Patents

Literature

279results about How to "Improve oil quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and compositions to enhance plant breeding

InactiveUS20060282911A1Enhanced agronomicEnhanced transgenic traitBiocideDead animal preservationGermplasmHaplotype

Owner:MONSANTO TECH LLC

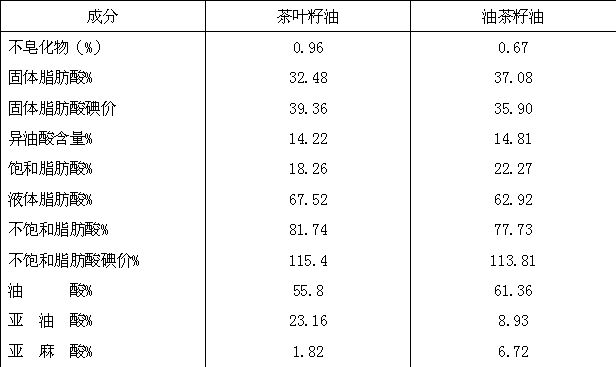

Preparation technique of big-leaf seed tea seed oil

InactiveCN101665742AAvoid the drawbacks of emulsification that is not easy to separateNot easy to blockFatty-oils/fats refiningFatty-oils/fats productionNutritive valuesHusk

The invention discloses a preparation technique of big-leaf seed tea seed oil. The preparation technique comprises the following steps: (1) squeezing the big-leaf seed tea seed oil: removing impurities, drying, husking, separating husks and kernels, softening, rolling embryos, braising, stir-frying and squeezing; and (2) refining the big-leaf seed tea seed oil: degumming raw oil, deacidifying, washing with water, dewatering, decolouring, deodorizing and filtering. The big-leaf seed tea seed oil prepared by the technique has the advantages of high oil output rate, superior oil quality, clear, bright and transparent colour, no bitter taste, pure fragrance and good mouth feel, and the nutritive value of the big-leaf seed tea seed oil is furthest protected. The big-leaf seed tea seed oil is not easy to be oxidized and deteriorate, has stable oil quality, safety, no toxicity, no side effect, and favorable properties of storage resistance and high-temperature resistance, is a better materialfor processing powdered oil, oleomargarin, salad oil and shortening oil and also can be used for cosmetics and medical oil.

Owner:陈军 +2

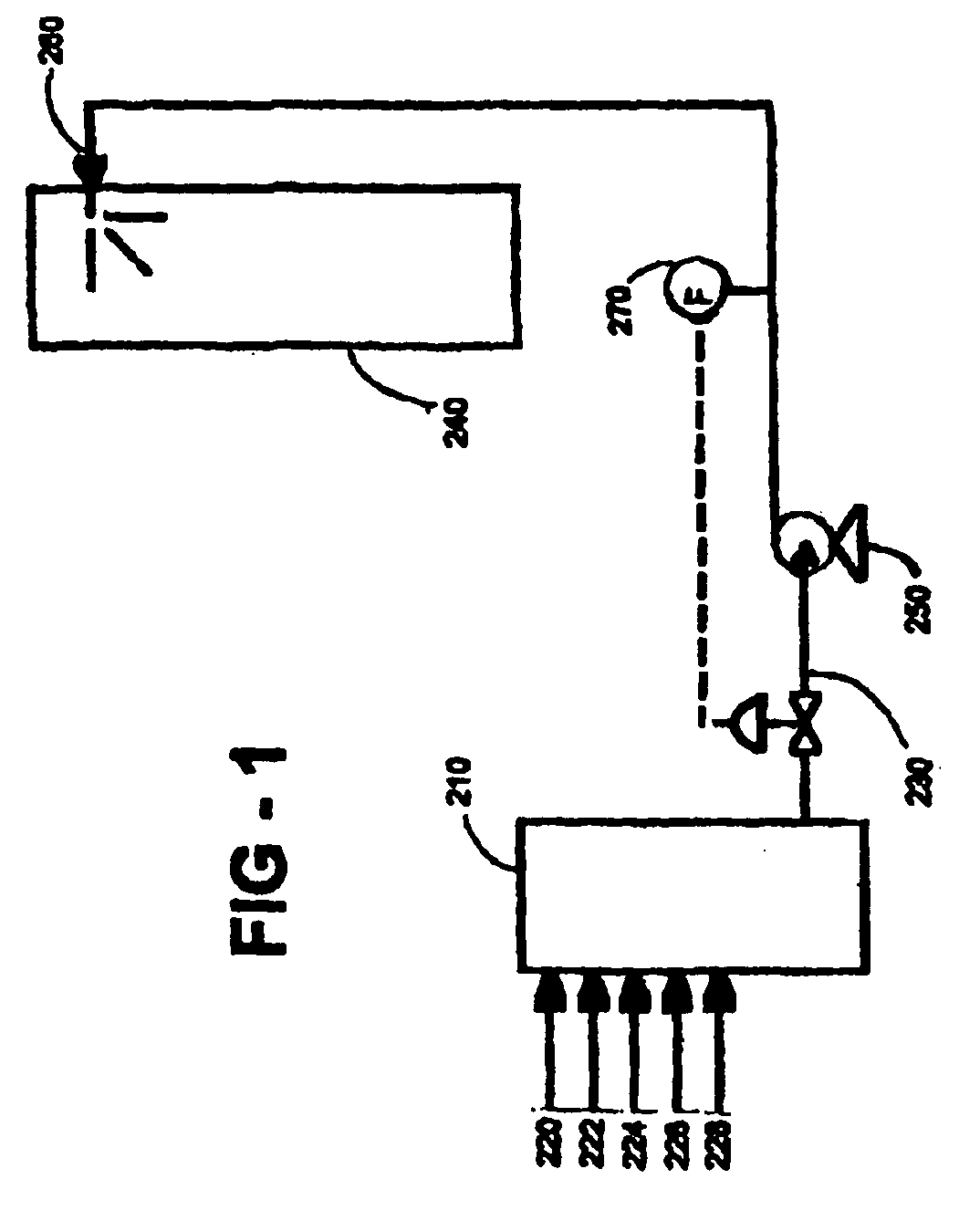

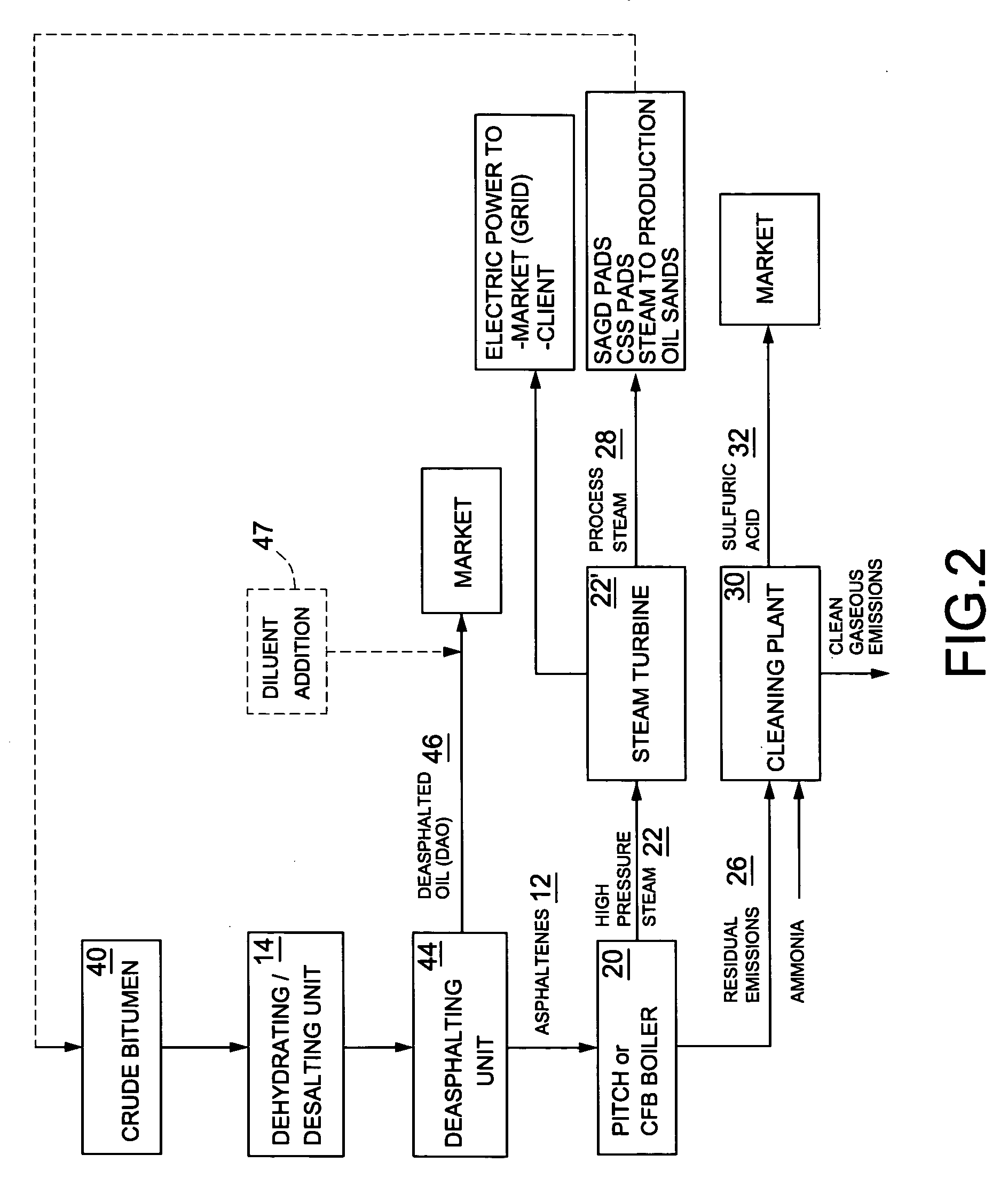

Process for producing fuel

InactiveUS20060027488A1Low costHigh thermal efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolid fuelsAlkaneSorbent

A fuel is produced from bitumen by precipitating a substantial portion of asphaltenes from bitumen by contacting the bitumen with a lower alkane solvent. Suitable burners include a fluidized bed boiler, a circulating fluidized bed boiler and a pitch boiler which utilize either pre-combustion sulfur sorbents or post-combustion flue gas desulfurization. The sulfur in emissions can be used to produce sulfuric acid. The process uses a low cost fuel, generates steam, power and sulfuric acid and meets all emission requirements for SO2, NOx and PM.

Owner:GAUTHIER RICHARD

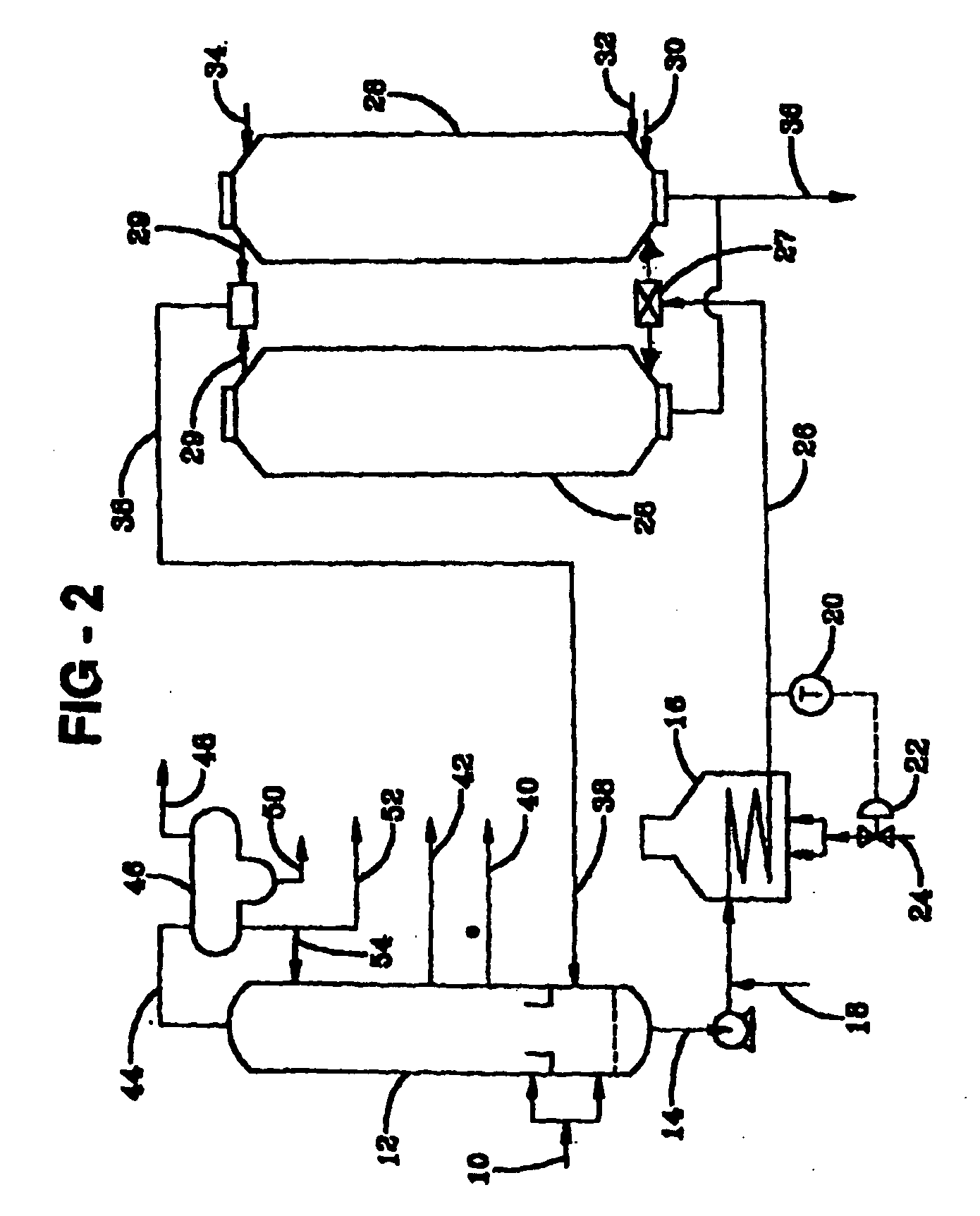

System and Method for Introducing an Additive into a Coking Process to Improve Quality and Yields of Coker Products

InactiveUS20090152165A1Promotes cokingImprove cokingThermal non-catalytic crackingTreatment with plural serial cracking stages onlyBoiling pointTar

Gas oil components, coking process recycle, and heavier hydrocarbons are cracked or coked in the coking vessel by injecting an additive into the vapors of traditional coking processes in the coking vessel. The additive contains catalyst(s), seeding agent(s), excess reactant(s), quenching agent(s), carrier(s), or any combination thereof to modify reaction kinetics to preferentially crack or coke these components. The quenching effect of the additive can be effectively used to condense the highest boiling point compounds onto the catalyst(s), thereby focusing the catalyst exposure to these target reactants. With a catalyst to crack these highest boiling point materials, this mechanism can effectively increase the catalyst's selectivity, thereby increasing its efficiency and reducing catalyst requirements and costs. Selective, catalytic conversion of the highest boiling point materials in the coking process product vapors (coker recycle and / or ‘heavy tail’ of the heavy coker gas oil) may be accomplished with an exemplary embodiment of the present invention in varying degrees. Exemplary embodiments of the present invention can also provide methods to control the (1) coke crystalline structure and (2) the quantity and quality of volatile combustible materials (VCMs) in the resulting coke. Pet coke from this process may have unique characteristics with substantial utility.

