Patents

Literature

65results about How to "Meet filling requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

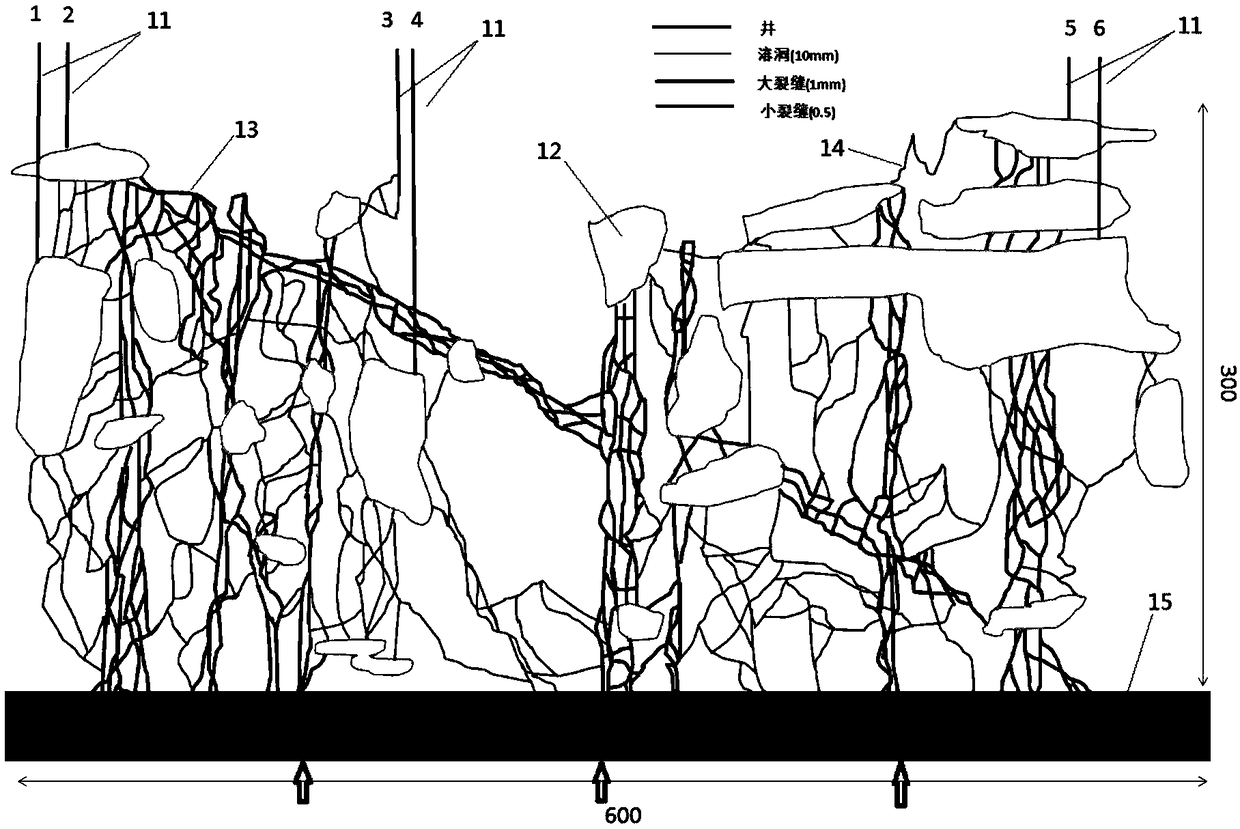

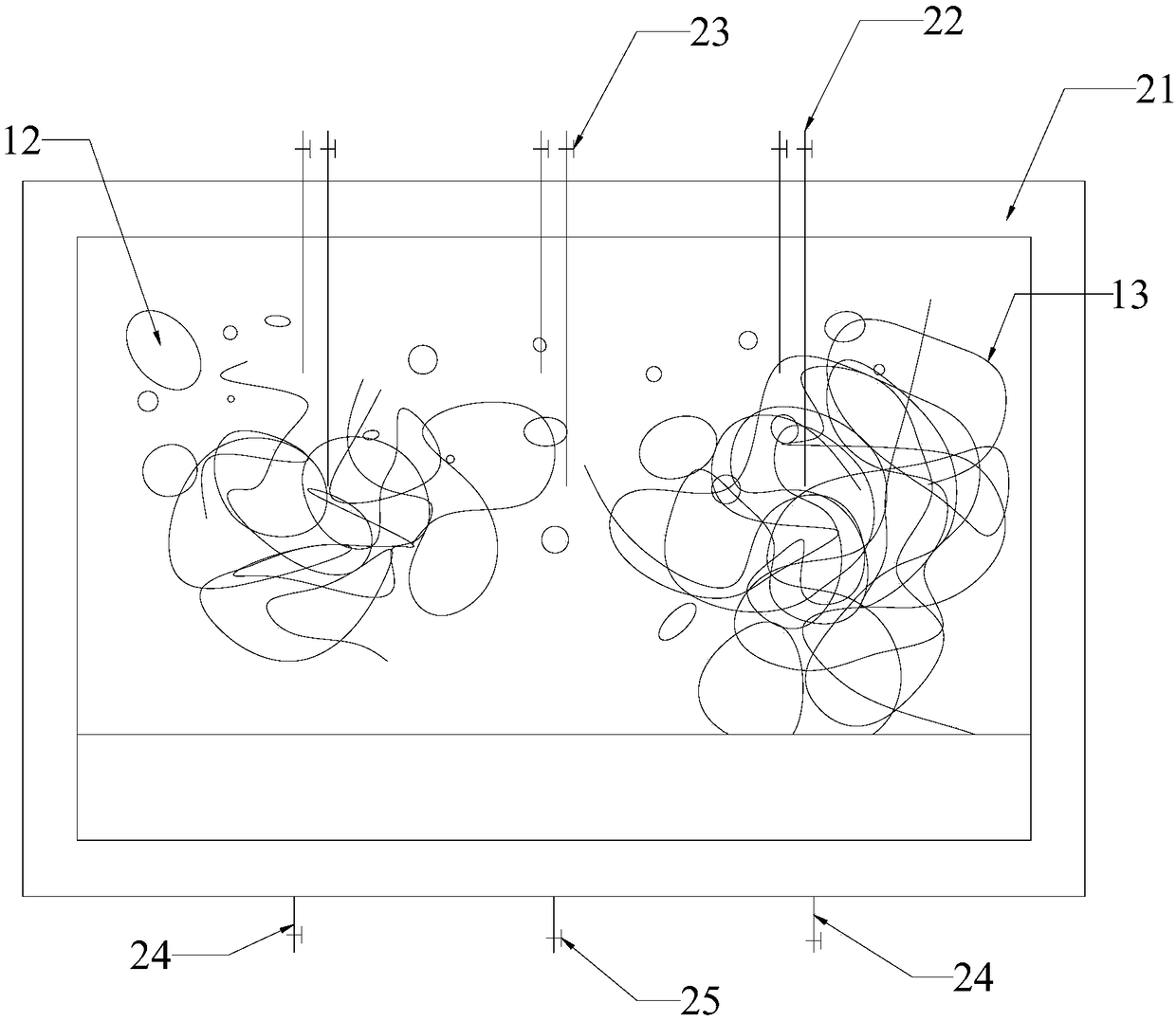

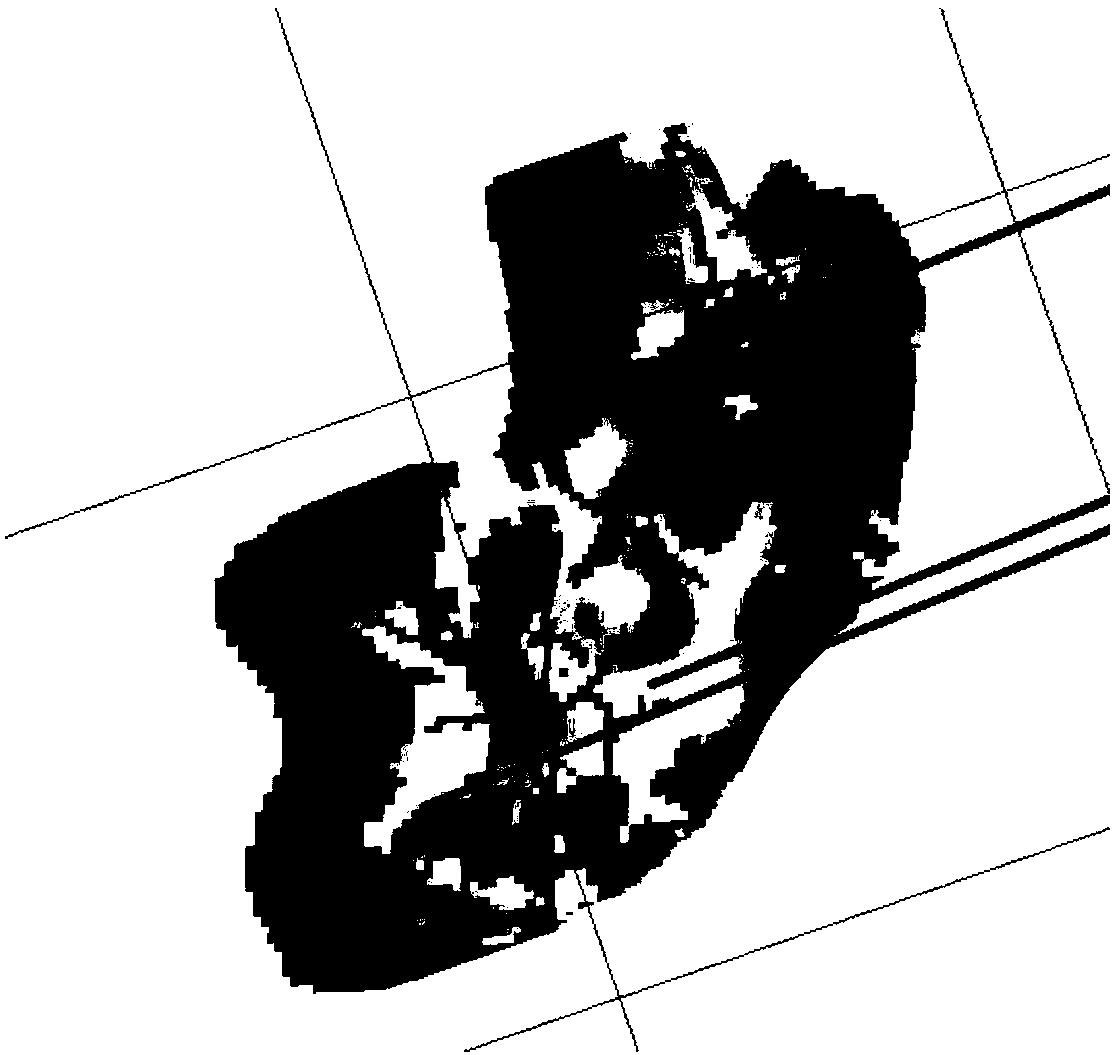

Establishment method for fracture-cave distribution diagram of fracture-cave carbonate reservoir, model and application

ActiveCN108875148AMeet filling requirementsFinely craftedGeometric CADConstructionsProfile diagramGeomorphology

The invention provides an establishment method for a fracture-cave distribution diagram of a fracture-cave carbonate reservoir, a model and an application. The method comprises the following steps ofbased on a built geological model of a target well group region, marking fractures, karst caves and underground rivers, and obtaining a three-dimensional profile structure diagram of the geological model of the target well group region; based on the three-dimensional profile structure diagram, performing layered display on the geological model, and selecting a most representative path between wells of the target well group region to perform two-dimensional cutting connection on the wells, thereby obtaining a two-dimensional profile diagram between the wells; based on the two-dimensional profile diagram, delineating regions of the karst caves and the underground rivers, taking a whole of the delineated closed region as the karst cave region, and obtaining a two-dimensional profile fracture-cave structure depiction diagram; and restoring middle-scale fractures around large-scale fractures in the two-dimensional profile fracture-cave structure depiction diagram, so as to obtain the fracture-cave distribution diagram of the fracture-cave carbonate reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

