Patents

Literature

67results about How to "Reduce the amount of mining and cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium-length hole mining method in multiple blasting free faces of high dipping thin veins

InactiveCN102635356AIncrease job securityStrong mining continuityUnderground miningSurface miningPunchingMineralogy

The invention discloses a medium-length hole mining method in multiple blasting free faces of high dipping thin veins. The medium-length hole mining method is characterized by comprising the steps of: arranging ore blocks along the trend of a core body, dividing the ore body into a medium section and a segment in the altitude; drilling a gate way in the segment and arranging in veins along the ore body; arranging a flat ore removal structure on the bottom along the veins; arranging a cutting raise from one ends of the ore blocks, arranging a manway at the other ends of the ore blocks; and upwards and downwards punching forwards leaning medium-length holes, with the cutting raise as free faces, and blasting caved ores in the segment by multiple free faces, and withdrawing the ore centrally at the bottom. The medium-length hole mining method has the remarkable characteristics of high mining safety, little resource dilution rate, good production continuity, high level of mechanization, low cost, high efficiency, low labor intensity and the like.

Owner:CENT SOUTH UNIV

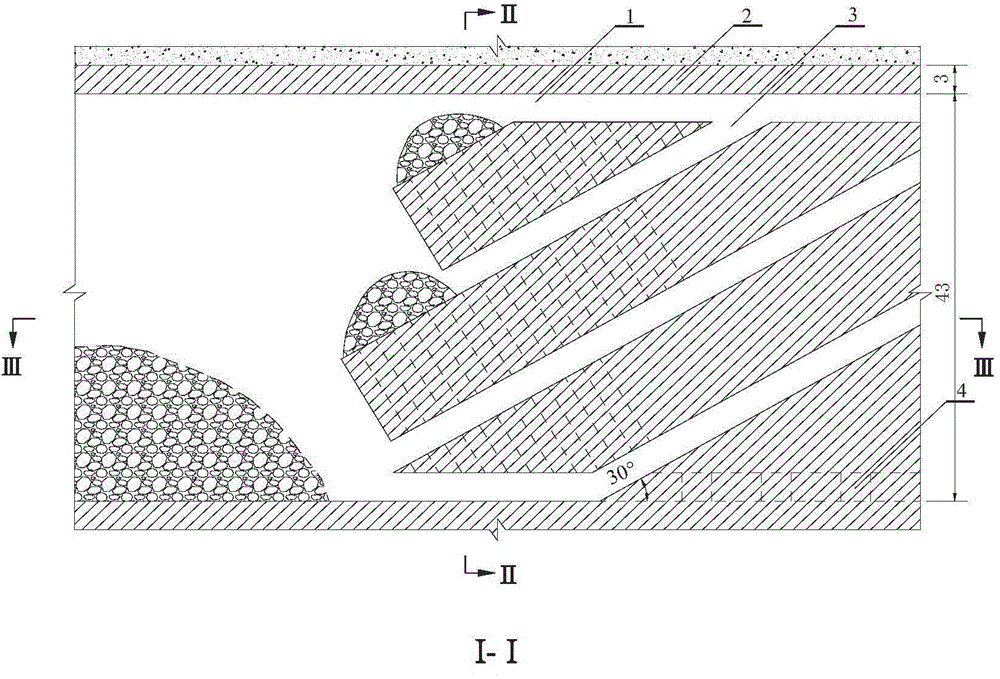

Novel mining method of gently-inclined thin and medium thickness ore bodies

InactiveCN103590831ARealize complementary advantagesJob safetyUnderground miningSurface miningWorkloadStoping

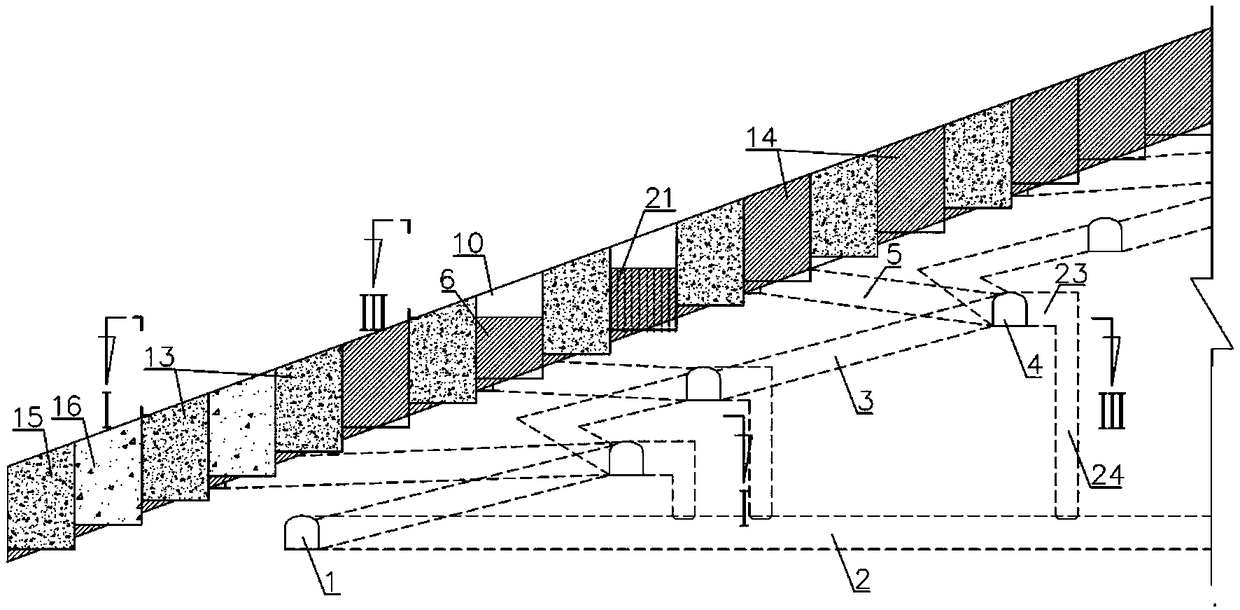

The invention discloses a novel mining method of gently-inclined thin and medium thickness ore bodies. According to the method, ore bodies in one stope are stoped by dividing the stope into two stope areas through steps: firstly, stoping is performed at the stope area (1) by using a pillarless sublevel caving method: the ore bodies are directly caved in single sublevel by using medium-length blastholes; a certain empty area formed after ore removal is used as a free surface for stoping of the stope area (2); then, the stoping is performed at the stope area (2) by using a blasting force carrying mining method; fan-shaped medium-length blastholes are arranged in a manner perpendicular to the ore body tendency, and are filled with powder according to sections, the decking parts are the parts from the lower disc boundaries of the ore bodies to the hole bottoms; the empty area formed during the stoping of the stope area (1) is used as a free surface for blasting row by row; ores in the stope area (2) are thrown in the empty area by using the blasting force. The method integrates the pillarless sublevel caving method and the blast force carrying mining method, so that the supporting difficulty and the workload are reduced, the operation is safer, the mining cost is low, and the labor productivity is high.

Owner:UNIV OF SCI & TECH BEIJING

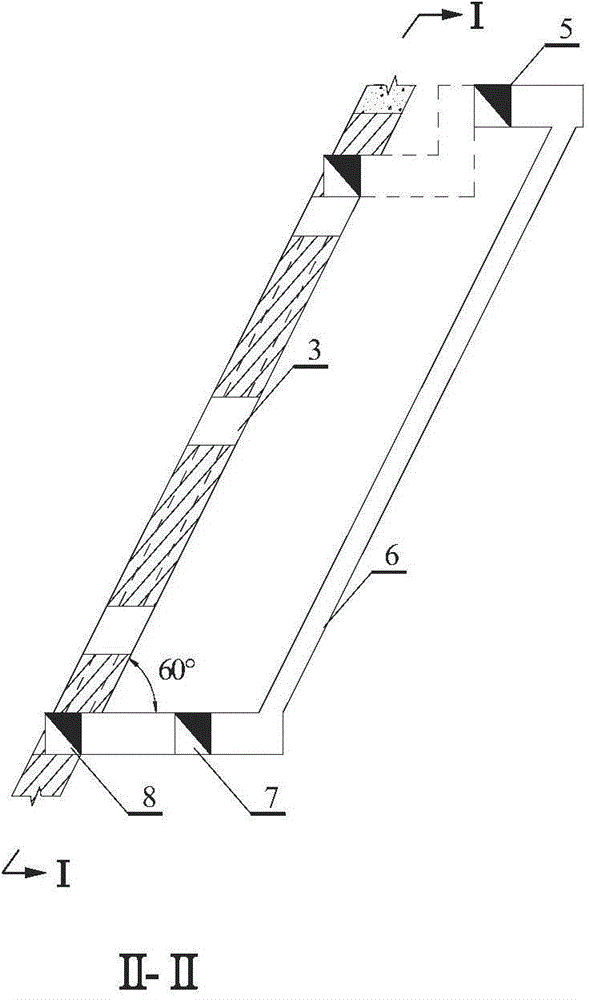

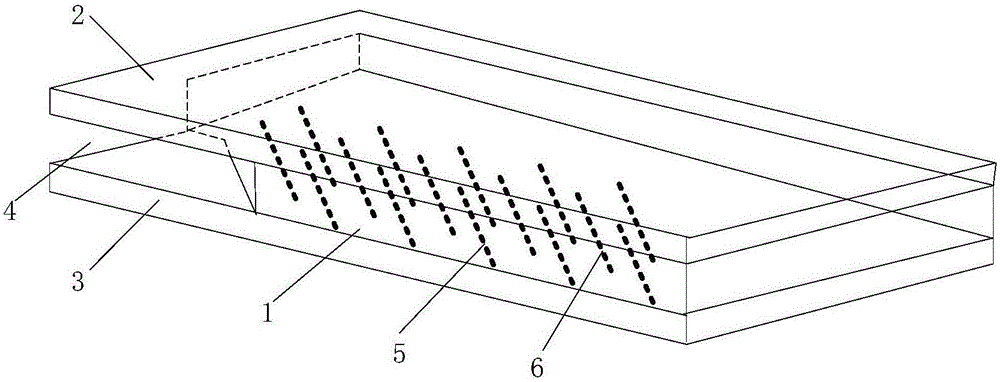

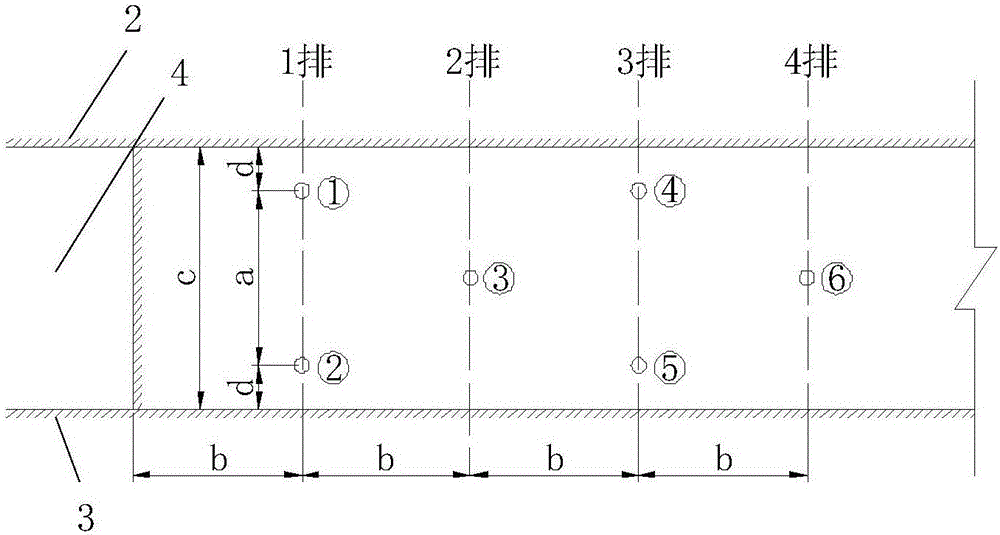

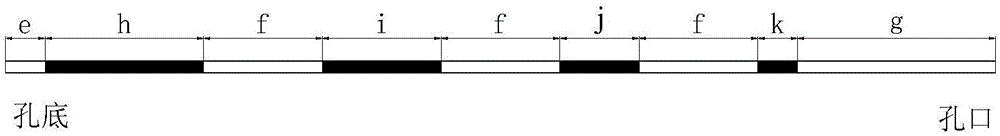

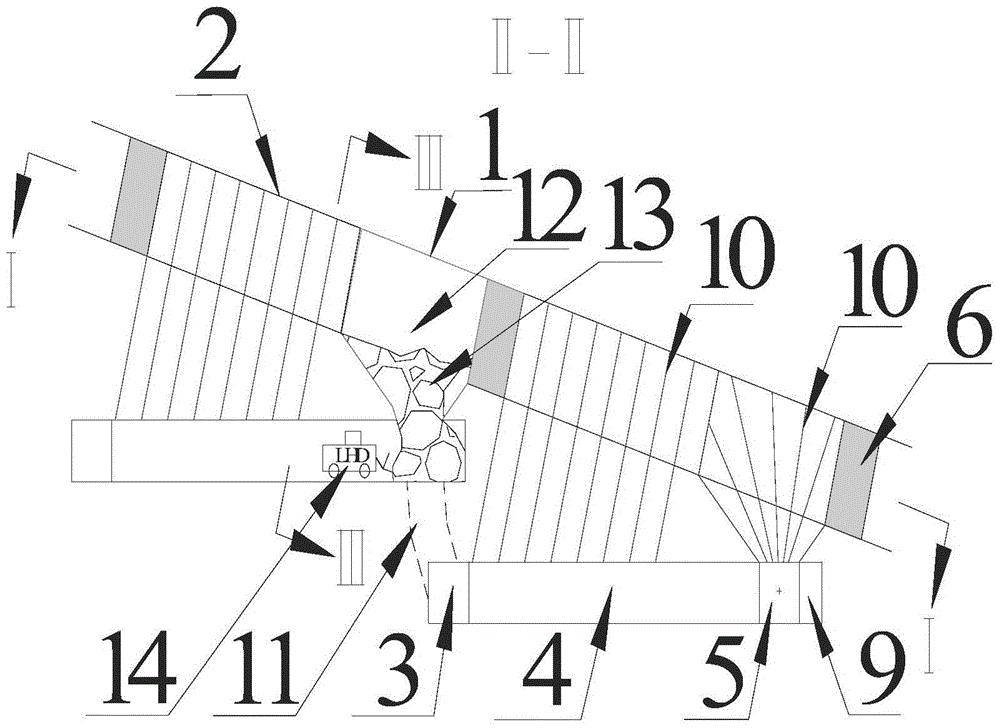

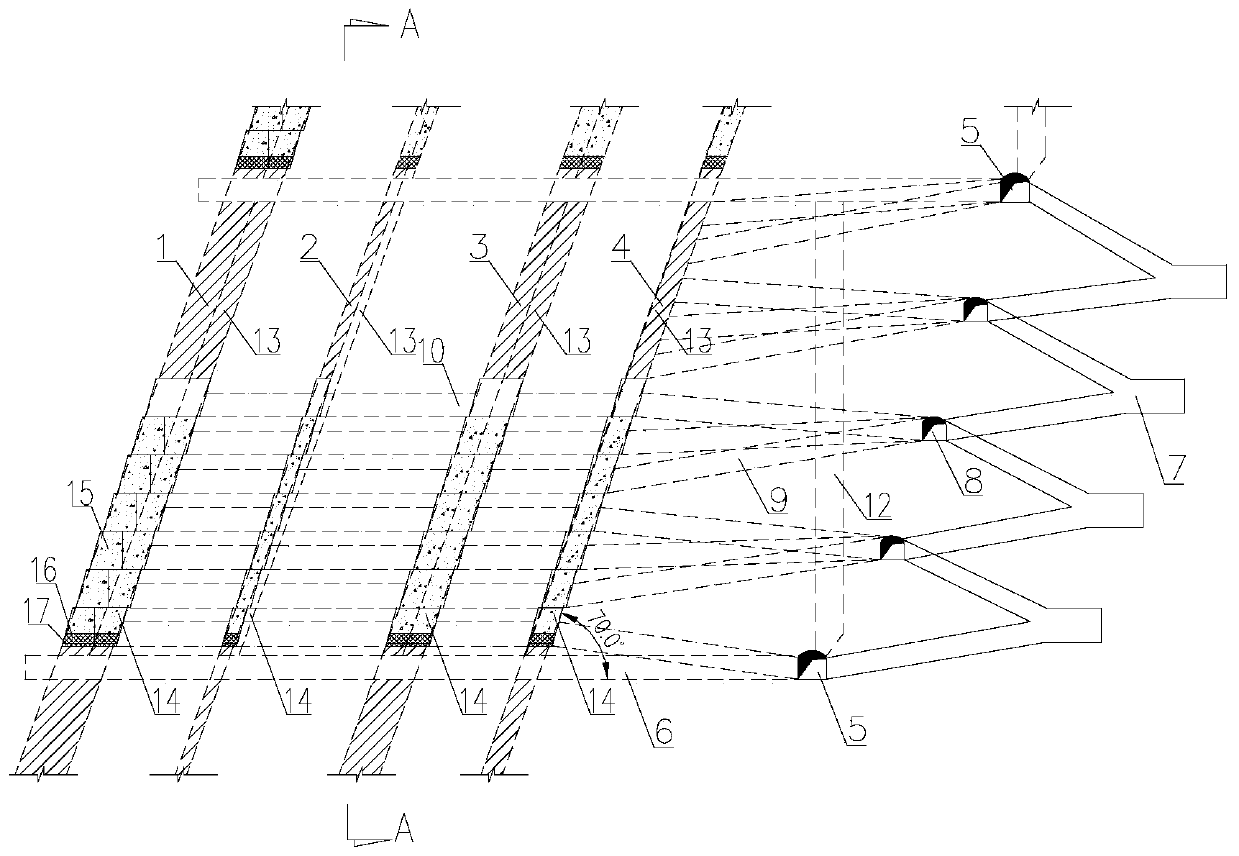

Diagonal ore-break-down medium-length hole mining method for steeply-inclined thin vein ore body

ActiveCN104989404AReduce depletionReduce lossesUnderground miningSurface miningRoom and pillar miningStart stop

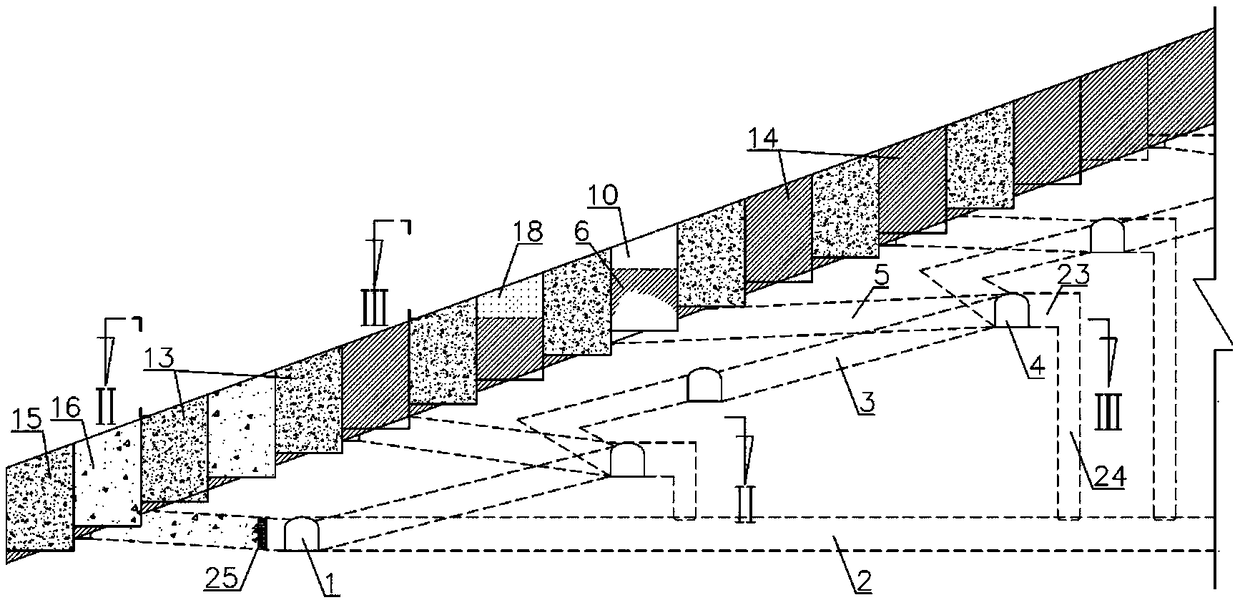

The invention discloses a diagonal ore-break-down medium-length hole mining method for a steeply-inclined thin vein ore body. The method comprises the following steps: arranging a stope according to the strike of the ore body, dividing rooms, pillars and sections according to the inclination direction of the ore body and arranging a level haulage roadway along the vein of the ore body from the footwall of the ore body; driving ore-drawing crosscuts into the ore body from where the level haulage roadway is located; horizontally arranging an undercutting roadway along the vein and parallely driving rock-drilling prospecting rises along slant height; arranging ore drop shafts to abut against the haulage roadway; starting stoping from one side of the stope, stopping stoping when the undercutting roadway is driven to the position of the first rock-drilling prospecting rise and then driving the rock-drilling prospecting rise; allowing a medium-length hole drilling machine to gradually travels from undercutting roadway to rock-drilling prospecting rise, drilling medium-length upward blast hole, carrying out denotation and drawing ore out from the bottom ore-drawing crosscuts; and after the first rock-drilling prospecting rise reaches a certain position, continuing driving the undercutting roadway until the position of the second rock-drilling prospecting rise is arrived at, carrying out medium-length hole mining, and repeating the above-mentioned operations until stoping of the stope is completed. The diagonal ore-break-down medium-length hole mining method has the advantages of high production efficiency, great production capacity and good operation security.

Owner:CENT SOUTH UNIV

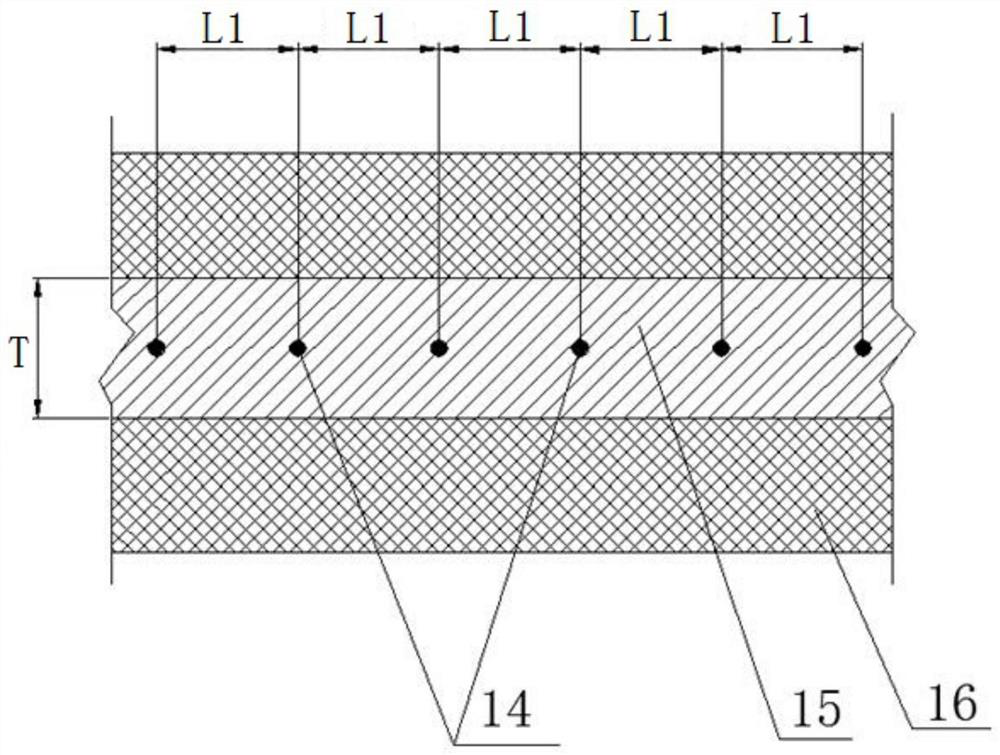

Full-staged combination drilling with blasting mining method

InactiveCN106761757AIncrease production capacityMaximum drilling efficiencyUnderground miningSurface miningEngineeringDeep hole

The invention discloses a full-staged combination drilling with blasting mining method. A stage haulage roadway, an ore drawing access road and a cutting undercut roadway are arranged at the bottom of a room. The ore drawing access road serves as a haulage channel of caved ores in the whole stage. The undercutting roadway serves as a construction space of a fan-shaped medium-depth hole on the lower portion, the fan-shaped medium-depth hole is drilled upwards, and after blasting, trench undercut is formed. A cut raise is formed through one-time blasting of a large-diameter deep hole, and then a cut groove is formed through the cut raise to serve as an ore caving compensation space. A drilling chamber or a roadway which communicates with a transverse drift is formed on the top of the room to serve as a construction space of the large-diameter deep hole on the upper portion. The large-diameter deep hole and the fan-shaped medium-depth hole at the lower portion are combined for drilling. After the large-diameter deep hole and the fan-shaped medium-depth hole drilling is finished, the cutting groove serves as a free face and combined, or separate charging is conducted to blast for lateral caving. The mining and cutting engineering quantity is small, the preparation time of stoping is reduced greatly, the production capacity of the room is large, and the investment cost is saved.

Owner:JIANGXI UNIV OF SCI & TECH +3

Sub-level shrinkage caving method

InactiveCN104481543ASolve construction difficultiesSolve the costUnderground miningSurface miningMineralogyGround pressure

The invention relates to a sub-level shrinkage caving method. According to the sub-level shrinkage caving method, no large-area mined-out space appears in an extraction process, a hanging wall rock is supported by utilizing a caved ore in the early stage of extraction, and an upper overburden rock downwards moves to fill a mined-out space to control ground pressure along with bottom ore removal in the later stage of the extraction, so that safe and high-efficiency extraction is achieved; ores are aggregated in a bottom trench in a bottom structure, and the bottom trench is connected with a travelling roadway by adopting a herringbone non-track ore loading feed path, so that the sub-level ore removal is realized; when undercutting work is carried out, only a part of caved ores are discharged, fragmented rock mass in an ore block keeps that the hanging wall rock is not collapsed and ensures that a sufficient free compensating space is enough for upper ore dropping, the dropped ore is discharged from the non-track ore loading feed path, and then is put into a mine car to leave from a stope, then ore dropping is carried out again, the process is circulated till the ores contained in the ore block all drop in a blasting way, and finally large-scale ore removal is carried out; and the overburden rock continuously moves downwards to fill a mining area to control the ground pressure along with the continuous extraction of the ores during the large-scale ore removal.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Double-layered and bidirectional horizontal stripping open-stope backfilling mining method

ActiveCN108708726AReduce the number of installationsReduce the proportionUnderground miningSurface miningComputer science

The invention relates to the technical field of mining, in particular to a double-layered and bidirectional horizontal stripping open-stope backfilling mining method. The double-layered and bidirectional horizontal stripping open-stope backfilling mining method comprises the following steps: S7, separately forming two lower slice slicing stope openings in two sides of the tail of a vein connectionroadway, separately arranging lower slice stope connection roadways towards an lower slice stope of a stope in step one and an lower slice stope of a stope in step two from every lower slice stope; S8, continuing tunneling and arranging upper and lower slice connection roadways in the extension direction of the vein connection roadway from the tail of the vein connection roadway, and enabling thetails of the higher and lower slice connection roadways to be positioned between the two higher slice stopes of an adjacent horizontal stope below a horizontal stope in step S6; and S9, separately forming two upper slice stope openings in the two sides of the openings of the upper and lower slice connection roadways, separately arranging upper slice stope connection roadways towards an upper slice stope of the stope in step one and an upper slice stope of the stope in step two from every upper slice stope opening, and enabling the opening of each upper slice stope connection roadway to be positioned in the center of the corresponding upper slice stope.