Owner:ETTER ROGER G

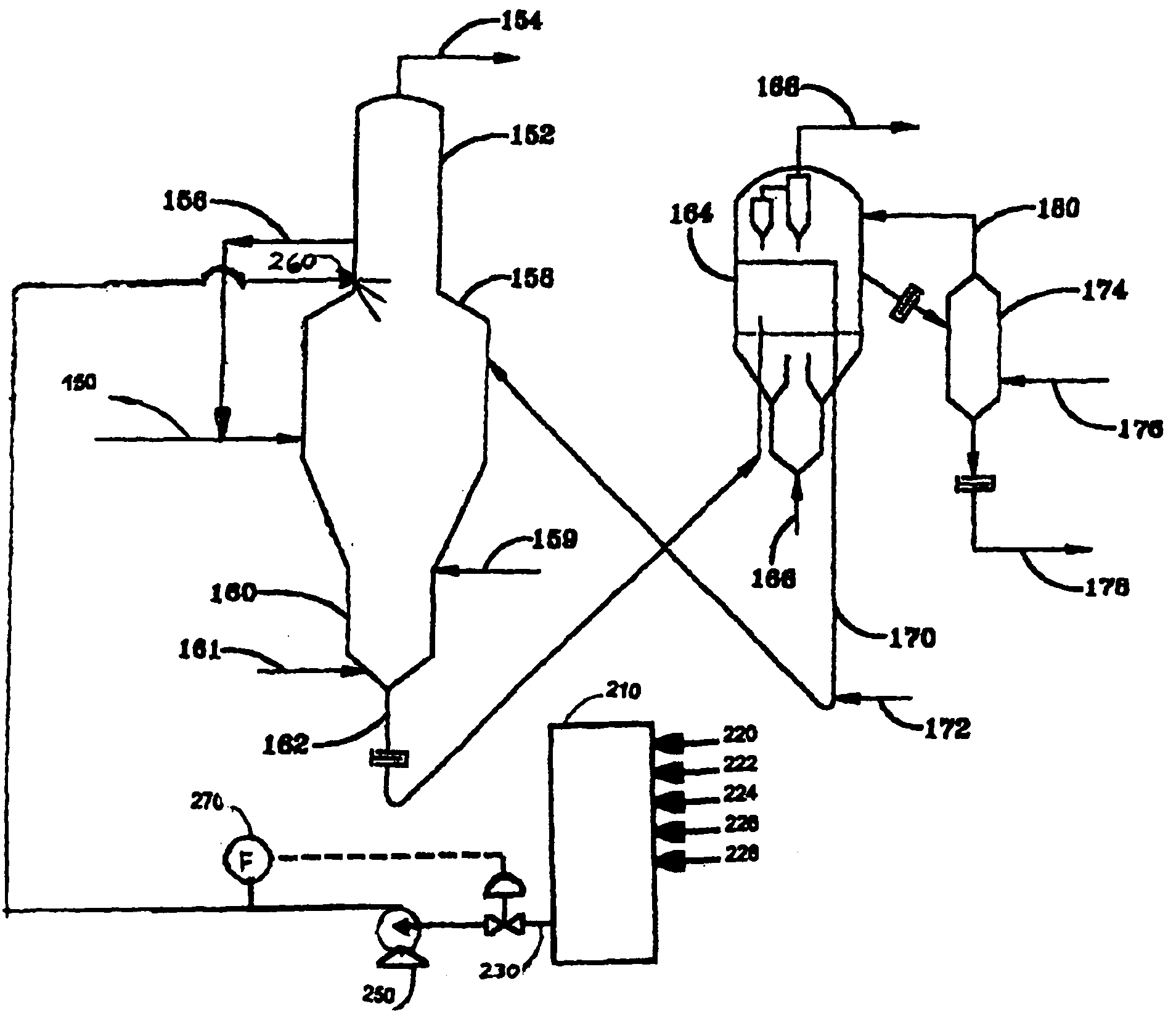

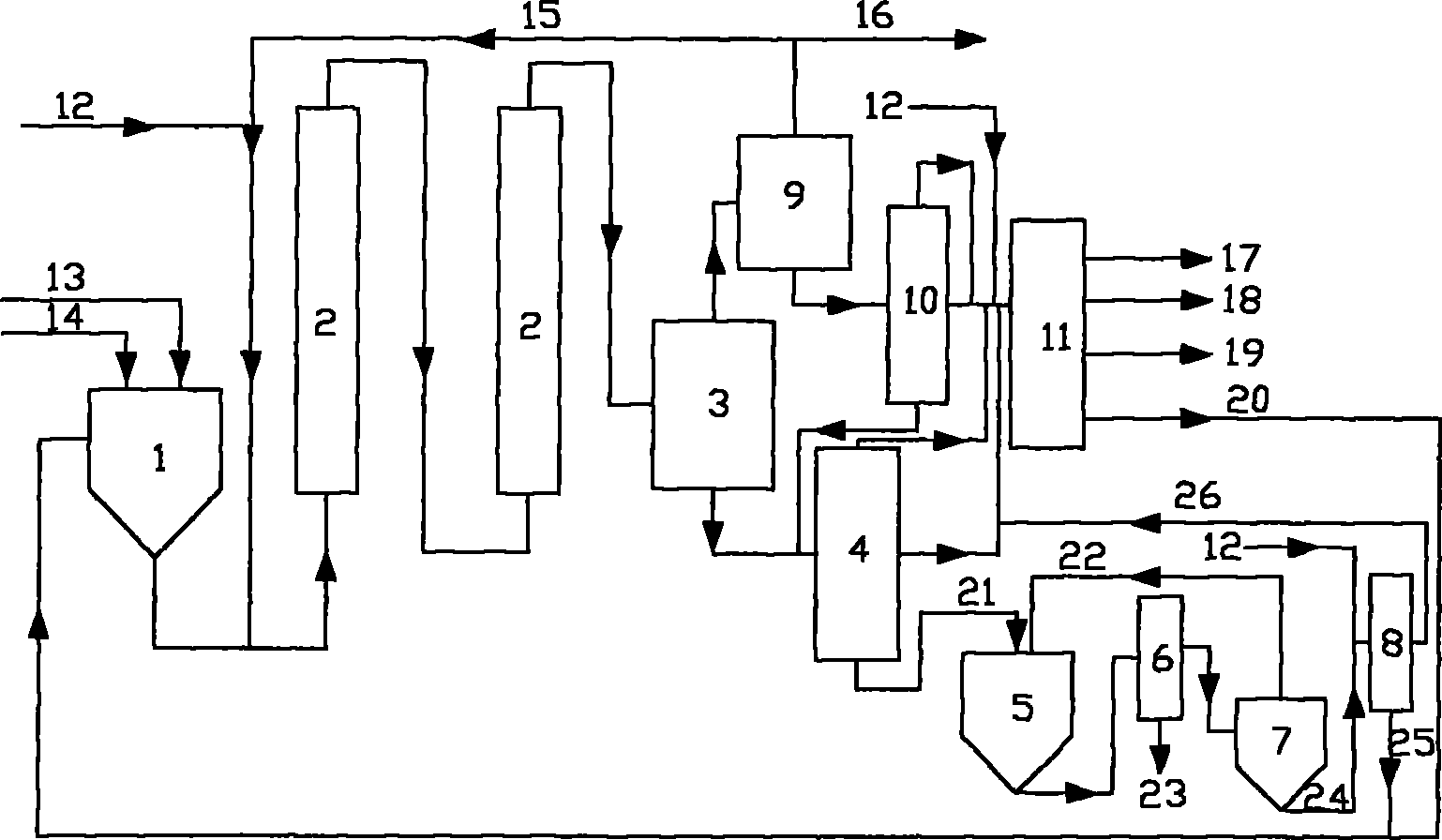

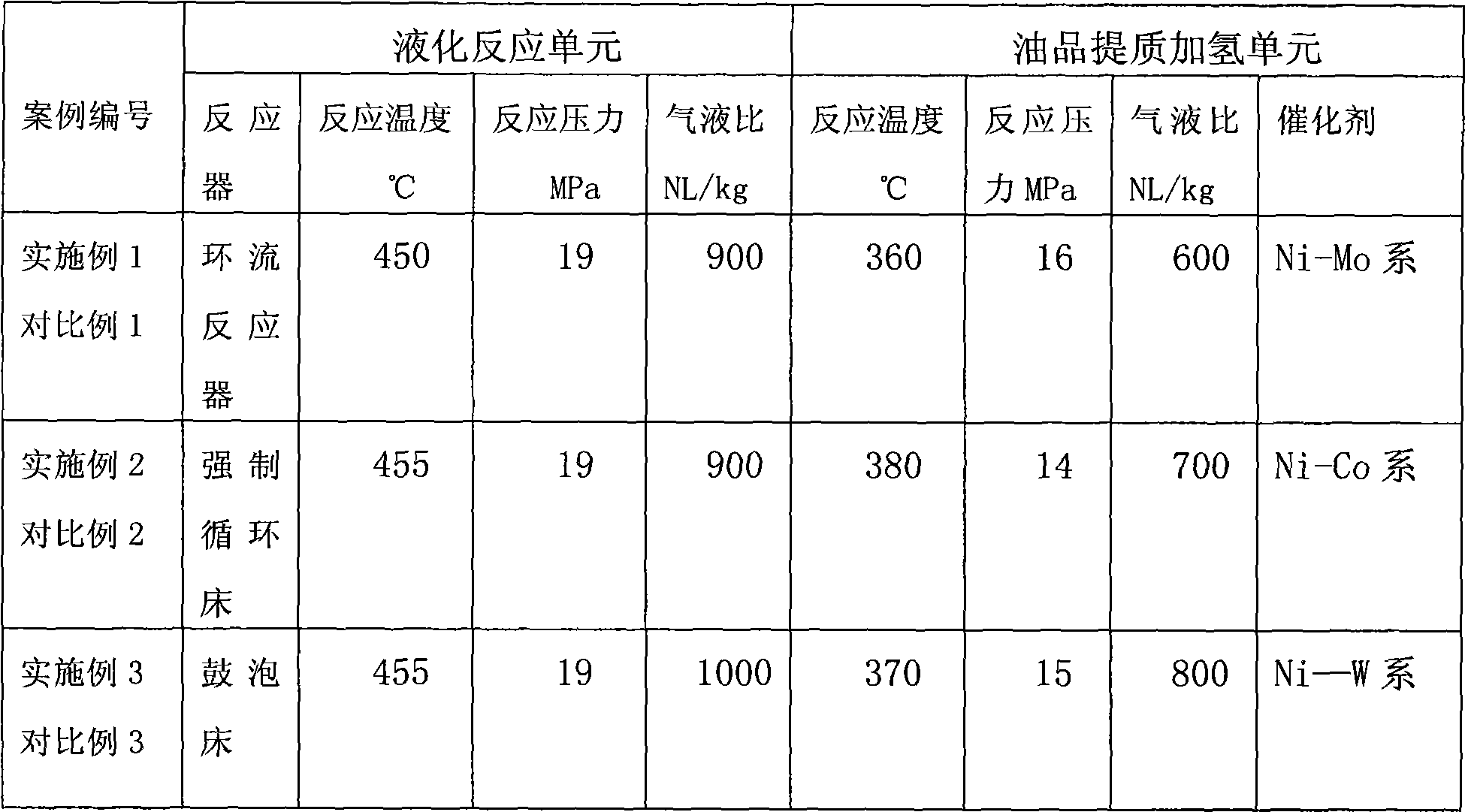

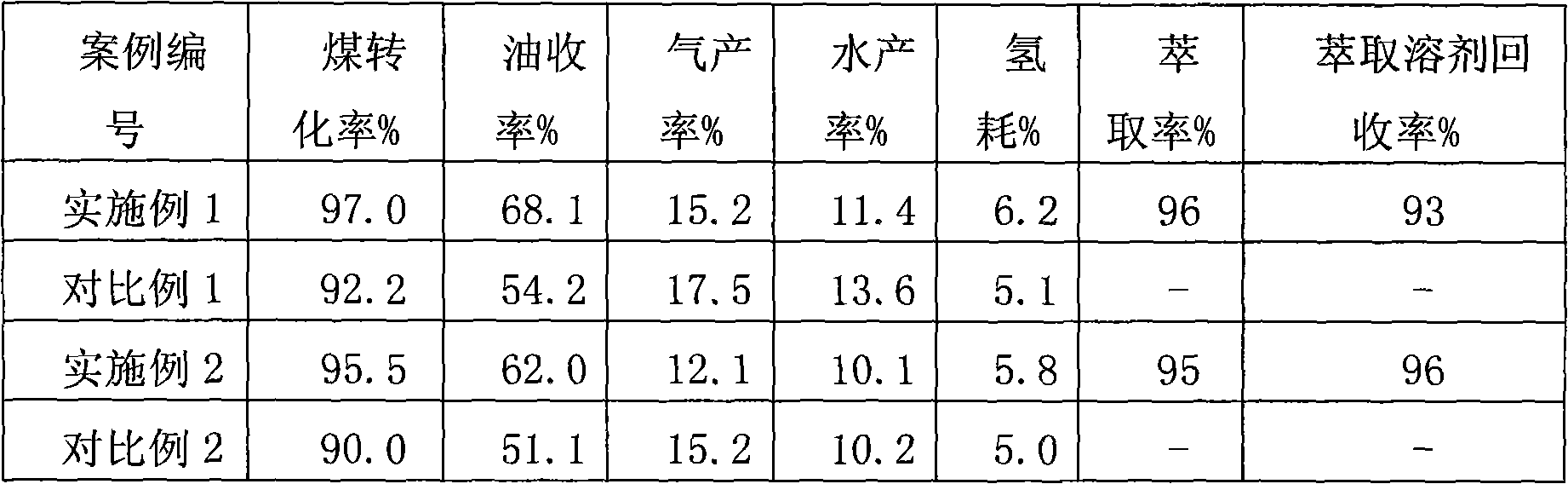

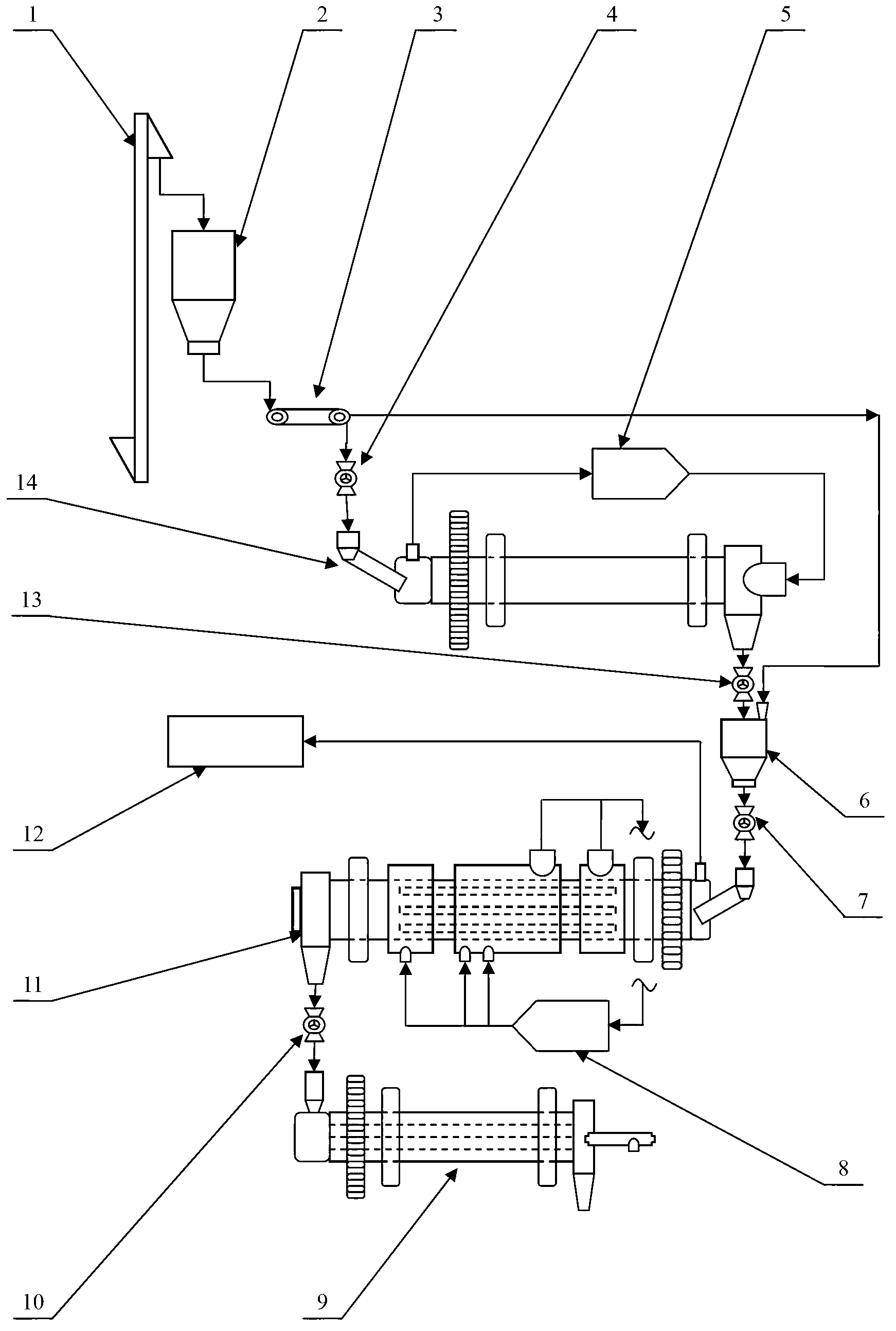

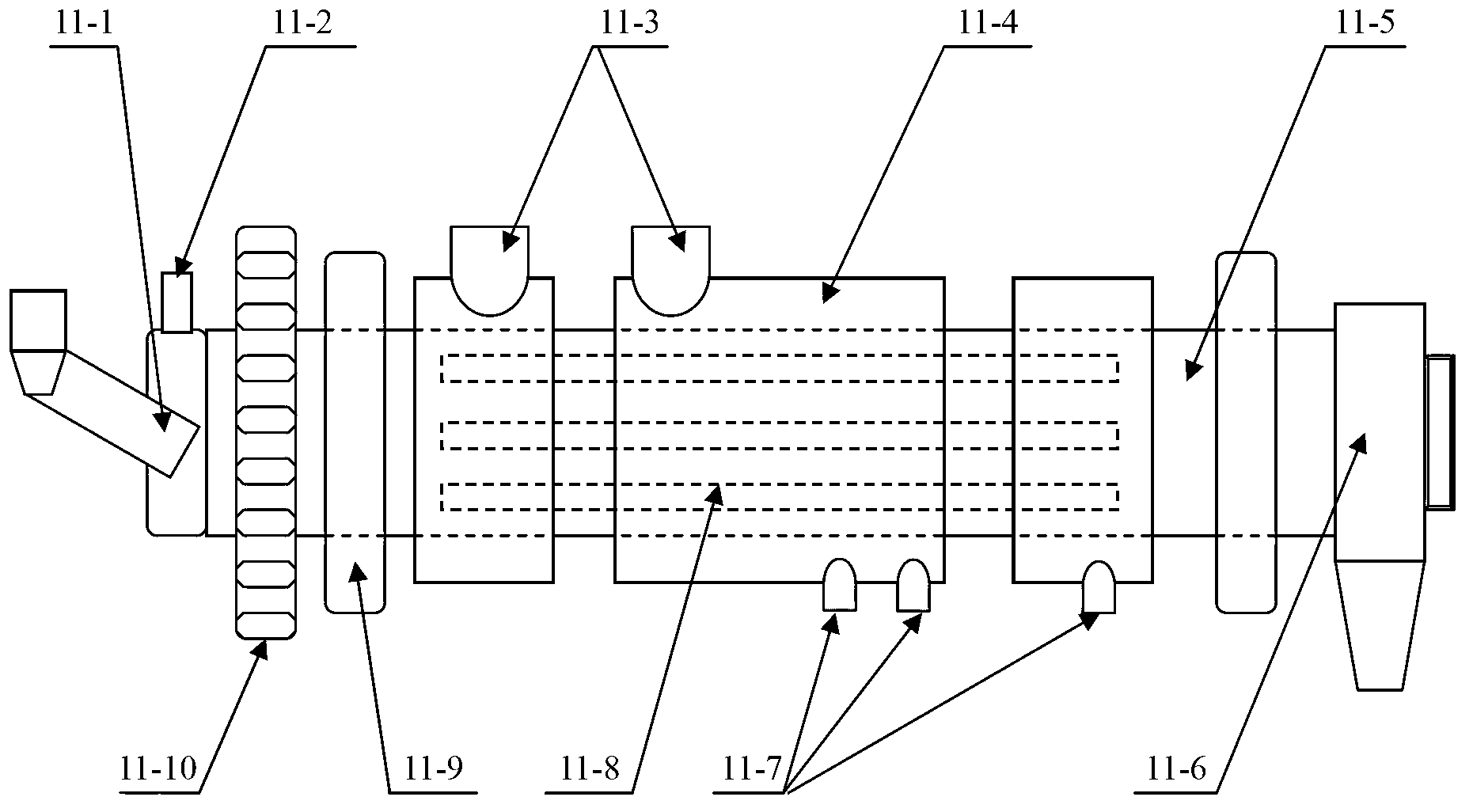

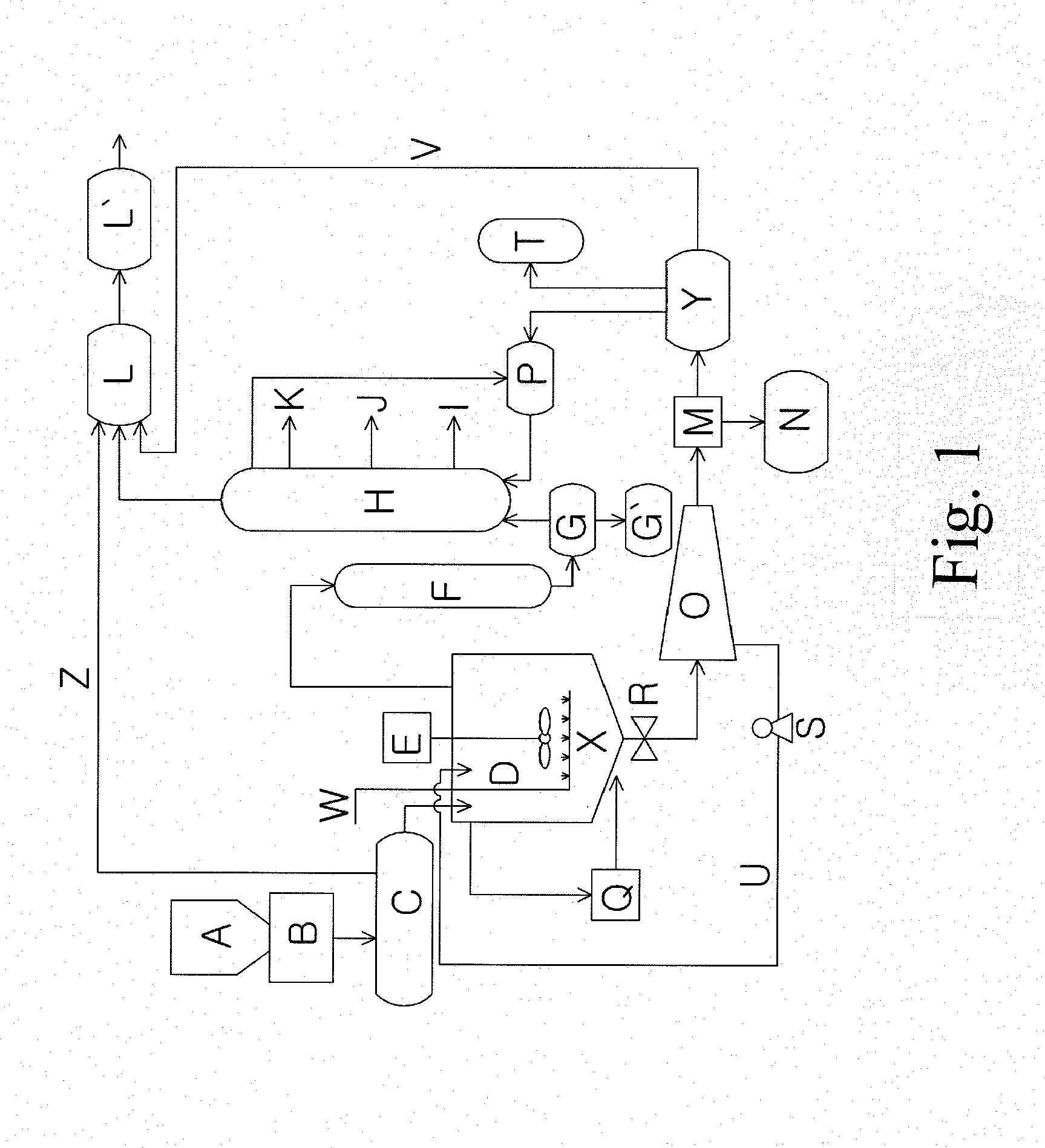

Method for directly liquefying coals with function of maximizing utilization of liquefied residues

ActiveCN102010741AGreat operating flexibilityHigh air hold-upLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesEconomic benefitsOil separation

The invention relates to a method for directly liquefying coals with a function of maximizing utilization of liquefied residues. The method comprises the following technical steps: preparing coal paste; carrying out hydrotreating and liquefaction on the coal paste; carrying out oil separation treatment on the obtained oil product; carrying out upgrading and hydrotreating on the obtained product; carrying out hot extraction on the residues and then carrying out solid-liquid separation on the residues; and recovering the solvent; and carrying out hydrotreating treatment on the mixture of heavy oils and asphalt materials so as to obtain the final product, then taking the heavy oils as recycled solvent to prepare the coal paste, and the like. The method provided by the invention has the advantages that because of organically combining the liquefaction process and the residue extraction, the utilization of liquefied residues is maximized, the conversion rate of coal is improved, the yieldsof light and middle oils subjected to coal liquefaction are improved