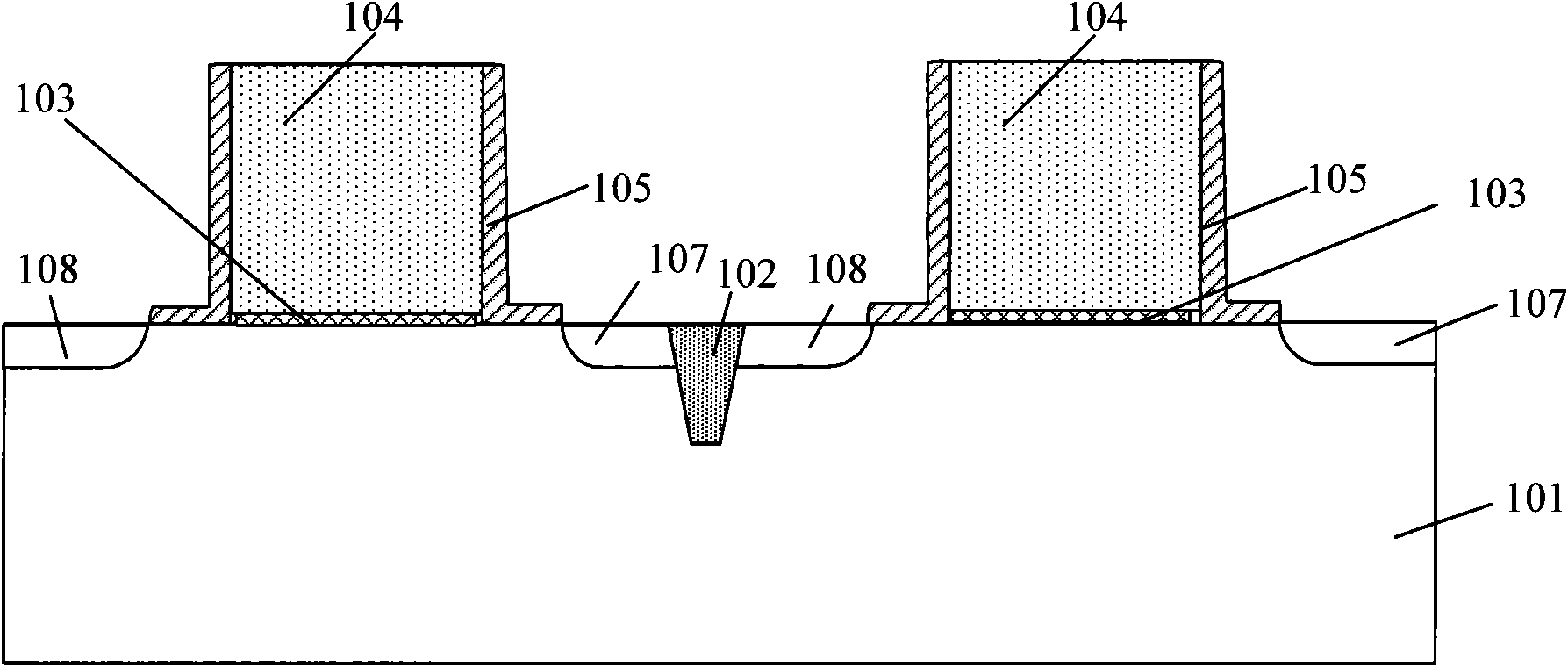

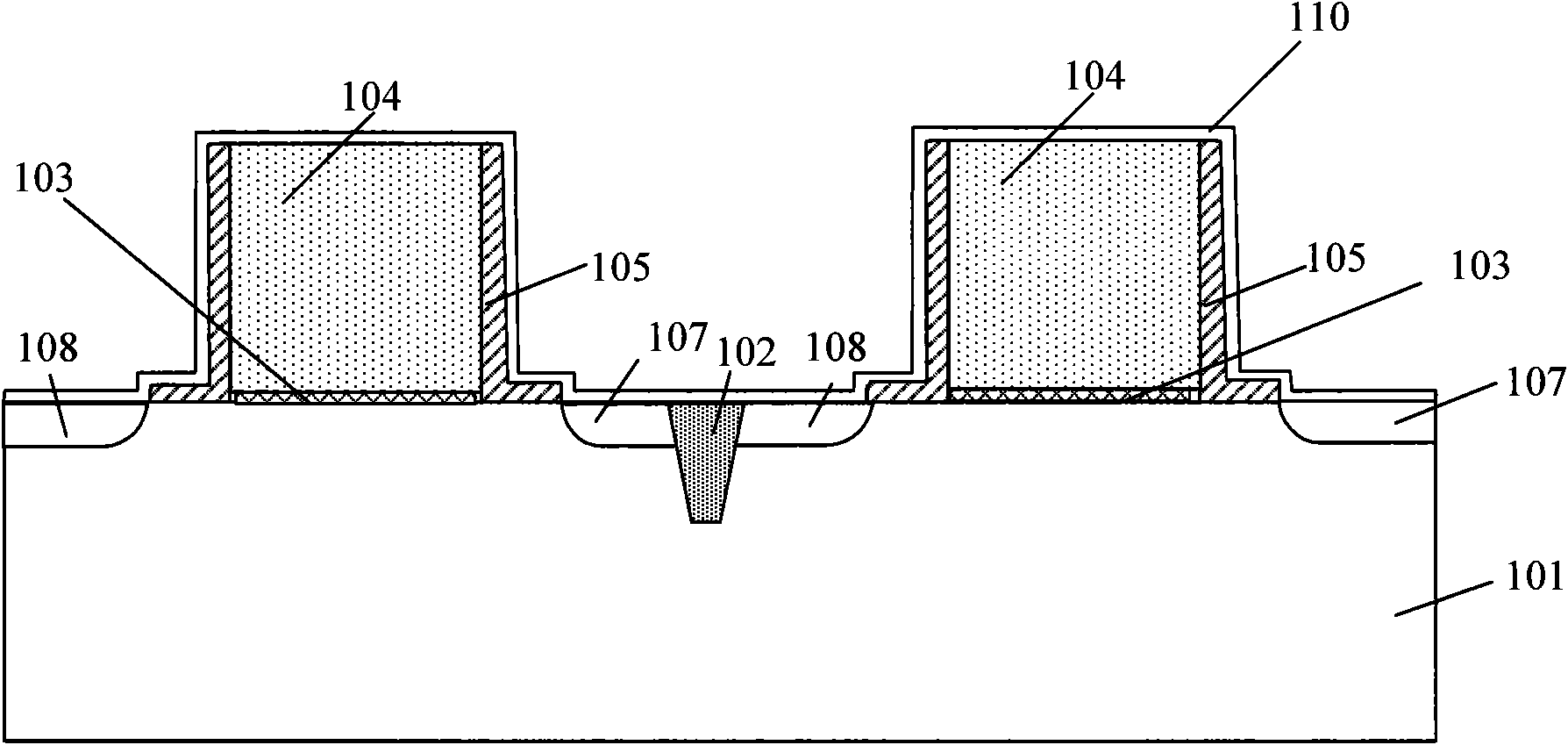

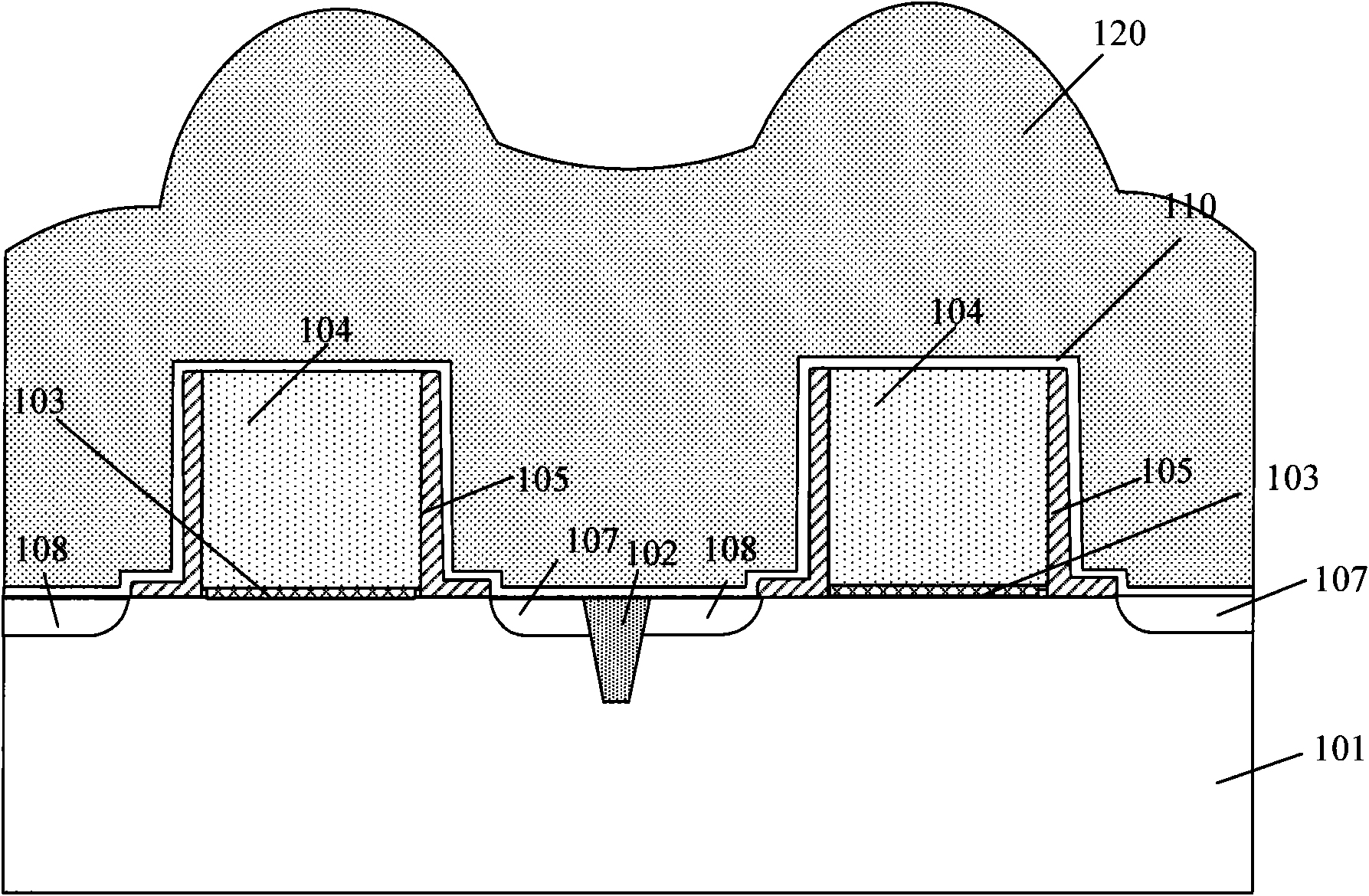

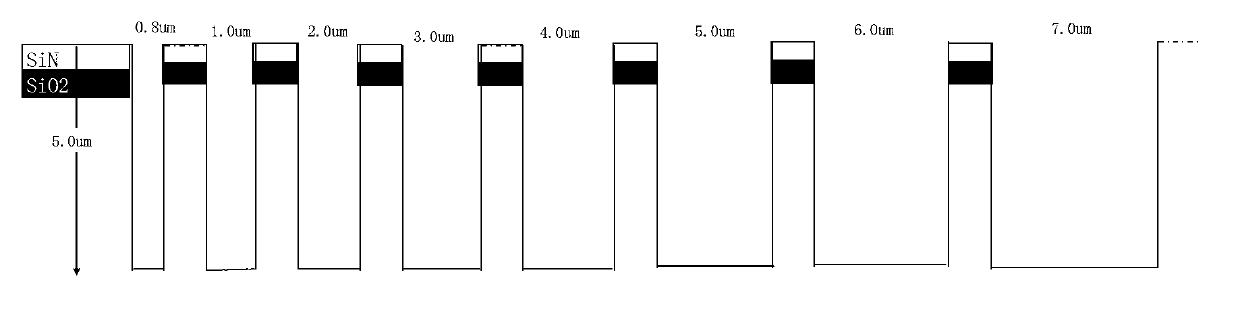

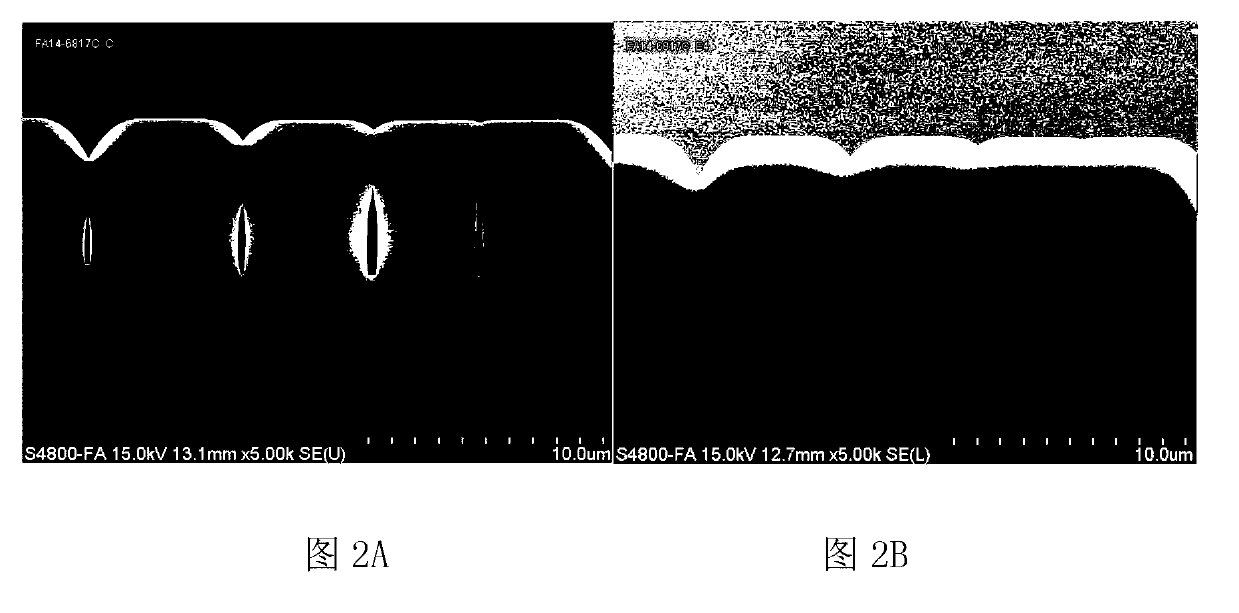

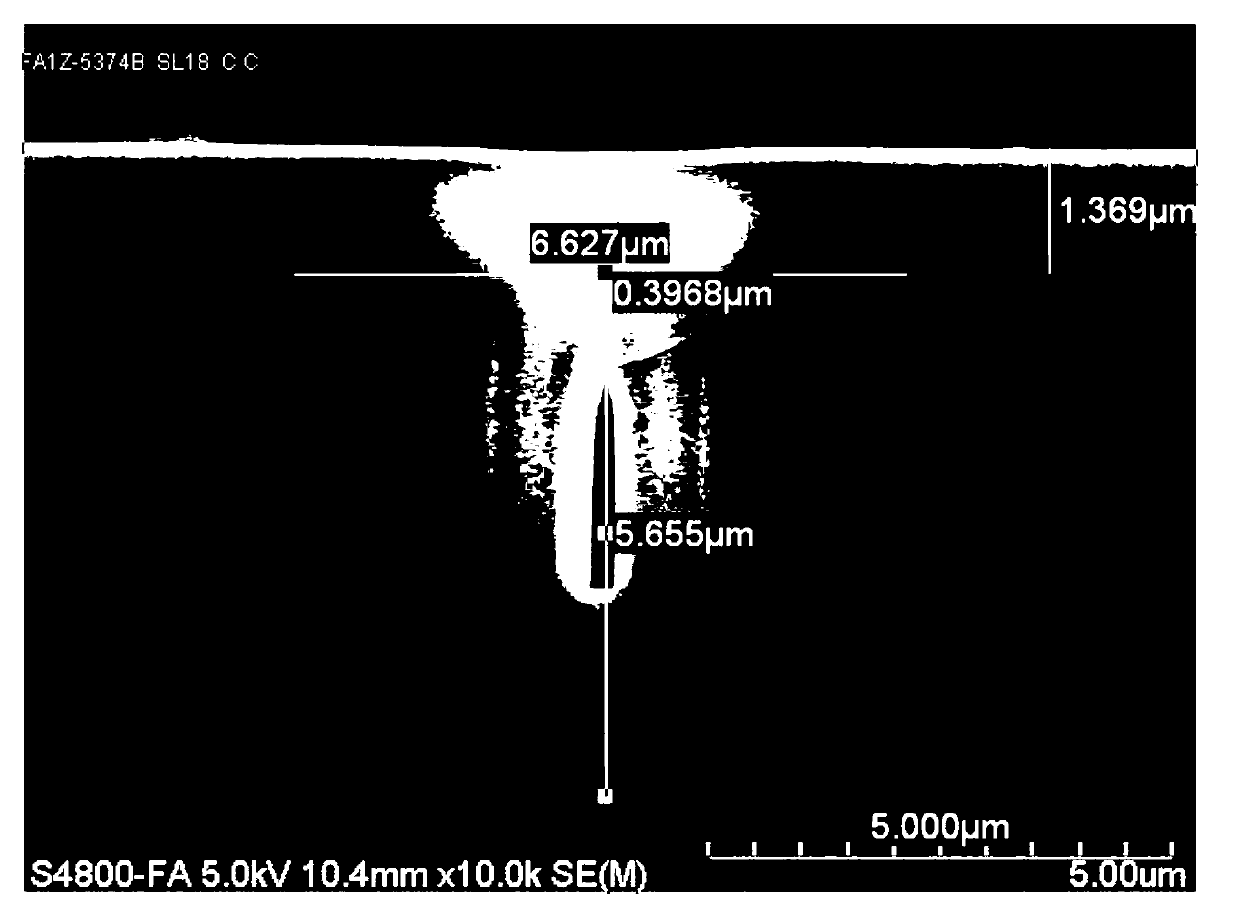

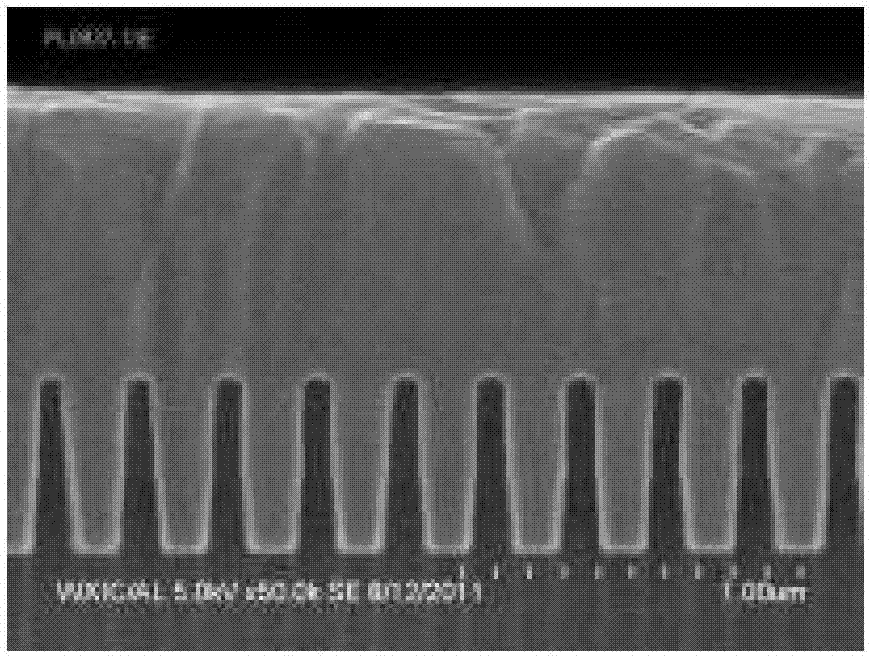

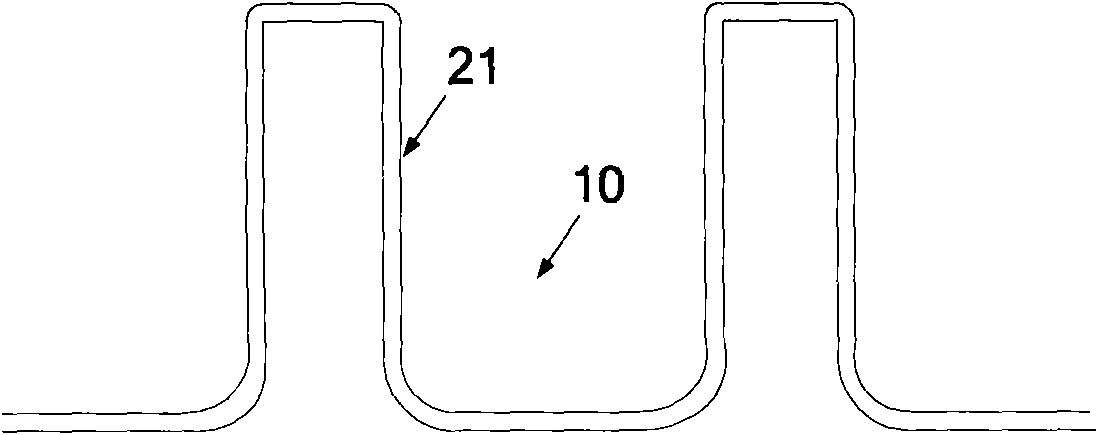

Flattening method of interlayer medium layer and forming method of contact hole

InactiveCN101577244AImprove flatnessMeet filling requirementsSemiconductor/solid-state device manufacturingHigh densityMedia layer

The invention discloses a flattening method of an interlayer medium layer, comprising the following steps: proving a substrate provided with a grid structure; performing high-density plasma chemical vapor deposition on the substrate to form a first interlayer medium layer, wherein the thickness of the first interlayer medium layer is larger than the height of the grid structure; flattening the first interlayer medium layer; and performing plasma enhanced chemical vapor deposition on the substrate which is flattened to form a second interlayer medium layer. The invention also discloses a forming method of a contact hole. Due to the adoption of the flattening method of the interlayer medium layer and the forming method of the contact hole, the planeness of the interlayer medium layers in a wafer can be improved, furthermore, the forming quality and the consistency of each contact hole in the wafer are obviously improved, and the rate of finished products is improved.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

Method for preparing drop pill by high-speed vibration in dropping way

InactiveCN104274322AMeet filling requirementsHigh drug loadingPharmaceutical product form changeMedicinePreparation procedures

The invention relates to the preparation process of a drop pill, in particular to a method for preparing the drop pill. The method is high in medicine loading capacity, simple in preparation procedure and high in production speed. The method comprises the following steps of (1) a material melting step, i.e. putting a medicine and a base material in the weight ratio of 1:5-5:1 into a homogenizer, homogenizing and mixing the materials at the rotation speed of 1,000 to 5,000 rpm for 1 to 200 minutes, and homogenizing the mixture at the rotation speed of 3,000 to 10,000 rpm for 1 to 100 minutes at the temperature of 60 to 100 DEG C to melt the materials, and obtaining a liquid intermediate material; (2) a dropping step, i.e. performing vibration dropping on the liquid intermediate material by a dripper, wherein the vibration frequency is 2 to 2,000Hz, the acceleration speed is 1 to 15G, the dropping pressure is 0.5 to 4.0 Bar, the dripper temperature is 70 to 200 DEG C, and the dropping speed is matched with the material melting speed in the step (1); (3) a condensing step, i.e. quickly cooling and condensing medicine drops which are formed by dropping into uncoated drop pills with the diameter of 0.2 to 4.0mm in a condensing agent, wherein a condensate is selected from liquid paraffin, methyl silicone oil, coal oil or a mixture of the liquid paraffin, the methyl silicone oil and the coal oil, the temperature of the condensate is 30 DEG C below zero to 80 DEG C, and the cooling time is not smaller than 30 seconds.

