Patents

Literature

33results about How to "Realize continuous mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

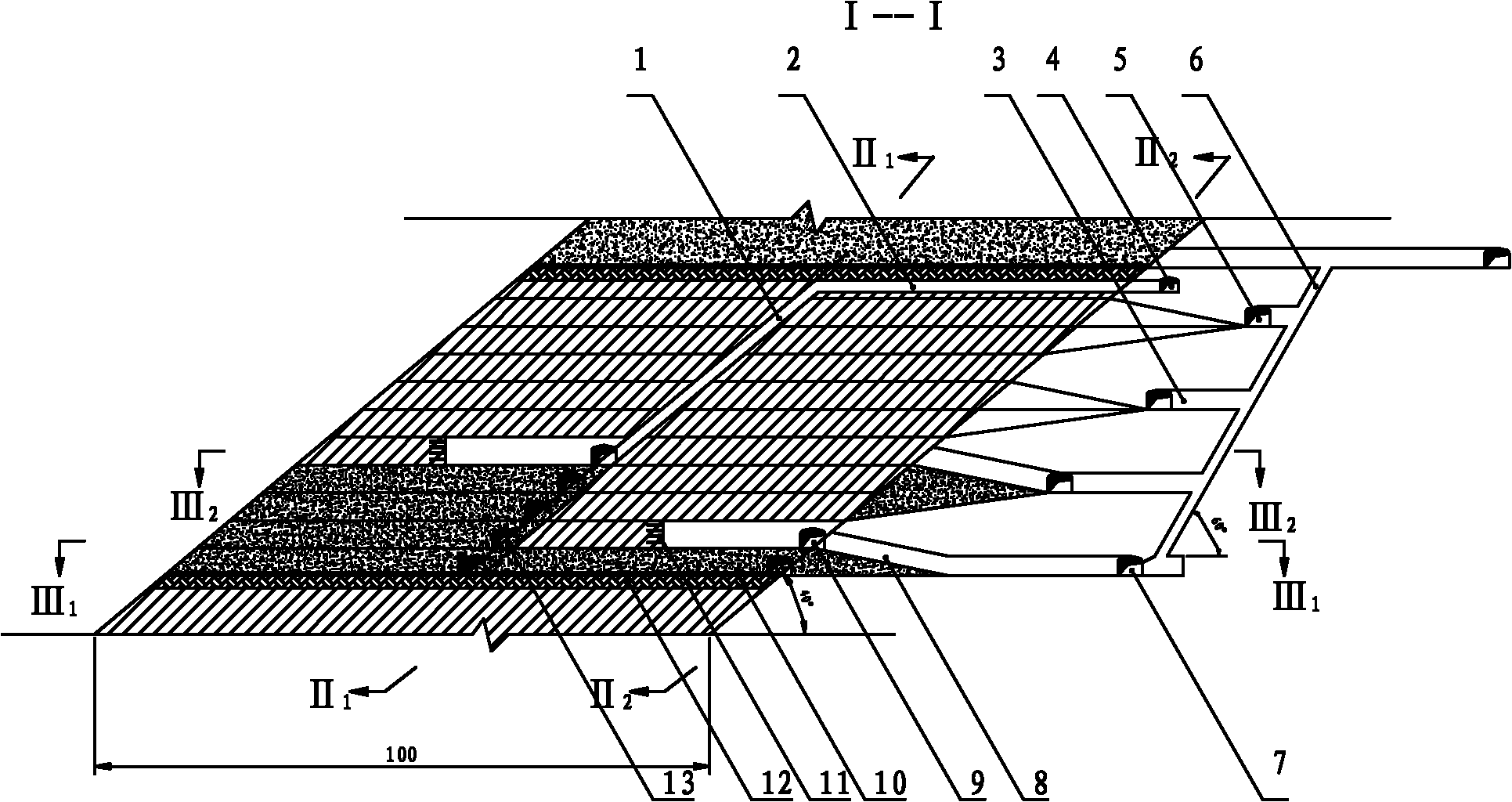

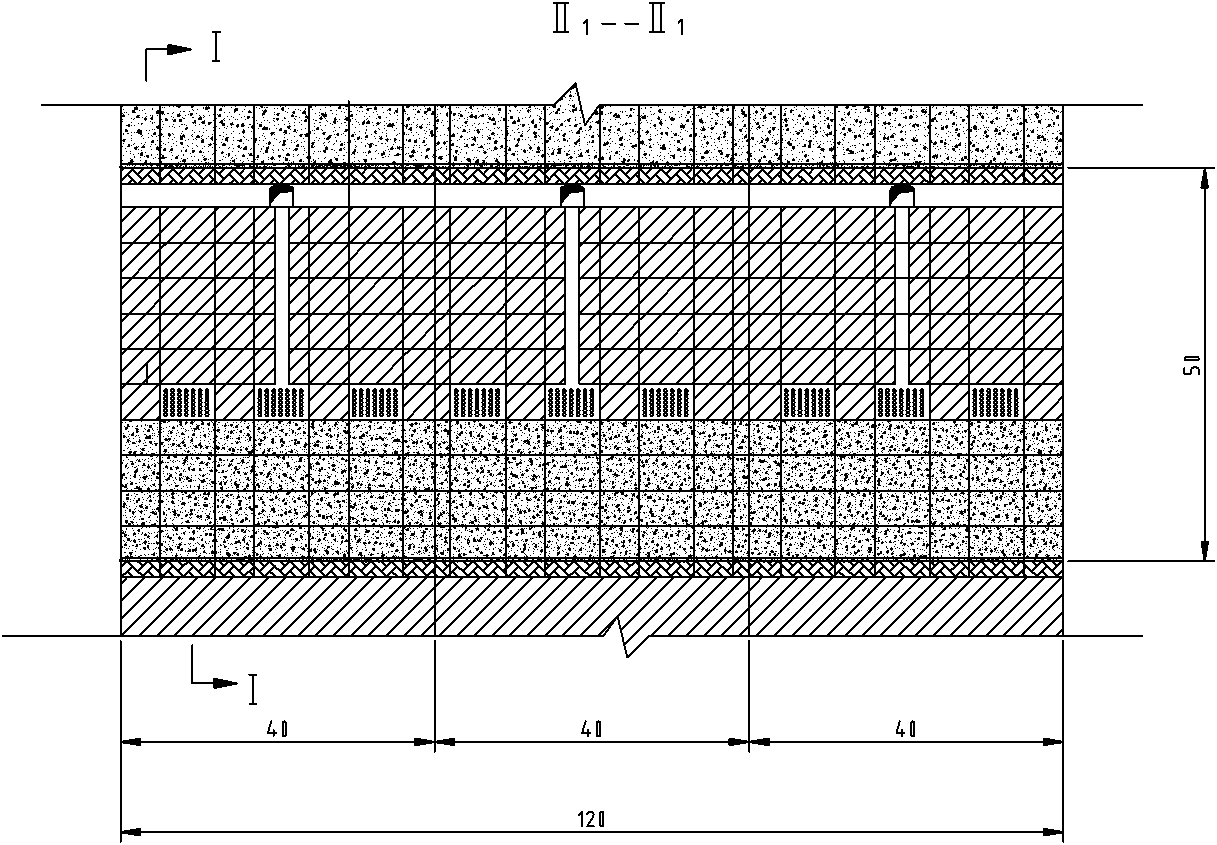

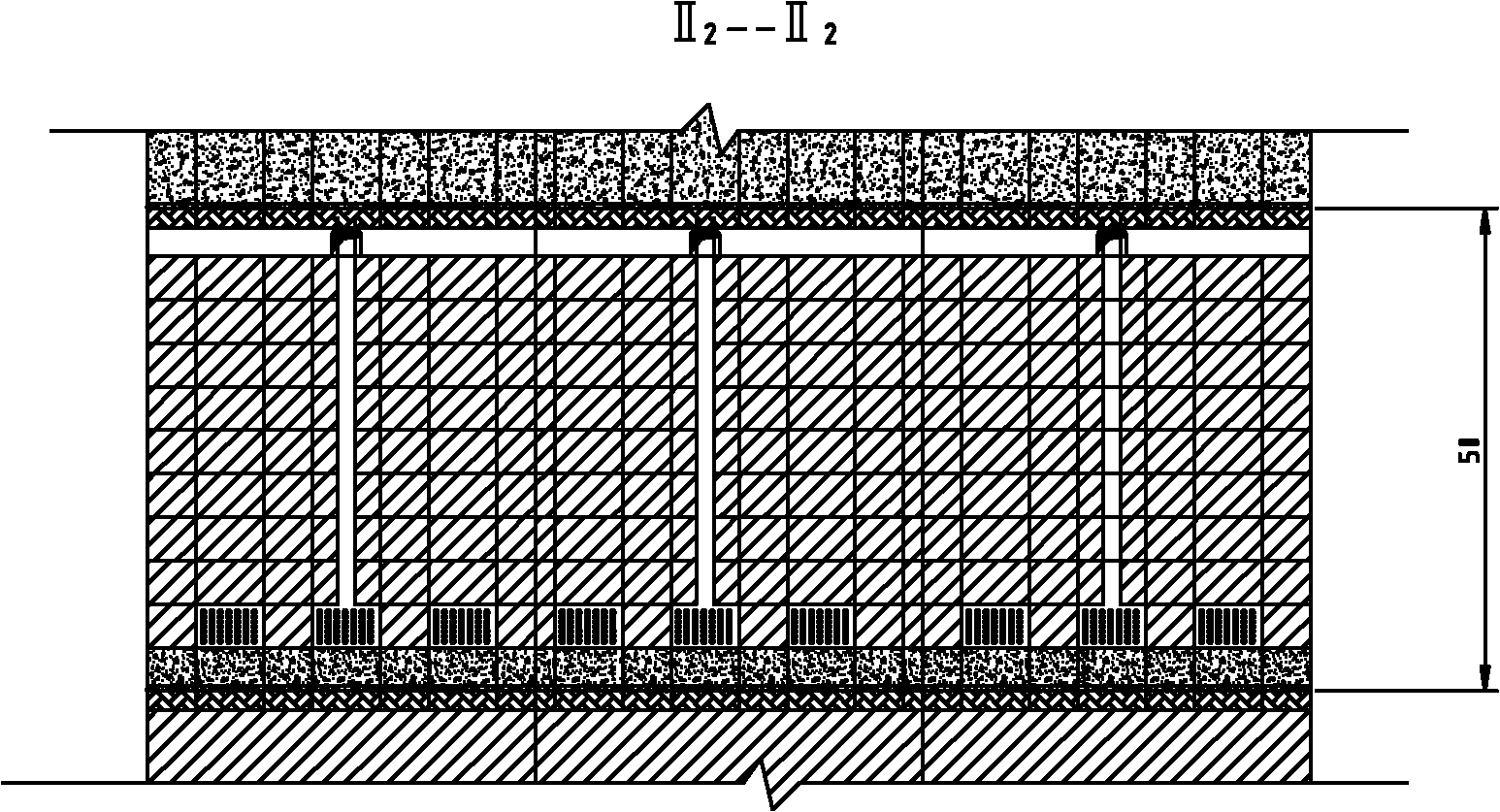

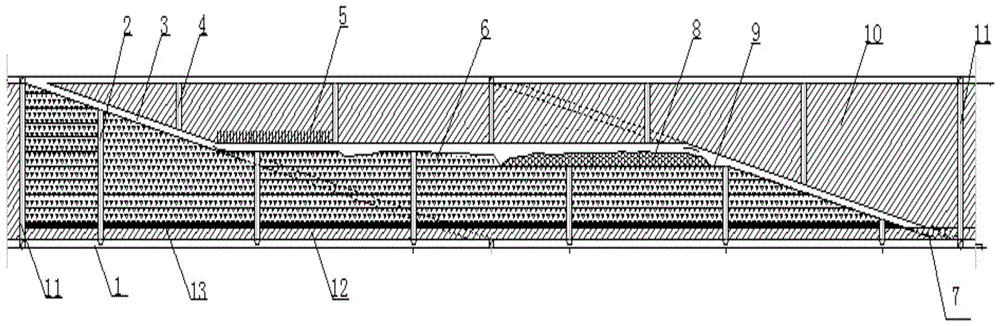

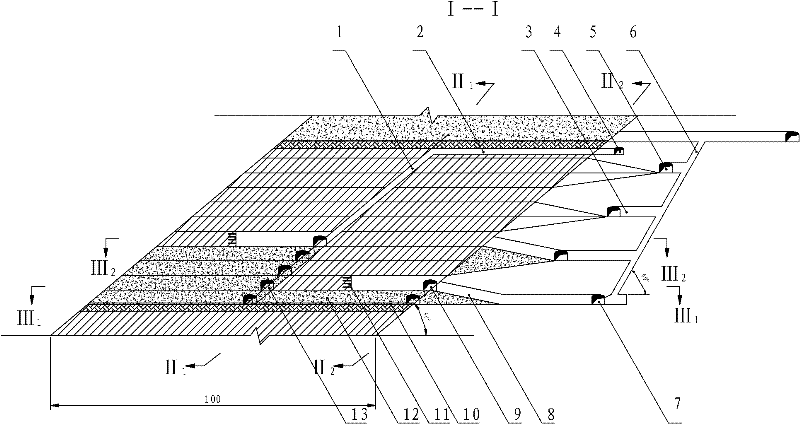

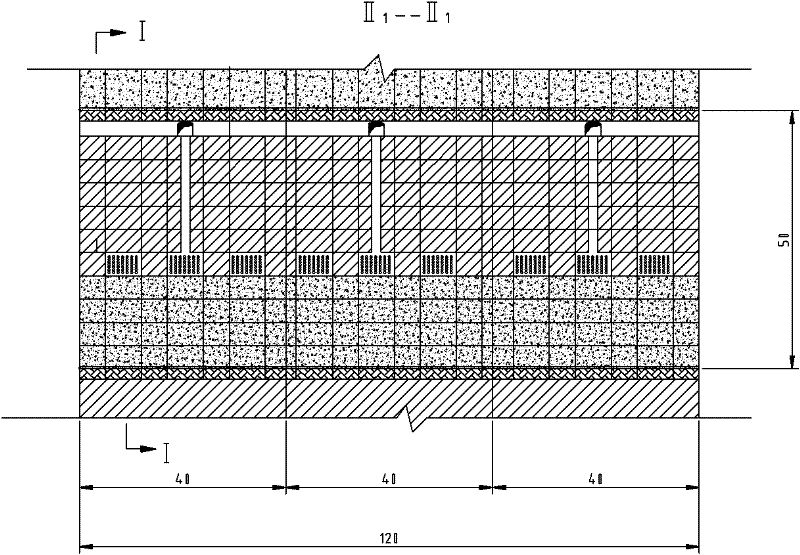

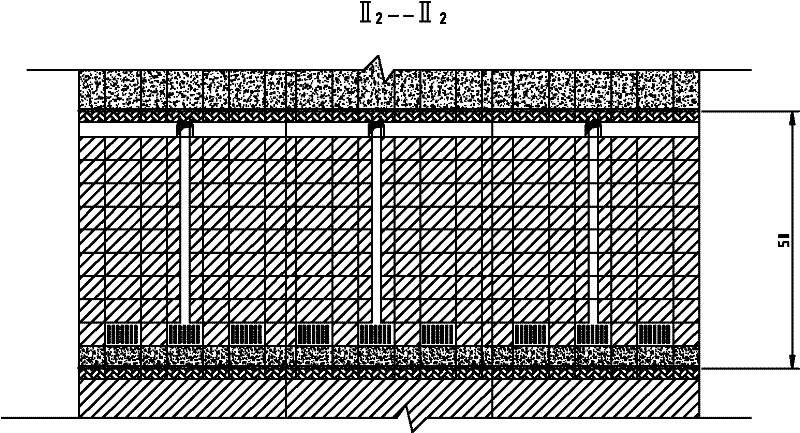

Stepped non-pillar continuous filling mining method for deep well super high large breaking ore body panel

InactiveCN101818643ASafe miningMining guaranteeUnderground miningSurface miningEngineeringCompressive strength

