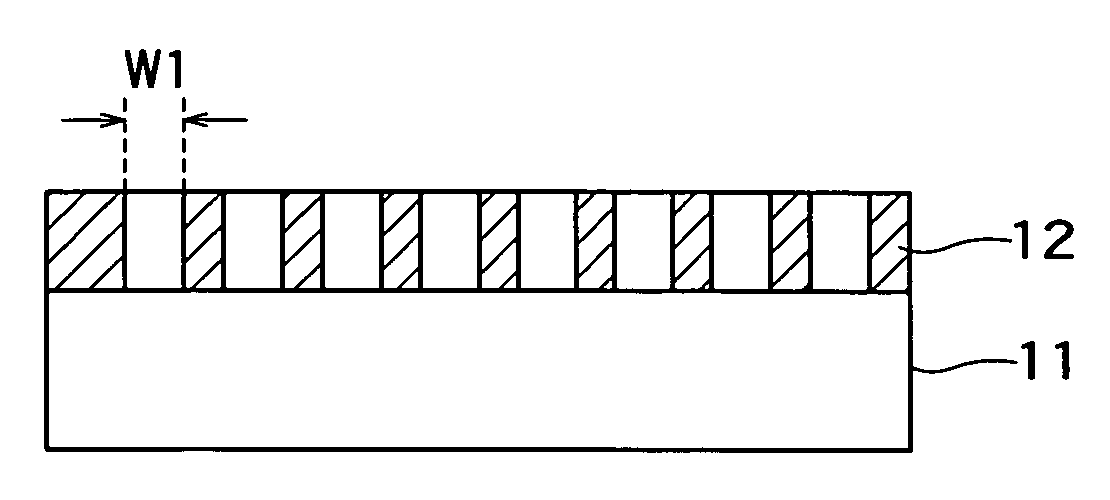

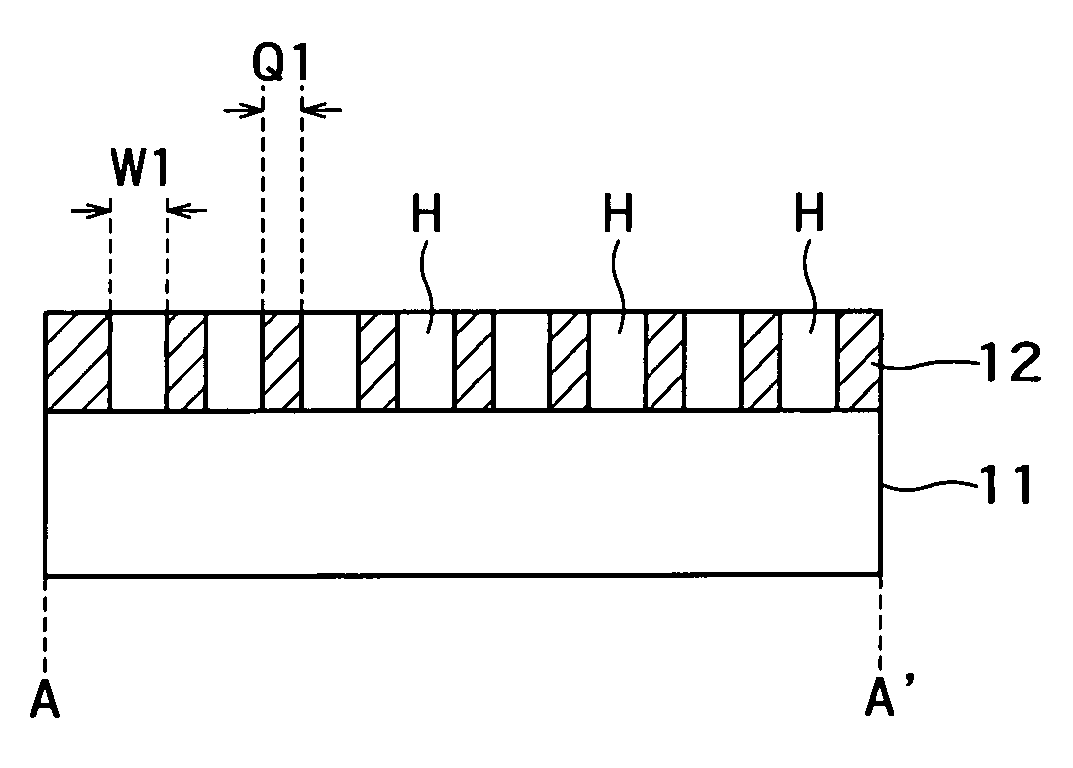

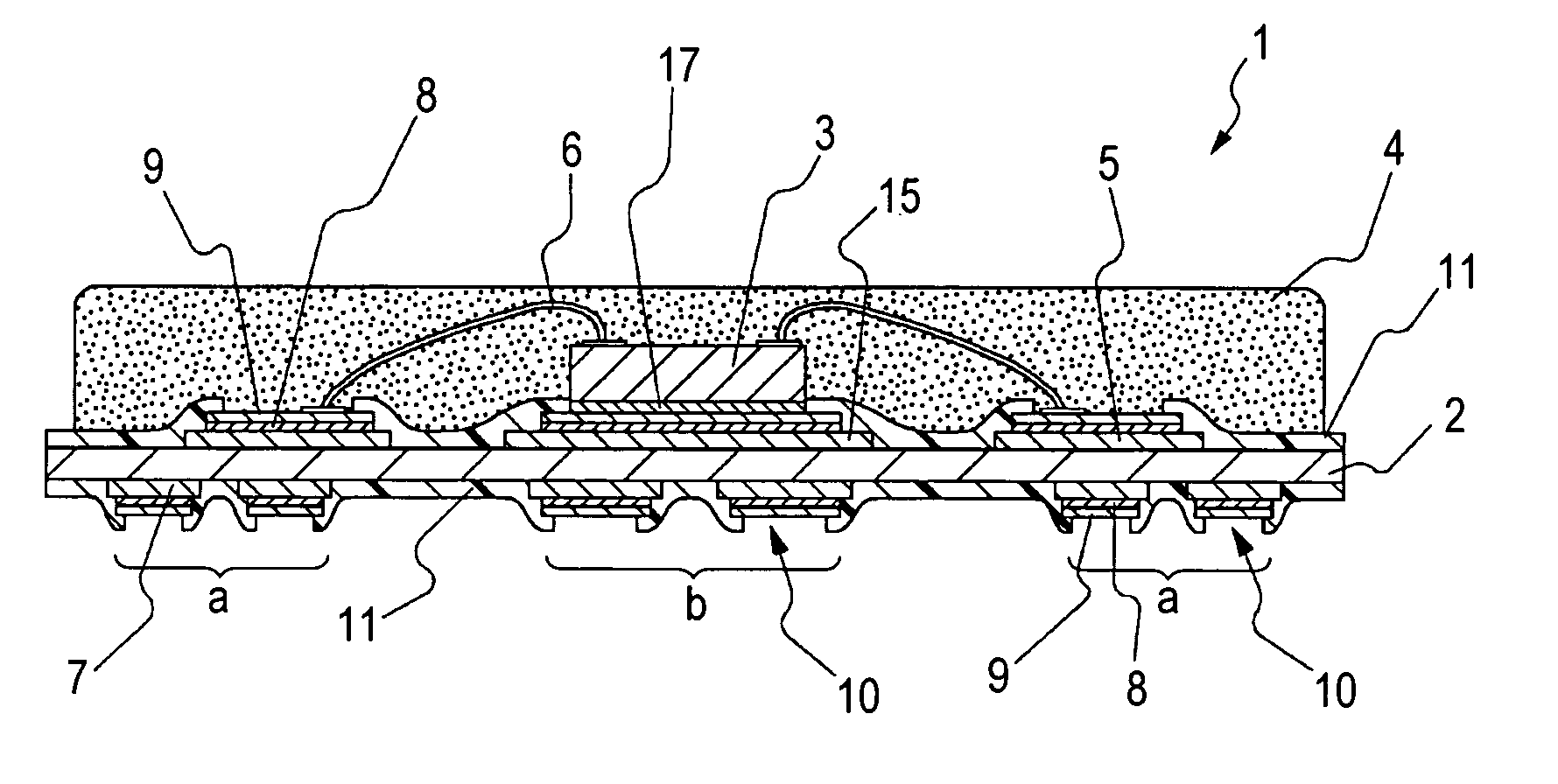

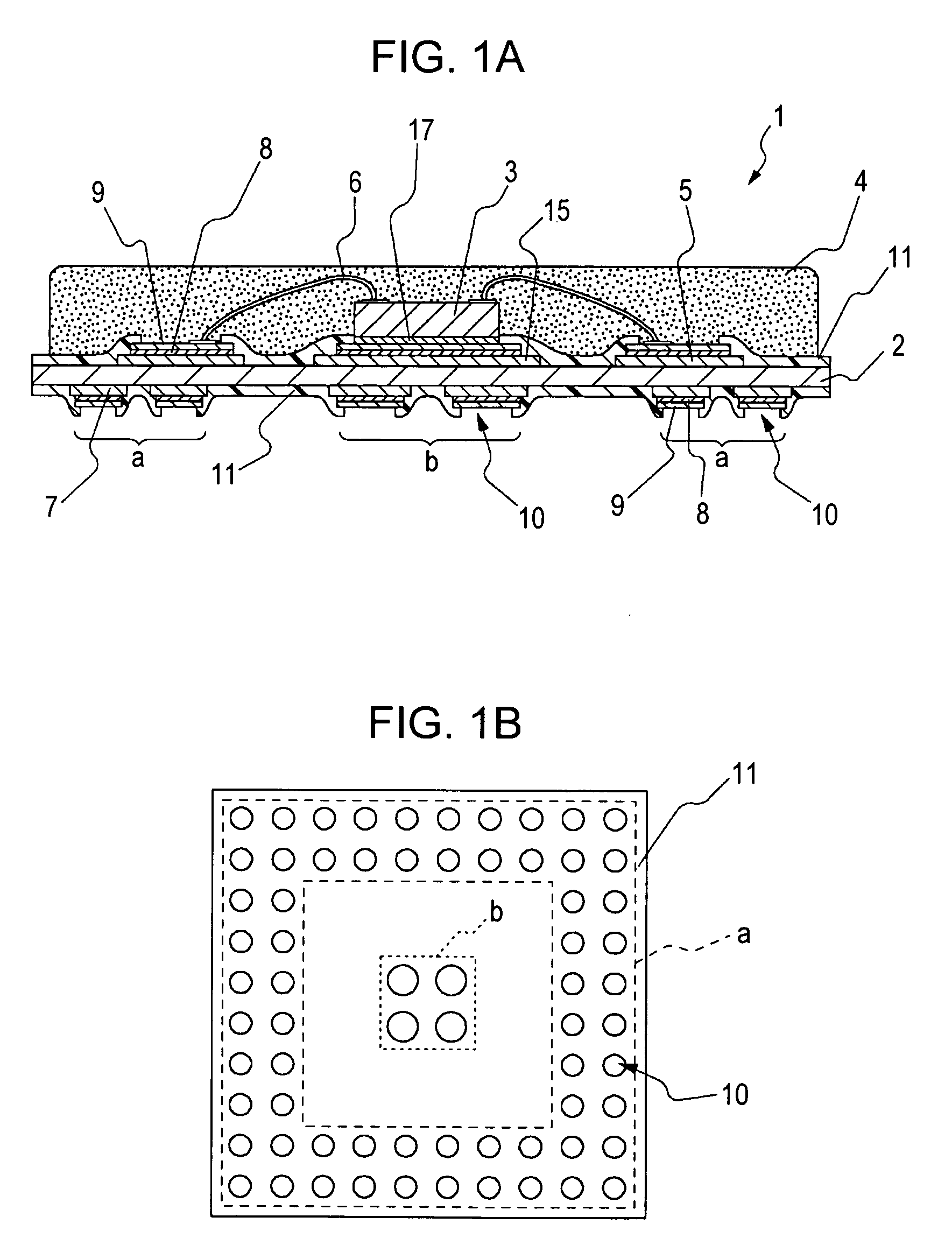

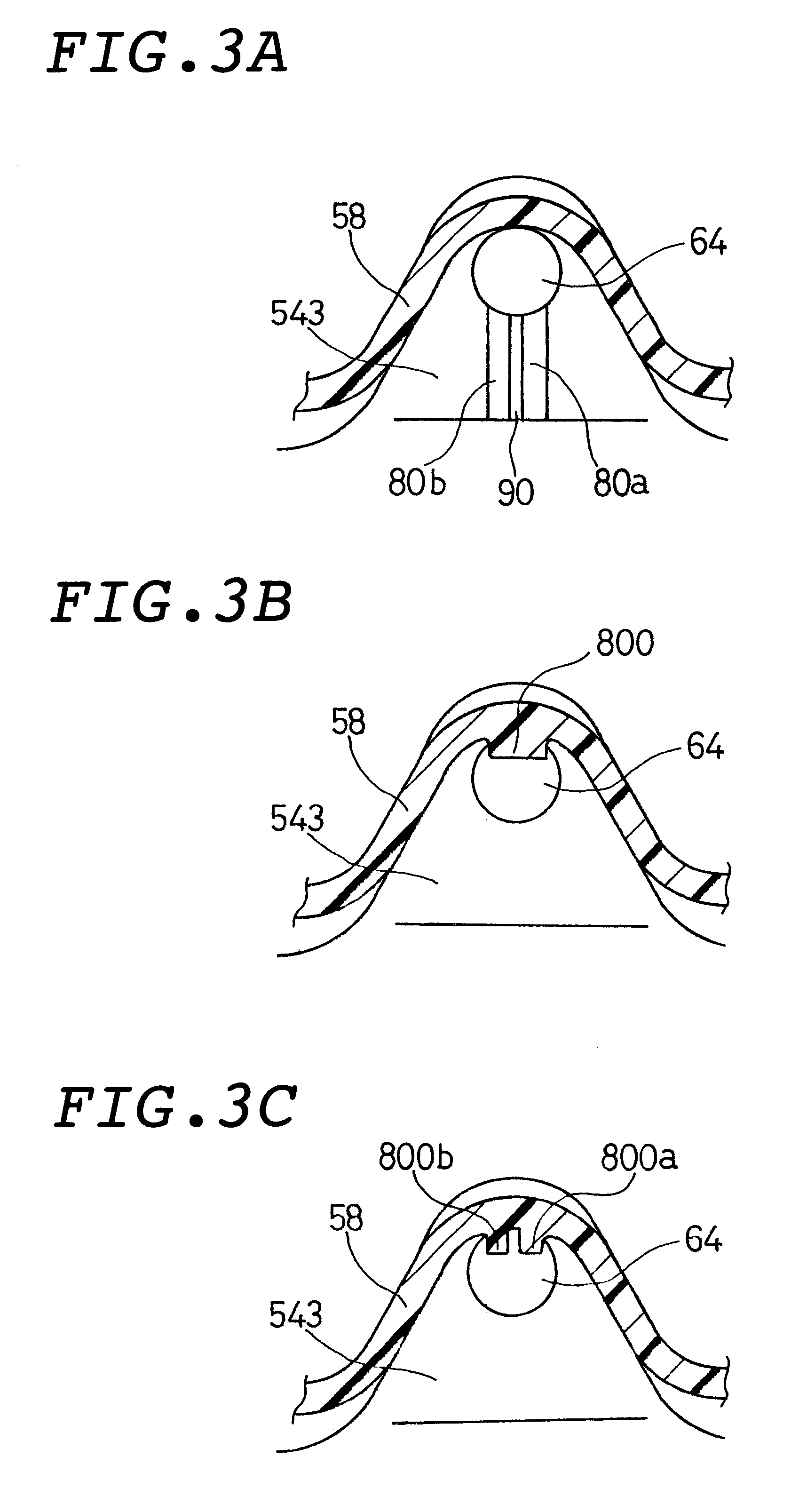

Solid-state imaging device and imaging apparatus

ActiveUS20100245648A1Avoid it happening againSimple structureTelevision system detailsTelevision system scanning detailsFloating diffusionWaveguide

An imaging device includes a basic cell having two or more the pixels that share floating diffusion. The imaging device also includes a transistor shared by the two or more pixels in the basic cell and arranged on the outside of the two or more pixels. The imaging device further includes a light receiving unit connected to the floating diffusion shared by the pixels in the basic cell through a transfer gate. In the imaging device, on-chip lenses are arranged substantially at regular intervals. Also, an optical waveguide is formed so that the position thereof in the surface of the solid-state imaging device is located at a position shifted from the center of the light receiving unit to the transistor and in the inside of the light receiving unit and the inside of the on-chip lens.

Owner:SONY SEMICON SOLUTIONS CORP

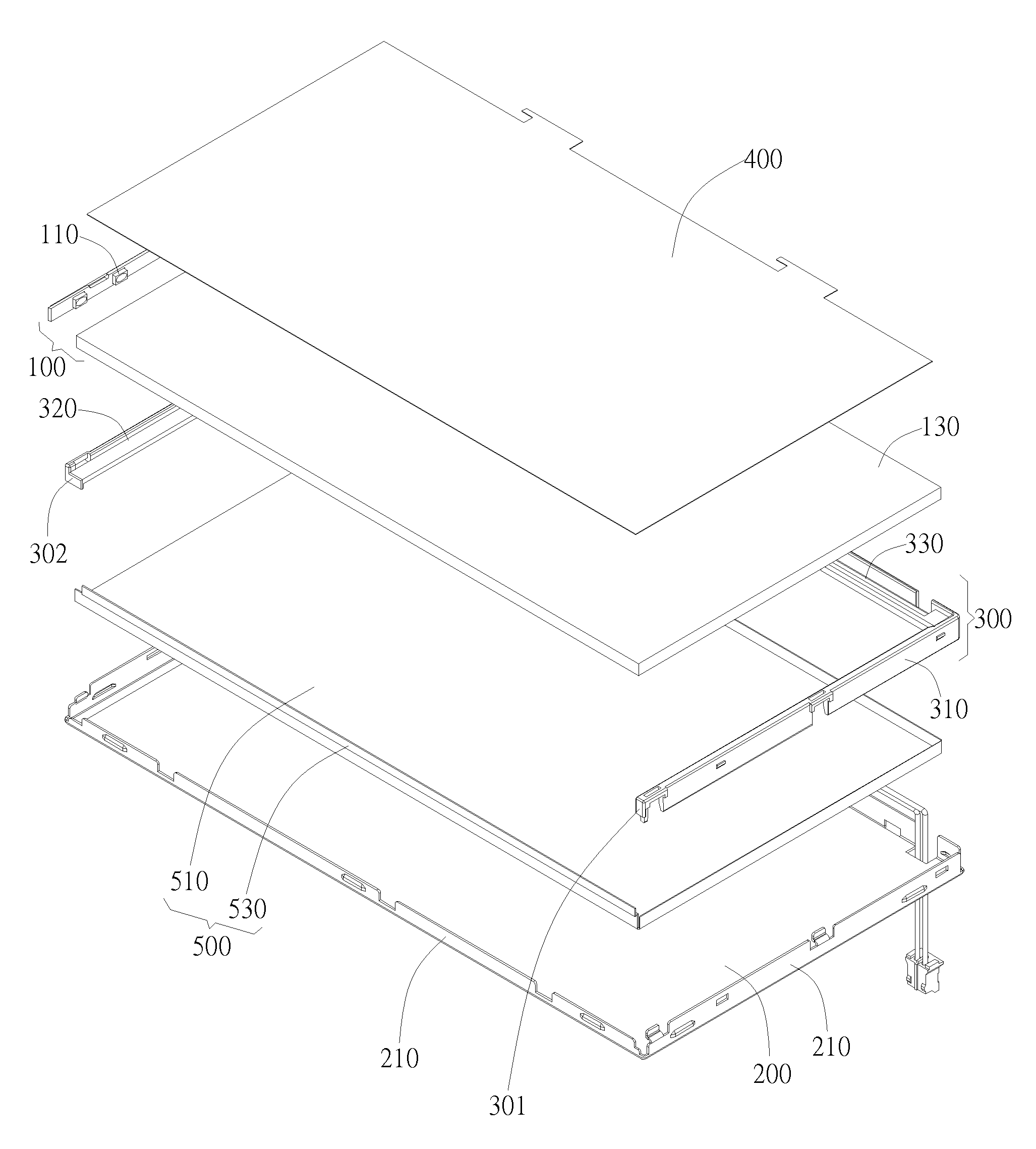

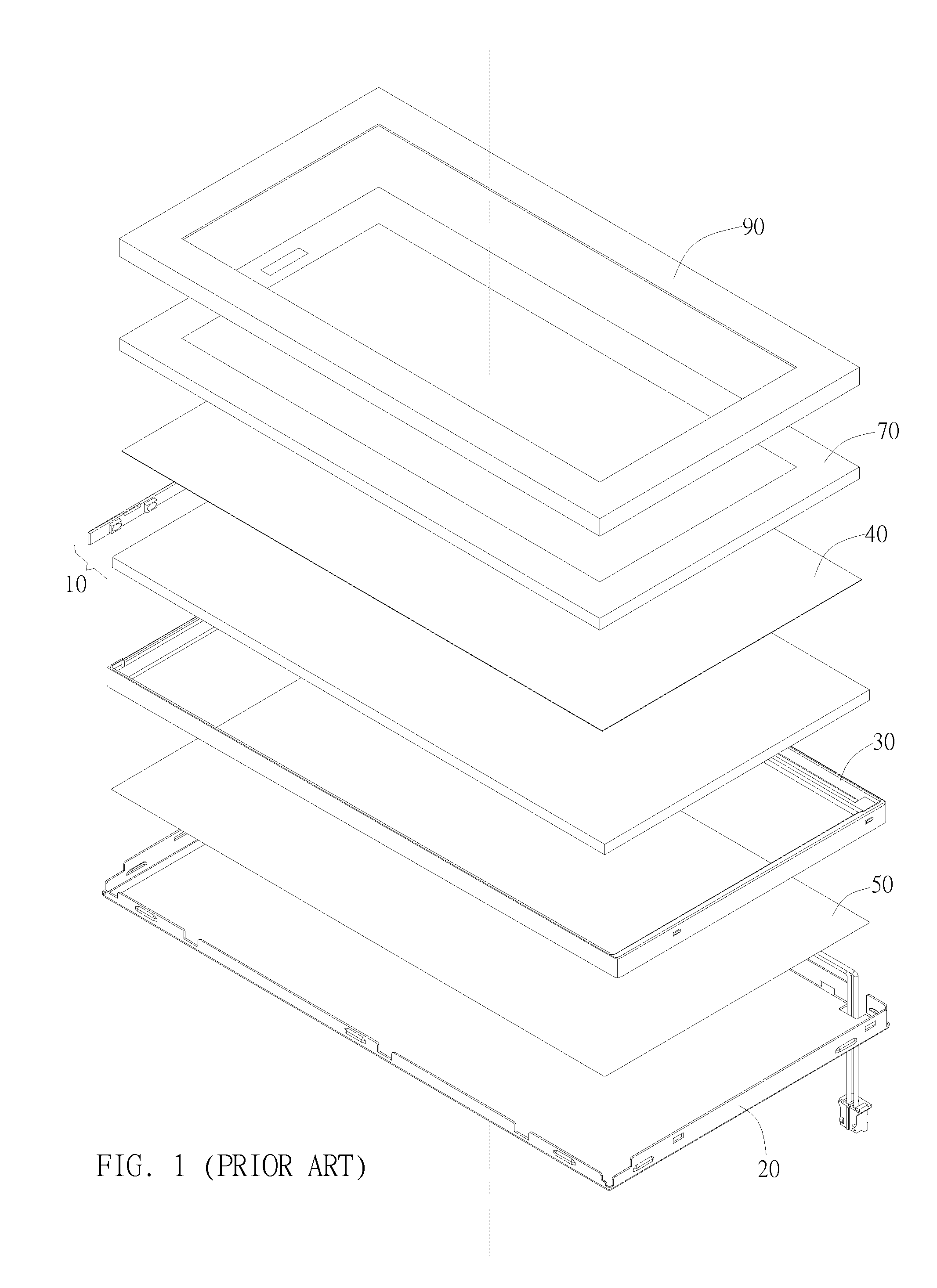

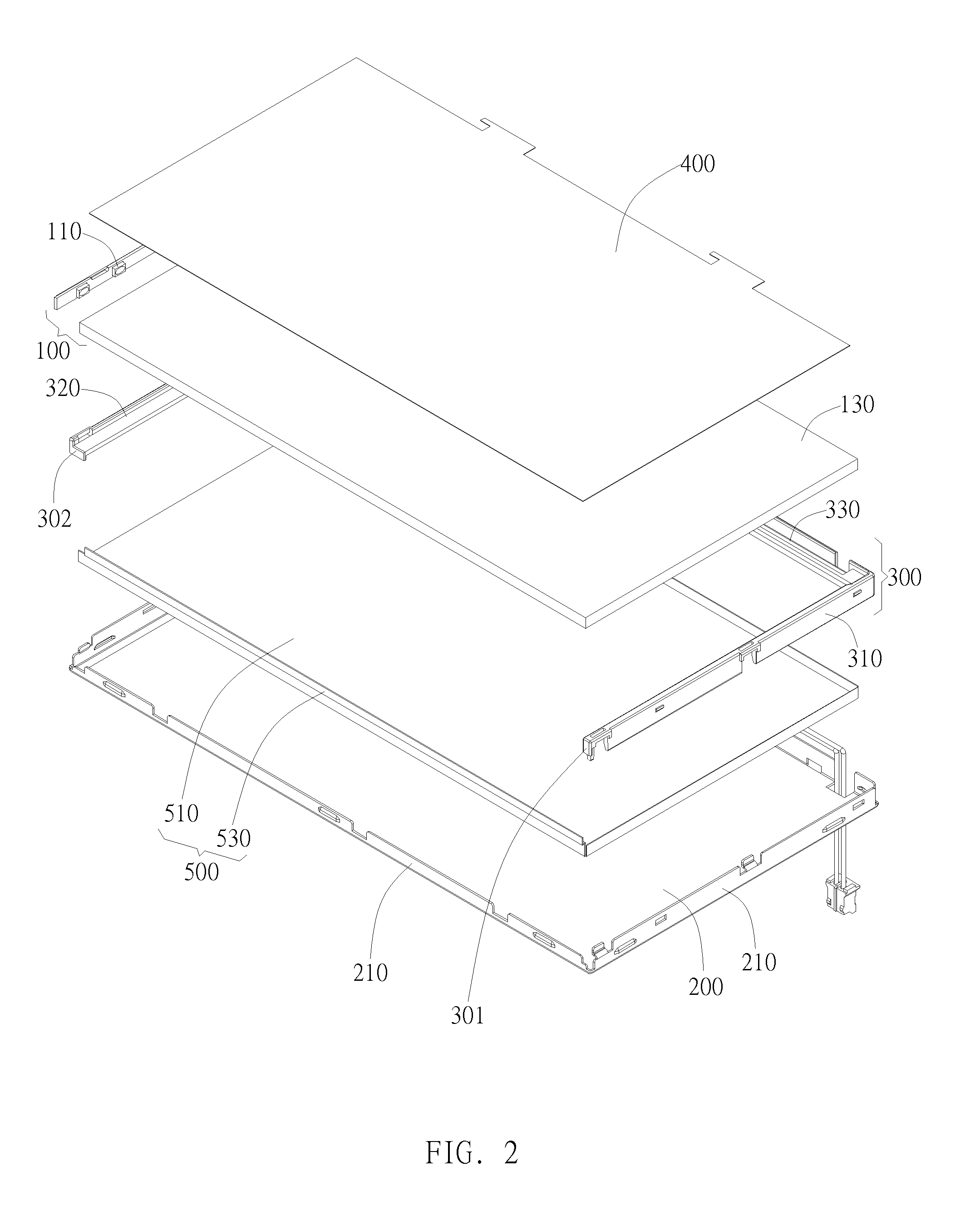

Backlight Module with Bended Reflector Sheet and Display Panel Device Using the Same

ActiveUS20100014015A1Reduced opening sizeConserve material costLighting support devicesIlluminated signsLiquid-crystal displayComputer science

A backlight module and a display panel device using the same are provided. The backlight module includes a light source module, an open frame, and a reflector sheet. The open frame is disposed around the light source module and has a first free-end and a second free-end. A space interval exists between the first and second free-ends. The reflector sheet is disposed on a rear side of the light source module and has a body and a sidewall. The sidewall corresponds to the space interval between the first and second free-ends and extends over the light source module. The display panel further includes a liquid crystal display panel (LCD panel) on the light source module and a front frame which is disposed on the LCD panel enclosing a lateral side of the LCD panel. The sidewall of the reflector sheet extends between the lateral side of the LCD panel and the front frame to provide insulation.