Owner:TIANJIN TASLY PHARMA CO LTD

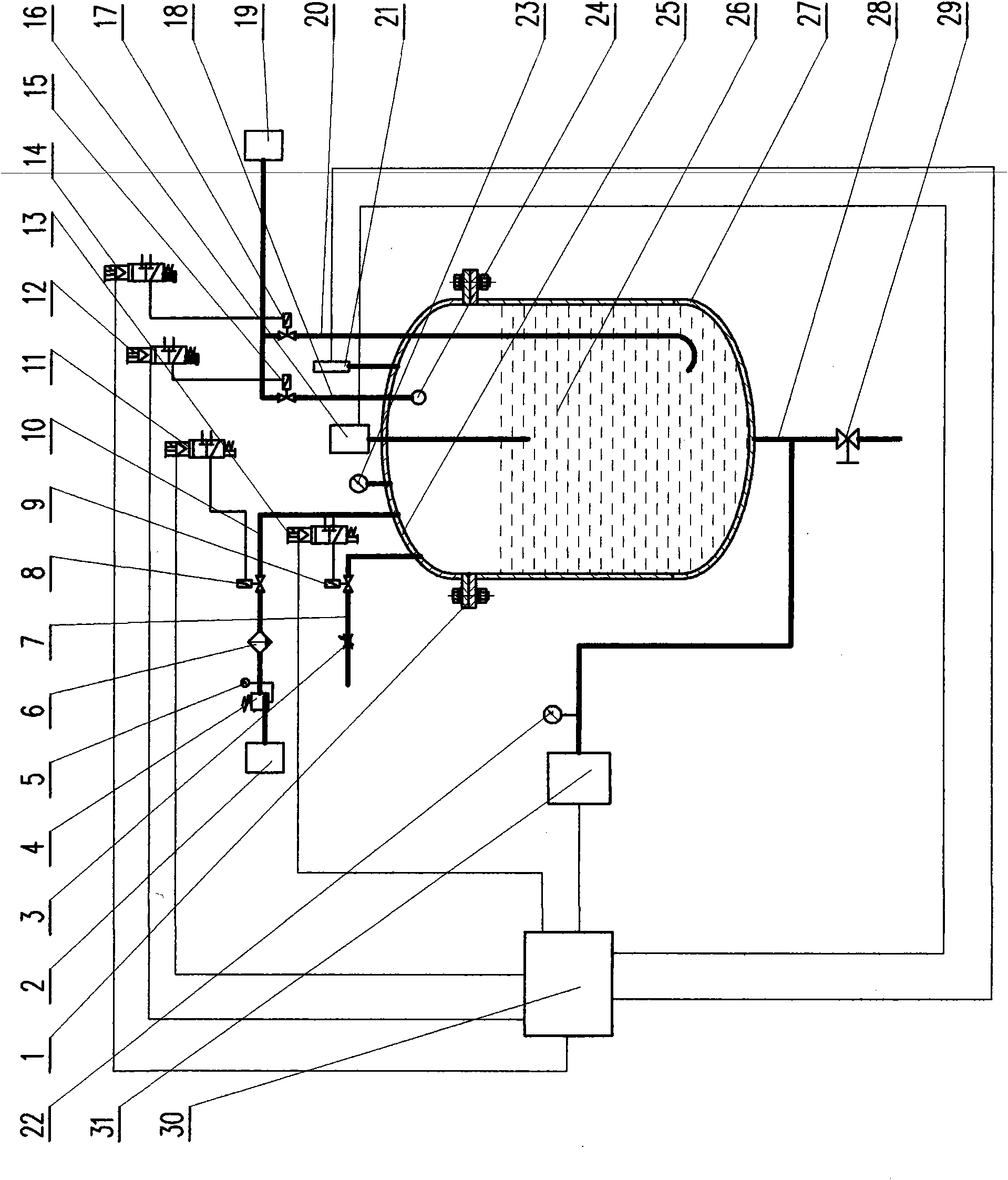

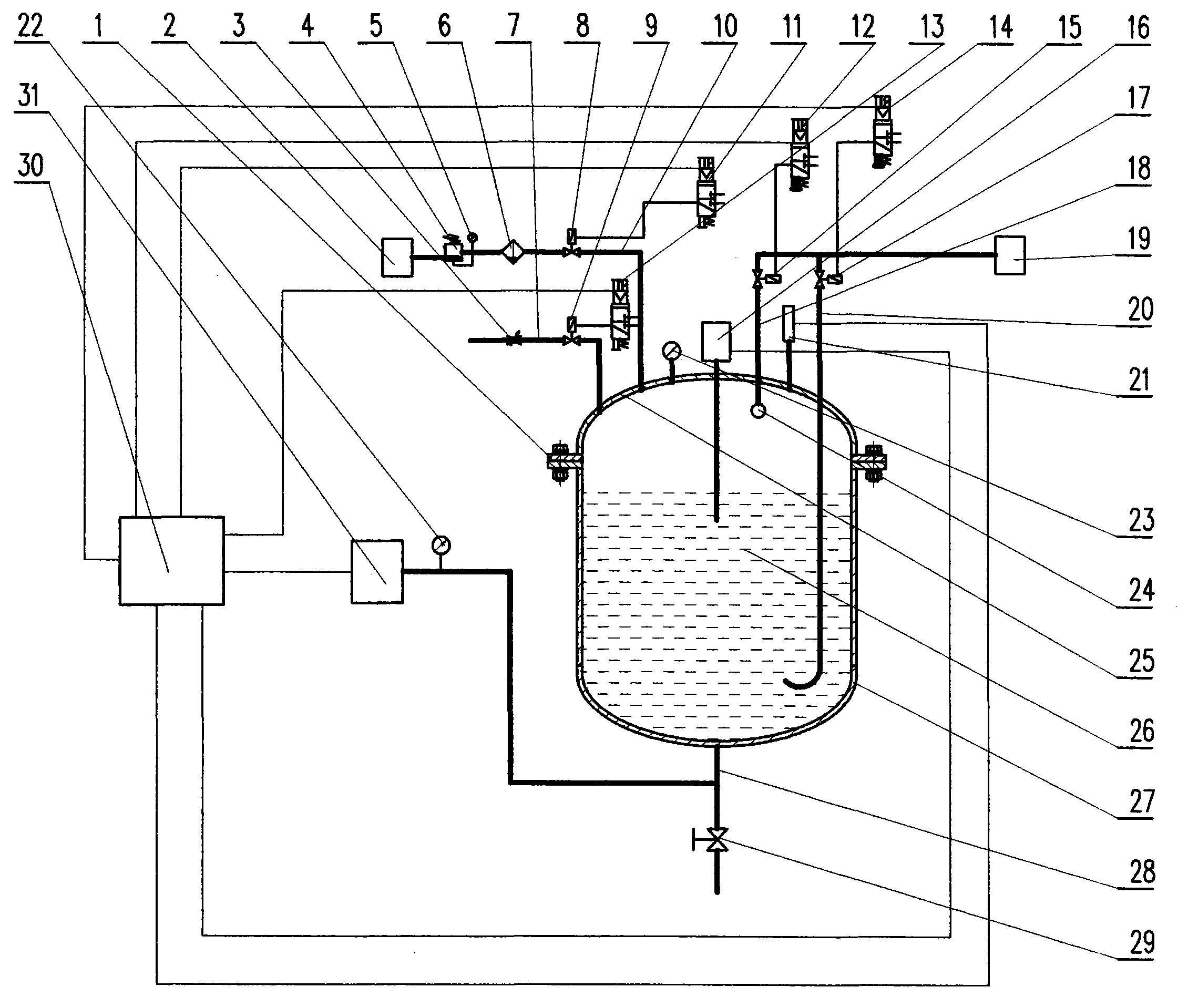

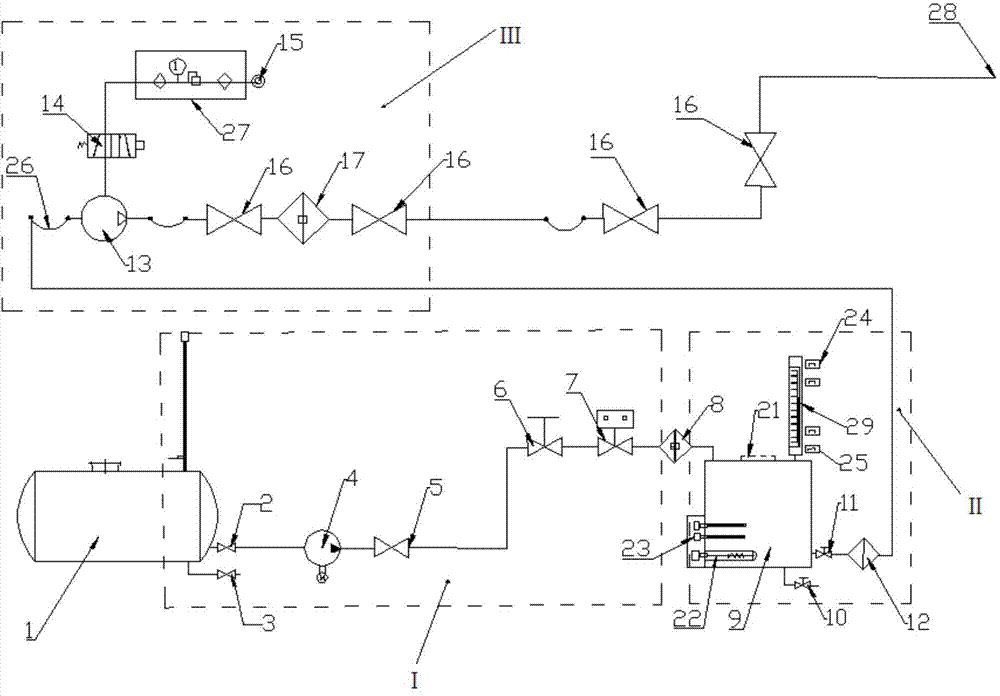

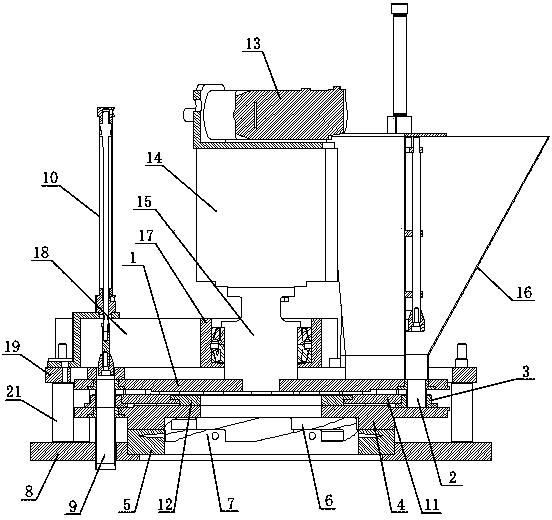

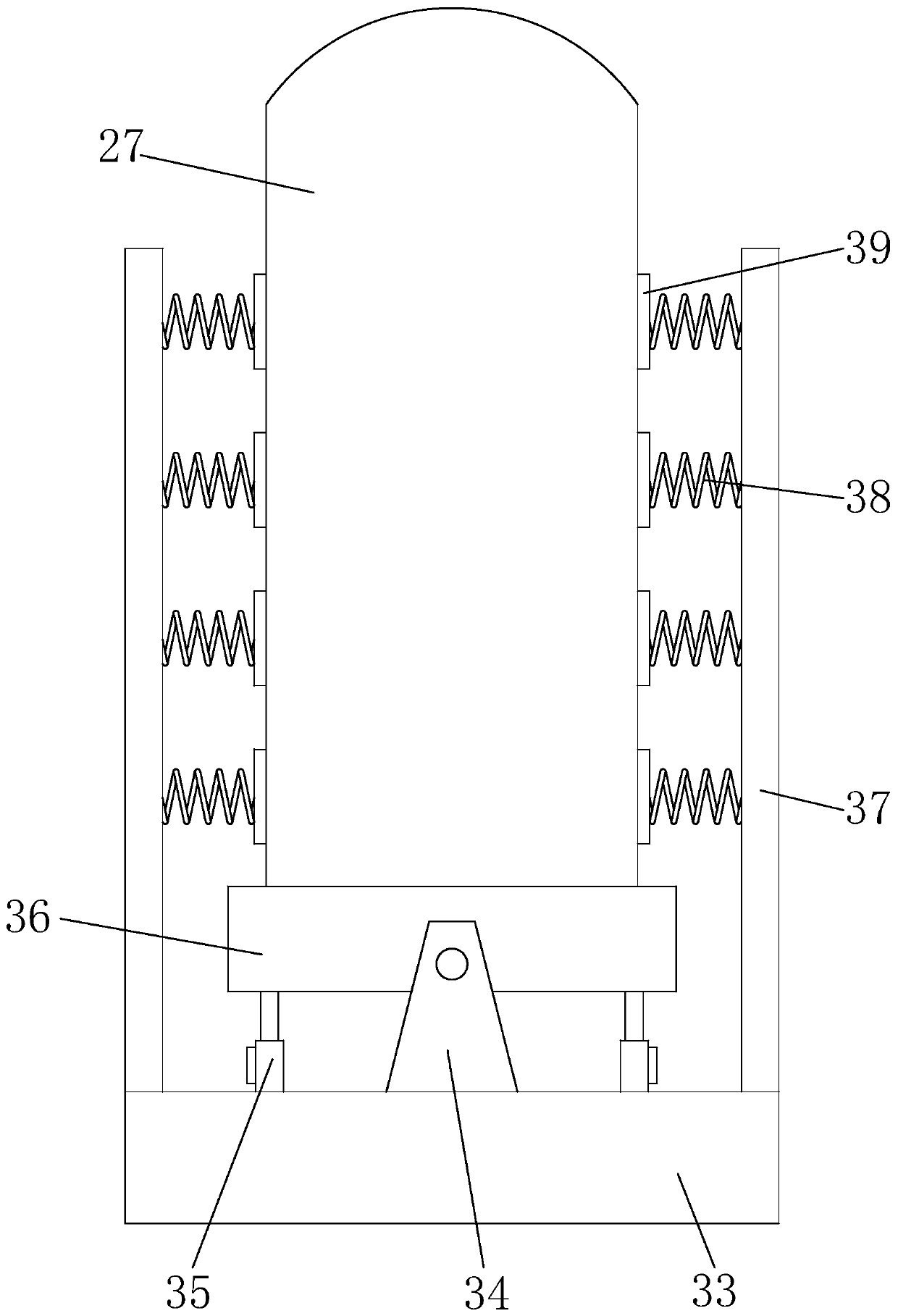

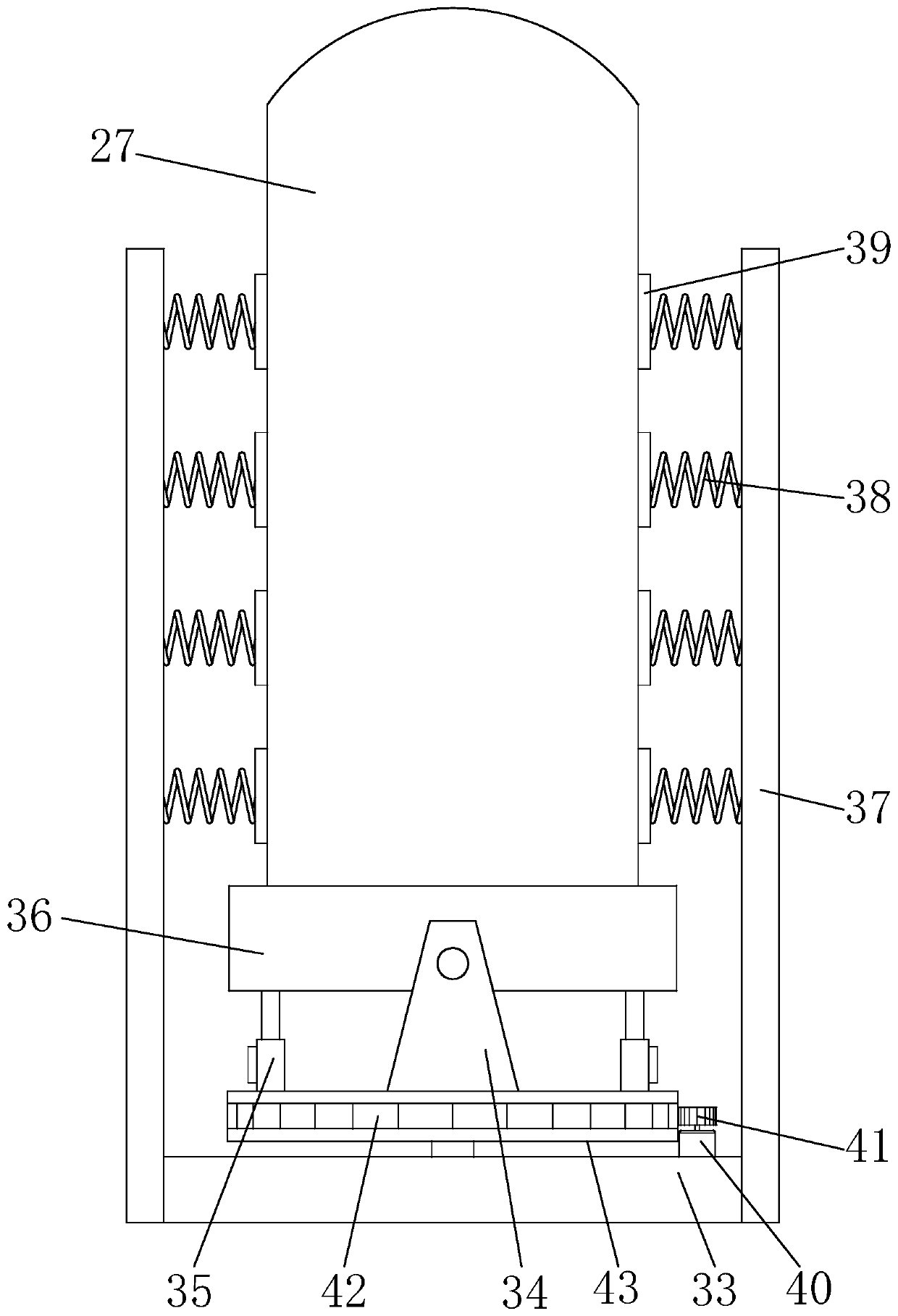

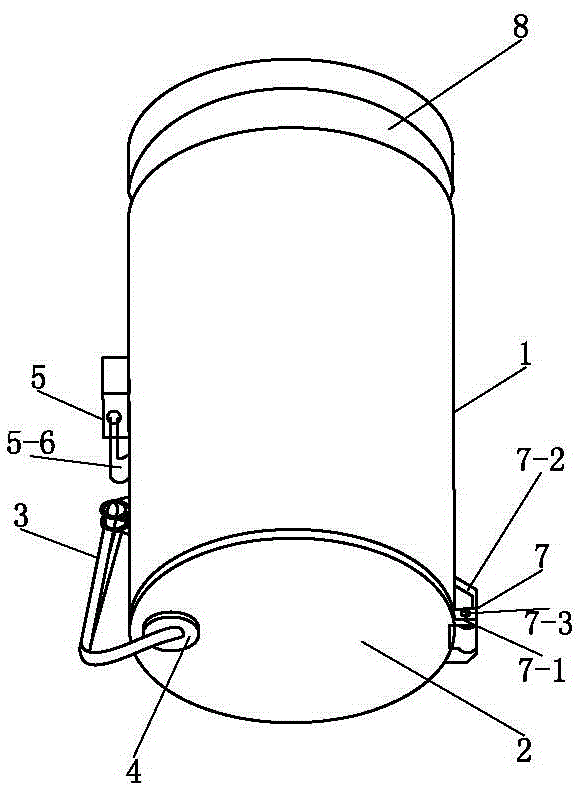

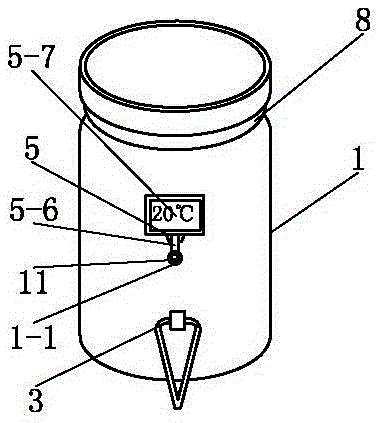

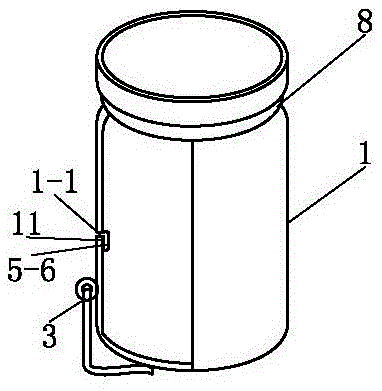

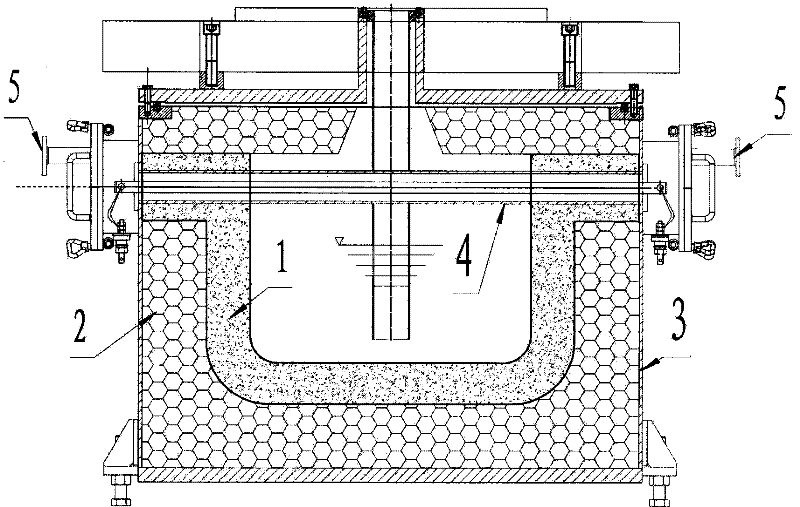

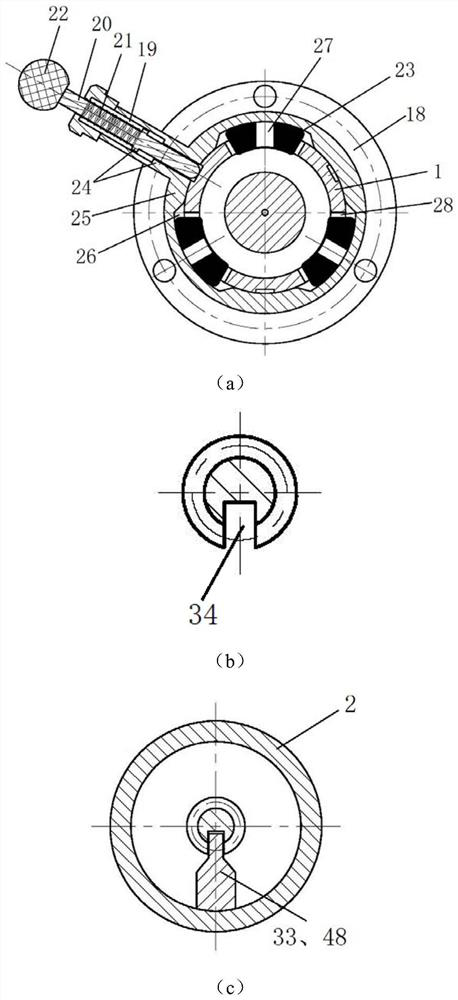

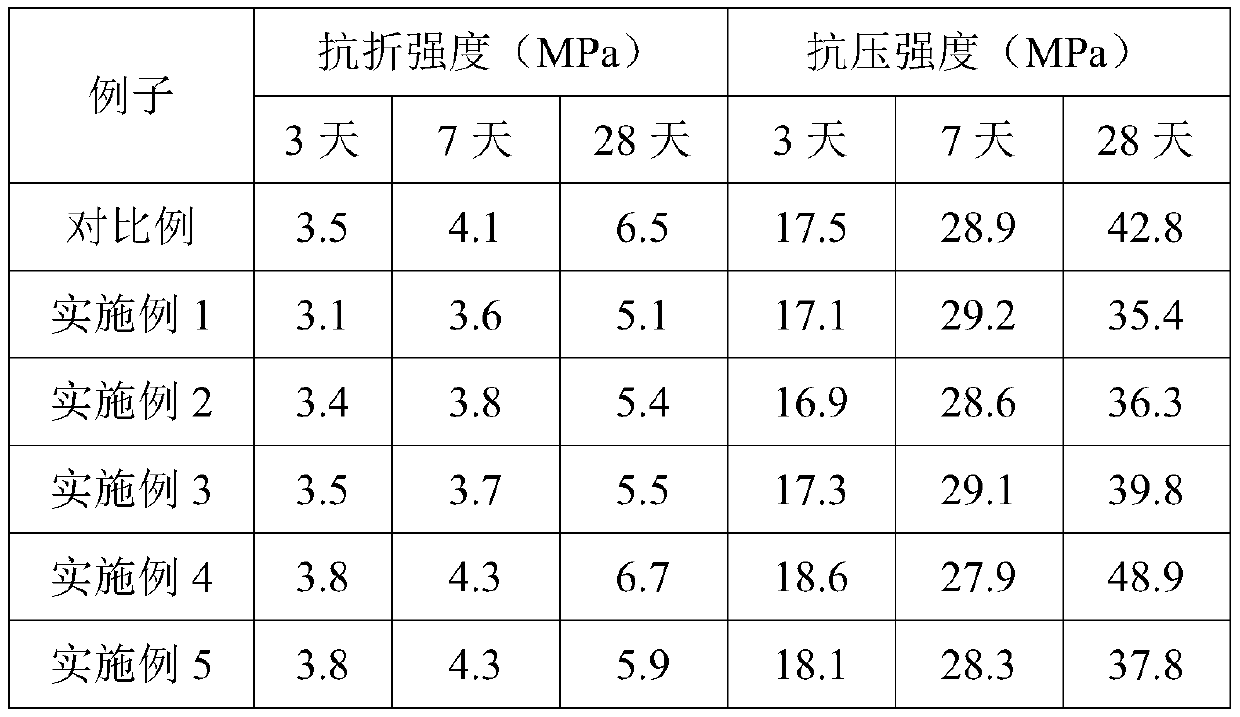

A pressure balance tank that can be cleaned and sterilized online

InactiveCN102275697AMeet filling requirementsRealize automatic adjustmentLarge containersPharmaceutical industryEngineering

The invention discloses a pressure balancing tank capable of realizing online cleaning and sterilization, relating to the technical field of pharmaceutical machinery. The pressure balancing tank is composed of a tank body 27, a tank cover 25, a liquid medicine input component, a pressure balancing component, a liquid outlet pipe 28, a pressure sensor 21, a pressure gauge 23, a liquid level meter 16, a data receiving and processing device 30 and an online cleaning and sterilization input component. The pressure balancing tank has the characteristics of simple structure, convenience in pressureadjustment, stable pressure of liquid medicine and the like, can meet the requirements of liquid medicine filling and realize online cleaning and sterilization, and can be used for conveying liquid medicine of large-volume infusion packages in the pharmaceutical industry and can also be used for conveying liquid raw materials in packages of other industries.

Owner:长沙汇一制药机械有限公司

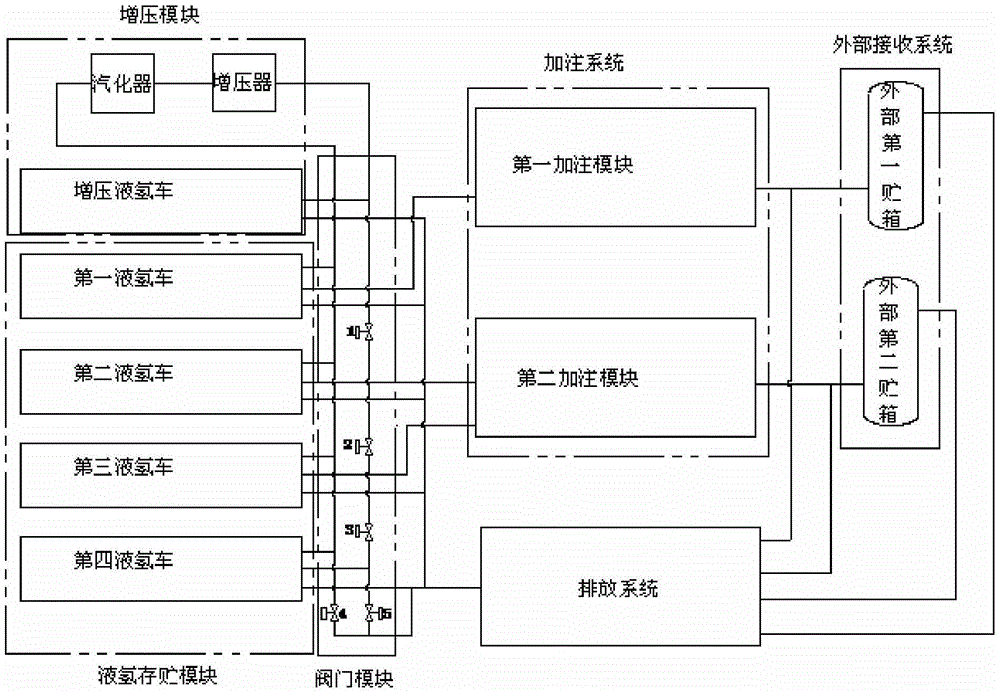

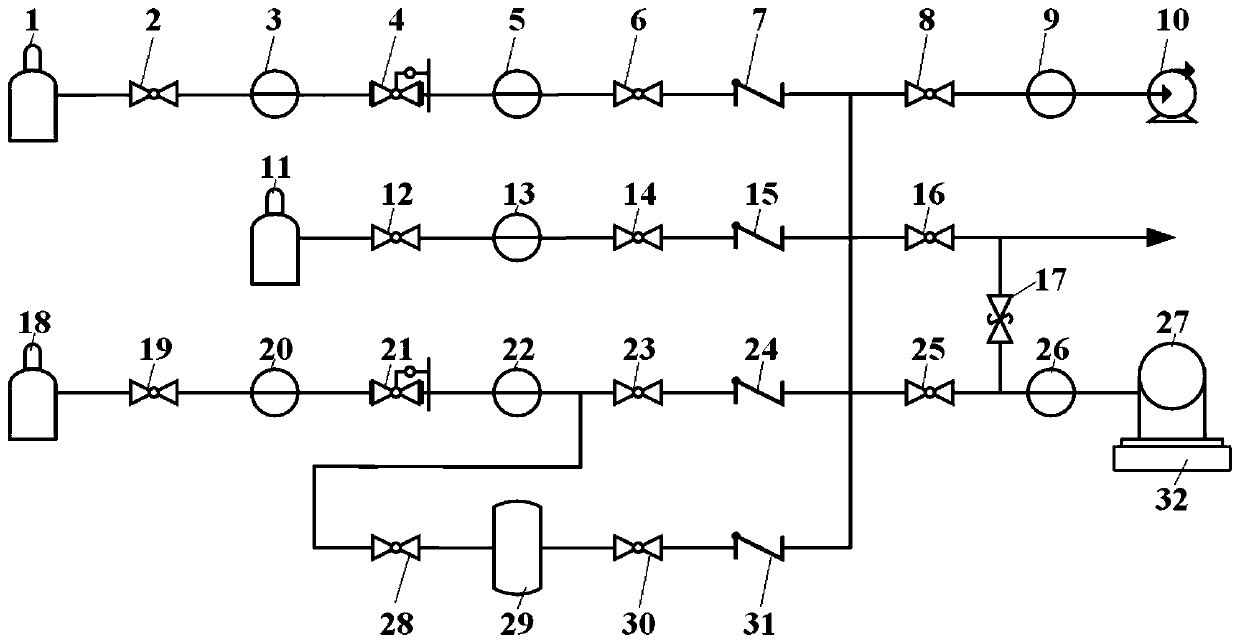

Liquid hydrogen loading system

ActiveCN105650460AChieve raiseRealize additionalVessel mounting detailsVessel geometry/arrangement/sizeTransfer systemQuality assurance

The invention discloses a liquid hydrogen loading system and relates to the field of low-temperature medium loading and transferring systems. The liquid hydrogen loading system comprises a pressurizing module, a liquid hydrogen storage module, a valve module, a loading system, a liquid hydrogen discharge system and an external receiving system. According to the liquid hydrogen loading system, through adoption of the liquid hydrogen extruding loading technology, the liquid hydrogen loading key equipment redundancy design, the loading flow distributing and adjusting technology, the pipeline flexible design, the liquid hydrogen propellant quality assurance technology and the like, purposes that the maximum pipeline drift diameter is DN150, the liquid hydrogen loading volume is 430 m<3>, the maximum loading flow is about 8,000 L / min and two storage tanks of a rocket can be loaded simultaneously are achieved, the safety and the reliability of a ground loading system are guaranteed, and the reliability of the liquid hydrogen loading system and the overall capability of a low-temperature loading system are improved.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