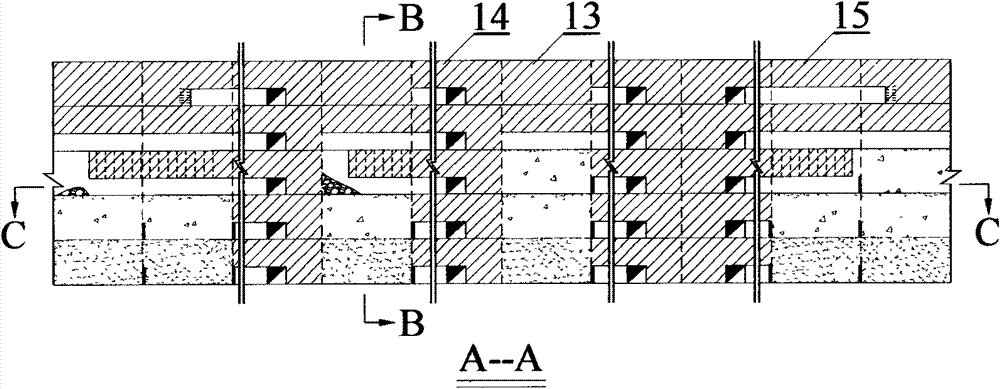

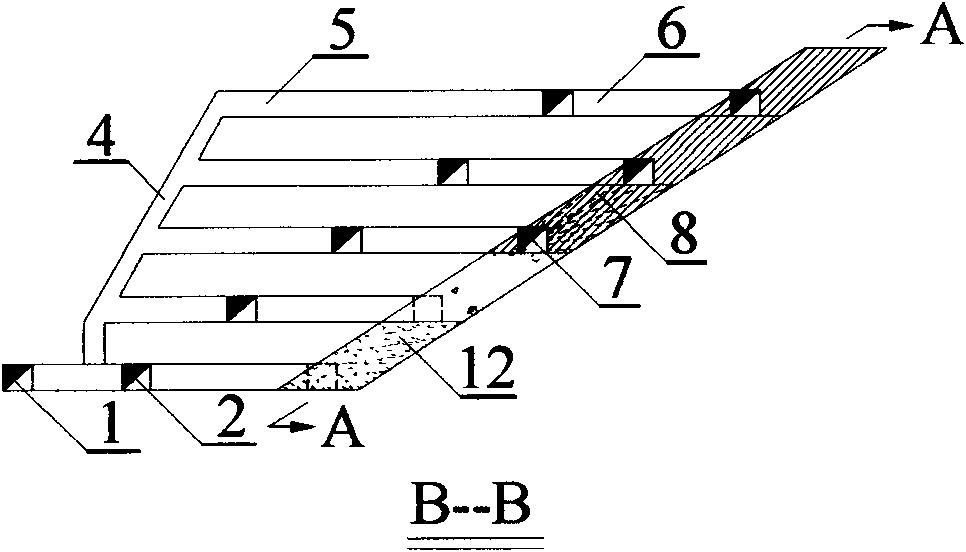

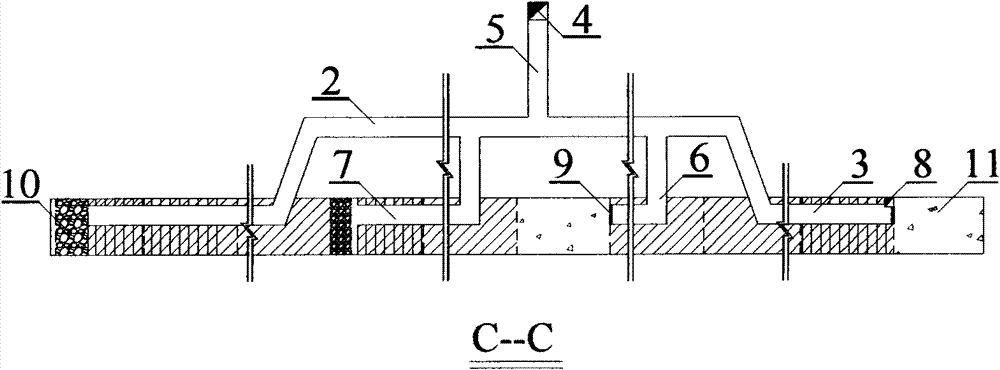

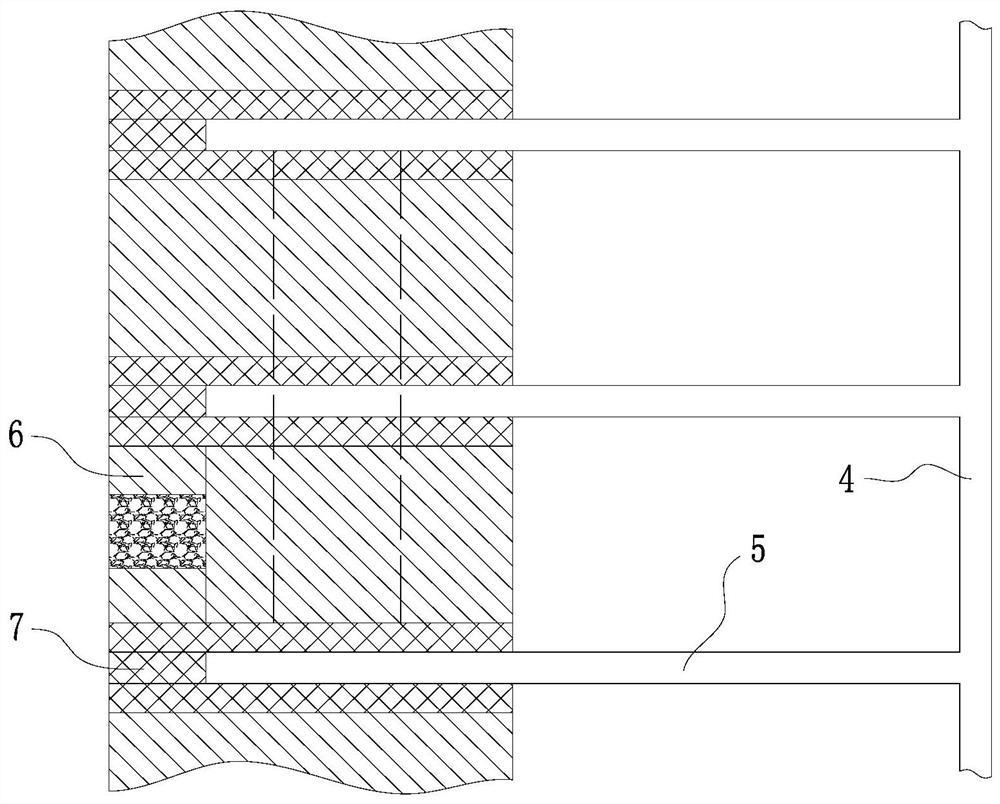

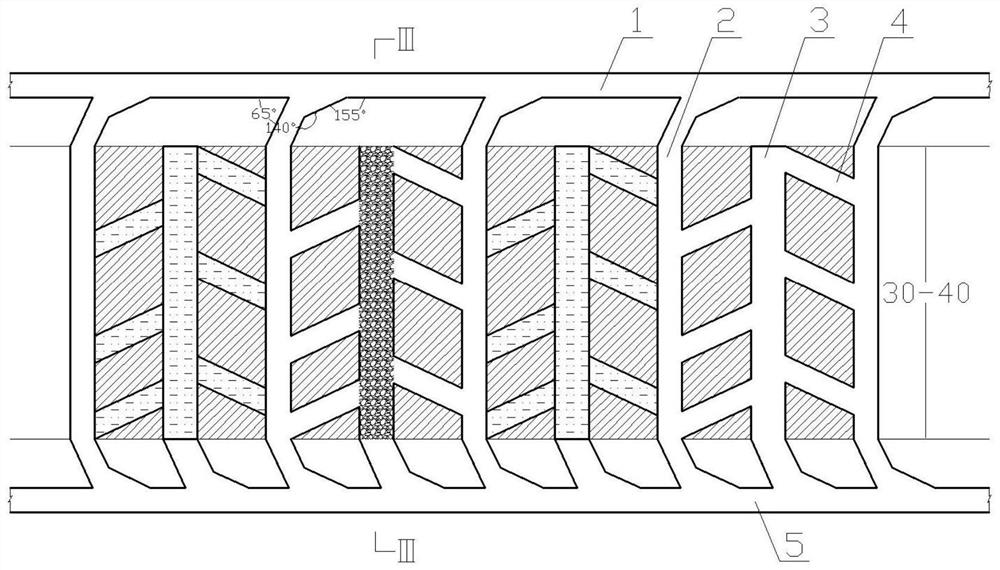

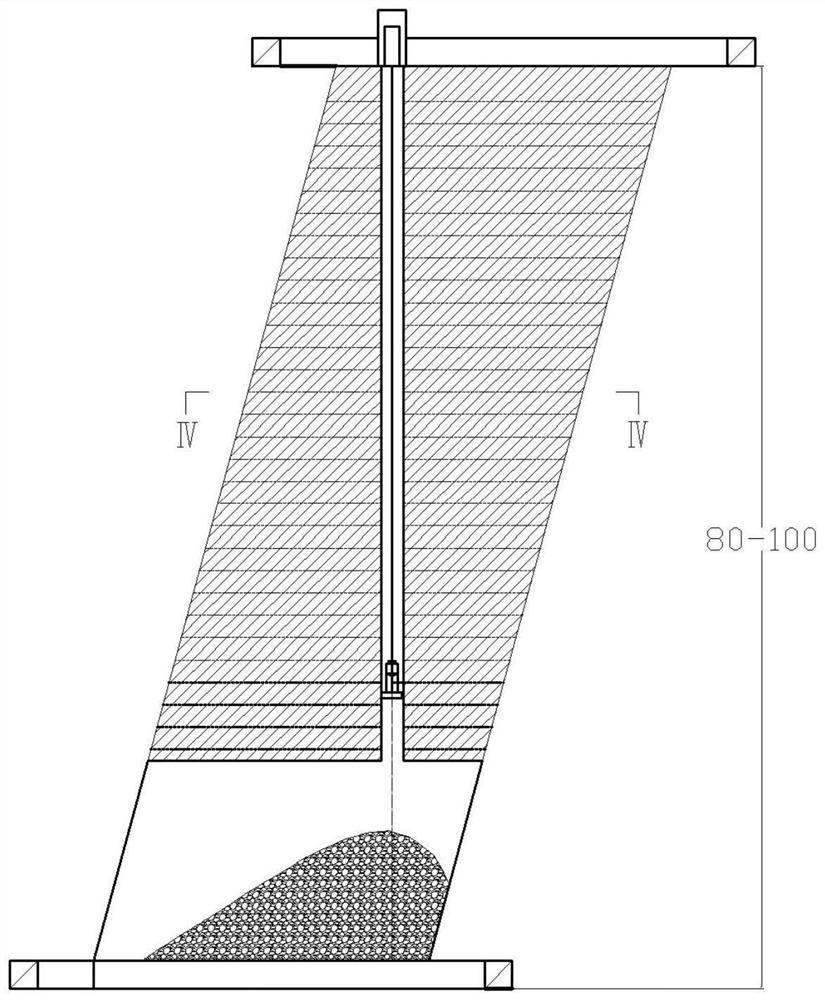

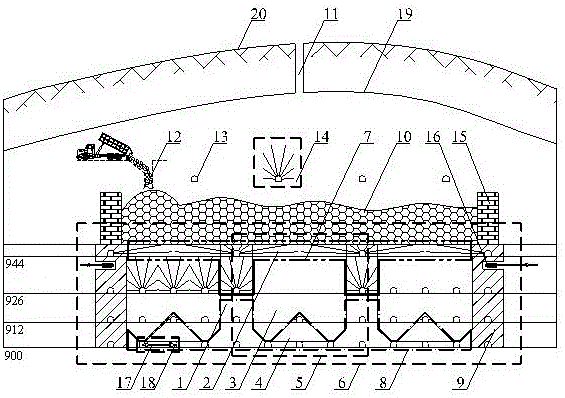

The invention discloses a stepped on-pillar continuous filling mining method for deep well super high large breaking ore body panel. An ore body is divided into a front part and a rear part in a super high large breaking ore body center by an transportation roadway, then the front part and the rear part are respectively divided into a plurality of panels, no pillar exists between pillars, each panel is partitioned into a primary extracting drift and a second extracting drift, the panels in the front part are extracted at first and then the panels in the rear part are extracted, the front and rear panels are extracted in a stepped manner, each production technology is carried out in the same level, and procedures can not influence each other; after the stop back production is finished, the primary extracting drift is filled with cement and the secondary extracting drift is filled by classifying tailings while roof-contacted filling is ensured; and the primary extraction drift and the secondary extraction drift adopt high strength filling topping, and binding materials are added in the filling tailings so as to improve the compression strength of a topping layer. The invention has the characteristics of high extraction safety, small loss and dilution, high mechanical degree, large stope amount, large back production strength, high production capability, short back production time and the like.

Owner:CENT SOUTH UNIV

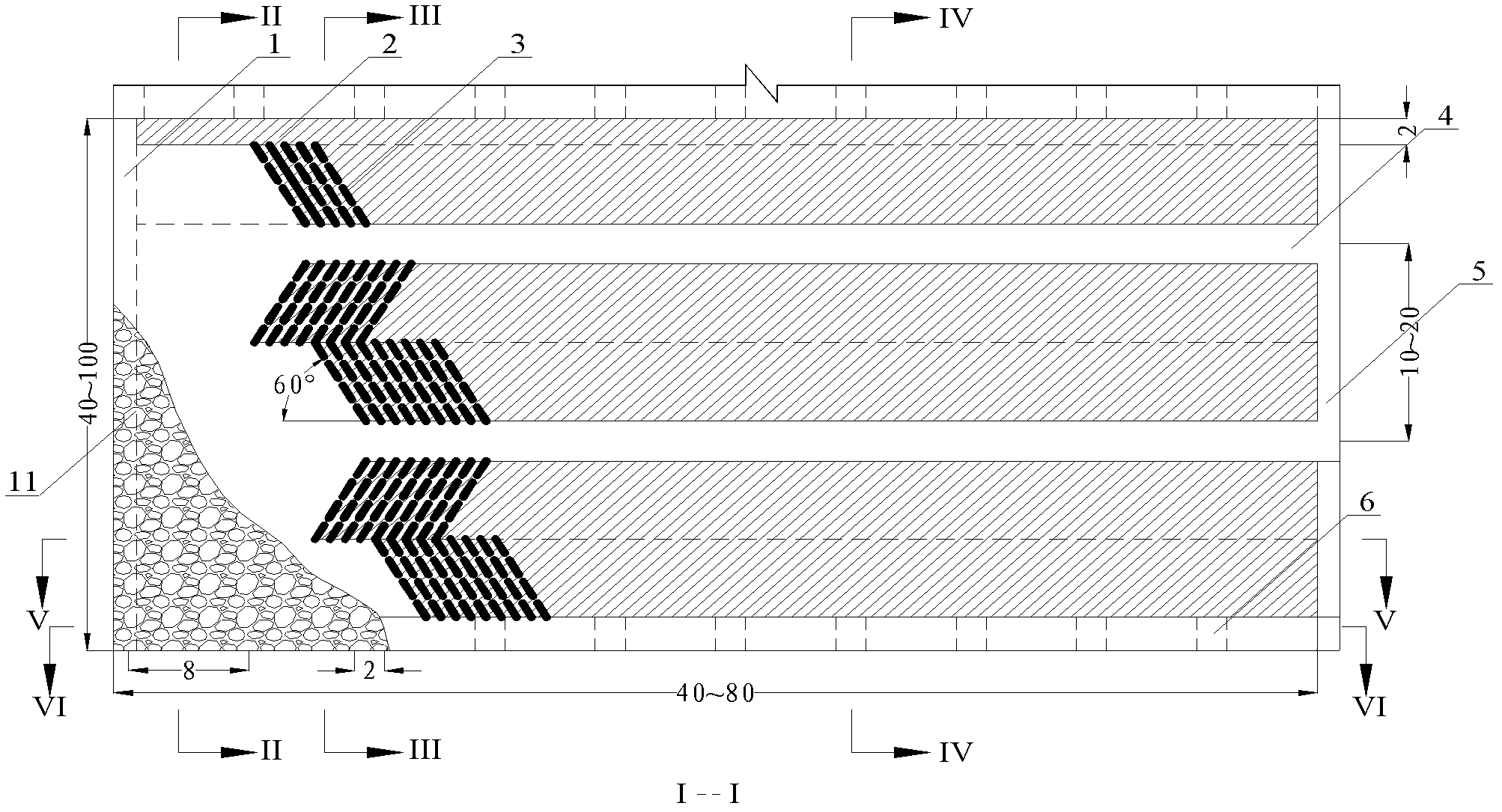

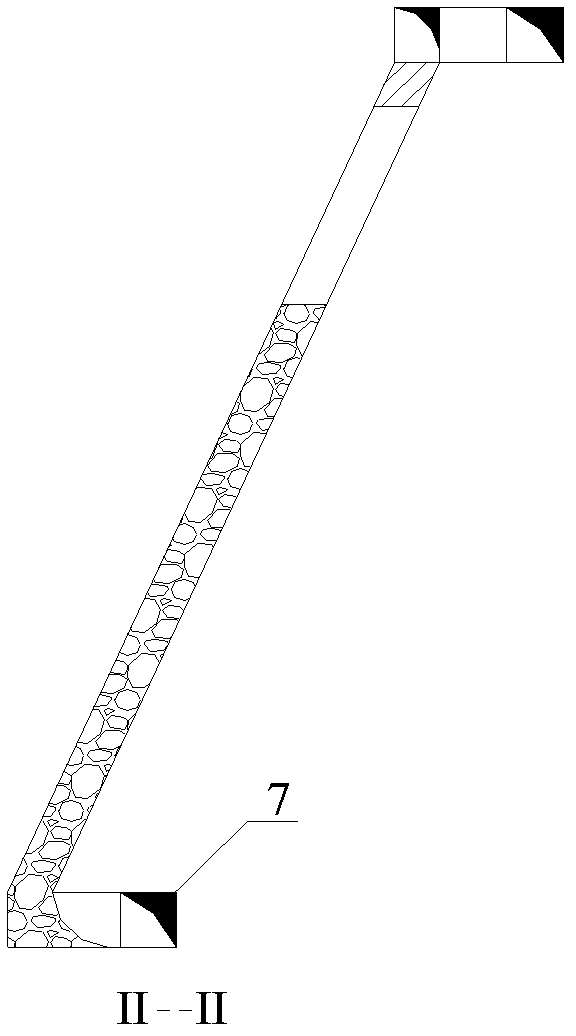

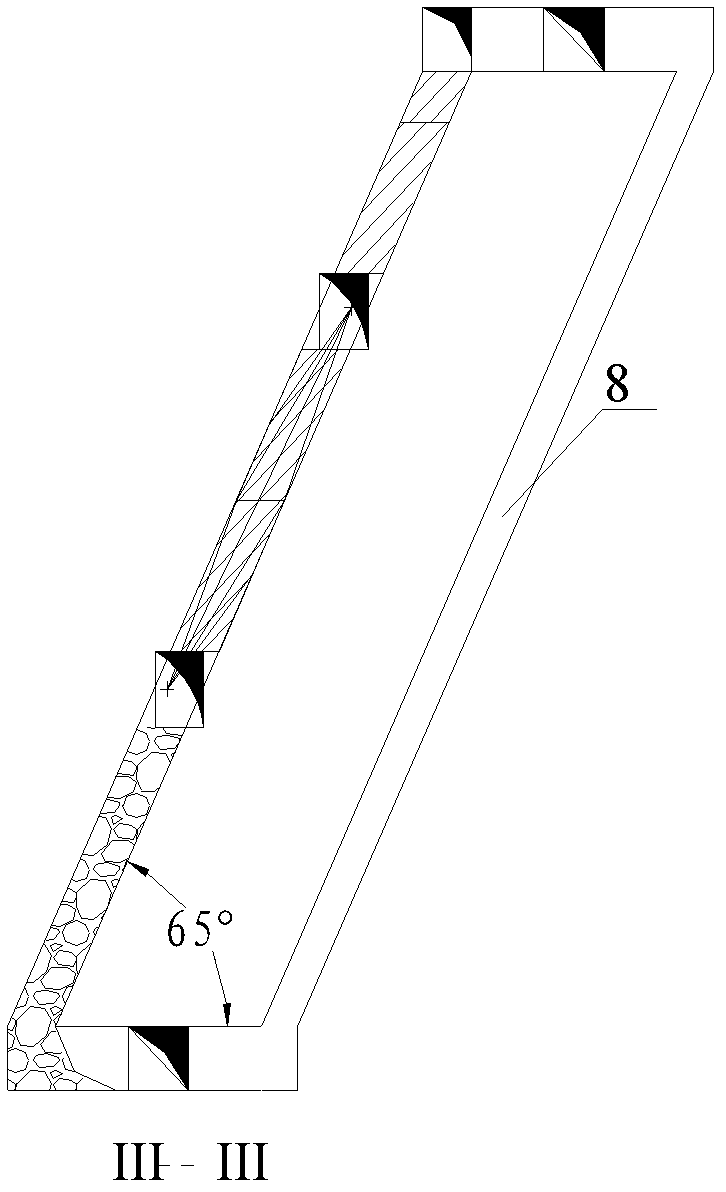

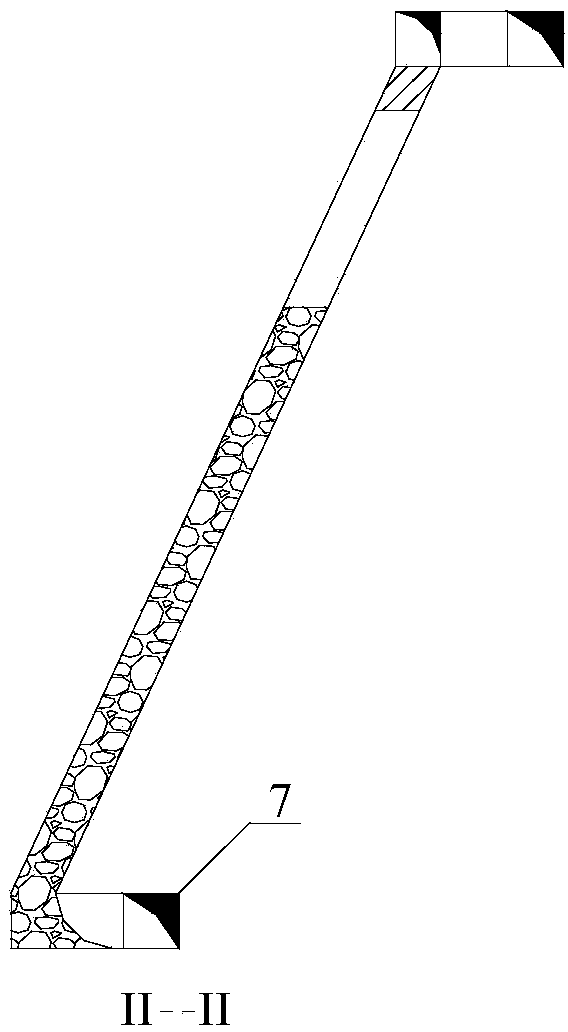

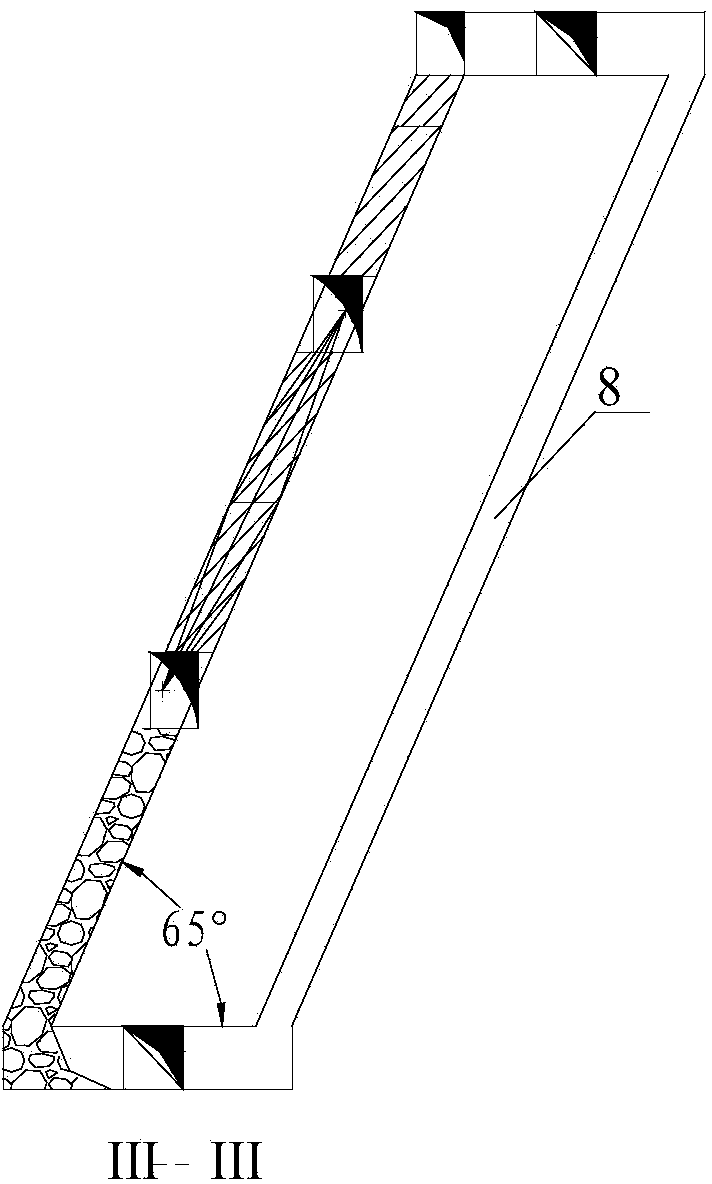

Medium-length hole mining method in multiple blasting free faces of high dipping thin veins

InactiveCN102635356AIncrease job securityStrong mining continuityUnderground miningSurface miningPunchingMineralogy

The invention discloses a medium-length hole mining method in multiple blasting free faces of high dipping thin veins. The medium-length hole mining method is characterized by comprising the steps of: arranging ore blocks along the trend of a core body, dividing the ore body into a medium section and a segment in the altitude; drilling a gate way in the segment and arranging in veins along the ore body; arranging a flat ore removal structure on the bottom along the veins; arranging a cutting raise from one ends of the ore blocks, arranging a manway at the other ends of the ore blocks; and upwards and downwards punching forwards leaning medium-length holes, with the cutting raise as free faces, and blasting caved ores in the segment by multiple free faces, and withdrawing the ore centrally at the bottom. The medium-length hole mining method has the remarkable characteristics of high mining safety, little resource dilution rate, good production continuity, high level of mechanization, low cost, high efficiency, low labor intensity and the like.

Owner:CENT SOUTH UNIV

Central outside-vein house pillar type combined crosscut two-end inside-vein continuous segment filling mining method

InactiveCN102953733AHigh degree of mechanizationReduce labor intensityUnderground miningSurface miningVeinEngineering

The invention discloses a central outside-vein house pillar type combined crosscut two-end inside-vein continuous segment filling mining method for medium-thickness inclined crushed phosphorus ores. The method comprises the following steps: dividing an ore into middle segments, dividing each of the middle segments into panels, dividing each of the panels into segments, dividing the center of each of the segments into ore houses and ore pillars, and dividing two ends of each of the segment along an inside-vein drilling ore-removal level non-pillar into recovery units; adopting a hanging side outside-vein trackless mining system which is formed by a panel ramp, a concentrated ore-removal ore-pass, segment levels at the central outside-vein and shifting to inside-vein at two sides, and an connection lane commonly used by the ore houses and the ore pillars; recovering the ore houses in the middle segments, filling close to back, and recovering the ore pillars; and carrying out parallel operations of technologies comprising drilling, exploding, supporting, ore removal, filling and the like of a plurality of the ore houses to realize continuous mining. The method disclosed in the invention has the substantial characteristics of improvement of the recovery safety and the panel productivity, reduction of the resource dilution rate and the mining-cutting ratio, increase of enterprise benefits and the like.

Owner:彭康

Continuous mining method of medium-thick heavy pitch ore body empty field

ActiveCN104847355AEfficient recyclingRealize continuous miningUnderground miningSurface miningEarth surfaceSubsidence

The invention discloses a continuous mining method of a medium-thick heavy pitch ore body empty field. The continuous mining method includes the following steps: dividing an extraction area and extraction units in the extraction area; determining the total extraction sequence of the extraction area; generally arranging the mining preparation project of the extraction area; cutting and strengthening the mining extraction units; constructing a temporary pillar recovery safe mining environment; recovering temporary pillars step by step. The continuous mining method of the medium-thick heavy pitch ore body empty field can achieve safe, efficient and low-cost mining of the ore body and adopts sectional step-by-step mining; chambers in the extraction area with sectional empty fields are extracted, then pillars in the extraction area are extracted on the basis of building the safe mining environment, so continuous mining in the area is achieved, and the continuous mining method can be applied to the non-consolidated filled mines with allowable surface subsidence, especially is applicable to medium-thick heavy pitch ore body resource extension mining, and can achieve continuous mining.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

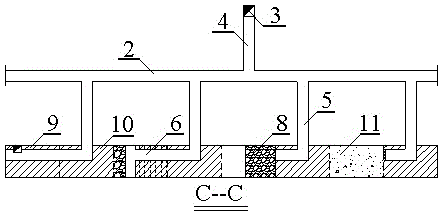

Diskless region type connection roadway continuous sectional cut-and-filling stoping method shared by chamber and jambs

InactiveCN103061768AControl stope pressureIncrease production capacityUnderground miningSurface miningMining engineeringRock cutting

The invention discloses a diskless region type connection roadway continuous sectional cut-and-filling stoping method shared by a chamber and jambs for an inclined fractured ore body with medium thickness. The stoping method comprises the following steps that: the ore body comprises middle sections, wherein each middle section is internally connected with a fragmented transport roadway along the direction of the ore body by adopting a screw type ramp; the fragments separates the chamber and the jambs in a continuous way; and when the chamber is exploited, the connection roadway is advanced towards the centers of the jambs, the level of the ore drift is advanced along the hanging wall of the ore body till reaching the whole chamber, and the chamber and the jambs share one connection roadway; a filling retaining wall is constructed on the joint of the chamber and the jambs after recovery, the cemented filling is carried on a worked-out section from the upper subsection, in the middle sections, the chamber is recovered first and filled close the back, and then the jambs are recovered; after the jambs are recovered, a filling retaining wall is constructed in the connection roadway after recovery of the jambs, and non-cemented or cemented surfaces with thickness of 1m are used for filling; and continuous mining is realized through a plurality of technological parallel workings including drilling, blasting, supporting, ore removal, filling and the like in one subjection. The method provided by the invention has the remarkable characteristics of low accurate mining ratio, low ore loss factor, safety and efficiency, capacity of increasing enterprise revenues and the like.