Owner:CENT SOUTH UNIV

Method for mining inclined or steeply inclined hard thin ore body

PendingCN112177611AChange in stabilityControl mining boundariesUnderground miningSurface miningMining engineeringBlast effects

The invention discloses a method for mining an inclined or steeply inclined hard thin ore body. As for the hard and stable inclined / steeply inclined hard thin ore body, stopes and studs are divided along the trend of the ore body, the height of a stope stage is 15-60 m, and the height of a subsection is 5-20 m. Mining from a middle section of each stope to the two ends or from one end to the otherend according to the overall stoping sequence of the stopes is carried out. Upward or downward medium-length holes are constructed in a rock drilling roadway, the medium-length holes in ore rock boundaries achieve ore rock presplitting, and the medium-length holes in the middle achieve ore breaking after presplitting. Pre-splitting blast holes are blasted by one step pitch before rock breaking blast holes, and the width of the step pitch is 3-5 m. Blasting of the pre-splitting blast holes is advanced to form pre-cracks through communication of the blast holes, and the effects of ore-rock boundary separation and blasting effect blocking are achieved. The rock breaking blast holes are formed in the middles of the stopes, so that the stability condition of the ore body is changed, and natural caving is generated. After stope mining is finished, goafs are filled with tailings or sealed by sealing facilities.