by 10 to 60 percent, and the quality of oil is improved, thereby greatly enhancing the economic benefits of direct coal liquefaction plants and improving environment protection; and the method provided by the invention has important economic and social significances, and can widely be applied to the field of coal direct liquefaction.

Owner:CHINA COAL RES INST

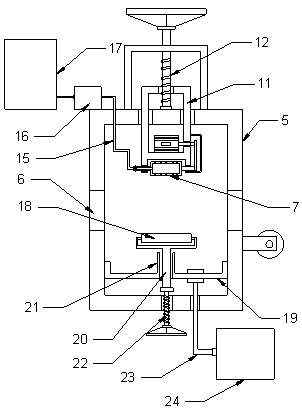

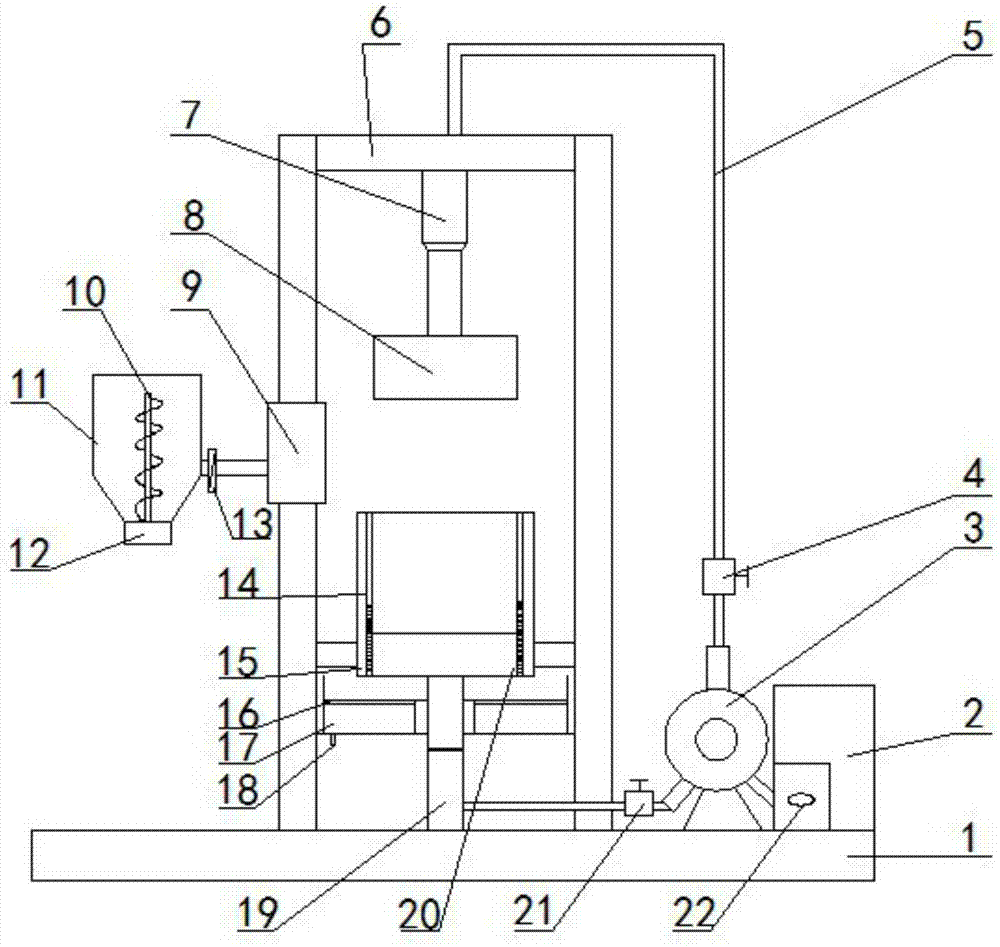

Low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass

ActiveCN103160301AIncrease profitReduce energy consumptionDirect heating destructive distillationBiofuelsCarbonizationOil shale gas

The invention discloses a low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass. The apparatus comprises a delivery apparatus, a storage bin, a metering apparatus, a drying furnace and a surge bin. The method comprises the following steps: drying, preheating, carbonizing, and cooling. The core of the invention is an external heating type rotary carbonization furnace which realizes the pyrolysis of oil sand, oil shale, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery) and biomass, and the product is high in purity and low in loss. The invention effectively solves the problems of solid materials such as adhesion, wall accretion and the like in the pyrolysis process by material returning. The technology provided by the invention is simple in process and reliable and stable in operation, and has obvious advantages in the treatment of small particle materials such as oil shale, oil sand, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery), biomass and the like.

