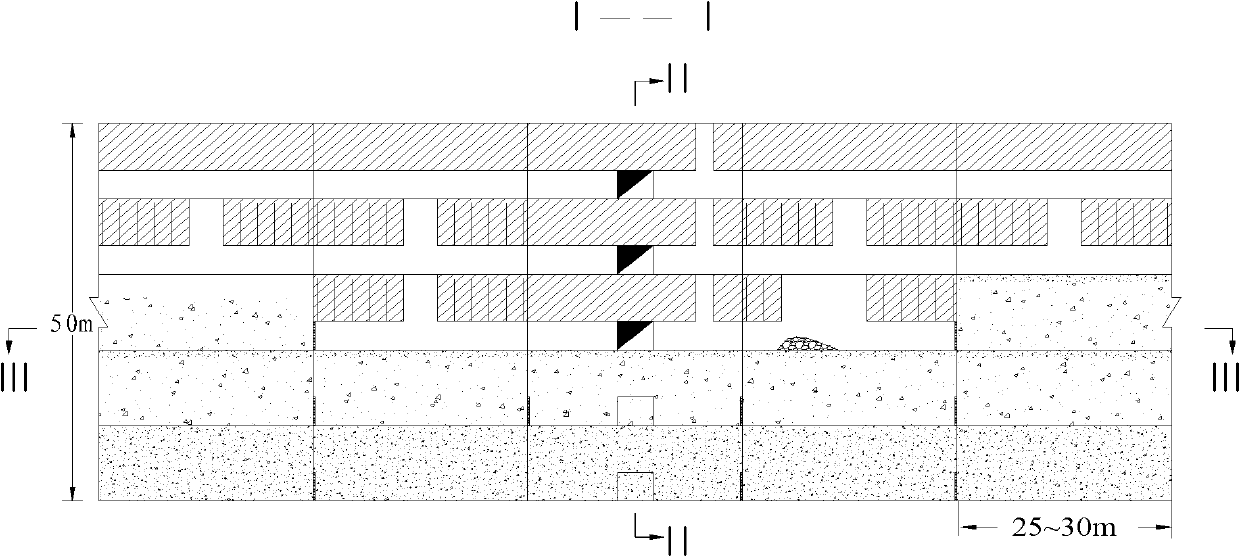

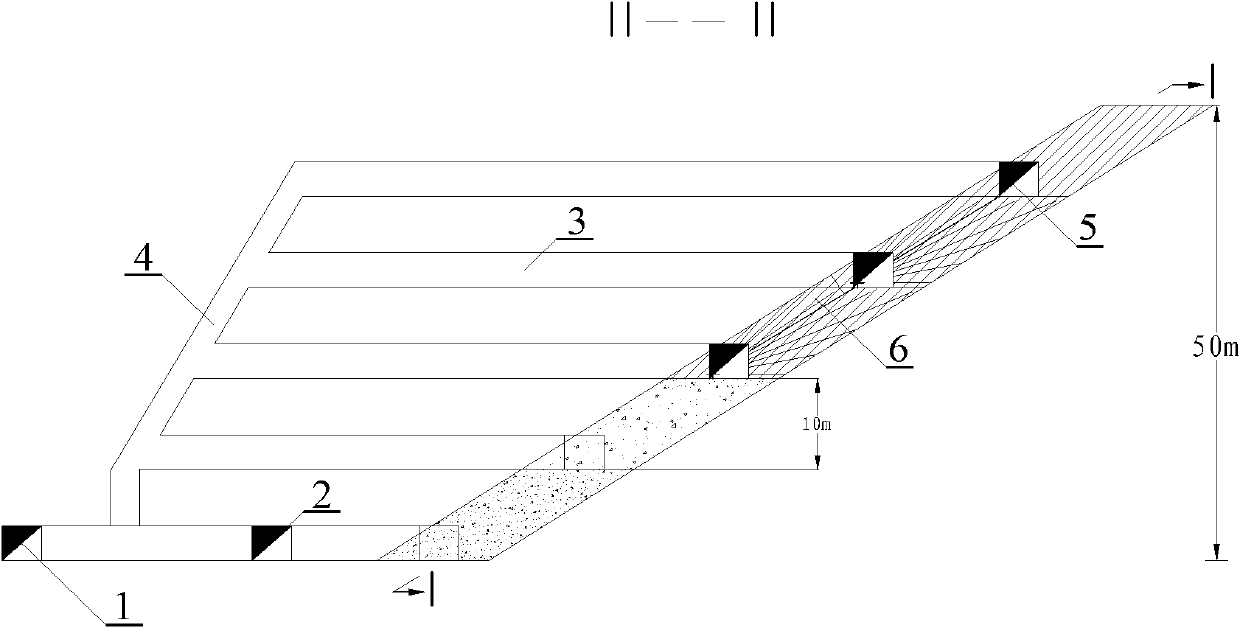

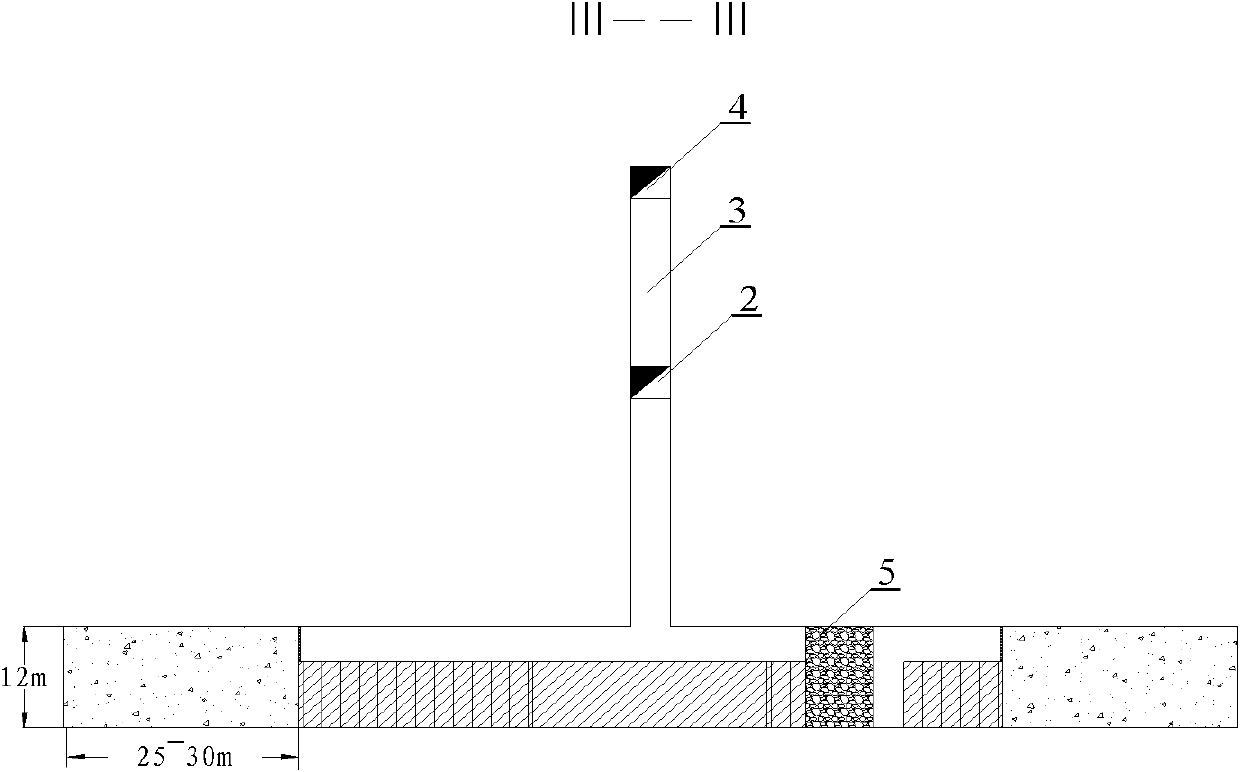

Rib-pillar-free continuous sublevel filling method for mining preparation in medium-thickness slope crushed ore body vein

A technology of endless pillars and ore bodies, which is applied in the fields of fillings, mining equipment, earthwork drilling, etc., can solve the problems of low mining value, complicated concrete pillar pouring process, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The continuous segmental filling mining method of quasi-continuous column in the vein of Guizhou Kailin Group Maluping Mine.

[0039] The mining area of Maluping Mine is part of the east wing of the Yangshui Anticline, starting from E in the south. 14+40 Exploration line, north to F 210 Fault, the strike length is 2880m; the average true thickness of the ore body is 6.5m, the average dip angle is 33°, and the bulk density is 2.78t / m 3 ; The inclination is 100°~125°, and the thickness of the ore bed is relatively stable on the strike; the average ore grade is 34.03%; The stable layer has a thickness of 0.5-5m, the indirect roof is dolomite, and the direct floor of the ore bed is quartz sandstone or red shale. The Maluping Mine has long been mined by the open-field method, and the loss and dilution rate is high, resulting in landslides, surface subsidence, and building damage. By adopting the continuous segmental filling mining method of quasi-intra-vein mining and q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com