Patents

Literature

256results about How to "Reduce exposed area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

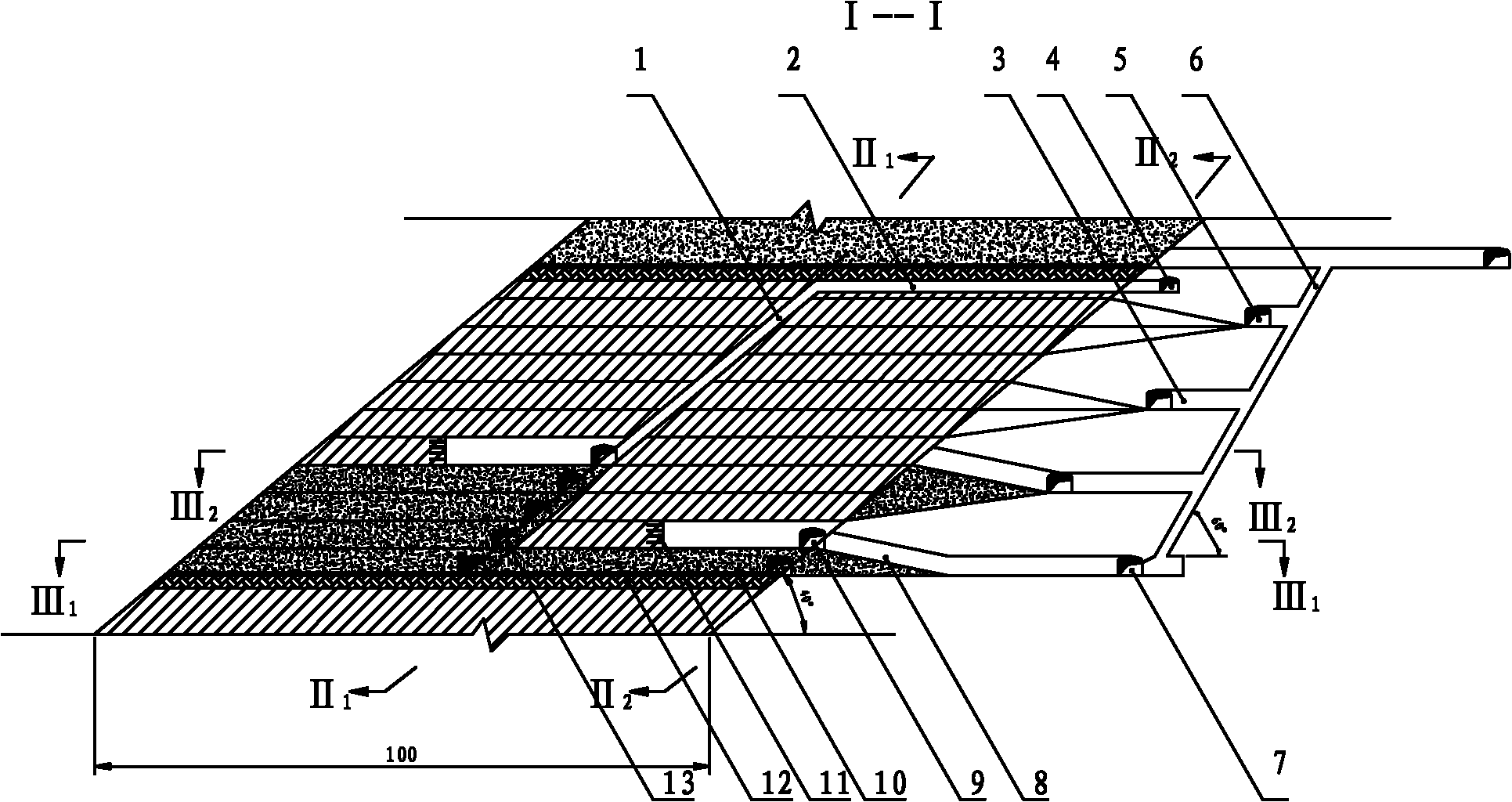

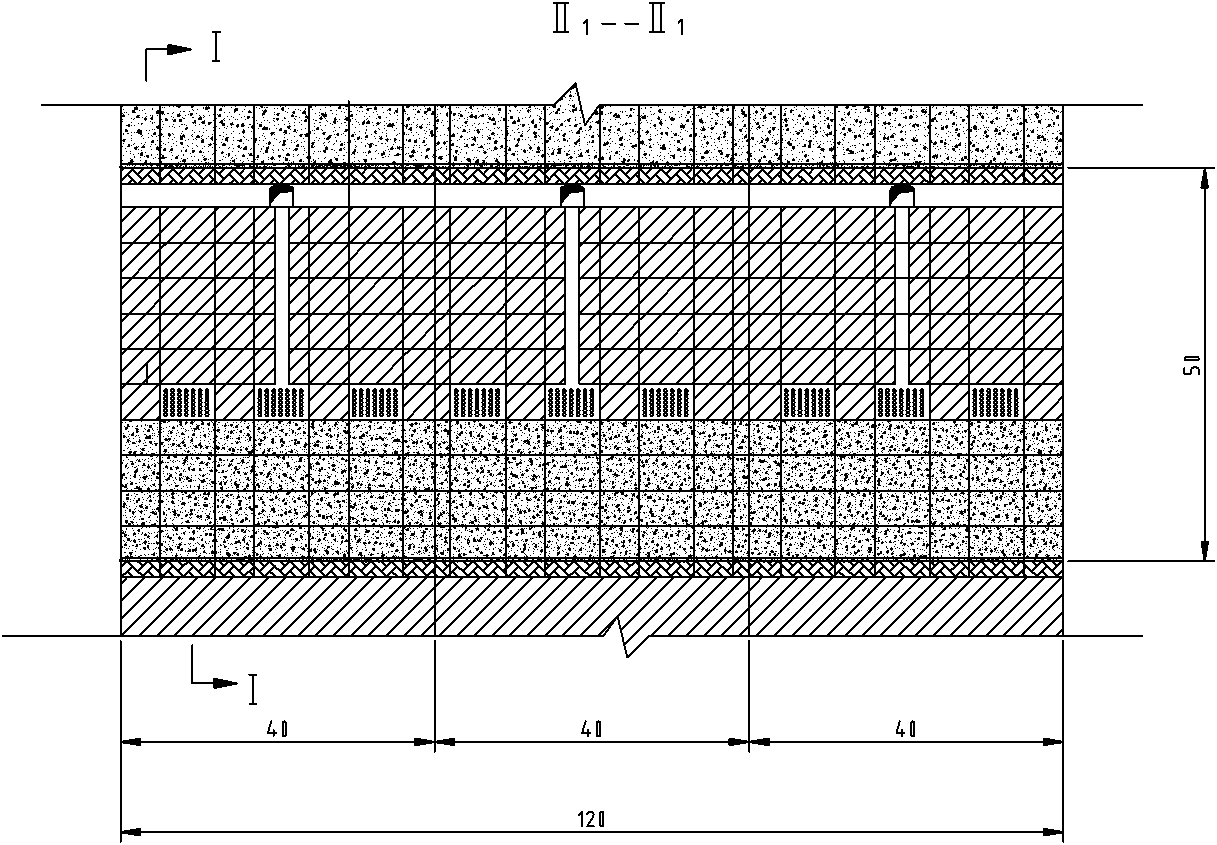

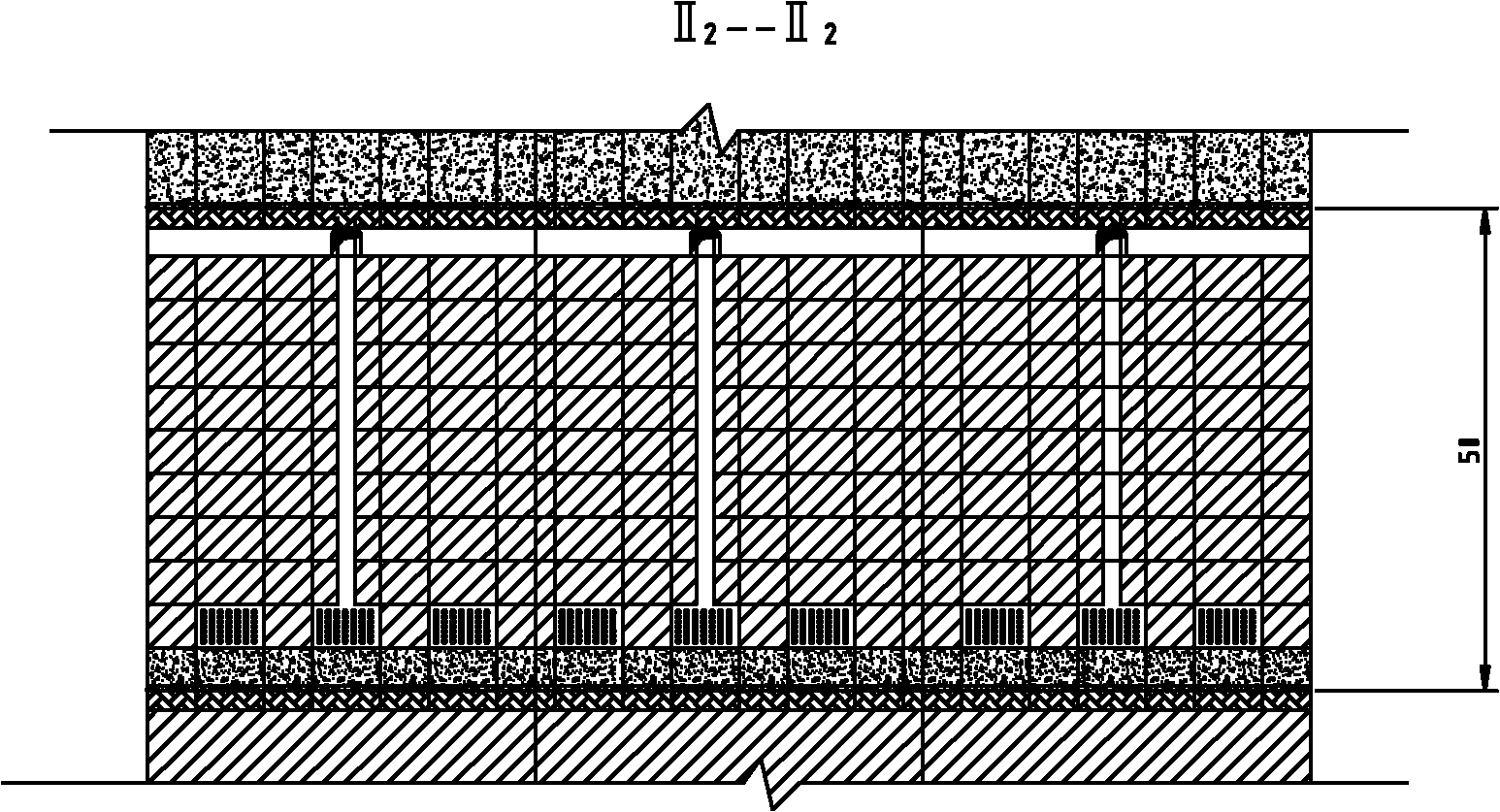

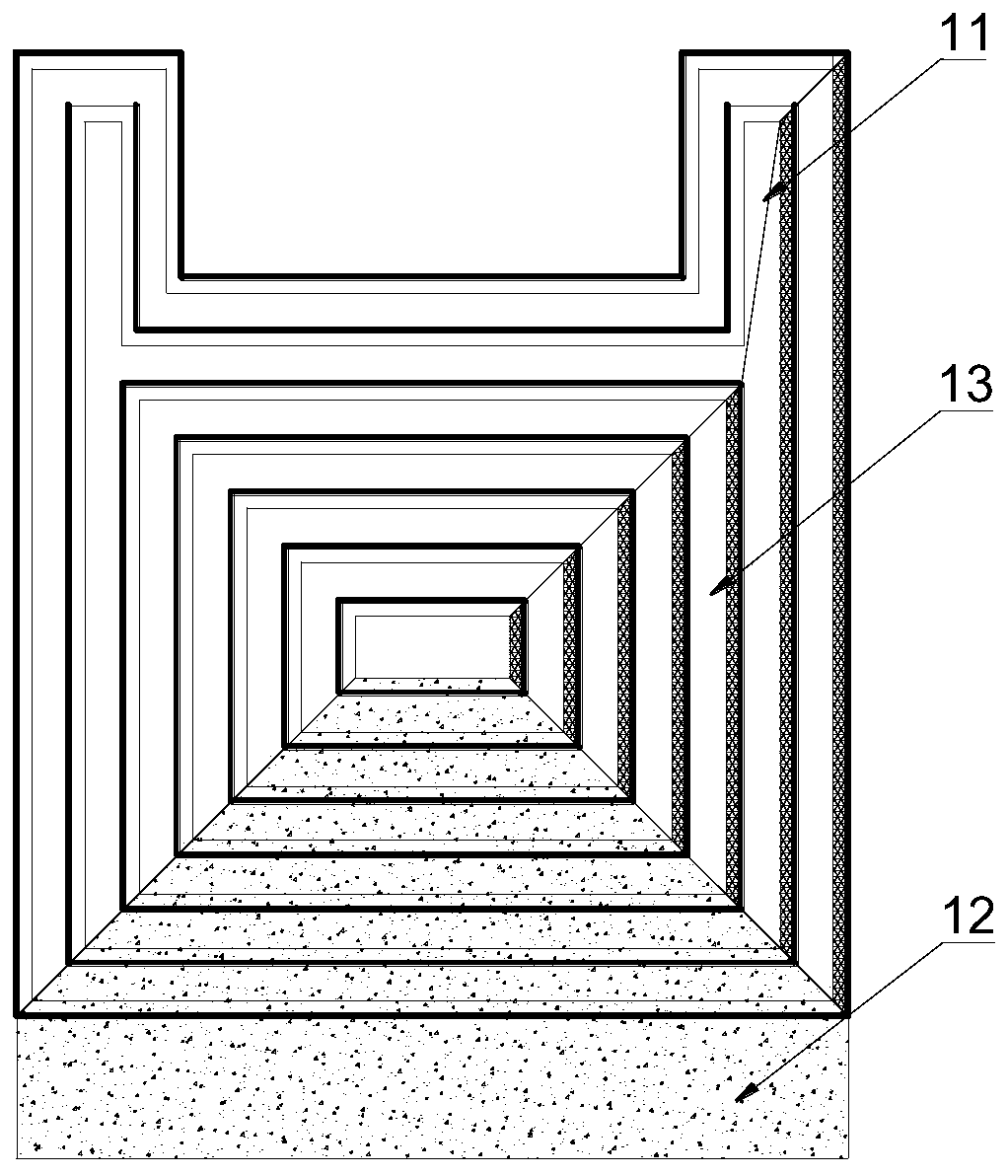

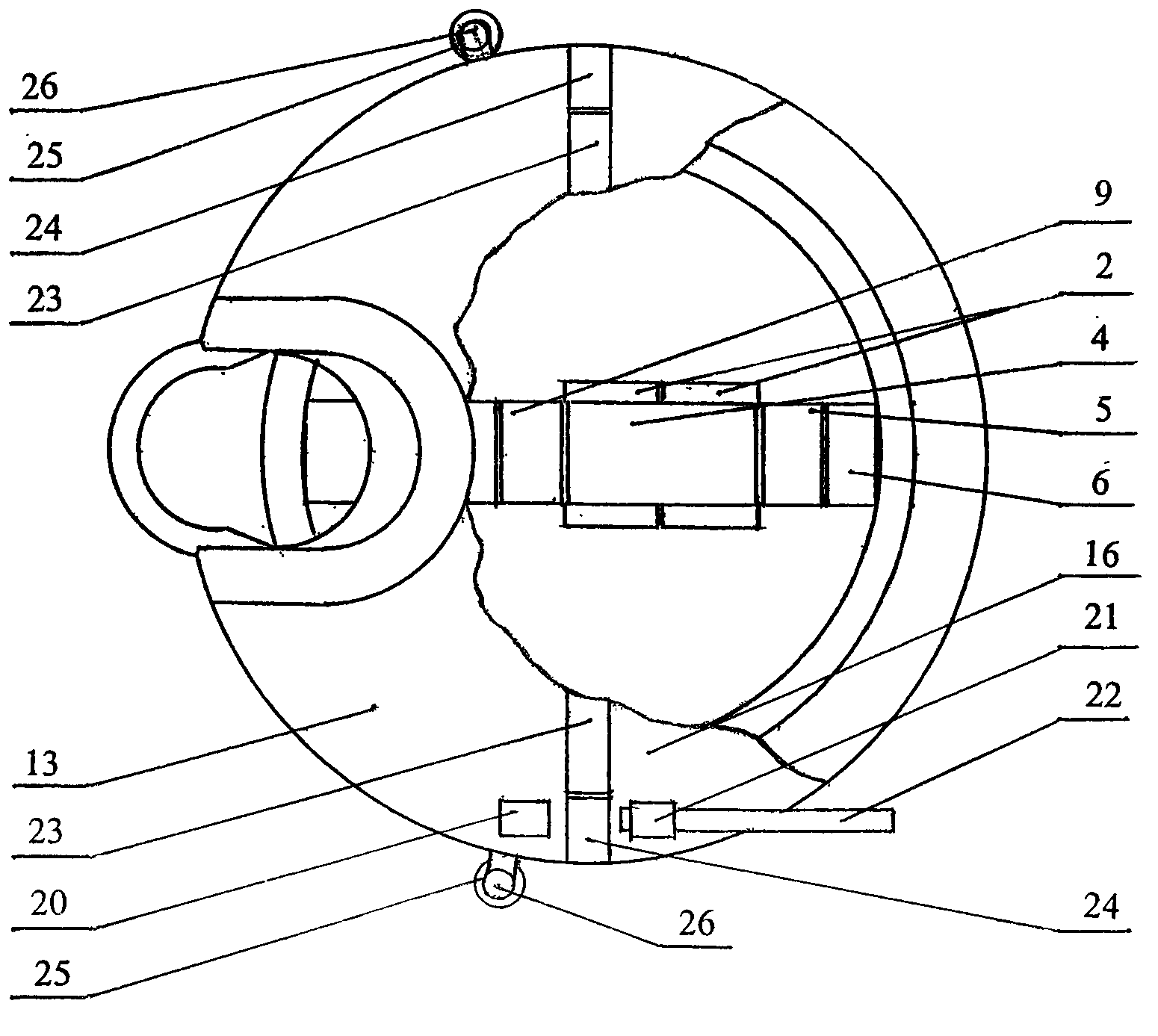

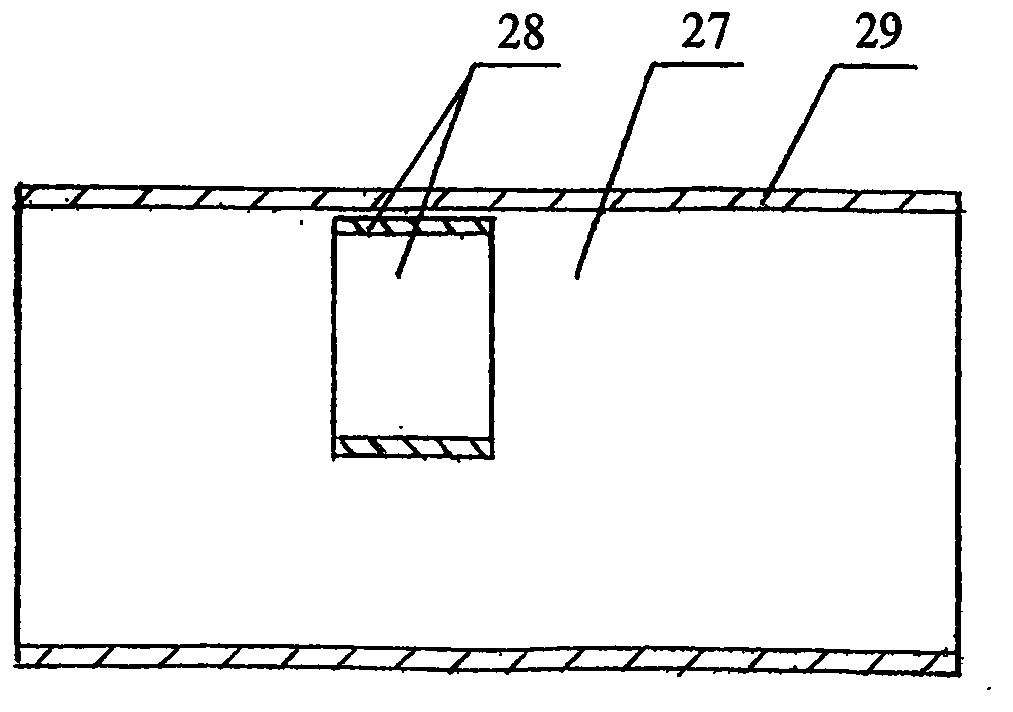

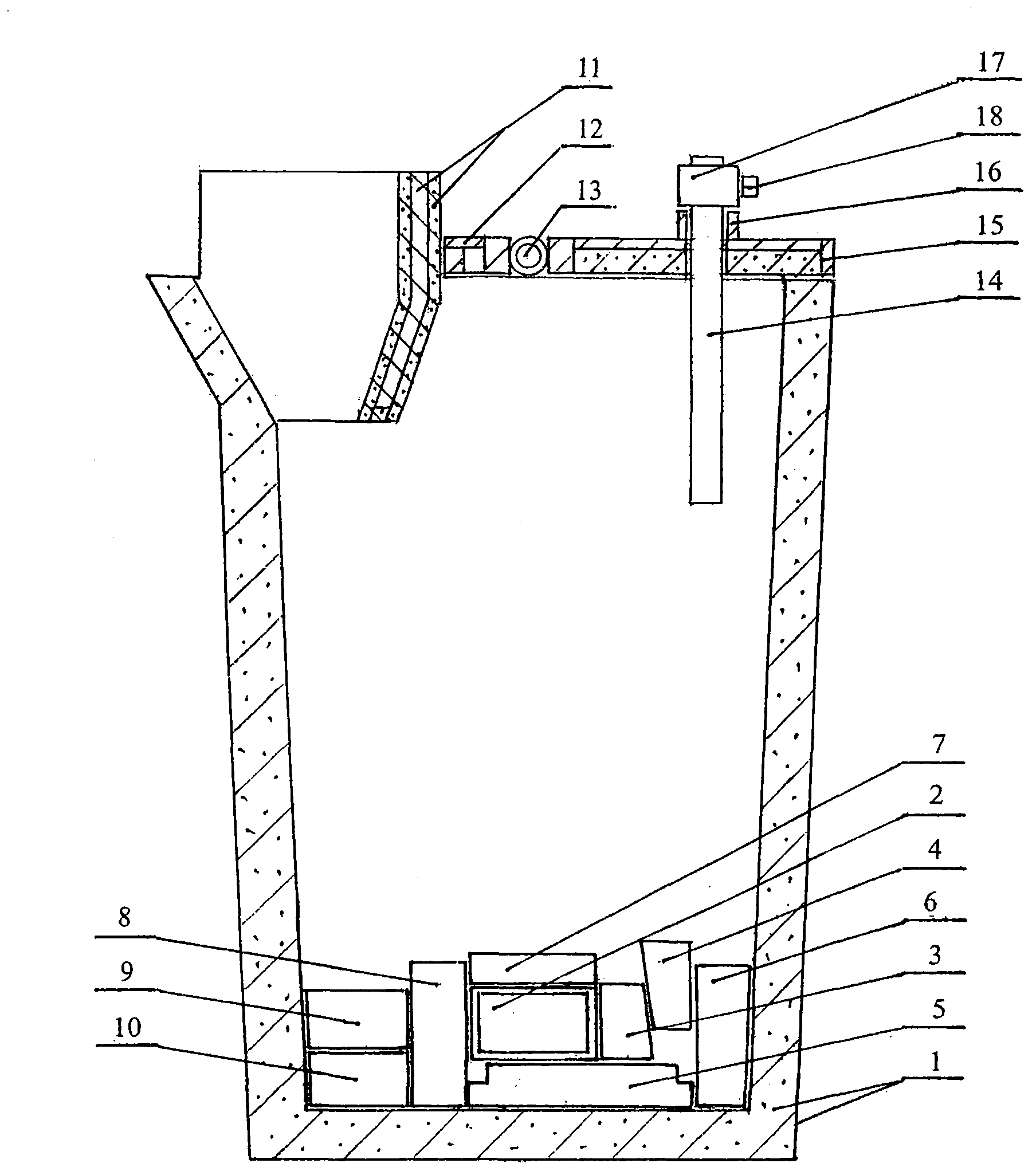

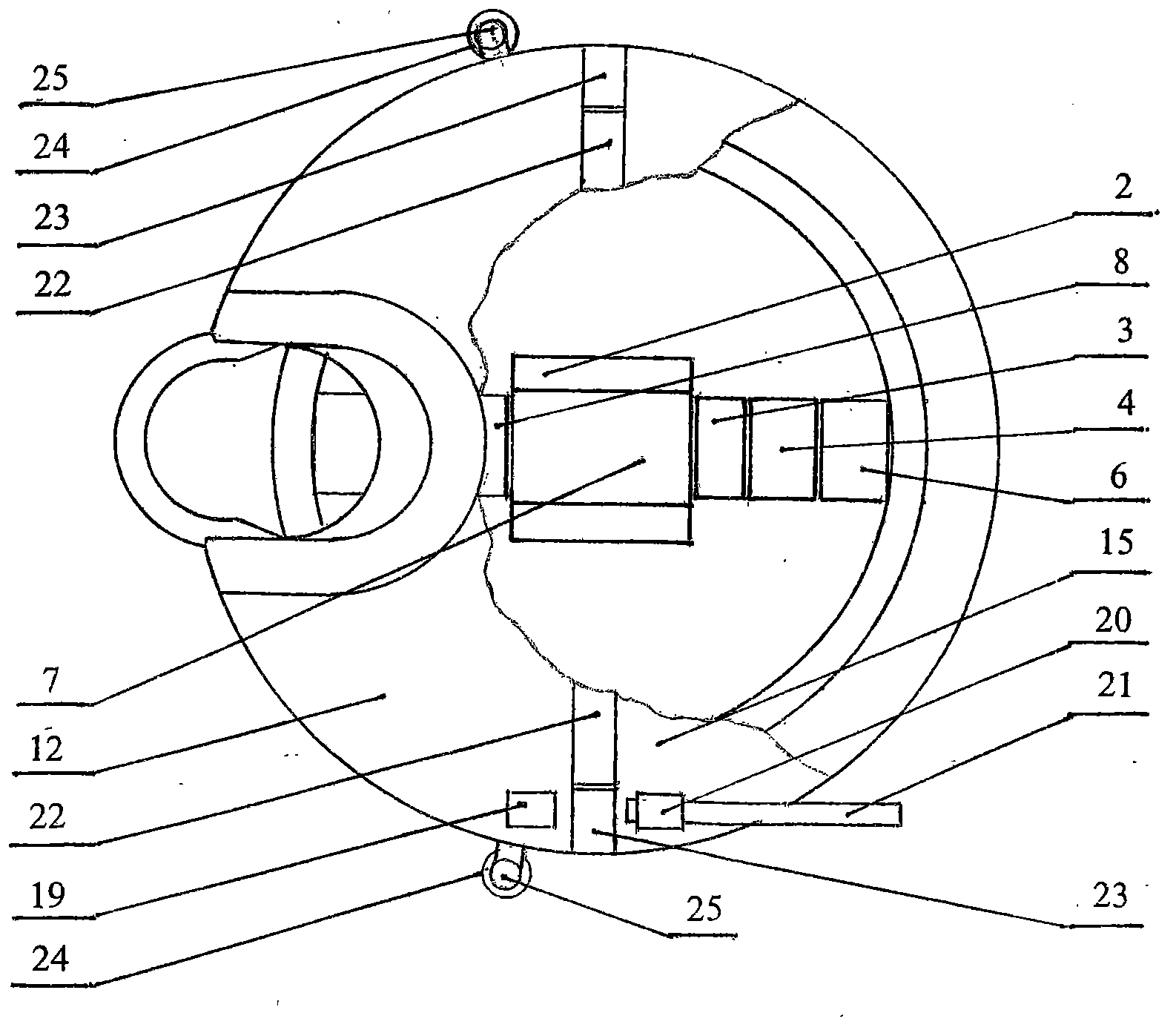

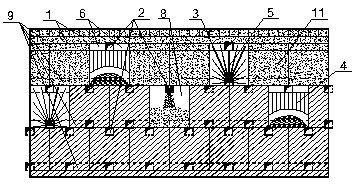

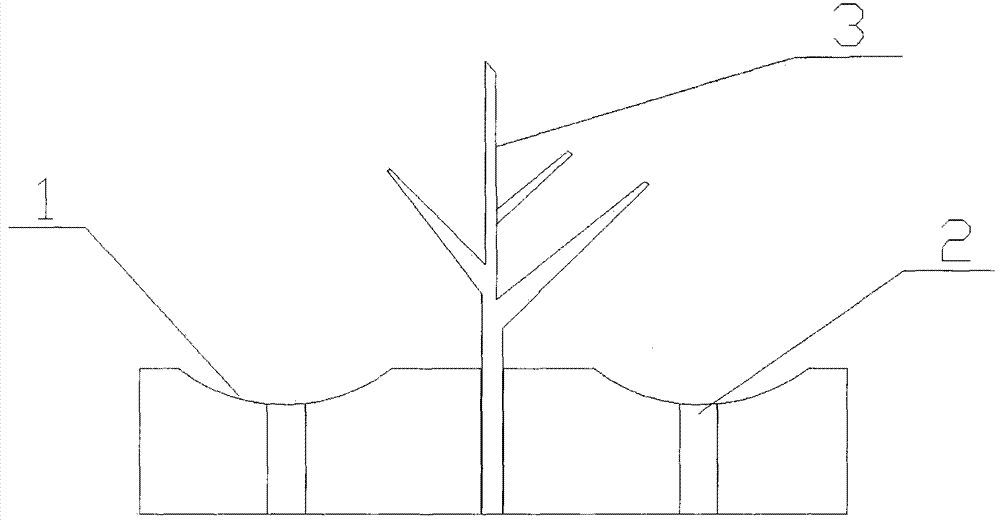

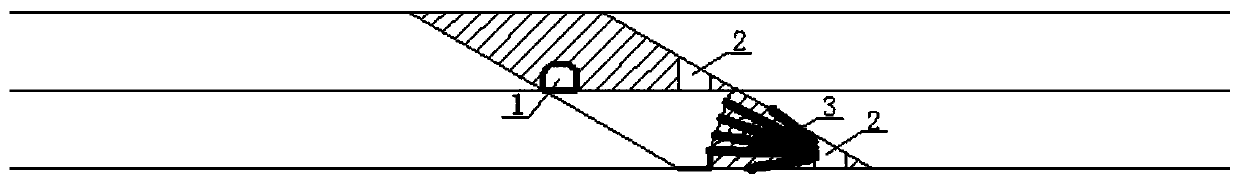

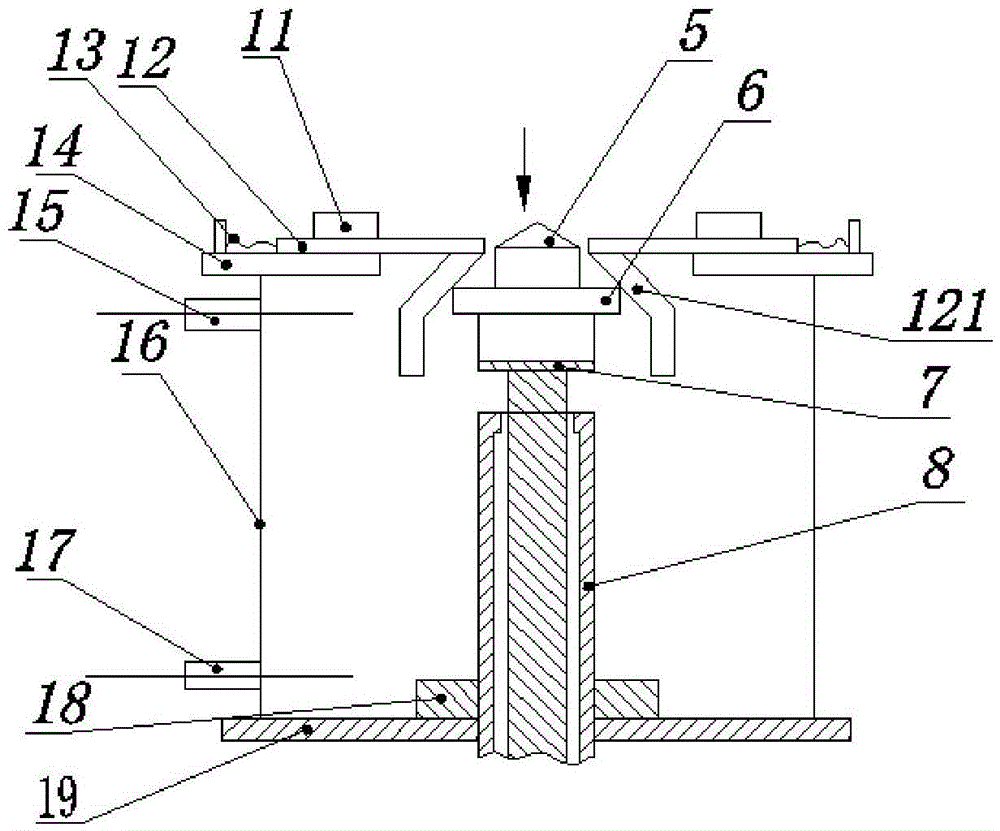

Stepped non-pillar continuous filling mining method for deep well super high large breaking ore body panel

InactiveCN101818643ASafe miningMining guaranteeUnderground miningSurface miningEngineeringCompressive strength

The invention discloses a stepped on-pillar continuous filling mining method for deep well super high large breaking ore body panel. An ore body is divided into a front part and a rear part in a super high large breaking ore body center by an transportation roadway, then the front part and the rear part are respectively divided into a plurality of panels, no pillar exists between pillars, each panel is partitioned into a primary extracting drift and a second extracting drift, the panels in the front part are extracted at first and then the panels in the rear part are extracted, the front and rear panels are extracted in a stepped manner, each production technology is carried out in the same level, and procedures can not influence each other; after the stop back production is finished, the primary extracting drift is filled with cement and the secondary extracting drift is filled by classifying tailings while roof-contacted filling is ensured; and the primary extraction drift and the secondary extraction drift adopt high strength filling topping, and binding materials are added in the filling tailings so as to improve the compression strength of a topping layer. The invention has the characteristics of high extraction safety, small loss and dilution, high mechanical degree, large stope amount, large back production strength, high production capability, short back production time and the like.