Owner:彭康

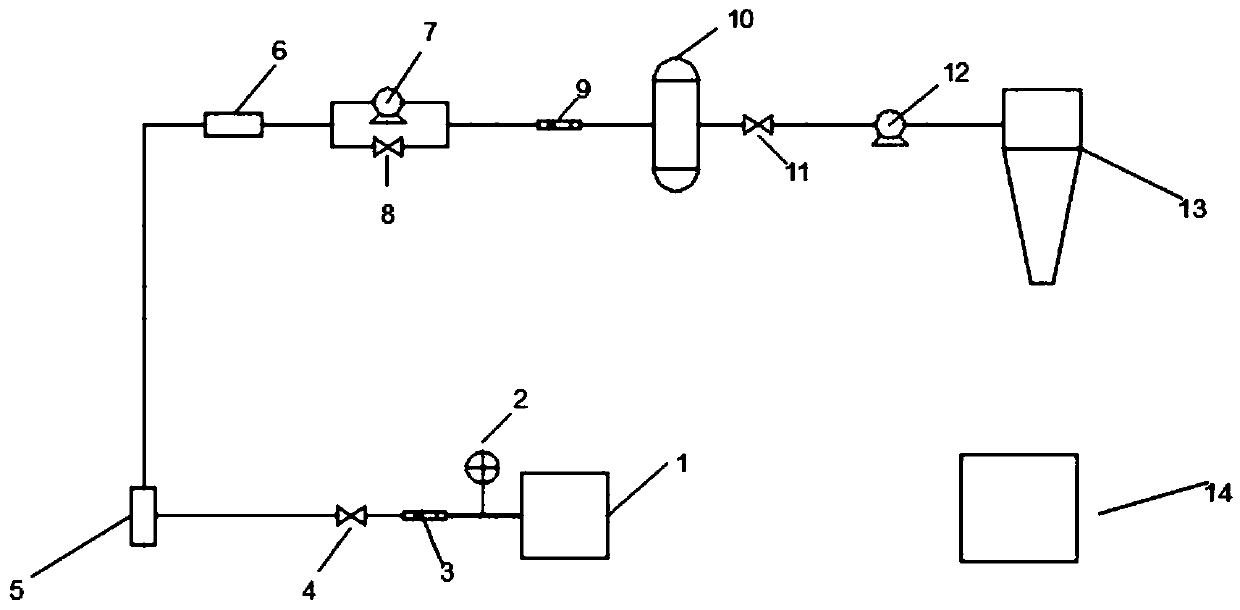

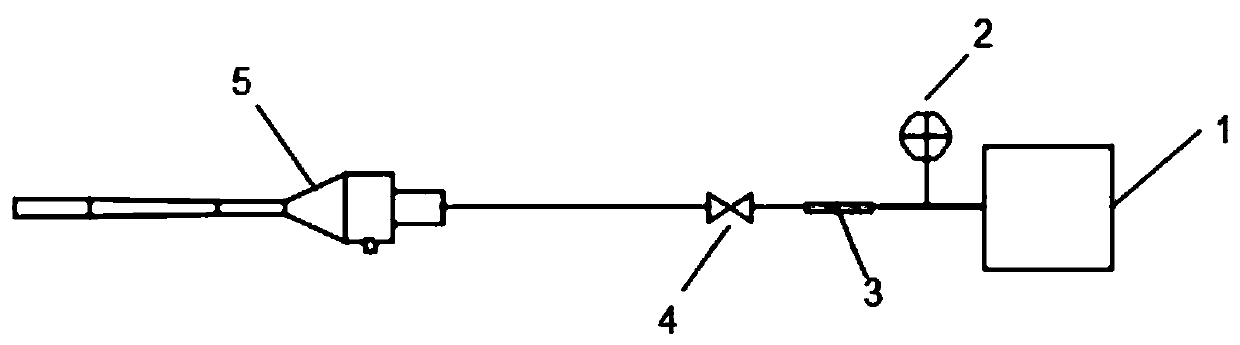

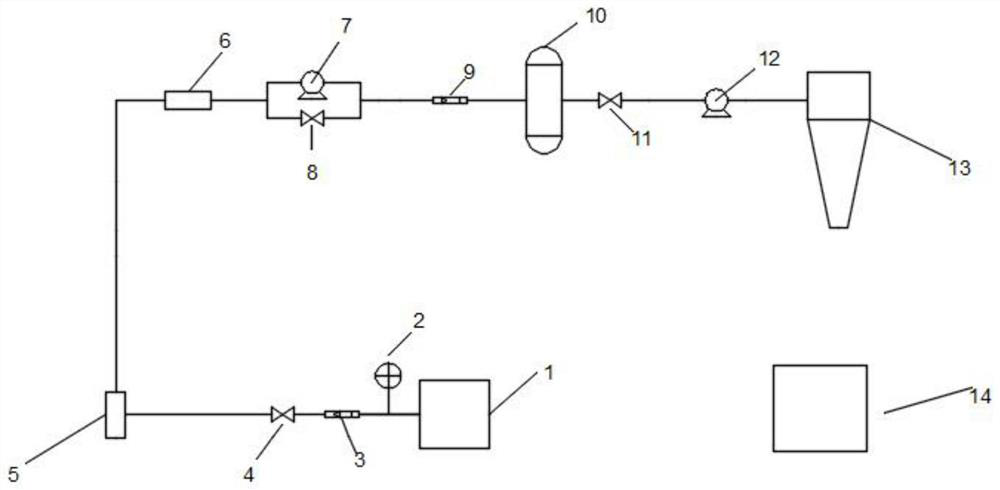

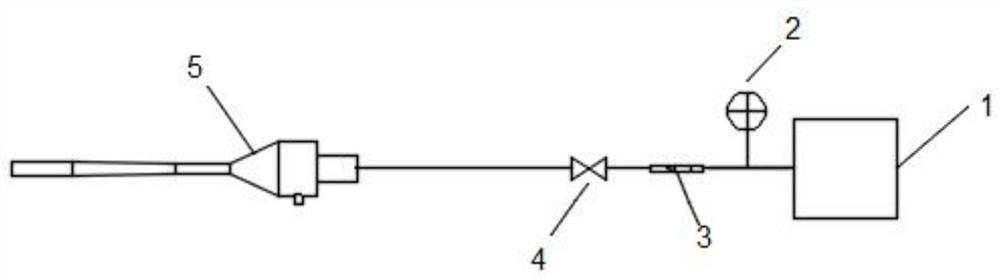

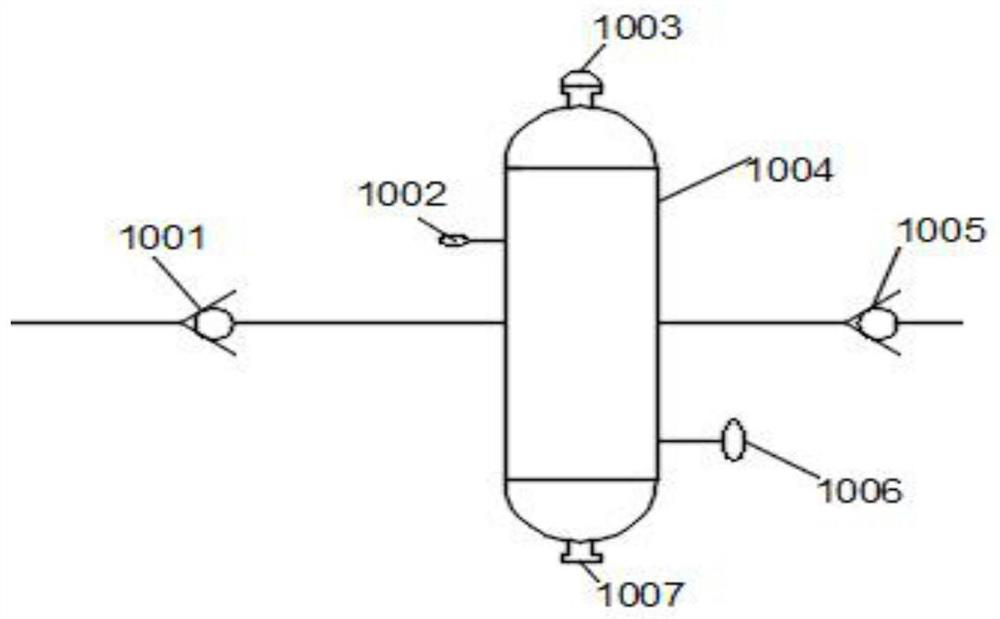

Oil well sand removal device based on pulsed jet technology and hydrocyclone separation mechanism

The invention belongs to the field of oil well drilling and workover development, and particularly relates to an oil well sand removal device based on a pulsed jet technology and a hydrocyclone separation mechanism. The main structures of the oil well sand removal device include a pulsed jet sand pumping system, a ground buffer system, a three-phase hydrocyclone deaeration and sand removal system,a connecting pipeline, a control system and a power system. A jet pump is adopted to change traditional hydraulic sand washing into hydraulic sand suction, during the downhole sand removal operation,working fluid enters the jet pump at a high speed from a working fluid inlet pipe and passes through a throat pipe of the jet pump at a high speed, a low pressure area in which the pressure is lowerthan the pressure in a well is formed inside the throat pipe, so that mixed fluid mixed up with a large amount of sand is sucked into the jet pump, and high-speed fluid does not carry part of oil gas,sand and the like to rush into an oil reservoir to damage the formation structure and affect the exploitation of petroleum and the like; and the system can realize the intelligent control over a whole sand removal system, greatly reduces the labor intensity of workers and improves the sand removal efficiency of a downhole and the yield of an oil well.

Owner:SHANDONG UNIV OF SCI & TECH

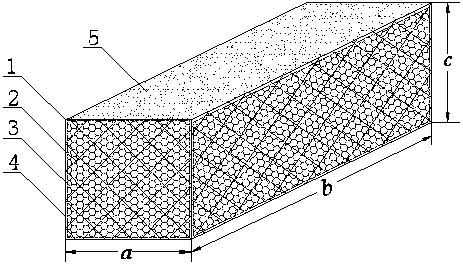

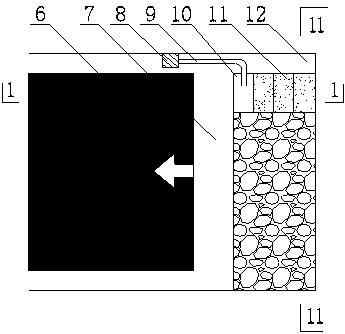

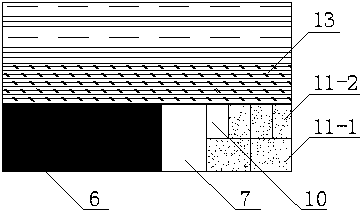

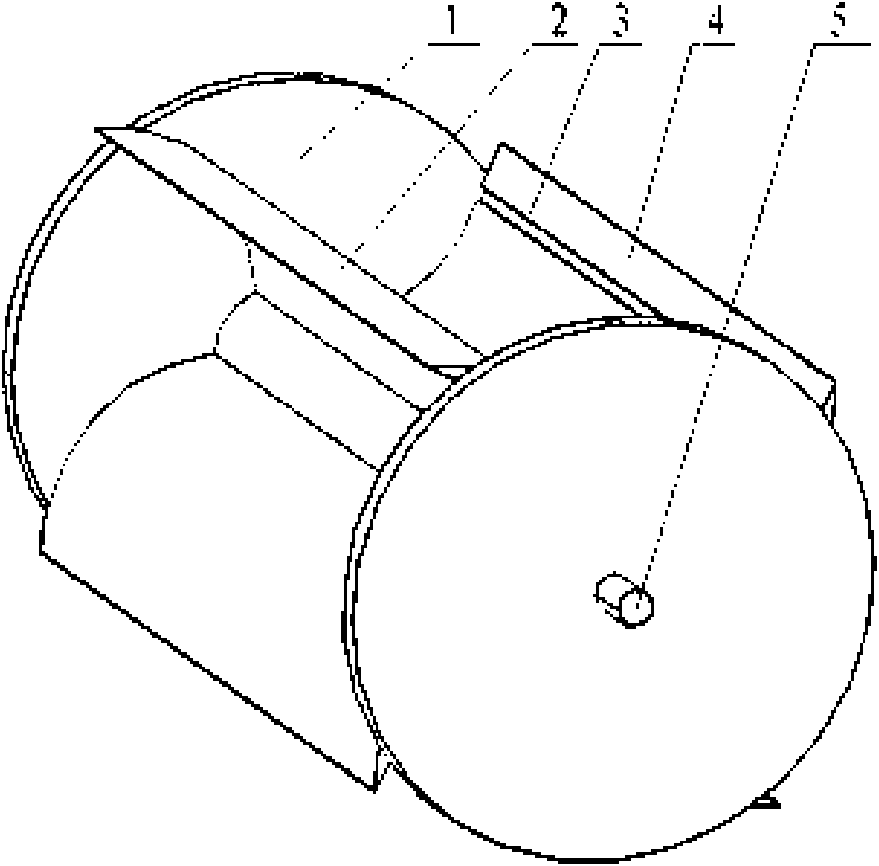

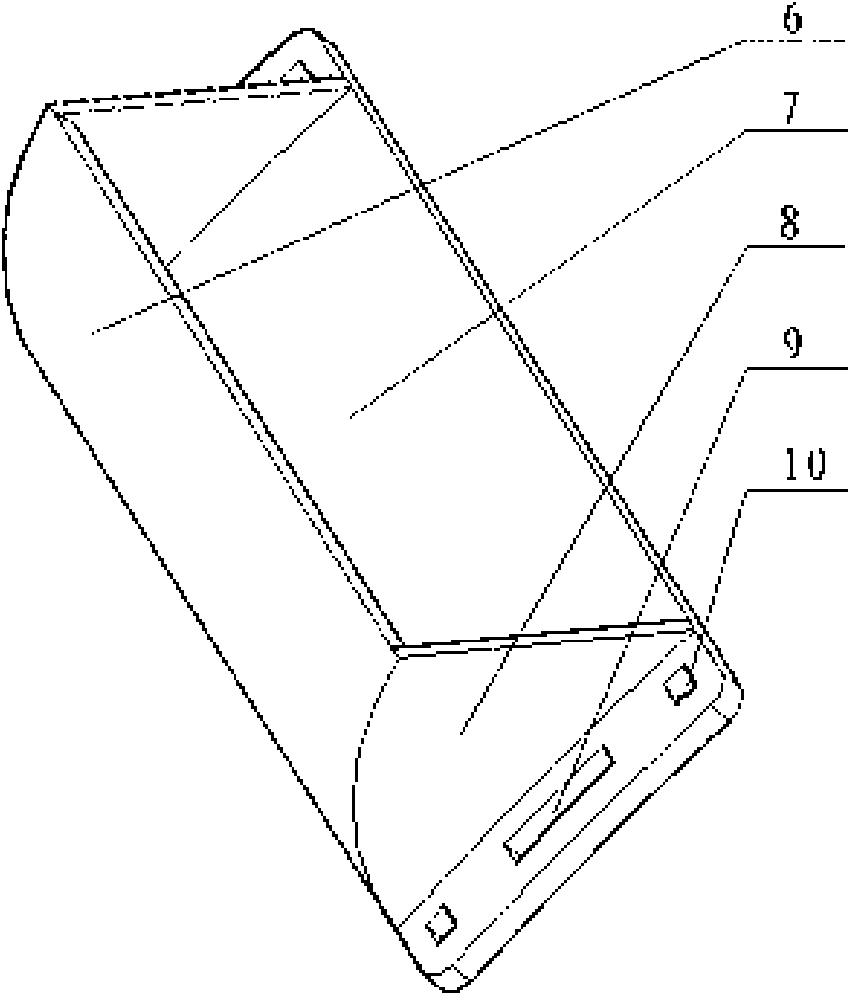

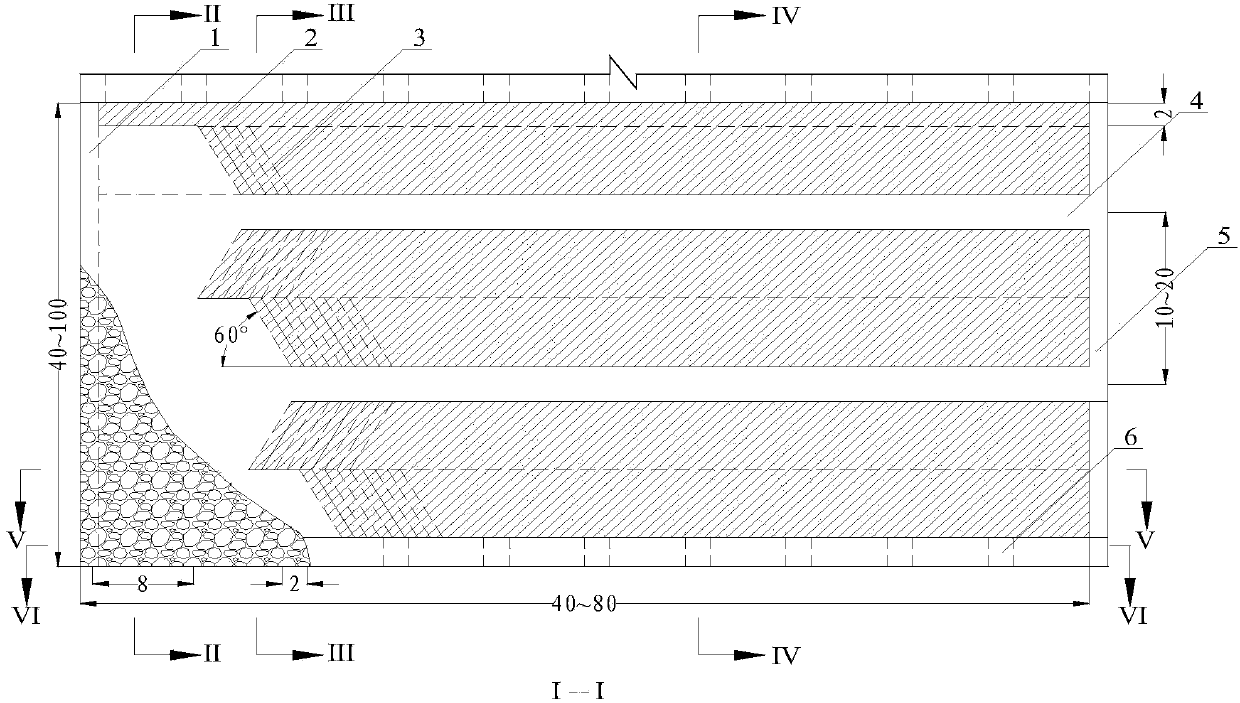

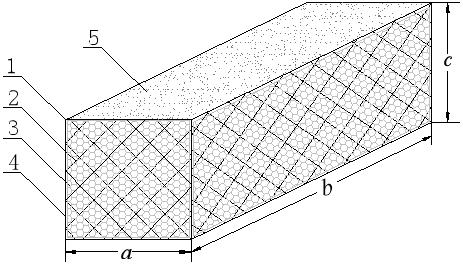

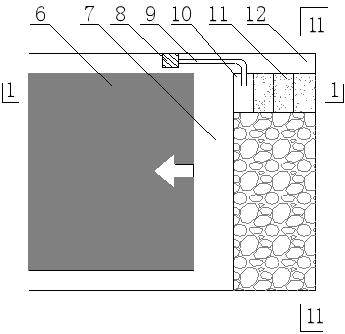

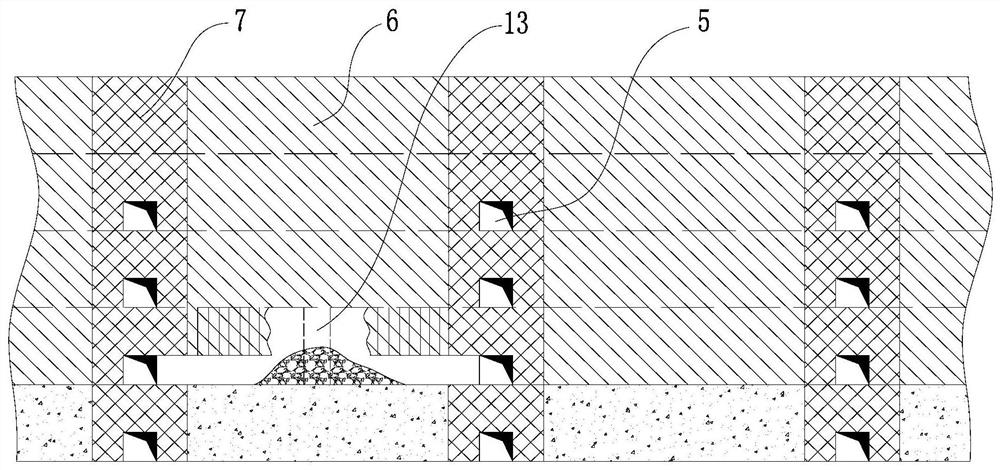

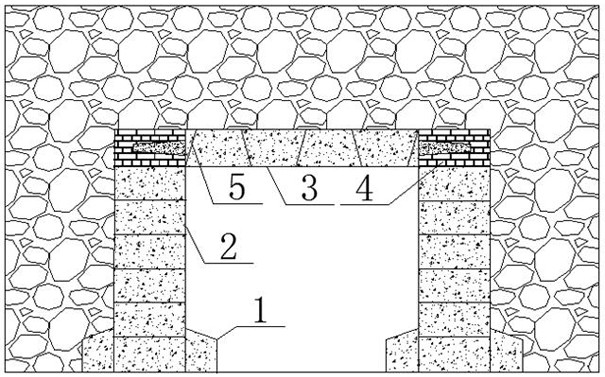

Method for constructing wall body for retaining and protecting roadway along goaf by filling net cage with aeolian sand

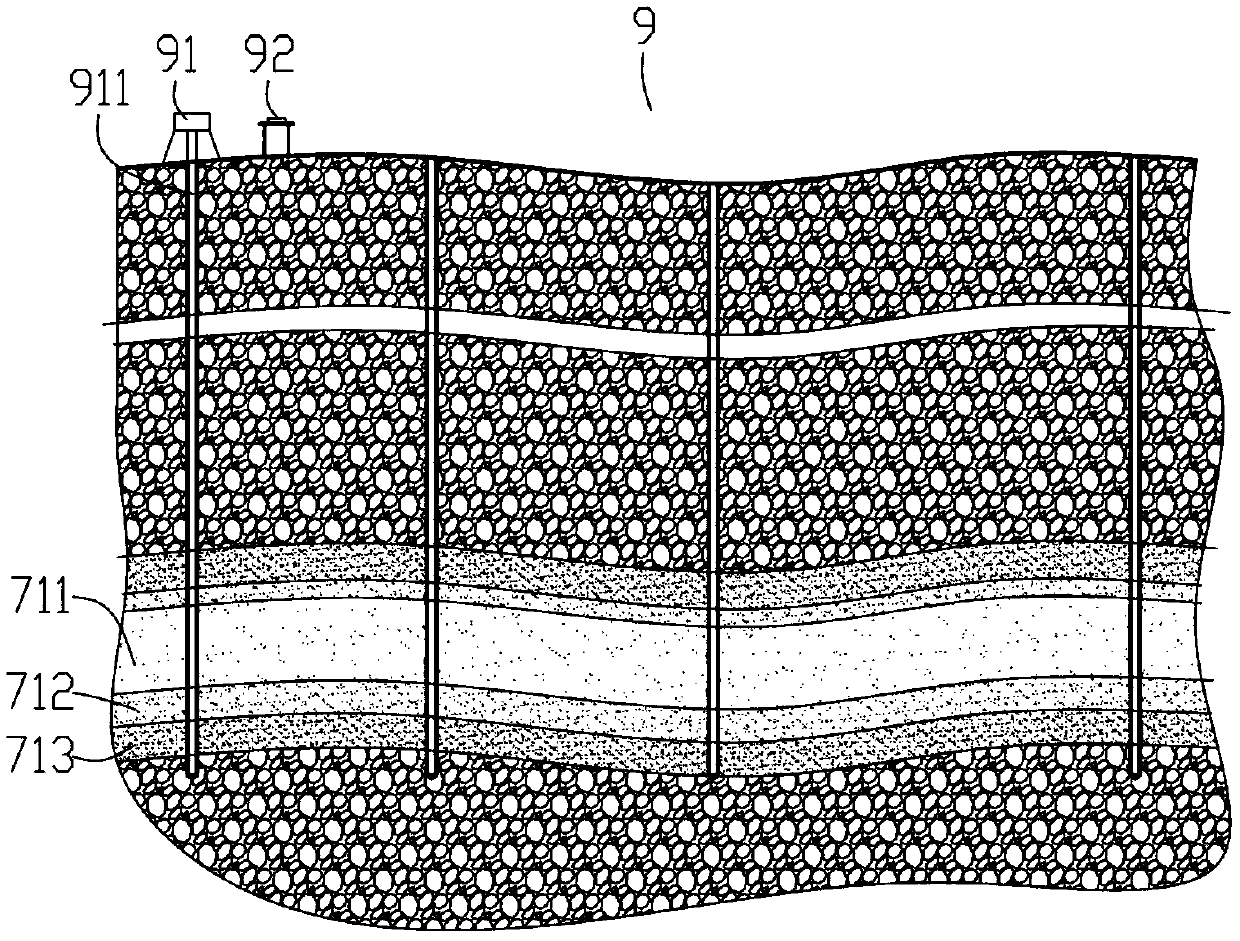

ActiveCN109268063AReduce construction costsGuaranteed support effectMining devicesMaterial fill-upEcological environmentWater resources

The invention relates to a method for constructing a wall body for retaining and protecting a roadway along a goaf by filling a net cage with aeolian sand. The method includes the following steps: firstly, filling the net cage to be filled which consists of a steel wire net cage and geotextile and is closed at four corners and opened at the upper part with the aeolian sand, vibrating and compacting, wherein the aeolian sand has the bearing capacity due to lateral restraint provided by the steel wire net cage and the geotextile; and effectively controlling the rotation and subsidence of roof strata of the retained roadway along the goaf after the wall body for retaining and protecting the roadway along the goaf built by the net cage filled with the aeolian sand is connected to the roof. According to the method for constructing the wall body for retaining and protecting the roadway along the goaf by filling the net cage with the aeolian sand, on the premise of not consuming water resources, the bearing performance of the aeolian sand is fully brought into play, and the effective support from the wall body for retaining and protecting the roadway along the goaf constructed by fillingthe net cage with the aeolian sand to the roof strata of the retained roadway along the goaf is guaranteed, so that the cost of retained the roadway along the goaf in the desertified arid mining areais reduced, the coal resource extraction rate in the mining area is improved, and meanwhile, the influence and damage of mining activities on the water resources and the local ecological environment are reduced.