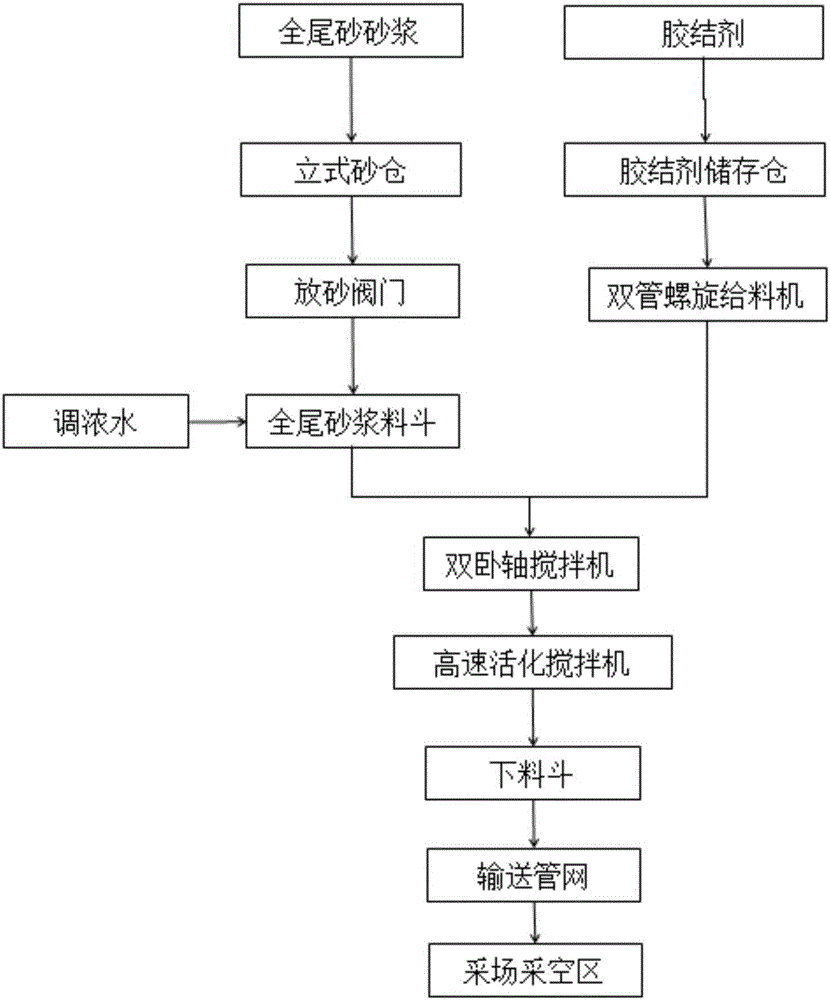

Mass flow high density structure flow entire-tailing cemented filling technology

InactiveCN106065782AEnhance mining safetyReasonable strength structureMaterial fill-upSocial benefitsHigh density

The invention discloses a mass flow high density structure flow entire-tailing cemented filling technology comprising the following steps: allowing entire-tailing mortar, a cementing agent and proper amount of concentration adjusted water to enter a feed hopper through each material supply line, wherein said materials are then conveyed to a stirrer, and all ingredients of the filling material are fully evenly stirred so as to prepare the filling slurry with proper concentration and excellent fluidity, i.e., the structure flow status can be formed; allowing the filling slurry to finally enter a filling slurry discharge hopper, wherein the filling slurry can be conveyed to fill underground stope goaf through filling drill holes and an underground filling pipe network through self-flow, thus realizing large structure stope non-interrupted high density self-flow filling, wherein the sand-lime ratio can be adjusted according to filling body intensity requirements. The mass flow high density structure flow entire-tailing cemented filling technology can satisfy large structure stope, high preparation capability, high preparation precision, and high density structure flow entire-tailing colloid filling requirements, can reduce filling cost, so the goaf filling tailings final concentration can be above 70-73%; the filing body intensity structure is reasonable, thus enhancing stope back production safety, and providing large economic benefits and social benefits.

Owner:ANHUI KAIFA MINING IND

Liquid lubricating oil winter filling system

InactiveCN104776308AMeet filling requirementsGuaranteed heating safetyMachines/enginesLubricant filling/drainingProduction lineControl system

The invention discloses a liquid lubricating oil winter filling system, comprising an oil storage tank; the oil storage tank is communicated with a heating control system by a liquid replenishing pipeline; the heating control system heats lubricating oil fed by the oil storage tank and controls temperature of the lubricating oil; the heating control system is connected with a filling control system; the filling control system conveys the lubricating oil to filling points of a production line by a pipeline. By the lubricating oil filling system, the problem that the lubricating oil is slowly filled in winter, and cannot meet the production pace is solved; in the past, when vehicles are produced, oil is slowly filled and can only meet the demands of 8 vehicles every day, by heating the lubricating oil through the lubricating oil filling system, the viscosity of the lubricating oil is reduced, the fluidity is increased, the production demand on 40 vehicles every day is met, and the efficiency is improved by more than 5 times; the heating temperature is below 35 DEG C, the performance of the lubricating oil is not changed and good oil quality is ensured.