Owner:CENT SOUTH UNIV

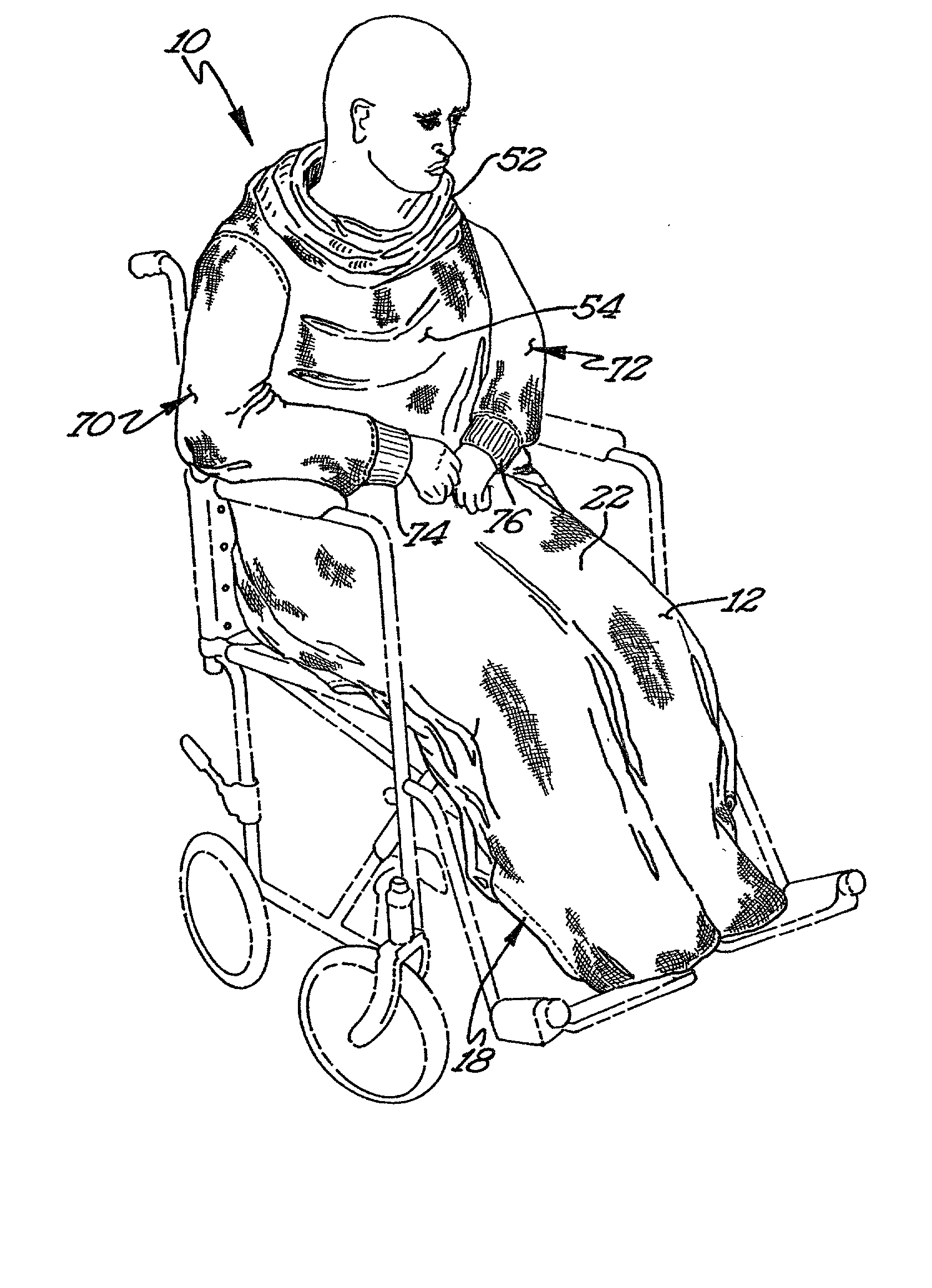

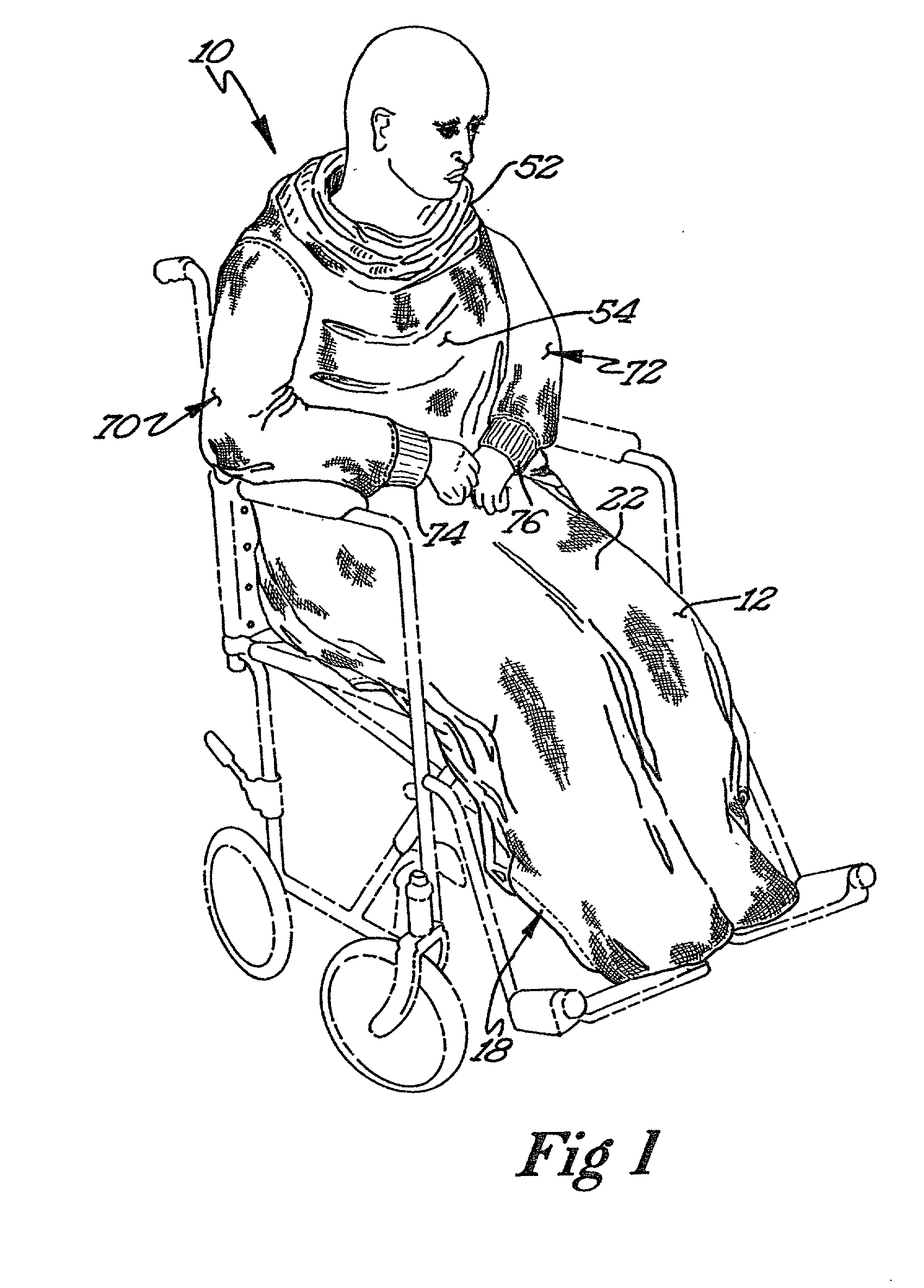

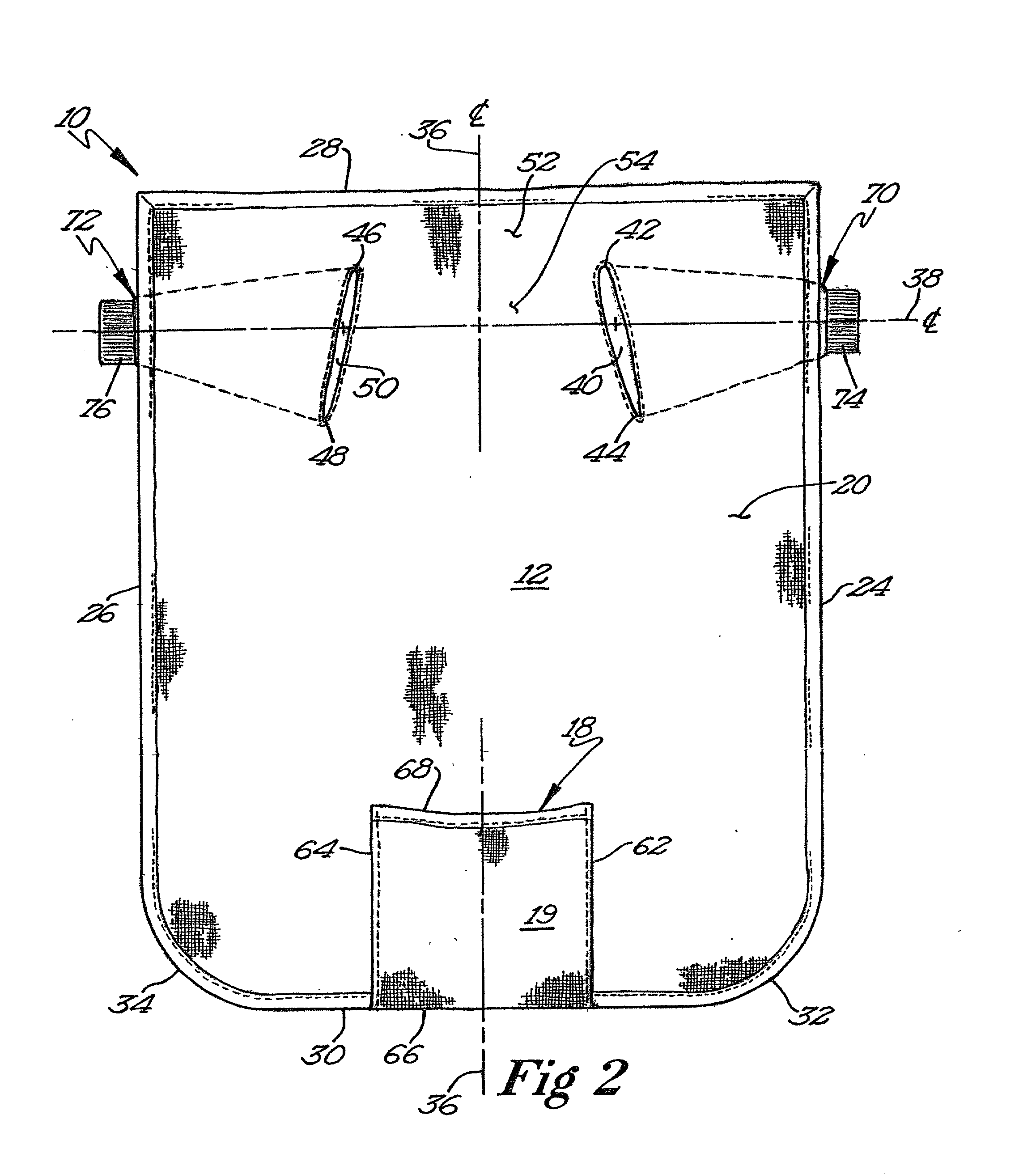

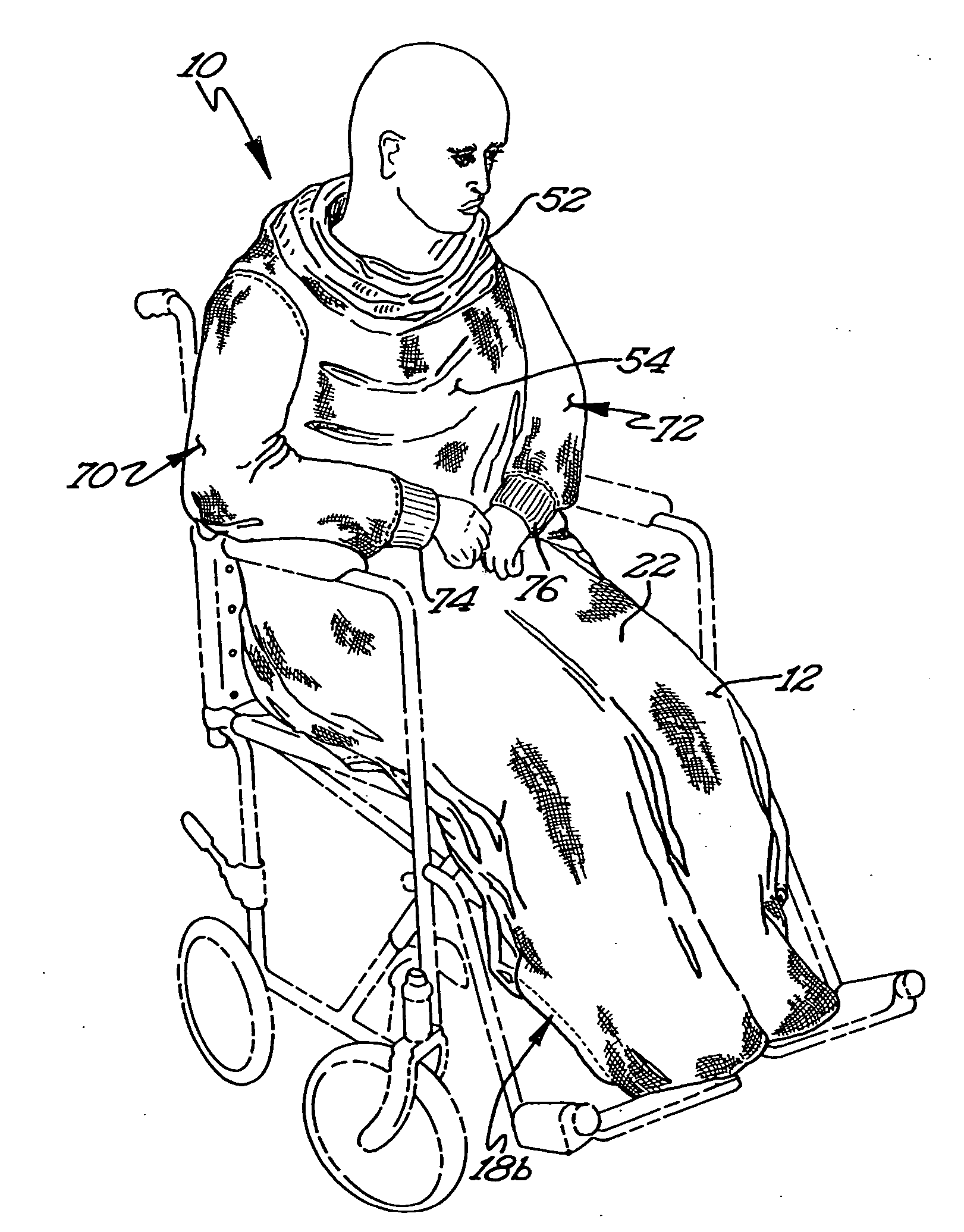

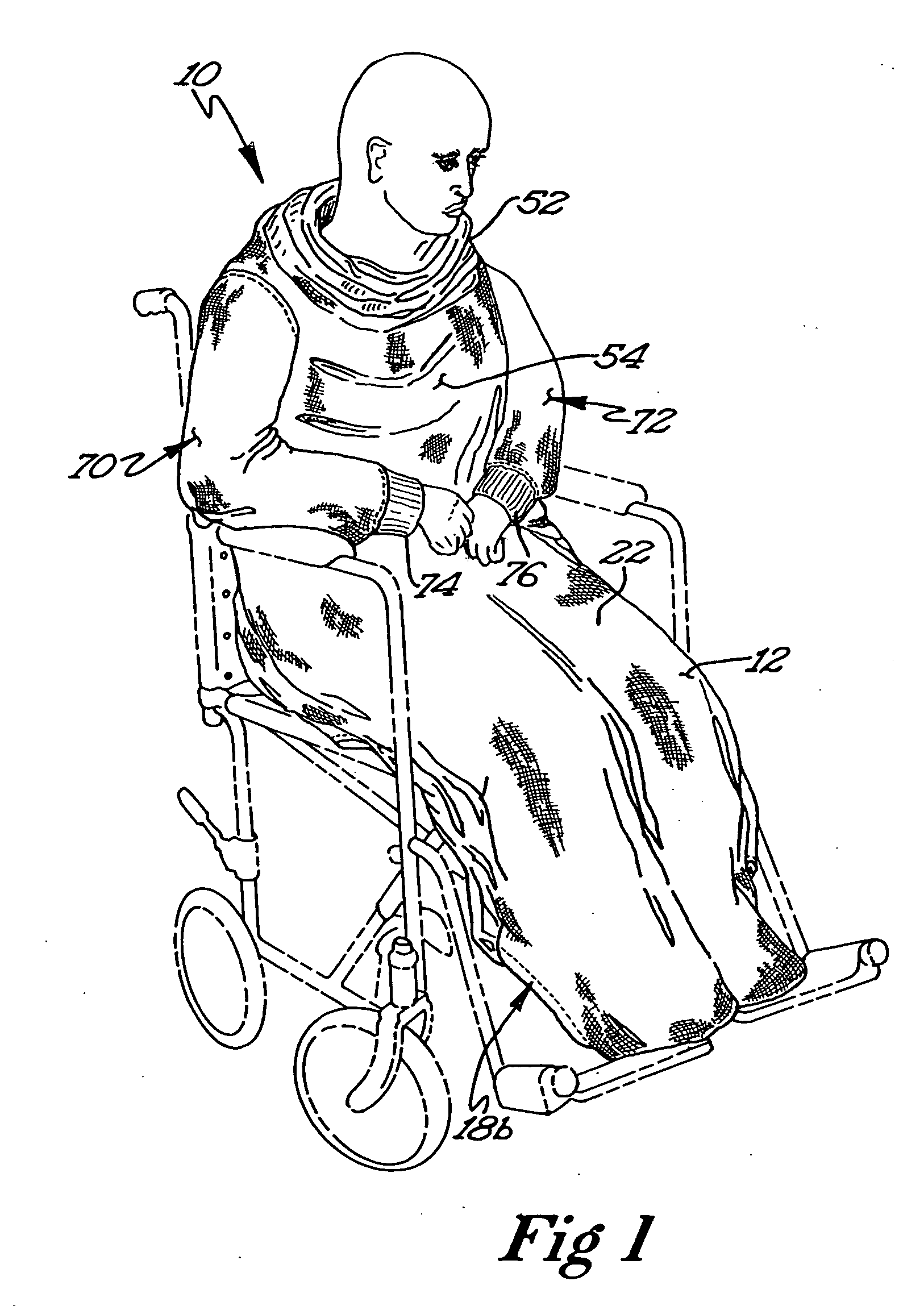

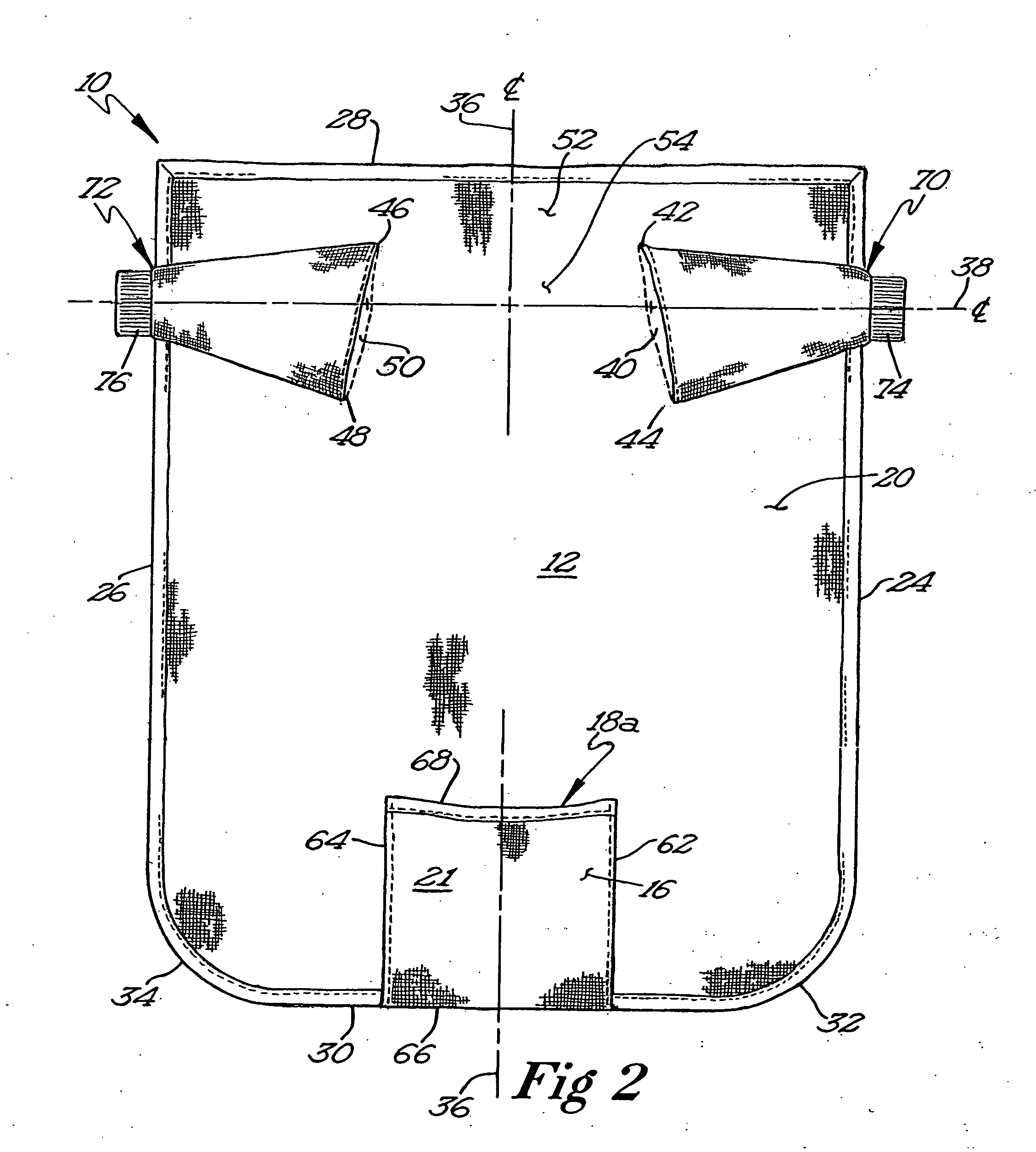

Pillow blanket

A pillow blanket comprises a blanket, foot pocket and a pair of sleeves. The foot pocket is made of a pocket panel secured at the side and bottom edges of the panel to the middle third portion of the blanket and the bottom edge of the blanket. A pair of sleeves is attached respectively to the perimeter of a pair of sleeve apertures in the blanket. The sleeve apertures have an oblong shape and oblique orientation. The blanket can be folded into the foot pocket to form a symmetrical pillow.

Owner:DEERING MANAGEMENT

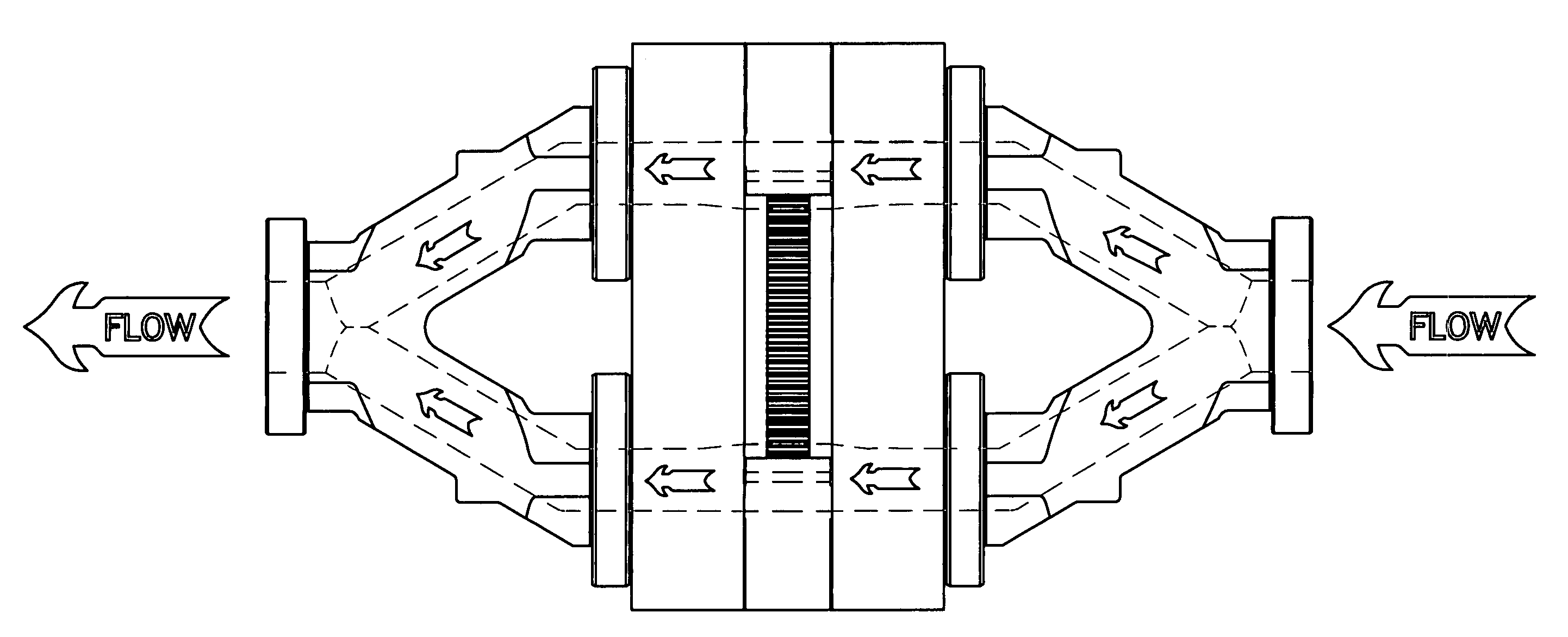

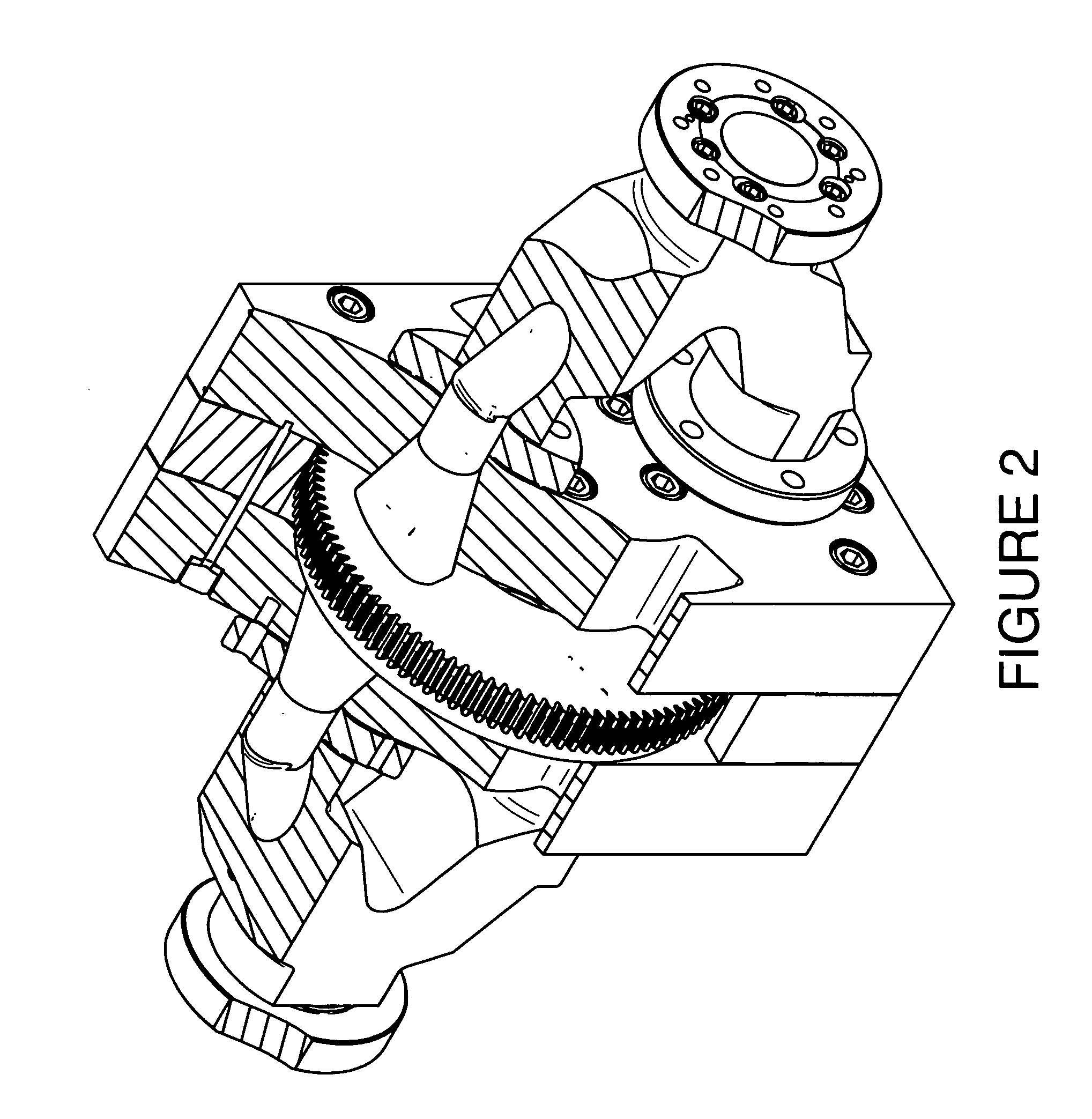

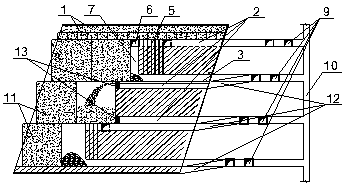

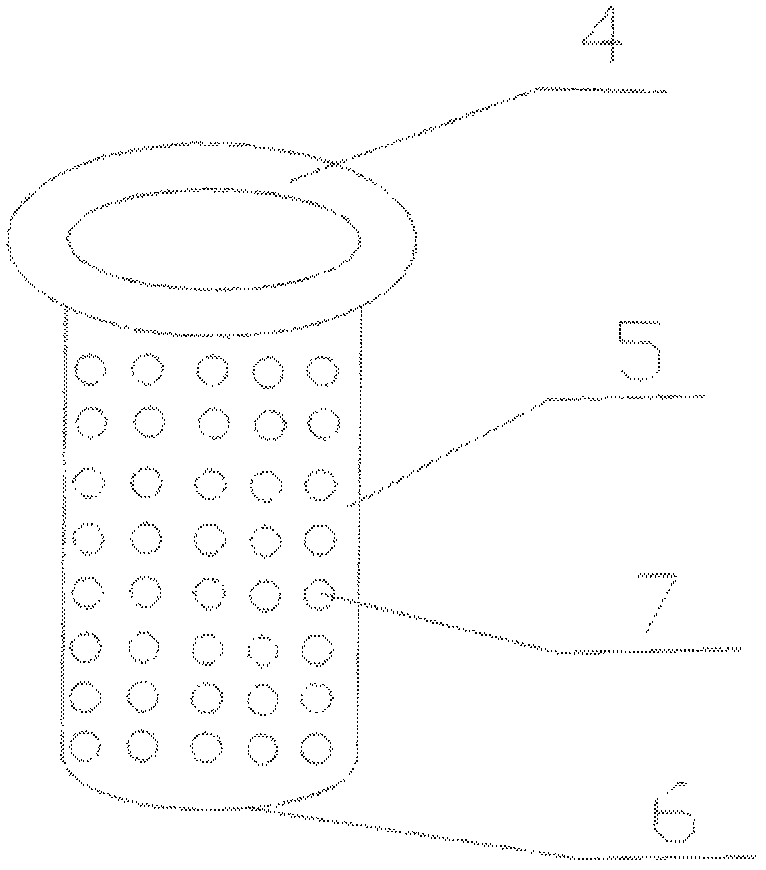

Single disc dual flow rotary filter

InactiveUS20080179261A1Little more spaceIncrease flow rateWater/sewage treatment by centrifugal separationSemi-permeable membranesCircular discEngineering

A filter with filter chambers disposed in an annular zone on a rotatable common disc has a multitude of separate flow passages, each flow passage containing within its flow stream at least one filter chamber on the common rotatable disc, and each identical flow passage is rotated around the axis of rotation of this common rotatable disc, thus multiplying the flow capacity of a rotatable disc filter by using the same disc to filter multiple streams. The rotatable common filter disc is disposed within a slot formed by body blocks and spacer blocks and rotates around a hub, the spacer blocks and hub controlling slot width such that rotatable metal to metal seals form between the disc and the body blocks in contact with a surface of the disc, forming leak free seals. The rotation of the rotatable common disc causes filter chambers, sealed within the slot, to change filter chambers as material accumulates within the filter chambers. An extension of the body block in contact with the rotatable disc on the surface without filter chambers provides further support, more temperature uniformity, and prevents fluid dripage. The filter improvement with multiple flow passages provides for higher flow through any specific rotatable filter disc size.

