Patents

Literature

72results about How to "Improve mining safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

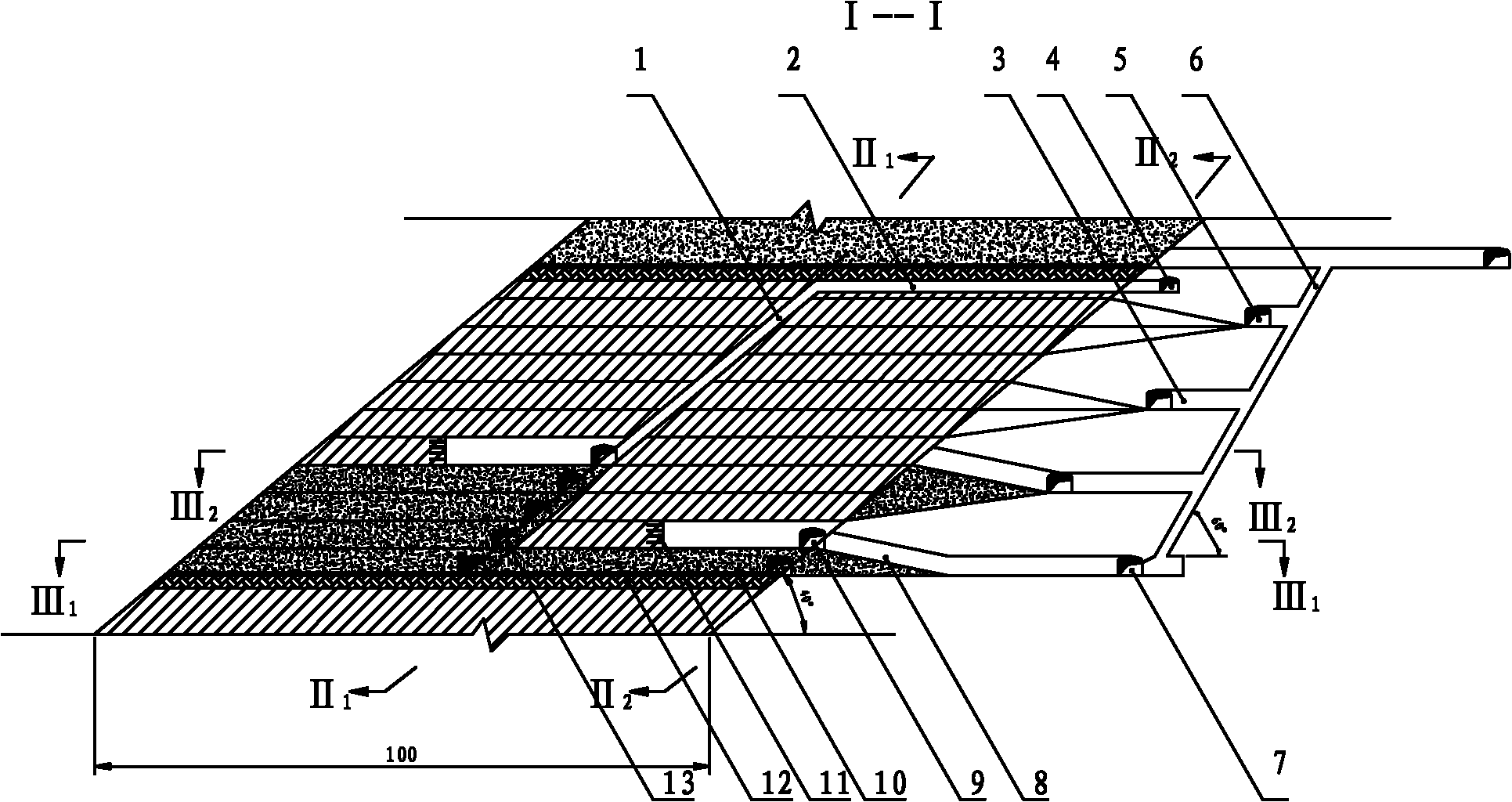

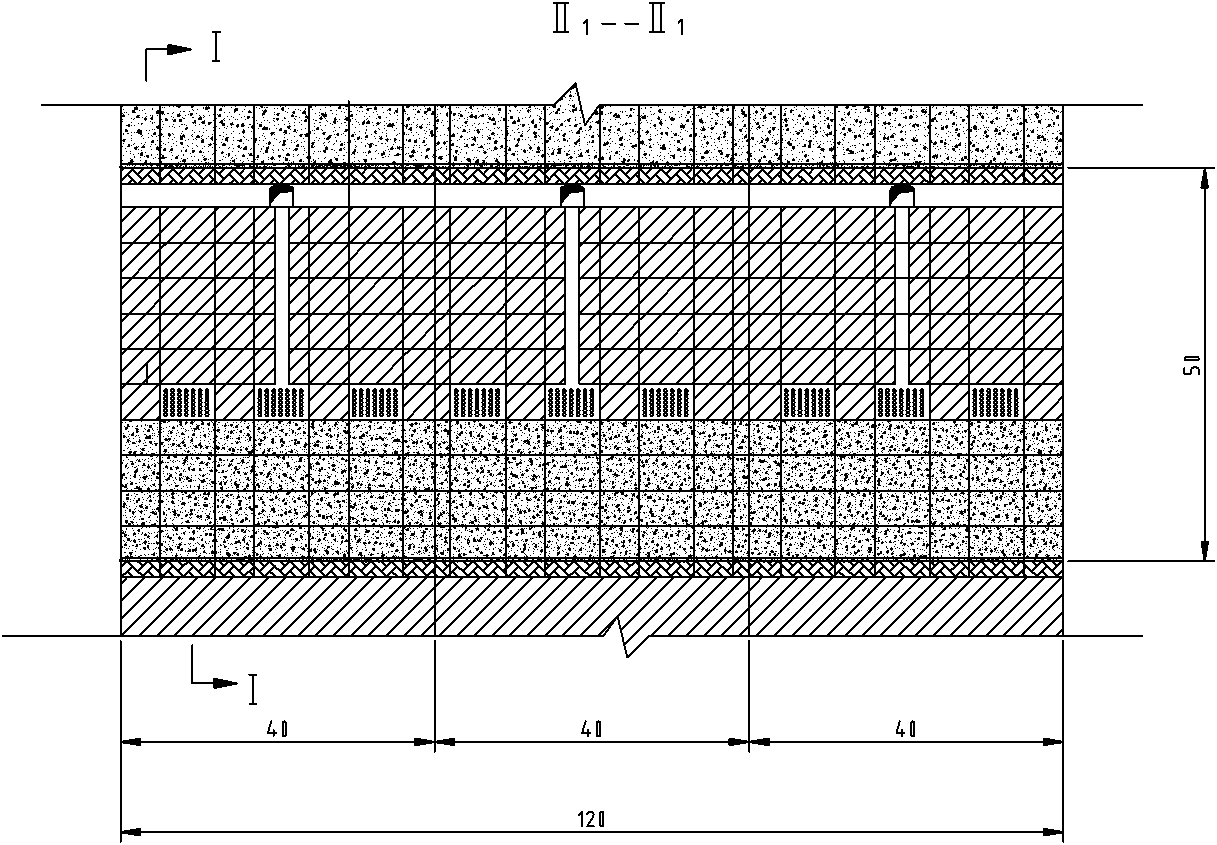

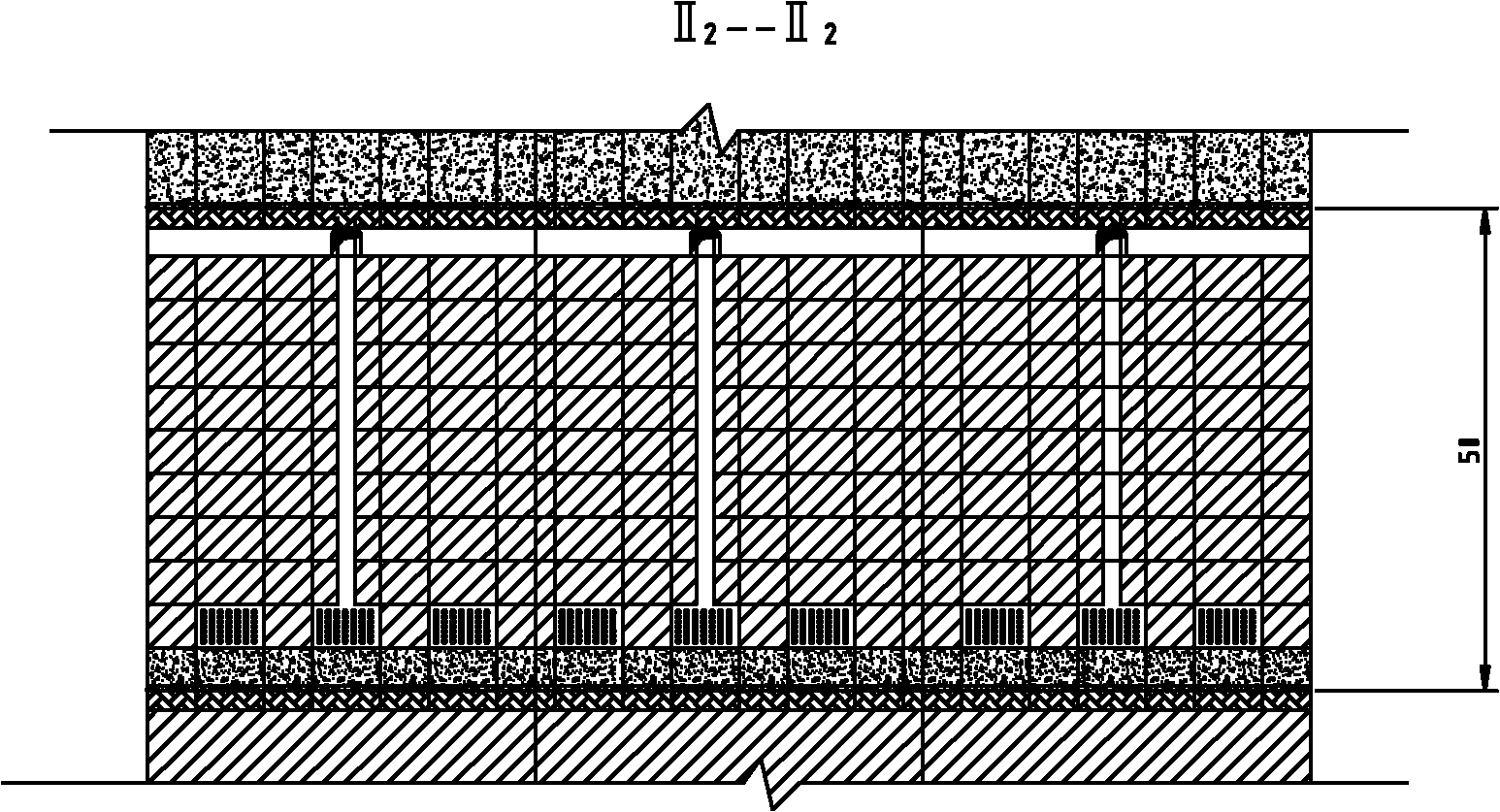

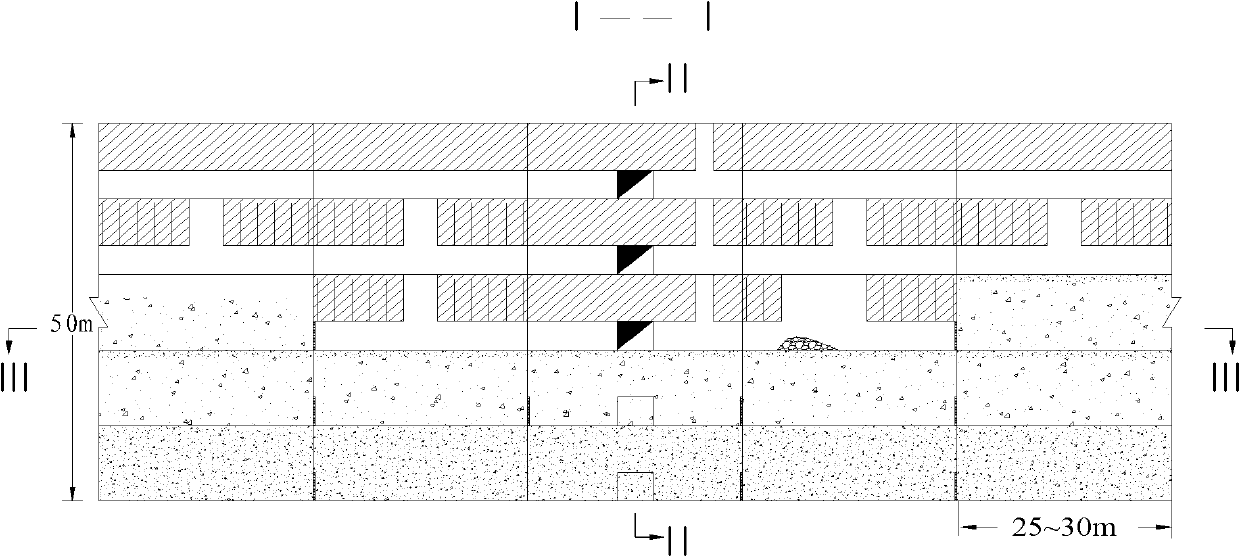

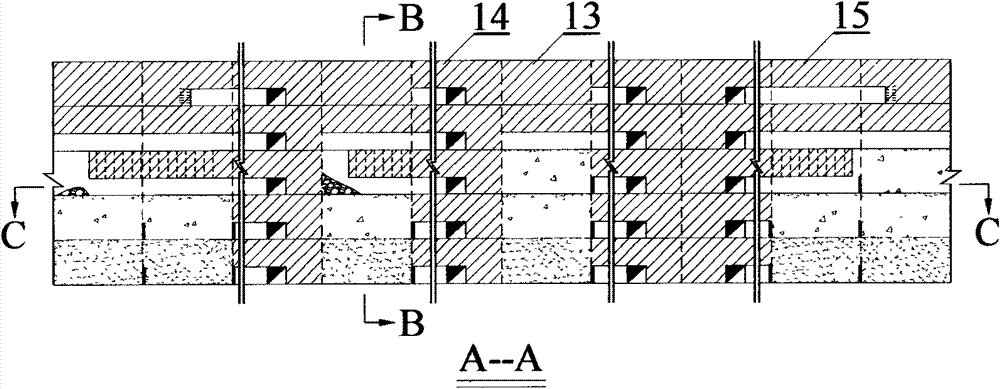

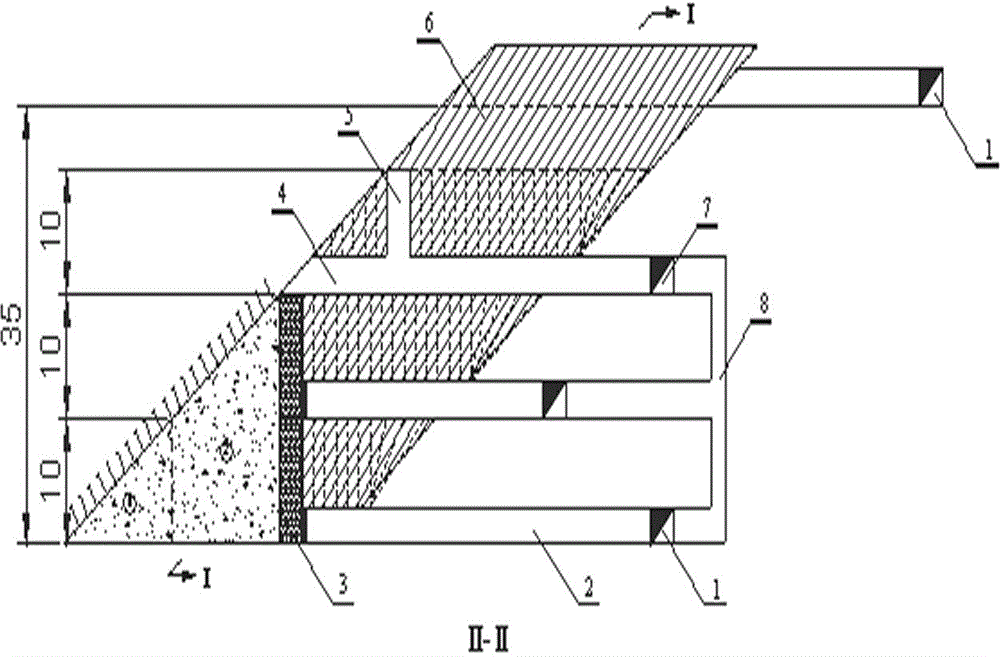

Stepped non-pillar continuous filling mining method for deep well super high large breaking ore body panel

InactiveCN101818643ASafe miningMining guaranteeUnderground miningSurface miningEngineeringCompressive strength