Owner:AU OPTRONICS CORP

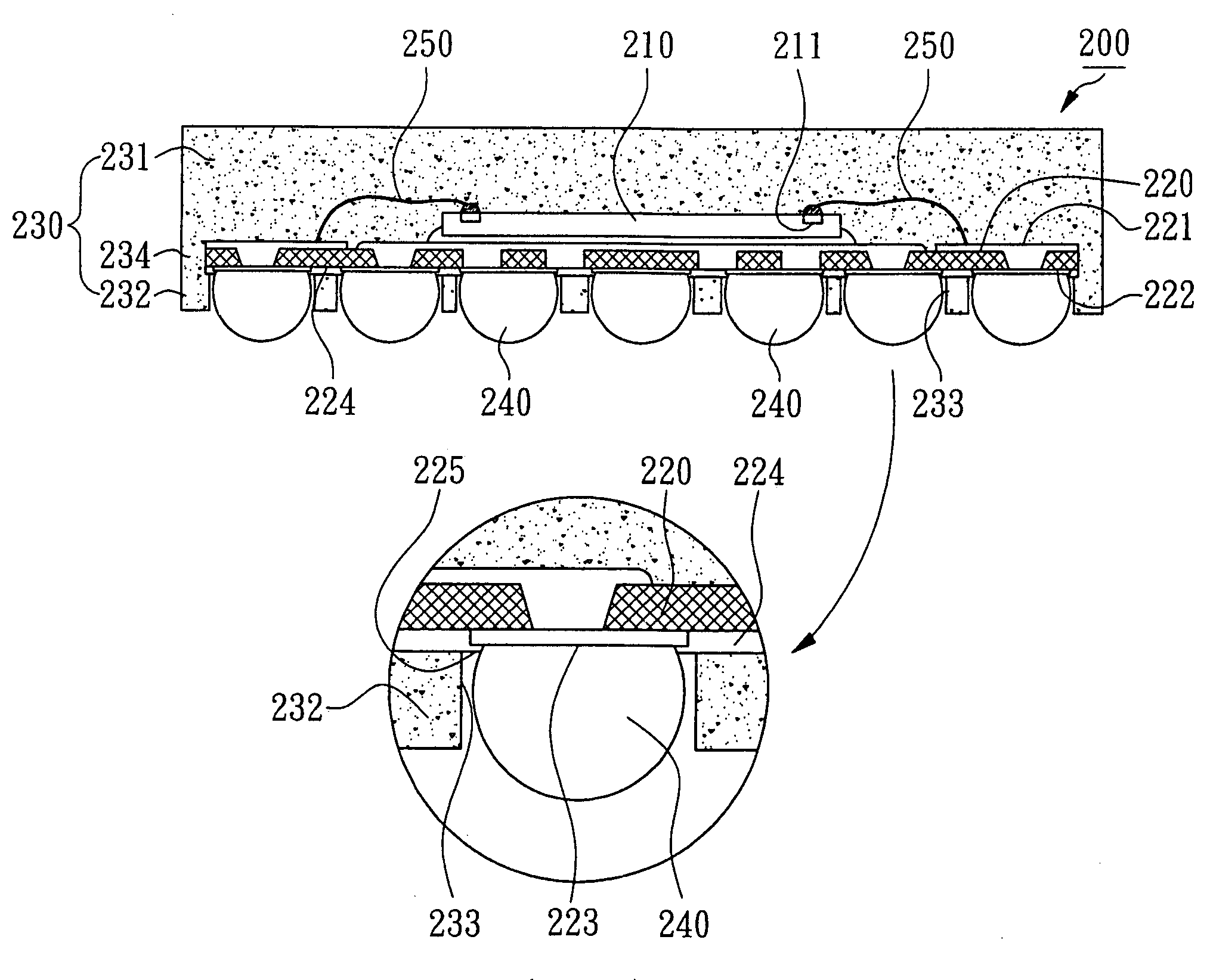

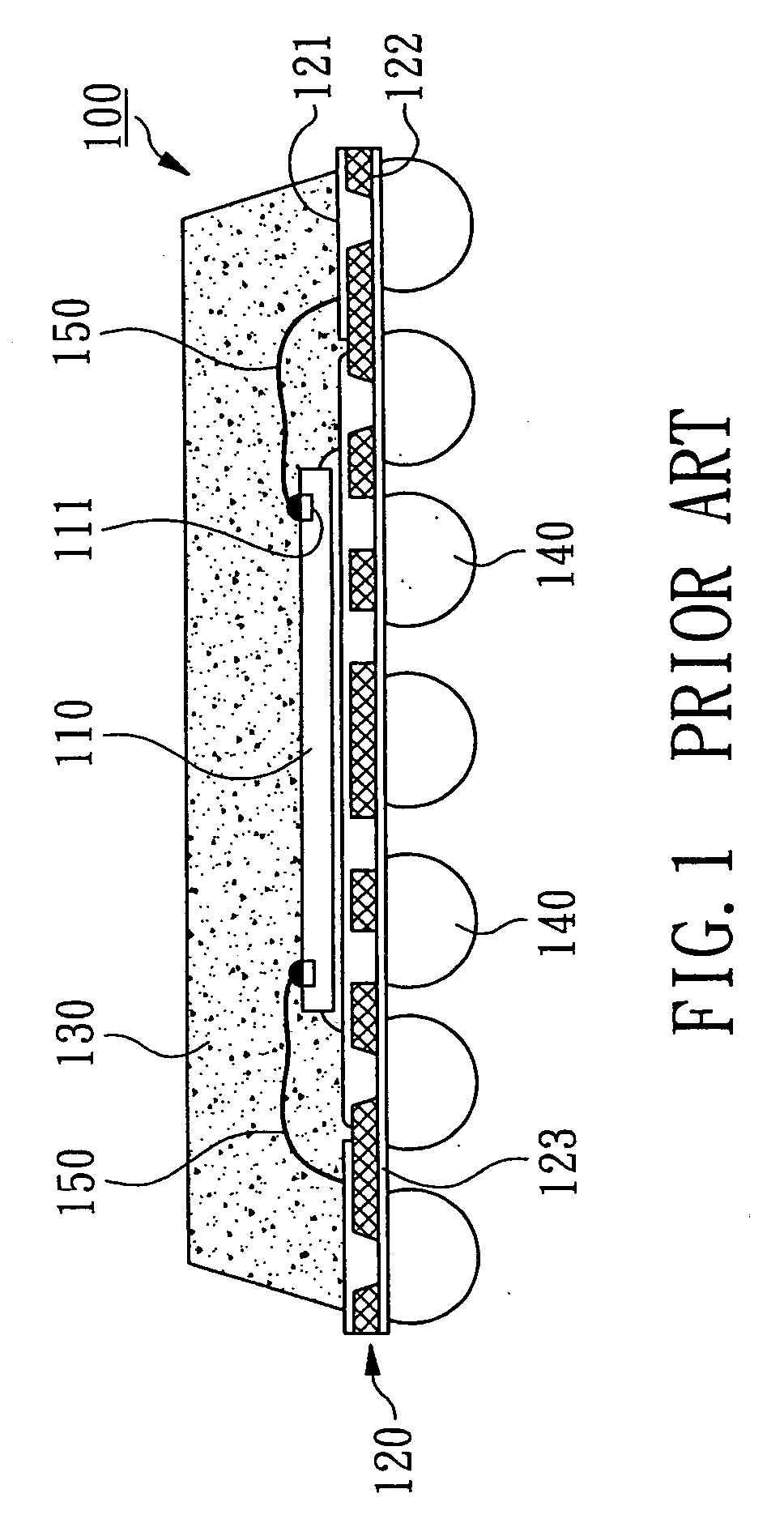

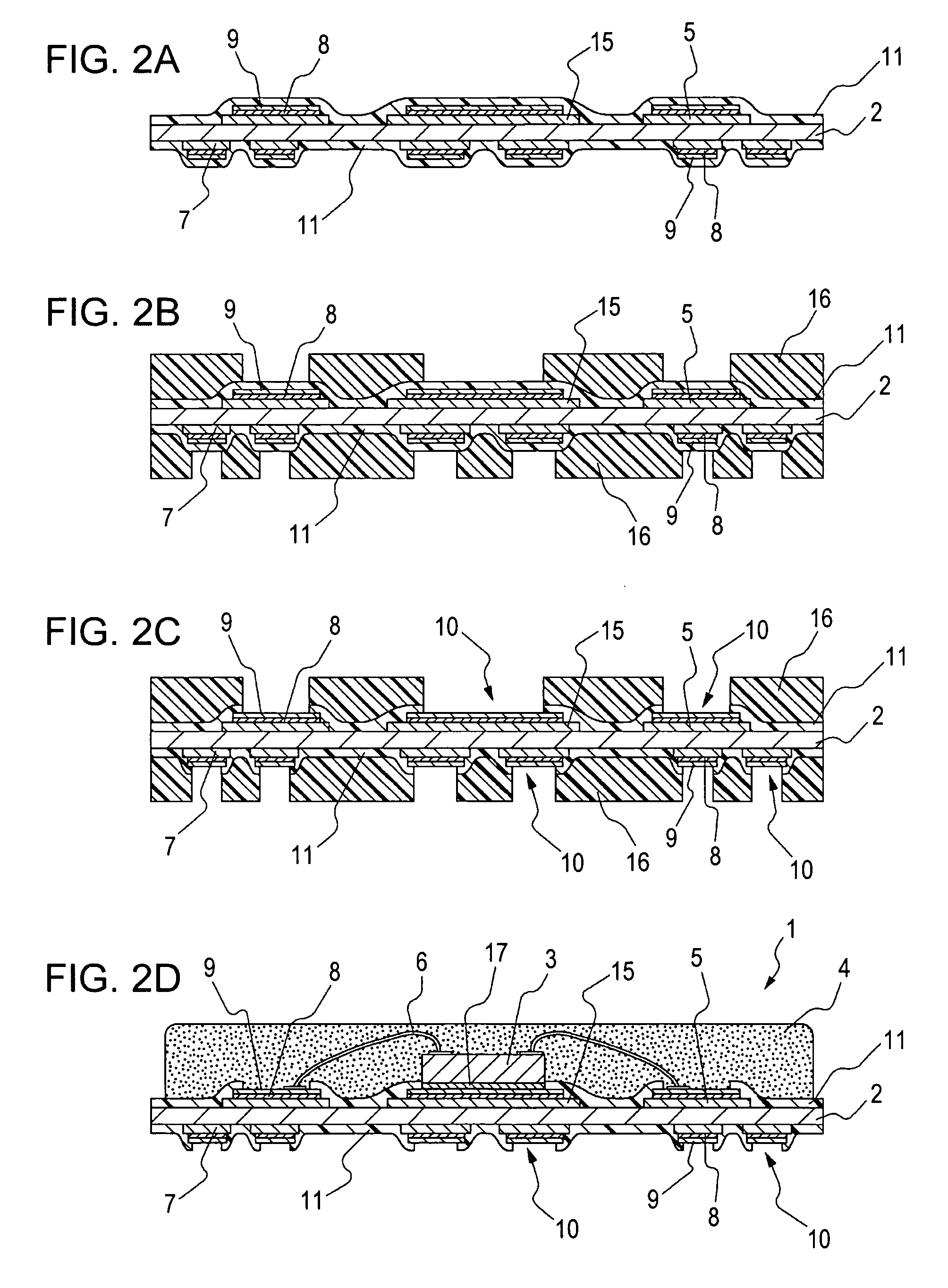

BGA package with encapsulation on bottom of substrate

InactiveUS20080116574A1Reduce exposed areaImprove semiconductor product moisture resistanceSemiconductor/solid-state device detailsSolid-state devicesResistMetallurgy

A BGA package with encapsulation on substrate bottom comprises a chip, a substrate, a molding compound and a plurality of solder balls. The substrate has a SMT surface placing a plurality of ball pads. The molding compound encapsulates a solder resist layer on the SMT surface of the substrate and has a plurality of through holes exposing the ball pads respectively. The hole diameter of the through holes is greater than that of the openings of the solder resist layer on the substrate to allow the solder balls not to contact the molding compound. The solder balls are disposed in the through holes and are bonded to the exposed ball pads of the substrate thereby enhancing moisture resistance of BGA products and preventing the solder balls from falling because of contact stress of the molding compound.