Owner:ANHUI TONGGUAN (LUJIANG) MINING CO LTD +1

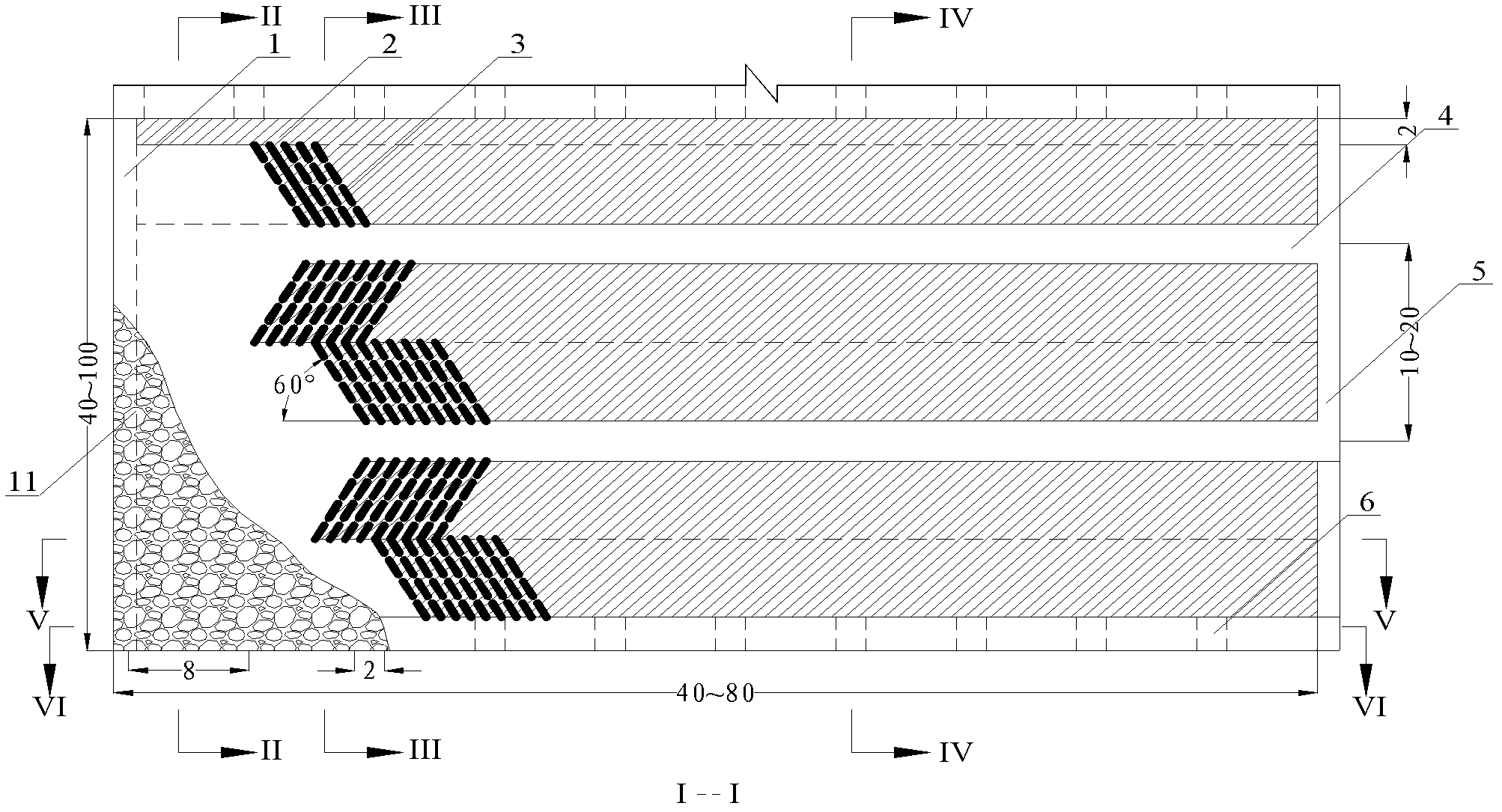

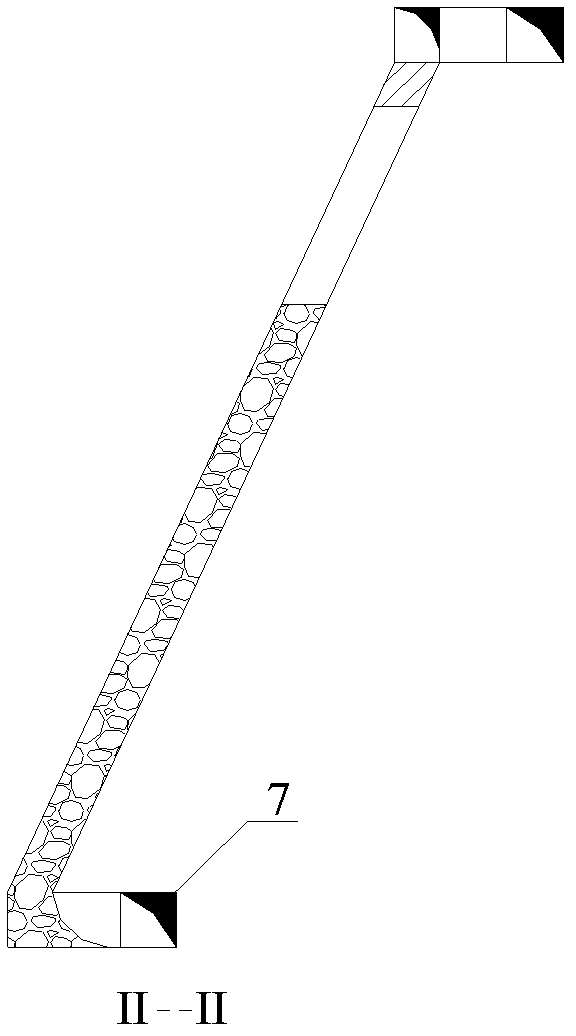

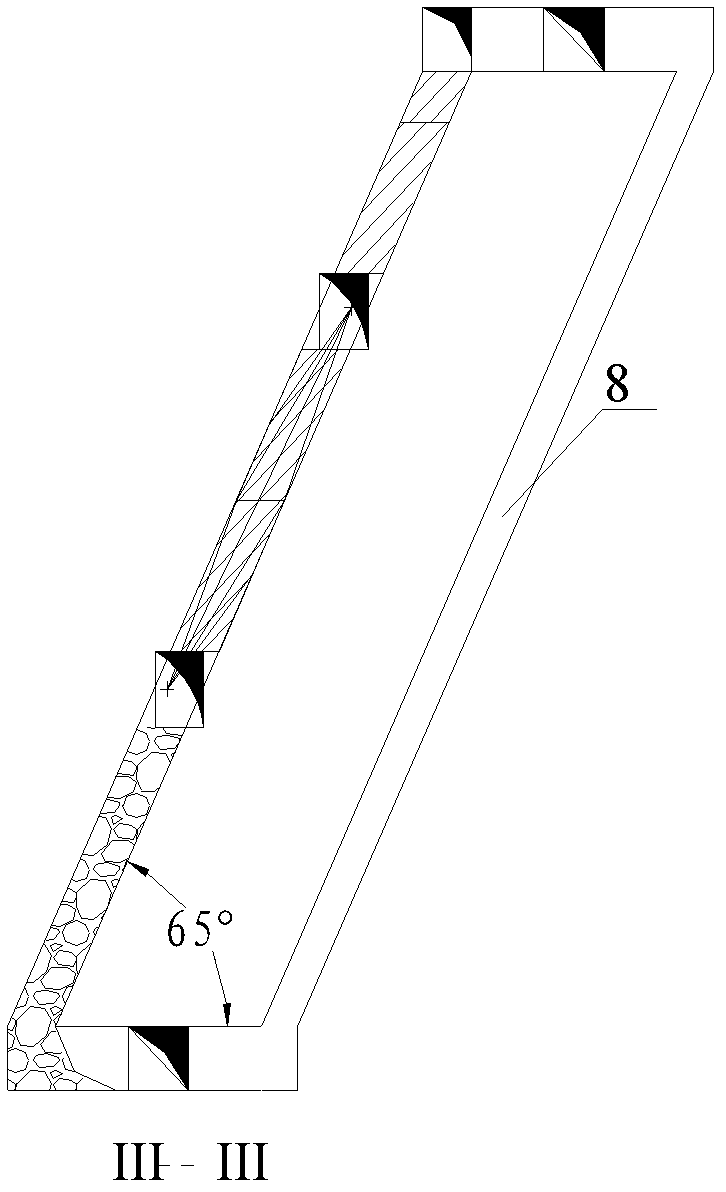

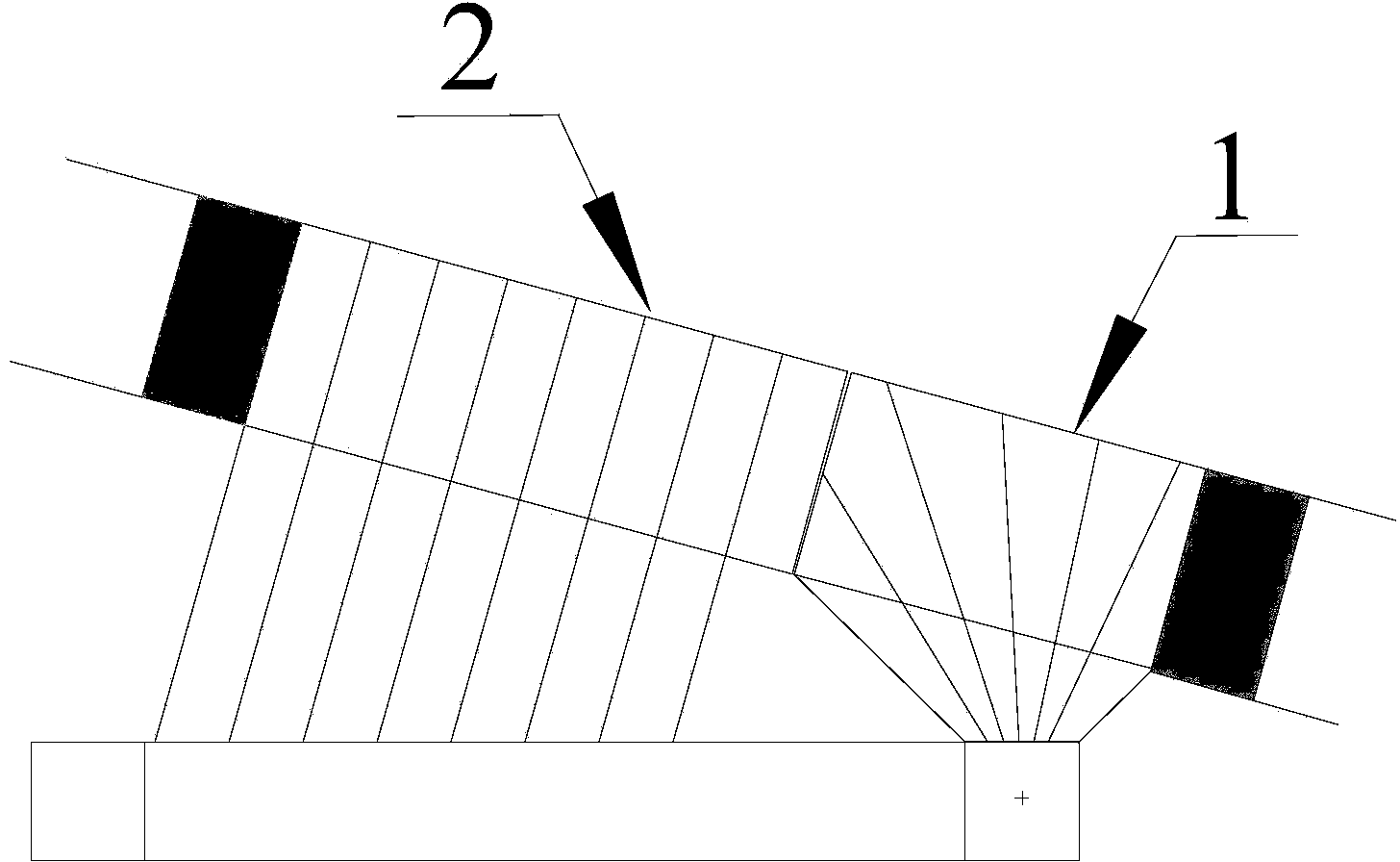

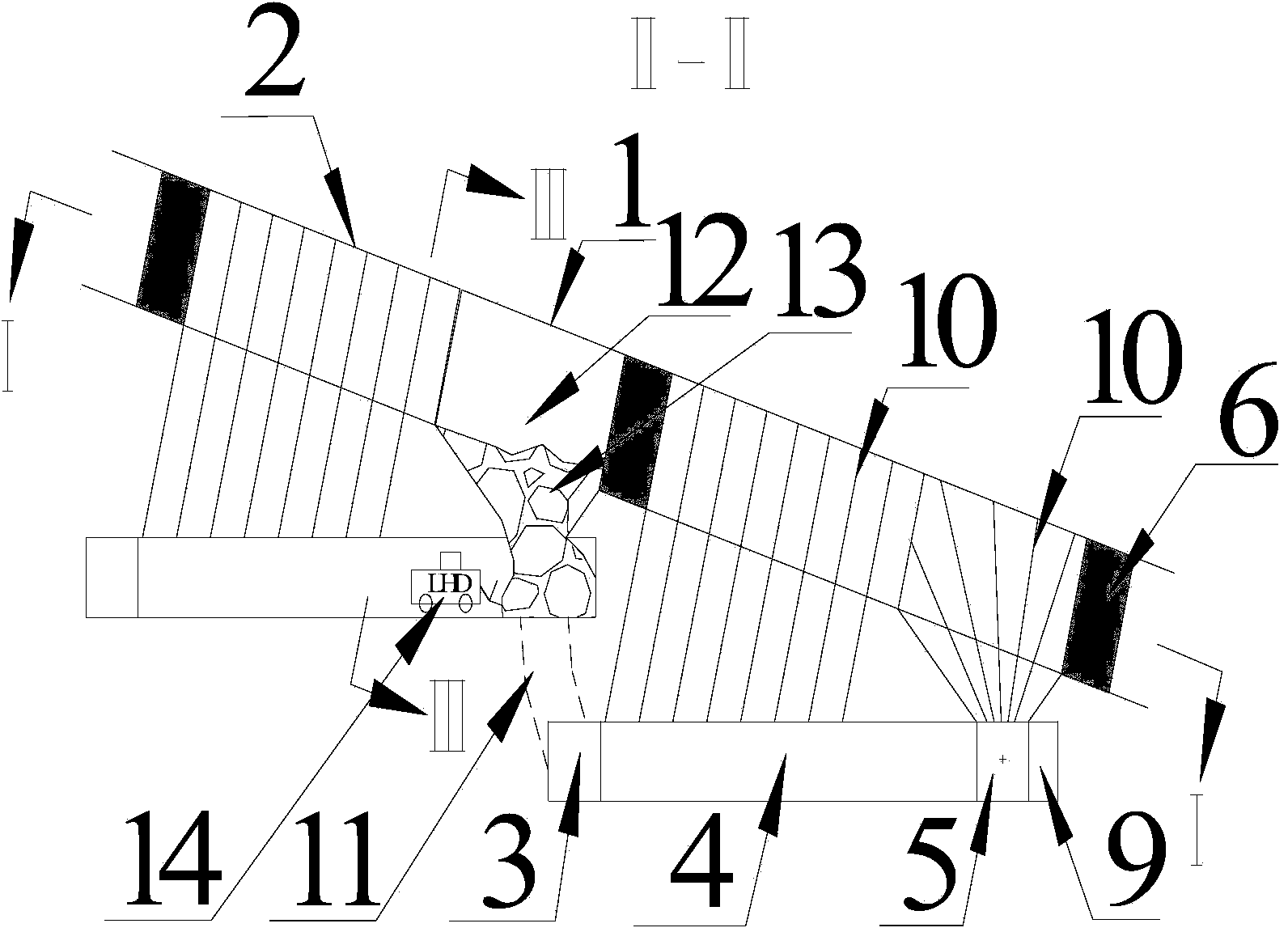

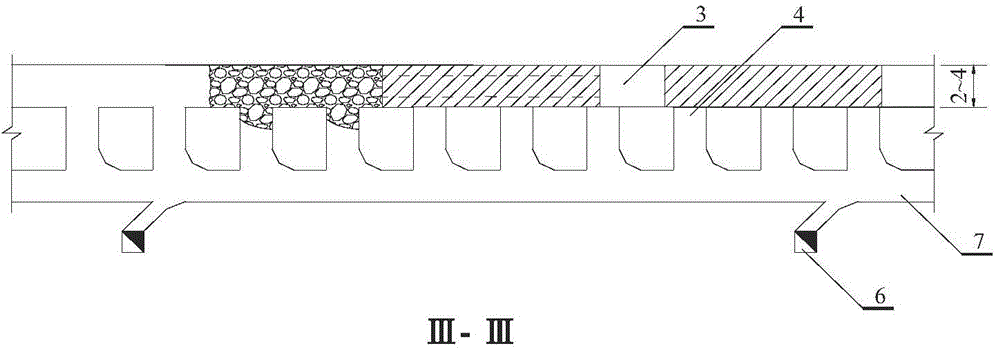

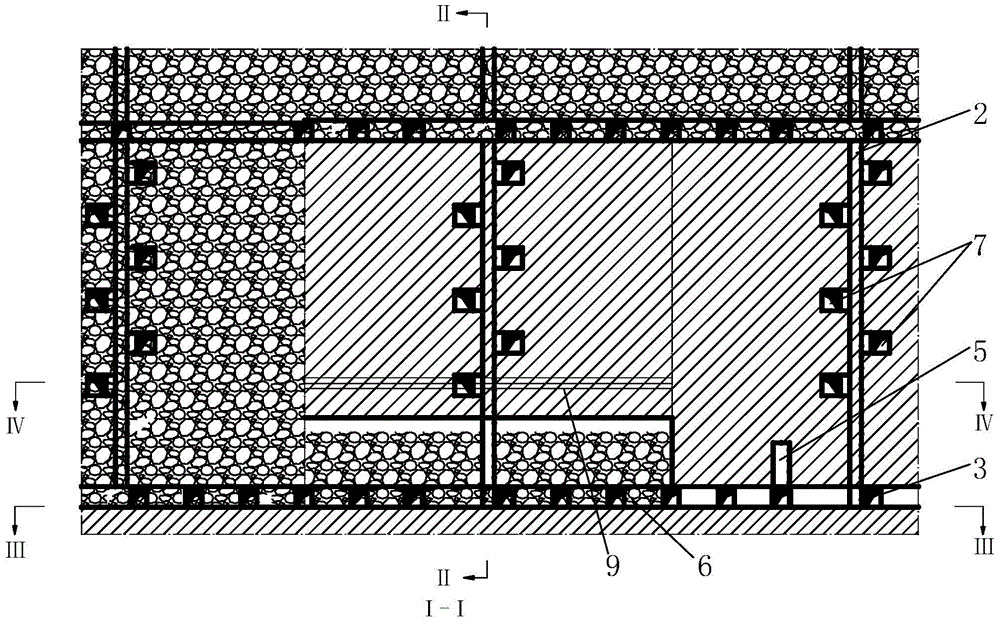

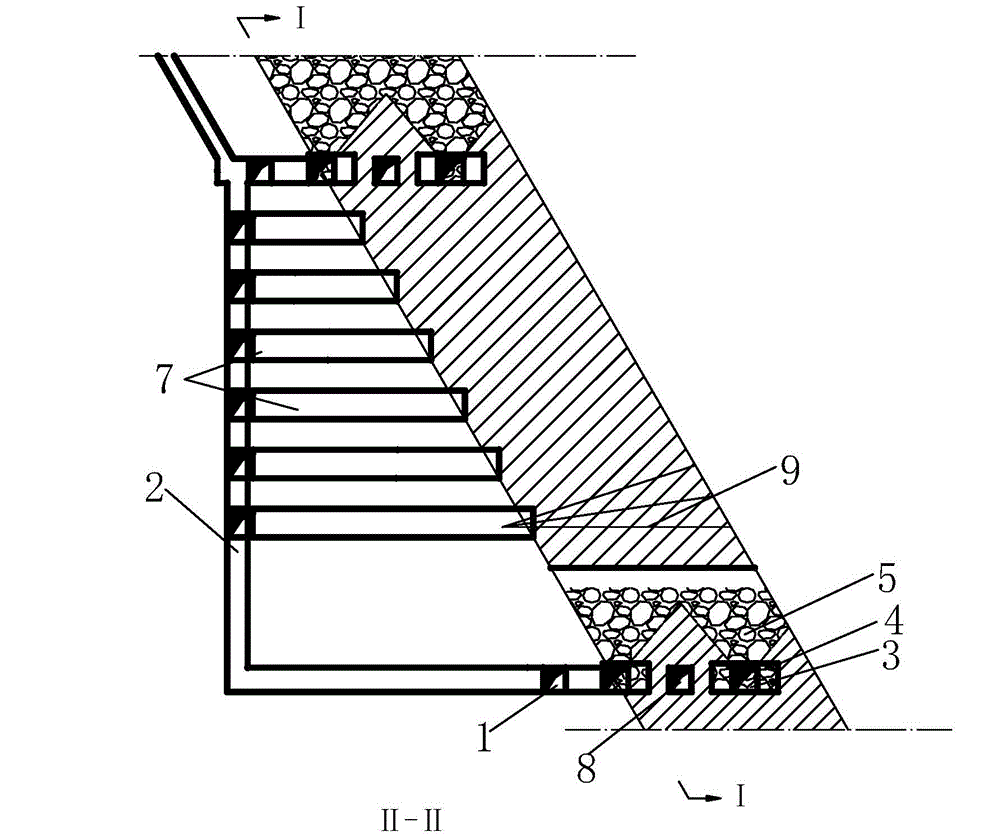

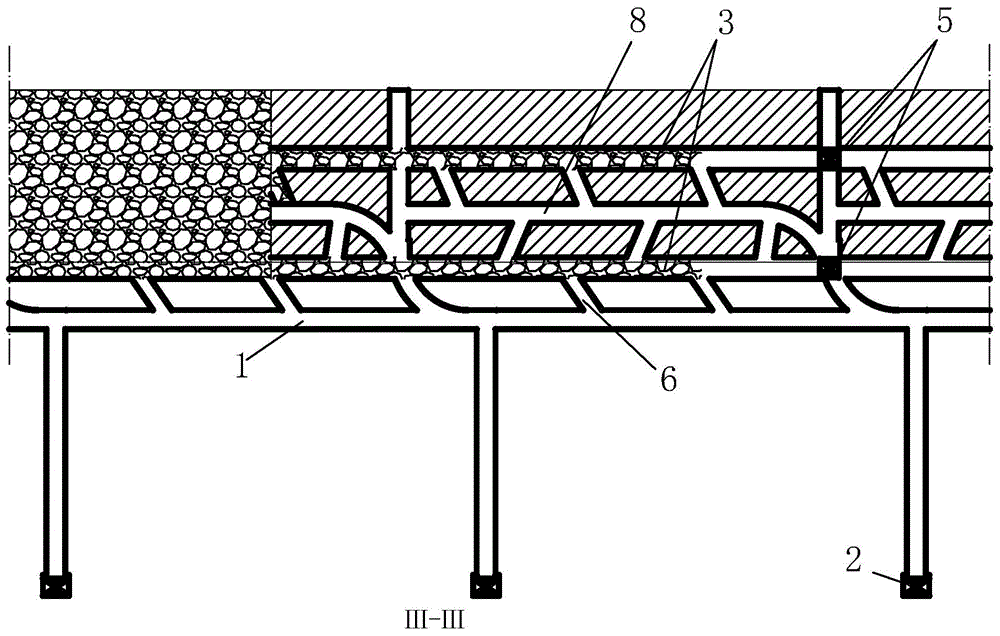

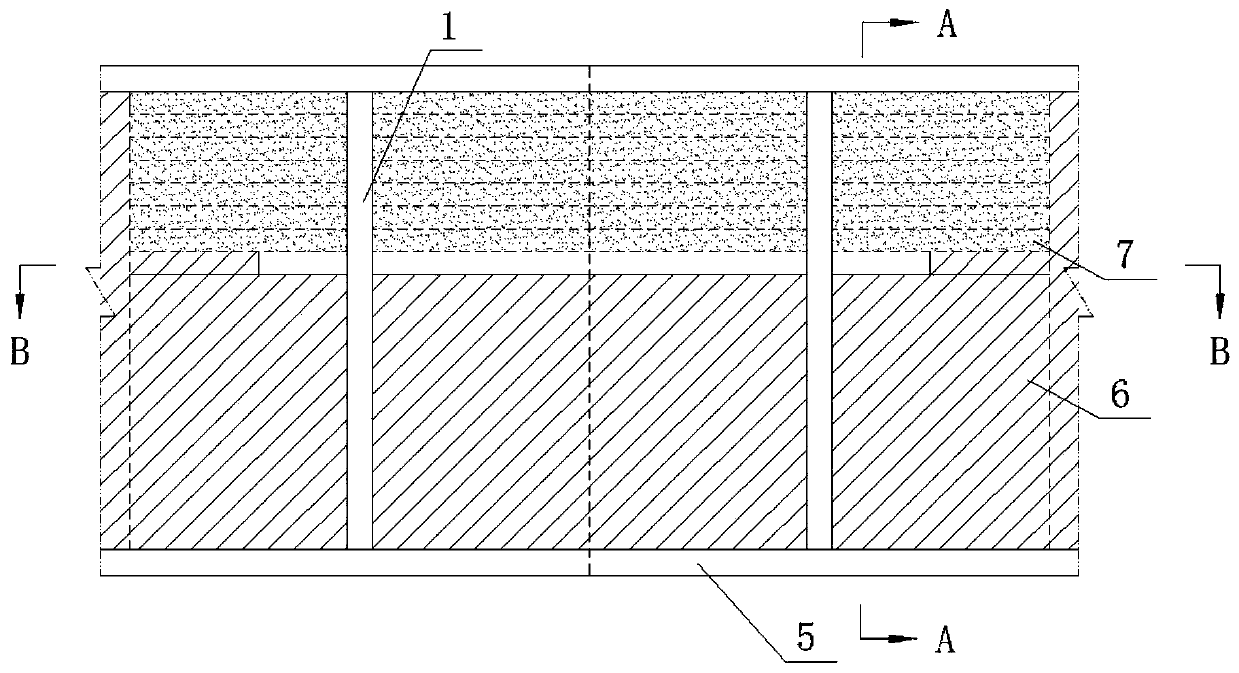

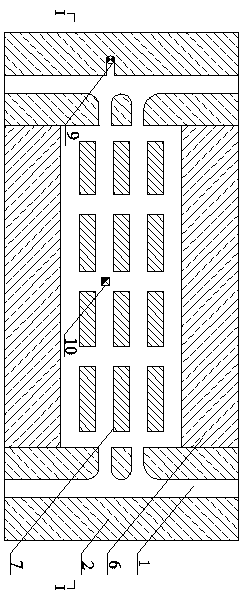

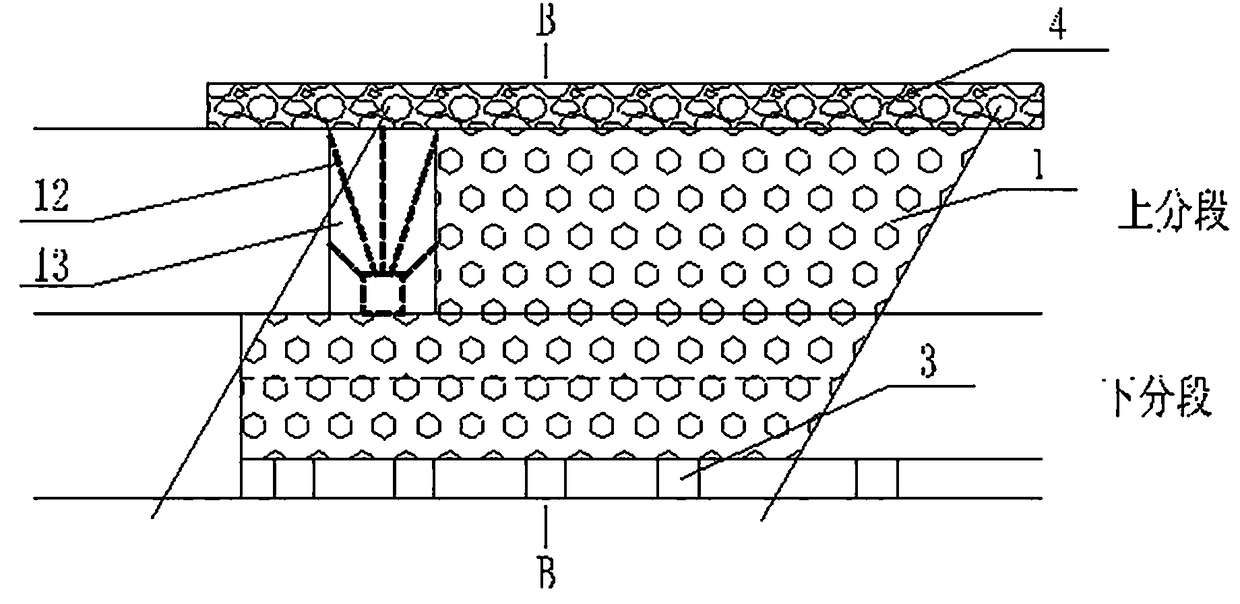

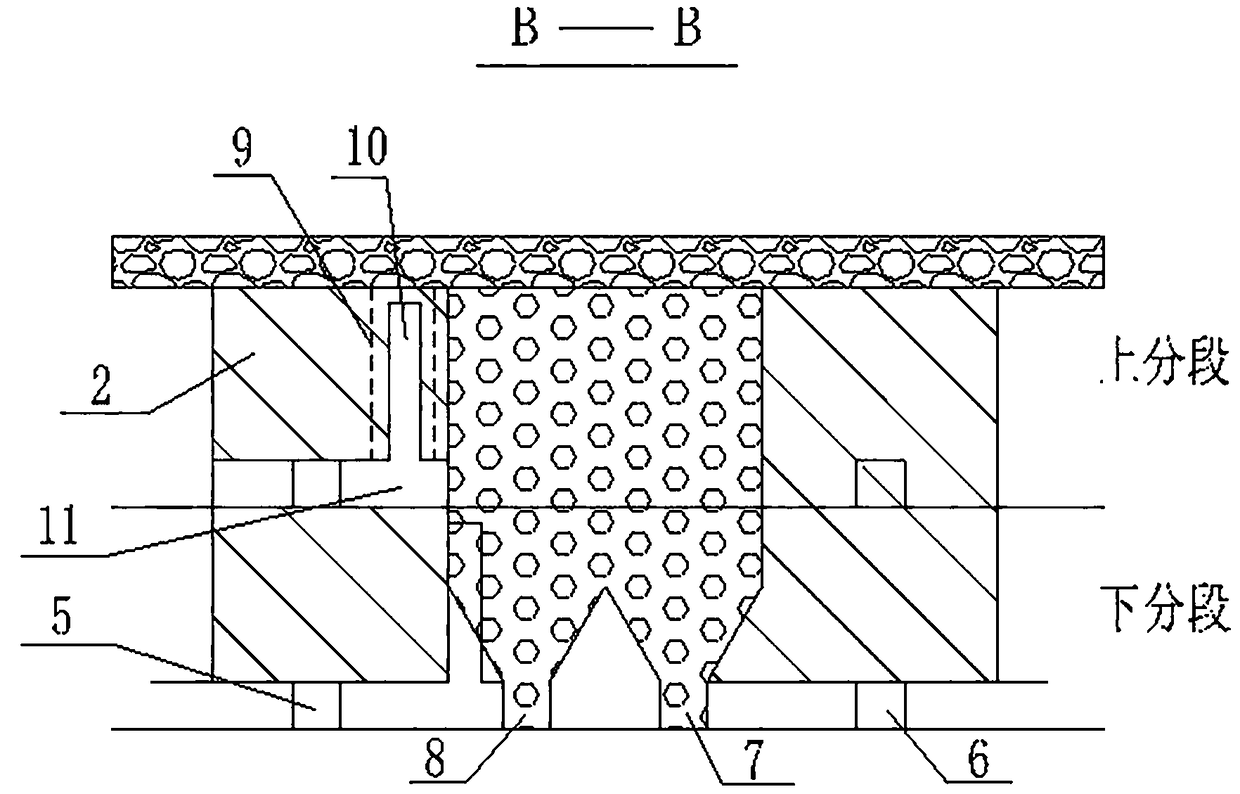

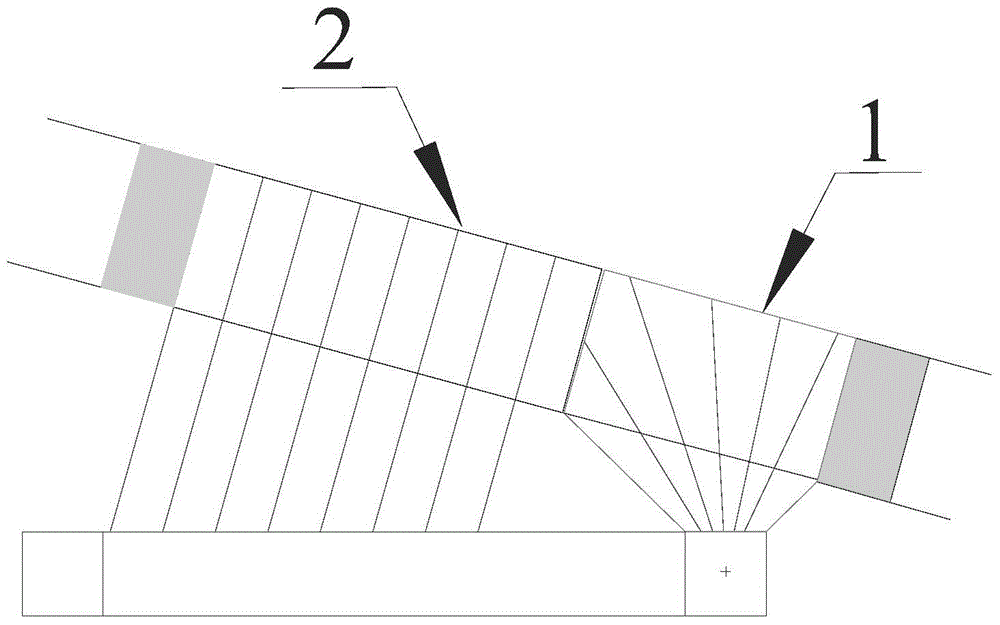

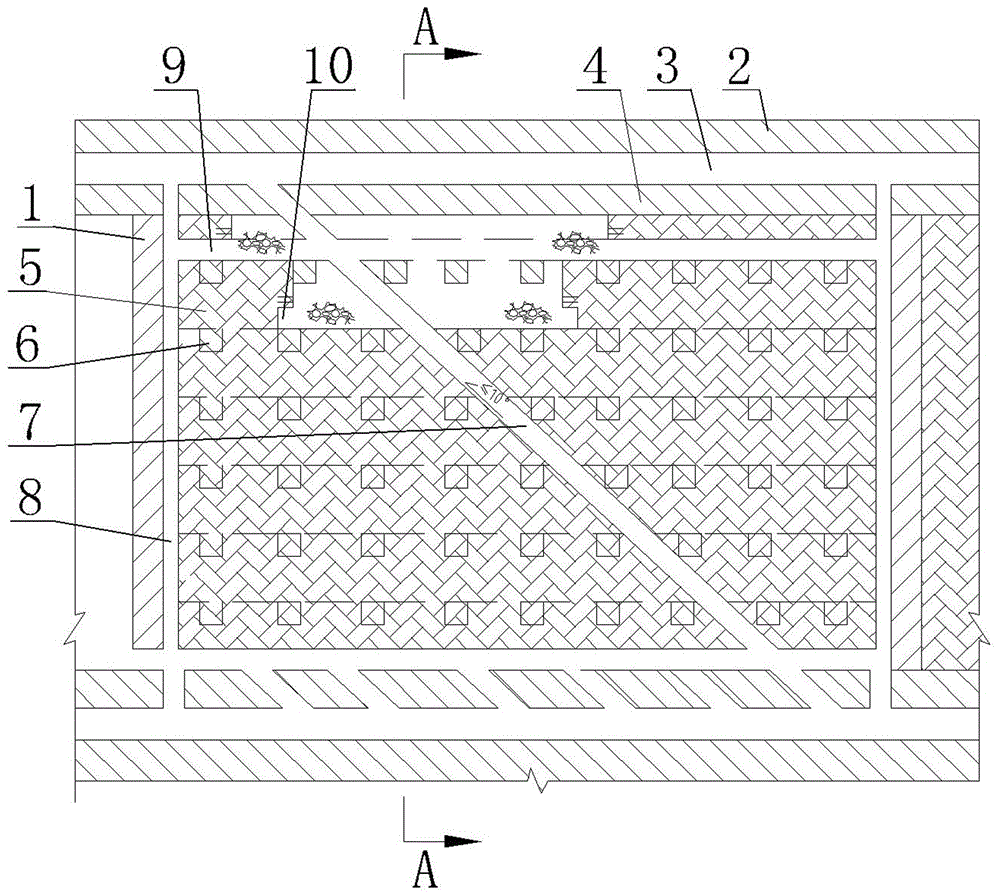

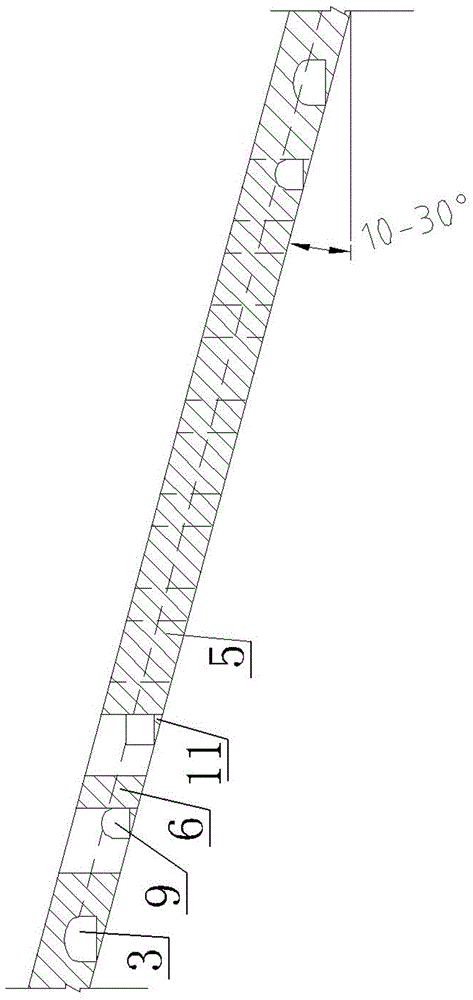

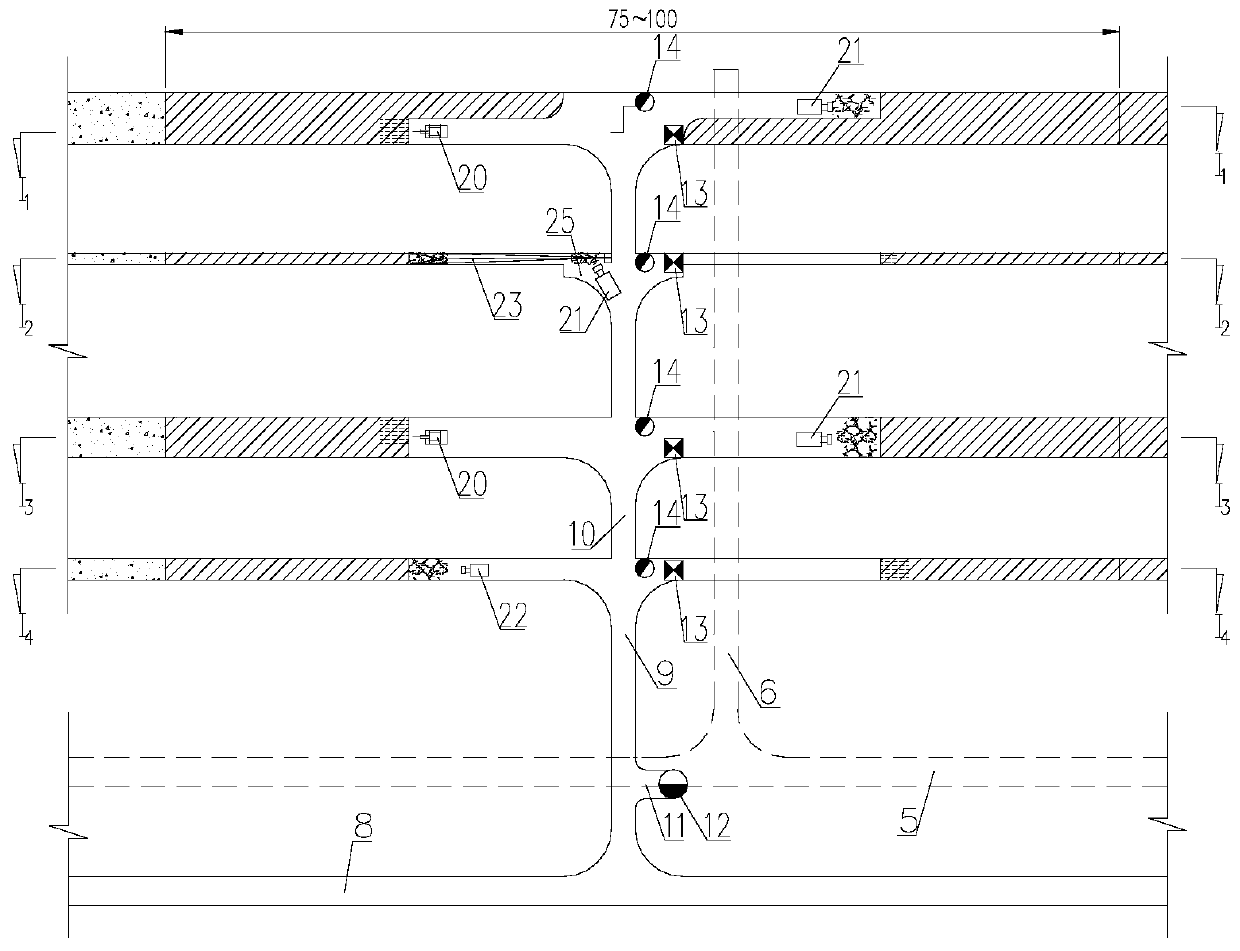

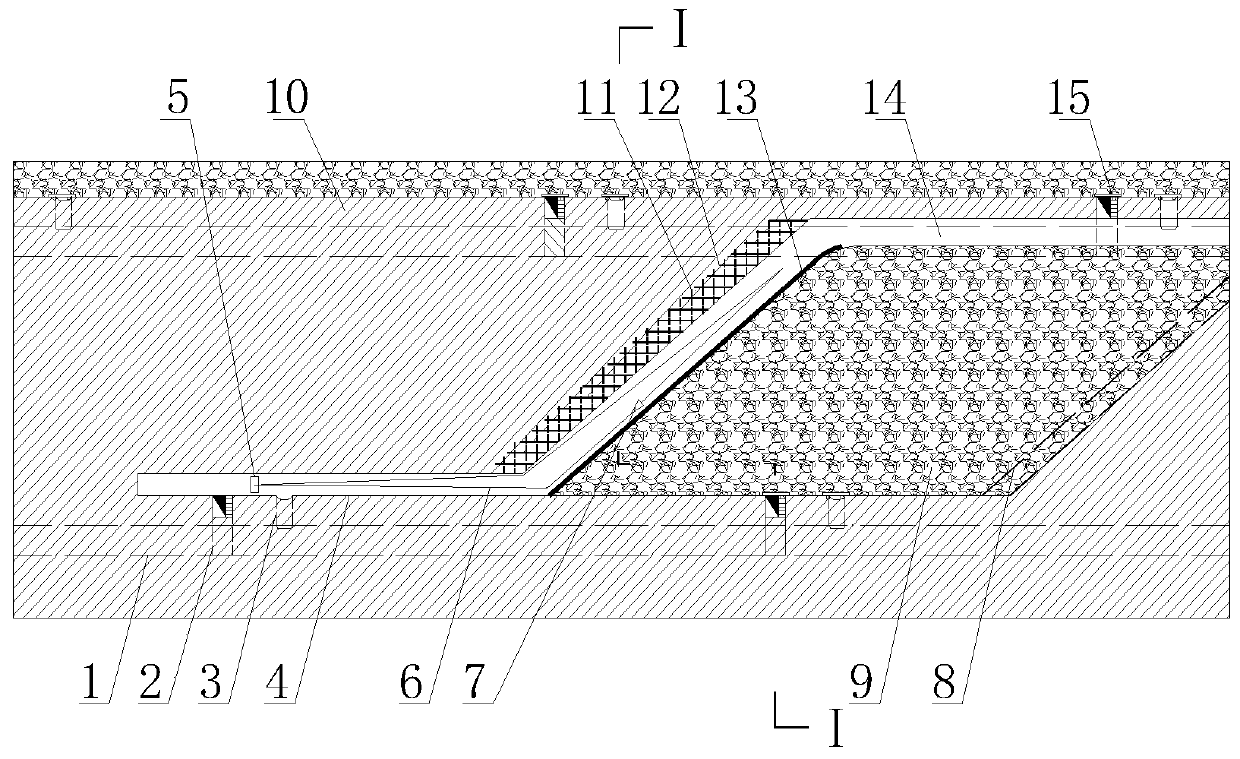

Sublevel open stoping backfilling mining method for gentle-dipping and medium-thickness ore body

