Method for electroplating copper

A technology for electroplating copper and electroplating layers, applied in circuits, electrolytic processes, electrolytic components, etc., can solve problems such as affecting the electrical conductivity of products, increasing lattice voids, affecting product yields, etc., to avoid void defects and meet filling requirements. , the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] It should be noted that, in the case of no conflict, the following technical solutions and technical features can be combined with each other.

[0041] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

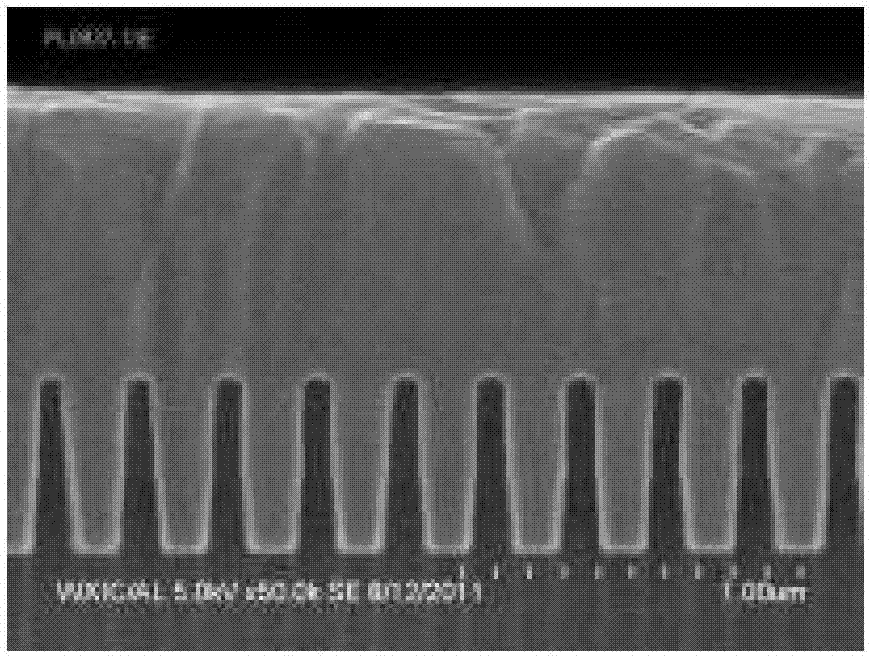

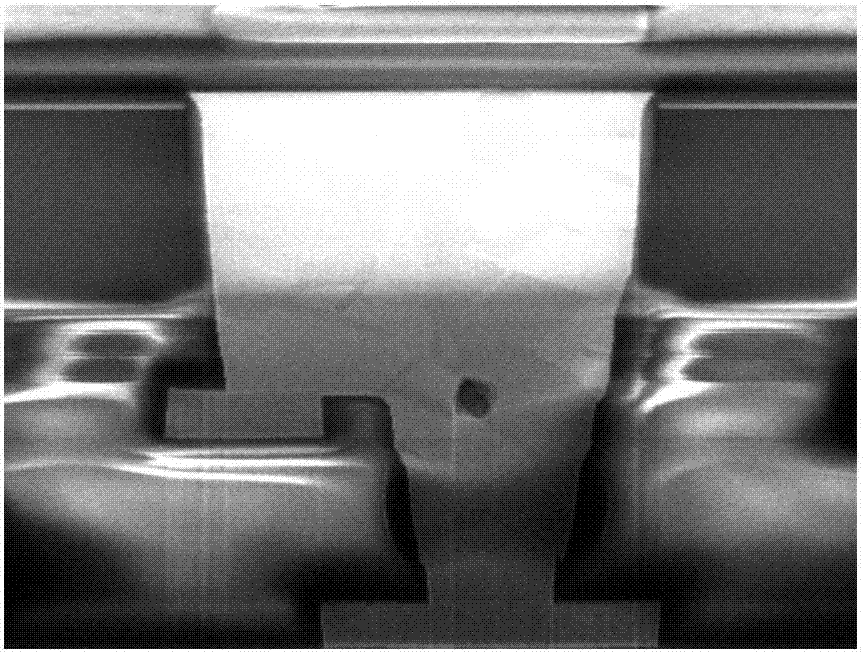

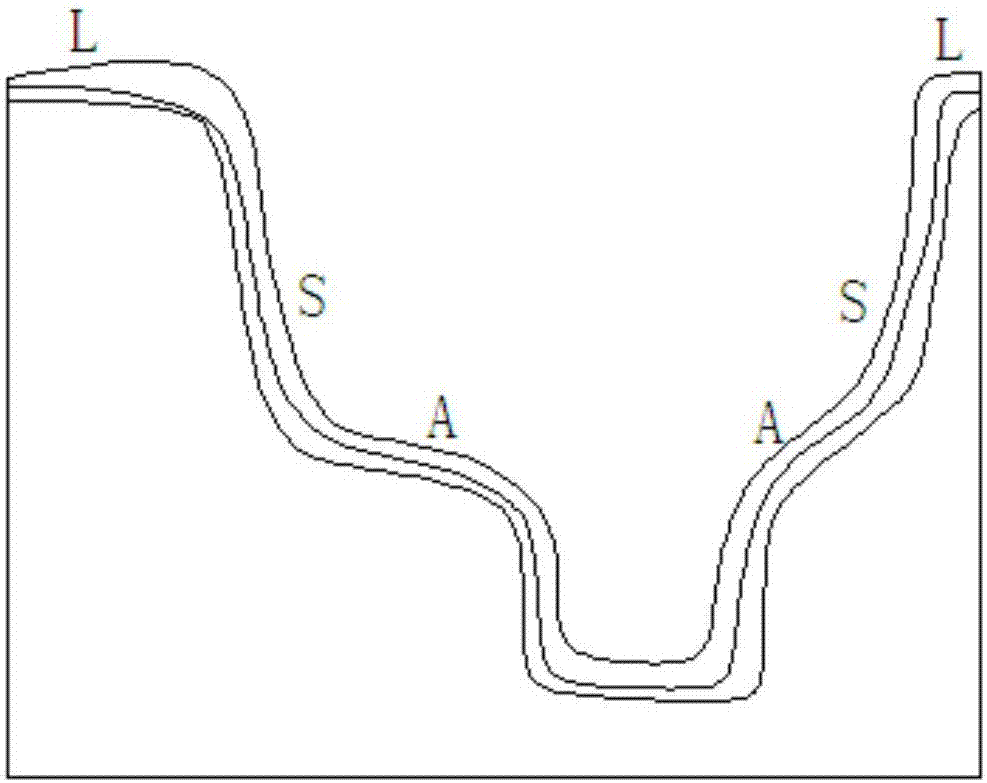

[0042] In the existing process, under the same electroplating equipment and the same additive system (L: leveler, S: inhibitor, A: accelerator), if the copper electroplating process for small-sized channels can be satisfied, then in large-sized channels trench copper plating process, such as Figure 3-5 As shown, void defects will eventually appear.

[0043] The method of electroplating copper is suitable for electroplating equipment to deposit a copper electroplating layer in the channel of the wafer. In the prior art, the above method of electroplating copper includes three stages: initial stage, second stage and overplating stage:

[0044] In the above-mentioned primary stage, the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com