Owner:POWERTECH TECHNOLOGY

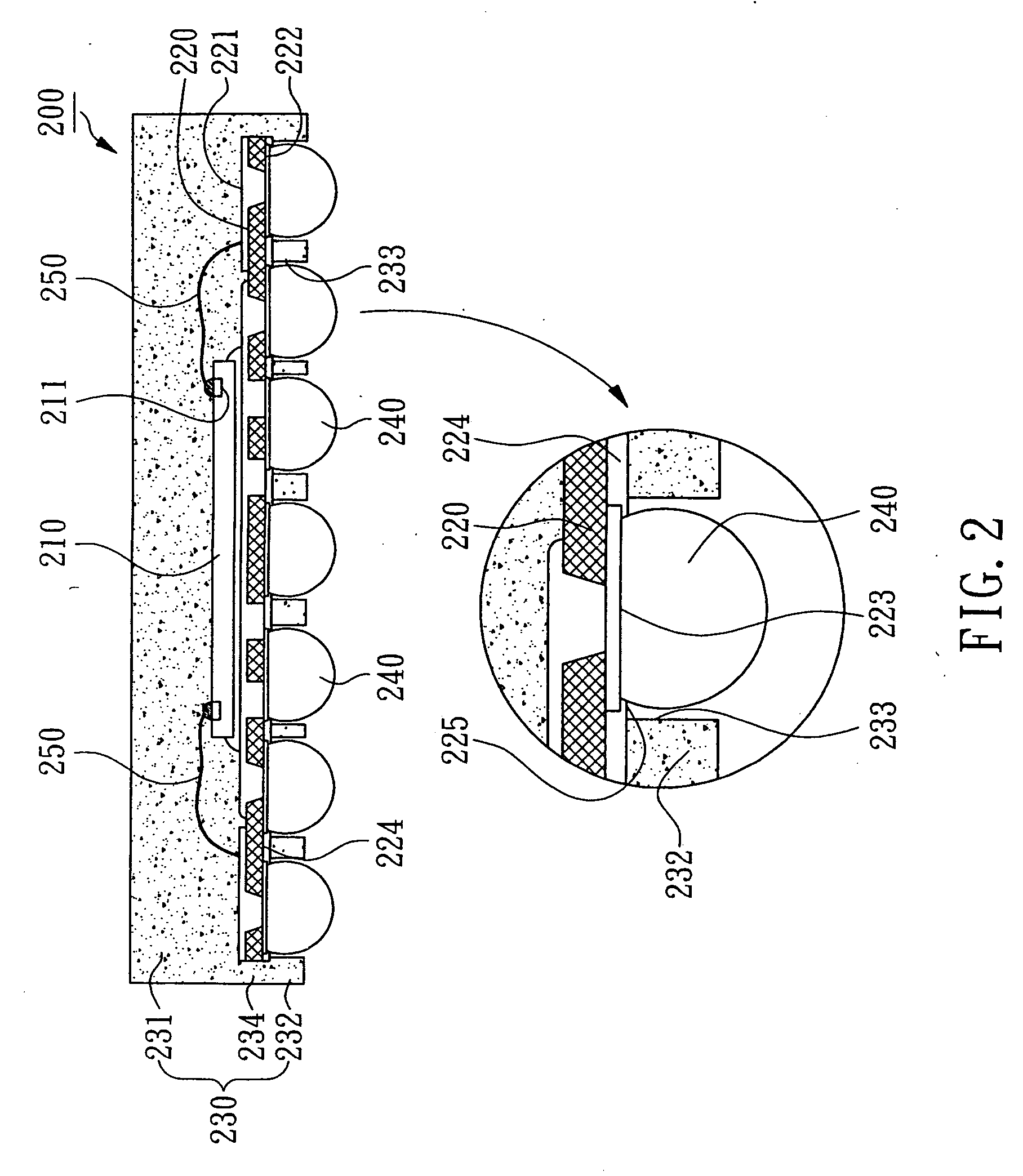

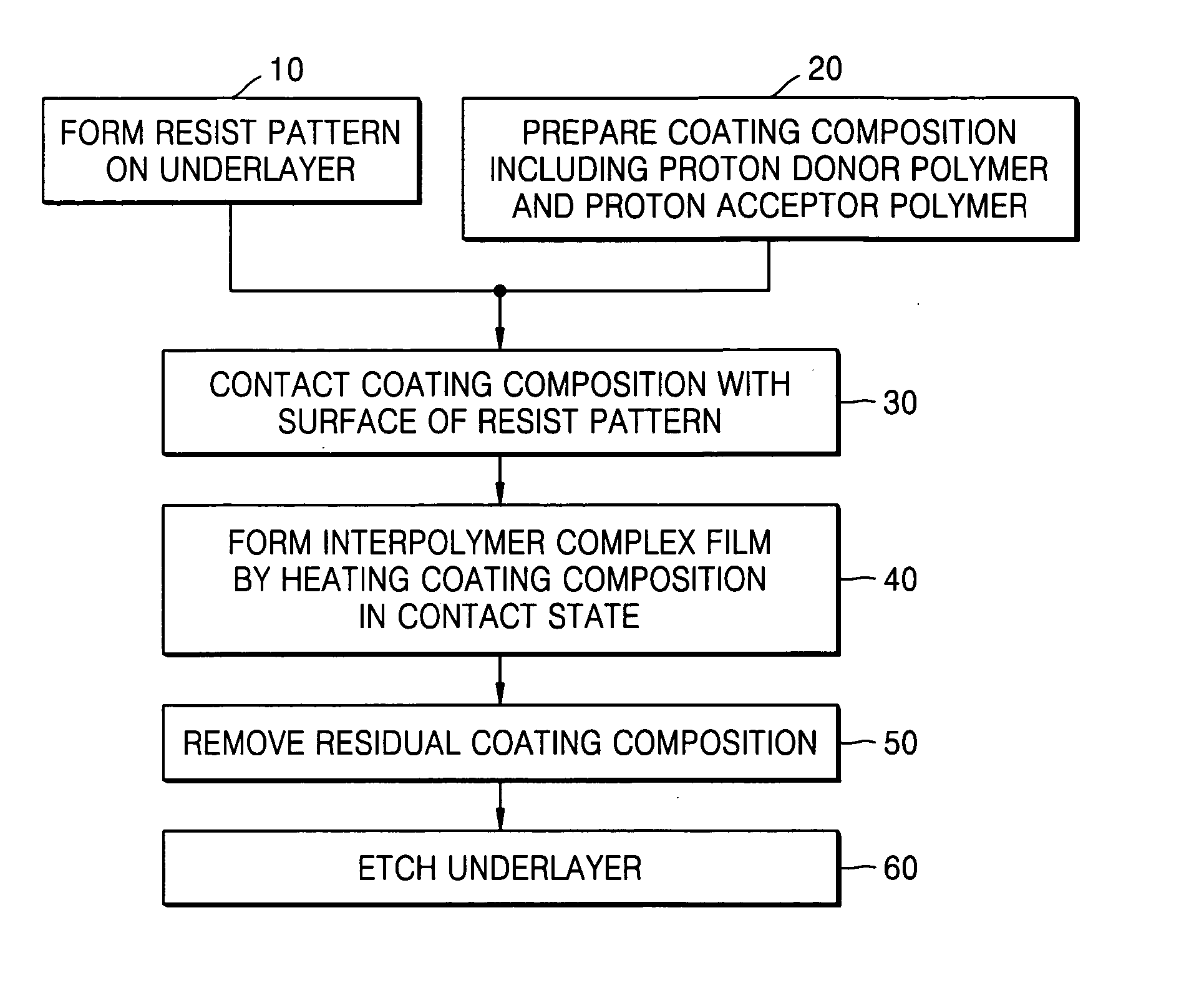

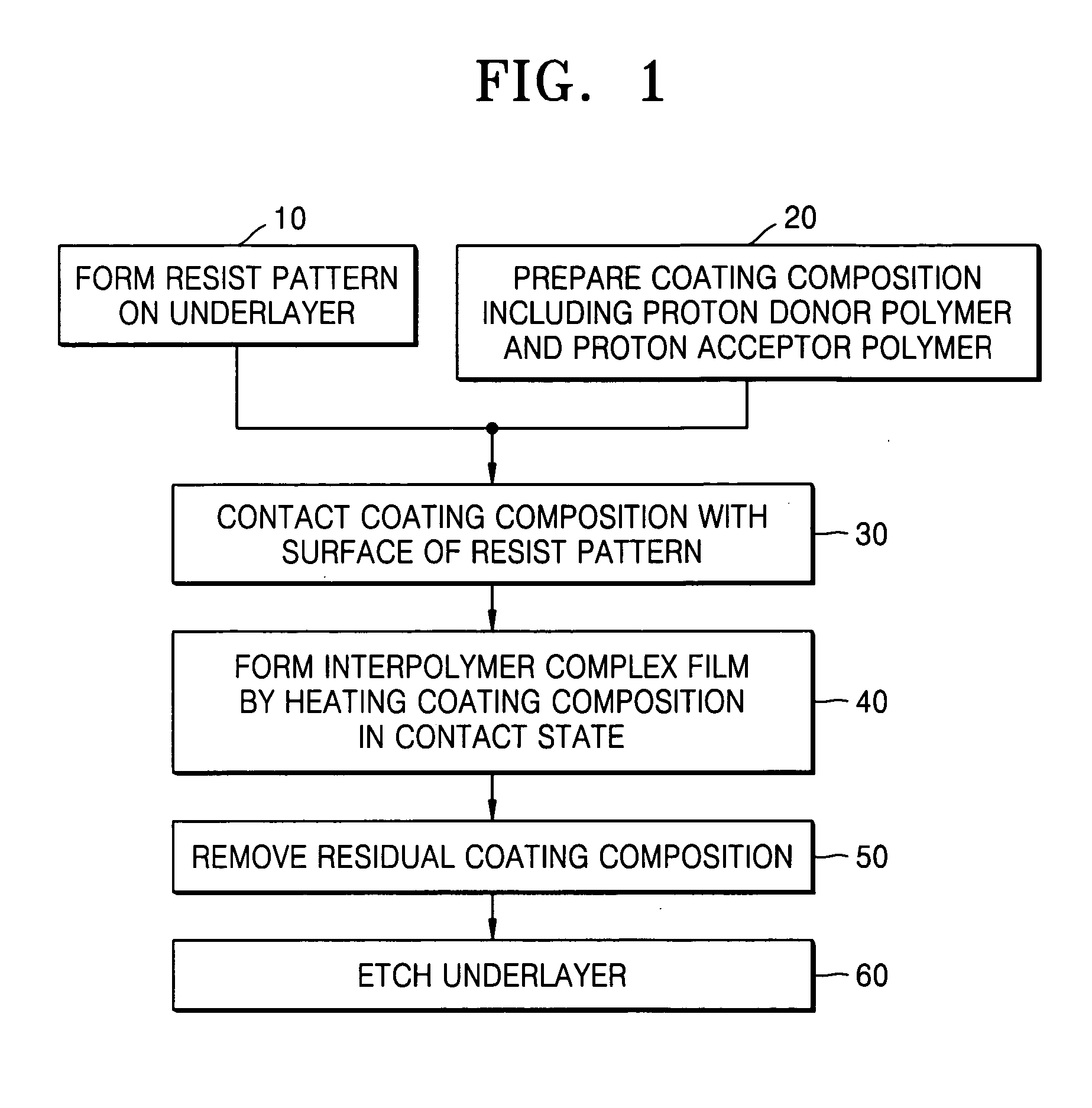

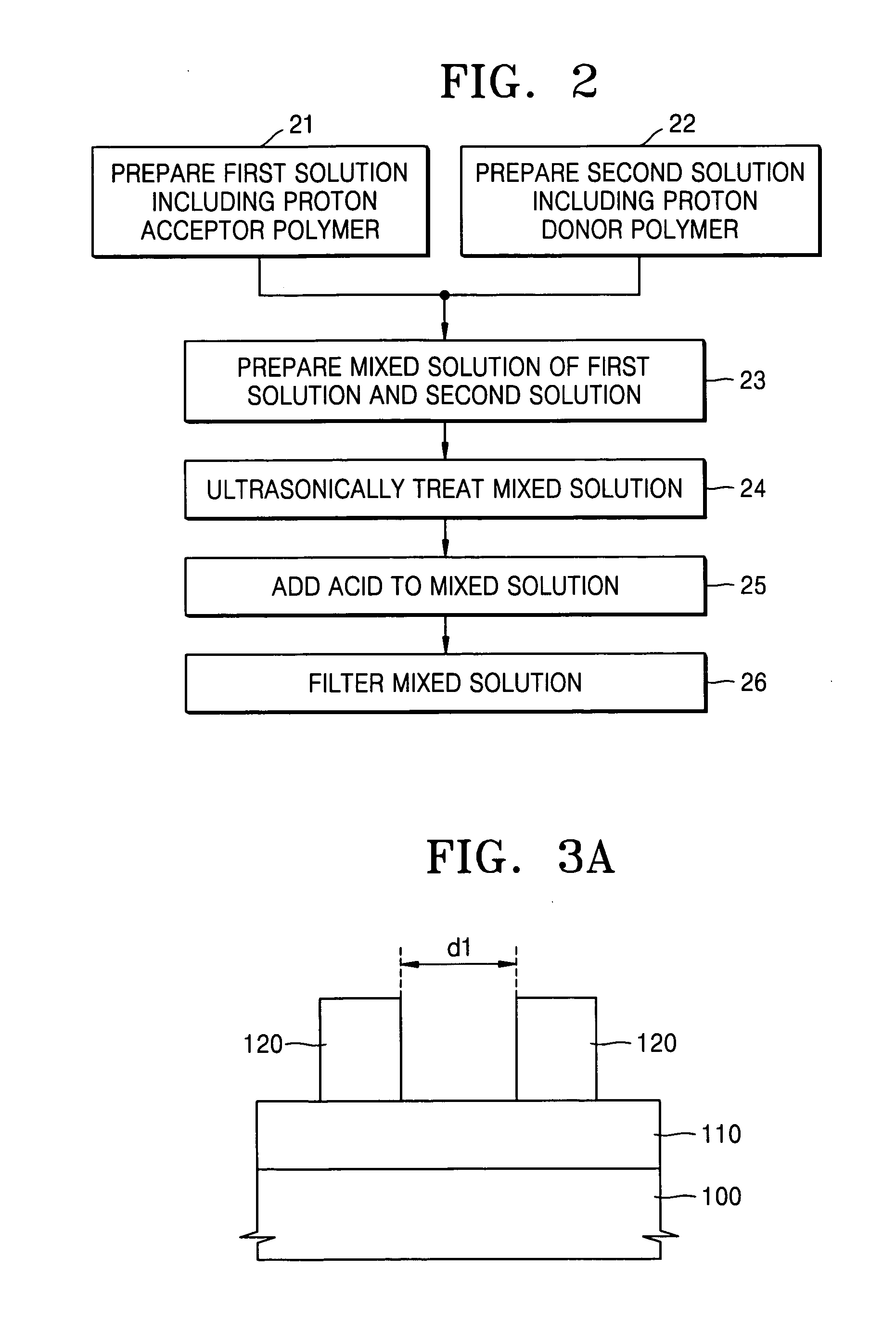

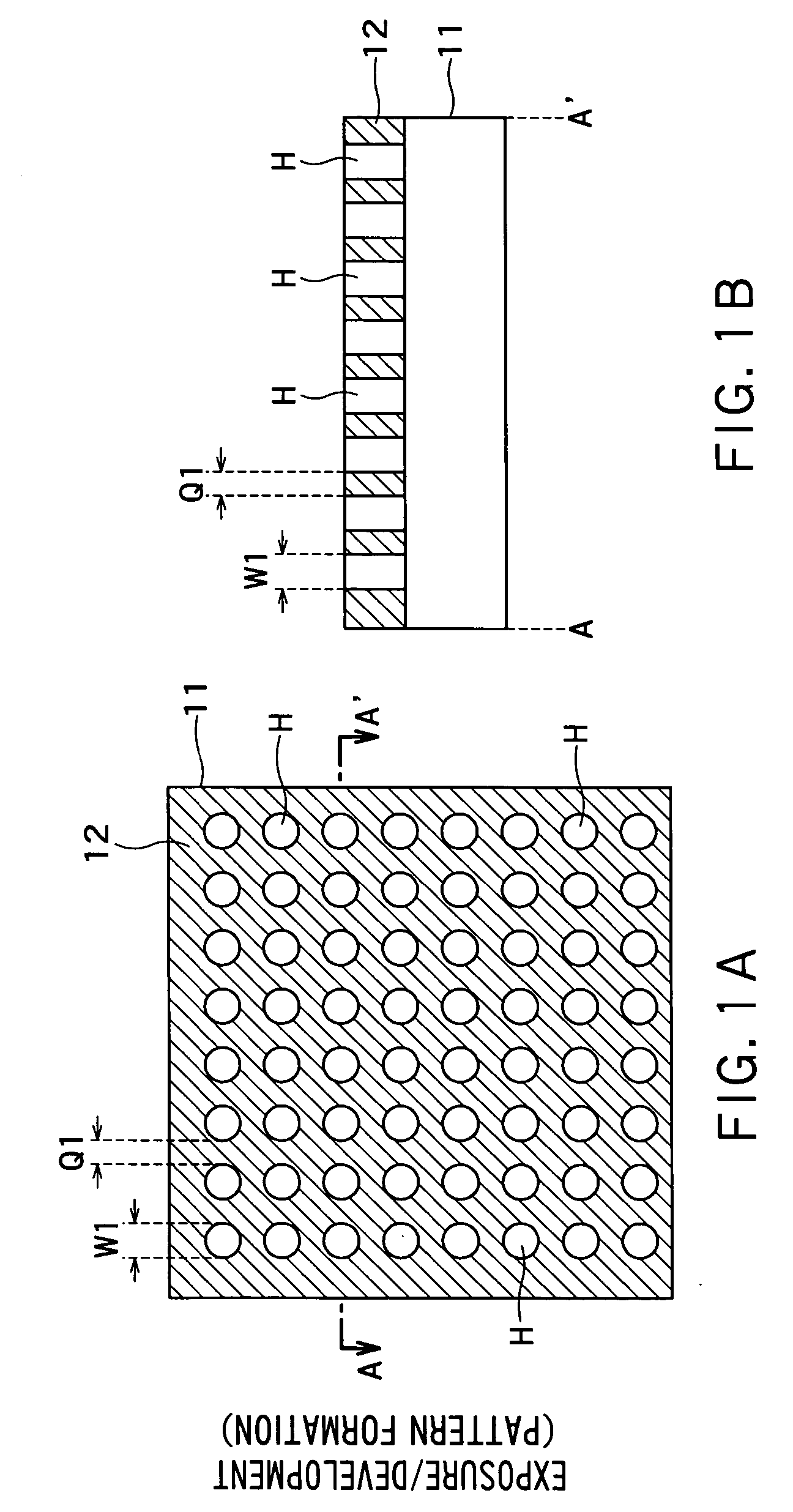

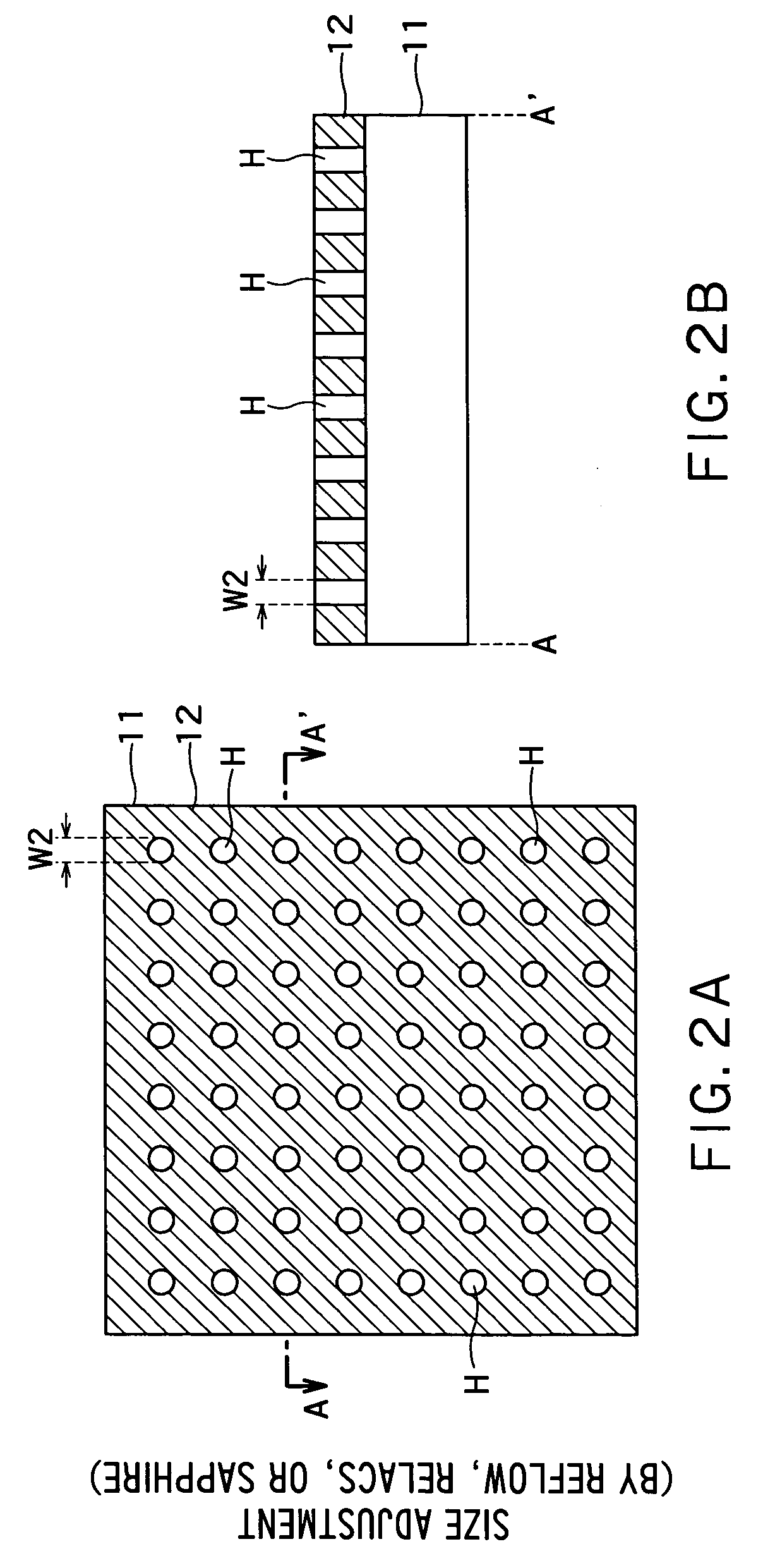

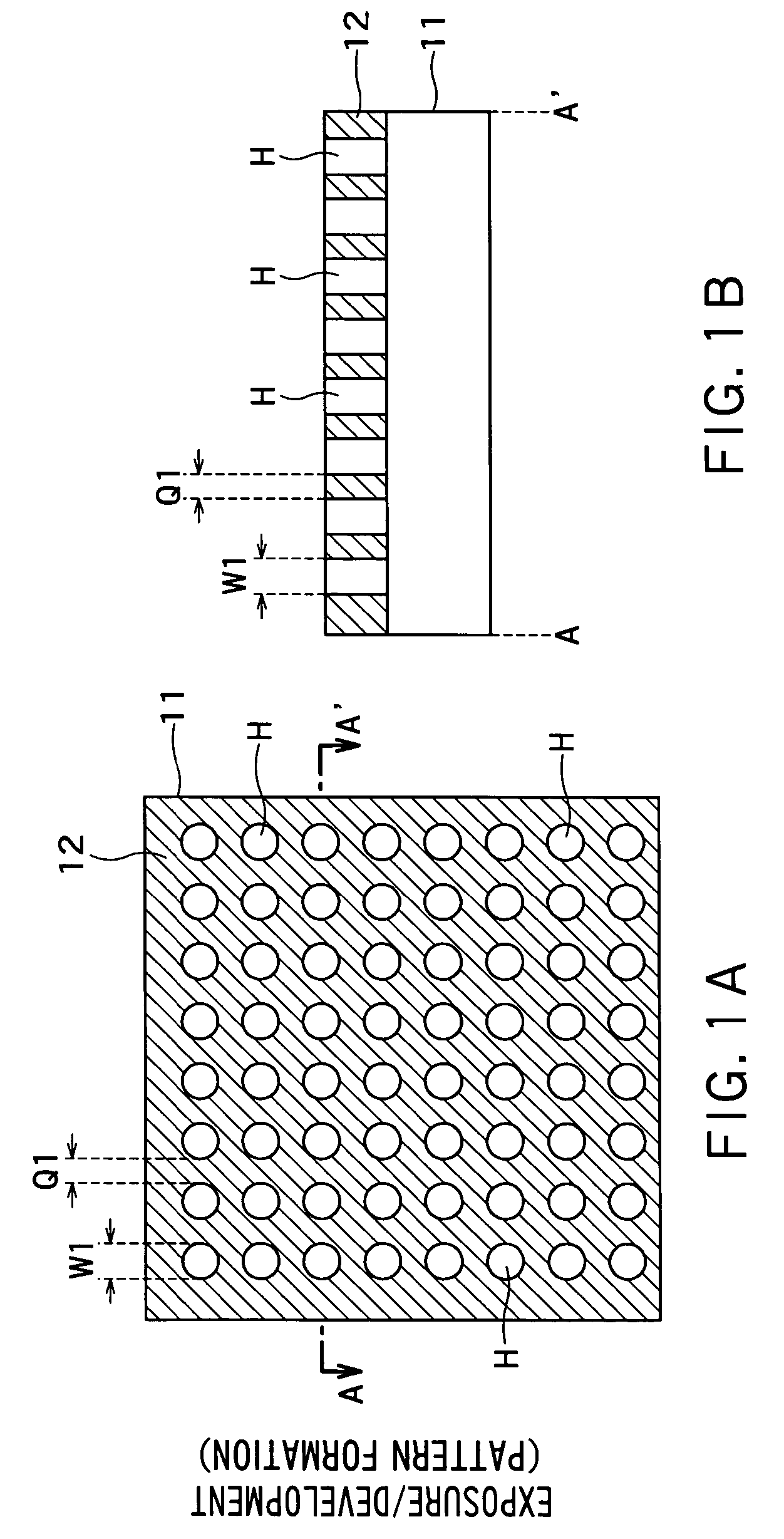

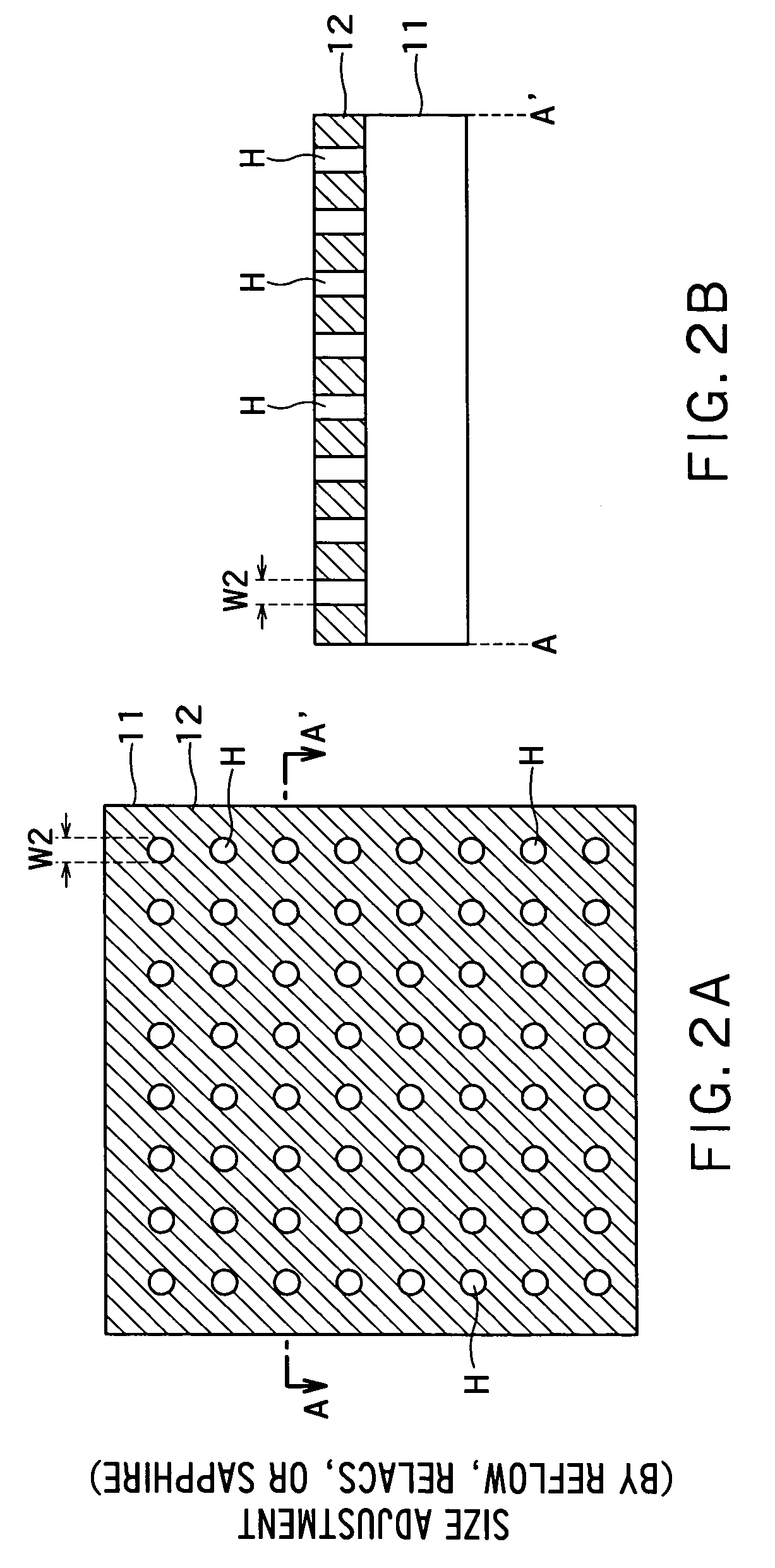

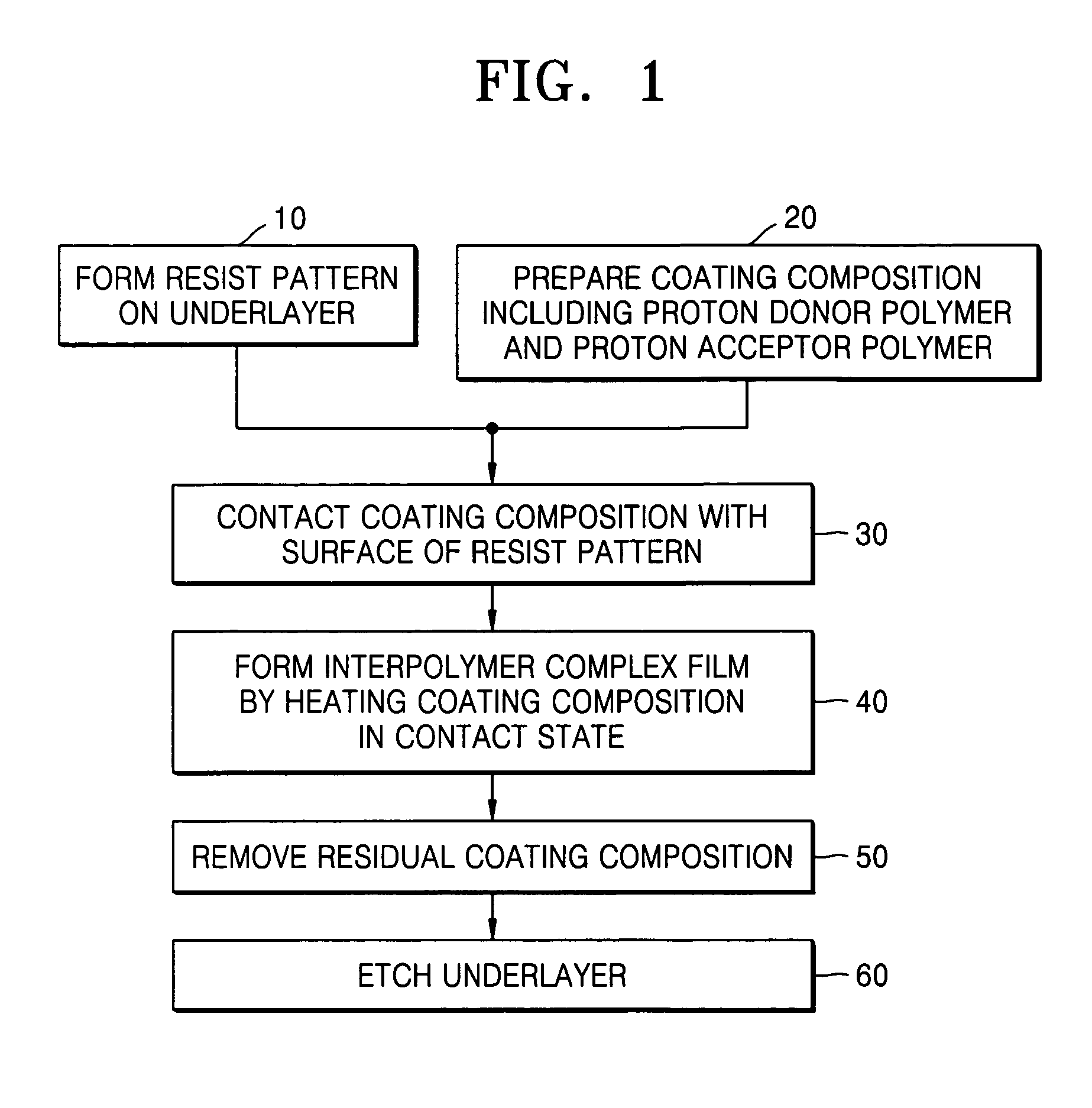

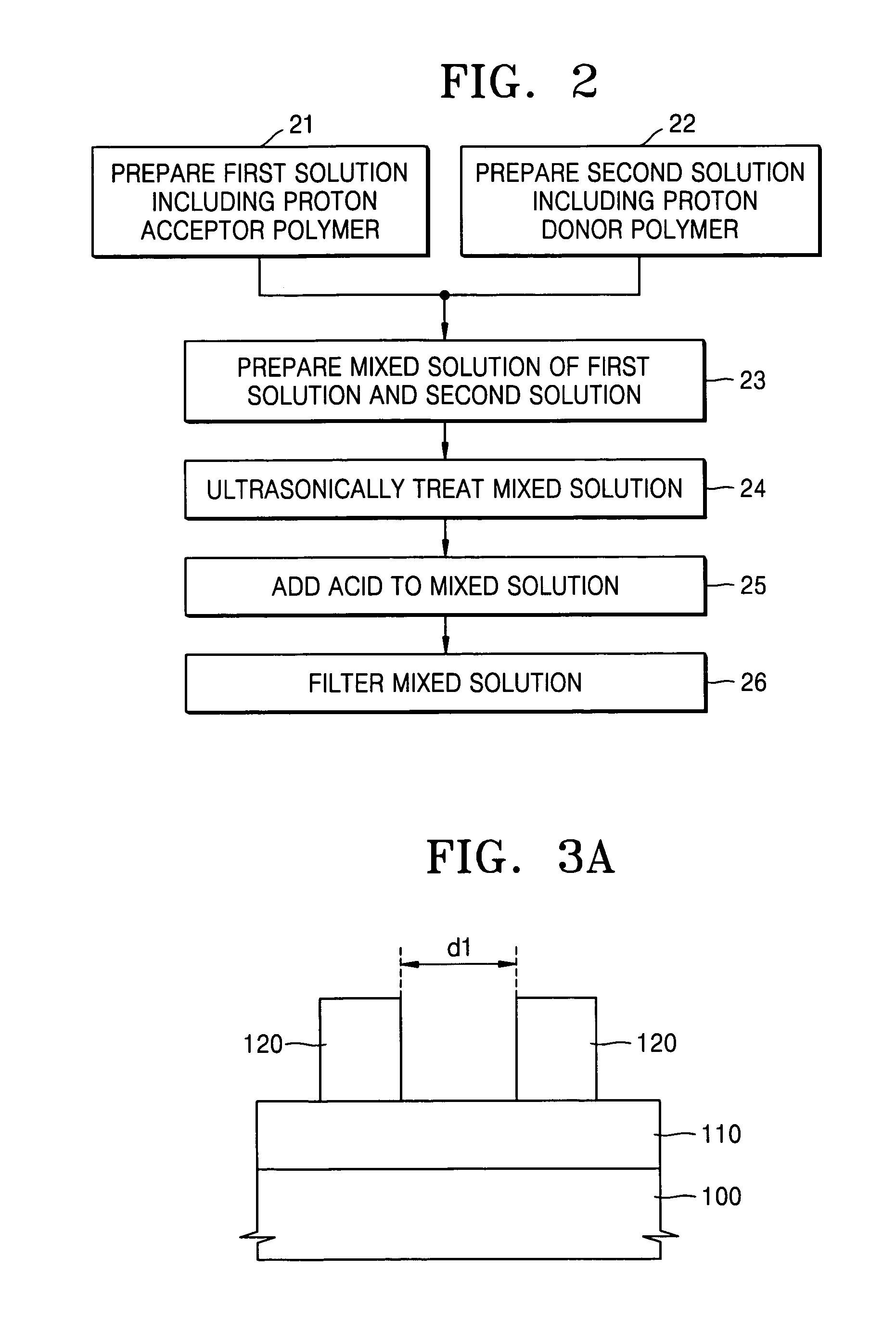

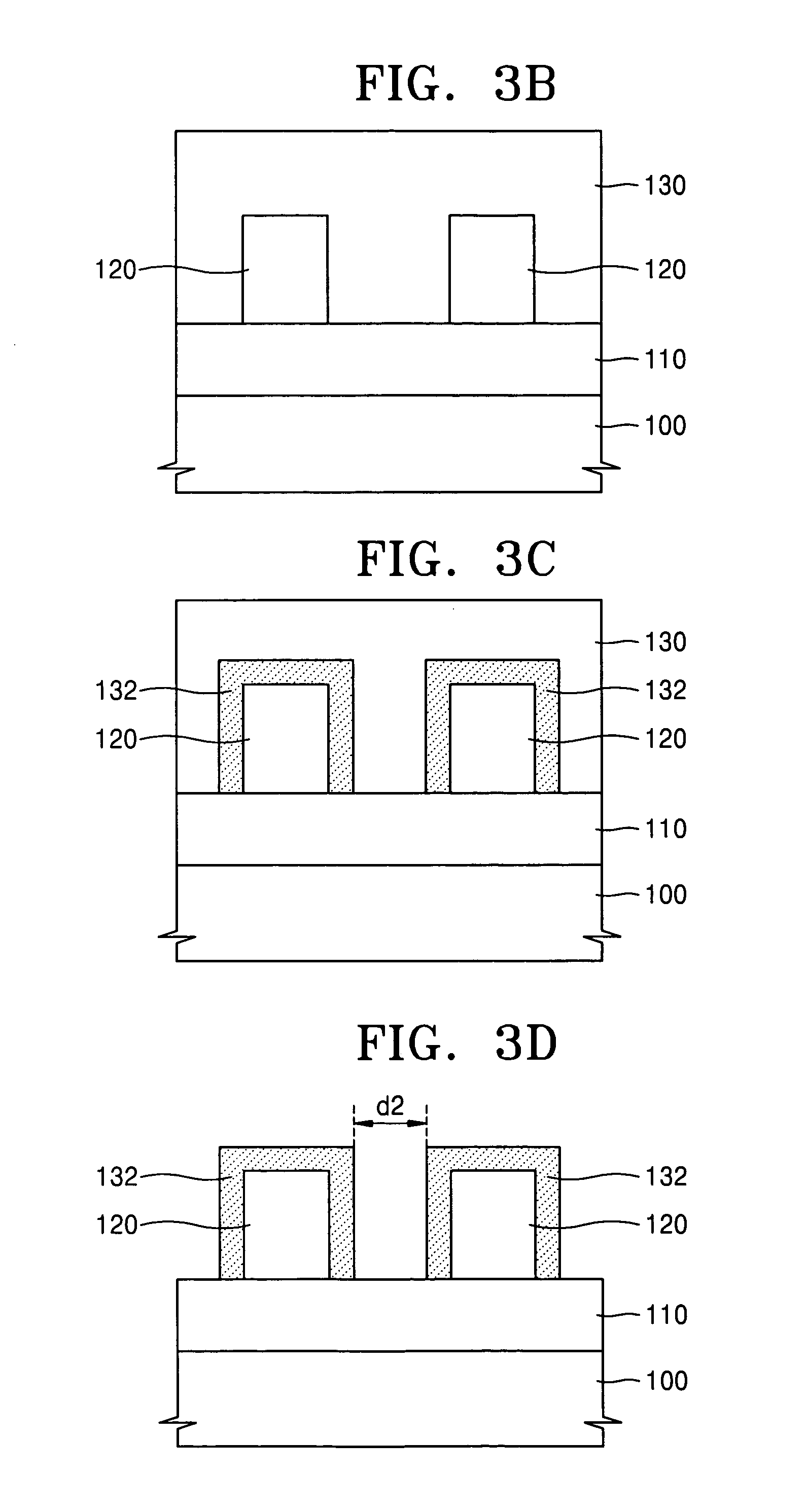

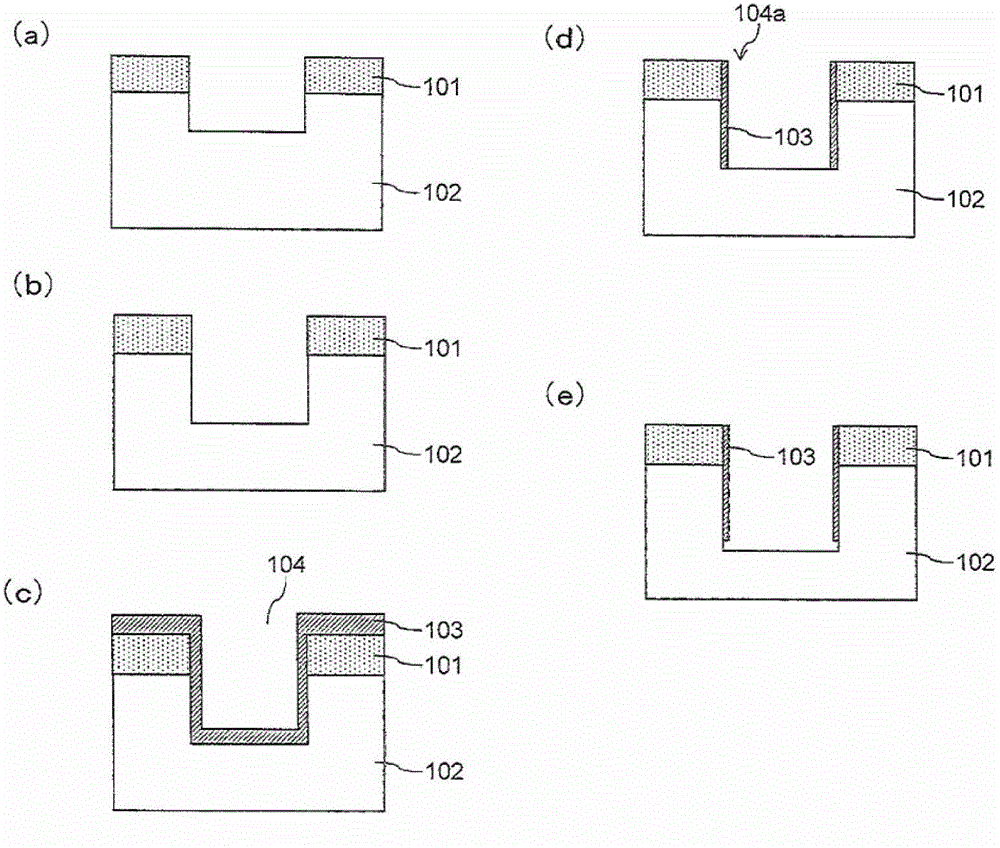

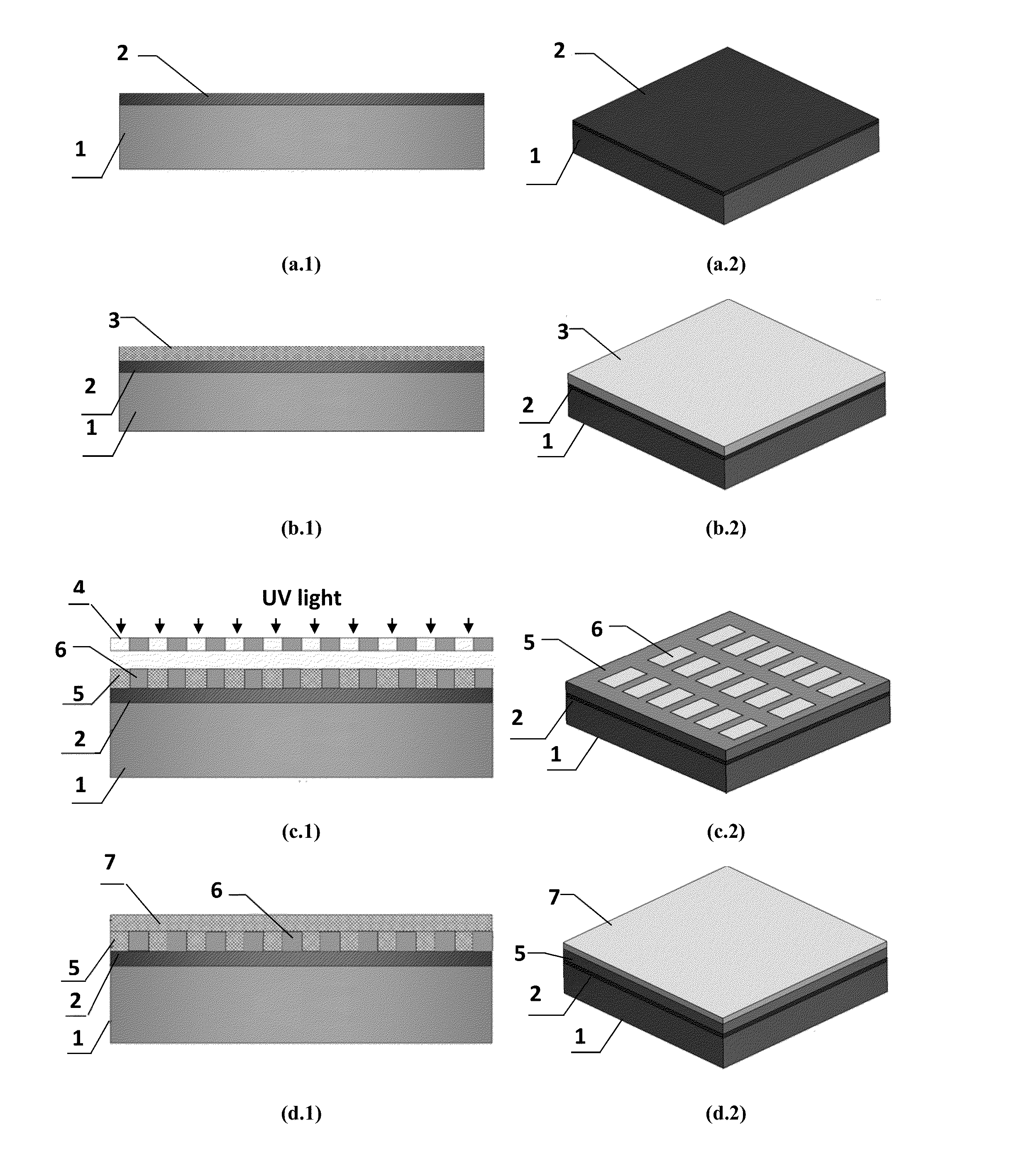

Mask pattern for semiconductor device fabrication, method of forming the same, method for preparing coating composition for fine pattern formation, and method of fabricating semiconductor device

ActiveUS20050227151A1Reduced opening sizeIso-dense bias can be minimizedSemiconductor/solid-state device manufacturingPretreated surfacesResistDevice material

A mask pattern for semiconductor device fabrication comprises a resist pattern formed on a semiconductor substrate, and an interpolymer complex film formd on the resist pattern, wherein the interpolymer complex film includes a network formed by a hydrogen bond between a proton donor polymer and a proton acceptor polymer.

Owner:SAMSUNG ELECTRONICS CO LTD

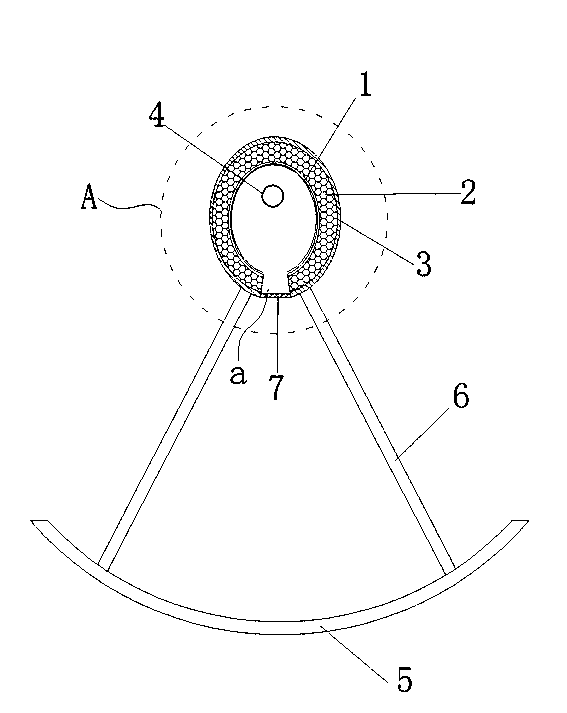

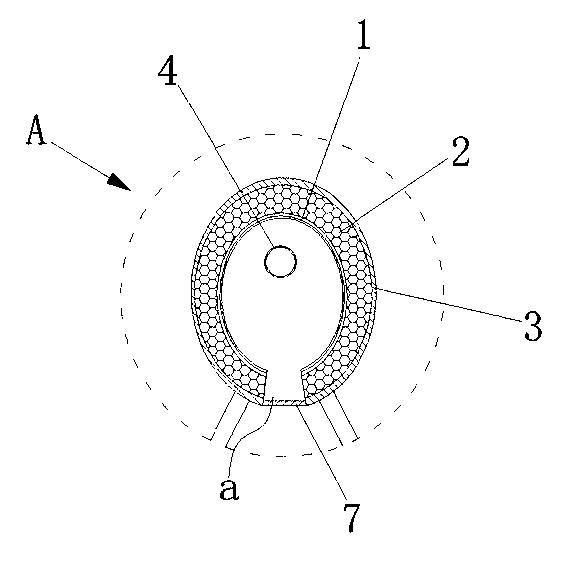

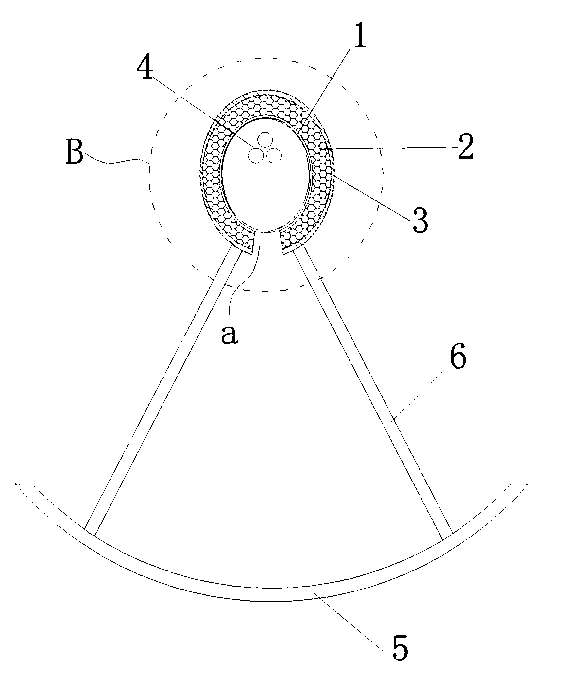

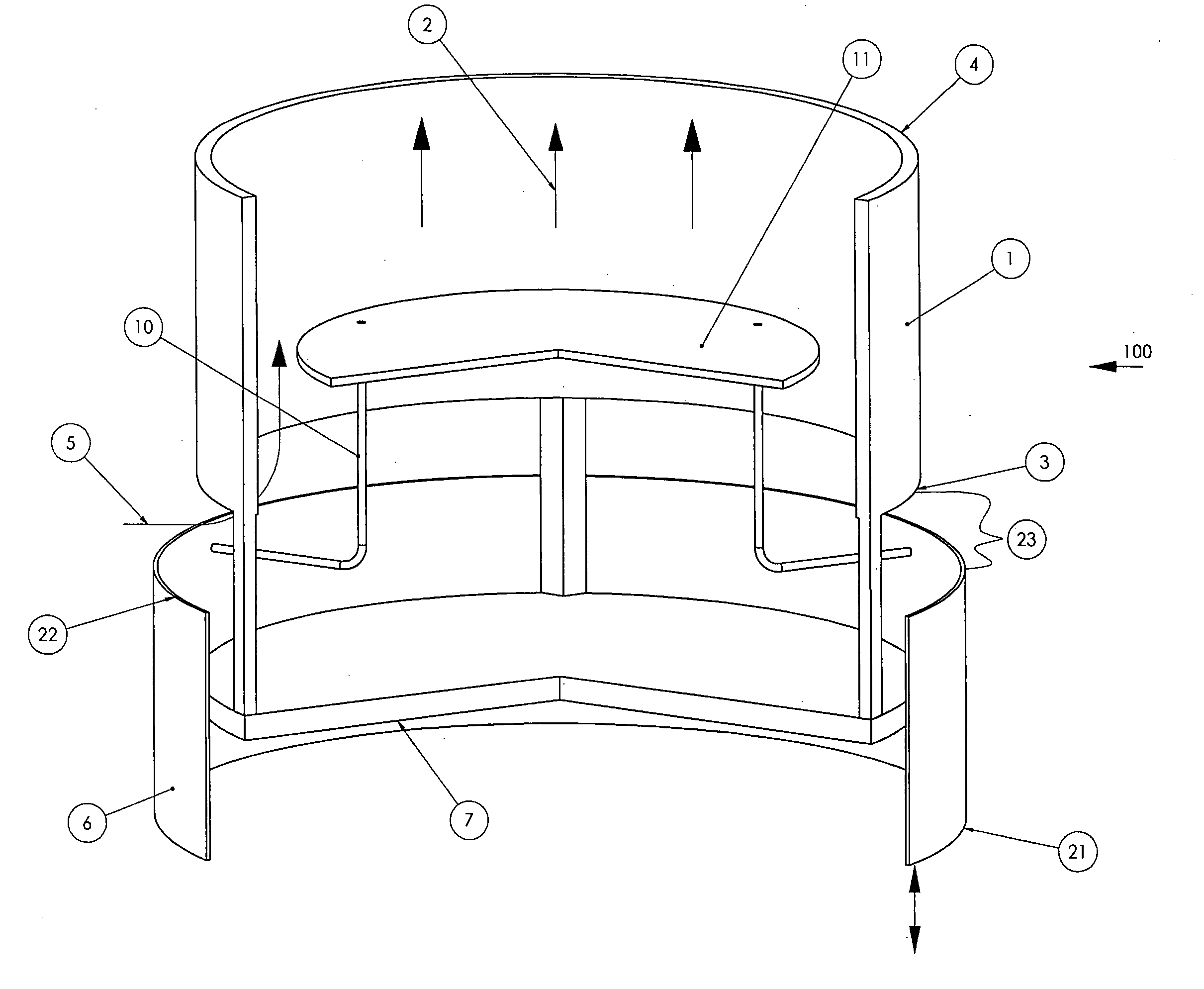

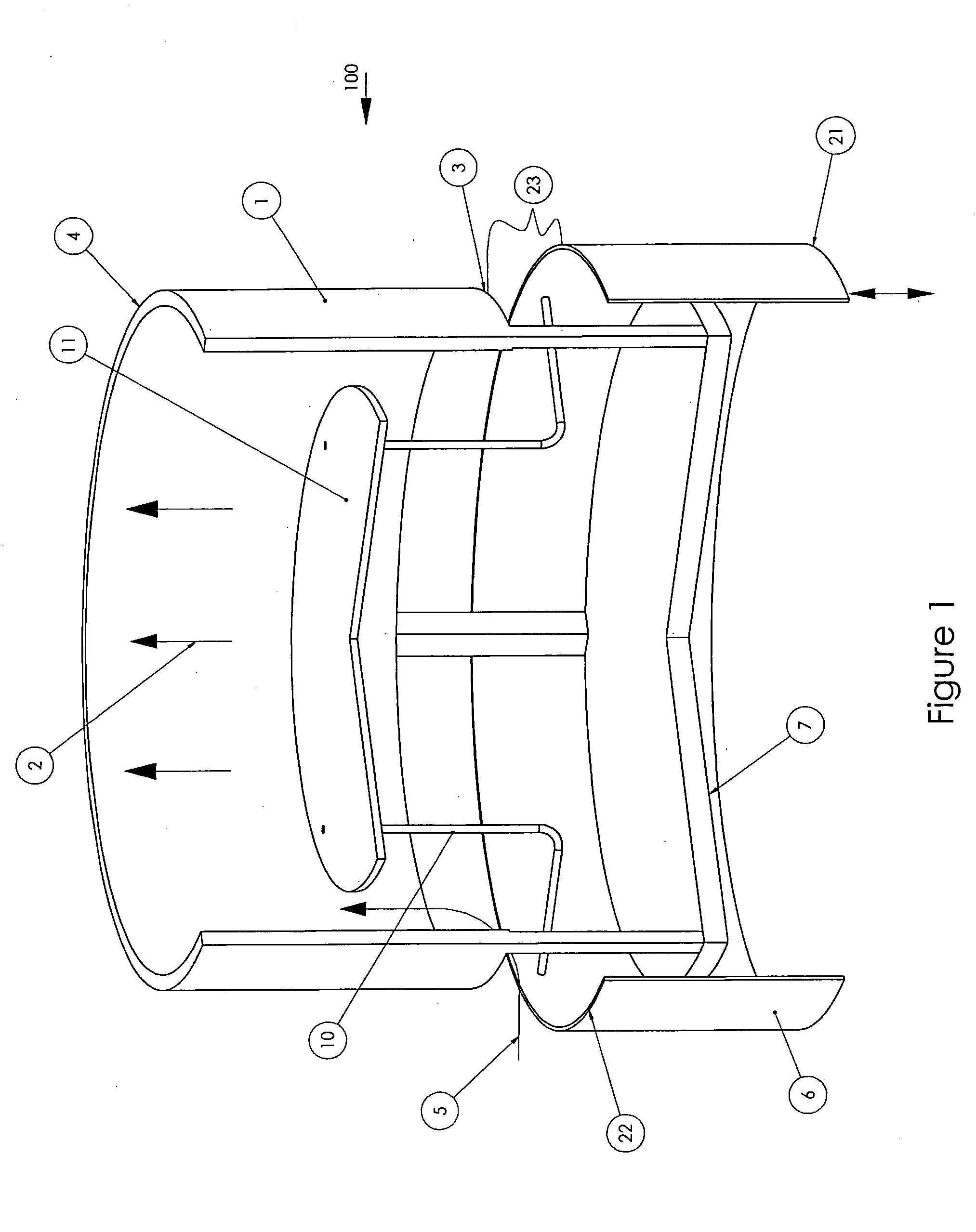

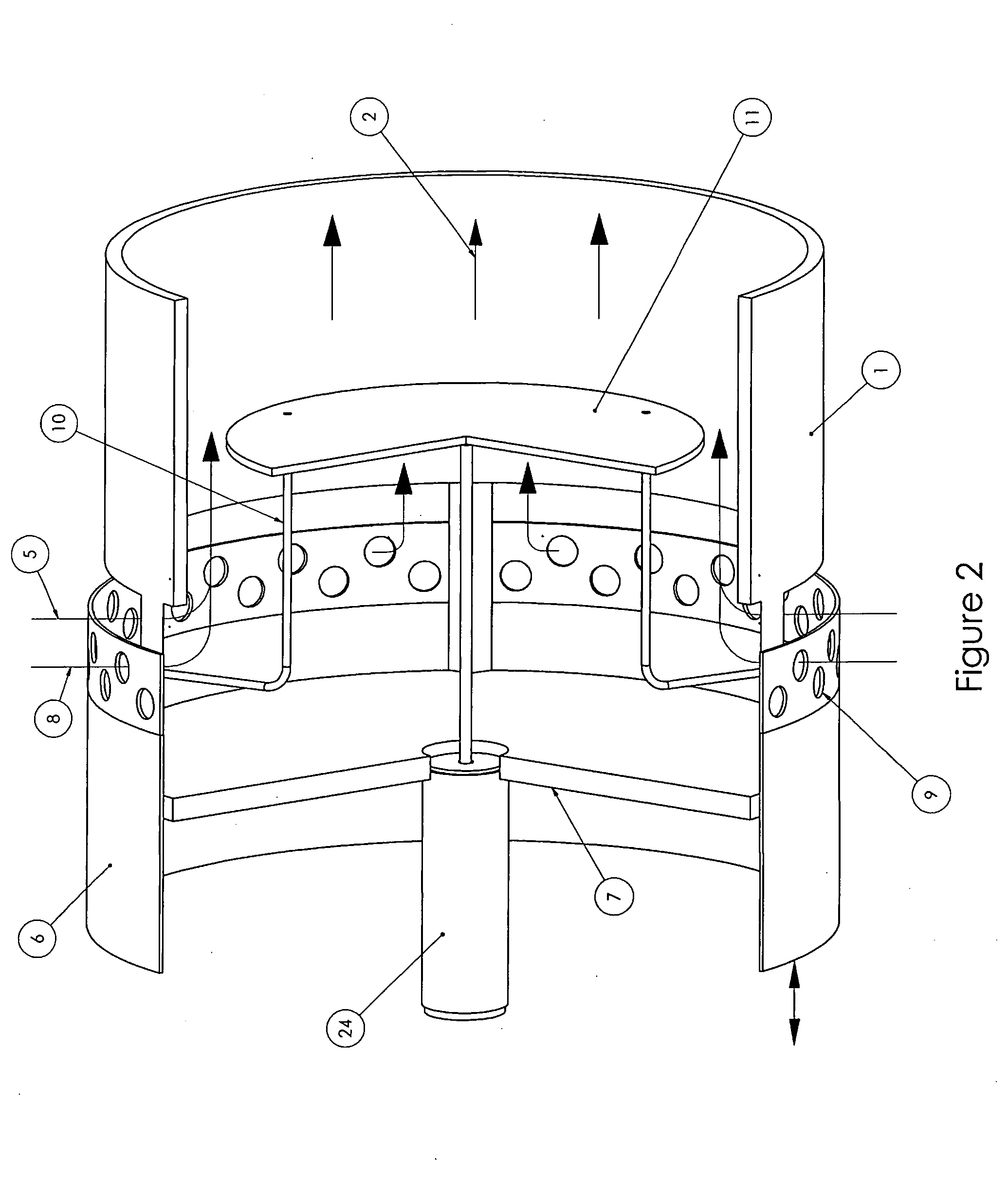

Pressure-bearing type solar collector based on groove-type parabolic mirror

ActiveCN103225900AImprove heat collection efficiencyReduce heat lossSolar heating energySolar heat devicesEllipseCollector device