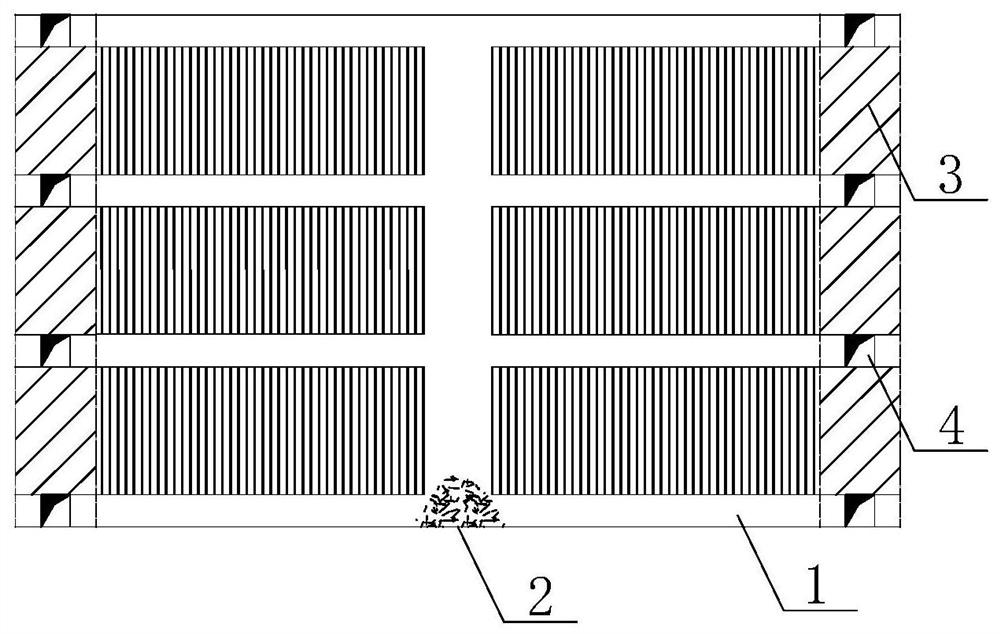

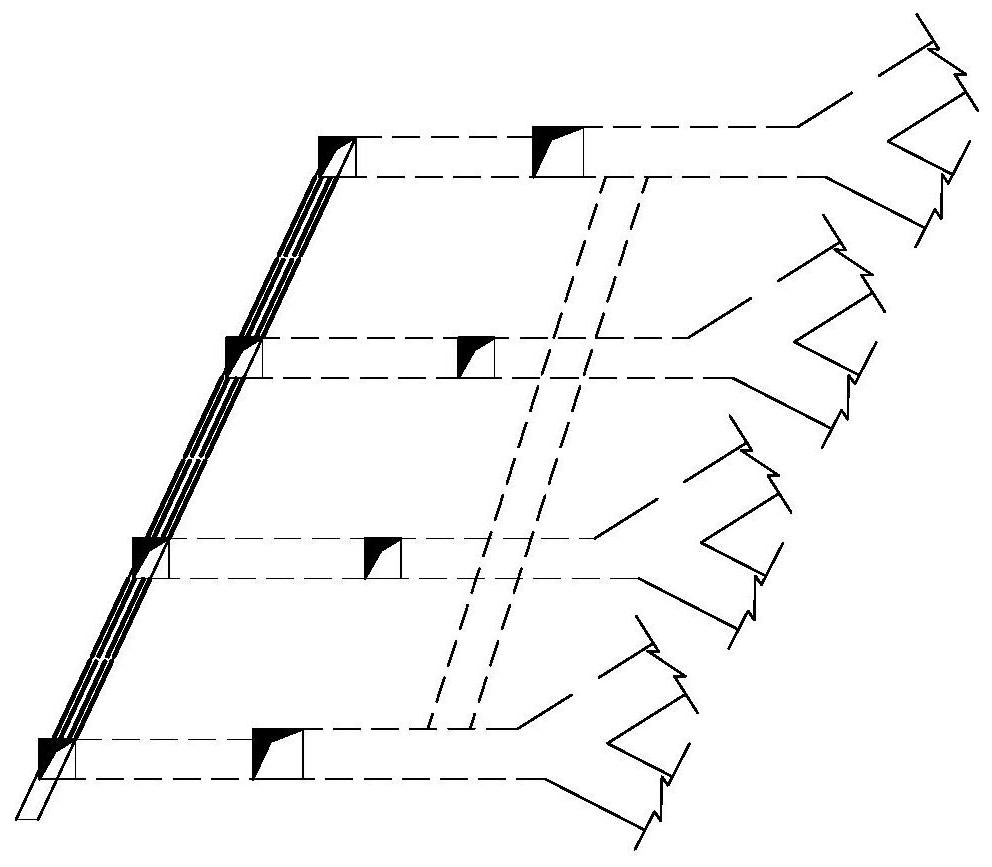

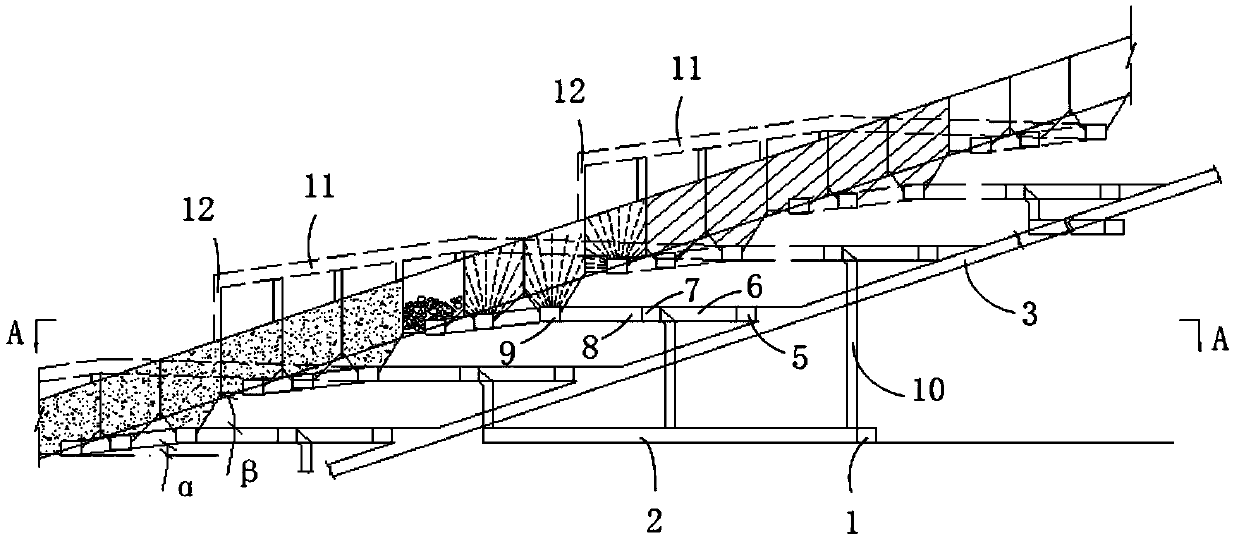

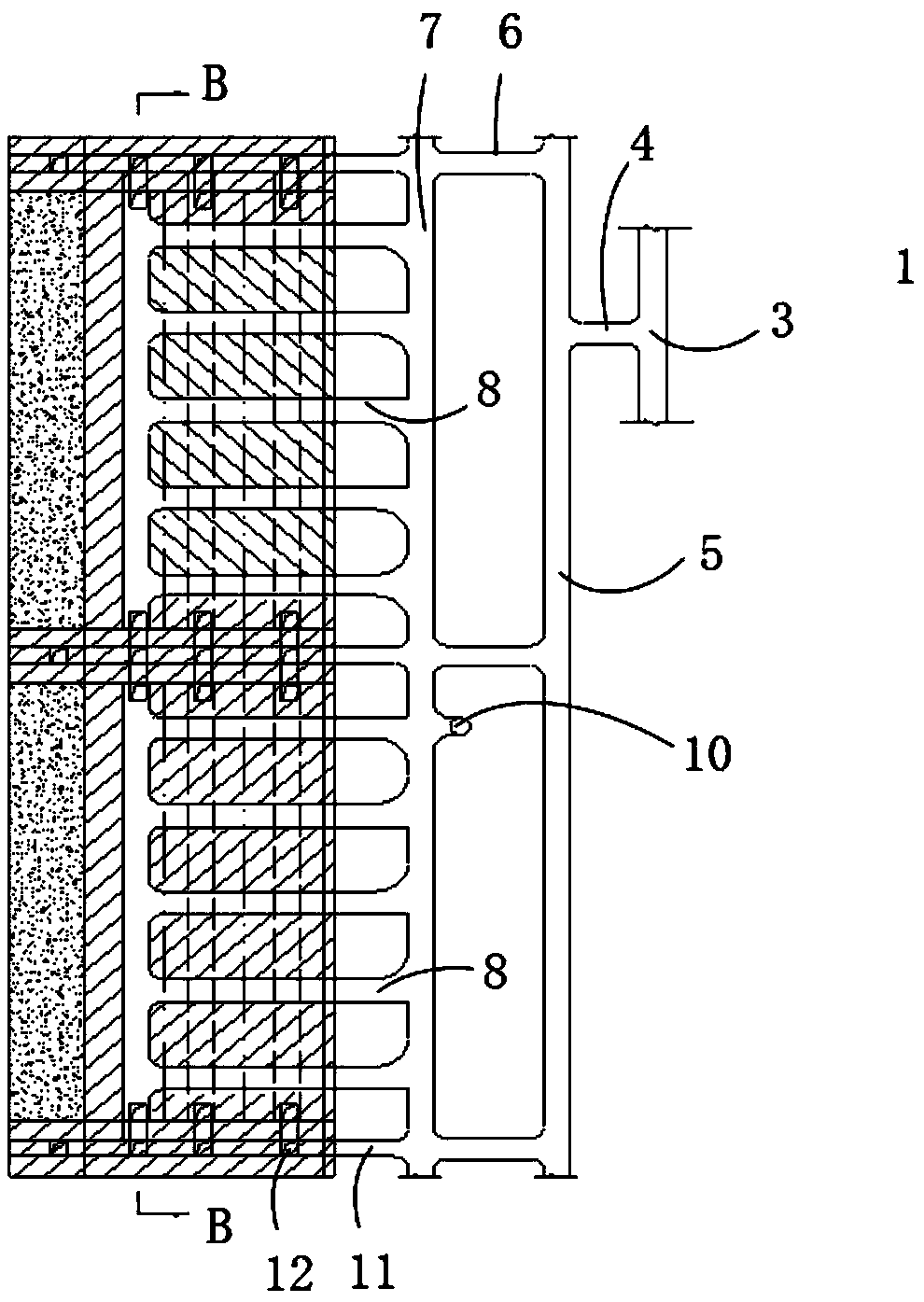

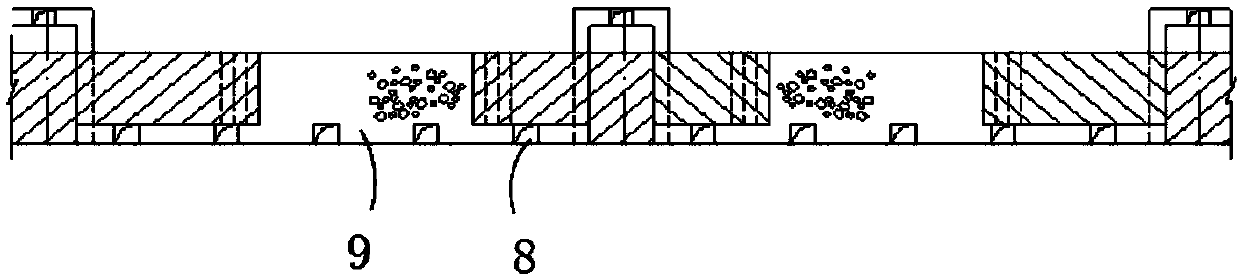

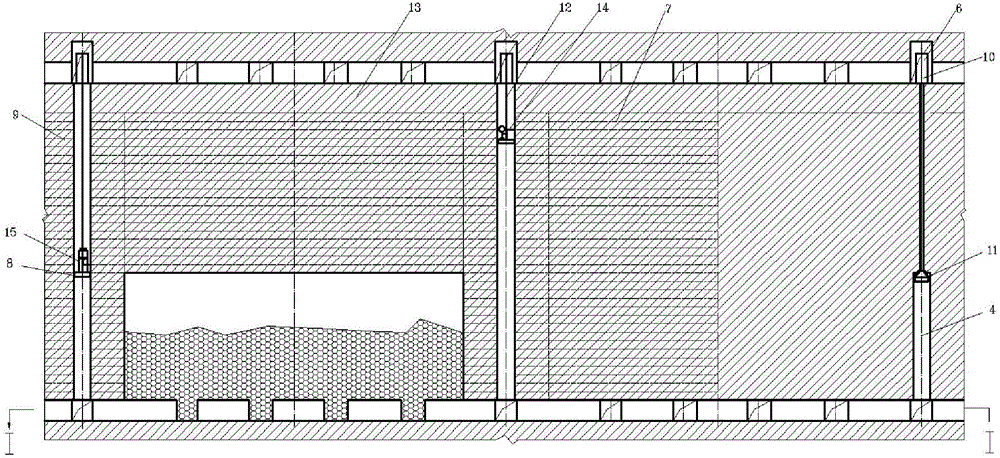

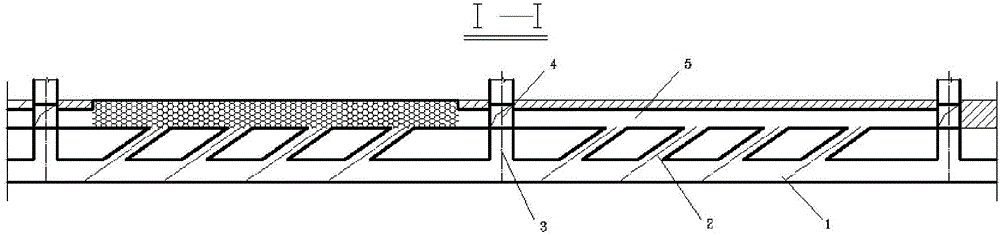

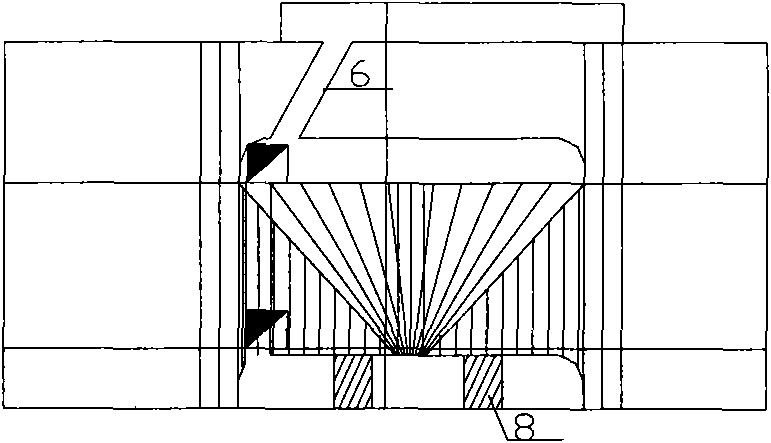

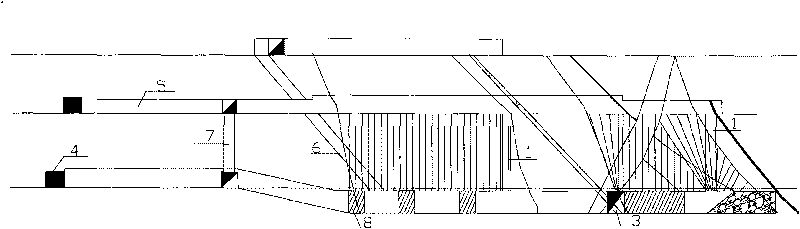

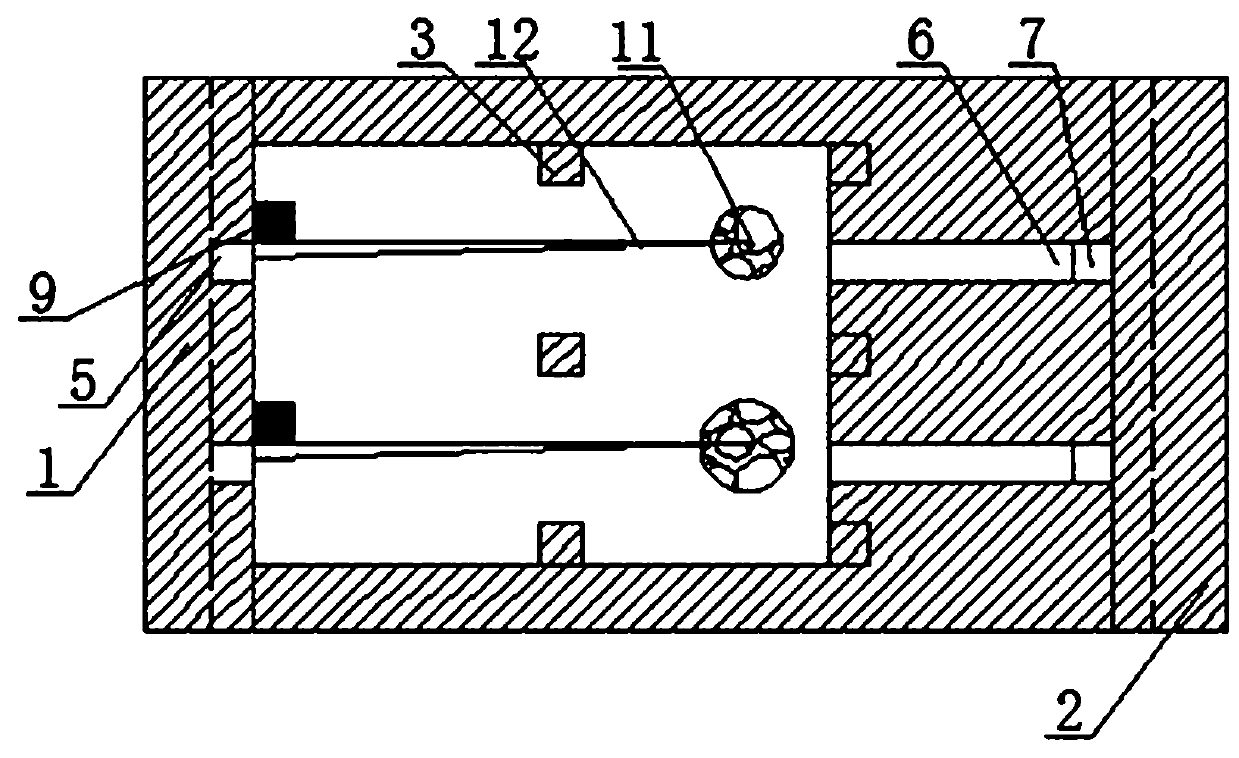

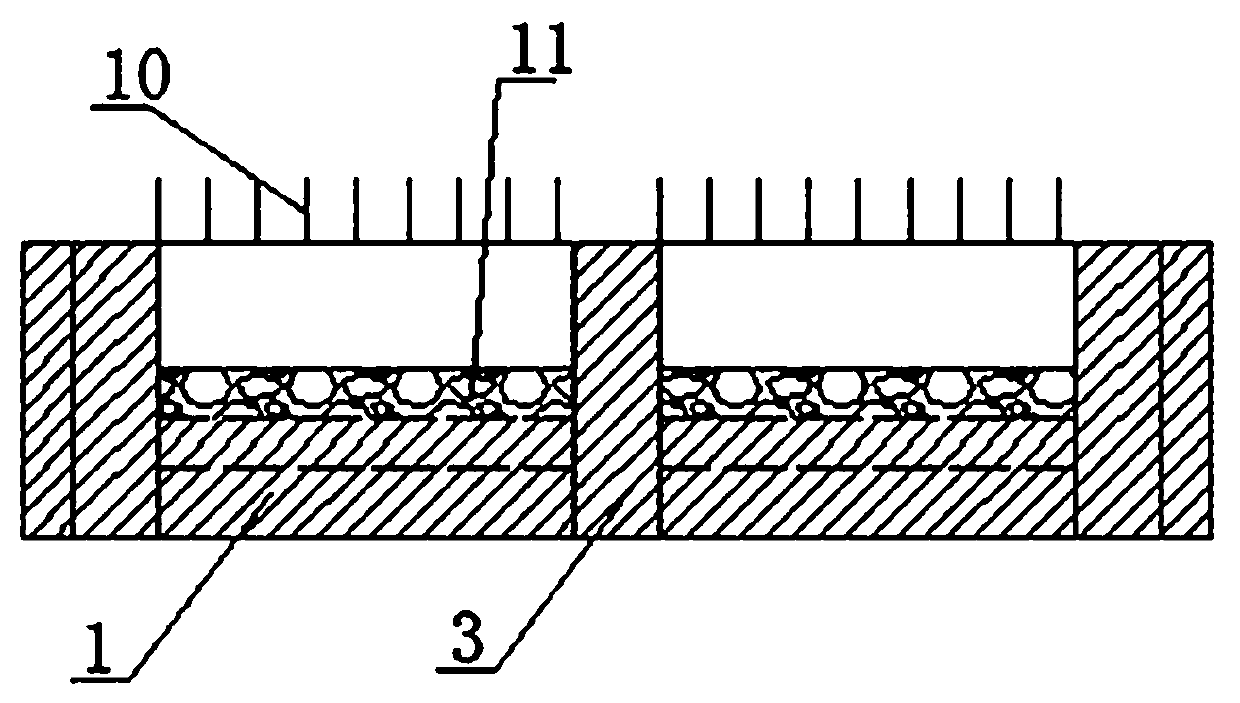

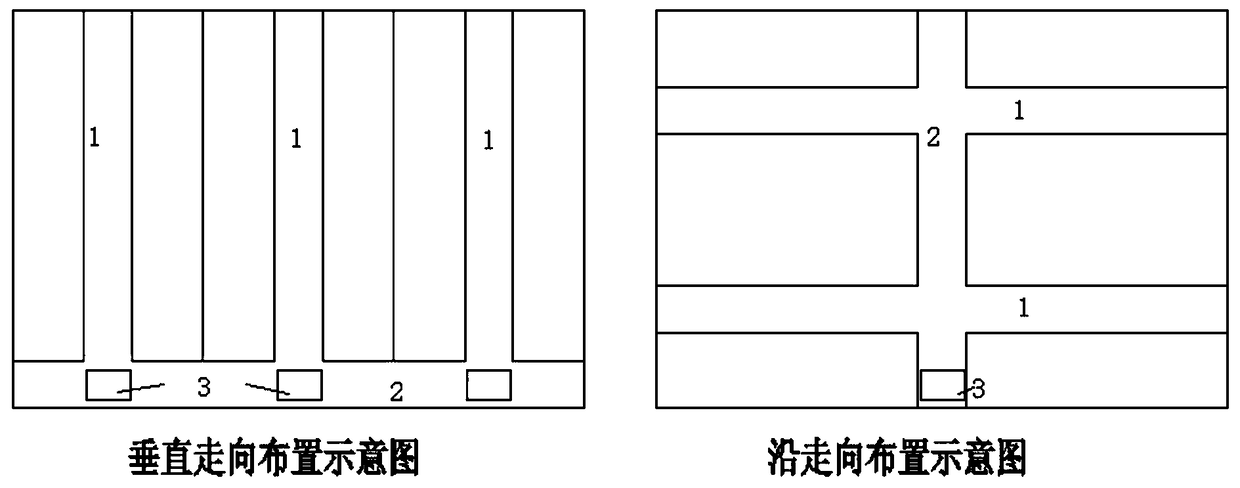

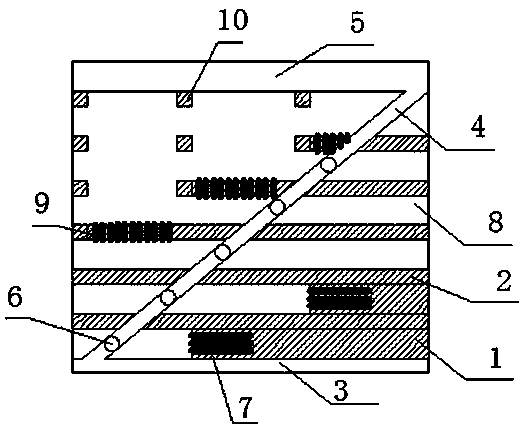

ActiveCN109630115AReduce the amount of mining and cuttingEfficient and safe mine transportationUnderground miningSurface miningMaterials science

The invention discloses a sublevel open stoping backfilling mining method for a gentle-dipping and medium-thickness ore body. The method comprises the following steps that ore blocks are arranged, wherein the ore body is divided into the ore blocks along the trend of the ore body, studs are reserved between the ore blocks, the ore blocks are divided into a plurality of strip-like stopes along thetrend of the ore body, filling ventilation liaison passages are formed in the studs, and each filling ventilation liaison passage is communicated with the corresponding strip-like stope through a stope filling ventilation well; the ore blocks are divided into a plurality of sublevel ore block bodies in the height direction, and ore withdrawal roadways are arranged outside lodes on the bottom of each sublevel ore block body respectively; a plurality of ore withdrawal inlet passages are tunneled along each ore withdrawal roadway, the ore withdrawal inlet passages laterally penetrate through thestrip-like stopes, and drilling drifts are tunneled from the ore withdrawal inlet passages; stoping for ore withdrawal is conducted, wherein blast holes are drilled in the drilling drifts and intensively filled with an explosive for blasting; the ore obtained after blasting is withdrawn into an ore pass through the ore withdrawal inlet passages and the ore withdrawal roadways; filling is conducted, wherein after stoping of the stopes in the same section is completed, one-time filling is intensively conducted. The method has the advantages that ore is efficiently and safely withdrawn and transported.

Owner:CHINA ENFI ENGINEERING CORPORATION

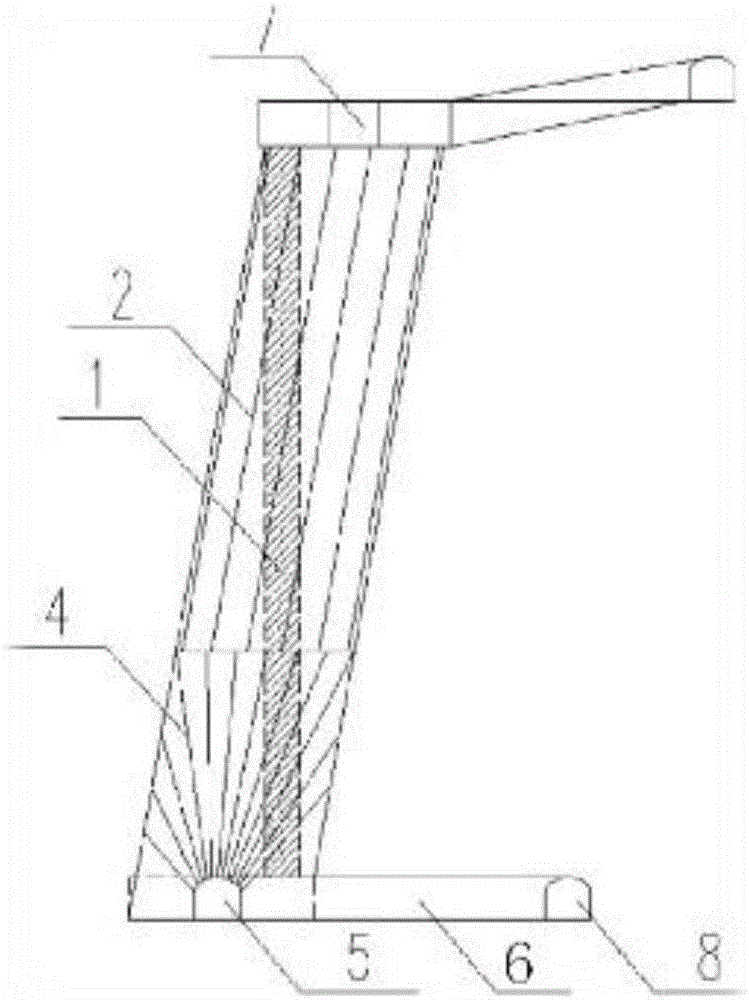

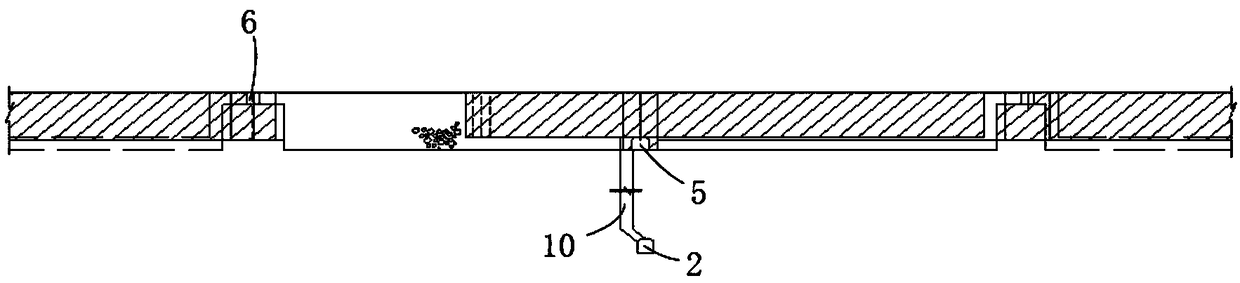

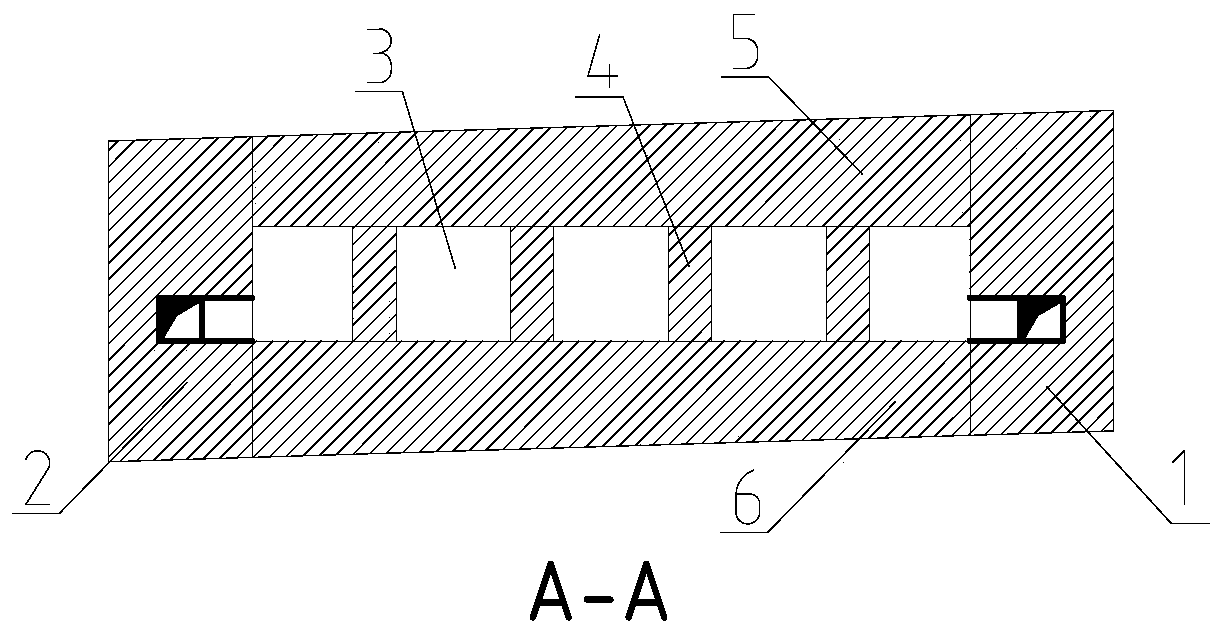

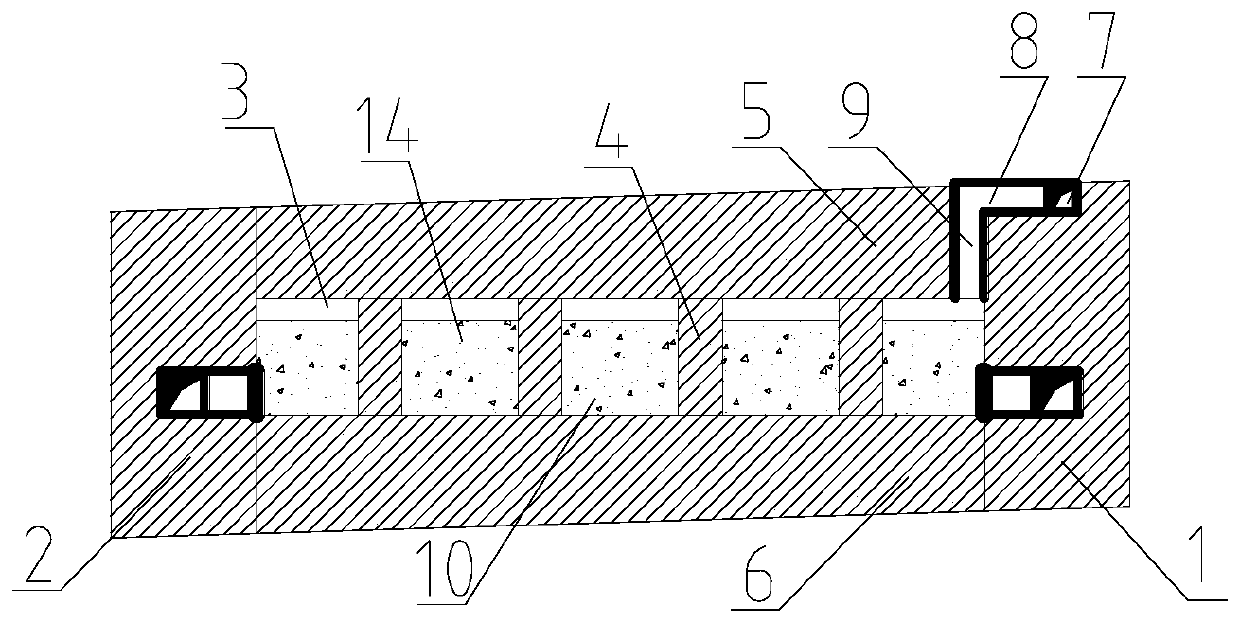

Medium-length hole raise mining subsequent filling method

ActiveCN106223956AFast well formationImprove ergonomicsUnderground miningSurface miningCut and fillEngineering

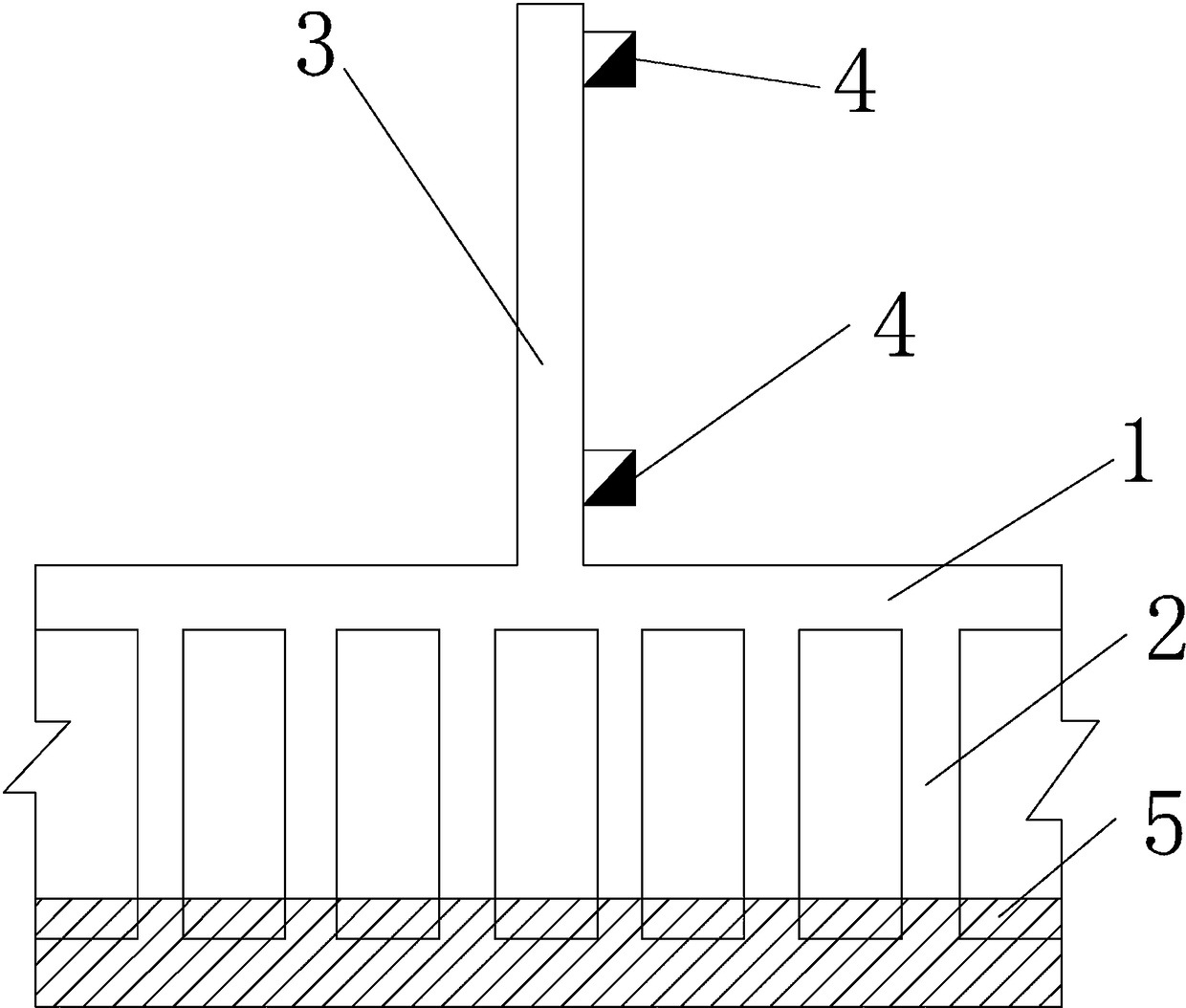

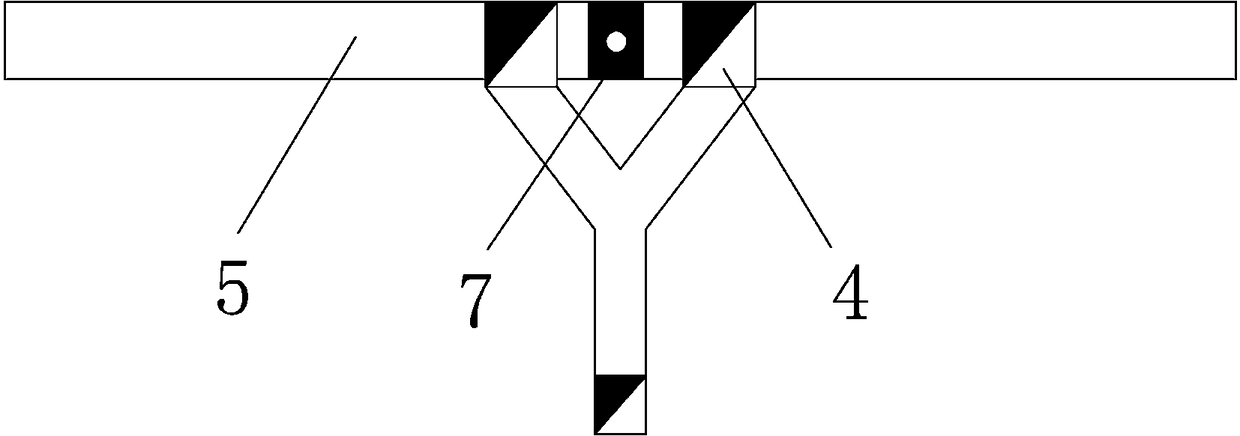

The invention discloses a medium-length hole raise mining subsequent filling method. Ore blocks are arranged in the ore body direction, and divided into stages in the vertical height. The two ends of the ore blocks are provided with mining preparation raises. The bottoms of the ore blocks are provided with a flat bottom ore removal structure. The upper portions of the ore blocks are provided with a raise boring machine chamber. A raise boring machine is adopted for drilling mining preparation raises; a raise boring machine lifting system is adopted for lifting and drilling rock and exploding a working platform, a down-the-hole drill drills horizontal parallel or annular medium-length hole blast holes from the two sides of the raise, and concentrated rock drilling, split blasting, concentrated ore removal and subsequent filling are carried out. The method is mainly applicable to heavy pitch thin and medium thickness ore bodies, the problems of a shrinkage method, a sublevel open stop mining method or a cut-and-fill mining method are solved, and the method has the advantages that the mining and cutting work amount is small, the stope mechanical operation degree is high, production efficiency is high, production capacity is large, workers do not need to enter a stope for work, and safety conditions are good.