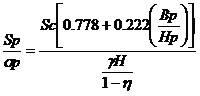

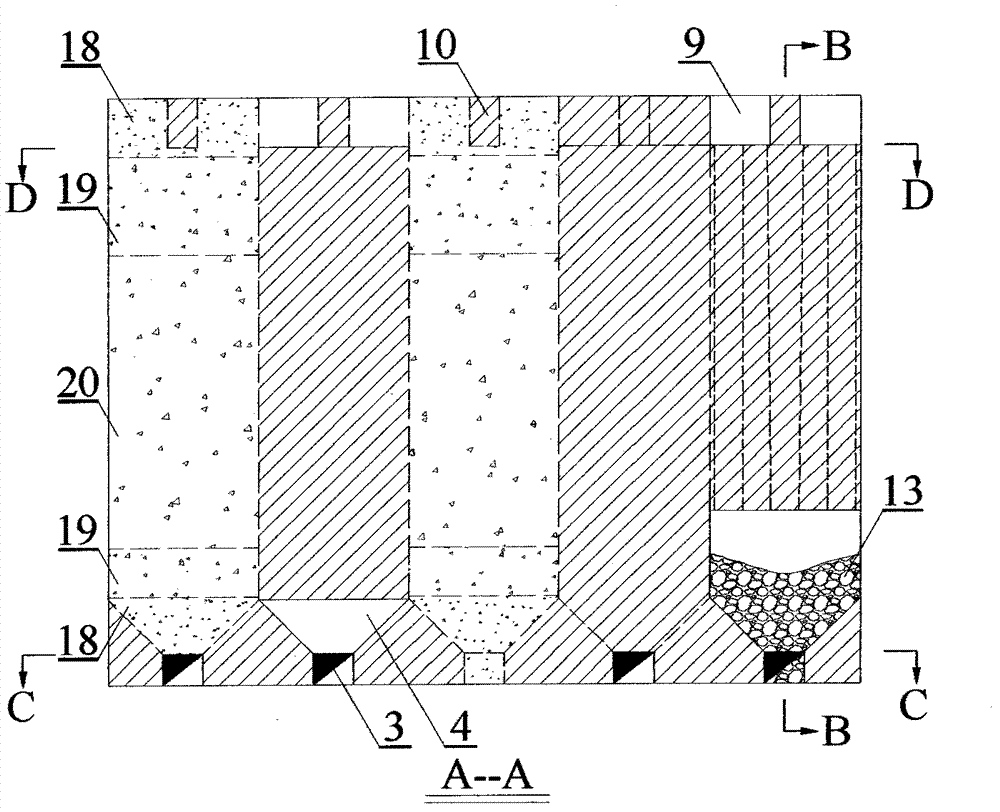

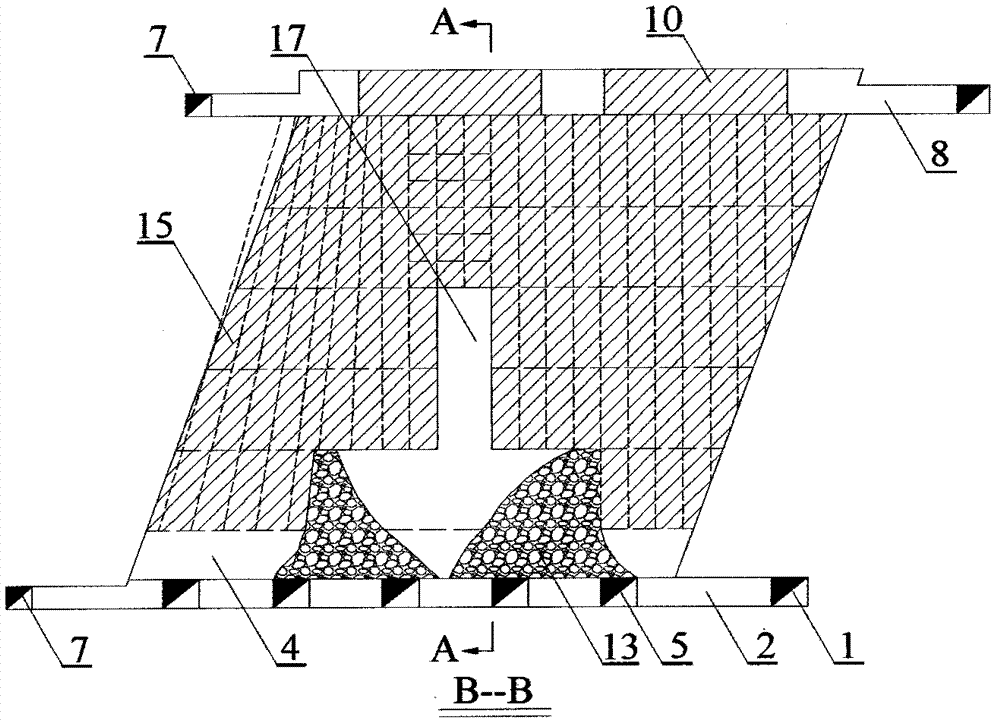

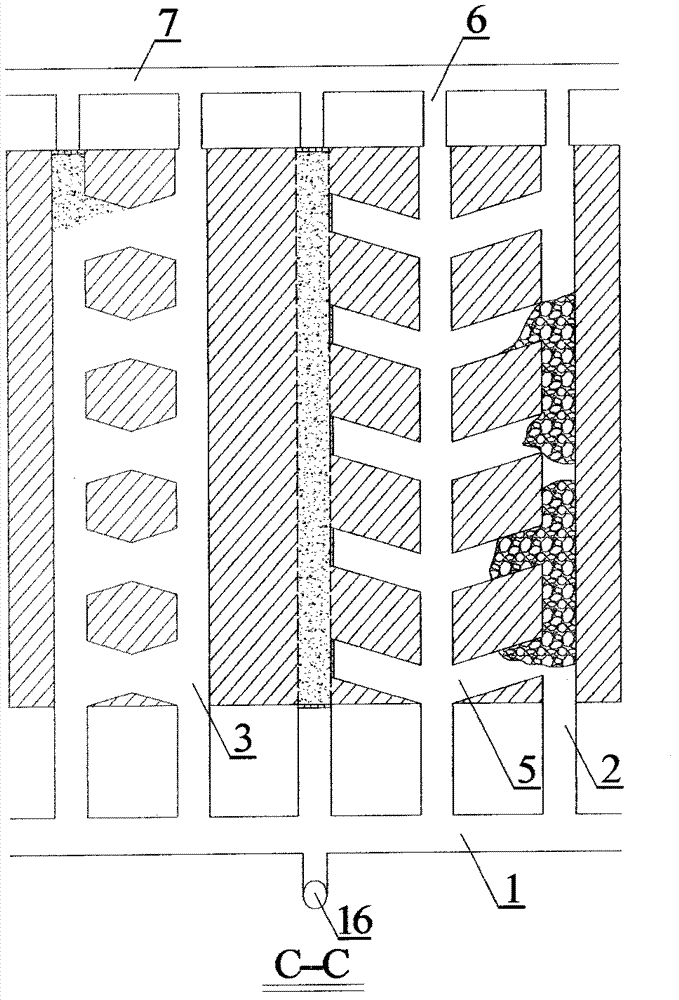

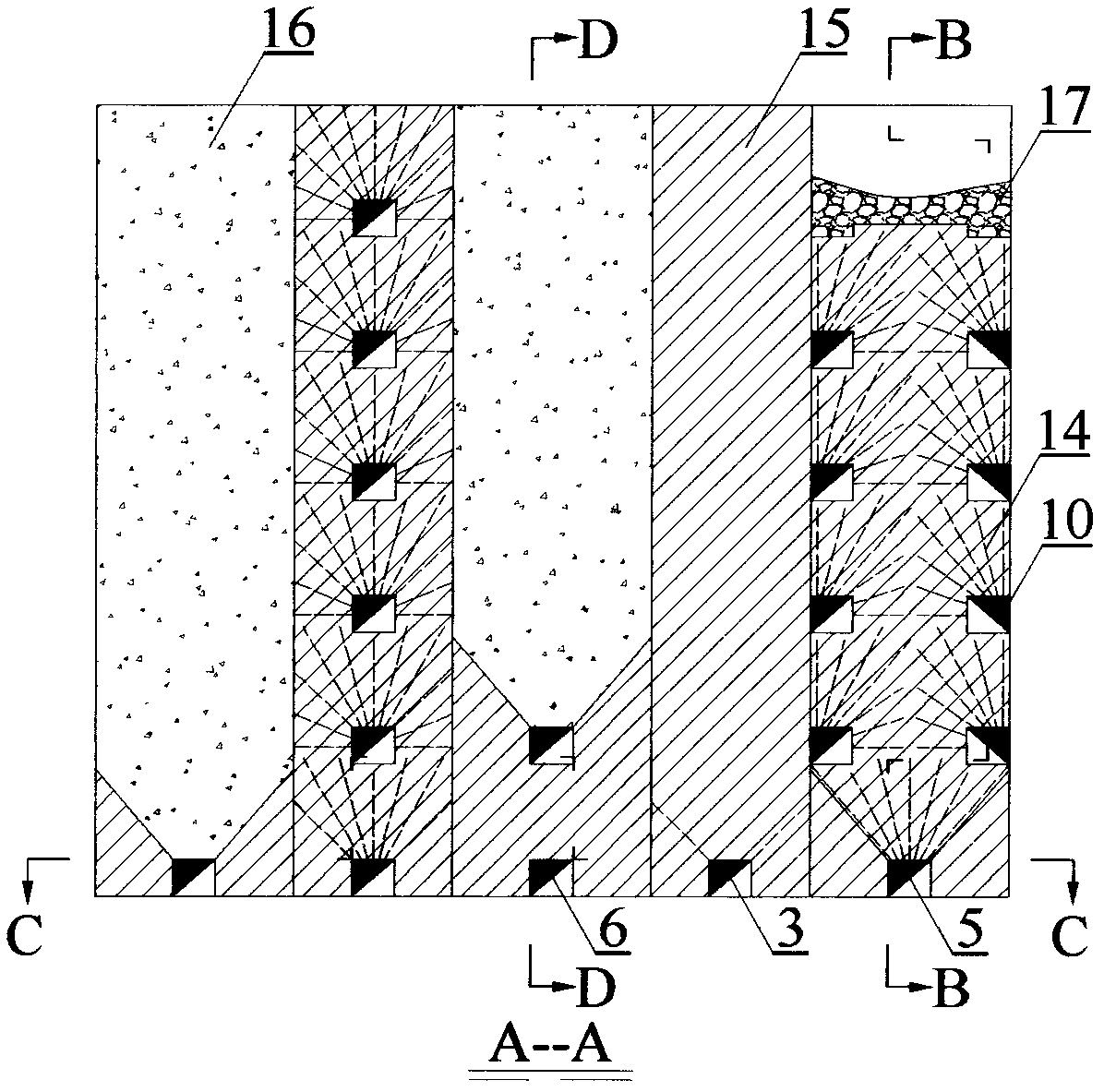

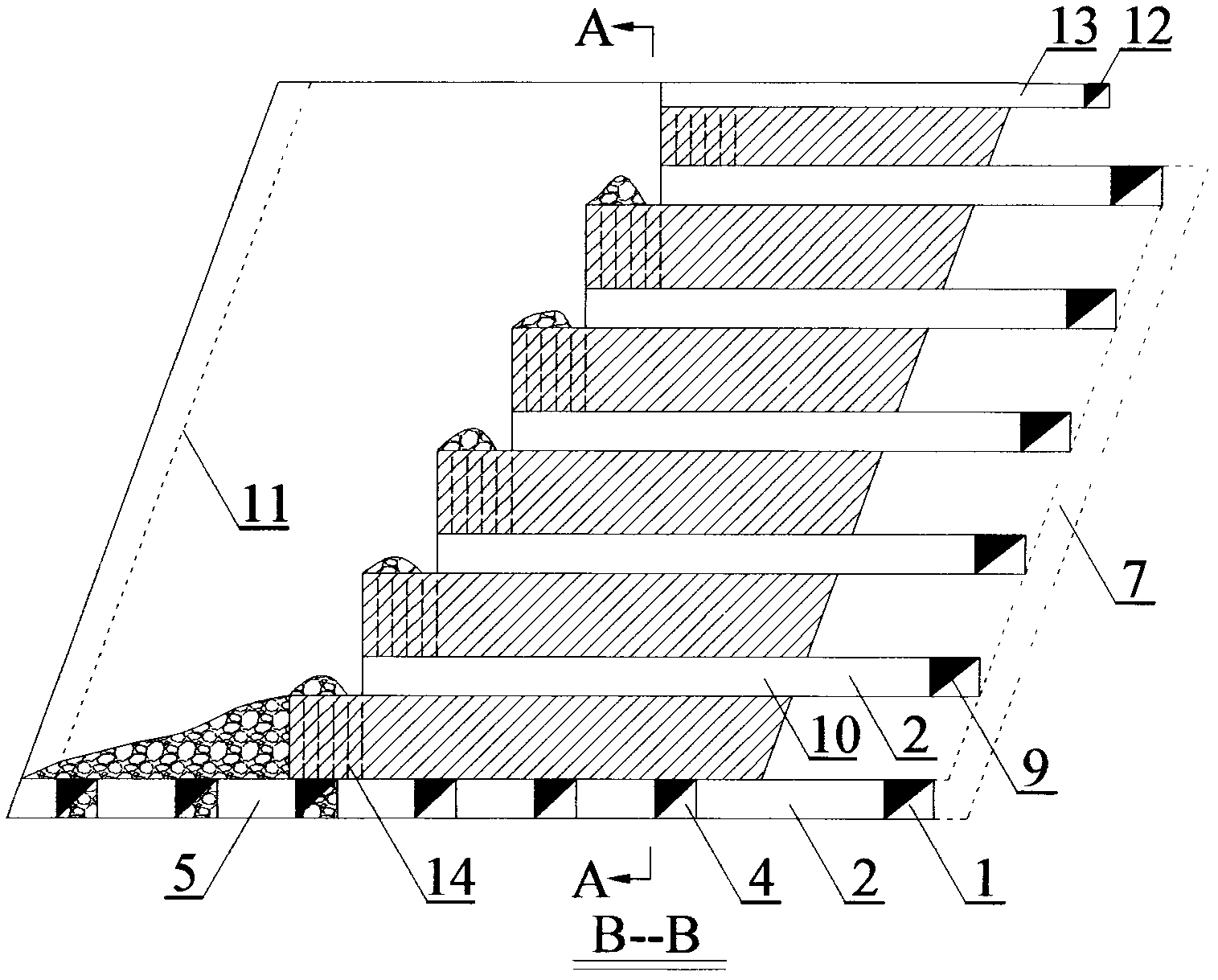

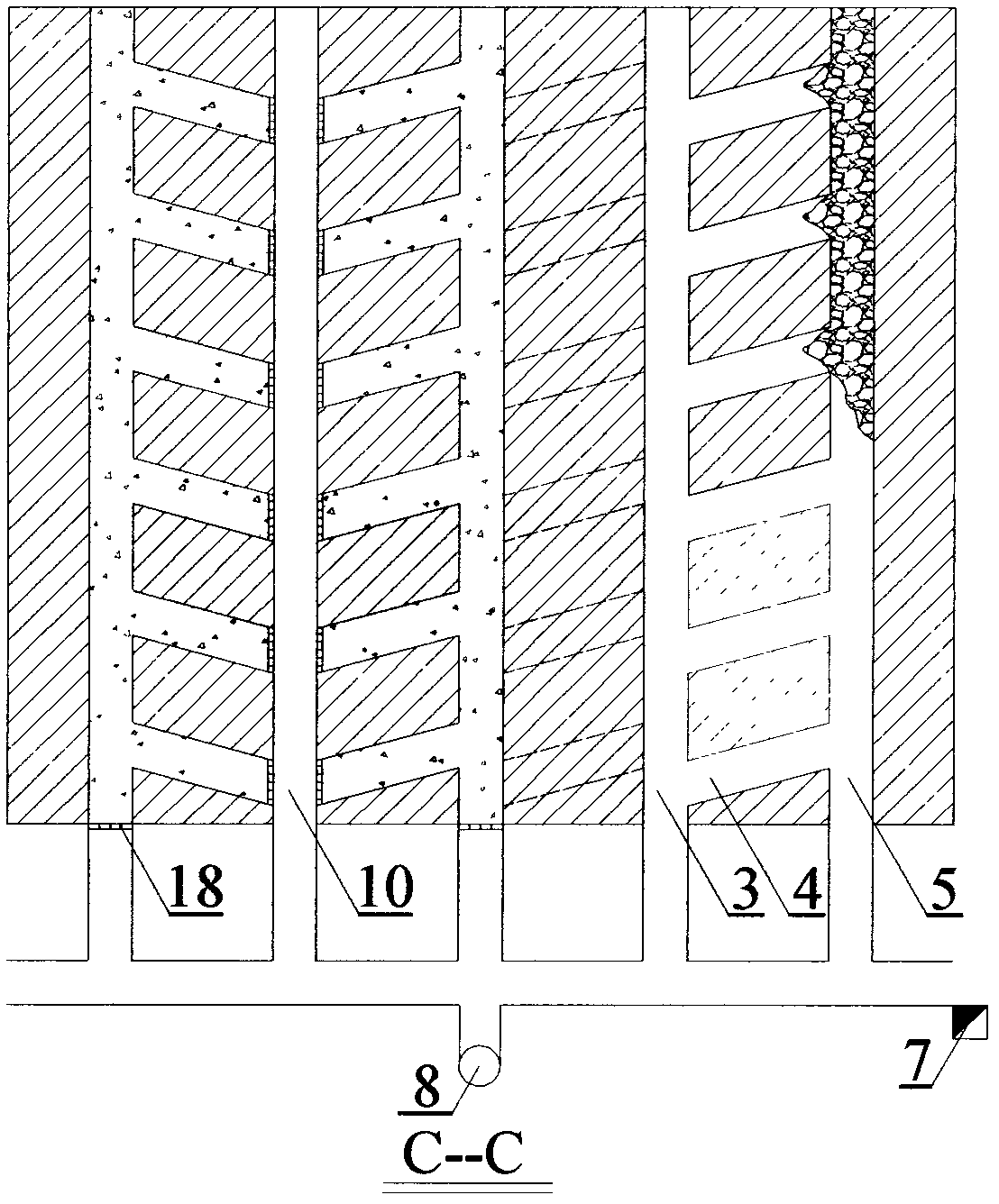

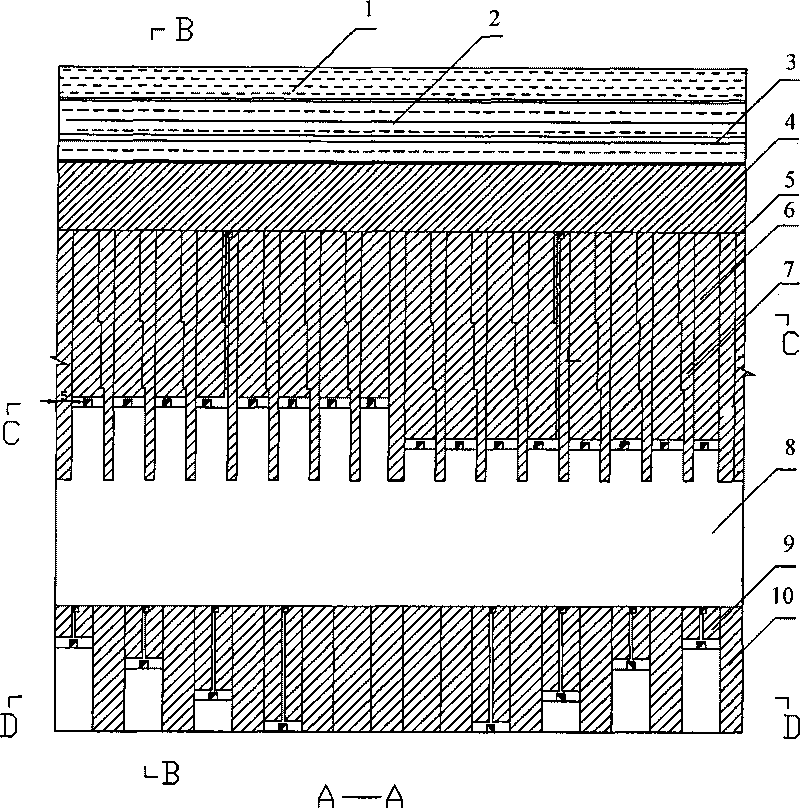

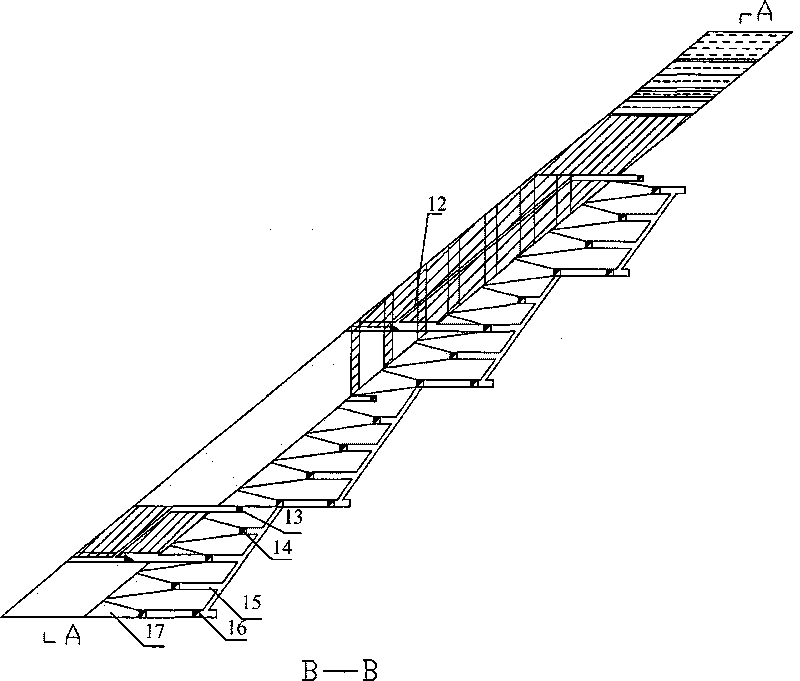

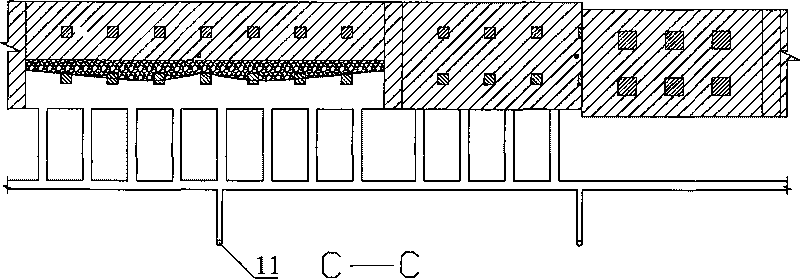

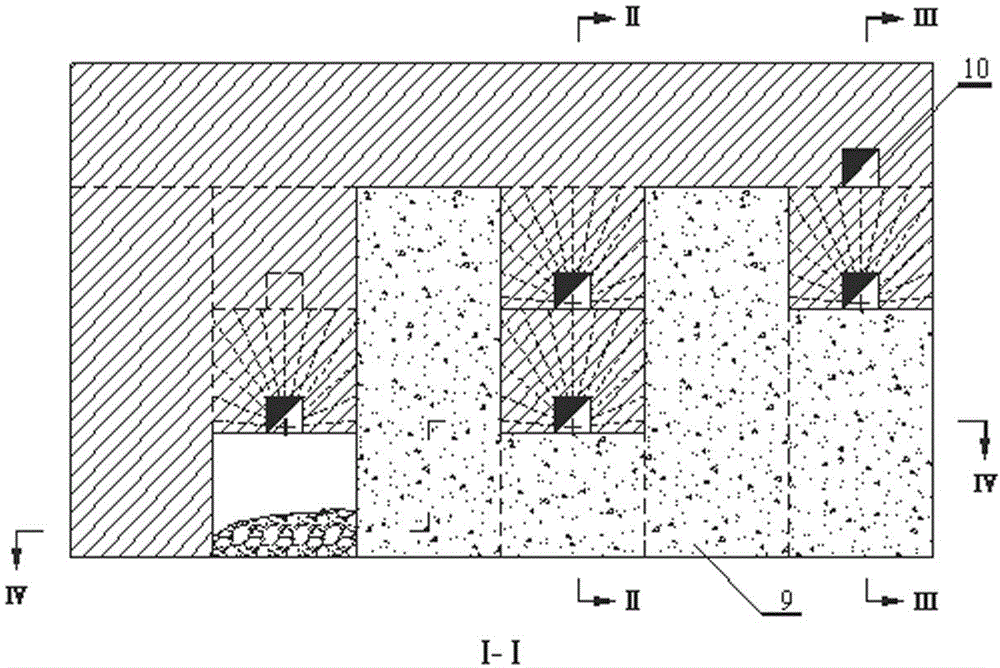

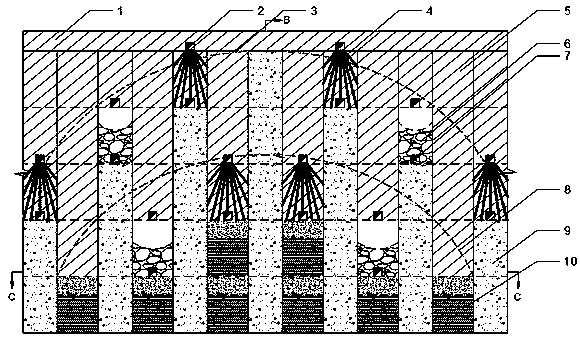

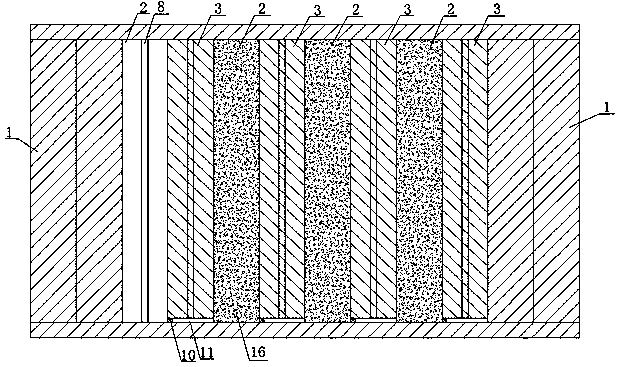

The invention discloses a stepped on-pillar continuous filling mining method for deep well super high large breaking ore body panel. An ore body is divided into a front part and a rear part in a super high large breaking ore body center by an transportation roadway, then the front part and the rear part are respectively divided into a plurality of panels, no pillar exists between pillars, each panel is partitioned into a primary extracting drift and a second extracting drift, the panels in the front part are extracted at first and then the panels in the rear part are extracted, the front and rear panels are extracted in a stepped manner, each production technology is carried out in the same level, and procedures can not influence each other; after the stop back production is finished, the primary extracting drift is filled with cement and the secondary extracting drift is filled by classifying tailings while roof-contacted filling is ensured; and the primary extraction drift and the secondary extraction drift adopt high strength filling topping, and binding materials are added in the filling tailings so as to improve the compression strength of a topping layer. The invention has the characteristics of high extraction safety, small loss and dilution, high mechanical degree, large stope amount, large back production strength, high production capability, short back production time and the like.