The invention relates to a pressure-bearing type solar collector based on a groove-type parabolic mirror. The parabolic mirror is characterized by comprising an elliptical reflecting canister, a housing, a groove-type parabolic condenser and a pressure resistant metallic heat collection pipe group, wherein the reflecting canister adopts an elliptical stainless steel mirror reflecting canister or a glass reflecting canister; a light inlet is formed in the elliptical reflecting canister; the housing is arranged outside the reflecting canister; a gap between the housing and the reflecting canister is filled with heat insulating materials; the pressure resistant metallic heat collection pipe penetrates the reflecting canister; and the light condensation focus of the groove-type parabolic condenser is positioned at one focus near or around one side of the light entrance port. According to the solar collector provided by the invention, the heat absorbing medium is positioned in the pressure resistant metallic heat collection pipe groups in the black body cavity, so as to enable the whole heat-collector to manufacture the pressure-bear structure smoothly, the requirement of the process and material is decreased greatly, the manufacturing cost of the pressure-bearing type solar collector based on the groove-type parabolic mirror is decreased, the performance of the heat collector is more steady and reliable, and the safety coefficient is high.

Owner:SUNSHORE SOLAR ENERGY IND +2

Flow regulator device

InactiveUS20090151800A1Reduced opening sizeIncrease opening sizePipe supportsOperating means/releasing devices for valvesEngineeringMechanical engineering

A fluid flow regulator of the present invention comprises in combination a stationary hollow duct housing having a first end and a second end through which fluid flows. The device also incorporates a movable member aligned concentric with the duct having an end essentially similarly shaped and sized to the first end of the housing. The member may be spaced apart from the duct so that fluid can enter the duct housing through an opening defined by the space between the end of the member and the first end of the duct, with the movement of the member serving to change the size of opening. The movement of the member is controlled by the movement of a float located within the duct. The position of the float can be preset by the operator of the invention so that when fluid flow into the duct is at a predetermined amount the float will remain stationary, and when the fluid flow increases above such predetermined level the float will be moved in the direction of the fluid flow and when fluid flow into the duct is below said predetermined amount, the float will move the member opposite the direction of fluid flow.

Owner:F L SMIDTH & CO AS

Method of forming contact hole and method of manufacturing semiconductor device

InactiveUS20050170294A1Reduced opening sizeSemiconductor/solid-state device detailsSolid-state devicesResistDevice material

A method of forming a contact hole according to an embodiment of the present invention comprises exposing a resist film formed on a semiconductor substrate to a light using a first photomask in which mask patterns are arranged two-dimensionally at a predetermined pitch; developing the resist film to form contact hole patterns corresponding to the mask patterns in the resist film; reducing an opening size of each of the contact hole patterns formed in the resist film; exposing the resist film to the light using a second photomask in which predetermined patterns are formed to set a reflow starting temperature of a first resist film area that corresponds to the predetermined patterns to be relatively higher than a reflow starting temperature of a second resist film area other than the first resist film area; and heating the semiconductor substrate at a temperature equal to or higher than the reflow starting temperature of the second resist film area and lower than the reflow starting temperature of the first resist film area to subject the second resist film area to reflow and eliminate the contact hole patterns formed in the second resist film area.

Owner:KK TOSHIBA

Absorbent article with urine-permeable coversheet

The present disclosure is directed to an absorbent article (e.g., a diaper or training pant) having a backsheet, an absorbent core and a topsheet provided with at least one opening adapted to receive fecal material. The article also includes a genital coversheet with one or more central longitudinal (partial) folds or fixed folds, which in use forms a pocket to cover the genitals, and which is positioned in, under or above part of the opening, such that a void space can be created between the genital coversheet and the absorbent core and such that a void space is present between the topsheet and the absorbent core. The present disclosure also relates to process for making pocket-shape genital coversheets for absorbent articles of the invention.

Owner:THE PROCTER & GAMBLE COMPANY

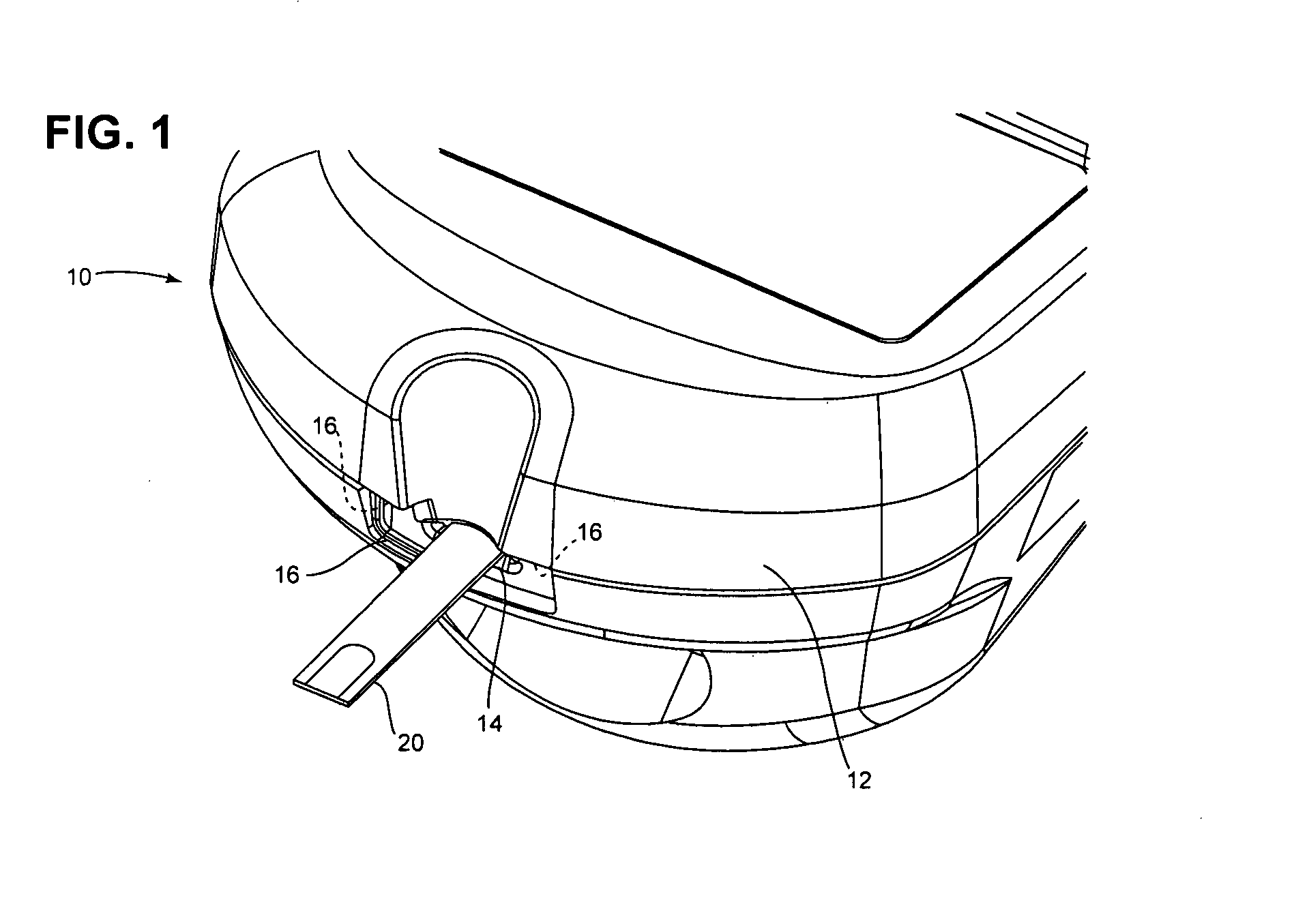

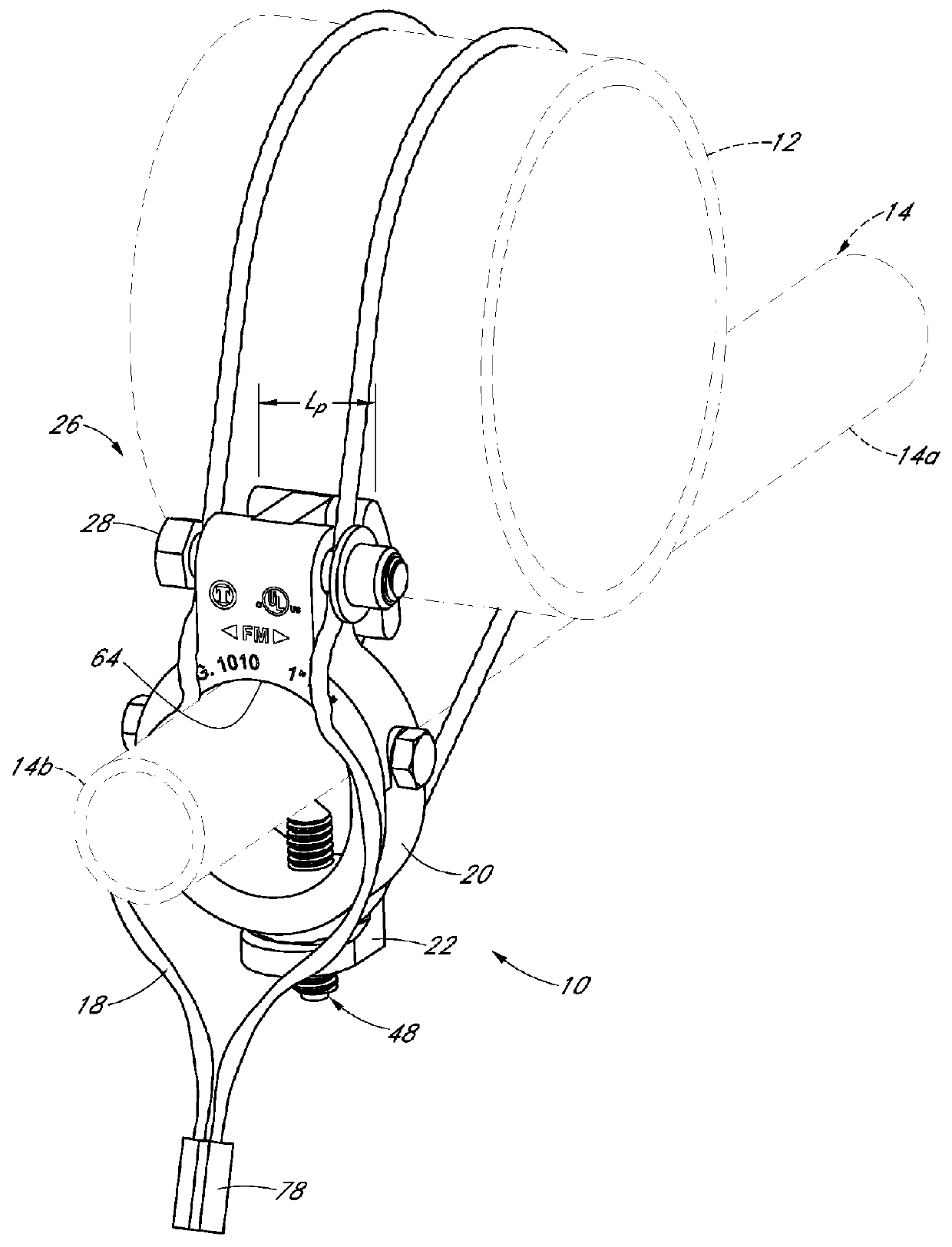

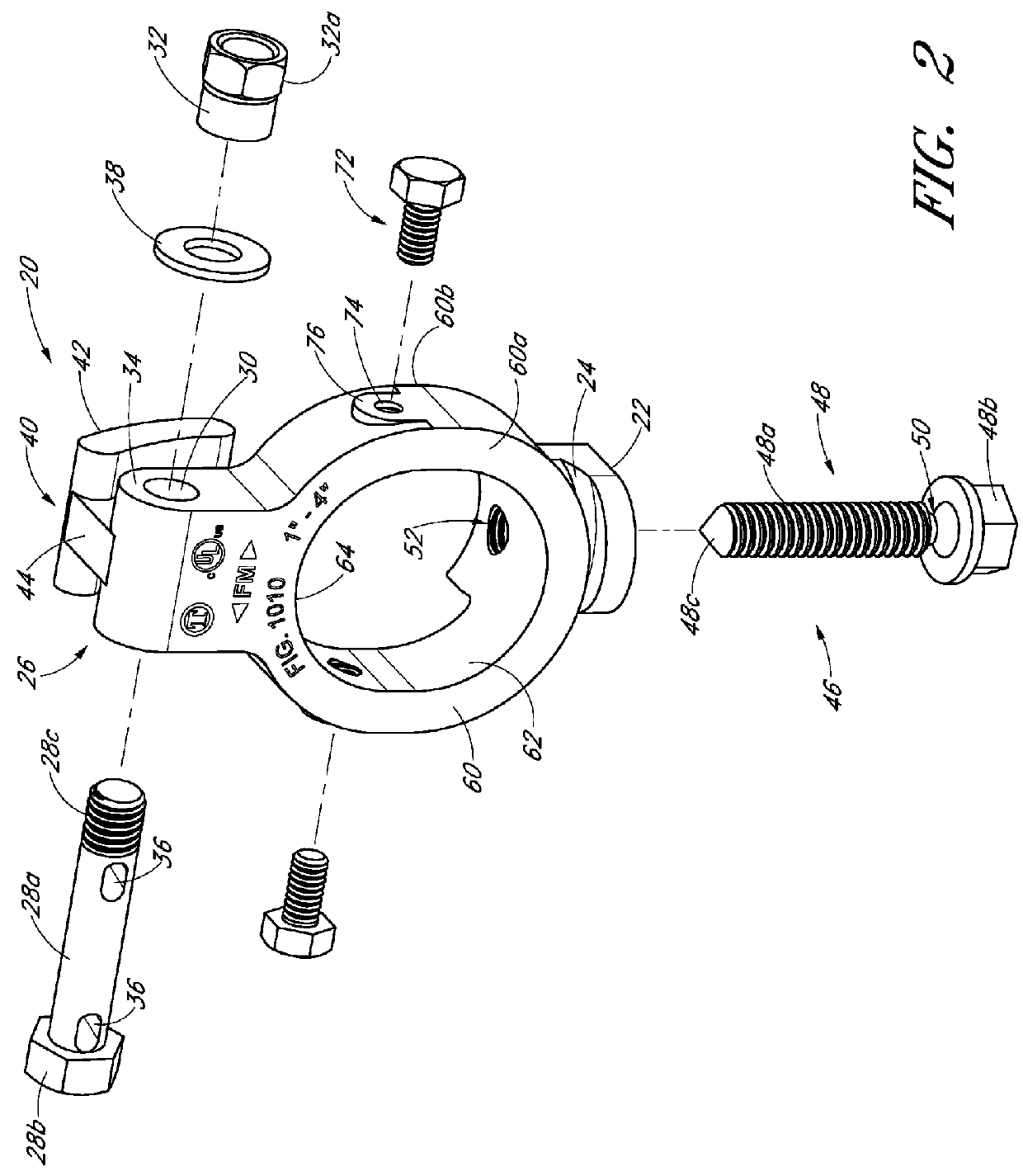

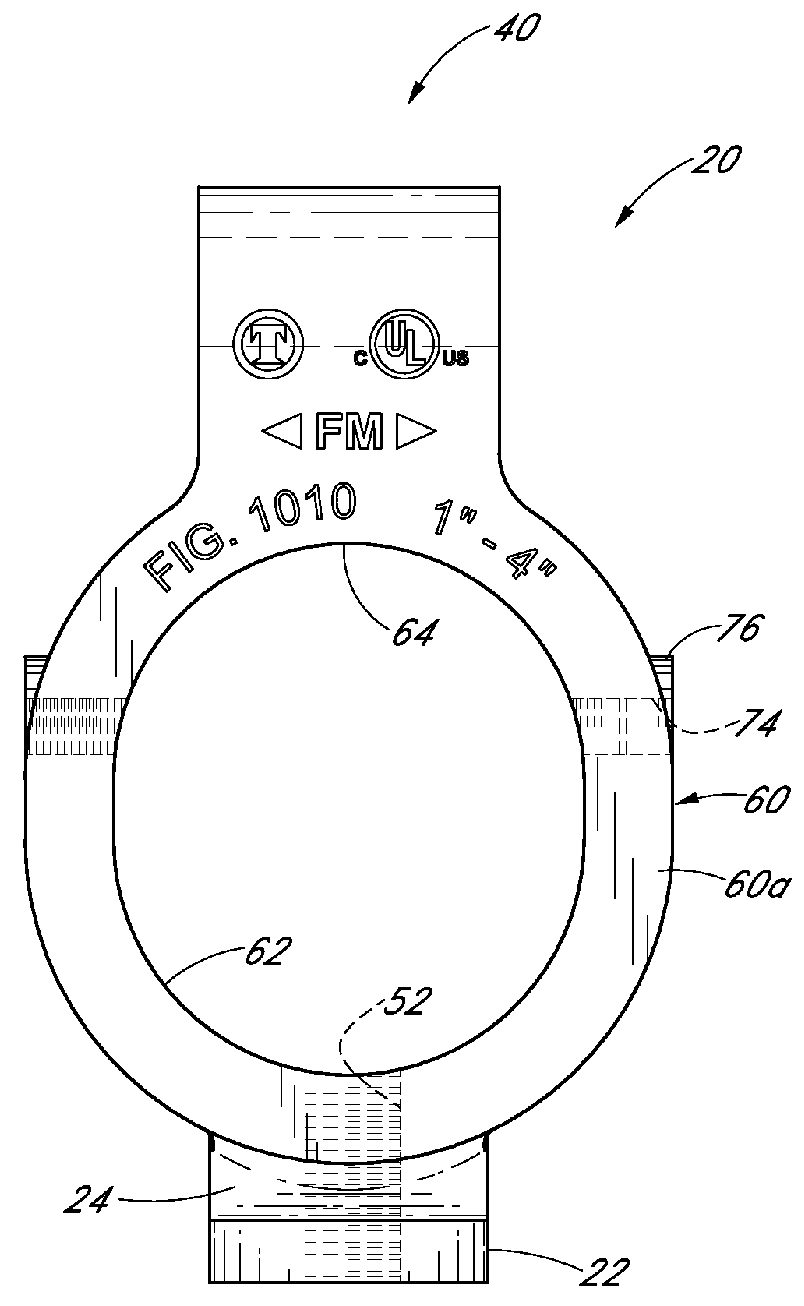

Pipe-to-pipe brace assembly

ActiveUS20130068900A1Reduce size of openingReduced opening sizePipe supportsStands/trestlesEngineeringWrap around

A pipe brace assembly includes a main clamp body that can be secured to a brace pipe. A cable, or other flexible tensioning member, can be wrapped around a braced pipe and secured to the main clamp body. The pipe brace assembly includes a method or mechanism for tensioning the cable or flexible tensioning member around the braced pipe. In some embodiments, the tensioning method or mechanism involves moving, such as rotating, the main clamp body to tension the cable or tensioning member. The clamping of the main clamp body and tensioning of the cable or tensioning member can occur simultaneously.

Owner:EATON INTELLIGENT POWER LIMITED

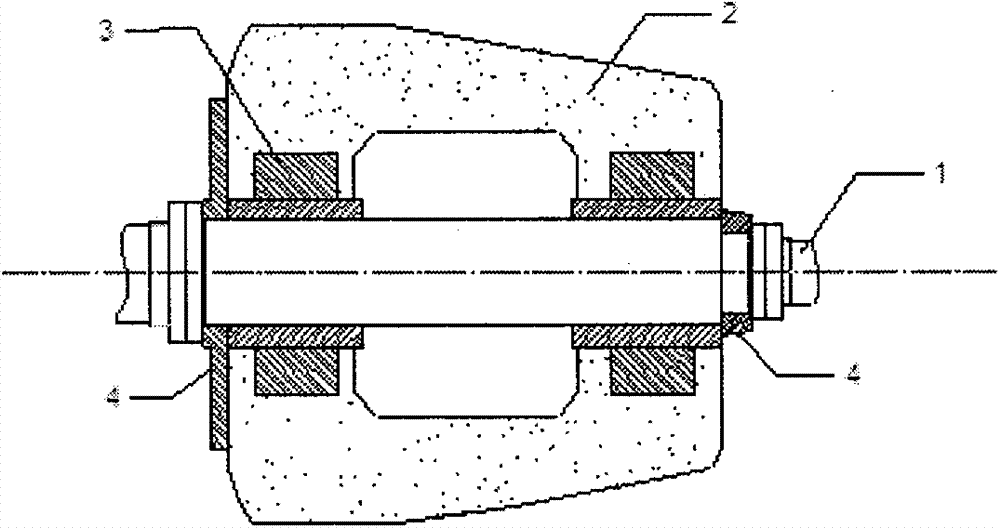

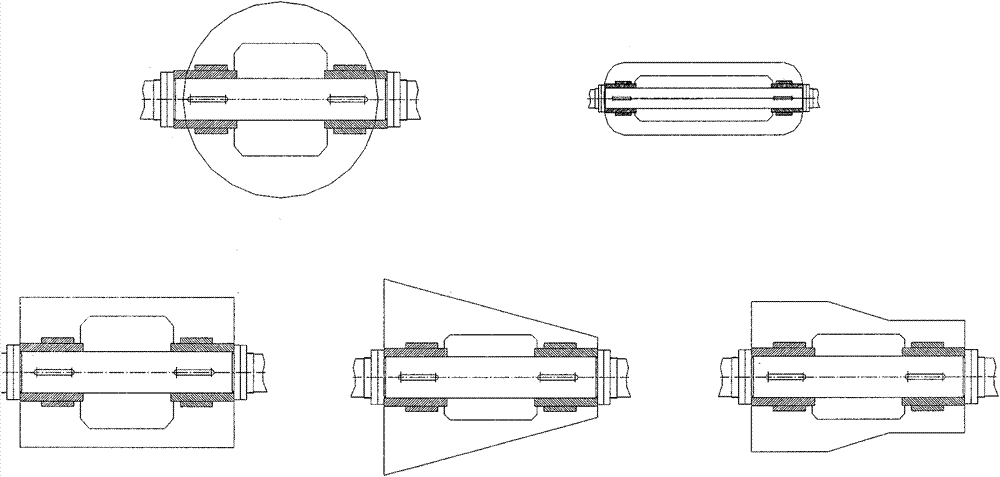

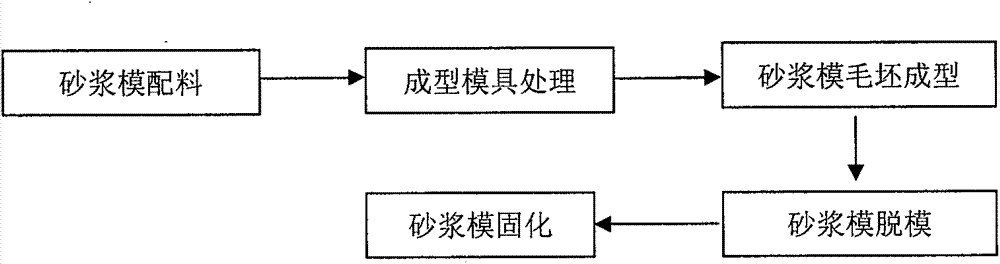

Preparation methods for soluble core mould and nonmetal-lining or no-lining fibre winding container

A preparation method of a solube core mold comprises: blank moulding of a mortar mould: a) the ingredients of the mortar die consists of quartz sand, polyvinyl alcohol and water with a weight ratio of 100:1-2:6; b) the inner sleeve of the mortar mould is sleeved in a moulding mould, then adding the uniformly stirred ingredients of the mortar mould into the moulding mould until the moulding mould is full; c) demoulding; and d) solidifying; and a mandrel is penetrated in the mortar mould, the mandrel and the mortar mould are fixed in a circumferential direction by using the inner sleeve of the mortar mould and fixed in an axial direction by using a locking ring. A preparation method of a nonmetal-lining or no-lining fibre winding container comprises: infiltrating a fibre reinforced material in a resin solution, winding the fibre reinforced material on the soluble core mould in a circumferential direction and in a longitudinal direction by using a winder, solidifying, washing with water and demoulding. By using the container, demoulding can be finished by water washing. The soluble core mould is especially suitable for preparing composite material containers with a complex-shape internal profile as well as hard to demould, is low in cost and reusable in raw materials.

Owner:北京玻钢院复合材料有限公司

Method of forming contact hole and method of manufacturing semiconductor device

InactiveUS7361454B2Reduced opening sizeSemiconductor/solid-state device detailsSolid-state devicesResistSemiconductor

A method of forming a contact hole according to an embodiment of the present invention comprises exposing a resist film formed on a semiconductor substrate to a light using a first photomask in which mask patterns are arranged two-dimensionally at a predetermined pitch; developing the resist film to form contact hole patterns corresponding to the mask patterns in the resist film; reducing an opening size of each of the contact hole patterns formed in the resist film; exposing the resist film to the light using a second photomask in which predetermined patterns are formed to set a reflow starting temperature of a first resist film area that corresponds to the predetermined patterns to be relatively higher than a reflow starting temperature of a second resist film area other than the first resist film area; and heating the semiconductor substrate at a temperature equal to or higher than the reflow starting temperature of the second resist film area and lower than the reflow starting temperature of the first resist film area to subject the second resist film area to reflow and eliminate the contact hole patterns formed in the second resist film area.

