Thick and large ore body mining method

A mining method and technology for thick and large ore bodies, applied in surface mining, mining equipment, underground mining, etc., can solve the problems of small stope production, poor safety conditions, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Present embodiment is an example of the thick ore body mining method described in the present invention, comprises the following steps:

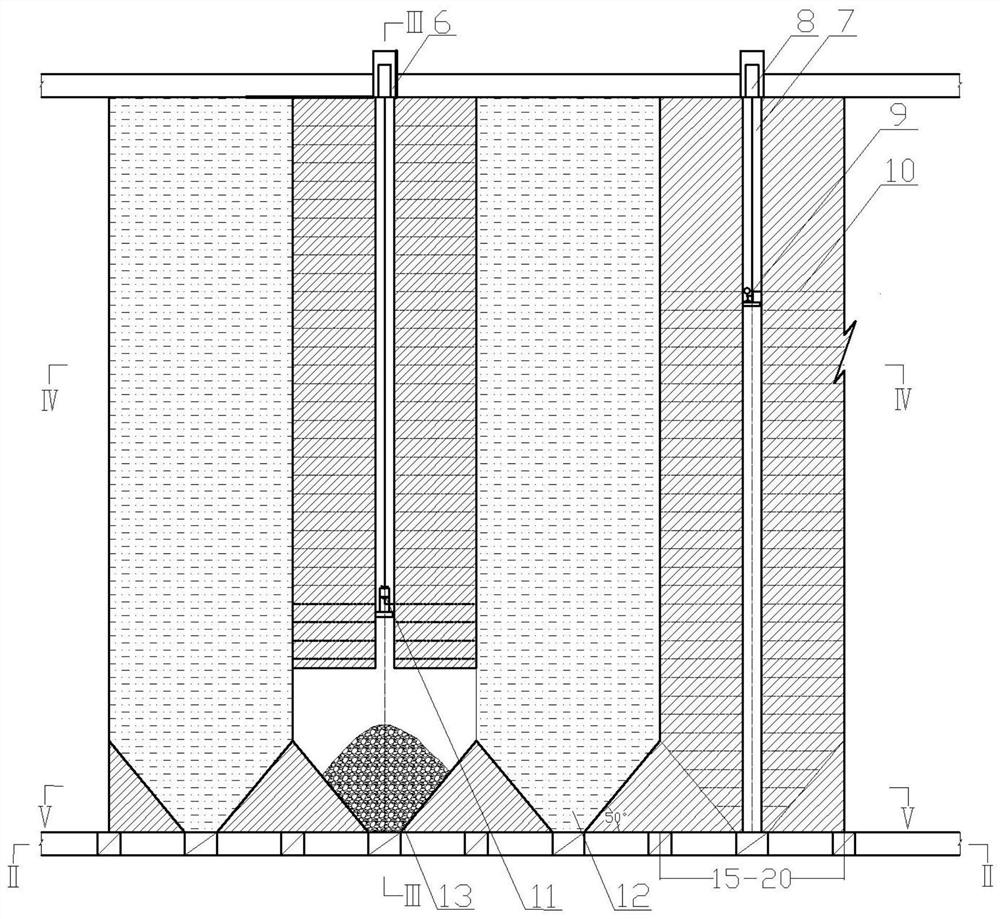

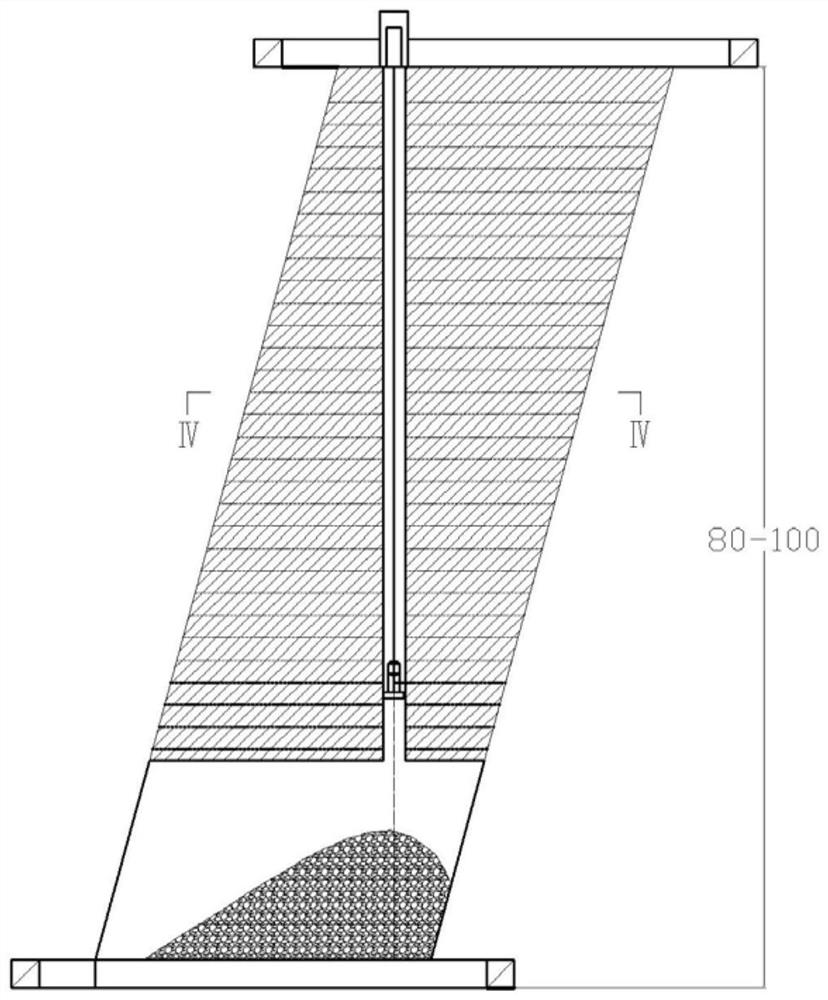

[0034] (1) The stope is arranged vertically to the direction of the ore body, which is divided into a one-step stope and a two-step stope. The width of the stope is 15-20m, and the length is the thickness of the ore body; the stage height is 80-100m.