Owner:PATROVSKY HUBERT

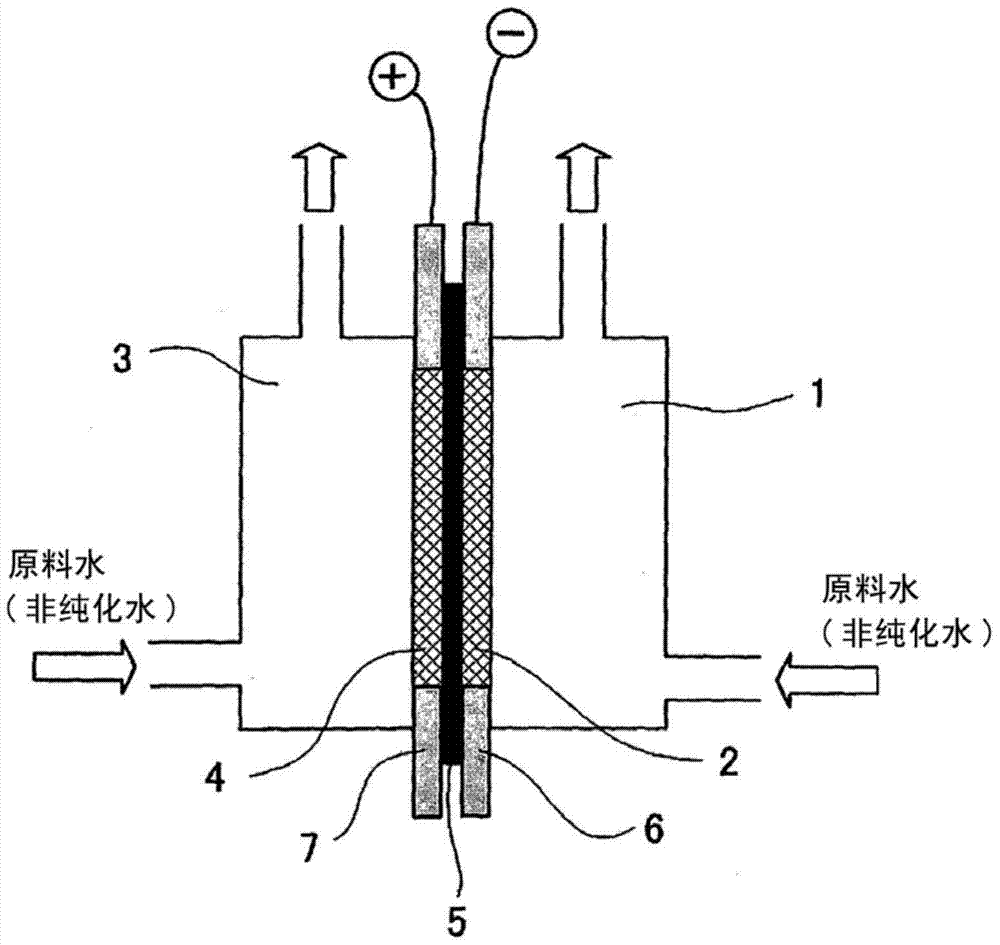

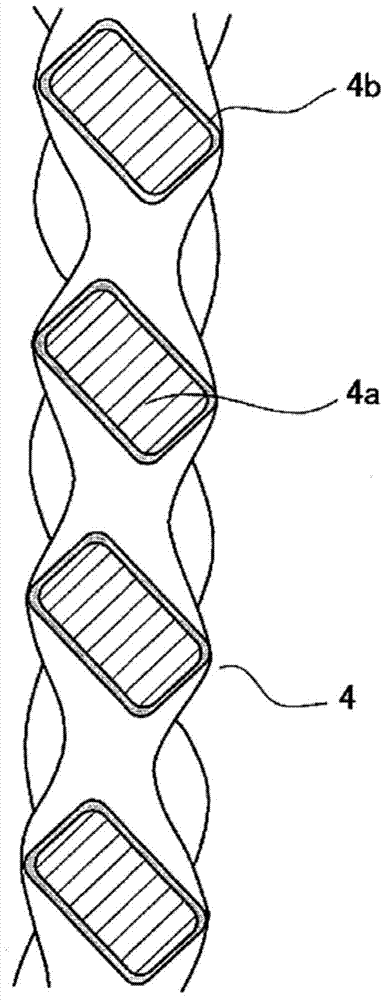

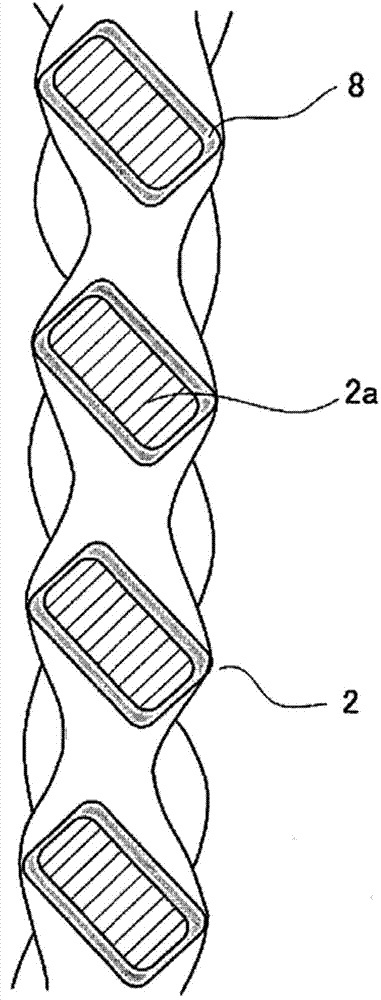

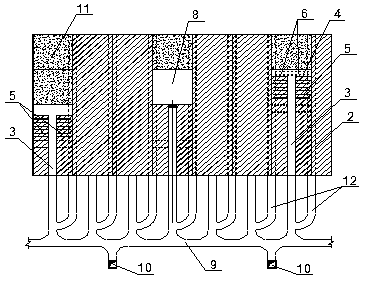

Electrolysis system and electrolysis method for the same

InactiveCN103781731AAvoid depositionSuppresses electrolysis voltage riseCellsWater/sewage treatment apparatusElectrolysisTrace Amounts

The present invention provides an electrolysis system and an electrolysis method for the same in which non-purified water containing a trace amount of alkali earth metal ions, such as calcium ion and magnesium ion is applied as raw material, having a configuration in which the raw material water is supplied to the cathode compartment (1), featuring that scale of the alkali earth metals including hydroxide can be prevented from depositing on the surface of the cathode (2) provided in the cathode compartment (1). The present invention prevents scales of hydroxide and others of the alkali earth metal from depositing on the cathode surface (2), by covering the substantially entire surface of the cathode (2) with the cation exchange resin-contained, alkali earth metal scale-preventive film in the electrolysis system having a configuration comprising a diaphragm (5), an anode compartment (3) separated by the diaphragm (5), a cathode compartment (1) separated by the diaphragm (5), an anode (4) provided in the anode compartment (3), a cathode (2) provided in the cathode compartment (1), and raw material water containing alkali earth metal ions supplied to the cathode compartment.

Owner:AQUAECOS +1

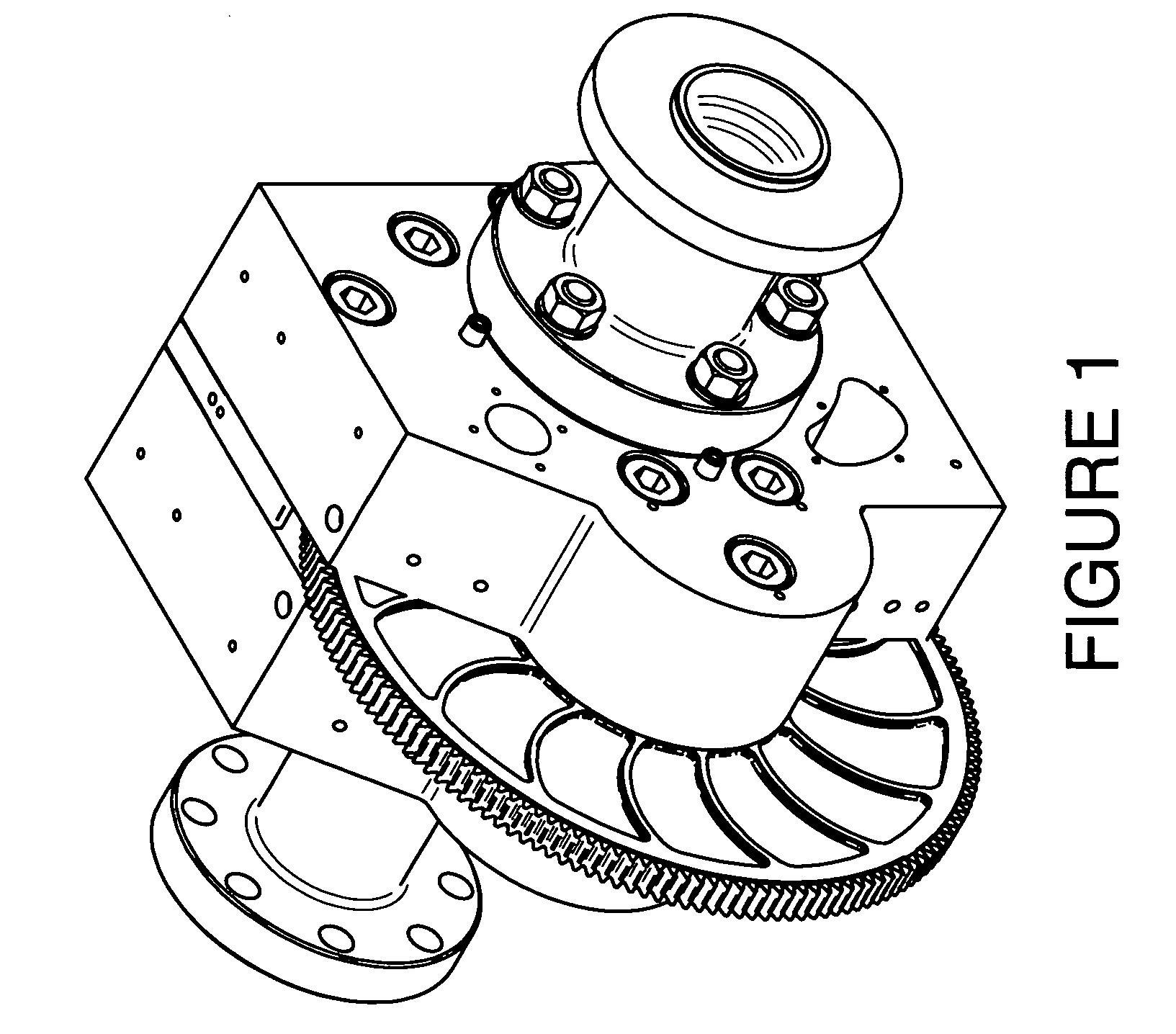

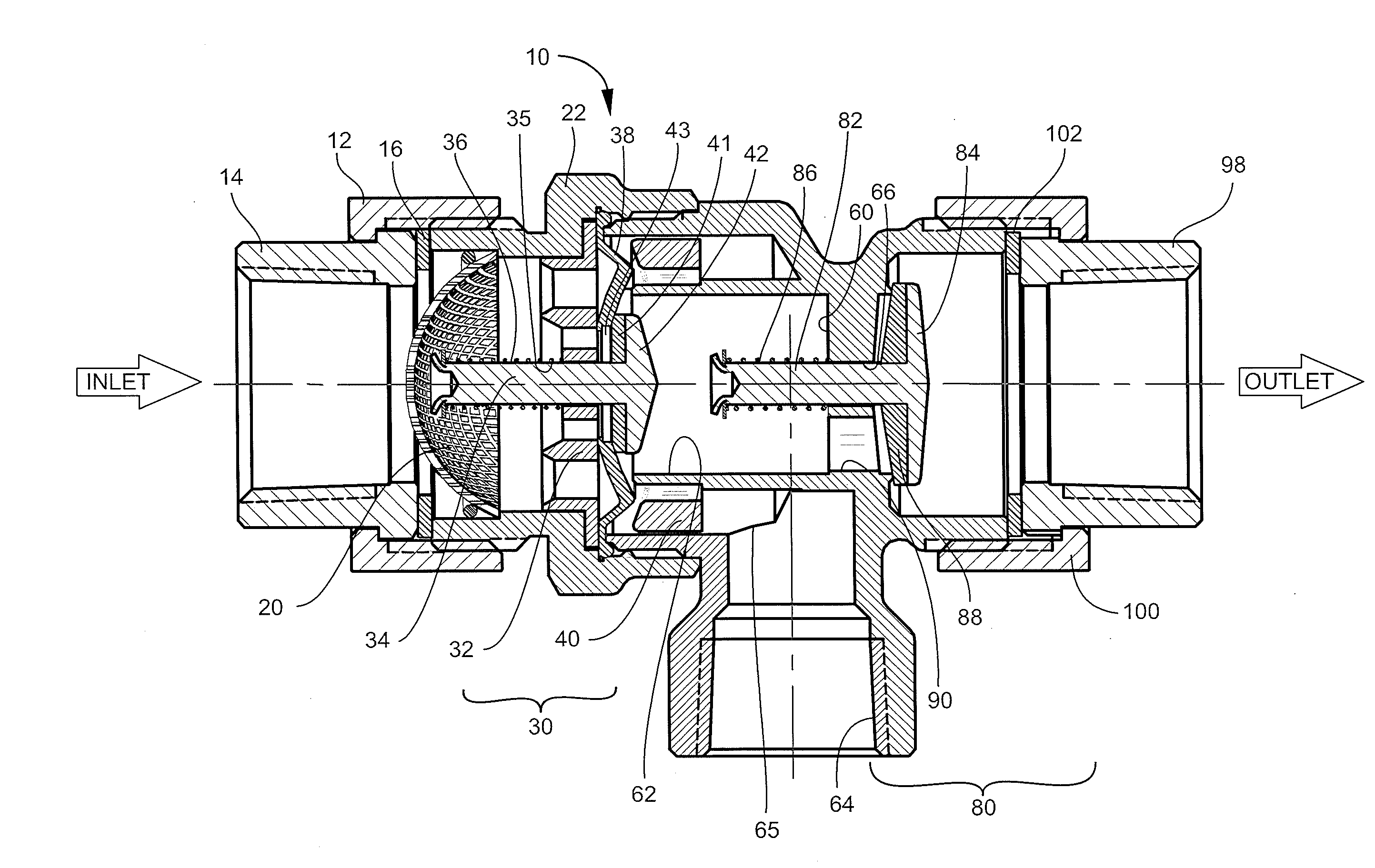

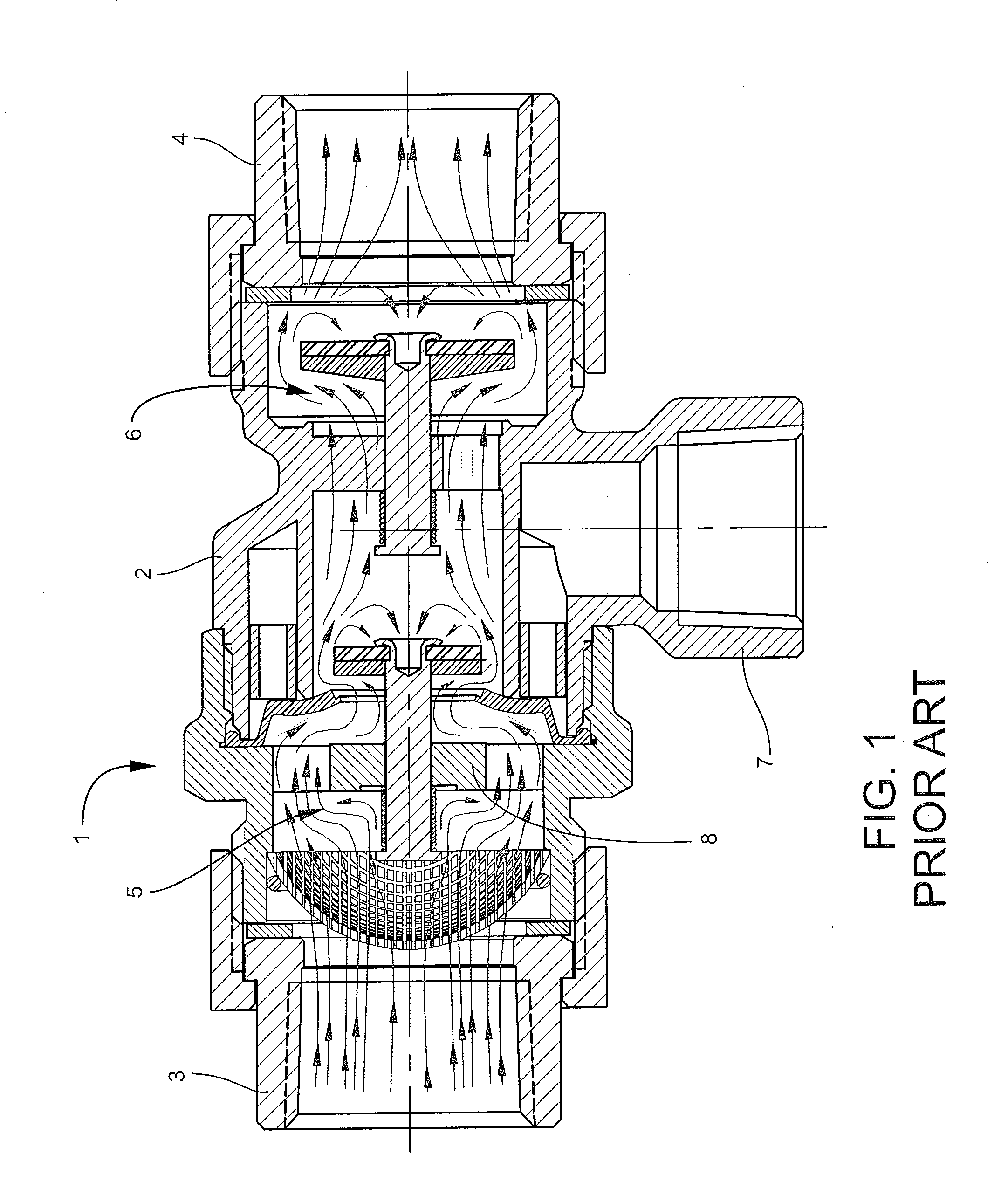

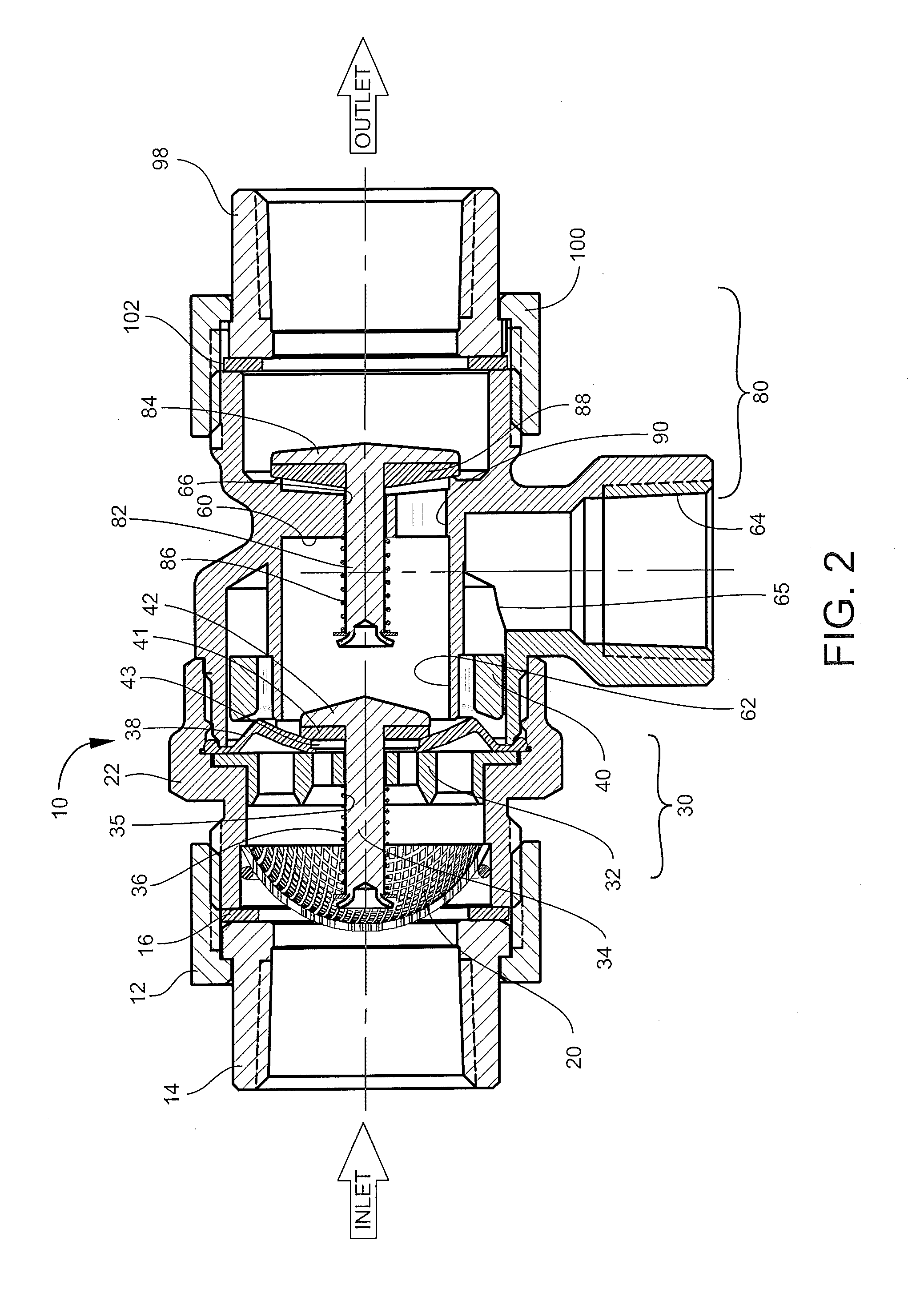

Dual check backflow preventer

ActiveUS20160178076A1Reduce flow turbulenceIncrease pressureCheck valvesDomestic plumbingBackflow prevention deviceEngineering

A backflow preventer that includes a housing having an inlet and an outlet adapted to be mounted in a liquid flow configuration in a liquid supply circuit. An upstream check disc assembly is positioned in the housing downstream of the inlet, and includes an upstream check plate supporting a downstream diaphragm. An upstream check disc is positioned downstream of the diaphragm and integrally formed with an upstream stem mounted in an aperture in a central hub formed in the check plate for movement between a normally open, flow position and a closed position preventing backflow of liquid through the inlet. A downstream check disc assembly is positioned in the housing downstream from the upstream check disc assembly. A vent discharges liquid to atmosphere upstream of the downstream check disc assembly.

Owner:CONBRACO IND

Pillow blanket

A pillow blanket comprises a blanket, foot pocket and a pair of sleeves. The foot pocket is made of a pocket panel secured at the side and bottom edges of the panel to the middle third portion of the blanket and the bottom edge of the blanket. A pair of sleeves is attached respectively to the perimeter of a pair of sleeve apertures in the blanket. The sleeve apertures have an oblong shape and oblique orientation. The blanket can be folded into the foot pocket to form a symmetrical pillow.

Owner:DEERING DIANE L +1

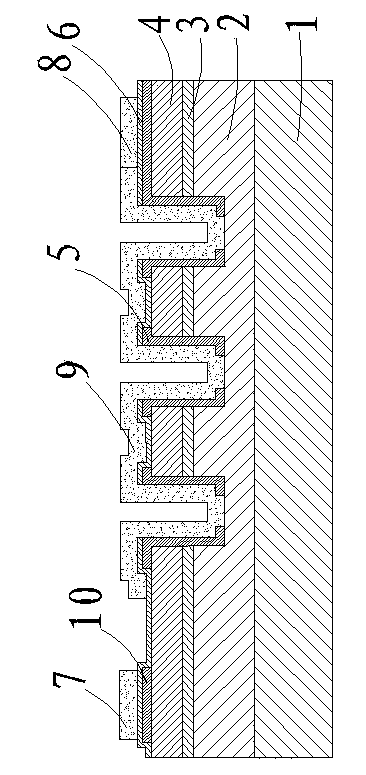

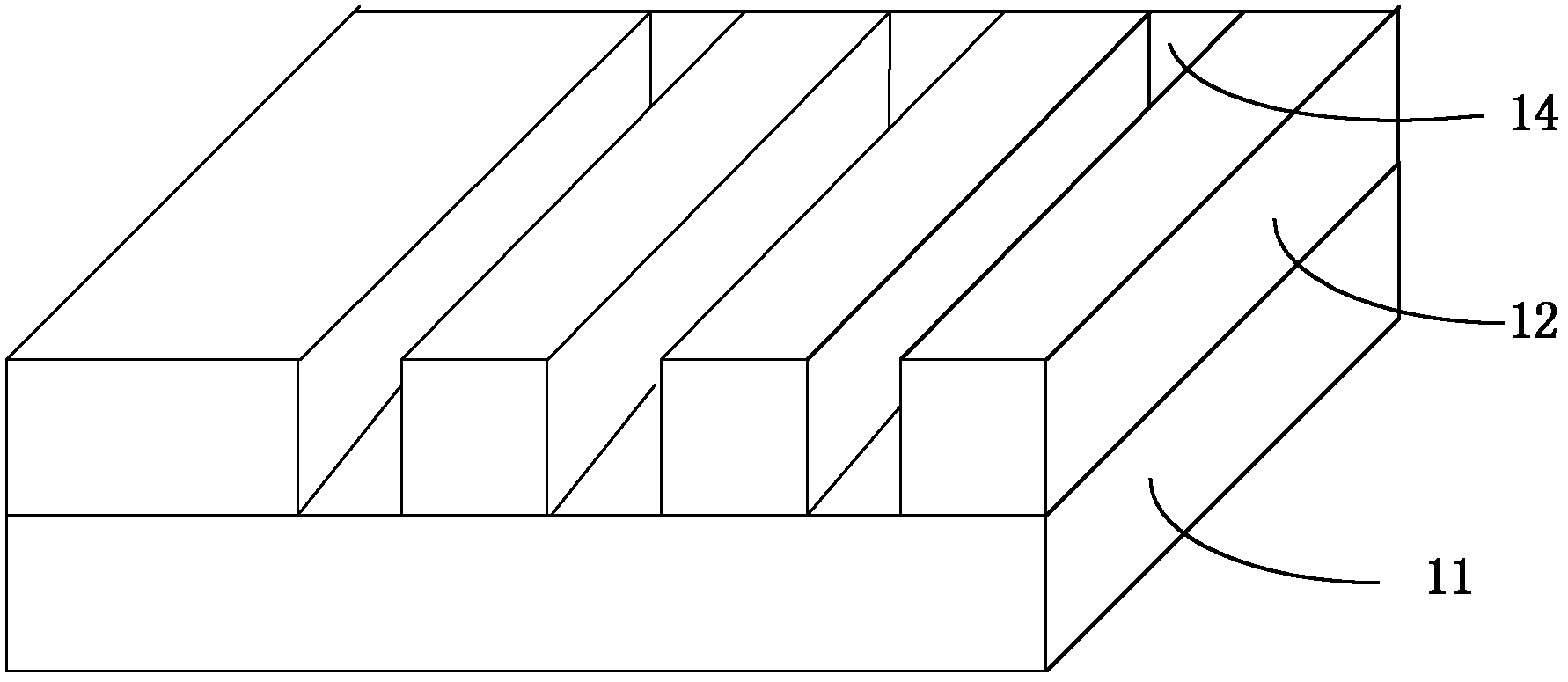

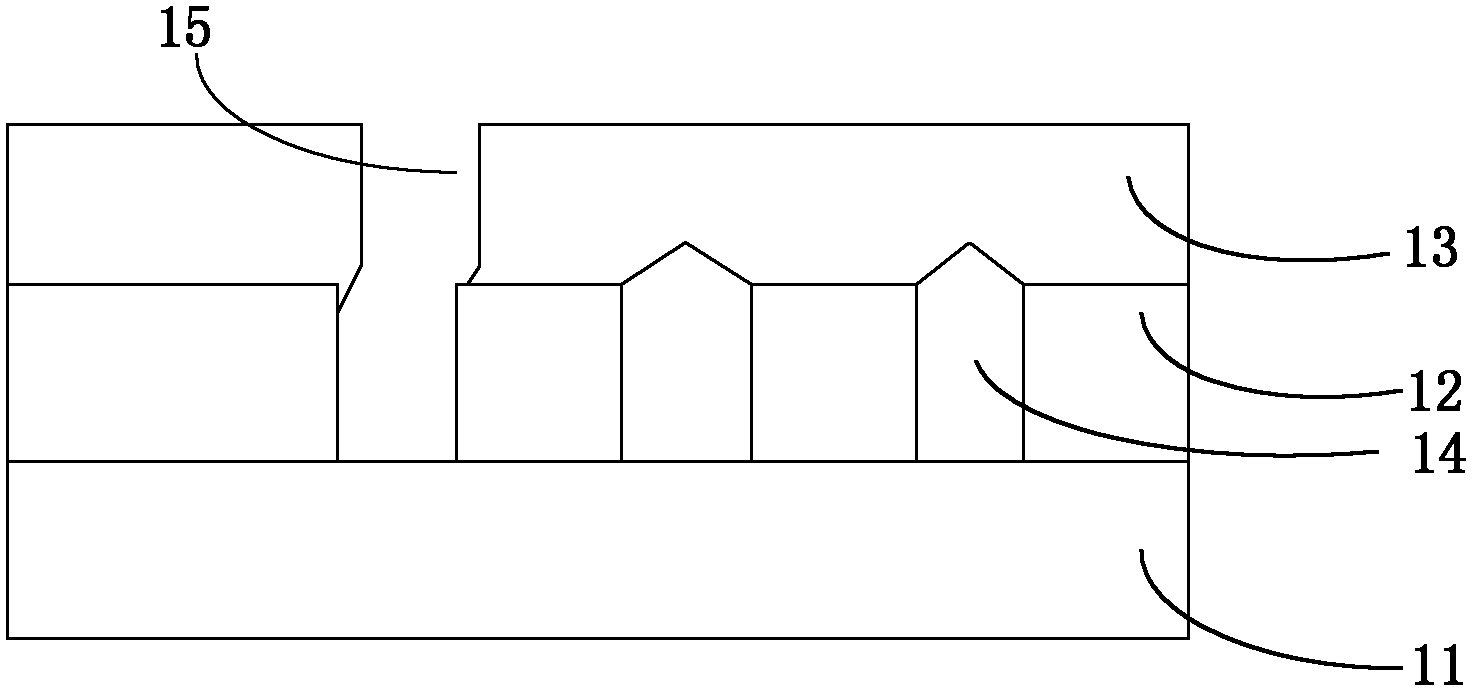

LED chip and processing technology thereof

InactiveCN103515504AIncrease the effective luminous areaIncrease brightnessSemiconductor devicesPower flowQuantum well

The invention relates to an LED chip and a processing technology thereof, and belongs to the technical field of manufacturing of photoelectron devices. The technology comprises the following steps: a P-type nitride layer on an epitaxial wafer substrate is etched to expose an N-type nitride layer; a current blocking layer is manufactured under a P-type electrode bonding pad area, an insulating substance under the P-type electrode bonding pad area, an insulating substance in direct contact with an N-type electrode bonding pad, and an expanding electrode and the P-type nitride layer, and an insulating substance on the side walls of a quantum well and P-type nitride are reserved through etching; an ITO film deposits on the surface of the substrate, a current expanding layer and alloy are manufactured through photoetching, a metal layer is formed on the surface of the substrate through vapor deposition, and after a part of the metal layer is stripped, a P-type electrode bonding pad, an N-type electrode bonding pad and an N metal expanding electrode are formed. Both the P-type electrode bonding pad and the N-type electrode bonding pad of the product are positioned on a P-type light-emitting surface and are the same in height; a part or all of the N metal expanding electrode is in direct contact with the N-type nitride layer. The invention has the advantages that the routing is convenient, the light-emitting efficiency and the brightness of the LED chip on the nitride substrate can be improved.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