Owner:何建祥

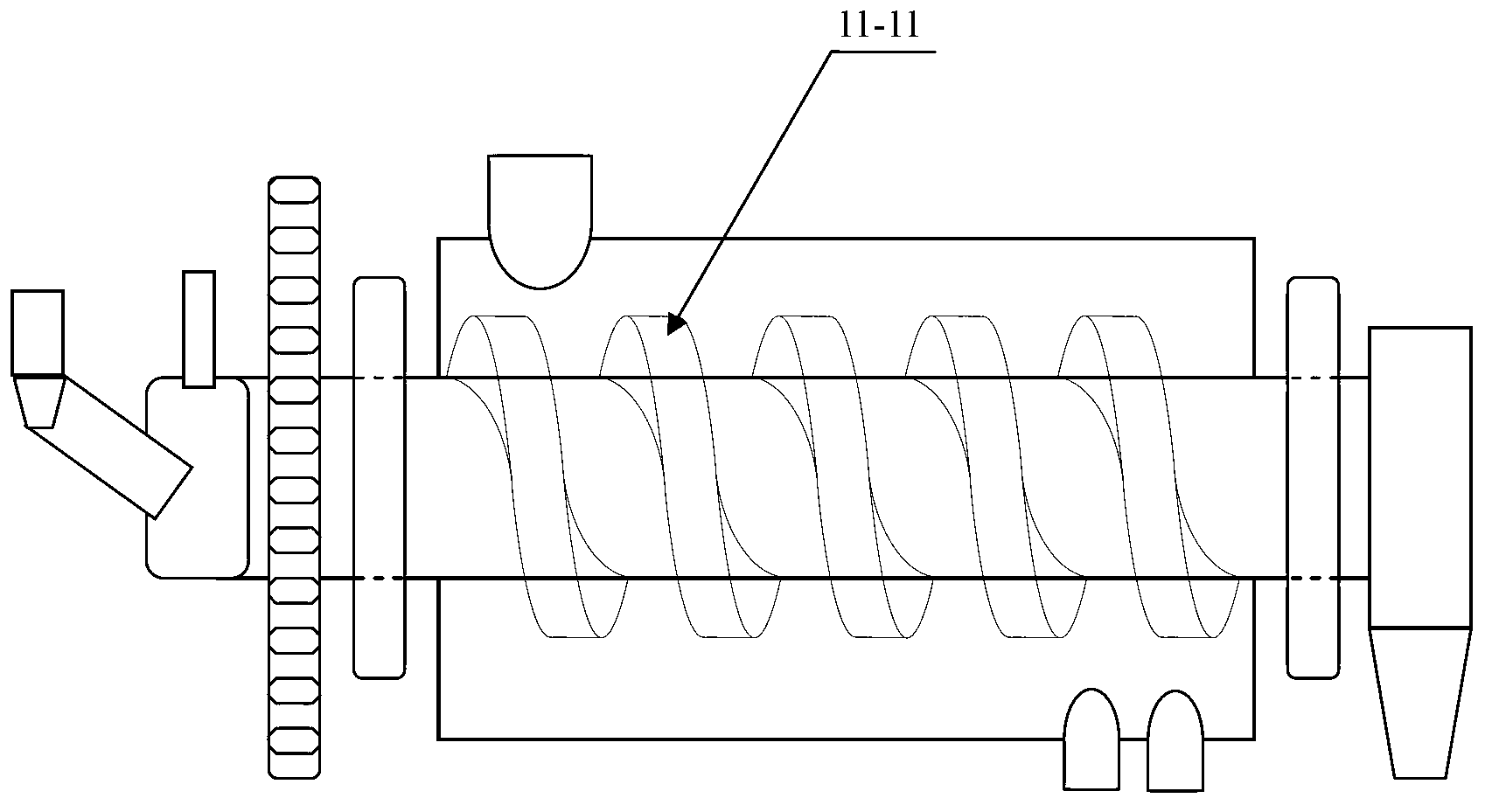

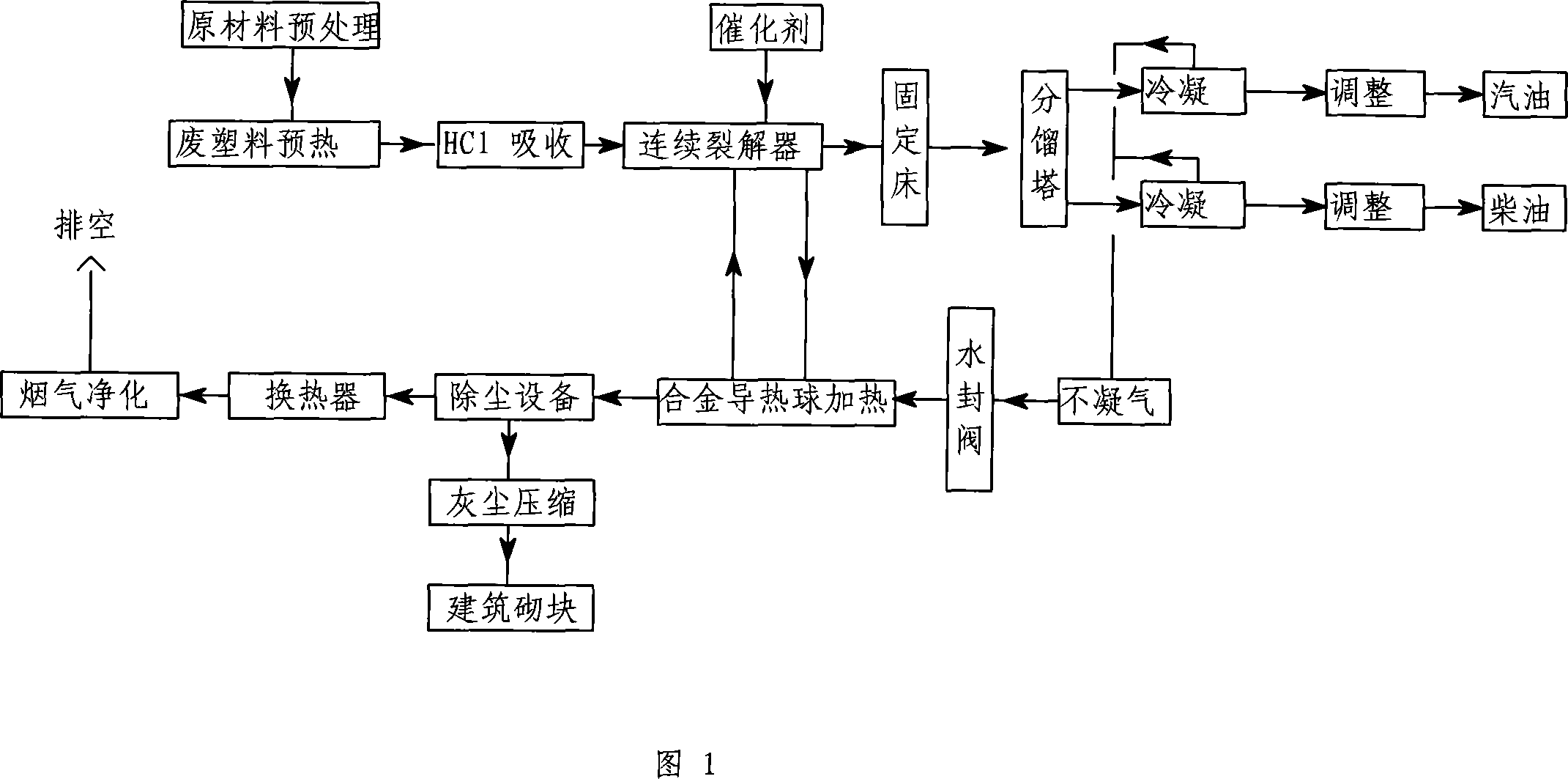

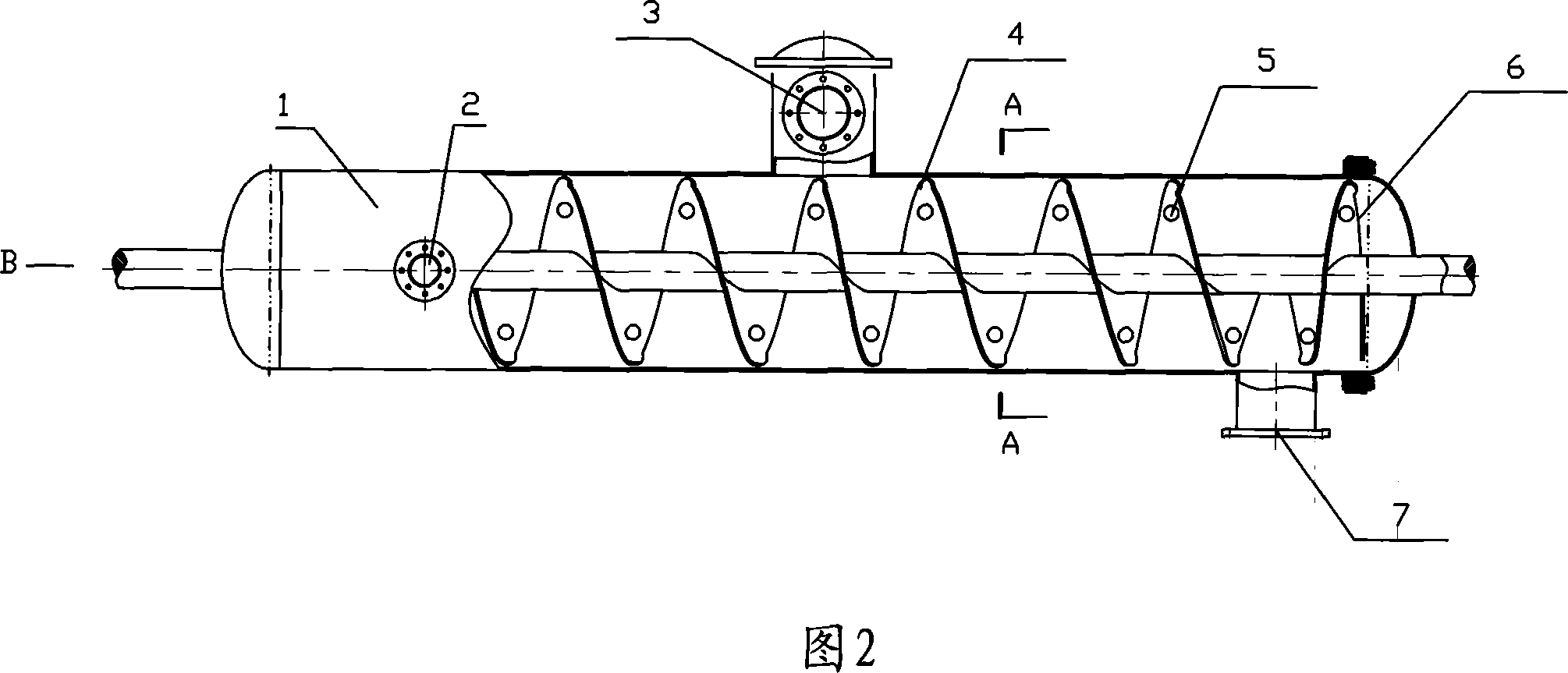

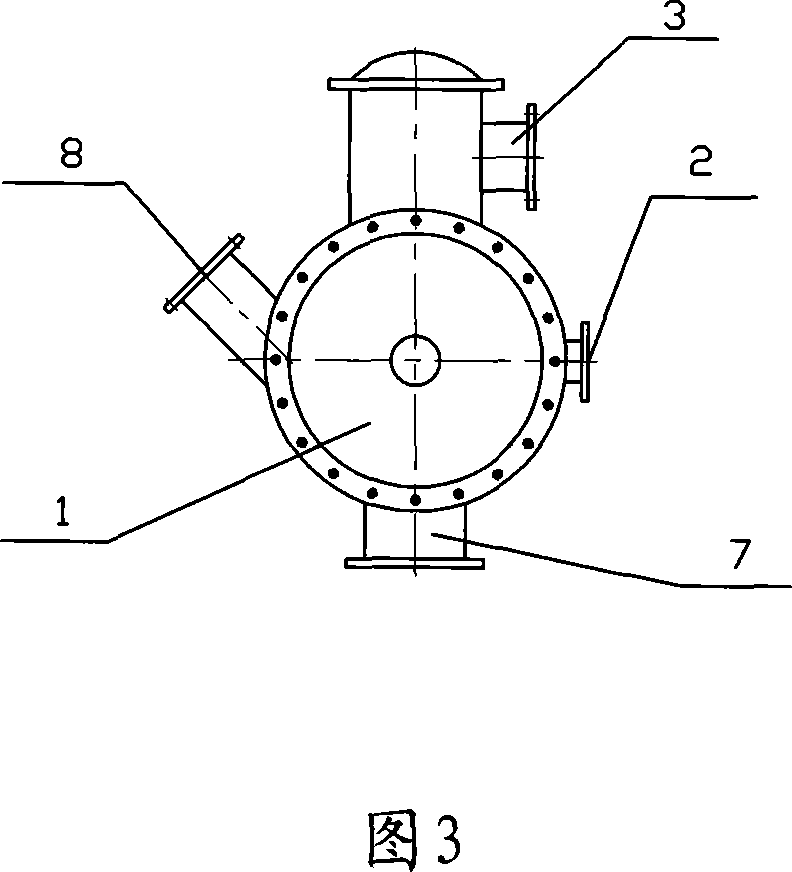

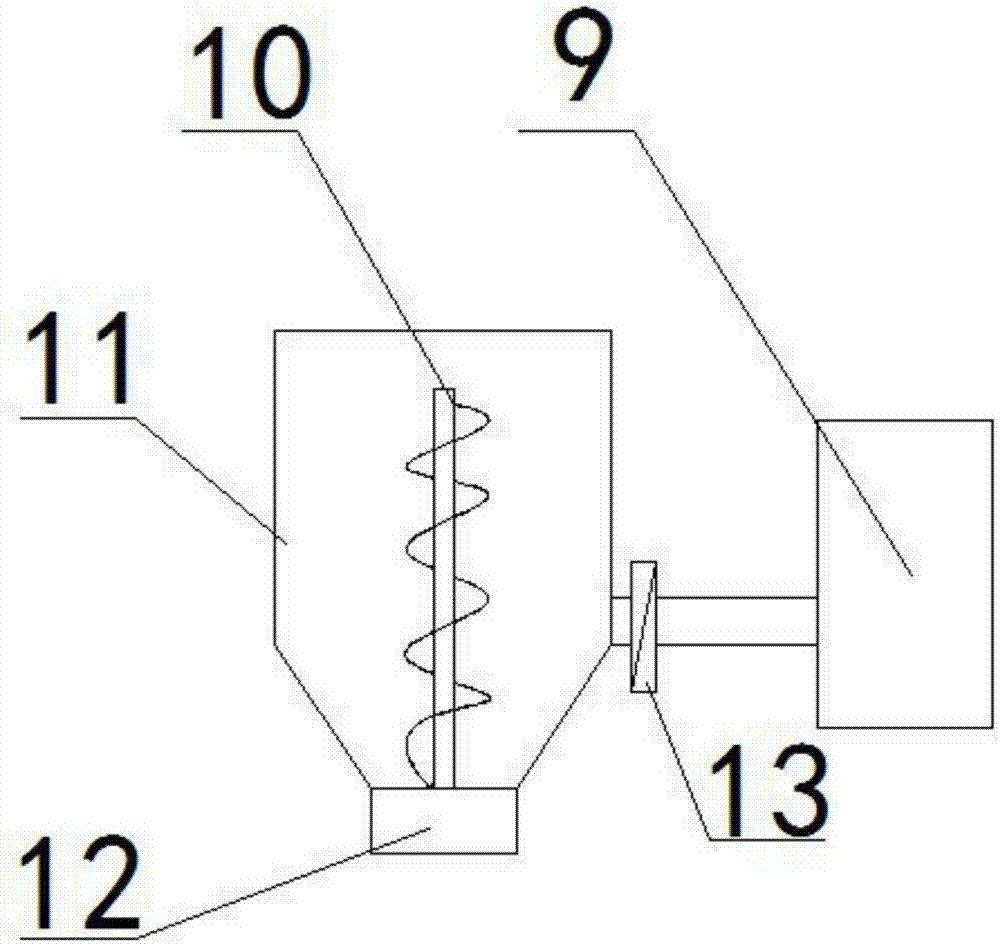

Waste-plastic continuous cracking process and cracker

ActiveCN101074385AFast responseImprove oil qualityLiquid hydrocarbon mixture productionExhaust gasHeat carrier

A process and apparatus for cracking plastic are disclosed. The process is carried out by mixing raw material with solid fluid heat carrier in cracker, moving co-currently, heating, while cracking continuously to obtain final product. Spiral impelling mechanism is arranged in casing, feed inlet and solid heat carrier inlet is arranged at front of casing; solid heat carrier and solid product outlet are arranged at rear of casing. It's cheap, automatic, efficient and convenient. It has no environmental pollution.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