Owner:KK TOSHIBA

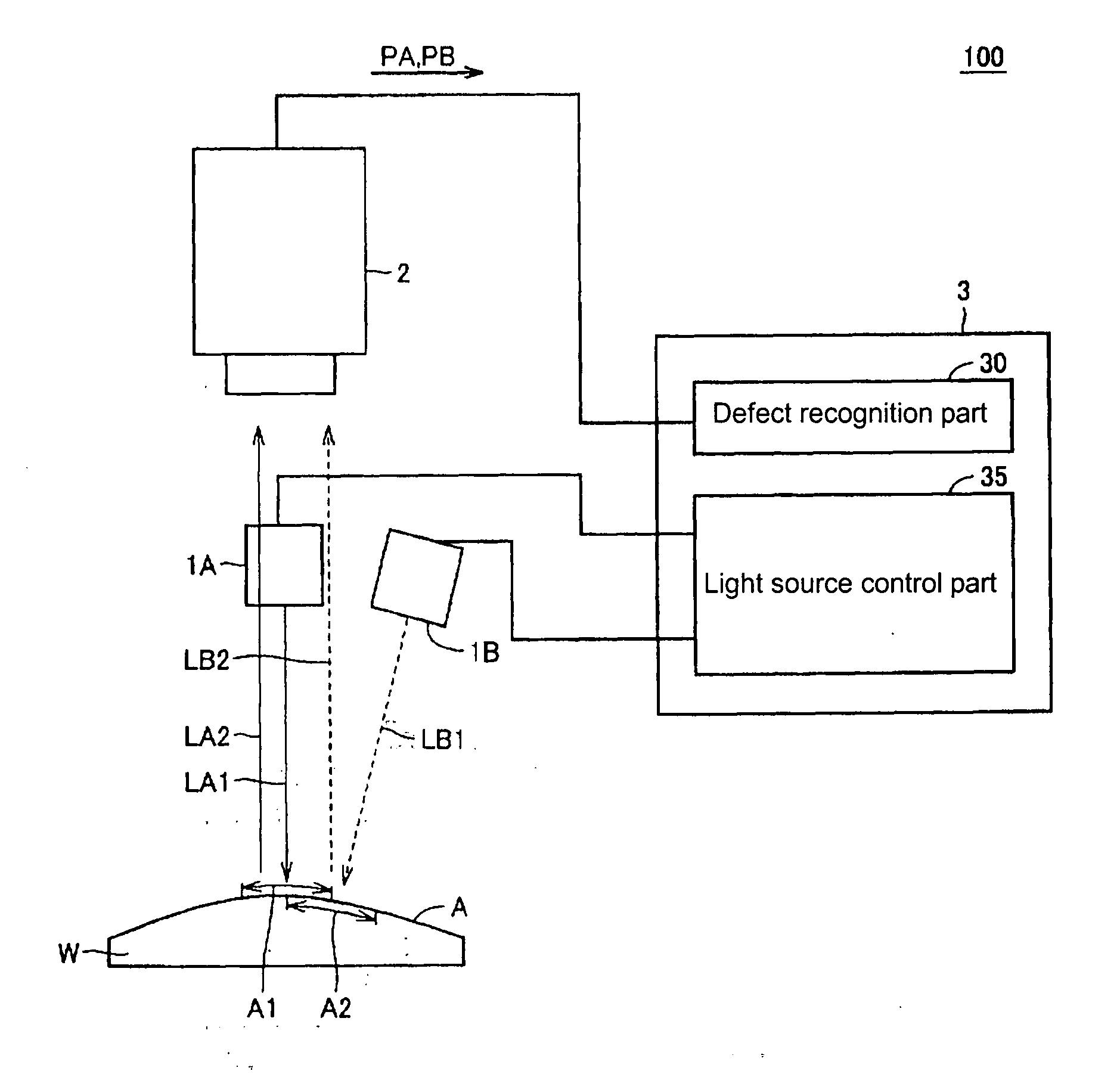

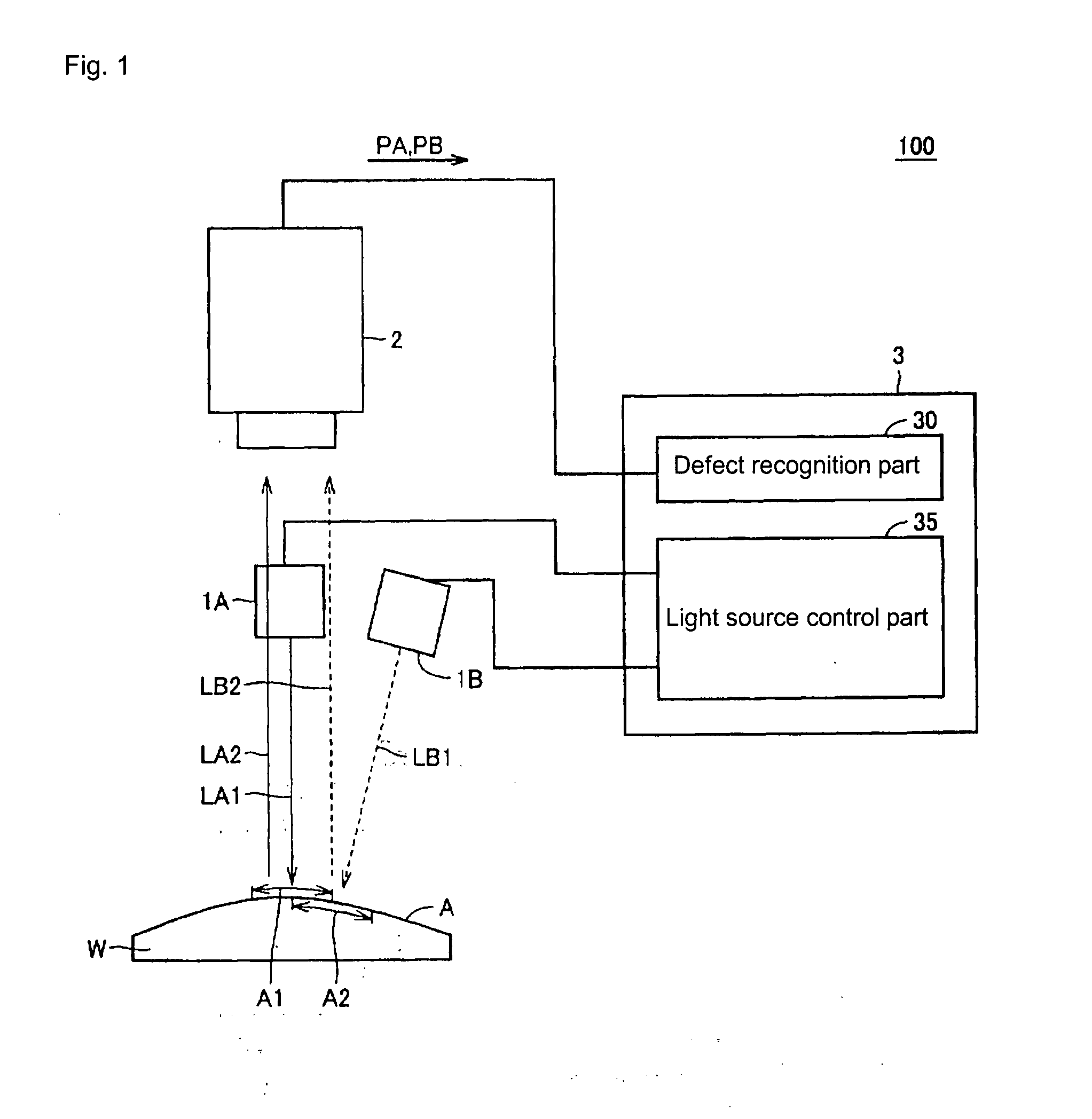

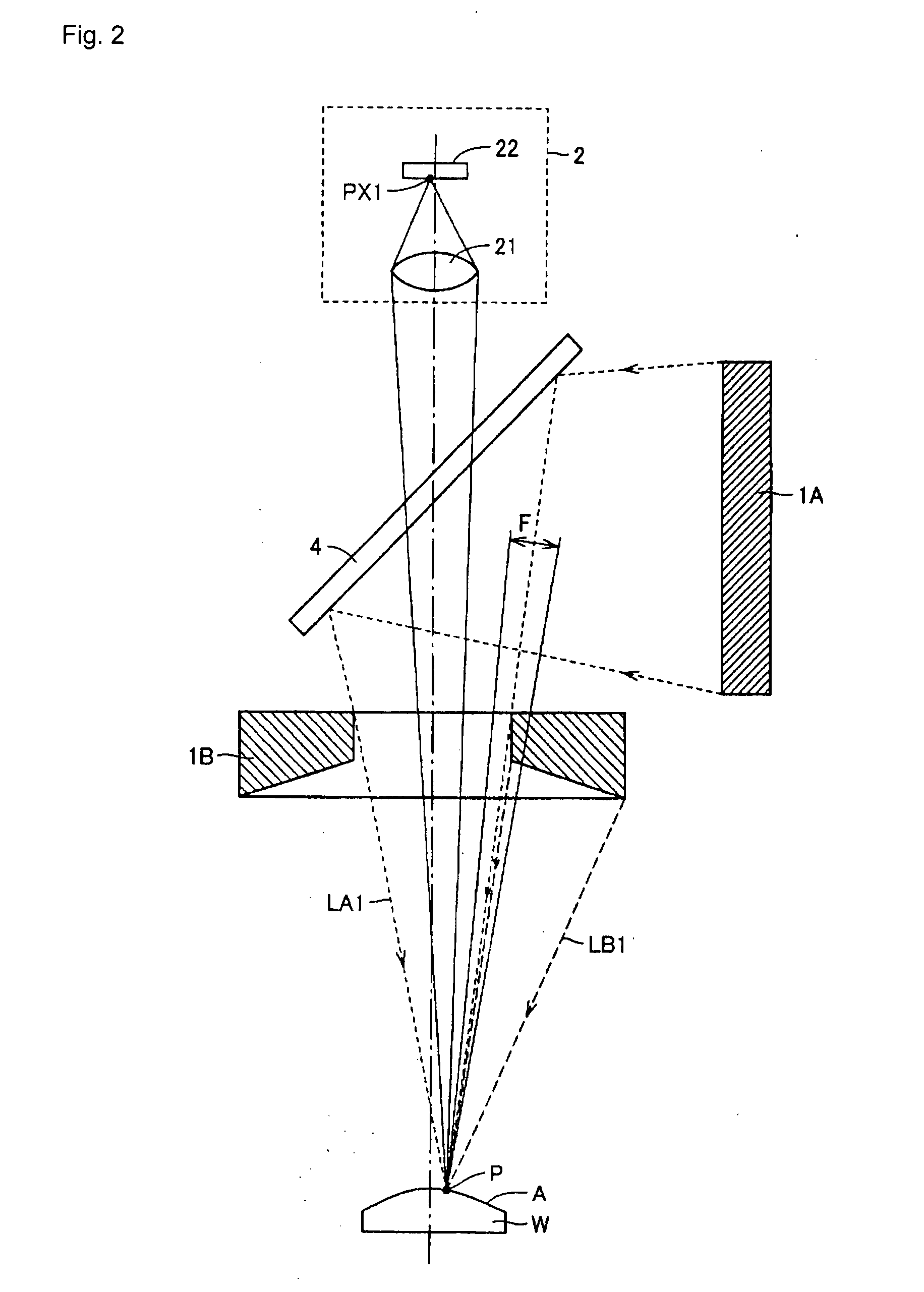

Defect inspection apparatus and defect inspection method

InactiveUS20070211242A1Increase the areaReduced opening sizeOptically investigating flaws/contaminationUsing optical meansPhysicsLight source

Light sources emit irradiation lights respectively, so that edge parts of mutual irradiation areas (inspection areas) are superposed one another. The imaging apparatus receives regular reflection lights and generates two images corresponding to each of the light sources. A main control part combines two images and determines presence / absence of a defect. By irradiating an inspected surface A with the irradiation lights from mutually different directions, a position of an area showing the defect in each image is slightly deviated. Therefore, even if a dimension of an area showing the defect is small in each image, by superposing two images one another, the dimension of the area showing a defect part becomes large in the image after composition. Thus, an accuracy of defect detection on the edge part of the inspection area can be improved.

Owner:ORMON CORPORATION

Mask pattern for semiconductor device fabrication, method of forming the same, method for preparing coating composition for fine pattern formation, and method of fabricating semiconductor device

ActiveUS7314691B2Reduced opening sizeIso-dense bias can be minimizedSemiconductor/solid-state device manufacturingPretreated surfacesResistDevice material

A mask pattern for semiconductor device fabrication comprises a resist pattern formed on a semiconductor substrate, and an interpolymer complex film formd on the resist pattern, wherein the interpolymer complex film includes a network formed by a hydrogen bond between a proton donor polymer and a proton acceptor polymer.

Owner:SAMSUNG ELECTRONICS CO LTD

Circuit board and manufacturing method therefor and semiconductor package and manufacturing method therefor

InactiveUS20060157865A1Improve mounting reliabilityIncrease opening sizeEngine sealsFinal product manufactureDevice materialSemiconductor package

A circuit board includes a circuit board body having a semiconductor device mounting area for mounting a semiconductor device, a wiring pattern to be electrically connected to a semiconductor device to be mounted on the semiconductor device mounting area, and an insulating layer for covering the wiring pattern, the insulating layer having openings formed therein at regions on which bumps for electrically connecting the wiring pattern to a mount substrate are disposed. The opening sizes of the openings are allowed to vary depending on the positions at which the openings are formed.

Owner:SONY CORP

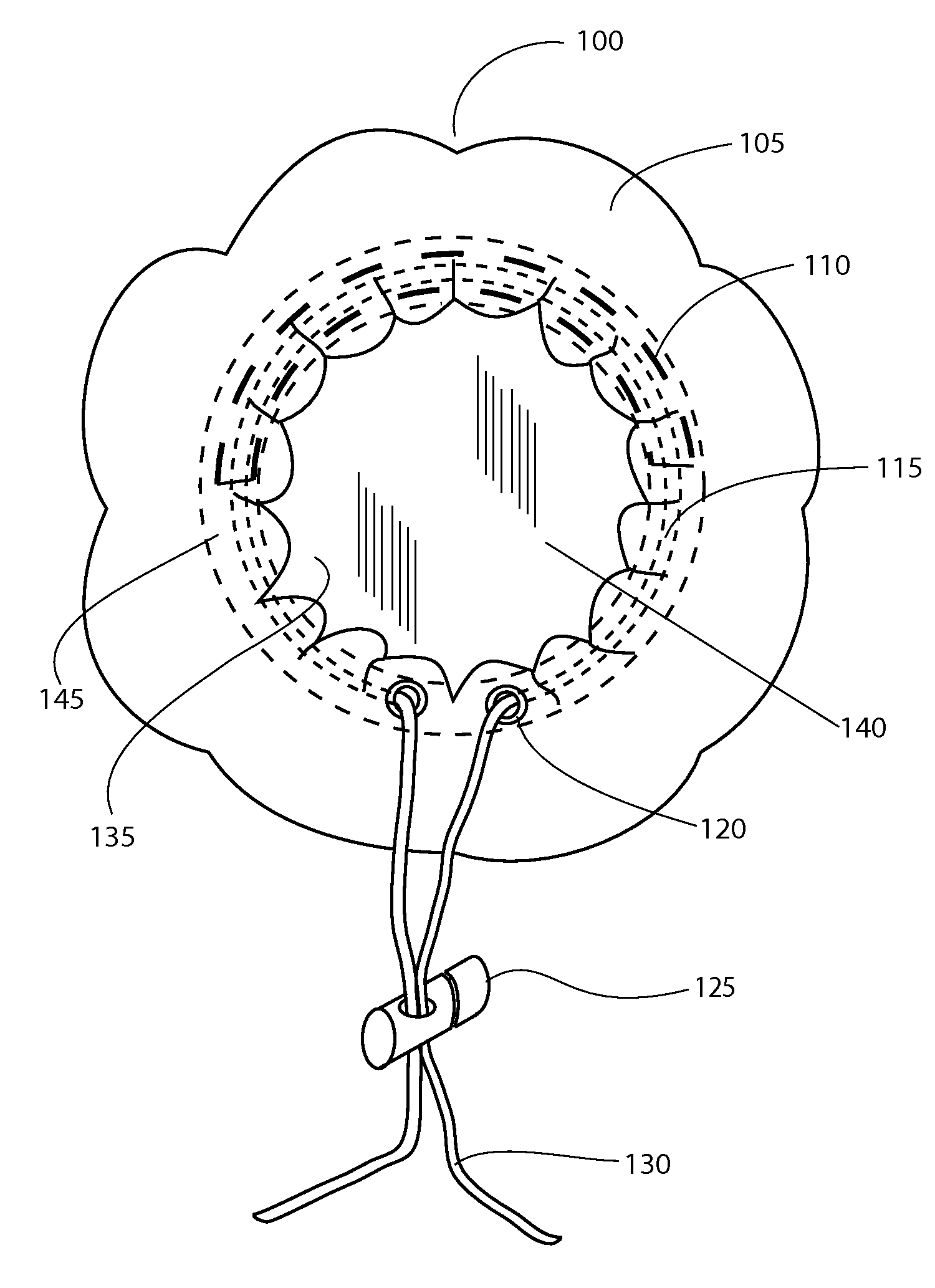

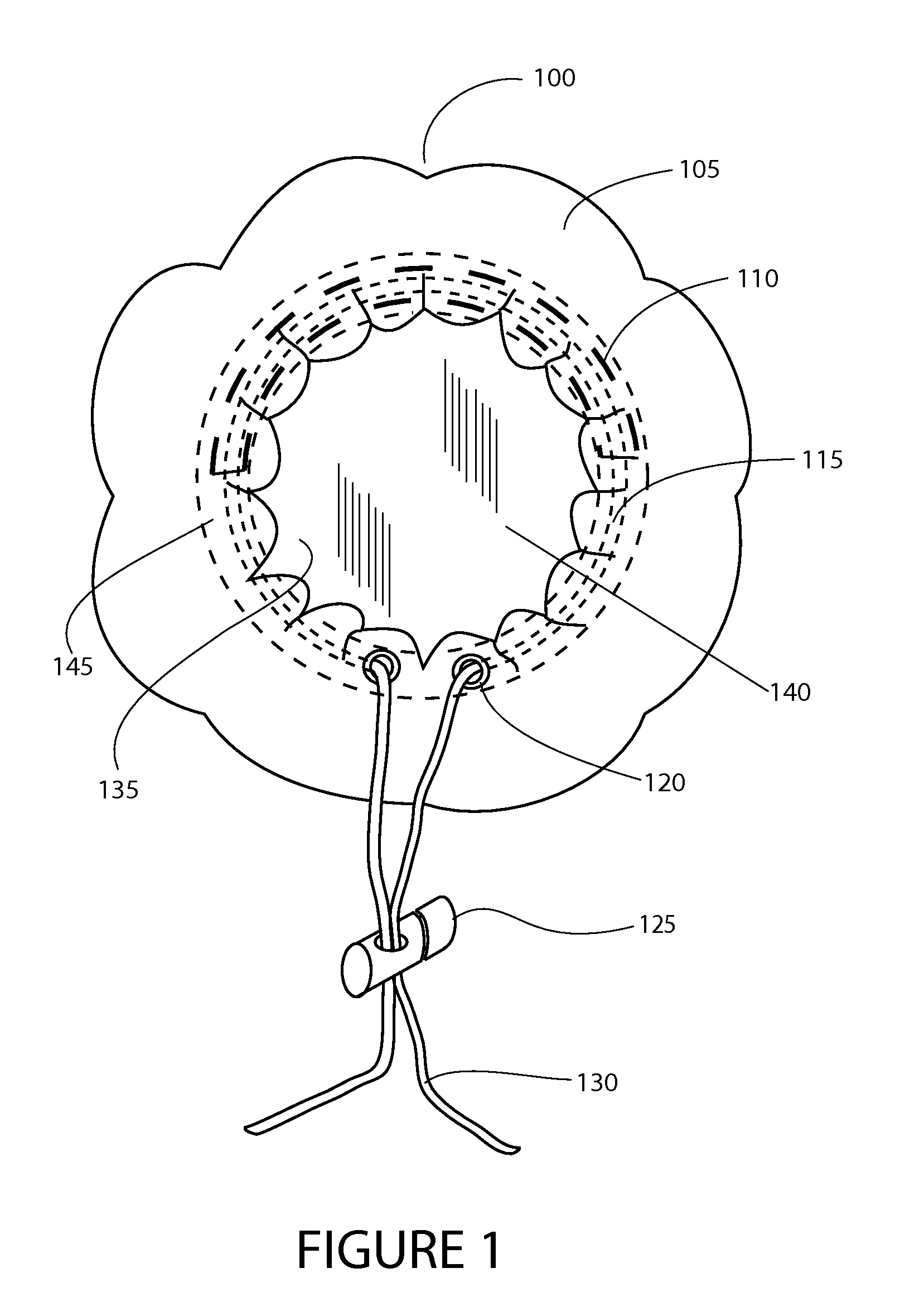

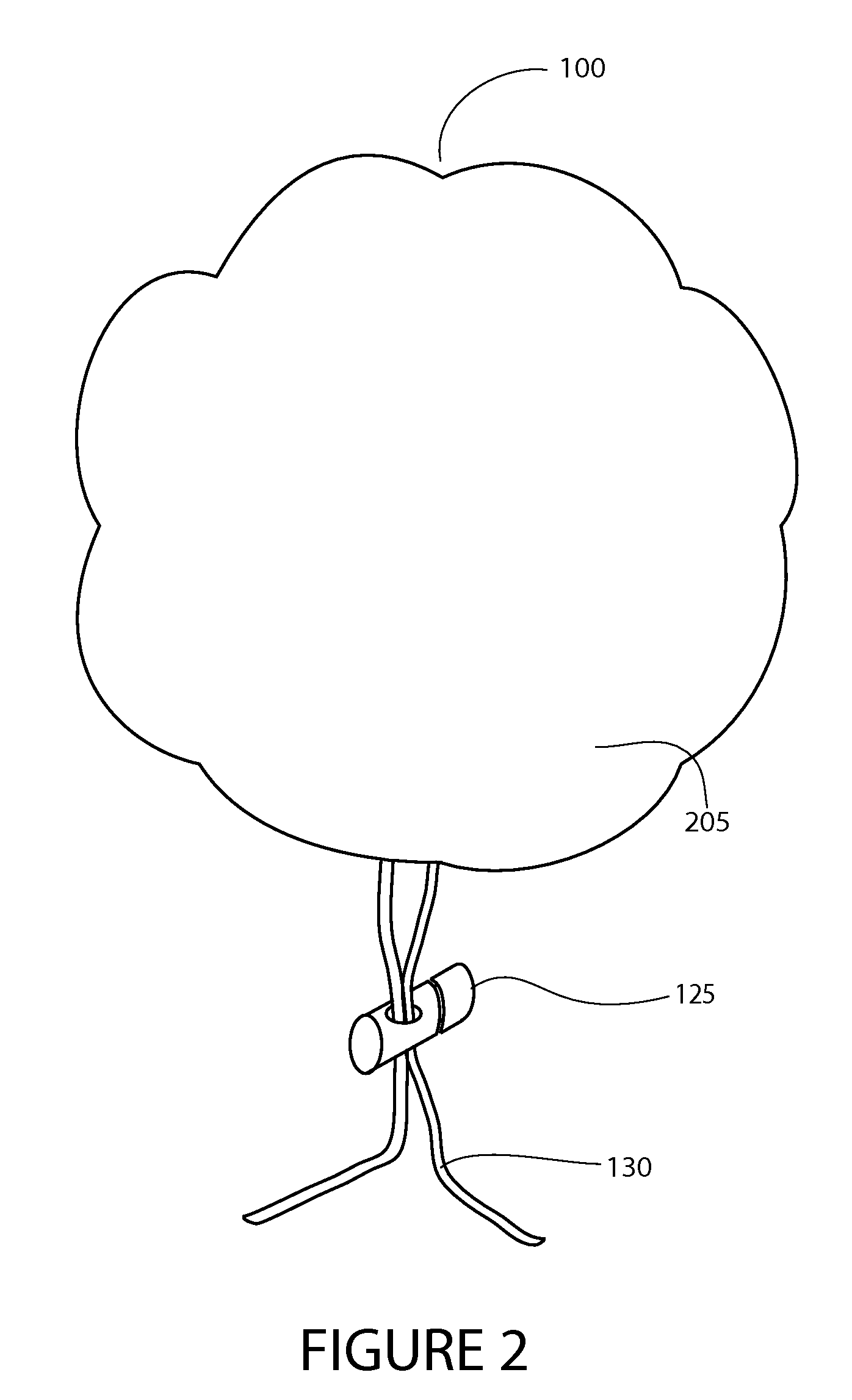

Ear cover with drawstring and concentric resilient aural helix hanger

InactiveUS20100186146A1Avoid driftingExcellent thermalEar treatmentPackaging toiletriesEngineeringMedial side

A soft flexible insulating ear cover is provided in the form of a pouch. The cover defines an open compartment for receiving an ear. The pouch has opposite superior and inferior sides. The pouch comprises a soft absorbent medial side and an insulating lateral side opposite the medial side. The medial side further includes an opening adapted to receive an ear. A seam defines a passage around the opening. A resilient tubular helix hanger (also referred to herein as an ear hook) is disposed in the superior side of the passage. A drawstring extends through the passage and through the tubular ear hook and is adapted to controllably close the opening. The interior lining is fusible fleece. The medial side fabric is terry cloth. The lateral side fabric is velvet. The dense pile of velvet provides superior thermal and audible insulation. A layer of quick dry foam batting is preferably provided between the fusible fleece and terry cloth, as well as between the fusible fleece and velvet. The resulting product is washable and reusable.

Owner:ASKEW FRANCENIA

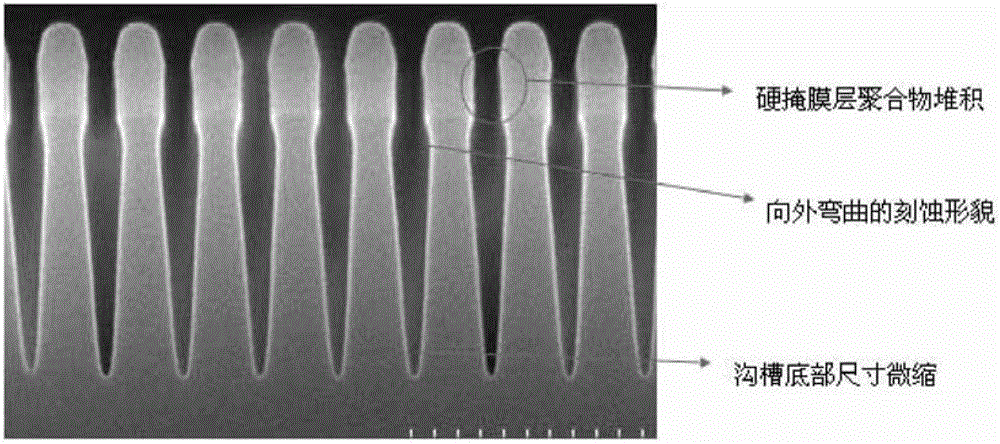

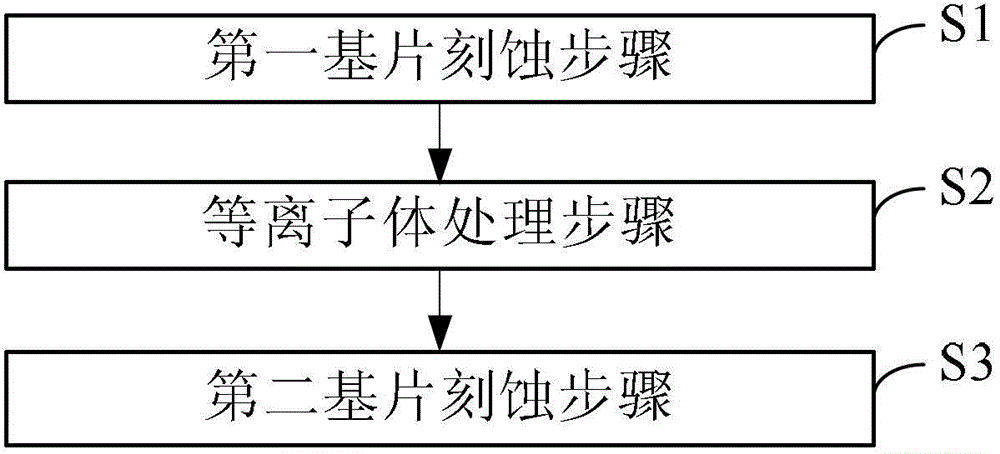

Substrate etching method

ActiveCN103915330AEtching steps are simpleReduce manufacturing costSemiconductor/solid-state device manufacturingEtchingWidth ratio

The invention provides a substrate etching method. The substrate etching method comprises the following steps of etching a substrate, wherein etching gas is injected into a reaction chamber, an excitation power supply and a grid bias power supply are started to etch the substrate at preset etching depth; processing plasma, wherein the etching gas is stopped from being injected into the reaction chamber, meanwhile, processing gas is injected into the reaction chamber, the grid bias power supply is turned off, and the processing gas is used for removing a part of reaction by-products accumulated on the side wall of the substrate; the steps of etching the substrate is carried out cyclically for at least two times, and one time of the step of processing the plasma is carried out with at least one cyclical time in the total cyclical times in the step of etching the substrate as an interval. According to the substrate etching method, under the premise that substrate etched appearance with an ideal depth-to-width ratio is obtained, etching steps can be simplified, etching equipment does not need to be changed, and thus the manufacturing cost of the equipment can be lowered.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