Owner:CENT SOUTH UNIV

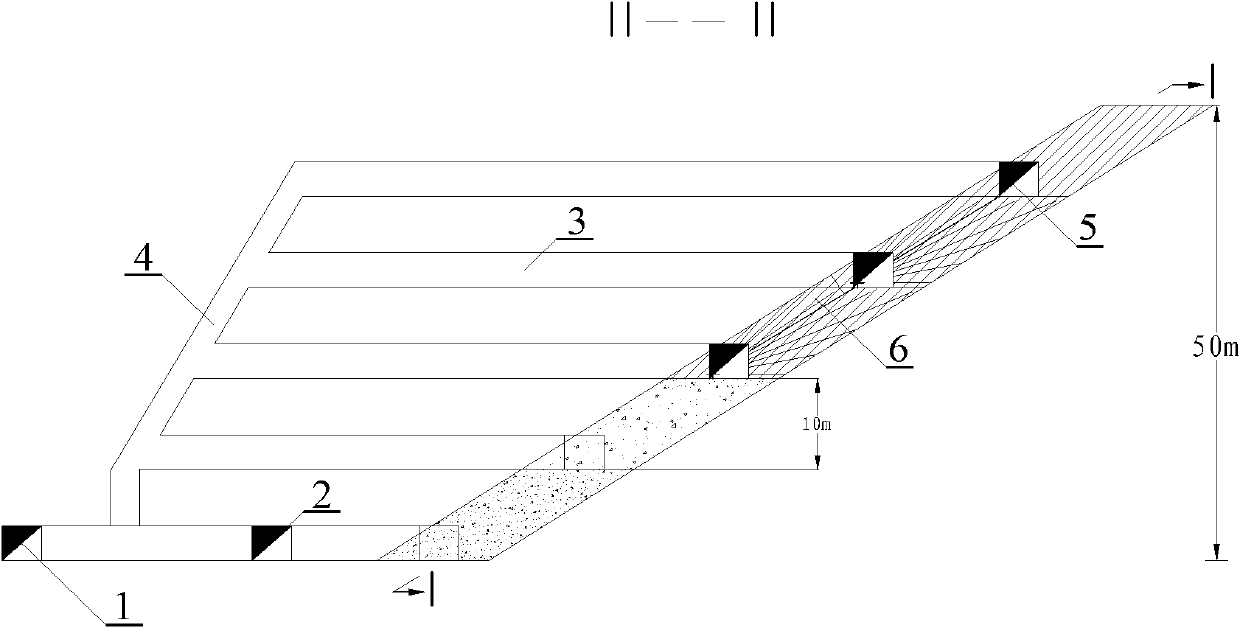

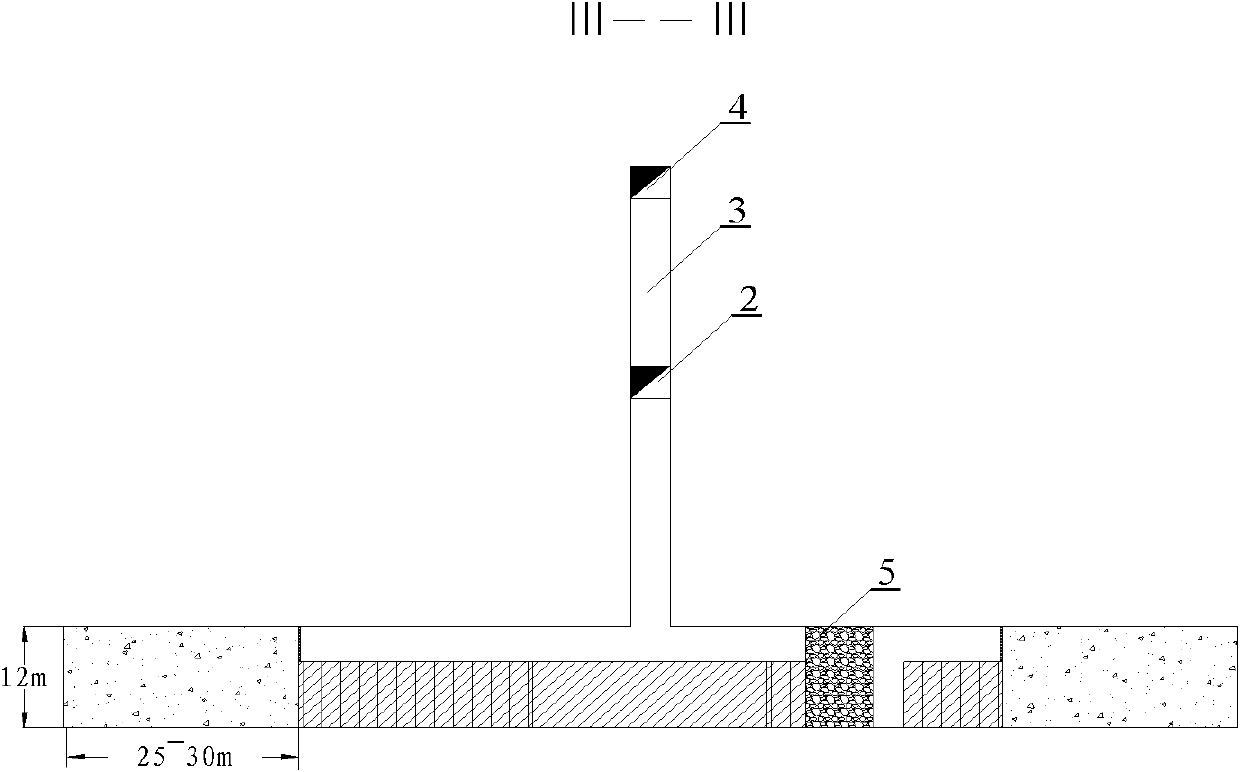

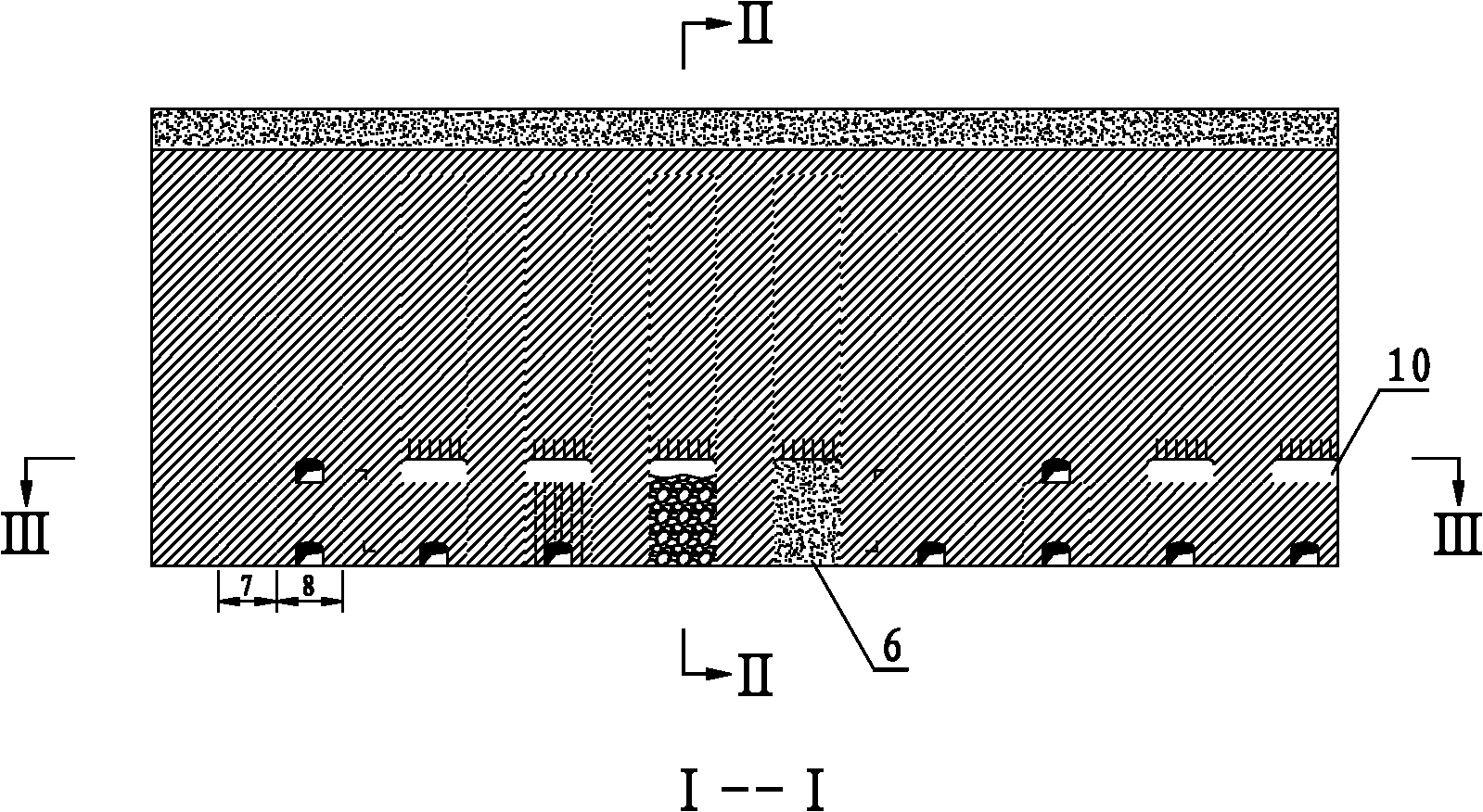

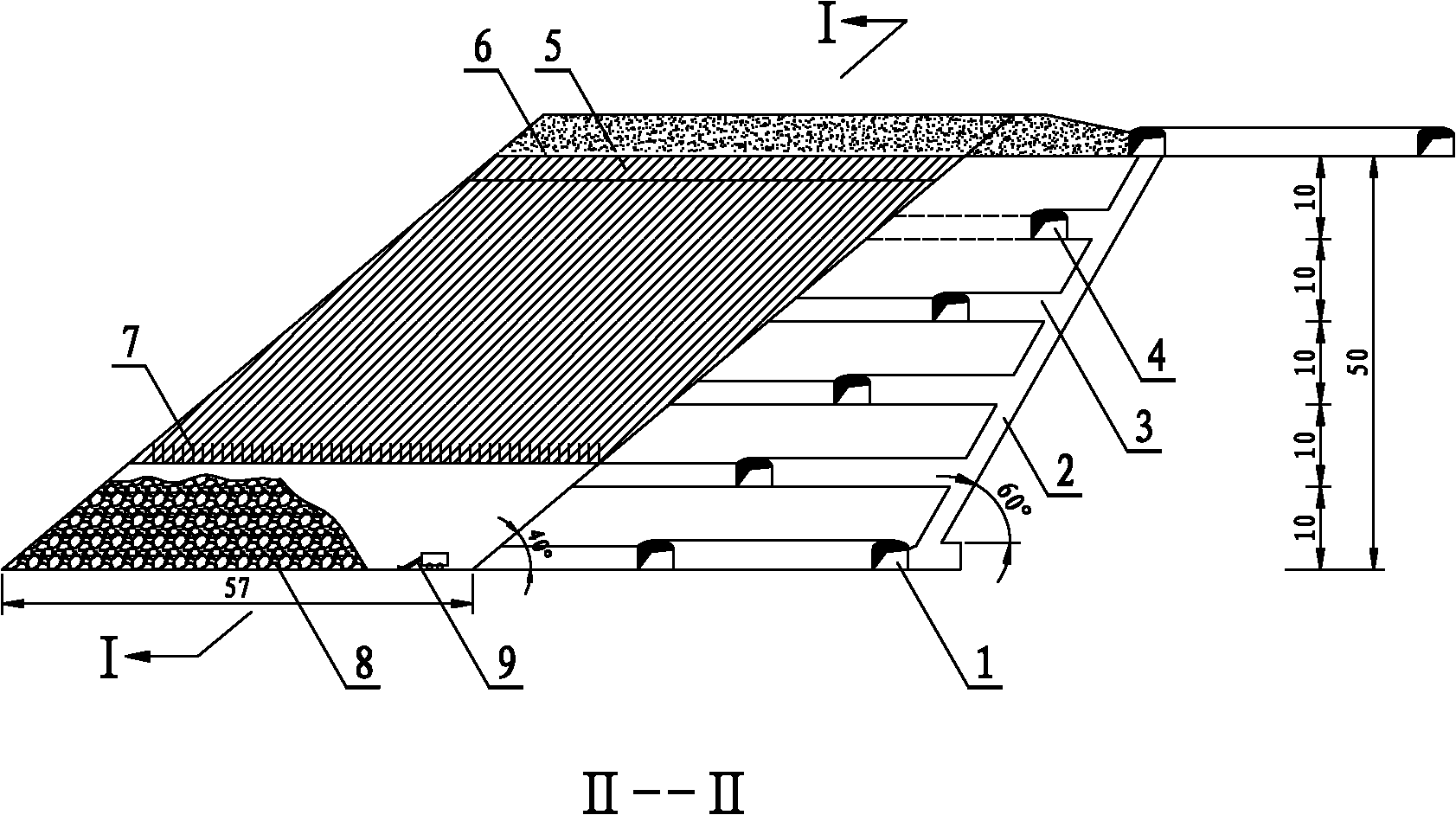

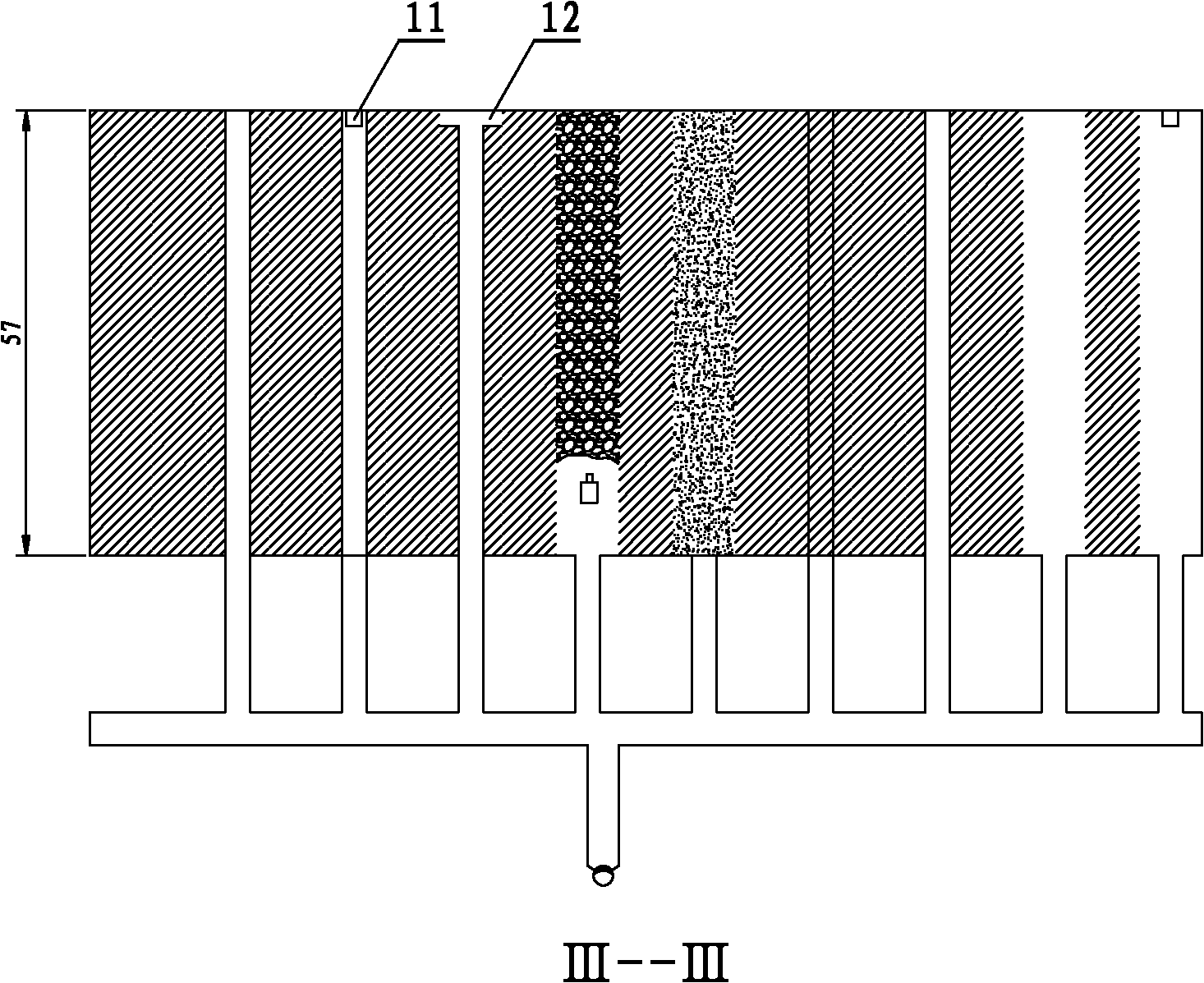

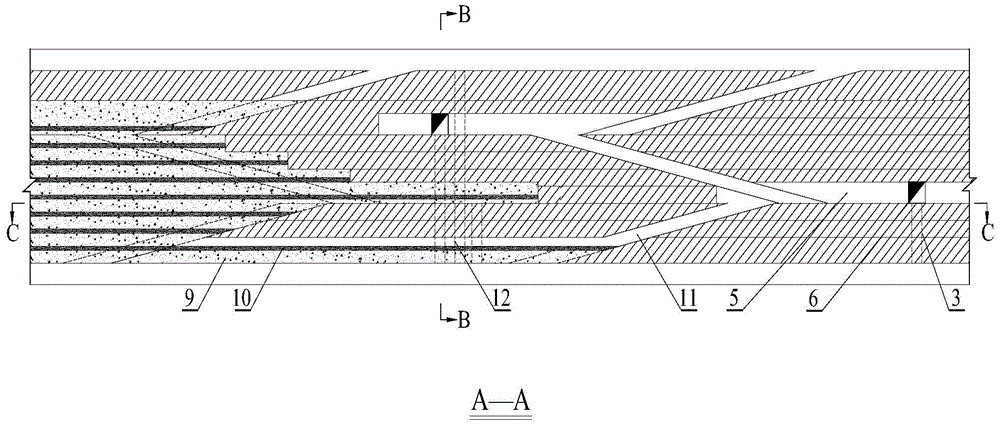

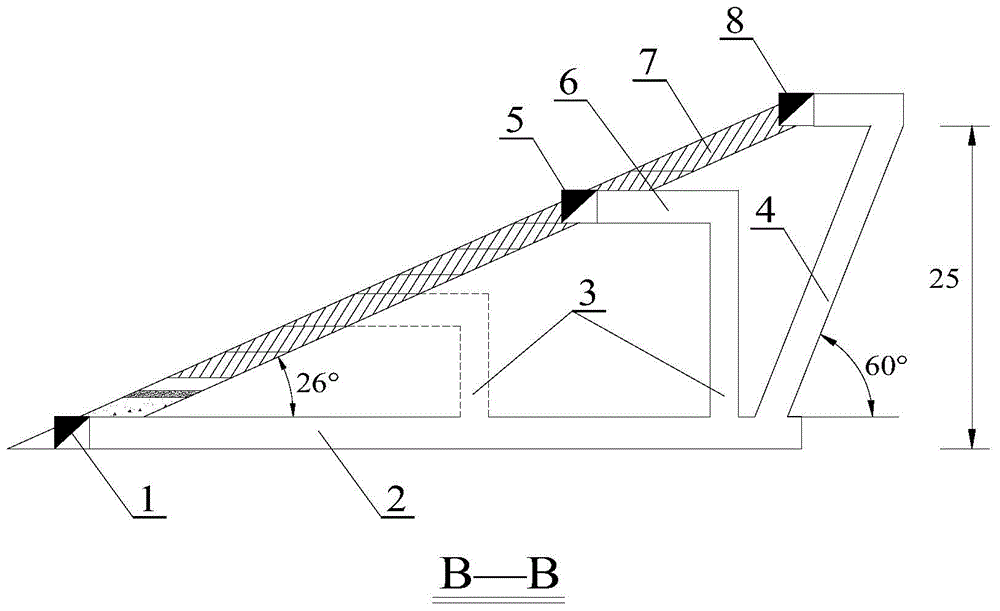

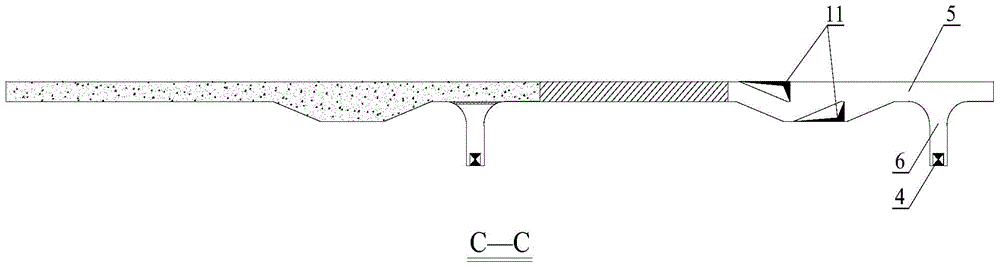

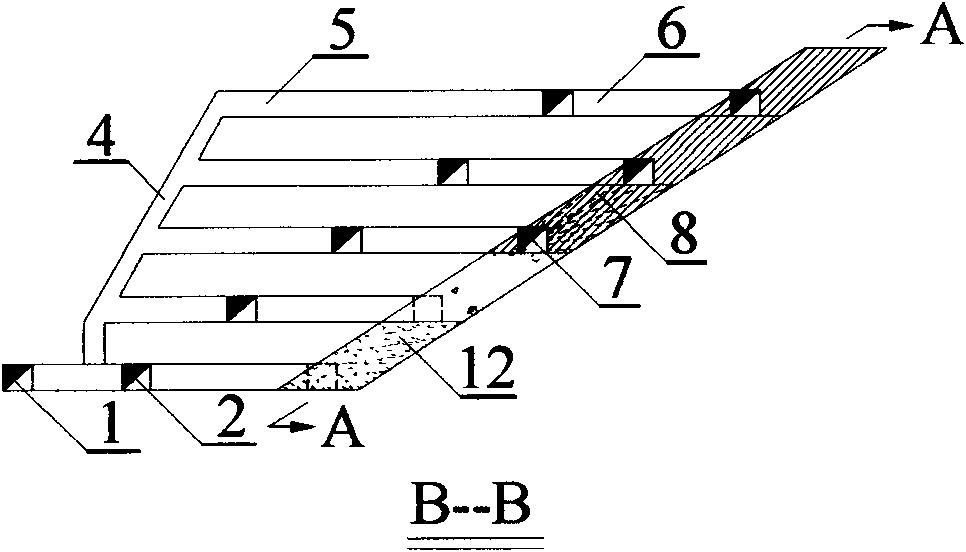

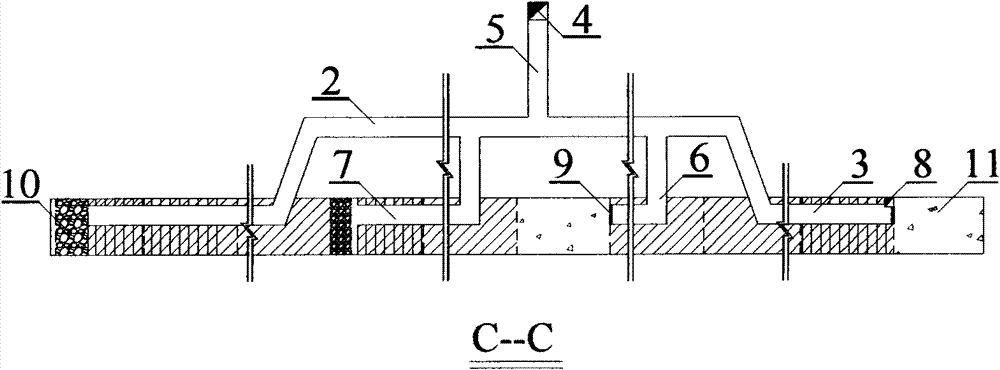

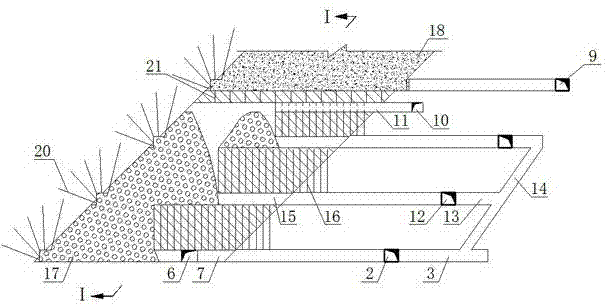

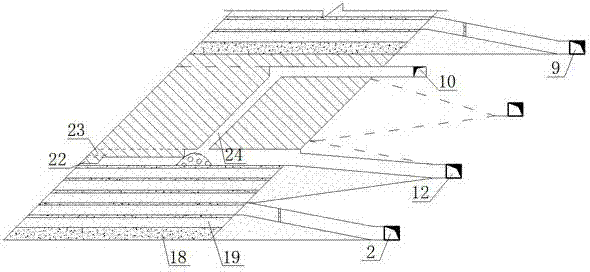

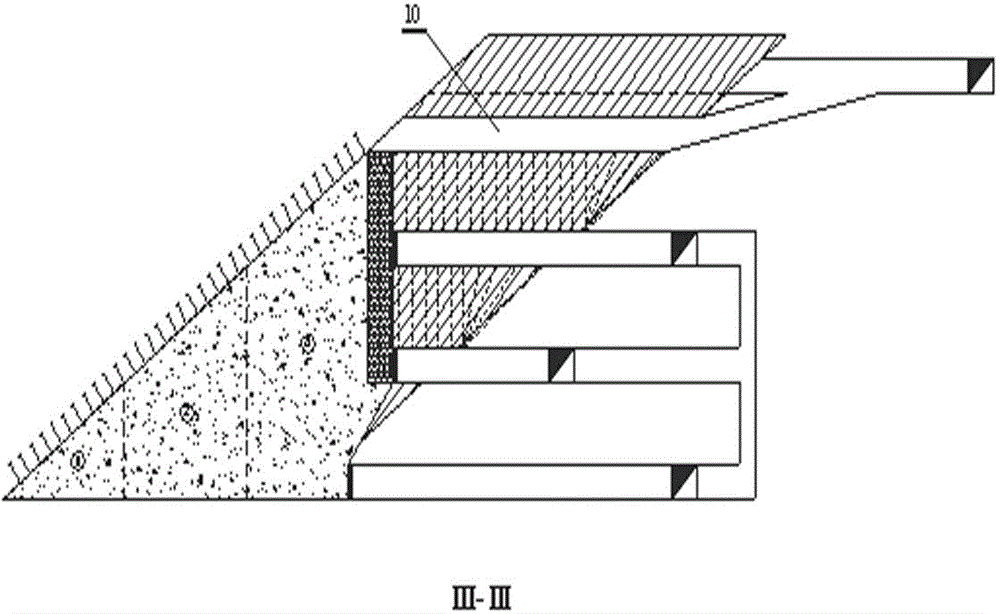

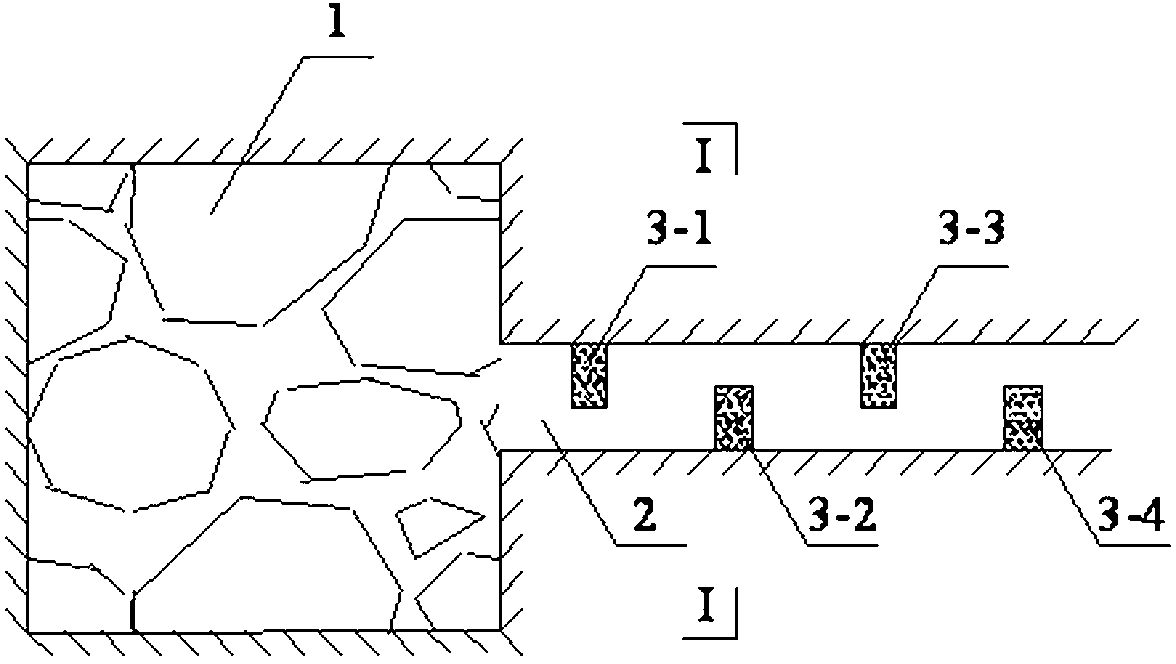

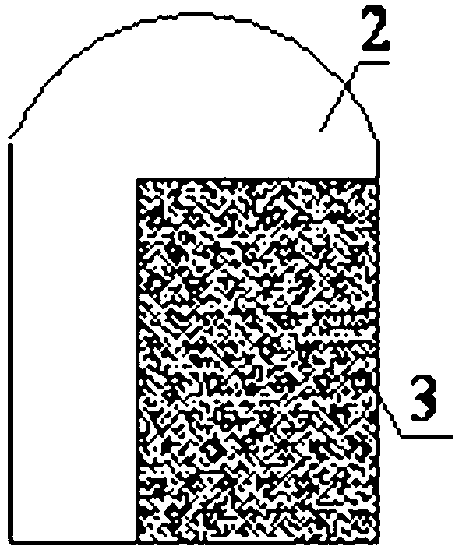

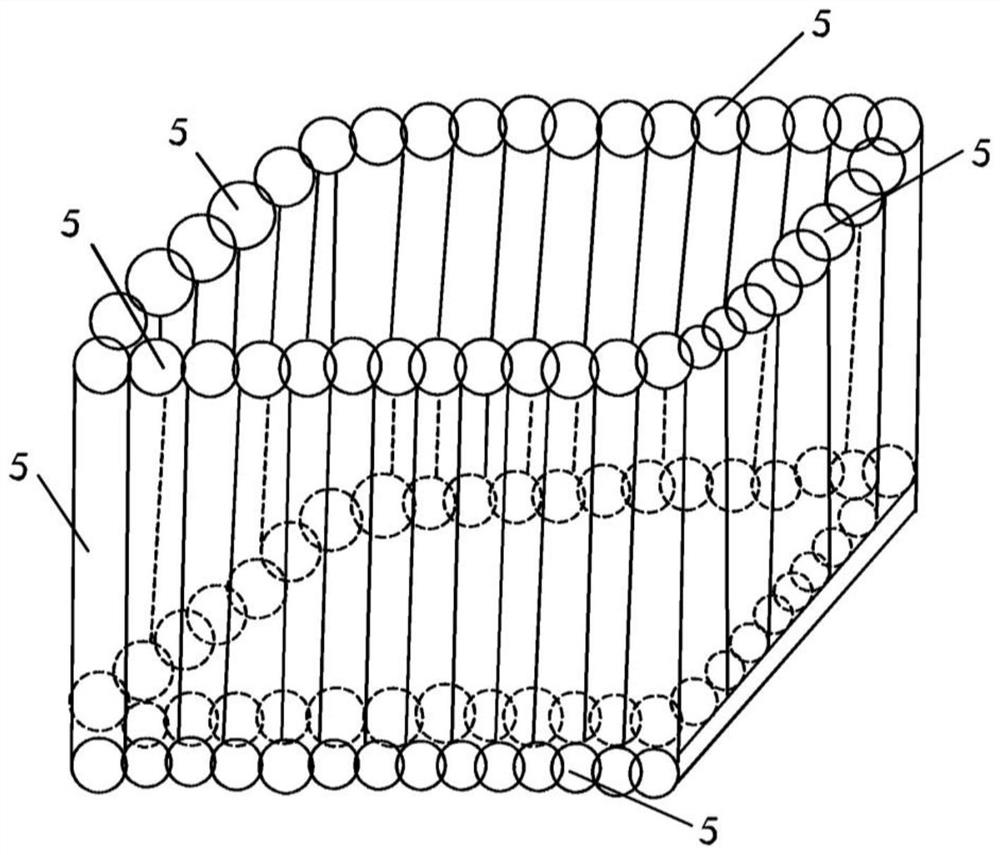

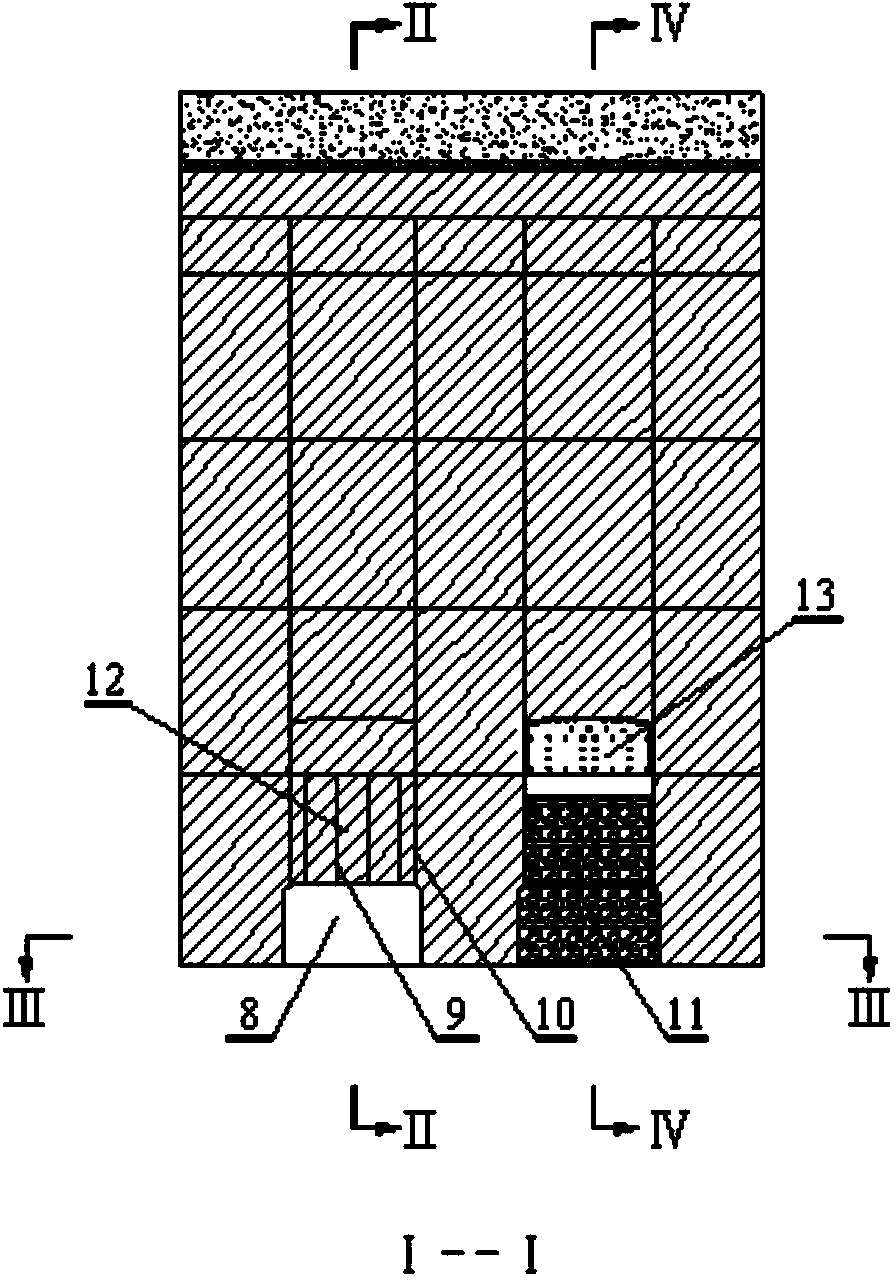

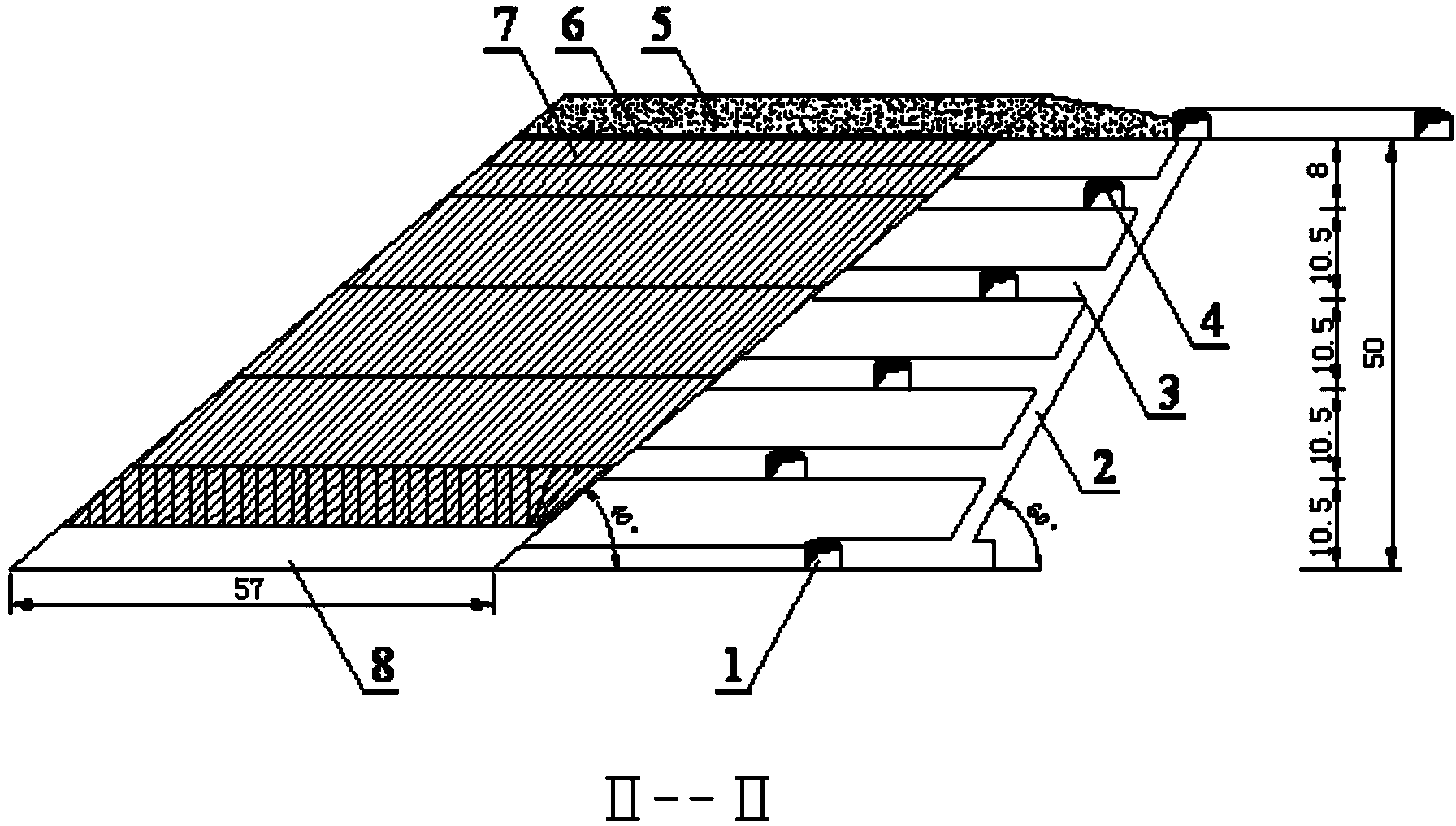

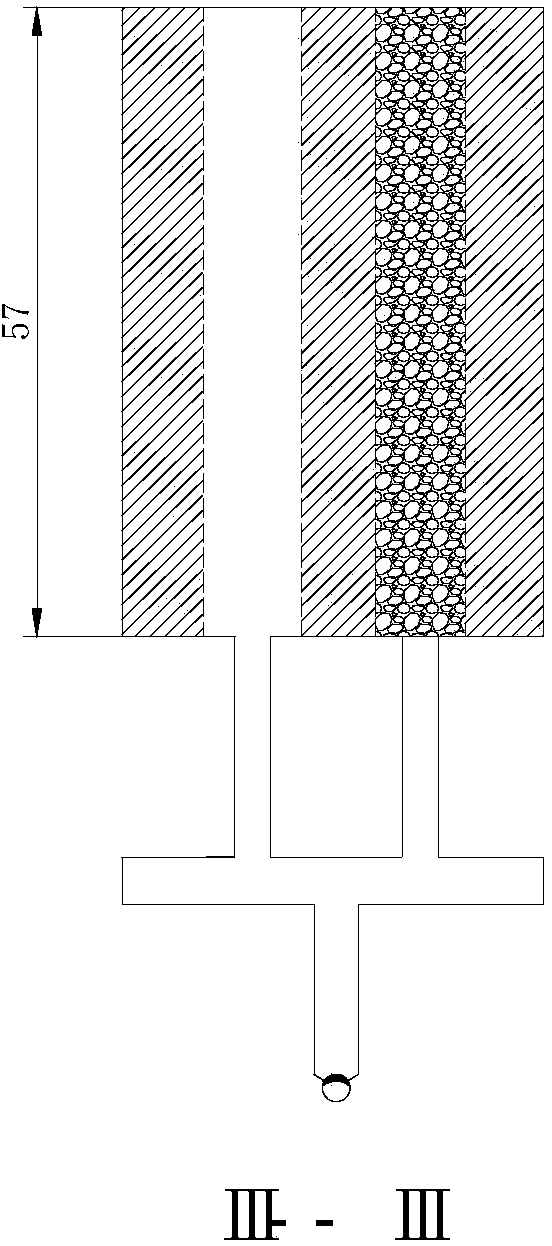

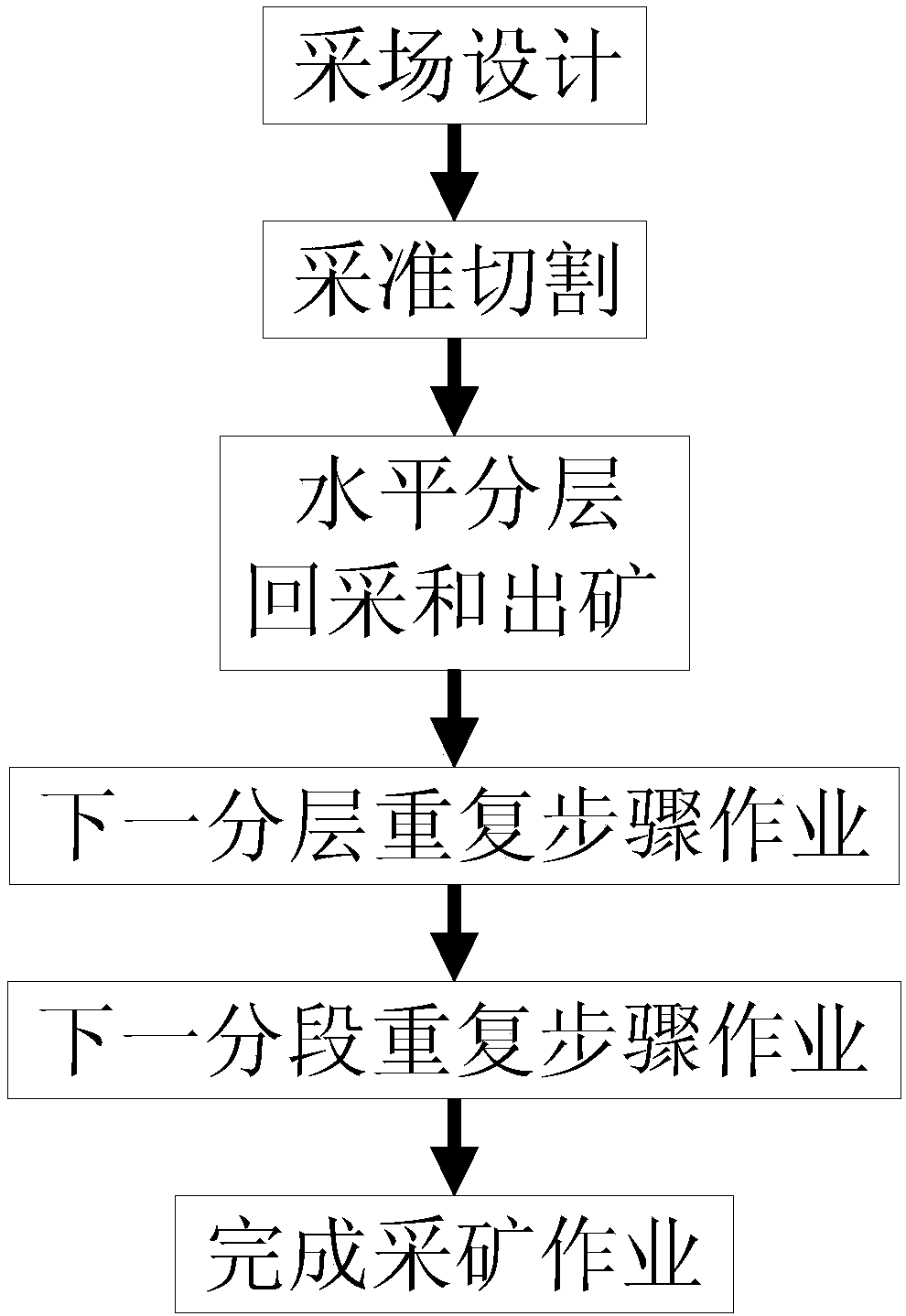

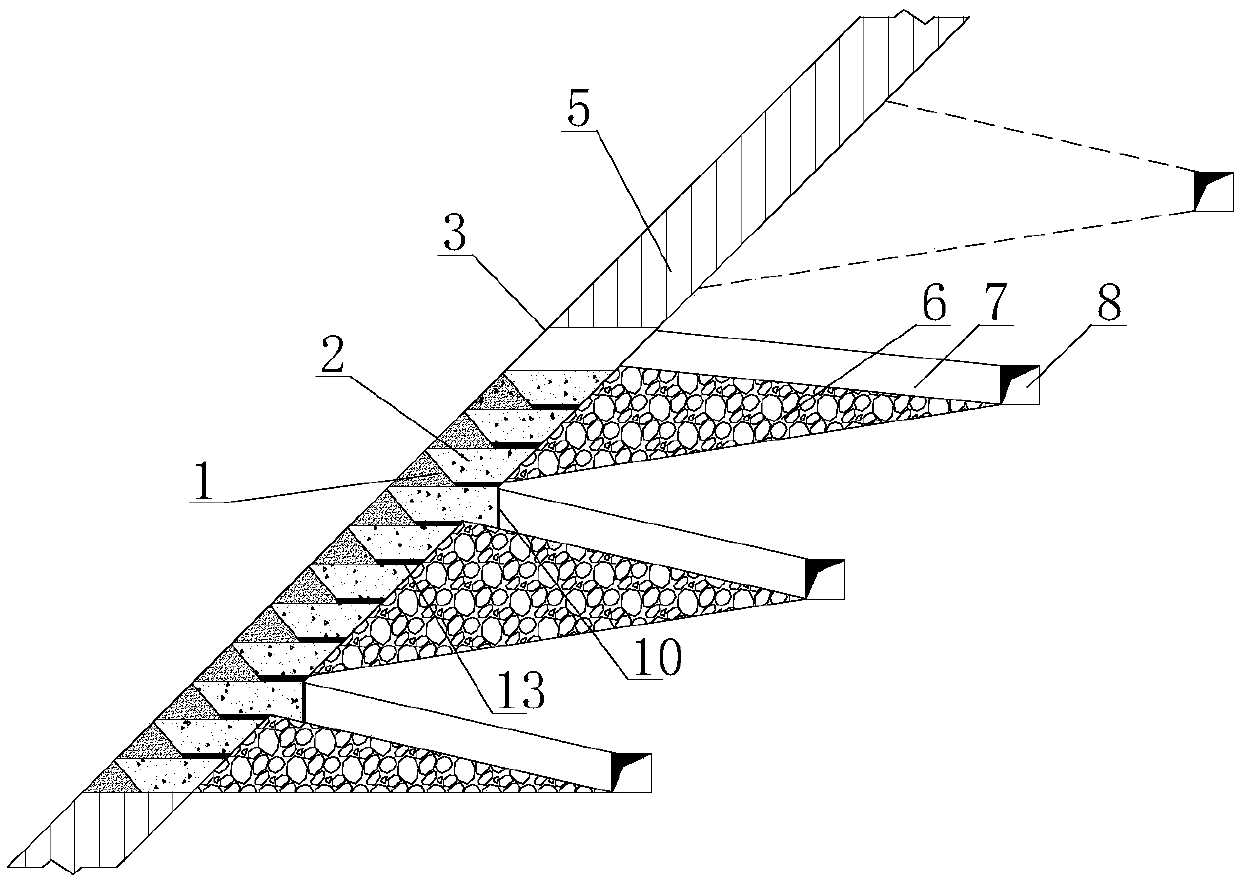

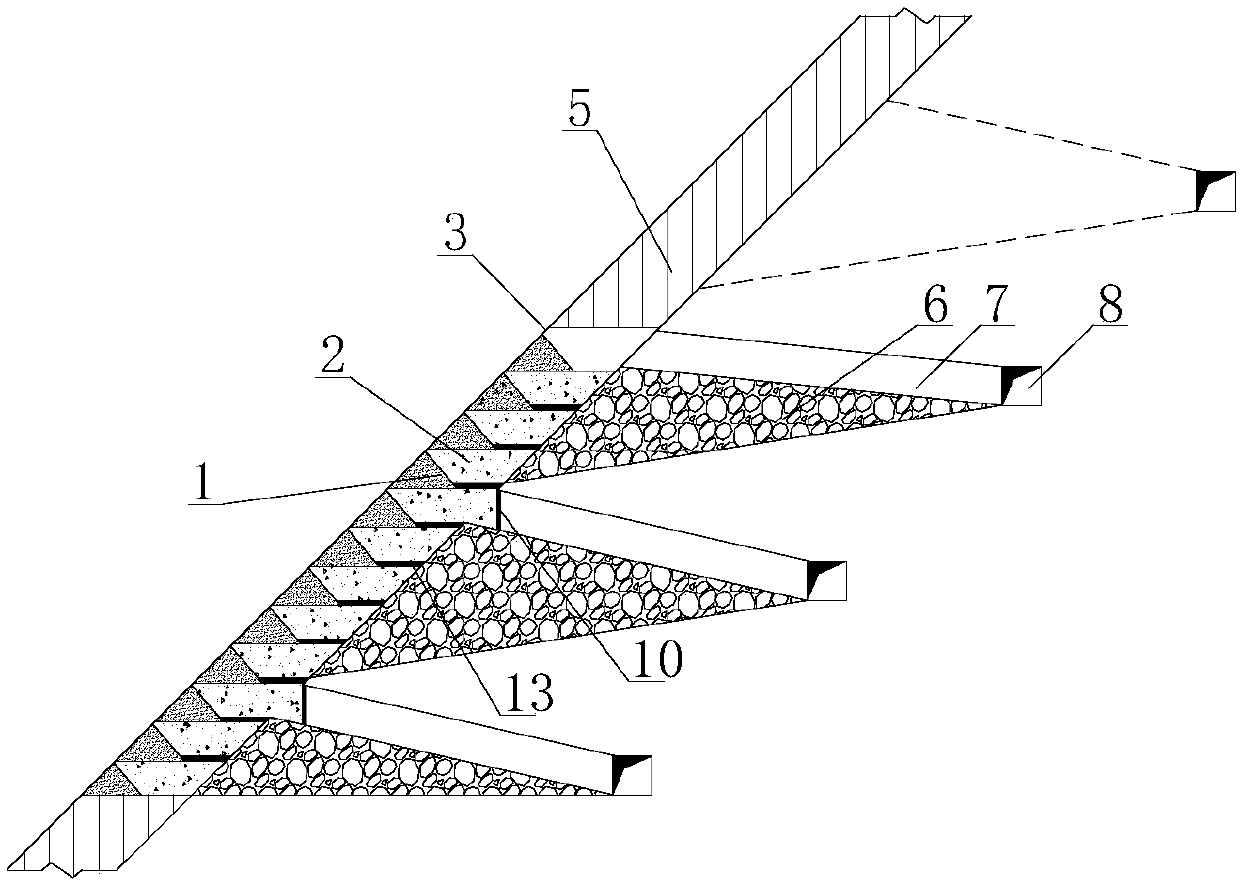

Rib-pillar-free continuous sublevel filling method for mining preparation in medium-thickness slope crushed ore body vein

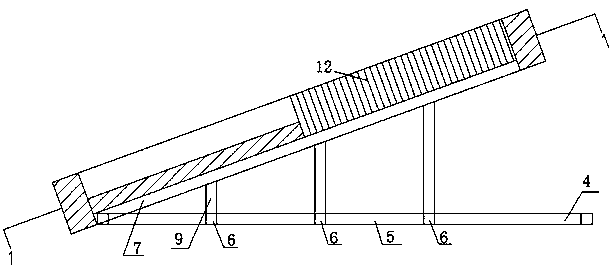

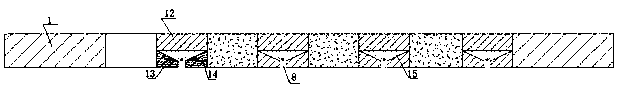

The invention discloses a rib-pillar-free continuous sublevel filling method for mining preparation in a medium-thickness slope crushed ore body vein. The method comprises the following steps of: dividing a mine block into panel structures with a plurality of sections and bunches, namely dividing sections in a panel, not leaving a rib pillar in the sections, and dividing continuous extraction units; arranging a slope ramp of the panel on an ore body hanging wall, and arranging sectional roadways namely rock drilling ore removal gate ways in the vein; making all the sectional roadways in the panel mutually communicated, and the allocation and transportation of trackless equipment flexible and convenient; performing quarry central up cutting before the extraction, and ensuring the deep hole construction in a quarry upward sector in good conditions; performing operation such as multiple-section quarry rock drilling, blasting, supporting, ore removing, filling and paralleling; using a rib-pillar-free continuous extraction way backing from two wings of the panel to the center in the same sectional quarry, wherein an extraction process is performed sequentially; and filling a gob with tailings or waste stones. The invention relates to the rib-pillar-free continuous sublevel filling method suitable for medium-thickness slope crushed ore bodies, which has a low mining preparation ratio, low loss and high efficiency and the extraction is safe.

Owner:CENT SOUTH UNIV +1

Fully-segmented presplitting squeezing primary-blasting mining method

InactiveCN102155228AHigh mining intensityImprove efficiencyUnderground miningBlastingMineralogyUltimate tensile strength

The invention discloses a fully-segmented presplitting squeezing primary-blasting mining method. The method comprises the following steps of: 1, performing sublevel mining on slowly inclined thick and large crushed ore bodies; 2, arranging a stope free with a bottom structure along a direction vertical to the direction of the ore bodies; 3, using a trackless development mode of a lower plate outside-vein sublevel tunnel and an outside-vein concentrated winze; 4, constructing a full-section pre-control top tunnel serving as a shoring tunnel and a drilling tunnel; 5, performing presplit blasting so as to form the outline of the stope, squeezing and blasting so as to form a mine, and performing presplitting, squeezing and primary-blasting on the fully-segmented ore bodies to form the mine; 6, concentratively removing the ore by trackless equipment under a fully-segmented open stope; and 7, concentratively filling in a large scale after full segmentation. The method has the remarkable characteristics of high mining safety, simple process, low loss and depletion, high mechanical degree and mining strength, high production capability of the stope, high efficiency, low cost, low labor intensity and the like.

Owner:CENT SOUTH UNIV

Upward cut-and-fill mining method for in-vein slope ramp of gentle dip thin vein

ActiveCN104060991AEnsure safetyImprove recovery efficiencyUnderground miningSurface miningVeinCut and fill