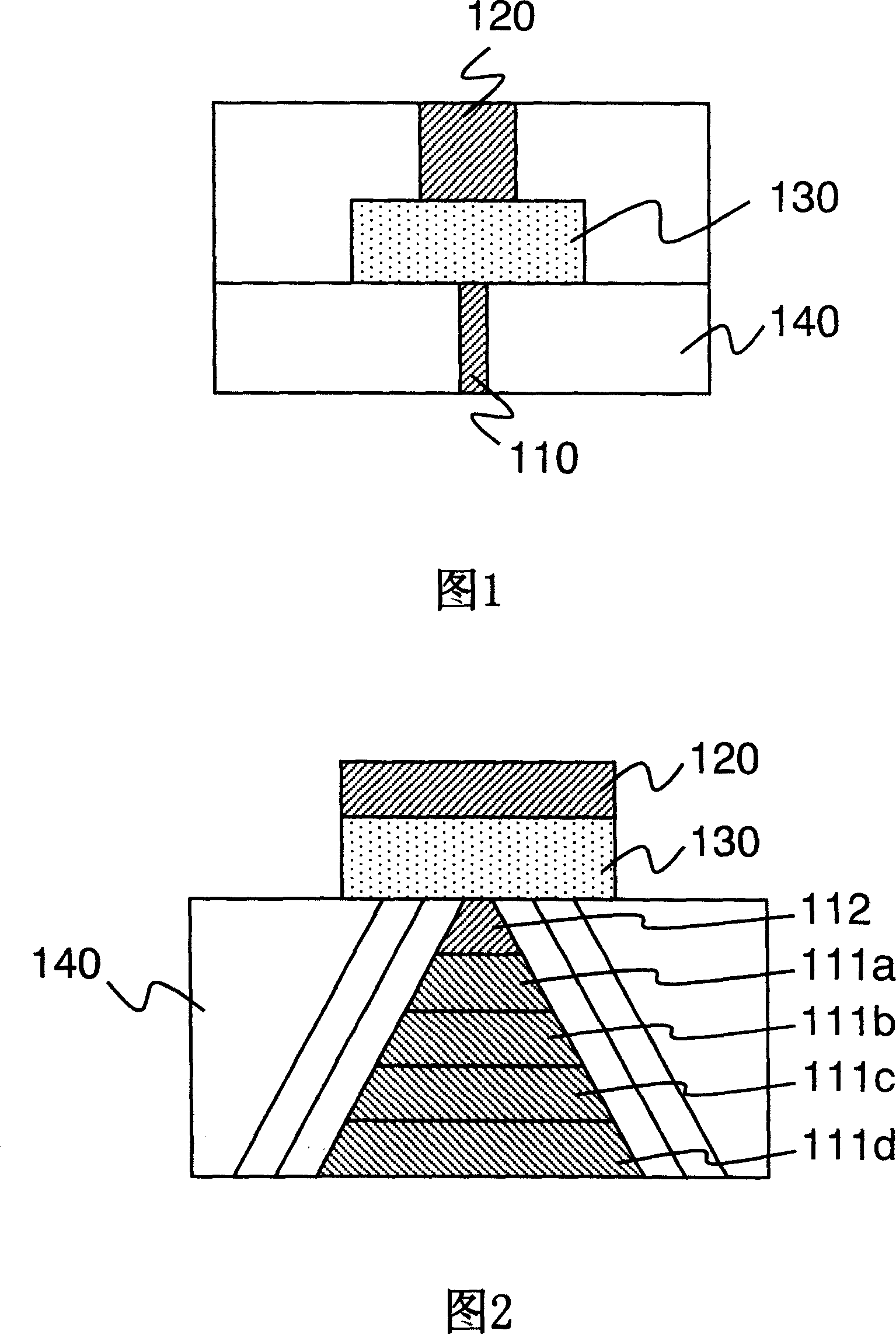

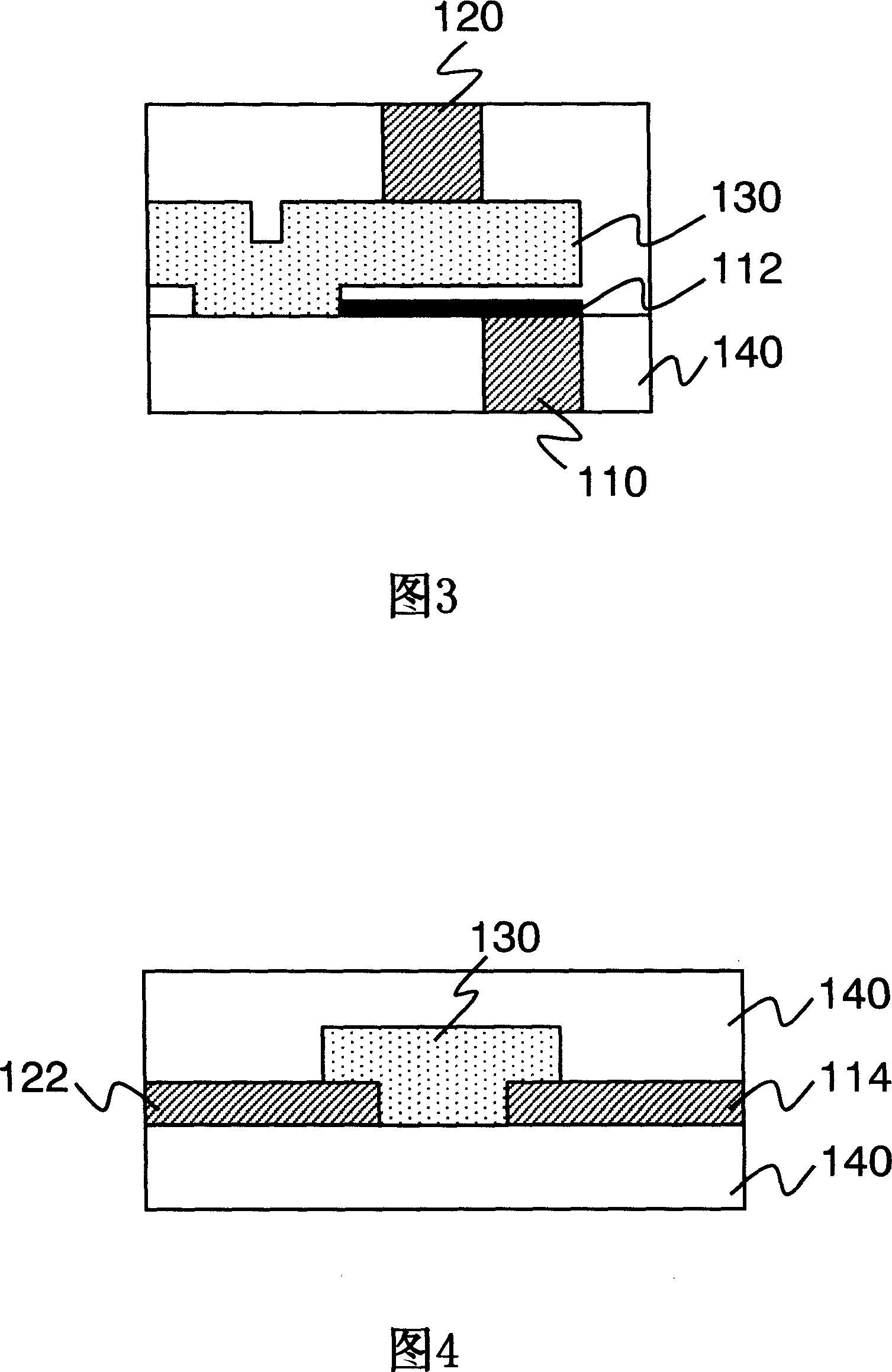

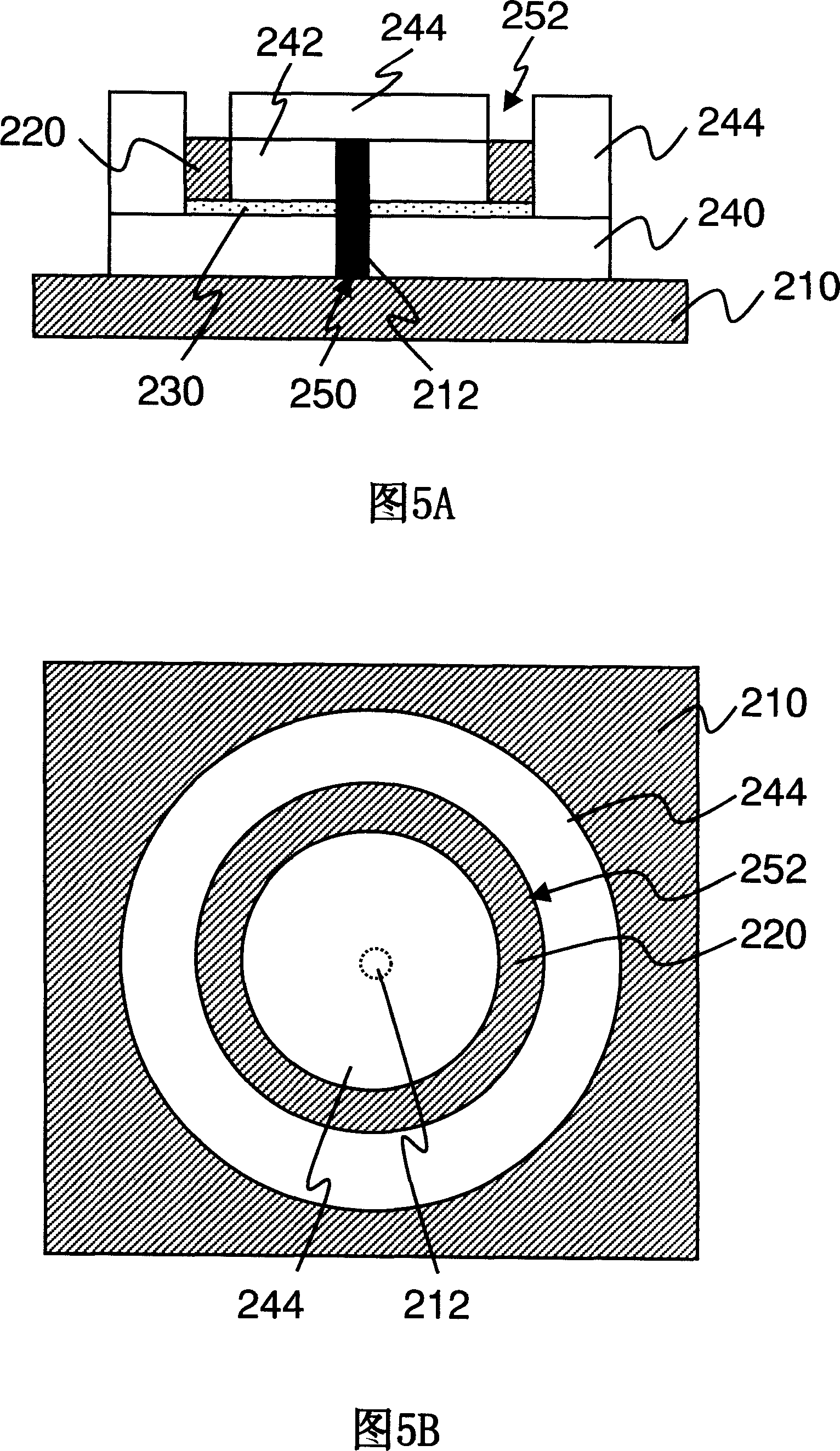

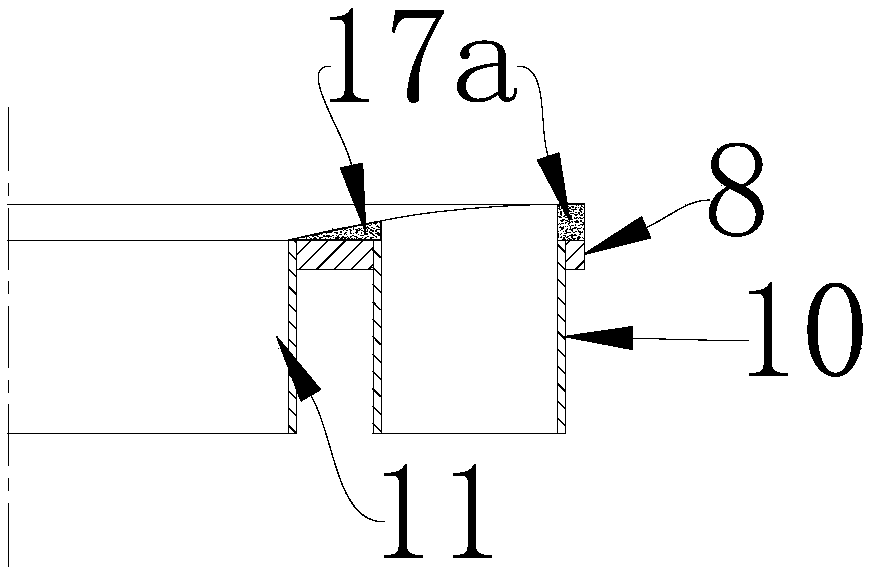

Phase storage element andmanuafcturing method thereof

InactiveCN101000945AJia hot limited abilityReduce contact areaElectrical apparatusLithographic artistPhase change

The invention discloses a phase-changing storage component and its manufacturing method, which is to bury the discoid phase transformation layer into the insulating material, use lithography technique to generate the center penetration hole which runs through and locates at the center of layer, and the ring penetration hole which rounds the center of penetration hole and locates on the verge of layer. At this time, the heating electrode installed in the center penetration hole heats the layer in Joule, and reduces the contacting areas by controlling the thickness of layer. Moreover, a ring second electrode is set in the ring penetration hole, through which, the heat which is sent to the ring interface between transformation layers diffuses, avoiding the heat diffuses to the borders of lay external, and furthermore avoiding etching defects and / or remnants spreading to the materials to lead to abnormal phase change.

Owner:IND TECH RES INST

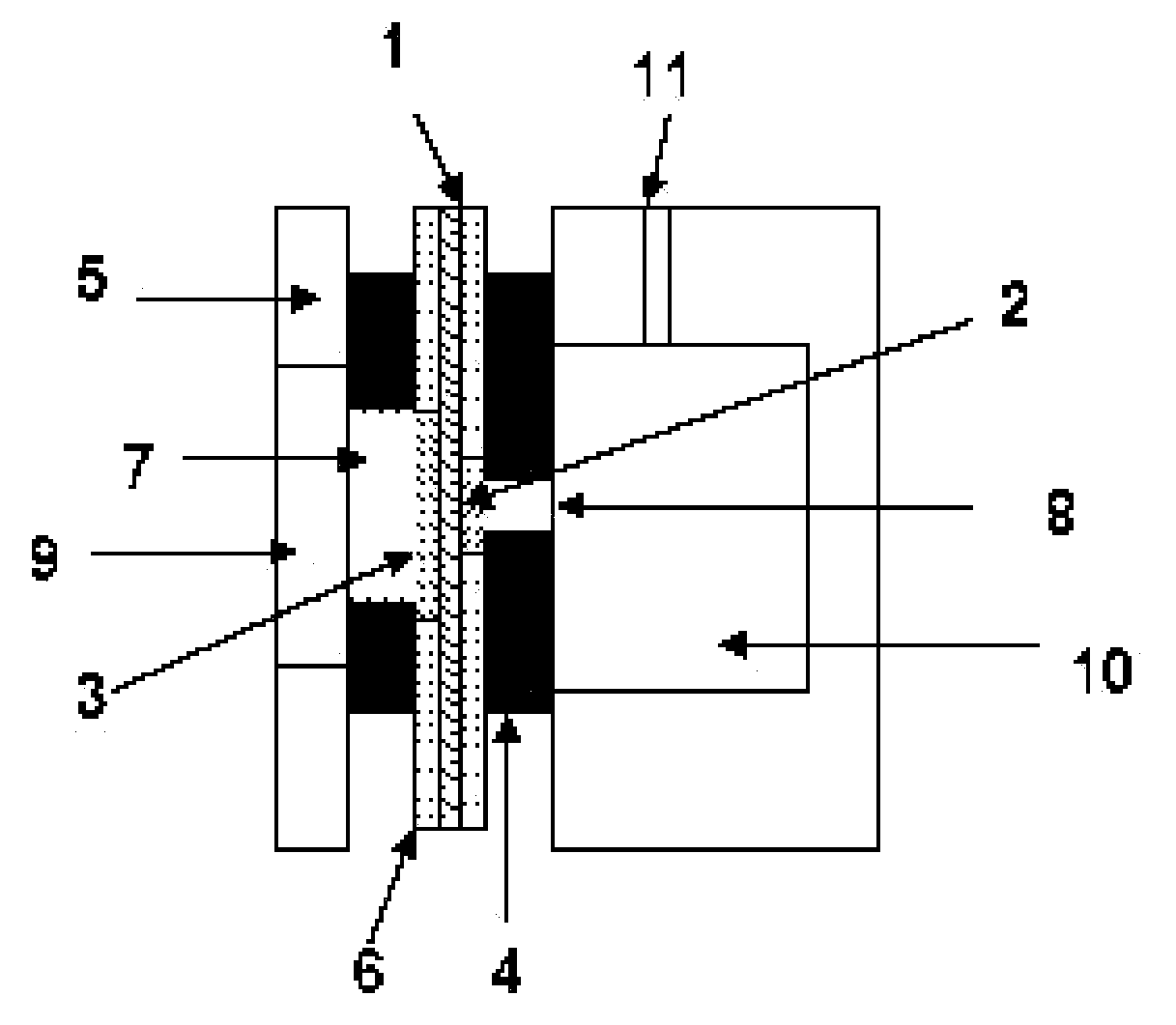

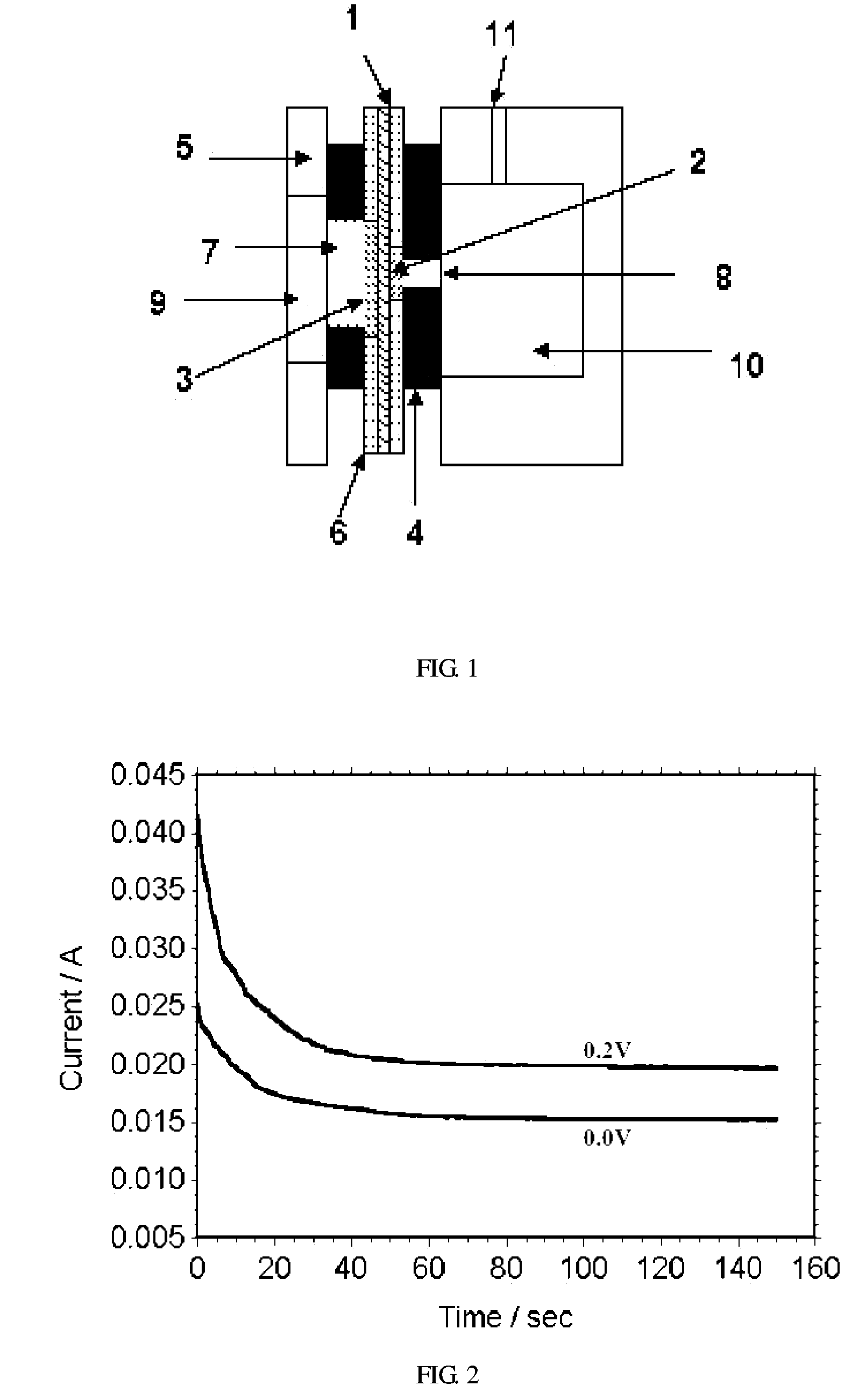

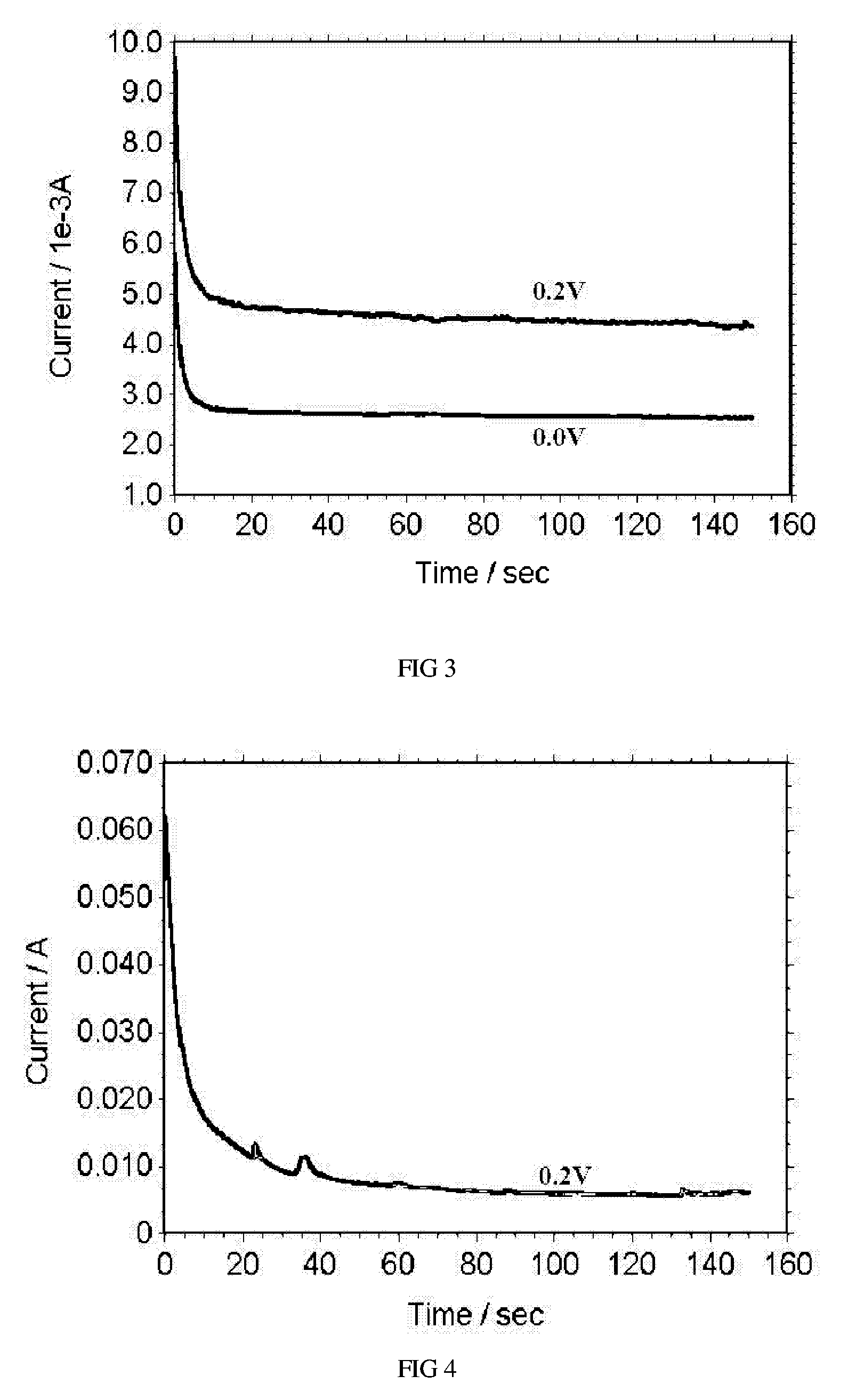

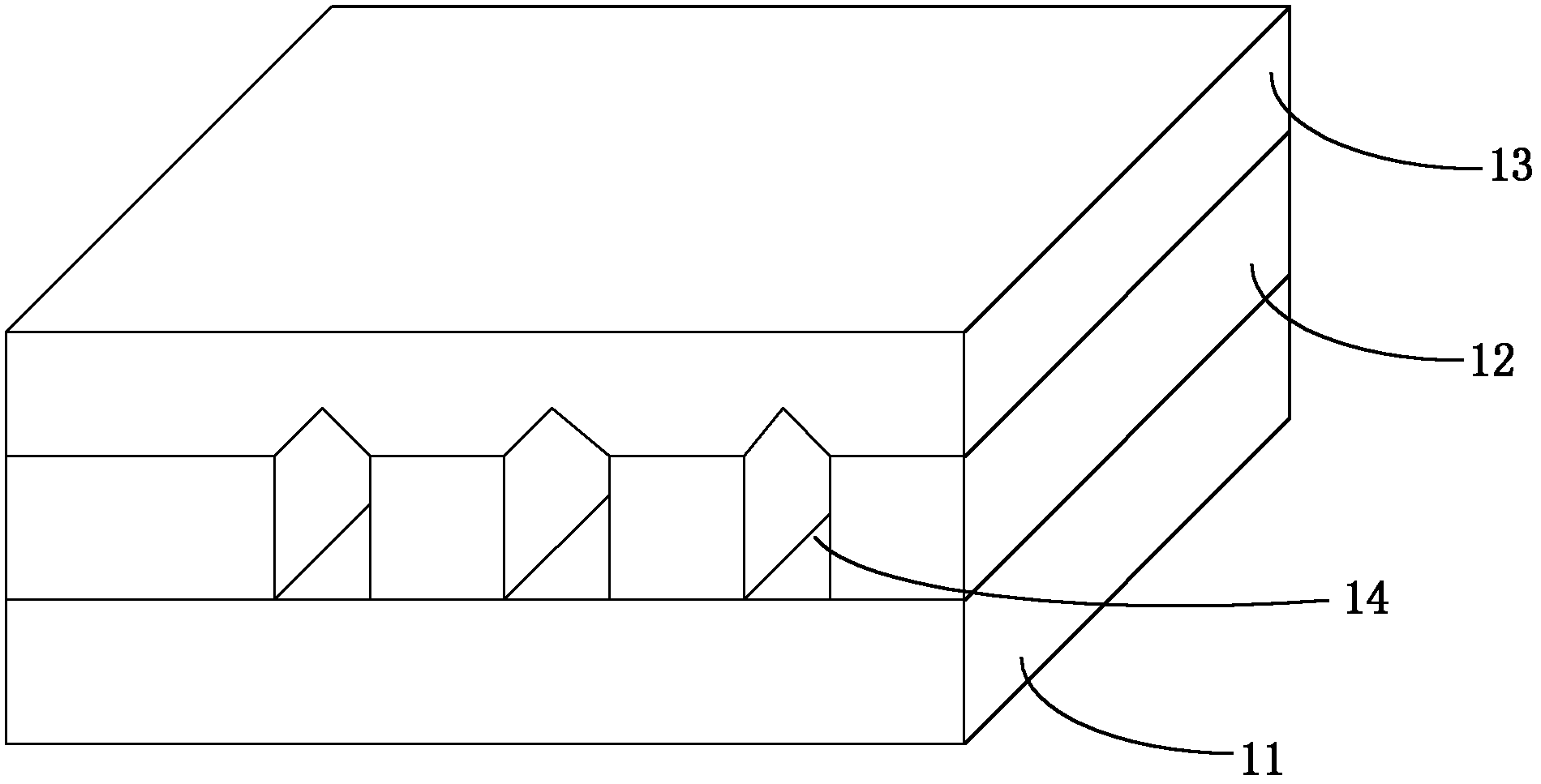

A versatile electrochemical sensor for sensing fuel concentration in an aqueous solution

InactiveUS20060272943A1Increase the exposed areaReduce exposed areaCell electrodesFuel testingCell systemMembrane electrode assembly

A simple fuel cell-type electrochemical sensor for sensing the concentration of a specific fuel, e.g., methanol, ethanol, formic acid, sodium borohydride, etc., prepared in an aqueous solution is developed. The sensor is mainly composed of a membrane electrode assembly (MEA), which is made by hot pressing a piece of electro catalytic anode and a piece of electro catalytic cathode on each side of a proton exchange membrane (PEM), such as Nafion® 117. It is uniquely designed to have an anode size much smaller than that of the cathode and utilizes ambient air as an oxidant. The innovative approach is to ensure the fuel diffused to the anode / membrane interface can be totally reacted so as to eliminate the interferences of fuel crossover and enhance output signal. Thus, the measured sensor current reflects the concentration of diffusion-limited fuel at the membrane / electrode interface, which is proportional to fuel concentration in the bulk. It can be easily operated in a passive mode as well as in an active mode with aqueous fuel solution under a stagnant or a flowing condition. The applications include uses in fuel cell systems, such as direct methanol fuel cell systems, for sensing and monitoring fuel concentration in an aqueous solution.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Air gap, air gap forming method and semiconductor device

ActiveCN103178002AEvenly distributedHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceHoneycomb

The invention provides an air gap forming method which includes: firstly, a metal interconnection structure is provided, and the metal interconnection structure comprises metal structures and an intermetallic dielectric layer between the metal structures; photoetching and etching are performed on the intermetallic dielectric layer of the metal interconnection structure to form air gaps; the air gaps are sealed by a deposition interlayer dielectric layer; finally a conductive plug is manufactured on the interlayer dielectric layer; and the air gaps formed in the photoetching and etching step are of a plurality of D-shaped structures which are distributed in the shape of a honeycomb and have small top and bottom areas and a large middle area. The invention further provides the air gap structures and a semiconductor device with the structures. A top dielectric layer formed by the technical scheme is enhanced in mechanical strength, is not prone to collapse, and has low requirements on self-alignment accuracy when through holes are formed in a next process.