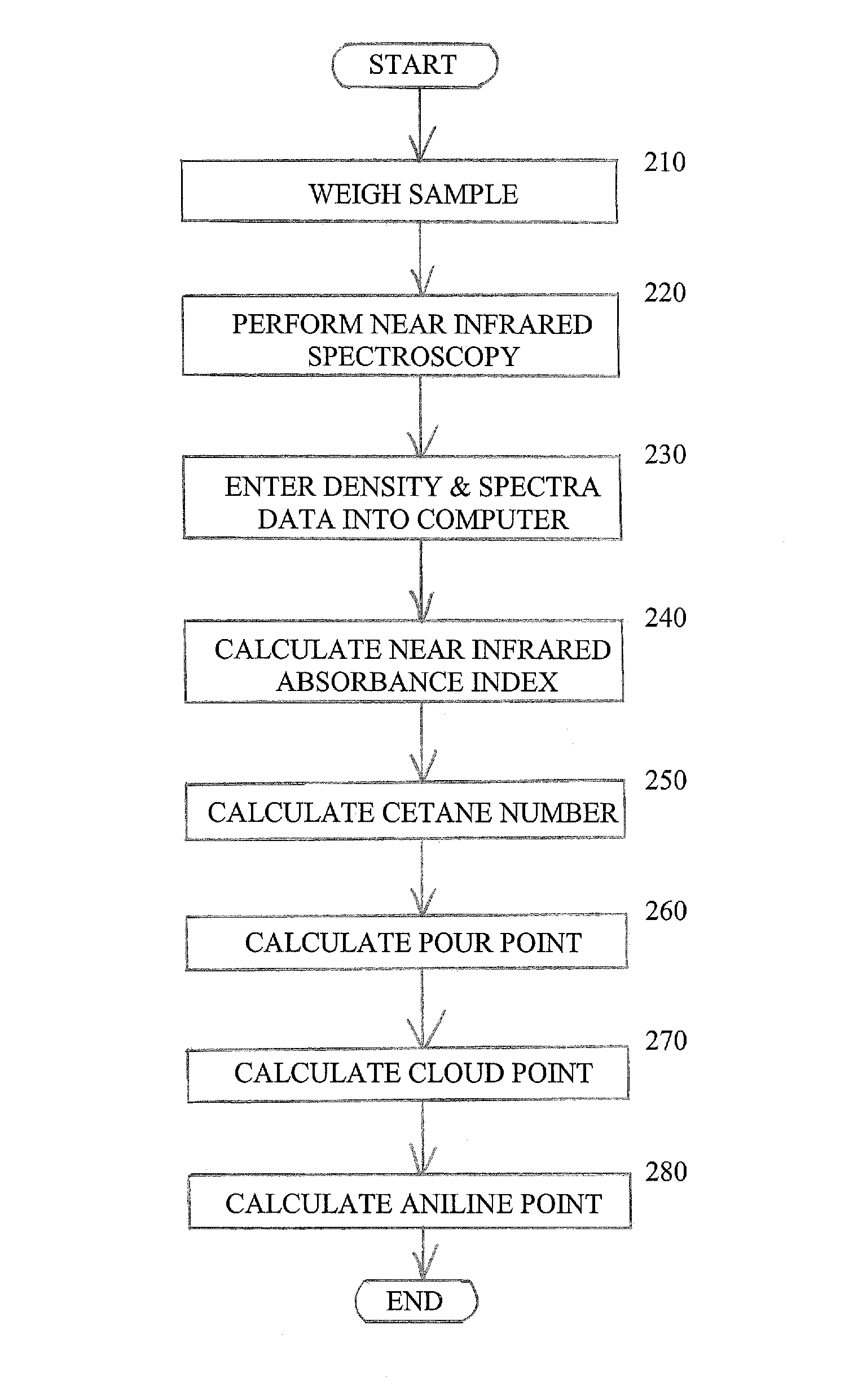

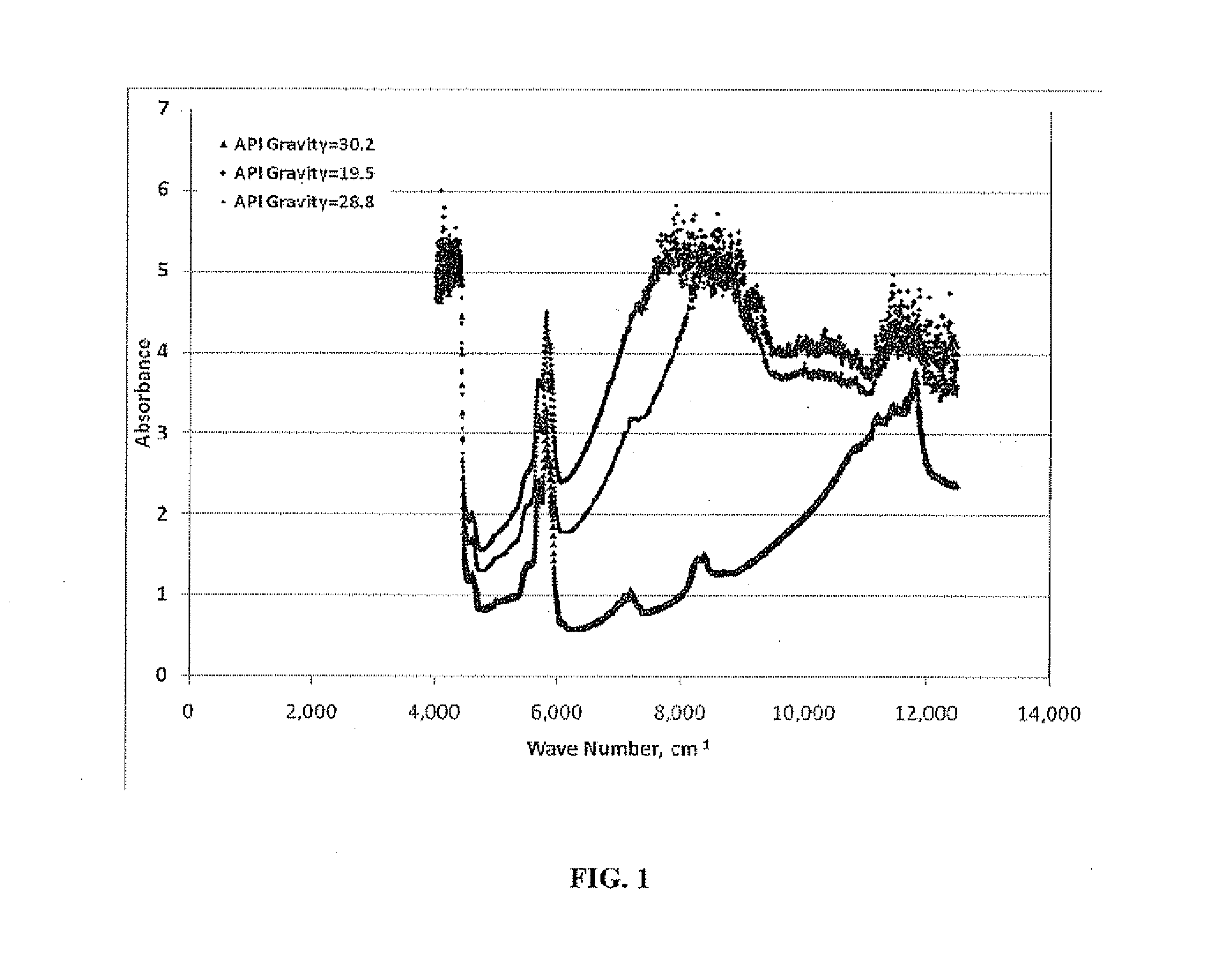

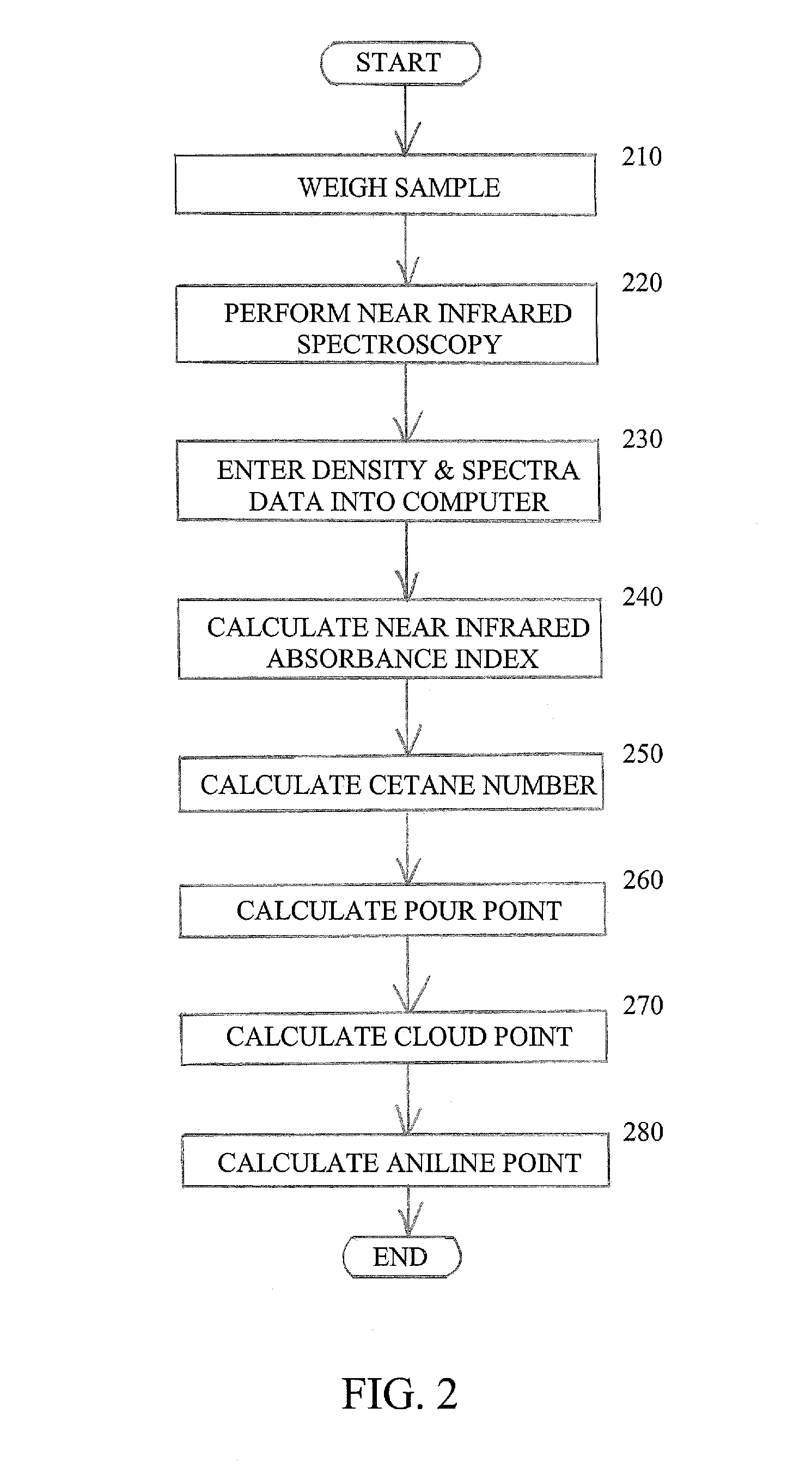

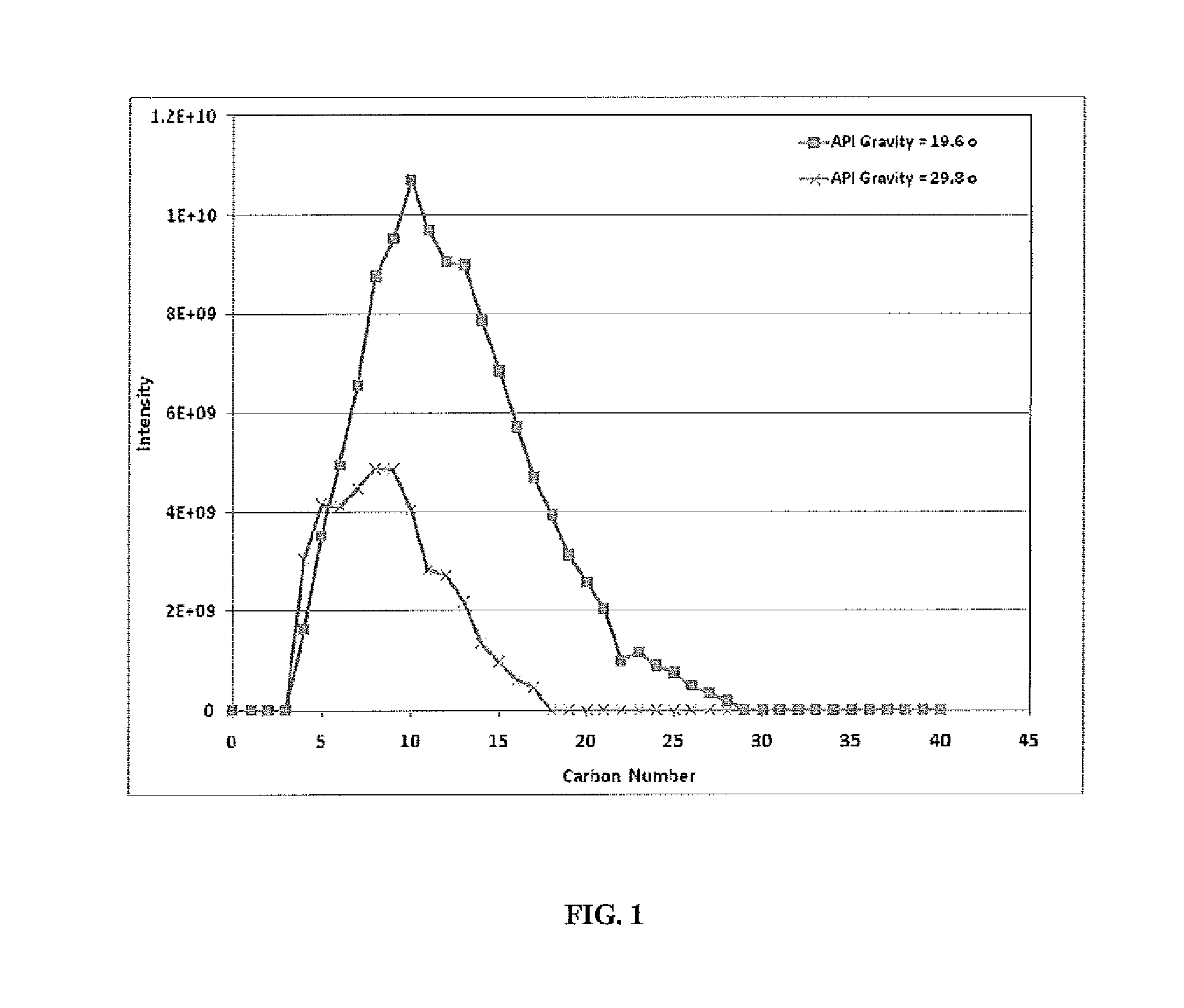

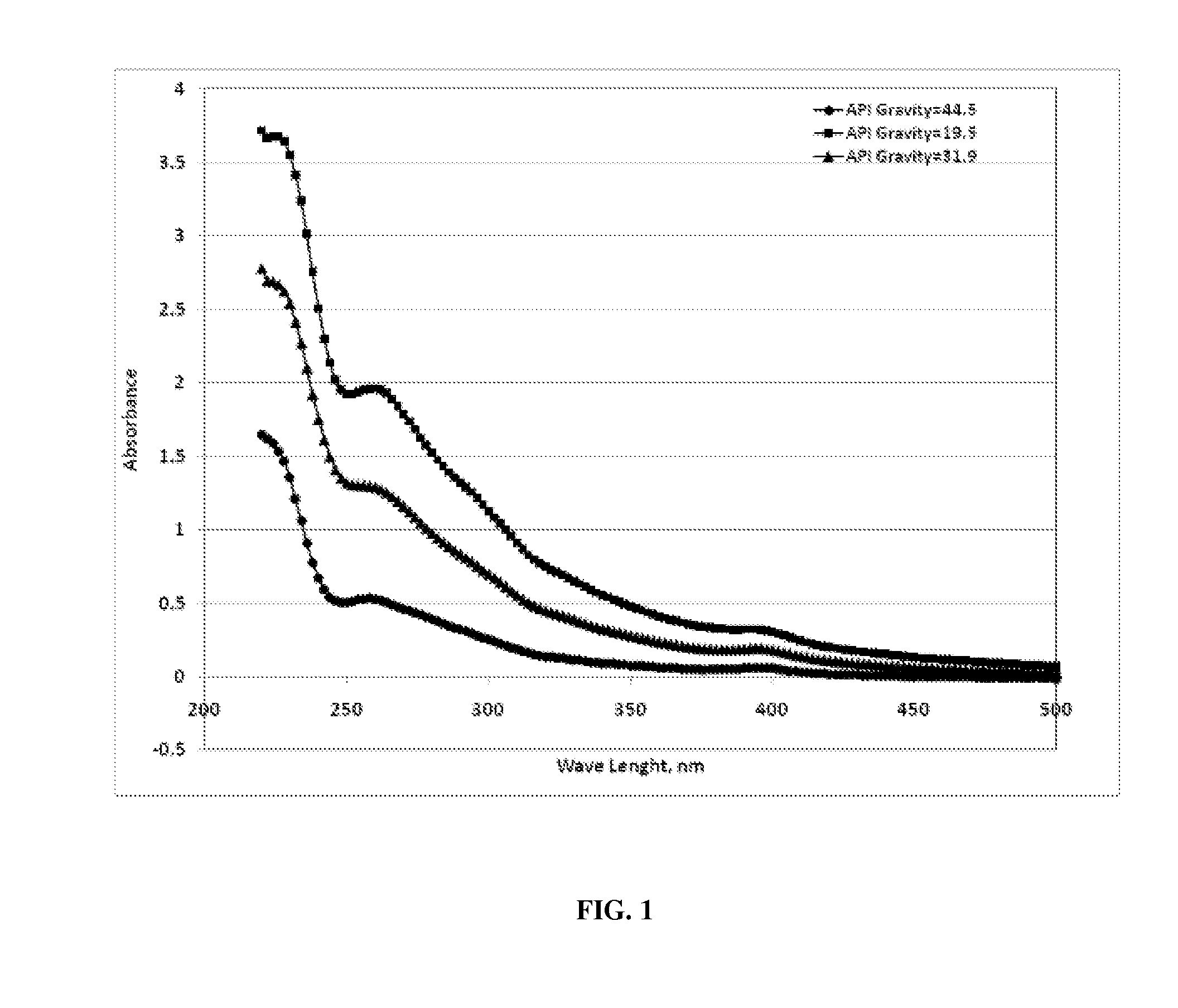

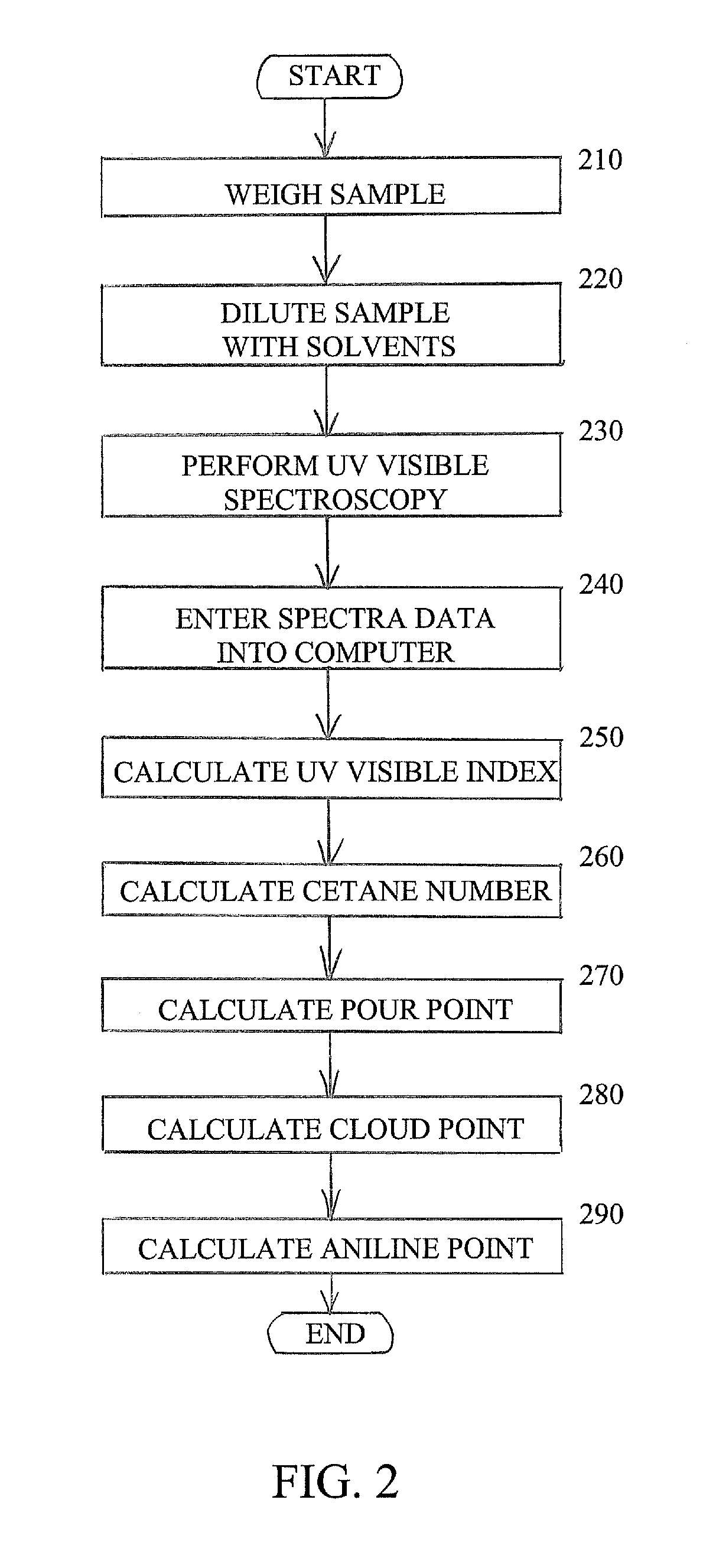

Characterization of crude oil by near infrared spectroscopy

InactiveUS20150106031A1Provide informationImprove oil qualityMaterial analysis by optical meansAbsorption/flicker/reflection spectroscopyAniline pointCloud point

A system and a method for calculating the cetane number, pour point, cloud point and aniline point of a gas oil fraction of a crude oil from the density and near infrared spectroscopy of a sample of the crude oil.

Owner:SAUDI ARABIAN OIL CO

Steel pipe mechanical-oiling equipment

InactiveCN109550640AReduce dosageEfficient dust removalLiquid surface applicatorsCoatingsArchitectural engineeringFuel tank

The invention discloses steel pipe mechanical-oiling equipment which comprises a base, an oiling mechanism, a dust removing mechanism and a feeding mechanism, wherein the oiling mechanism comprises anoiling tank which is fixedly connected with the base; an oiling roll is arranged in the oiling tank; uniformly-distributed overflow holes are formed in the circumferential surface of the oiling roll;the dust removing mechanism comprises a dust removing tank; and a ring-shaped brush is arranged in the dust removing tank. The steel pipe mechanical-oiling equipment disclosed by the invention has the beneficial effects that through the arrangement of the hollow oiling roll provided with the overflow holes as well as a spreading roll capable of rising and falling, the surface of a steel pipe canbe uniformly coated with anti-rust oil, thereby improving the oiling quality when the consumption of the anti-rust oil is reduced; and through the arrangement of the ring-shaped brush, a dust collecting hood and a dust collecting tank which communicates with a suction piston cylinder, the efficient dust removing operation on the to-be-oiled steel pipe can be achieved, thereby guaranteeing the oiling quality; and through the arrangement of a rotating cylinder and a sliding frame which are equipped with a clamping mechanism, the steel pipe can be rotated when fed, thereby facilitating the oilingoperation on the circumferential surface of the steel pipe.