The invention discloses an upward cut-and-fill mining method for an in-vein slope ramp of a gentle dip thin vein. The method comprises the following steps: stoping layers of an ore body, tunneling a cross gateway from a bottom middle haulage drift to the ore body, tunneling a diagonal slope ramp along the vein to rise for certain height, and tunneling a slice drift, a reversing chamber and a sectional ore removal draw shaft forwards along the vein, wherein the reversing chamber and the sectional ore removal draw shaft are perpendicular to the slice drift; reversely tunneling the diagonal slope ramp along the vein from one side of the slice drift to rise for the certain height, and tunneling the slice drift, the reversing chamber and the sectional ore removal draw shaft along the vein; dividing a stope by using the diagonal slope ramp as the boundary, continuously propelling from one end of the vein to the other end of the vein, reaching all the layers of the ore body by virtue of the diagonal slope ramp which is tunneled in the vein, and sequentially stoping and filling from bottom to top by virtue of each layer stoping unit in the stope. The upward cut-and-fill mining method for the in-vein slope ramp of the gentle dip thin vein is high in mechanization degree, small in out-vein stope preparation engineering amount, low in labor intensity, low in ore dilution loss, safe to operate and high in efficiency.

Owner:河南发恩德矿业有限公司

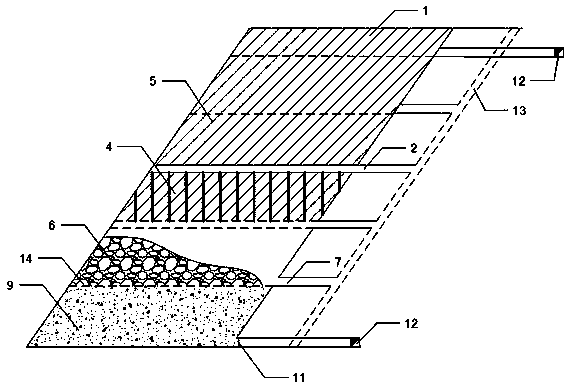

Sublevel stripe tail salt stoping dry-type filling-mining method

ActiveCN102003185AImprove mining safetyIncrease production capacityUnderground miningSurface miningMining engineeringMechanical engineering

The invention discloses a sublevel stripe tail salt stoping dry-type filling mining method, which is characterized in that the ore body is divided into a plurality of panels along the run of the ore body, and panel jambs are uniformly arranged around the panels; each panel is divided into a plurality of sublevels according to the thickness of the ore body; each sublevel is divided into a plurality of slices according to the thickness of the ore body; the stoping sequence is upward slice stoping; the same slice adopts bringing-back stoping; a tunneling machine is adopted to cut the caved ore; a trackless scraper is used for ore removal; access stoping is adopted in each mining room; the tailings in a processing factory is used for filling after each access stoping in one mining room is finished; and the upper slice stripping, stoping and filling procedures are carried out by taking a filling body as a bottom plate after the slice stoping is completely finished. The sublevel stripe tailsalt stoping dry-type filling mining method of the invention reasonably utilizes resources, protects the mining environment, also improves the production capacity, and lowers the production cost to some extent.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

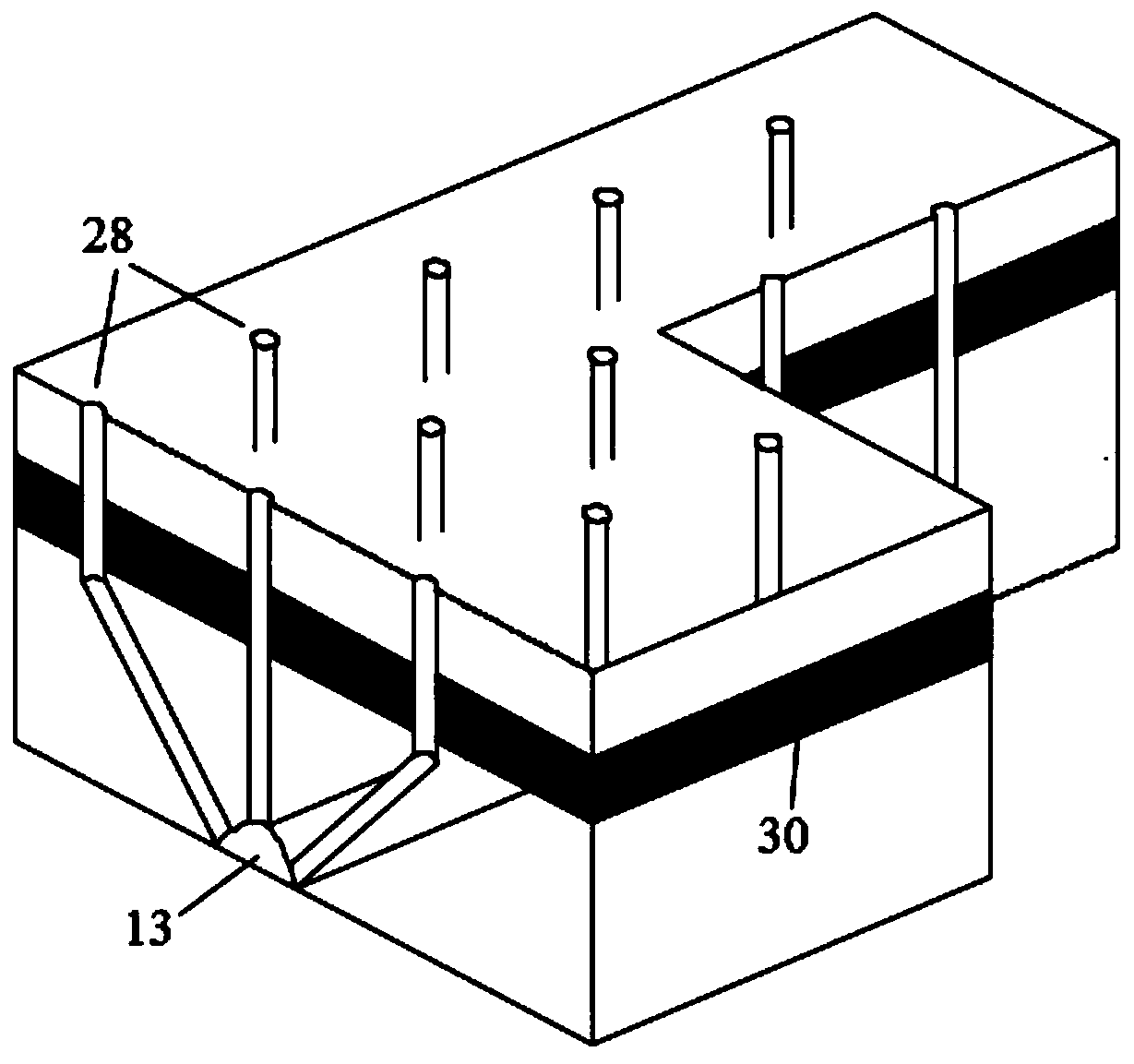

Room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method

InactiveCN102953732AImprove mining safetyGood for stope stabilityUnderground miningSurface miningRoom and pillar miningSingle stage

The invention discloses a room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method for a steeply-inclined medium-thick orebody and gently-inclined and inclined extremely-thick orebodies with steady surrounding rocks at upper and lower panels. The method is characterized in that: an orebody is divided into panels, then the panels are divided into continuous single-stage stoping units, and mining is carried out by using a stoping sequence of stoping one unit every other unit, i.e., mining a room at first and a pillar next; when mining a room, a V-shaped trench bottom structure is employed, a longhole drilling chamber is arranged at the upper part of stope, bar-shaped pillars are left to support the top plate of the chamber, a down-the-hole drill is used for drilling rocks, an explosion mode of light section VCR method underholing inverted-step-like lateral caving with a common emulsion explosive is employed, access roads towards the room for ore removal are arranged in the pillars, and cemented roof-contact filling is employed; and during stoping of the pillars, access roads for ore removal are dug towards the pillars in cemented bodies in the room, a stoping manner for the pillars is identical to that for the room, and non-cemented filling with tailings and waste is employed. The method provided by the invention has the advantages of high security, a low production cutting ratio, great production capacity, low operation cost and small loss and dilution of resources.