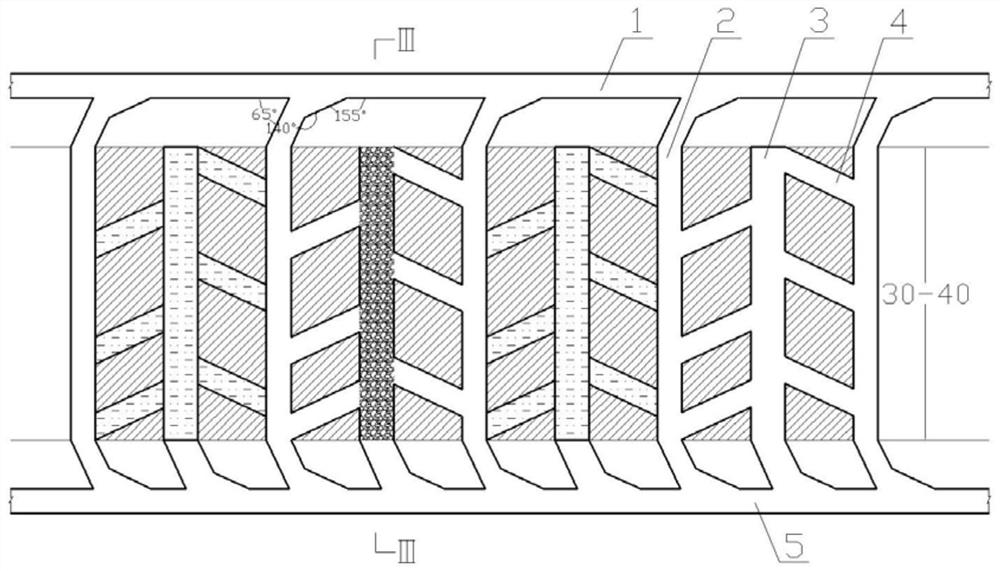

[0035] (2) In the surrounding rocks of the upper and lower walls 10-15m away from the ore body, excavate the out-of-vein transportation roads 1 and 5 along the ore body, and use the mining roadway 2 arranged between the first-step stope and the second-step stope Unicom, the bottom roadway 3 is arranged in the center of the bottom of the stope, and the ore loading route 4 with a spacing of 8-12m is used to connect the ore exit level roadway 2 and the bottom roadway 3.

[0036] (3) Lower the down-the-hole drilling rig rock drilling unit 9 to the rock drilling face with the hoisting equipm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com