Downward parallel middle-deep hole sublevel fill stoping mining method for steep and medium-thick hard-to-mine ore body

A technology of backfill mining and steep inclination, which is applied in the fields of backfill, mining equipment, earthwork drilling, etc. Effects of increased strength, lower yield stress and viscosity values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

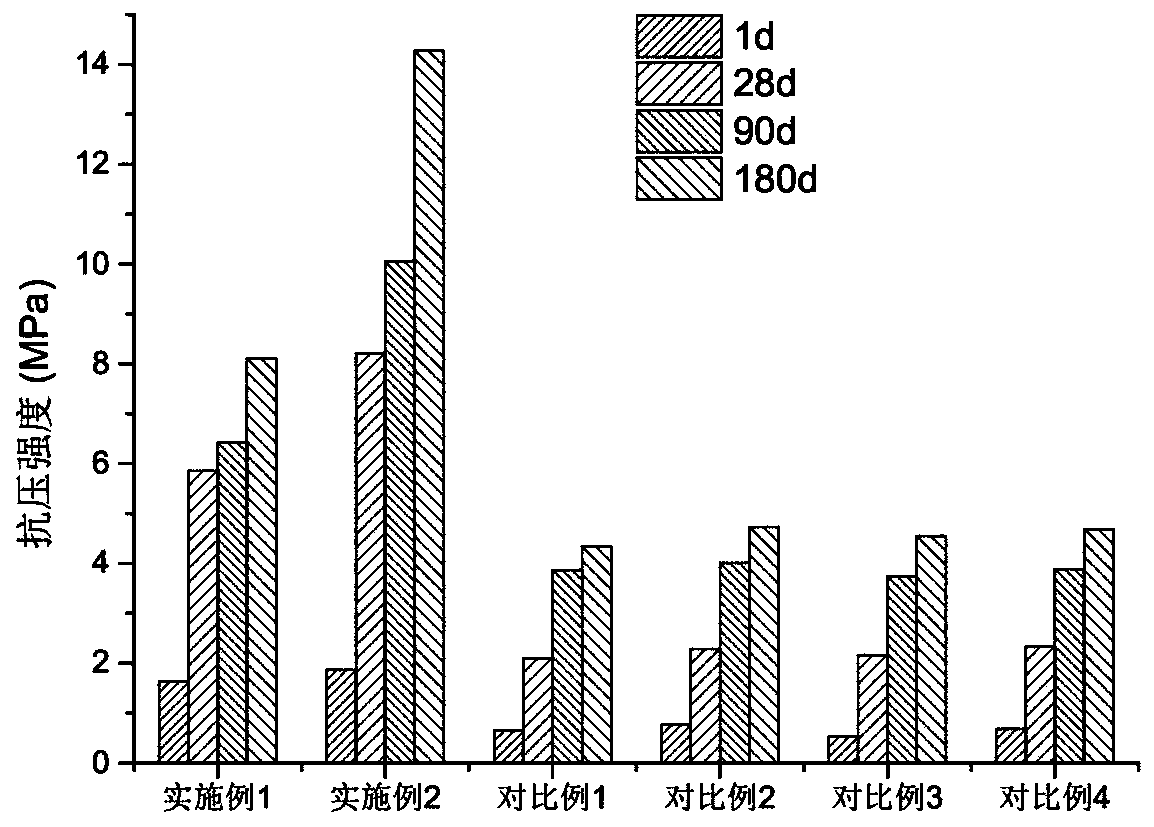

Embodiment 1

[0052] A kind of filling material for gobs, including, by weight, 71 parts of full tailings, 8.3 parts of 42.5 grade Portland cement, 11 parts of slag, and 0.7 part of activator; the chemical composition of cement and slag is shown in the table 1. The particle size distribution of the slag is shown in Table 2; the specific gravity, bulk density test and chemical composition analysis of the whole tailings used are carried out, and then the porosity of the whole tailings is obtained from the measured specific gravity and bulk density, and the final tailings obtained Physical properties: loose bulk density (g / cm 3 ) was 1.21, the specific gravity was 2.76, and the porosity (%) was 55.34. The chemical composition analyzed is mainly SiO 2 , Fe 2 o 3 、Al 2 o 3 , CaO, MgO, S, Cu, Au, Ag, etc. The final results of chemical analysis are shown in Table 3, where SiO 2 The content of is relatively high, indicating that the whole tailings is a relatively good inert material, and it c...