Owner:XINJIANG UNIVERSITY

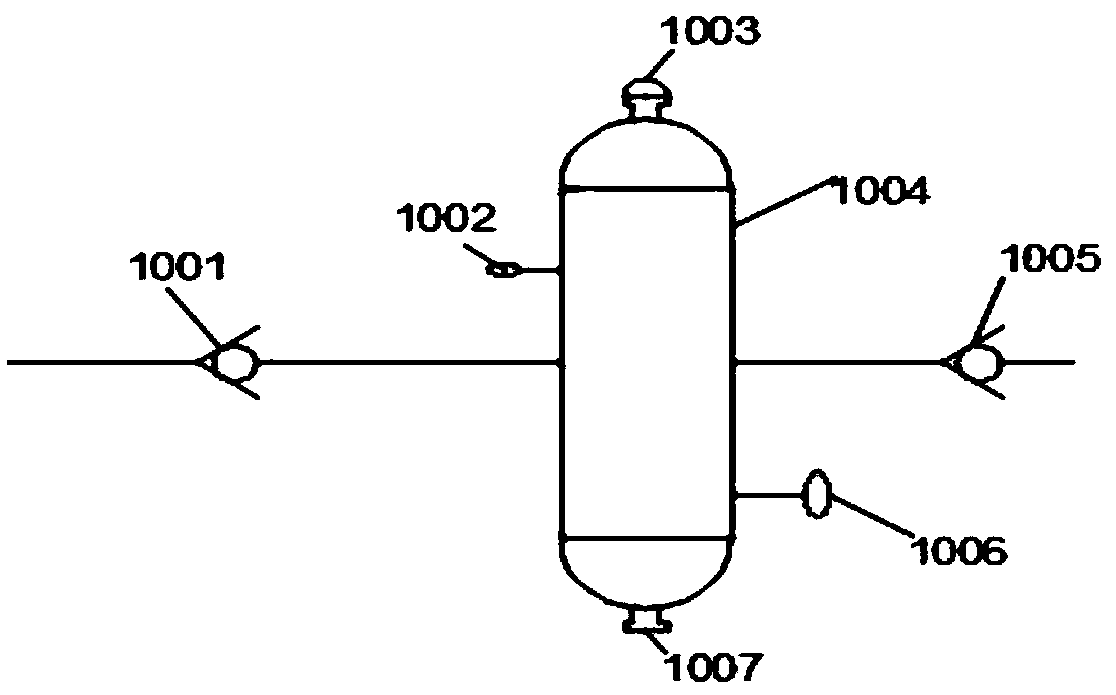

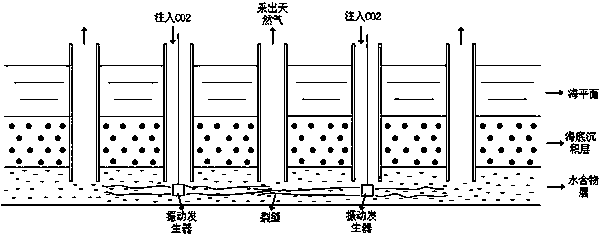

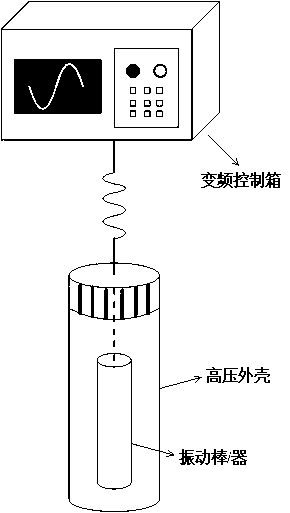

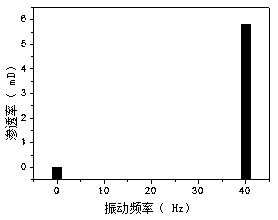

Method of combining gas replacement with vibration field for extracting natural gas hydrate reservoir

ActiveCN108952639AImprove seepage capacityImprove speed and efficiencyConstructionsFluid removalProduct gasNatural gas

The invention discloses a method of combining gas replacement with a vibration field for extracting a natural gas hydrate reservoir. The method includes the steps that (1) a CO2 medium injection welland a natural gas production well are deployed on the natural gas hydrate reservoir; (2) partial free gas is extracted, and the pressure of the hydrate reservoir is decreased to 3-5 MPa; (3) a vibrator is put into the hydrate reservoir, and a CO2 medium is injected into the reservoir to achieve replacement of the natural gas in hydrates; (4) the vibrator is continuously or intermittently turned on, and vibration waves are utilized to promote dispersion of CO2 in a settled layer; (5) when the concentration of CO2 in the free gas of the reservoir is unchanged or changes slowly, the work load ofthe vibrator is increased, and the energy of the vibration waves is utilized to generate cracks in a CO2-natural gas hydrate mixed reservoir and the hydrate reservoir; (6) when the concentration of CO2 in the free gas of the hydrate reservoir is lower than 30 mol%, production of natural gas is carried out. By means of the method, the efficiency of CO2 medium replacement for extraction of natural gas hydrates can be improved, and the speed of the CO2 medium replacement for the extraction of the natural gas hydrates can be increased. Meanwhile, the stability of the reservoirs is maintained, anda broad application prospect is provided.

Owner:SOUTHWEST PETROLEUM UNIV

Drum-type continuous excavator

InactiveCN101851938ARealize continuous miningStrengthen excavationConveyorsMechanical machines/dredgersControl systemClosed loop

The invention relates to a drum-type continuous excavator, which comprises a power system, a control system and an excavation system, wherein the excavation system comprises a bucket. The invention is characterized in that the bucket is a drum-type bucket, the oblique lower part of the drum-type bucket is connected with the low end of a chain-type closed-loop loading system formed by a driving chain wheel installed at the upper part of a frame, a guide chain wheel installed at the lower part of the frame and a plurality of loading buckets and chains. The invention has the advantages that the continuous excavation can be realized, the operating speed is fast and the work efficiency is high. The drum-type continuous excavator is particularly suitable for construction in sandy soil fields and muddy fields, removal and transportation of construction wastes on construction sites and the like.