Owner:SINO TRUK JINAN POWER

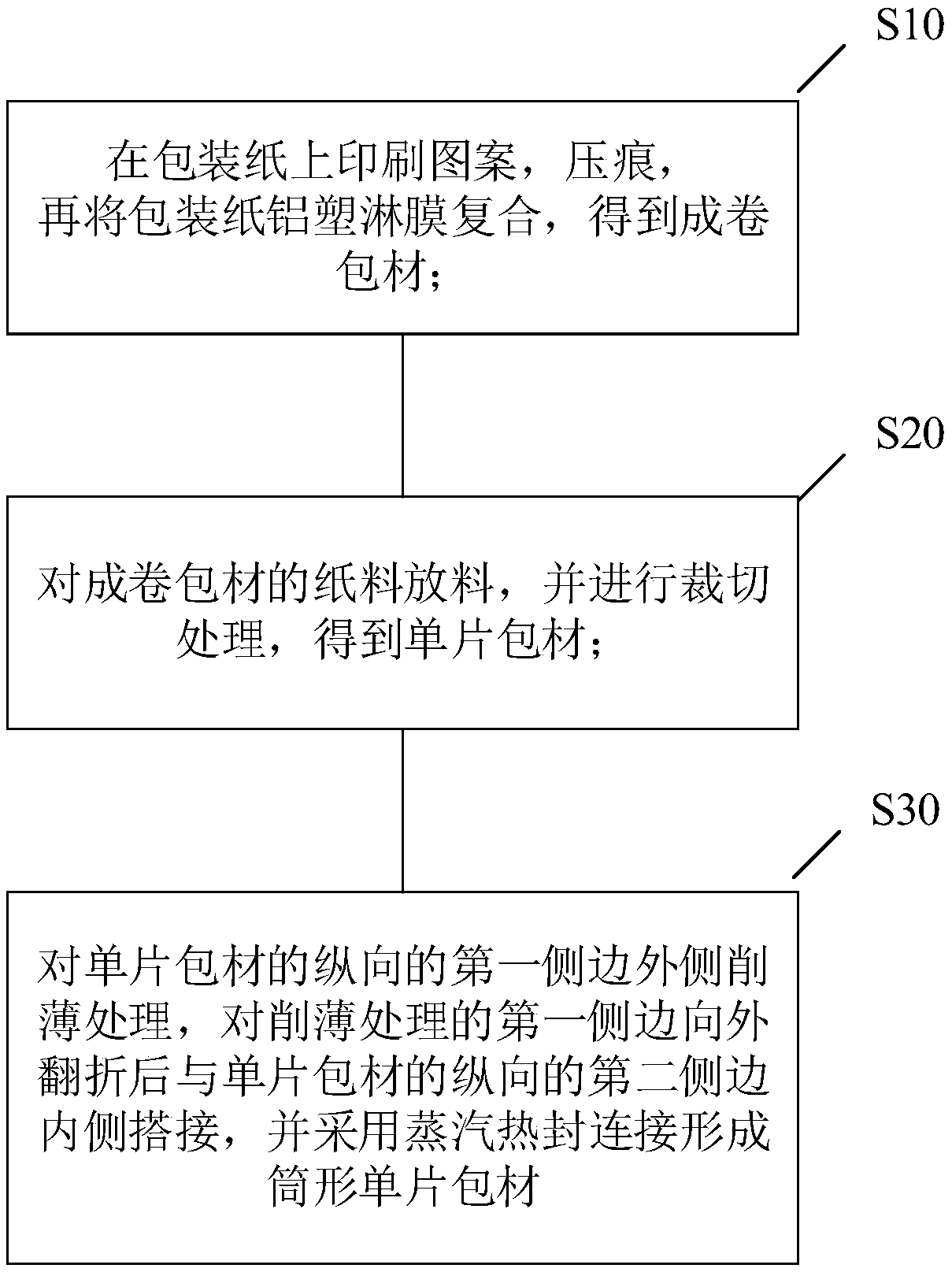

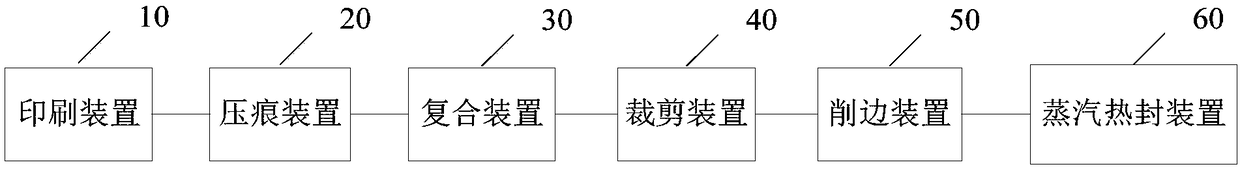

Packaging box and single-sheet packaging box prefabricating material and forming method and system thereof

PendingCN109454924AImprove yieldImprove leakageSpecial paperBox making operationsLap jointEngineering

The invention discloses a packaging box, a single-sheet packaging box prefabricating material and a forming method and system thereof. The forming method of the single-sheet packaging box prefabricating material comprises the following steps that S10, patterns are printed on packaging paper, indenting is carried out, the packaging paper and an aluminum plastic laminating film are compounded, and arolled packaging material is obtained; and S20, paper of the rolled packaging material is discharged, cutting is carried out, and a single-sheet packaging material is obtained; S30, the outer side ofthe first longitudinal side of the single-sheet packaging material is thinned, the thinned first side is turned outwards to be in lap joint with the inner side of the longitudinal second side of thesingle-sheet packaging material, steam heat sealing connection is adopted, and a barrel-shaped single-sheet packaging material is formed. According to the packaging box, the single-sheet packaging boxprefabricating material and the forming method and system thereof, the packaging paper is printed and indented, and then combining, cutting, edge cutting and steam heat sealing are carried out; on one hand, the problem that printed content is likely to be separated is avoided; and on the other hand, the yield of the single-sheet packaging box is increased, and the problem of packaging box leakageis relieved.

Owner:GREATVIEW BEIJING TRADING CO LTD

Method for dropping drop pills by vibration

InactiveCN104274319AReduce the amount of excipients and dosageIncrease production capacityPharmaceutical product form changeDropped headPreparation procedures

The invention relates to a preparation process of drop pills and particularly relates to a drop pill preparation method which has high drug loading capacity, and is simple in preparation procedure and high in production speed. The method comprises the following steps: (1) heating and fusing drugs and auxiliary base materials; (2) conveying fused drug liquid to a dropping head and dropping out the drug liquid by using a vibration dropping method; (3) cooling by low-temperature gas to obtain the drop pills.

Owner:TIANJIN TASLY PHARMA CO LTD

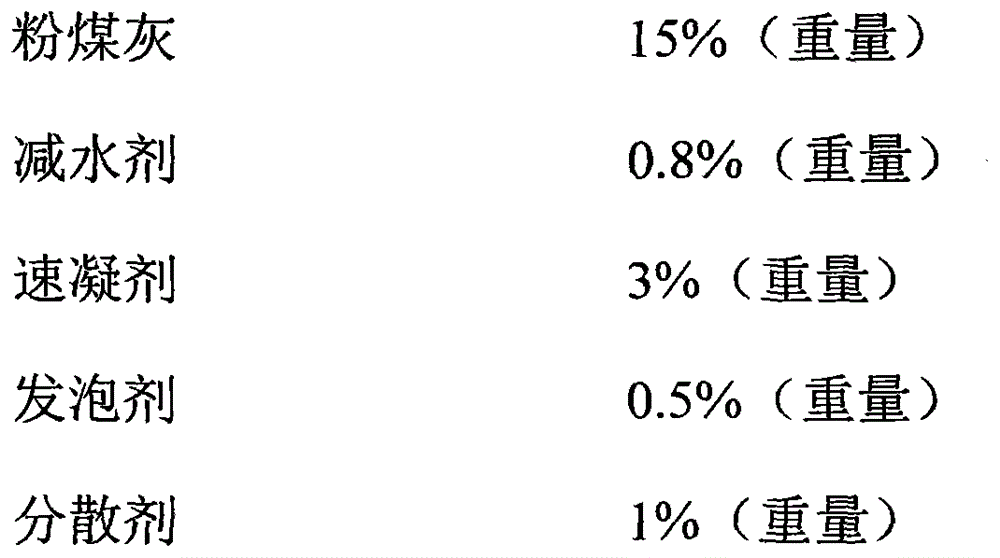

Lightweight quick setting top-caving area filling material

The invention discloses a lightweight quick setting top-caving area filling material. The lightweight quick setting top-caving area filling material is mixed by primary materials B and primary materials B, wherein the primary materials consist of sulfate aluminum cement, coal ash, a water reducer, a setting accelerator, a foaming agent and a dispersing agent; the primary materials B consist of gypsum, lime, a water reducer, a setting accelerator, a dispersing agent and a foaming agent. The lightweight quick setting top-caving area filling material has the lightweight quick setting characteristic; after entering and filling into a top-caving area, the foamed slurry can quickly lose mobility and is solidified within 5 minutes to form a lightweight filling body, wherein the density of the filling body is about 1.4t / m<3>, the 2h uniaxial compressive strength can reach 4 MPa, certain compression performances are provided, the performances of the filling body are stable, the cracking deformation is avoided, and the filling needs of the top-caving area can be met very well.

Owner:HENAN COLLEGE OF IND & INFORMATION TECH

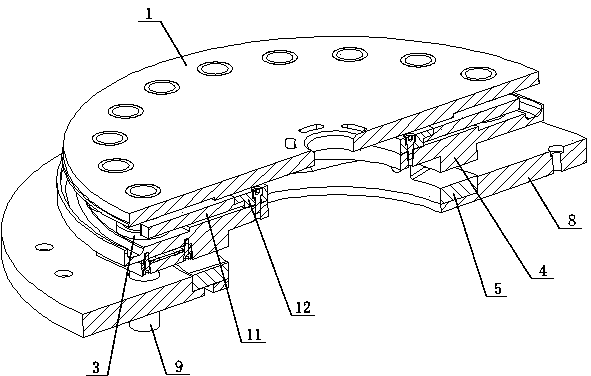

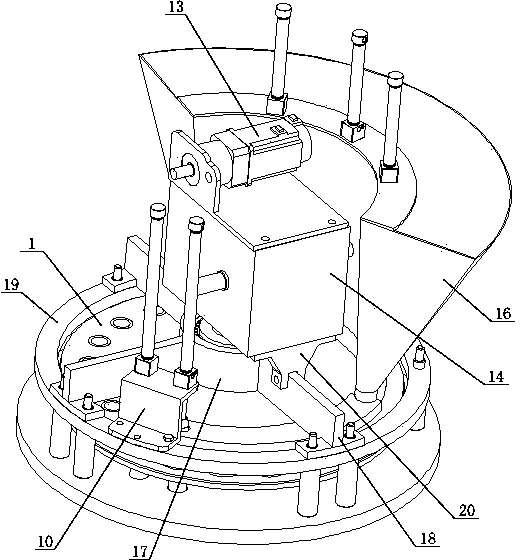

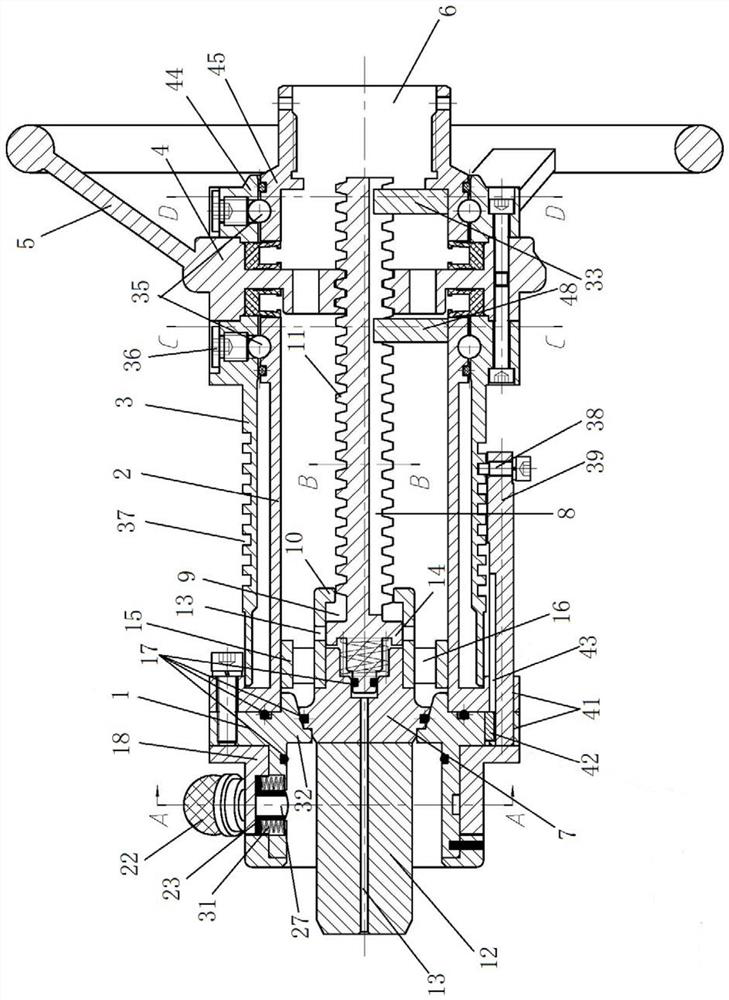

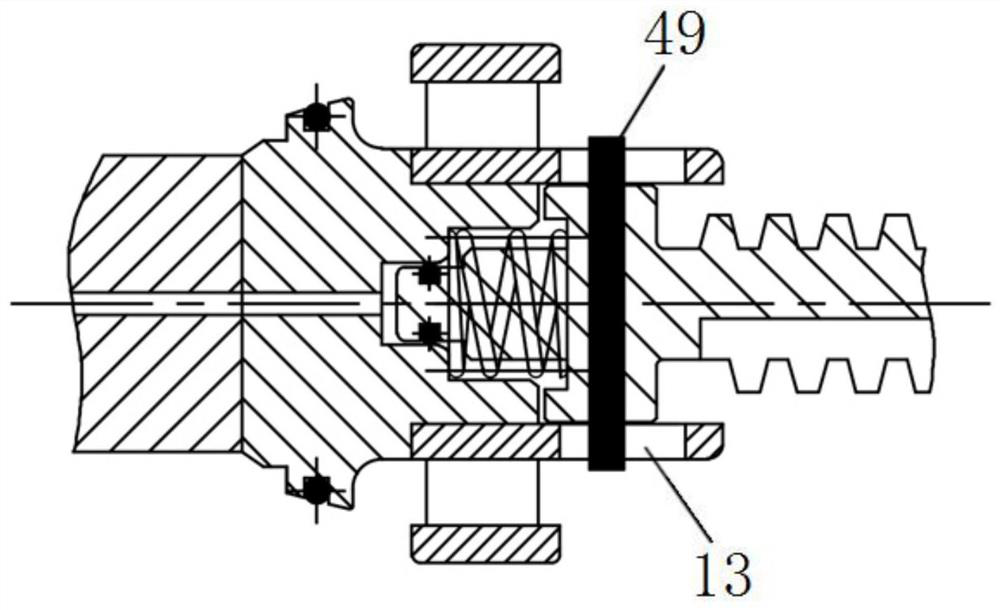

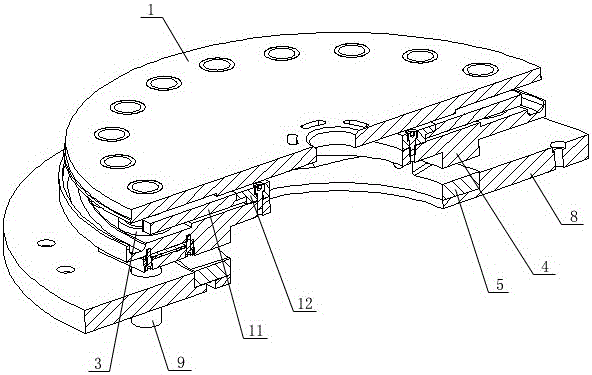

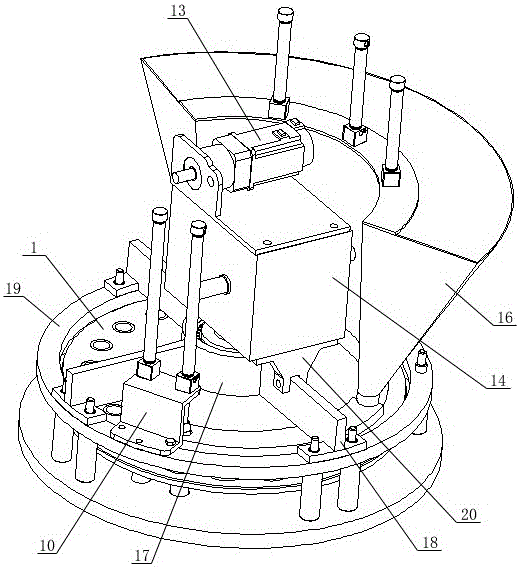

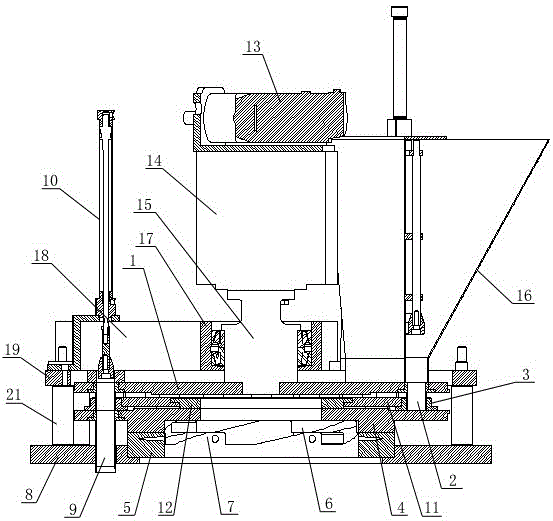

Measuring adjustable turntable device used for filling machine

ActiveCN103847994ARealize moving up and downMeet filling requirementsLiquid materialEngineeringMeasuring cup