Owner:GUANGXI UNIV

Pre-control roof open stoping spallation subsequent filling mining method

InactiveCN101725348AReduce the amount of mining and cuttingImprove efficiencyUnderground miningSurface miningEngineeringSpallation

'pre-control roof open stoping spallation subsequent filling mining method' is characterized in that advantages of backfill mining method and spallation mining method are adopted, respective disadvantages are made up, a bran new mining technology is formed, and the method has the advantages of low ratio of mined tonnage to development, high efficiency, good safety and strong practicability and is especially applicable to the mine industry.

Owner:招金矿业股份有限公司大尹格庄金矿

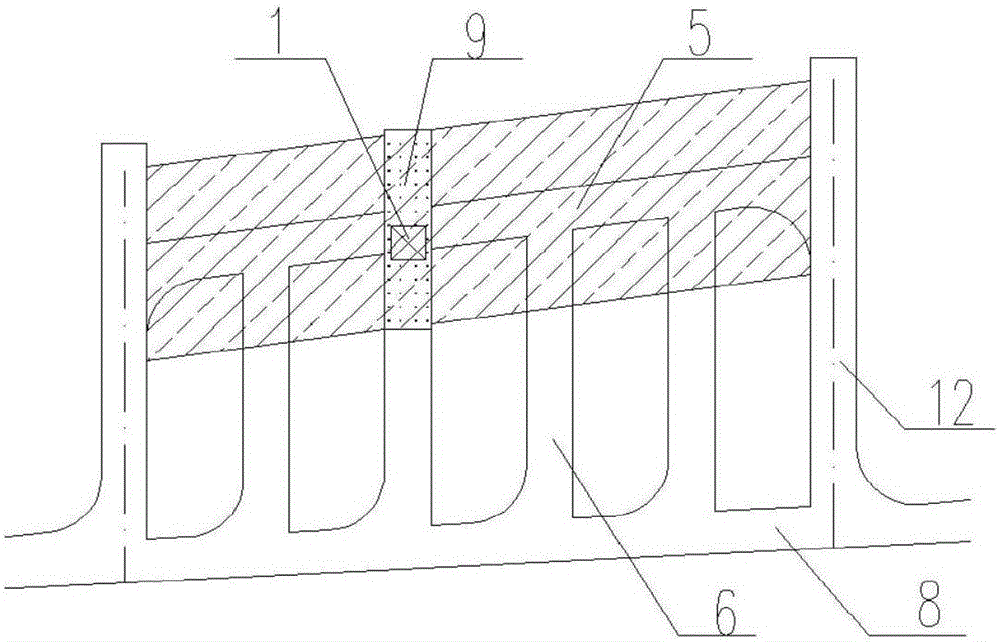

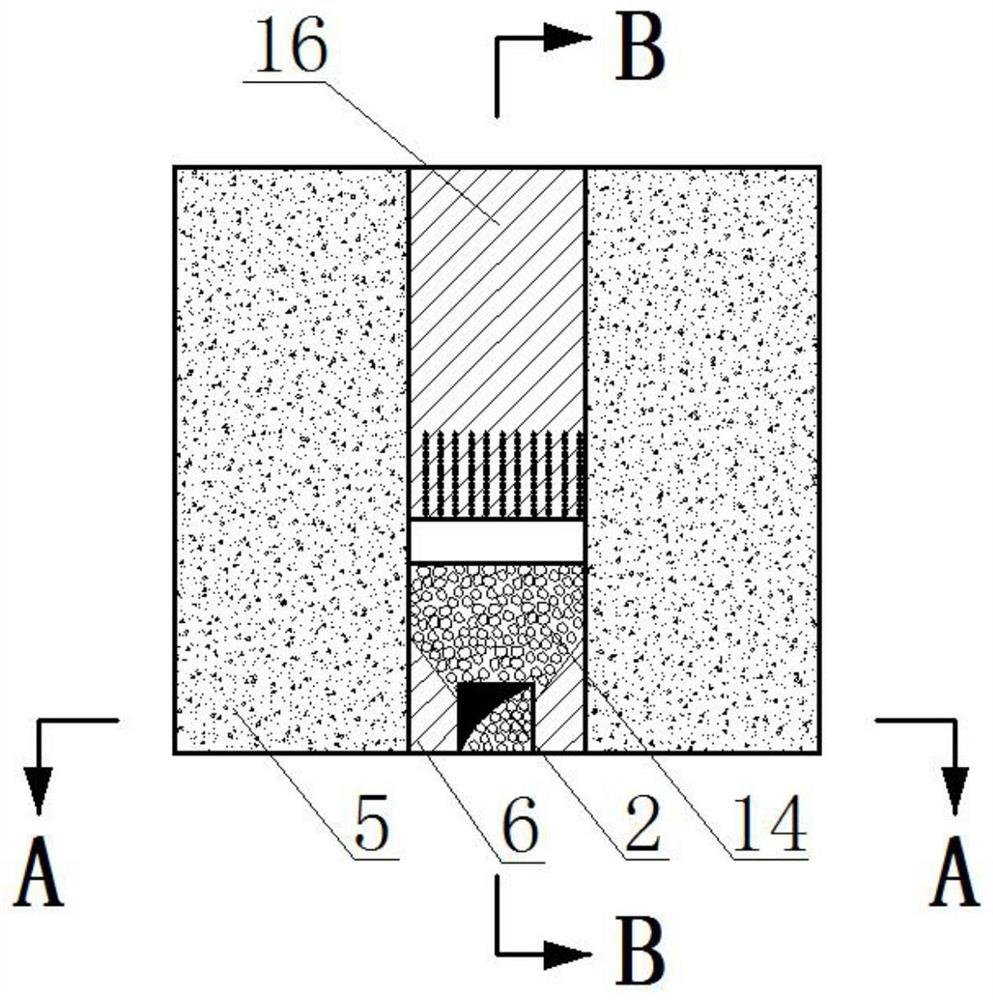

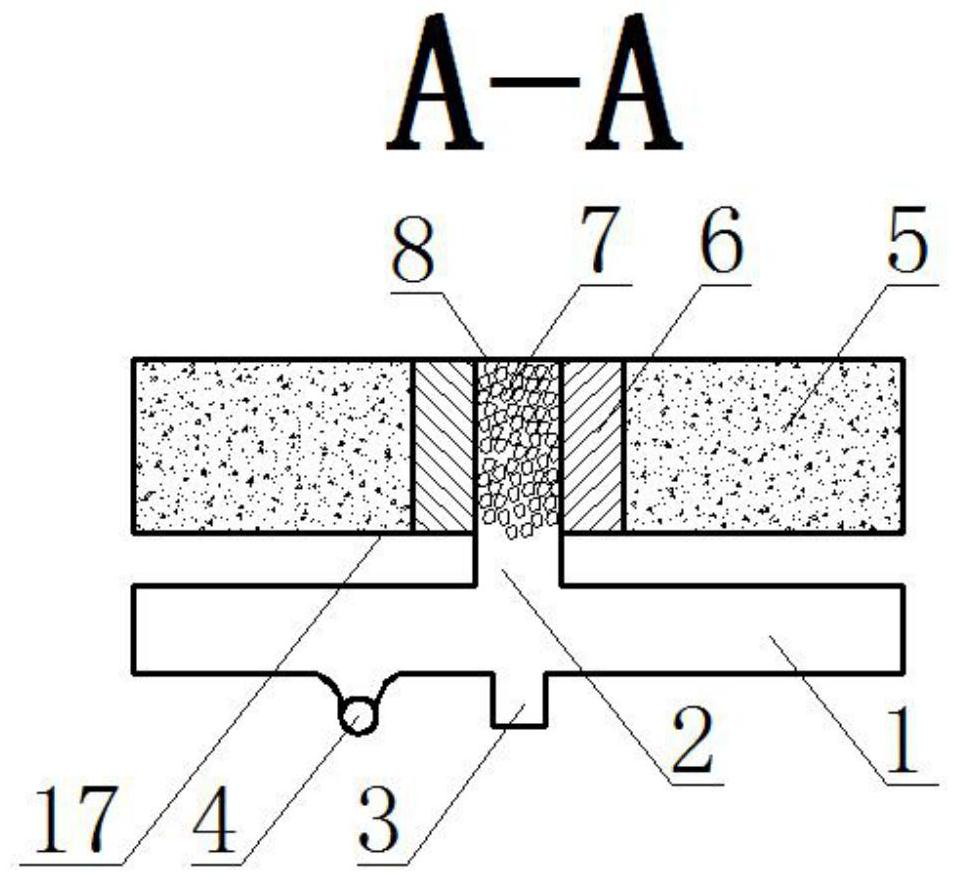

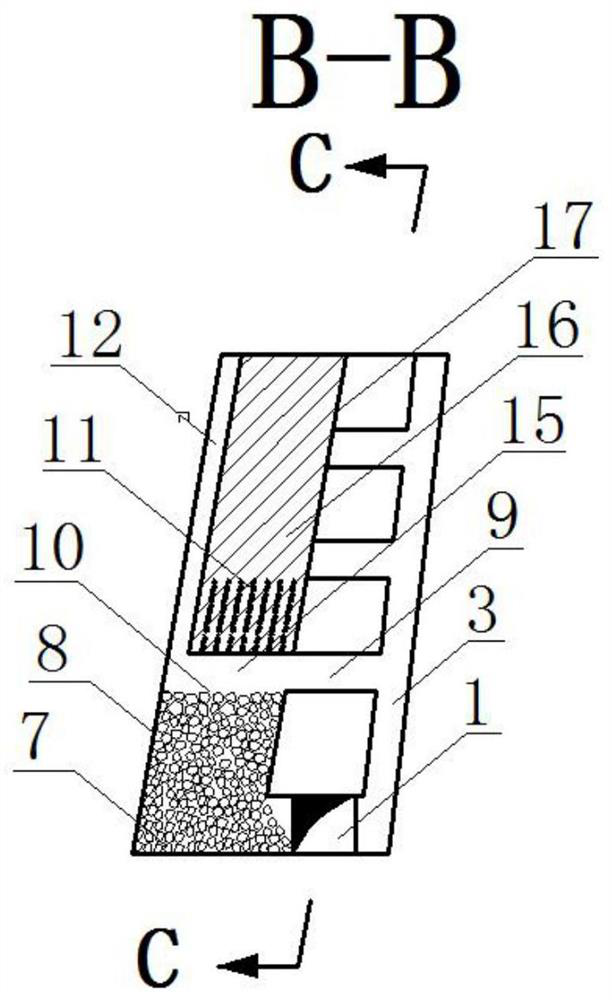

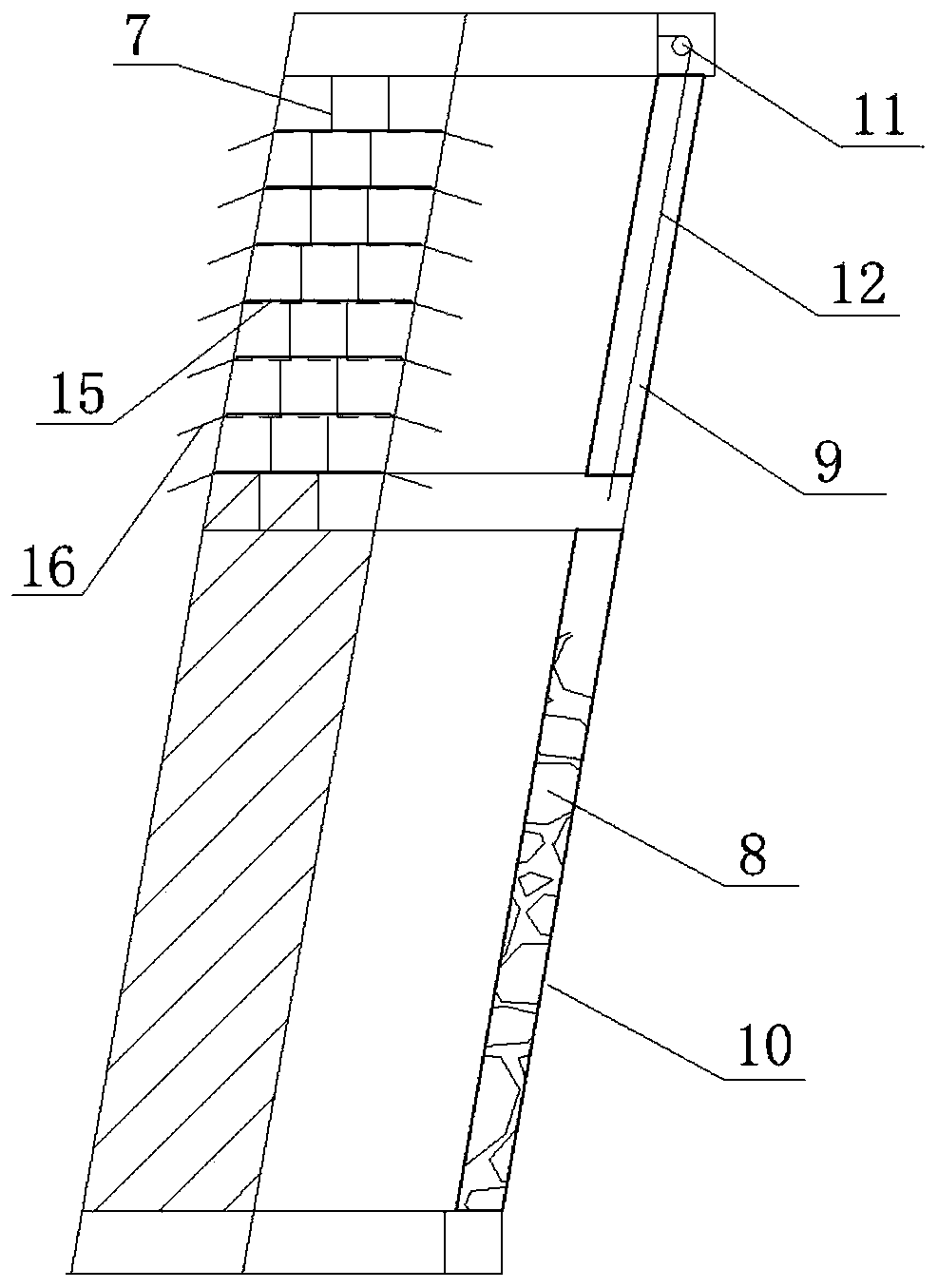

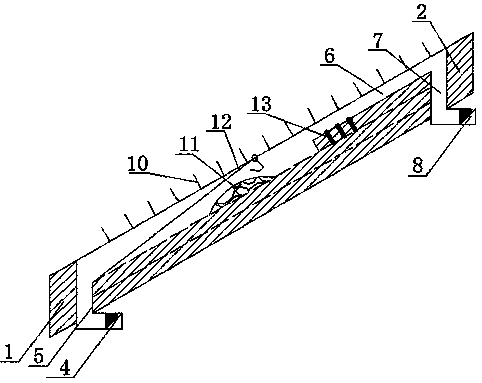

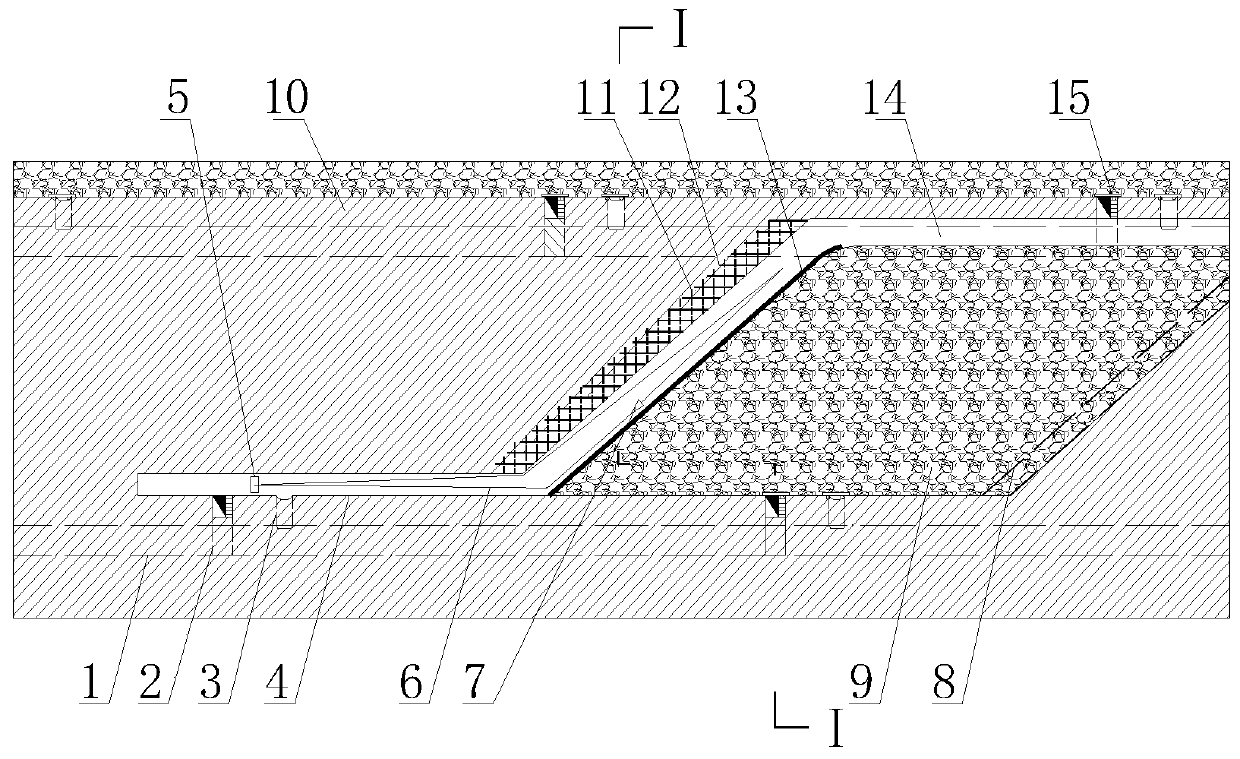

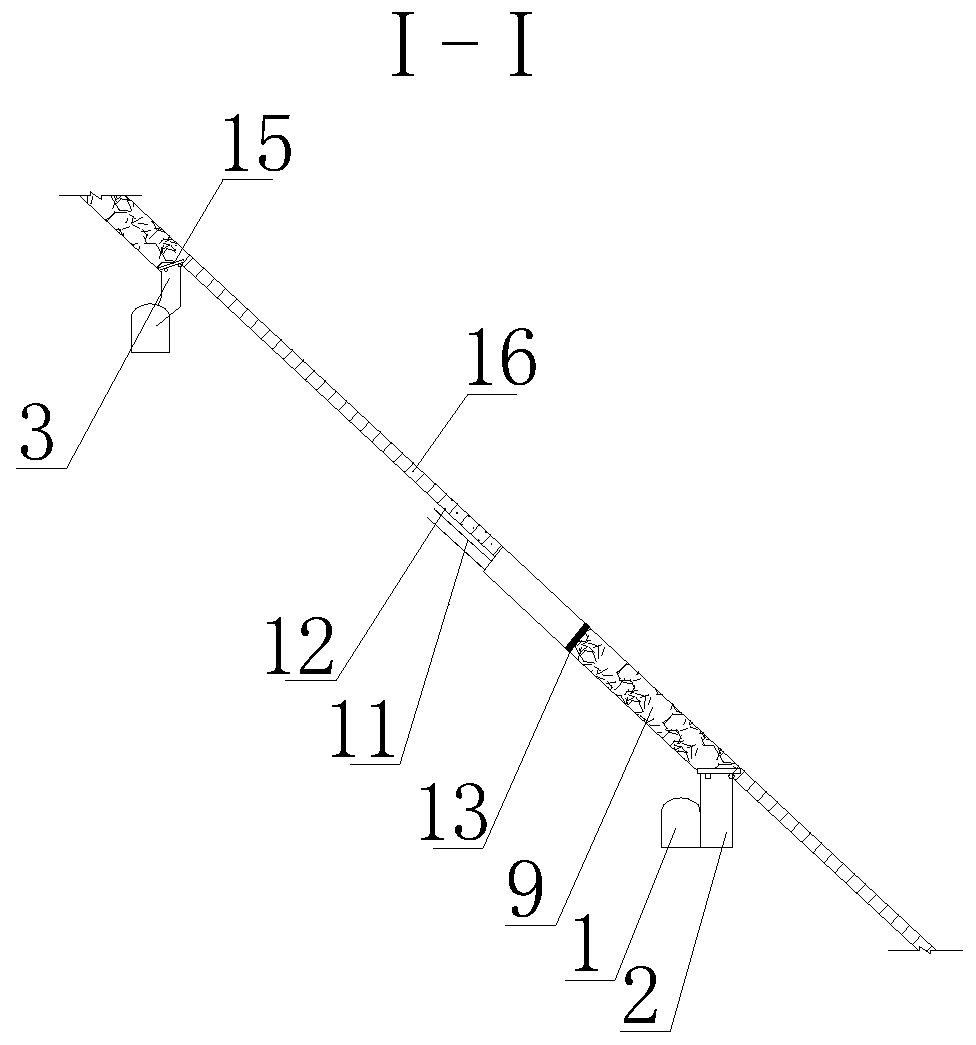

Recovery method of underground mine goaf remaining studs

ActiveCN111828007AImprove recovery rateReduce depletion rateUnderground miningBlastingMining engineeringWorking environment

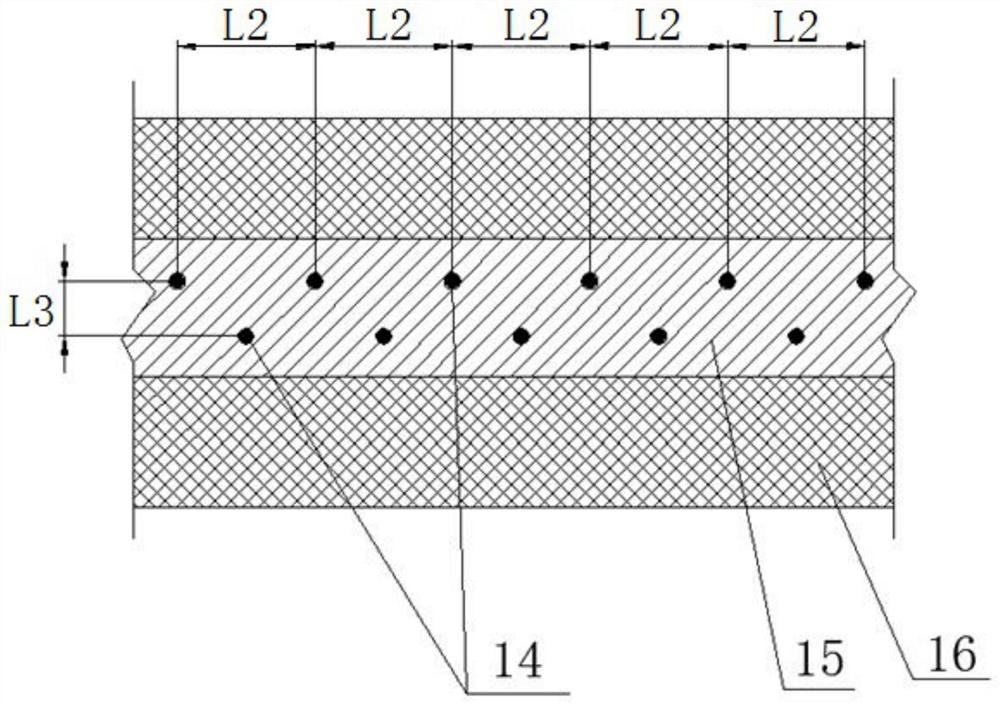

The invention discloses a recovery method of underground mine goaf remaining studs. The recovery method comprises the following steps that an ore removal roadway is tunneled into a stub (16) on one side of a middle section transportation roadway (1) to reach an ore body hanging wall, and the top of the ore removal roadway is expanded by adopting a fan-shaped medium-length hole to form a horn-mouth-shaped bottom structure; a cutting raise (12) and a pedestrian ventilation raise (3) are arranged in the stud pillar hanging wall ore rock contact face and the footwall surrounding rock respectivelyand communicate with an upper middle section air return roadway, layered connection ways (9) are tunneled in the pedestrian ventilation raise (3) in the vertical direction at intervals of a certain height to reach the stud pillar footwall boundary, the operation links that upward parallel blast holes (11) are drilled layer by layer in circulating mode one by one from bottom to top, charging blasting, forced ventilation and caving ore discharging are conducted till whole interval column is completely mined, then the caved ore (7) is completely discharged through a carry-scraper and fills the goaf, the recovery rate of the stud ore is increased, the ore dilution rate is reduced, and the working environment of a working surface is improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Combined downward mechanized filling mining method used for steeply inclined and extremely broken ore vein

ActiveCN111255459AReduce the amount of mining and cuttingReduce mining costsUnderground miningTunnel/mines ventillationMining engineeringSlag

The invention discloses a combined downward mechanized filling mining method used for a steeply inclined and extremely broken ore vein. According to the combined downward mechanized filling mining method used for the steeply inclined and extremely broken ore vein, the downward drift filling mining method is adopted, stopes are arranged along the ore body trend, a plurality of routes are divided, each stope is equipped with a extravein raise, pedestrian ventilation and ore pass are realized through the extravein raise, a layered connection road is constructed to the ore body from the extraveinraise, a stope layered connection road is continuously constructed in the ore body, a connection access is constructed from the stope layered connection road to a connected stope, because of the smallwork amount of mining and cutting work, the two stopes can be combined into one stope for stopping, so that the stopping efficiency is improved, the mining cost is saved, mechanized ore removal is carried out through a minitype slag raking machine + self powered electric tipper or a sliding type loader, personnel does not be requires to enter the connection road, the mechanization degree is high,the safety is high, the mining and cutting work amount do not be increased, because the method do not need large cross-section when working, and the method can not only solve the problem of large quantities of the mining and cutting work amount caused by high mechanization, but also solve the problem of high labor intensity caused by low mechanization.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Gently-inclined broken thin lode medium-depth hole mining method

InactiveCN108590649AAvoid homeworkEnsure safetyDisloding machinesUnderground miningRoom and pillar miningTransportation technology

The invention discloses a gently-inclined broken thin lode medium-depth hole mining method. According to the mining method, the sizes of ore rooms and ore pillars are determined according to the mechanical properties of rock mass and the explosion power cast blasting energy distance so as to rationally divide and arrange the ore rooms and the ore pillars; medium-depth blast holes are drilled in the ore pillars, and ore mining is performed; and by combing explosion power transportation and mechanical transportation, the caving ore is transported, such that the safe and efficient mining is performed on the gently-inclined broken thin lode. According to the present invention, by using the medium-depth mining ore extraction method, the operation of the construction personnel under the stope roof can be avoided so as to ensure the safety of the construction personnel and improve the production capacity and the production efficiency of the stope; by using the explosion power transportation technology, the caving ore transportation efficiency is improved, the mining cutting engineering arrangement is optimized, the mining cutting engineering amount is reduced, and the mining process is simplified; and with the method, the problems of low production efficiency, high safety risk of the construction personnel and the like of the traditional room and pillar method can be effectively improved, and the wide practicality is provided.