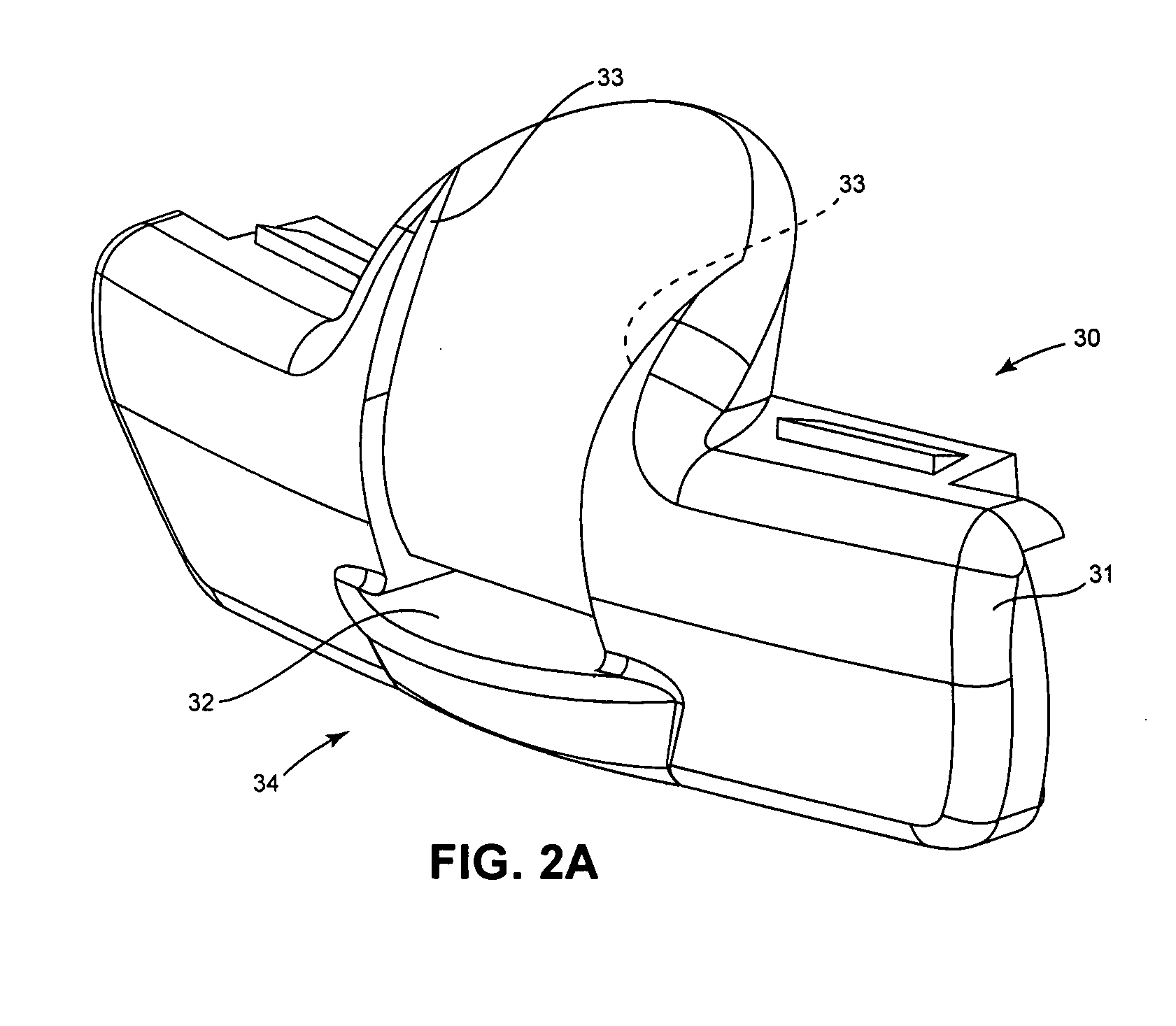

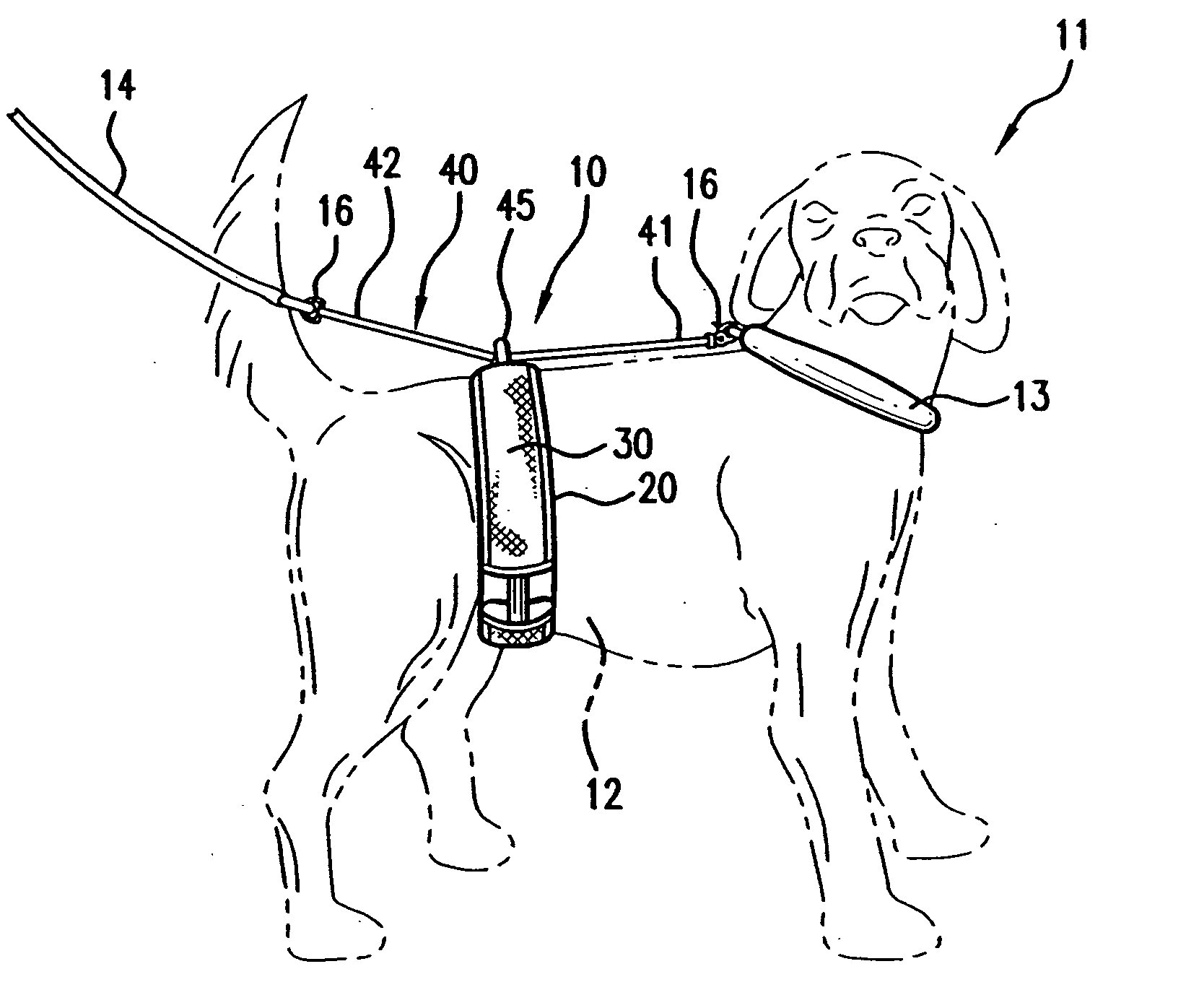

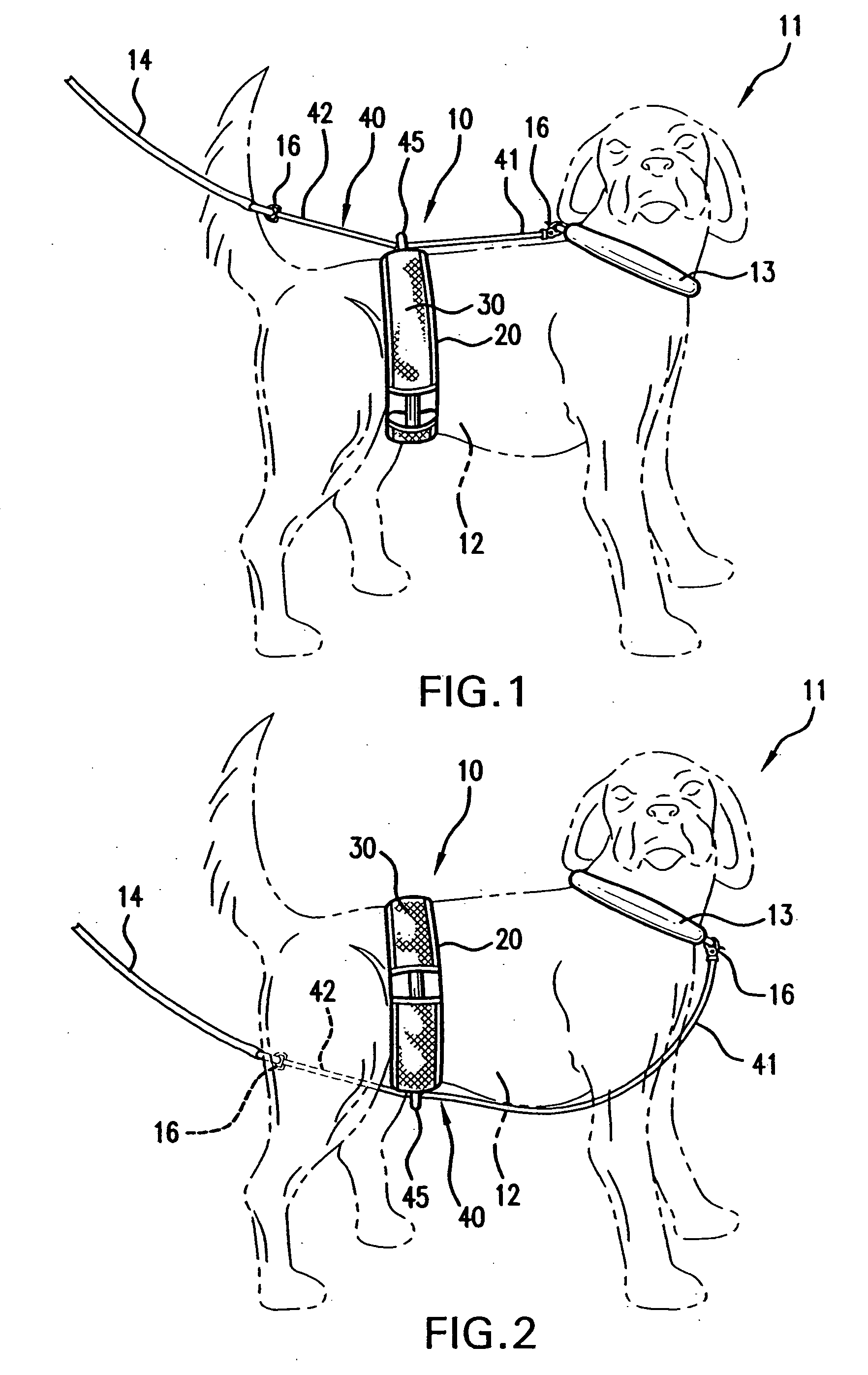

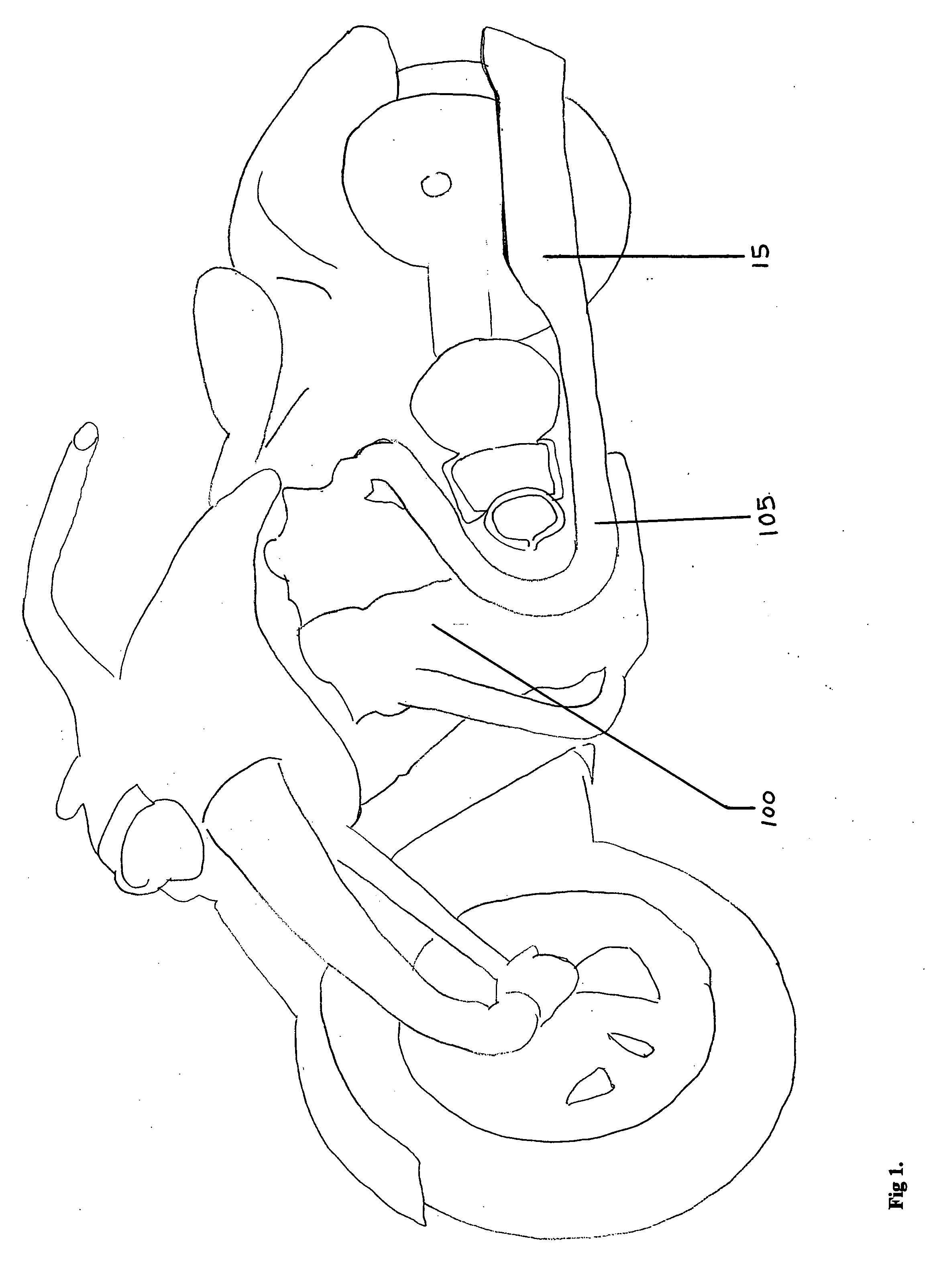

Animal restraining apparatus

InactiveUS20060236954A1Reduces undesirable forceReduce pulling forceTaming and training devicesEngineeringMechanical engineering

Owner:ABINANTI T MICHAEL

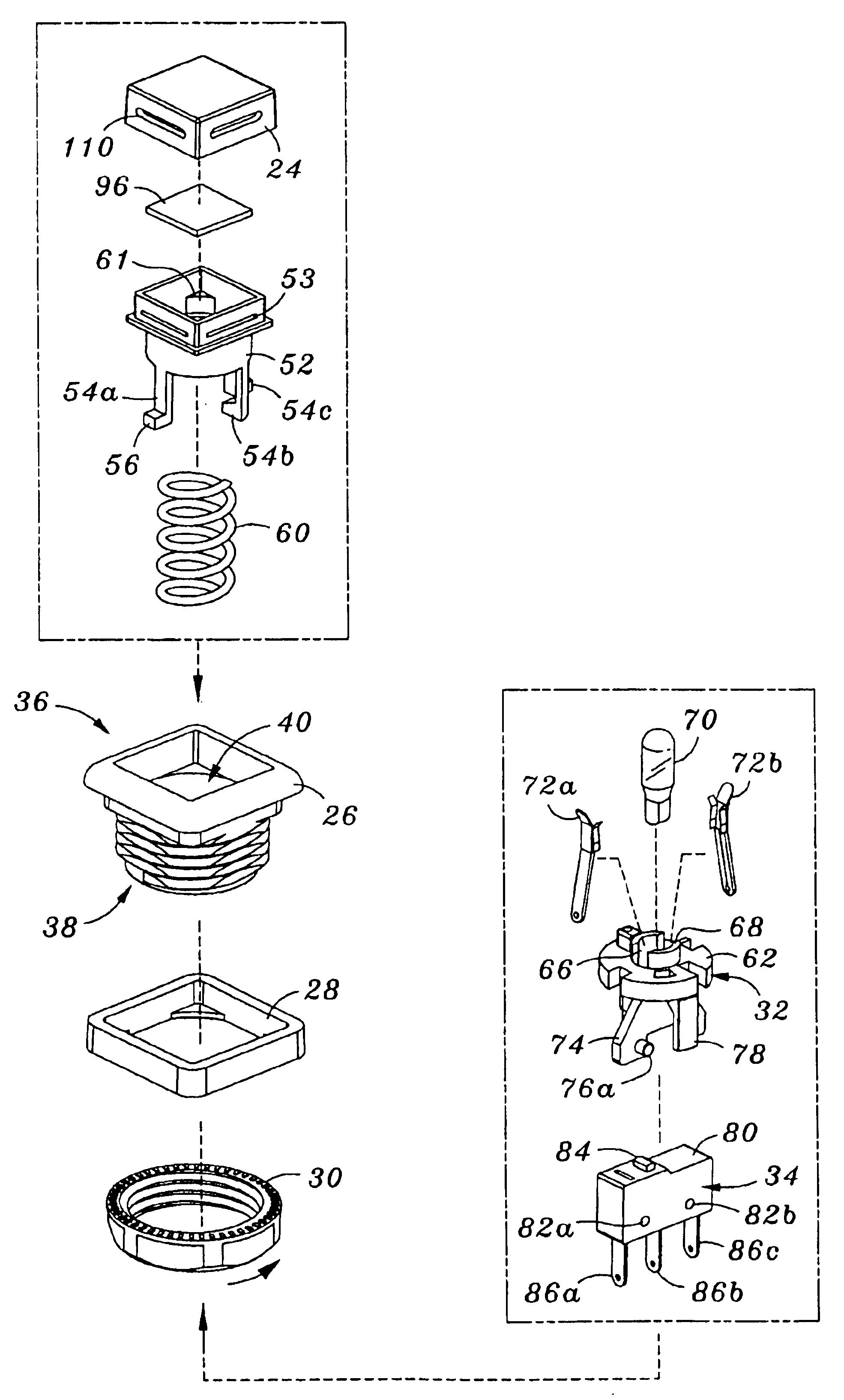

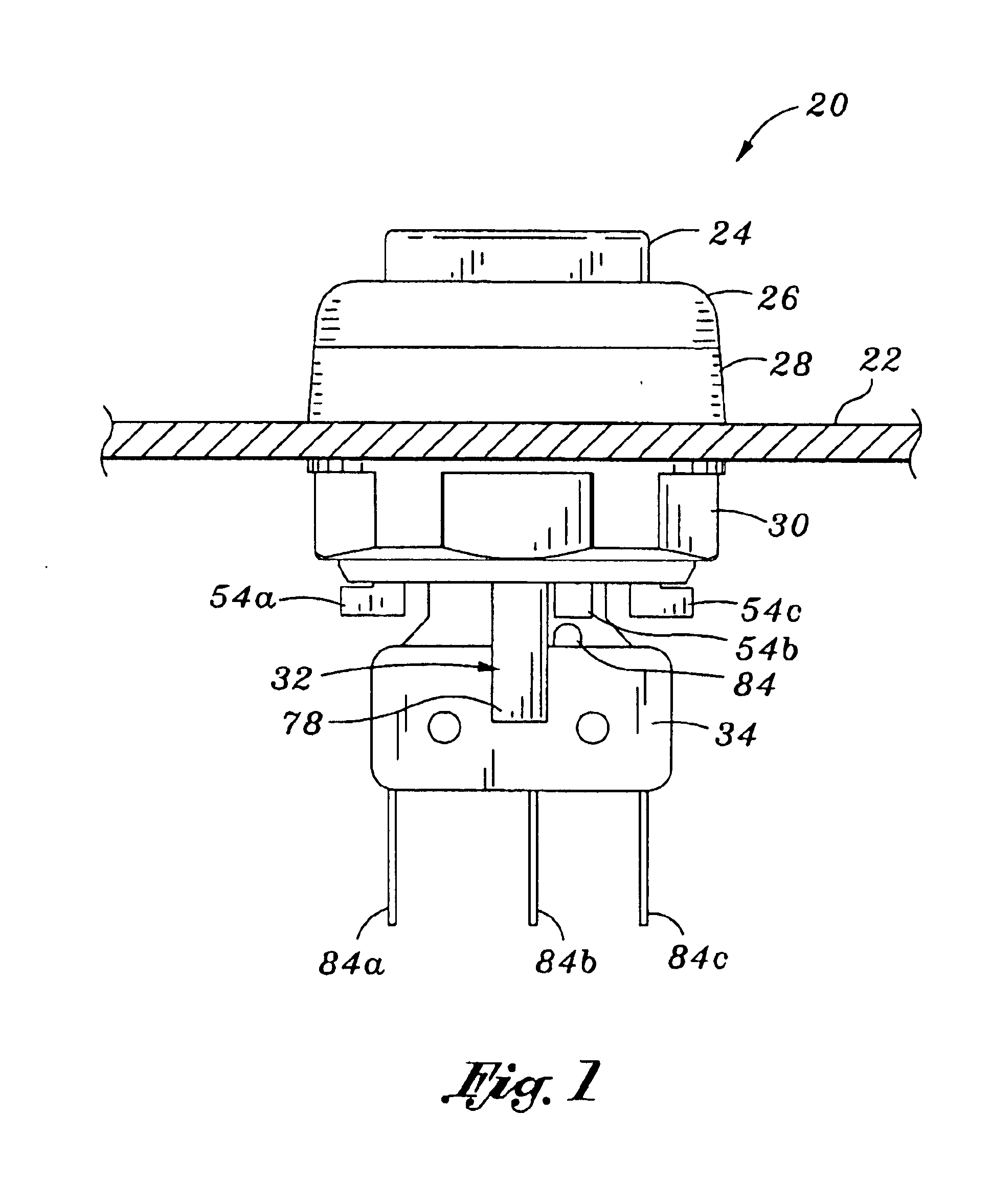

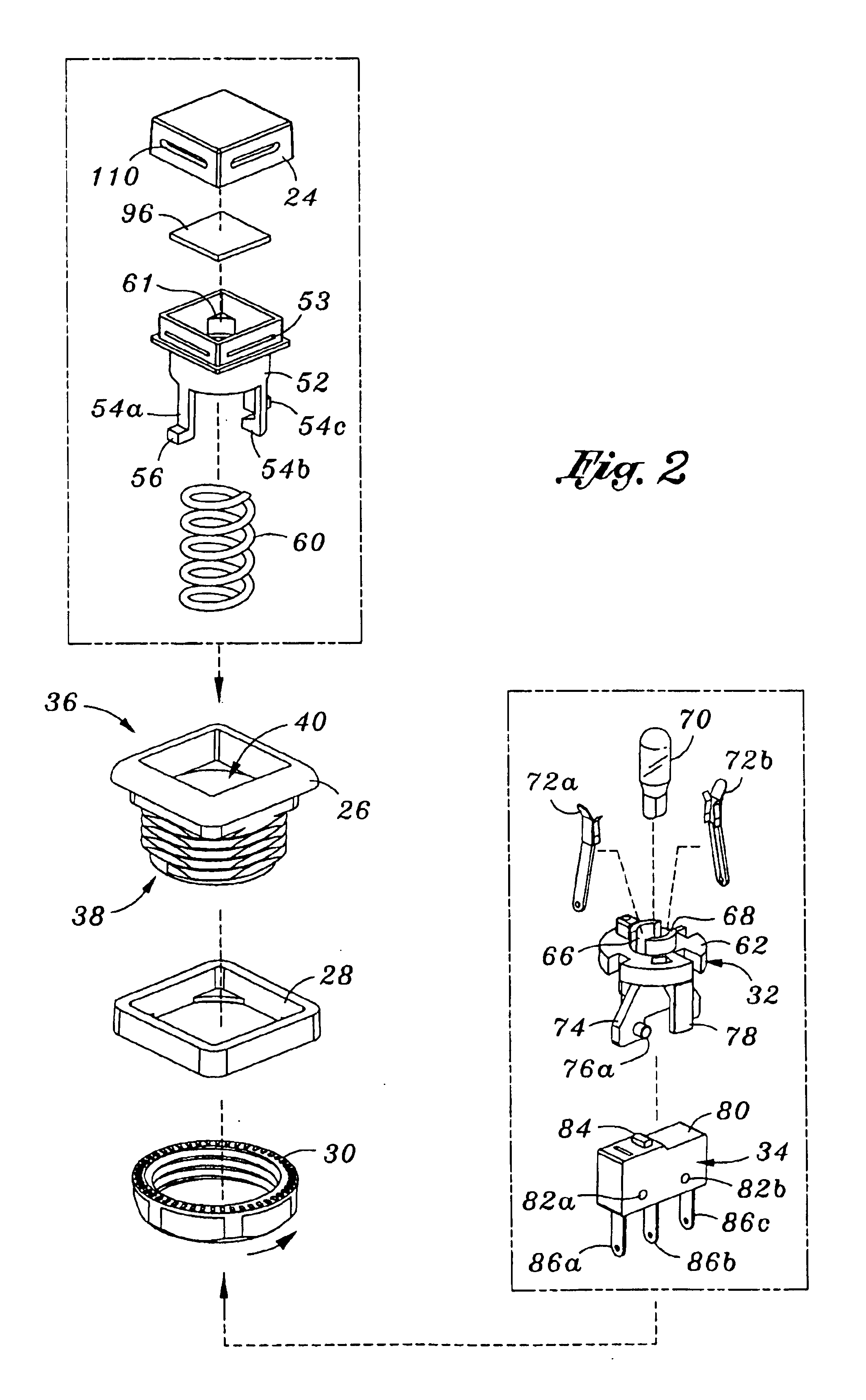

Method and apparatus for removing and replacing bulb of push-button type electrical switch

InactiveUS6870114B2Reduced opening sizeEasy to disassembleLegendsContact operating partsEngineeringPush-button

A tool for use in removing and replacing a bulb of a push-button type actuatable switch comprises a tool body having a first end defining a bulb-accepting opening. A plurality of tines surround at least a portion of the opening. When the tines are in a first position, the opening is sufficiently large to accept a bulb. When pressed inwardly, the tines reduce the size of the opening and engage a bulb located therein. Movement of a sleeve over the outside of the body presses the tines inwardly. In one embodiment, a flexible sleeve is located in the opening for gripping and protecting a bulb. A stop extends into the insert, limiting the extent to which a bulb may be pressed into the tool. An opposing end of the tool may include a prong or blade for engaging and removing a lens cover over a bulb.

Owner:COLE JOSEPH W +1

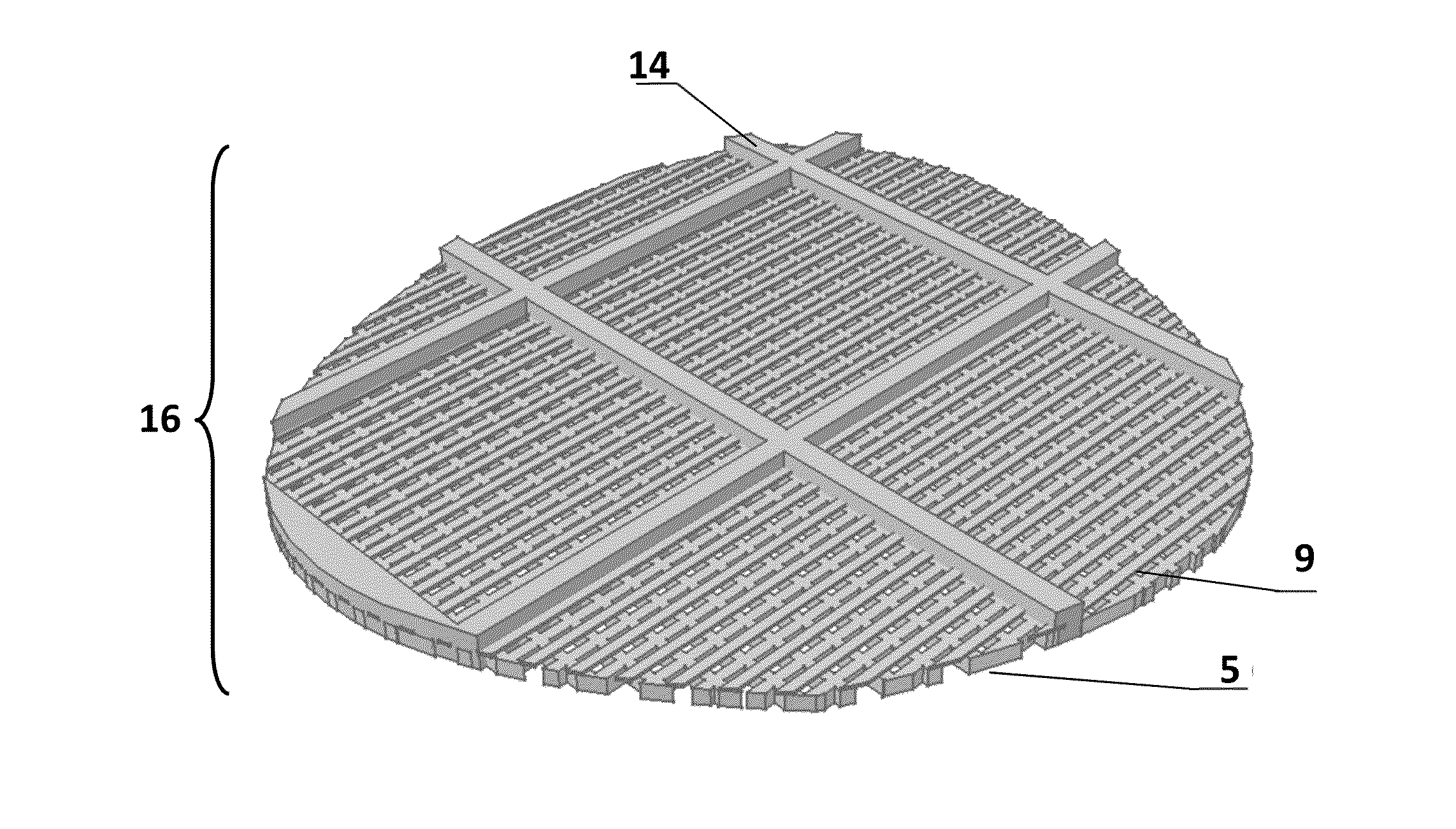

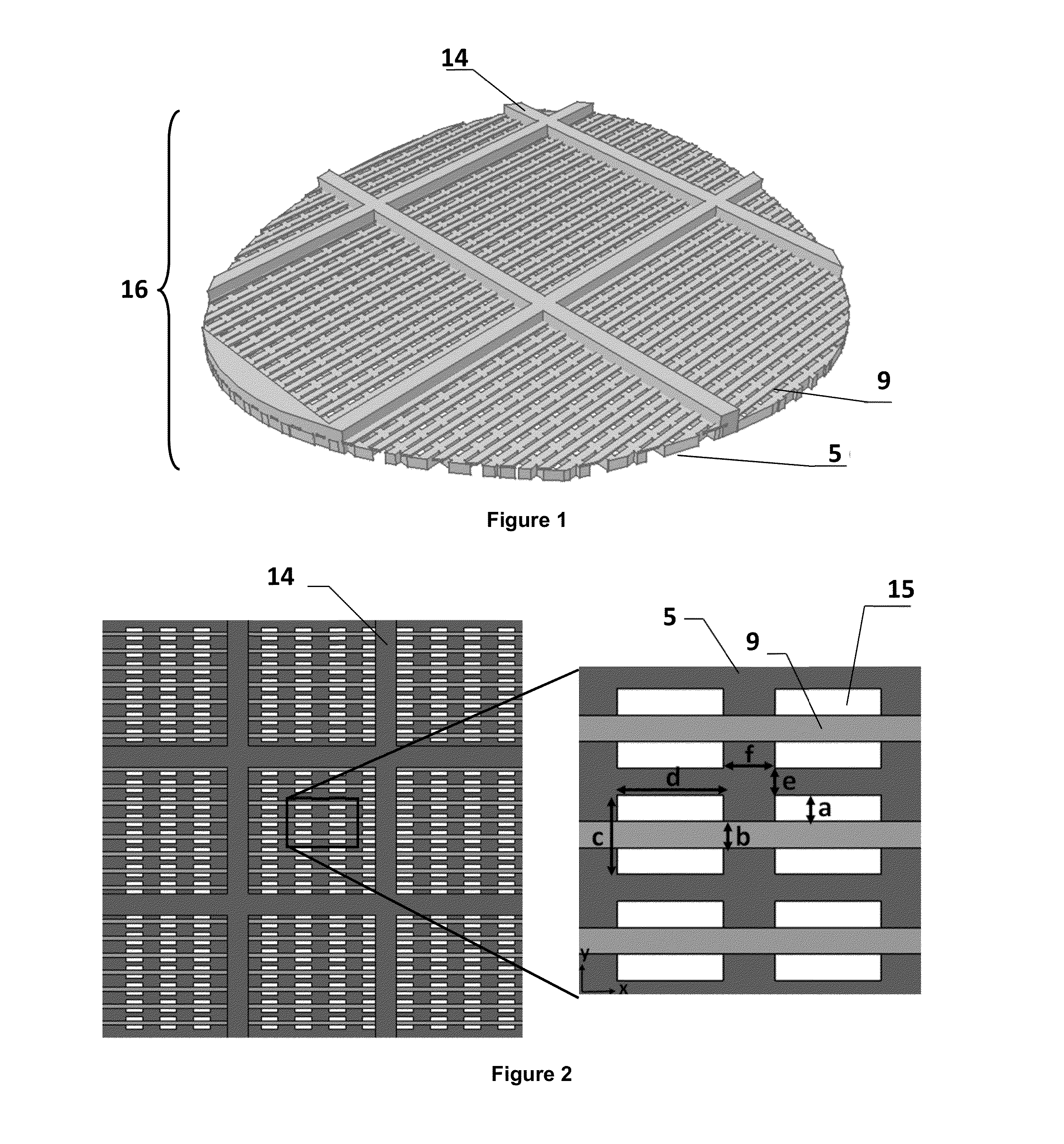

Multilayer filter

InactiveUS20140223873A1Reduce in sizeReduced opening sizeCombination devicesSemi-permeable membranesPhysicsMechanical engineering

This invention relates to a multilayer filter. The filter comprises at least a first layer comprising a plurality of openings and at least a second permeable layer overlaying the first layer and reducing the size of the openings. The filter may further comprise one or more successive layers overlaying the second layer, wherein each layer further successively reduces the size of the openings. The filter may be used for separation of particles from fluid or gas. There is also provided a method for fabricating a multilayer filter.

Owner:NANYANG TECH UNIV

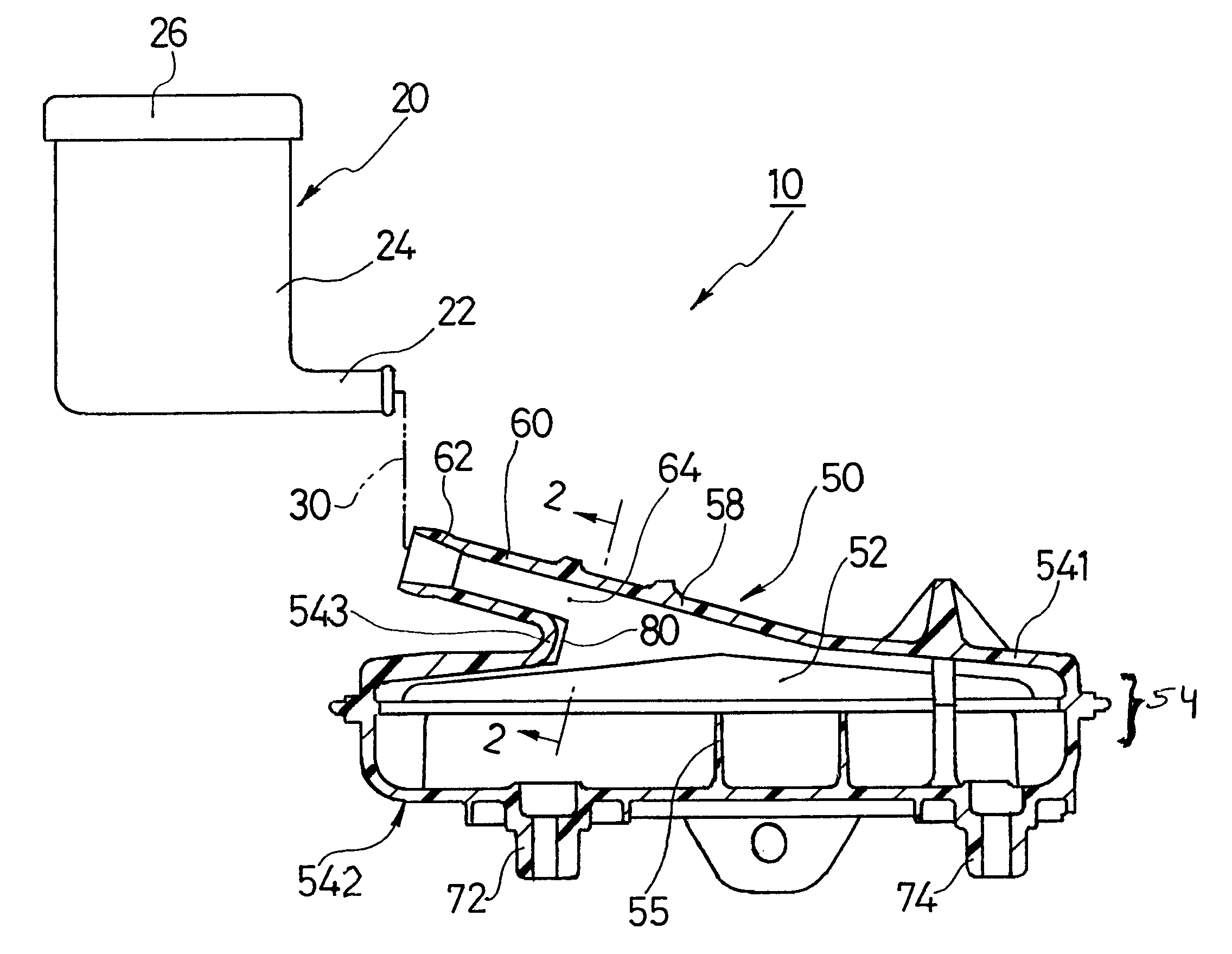

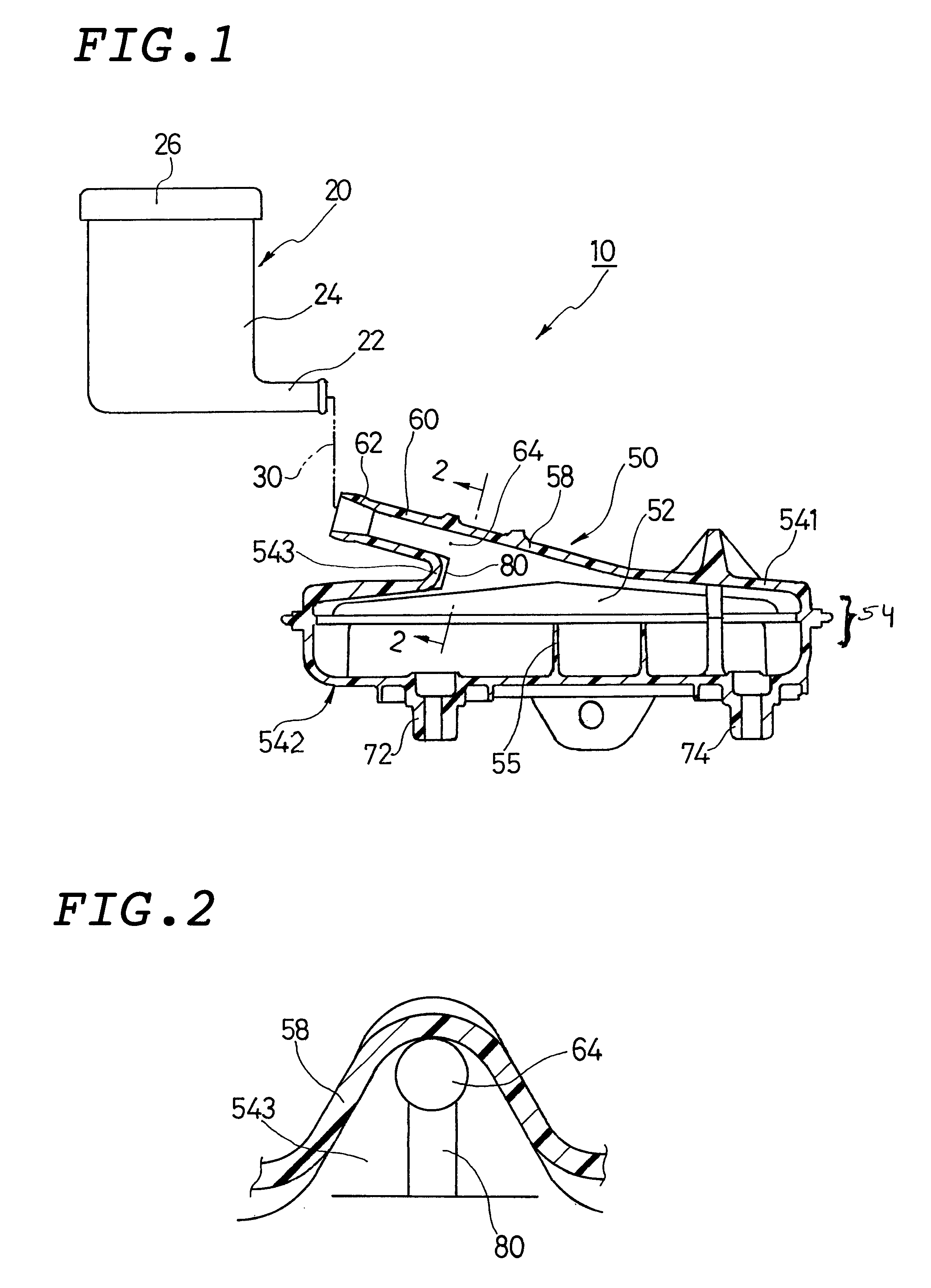

Reservoir apparatus and auxiliary reservoir

InactiveUS6550591B2Reduced opening sizeSmall sizeRotary clutchesTelemotorsWorking fluidAtmospheric air

To provides a technique capable of replenishing a working fluid smoothly while employing a method for replacing an atmospheric air with the working fluid. The reservoir apparatus (10) includes a main reservoir (20) having an inlet opening for feeding a hydraulic fluid, and an auxiliary reservoir (50) connecting thereto through a piping (30). There is a diagonally extending connecting pipe (60) at the auxiliary reservoir (50). There is a recessed portion (80) at an opening portion (64) of an inner periphery of the connecting pipe (60). This recessed portion (80), when compared with the case where there is no such a recessed portion, serves to enlarge the opening portion (64) of the connecting pipe (60) and more smoothly flow the replenishment working fluid at a nearby area of the opening portion (64). By doing so, the opening portion (64) of the connecting pipe (60) can be more enlarged at the time of replenishment of the working fluid and formation of a film of the working fluid can be prevented at the opening portion (64).

