Liquid lubricating oil winter filling system

A filling system and lubricating oil technology, applied in the direction of lubricating parts, pressure lubricants, engine lubrication, etc., can solve problems such as damage to filling equipment and pipelines, affecting the production rhythm of automobiles, increasing transportation resistance, etc., to ensure oil quality, reducing viscosity and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

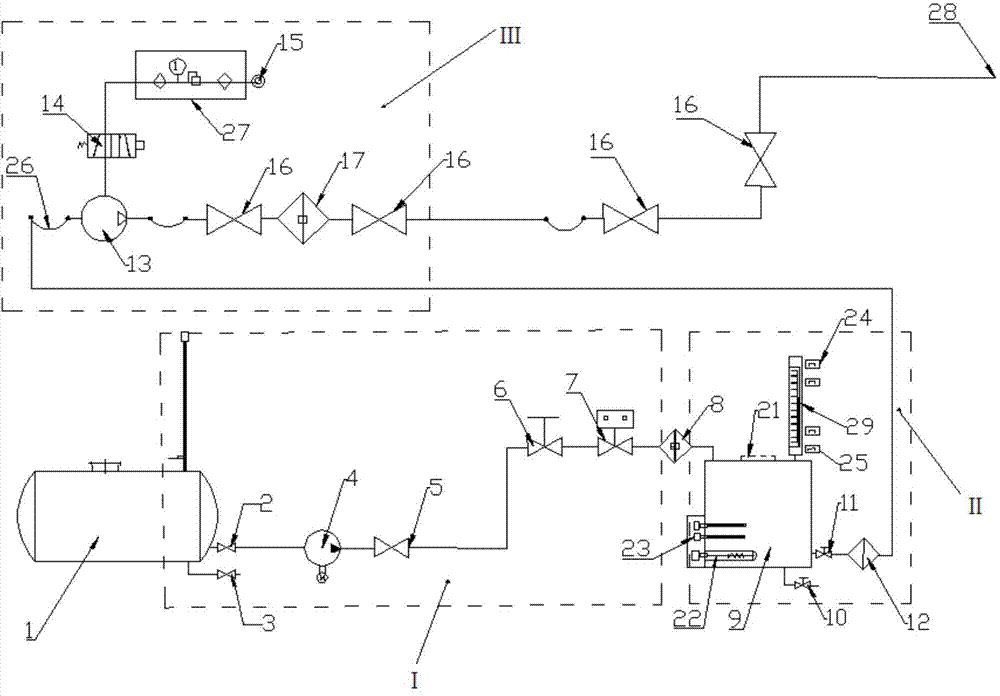

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] Such as figure 1 As shown, the liquid lubricating oil filling system in winter includes the oil storage tank 1, the liquid replenishment pipeline I, the heating control system II, the filling control system III, and the filling point 28 of the production line. The pipeline of the entire filling system is long, and multiple ball valves are installed to facilitate construction and maintenance in sections. Some ball valves have a fixed base and can be fixed on the wall, and some are directly connected to the pipeline without fixing. The main difference is the installation The structure is different.

[0027] (1) Liquid replenishment pipeline I is composed of oil transfer valve 2, replenishment pump 4, valve 5 (DN40), first ball valve 6, second ball valve 7, and first filter 8 connected in sequence. Oil transfer valve 2 and oil storage tank Connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com