Owner:彭康

Boundary-controlled room column type sublevel open stoping subsequent stage filling mining method

InactiveCN103032070AImprove mining safetyMining safetyUnderground miningSurface miningEngineeringControl room

The invention discloses a boundary-controlled room column type sublevel open stoping subsequent stage filling mining method which is used for slight pitch-steep pitch very thick and big ore bodies with firm surrounding rocks of upper plates and lower plates. The method is characterized by comprising the following steps of: dividing a plate area of the ore body, incessantly dividing three ore rooms and two ore columns in the plate area, performing step-like retrusive sublevel rock drilling stage ore removal from an upper plate to a lower plate of the ore body by adopting bottom structures of V-shaped trenches, and connecting sublevel fringe drifts through a service raise; during mining of the ore rooms, respectively tunneling rock drilling cross drifts on the two sides of a stope, controlling the boundary of the stope by adopting pre-splitting blasting in side holes, arranging ore removal routes in the ore columns for ore removal, leaving a first sublevel in the middle ore room without mining, and performing top tight filling by adopting cemented bodies with different mixture ratios; and during the mining of the ore columns, tunneling the rock drilling cross drift at the center of the stope, arranging bilateral ore removal routes in the reserved sublevel in the middle ore room for serving the two ore columns for ore removal, and performing the top tight filling on the ore columns by adopting non-cemented bodies. The method has the advantages of high safety, great production capacity, low operation cost and low loss and dilution rate of ores.

Owner:彭康

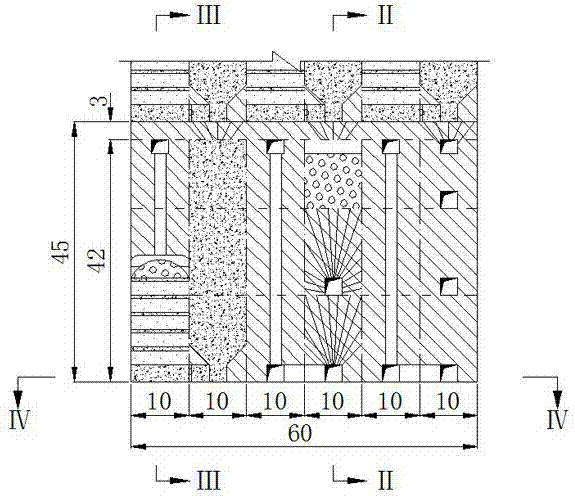

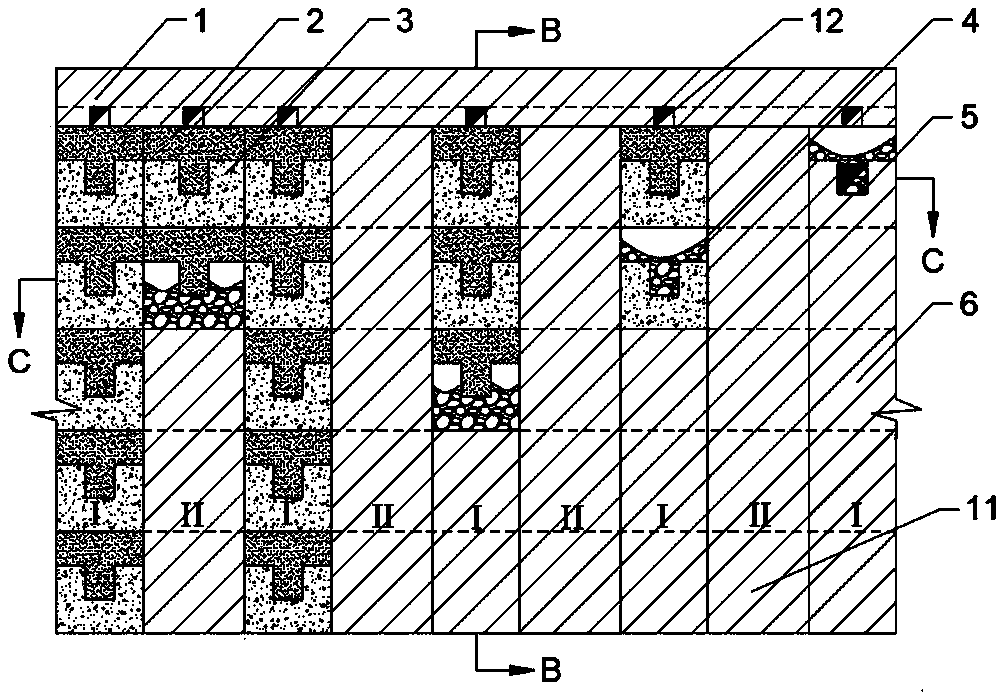

Central outside-vein house pillar type combined crosscut two-end inside-vein continuous segment filling mining method

InactiveCN102953733AHigh degree of mechanizationReduce labor intensityUnderground miningSurface miningVeinEngineering

The invention discloses a central outside-vein house pillar type combined crosscut two-end inside-vein continuous segment filling mining method for medium-thickness inclined crushed phosphorus ores. The method comprises the following steps: dividing an ore into middle segments, dividing each of the middle segments into panels, dividing each of the panels into segments, dividing the center of each of the segments into ore houses and ore pillars, and dividing two ends of each of the segment along an inside-vein drilling ore-removal level non-pillar into recovery units; adopting a hanging side outside-vein trackless mining system which is formed by a panel ramp, a concentrated ore-removal ore-pass, segment levels at the central outside-vein and shifting to inside-vein at two sides, and an connection lane commonly used by the ore houses and the ore pillars; recovering the ore houses in the middle segments, filling close to back, and recovering the ore pillars; and carrying out parallel operations of technologies comprising drilling, exploding, supporting, ore removal, filling and the like of a plurality of the ore houses to realize continuous mining. The method disclosed in the invention has the substantial characteristics of improvement of the recovery safety and the panel productivity, reduction of the resource dilution rate and the mining-cutting ratio, increase of enterprise benefits and the like.

Owner:彭康

Chamber and overhand cut combined cut-and-filling stoping method in pre-roof-protecting stage

InactiveCN104847352AImprove mining safetyImprove stope production capacityUnderground miningSurface miningEngineeringCut and fill

The invention relates to a chamber and overhand cut combined cut-and-filling stoping method in a pre-roof-protecting stage. The method comprises the following steps: dividing a middle ore body into panels along the trend of the ore body, further dividing the middle section into a plurality of sections in the vertical direction, and mainly adopting a footwall out-out-pulse traceless accurate mining mode; arranging chambers and pillars in the panels at intervals; recovering the chambers first, and adopting a sublevel open stoping method with subsequent backfilling; after recovering the chambers, recovering the pillars and adopting an overhand horizontal cut-and fill method for the pillars, and before recovering the chamber in stages, pre-supporting a long cable in advance for an upper panel in a sublevel upper panel supporting lane; pre-supporting the fore-set by using an anchor rod and a metal net in an air return cross gateway below the fore-set; when the pillars are recovered in layers, stopping mining when the pillar is 3m close to the main crack of the upper panel F1 in horizontal distance and reserving the panel as an upper panel roof-protecting ore of the sub layer, and when the lower layer is recovered, fully recovering the upper panel roof-protecting ore reserved in the previous layer, and meanwhile, reserving the upper panel roof-protecting ore in the lower sub layer; and sequentially circularly recovering and reserving the upper panel roof-protecting ore. By virtue of the method provided by the invention, safe, efficient and low-cost mining can be implemented for thick and large ores which are relatively broken.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