Owner:DIESEL KIKI CO LTD

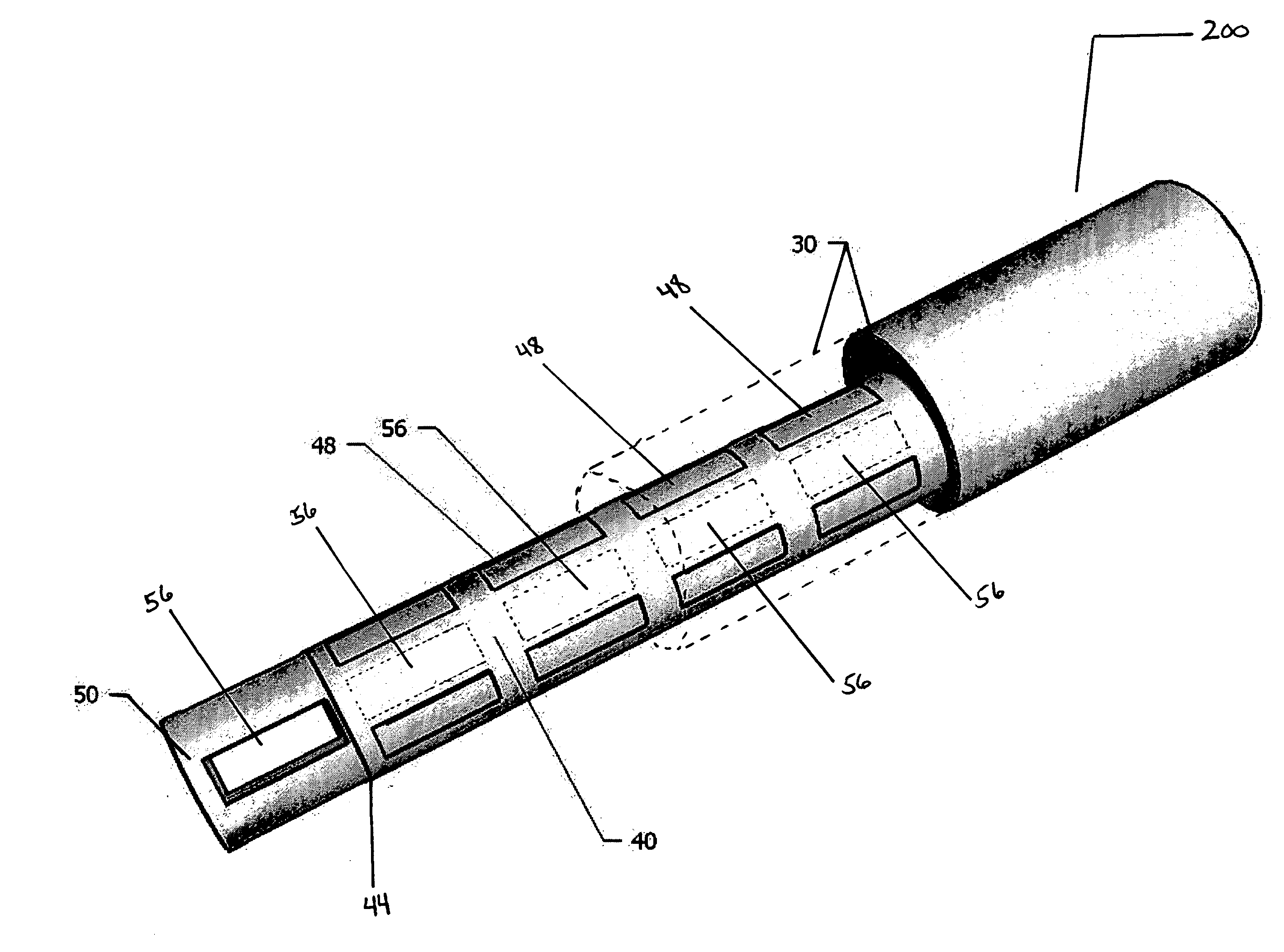

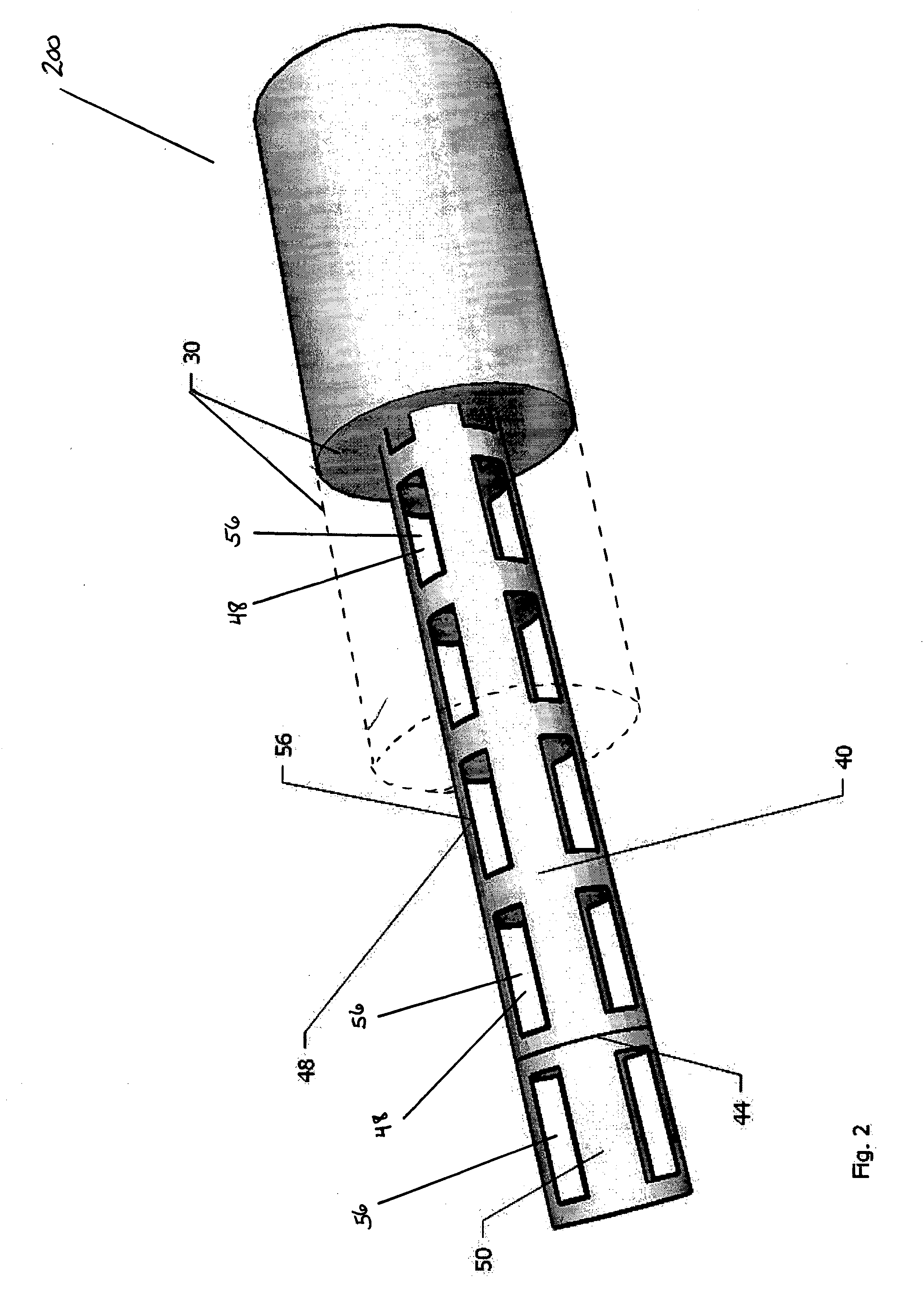

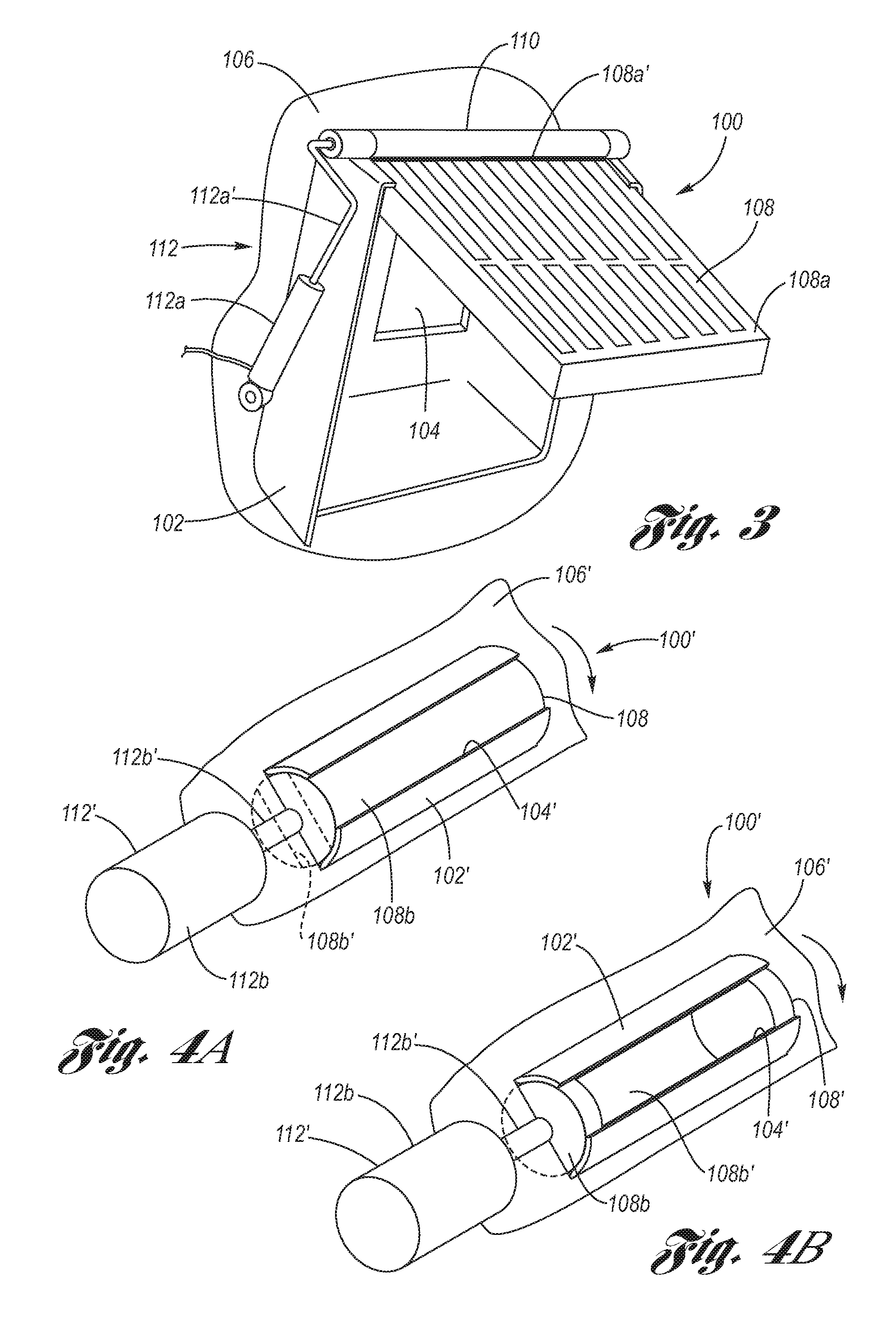

Sound adjustable device for coupling to an engine and method for manufacturing thereof

InactiveUS20070246292A1Decreasing and increasing sound volumeIncrease and decrease air flowExhaust apparatusSilencing apparatusEngineeringMechanical engineering

A sound adjustable device that varies exhaust-noise having a casing including a sound-dampening material that dampens exhaust-noise, an outer slotted pipe inside the casing, an inner slotted pipe inside the outer slotted pipe, and wherein at least one of the outer and inner slotted pipes is movable with respect to the other to alternately align the slots of the respective slotted pipes for a quieter exhaust-noise and to misalign the slots of the respective slotted pipes for a louder exhaust-noise. The sound adjustable device may also include a heat-shielding material inserted between the casing and the sound-dampening material to shield the casing from heat emitted by the exhaust, and a heat-resistant material may be included in the inner and outer slotted pipes.

Owner:SICHAU GARY STEVEN

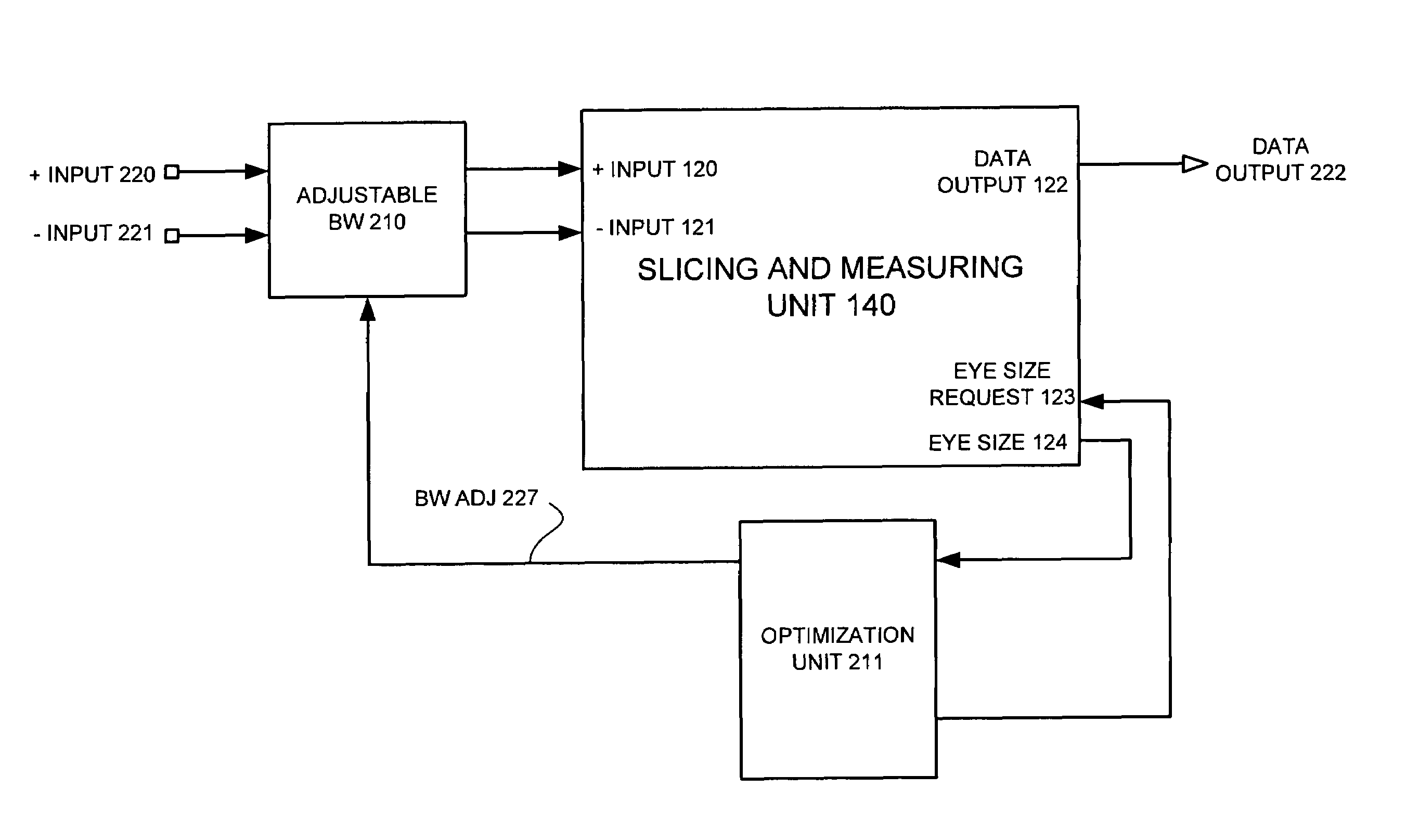

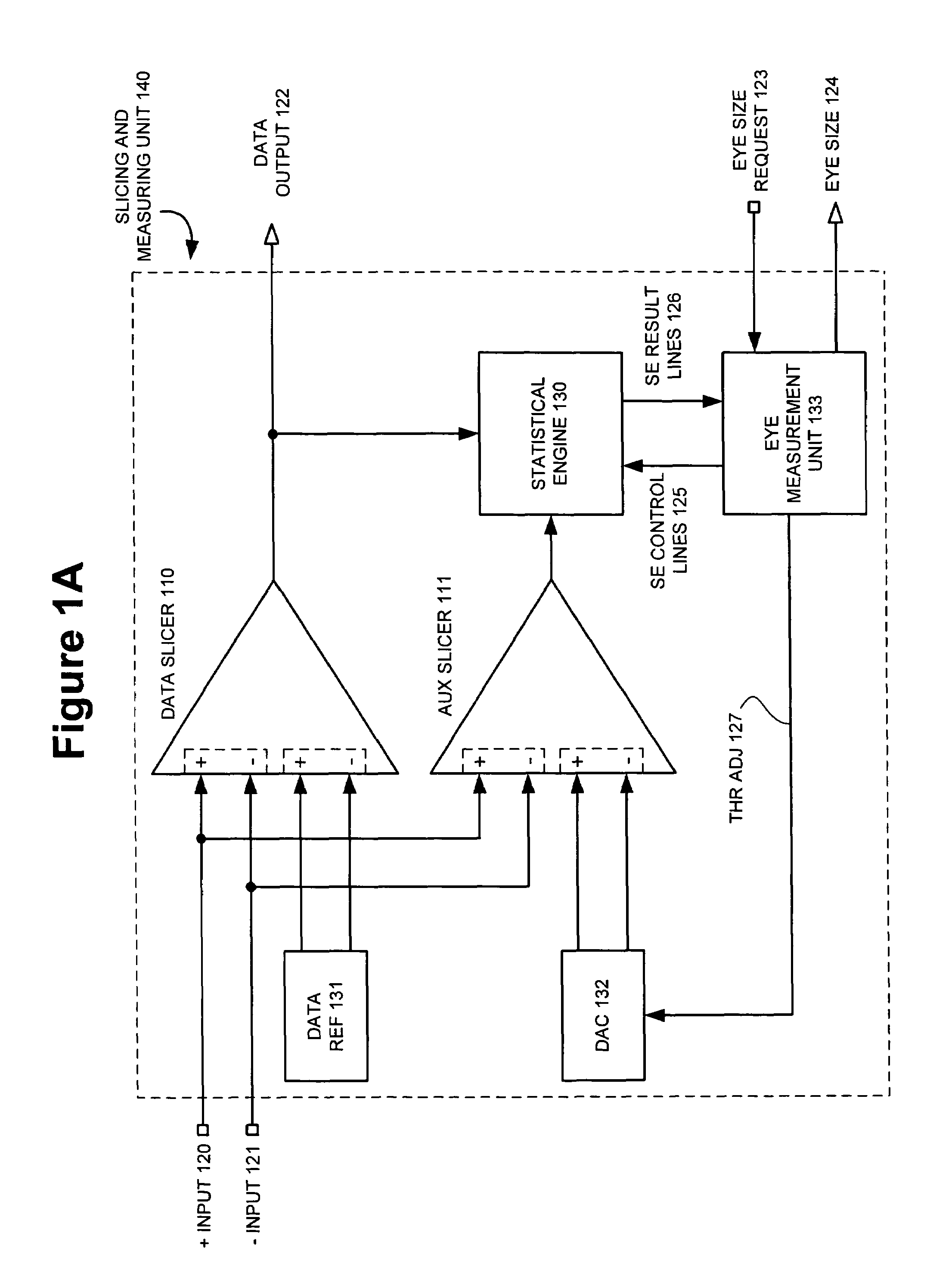

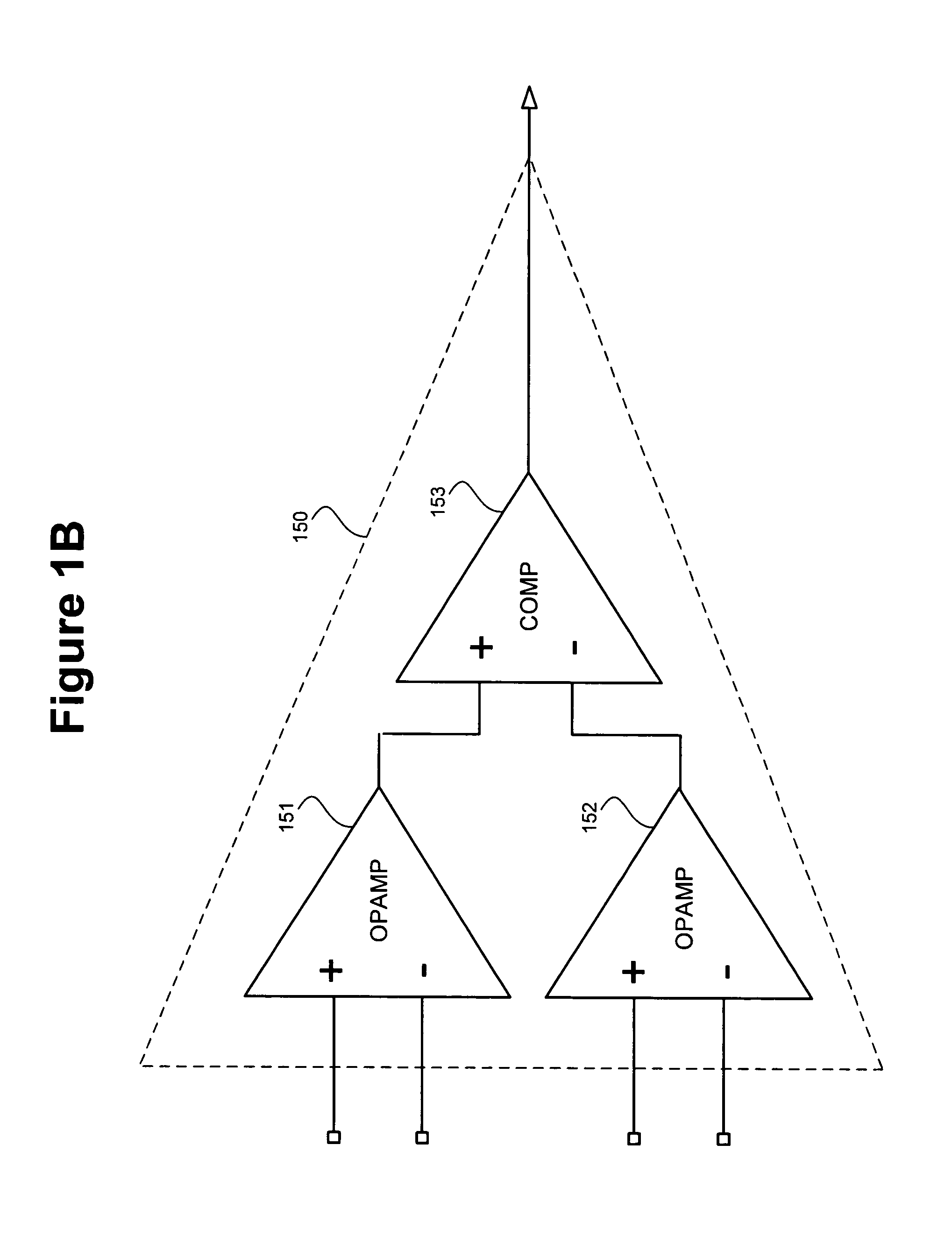

Method and apparatus for eye-opening based optimization

ActiveUS7400694B1Reduced opening sizeModulated-carrier systemsPulse demodulatorEngineeringSearch procedure

An eye opening measurement technique, that does not interrupt a receiver's normal operation, is used as a metric for optimizing any selected parameters of the receiver's operation. If eye opening size decreases, as a result of a change to a receiver parameter, the polarity for stepwise changes is reversed such that the next change is in the opposite direction. Other types of search procedures can be used.Eye opening size is the difference between the eye's upper and lower edges. Measurement of eye opening size is accomplished using a data and auxiliary slicer that find each “edge” of an eye opening based upon the slicers' level of agreement.Depending upon the level of agreement, and whether symbols of the upper or lower region of the eye are counted, the threshold of the auxiliary slicer can be adjusted in the direction necessary to converge on the eye edge sought.

Owner:SYNOPSYS INC

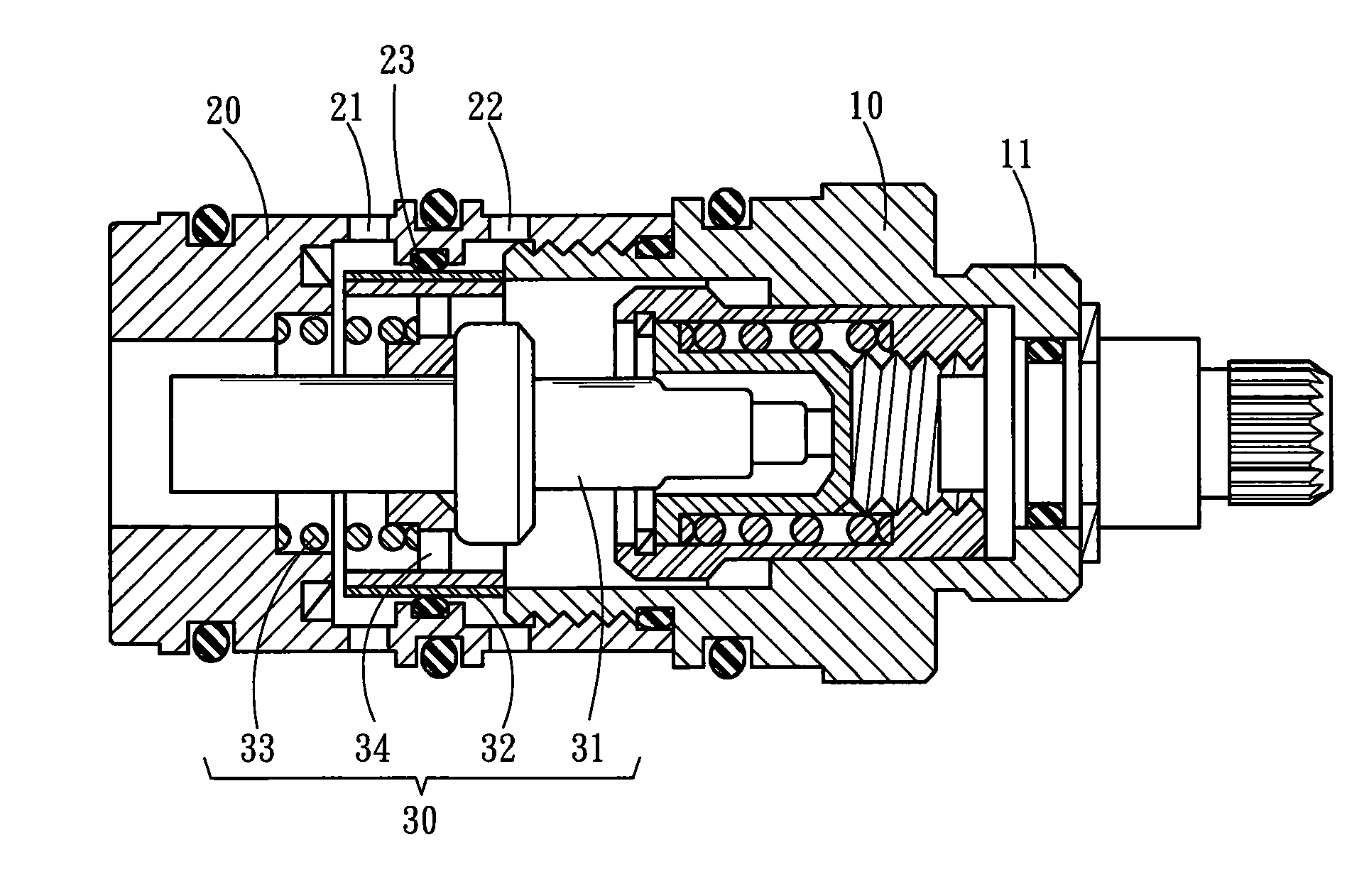

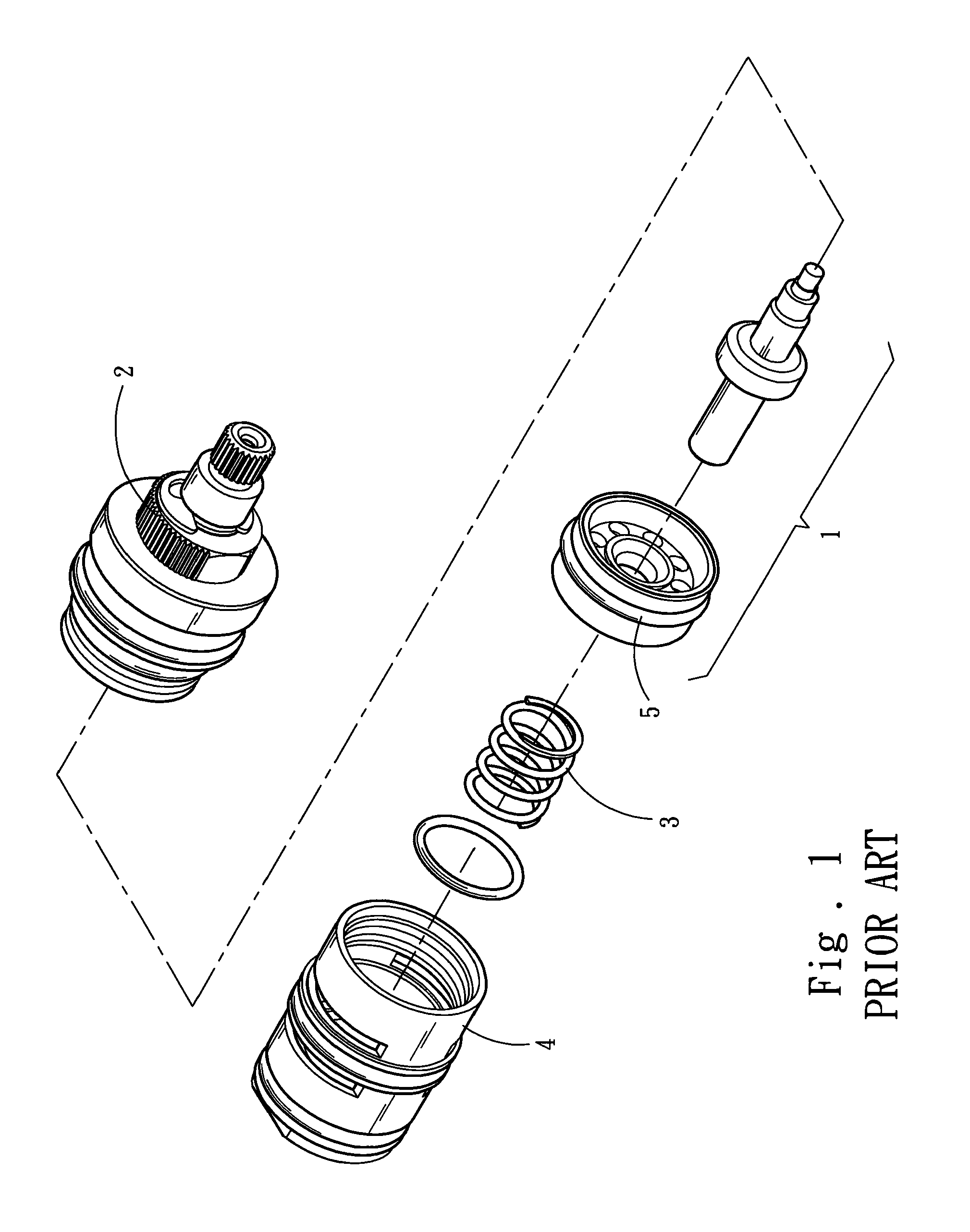

Thermostatic valve control structure

InactiveUS20110146812A1Increase frictionLife-span is affectedTemperature control without auxillary powerTemperature control with auxillary non-electric powerThermal waterMechanical engineering

A thermostatic valve control structure mainly has an axial movement element movable axially to control opening size of a hot water inlet and a cold water inlet. The axial movement element has a ceramic layer which has a smooth surface to reduce friction with a sealing ring. The ceramic layer provides advantages of resisting acid and alkali, less likely to accumulate water dregs, simpler structure and longer life span. Thus the total life span and durability of the thermostatic valve control structure can be enhanced.