Owner:HUNAN UNIV OF SCI & ENG

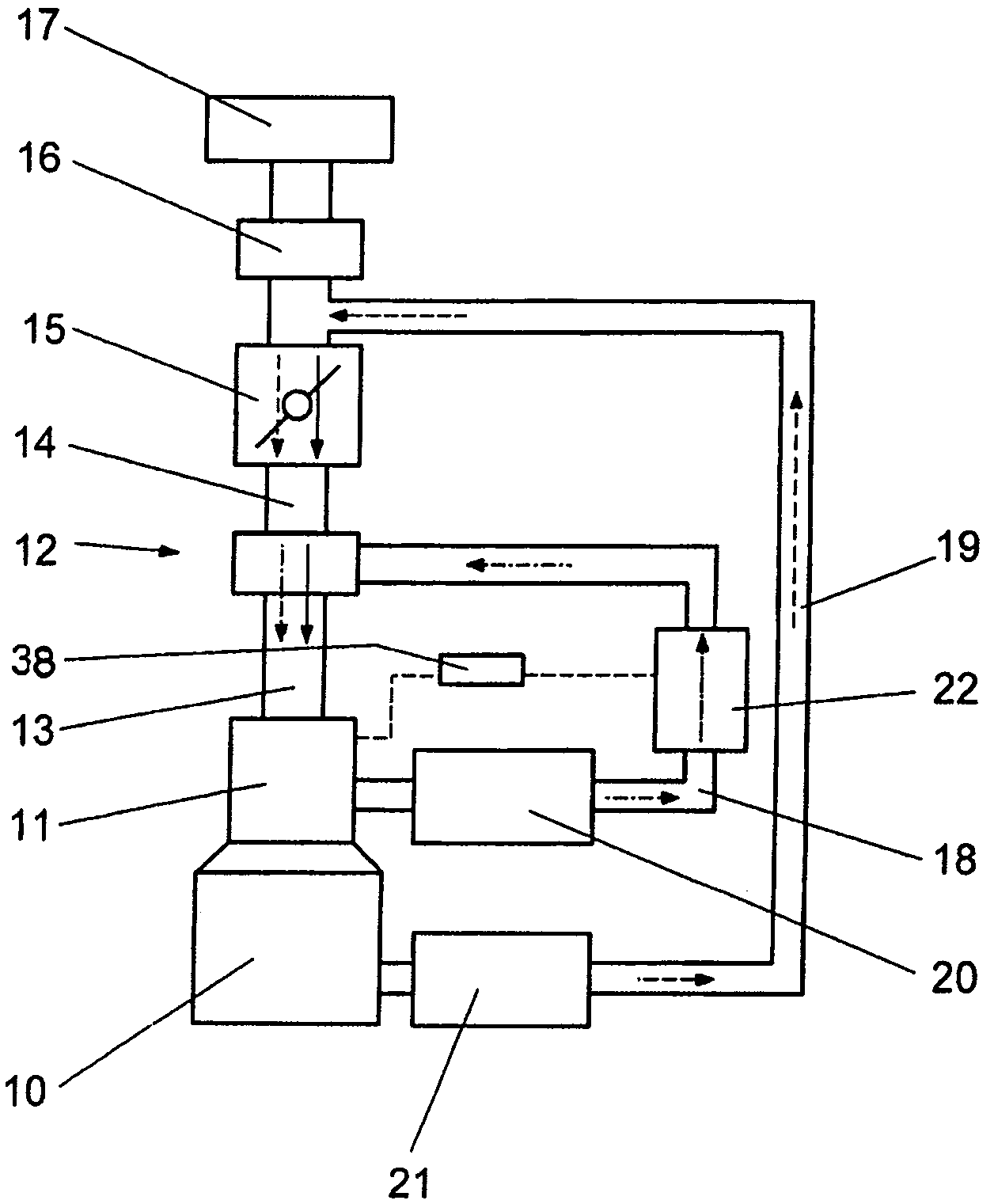

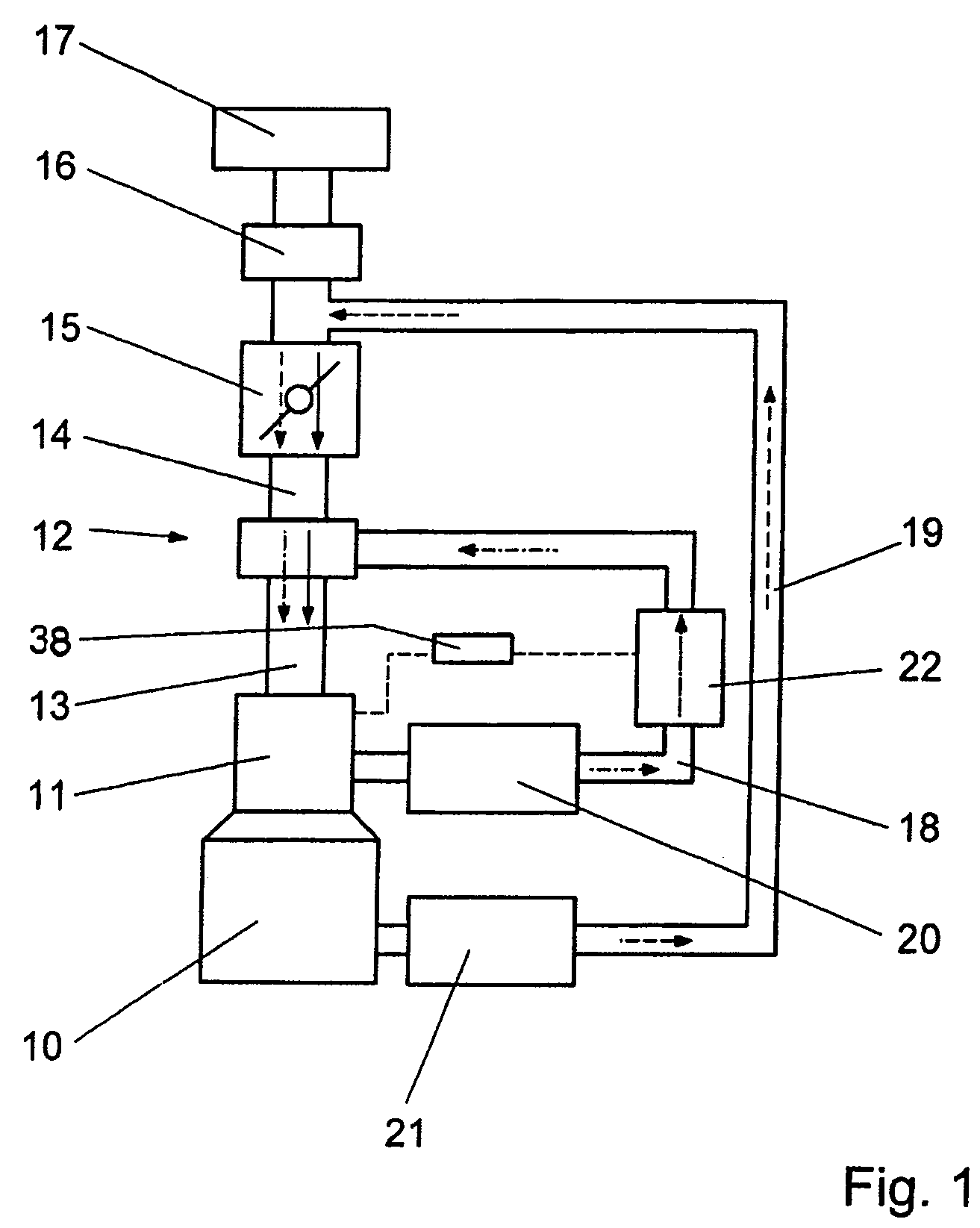

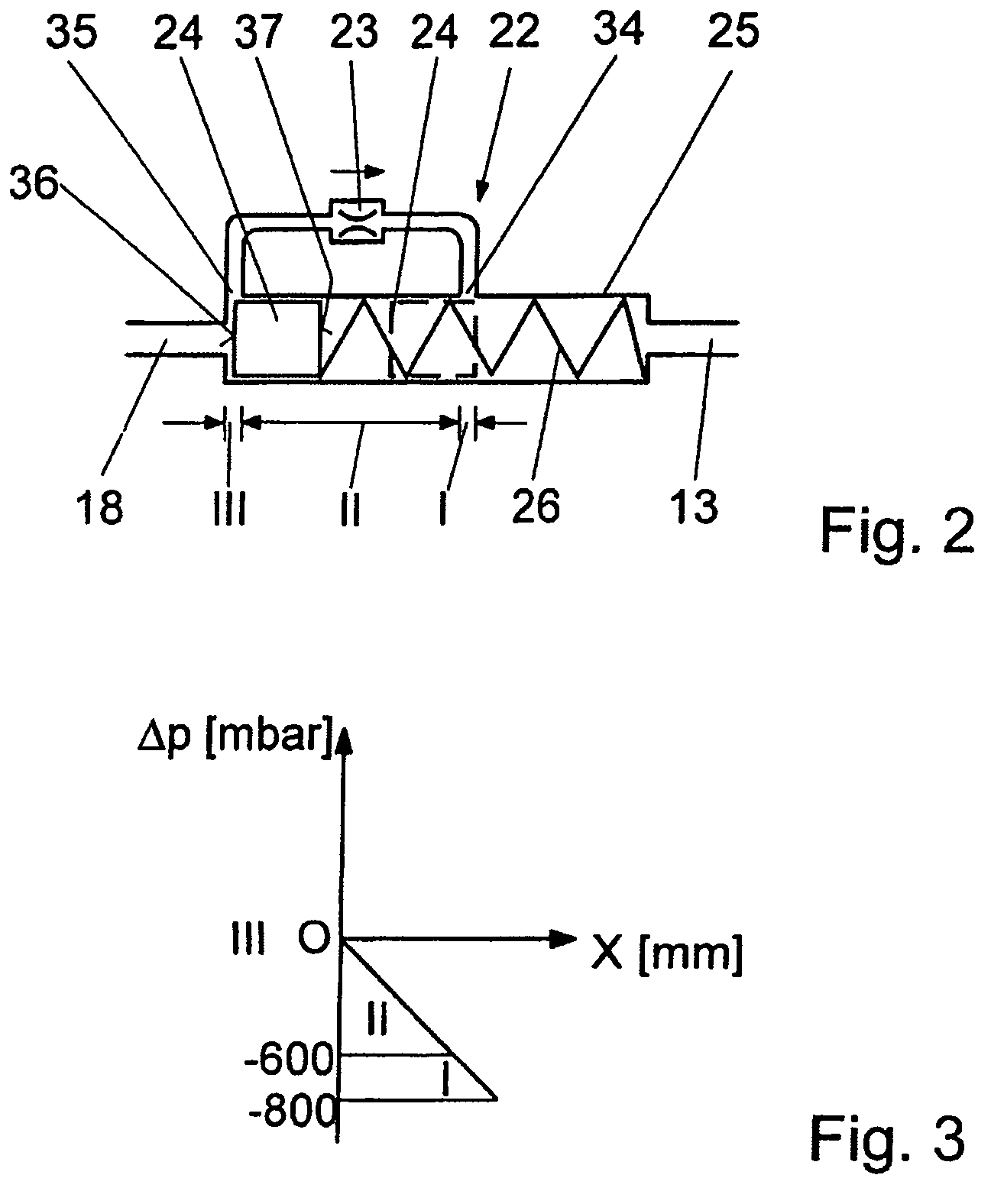

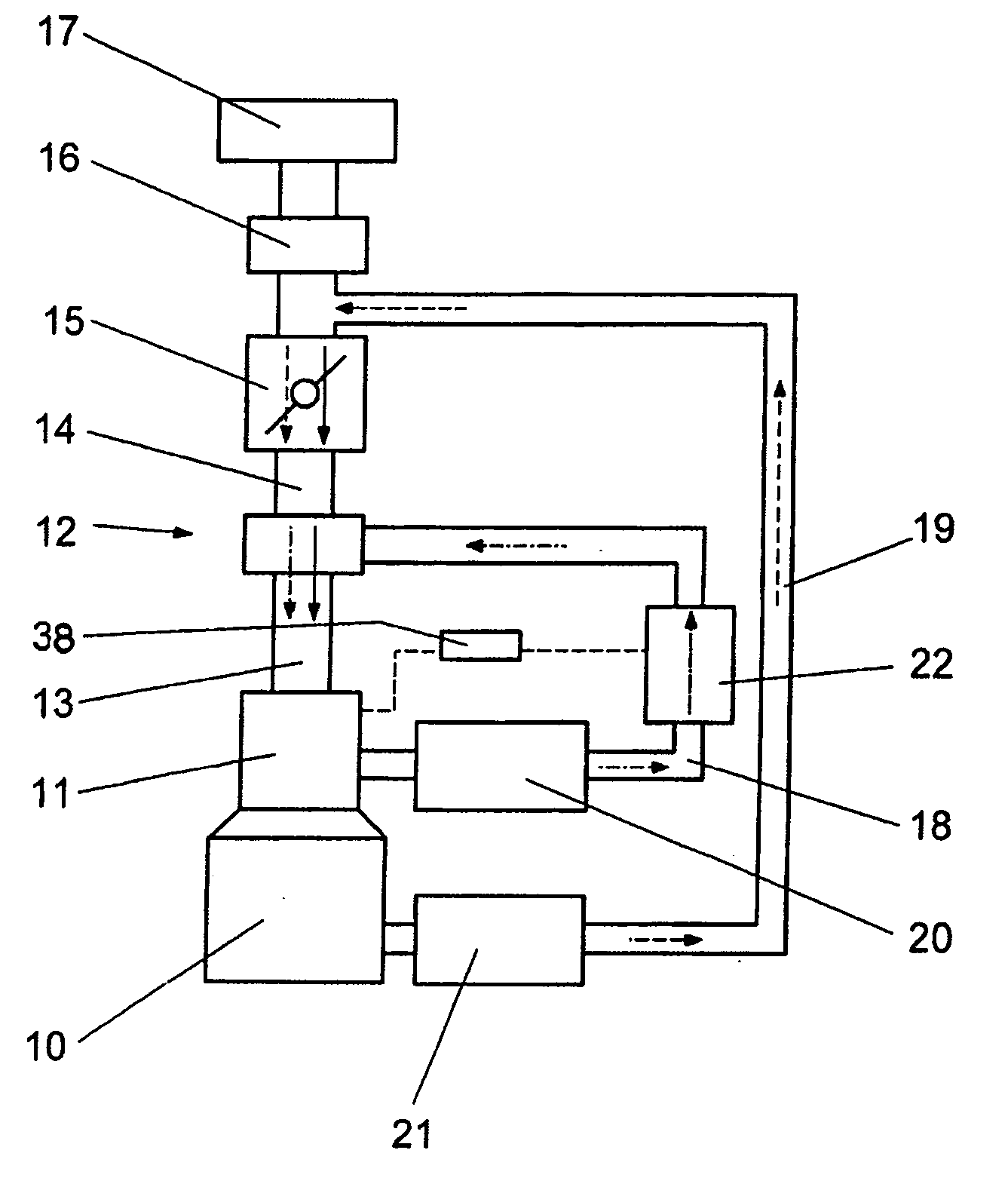

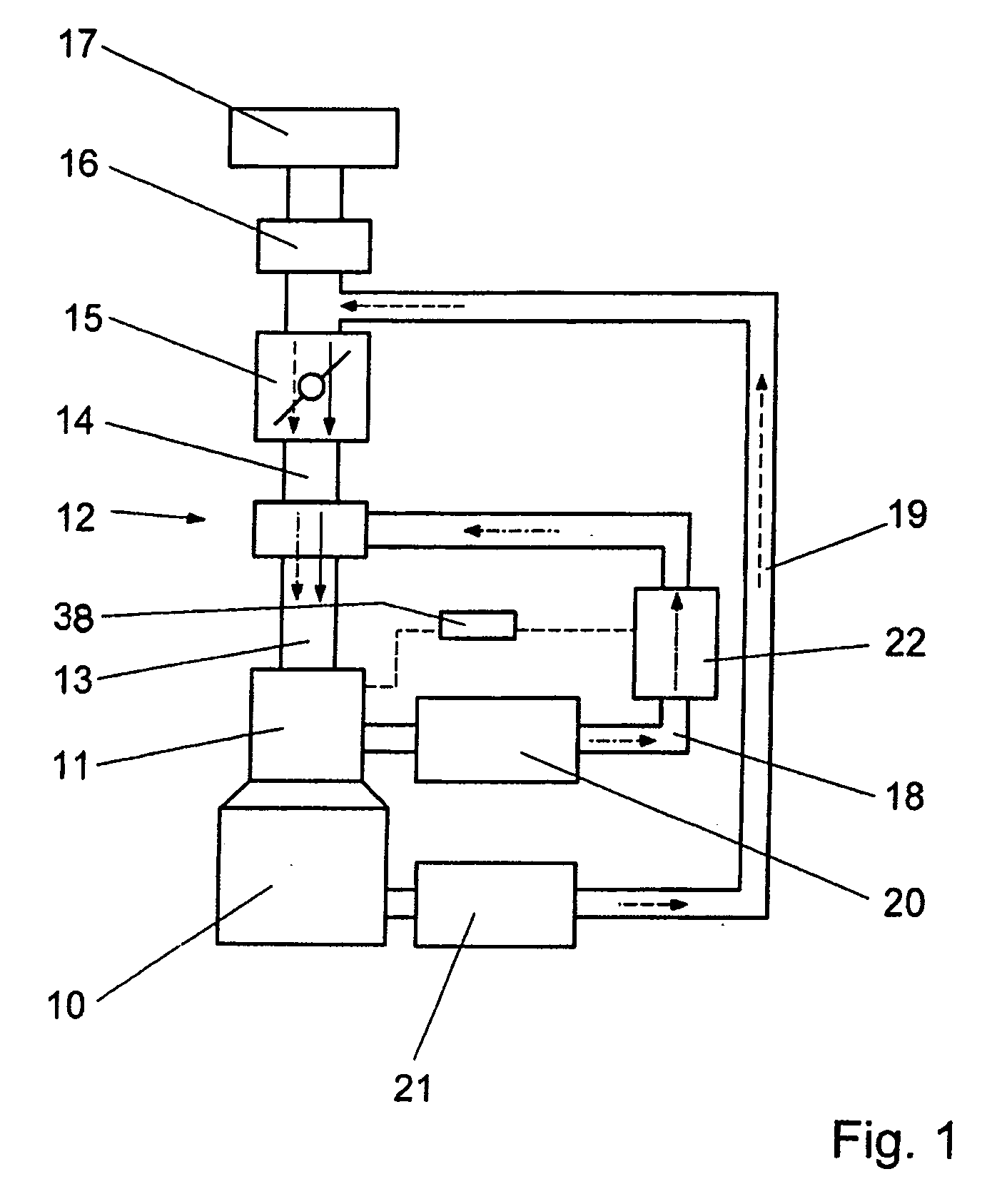

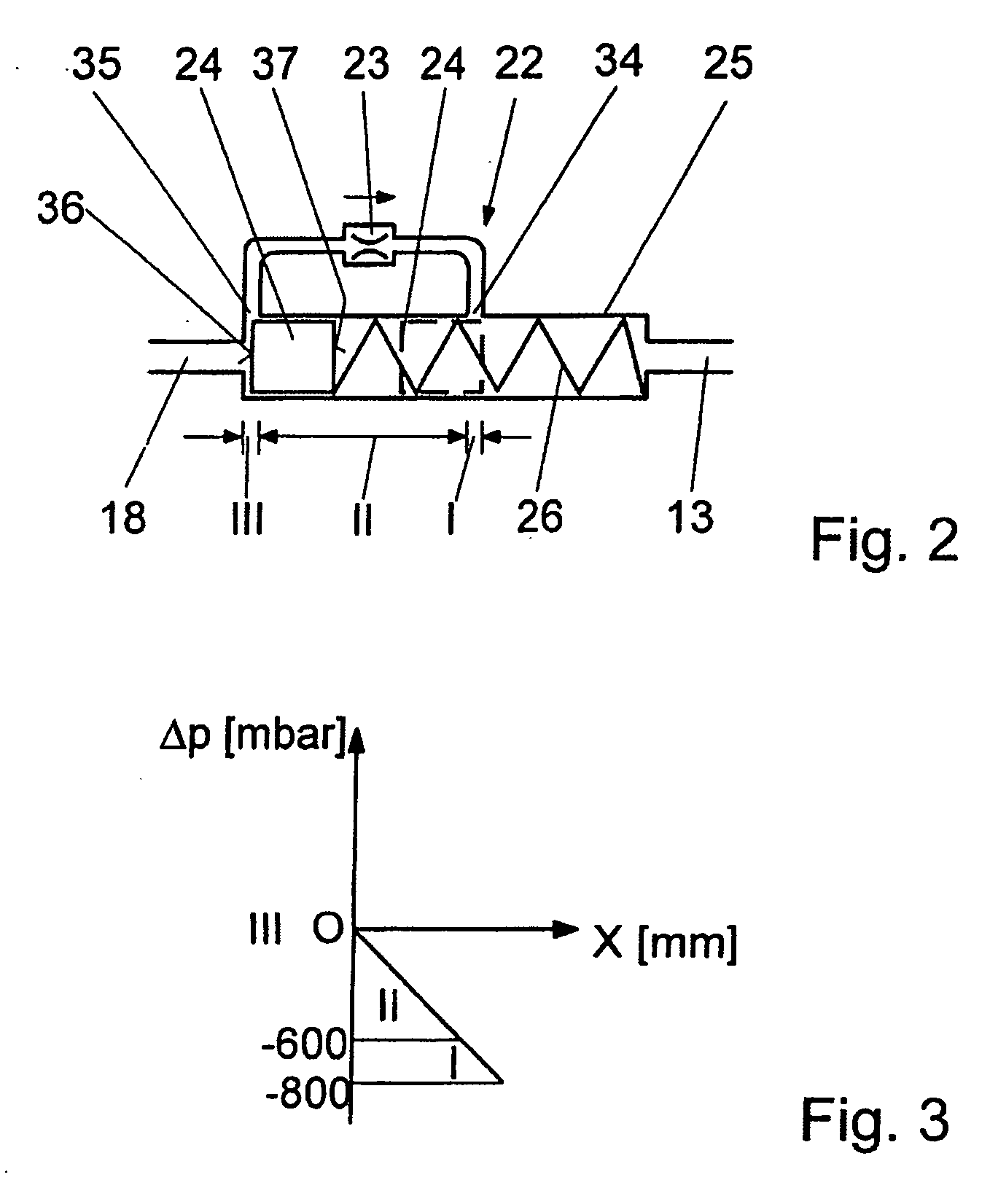

Method and apparatus for venting a crankcase of an internal combustion engine

ActiveUS7275527B2Large sectionIncrease volume flowCombustion enginesCrankcase ventillationLine tubingExternal combustion engine

In a method for venting a crankcase of an internal combustion engine, in which, in a first operating range under part-load, the crankcase is vented via a first venting line, which opens into an intake line of the internal combustion engine downstream of a throttle valve, and in a second operating range under full load engine operation, the crankcase is vented via a second venting line, which opens into the intake line upstream of the throttle valve, the first venting line includes a control valve and a central unit is provided which operates the control valve so as to control the flow of vent gases through the first venting line over a range including a complete flow interruption under engine overrun condition to prevent venting gases from reaching the engine exhaust system when the internal combustion engine is operating in an overrun mode.