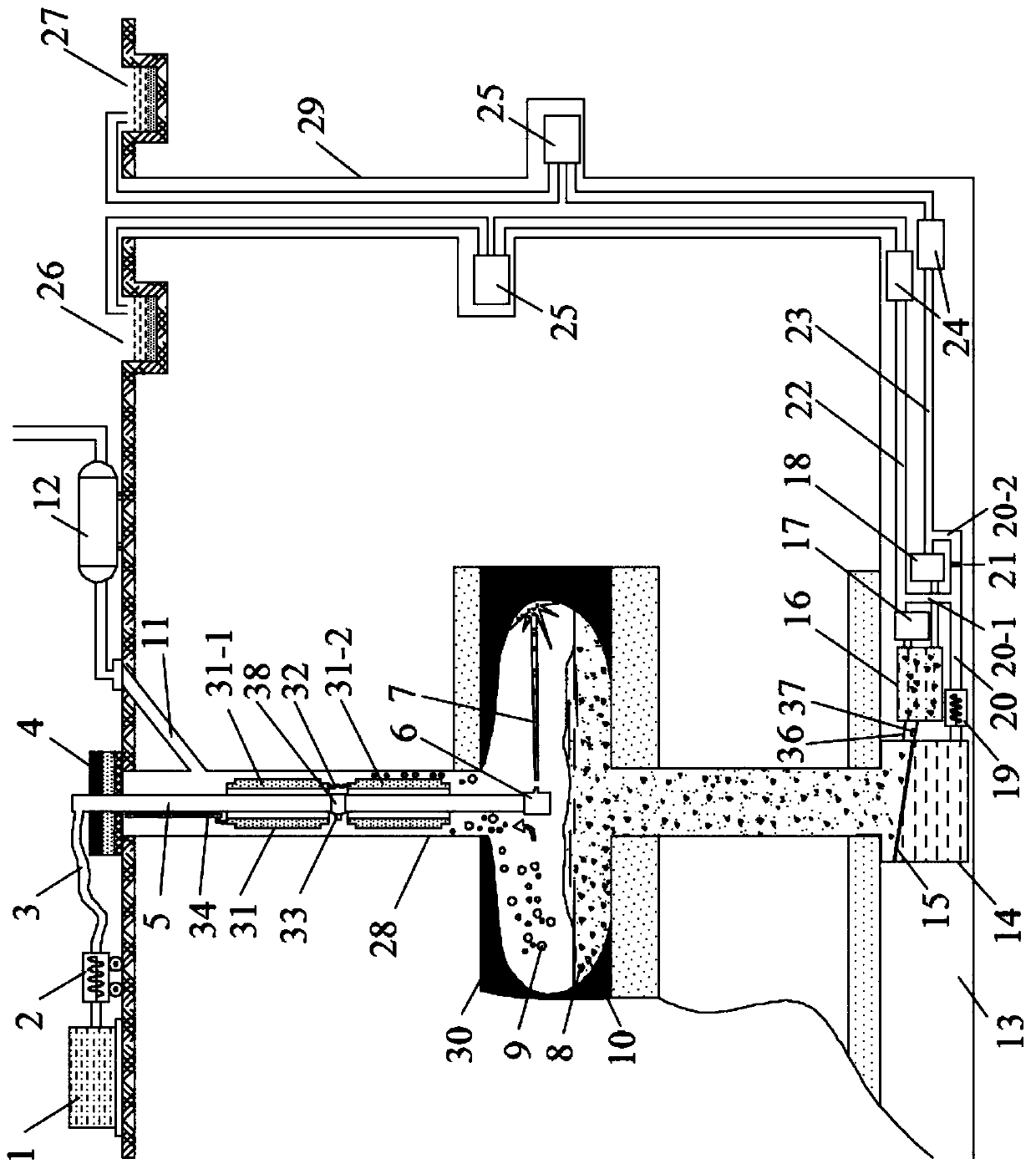

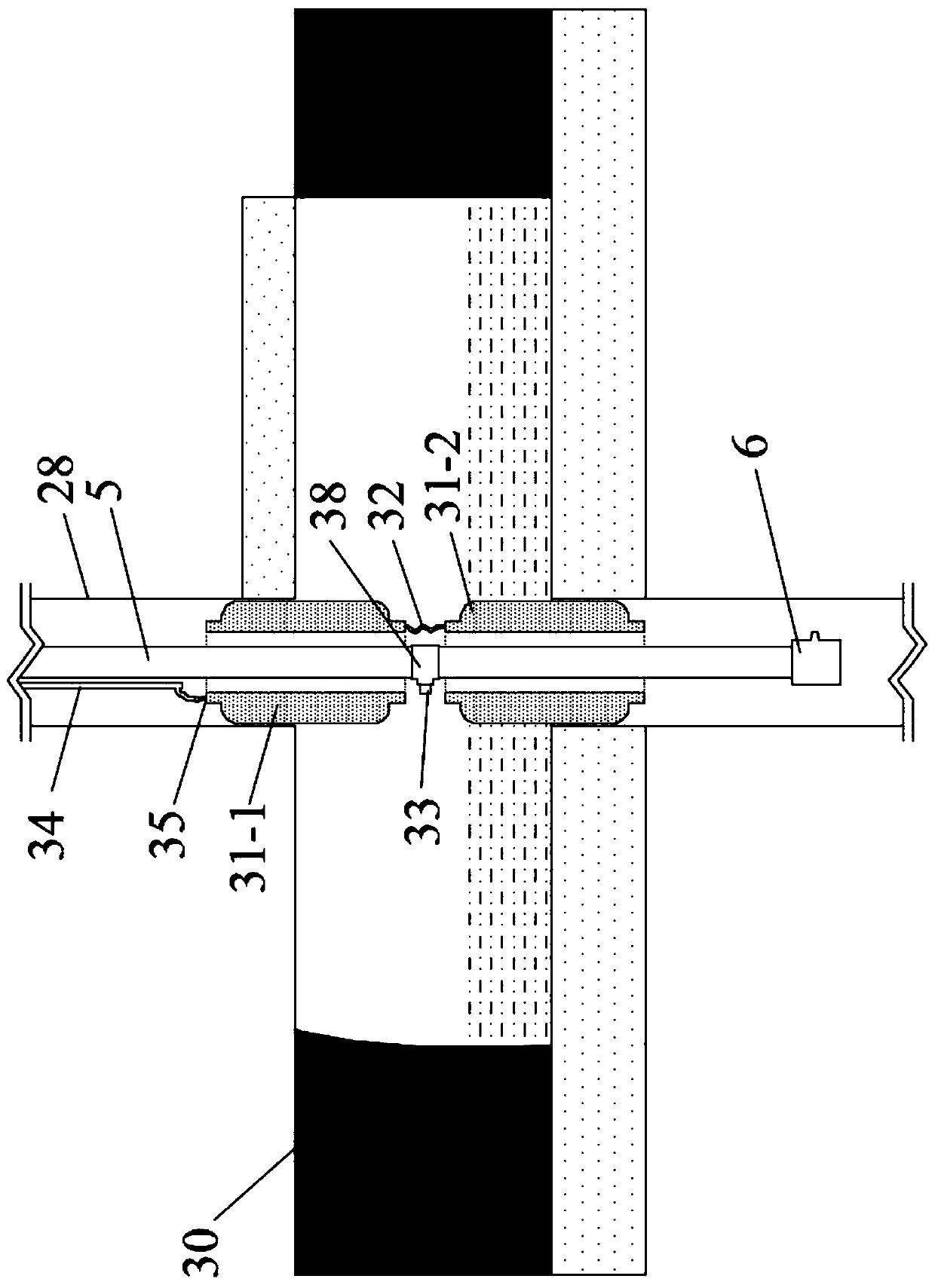

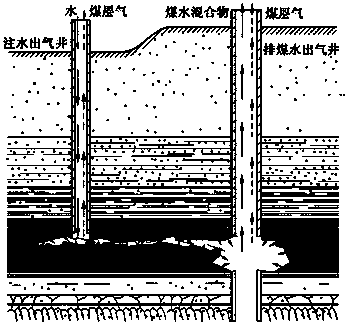

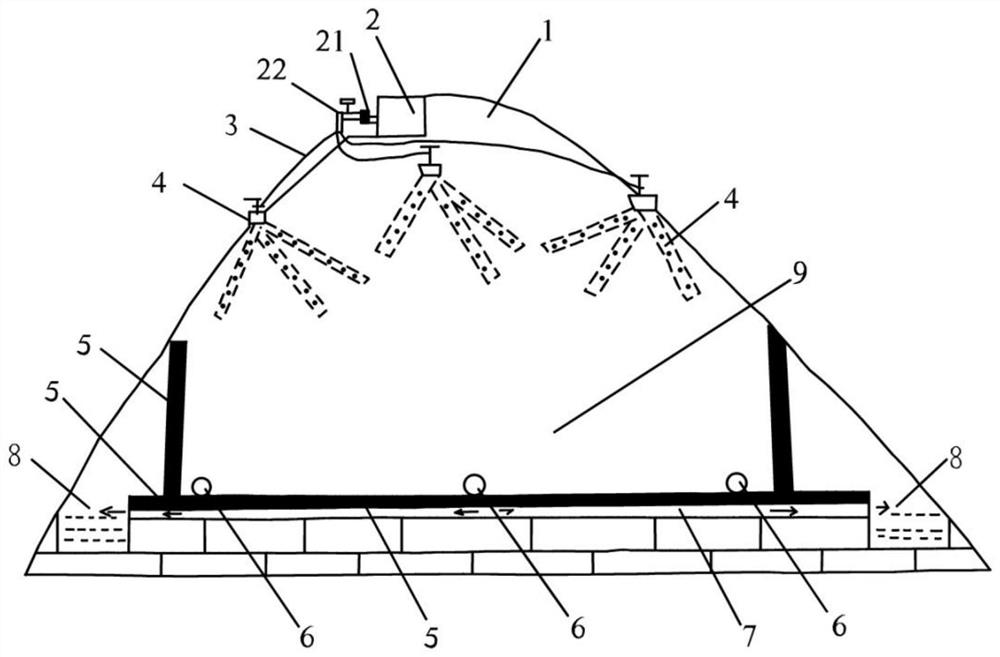

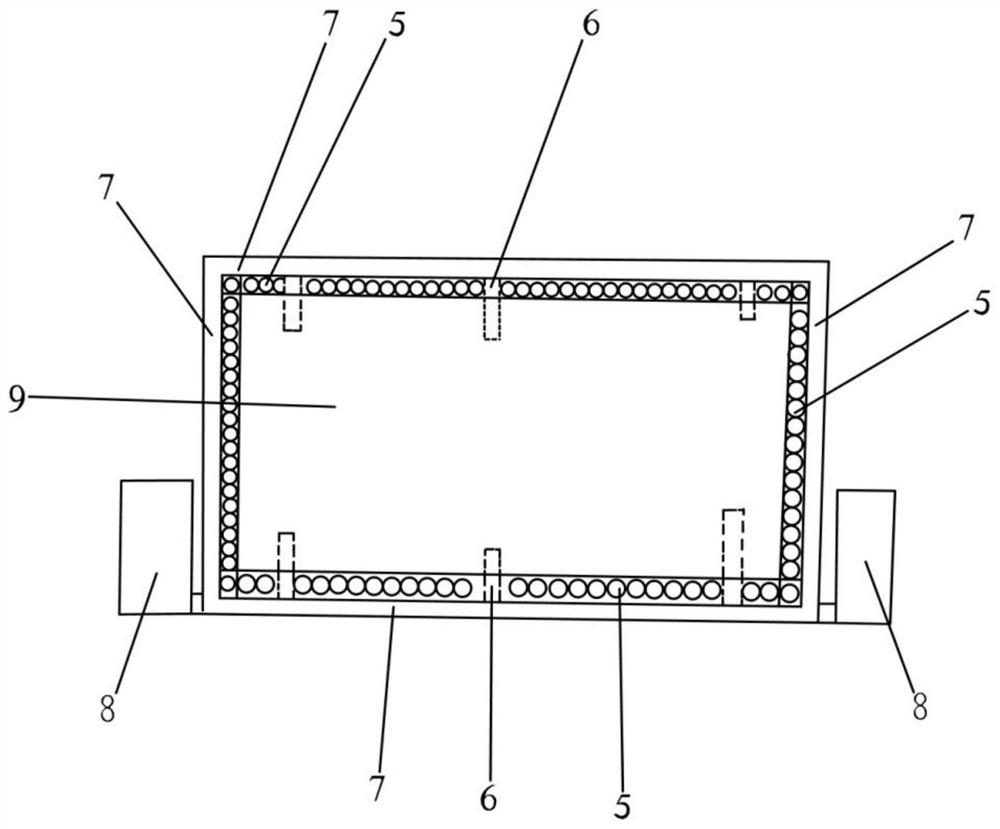

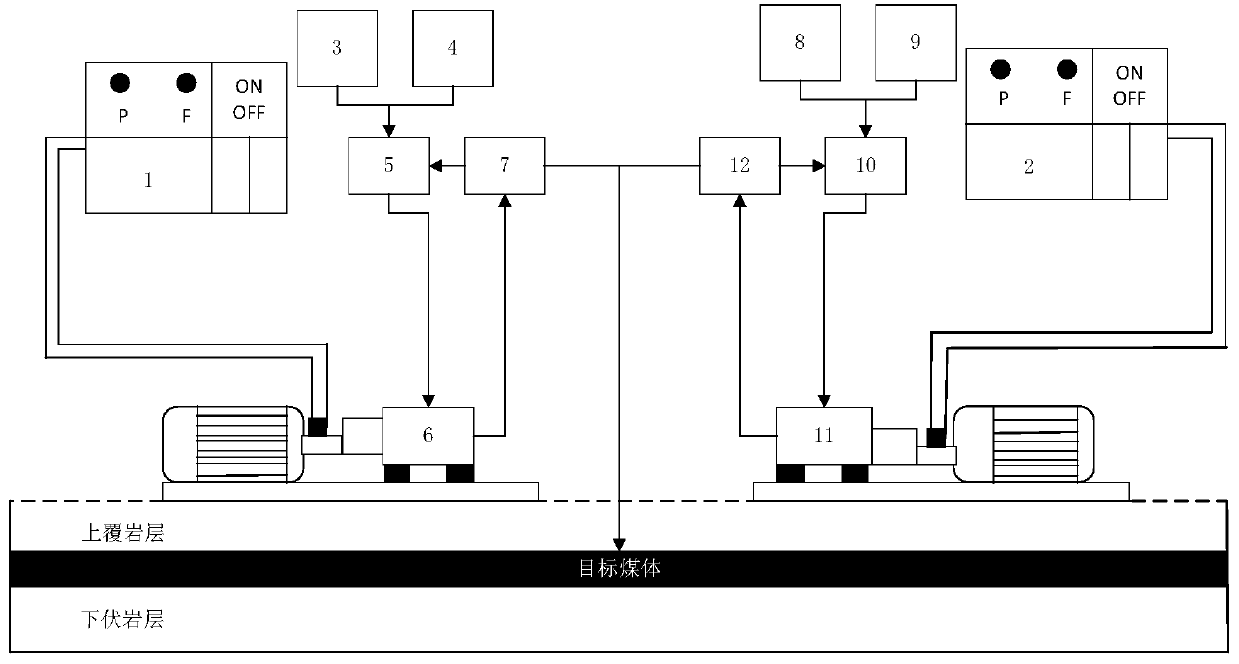

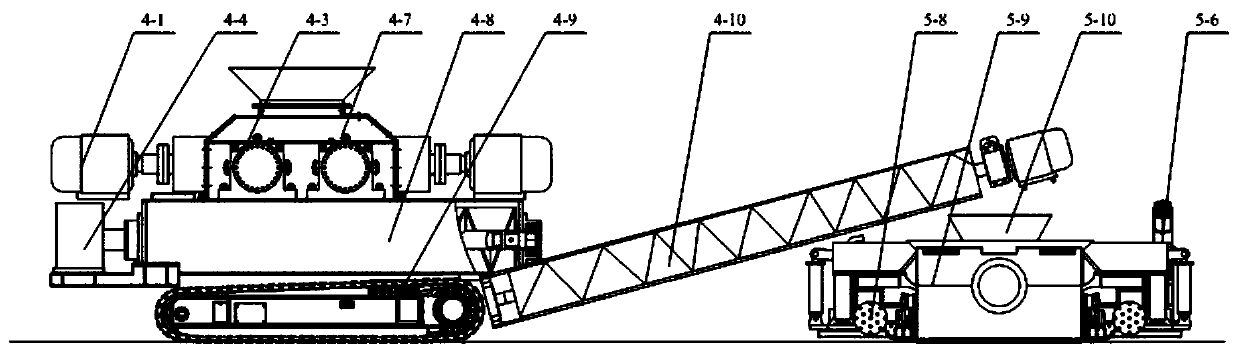

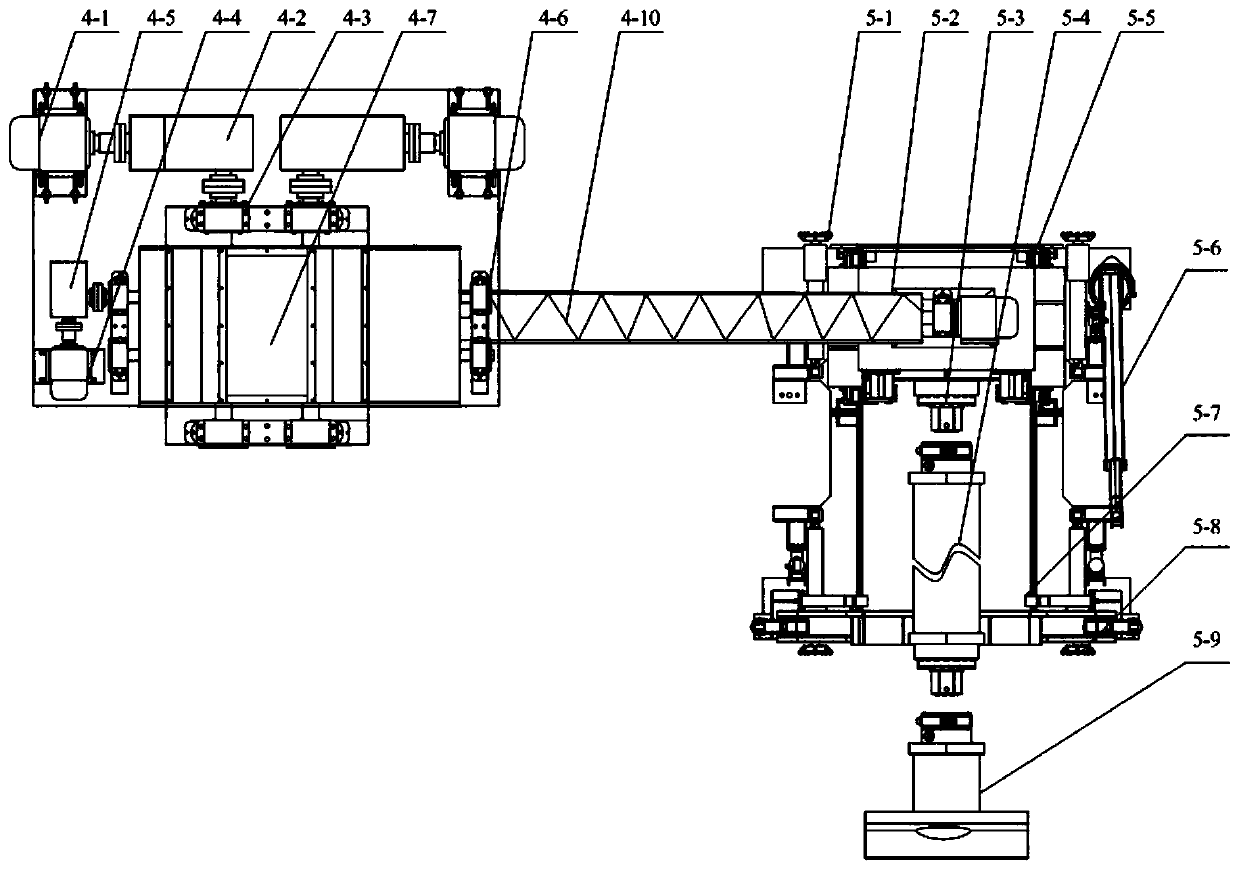

Fluidized coal and gas simultaneous mining system and synchronous mining method of system

ActiveCN110656937AInhibition releaseImprove reliabilityUnderground miningFluid removalWell drillingGas release

The invention discloses a fluidized coal and gas simultaneous mining system and a synchronous mining method of the system. The fluidized coal and gas simultaneous mining system comprises a hydraulic mining part, a shaft bottom coal and rock treatment part and a coal and rock transport part. Gas released in a hydraulic mining process can be extracted by a gas extraction pump through a gas extraction inclined hole formed in the top of a coal mining driller, a hydraulic mined coal and rock mixture can be subjected to coal and rock separation by the shaft bottom coal and rock treatment part and the coal and rock transport part and then transported upwards and out of a well in a classified manner, the hydraulic mining part and the shaft bottom coal and rock treatment part work respectively without influence to each other, and reliability and mining efficiency of the hydraulic mining process can be greatly improved; automatic work of manless mining can be realized, and mining safety of a coal and gas outburst coal seam is greatly improved; and the system is suitable for mining coal seam resources such as boundary coal and wandering coal seams with low coal content and complex geologicalconditions and is particularly applicable to coal mining of a soft and weak coal seam where coal and gas are prone to outburst.

Owner:CHINA UNIV OF MINING & TECH

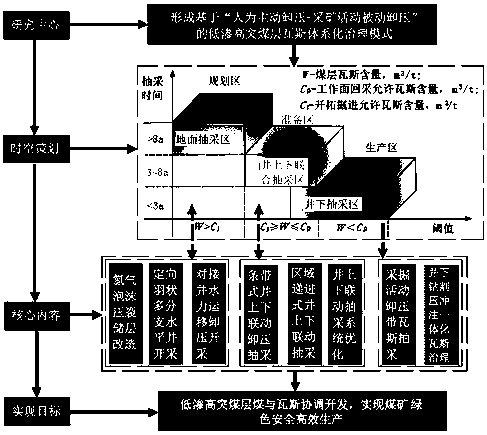

Low-permeability high-outburst coal seam systematic gas production method

InactiveCN107905834AReduce leakageImprove anti-reflection effectFluid removalGas removalWell drillingHydraulic fracturing

The invention discloses a low-permeability high-outburst coal seam systematic gas production method. The low-permeability high-outburst coal seam systematic gas production method comprises the following steps that 1, a well field is divided into a planning area, a preparation area and a production area; 2, the planning area adopts ground drilling pressure relief permeability increasing per-pumping; 3, the preparation area adopts well up-down combined fracturing pressure relief permeability increasing extraction; and 4, the production area adopts a mining activity pressure relief coordinated hydraulic integrated extraction technology. According to the low-permeability high-outburst coal seam systematic gas production method, planning area ground drilling pressure relief permeability increasing extraction, preparation area well up-down combined hydraulic fracturing pressure relief permeability increasing extraction and production area mining activity pressure relief permeability increasing extraction are used as key links, removing of low permeability restricting gas efficient flow is used as a basic starting point, and through two kinds of permeability increasing types of artificialactive pressure relief and passive pressure relief influenced by mining activity, three-area linkage stereoscopic extraction is conducted on gas of the coal mine planning area, the preparation area and the production area; and a three-area linkage stereoscopic pressure relief permeability increasing efficiency extraction mode of gas production and then coal mining is formed, so that coordinated development of coal and the gas is achieved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

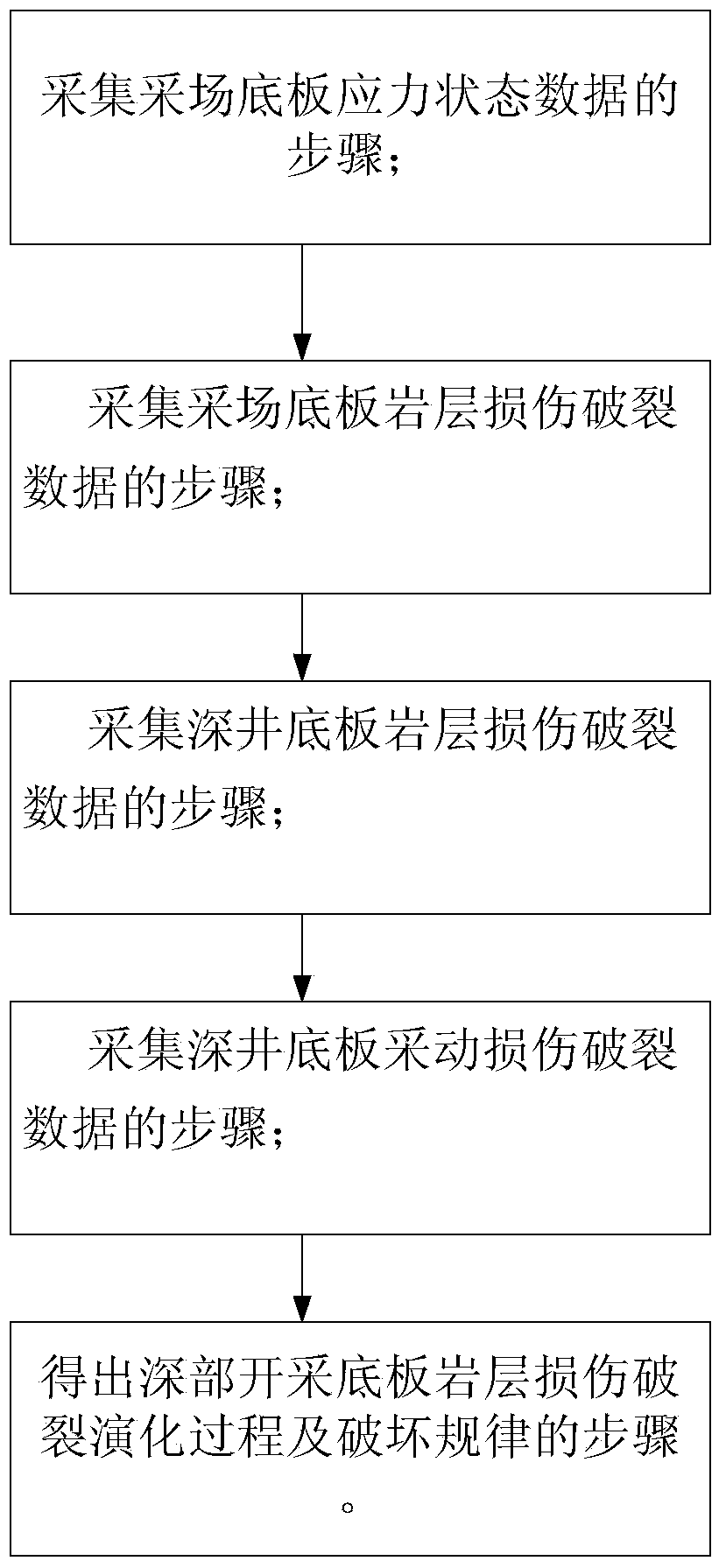

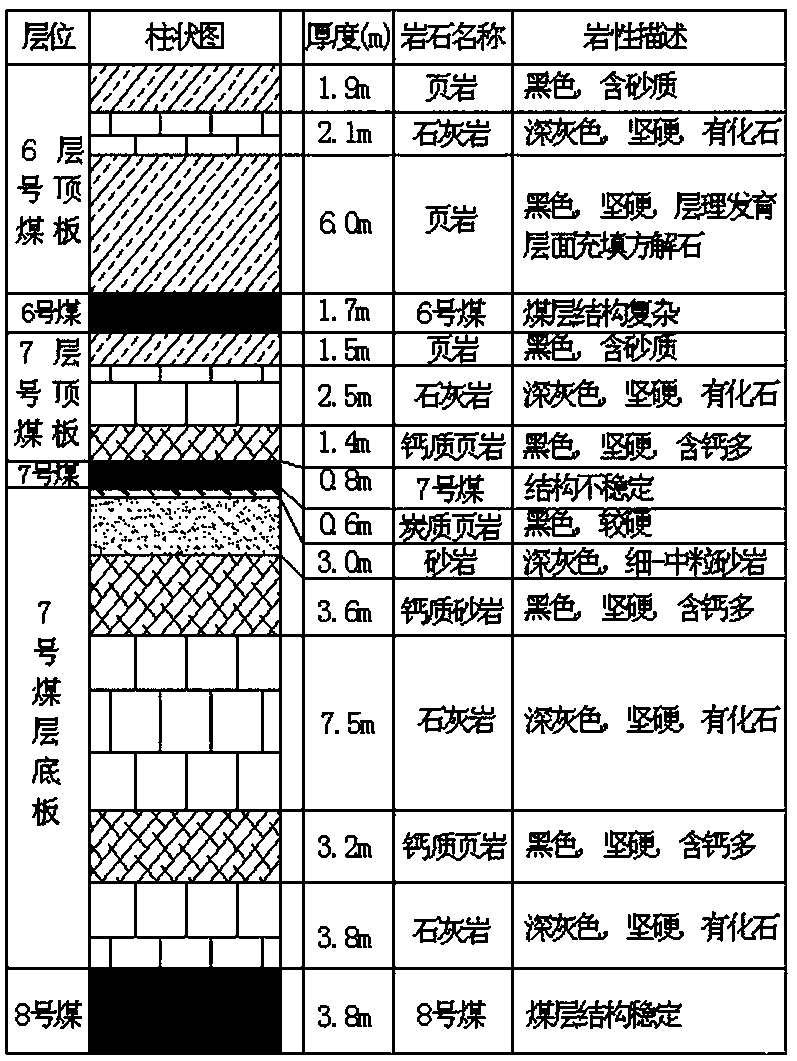

Analytical method of deep mining floor rock stratum damage and fracturation evolution and failure law

The invention discloses an analytical method of deep mining floor rock stratum damage and fracturation evolution and failure law. The analytical method comprises the following steps: Step 1, stope floor stress state data is acquired; Step 2, stope floor rock stratum damage and fracturation data is acquired; Step 3, deep well floor rock stratum damage and fracturation data is acquired; Step 4, deep well floor mining-induced damage and fracturation data is acquired; Step 5, the above stope floor stress state data, the stope floor rock stratum damage and fracturation data, the deep well floor rock stratum damage and fracturation data and the deep well floor mining-induced damage and fracturation data are analyzed so as to obtain deep mining floor rock stratum damage and fracturation evolution and failure law. By obtaining the deep mining floor rock stratum damage and fracturation evolution and failure law, data foundation is provided for specific deep mining, so as to further provide technical support for raising deep mining efficiency and mining safety.

Owner:SHANDONG UNIV OF SCI & TECH

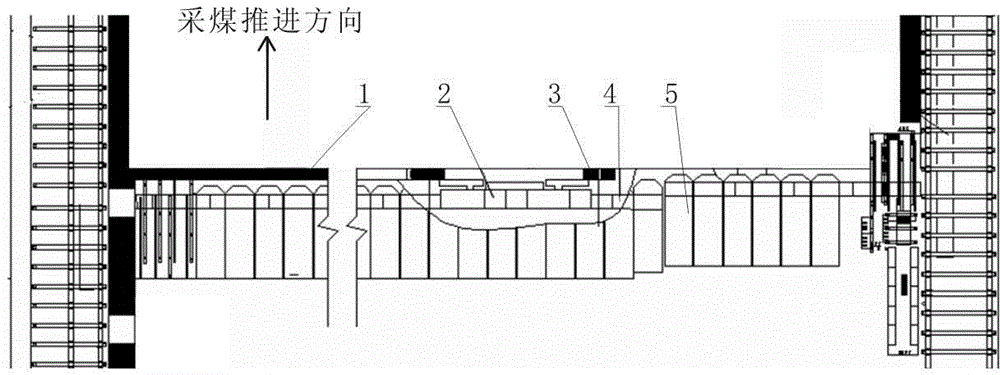

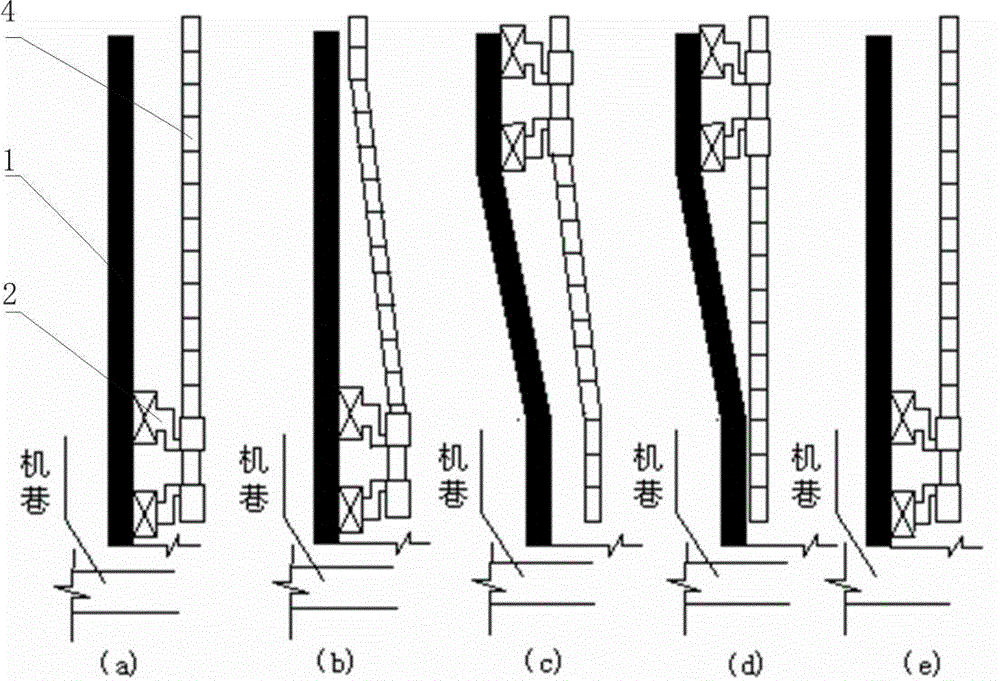

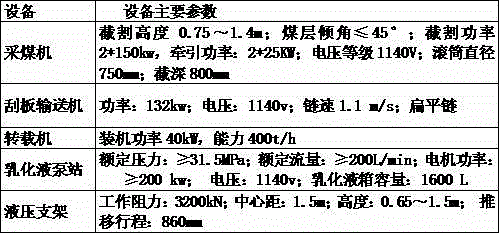

High-efficiency thin coal seam complete-set coal mining equipment and coal mining method

InactiveCN104912557ASolve the problem of mechanized comprehensive miningReduce engagementUnderground miningSurface miningProcess engineeringElectric traction

The invention relates to high-efficiency thin coal seam complete-set coal mining equipment and a coal mining method; a coal mining machine is an electric traction coal mining machine, and a machine body is hung out of a scraper conveyer. The coal mining method includes the steps: the equipment is arranged on a coal mining working face in a complete-set mode; the coal mining machine is moved to a position of an advanced notch for feeding, after feeding, the scraper conveyer is propelled by a transition way, and the coal mining machine goes forward to cut coal so as to complete feeding; after completion of feeding, the coal mining machine goes forward to cut the coal at a speed of 3-4 m per minute along a coal wall and allows the coal to be loaded to a middle groove of the scraper conveyer; after the coal mining machine walks, a hydraulic support is pushed to move; and pushing downspouting is carried out in the range of 10-15 m behind the hydraulic support propelled to move. The problem of extremely thin coal seam mechanization comprehensive mining is solved, all mining devices are mechanized, and the mining devices satisfy the problem of extremely low mining height space arrangement, the complete set of equipment is rational in layout, the coal mining steps are reasonably carried out, the production efficiency is improved, the worker participation degree is reduced, and the mining safety is improved.

Owner:XIAOHEZUI COAL MINE OF SICHUAN COAL GRP DA ZHU CO

Middle-waisted bidirectional filling and mining method under canopy guard in thick and great metal mine in sea bed

InactiveCN101761340ASmall amount of deformationImprove mining safetyMineral miningMaterial fill-upOcean bottomFilling materials

The invention discloses a middle-waisted bidirectional filling and mining method under canopy guard in a thick and great metal mine in sea bed, which is characterized in that a safety isolating layer is preserved between an ore body and the sea bed; the ore body is divided into an upper part and a lower part at the middle waist in the altitude direction; the altitude from the middle waist position to the sea bed sea mud is 100-150m; stoping is carried out from the middle waist position of the ore body, wherein the upper part adopts upstroke mining and the lower part adopts downstroke mining; a rock trackless quasi-upward slicing cemented method with a regular post pillar is adopted in the upstroke mining method; a rock trackless quasi-ordinary slicing cemented method is adopted in the downstroke mining; the gob in the stope is filled with filling materials. The invention is characterized by having high safety of mining, little loss of resources, high degree of mechanism, low labor intensity, great production capacity, short stoping time, low mining settlement and the like.

Owner:CENT SOUTH UNIV +1

Air column well completion back coming subsequent filling mining method

ActiveCN104695960ASafe miningEfficient miningUnderground miningSurface miningStop timeUltimate tensile strength

The invention discloses an air column well completion back coming subsequent filling mining method of a thick and large metal ore bed under an ore rock unstable condition. Subsections are divided in a vertical level to carry out stope preparation; a stope is divided along the moving direction of a crushed body to be used as a back stoping unit; in each stope, back coming is carried out by a middle depth hole from an upper disc to a lower disc; the back stoping is carried out at the same time in the plurality of subsections; and the roof exposed area of the stope is controlled. When one section is exploited and ores are discharged, an air column is put down from an upper subsection rock drilling roadway and is distributed nearby an unexploded ore body; after filling and curing, 1-2 rows of cannon arrangement holes in the rear row are exploded for two times to form grooves. The stope width, the recovery length of each time, the filling material ratio, the strength of a filling body and the like are obtained by an ore rock mechanical parameter test, mechanical analysis and numerical value simulation analysis. The rock drilling, the explosion, the ore removal and the shoring are finished by trackless equipment; and the air column well completion back coming subsequent filling mining method has the characteristics of high exploiting safety, small resource loss, high mechanical degree, low labor intensity, great production capability, short back stoping time, and the like.

Owner:SHANDONG GOLD MINING LINGLONG

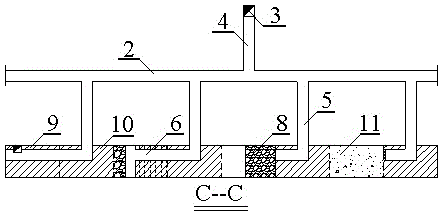

Diskless region type connection roadway continuous sectional cut-and-filling stoping method shared by chamber and jambs

InactiveCN103061768AControl stope pressureIncrease production capacityUnderground miningSurface miningMining engineeringRock cutting

The invention discloses a diskless region type connection roadway continuous sectional cut-and-filling stoping method shared by a chamber and jambs for an inclined fractured ore body with medium thickness. The stoping method comprises the following steps that: the ore body comprises middle sections, wherein each middle section is internally connected with a fragmented transport roadway along the direction of the ore body by adopting a screw type ramp; the fragments separates the chamber and the jambs in a continuous way; and when the chamber is exploited, the connection roadway is advanced towards the centers of the jambs, the level of the ore drift is advanced along the hanging wall of the ore body till reaching the whole chamber, and the chamber and the jambs share one connection roadway; a filling retaining wall is constructed on the joint of the chamber and the jambs after recovery, the cemented filling is carried on a worked-out section from the upper subsection, in the middle sections, the chamber is recovered first and filled close the back, and then the jambs are recovered; after the jambs are recovered, a filling retaining wall is constructed in the connection roadway after recovery of the jambs, and non-cemented or cemented surfaces with thickness of 1m are used for filling; and continuous mining is realized through a plurality of technological parallel workings including drilling, blasting, supporting, ore removal, filling and the like in one subjection. The method provided by the invention has the remarkable characteristics of low accurate mining ratio, low ore loss factor, safety and efficiency, capacity of increasing enterprise revenues and the like.