Owner:SEMICON MFG INT (SHANGHAI) CORP

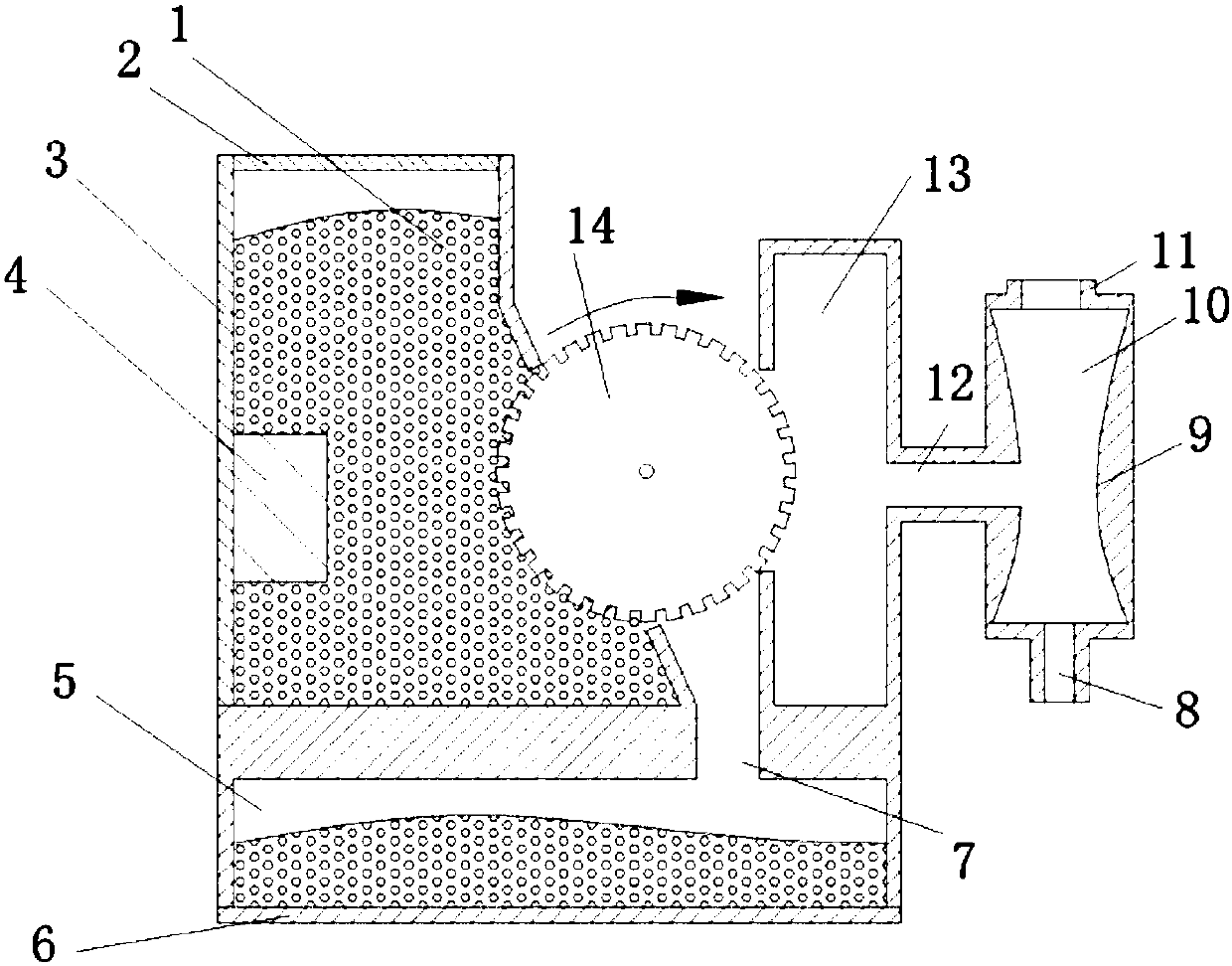

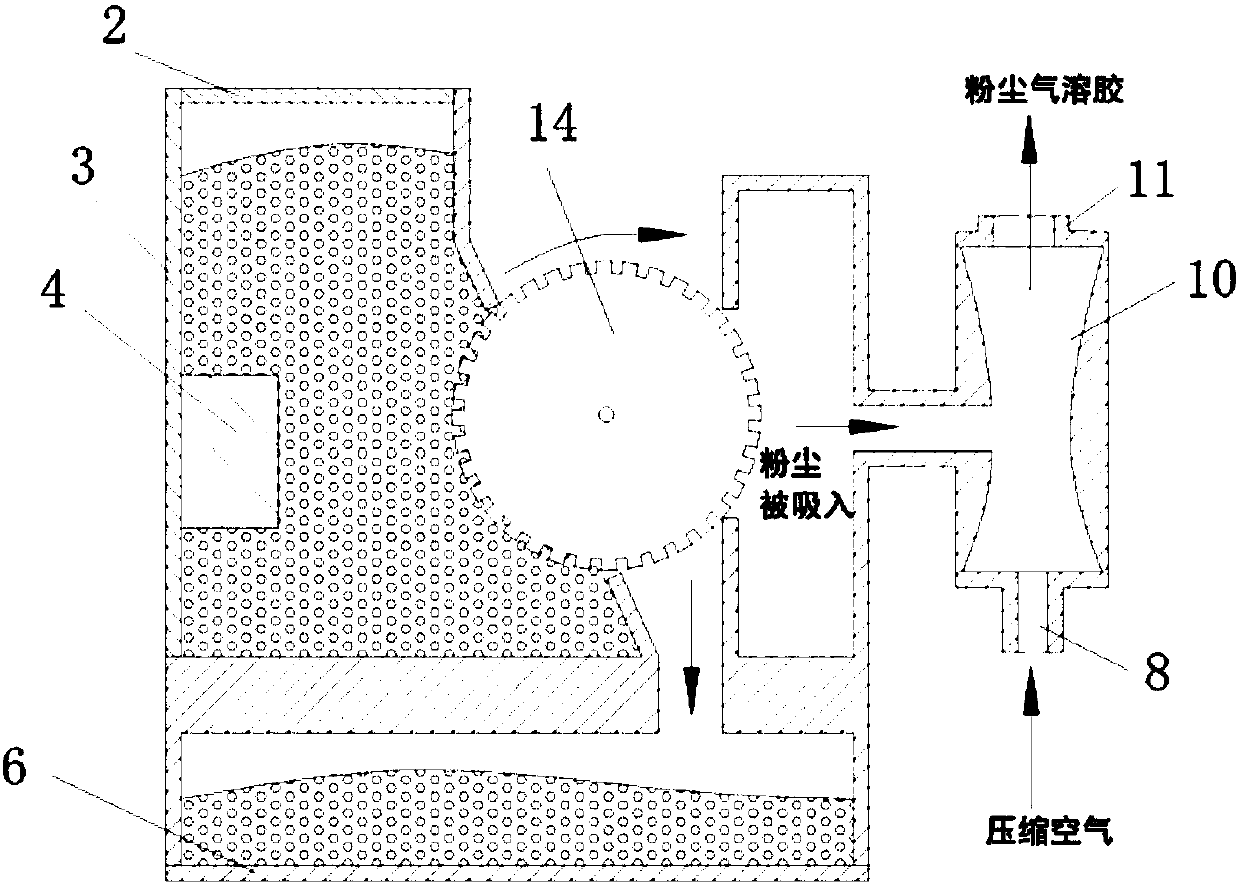

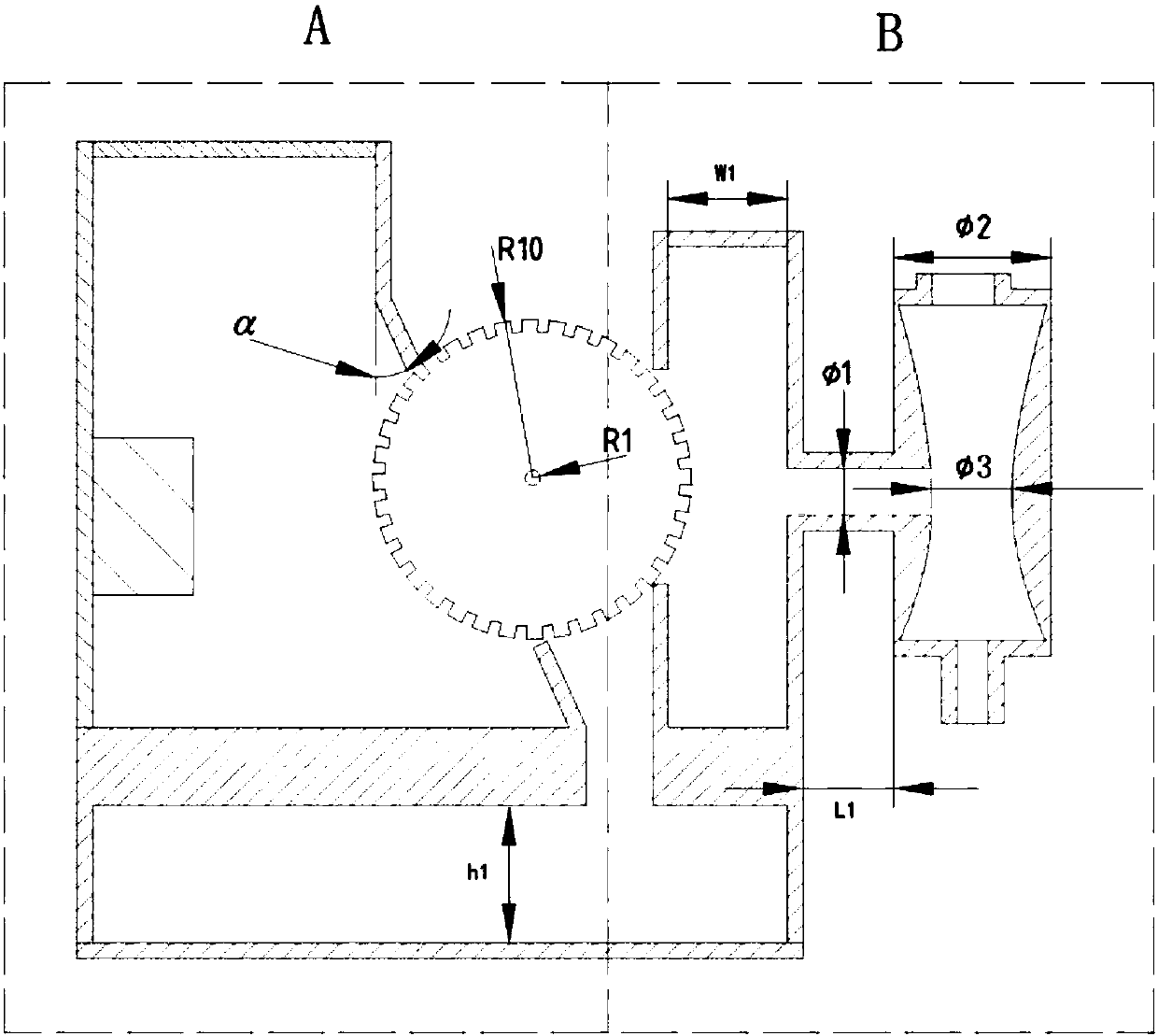

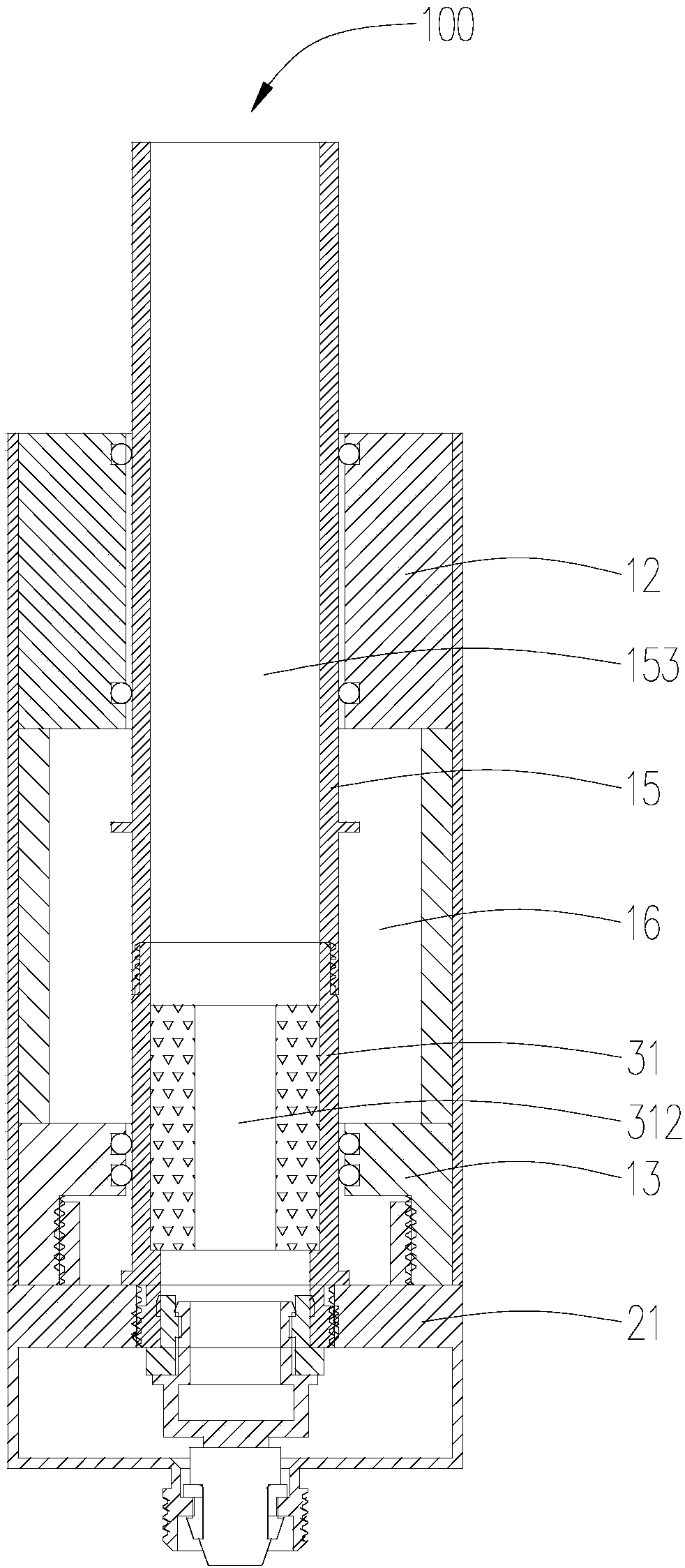

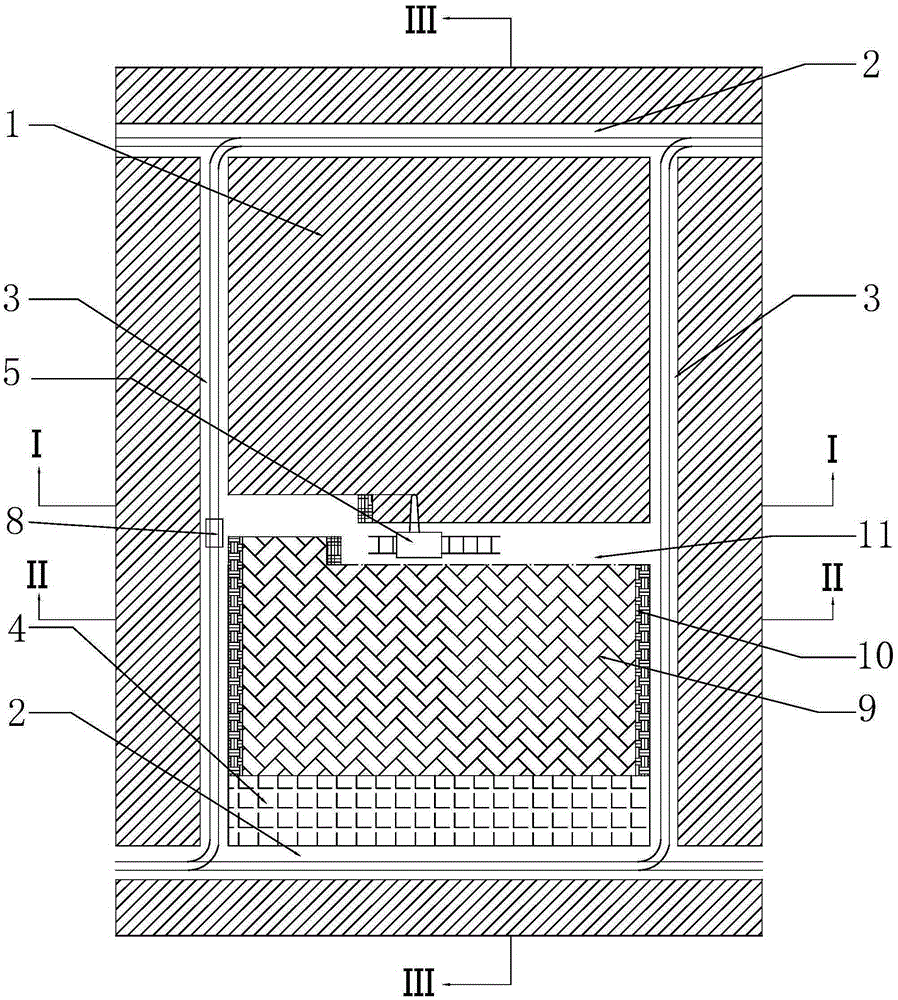

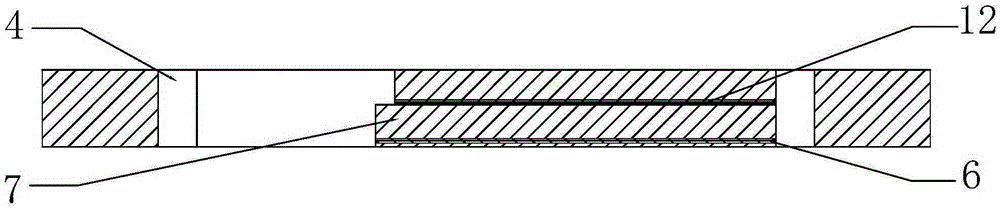

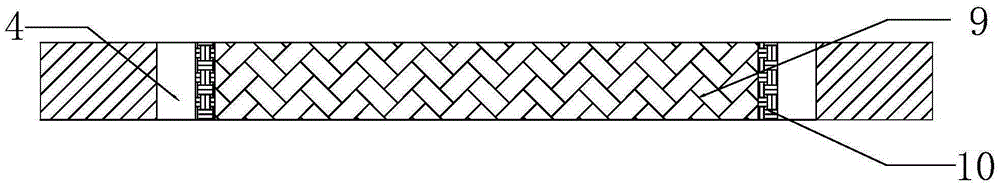

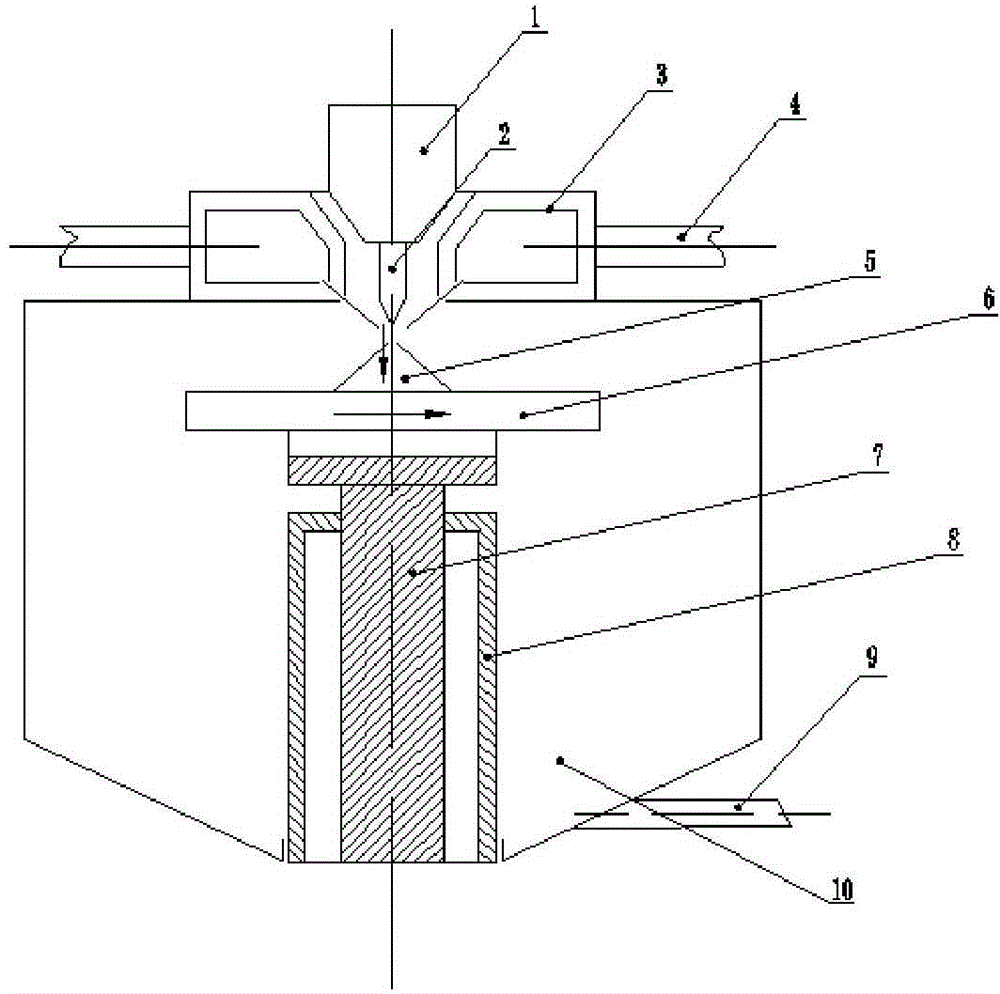

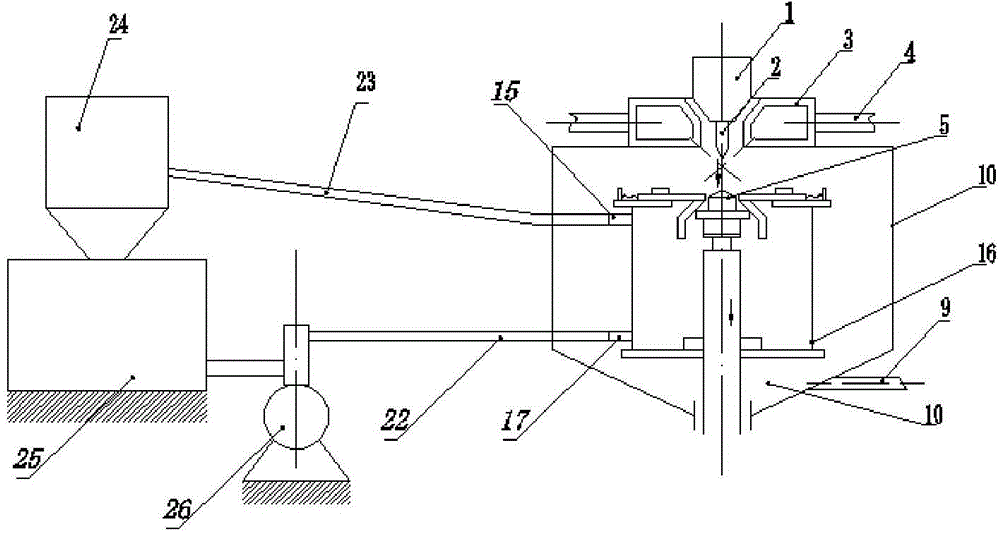

Solid dust aerosol generation device and method

InactiveCN107670518AReduce exposed areaNot easy to polluteTransportation and packagingMixersDust particlesMixing chamber

The invention provides a solid dust aerosol generation device and method. The aerosol generation device comprises an ash storage chamber, a mixing chamber, a Venturi tube and a rotating disk; the rotating disk is arranged between the ash storage chamber and the mixing chamber; a plurality of conveying pits are arranged on the side surface of the rotating disk, the conveying pits on the side surface of the rotating disk are filled with dust particles in the ash storage chamber and then enter the mixing chamber from the top of the rotating disk, the conveying pits return to the ash storage chamber from the bottom of the rotating disk, and negative pressure is generated in the mixing chamber by gasflow passing through the Venturi tube, so that the dust is absorbed from the mixing chamber andcan form stable aerosol after being sprayed out of the Venturi tube along with the gasflow. The solid dust aerosol generation device is more suitable for being used under the conveying conditions of fine dust and low-flow dust, is simple and compact in structure, low in cost and high in precision; the generated solid dust aerosol is distributed uniformly and has stable quality.

Owner:CHANGAN UNIV

Smelting method of high-aluminum nitriding steel

ActiveCN105463299AReduce lossReduce exposed areaElectric furnaceProcess efficiency improvementAlloyHigh aluminum

The invention belongs to the technical field of alloy structural steel, and particularly relates to a manufacturing method of high-aluminum nitriding steel. The process route of EAF-CONVERTER smelting and LF+VD+CCM are adopted to smelt the high-aluminum nitriding steel, and according to the component requirement range of the obtained high-aluminum nitriding steel, the high-aluminum nitriding steel comprises 0.35% to 0.40% of C, 0.20% to 0.30% of Si, 0.40% to 0.50% of Mn, 1.40% to 1.50% of Cr, 0.15% to 0.25% of Mo, 0.75% to 1.00% of Al, not larger than 0.020% of P, not larger than 0.015% of S, and the balance Fe. Round steel obtained through rolling is even in steel texture, high in cleanness and stable in performance quality.

Owner:ZENITH STEEL GROUP CORP +1

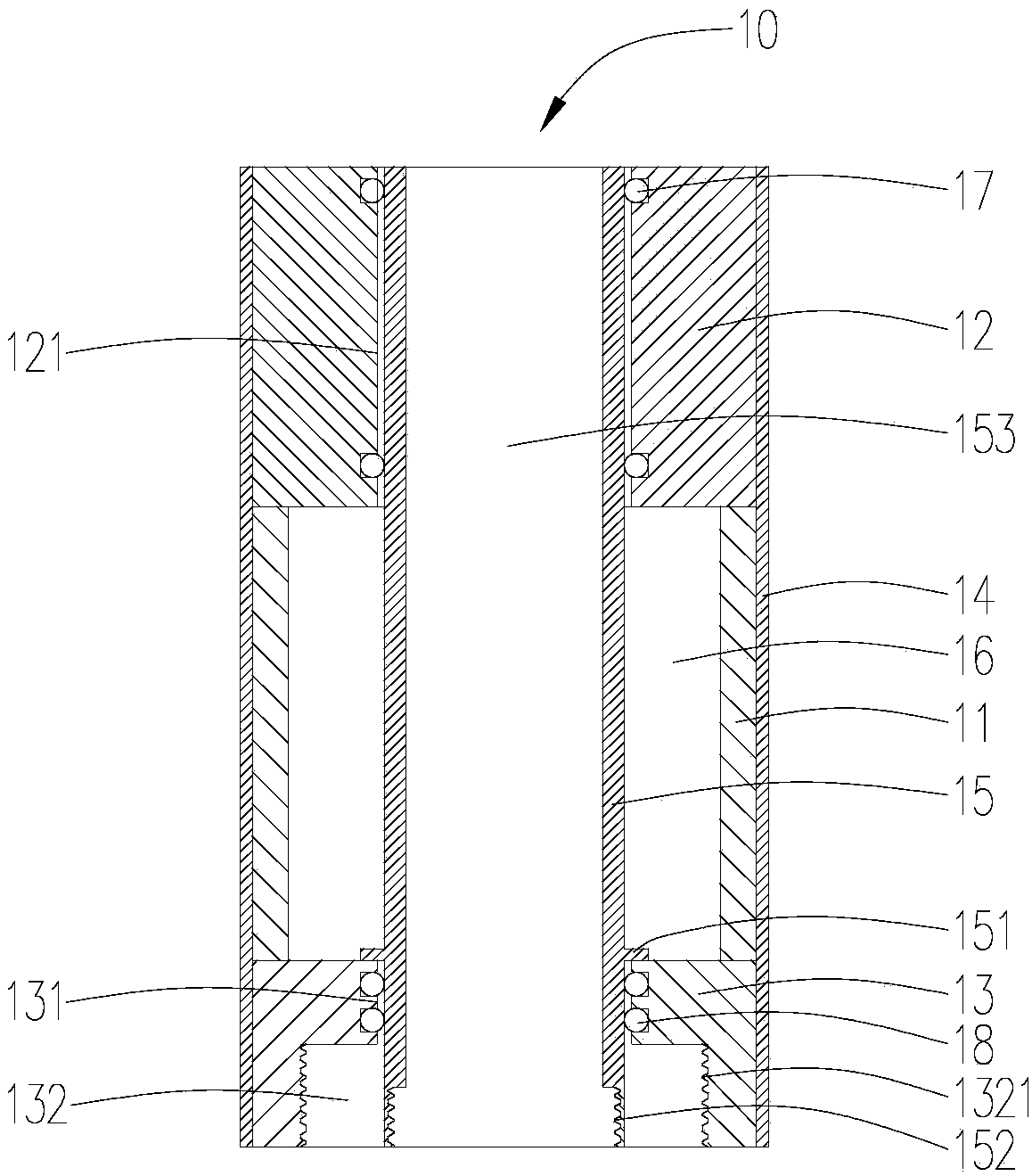

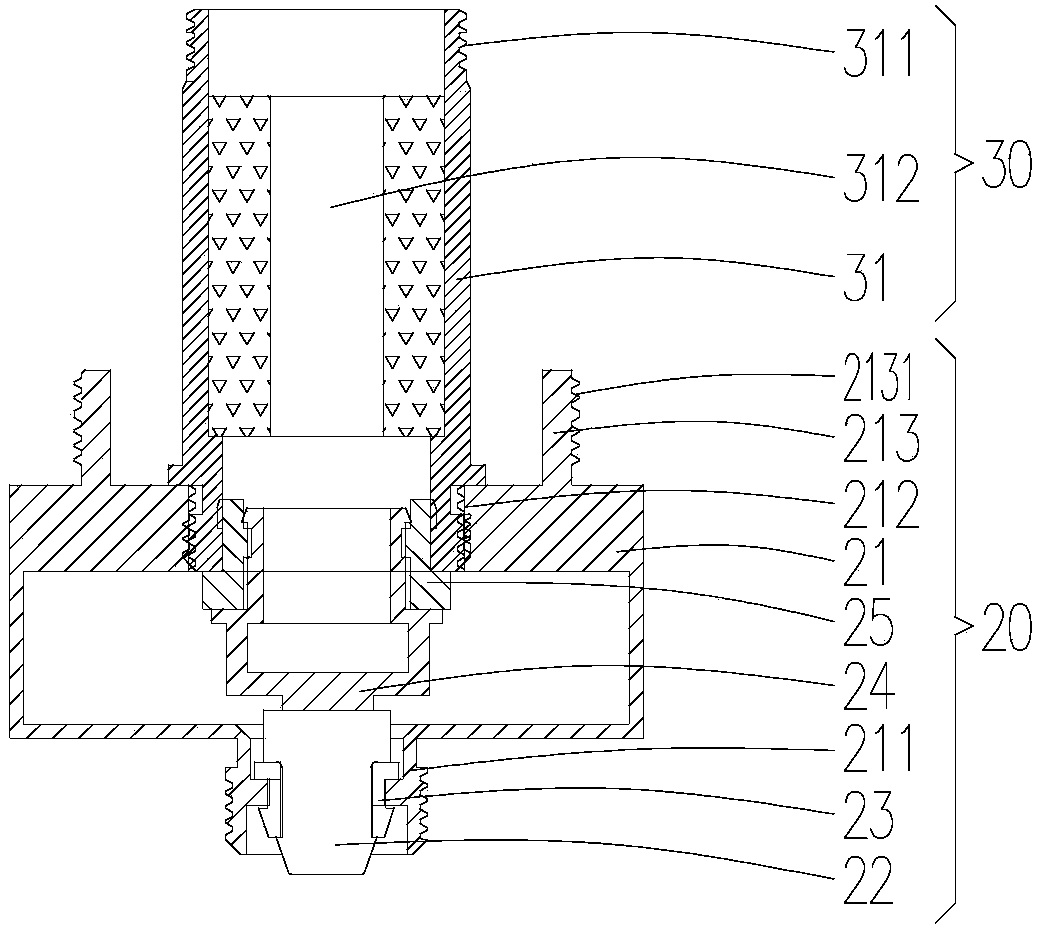

Atomizer and electronic cigarette thereof

PendingCN108208936AReduce exposed areaReduce the possibility of bacterial infectionTobacco devicesSmoke bombAirflow

The invention provides an atomizer. The atomizer comprises a cartridge, a base component detachably connected with the smoke bomb and an atomizer head arranged on the base component, the cartridge comprises a smoke flue in airflow communication with the atomizer head, and the cartridge is movably connected with the atomizer head in an axial direction; fluid communication between the cartridge andthe atomizer head is communicated or cut off by axial displacement, when the cartridge is in fluid communication with the atomizer head, the atomizer body protrudes from the smoke flue to make a usertake a cigarette. According to the atomizer, when the cartridge is separated with the base component, a drip tip can be retracted, and an exposed area of the drip tip can be reduced to decrease the possibility of bacterial infection. The invention further provides an electronic cigarette with the atomizer.