Owner:DAIMLER AG

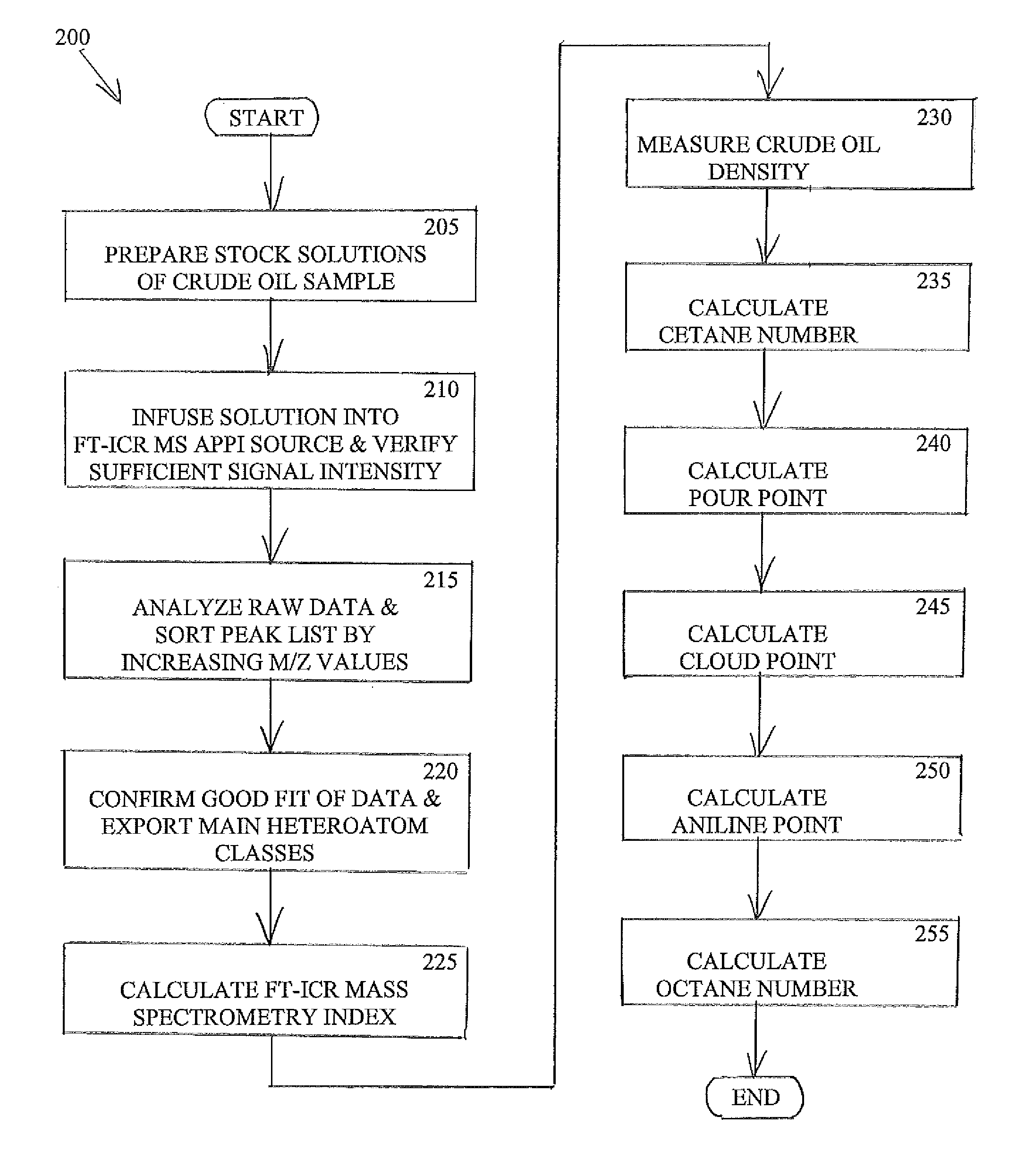

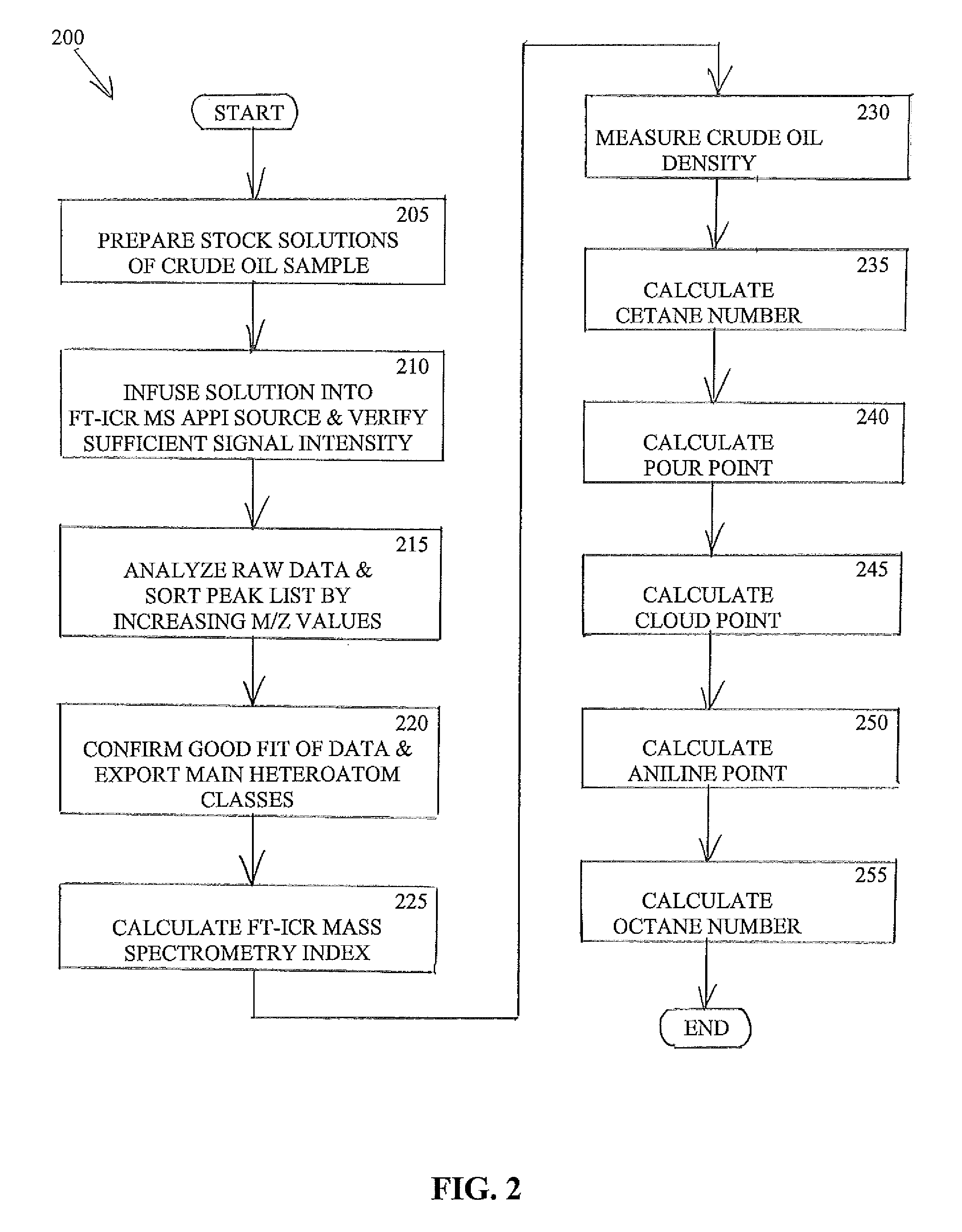

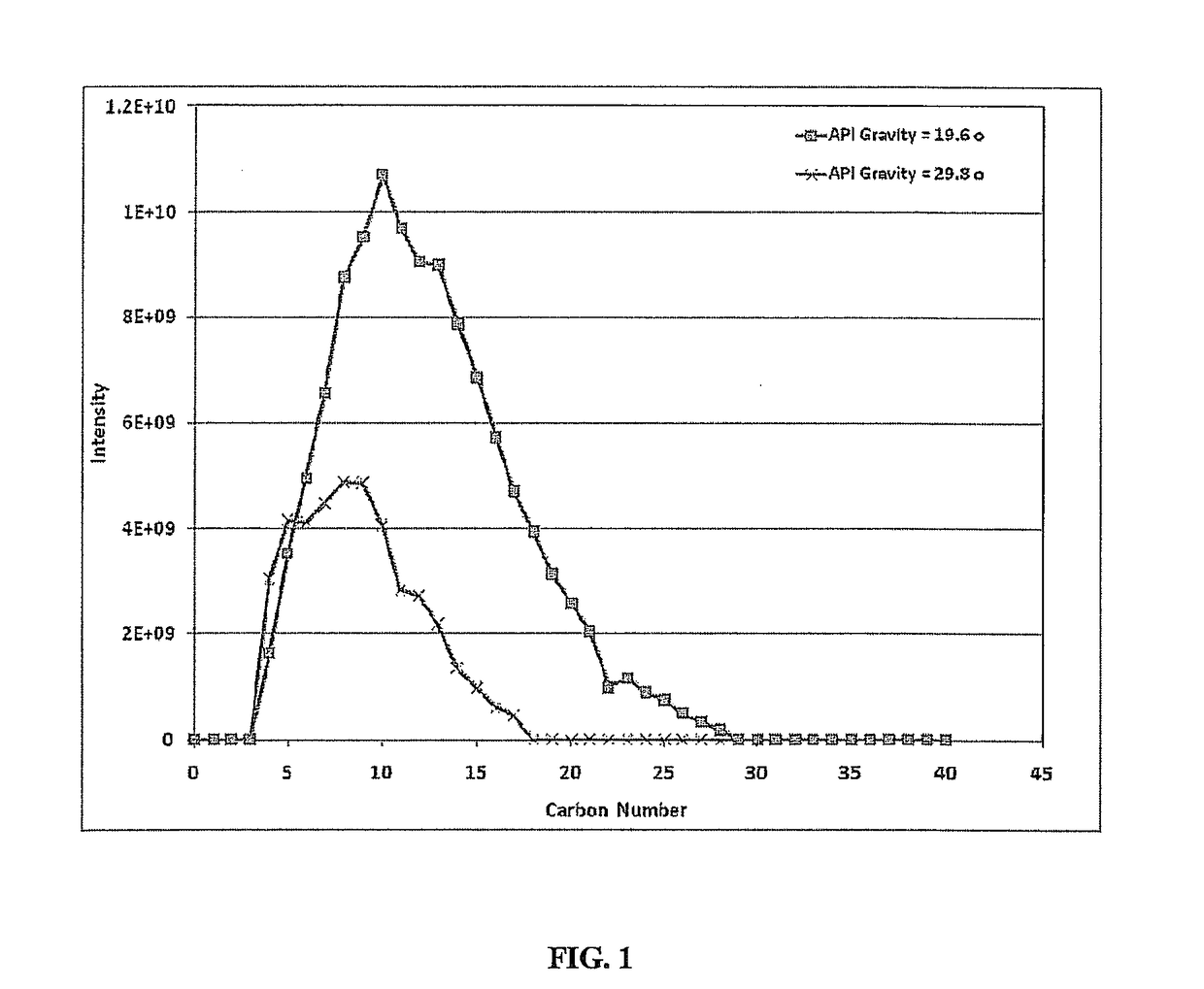

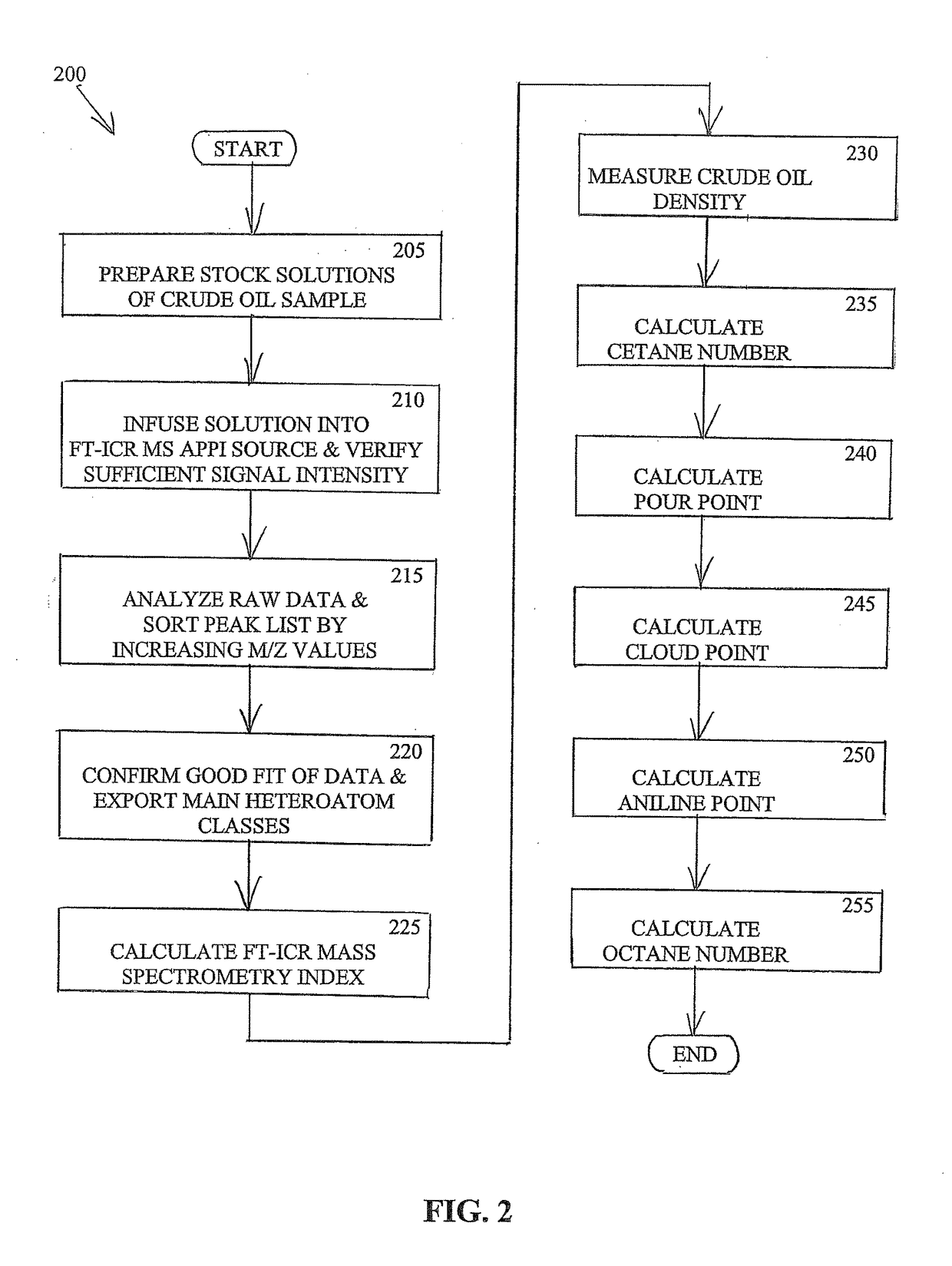

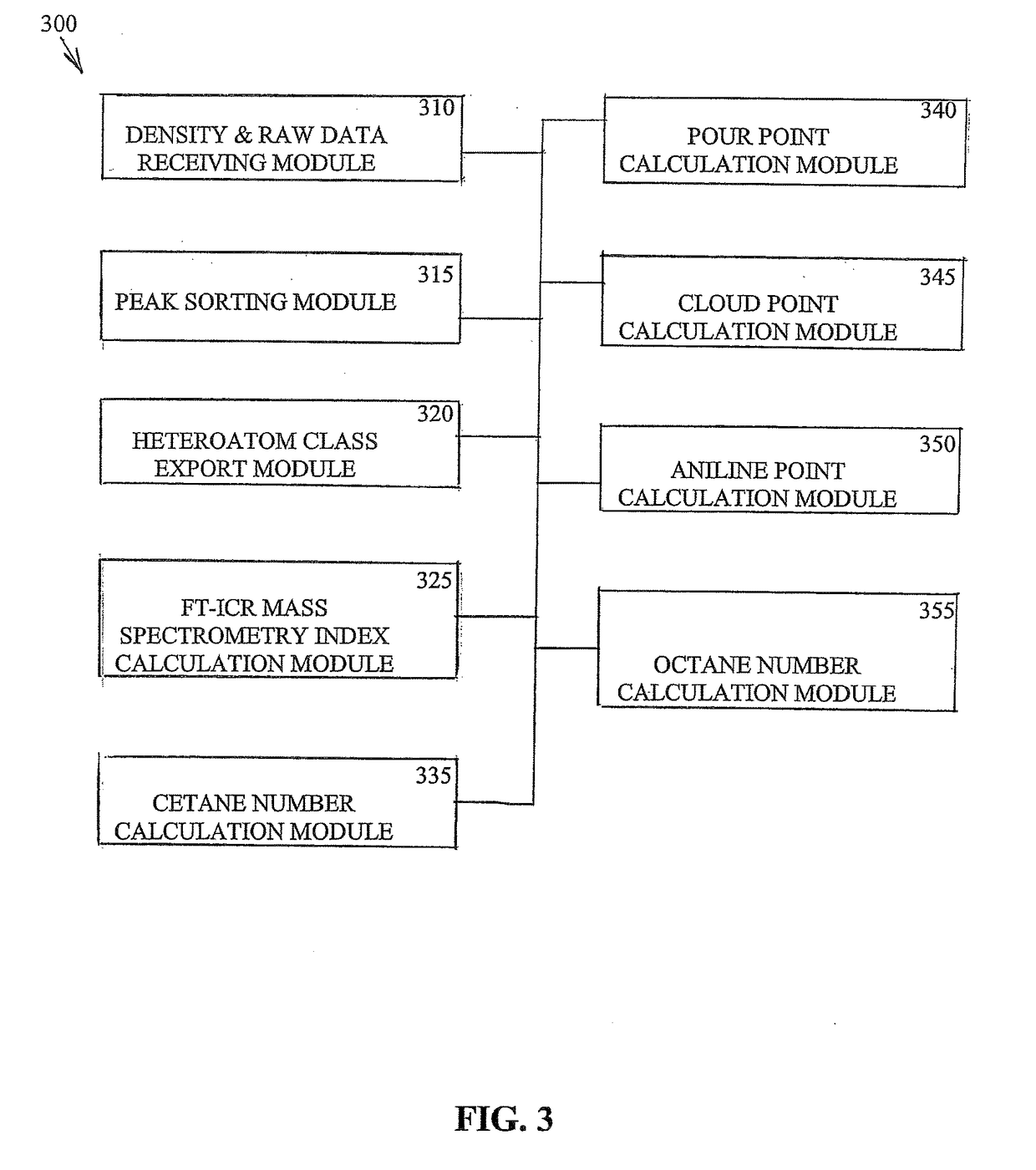

Characterization of crude oil by fourier transform ion cyclotron resonance mass spectrometry

InactiveUS20150106028A1Provide informationImprove oil qualityChemical property predictionOmegatronsChemistryFourier transform

A system, method and computer program product are provided for calculating the cetane number, octane number, pour point, cloud point and aniline point of crude oil fractions from the density and Fourier transform ion cyclotron resonance mass spectrometry (FT-ICR MS) of a sample of the crude oil.

Owner:KOSEOGLU OMER REFA +3

Automatic continuous production process for producing diesel oil with waste oil through catalytic cracking method

InactiveCN102585896AGuaranteed uniformitySolve the problem of not being able to feedTreatment with plural serial stages onlyLiquid hydrocarbon mixture productionWaste oilFuel oil

The invention relates to the technical field of waste oil comprehensive utilization and fuel oil processing, particularly to an automatic continuous production process for producing diesel oil with waste oil through a catalytic cracking method. The production process comprises the following process steps: 1, the waste oil is pretreated; 2, the pretreated waste oil is subjected to hot cracking and catalytic cracking, so as to obtain crude oil, wherein the catalytic cracking comprises liquid-phase catalysis and gas-phase catalysis; 3, the crude oil is fractionated; and 4, the finished product is obtained through refining and filtering. The invention has the advantages that gelatine, asphaltene, sulfide, oxide, unsaturated hydrocarbon and the like can be well removed, so that the finished oil is clear and transparent, has a pure smell, and cannot deteriorate after being stored for a long time; viscosity and pipeline blockage are avoided in the production process, the production process is simple, the conditions are easy to control, the investment is low, the results are quick, the efficiency is high, the use is simple, and the operation is convenient.