Owner:彭康

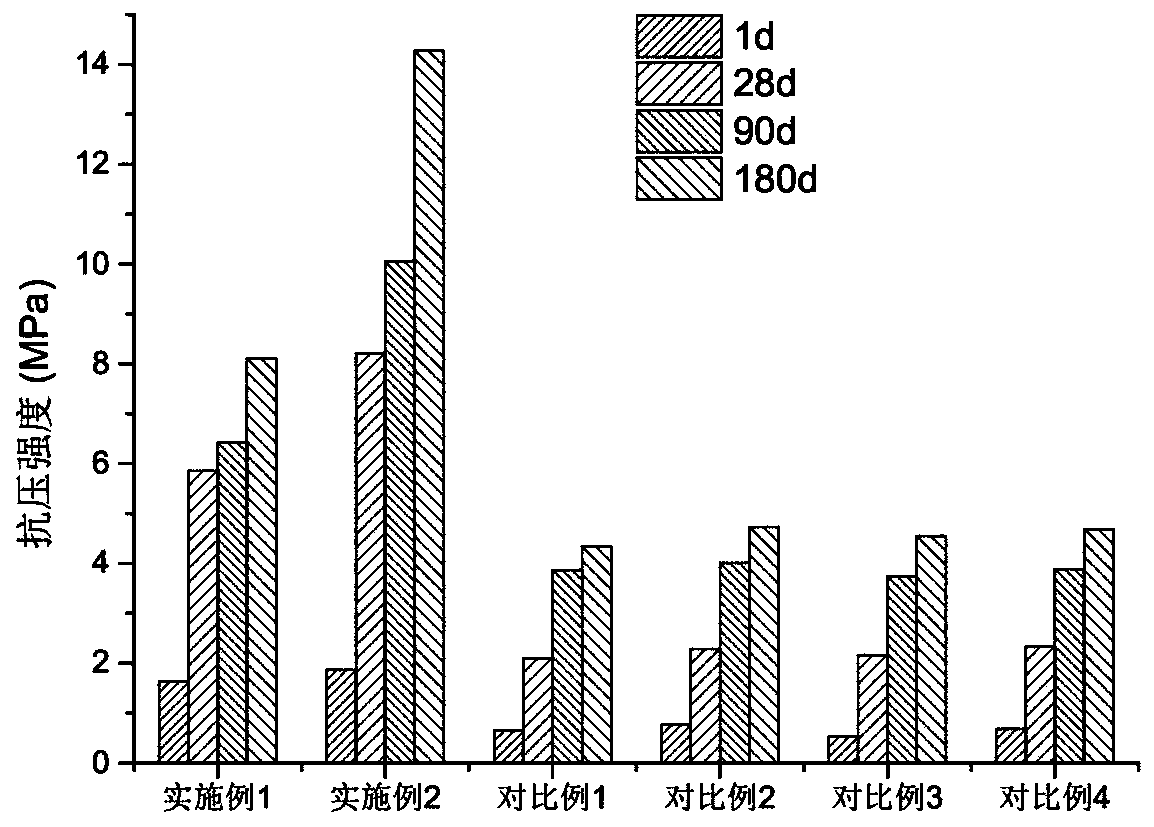

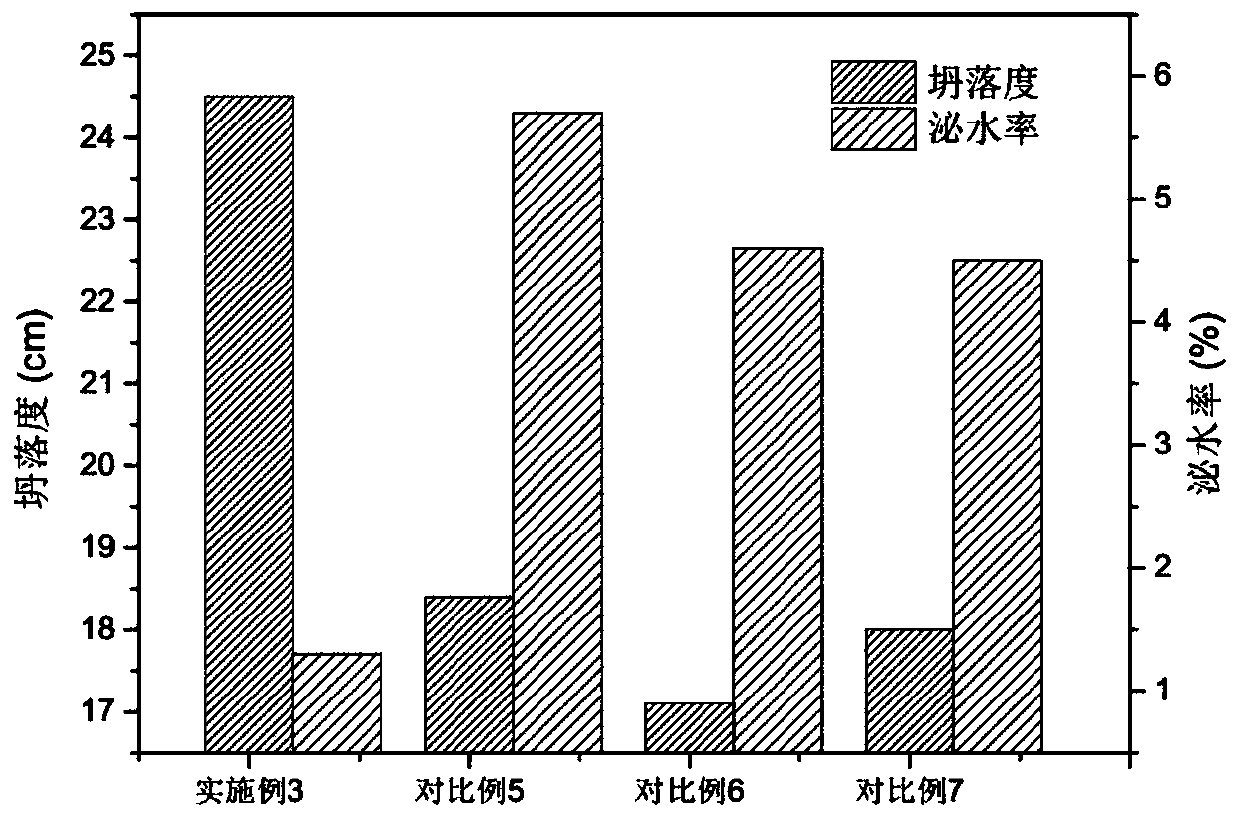

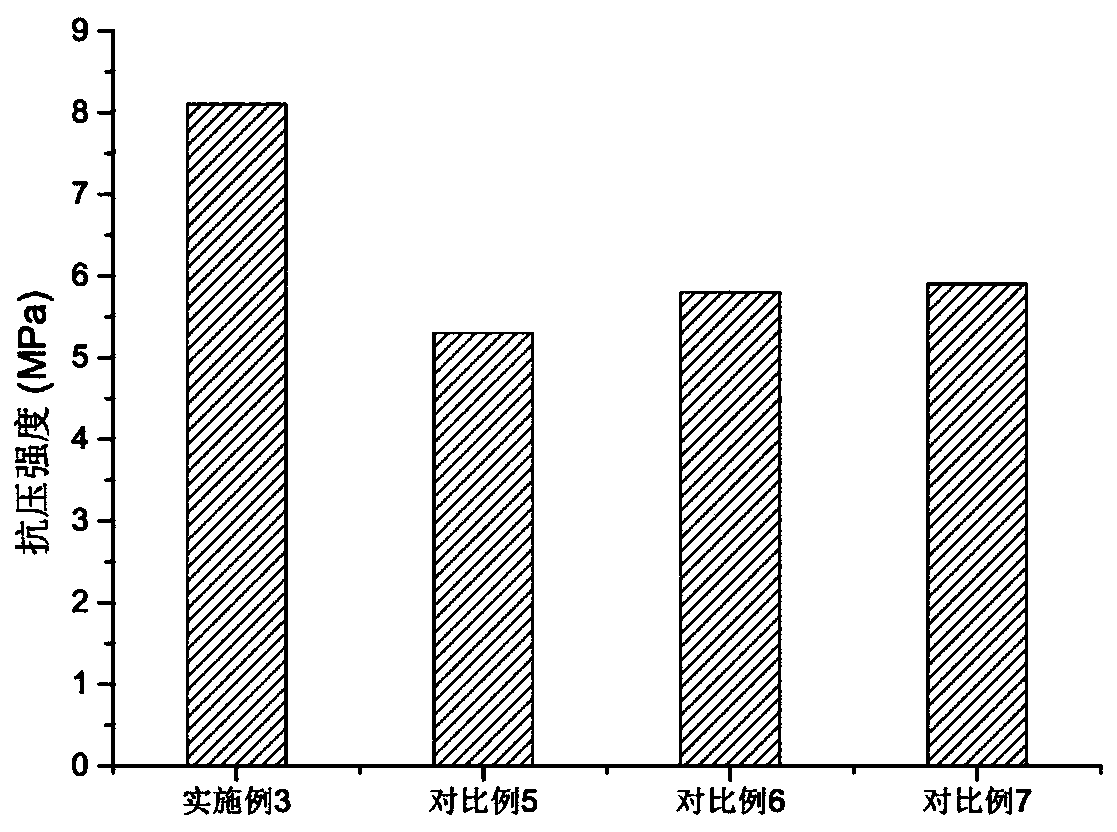

All-solid-waste cementing material for fine tailing filling and preparation method thereof

The invention provides an all-solid-waste cementing material for fine tailing filling and a preparation method, and belongs to the technical field of tailing filling mining. According to the material,steel slag is used for replacing clinker or lime or other alkaline materials, the synergistic and self-excitation action mechanism of steel slag and chemical gypsum is utilized, no artificial material is added, and the cementing material is prepared from, by weight, 35%-50% of steel slag, 15%-25% of chemical gypsum and 25%-50% of slag. The cementing material is high in utilization rate of low-quality solid waste, wide in source, low in material cost and suitable for preparation of fine tailing filling slurry for filling method mining, the fine tailing filling body has micro-expansibility, roof contact of a filling stope is facilitated, and therefore the stability of the filling stope is improved.

Owner:UNIV OF SCI & TECH BEIJING +1

Prevention method of air shock wave disaster in mine goaf

InactiveCN103244182AImprove mining safetyReduce air pressureMining devicesShock waveReinforced concrete

A prevention method of an air shock wave disaster in a mine goaf comprises constructing wall bodies through reinforced concretes in a stagger mode on the left side and the right side of a range within 5 to 20 m of existing periphery tunnels which are communicated with a goaf to form into a tooth-shaped wave obstruction wall when the air shock wave disaster happens in the periphery tunnels due to goaf collapse after mining of a mine. The prevention method of the air shock wave disaster in the mine goaf has the advantages of being simple to achieve and practical and wide in applicability, being capable of reasonably optimizing wall body building mode according to actual conditions, avoiding goaf stability monitoring difficulties caused by closeness of the goaf at the same time, effectively preventing or reducing impact air flow or air blast disasters caused by compressed air in the periphery tunnels when the goaf is collapsed and being beneficial to effective management of same type mine goaves.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

System and method for in-situ ore leaching of southern ionic rare earth

PendingCN112921173APrevent outflowImprove pollutionProcess efficiency improvementMining engineeringSurface water

The invention relates to an in-situ ore leaching mining technology, in particular to a system and a method for in-situ ore leaching of southern ionic rare earth. According to the system and the method, continuous waterproof curtains are formed on the periphery and the bottom of an ore body through a high-pressure jet grouting construction technology, the area formed by the waterproof curtains serves as an ore leaching area, ore leaching liquid can be prevented from flowing out of the ore body, and the problem that surface water and underground water are seriously polluted due to the fact that the ore leaching liquid leaks along rock and ore body cracks is effectively solved. A drilling machine is used for drilling a horizontal hole and inserting a liquid collecting pipe to replace manual excavation of a liquid collecting roadway, the rare earth mining safety can be improved, waste soil discharge is reduced, a dredger is installed in the liquid collecting pipe, the liquid collecting pipe is prevented from being blocked, and the liquid collecting efficiency is improved.

Owner:JIANGXI UNIV OF SCI & TECH +2

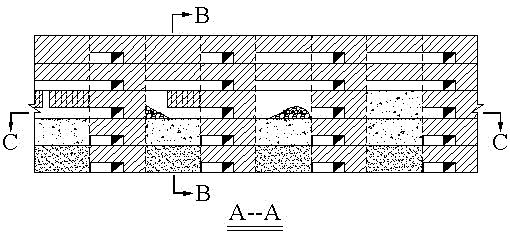

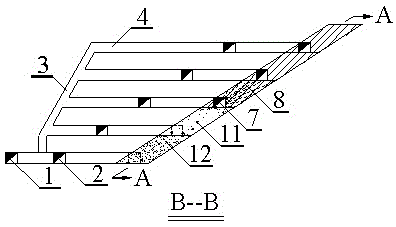

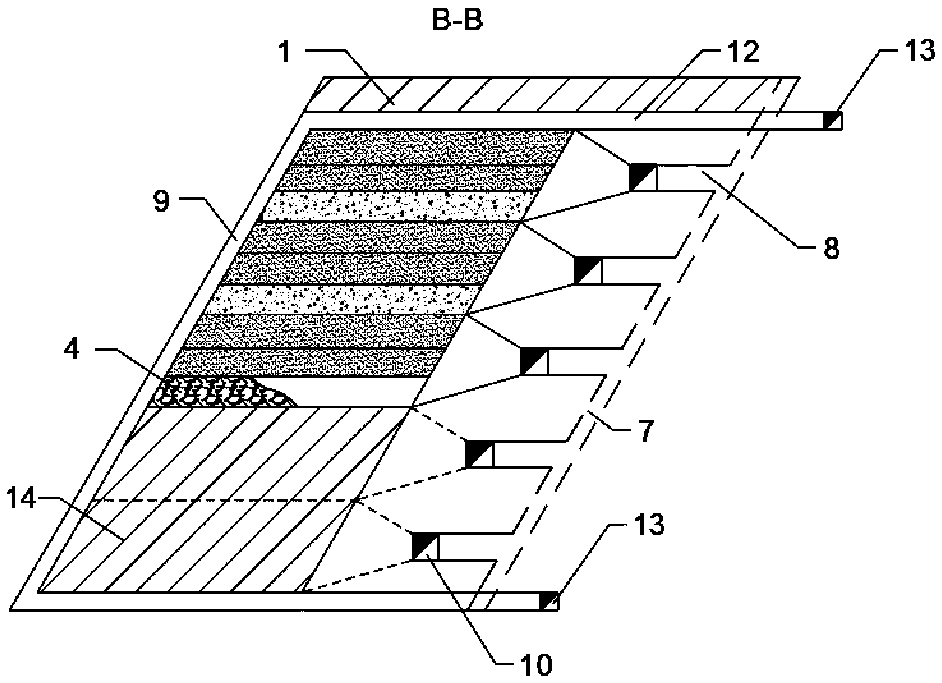

Mechanical sublevel filling mining method adopting vertical hole and horizontal hole cooperative recovery

InactiveCN103982185AImprove mining safetyImprove recovery efficiencyUnderground miningSurface miningRemote controlHigh intensity

The invention discloses a mechanical sublevel filling mining method adopting vertical hole and horizontal hole cooperative recovery. According to mine sublevel recovery, vertical hole recovery and horizontal hole recovery are cooperatively performed in a sublevel recovery unit; a vertical hole comprises a pre-splitting hole and an ore breaking hole, most of the ore in the unit is recovered in the vertical ore breaking hole, a unit ejector plate is formed by horizontal hole recovery, two outlines of the unit are controlled by the vertical pre-splitting hole, the ore is discharged cooperatively by a common scraper and a remote control scraper after recovery canopy guard, a unit goaf is filled at a time, and a drilling space is reserved for the upper recovery next sublevel. The operation is cycled until the whole one-step stope recovery is finished. The characteristics of high strength, high efficiency and low cost of sublevel recovery are exerted, the two outlines of the sublevel recovery unit are controlled by utilizing pre-splitting blasting, and the outline of a recovery unit ejector plate is controlled through the horizontal hole recovery. The method has the advantages of safety, high efficiency, simple process, low loss and dilution and high mechanical degree.

Owner:CENT SOUTH UNIV

Two-step mechanization cooperative high-section non-solid waste mining process for controlling ground pressure house column

InactiveCN109723441ARealize safe and green mining without solid wasteImprove mining safetyUnderground miningSurface miningRoom and pillar miningRemote control

The invention discloses a two-step mechanization cooperative high-section non-solid waste mining process for controlling a ground pressure house column, which comprises the following steps of: (1) mining a house and a mine column in two steps, wherein a two-step mining semicircular arch is formed in sequence in the mining process to maintain the stability of a quarry; (2) forming a trackless slopetrack mining system and a full tailing cementing filling system outside the quarry; (3) using a high-section medium-deep hole breaking technology to carry out ore caving at the quarry, wherein the first mining section is divided into an upper part and a lower part, a section rock drilling heading is tunneled firstly; (4) transferring the caved ore to a quarry pass through a remote control scraperto finish ore extraction; (5) after the quarry mining is finished, constructing a filling retaining wall at the lower part of the section, and filling the quarry gap at the upper part; (6) after thelower section mining is finished, digging a rock drilling roadway at the upper part to start mining the upper section. The method can effectively control the mine pressure of the roof, the workers donot directly work under the roof, the mining safety is high, the mechanization degree is high, and the mining efficiency is high.

Owner:FUZHOU UNIV

Method for uniformly fracturing coal body by compounding hydraulic power and liquid nitrogen

InactiveCN110924900AFully uniform crackingImprove production safetyFluid removalThermodynamicsHydraulic fracturing

The invention discloses a method for uniformly fracturing a coal body by compounding hydraulic power and liquid nitrogen. The method comprises the following specific steps: constructing a horizontal fracturing drilling hole in a selected side of an excavation roadway, sealing the hole, and connecting the hole to a hydraulic fracturing system and a liquid nitrogen fracturing system separately; starting the master control to coal body hydraulic fracturing through a hydraulic fracturing control operation table, wherein a hydraulic fracturing process comprises two stages, the first stage is a conventional hydraulic fracturing stage, and the second stage is a sand-containing hydraulic fracturing stage; after the hydraulic fracturing process is ended, immediately starting liquid nitrogen freezing to a coal body to cause fracture through a liquid nitrogen fracturing control operation table; and after the fracturing of each fracturing drilling hole is ended for 48 hours, performing the hydraulic fracturing and liquid nitrogen fracturing of next fracturing drilling hole until the fracturing of the last fracturing drilling hole is completed.

Owner:CHINA UNIV OF MINING & TECH

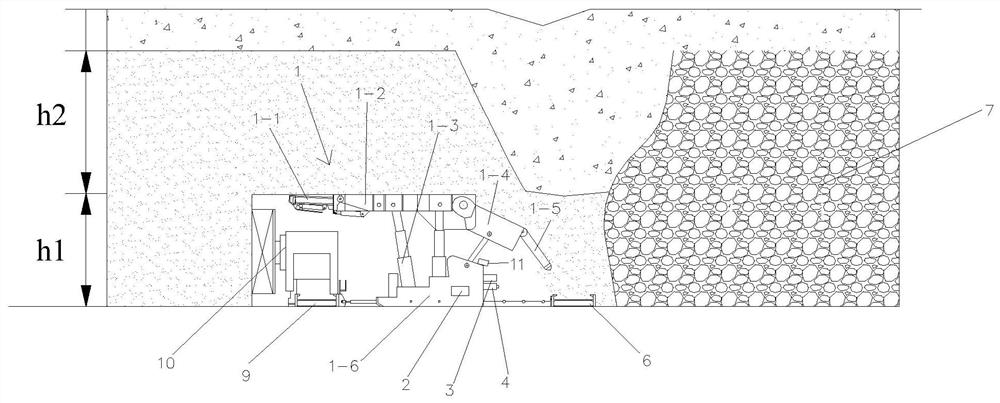

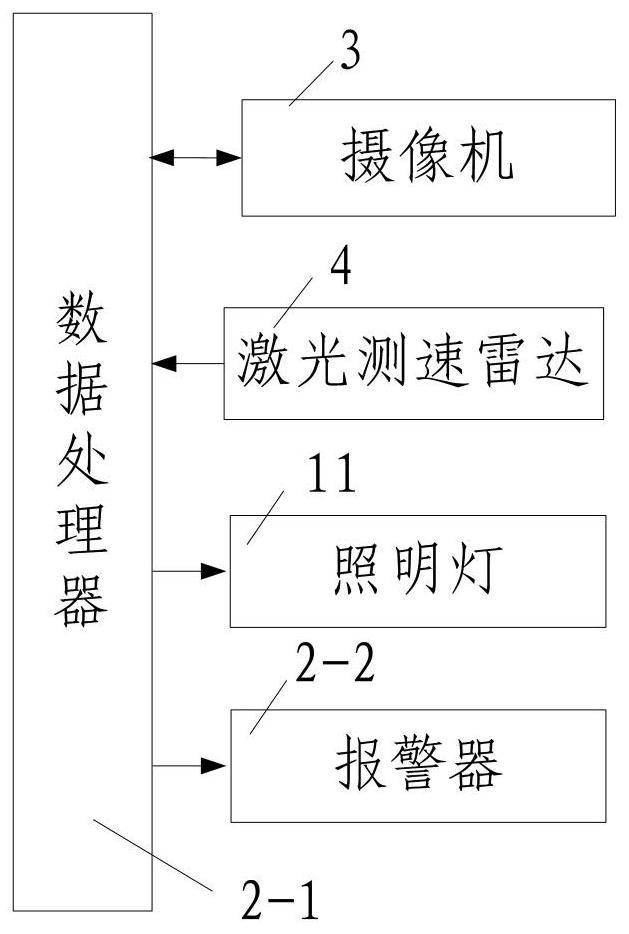

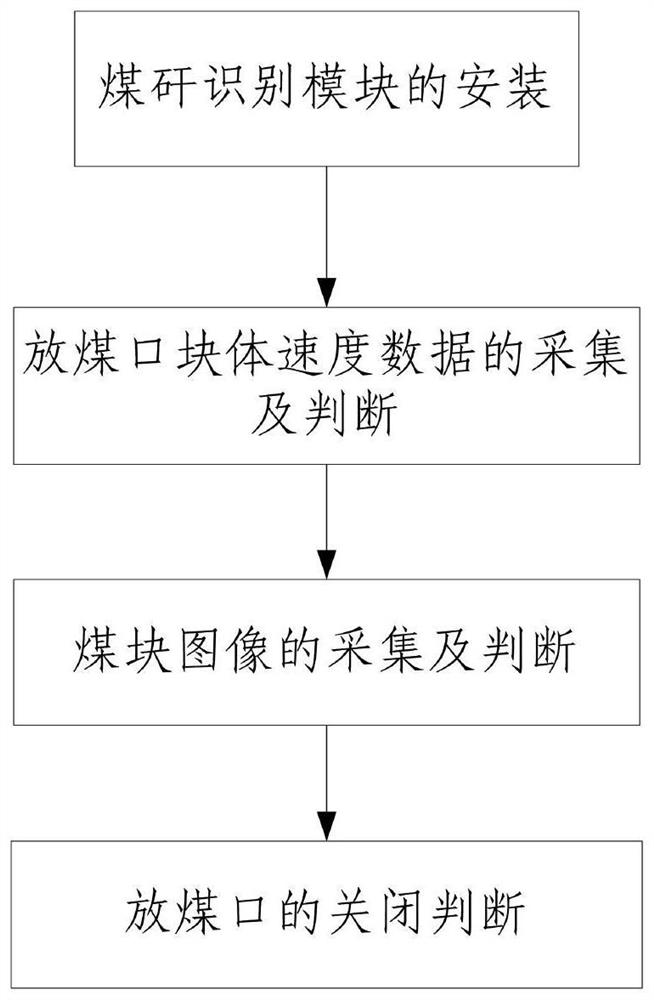

Method for intelligently judging closing of coal caving openings of top coal caving hydraulic supports

ActiveCN112211657AThe method steps are simpleReasonable designMining devicesCharacter and pattern recognitionMining engineeringMechanical engineering

The invention discloses a method for intelligently judging closing of coal caving openings of top coal caving hydraulic supports. The method comprises the following steps that 1, coal gangue recognition modules are installed; 2, speed data of coal caving opening blocks are collected and judged; 3, block images are acquired and judged; and 4, closing of the coal caving openings is judged. The method is simple in step and reasonable in design, the coal gangue recognition accuracy is improved, meanwhile, the quality of gangue discharged from the coal caving openings is determined, the coal cavingopenings are closed in time, economic benefits are improved, and follow-up intelligent unmanned top coal caving mining is facilitated.

Owner:XIAN UNIV OF SCI & TECH

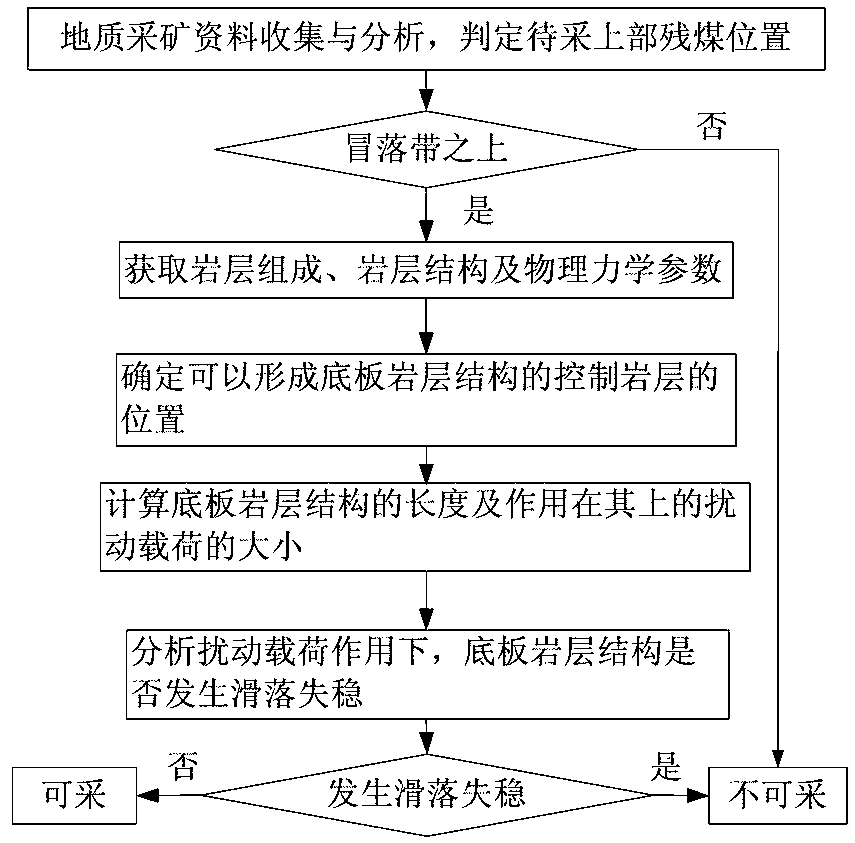

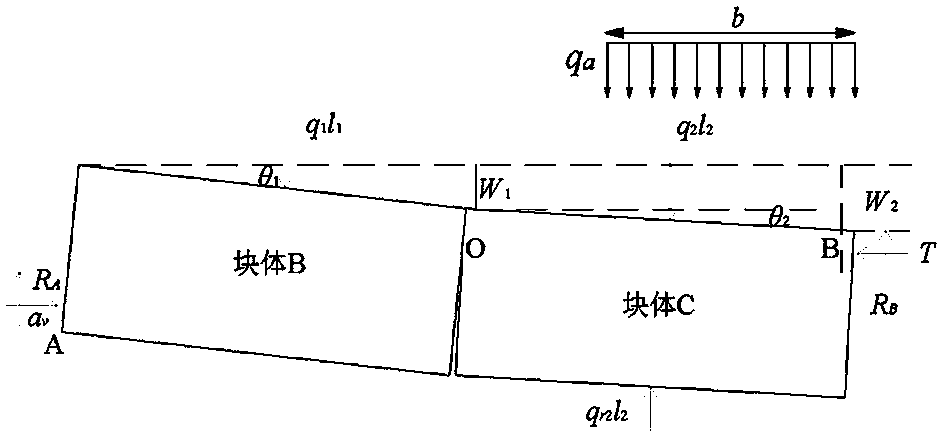

Quantitative determination method of ascending mining feasibility of composite residual mining area

ActiveCN107657084ARelatively small errorImprove the accuracy of recoverability judgmentGeometric CADDesign optimisation/simulationQuantitative determinationPropagation attenuation

The invention belongs to the field of coal mining, and provides a quantitative determination method of ascending mining feasibility of a composite residual mining area. The method comprises the following steps: S1, judging an upper-part residual coal position, carrying out step S2 if the same is located above a caving zone of lower coal seam mining, and otherwise, determining that mining cannot becarried out; S2, obtaining stratum composition, stratum structures and physical and mechanical stratum parameters of the residual coal mining area through drilling; S3, determining positions of control strata forming bottom plate voussoir beam stratum structures; S4, calculating intervals of roofing breaking of the control strata and a disturbance load of abutment pressure acting on the bottom plate voussoir beam stratum structures after propagation attenuation; and S5, analyzing whether sliding instability of the bottom plate voussoir beam stratum structures of the composite residual miningarea occurs under the action of the disturbance load, and determining that mining can be carried out if the sliding instability of the bottom plate voussoir beam stratum structures does not occur. The method improves accuracy of mining admissibility determination and safety of mining, and is suitable for use in conditions that the control strata are hard and the voussoir beam structures are formed.