Owner:黄银飞

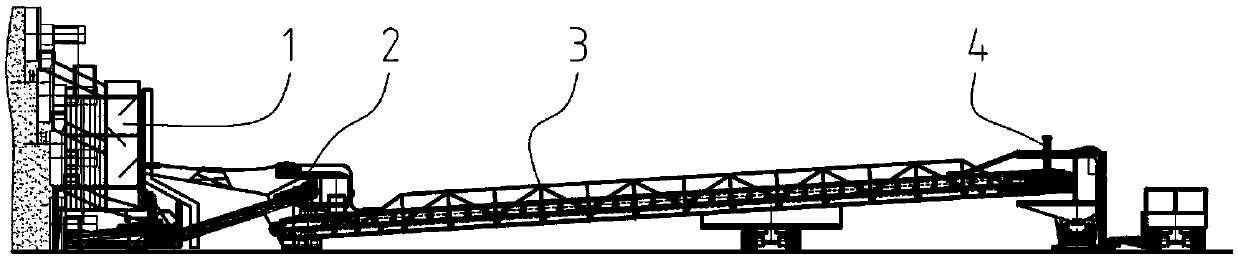

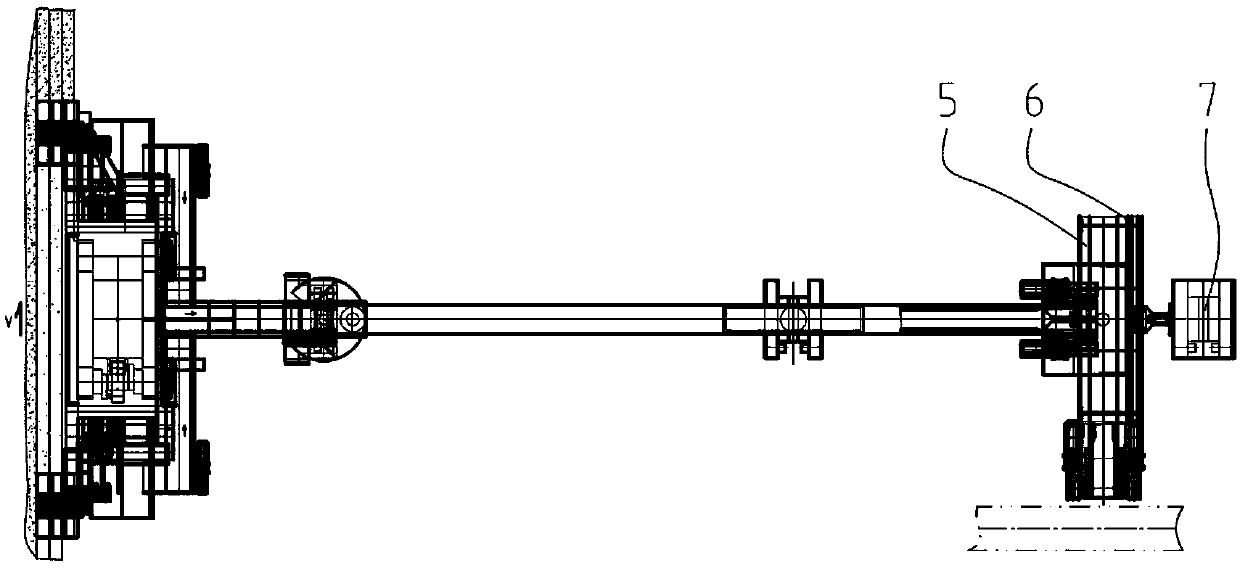

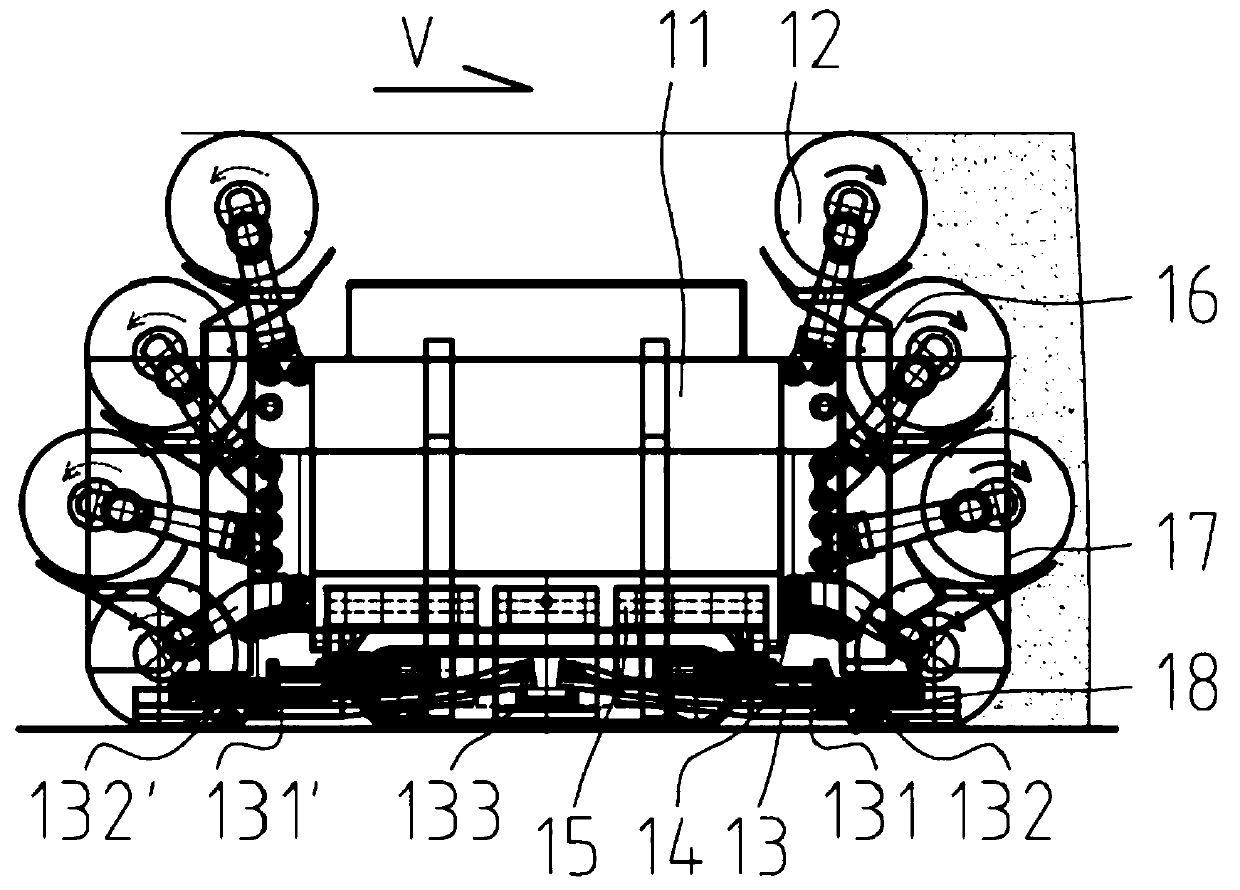

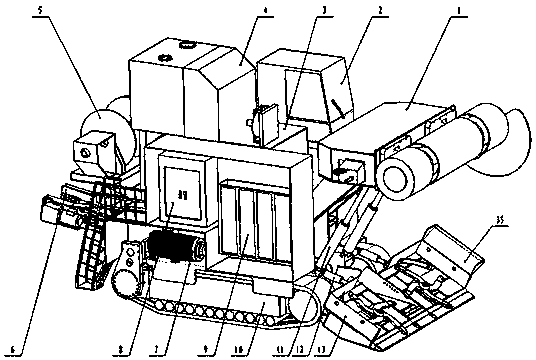

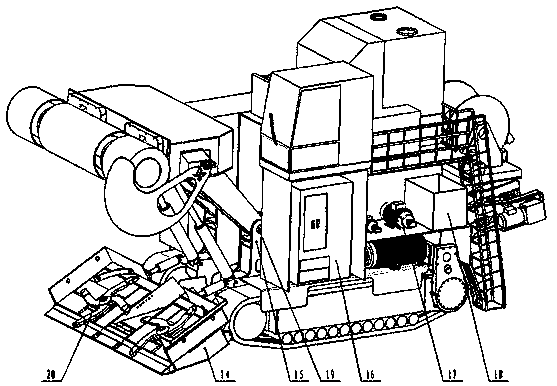

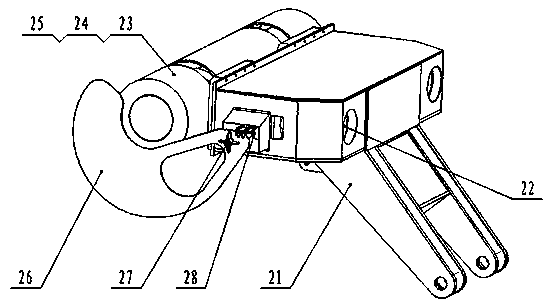

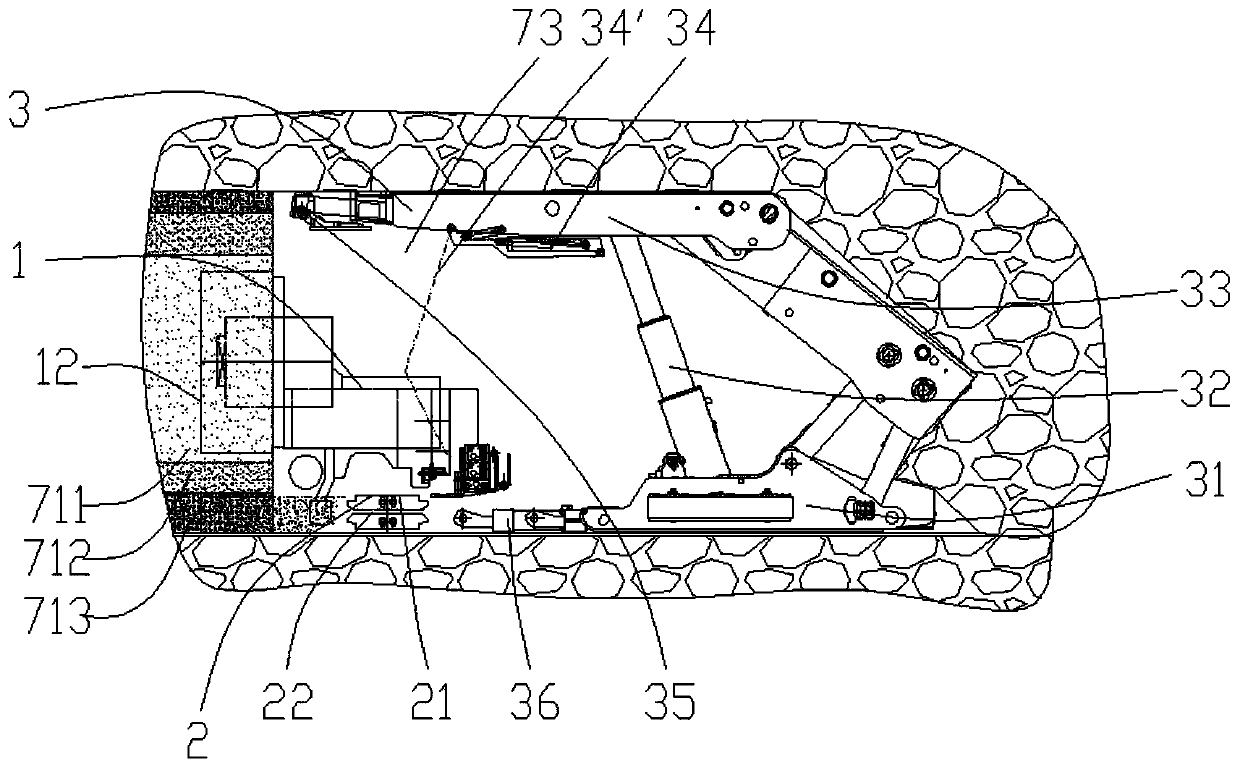

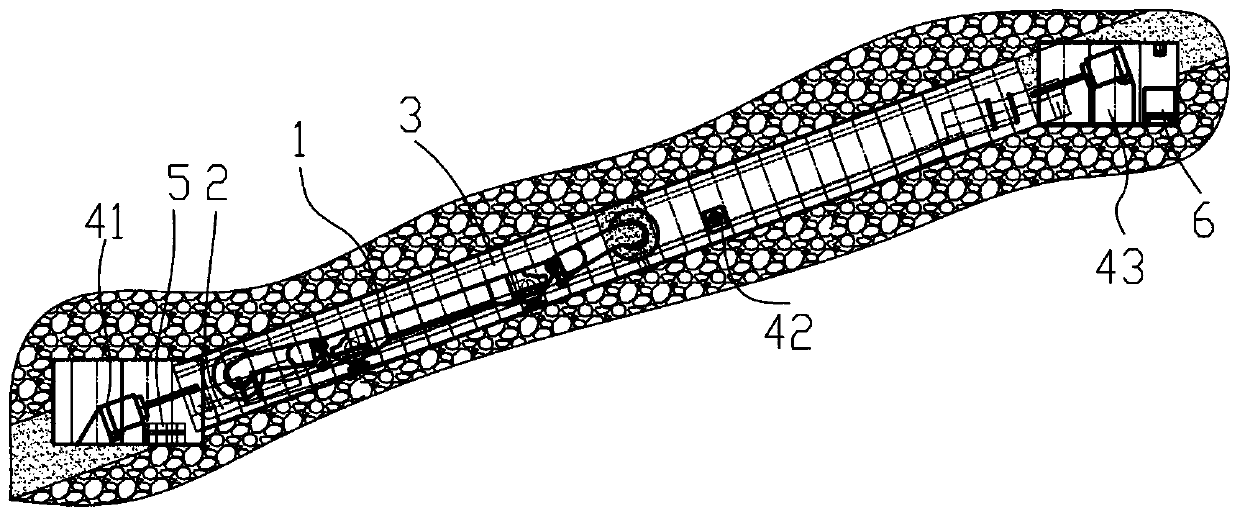

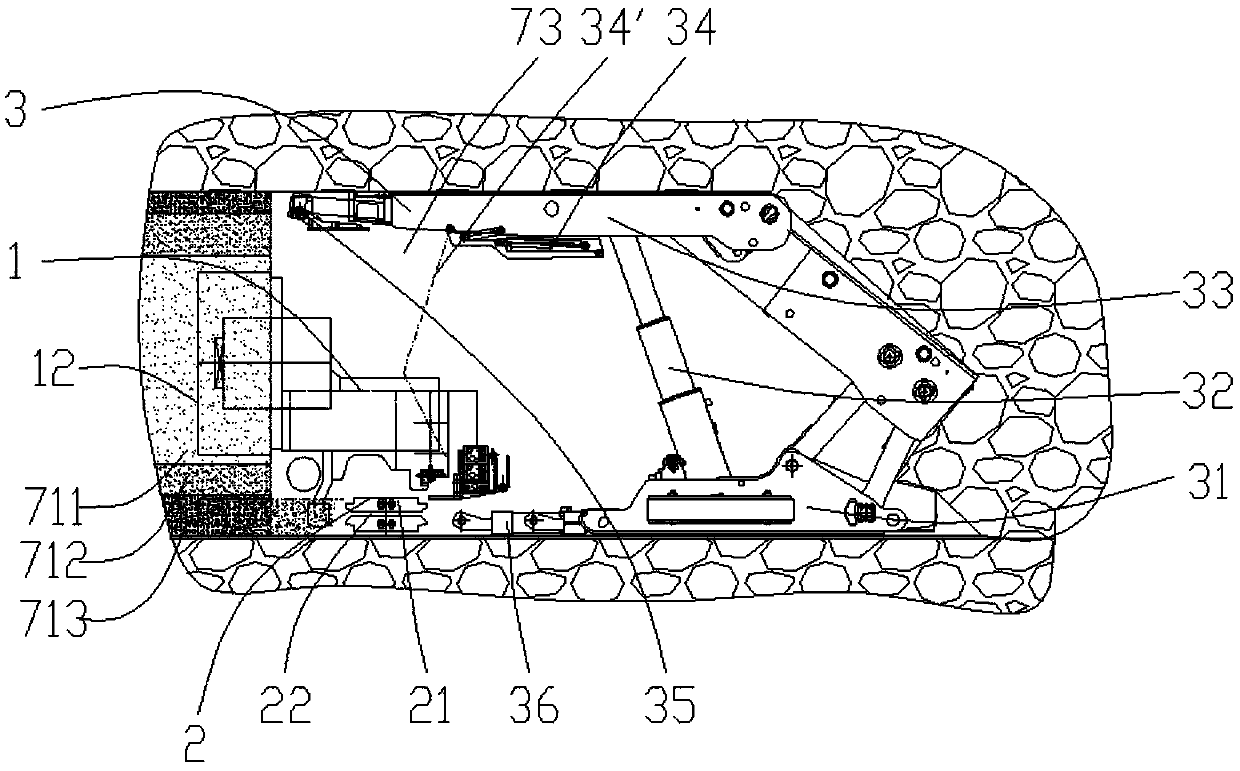

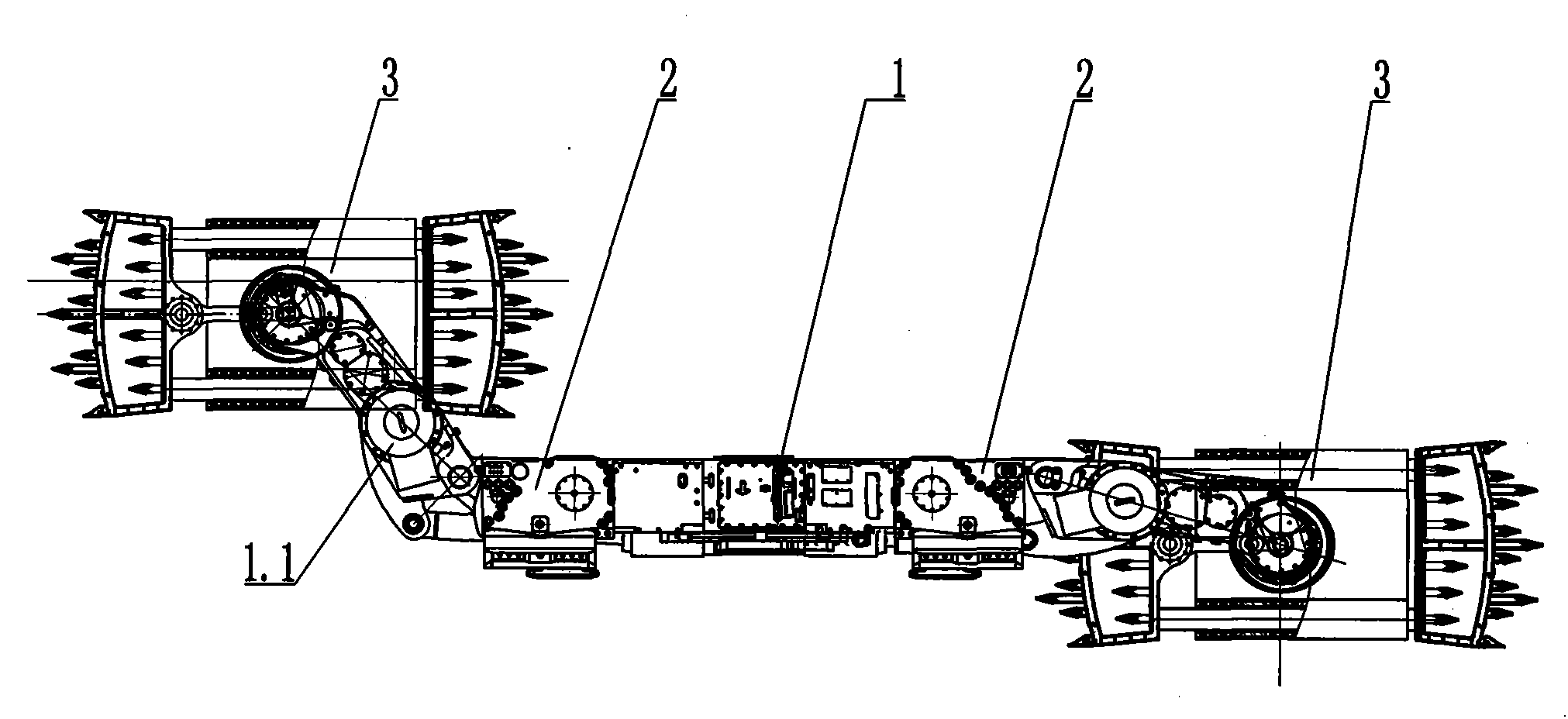

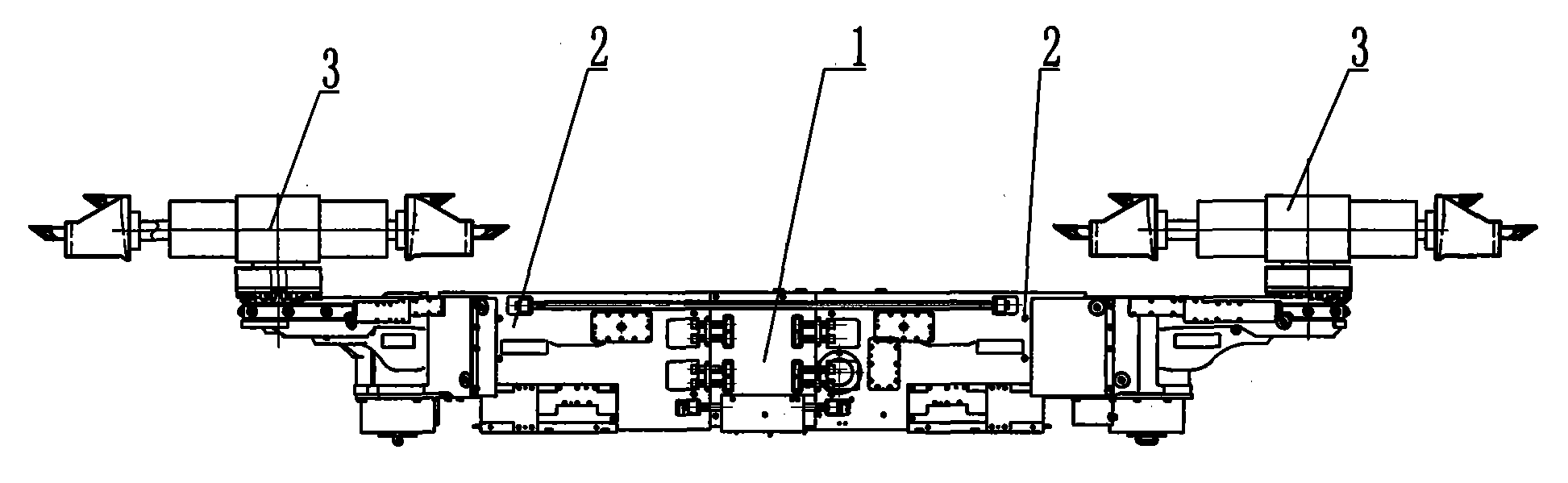

Strip mine continuous mining system

PendingCN108678748ARealize continuous miningRealize continuous reprintOpen-pit miningPropulsionEngineeringMechanical engineering

The invention relates to a strip mine continuous mining system. The strip mine continuous mining system comprises a mining machine, a transfer loading conveyor and a working face conveyor, the rear end of a middle conveying device of the mining machine is hinged with the front end of the transfer loading conveyor through a front-stage connection mechanism, the hinging axis extends vertically, therear end of the middle conveying device is located on the upper position, universal wheels are arranged at at least one position below the main body of the transfer loading conveyor, the rear end of the transfer loading conveyor is hinged with a back-stage connection mechanism, the hinging axis extends vertically, the back-stage connection mechanism is provided with a back-stage material receivinghopper, the back-stage material receiving hopper is located below the rear end of the transfer loading conveyor, an unloading port of the back-stage material receiving hopper is located above the working face conveyor, the working face conveyor extends left and right, and the back-stage connection mechanism is slidably connected relative to the left and right directions of the working face conveyor. The strip mine continuous mining system can achieve all procedures of cutting, collecting, conveying in a host machine, transfer loading, working face conveying and the like, is low in purchasingand management cost, easy to maintain, and particularly suitable for mining small and medium-sized mine ore deposits.

Owner:SHANGHAI BRANCH TIANDI SCI&TECH CO LTD +1

Downward parallel middle-deep hole sublevel fill stoping mining method for steep and medium-thick hard-to-mine ore body

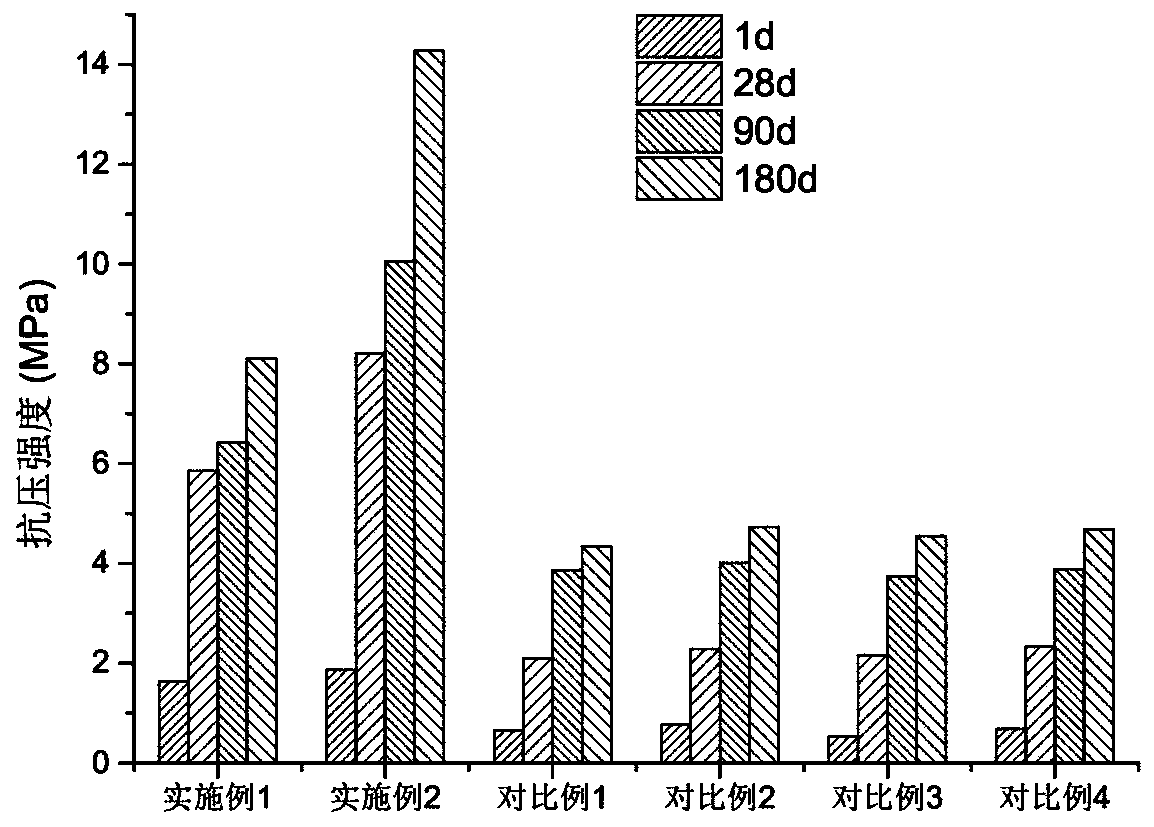

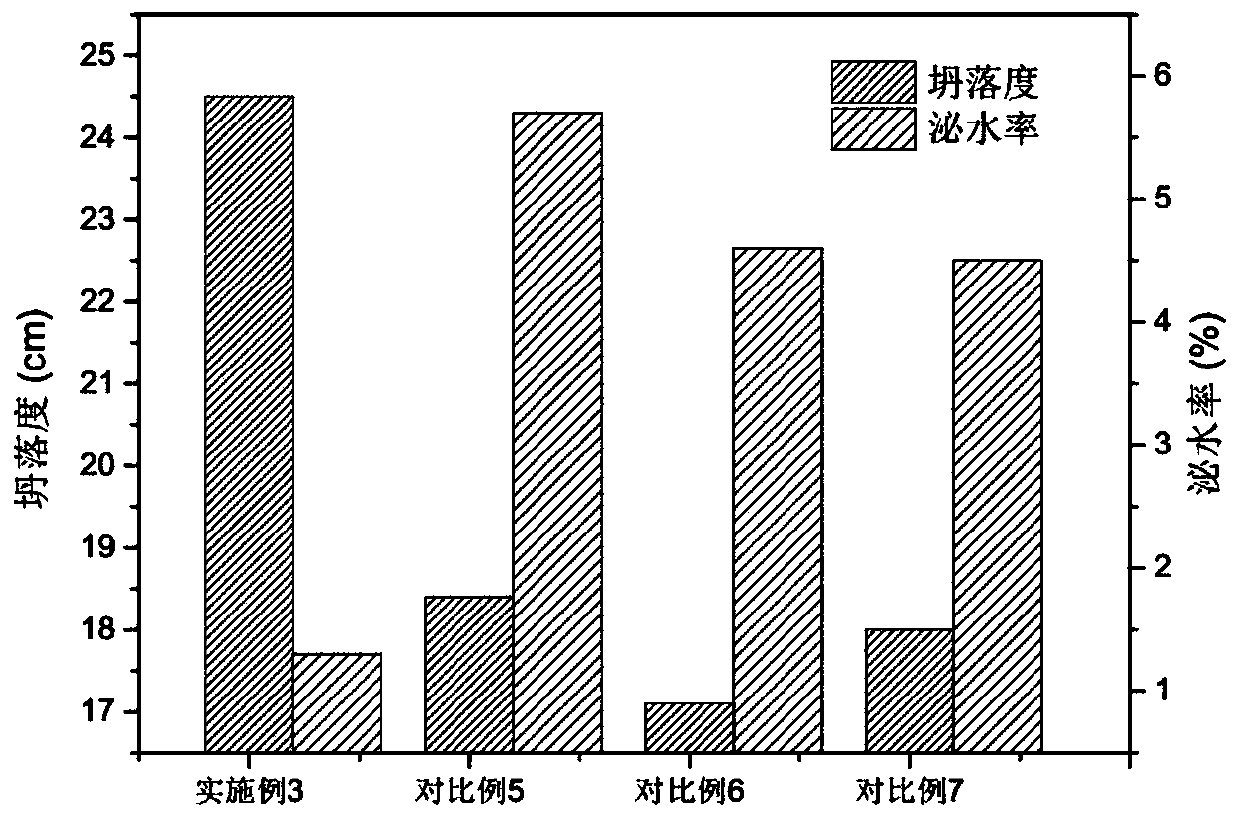

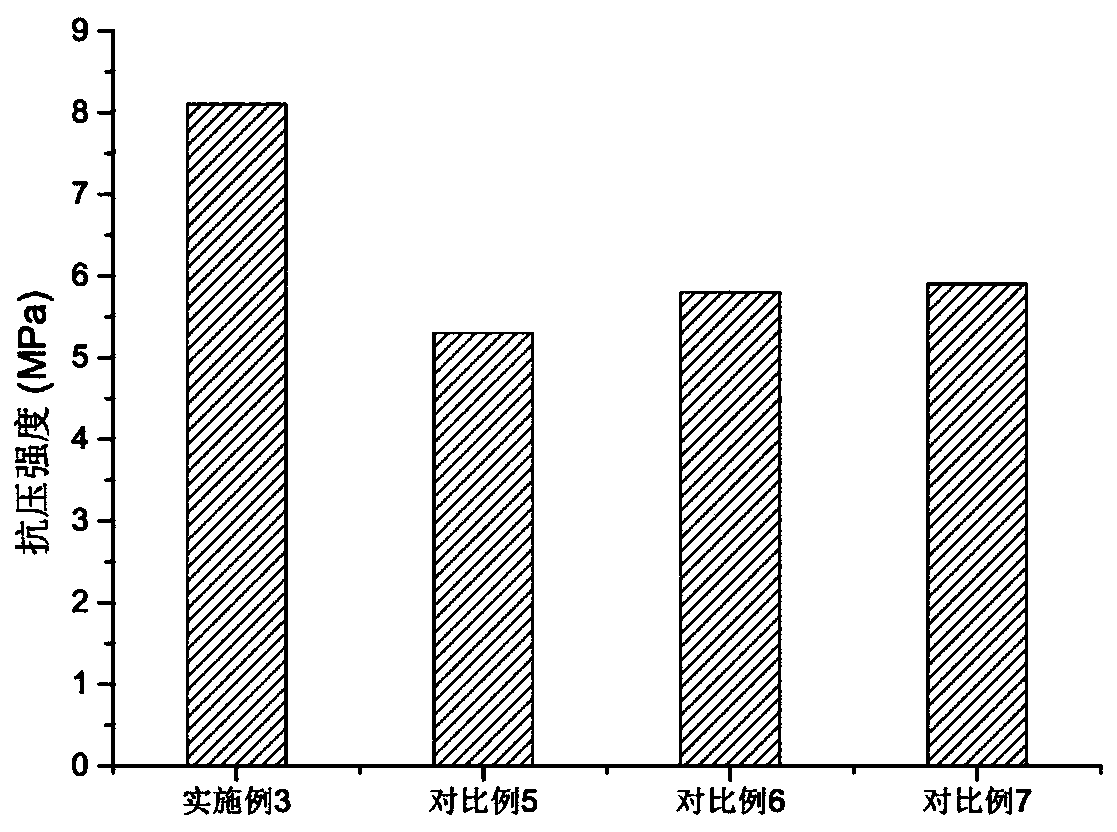

PendingCN110985114AImprove early strengthHigh compressive strengthMaterial fill-upSlagMining engineering

The invention provides a downward parallel middle-deep hole sublevel fill stoping mining method for a steep and medium-thick hard-to-mine ore body, and belongs to the technical field of mining. The ore body is divided into a plurality of sublevels according to the middle sublevel, stope rooms and stope pillars are divided in the ore body direction, the middle sublevel is divided in the inclined direction of the ore body, sublevel rock drilling roadways are arranged along veins, artificial false roofs and false bottoms are constructed in the sublevel rock drilling roadways in advance, and middle-deep hole stoping ore blocks are adopted from top to bottom. After the stope rooms are mined, the stope rooms are filled with filling materials. After the stope pillars are mined, the stope pillarsare filled with full tailings and / or barren rock powder. The content of particles with the particle size being less than or equal to 30[mu]m in the full tailings for the filling materials accounts for75-77%; the content of the particles with the particle size being less than or equal to 35[mu]m in slag accounts for 86-88%; and an activator is prepared from glauberite and green vitriol with a weight ratio of 1 to (0.5-0.7). According to the downward parallel middle-deep hole sublevel fill stoping mining method, safe, efficient and low-cost mining of the ore body can be realized, continuous mining in an area can be realized, and the sublevel fill stoping mining method is mainly suitable for a gold mine with an inclination of 50-90 degrees and a horizontal thickness of 4-10 m.

