Stripped fluid expansion filling mining method for below middle thick coal seam

A mining method and strip-type technology, which is applied in the direction of filling, underground mining, surface mining, etc., can solve the problems of low filling efficiency, inability to realize full filling, difficulty in control, etc., and achieve the effect of improving the recovery rate of the mining area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

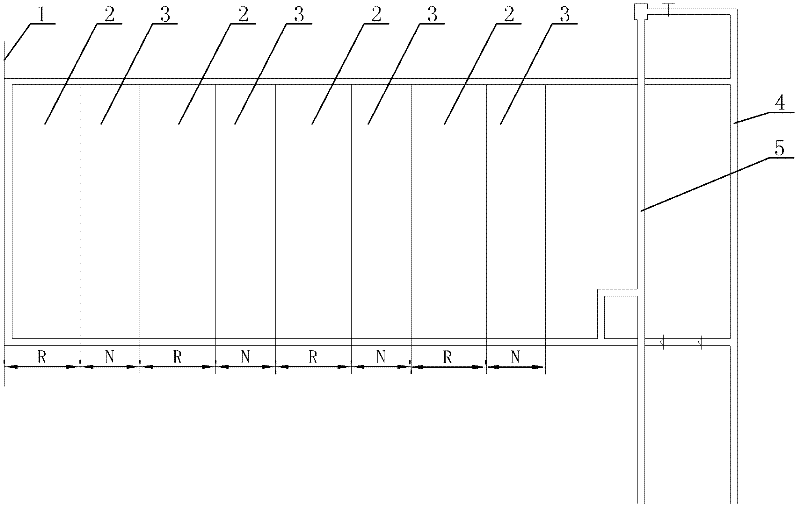

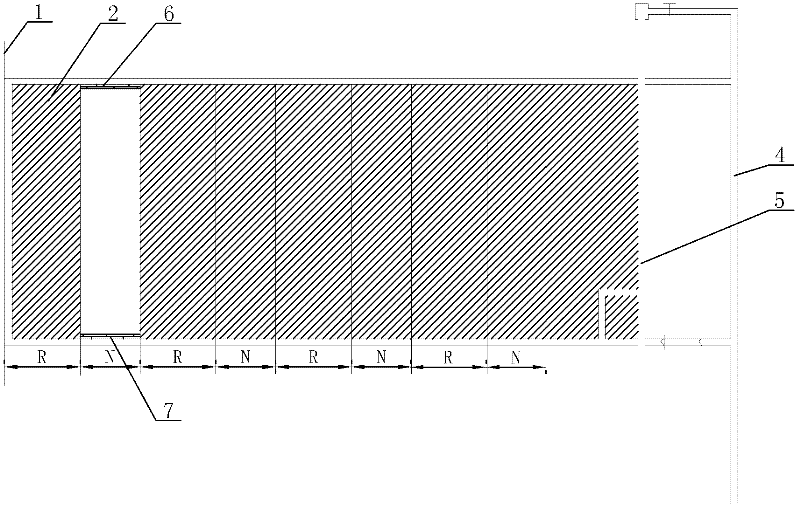

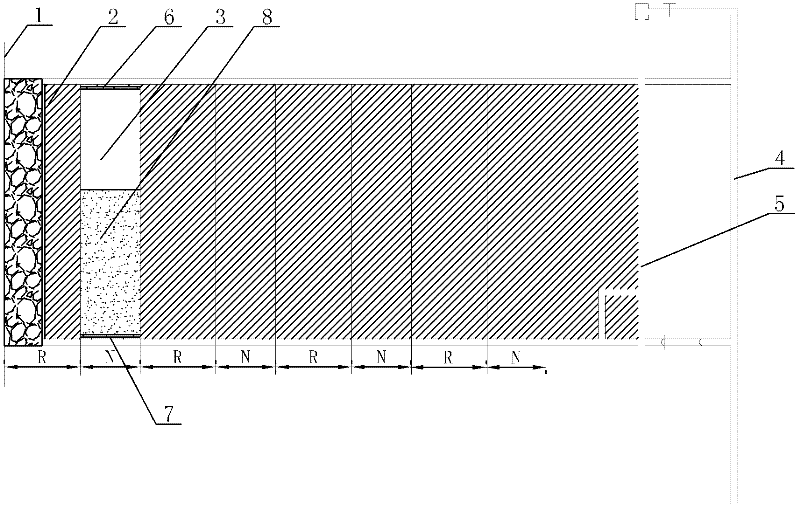

[0026] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0027] Specifically in conjunction with the strip filling mining of the 259 mining area, the present invention is specified:

[0028] 1. Arrange the roadway in the mining area according to the direction of the longwall coal mining face, and the length of the working face is 120 meters.

[0029] 2. Roof lithology analysis, key layer and determination of filling size of Coal-9:

[0030] The thickness of Mei-9 is 1.5-1.8 meters, and the thickness of the direct roof is 1.2-1.5 meters. Its lithology is shale or sand-shale interbedded, and some blocks are mudstone. The upper parts of the immediate roof are: 1. Limestone with a thickness of about 1 meter, 2. Siltstone with a thickness of about 4.3 meters, 3. Carbonaceous mudstone and mudstone with a thickness of 2 to 3 meters, 4. Sandstone with a thickness of about 5 meters , 6. All above are rock formations with a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com