Owner:TAIYUAN UNIV OF TECH

Trench integrated mine collecting and mining method of inclined ore body

ActiveCN107654232AStable supportImprove concentrationUnderground miningSurface miningEconomic benefitsEngineering

The invention discloses a trench integrated mine collecting and mining method of an inclined ore body. A trench construction area is arranged in an empty area formed after mining. Trench constructionof the trench construction area specifically includes the steps that a trench slope used for guiding falling ore to move downward and / or protect the upper disc surface of the ore body is constructed at the corner of the upper disc surface and a bottom plate surface of the trench construction area; a mine collecting channel is reserved in the bottom plate surface when the trench slope is constructed, and the constructed trench slope, the reserved mine collecting channel and the lower disc slope of the ore body form a trench used for gathering the falling ore extracted from the upper portion ofthe trench to the mine collecting channel; the ore body on the upper portion of the trench is extracted and output from the upper portion and / or the side face of the mine collecting channel. The method easily improves the ore recovery rate, ore output efficiency, productivity, recovery safety and comprehensive economic benefits, and is suitable for exploitation of inclined ore bodies with medium stability from thin to medium thick and construction of a trench type mine output bottom structure.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

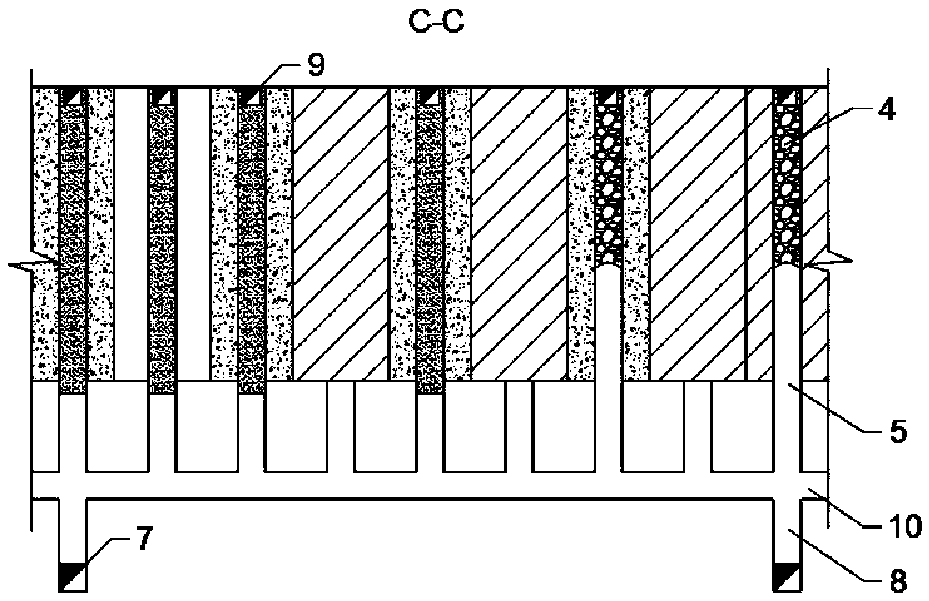

Downward concave-convex rib-free inlaying continuous layered filling mining method

ActiveCN109751050ARaise the gradeImprove mining safetyUnderground miningSurface miningRoom and pillar miningStopped work

The invention relates to a downward concave-convex rib-free inlaying continuous layered filling mining method which comprises the following steps: (1) dividing an ore body into stages, and dividing the stages into a plurality of layers of middle sections in the height direction; (2) arranging a first-step stope in an ore room, arranging a second-step stope in an ore pillar, and enabling every 5-7stopes in rooms / columns to form a panel area; (3) adopting an extrapulse trackless accurate mining system, transferring mined ores of a central drift of each middle section and an upper wing ore bodyand an lower wing ore body to a panel draw shaft through a transfer layer connection channel, and completing the ore removal process of the stopes; and (4) guaranteeing that the stope of the middle section of each layer is composed of a central drift, a first layer and a second layer, completing the stoping work of each layer of the ore body of the first-step stope of the stope of the panel area,and conducting stoping on the second-step stope of the ore pillar of the panel area under the lateral protection of a first-step stope filling body. The filling mining method has the remarkable advantages that the production capacity of a panel stope is high, the ore drawing time is short, the mining safety is high, the resource loss is small, and the mining and filling process circulation substitution is reasonable.

Owner:FUZHOU UNIV

Open-stope subsequent filling mining method suitable for gently inclined medium-thick ore bodies

ActiveCN110644996AShort mining timeShort mining securityUnderground miningSurface miningMining engineeringMechanical engineering

The invention discloses an open-stope subsequent filling mining method suitable for a gently inclined medium-thick ore body. The open-stope subsequent filling mining method particularly includes the steps that the ore body is divided into mining middle sections in the vertical direction, an inclined top column is reserved between every two middle sections, mining panels are divided in the trend direction of the ore body in each middle section, panel barriers are reserved between the adjacent mining panels, stope rooms and ore columns are divided in the mining panels, and preparation project arranging, cutting, stoping and filling are carried out; the whole panels are stoped by two steps that step 1, the stope rooms are stoped, after stoping of the stope rooms is finished, and tailings areadopted for cemented filling; and step 2, the ore columns are stoped, and the steps are repeated until stoping of a stope is finished. The open-stope subsequent filling mining method is very suitablefor mining of the gently inclined medium-thick ore body, ore drawing is efficient carried out by adopting a V-shaped trench, short draw shaft ore-breaking and a scraper, and the problem of difficult ore drawing of gently inclined d ore bodies is solved; meanwhile, the method is short in ore drawing time, high in mining safety, and low in dilution loss; and the ore drawing efficiency is improved, the stoping time of the stope rooms is shortened, and the production capacity of the stope rooms is improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

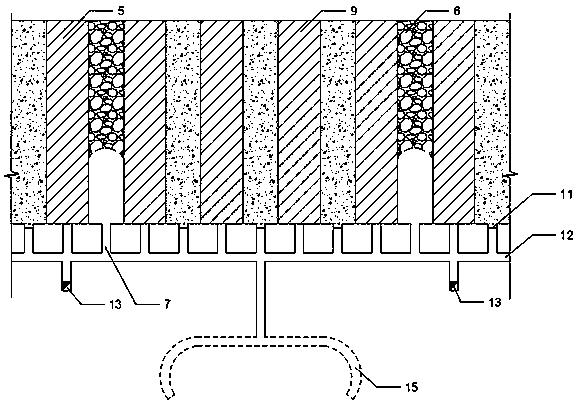

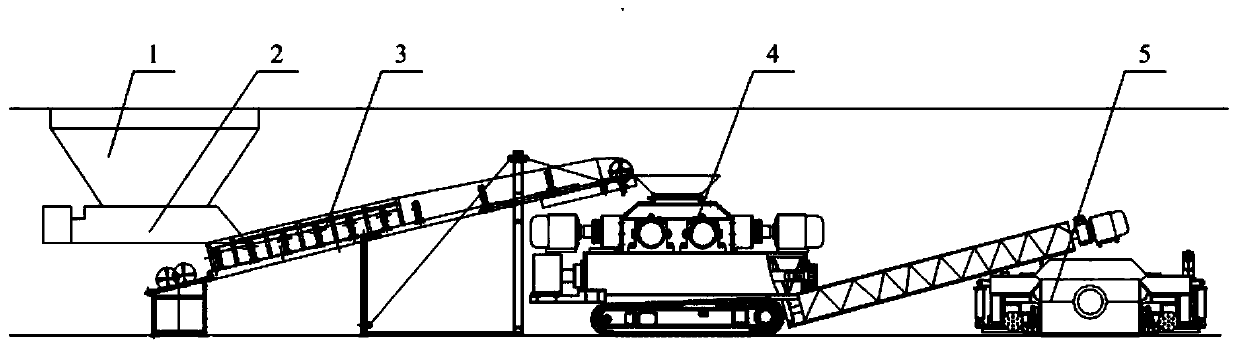

Pneumatic filling system and process for open-air side coal goaf

ActiveCN109736809APrevent collapseEasy to transportUnderground miningSurface miningHydraulic cylinderHigh pressure

The invention relates to a pneumatic filling system and process for an open-air side wall coal goaf. The filling system mainly is composed of a gangue bin, a feeding vibrating screen, a feeding belt conveyor, a crawler crusher and a pneumatic filling device, and the pneumatic filling device comprises a pneumatic filling pump, a pushing hydraulic cylinder, a pneumatic filling pipe, a high-pressurepneumatic inlet, a first-section filling pipe and a feeding hopper. The filling process comprises pipe connecting operation, gangue filling operation and continuous pneumatic filling operation. The filling requirements of the goaf of a drilling and production method can be met, the mining safety of the drilling and production method is enhanced, and safety accidents such as collapse of the goaf are prevented. The device has the advantages that parallel operation is easy to achieve, the occupied space is small, material transportation and configuration of various devices are convenient, the recovery rate of coal resources is increased, and the filling cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

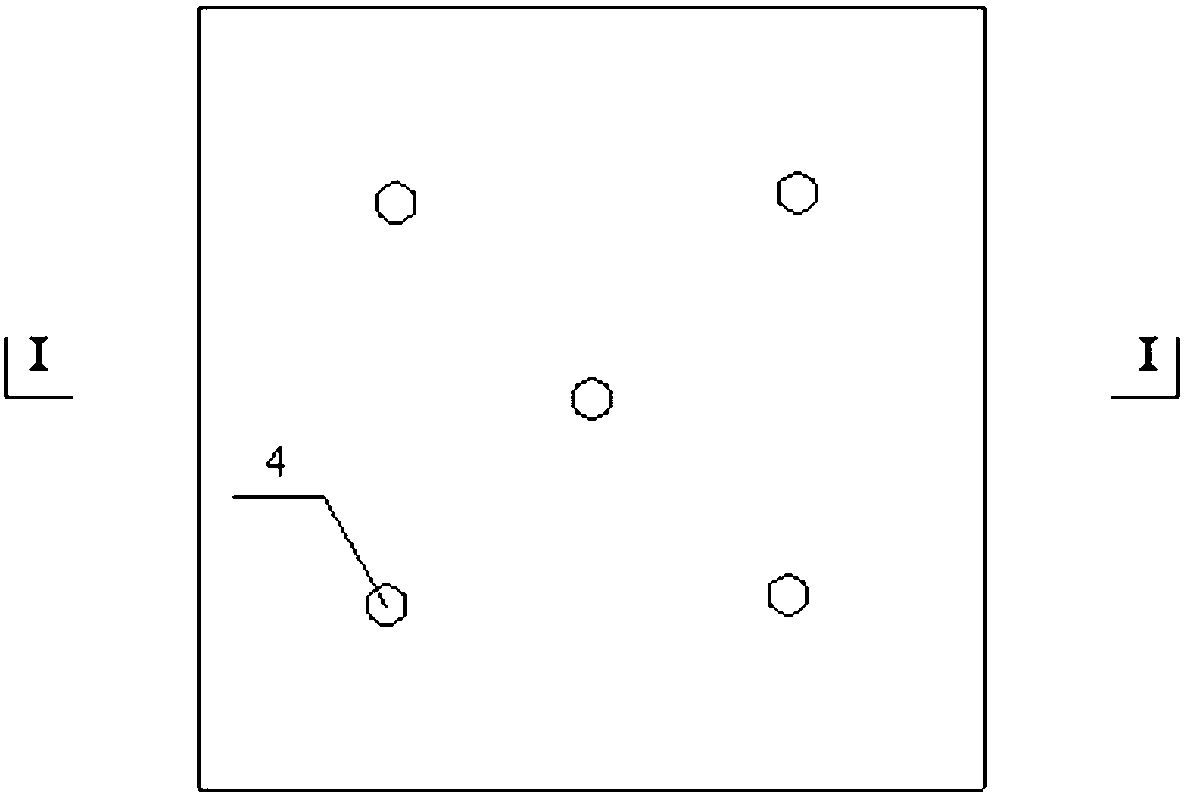

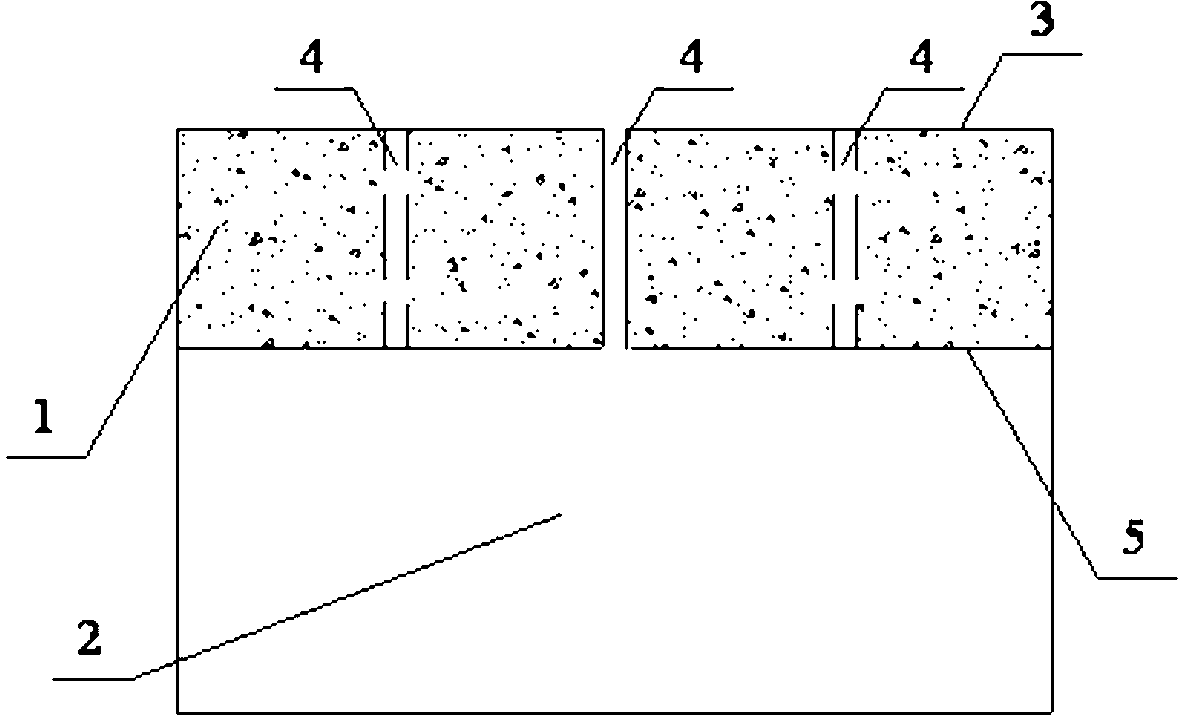

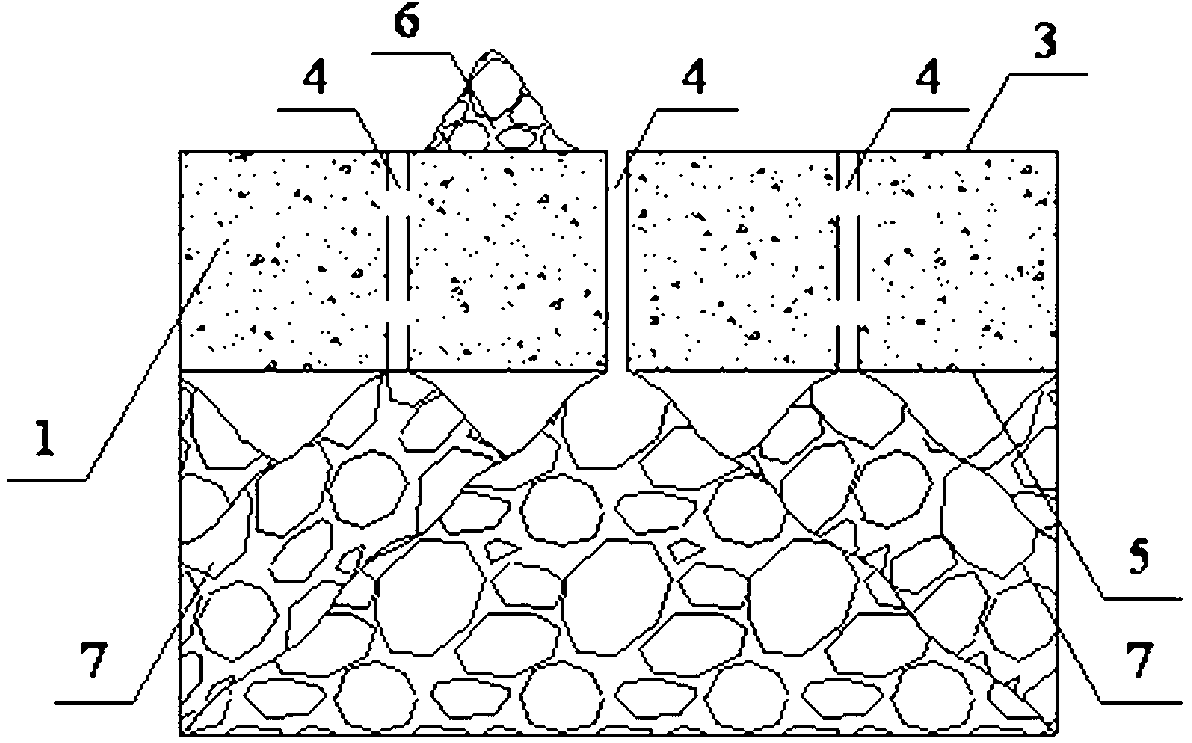

Downward parallel middle-deep hole sublevel fill stoping mining method for steep and medium-thick hard-to-mine ore body

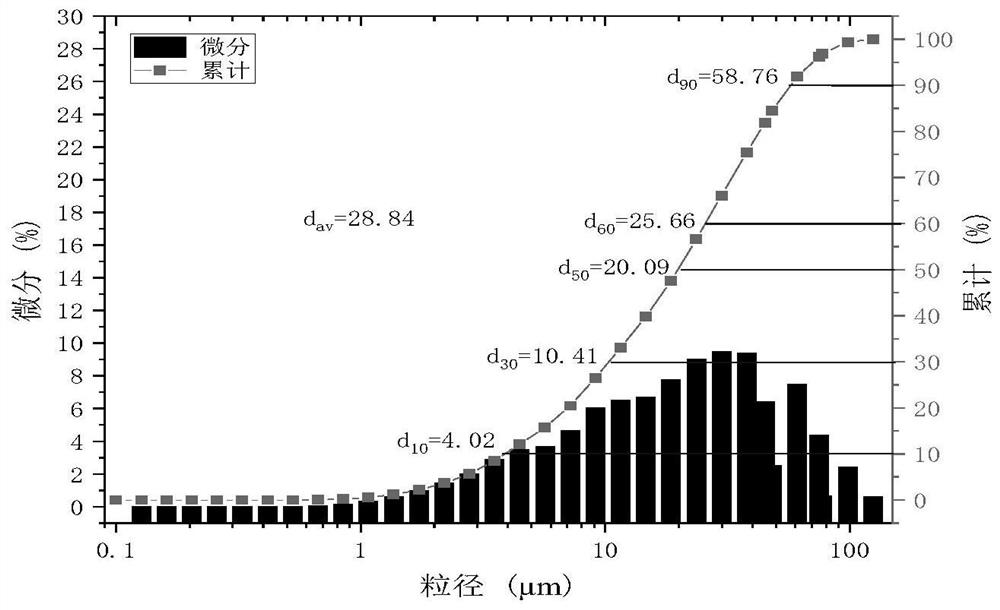

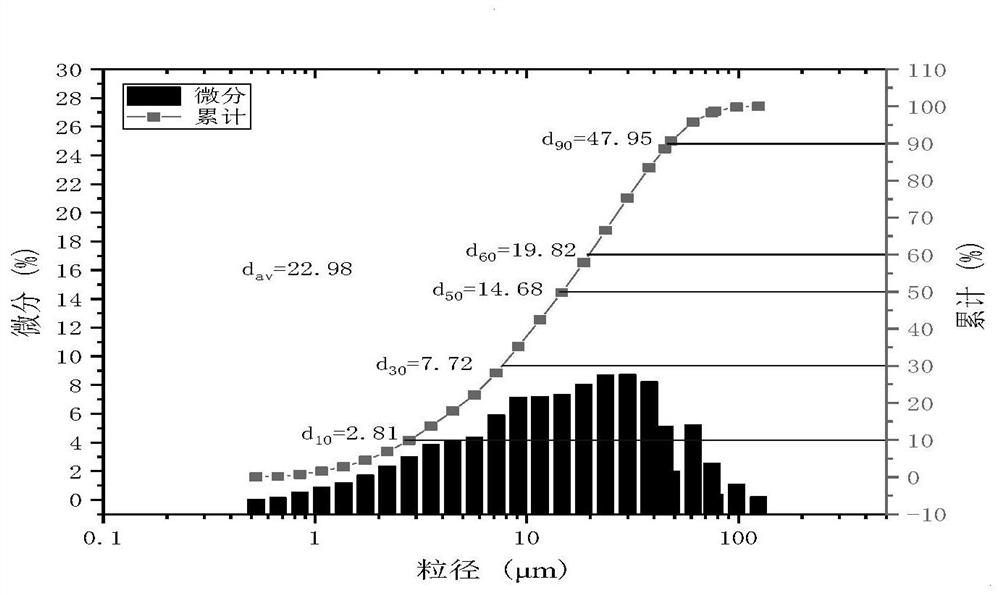

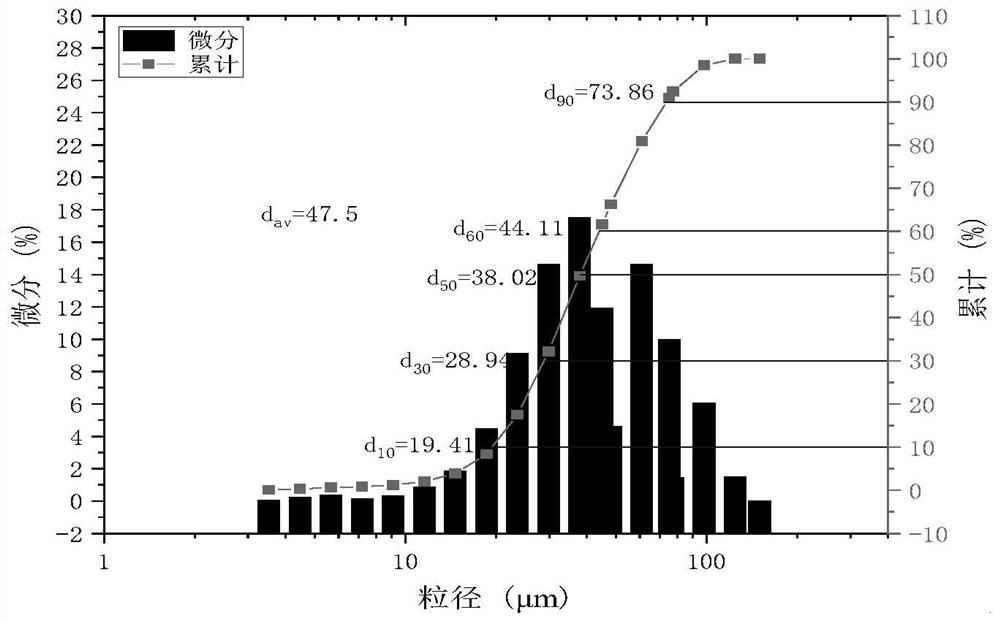

PendingCN110985114AImprove early strengthHigh compressive strengthMaterial fill-upSlagMining engineering

The invention provides a downward parallel middle-deep hole sublevel fill stoping mining method for a steep and medium-thick hard-to-mine ore body, and belongs to the technical field of mining. The ore body is divided into a plurality of sublevels according to the middle sublevel, stope rooms and stope pillars are divided in the ore body direction, the middle sublevel is divided in the inclined direction of the ore body, sublevel rock drilling roadways are arranged along veins, artificial false roofs and false bottoms are constructed in the sublevel rock drilling roadways in advance, and middle-deep hole stoping ore blocks are adopted from top to bottom. After the stope rooms are mined, the stope rooms are filled with filling materials. After the stope pillars are mined, the stope pillarsare filled with full tailings and / or barren rock powder. The content of particles with the particle size being less than or equal to 30[mu]m in the full tailings for the filling materials accounts for75-77%; the content of the particles with the particle size being less than or equal to 35[mu]m in slag accounts for 86-88%; and an activator is prepared from glauberite and green vitriol with a weight ratio of 1 to (0.5-0.7). According to the downward parallel middle-deep hole sublevel fill stoping mining method, safe, efficient and low-cost mining of the ore body can be realized, continuous mining in an area can be realized, and the sublevel fill stoping mining method is mainly suitable for a gold mine with an inclination of 50-90 degrees and a horizontal thickness of 4-10 m.

Owner:中国黄金集团石湖矿业有限公司

Goaf treatment method based on filling raises with surface barren rock

InactiveCN103244177AImprove stabilityReduce the likelihood of collapseMaterial fill-upBedrockEarth surface

A goaf treatment method based on filling raises with surface barren rock includes; during the post-mining thin bedrock and shallow-buried goaf treatment in a mine, utilizing a full face digging method to dig downwards at least three raises to be straight communicated with the goaf through a digging machine, and then filling the goaf with the surface barren rock in a freely-dropping mode. According to the goaf treatment method based on filling the raises with the surface barren rock, the goaf can be filled up with the barren rock as much as possible and the roof exposure of the goaf can be reduced or even eliminated, so that the stability of the goaf can be enhanced and the collapse possibility of the goaf can be reduced; and meanwhile, due to the fact that the goaf is filled up with the barren rock, the intensity of the disaster caused by the collapse of the goaf roof can be reduced significantly and the mining safety of the mine can be effectively enhanced, so that the goaf treatment can be achieved. The goaf treatment method based on filling the raises with the surface barren rock is high in practicality, easy to achieve and capable of saving the cost effectively.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com