Owner:中国黄金集团石湖矿业有限公司

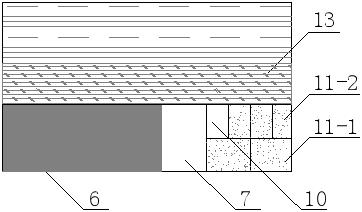

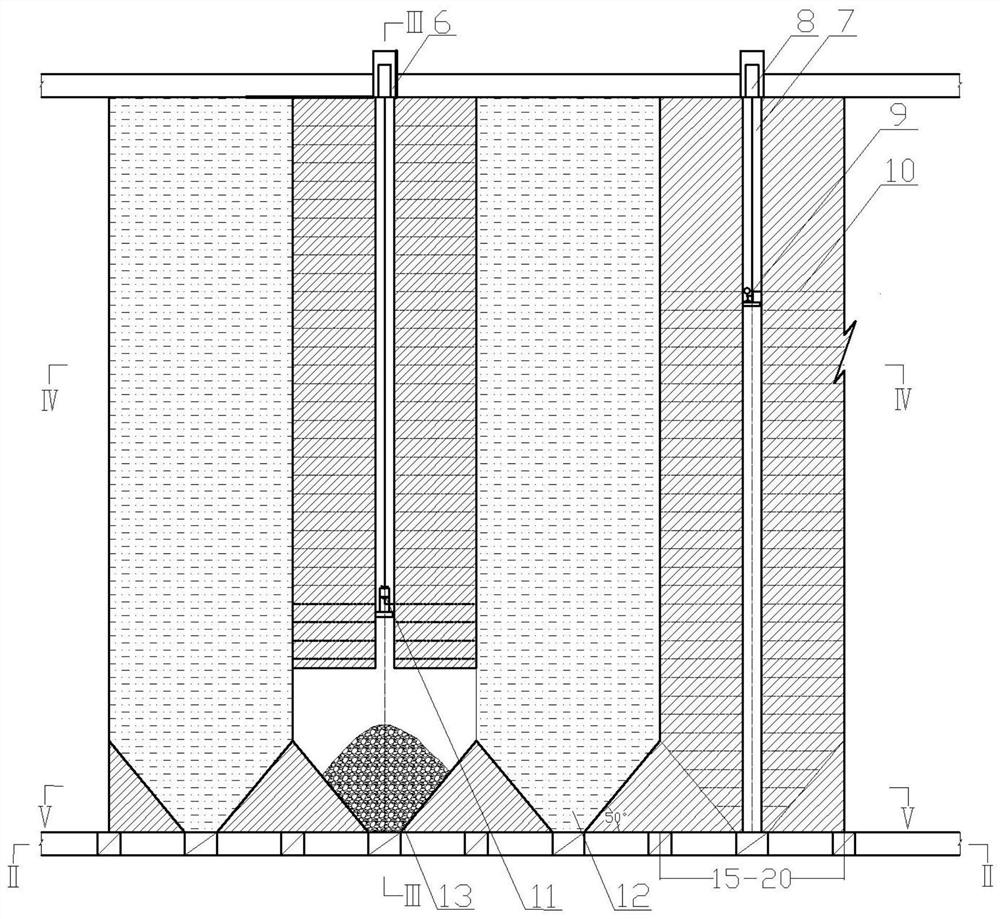

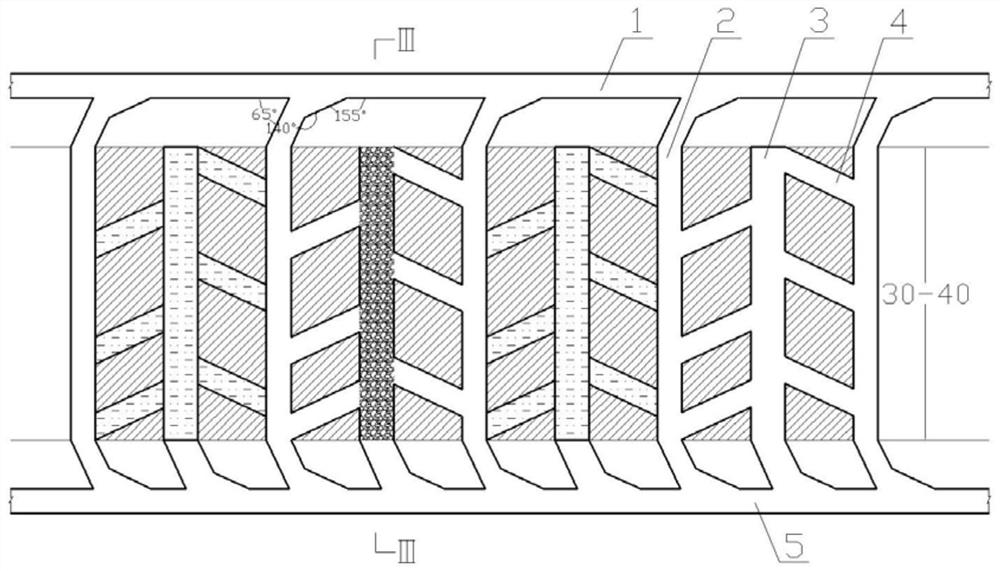

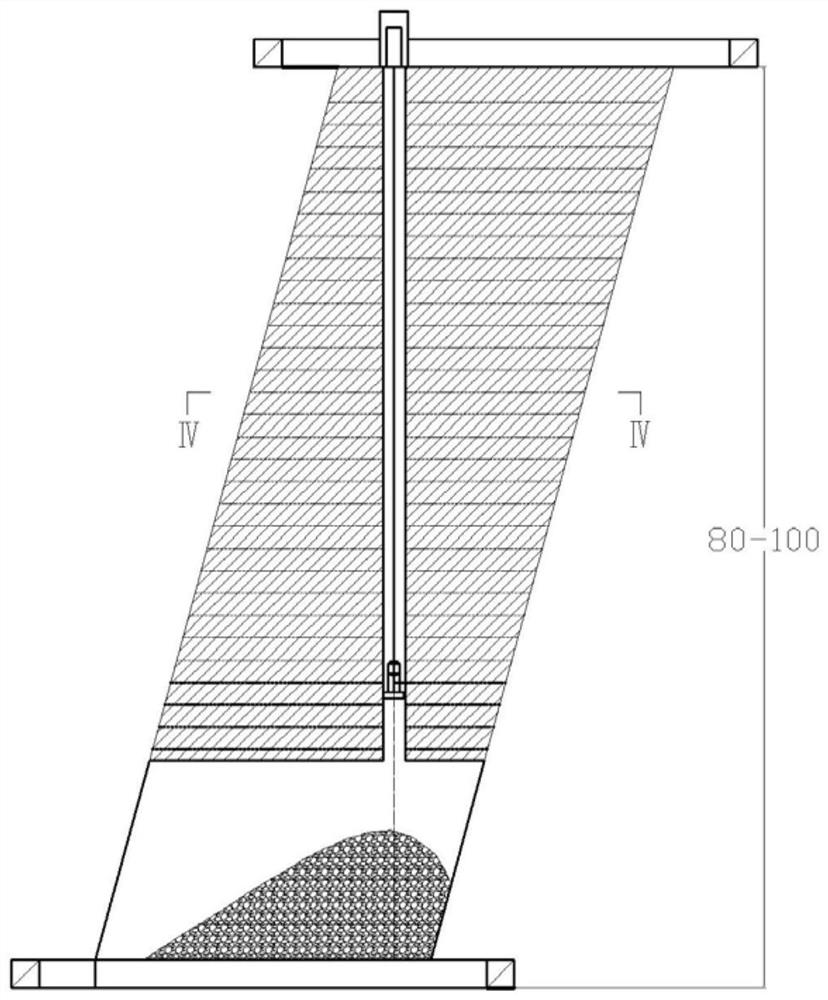

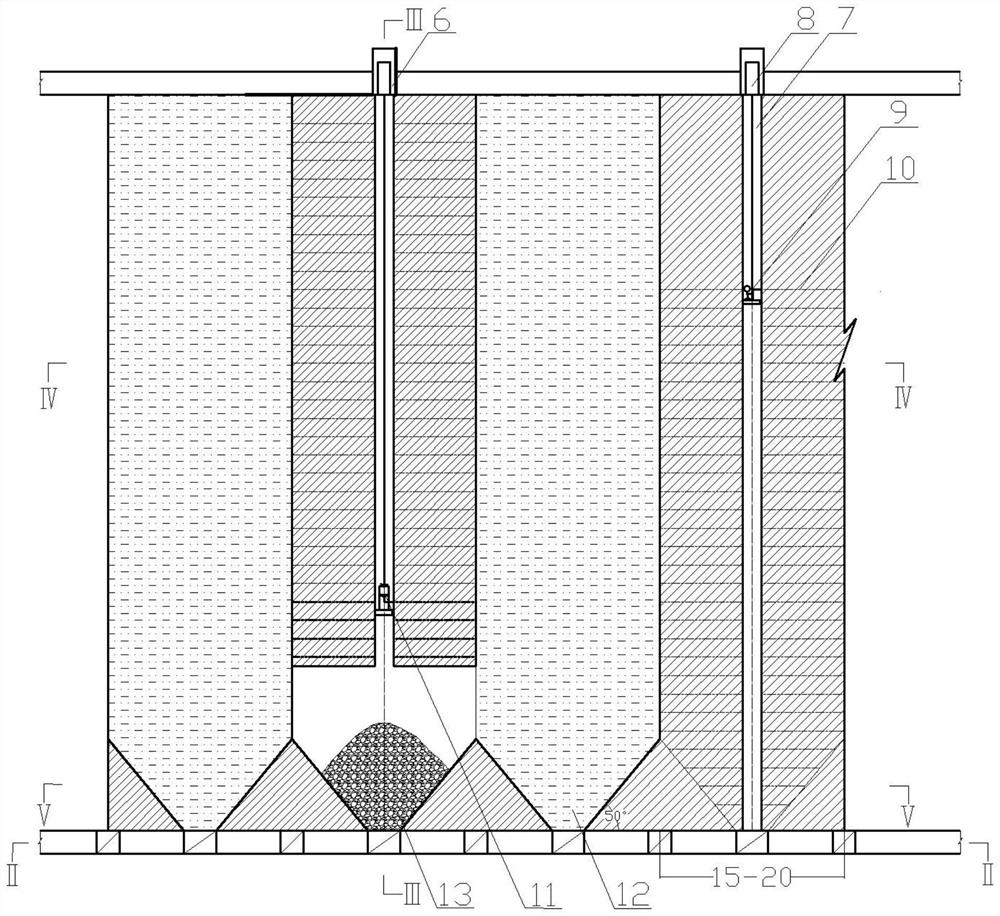

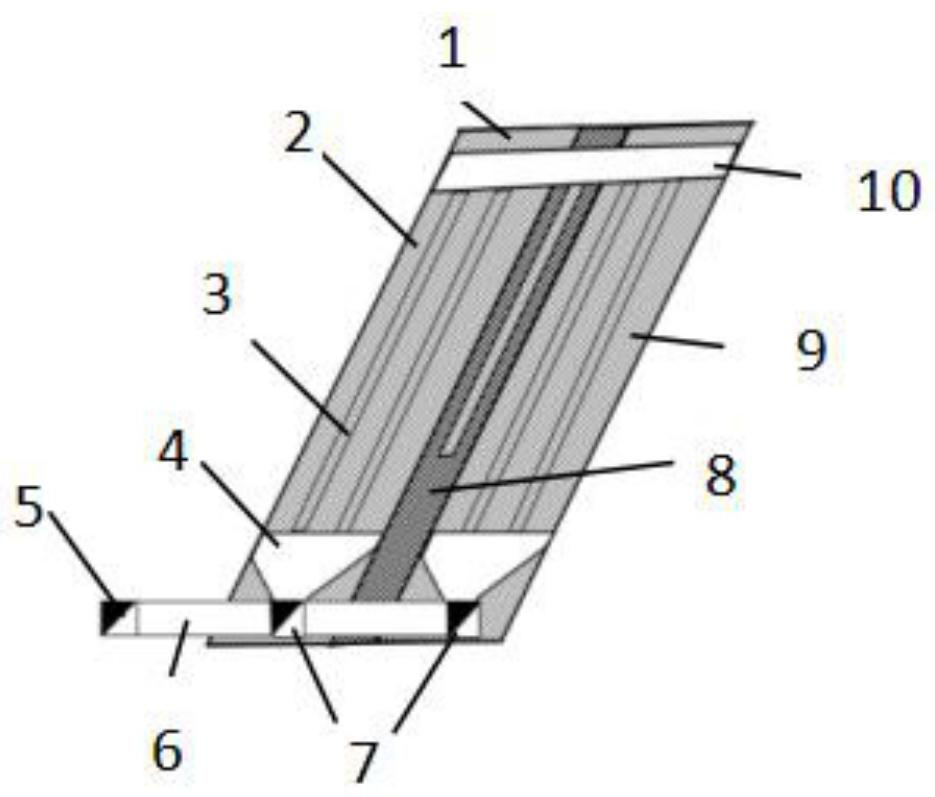

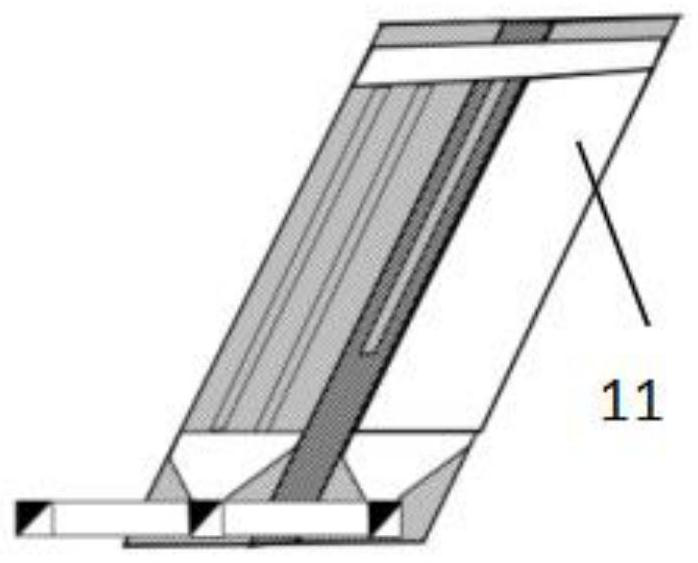

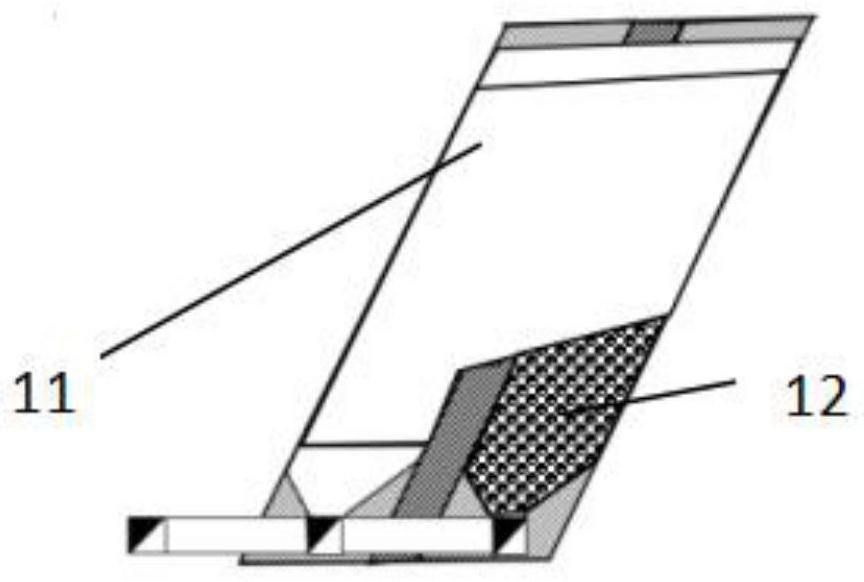

A thin ore body mechanized high layered continuous mining method

ActiveCN104747190BQR is smallIncrease production capacityUnderground miningSurface miningDetonationMineralogy

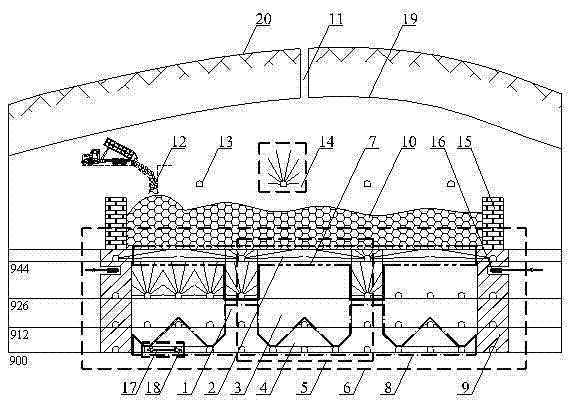

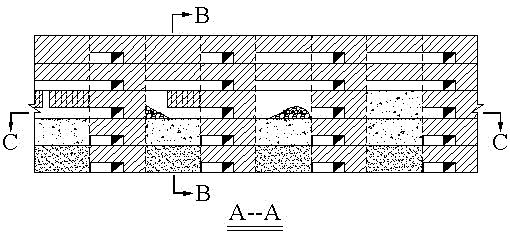

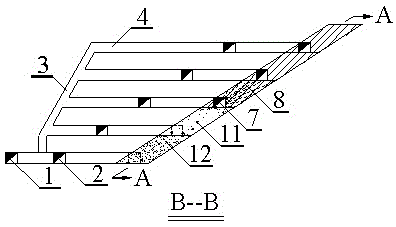

The invention discloses a thin ore-body mechanized highly-layering continuous mining method. The method comprises the following steps: (a) a vein division stage: dividing a vein into a plurality of parallelogram ore blocks by utilizing 15 to 20 percent gradient slope ramps along the direction of an ore body; (b) arranging a pedestrian ventilation raise and a filling raise, and pouring an artificial fake bottom; (c) carrying out layering extraction from an undercutting layer of a stope room, and forming a complete in-vein slope ramp; (d) dividing the stope room into a rock drilling working face, an ore production working face and a filling working face, wherein the three working faces are alternately operated in parallel; (e) carrying out layering operation on a stope, wherein the layering operation includes rock drilling, explosive loading, detonation, ventilation, prying, ore discharging, ore powder clearing, arranging of an on-the-way ore chute, filling, stope support and laying of a concrete soleplate; (f) recovering a bottom column after the stope room is extracted. By adopting the method, the slope ramp stope preparation in the vein, fully mechanized operation and highly-layering filling can be realized. The method has the advantages of high mining safety, small mining-cutting ratio, small ore loss and depletion and high production efficiency.

Owner:GUANGXI UNIV

Electric-driven track travelling type open-air continuous coal cutter

PendingCN110005410ARealize continuous miningIncrease productivityDriving meansCutting machinesElectricityElectric drive

The invention discloses an electric-driven track travelling type open-air continuous coal cutter. The overall coal cutter is composed of main parts such as a cutting part, a loading part, a conveyingpart, a travelling part, a main rack, a cab and a cable coiling device, can be matched with a scraping plate continuous transporting system or a belt-type continuous transporting system to be used forachieving continuous mining of an open-pit coal mine thin coal seam, and can also serve as coal mining equipment to be used independently, and mined coal does not need to be broken independently.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Medium-length hole mining method in multiple blasting free faces of high dipping thin veins

InactiveCN102635356BIncrease job securityStrong mining continuityUnderground miningSurface miningPunchingMineralogy

The invention discloses a medium-length hole mining method in multiple blasting free faces of high dipping thin veins. The medium-length hole mining method is characterized by comprising the steps of: arranging ore blocks along the trend of a core body, dividing the ore body into a medium section and a segment in the altitude; drilling a gate way in the segment and arranging in veins along the ore body; arranging a flat ore removal structure on the bottom along the veins; arranging a cutting raise from one ends of the ore blocks, arranging a manway at the other ends of the ore blocks; and upwards and downwards punching forwards leaning medium-length holes, with the cutting raise as free faces, and blasting caved ores in the segment by multiple free faces, and withdrawing the ore centrally at the bottom. The medium-length hole mining method has the remarkable characteristics of high mining safety, little resource dilution rate, good production continuity, high level of mechanization, low cost, high efficiency, low labor intensity and the like.

Owner:CENT SOUTH UNIV

The Method of Using Aeolian Sand to Fill the Net Cage to Construct the Wall of Gob-side Entry Retention

ActiveCN109268063BReduce construction costsGuaranteed support effectMining devicesMaterial fill-upWater resourcesCoal

The invention relates to a method for constructing a wall body for retaining and protecting a roadway along a goaf by filling a net cage with aeolian sand. The method includes the following steps: firstly, filling the net cage to be filled which consists of a steel wire net cage and geotextile and is closed at four corners and opened at the upper part with the aeolian sand, vibrating and compacting, wherein the aeolian sand has the bearing capacity due to lateral restraint provided by the steel wire net cage and the geotextile; and effectively controlling the rotation and subsidence of roof strata of the retained roadway along the goaf after the wall body for retaining and protecting the roadway along the goaf built by the net cage filled with the aeolian sand is connected to the roof. According to the method for constructing the wall body for retaining and protecting the roadway along the goaf by filling the net cage with the aeolian sand, on the premise of not consuming water resources, the bearing performance of the aeolian sand is fully brought into play, and the effective support from the wall body for retaining and protecting the roadway along the goaf constructed by fillingthe net cage with the aeolian sand to the roof strata of the retained roadway along the goaf is guaranteed, so that the cost of retained the roadway along the goaf in the desertified arid mining areais reduced, the coal resource extraction rate in the mining area is improved, and meanwhile, the influence and damage of mining activities on the water resources and the local ecological environment are reduced.

Owner:XINJIANG UNIVERSITY

Thick and large ore body mining method

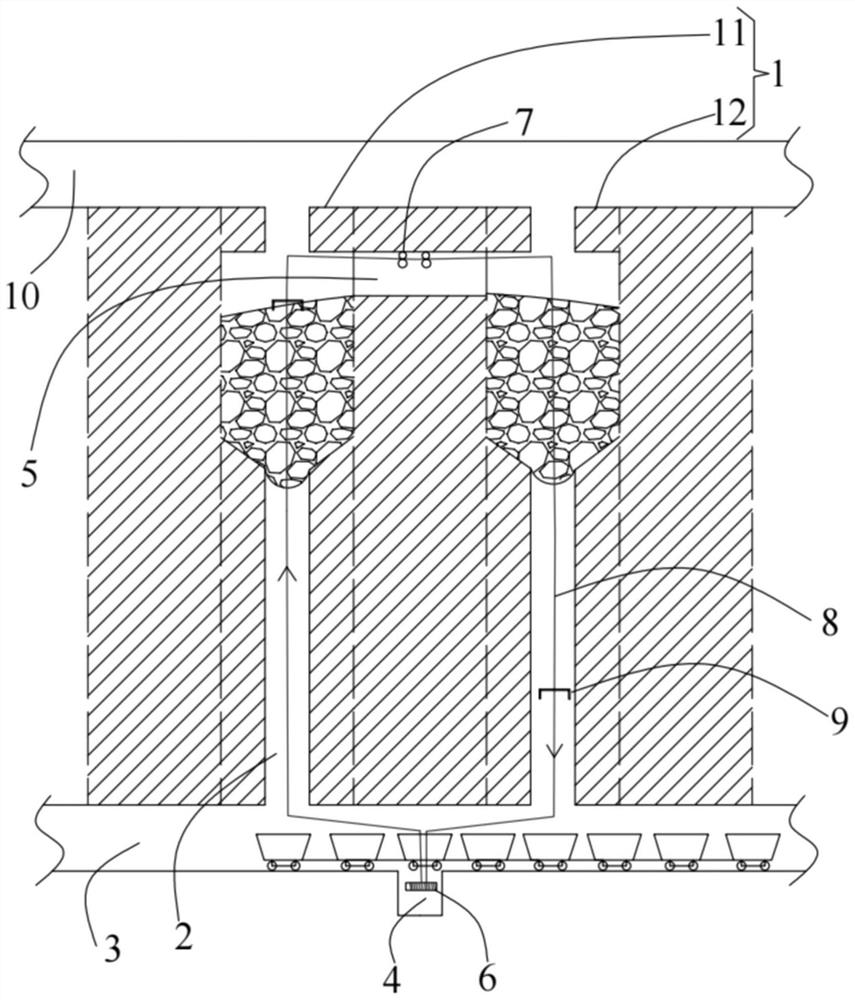

ActiveCN111963175ASimple planReduce the amount of mining and cuttingUnderground miningBlastingMining engineeringRock cutting

A thick and large ore body mining method comprises the following steps that a stope is arranged in the direction perpendicular to an ore body, stages are divided in the vertical height direction, a stope preparation raise is arranged in the center of the stope, an annular conveying channel of a trench ore removal structure is arranged at the bottom of the stope, and a lifting chamber is arranged at the top of the stope; a down-the-hole drill drills annular horizontal deep holes from the two sides of a raise, and centralized rock drilling, fractional blasting, reinforced ore removal and delayedfilling are conducted. The mining and cutting work amount is small, the mechanical operation degree is high, the production efficiency is high, the production capacity is large, personnel do not needto enter a stope for operation, and safety conditions are good.

Owner:GUANGXI UNIV

Stepped non-pillar continuous filling mining method for deep well super high large breaking ore body panel

InactiveCN101818643BImprove mining safetySafe miningUnderground miningSurface miningEngineeringCompressive strength

The invention discloses a stepped on-pillar continuous filling mining method for deep well super high large breaking ore body panel. An ore body is divided into a front part and a rear part in a super high large breaking ore body center by an transportation roadway, then the front part and the rear part are respectively divided into a plurality of panels, no pillar exists between pillars, each panel is partitioned into a primary extracting drift and a second extracting drift, the panels in the front part are extracted at first and then the panels in the rear part are extracted, the front and rear panels are extracted in a stepped manner, each production technology is carried out in the same level, and procedures can not influence each other; after the stop back production is finished, theprimary extracting drift is filled with cement and the secondary extracting drift is filled by classifying tailings while roof-contacted filling is ensured; and the primary extraction drift and the secondary extraction drift adopt high strength filling topping, and binding materials are added in the filling tailings so as to improve the compression strength of a topping layer. The invention has the characteristics of high extraction safety, small loss and dilution, high mechanical degree, large stope amount, large back production strength, high production capability, short back production time and the like.