Owner:CHANGZHOU PATENT ELECTRONICS TECH CO LTD

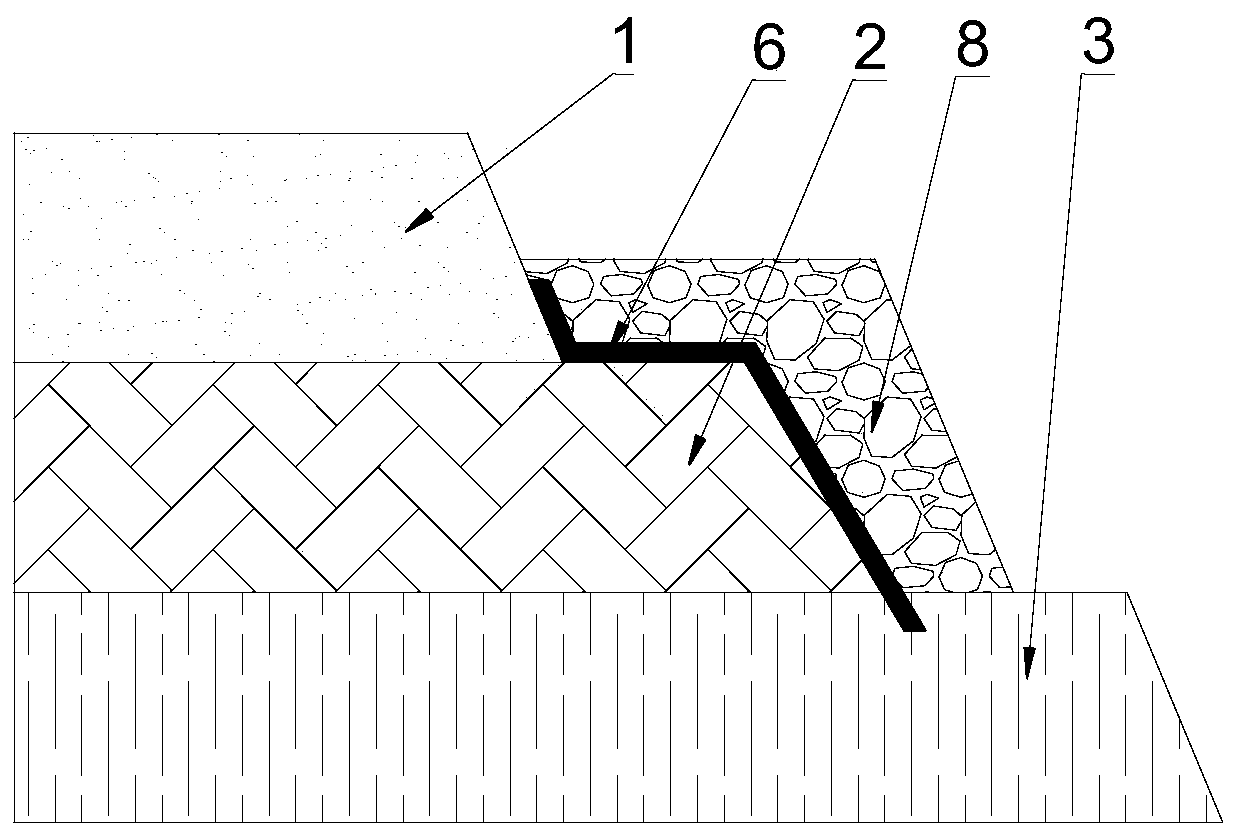

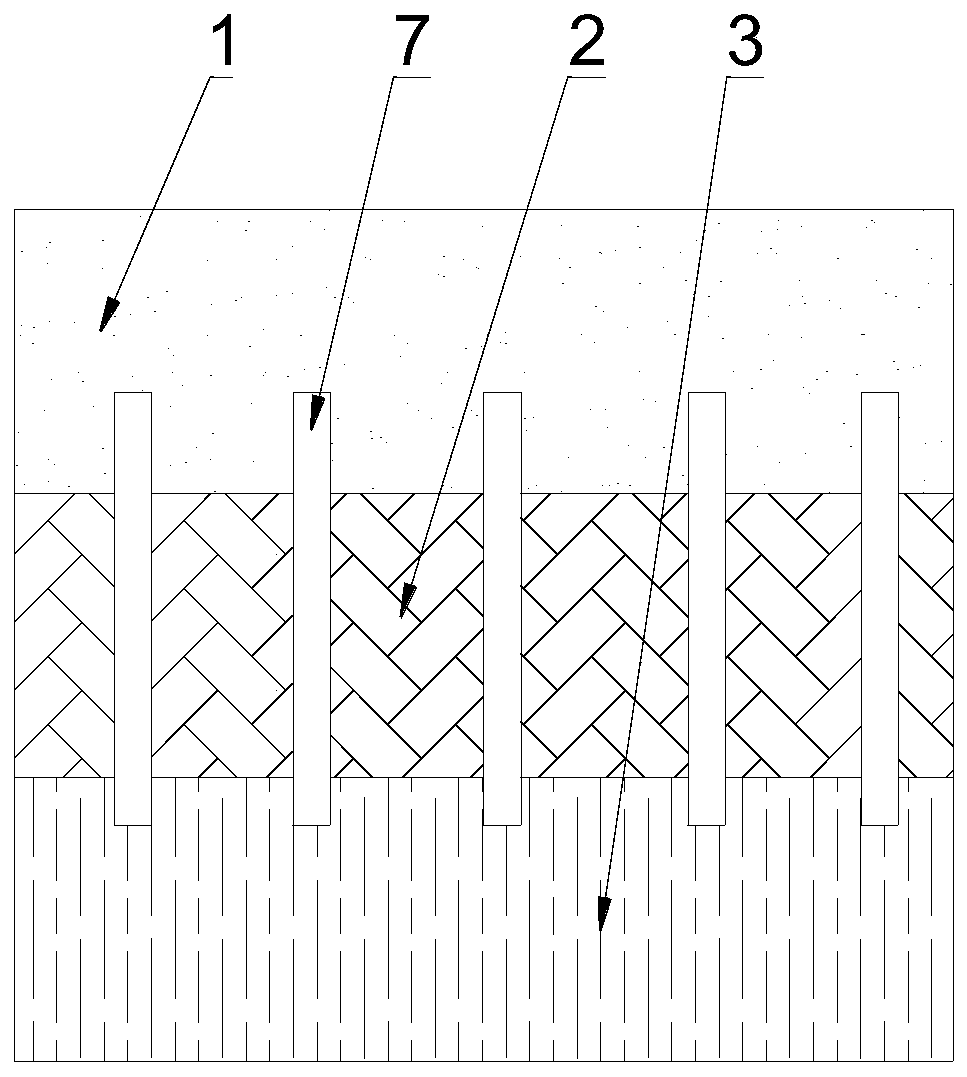

Open pit mine inner dump aquifer communication method

ActiveCN111088788AReduce exposure timeReduce exposed areaSoil preservationMining engineeringWater resources

The invention discloses an open pit mine inner dump aquifer communication method. The open pit mine inner dump aquifer communication method comprises the work procedures of plugging an original aquifer, building an artificial water-resisting layer, building an artificial aquifer, dredging the aquifer, conducting artificial water replenishing and the like. According to the open pit mine inner dumpaquifer communication method, the original aquifer is plugged with degradable plastics, water resource loss is reduced, and the safety of a pit is guaranteed; construction raw materials of the artificial water-resisting layer come from the mine lot, the construction difficulty is low, cost is low, and the waterproof effect is guaranteed; the aquifer adopts the manner that the middle part bulges, and it is avoided that natural settling of the inner dump causes the aquifer to be compacted, sink and even be blocked; the artificial aquifer is arranged into multiple strips, a water retaining wall is built to reduce the influence of the internal water pressure on the stability of the inner dump, artificial water replenishing according to regions in a later period can be achieved, and water cannot flow into the pit; the artificial water replenishing manner is adopted to accelerate communication between the artificial aquifer and the original aquifer of the inner dump, underground water circulation in the mine lot is guaranteed, pit water can be utilized, and pit water waste is reduced.

Owner:CHINA UNIV OF MINING & TECH

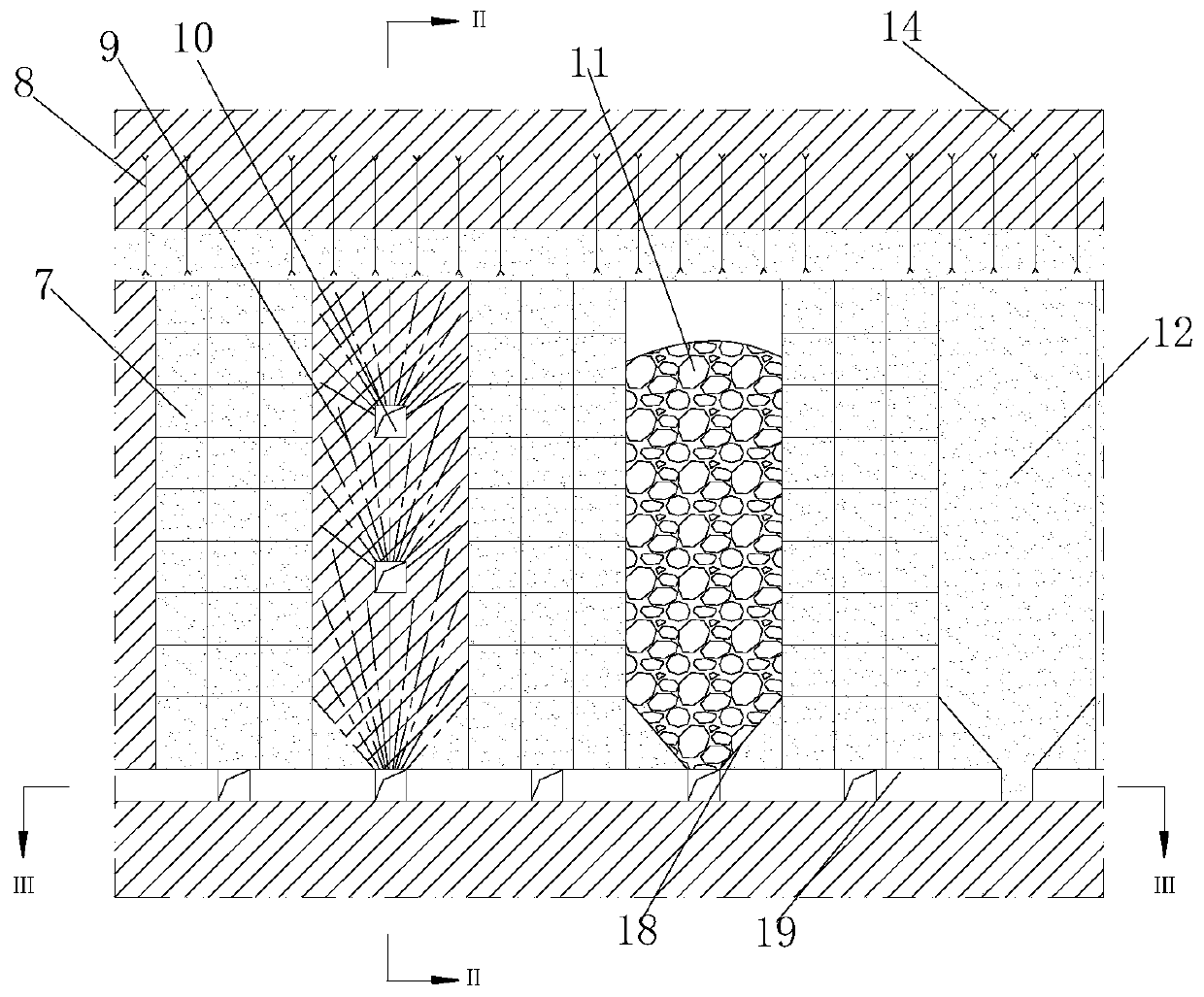

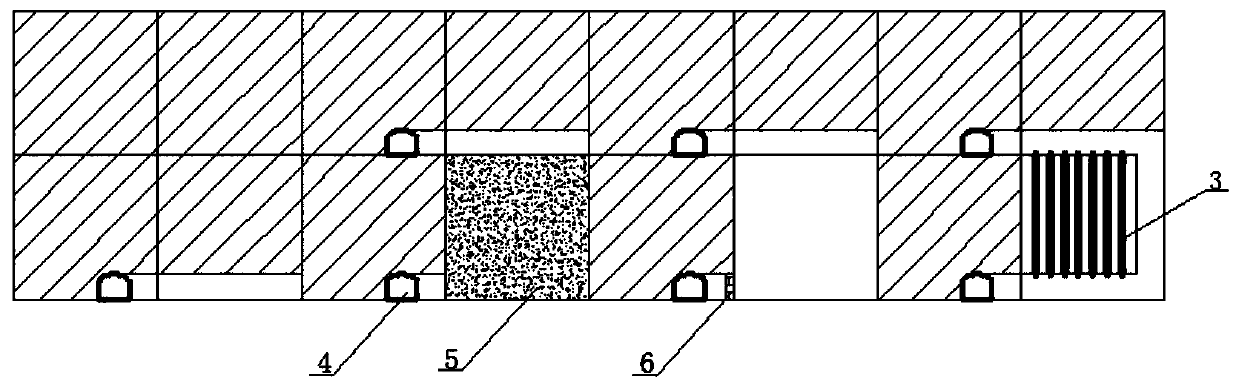

Environmental reconstruction subsection medium-length hole subsequent filling mining method

ActiveCN110331978AImprove securityEnsure safetyUnderground miningSurface miningTwo stepOperation safety

The invention discloses an environmental reconstruction subsection medium-length hole subsequent filling mining method which is mainly suitable for ore rock crushing and thick or extremely thick inclined ore body stopping. An ore body is divided into disc areas and ore blocks, the ore blocks are divided into first-step stopes and second-step stopes, and stopping is conducted through two steps. Themethod comprises the steps that firstly, the first-step stopes, ore bodies in the range of top columns arranged on the upper portions of the second-step stopes and ore bodies at the bottoms of the second-step stopes are stoped by adopting a drift-and-fill method, and filling is conducted by adopting high-strength cemented filling bodies; secondly, disc ore bodies on the first-step stopes and thesecond-step stopes are stoped by adopting the drift-and-fill method; and lastly, the second-step stopes are stoped by adopting a staged deep-hole empty-field subsequent filling method. The environmental reconstruction subsection medium-length hole subsequent filling mining method has the advantages that the stopping operation safety is good, the production capacity of the stopes is high, the production cost is low, and the ore body production condition change and horse stone adaptability is good.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

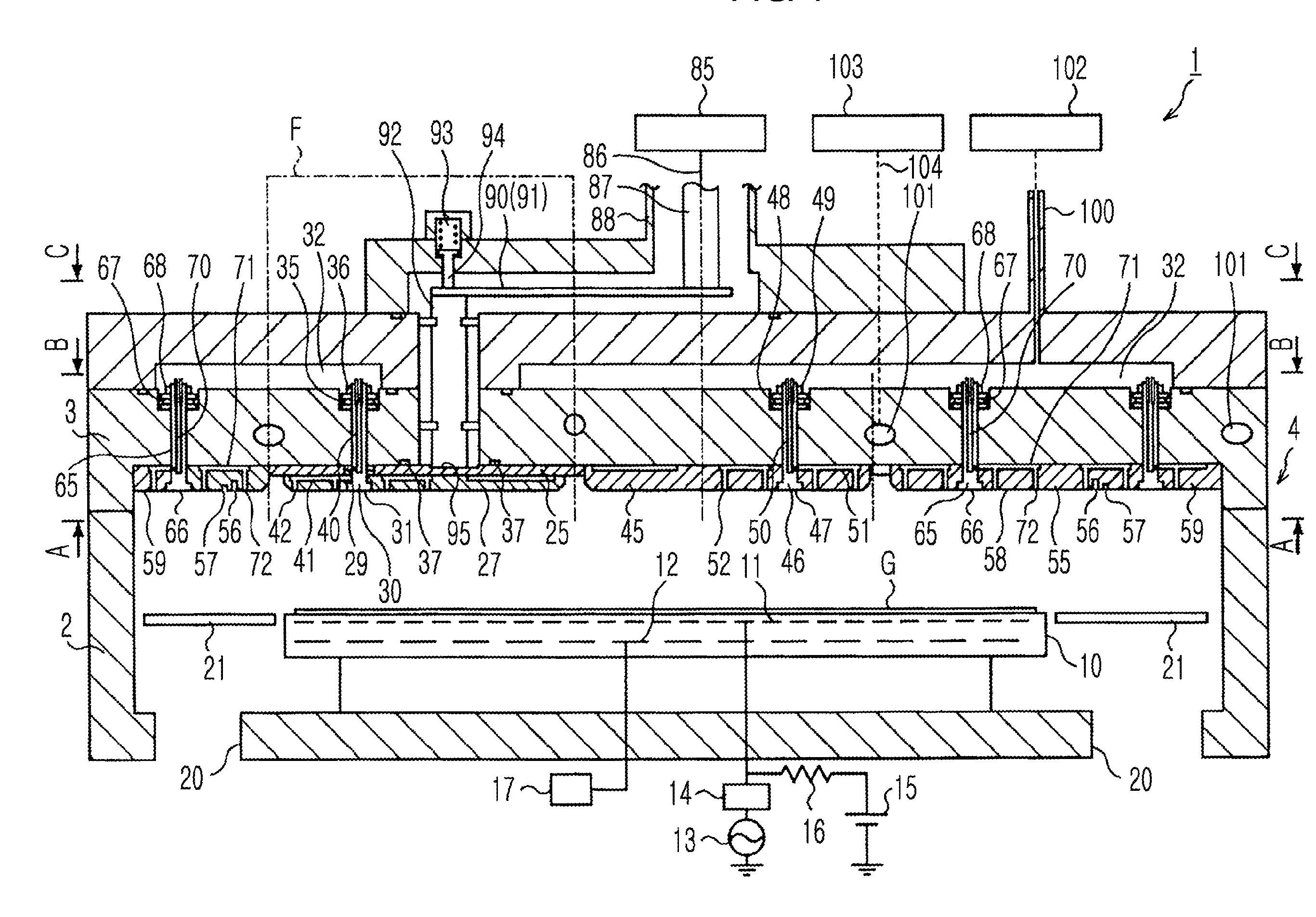

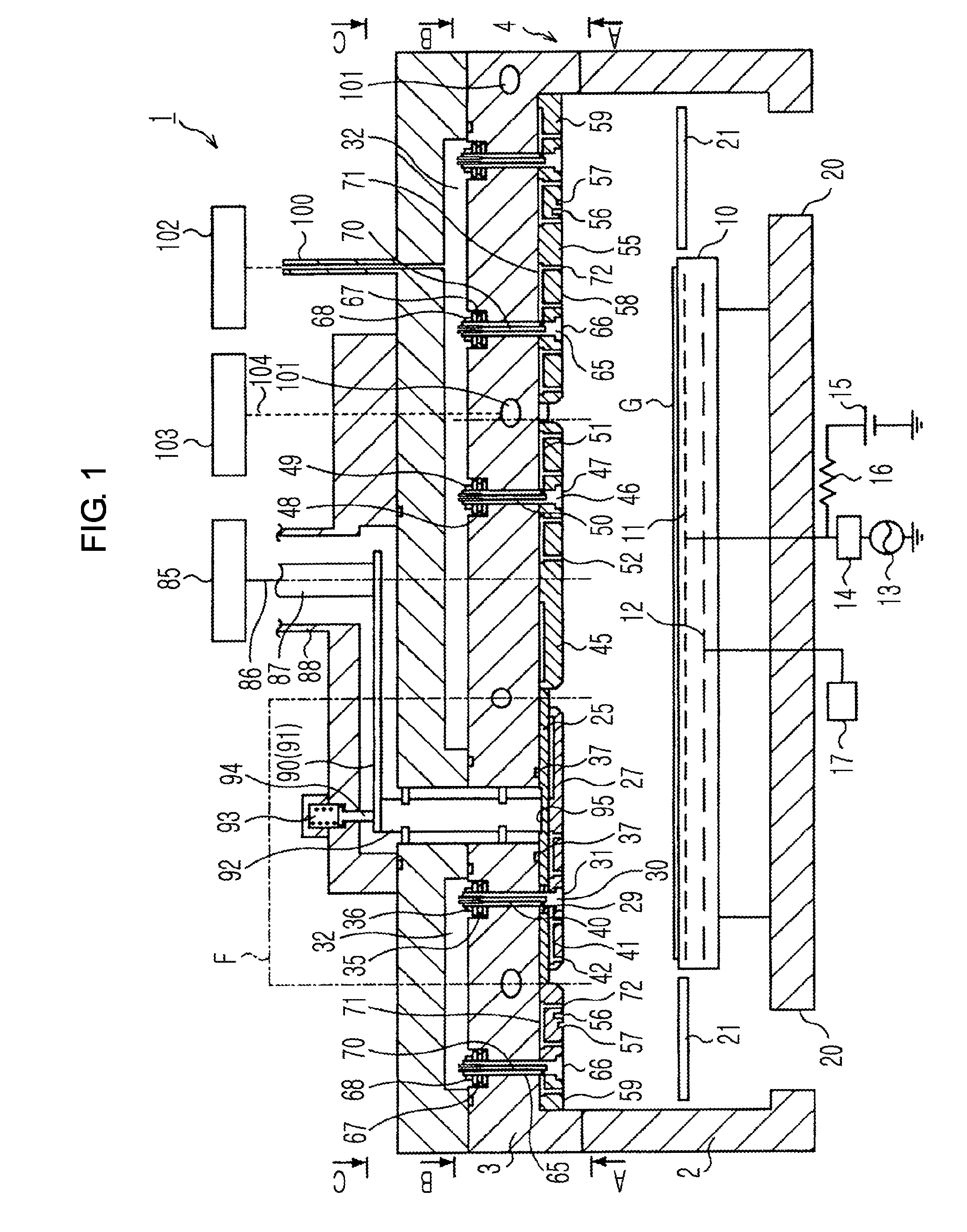

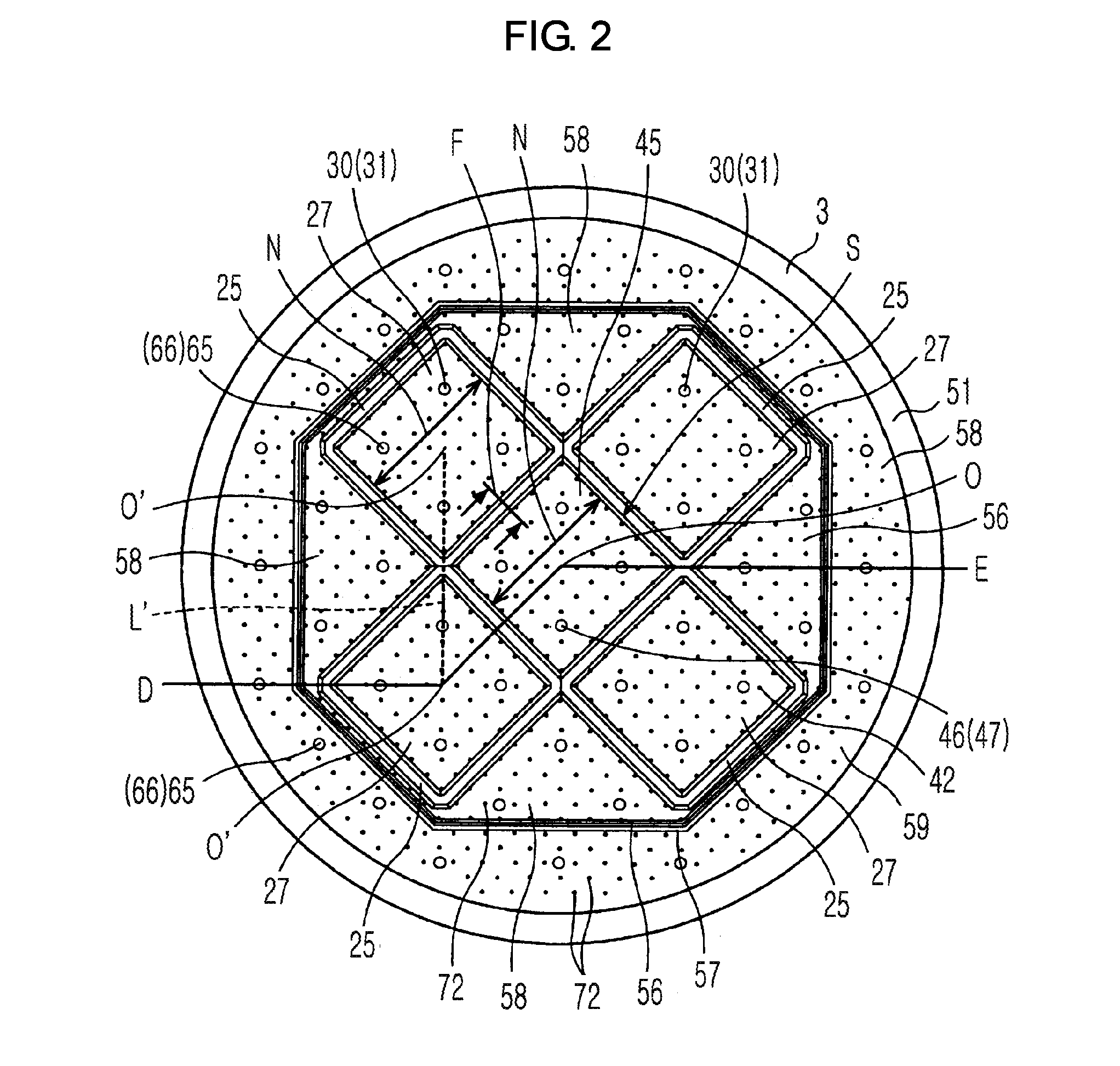

Plasma processing apparatus

InactiveUS20110146910A1Reduce usageQuality improvementElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricElectromagnetic electron wave

Uniformity of a process on a substrate is improved. A plasma processing apparatus including a processing container which is formed of metal and receives a substrate to be plasma-processed, an electromagnetic wave source which supplies an electromagnetic wave required to excite plasma in the processing container, and a plurality of dielectrics, through which the electromagnetic wave supplied from the electromagnetic wave source transmits to the inside of the processing container and which have a part that is exposed to the inside of the processing container, on a lower surface of a lid of the processing container, wherein a metal electrode, which is electrically connected to the lid, is formed on a lower surface of each dielectric, a part of each dielectric exposed between the lower surface of the lid and the metal electrode has a substantially polygonal outline when viewed from the inside of the processing container, the plurality of dielectrics are disposed with vertical angles of the polygonal outlines being adjacent to each other, and a surface wave propagating portion, through which the electromagnetic wave is propagated, is formed on the lower surface of the lid exposed inside the processing container and a lower surface of the metal electrode.

Owner:TOKYO ELECTRON LTD +1

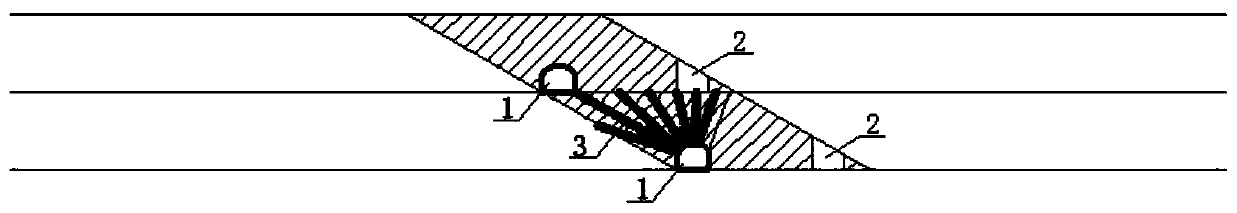

Spheroidizing method

InactiveCN102690985APrevent the problem of moving up after meltingAvoid lostMelt-holding vesselsRare-earth elementBrick

The invention relates to a spheroidizing method for producing spheroidal graphite cast iron, and the method comprises the following steps: injecting rare earth magnesium silicon iron inoculant alloy fluid containing less than or equal to 20% of Mg, less than or equal to 65% of Si and less than or equal to 3% of RE into a square steel pipe for solidifying and cooling; fixing the whole rare earth magnesium silicon iron inoculant of the outer lining square steel pipe in a spheroidizing bag by using refractory bricks and wedge-type chocks at the bottom of the spheroidizing bag covered, and then carrying out spheroidizing by utilizing a bag injecting method. The time for controlling spheroidizing is accurate, the molten iron cooling is less in the spheroidizing and casting process, the absorption rate of Mg, RE and Si after the spheroidizing is high, degradated spheroidization is avoided 15min after spheroidizing, the environment for producing and using a spheroidizing agent is improved, the production cost is remarkably reduced and the quality of the product is improved. Compared with the traditional magnesium silicon iron spheroidizing agent with the rare-earth element RE content of 2-8%, the spheroidizing method can be used for reducing the use amount of the rare-earth element RE by 50-75%.

Owner:TIANJIN WANLU LTD CO OF SCI & TECH +2

Nodulizing method

The invention relates to a nodulizing method for producing nodular cast iron, which comprises the following steps: injecting a fused rare-earth (RE) magnesium silicon iron nodulizer alloy liquid, which contains at most 20% of Mg, at most 65% of Si and at most 3% of RE, into a rectangular steel tube, solidifying, and cooling; and fixing the integral RE magnesium silicon iron nodulizer of the outer lining rectangular steel tube into the nodulizing ladle by using refractory bricks and wedged blocks on the bottom in the cladded nodulizing ladle, and nodulizing by a ladle-in process. The nodulizing reaction time is controlled precisely, the temperature drop in the nodulizing process and casting process is low, the absorptivity of Mg, RE and Si after nodulization is high, and no degraded nodulization appears within 15 minutes after the nodulizing reaction finishes, thereby improving the production environment in the nodulizer manufacturing process and use process, obviously lowering the production cost and improving the product quality. Compared with the traditional rare-earth magnesium silicon iron nodulizer with the RE content of 2-8%, the nodulizing technique provided by the invention lowers the consumption of the RE by 50-75%.

Owner:TIANJIN WANLU LTD CO OF SCI & TECH +2

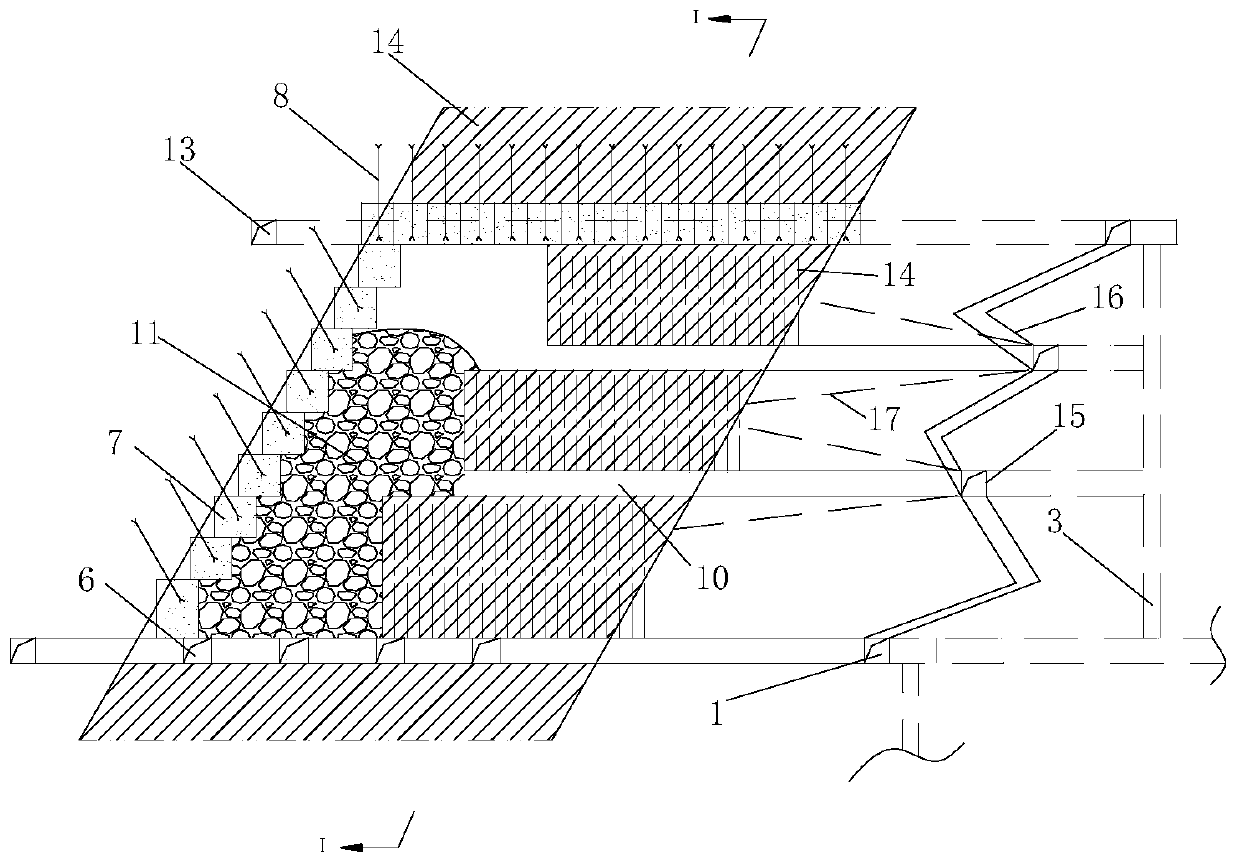

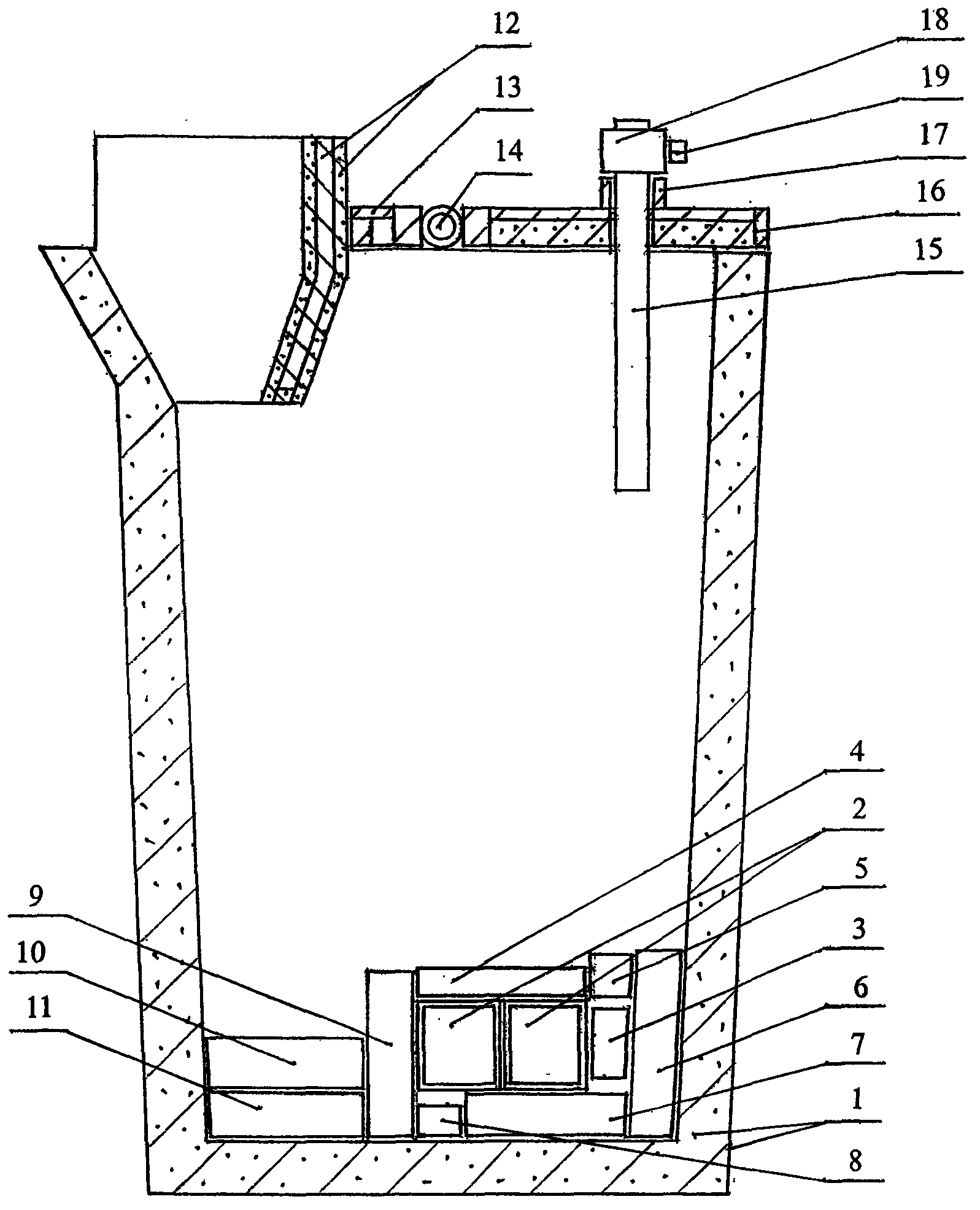

High-ground-stress large ore body downward sublevel filling mining method

ActiveCN109577979AReduce exposed areaReduce exposure timeUnderground miningSurface miningDetonationInstability

The invention relates to a high-ground-stress large ore body downward sublevel filling mining method. The high-ground-stress large ore body downward sublevel filling mining method comprises the stepsof layering the top of an ore body to be recovered; diving the ore body into sublevels and mid-levels for recovery; digging up a filling ventilation roadway and a drilling and ore discharging roadwayinside a working site, and performing primary filling after recovery is completed; before recovery is implemented, digging up a drilling chamber and drilling out vertical blastholes to form a cut vertical groove, forming upward sector-shaped blastholes in the drilling ore discharging roadway, and sequentially performing recovery section powder charging, detonation, ventilation and ore discharginguntil recovery of a recovery section is completed; building a filling retaining wall after recovery is completed, and starting operation in a next recovery section; filling the goaf after recovery ofevery section is completed to achieve a recovery and filling medium-length hole ore breakdown recovery process. Under the premise of improving the productivity of the working site, the high-ground-stress large ore body downward sublevel filling mining method achieves control over the exposed area of the goaf, avoids the problem of large-area and long-time exposure of the goaf and reduces the riskof instability of the working site.