The invention discloses a measuring adjustable turntable device used for a filling machine. The measuring adjustable turntable device used for the filling machine comprises a turntable and a plurality of measuring cups arranged on the turntable, wherein the turntable is connected with a turntable driving device, adjustable sleeves are sleeved at the lower parts of the measuring cups, the adjustable sleeves are arranged on a movable plate under the turntable, an adjustable plate is arranged under the movable plate and supports the movable plate, a first boss is arranged on the lower end surface of the movable plate, a second boss is arranged on the upper end surface of the adjustable plate and corresponds to and matches with the first boss, the adjustable plate is connected with a rotating and driving mechanism, and the movable plate can move up and down along a shaft through the rotation of the movable plate. Through the matching of the corresponding bosses on the adjustable plate and on the movable plate and the rotation of the adjustable plate, the movable plate can move up and down, and meanwhile, the adjustable sleeves on the movable plate move up and down relative to the measuring cups. The reserve volume formed between the measuring cups and the adjustable sleeves changes so that the specific filling requirements can be satisfied.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

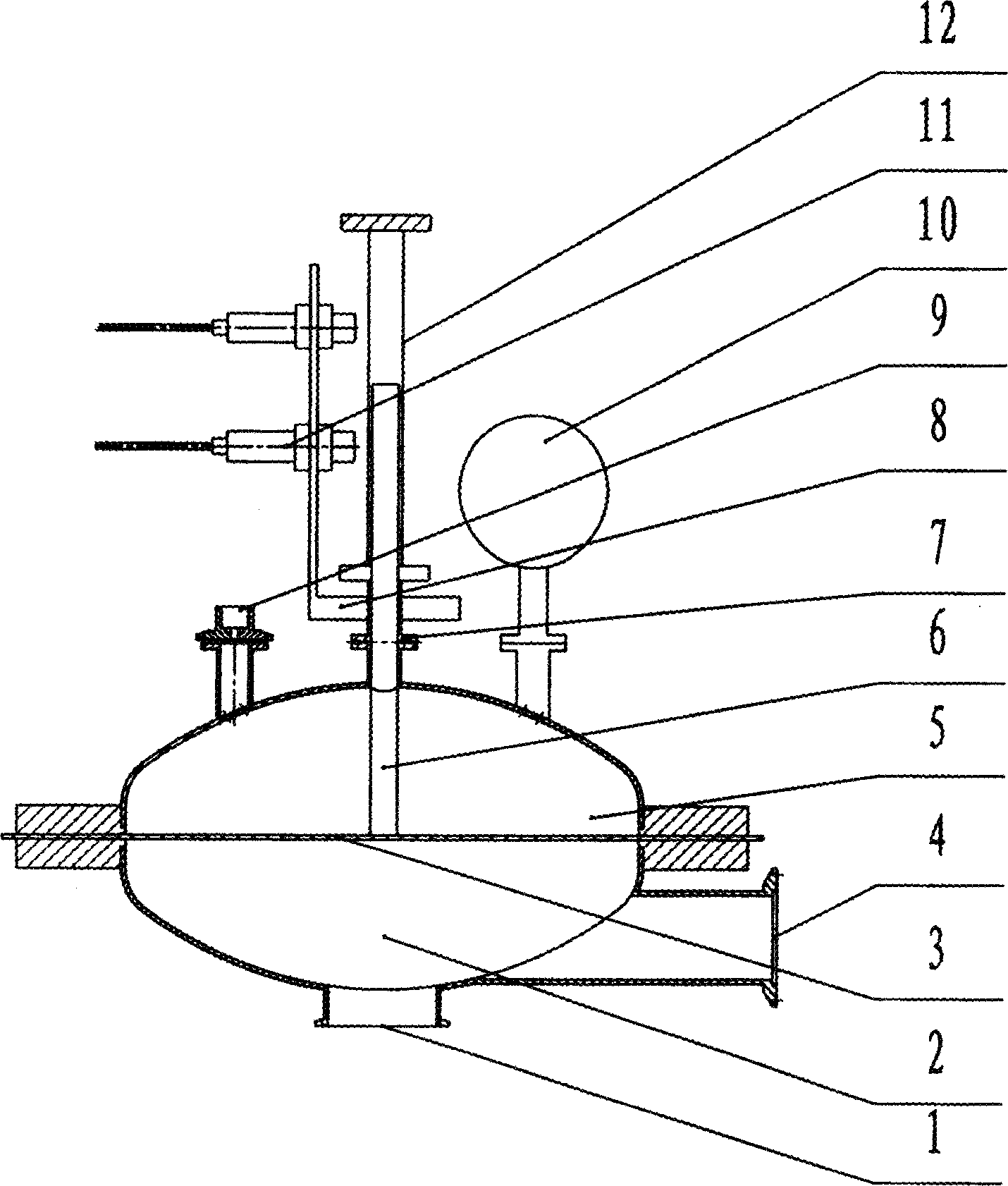

Pressure balancing tank

InactiveCN1868858AEasy pressure adjustmentLarge adjustment rangeLiquid bottlingEngineeringPressure balance

A pressure balanced tank with stable pouring pressure for the liquid contained in it features that a buffer membrane is used to divide the internal cavity of tank body into an upper gas cavity with gas inlet and outlet having relative gas valves, and a lower liquid cavity with liquid inlet and outlet, and a membrane position indicating column with a lower end in contact with said buffer membrane passes through said gas cavity. It can quickly compensate the pressure loss caused by pouring liquid.

Owner:SHINVA MEDICAL INSTR CO LTD

Fire extinguishing agent filling equipment and filling method thereof

ActiveCN110778912AGood for vacuuming and leak detectionReduce filling pressure errorVessel geometry/arrangement/sizeFire rescuePumping vacuumNitrogen gas

The invention discloses fire extinguishing agent filling equipment and a filling method thereof. The equipment comprises a vacuum pump, a first storage container, a first filling assembly, a second storage container, a second filling assembly, a third storage container, a third filling assembly, a fourth storage container and a fourth filling assembly. According to the fire extinguishing agent filling equipment, a fire extinguisher is vacuumized through the vacuum pump, and then the fire extinguisher is sequentially filled with at least one solvent stored in the second storage container through the second filling assembly, helium stored in the third storage container through the third filling assembly, at least one fire extinguishing agent stored in the first storage container through thefirst filling assembly, and nitrogen stored in the third storage container. According to the fire extinguishing agent filling equipment and the filling method thereof, vacuumizing and leakage detection are facilitated, the internal air pressure of the fire extinguisher is increased, the fire-extinguishing-agent filling pressure error caused by pipeline factors is effectively reduced, therefore thefilling efficiency is improved, and various filling requirements are met.

Owner:安徽英杰精工机械股份有限公司

Method for preparing paste filling material by using oil shale waste residue

ActiveCN102108020AAvoid accumulationMeet filling requirementsSolid waste managementSlagEconomic benefits

The invention discloses a method for preparing paste filling material by using oil shale waste residue, which comprises the following steps: (1) crushing oil shale waste residue and screening to obtain oil shale waste residue aggregate; (2) mixing oil shale waste residue with quick lime, grinding for 15 to 60 minutes to obtain 300 to 600-mesh oil shale waste residue fine powder for later use; (3) grinding water tempered slag ash to obtain 300 to 600-mesh water tempered slag fine powder for later use; (4) uniformly mixing alum, an organic additive, the oil shale waste residue aggregate, the oil shale waste residue fine powder and the water tempered slag fine powder; and (5) adding an alkali activator at a mass concentration of 5 to 10 percent into the mixture obtained by the step (4), and uniformly mixing to obtain the paste filling material. When the method is used, the oil shale waste residue can be fully used, the utilization rate is increased to 70 and 85 percent, the paste filling material meets coal filling requirements, a new approach is developed for the exploitation of coal bed beneath three strata, economic benefit is increased, waste is changed into valuable material, bulk deposition of waste residue is avoided, land occupation is reduced and environmental pollution is reduced.

Owner:FUSHUN MINING IND GROUP

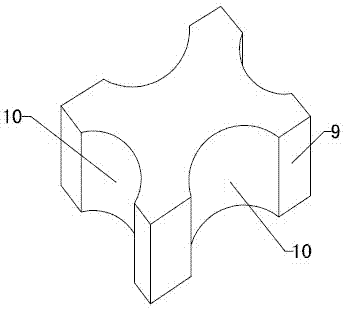

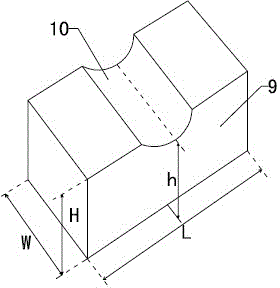

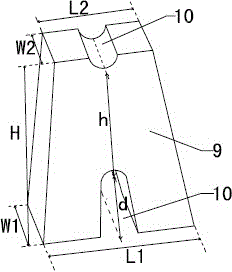

Blocking device for concrete conveying pipe pouring port and connection structure of blocking device

The invention discloses a blocking device for a concrete conveying pipe pouring port and a connection structure of the blocking device. The blocking device comprises a barrel pipe provided with a baffle capable of closing or opening a discharge outlet of the barrel pipe. When the discharge outlet of the barrel pipe is closed, the baffle and the barrel pipe are in locking connection through a locking component. The concrete conveying pipe pouring port in the connection structure is composed of an annular ring made of hard materials. The outer side wall of the annular ring is provided with circumferential connection grooves. The blocking device in the connection structure is the blocking device for the concrete conveying pipe pouring port. The part, close to the discharge outlet end, of the outer side face of the barrel pipe is provided with circumferential connection grooves. The concrete conveying pipe pouring port and a feed inlet of the blocking device are connected in a sealing and butt-joint mode through a clamp. According to the blocking device for the concrete conveying pipe pouring port and the connection structure of the blocking device, in the moving process of the concrete conveying pipe pouring port, concrete in a concrete conveying pipe is not liable to be leaked through the blocking device, and the concrete conveying pipe pouring port and the clocking device are connected in a sealing mode very easily.

Owner:CHINA XINXING BAOXIN CONSTR CORP

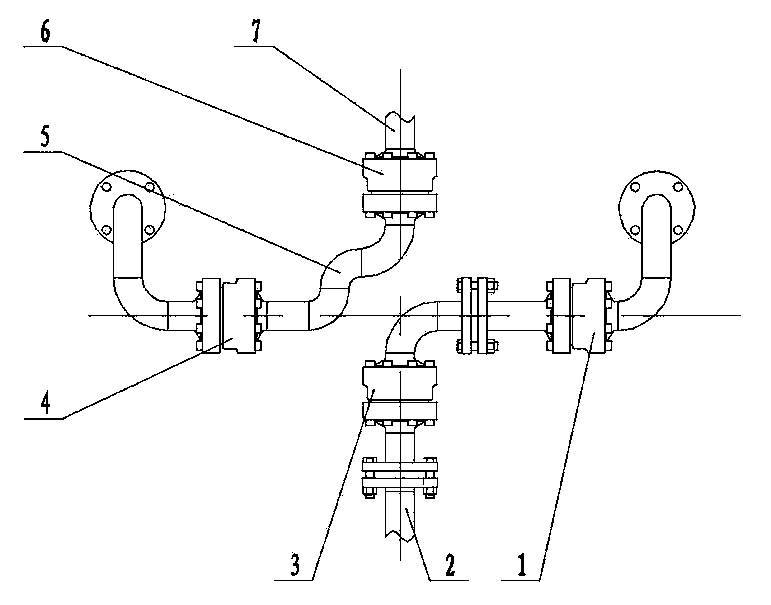

Pipeline steering mechanism of crane type marine cryogenic fluid filling device

ActiveCN103423585AMeet filling requirementsAdjustable jointsContainer filling under pressureEngineeringFill device

The invention discloses a pipeline steering mechanism of a crane type marine cryogenic fluid filling device. The pipeline steering mechanism comprises a horizontal rotary joint I and a horizontal rotary joint II, a vertical rotary joint I and a vertical rotary joint II, wherein the horizontal rotary joint I and the horizontal rotary joint II are arranged right oppositely in an up-and-down mode, and the vertical rotary joint I and the vertical rotary joint II are arranged right oppositely in a left-and-right mode. The horizontal rotary joint I and the vertical rotary joint I are connected through a bend assembly, and the horizontal rotary joint II and the vertical rotary joint II are connected through a corner joint. According to the pipeline steering mechanism of the crane type marine cryogenic fluid filling device, by utilizing the horizontal rotary joint I and the horizontal rotary joint II which are arranged right oppositely in the up-and-down mode, the filling device can rotate around the rotation axes of the horizontal rotary joint I and the horizontal rotary joint II, and by utilizing the vertical rotary joint I and the vertical rotary joint II which are arranged right oppositely in the left-and-right mode, the filling device can rotate around the rotation axes of the vertical rotary joint I and the vertical rotary joint II. Thus, the filling device is suitable for being used in various special conditions of a wharf, and the filling requirement of cryogenic liquid media is met between a cargo boat and the wharf.

Owner:连云港远洋流体装卸设备有限公司 +1

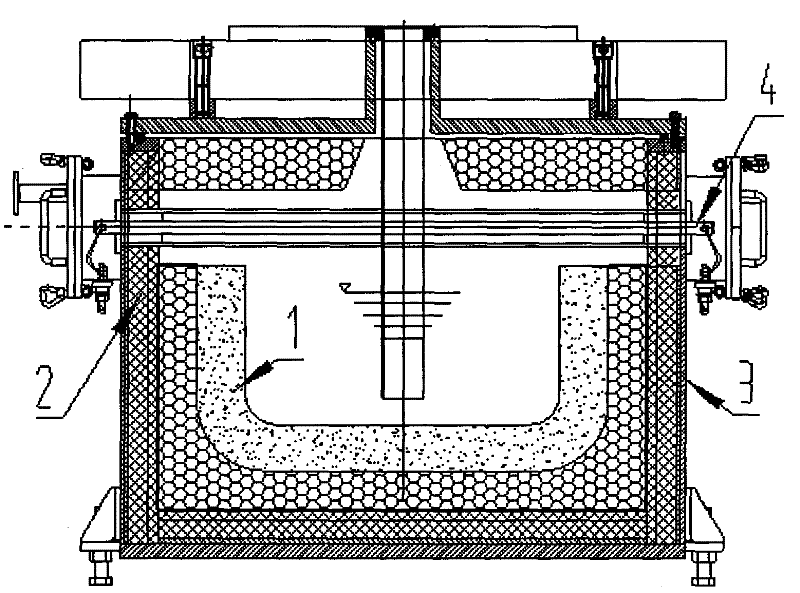

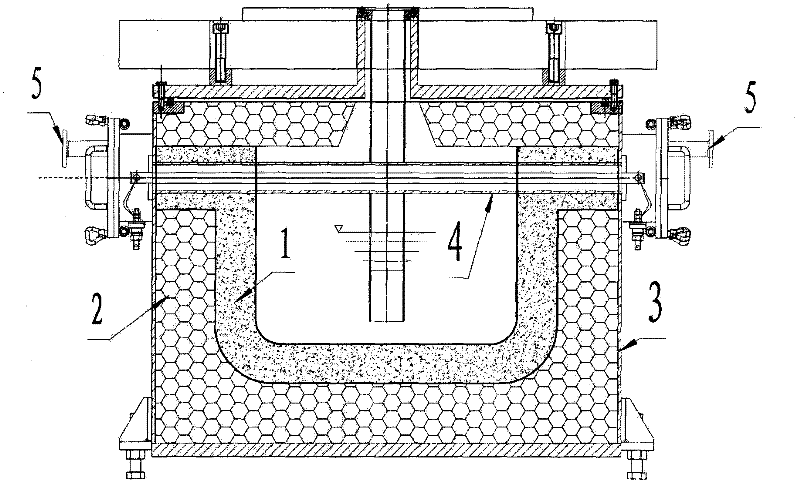

Highly turbocharged low pressure die casting machine

The invention relates to a highly turbocharged low pressure die casting machine, comprising a pouring layer (1), a thermal insulation layer (2), a case (3), a heating rod (4) and air inlet / exhaust holes (5), wherein the upper part of the hearth is provided with the heating rod (4), the lower part is provided with the pouring layer (1) and the thermal insulation layer (2). The highly turbocharged low pressure die casting machine is characterized in that the two sides of the upper part of the hearth are provided with the air inlet / exhaust holes (5). In the structure in the invention, the pouring layer is directly contacted and sealed with the case of a furnace in a filling way, thus high pressure gas can not enter into the thermal insulation layer and the pouring layer is protected. The air inlet / exhaust holes are arranged in heating tanks at the two sides, air is introduced / exhausted at the two sides simultaneously, the speed for introducing / exhausting the air can meet the requirement of mould filling during high pressure casting, structure compactness of a casting is good, and the strength and elongation percentage can meet product requirements.