Owner:CENT SOUTH UNIV

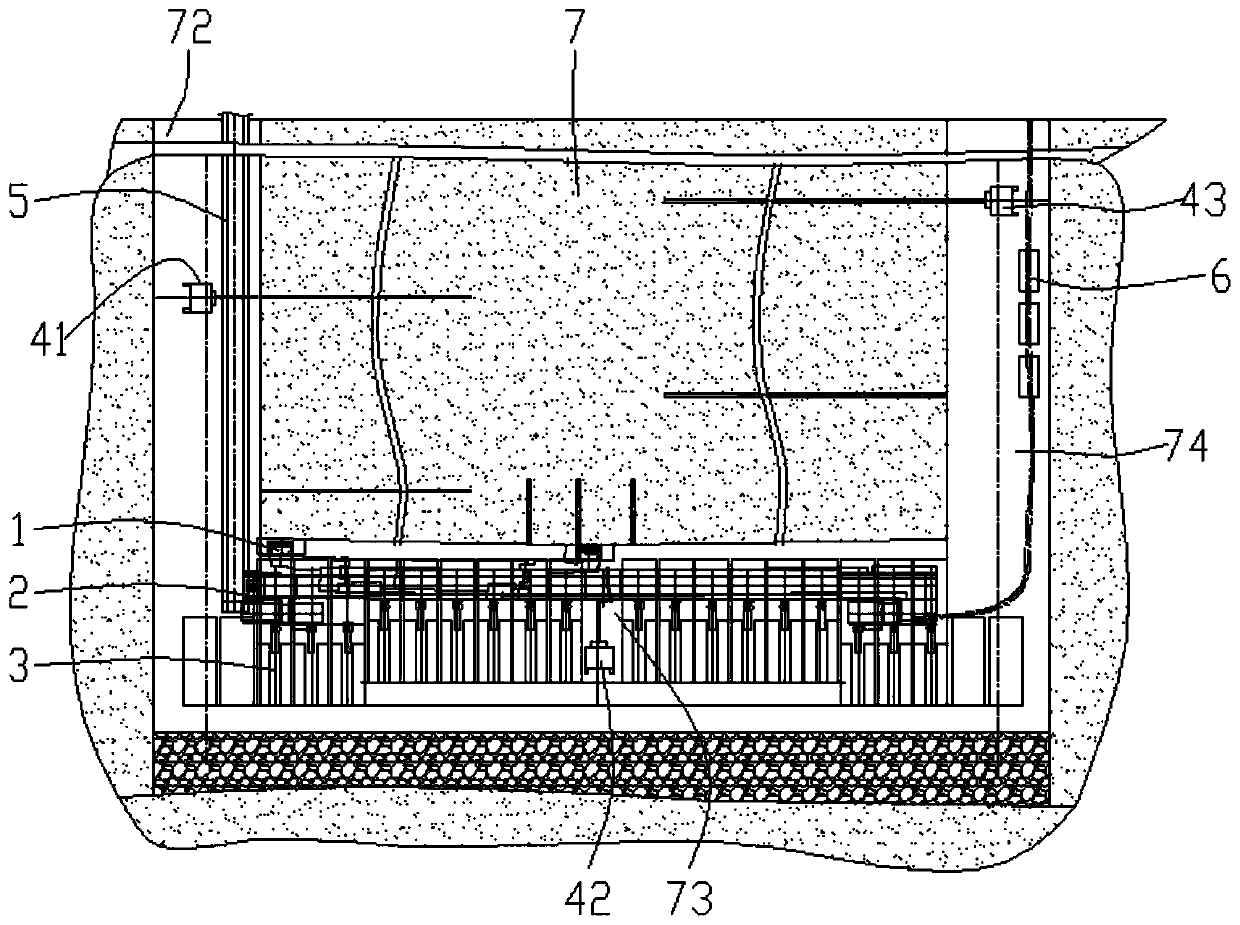

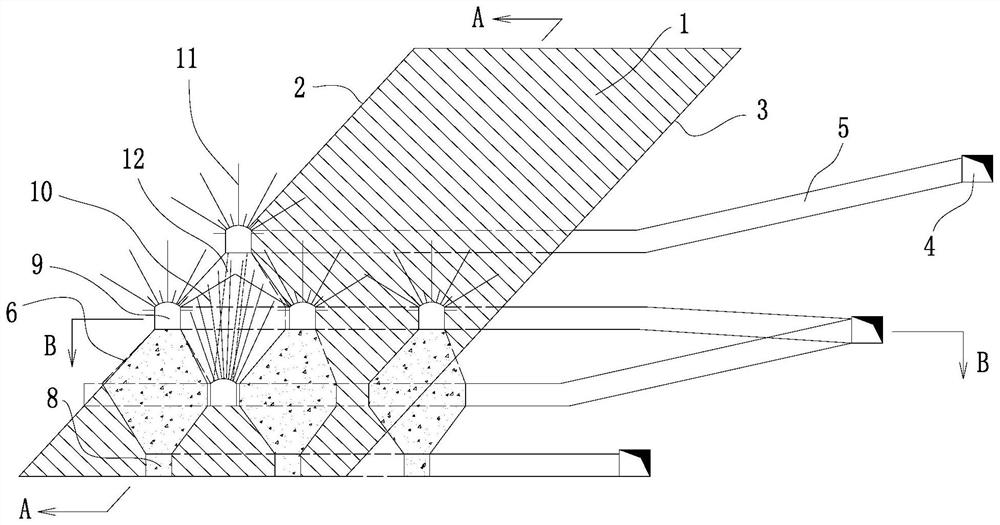

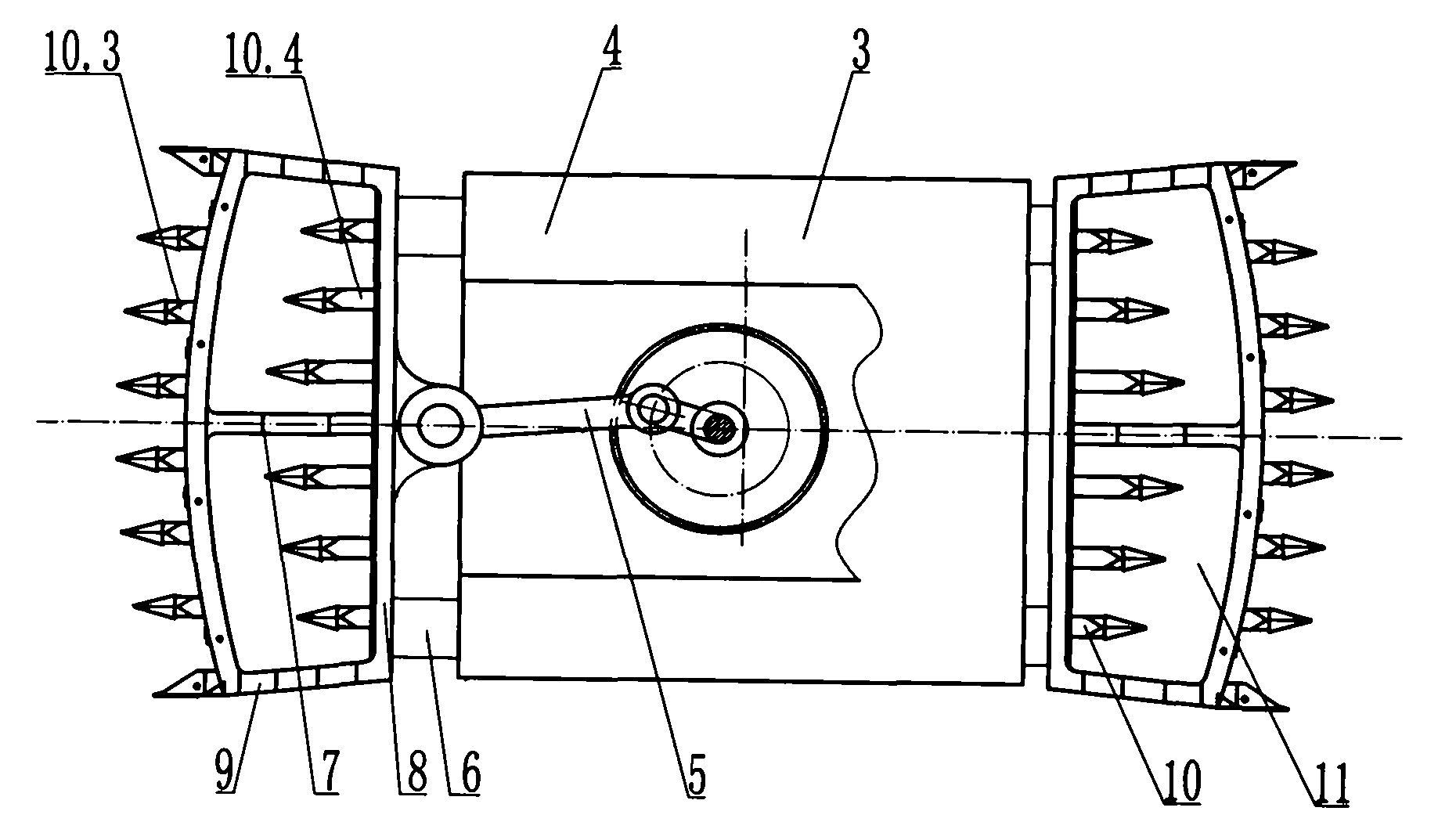

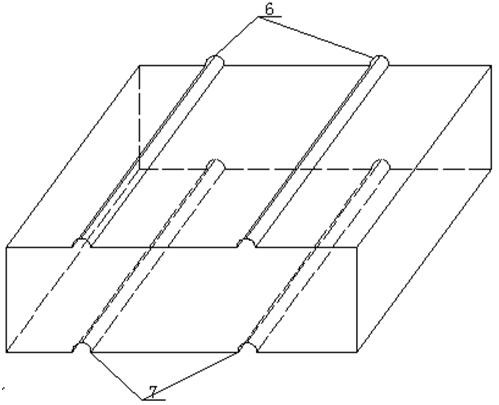

Underground Mechanized Continuous Mining Method of Hard Mineral Materials

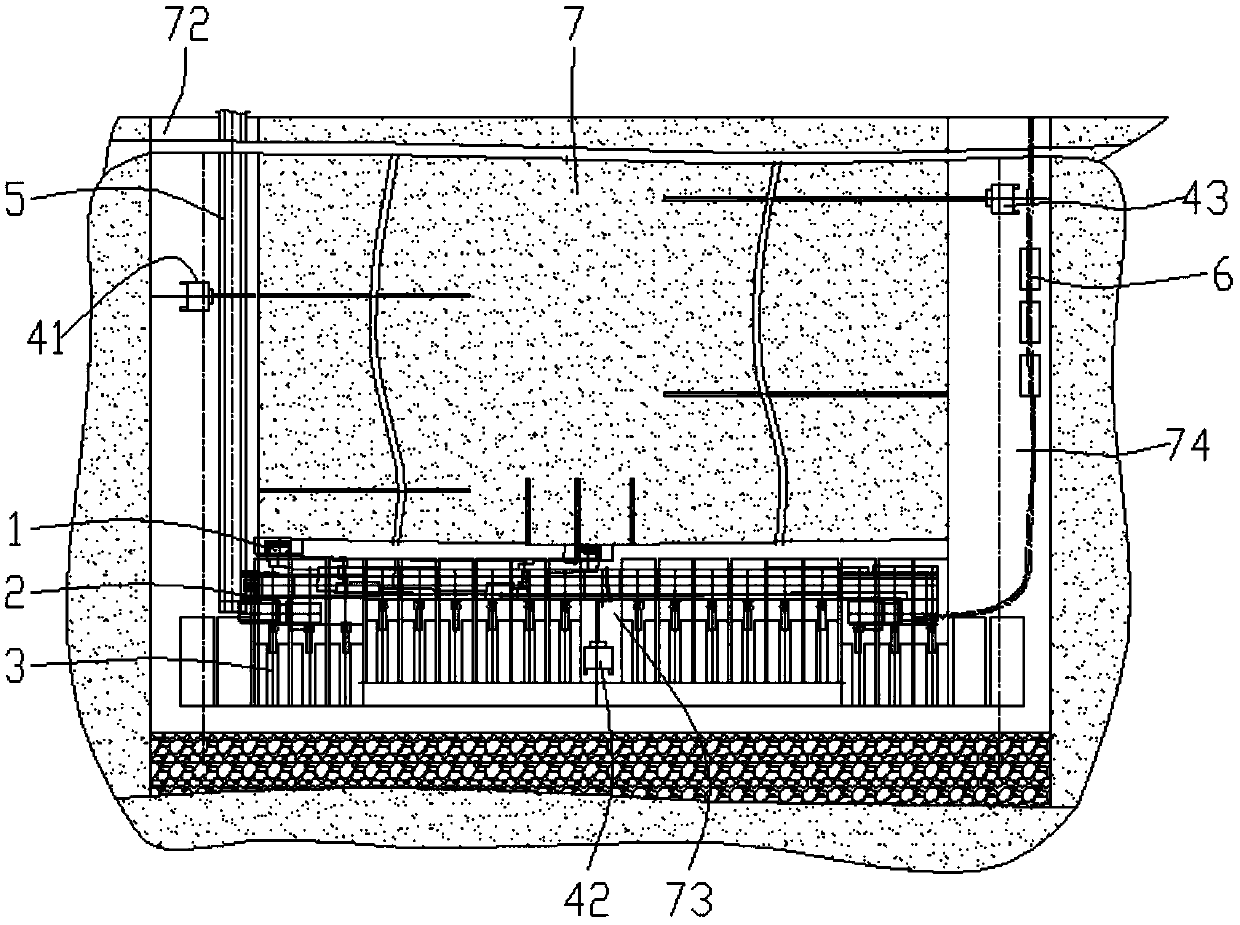

ActiveCN109403978BEconomical miningReduce refining costsUnderground miningSurface miningMining engineeringMechanical engineering

The invention relates to an downhole mechanized continuous mining method for hard mineral aggregates. The downhole mechanized continuous mining method includes forming a conveying channel, a working face channel and a power channel, which are communicated in sequence, around a region block where a to-be-extracted ore body is located, wherein one end of each of the conveying channel and the power channel leads to the ground, and one side face, facing the working face channel, of the region block is a working face mining ore wall; initially weakening the ore body of the region block; dividing different ore layers on the working face mining ore wall according to the different grades of the mineral aggregates, mining the one layers by a cylindrical mining machine one by one, weakening a near-working-face ore body once before mining of each follow-up working face or continuous multiple working faces, performing ore body composition detection once before mining of each working face or the continuous multiple working faces, and dividing different ore layers on the working face mining ore wall according to detection results and the grades of the mineral aggregates. The downhole mechanizedcontinuous mining method has the advantages that the grades of the mineral aggregates can be improved, the extraction cost can be reduced, the mining economy is high, and the method can be applicableto mining of the hard mineral aggregates with different rigidities.

Owner:SHANGHAI BRANCH TIANDI SCI&TECH CO LTD +3

A Mining Method for Segmented Filling of Inclined Medium Thickness and Above Orebody

ActiveCN112761640BIncrease production capacityImprove efficiencyUnderground miningTunnel/mines ventillationMining engineeringRock cutting

Owner:NORTHEASTERN UNIV LIAONING

Efficient ore removal method for gently inclined thin ore body

ActiveCN114810081AImprove mining efficiencyReduce investmentUnderground miningSurface miningMining engineeringEconomic benefits

The invention provides an efficient ore removal method for a gently inclined thin ore body, which comprises the following steps of: taking two separated stopes as synchronous stoping units, and adopting retreating mining; an electric scraper bucket in the uphill roadway on one side is pulled by an electric scraper wire of the electric scraper winch to move upwards to an ore falling point of the stope; the rotating direction of the scraper winch is changed, the scraper bucket rakes out the ore downwards, and meanwhile, the scraper bucket in the uphill roadway on the other side passively moves upwards to the ore falling point of the stope; and then the rotating direction of the scraper winch is changed again, so that the scraper bucket on the side rakes out the ore downwards. A single chamber and a single scraper winch are arranged to serve double-scraper-bucket combined ore removal of the double stopes, the scraper winches are circularly turned to achieve alternate ore raking and ore removal of the electric scraper buckets on the two sides, the ore removal efficiency in a panel is doubled, and the investment of the scraper winches and the chambers is doubled; the mining cost is reduced while mining and ore removal are improved, good economic benefits are achieved, and good practical application value is achieved.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Mineral aggregate mechanized continuous production method

PendingCN109538204AReduce refining costsImprove profit marginsTesting machinesSlitting machinesContinuous productionHardness

The invention relates to a mineral aggregate mechanized continuous production method. The method comprises the steps that the area where to-be-exploited mineral aggregate bodies are located is explored firstly to form an underground seam model, mineral aggregate grade level distributing situation data is obtained, primary parameters of mineral aggregate exploitation equipment are determined, a mine shaft is exploited, fitting exploitation equipment is arranged, and continuous exploitation is conducted; when the continuous exploitation is conducted, different seams are divided on a working surface exploitation mine wall according to the difference of mineral aggregate grade levels, or one or more working sections are transversely divided simultaneously, one-by-one seam exploitation is conducted on the working surface exploitation mine wall by using a mining machine according to the sequence from high mineral aggregate grade levels to low mineral aggregate grade level or the mining machine is used for exploiting the working sections one by one in the moving process from one end of the working surface to the other end of the working surface, and the seams are exploited one by one in each working section according to the sequence from high mineral aggregate grade level to low mineral aggregate grade level. The method has the advantages that the grade level of the mineral aggregatescan be improved, the refining cost is reduced, the exploitation economical performance is good, and the method can adapt to the exploitation of hard mineral aggregates with different hardness levels.