Owner:赤峰柴胡栏子黄金矿业有限公司

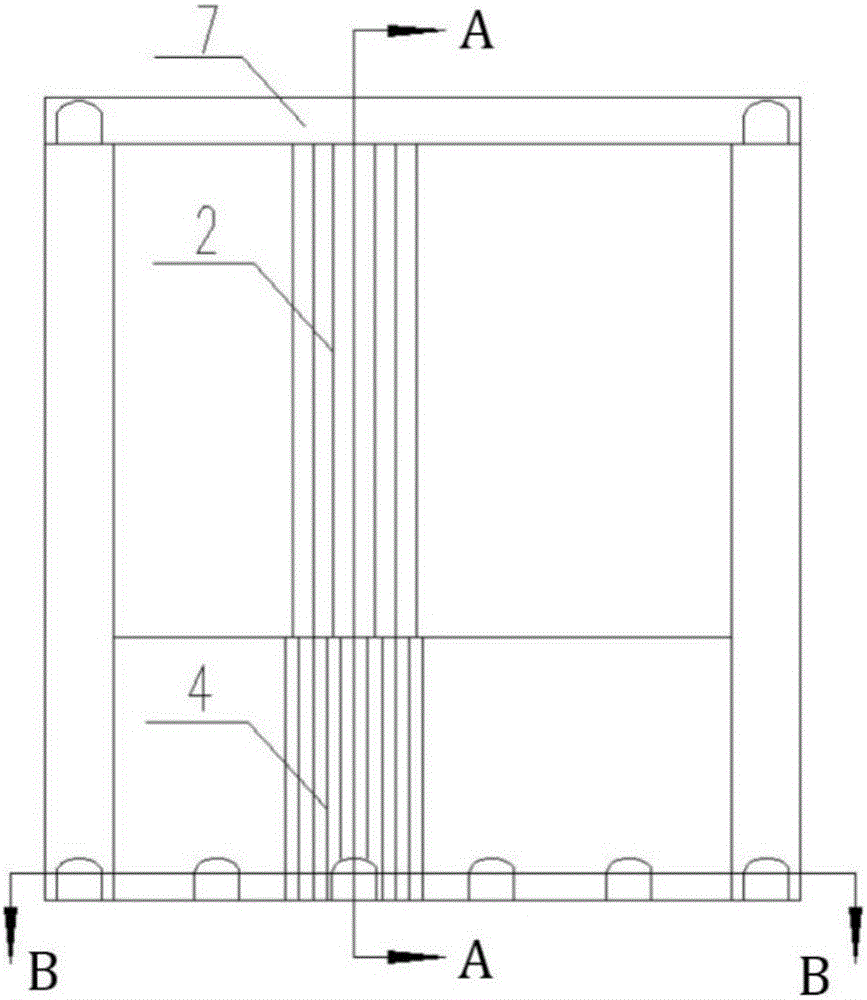

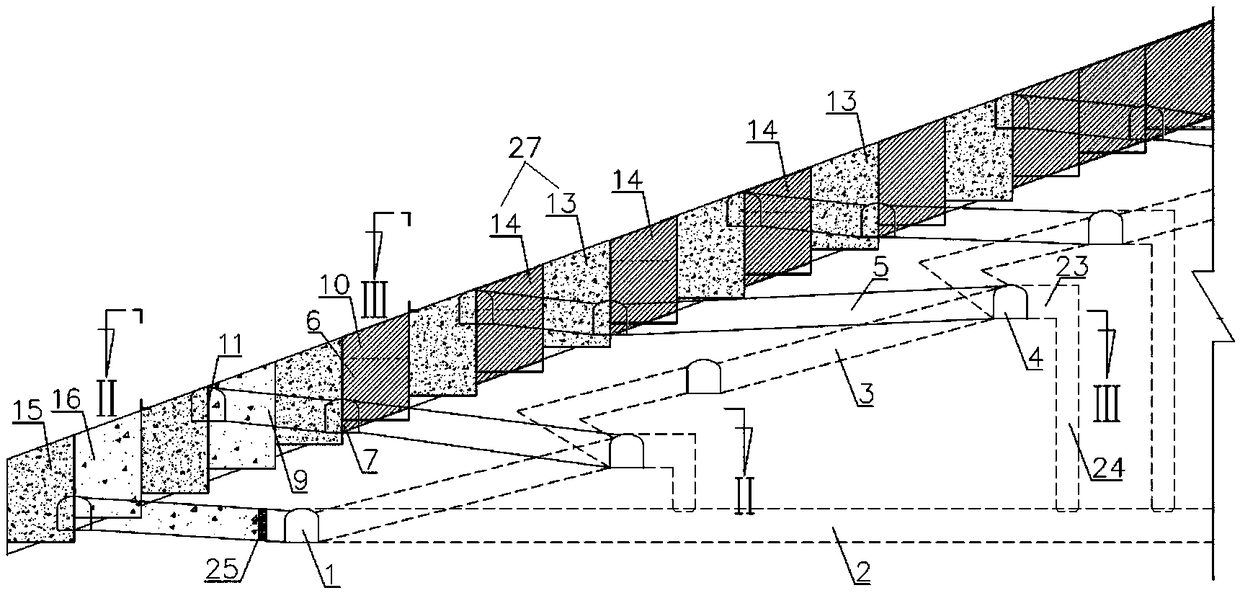

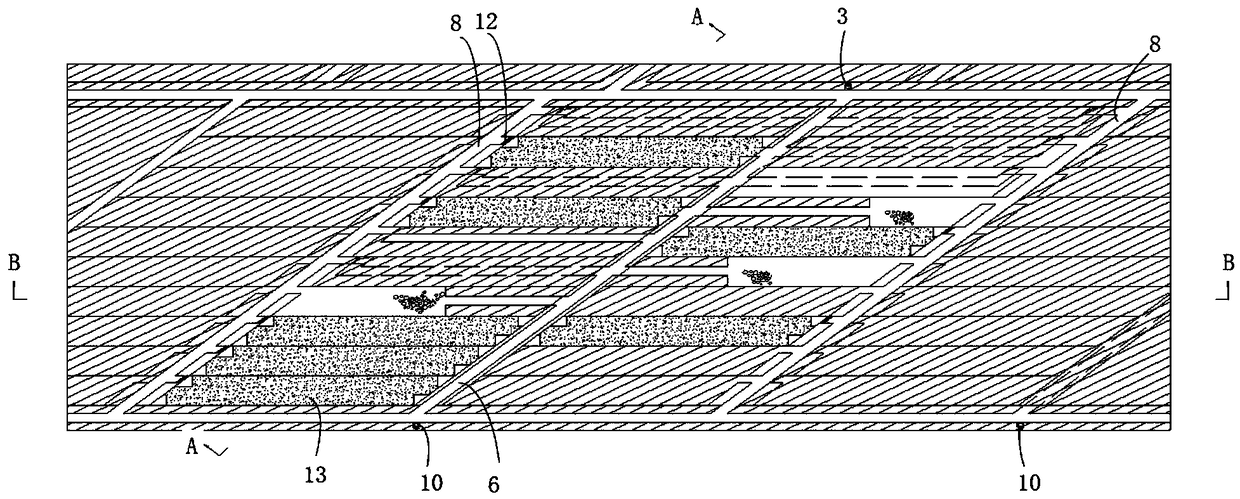

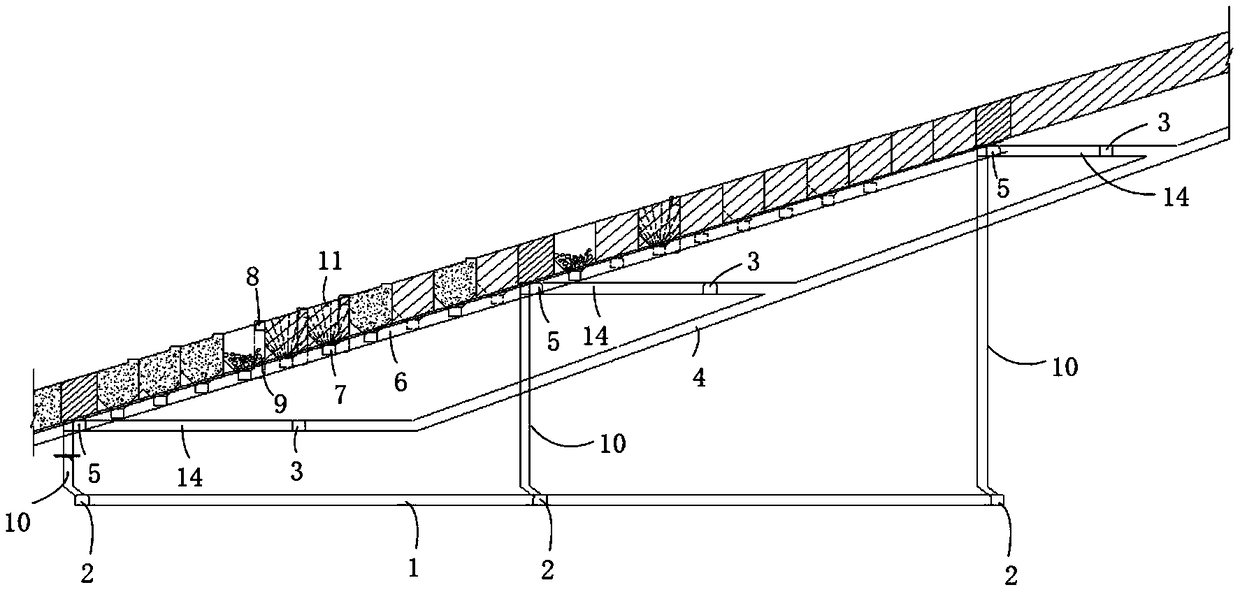

Approach open stope subsequent filling mining method for gently inclined medium-thick ore body

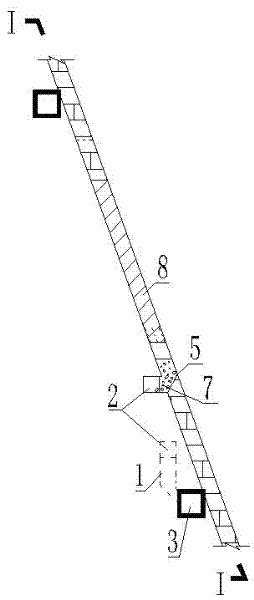

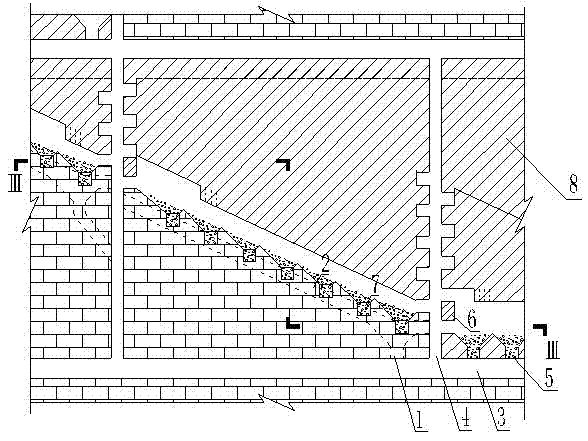

ActiveCN109339783AControl recovery dilution rate and loss rate indicatorsReduce the amount of mining and cuttingUnderground miningSurface miningMineralogyDeep hole drilling

The invention discloses an approach open stope subsequent filling mining method for a gently inclined medium-thick ore body. The approach open stope subsequent filling mining method for the gently inclined medium-thick ore body comprises the following steps that panel layout is carried out, specifically, panel dividing is carried out in the direction of the ore body, and columns are arranged between panels; a plurality of strip-shaped approach stopes are arranged in each panel in the ore body inclination; ore removal roadways are arranged at the bottom layer outside the vein of the ore body inthe ore body inclination, ore removal transverse drifts are arranged at the bottom of ore pillars reserved at the lower ends of the panels, drilling roadways are arranged at the bottoms of the strip-shaped approach stopes in the panels, and the ore removal transverse drifts and drilling roadways separately communicate with the ore removal roadways; filling ventilation connection channels are arranged at the positions, near the upper panel vein of the ore body, of the inner parts of the columns to connect the strip-shaped approach stopes; extraction and ore removal are carried out, specifically, medium-deep hole drilling trolley is used for drilling upward fan-shaped blast holes in the drilling roadways, and centralized charge blasting is carried out; the blasted ore is discharged to a jack shaft through a scraper through the drilling roadways, the ore removal roadways and the ore removal transverse drifts; and filling is carried out, specifically, once the extraction of the strip-shaped approach stopes is completed, one-time filling concentrating is carried out. The approach open stope subsequent filling mining method for the gently inclined medium-thick ore body greatly reduces the amount of mining and cutting work and has high ore removal and transportation efficiency.

Owner:CHINA ENFI ENGINEERING CORPORATION

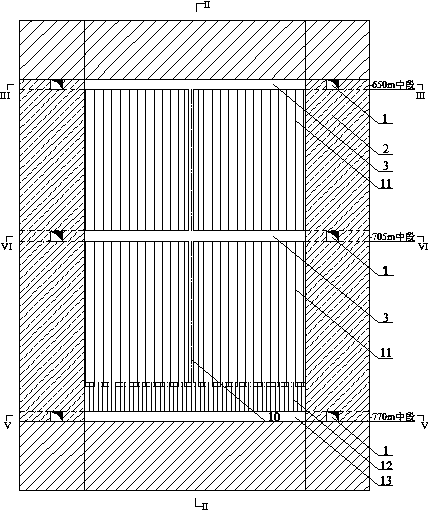

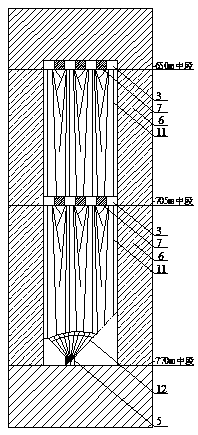

Super-large-scale stope large-diameter deep-hole high-stage open stope subsequent filling mining method and application

InactiveCN109989754AImprove rock drilling efficiencyLarge amount of mining and cuttingUnderground miningSurface miningStopingMaterials science

The invention discloses a super-large-scale stope large-diameter deep-hole high-stage open stope subsequent filling mining method and application. The method comprises the following steps: (1) a stoping scheme: ore blocks are arranged perpendicular to the trend of an ore body, the ore blocks are divided into ore chambers and ore columns, the ore chambers and the ore columns are arranged at intervals, a stope is divided into two middle sections by adopting double-middle-section continuous stoping, and a stoping method of middle-section rock drilling, double-middle-section continuous ore breaking ground, bottom ore removal structure sharing and subsequent first filling is adopted; (2) stope preparations; (3) courtyard cutting; (4) rock drilling and blasting; (5) ore removal; and (6) filling.The method has the beneficial effects that the super-large-scale stope has the advantages of being small in stope cutting work amount, large in stope ore quantity and the like; the stope is divided into two middle sections for rock drilling, the technical difficulty of deep-hole rock drilling of the stope is reduced, and the rock drilling efficiency of the stope is improved; the double-middle-section continuous ore breaking ground is adopted, and the bottom ore removal structure is shared, and the method has the advantages that the production capacity of a single stope is improved, the miningand cutting cost is reduced, the stoping efficiency is improved, and the like.

Owner:ANHUI TONGGUAN (LUJIANG) MINING CO LTD

Efficient precise blasting method of extremely-thin ore

ActiveCN106150505APrecisely Controlled BlastingGuaranteed smoothUnderground miningBlastingStable stateStructure of the Earth

The invention discloses an efficient precise blasting method of extremely-thin ore and belongs to the field of mining. The efficient precise blasting method includes: step 1, arranging rock drilling engineering: when an inclination angle of the ore is less than or equal to 30 degrees, tunneling and drilling in a direction perpendicular to the forming direction of the ore, and when the inclination angle of the ore is greater than 30 degrees, arranging a sectional drilling roadway along the forming direction of the ore; step 2, arranging blasting holes: arranging a plurality of blasting holes along two sides of the ore, wherein the blasting holes and a central line of the roadway form an included angle of 40-60 degrees, and the blasting holes include lateral blasting holes and middle blasting holes; step 3, charging explosive: adopting a gradient charging structure matched with a blasting resistant line in size to charge each blasting hole with the explosive for blasting; step 4, detonating: according to stable state of top and bottom plates of ore rock, selecting all blasting holes to be detonated for blasting according to a set sequence. By using the method, production capacity can be increased, mining and cutting engineering quantity can be reduced, dilution rate can be lowered, and precise blasting control in limited space can be realized; the efficient precise blasting method is brand new, deep-hole efficient blasting is adopted, and only ore is stopped while surrounding rock is not damaged.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Underhand slicing open stope mining method for gently inclined medium-thick ore body

InactiveCN110344832APrevent spontaneous combustionAvoid cakingUnderground miningSurface miningSpontaneous combustionRock bolt

The invention belongs to the technical field of underground mining methods for metal deposits, and discloses a underhand slicing open stope mining method for a gently inclined medium-thick ore body tosolve the problems existing in the mining of the gently inclined medium-thick ore body in the prior art. The method includes the following steps: dividing the ore body into ore blocks, reserving a bottom column, a top column and intermediate columns, digging a raise shaft for air intaking and people walking in the bottom column, digging a roof cutting tunnel to the top column, and digging a raiseshaft for air returning and people walking in the top column to be communicate with a transportation tunnel in a previous stage; drilling horizontal blastholes in the roof cutting tunnel, blasting the ore body at an uppermost layer, scraping collapsed ore to an ore pass, and mounting hanging wall roof protecting anchor rods; and drilling downward blastholes by using a layer-by-layer breakdown method from top to bottom, blasting and collapsing the layered ore body, blasting the ore and scraping the ore body to the ore pass. The downward stratified open stope mining method of the invention adopts an extracting method, has the advantages of simple process, less mining and cutting work amount, low dilution rate and the like, avoids ore spontaneous combustion or agglomeration caused by ore overstocking in a stope, and is suitable for the ore bodies having hanging walls with medium stability or less and the ore having the characteristics of spontaneous combustion or agglomeration.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Mining method for treating upward pinch-out of inclined thin ore body

InactiveCN102392645AReduce the amount of mining and cuttingImprove securityUnderground miningSurface miningEngineeringFunnel shape

Owner:CHINA NERIN ENG

High sublevel double-hexagon caving mining method

InactiveCN109356581AHigh recovery rateReduce depletionDisloding machinesUnderground miningMineralogy

The invention belongs to the technical field of mining, and particularly relates to a high sublevel double-hexagon caving mining method. The method comprises the following steps of 1, preliminary mining cutting; 2, rock drilling; 3, exploding and ore breaking; and 4, ore removing. The method integrates the advantages of the sublevel caving without sill pillar method, the block stoping method, thehigh-end wall drawing method and other methods, and therefore the recovery rate of pure ore is improved, and the problem of excessive loss and dilution is solved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Gently inclined medium-thick-thick large ore body remaining ore stopping method

ActiveCN110952981APrevent collapseGuarantee mining safetyUnderground miningSurface miningMining engineeringMechanical engineering

The invention provides a gently inclined medium-thick-thick large ore body remaining ore stopping method which is applicable to stopping of gently inclined medium-thick-thick large ore body remainingore with a high ore grade and a high value. According to the method, firstly, an original room-and-pillar method goaf is filled with a high-intensity cemented filling body; and during filling, a vacant area being 1.5 to 2 m on the top is reserved to be used as a free surface and a compensation space for upper layer ore body stopping. According to the thickness of an upper layer ore body, a shallowhole room-and-pillar method or a point pillar type upward layered filling method is used for stopping the upper layer ore body according to different conditions, and roof-contacted filling is performed; and then, an upward layering drift-and-fill method is used for stopping a lower layer ore body. Compared with the prior art, the gently inclined medium-thick-thick large ore body remaining ore stopping method has the advantages of safe stopping operation, high ore recovery rate, low dilution rate, maneuverability, flexibility and the like.

Owner:NANHUA UNIV

A Novel Mining Method for Gently Dipping Thin-Medium Thick Orebodies

InactiveCN103590831BRealize complementary advantagesJob safetyUnderground miningSurface miningWorkloadStoping

The invention discloses a novel mining method of gently-inclined thin and medium thickness ore bodies. According to the method, ore bodies in one stope are stoped by dividing the stope into two stope areas through steps: firstly, stoping is performed at the stope area (1) by using a pillarless sublevel caving method: the ore bodies are directly caved in single sublevel by using medium-length blastholes; a certain empty area formed after ore removal is used as a free surface for stoping of the stope area (2); then, the stoping is performed at the stope area (2) by using a blasting force carrying mining method; fan-shaped medium-length blastholes are arranged in a manner perpendicular to the ore body tendency, and are filled with powder according to sections, the decking parts are the parts from the lower disc boundaries of the ore bodies to the hole bottoms; the empty area formed during the stoping of the stope area (1) is used as a free surface for blasting row by row; ores in the stope area (2) are thrown in the empty area by using the blasting force. The method integrates the pillarless sublevel caving method and the blast force carrying mining method, so that the supporting difficulty and the workload are reduced, the operation is safer, the mining cost is low, and the labor productivity is high.

