Recovery method of underground mine goaf remaining studs

A goaf and mine technology, which is applied in the field of mining leftover pillars in goafs of underground mines, can solve the problems of ore dilution, mixing of waste rock, poor operation safety conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

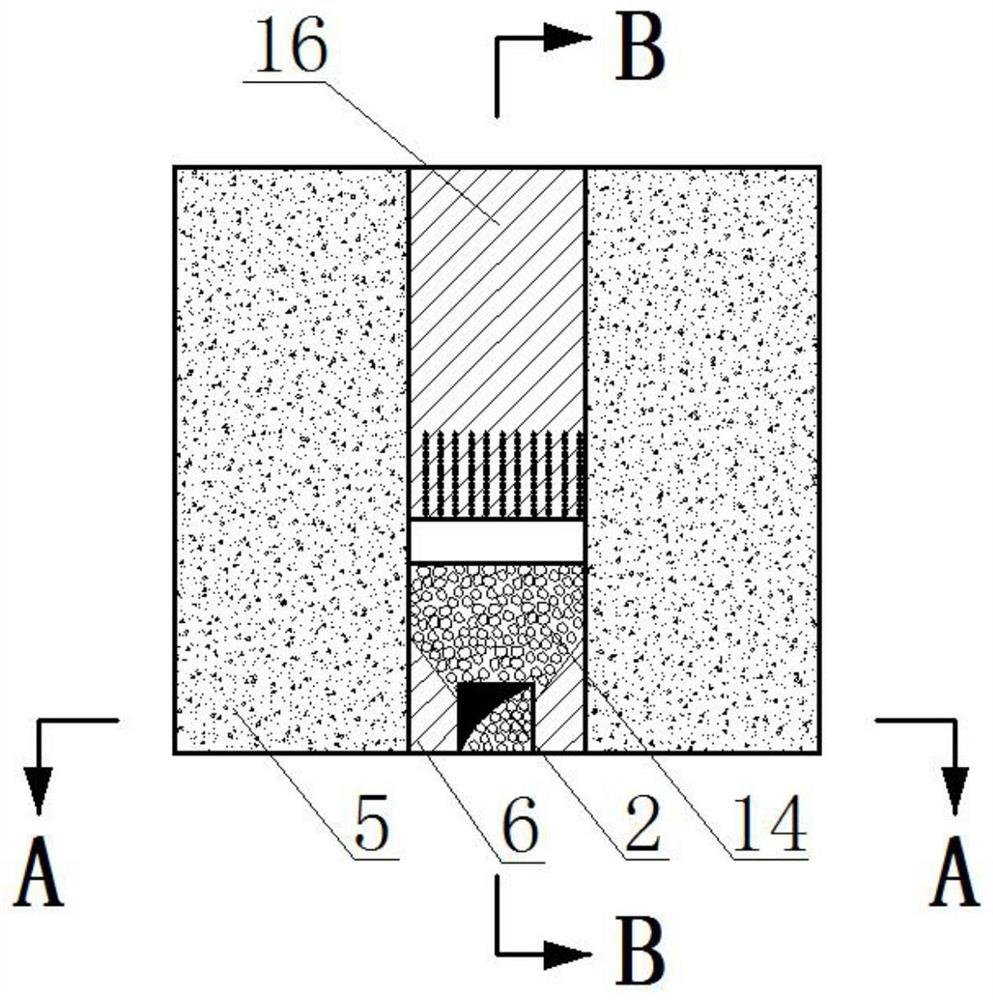

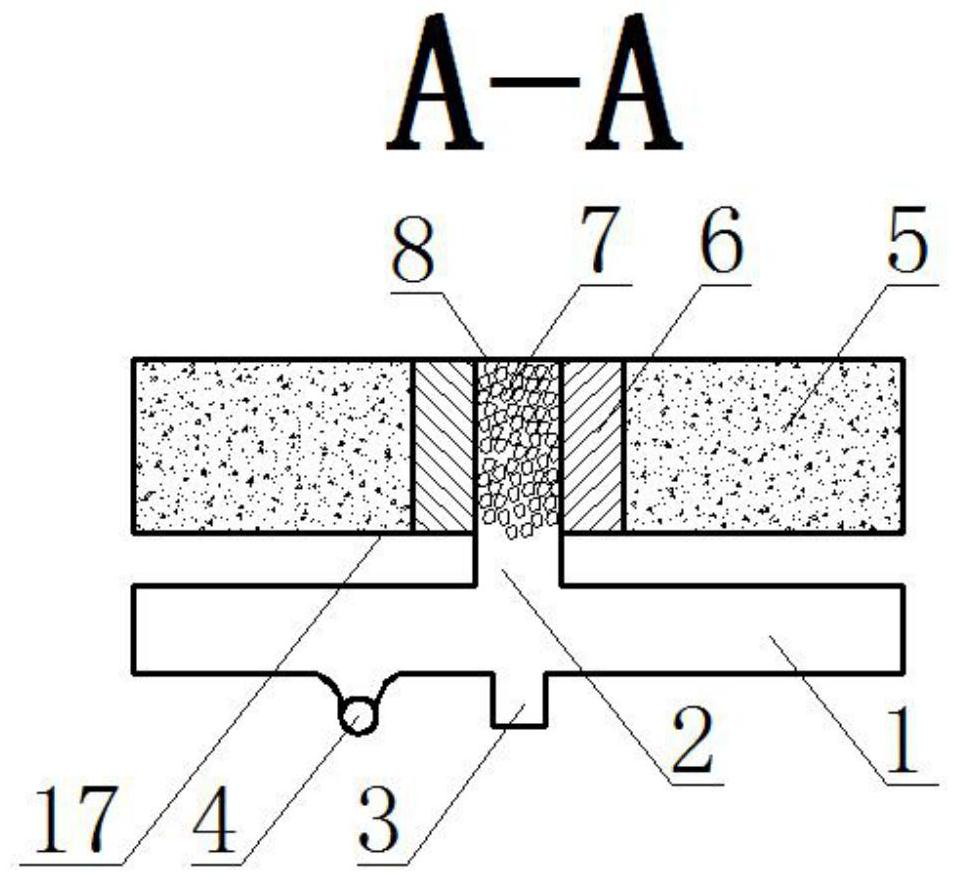

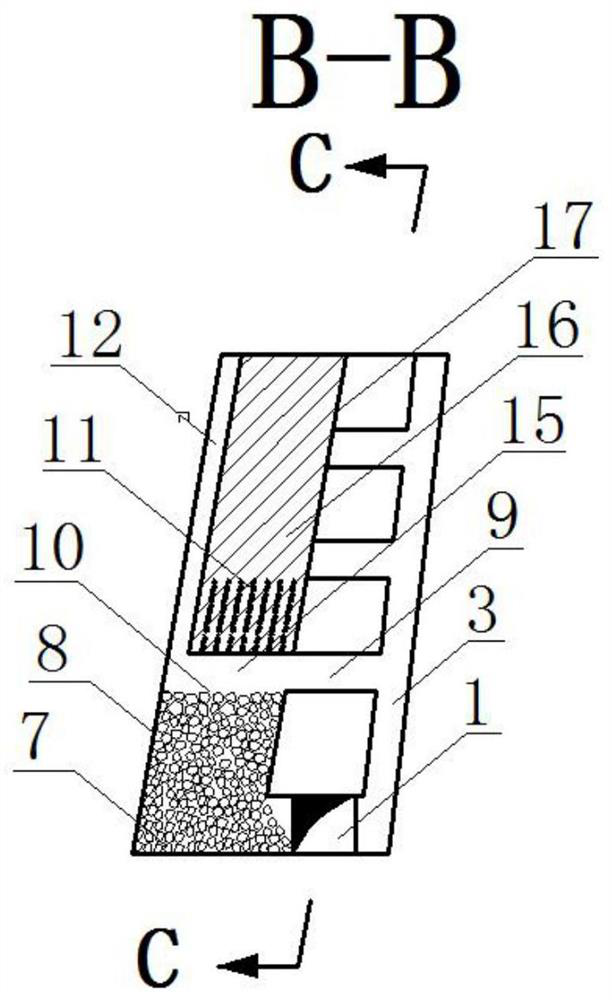

[0037]In order to describe the present invention better, below in conjunction with accompanying drawing, a kind of mining method of the underground mine goaf leftover column of the present invention will be further described in detail.

[0038] Depend on figure 1 The front view of the mining method of the left space column in a kind of underground mine mined-out area of the present invention shown and combined figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 It can be seen that the mining method of a kind of underground mine goaf left over pillars in the present invention is provided with pillars 16 in the ore body, and the two sides of pillars 16 are mine houses, and the middle section transportation roadway 1 is provided at the ore body footwall, specifically Implement the following steps:

[0039] 1) When the backing of the mine house is completed and the filling body 5 formed by tailings cemented filling reaches 1.5 MPa, along the direction perpendicular to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com