Owner:SHANGHAI BRANCH TIANDI SCI&TECH CO LTD +3

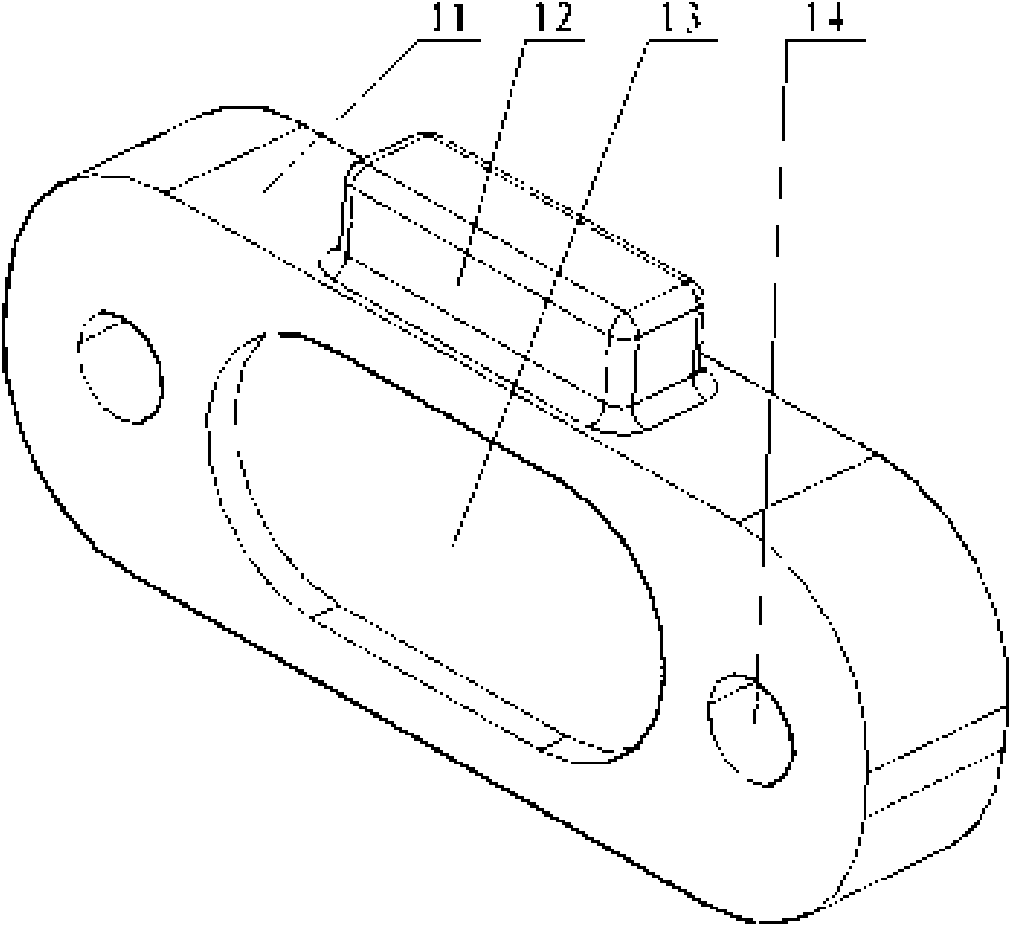

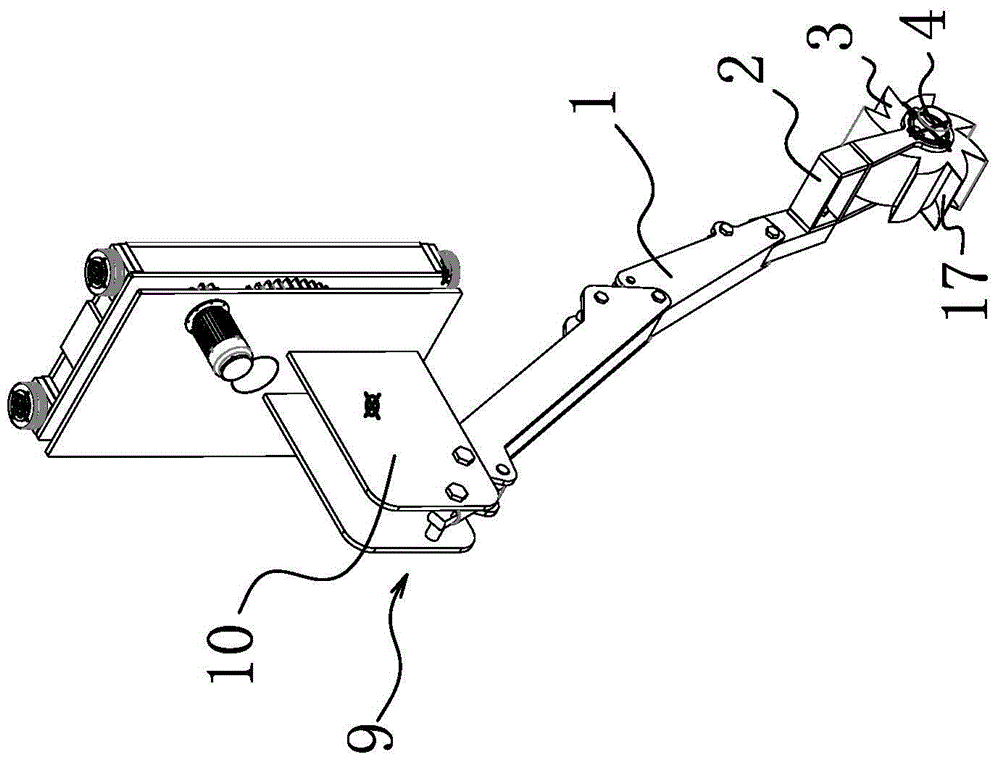

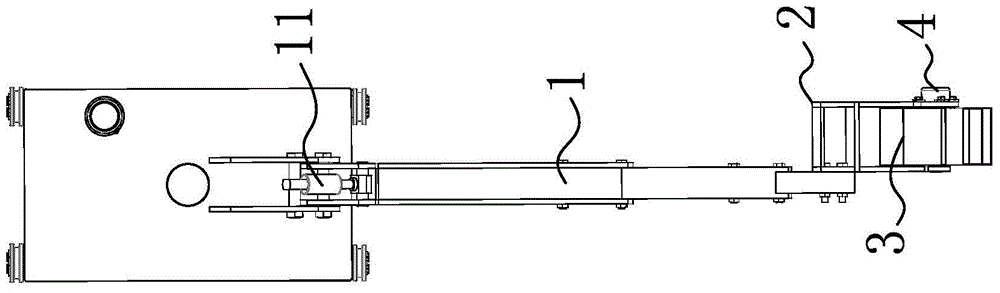

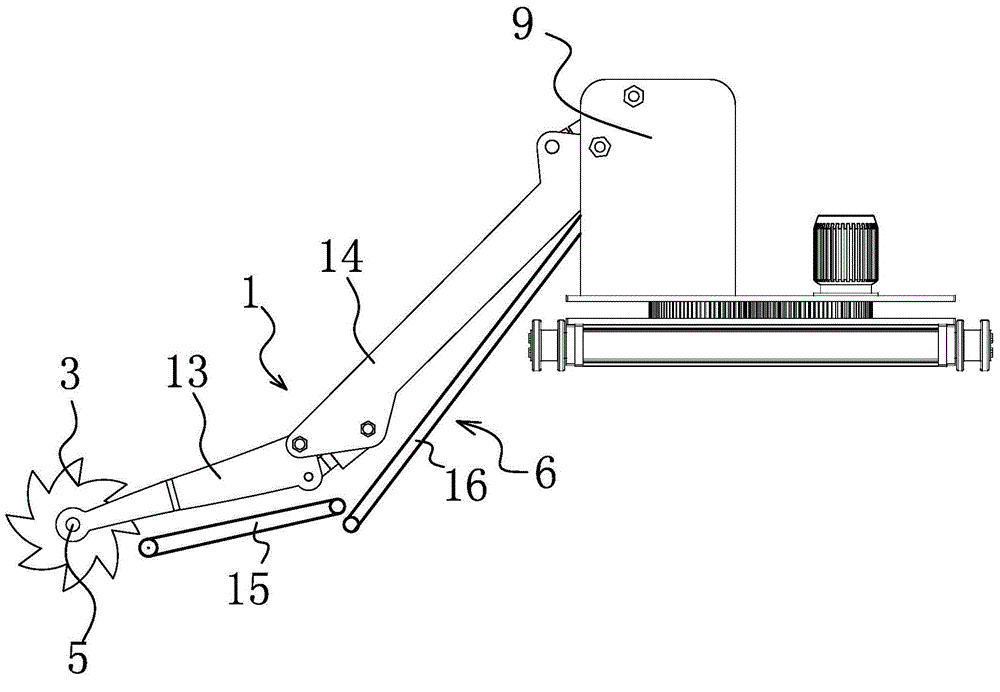

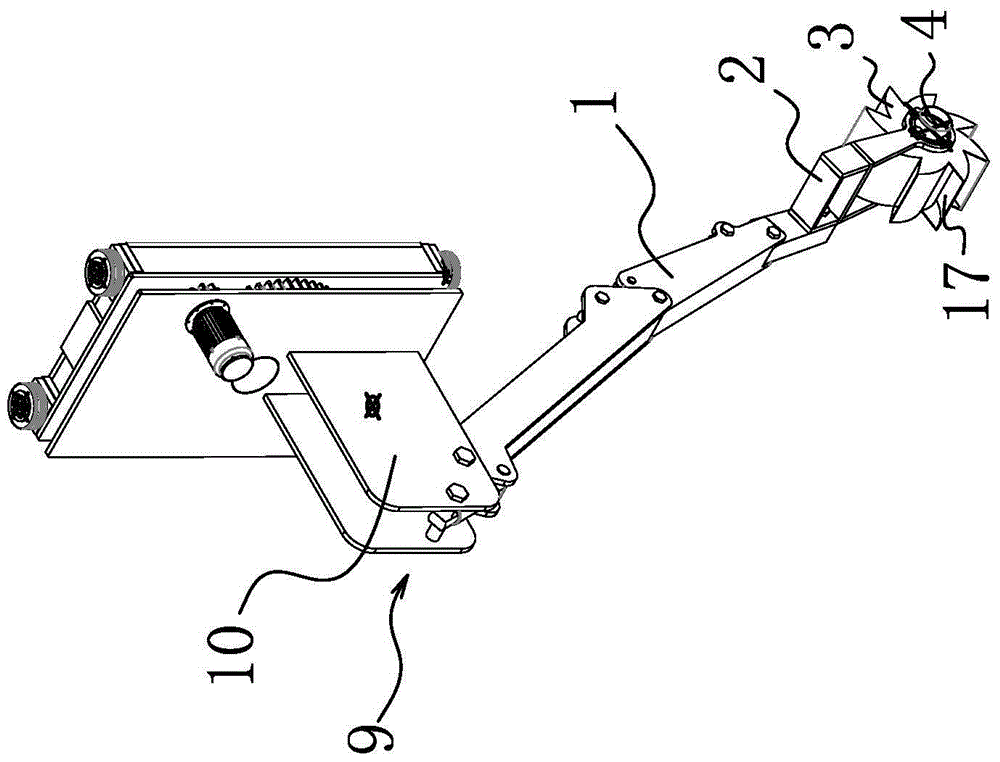

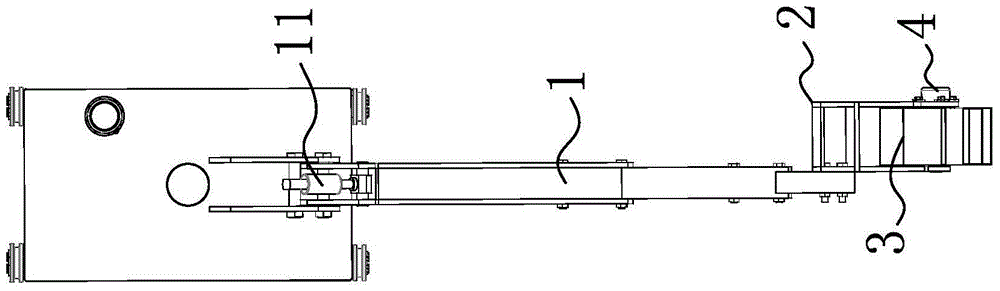

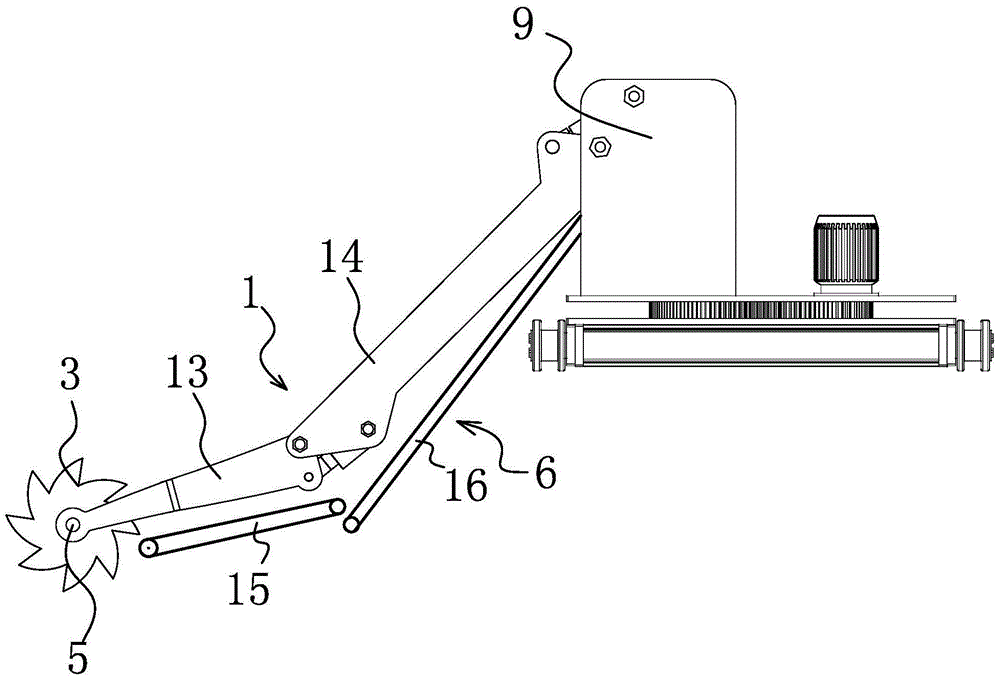

Continuous excavator digging arm assembly

ActiveCN105019491ARealize continuous miningIncrease digging speedMechanical machines/dredgersExcavator

The invention belongs to the technical field of buildings, and relates to a continuous excavator digging arm assembly. The technical problem that digging efficiency is low in the prior art is solved. The continuous excavator digging arm assembly comprises a digging arm. A digging bucket fixing rack is fixed to the side wall of the end of the digging arm. A digging bucket is connected in the digging bucket fixing rack in a rotating mode. A driver is fixed to the side wall of the digging bucket fixing rack. The driver is connected with the digging bucket so that the digging bucket can be driven to rotate circumferentially. The continuous excavator digging arm assembly can be used in an excavator; the driver can drive the digging bucket to rotate in a circulating mode, and thus the excavation speed is increased; the bucket can achieve continuous digging, and a conveying belt mechanism can continuously convey materials excavated by the bucket.

Owner:周兆弟 +7

Method used for reciprocating impact excavation by arranging discharge port for discharging, and reciprocating impact excavator used for implementing method by arranging discharge pot for discharging

The invention discloses a method used for reciprocating impact excavation by arranging a discharge port for discharging, and a reciprocating impact excavator used for implementing the method by arranging the discharge pot for discharging. The reciprocating impact excavator comprises an impact blanking mechanism. The impact blanking mechanism comprises an impact power box, a powered impact component, an impact guiding element, and an impact head; the impact head is composed of a supporting seat, a discharge port frame, and impact teeth, or is composed of the supporting seat and the impact teeth; the discharge port frame is arranged on the supporting seat; the discharge port frame comprises one or more discharge ports; the discharge port is advantageous for discharging material punched out by teeth for impacting the inner material layer; the impact blanking mechanism is arranged on a machine body, a travelling mechanism is arranged on the machine body; the impact head is driven by the powered impact component to complete reciprocating motion, the discharge port is used for discharging materials; so that the machine body is capable of moving smoothly; continuous excavation is realized; a problem that continuous excavation can not be realized because materials clamped between the impact teeth can not be discharged is solved; material collection, material discharge and material charging of the excavator provided with the impact head are realized smoothly; and excavation efficiency is increased.

Owner:刘素华

A mining method for thick and large ore bodies

ActiveCN111963175BSimple planReduce the amount of mining and cuttingUnderground miningBlastingMining engineeringRock cutting

Owner:GUANGXI UNIV

An oil well desanding device based on pulse jet technology and cyclone separation mechanism

Owner:SHANDONG UNIV OF SCI & TECH

Continuous Excavator Arm Assemblies

ActiveCN105019491BRealize continuous miningIncrease digging speedMechanical machines/dredgersEngineeringExcavator

The invention belongs to the technical field of buildings, and relates to a continuous excavator digging arm assembly. The technical problem that digging efficiency is low in the prior art is solved. The continuous excavator digging arm assembly comprises a digging arm. A digging bucket fixing rack is fixed to the side wall of the end of the digging arm. A digging bucket is connected in the digging bucket fixing rack in a rotating mode. A driver is fixed to the side wall of the digging bucket fixing rack. The driver is connected with the digging bucket so that the digging bucket can be driven to rotate circumferentially. The continuous excavator digging arm assembly can be used in an excavator; the driver can drive the digging bucket to rotate in a circulating mode, and thus the excavation speed is increased; the bucket can achieve continuous digging, and a conveying belt mechanism can continuously convey materials excavated by the bucket.

Owner:周兆弟 +7

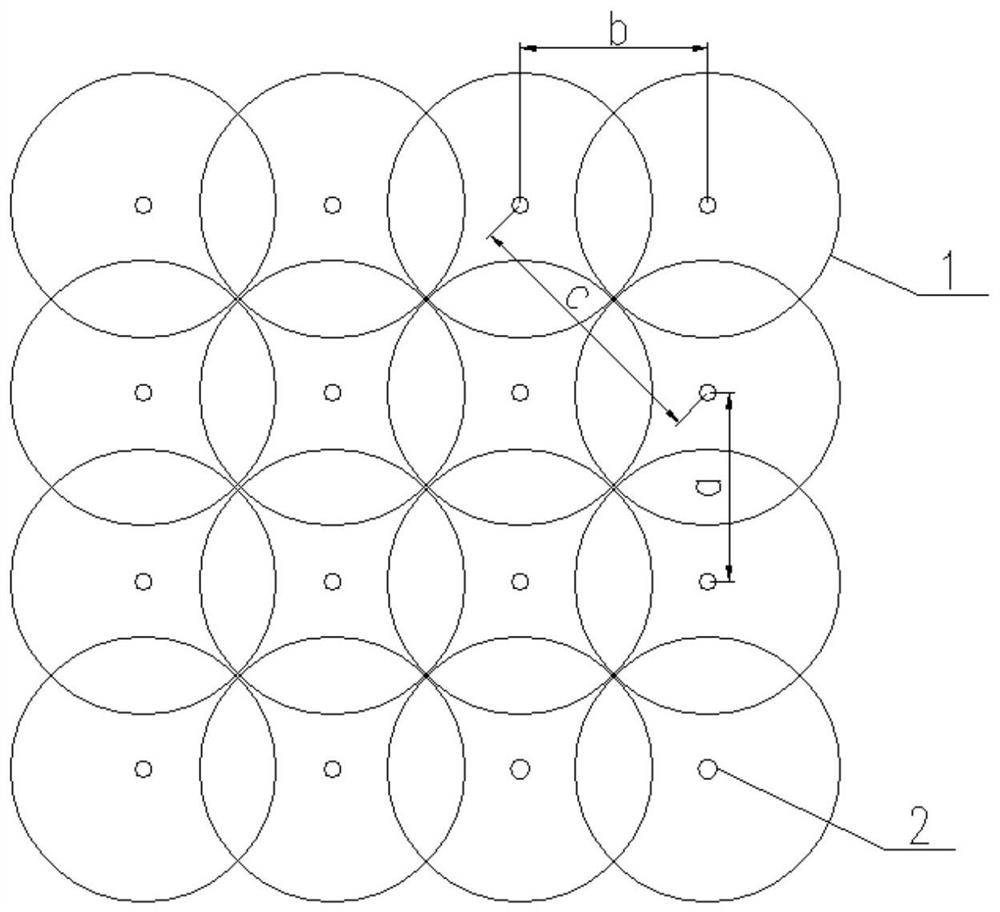

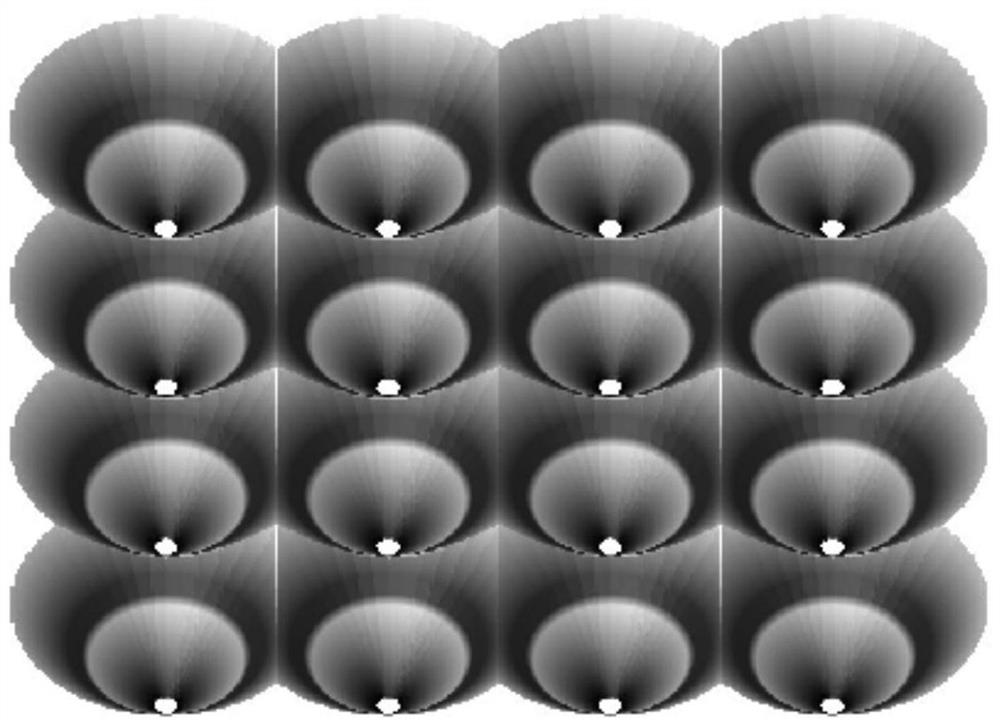

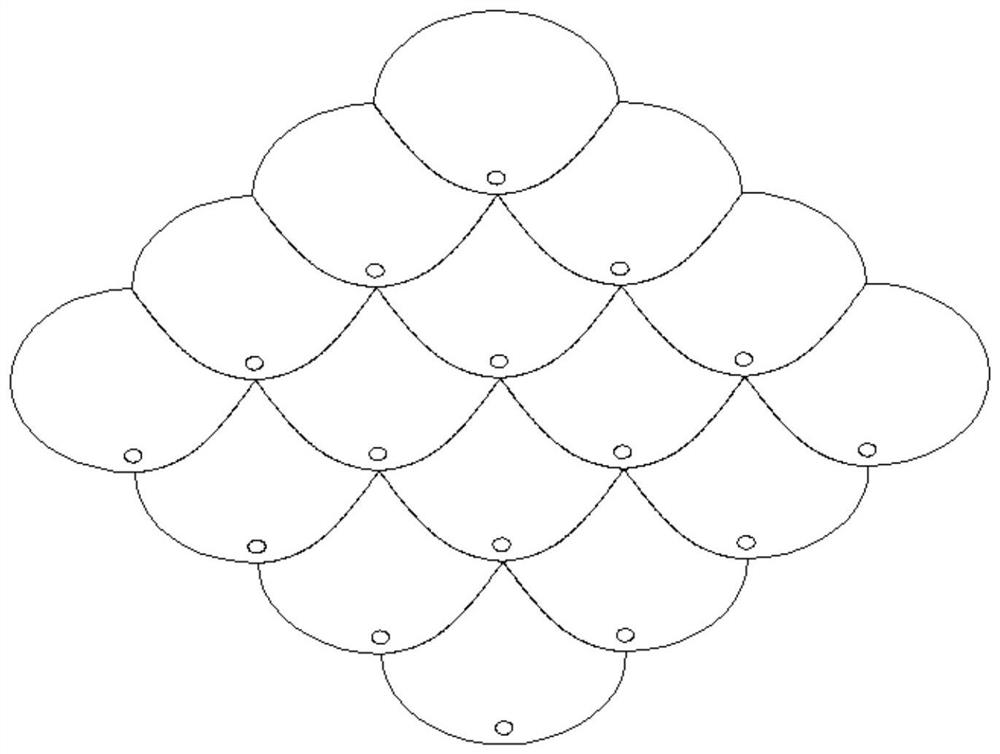

A kind of natural caving mining method of inverted cone-shaped ore accumulation

ActiveCN113216958BReduce production and operation costsRealize continuous miningDisloding machinesSlitting machinesMining engineeringMechanical engineering

The invention relates to a natural caving mining method of rounded table-shaped ore accumulation. The rounded table-shaped ore-accumulating trough is arranged in a determinant manner, the top surface of the rounded table is used as the entrance of the caving ore, and the lower top surface of the rounded table is connected to the chute as the ore outlet, which can make the natural The caving ore falls into the ore-gathering tank of the inverted round table and slides into the chute, which has the advantages of reducing operation links, reducing operating costs, and realizing continuous ore extraction. It is suitable for mining metal mines.

Owner:ZIJIN MINING GROUP

A multi-layer inclined ore body ore waste separation and collaborative mining method

ActiveCN110905514BRealize continuous miningOvercoming the impact of large-scale ore collapse effectsUnderground miningSurface miningMining engineeringRock cutting

The invention discloses a multilayer inclined ore body ore and waste separation collaborative mining method. An interlayer serves as an ore body in the ore body mining process, the mining is conductedaccording to the continuous thick large ore body, a conventional low-efficiency layered independent stoping mode is changed, a high-efficiency deep hole is adopted to conduct rock drilling, the ore body and the interlayer are orderly caved by themselves, the ore which is caved is completely sent out, and the waste rock of the interlayer which is caved is reserved at the bottom of the interior ofa stope and serves as the filling waste rock. The footwall ore body is extracted, then a goaf region which is reserved by the mining of the bottom ore body is utilized to serve as a free space, the interlayer is caved at one time, the waste rock which is caved is completely reserved inside the goaf region, the surface of the waste rock is treated, and the ore and waste separation is achieved. Thegoaf region which is formed by the caving operation of the bottom ore body and the interlayer is utilized to serve as a blasting compensation space of the stoping operation of the hanging wall ore body, the large-scale ore caving operation is carried out, and then the large-scale ore removal is conducted. The multilayer inclined ore body ore and waste separation collaborative mining method can achieve the safe efficient and waste-free mining of the multilayer inclined ore body.

Owner:正镶白旗乾金达矿业有限责任公司

A concrete modular gob-side roadway support structure for coal pillar-free mining

ActiveCN111911196BAchieve miningImprove surface recovery rateUnderground chambersTunnel liningMineral SourcesArchitectural engineering

Owner:山西煤炭运销集团晋城有限公司

Open field continuous mining method of medium-thick steeply inclined ore body

ActiveCN104847355BEfficient recyclingRealize continuous miningUnderground miningSurface miningEarth surfaceSubsidence

The invention discloses a continuous mining method of a medium-thick heavy pitch ore body empty field. The continuous mining method includes the following steps: dividing an extraction area and extraction units in the extraction area; determining the total extraction sequence of the extraction area; generally arranging the mining preparation project of the extraction area; cutting and strengthening the mining extraction units; constructing a temporary pillar recovery safe mining environment; recovering temporary pillars step by step. The continuous mining method of the medium-thick heavy pitch ore body empty field can achieve safe, efficient and low-cost mining of the ore body and adopts sectional step-by-step mining; chambers in the extraction area with sectional empty fields are extracted, then pillars in the extraction area are extracted on the basis of building the safe mining environment, so continuous mining in the area is achieved, and the continuous mining method can be applied to the non-consolidated filled mines with allowable surface subsidence, especially is applicable to medium-thick heavy pitch ore body resource extension mining, and can achieve continuous mining.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com