Owner:UNIV OF SCI & TECH BEIJING

Mechanized benching room-and-pillar mining method

ActiveCN106837332AReduce mining and cutting worksReduce cutting costUnderground miningSurface miningRoom and pillar miningStopped work

The invention discloses a mechanized benching room-and-pillar mining method. Internal-pulse slope ramp mining preparation is adopted in a stope, and the main mining and development engineering comprises a stope slope ramps, a pedestrian and ventilation raise and a cutting roadway; during stope mining, stopping is conducted between ribbons from top to bottom, working faces start from the intersections of the stope slope ramp and the ribbons and are propelled to the two sides along the strike, and the upper ribbon stoping working face is ahead of the lower ribbon stoping working face; the first-mining ribbon takes the cutting roadway as a free face and compensation space for rib expanding and coping; one pilot tunnel is arranged at the advanced stoping working face on the lower sides of the other ribbons, and then the pilot tunnel serves as a free face for rib expanding and coping on the corresponding ribbons; stope mining is conducted through operation of trackless equipment, and during ribbon stoping in the stope, a trigonal bench is reserved on the bottom of the lower side of each ribbon, and the trigonal benches serve as running channels and operation platforms of the trackless equipment; during ribbon stoping, the trigonal benches on the bottoms of the adjacent ribbons on the upper portion are recycled synchronously. The production capacity and efficiency are high, the mining and development engineering quantity is low, and the construction difficulty and the cost are low.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

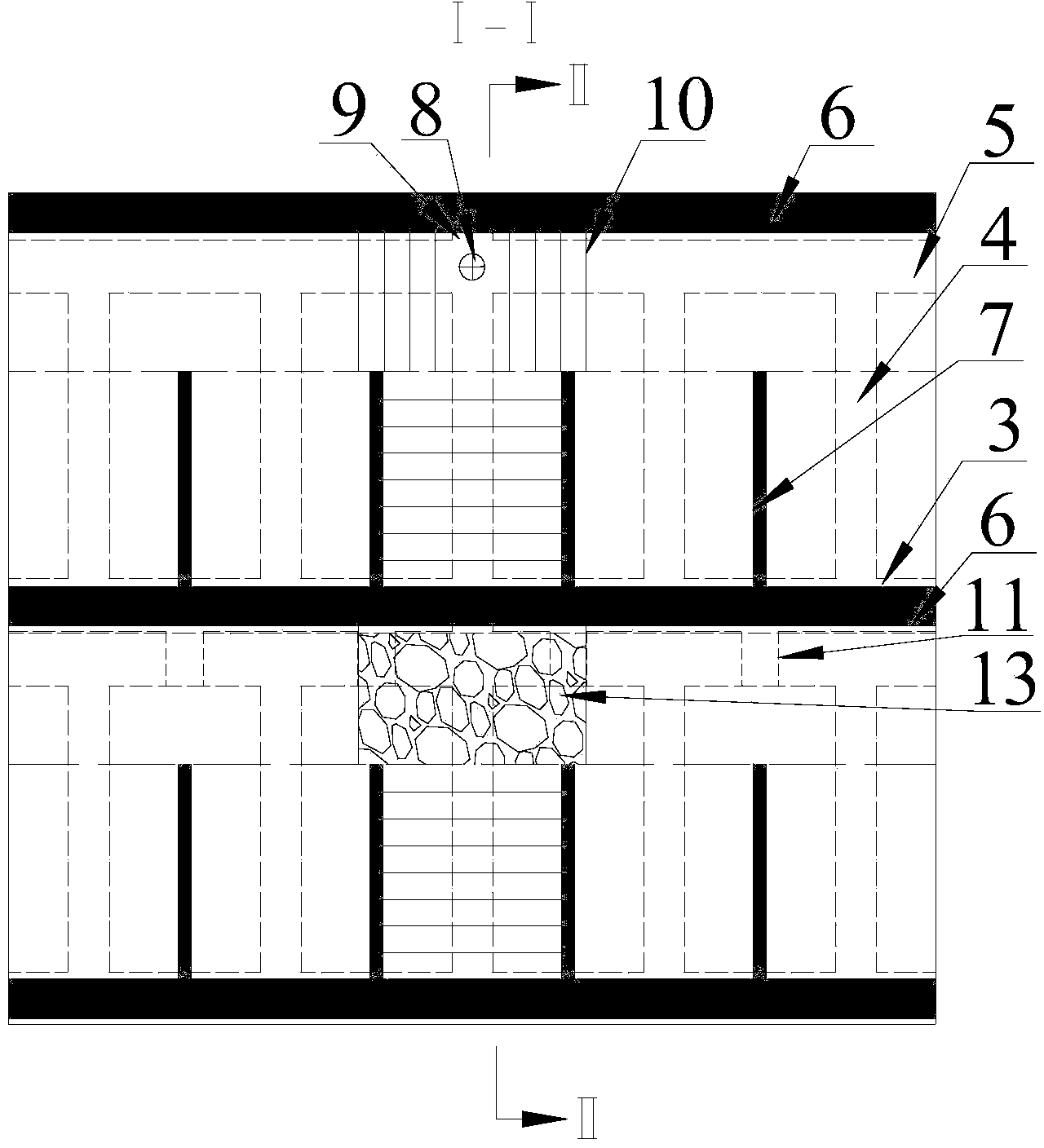

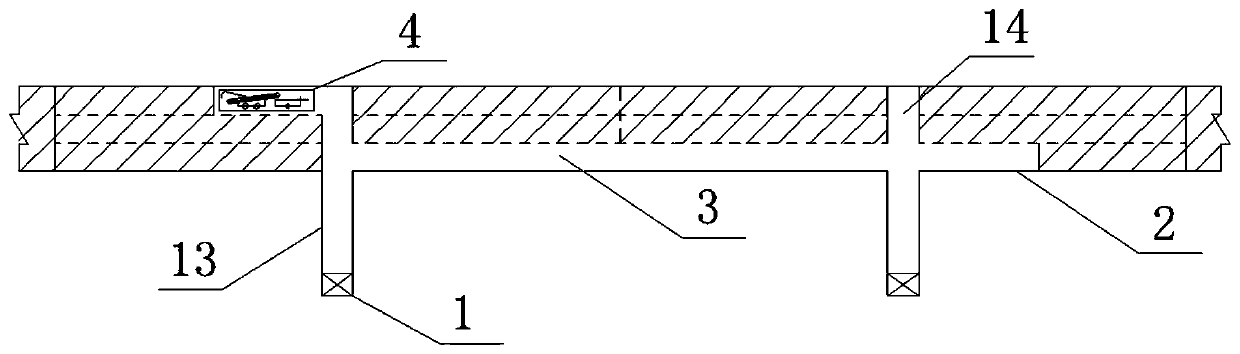

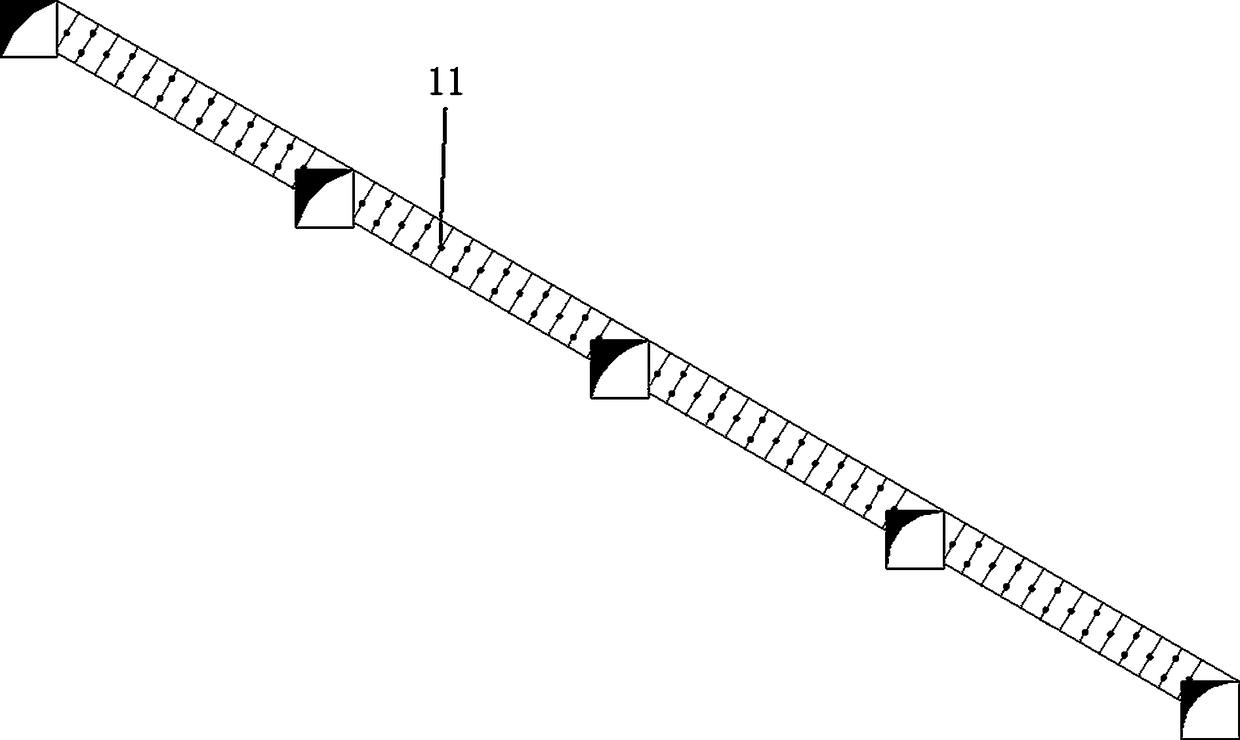

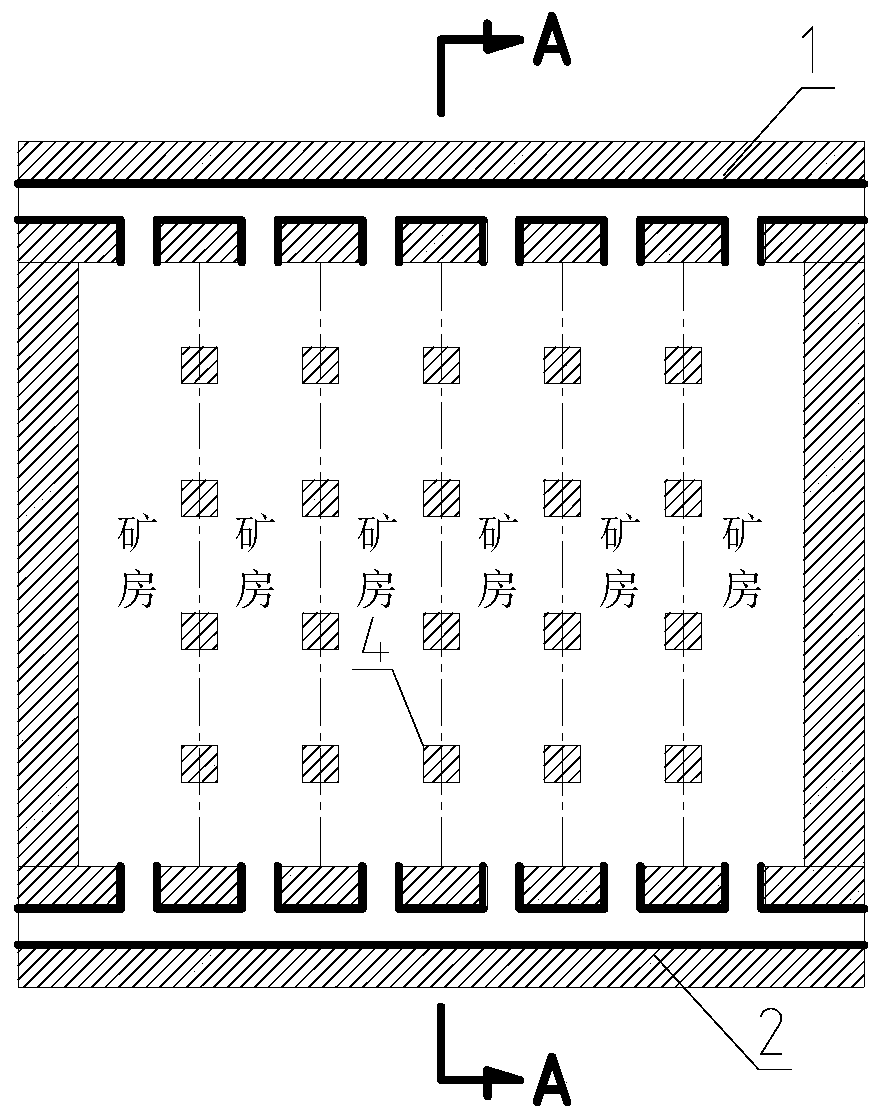

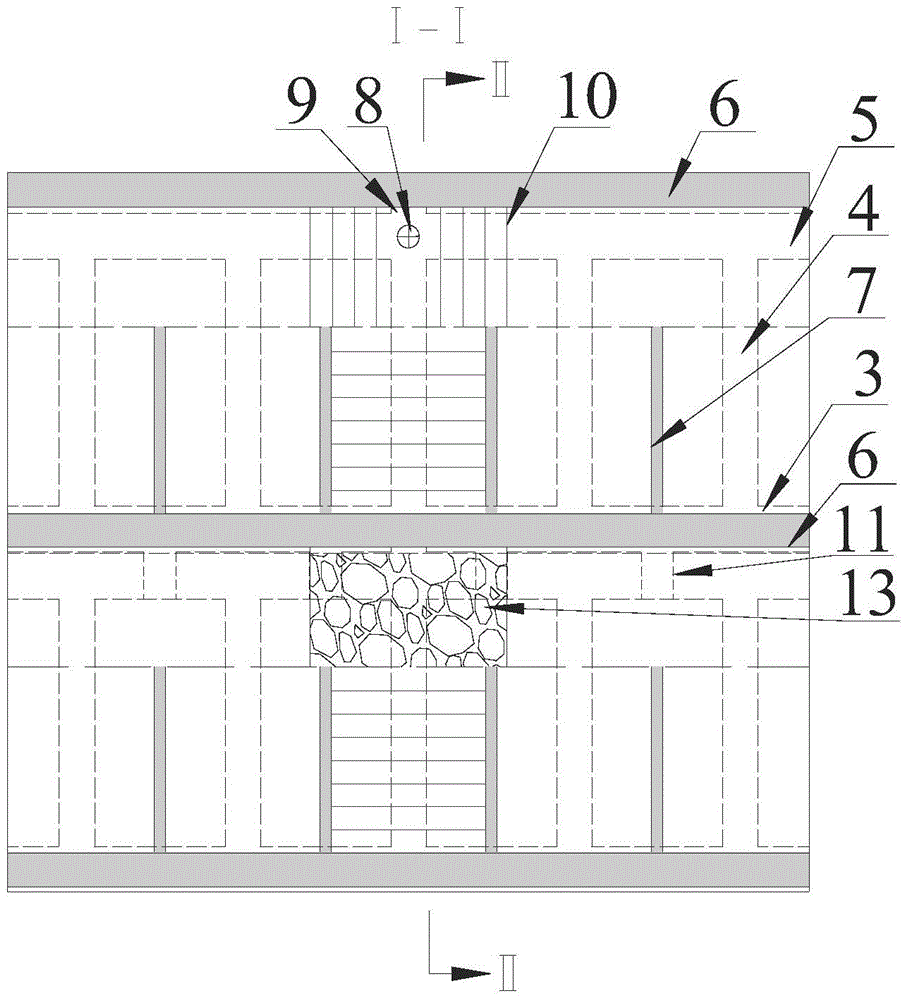

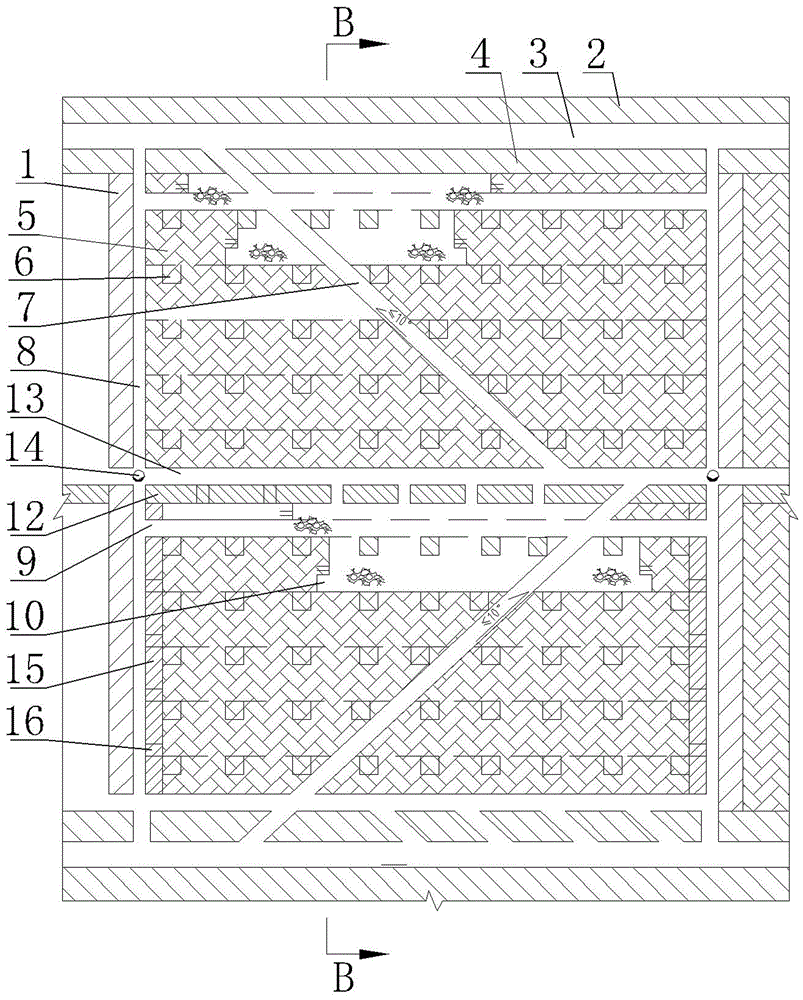

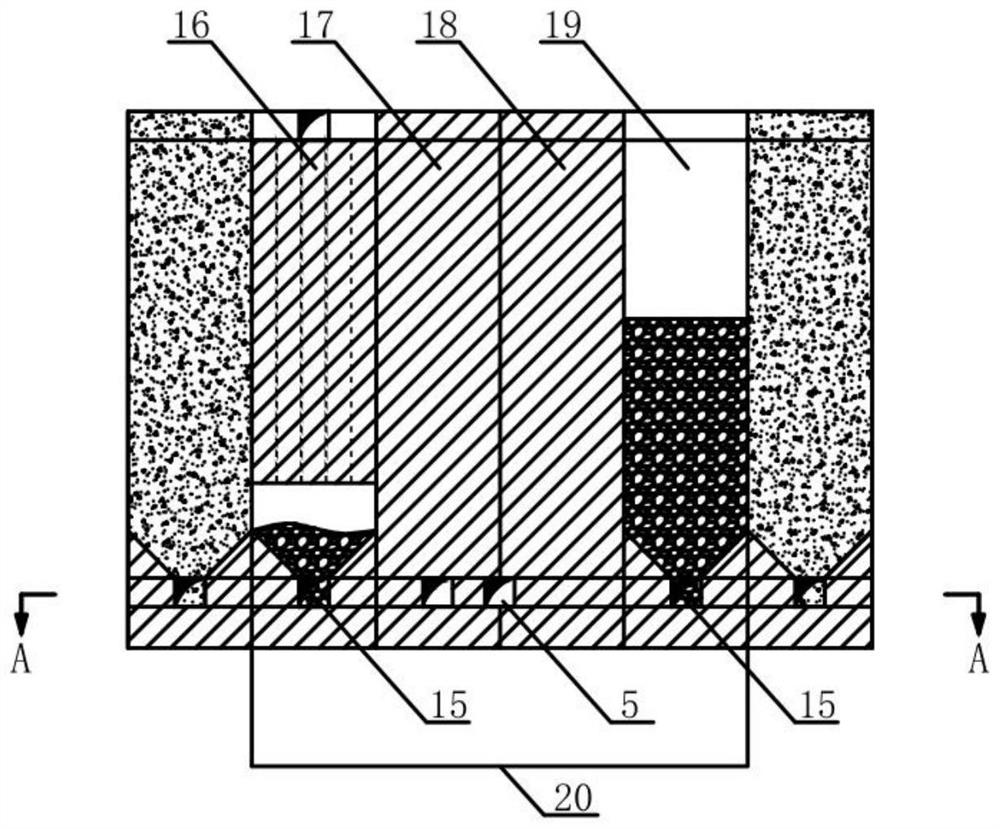

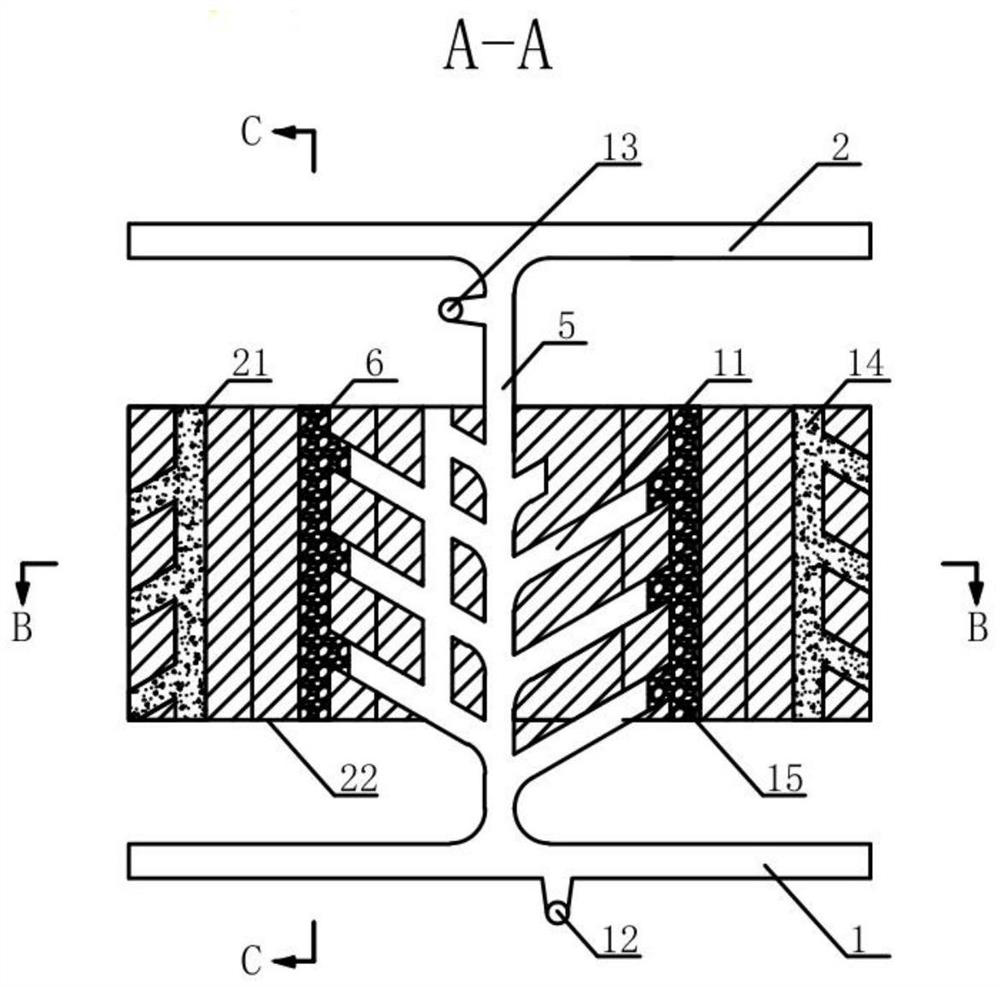

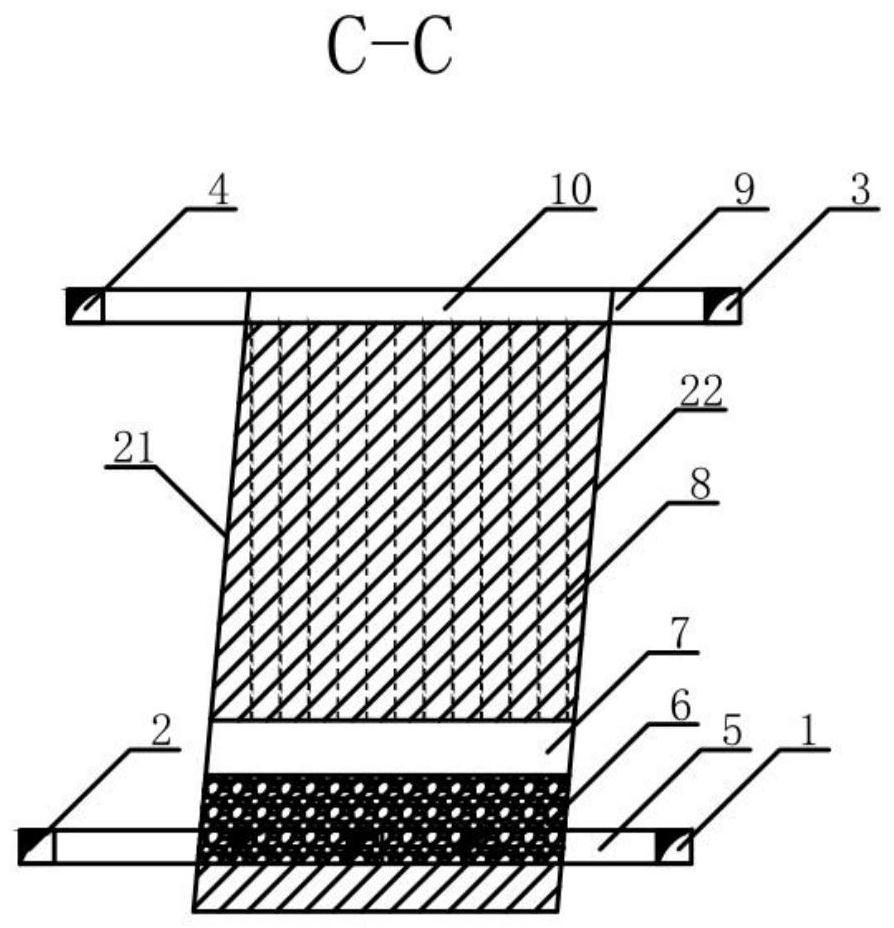

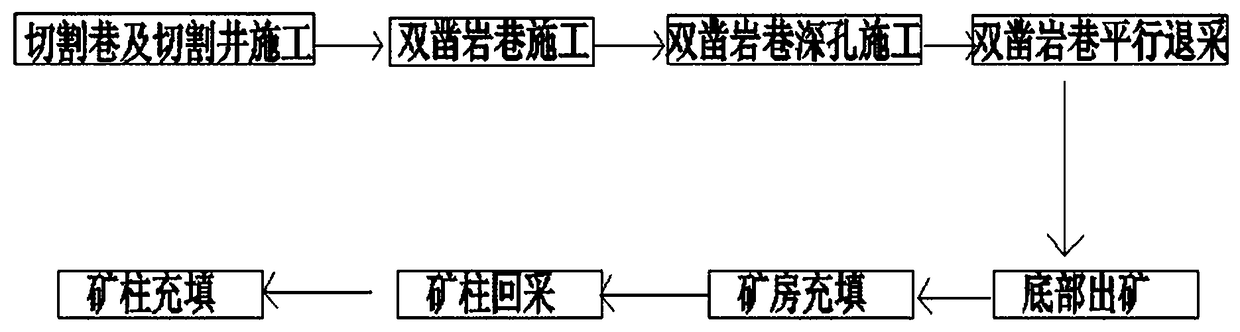

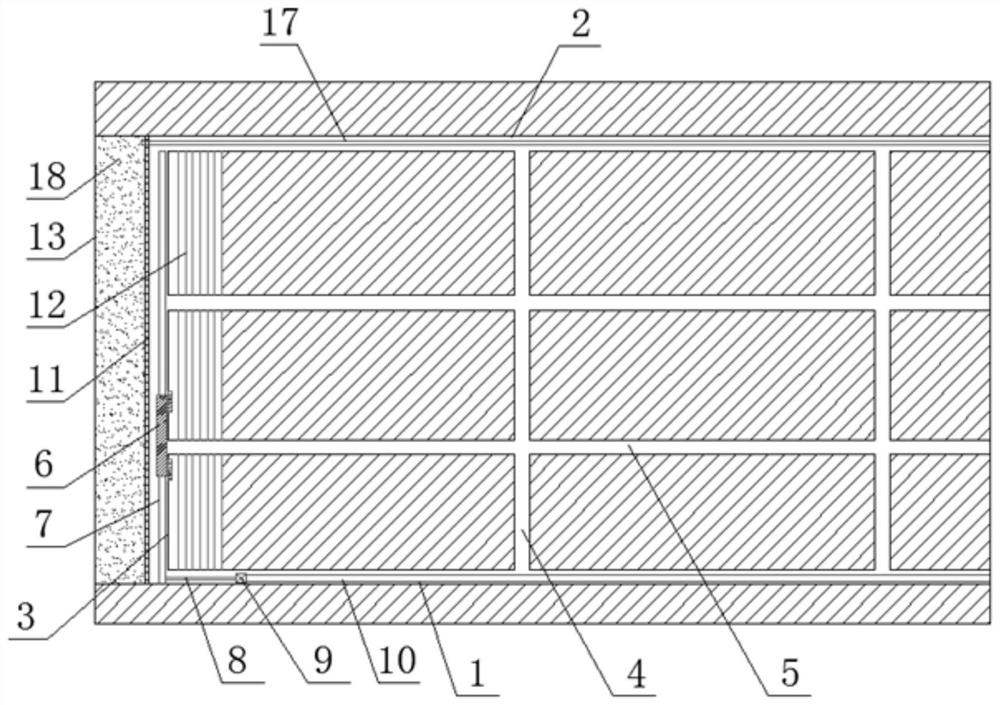

Structural arrangement of multi-stope synchronous mining of steeply inclined thick and large ore bodies with stable ore rocks

ActiveCN112031769AImprove filling efficiencyLow costUnderground miningClimate change adaptationMineralogyMining engineering