Embodiment 2

[0062] A kind of filling material used in gobs, including, by weight, 71 parts of full tailings, 8.3 parts of 42.5 grade Portland cement, 11 parts of slag, and 0.4 part of activator; the chemical composition of cement and slag is shown in the table 1. The particle size distribution of the slag is shown in Table 2; the final results of the chemical analysis of the tailings are shown in Table 3, and the particle size composition is shown in Table 4; acid aluminum.

Embodiment 3

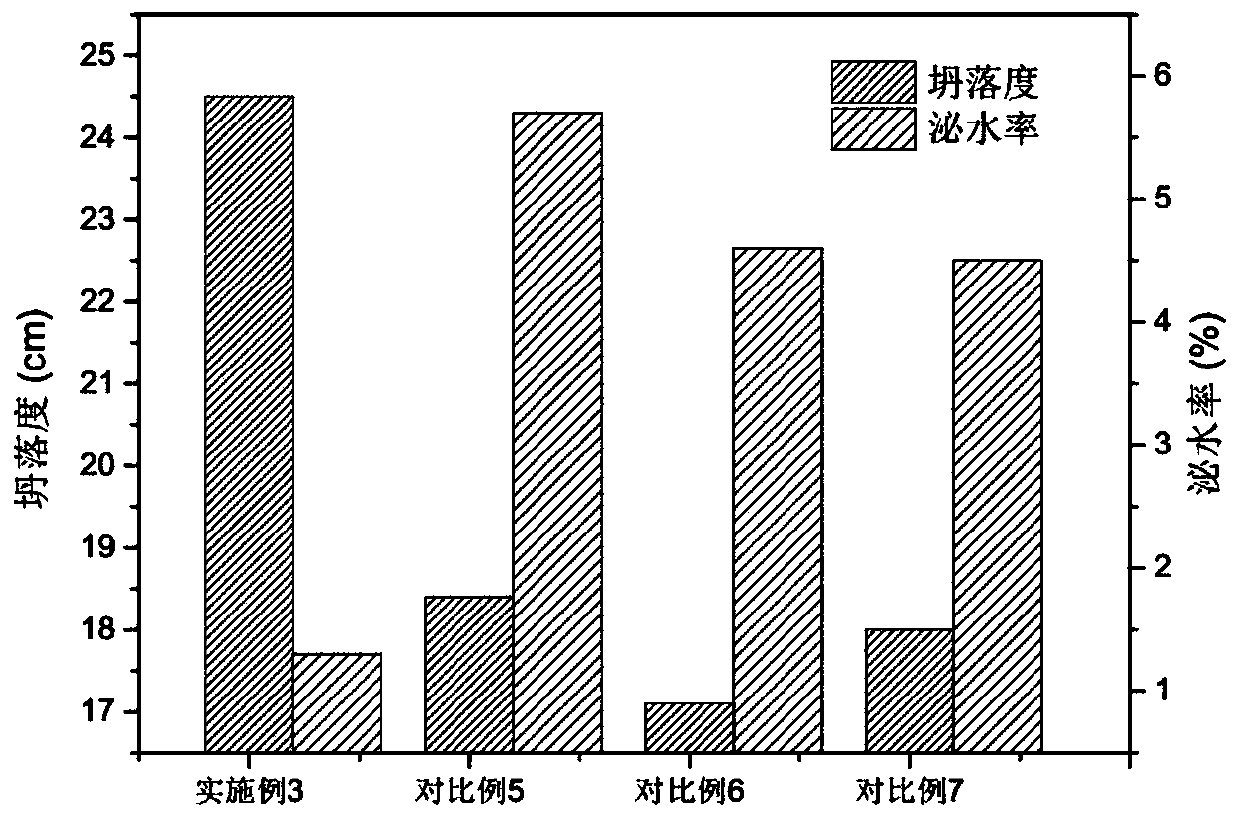

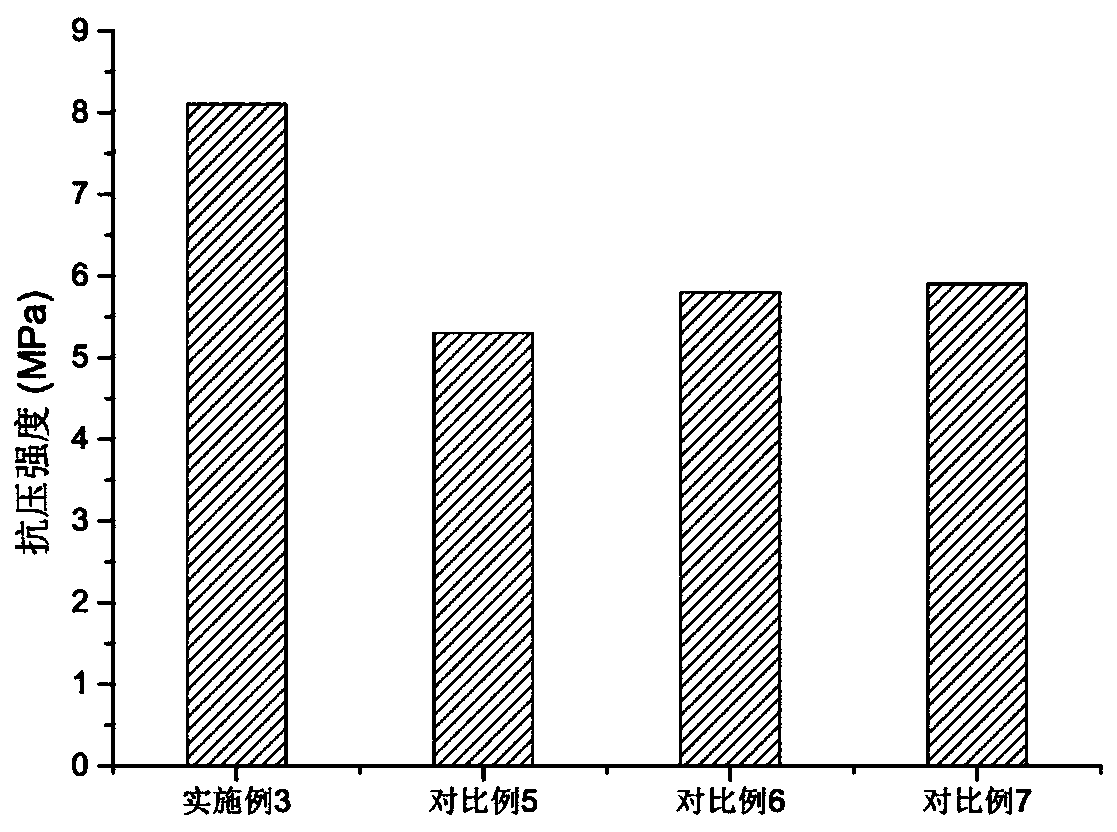

[0064]The concrete is calculated by weight, including 61 parts of full tailings (the final results of the chemical analysis of the whole tailings are shown in Table 3, and the particle size composition is shown in Table 4), 9 parts of 42.5 grade Portland cement (see Table 1 for the chemical composition of cement) , 3.8 parts of basalt short fiber, 2.7 parts of hydroxymethyl cellulose, 0.09 part of sodium hyaluronate, 0.04 part of potassium sodium tartrate, 0.02 part of aluminate coupling agent; wherein, the mass concentration of concrete is 83%; The preparation method is: dissolving hydroxymethyl cellulose and sodium hyaluronate in water to form a colloidal solution with a water-to-binder ratio of 0.25; dissolving basalt short fibers in the colloidal solution so that the basalt short fibers are evenly suspended in the colloidal solution ; Mix the whole tailings, cement, potassium sodium tartrate and water evenly to make semi-finished concrete; mix the colloid solution with basa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com