Owner:DELUXE BRASSWARE

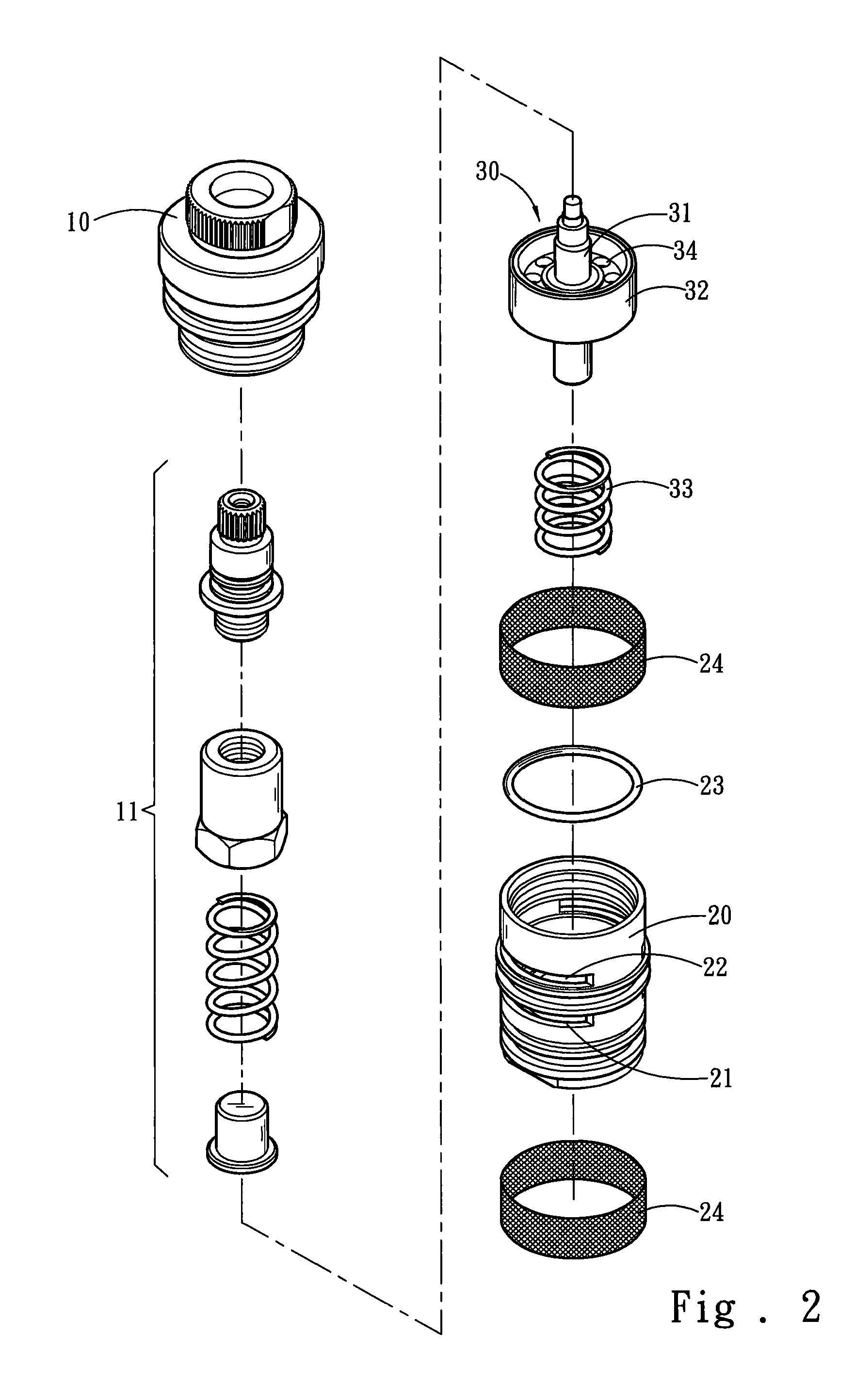

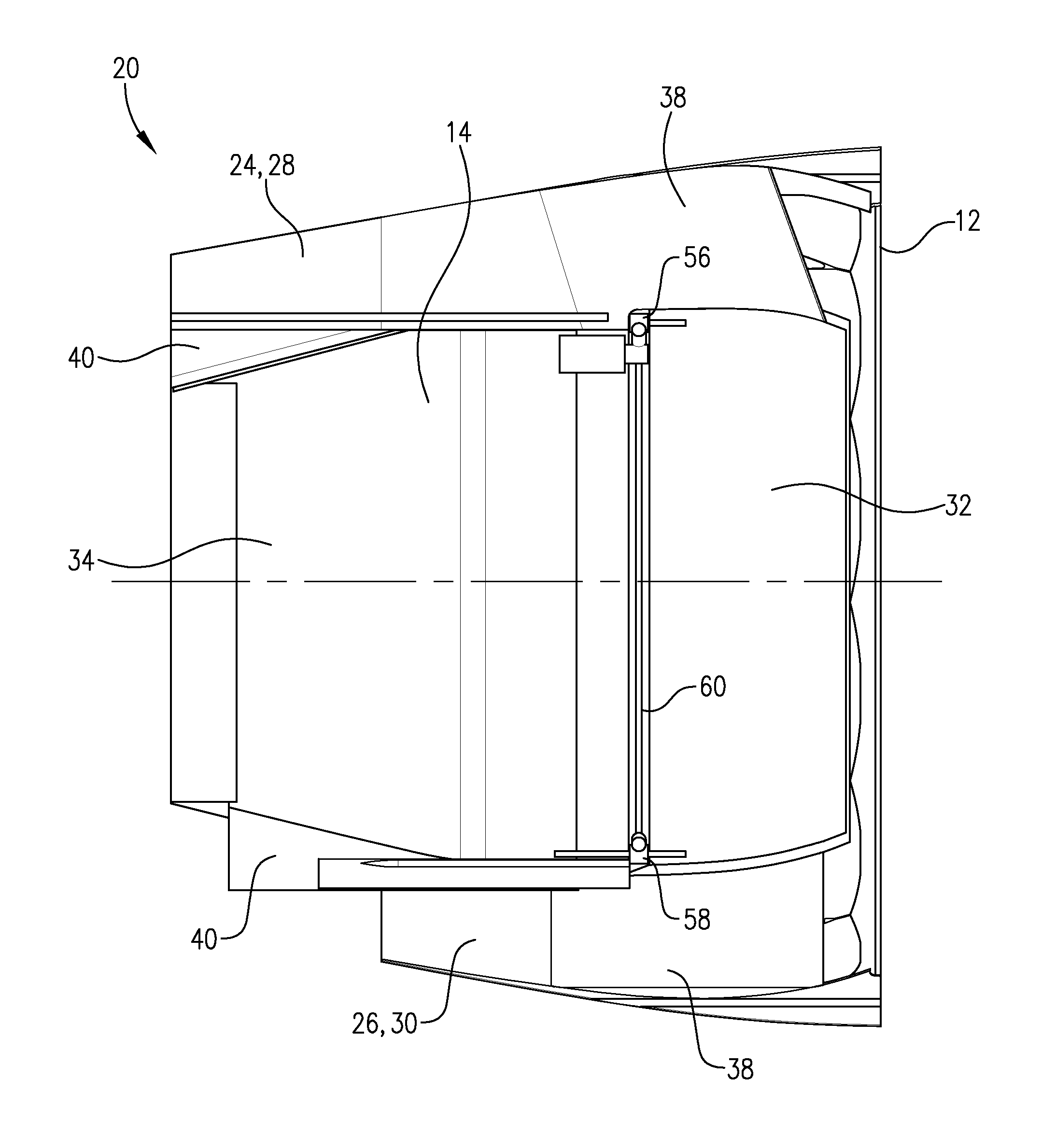

Variable fan duct nozzle

An aircraft nacelle comprising an outer cowl and an inner cowl located inward of the outer cowl with an air flow path formed therebetween. The inner cowl may comprise a forward portion and an aft portion slidable in a forward-to-aft direction via one or more actuators. When translated aftward, the aft portion may decrease the area of the nacelle's fan duct nozzle. The greatest radial distance between the inner cowl and a center axis of the nacelle may occur at or forward of a location in which the forward and aft portions overlap each other. The forward portion may be comprised of a different material than the aft portion.

Owner:SPIRIT AEROSYSTEMS

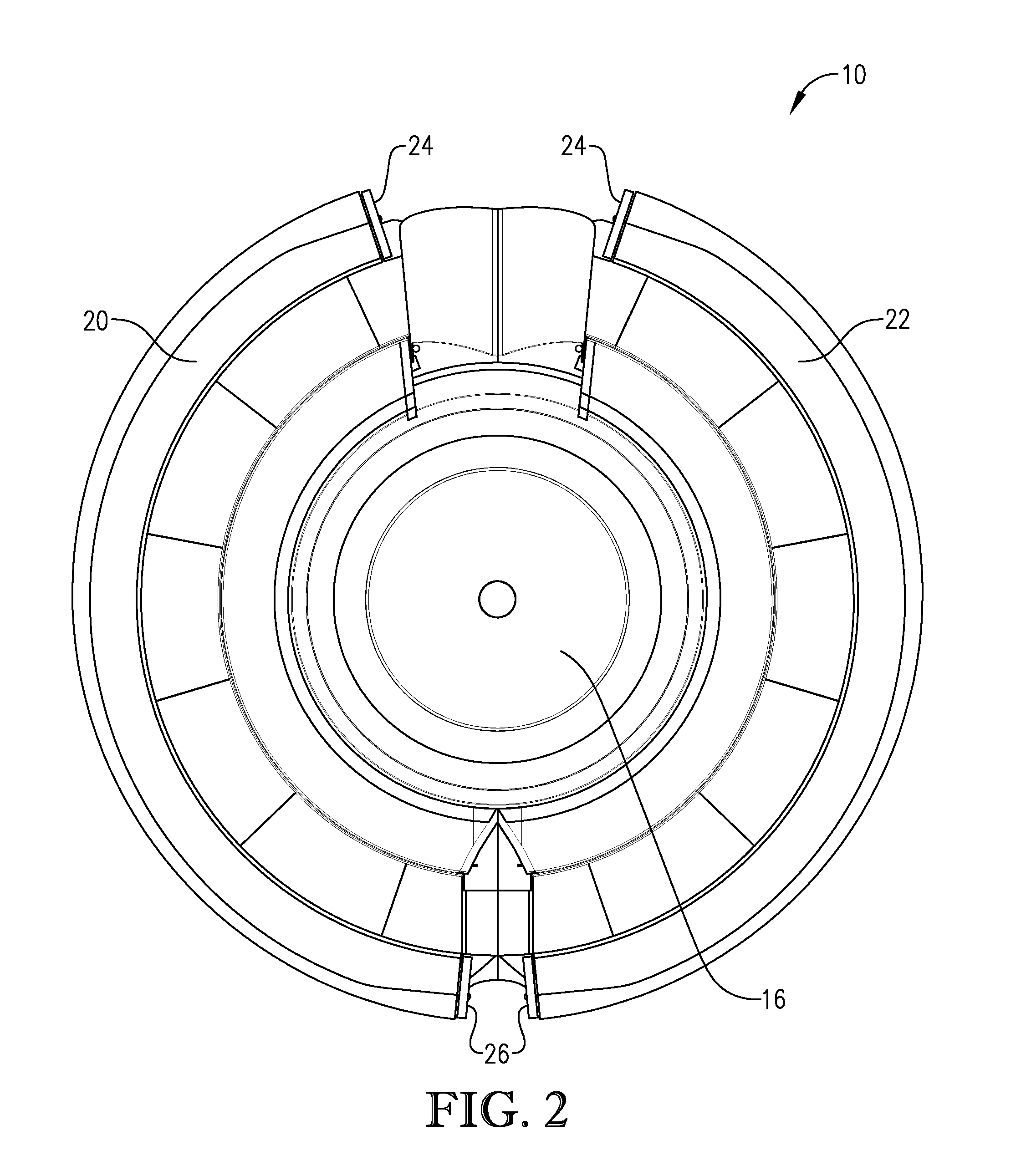

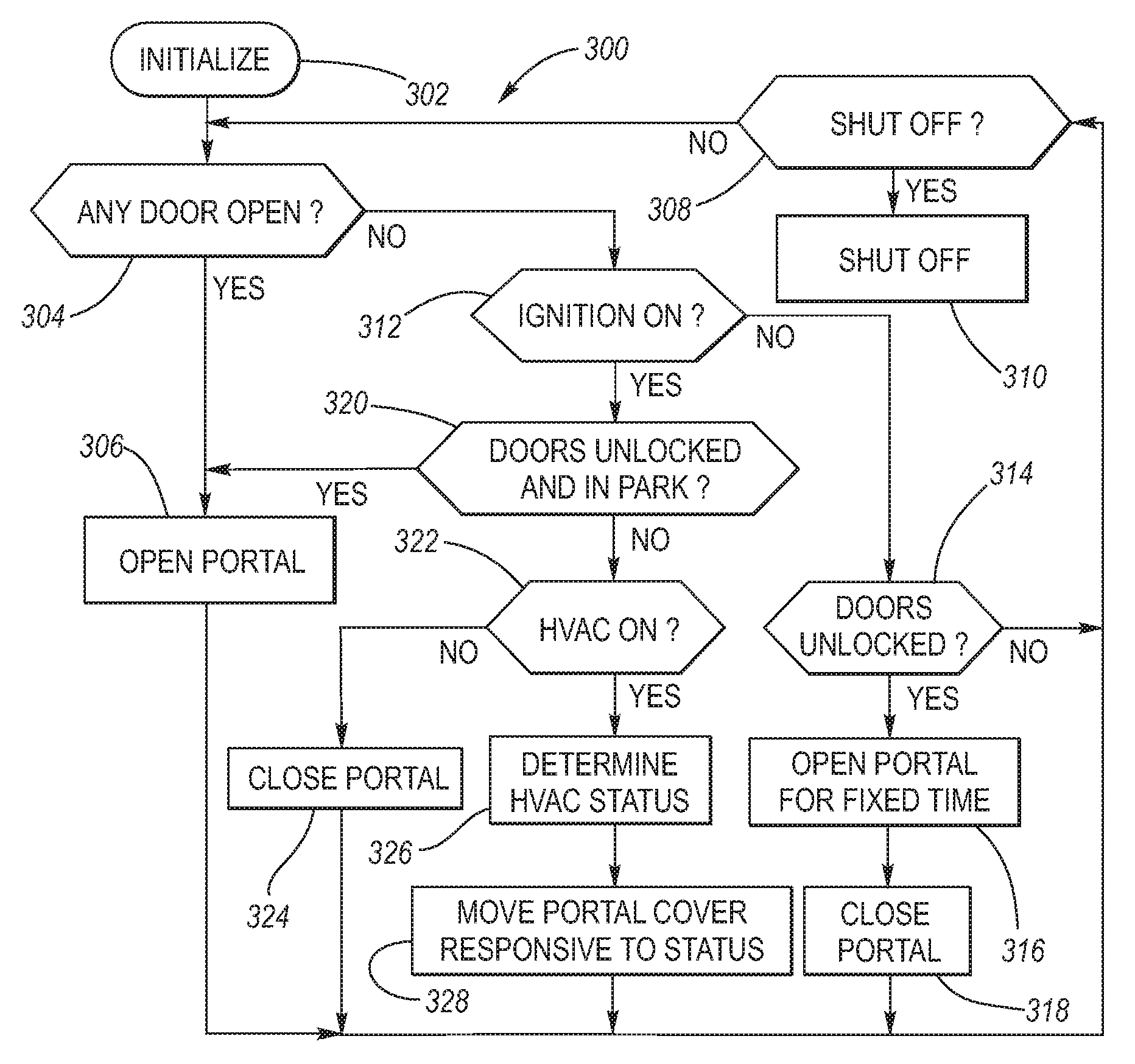

Active Body Ventilation System

InactiveUS20080186158A1Increase and decrease unobstructed sizeReduced opening sizeAuxillariesOptical signallingMobile vehicleState parameter

An active body ventilation system which is dynamically responsive to vehicle status parameters, including for example the door open / closed status and the HVAC system status. An active ventilation unit is attached with a body wall which includes a portal housing defining a portal, a portal cover and a portal cover actuator for selectively adjusting the portal cover to thereby increase or decrease the unobstructed size of the opening of the portal. The active ventilation unit is interfaced electronically to various sensors of the motor vehicle, in which programming of an electronic control module determines optimum positioning of the portal covering via selective actuation of the portal cover actuator.

Owner:GM GLOBAL TECH OPERATIONS LLC

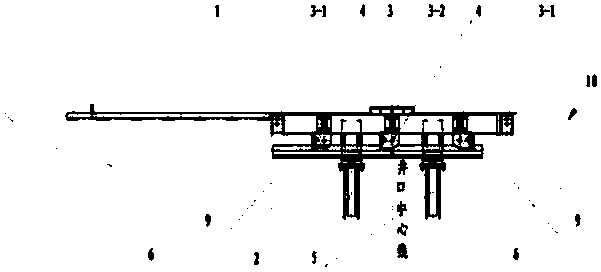

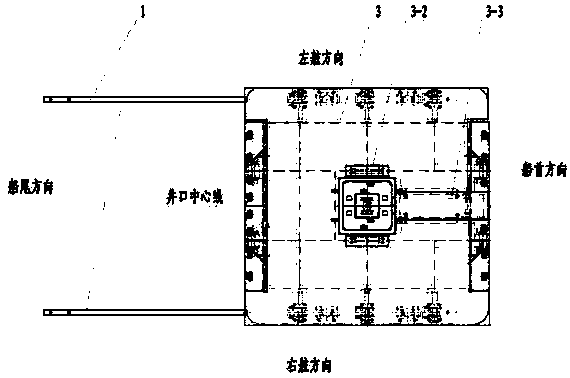

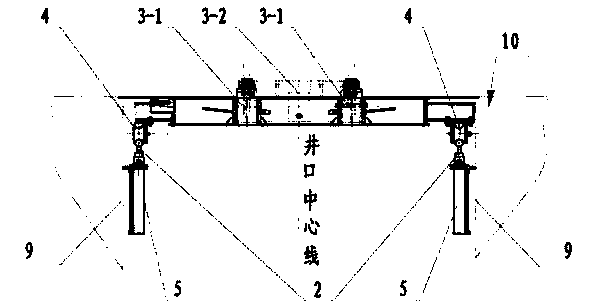

Novel moonpool cover for drilling ship

The invention discloses a novel moonpool cover for a drilling ship. The moonpool cover comprises a rectangular moon pool cover body, wherein at least two pairs of connecting pieces b are oppositely arranged on the two sides, close to the head and tail of a ship body, of the moon pool cover main body, the connecting pieces b are installed on the moonpool wall, at least three pairs of rolling wheelsare oppositely arranged on the two sides, close to a larboard and a starboard of the ship body, of the moon pool cover main body, two moonpool inner rails are clamped in the bottoms of the rolling wheels, at least two pairs of lifting oil cylinders are oppositely mounted at the bottoms of the two month pool inner rails, the lifting oil cylinders are installed on the moon pool wall, and a slip supporting disc is arranged in the middle of the moon pool cover body. The novel moonpool cover solves the problems that a moon pool cover is large in volume, short in service life, small in bearing drill column load and limited by the capacity and space of a ship crane in the prior art.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

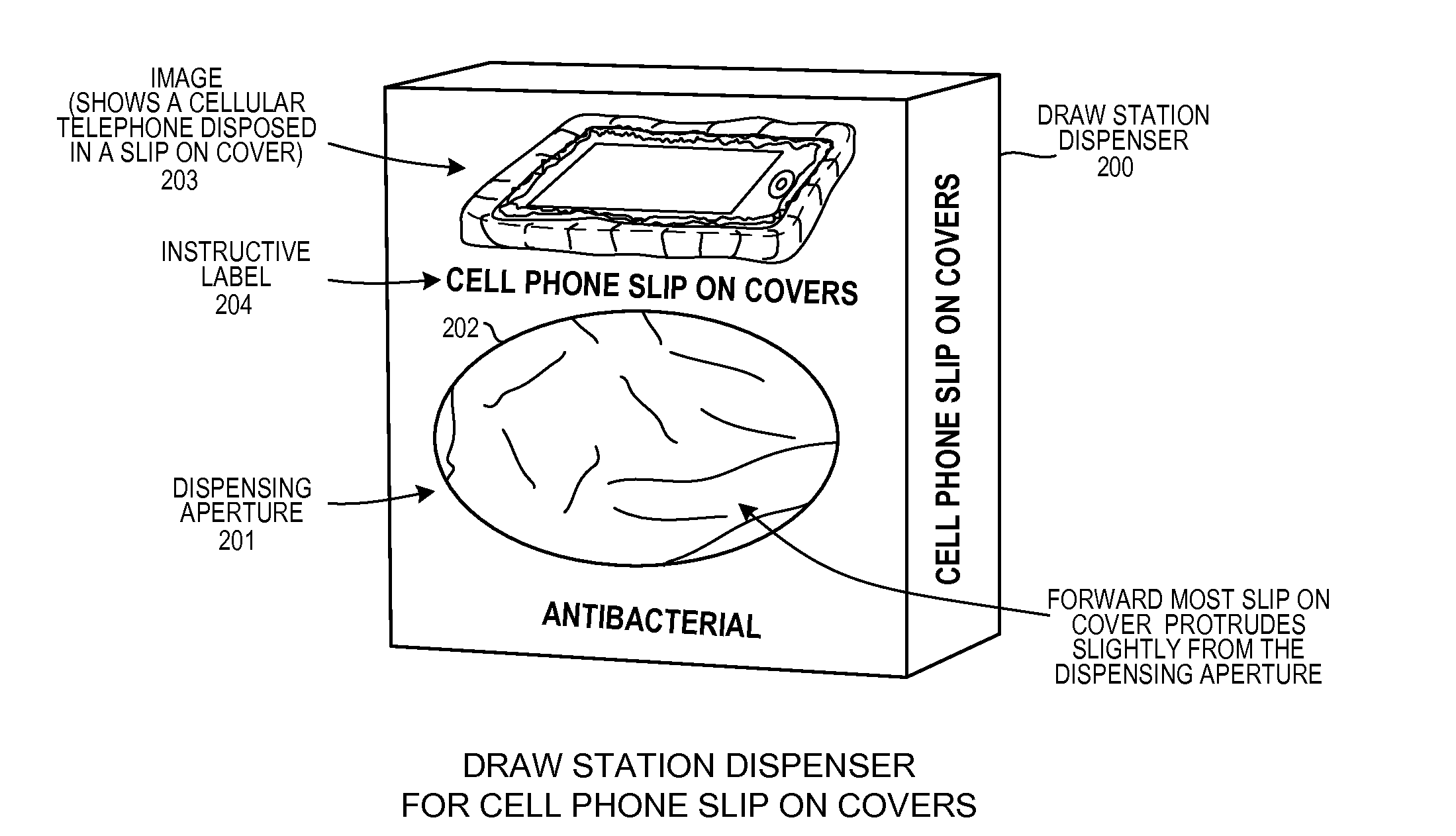

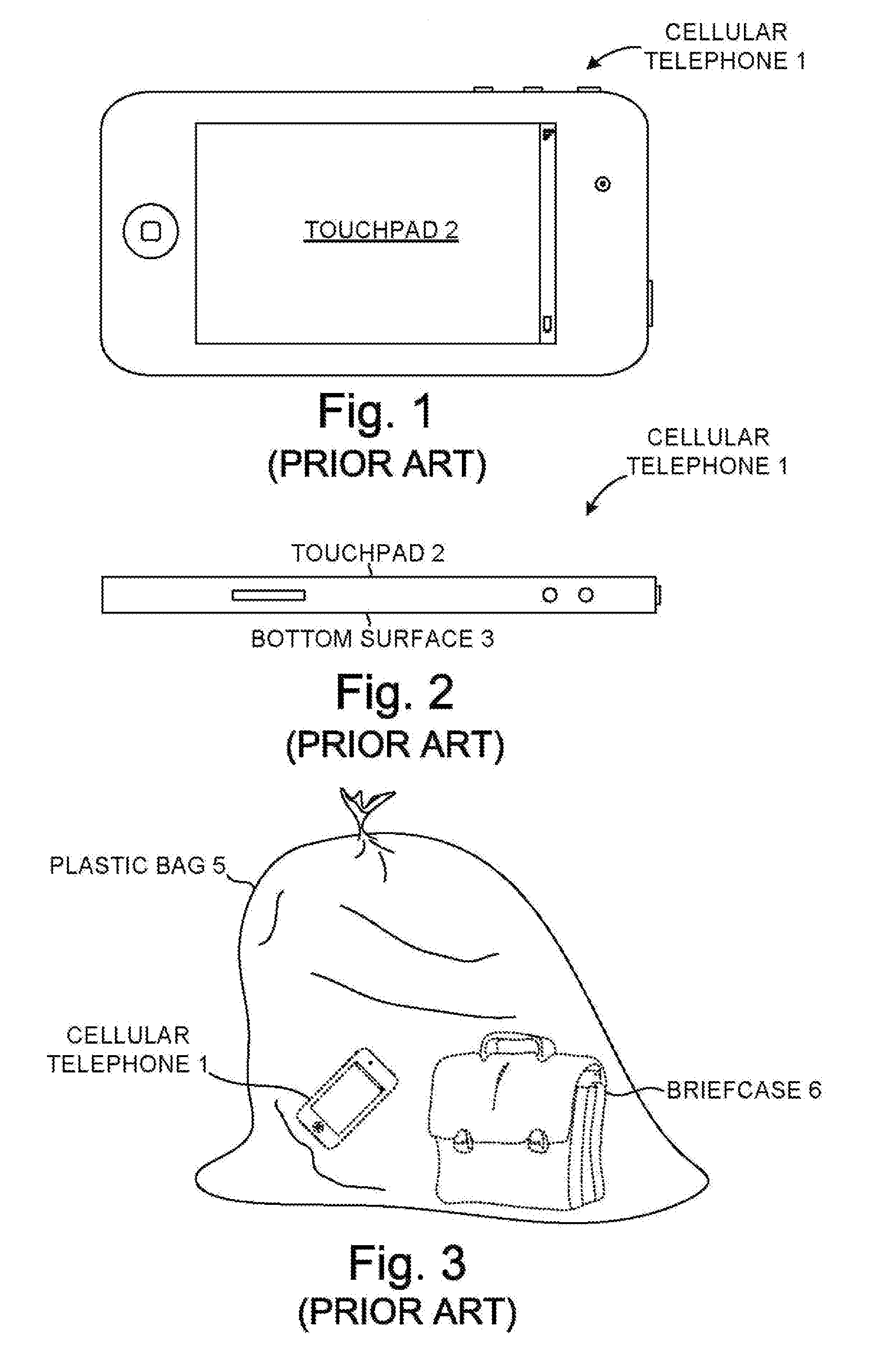

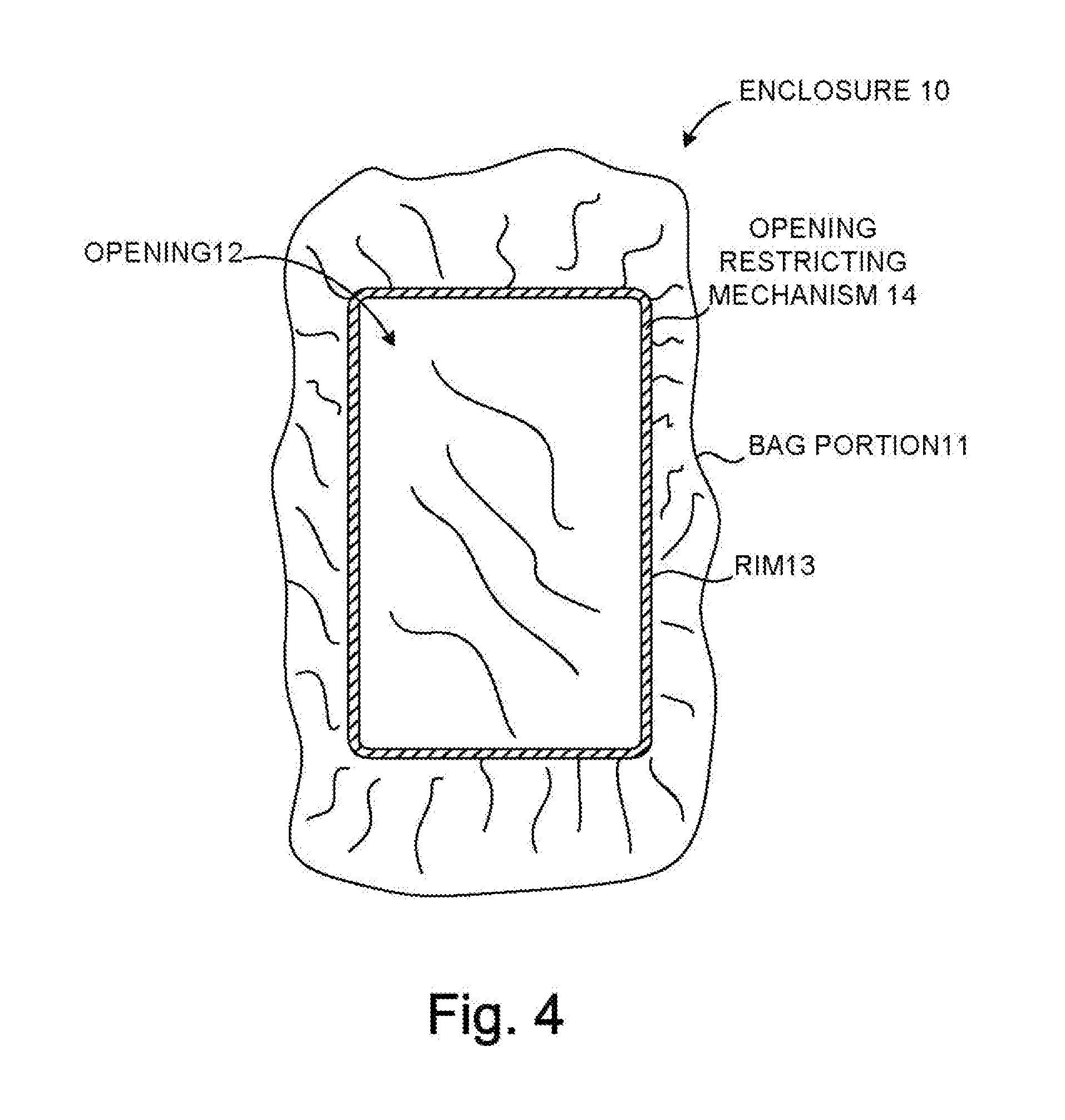

Enclosure And Method For Prevention Of Health-Care-Associated Infections From Contaminated Devices

ActiveUS20140260091A1Avoid spreadingReduce manufacturing costOperating tablesDiagnosticsTablet computerEngineering

A novel enclosure is used to prevent health-care-associated infections caused by contamination of devices such as cellular telephones, laptops, tablet computers, purses, and briefcases. Such a device is placed into the enclosure and is carried into a disinfected or clean environment, such as an operating room. The enclosure prevents infectious agents or other contaminants on the surface of the device from contaminating the clean environment. The enclosure also protects the environments outside the operating room from contaminants within the operating room. The enclosure is inexpensively manufactured and disposable. The enclosure may include an effective amount of antibacterial, antifungal, and / or antiviral compounds. The enclosure may be used in the residence of an individual with a compromised immune system. The enclosure may be used to bring a device into and out of a home or room of an individual who is extremely neat or is inflicted with an obsessive-compulsive disorder.

Owner:SACKS KENNETH R

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com