Owner:JINCHUAN GROUP LIMITED

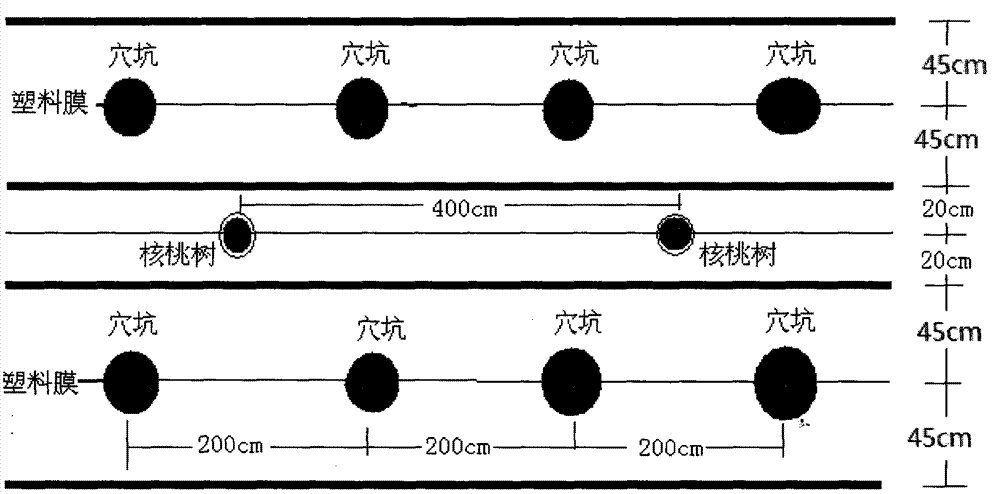

Method for storing fertilizer and water in holes by film coverage

InactiveCN104770253AMeet water and fertilizer needsImprove soil conditionsCultivating equipmentsPlant protective coveringsFruit treeEvaporation

The invention discloses a method for storing fertilizer and water in holes by film coverage, belonging to the technical field of fertilization. The method for storing the fertilizer and the water in the holes by film coverage comprises the following steps specifically: building ridges, ditching, digging the holes, putting straw bundles in the holes, applying fertilizer to the holes and irrigating the holes, covering the holes by plastic films; pressing the edges of the plastic films tightly by soil, digging a hole with a diameter of 10 cm in the center of each hole by a thin film hole puncher, inserting a rain-collecting fertilizer applicator in the center of each hole along the center of the hole of the plastic film until the upper edge of the rain-collecting fertilizer applicator is inserted in the hole. By adoption of the method for storing the fertilizer and the water in the holes by film coverage, rain and snow are sent to the effective parts of fruit tree roots with well developed root systems for absorbing water by the rain-collecting fertilizer applicators so as to meet needs of the fruit trees; therefore, the non-available water is changed into effective water; meanwhile, by film coverage, the low temperature is improved and the soil moisture evaporation is reduced; the fruit garden can save water by more than 70%; the manpower and material resources investment is reduced; the method has an effect of saving resources and cost.

Owner:刘朝斌 +2

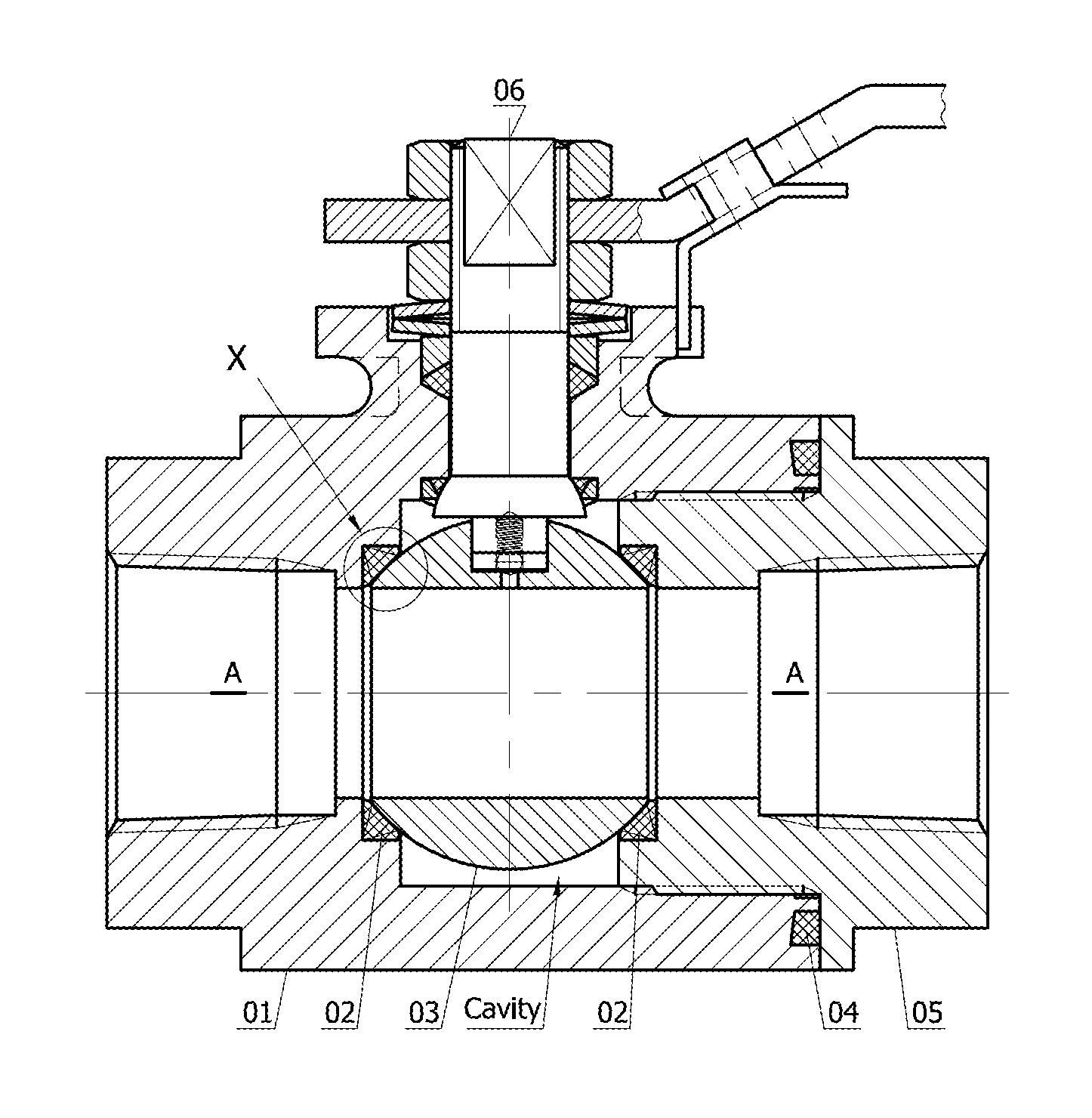

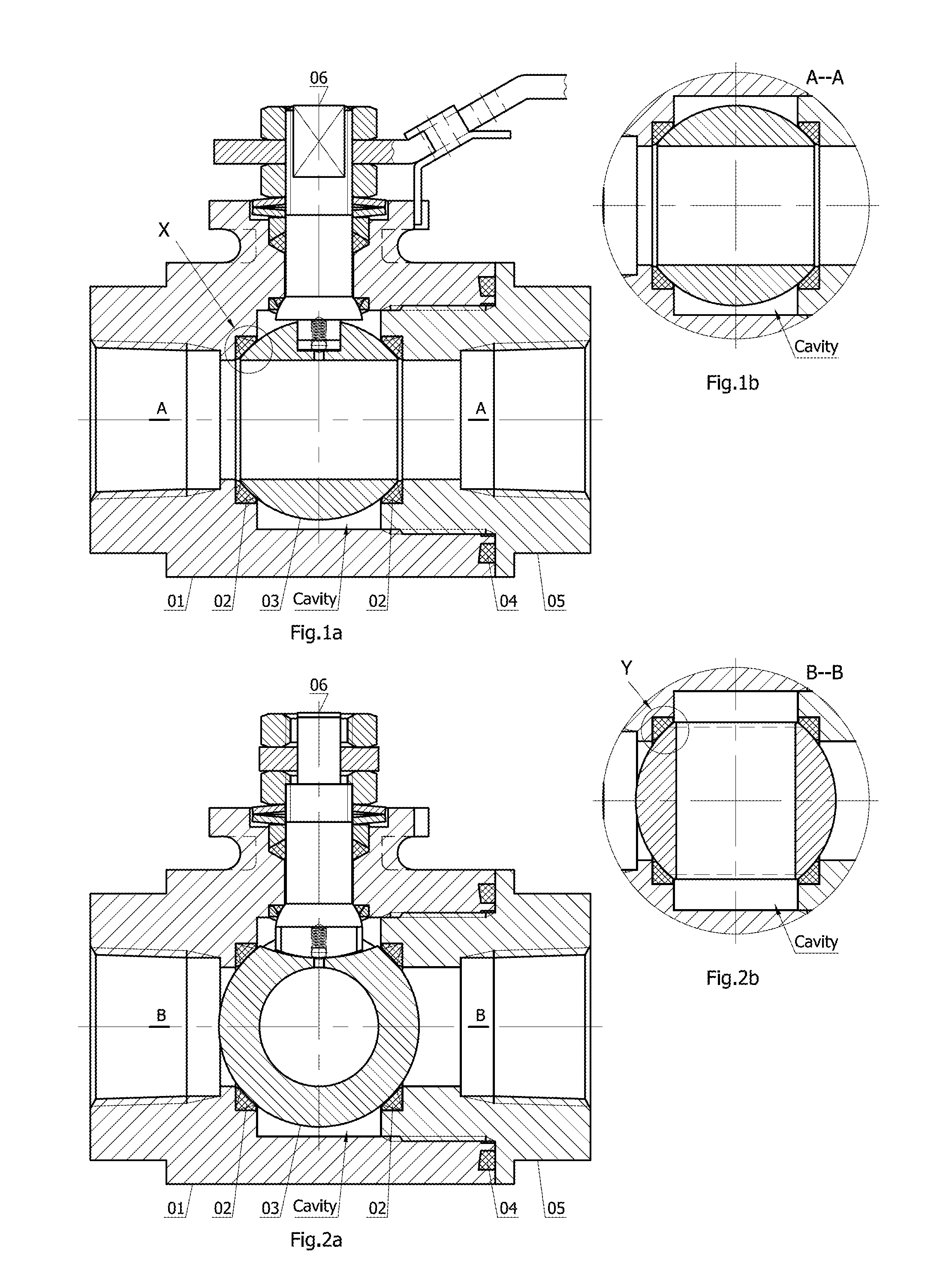

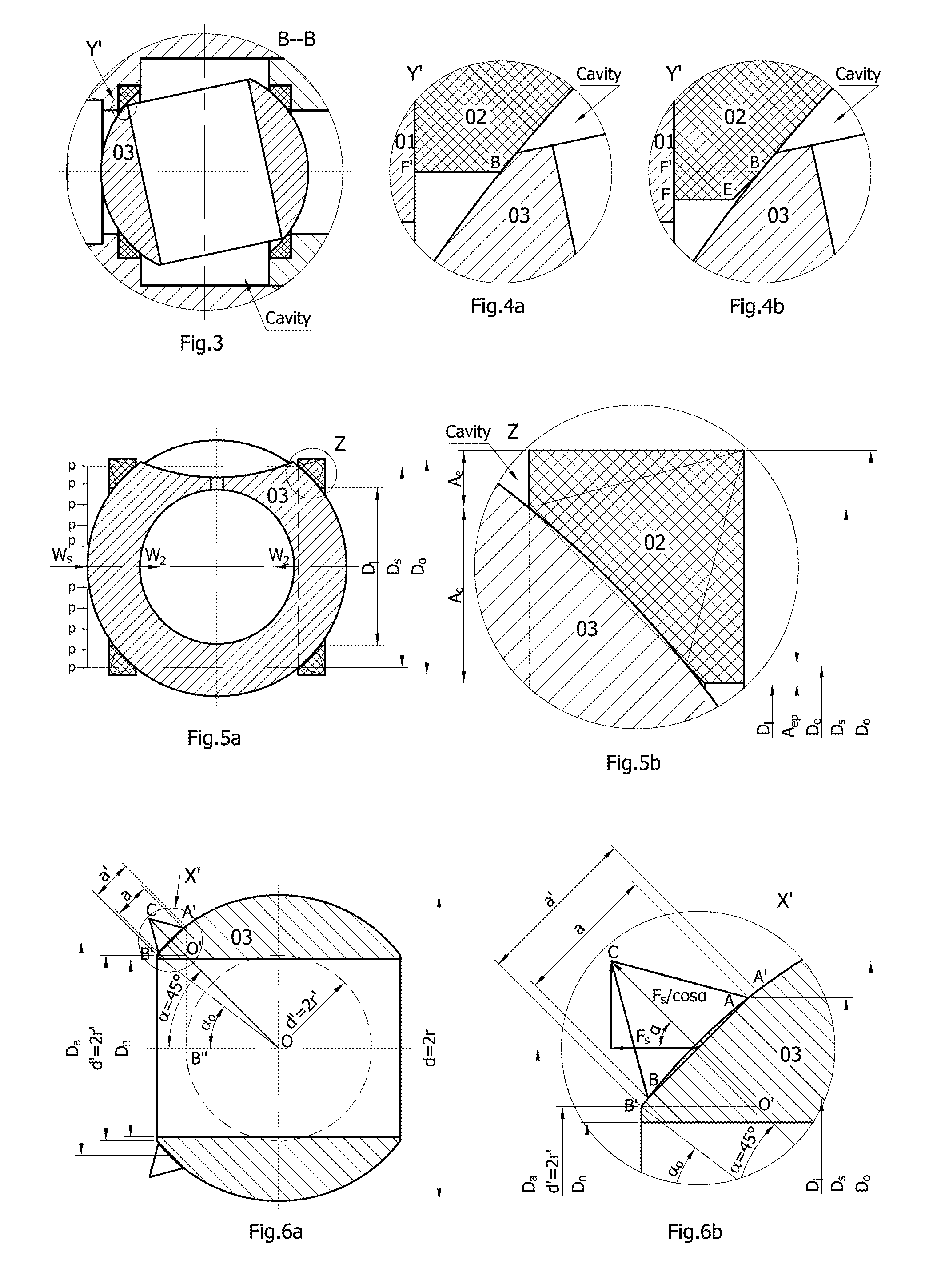

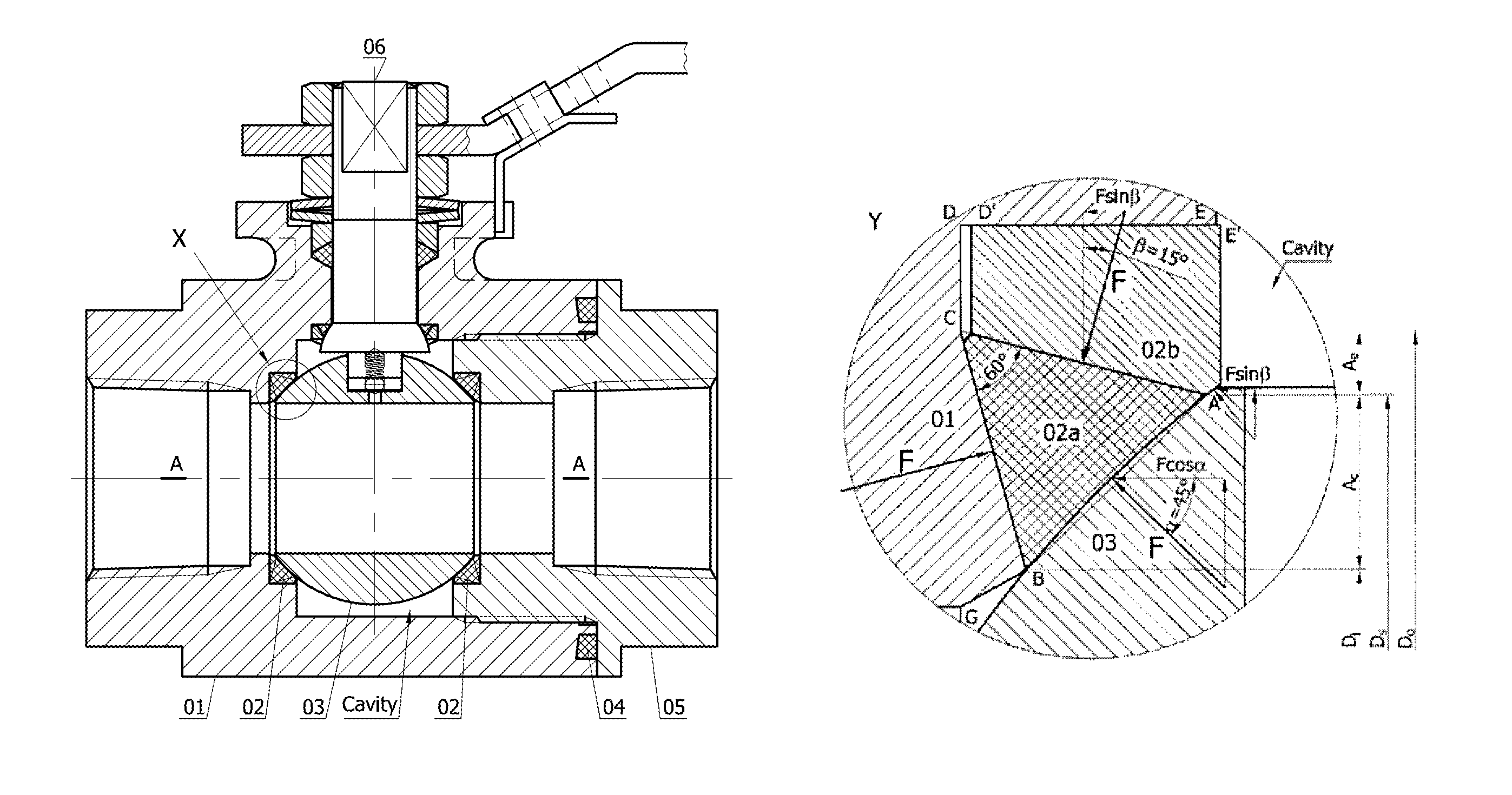

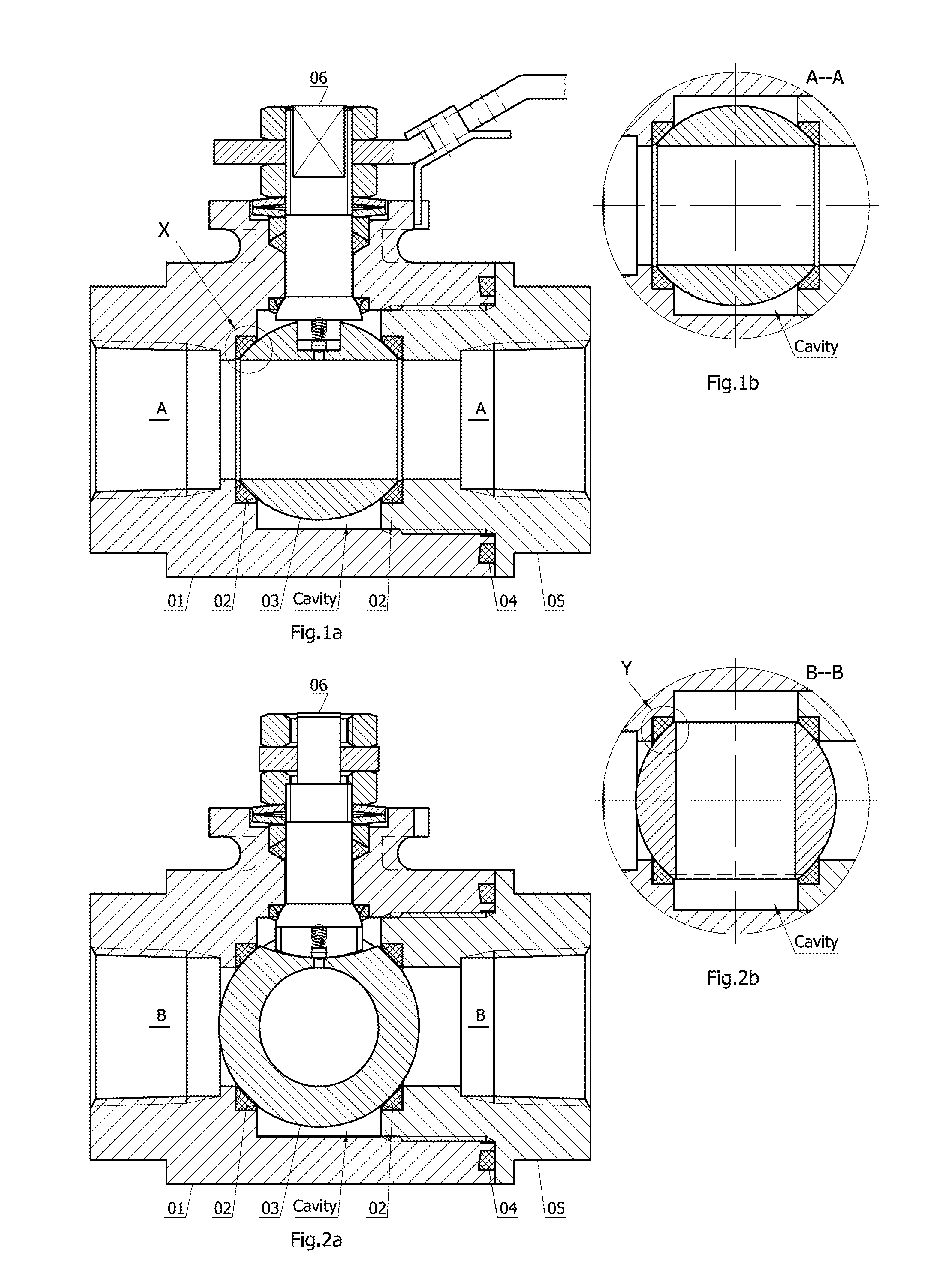

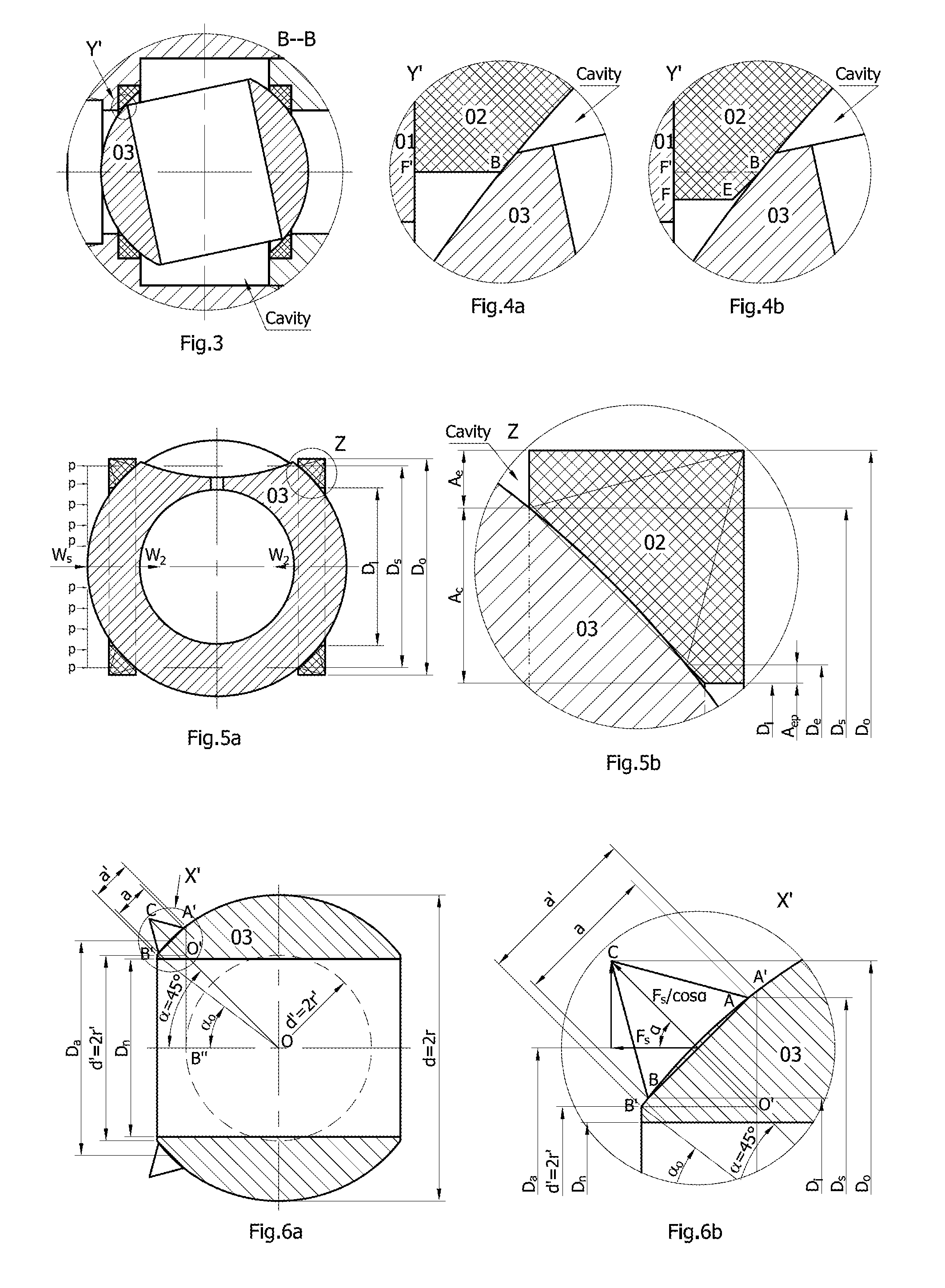

Ball Valve Seats and Ball Valves Designed with Equilateral Triangle Section Methods

InactiveUS20110260089A1Improve anti-interference abilityReduce areaPlug valvesIsoetes triquetraPulse amplifiers

It is inevitable for the tight closure of a ball valve to be disturbed by its ball's wedging action, and its ball seat is an upset impulse amplifier with an inherent disturbance resistance index or a sealing maintaining factor m. The ball valve seat designed with equilateral triangle section methods of the invention can positively ensure itself a resistance to ball-wedged disturbance from eccentric drive to make a ball valve realize its tight closure by the floated pressure of balls or seats onto each other and ensure that the ultimate rotational resistance to the ball only relates to the ultimate pressure from / on one seat. Because the seat of the prior art can not ensure balls or seats against each other a floated pressure sufficient to resist to the ball-wedged disturbance from eccentric drive, the tight closure of the ball valve has to be realized by either larger preclamping force or larger spring preload between seats and balls so as for the ultimate rotational resistance to balls to be from larger ball-clamping forces from two seats. Therefore, the ball valve in accordance with the invention is a real floating or mounted ball valve, whose operation torque can be at most half of that of a formal or false floating ball valve of the prior art.

Owner:XU CHANGXIANG +2

Block-shaped cutting, jacking and pushing ore removal mining method of double-layer extreme-thin jade mine

InactiveCN105240017AAvoid damageHigh degree of standardizationUnderground miningSurface miningEconomic benefitsAtmospheric pressure

The invention provides a block-shaped cutting, jacking and pushing ore removal mining method of double-layer extreme-thin jade ore. The method includes the steps that firstly, an ore body is divided into ore blocks according to the trend of the ore body, the ore blocks are subjected to mining-cutting for forming a back production space, and a chain saw arm is utilized for conducting transverse and vertical cutting on the upper-layer ore body and surrounding rock along a service tunnel, so that the ore body can be cut into small regular ore blocks and be separated from the upper surrounding rock and the lower surrounding rock; an air pressure jacking and pushing bag is placed in a cutting seam in the upper portion of the ore body for downward squeezing the ore body, the root of the ore body is broken for achieving ore rock separation, and the separated upper-layer ore body is taken down and transported out through a flat car; then, the chain saw arm is utilized for cutting the surrounding rock along a top plate, the jacking and pushing bag is placed in a space formed after the cutting seam and the produced ore body, and the surrounding rock is squeezed and crushed and carried to a goaf for filling the goaf; after the upper surrounding rock is cleaned, the lower-layer ore body is mined through the same cutting squeezing and filling processes. According to the block-shaped cutting, jacking and pushing ore removal mining method, pure mechanical work is adopted, operation is simple, labor intensity is small, economic benefits are high, safe operation of a mining field can be guaranteed, and the ground environment can be protected.

Owner:WUHAN UNIV OF TECH +1

Ball valve seats and ball valves designed with equilateral triangle section methods

InactiveUS8864105B2Improve anti-interference abilityReduce areaPlug valvesEngine sealsIsoetes triquetraEngineering

It is inevitable for the tight closure of a ball valve to be disturbed by its ball's wedging action, and its ball seat is an upset impulse amplifier with an inherent disturbance resistance index or a sealing maintaining factor m. The ball valve seat designed with equilateral triangle section methods of the invention can positively ensure itself a resistance to ball-wedged disturbance from eccentric drive to make a ball valve realize its tight closure by the floated pressure of balls or seats onto each other and ensure that the ultimate rotational resistance to the ball only relates to the ultimate pressure from / on one seat. Because the seat of the prior art can not ensure balls or seats against each other a floated pressure sufficient to resist to the ball-wedged disturbance from eccentric drive, the tight closure of the ball valve has to be realized by either larger preclamping force or larger spring preload between seats and balls so as for the ultimate rotational resistance to balls to be from larger ball-clamping forces from two seats. Therefore, the ball valve in accordance with the invention is a real floating or mounted ball valve, whose operation torque can be at most half of that of a formal or false floating ball valve of the prior art.

Owner:XU CHANGXIANG +2

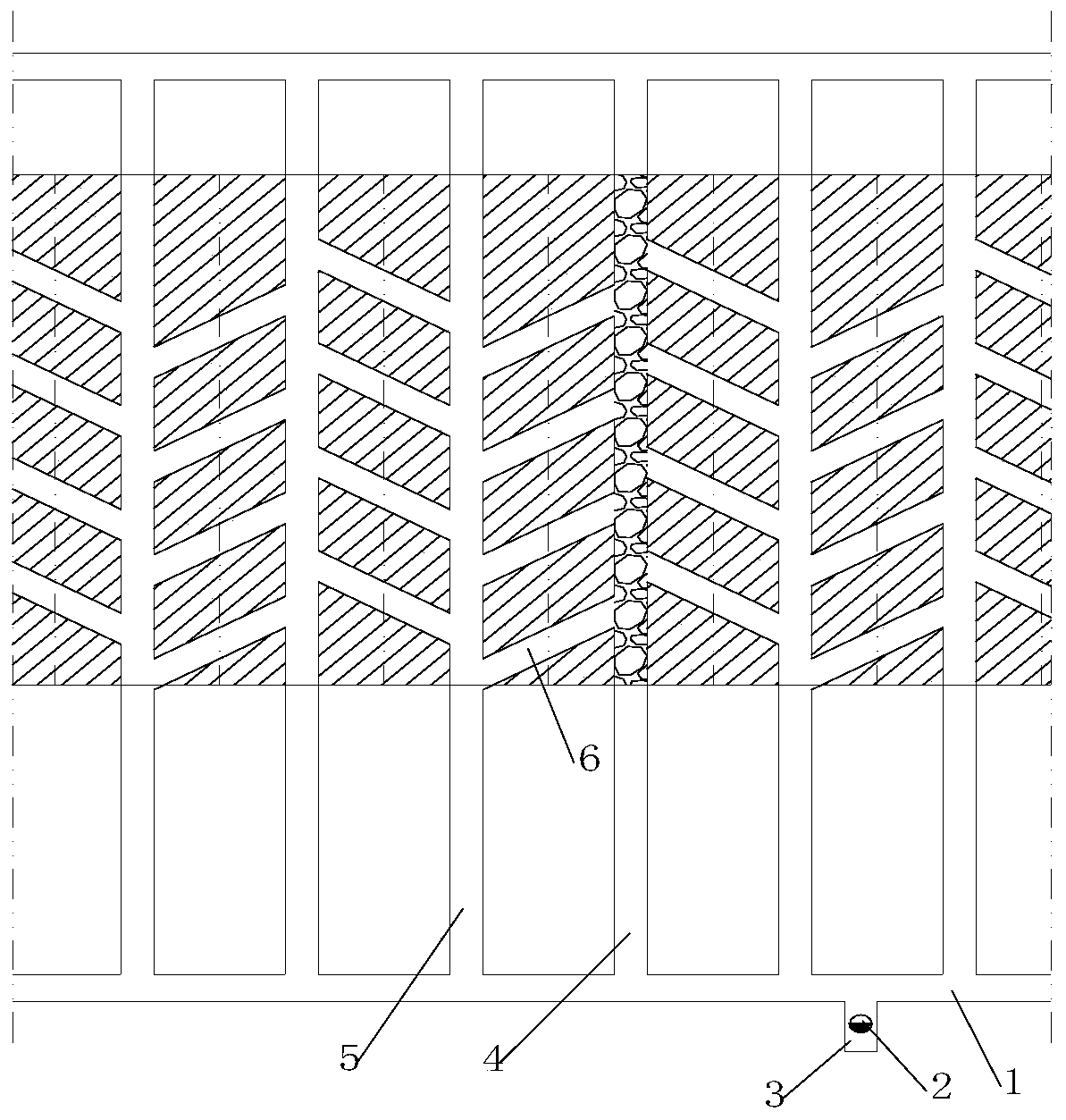

Underground mining method for gently-inclined medium-thick or thick phosphorus ore bodies

ActiveCN110145311AReduce exposed areaShorten working timeUnderground miningSurface miningMineralogyWork time

The invention relates to the technical field of mining, and particularly relates to an underground mining method for gently-inclined medium-thick or thick phosphorus ore bodies. The underground miningmethod for the gently-inclined medium-thick or thick phosphorus ore bodies comprises the following steps: dividing a middle section in the inclination direction of the ore bodies, dividing a panel inthe orientation direction of the ore bodies, and dividing a sub-layer in the panel in the inclination direction; dividing a stope in the sub-layer in the orientation direction; constructing a drilling roadway in the stope in a roof direction; and then constructing two drilling roadways along a bottom plate of the ore bodies. According to the underground mining method for the gently-inclined medium-thick or thick phosphorus ore bodies, the original thick ore bodies are divided into two parts during extraction, so that the roof exposure area of the stope is reduced, the working time of personnel and equipment in an open stope is reduced, and the safety of the personnel and equipment in an extraction process is greatly improved; and meanwhile, triangular ores on the bottom plate can be efficiently recovered, so that the recovery rate for the ores is greatly increased.