Owner:JIANGSU TIANHONG MACHINERY IND

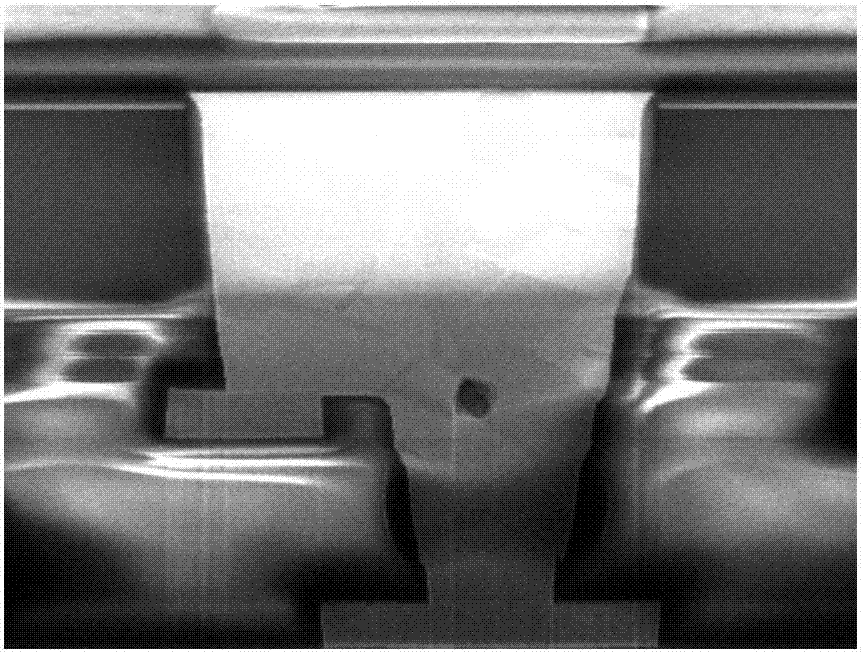

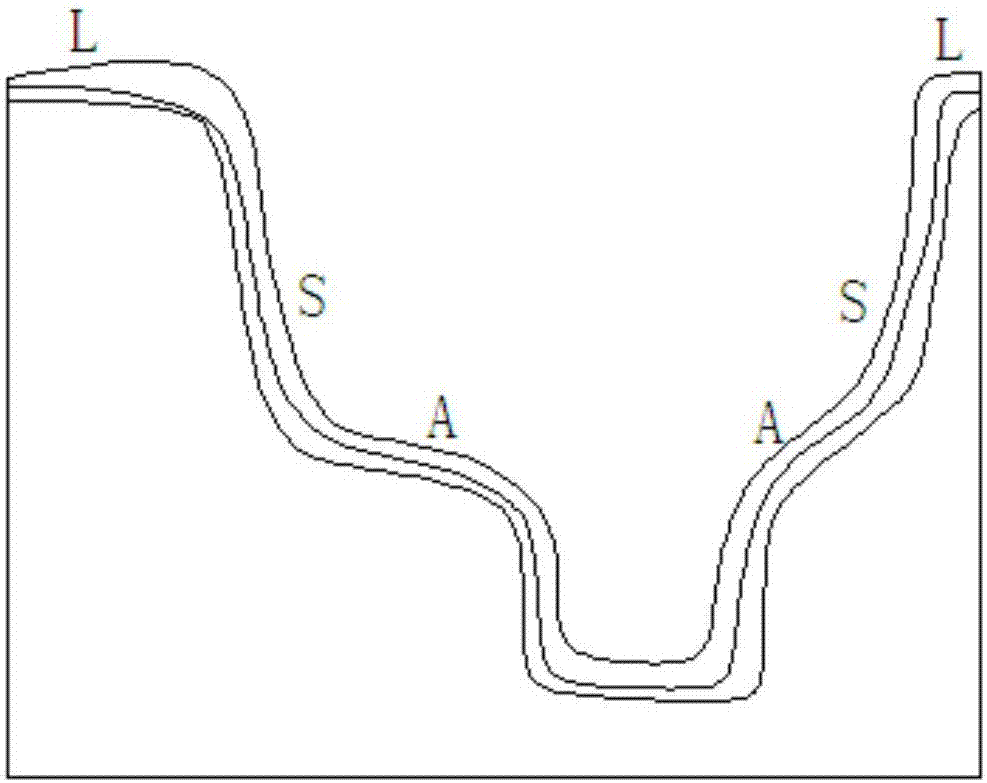

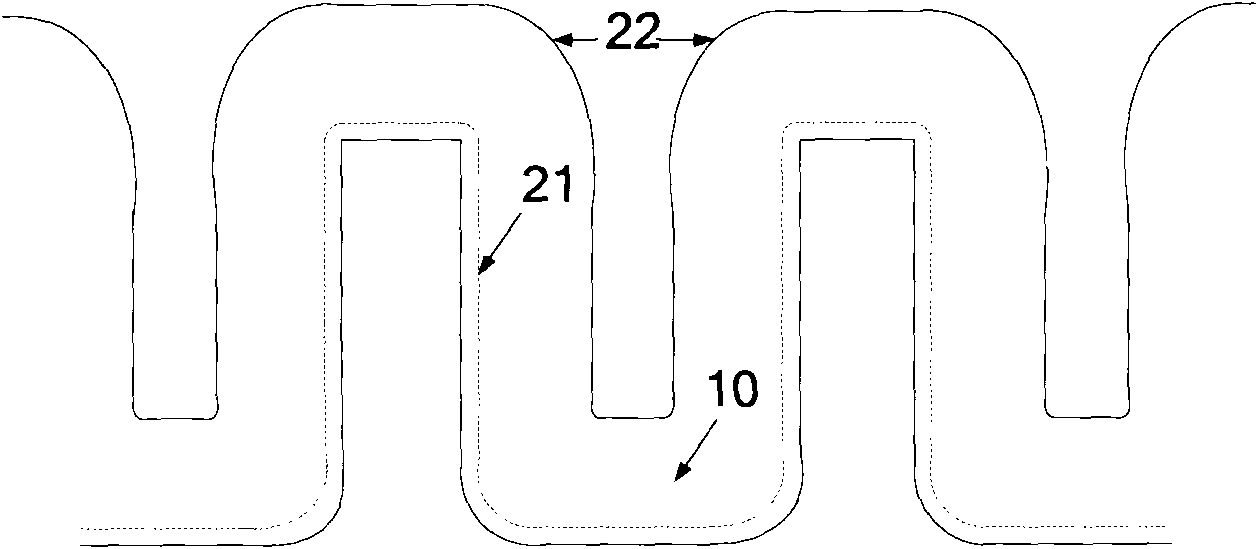

Filling method of groove

ActiveCN103035515ASolve the matching of stressMeet filling requirementsSemiconductor/solid-state device manufacturingMatch problemSemiconductor

The invention discloses a filling method of a groove. The filling method of the groove is finished by filling the groove in the manufacturing process of a semiconductor device, wherein a first monox thin film and a second monox thin film are circularly deposited and etched back in the groove. Stress of the first monox thin film is opposite to the stress of the second monox thin film. The two monox thin films with opposite stresses resolve the matching problem of stresses among different monox thin films. Filling requirements of large openings and deep grooves are simultaneously met.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

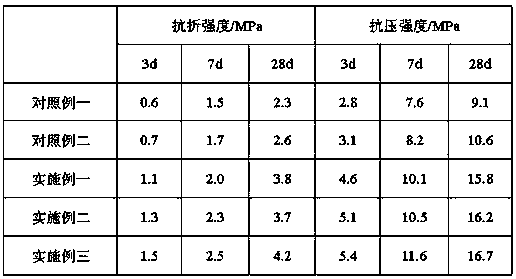

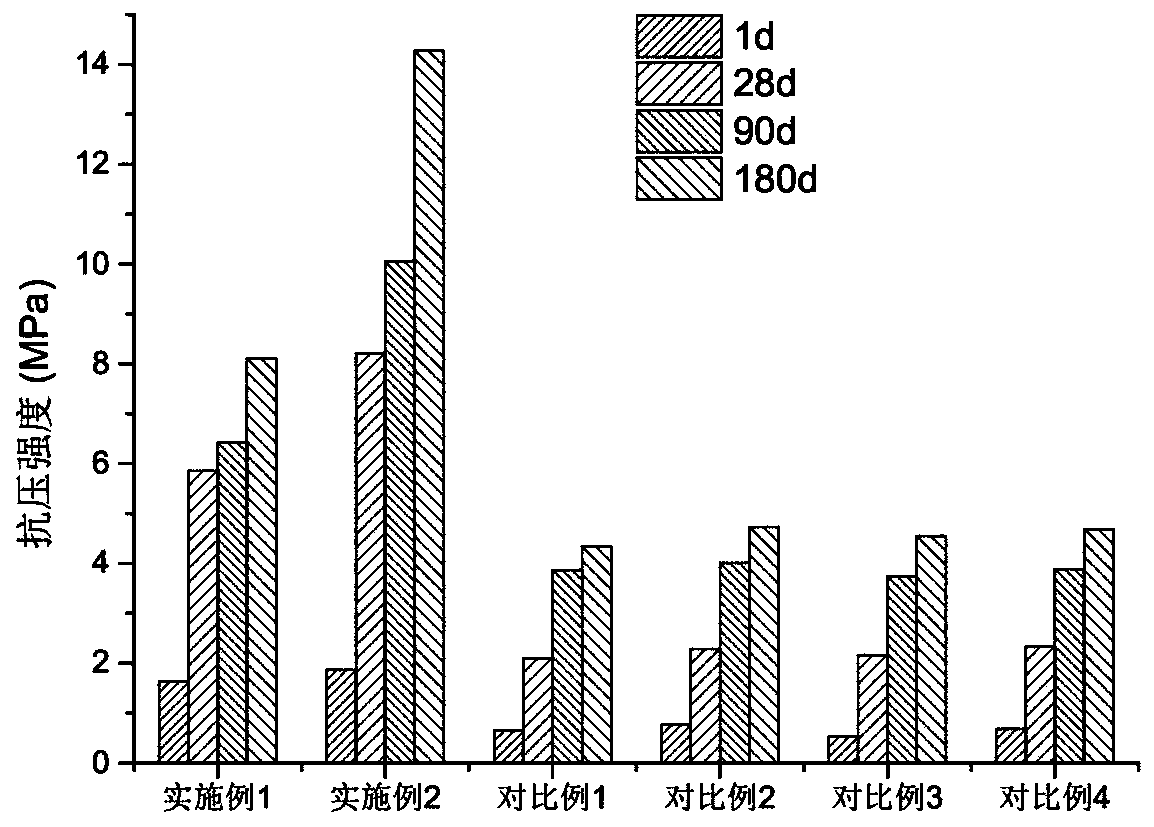

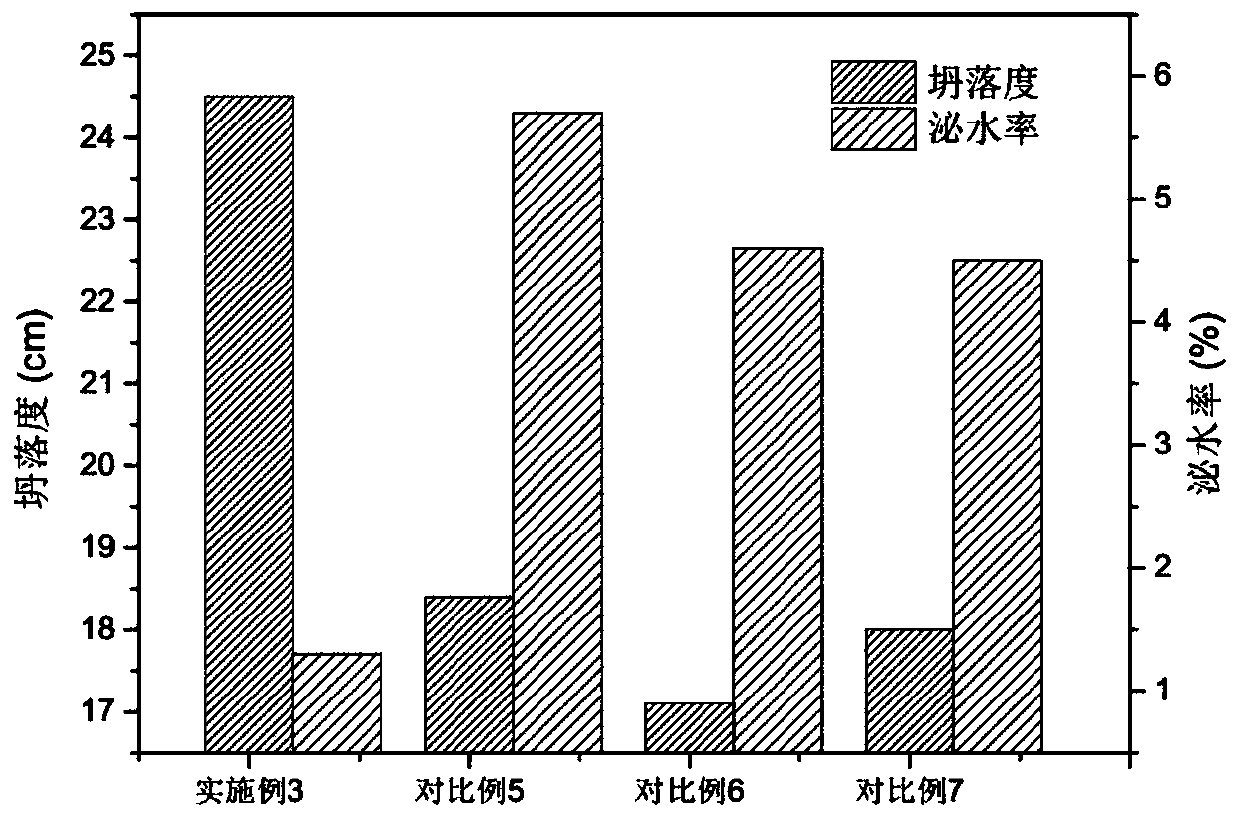

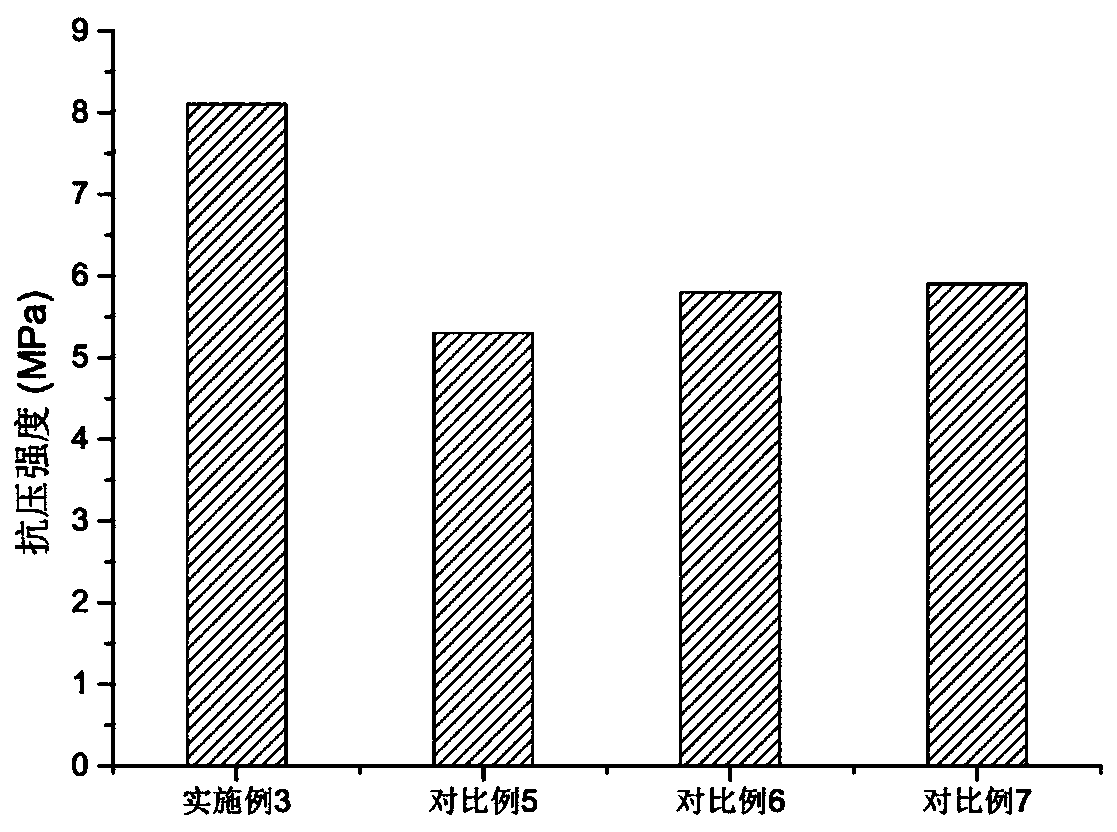

Preparation method of filling cementitious material

ActiveCN110218010AImprove system strengthHas hydration gelling activityCement productionResource utilizationSlag

The invention provides a preparation method of a filling cementitious material. The specific steps are as follows: mixing 50%-70% of a lime-sulphur-synthetic-solution residue with 30%-50% of dry and semi-dry desulfurization ash according to weight, performing calcination at 300 DEG C-450 DEG C to obtain a modified slag, and performing grinding on a steel slag, an ore slag and the modified slag according to a ratio of 30-50:40-70:5-20 to obtain the cementitious material. The method has the characteristics of simple process, low energy consumption, high waste slag doping content, low productioncost, and the like, realizes synergetic resource utilization of various industrial waste slags such as steel slag, ore slag, lime-sulphur-synthetic-solution residue, and desulfurization ash, solves the problem of land occupation of waste slags, and reduces environmental pollution.