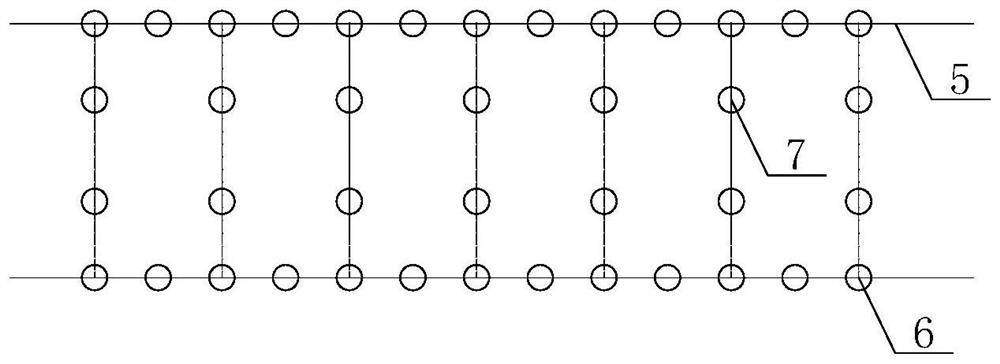

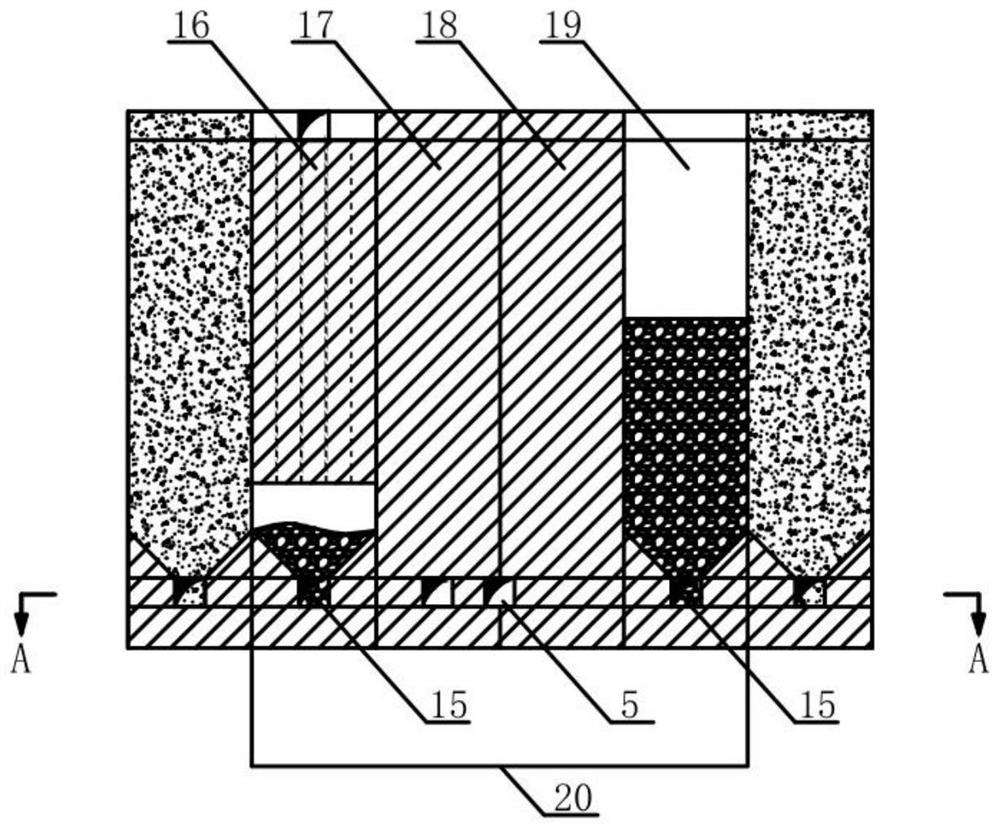

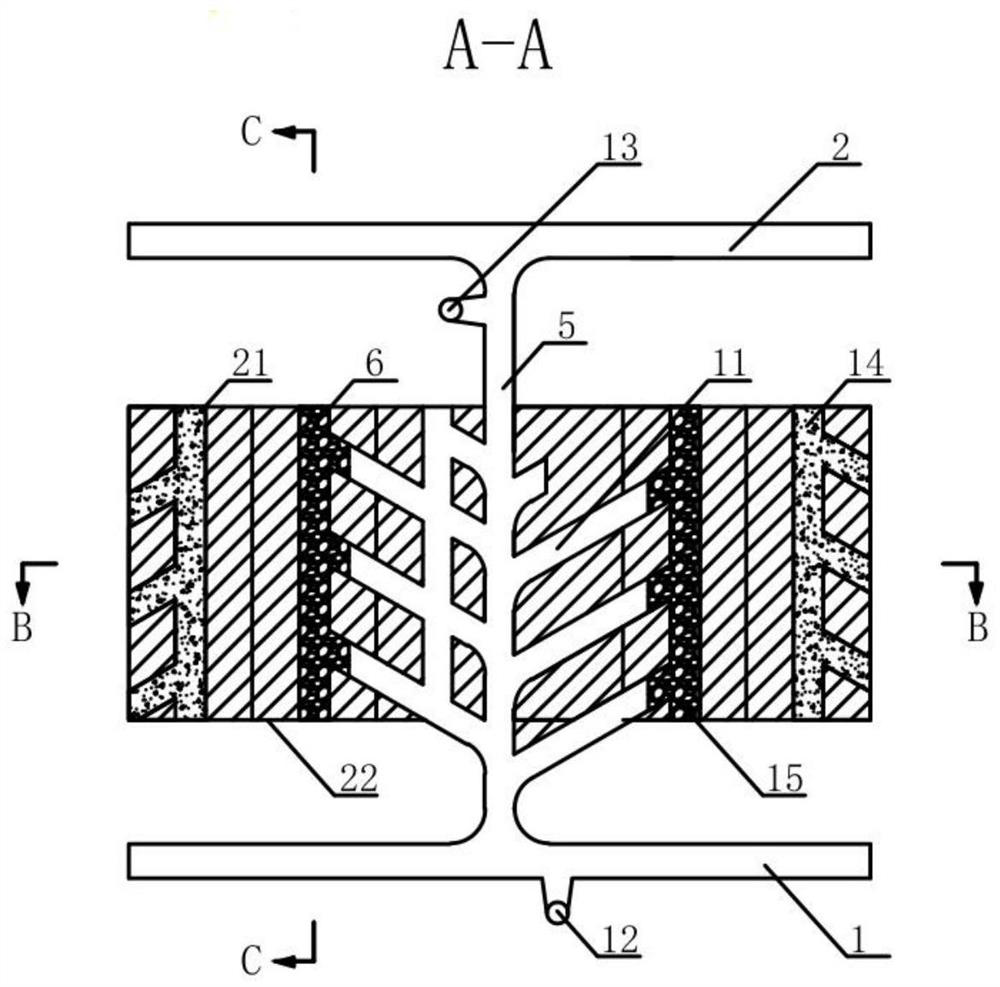

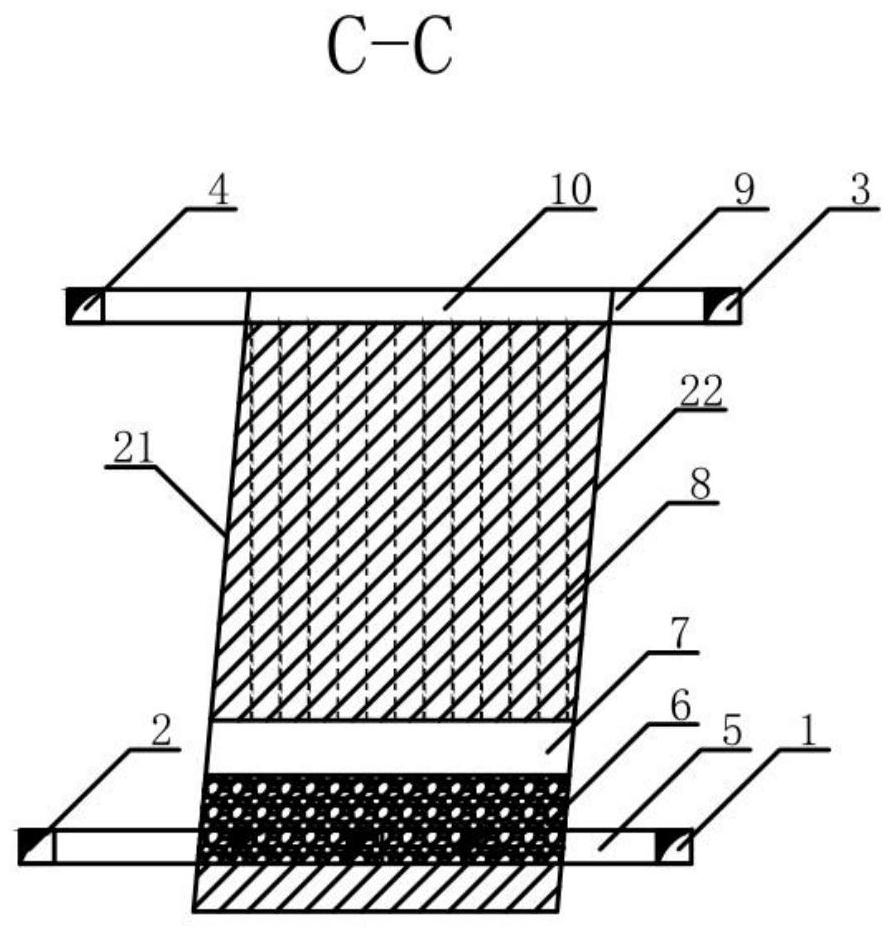

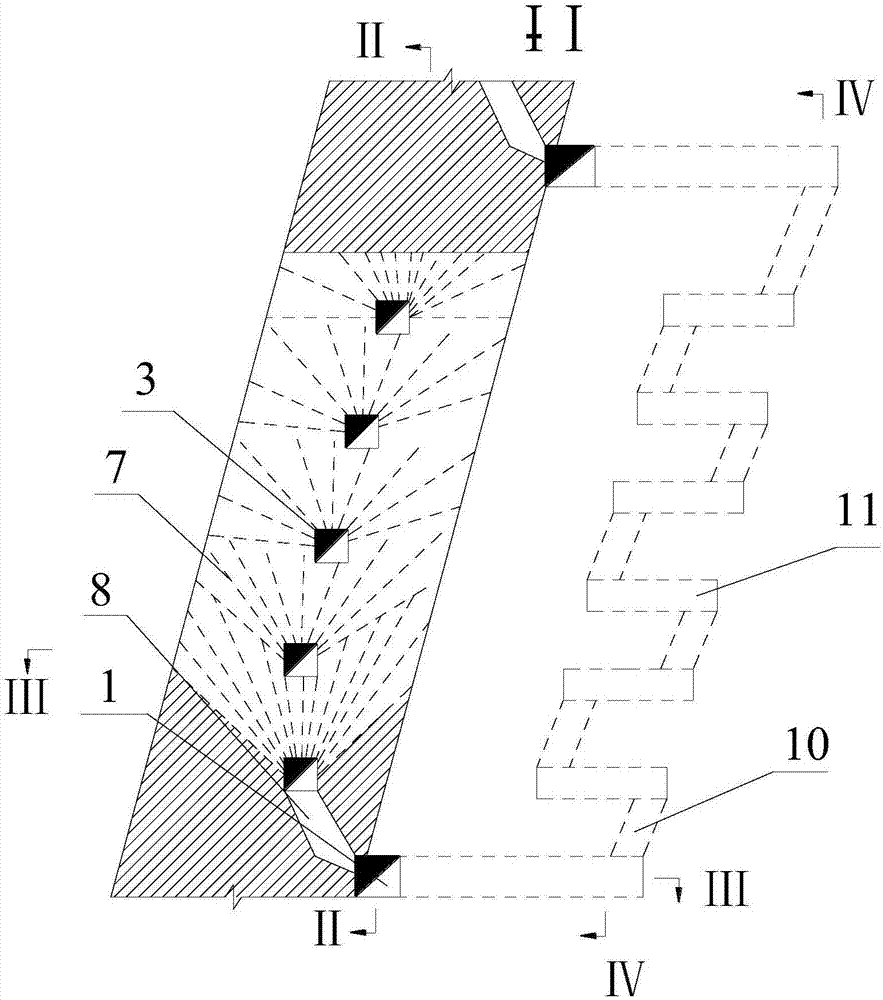

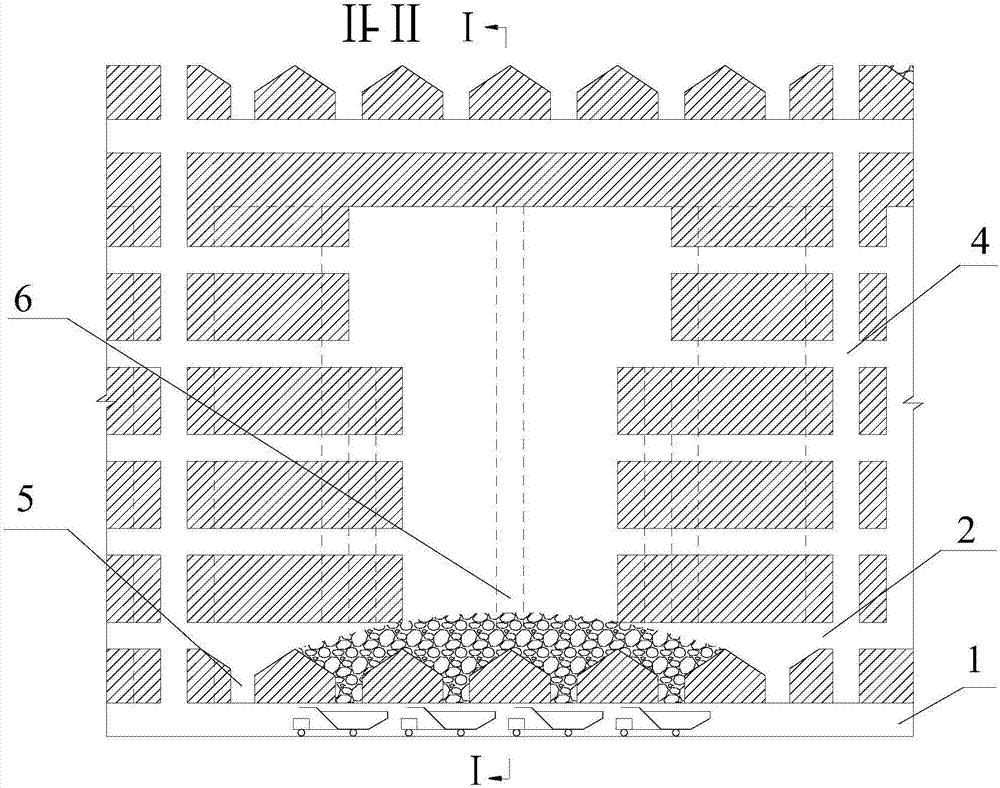

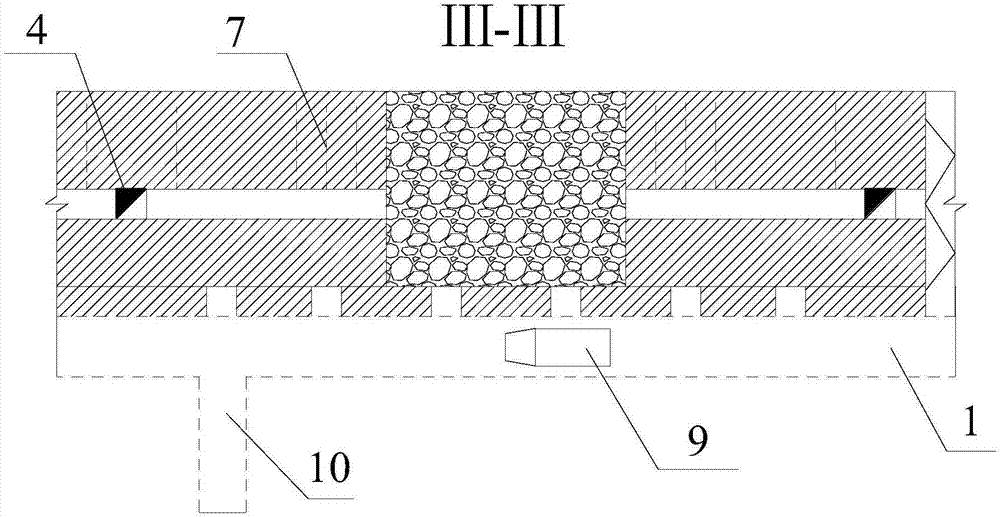

The invention discloses a structural arrangement of multi-stope synchronous mining of steeply inclined thick and large ore bodies with stable ore rocks. The structural arrangement is divided into a plurality of panel areas (20) along the ore body trend, and the panel areas (20) are divided into 4 stopes; a vein-crossing transportation roadway (5) is tunneled in the center position of the bottoms of the panel areas (20); a plurality of ore removal access ways (11) are tunneled at two sides of the vein-crossing transportation roadway (5) to penetrate through all stopes and to be served as shoveling and transporting passages during stope ore removal; and an ore collecting trench (15) and a bottom pulling space (7) are arranged at the bottom of each stope. All stopes in the panel areas (20) share one vein-crossing transportation roadway (5). The structural arrangement provided by the invention has the advantages that only one vein-crossing transportation roadway needs to be arranged in thecenter of the bottoms of the panel areas, and all stopes in the panel areas share the vein-crossing transportation roadway, so that the thousand-ton mining and cutting ratio is reduced by about 35%,the mining preparation work specific gravity is reduced by about 29%, and the mining and cutting engineering quantity is effectively reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Stoping blast mining process for thick and large ore body

InactiveCN108825241AReduce manufacturing costReduce miningUnderground miningBlastingRetreat miningCopper mine

The invention provides a stoping blast mining process for a thick and large ore body. Rock drilling roadways of upper and lower layers are arranged in the thick and large ore body in the direction ofthe ore body, and double rows of rock drilling roadways are arranged at each layer. Upward vertical fan-shaped recovery medium-depth holes are formed in each rock drilling roadway, the medium-depth holes of every two rows are subjected to simultaneous line-connection blasting, and in the blasting recovery process, the step-shaped retreat mining from top to bottom is adopted. An original method that a thick and large ore body is subjected to stoping by adopting vertically-arranged rock drilling roadways is changed to the method that the thick and large ore body of a copper mine is subjected tostoping by double rock drilling roadways in the ore body direction, so that the construction amount of mining preparation roadways and deep holes is effectively reduced, the production cost of the copper mine is reduced, and the mining efficiency is high.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

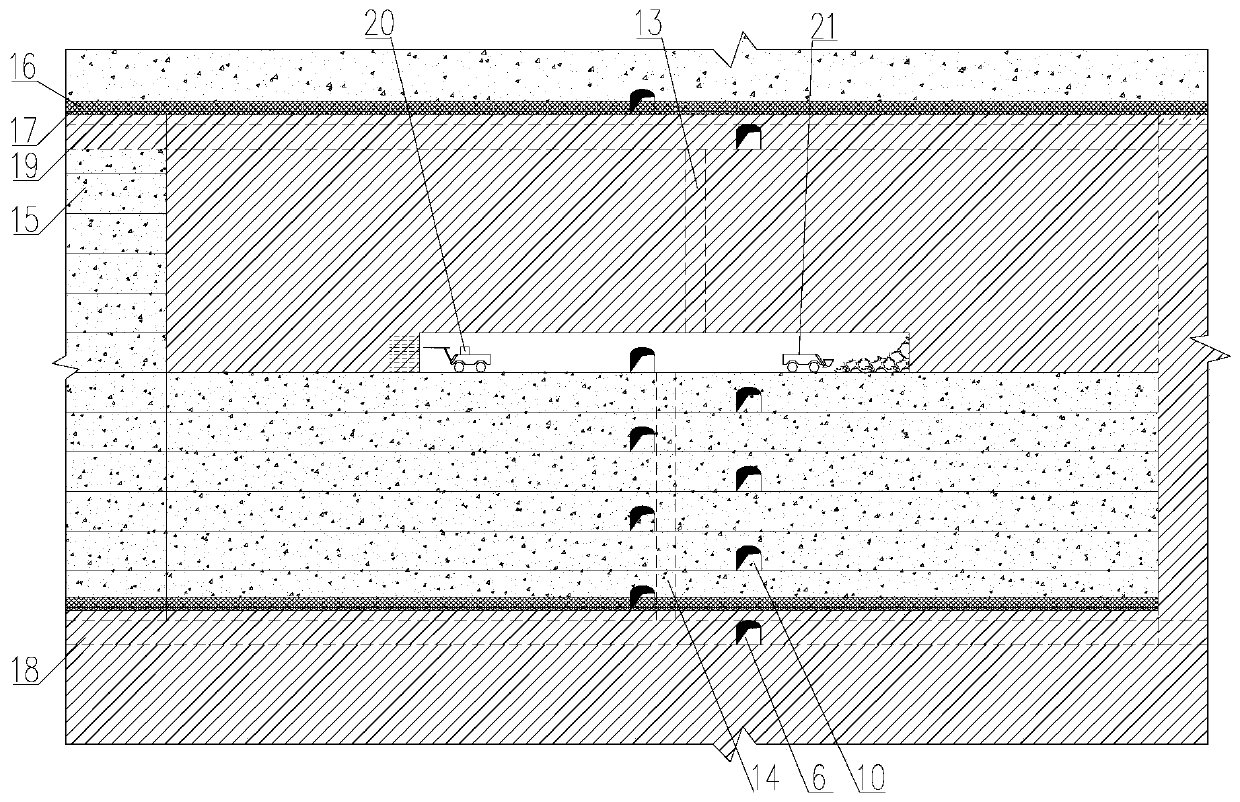

Novel mining method suitable for multi-stope synchronous mining of thick and large ore bodies

ActiveCN112031770AImprove filling efficiencyLow costUnderground miningSurface miningMineralogyMining engineering

The invention discloses a novel mining method suitable for multi-stope synchronous mining of thick and large ore bodies. The method comprises the following steps of: dividing the ore bodies into a plurality of panel areas (20) along the trend of the ore bodies, and dividing the panel areas (20) into four stopes; and a vein-crossing transportation roadway (5) is tunneled in the center of the bottoms of the panel areas (20), a plurality of ore removal access ways (11) are tunneled from the two sides of the vein-crossing transportation roadway (5) to penetrate through all the stopes to serve as shoveling and transporting channels during stope ore removal, and an ore collecting trench (15) and a bottom pulling space (7) are arranged at the bottom of each stope. All the stopes in the panel areas (20) share one vein-crossing transportation roadway (5), the first stope (16) and the fourth stope (19) are stoped synchronously, and after stoping is finished and filling is conducted, the remaining two stopes are mined synchronously. Air flow communication can be achieved, and the working environment of a working face is improved; all the stopes share one vein-crossing transportation roadway (5), so that the mining and cutting work amount is reduced, and the mining production cost is reduced; and one panel area (20) is synchronously mined in two times, so that the ore production efficiencyis improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Mechanized Combined Mining Method of Steeply Inclined Multilayer Thin Orebody

ActiveCN108060924BReduce ground pressure disturbanceRealize no holesUnderground miningSurface miningEngineeringMechanization

The invention discloses a mechanical combined mining method for steep multi-layer thin ores. The multi-layer thin ores are combined into a vein, stope rooms are arranged in the direction of the vein,cap sill pillars of stope are reserved, and intermediate pillars are not reserved; a middle-section conveying roadway is arranged on the heading side of the vein, and a middle-section transverse driftis excavated in the direction perpendicular to the direction of the vein; panel ramps are arranged to connect an upper-section conveying roadway, a lower-section conveying roadway and the middle-section conveying roadway; segmented roadways parallel to the direction of the vein are excavated along the panel ramps, and layered cross gateways are excavated in the direction perpendicular to the direction of the vein; layered transverse drifts are excavated along the layered cross gateways; a vertical drop shaft is arranged on the heading side of the vein, and drop shaft cross gateways are excavated to be connected with the mining layered cross gateways; according to the different thicknesses of the ores, different mining methods are adopted for mining simultaneously, and completed access roads are filled in time; and air-return filling courtyards are excavated in the ores, and filter wells are erected along with layered filling. The mechanical combined mining method can adapt to mining of ore rock with poor stability and has the characteristics of high mechanization degree and low dilution and loss ratio.

Owner:CENT SOUTH UNIV

Mining method for stoping inclined extremely-thin mineral veins

The invention discloses a mining method for stoping inclined extremely-thin mineral veins. The mining method for stoping the inclined extremely-thin mineral veins comprises the steps that mining areasare divided in the direction of an ore body for continuous stoping; a working face is arranged in a forward pseudo-inclining mode; mining is carried out in the unit of pseudo-inclining strips, and the bottoms of all the strips are cut firstly; a rubber cushion is laid on waste rock after waste discarding is completed, and then upper-layer ore is blasted down; bottom cutting blast holes are parallelly formed in the inclining direction of the ore body, and the blasting direction points to one side of a mined area; ore caving blast holes are parallelly formed in the direction of the ore body andare perpendicular to the bottom cutting blast holes, and the blasting points to an ore body bottom plate and the lower parts of the mining areas; and directional pinpoint blasting is carried out by means of sublevel millisecond ignition. According to the mining method for stoping the inclined extremely-thin mineral veins, improvement of safety of the working face is facilitated, the ore recoveryrate and mined ore grade of the mining of the inclined extremely-thin mineral veins are improved, the stope preparation work amount is less, and the mining cost is low.

Owner:KUNMING METALLURGY COLLEGE

Hydraulic fracturing comprehensive mechanized continuous mining method for gently inclined hard rocks

PendingCN113153291ADamage stabilityReduce intensityMining devicesDisloding machinesHydraulic fracturingStoping

The invention provides a hydraulic fracturing comprehensive mechanized continuous mining method for gently inclined hard rocks. The hydraulic fracturing comprehensive mechanized continuous mining method for the gently inclined hard rocks comprises the following steps of (1) determining ore block structure parameters; (2) arranging a mining and cutting project, and forming a mining working face; (3) forming fracturing holes in the mining working face; (4) hydraulically fracturing an ore body in the fracturing holes; (5) adopting comprehensive mechanized stoping; and (6) filling a goaf. Compared with the prior art, when the hydraulic fracturing comprehensive mechanized continuous mining method for the gently inclined hard rocks is used for mining the hard rocks, the mining and cutting engineering amount, the fixed number of workers and the ventilation energy consumption are greatly reduced, and the production efficiency is improved.

Owner:CINF ENG CO LTD

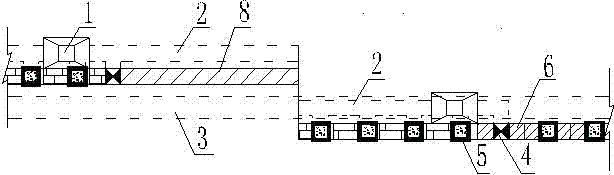

Truck coordinated mine removal subsection drilling stage room mining method

ActiveCN106939788AIncrease productivityReduce the amount of mining and cuttingUnderground miningSurface miningTruckMechanization

Provided is a truck coordinated mine removal subsection drilling stage room mining method. The method comprises the following steps that a thin vein belt formed by a thick or extremely thick steeply inclined mine body or a steeply inclined parallel extreme thin vein of a solid mine rock is divided into stages, mine blocks are divided in the stages, and the mine blocks are divided into mine rooms and mine columns; a transportation roadway is arranged at the boundary of the mine rock, and a slope ramp is distributed outside the vein; an air pedestrian patio is excavated in a studding, and a section drilling roadway is excavated from the patio; a mine drawing funnel and a short chute well accessible mine body are excavated through the transportation roadway; and a medium length hole mine drawing in an upper fan section is adopted when the mining is conducted, and the mine block is directly put into the track through the short chute well and the mine drawing funnel and then is transported out through the slope ramp. According to the truck coordinated out of mine section drilling stage room mining method, the method improves a traditional subsection drilling stage mine room method, the work amount of mining and cutting is reduced, the degree of mechanization is improved, cooperation of mine extraction and mine removal is ensured, and the production efficiency of the mine is improved.

Owner:GUANGXI UNIV

Gently inclined-inclined medium-thick orebody mining method

InactiveCN110284884ASimple processReduce the amount of mining and cuttingUnderground miningSurface miningRoom and pillar miningMineralogy

The invention belongs to the technical field of metallic mineral deposit underground mining methods and discloses a gently inclined-inclined medium-thick orebody mining method which aims to slove the problems existing in inclined and gently inclined orebody mining in the prior art. The method comprises the steps of ore block division and ore block division section, each section is subdivided into a section ore room and a section top column, an intraminal diagonal slope path is tunnelled from a stage transport roadway to an upper stage transport roadway and one ore-pass is arranged at an opening of each section of the intraminal diagonal slope path, a rock drilling trolley enters the section ore rooms through the intraminal diagonal slope path to drill ore room mining blast holes and enters section ore room mined-out areas through the intraminal diagonal slope path to drill top column mining blast holes to the section top columns, collapsed top column ore is transported to the ore-passes through a scraper, and permanent interstitial columns are left every 5-8 m. According to the gently inclined-inclined medium-thick orebody mining method, by means of the advanced rock drilling trolley technology, the gently inclined-inclined medium-thick orebody mining method has the advantages of a sublevel open field method, a room column mining method and the large-section roadway tunneling technology at the same time and has the advantages of being simple in process, small in mining cutting engineering quantity and the like.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com