Pressure-bearing type solar collector based on groove-type parabolic mirror

A technology of solar heat collectors and trough paraboloids, applied in solar heat collectors, solar heat collectors using working fluid, solar thermal energy, etc., can solve the process requirements that are very high, cannot withstand large pressure, heat collection Problems such as barriers to the popularization of the device, to achieve the effect of high safety factor, long service life and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

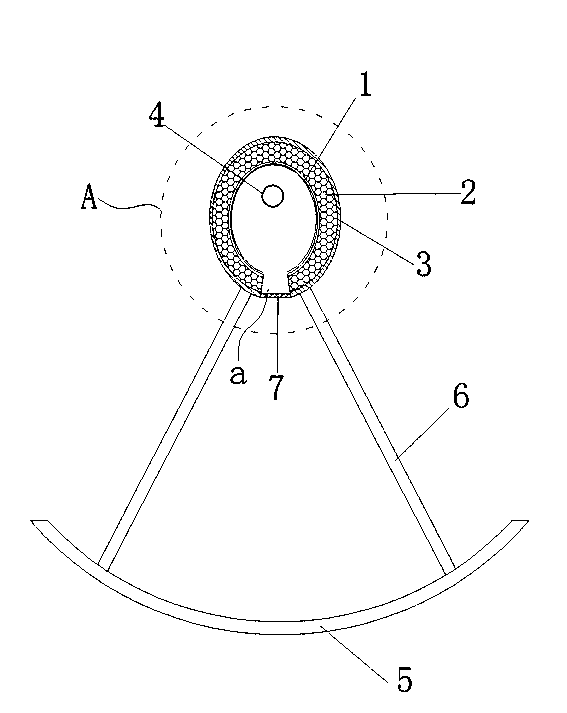

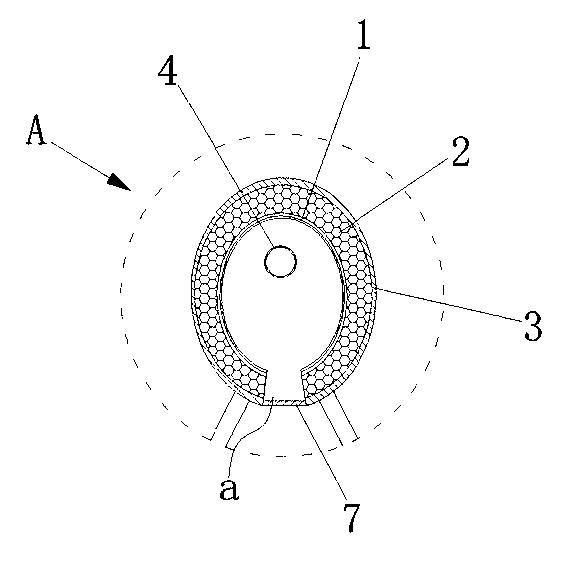

[0041] figure 1 Shows the structure of an embodiment of the pressurized solar collector in the present invention, including an elliptical reflector, an elliptical shell 2, filled with insulating material 3, a trough-type parabolic concentrator 5, a metal support assembly 6, a pressure-resistant Metal heat collecting tube group, light entrance a.

[0042] An elliptical reflector, the elliptical reflector is made of stainless steel, such as figure 2 As shown, the cross section is an elliptical stainless steel mirror reflector 1 with an opening, the opening of the stainless steel mirror reflector 1 is used as the light entrance a of the trough parabolic condenser, and the light entrance a extends along the stainless steel mirror reflector 1 axially , and the light incident port a is located at or near the intersection of the outer contour of the ellipse and the long axis of the ellipse on the cross-section of the stainless steel specular reflection cylinder 1 .

[0043] An ell...

Embodiment 2

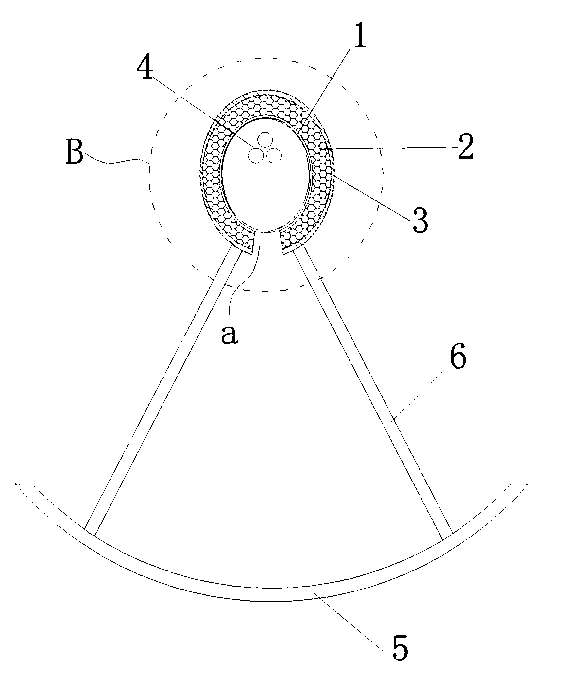

[0049] image 3 It shows the structure of another embodiment of the pressurized solar collector in the present invention, which is basically the same as the above embodiment, and also includes an elliptical reflector, an elliptical shell 2, filled with insulating material 3, and a trough-type parabolic concentrator 5. Metal support assembly 6. Pressure-resistant metal heat collecting tube group, light entrance a.

[0050] The difference is:

[0051] Such as Figure 4 As shown, the elliptical reflective cylinder adopts a glass reflective cylinder 1 with an elliptical cross section, and the light entrance a is located at the intersection of the outer contour of the ellipse and the long axis of the ellipse on the cross section of the glass reflective cylinder 1, and along the glass reflective cylinder 1 Axially extending; the surface of the glass reflective cylinder 1 near the housing side is coated with a specular reflective coating 11 in the area of the non-light entrance a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com