Owner:贵州开磷有限责任公司

Mulching method for sugarcane weeding mulching films on all ground and in whole growing period

InactiveCN104082011AReduce exposed areaShorten the timePlant protective coveringsPlastic mulchFertilizer

A mulching method for sugarcane weeding mulching films on all ground and in a whole growing period comprises the steps that after sugarcane cultivation earthing or perennial root sugarcane loose stalk base fertilizer application is conducted, the wide mulching films are adopted for wholly covering the sugarcane ground surface, gaps are not reserved among the films, the mulching films are connected to achieve covering and are compacted at the joints through soil, and a relatively-sealed water, fertilizer and temperature circulating system is formed on the part below the ground surface of a sugarcane field. When the mulching films are arranged in the covering mode, the mulching films are compacted at the centers of sugarcane furrows with fine soil, and the mulching films are arranged in the covering mode until harvesting is conducted.

Owner:耿马傣族佤族自治县蔗糖产业办公室

Spray forming cooling system and method for decreasing temperature of ingot blank through spray forming cooling system

The invention discloses a spray forming cooling system and a method for decreasing the temperature of an ingot blank through the spray forming cooling system. The system comprises a spray forming device and a cooling system, the cooling system comprises a heat absorption structure, a cooling device, a circulation power pump, heat conduction media and a heat conduction medium conveying pipeline which is sequentially connected with the heat absorption structure, the cooling device and the circulation power pump to form a heat condition loop. The heat absorption structure is located inside an atomization chamber of the spray forming device and used for cooling the ingot blank or a tray, and the cooling device is located outside the atomization chamber of the spray forming device and used for cooling the heat conduction media of which the temperature is increased because heat of the atomization chamber is absorbed. The heat conduction media flow inside the heat conduction loop in a circulation mode under the action of the circulation power pump to absorb heat in the atomization chamber and perform cooling inside the cooling device. The spray forming cooling system has the advantage that the heat conduction media are adopted for directly cooling the ingot blank or the tray, so that the ingot blank of which the performance meets the requirement is obtained.

Owner:天津佐源新材料科技有限公司

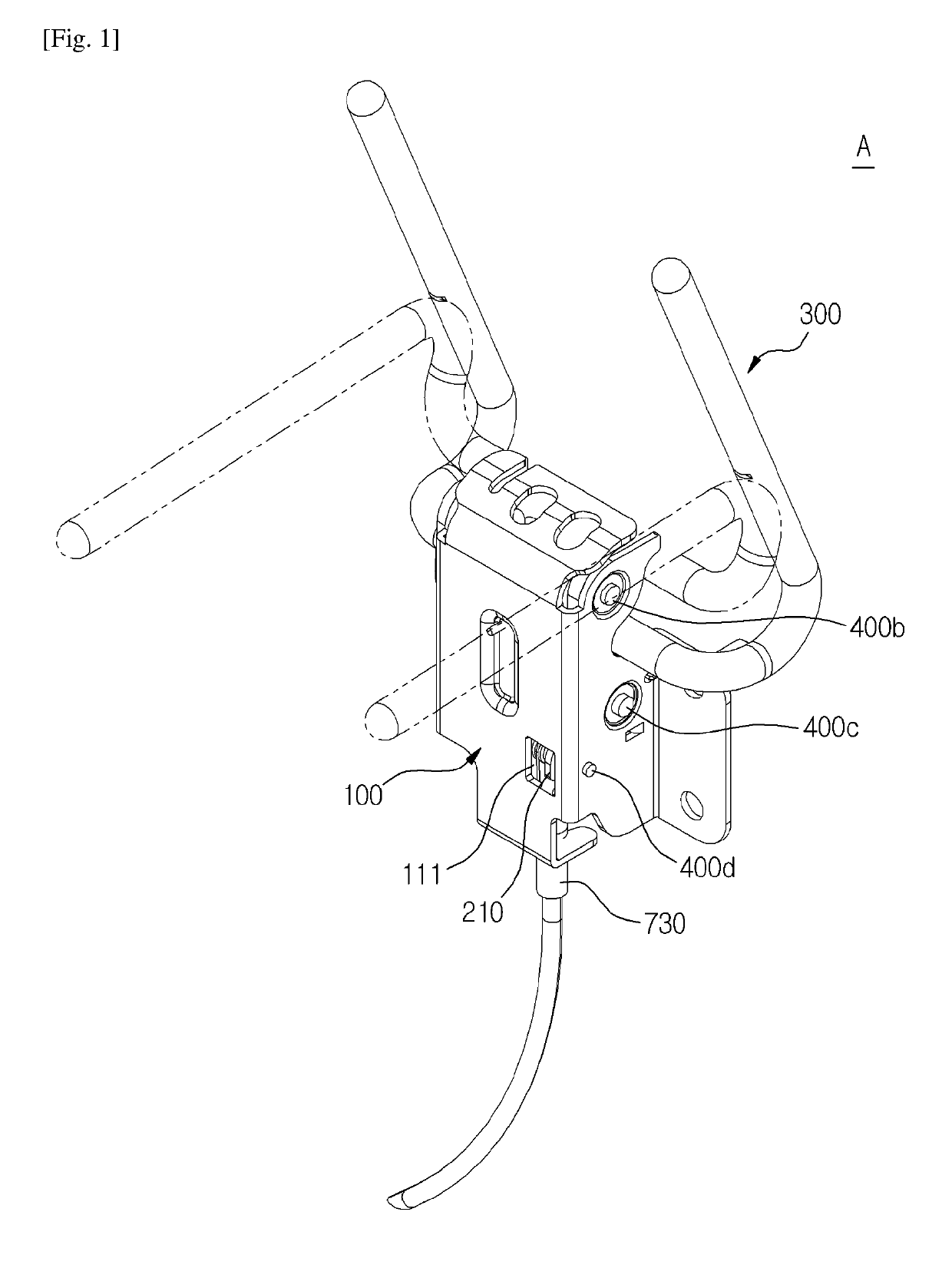

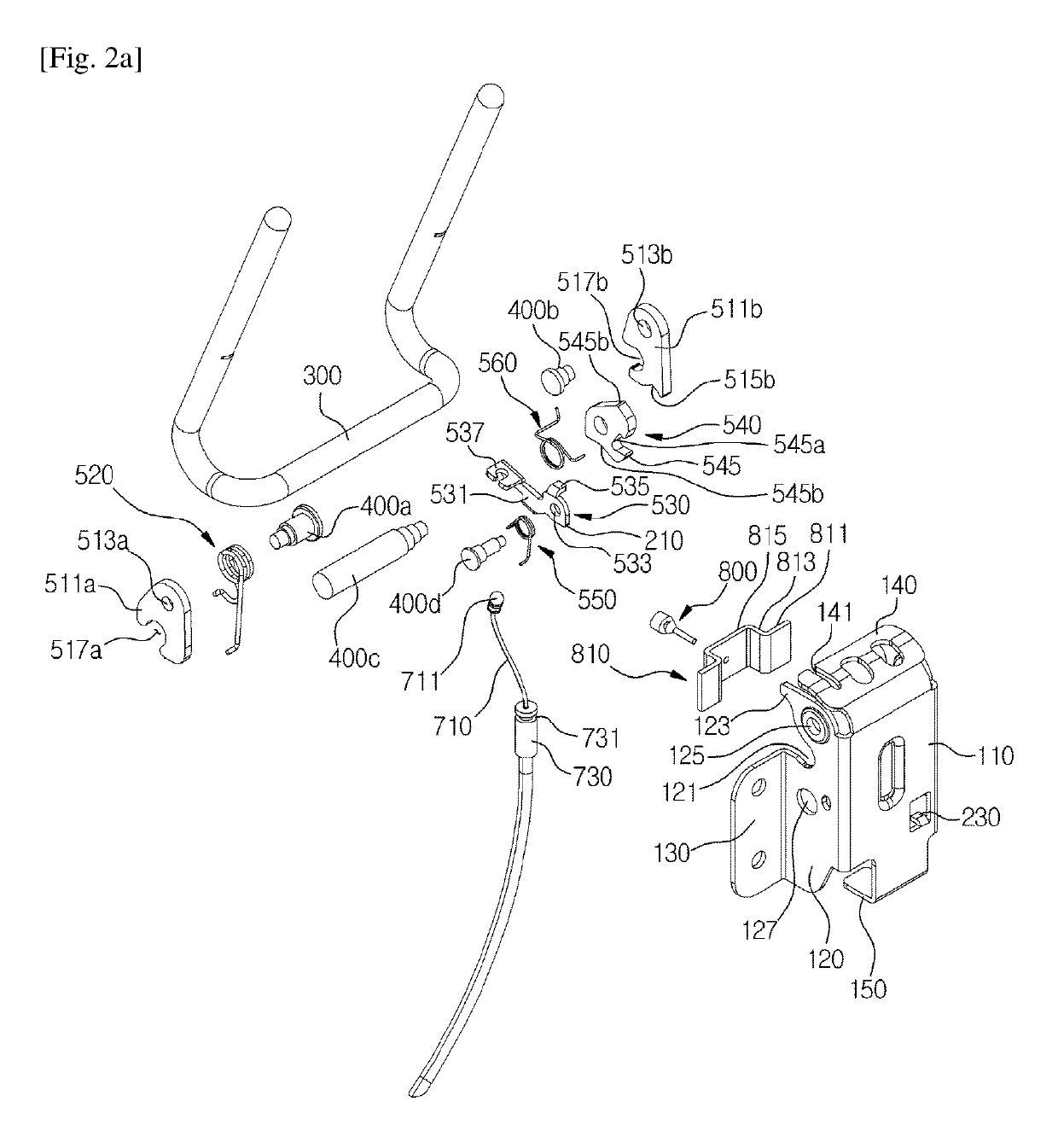

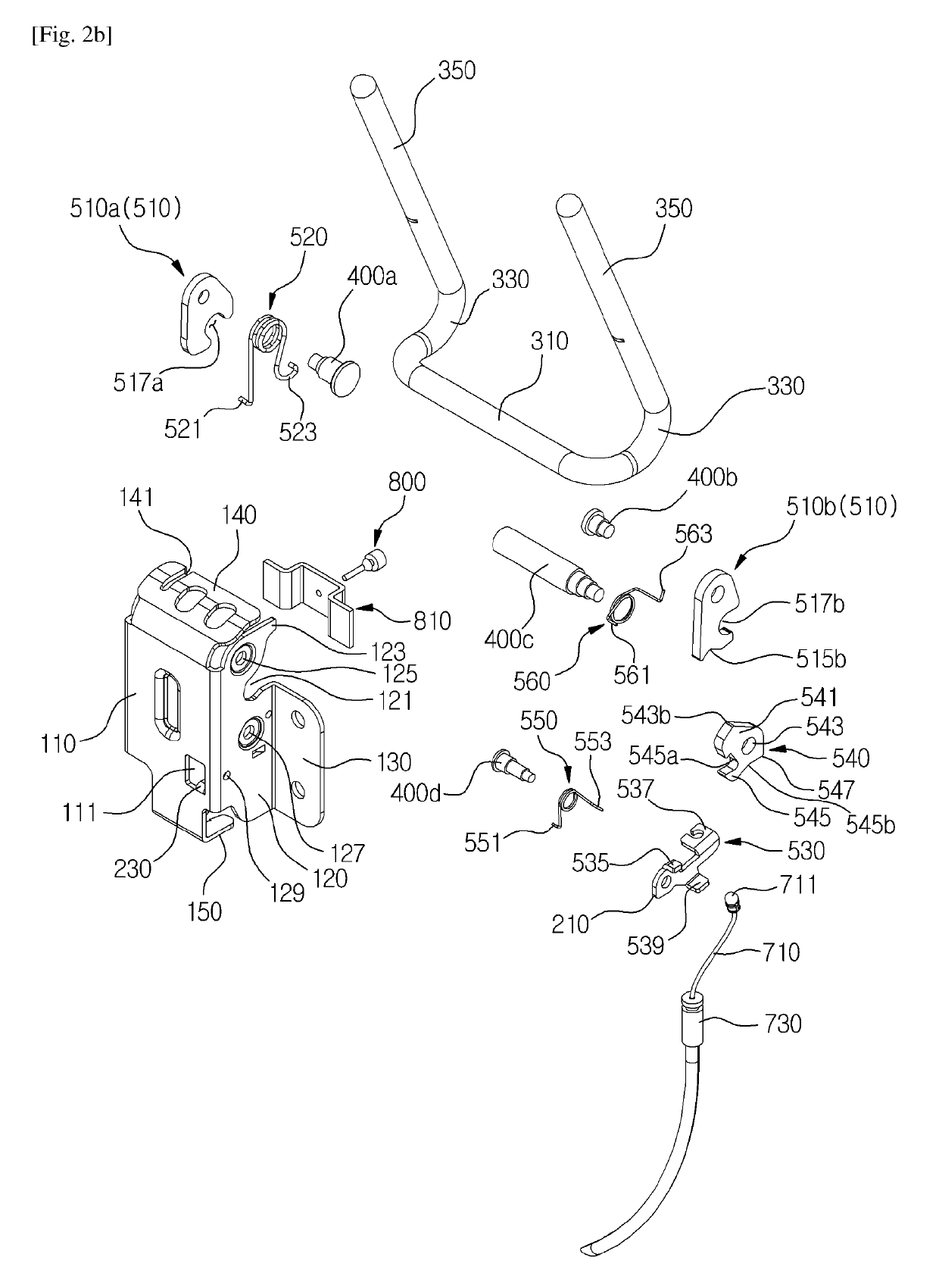

Headrest folding device

ActiveUS10427572B2Softly and smoothly operateHigh strengthHead restsEngineeringElectrical and Electronics engineering

The present invention relates to a headrest folding device, more particularly, to a headrest folding device wherein a ratchet is connected between a release lever and a lock link which maintains the unfolding (upright) of a headrest, so that the operation of the release lever is not directly transferred to the lock link, but rather indirectly transferred to the lock link through the ratchet, thereby smoothing the operation of the release lever.

Owner:WOOBO TECH

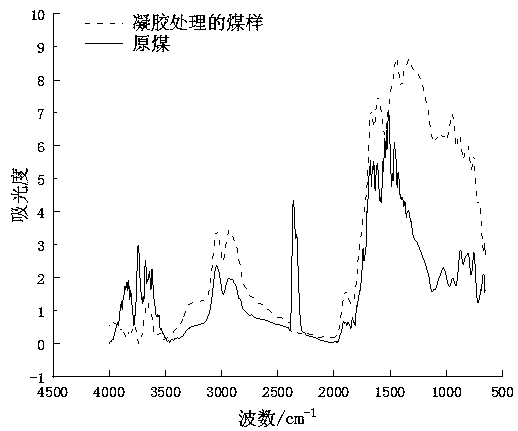

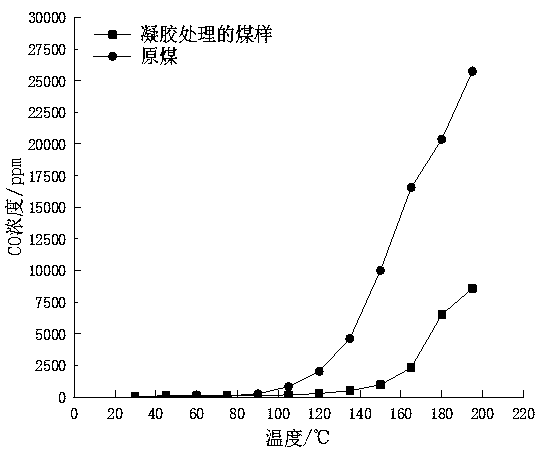

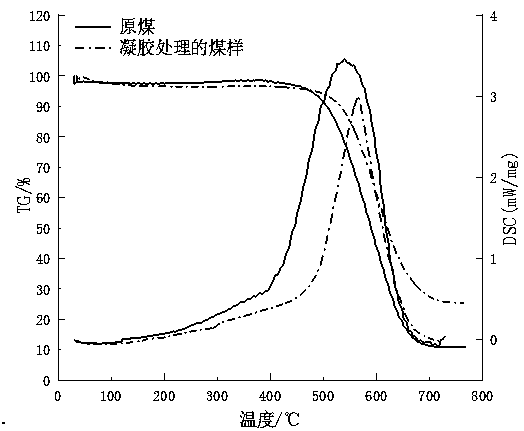

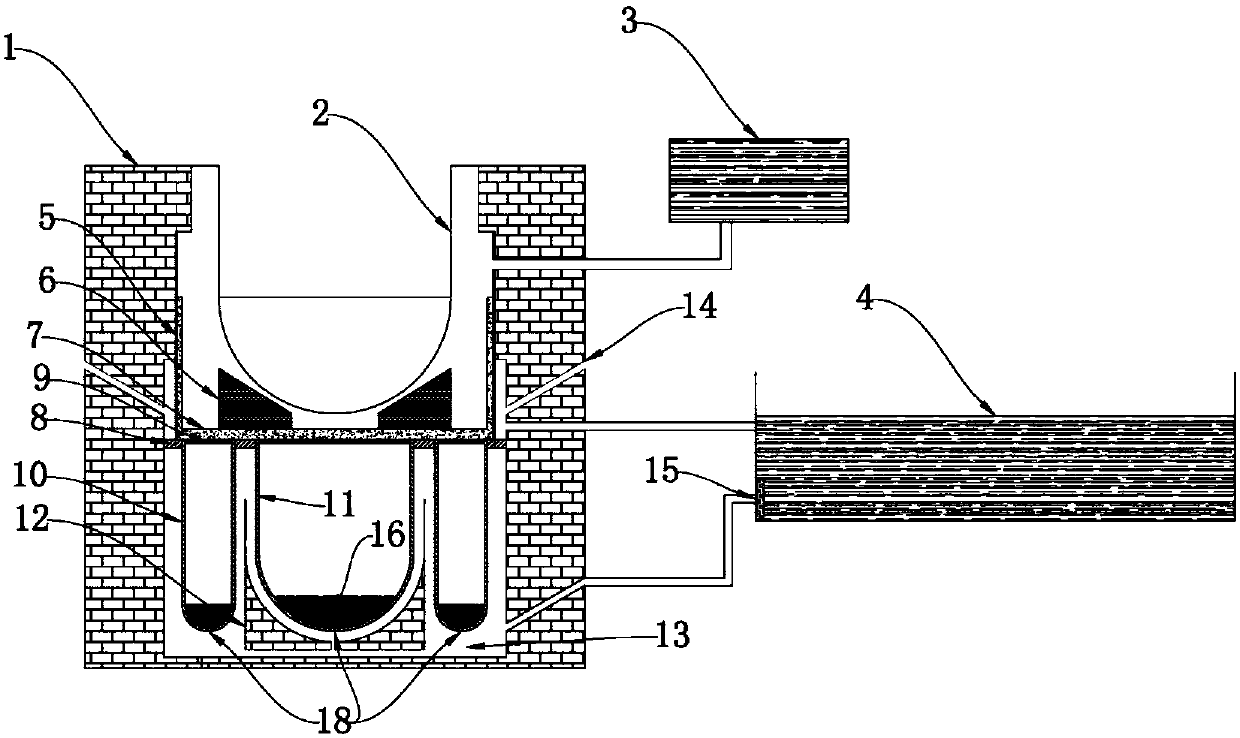

Fire preventing and extinguishing gel for coal mine, and preparation method thereof

InactiveCN111214799ASuppress spontaneous combustionEffective fire preventionFire extinguisherCelluloseGluconic acid

The invention discloses a fire preventing and extinguishing gel for coal mines, and a preparation method thereof. According to the invention, sodium carboxymethyl cellulose is used as a polymer, zirconium citrate with a cross-linking effect is introduced, gluconic acid-delta-lactone capable of controlling a gelling time by controlling the zirconium ion release speed is taken as a pH modifier, andascorbic acid for inhibiting the activity of coal free radicals is added; the gel is easy to prepare, the gelling time is controllable, and the gels with different proportions can be selected according to different requirements to meet the time requirement; physical and chemical effects are combined to extinguish fire, and the effect is remarkable; the state is stable and can be restored to the original state after being physically destroyed, and a good colloidal state is still kept after one month; and the gel has good viscoelasticity and strong thermal stability, can meet the requirements ofmine fire prevention and extinguishment sites, and is suitable for coal mine fire prevention and extinguishment.

Owner:TAIYUAN UNIV OF TECH

Reactor core melt capturing apparatus capable of realizing reinforced cooling through split charging

ActiveCN108053895AEfficient captureCompact layoutNuclear energy generationEmergency protection arrangementsCore catcherCrucible

The invention relates to a reactor core melt capturing apparatus capable of realizing reinforced cooling through split charging, belonging to the technical field of nuclear safety control. The reactorcore melt capturing apparatus comprises a reactor pit, a reactor pressure vessel, a melt retention container, crucibles, a retention water tank, a cooling water tank and connecting pipelines, whereinthe melt retention container with an opened top is located in the reactor pit; the lower part and the bottom of the reactor pressure vessel are located in the melt retention container; space, locatedbelow the melt retention container, in the reaction pit forms cooling space; the crucibles are arranged in the reaction pit and located below the base plate of the melt retention container; the retention water tank is located out of the reaction pit and connected with the reaction pit via one connecting pipeline; and the cooling water tank is located out of the reaction pit and connected with thecooling space via another connecting pipeline. The reactor core melt capturing apparatus provided by the invention can cope with serious accidents in a nuclear power station by employing compactly arranged core catchers with high cooling efficiency and realizing effective capturing and accommodating of core melts through temporary retention and reinforced cooling via split charging.

Owner:CHINA NUCLEAR POWER ENG CO LTD

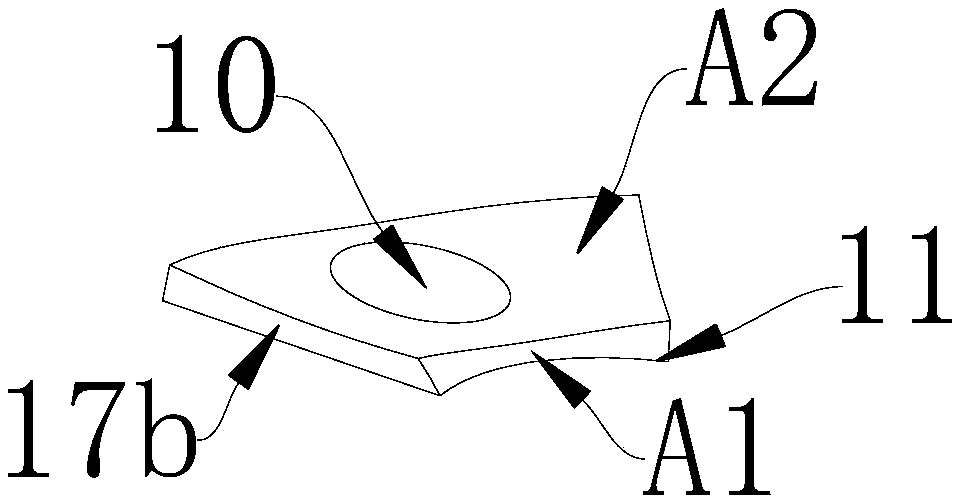

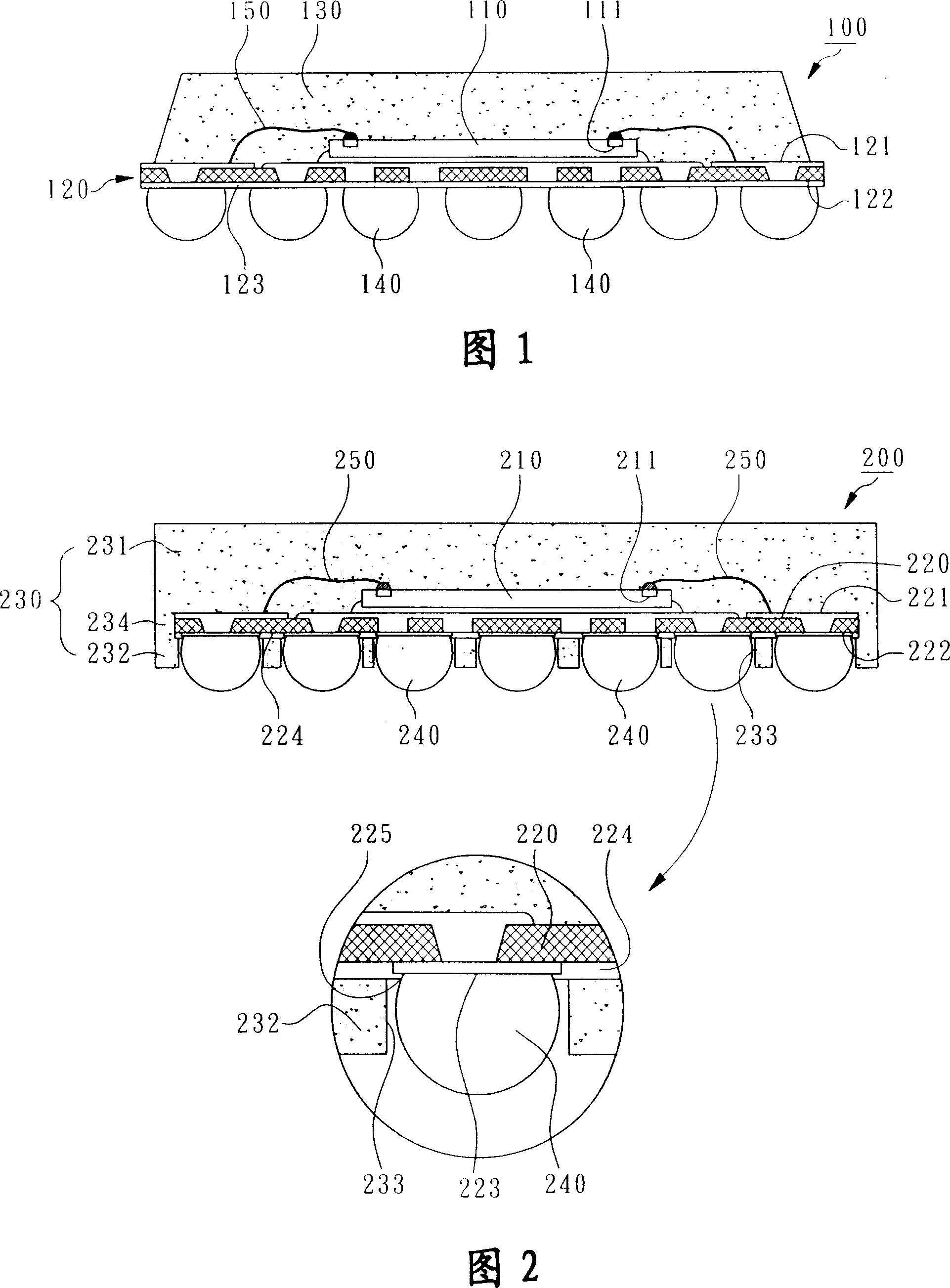

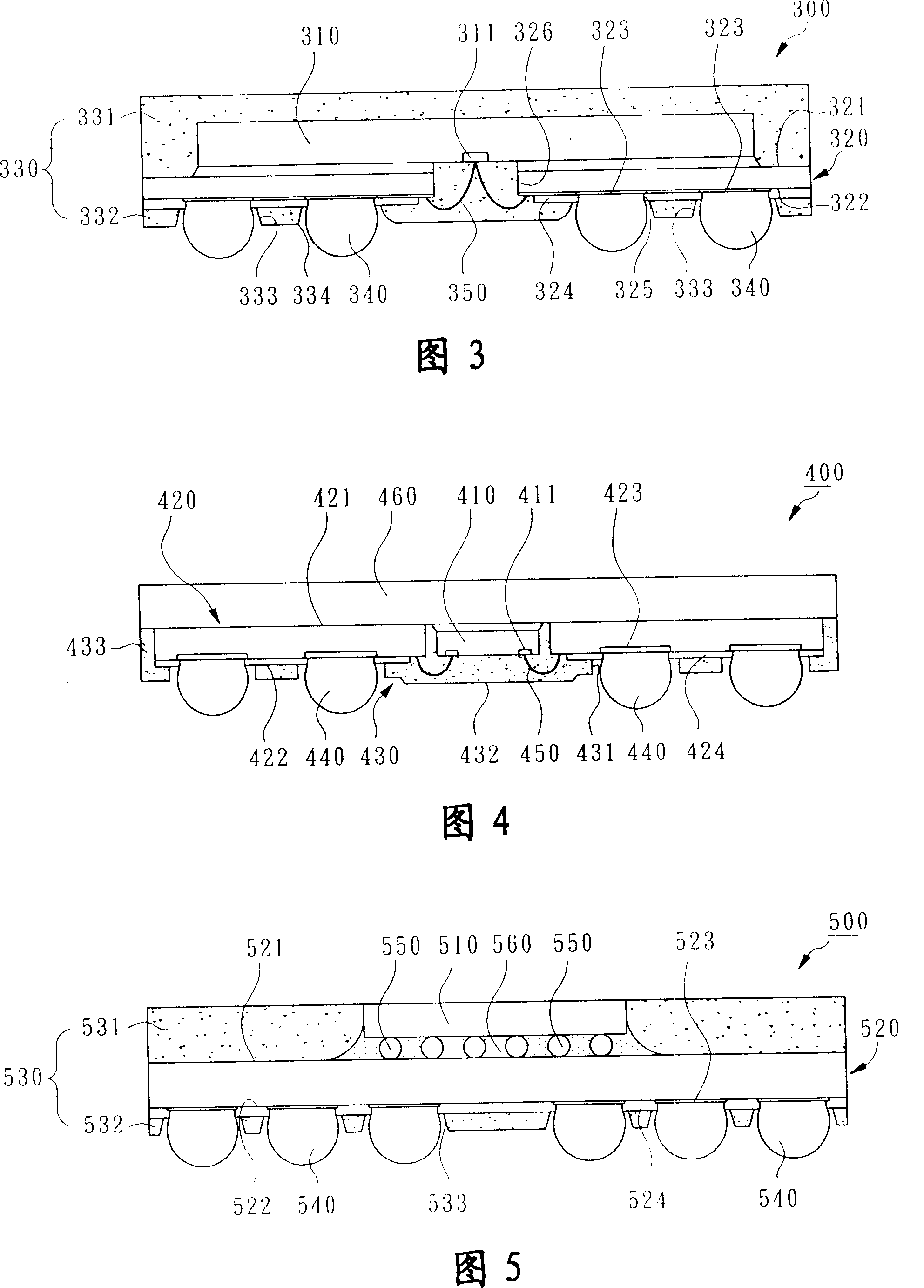

Spherical grid array encapsulation structure of base plate bottom glue encapsulation

InactiveCN101106120AReduce exposed areaImprove moisture resistanceSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSolder ball

The invention relates to a ball grid array (BGA) encapsulating structure of adhesive-sealing the bottom of the baseplate, mainly comprising a wafer, a baseplate, a model encapsulating colloid and a plurality of solder balls. The baseplate has a surface jointing plate, and a plurality of ball pads and a solder-preventing layer. The model encapsulating colloid at least covers the surface jointing plate of the baseplate and has a plurality of ball-holding holes corresponding to the solder balls, and the sizes of the openings of the ball-holding holes are larger than those of the holes in the solder-preventing layer so as to keep the solder balls away from the model encapsulating colloid. The solder balls are aligned to the ball-holding holes and are jointed to the ball pads of the baseplate, by which the humidity resistance of BGA products is enhanced, and the solder balls are kept not to drop without the pushing from the stress of the encapsulating colloid.

Owner:POWERTECH TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com