Owner:ZUNHUA ZHONGHUAN SOLID WASTE COMPREHENSIVE UTILIZATION CO LTD

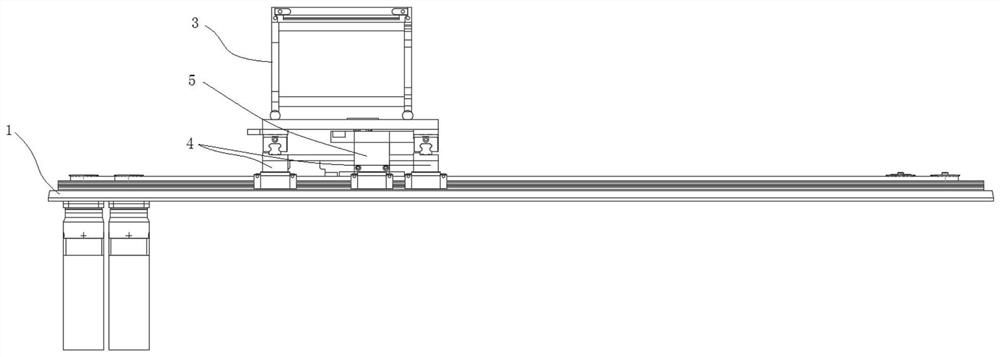

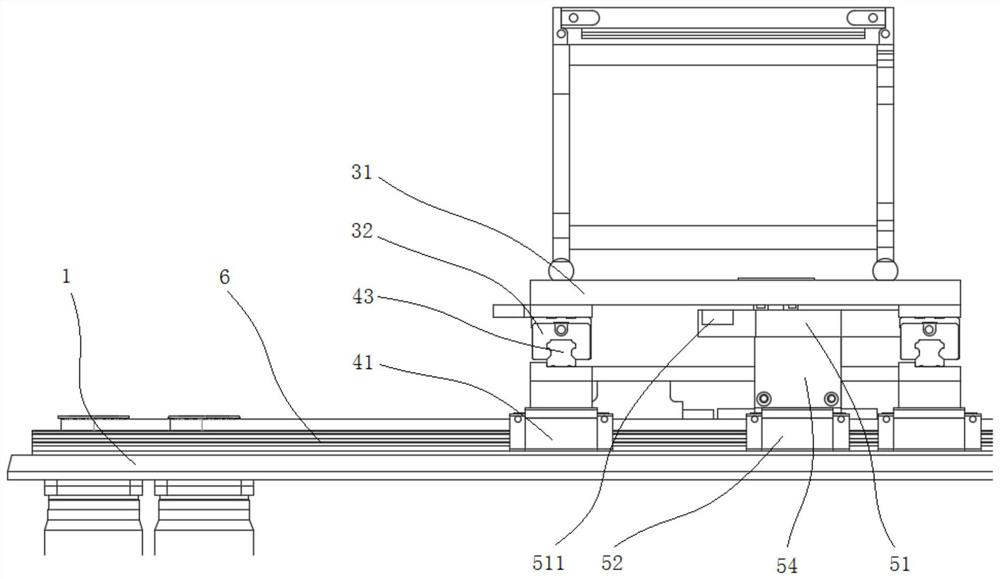

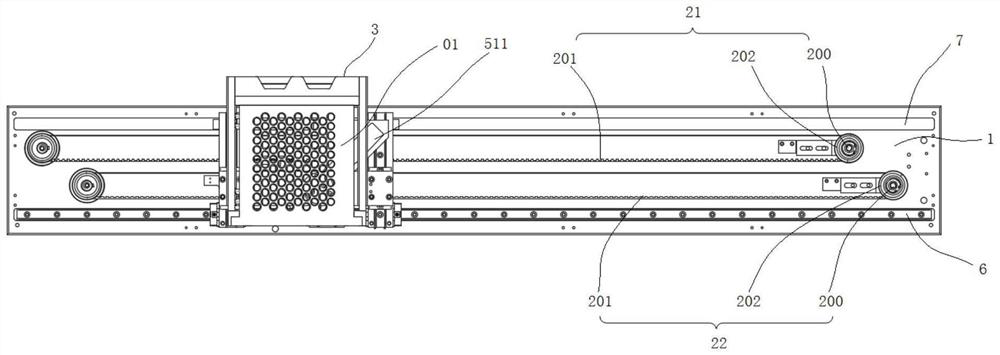

Material tray moving device

PendingCN114229063AMeet filling requirementsLiquid materialPackaging machinesMoving frameEngineering

The invention discloses a material tray moving device which comprises an operation platform, a transverse moving synchronous belt, a longitudinal moving synchronous belt and a moving frame. The transverse moving synchronous belt and the longitudinal moving synchronous belt are parallel, and belt wheel shafts of the transverse moving synchronous belt and the longitudinal moving synchronous belt are vertically fixed to the working platform. The longitudinal moving synchronous belt is provided with a longitudinal moving bracket; a horizontal guide groove of the longitudinal moving bracket is intersected with the longitudinal moving synchronous belt at an angle of 45 degrees; the bottom of the moving frame is provided with a first sliding part in sliding fit with the horizontal guide groove and a second sliding part in sliding fit with the transverse moving support. The sliding direction of the second sliding part is horizontal and perpendicular to the conveying direction of the transverse moving synchronous belt. The device can be used for filling operation of medicine bottle containers, the longitudinal moving synchronous belt and the transverse moving synchronous belt are used for driving the moving frame to generate transverse and longitudinal displacement, the material disc clamped on the moving frame drives the medicine bottle containers to synchronously move, then the filling needles are sequentially inserted into the multiple medicine bottle containers, the driving mode is simpler and easier to implement, movement is more stable and reliable, and the filling efficiency is improved. And the sterile operation requirement can be met.

Owner:SHINVA MEDICAL INSTR CO LTD

Downward parallel middle-deep hole sublevel fill stoping mining method for steep and medium-thick hard-to-mine ore body

PendingCN110985114AImprove early strengthHigh compressive strengthMaterial fill-upSlagMining engineering

The invention provides a downward parallel middle-deep hole sublevel fill stoping mining method for a steep and medium-thick hard-to-mine ore body, and belongs to the technical field of mining. The ore body is divided into a plurality of sublevels according to the middle sublevel, stope rooms and stope pillars are divided in the ore body direction, the middle sublevel is divided in the inclined direction of the ore body, sublevel rock drilling roadways are arranged along veins, artificial false roofs and false bottoms are constructed in the sublevel rock drilling roadways in advance, and middle-deep hole stoping ore blocks are adopted from top to bottom. After the stope rooms are mined, the stope rooms are filled with filling materials. After the stope pillars are mined, the stope pillarsare filled with full tailings and / or barren rock powder. The content of particles with the particle size being less than or equal to 30[mu]m in the full tailings for the filling materials accounts for75-77%; the content of the particles with the particle size being less than or equal to 35[mu]m in slag accounts for 86-88%; and an activator is prepared from glauberite and green vitriol with a weight ratio of 1 to (0.5-0.7). According to the downward parallel middle-deep hole sublevel fill stoping mining method, safe, efficient and low-cost mining of the ore body can be realized, continuous mining in an area can be realized, and the sublevel fill stoping mining method is mainly suitable for a gold mine with an inclination of 50-90 degrees and a horizontal thickness of 4-10 m.

Owner:中国黄金集团石湖矿业有限公司

Quick coupling for fluid loading and unloading

PendingCN112393044ANo accidental disengagementShorten retrofit timeLiquid transferring devicesCouplingsPilot holeCoupling

The invention provides a quick coupling for fluid loading and unloading. The quick coupling comprises a valve, a fixed inner ring, a guide inner ring, an outer ring, a nut flange and a hand wheel, wherein the valve is arranged in the guide inner ring, the guide inner ring is connected with the fixed inner ring, and the outer ring and the hand wheel are respectively connected with the nut flange; the rear end of the valve is of a screw structure, and thread is arranged in the nut flange and matched with a thread on the screw structure; guide holes are formed in the edge of the end surface of the fixed inner ring, or guide holes are correspondingly formed in the edge of the end surface of the fixed inner ring and the edge of the end surface of the guide inner ring; an interlocking limiting guide rod is arranged in each guide hole; a guide centre is fixed to the rear end of each interlocking limiting guide rod, a spiral groove is formed in the outer surface of the outer ring, and the guide centres are located in the spiral groove; the thread of the spiral groove is opposite to the thread of the screw structure in rotating direction; a sliding-moving device is fixed to the valve and can drive the valve to slide in the guide inner ring along the axis. and a limiting structure is arranged on the fixed inner ring. The quick coupling has the advantages that a tank car does not need tobe transformed, and operation is easy.

Owner:连云港天邦科技开发有限公司

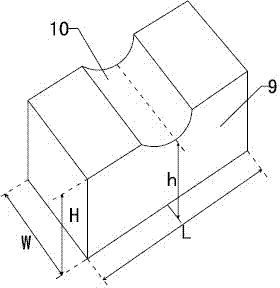

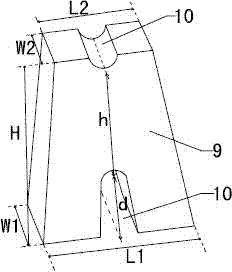

Concrete cushion block and preparation technology thereof

The invention relates to a concrete cushion block and a preparation technology thereof, belonging to the technical field of a strutting piece for a building. The concrete cushion block is characterized in that a cushion block body comprises the following raw materials in parts by weight: 100 parts of cement, 460-520 parts of aggregate chips, and 42-61 parts of water, wherein the aggregate chips and water are mixed according to the ratio of 1:0.2-0.12, and according to the difference of particle sizes D of aggregate chips, the mass percentages are as follows: the aggregate chips with D of no more than 0.1cm accounts for 40-50%, the aggregate chips with D of more than 0.1cm and no more than 0.2cm accounts for 20-25%, the aggregate chips with D of more than 0.2cm and no more than 0.3cm accounts for 15-20%, and the aggregate chips with D of more than 0.3cm and no more than 0.5cm accounts for 12-15%. According to the technology, a reinforcement steel bar slot is formed in the side surface, and demolding and maintenance are immediately conducted after pressing is conducted for 1-4s. The cushion block is short in maintenance time, high in early strength, adaptive to concrete of buildings, convenient and fast in technological process, firm and difficult to loose, short in preparation period and convenient to use.

Owner:曹连涛

Concrete cushion block and preparation technology thereof

The invention relates to a concrete cushion block and a preparation technology thereof, belonging to the technical field of a strutting piece for a building. The concrete cushion block is characterized in that a cushion block body comprises the following raw materials in parts by weight: 100 parts of cement, 460-520 parts of aggregate chips, and 42-61 parts of water, wherein the aggregate chips and water are mixed according to the ratio of 1:0.2-0.12, and according to the difference of particle sizes D of aggregate chips, the mass percentages are as follows: the aggregate chips with D of no more than 0.1cm accounts for 40-50%, the aggregate chips with D of more than 0.1cm and no more than 0.2cm accounts for 20-25%, the aggregate chips with D of more than 0.2cm and no more than 0.3cm accounts for 15-20%, and the aggregate chips with D of more than 0.3cm and no more than 0.5cm accounts for 12-15%. According to the technology, a reinforcement steel bar slot is formed in the side surface, and demolding and maintenance are immediately conducted after pressing is conducted for 1-4s. The cushion block is short in maintenance time, high in early strength, adaptive to concrete of buildings, convenient and fast in technological process, firm and difficult to loose, short in preparation period and convenient to use.

Owner:曹连涛

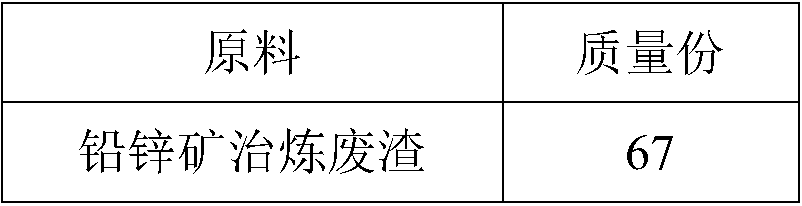

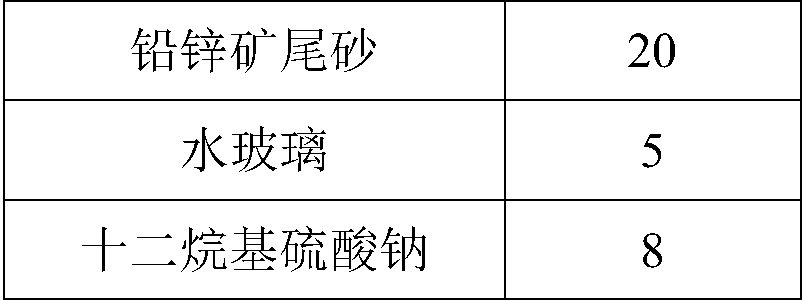

Mine filling cementing material as well as preparation method and application thereof

InactiveCN111548032AMeet filling requirementsCement productionMaterial fill-upMining engineeringSlag

The invention discloses a mine filling cementing material as well as a preparation method and application thereof. The mine filling cementing material is composed of lead-zinc ore smelting waste residues, lead-zinc ore tailings and an alkali activator. The invention also discloses a mine filling material containing the mine filling cementing material. According to the method for producing the cementing filling cementing material for the mine by utilizing the smelting solid waste slag of the lead-zinc ore and the tailings in the mining process, the performance of the cementing filling cementingmaterial can completely meet the requirements of mine filling, and the cementing filling cementing material plays a positive role in effectively utilizing the solid waste of the lead-zinc ore at present.

Owner:GUYAN TECH DEV CO LTD

Pressure balancing tank capable of realizing online cleaning and sterilization

InactiveCN102275697BMeet filling requirementsRealize automatic adjustmentLarge containersPharmaceutical industryEngineering

The invention discloses a pressure balancing tank capable of realizing online cleaning and sterilization, relating to the technical field of pharmaceutical machinery. The pressure balancing tank is composed of a tank body 27, a tank cover 25, a liquid medicine input component, a pressure balancing component, a liquid outlet pipe 28, a pressure sensor 21, a pressure gauge 23, a liquid level meter 16, a data receiving and processing device 30 and an online cleaning and sterilization input component. The pressure balancing tank has the characteristics of simple structure, convenience in pressureadjustment, stable pressure of liquid medicine and the like, can meet the requirements of liquid medicine filling and realize online cleaning and sterilization, and can be used for conveying liquid medicine of large-volume infusion packages in the pharmaceutical industry and can also be used for conveying liquid raw materials in packages of other industries.

Owner:长沙汇一制药机械有限公司

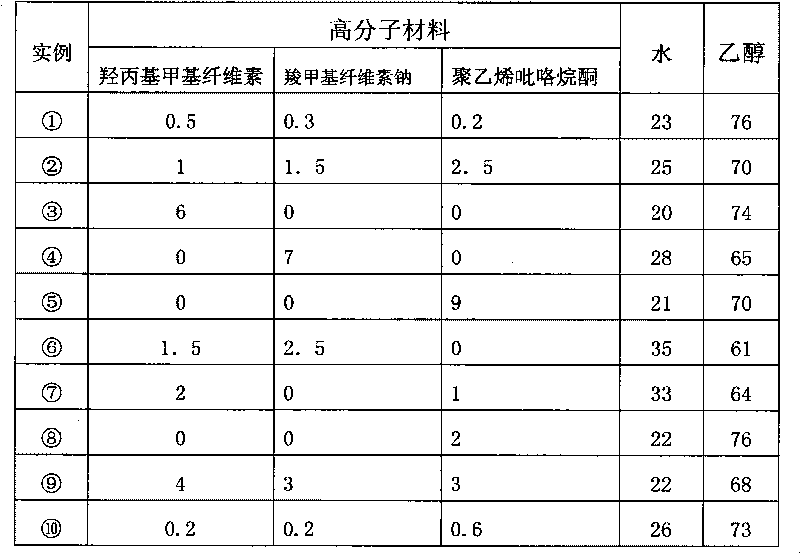

Method for granulating medicament for treating osteoporosis

InactiveCN101708251AIncrease salesEasy to useSkeletal disorderPharmaceutical non-active ingredientsPrillSoft materials

The invention relates to a method for granulating a medicament for treating osteoporosis, which comprises the following steps of: firstly uniformly mixing the medicament and auxiliary materials; adding a polymer blend, and stirring the mixture to obtain a soft material; preparing wet granules from obtained soft material with a granulator; placing the prepared wet granules into a boiling drier to dry; discharging the granules after drying the granules; passing the granules through a 25-mesh screen; mixing the granules; and encapsulating 0.45g of granules into each number 1 capsule to obtain a capsule preparation. The polymer blend has the functions of adhesion and coating, and ensure that the medicament fine powder is tightly prepared into balls and each ball is coated with a layer of film coating, so that powder granule gaps are reduced, the requirements of encapsulating materials into the number 1 empty capsule is met, the medicament only encapsulated by a large number 0 empty capsule can be successfully encapsulated by the small number 1 empty capsule, the volume of the finished capsule is decreased which is convenient for administration, the compliance of medication is increased, sale and use of the medicament are promoted, and good benefits for society and enterprises can be created.

Owner:SICHUAN MEDCO PHARML

Method for electroplating copper

InactiveCN107502935AMeet filling requirementsAvoid Void DefectsCellsSemiconductor devicesPower flowThree stage

The invention provides a method for electroplating copper, and is applicable to electroplating equipment to deposit a copper electroplating layer in a channel of a wafer. The method for electroplating the copper comprises an initial stage, a second stage, a third stage, a fourth stage and the three stages of an excessive electroplating stage; and compared with the prior art, the third stage and the fourth stage are added, the rotation speed range of the wafer is increased in the initial stage while the range of electroplating current is kept unchanged, in the second stage, the third stage and the fourth stage, the rotating speed range of the wafer is kept unchanged while the range of the electroplating current is adjusted in a section-by-section mode, and the rotation speed range of the wafer and the range of the electroplating current are kept unchanged in the excessive electroplating stage. The method for electroplating the copper has the beneficial effects that technology is simple and low in cost, and finally, under the condition of the same type of the electroplating equipment and a same additive system, filling requirements of both a large-size channel and a small-size channel are met, so that a hole defect is avoided when the large-size channel is filled.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

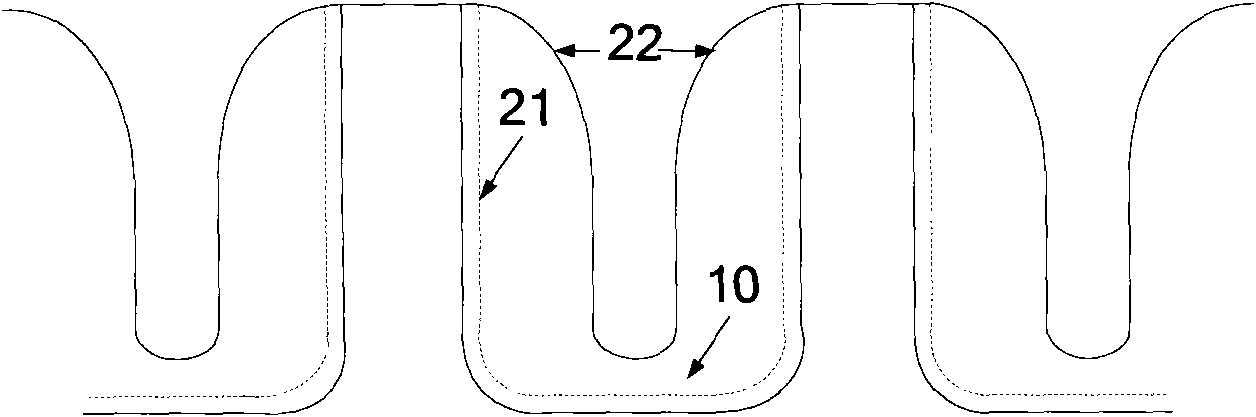

Slot filling method in multilayer integrated circuit

ActiveCN101866873AImprove liquidityMeet filling requirementsSemiconductor/solid-state device manufacturingSilicon dioxideImpurity

The invention discloses a slot filling method in a multilayer integrated circuit. In the method, slots are etched on the surface of a silicone wafer, and a layer of silicon dioxide is grown by thermal oxidation, and then the following steps are carried out: firstly, depositing a layer of silicon dioxide on the surface of the silicon wafer with the slots, wherein the layer of the silicon dioxide is a laying layer; secondly, depositing a layer of silicon dioxide mixed with p type or n type impurities on the laying layer, wherein the silicon dioxide mixed with the impurities fills the slots and is the material of the interlayer media of the first layer; and thirdly, carrying out planarization treatment on the silicon dioxide on the surface of the silicon wafer by a chemical mechanical polishing process until the required thickness of the interlayer media of the first layer is met. In the invention, the filling of the slots and the preparation of ILD-1 are skillfully integrated, and the material of the ILD-1 is determined as the silicon dioxide mixed with the impurities simultaneously. The silicon dioxide mixed with the impurities has good fluidity, and therefore, the requirements for filling deep slots with different widths can be completely met.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

A metering adjustable turntable device for filling machine

ActiveCN103847994BRealize moving up and downMeet filling requirementsLiquid materialEngineeringMeasuring cup

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com