Owner:HANGZHOU LVHUI ENERGY TECH

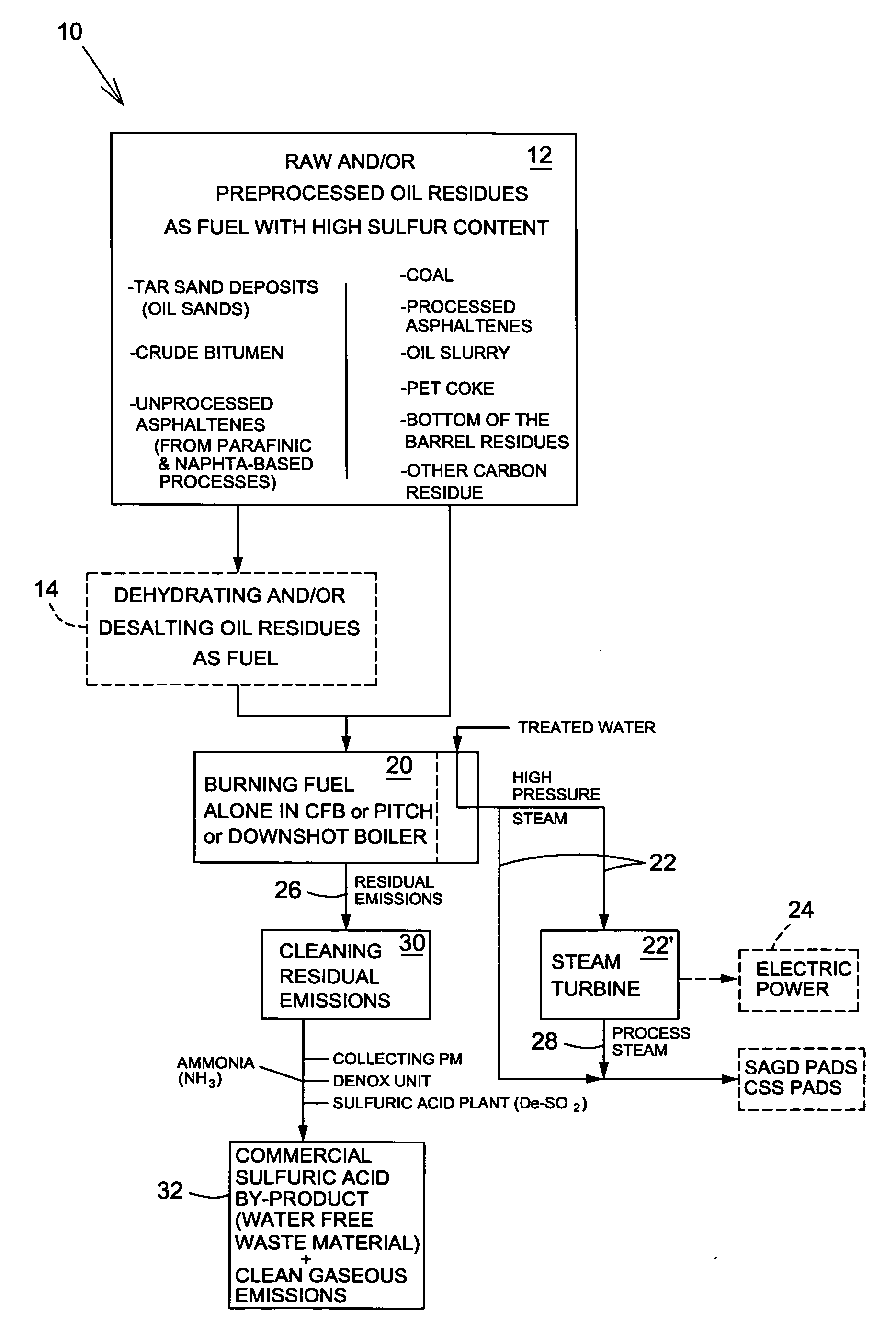

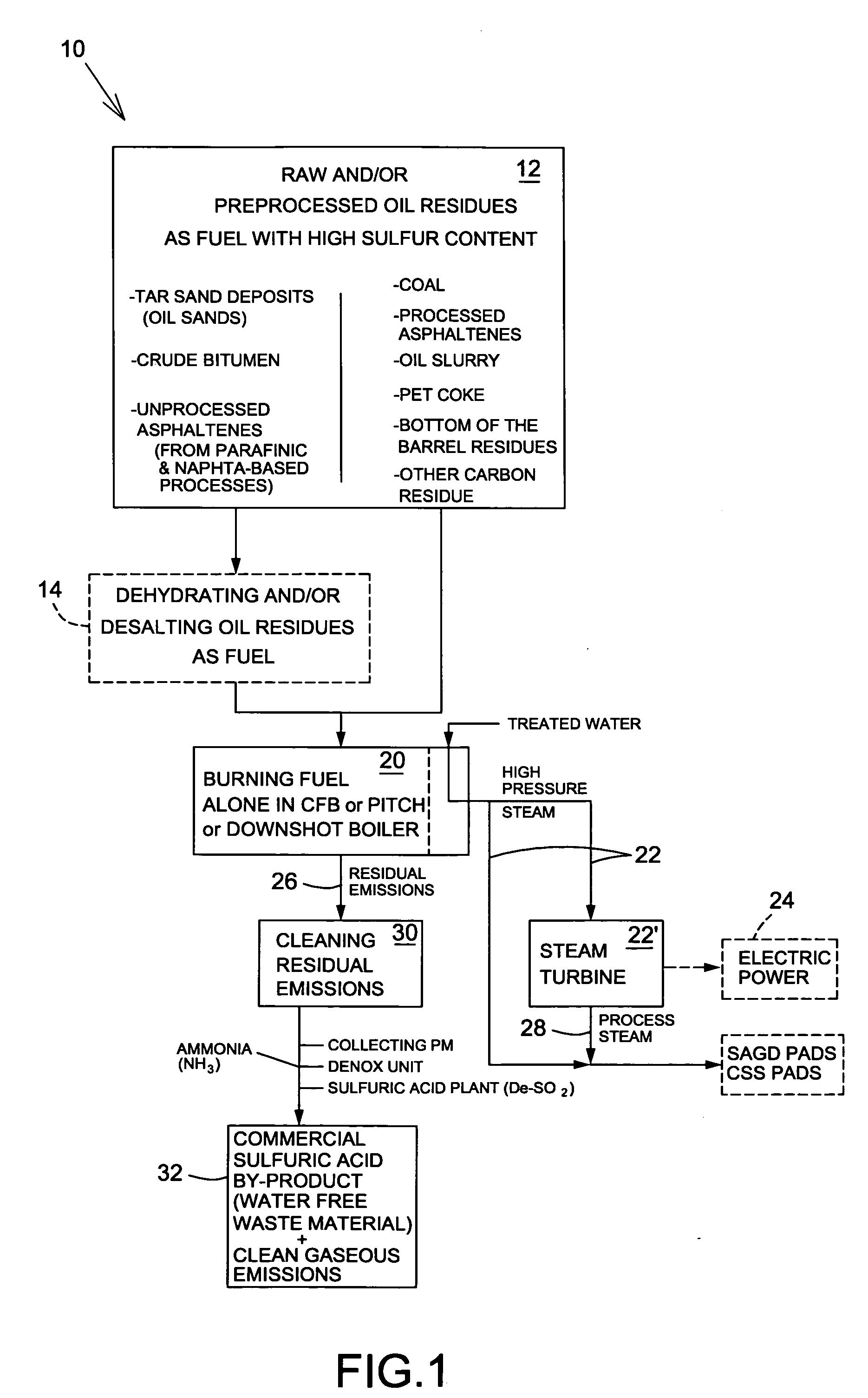

Process for producing steam and/or power from oil residues with high sulfur content

InactiveUS20100126395A1Low costWeaken energyDispersed particle separationSulfur compoundsSorbentDiluent

Power is produced using fuel, preferably with a sulfur content larger than 1% wt, from raw and / or preprocessed oil residues which are burned alone, i.e. without any addition of sorbents, diluents or the like, with a CFB boiler, a pitch boiler or a downshot boiler to generate high pressure steam and / or power and residual emissions. Residual emissions are cleaned to simultaneously remove PM, NOx and SO2 therefrom. The sulfur in emissions can be used to produce sulfuric acid. The process uses a low cost fuel, generates steam, and / or power and sulfuric acid and meets all emission requirements for PM, NOx and SO2.

Owner:GAUTHIER RICHARD

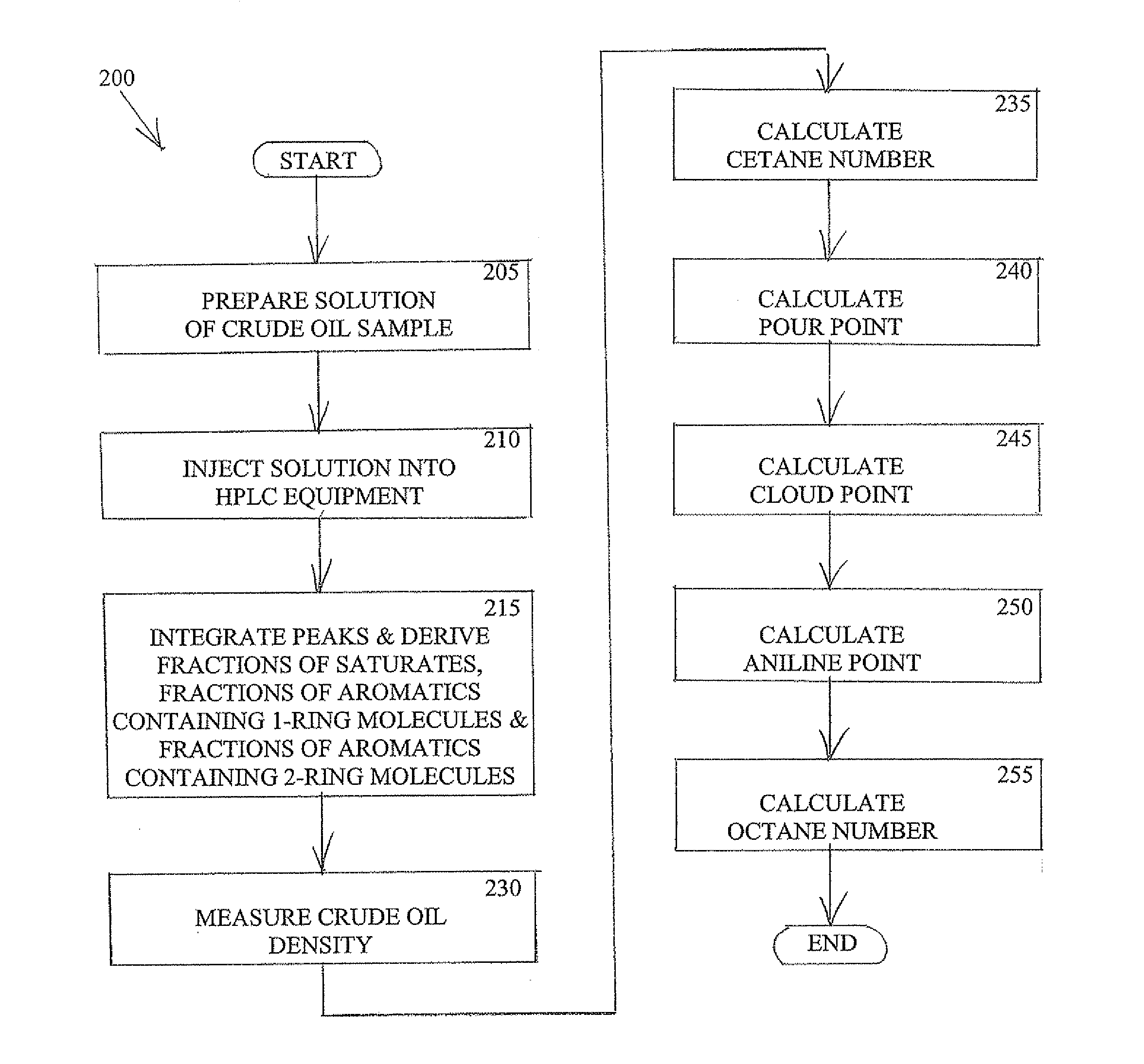

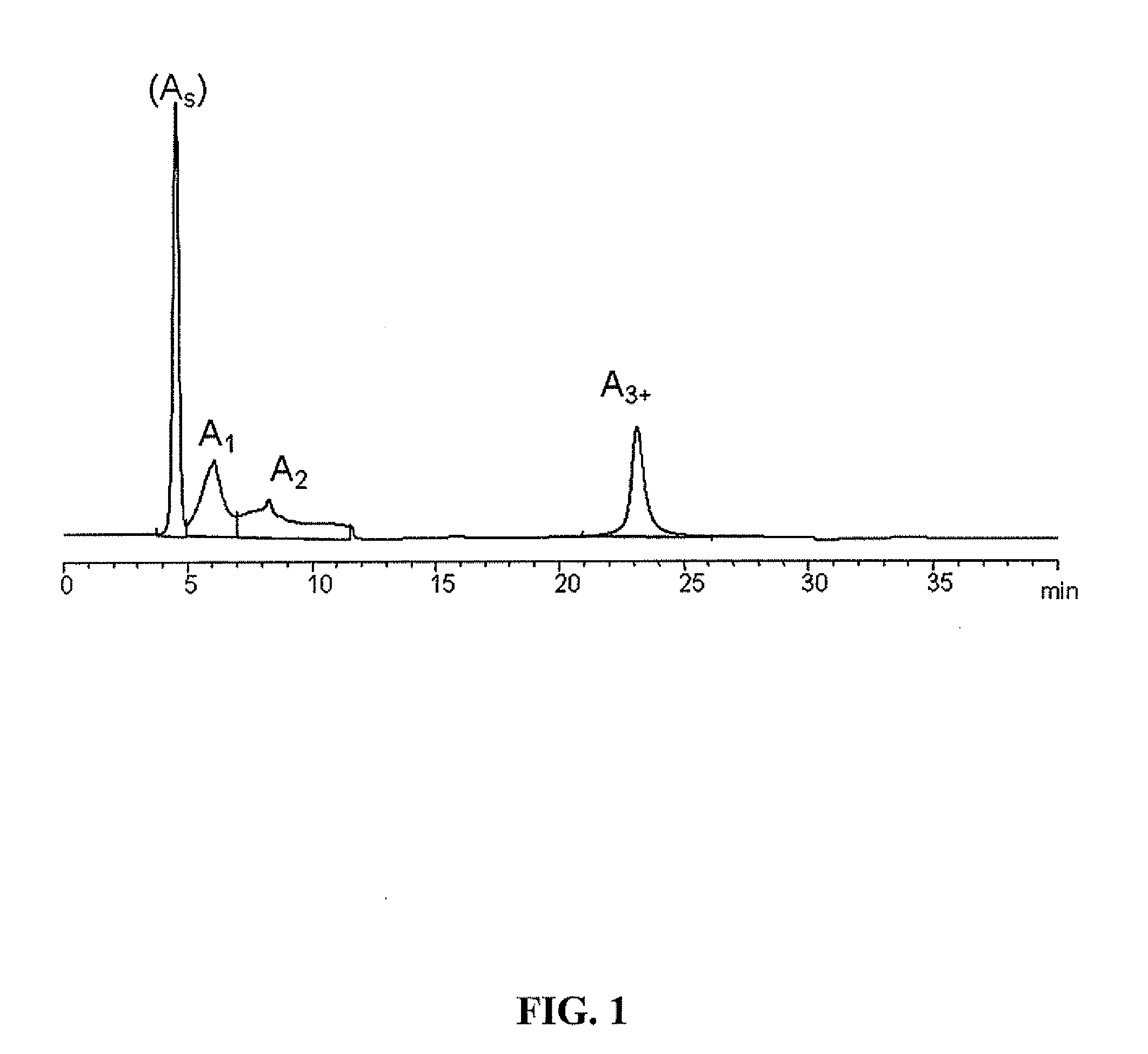

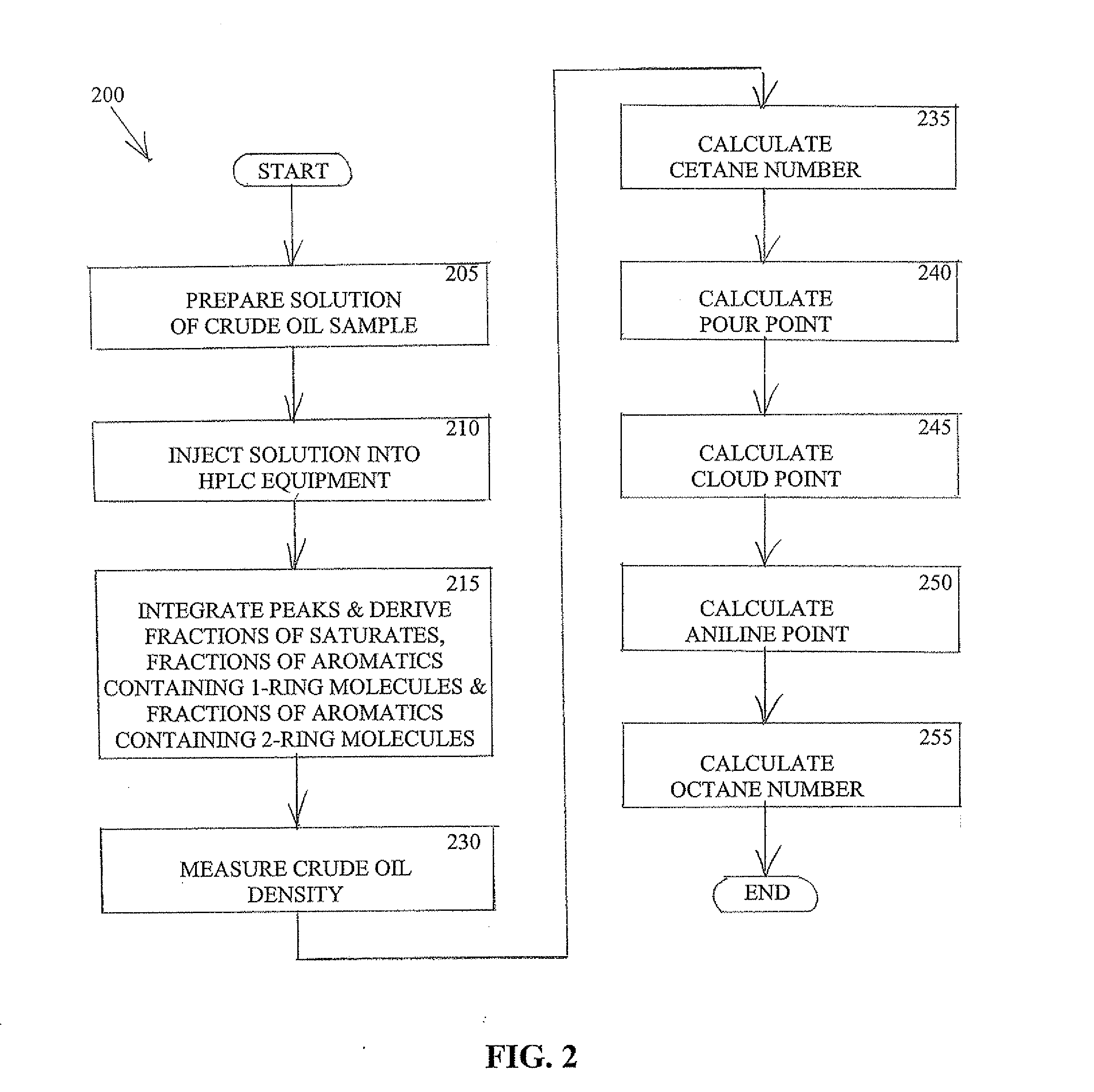

Method of characterizing crude oil by high pressure liquid chromatography

InactiveUS20150106029A1Substantial time and expenseProvide informationComponent separationMaterial testing goodsChemistryHigh pressure

A system and a method are provided for calculating the cetane number, octane number, pour point, cloud point and aniline point of a crude oil fractions from the density and high pressure liquid chromatography (HPLC) of a sample of the crude oil.

Owner:SAUDI ARABIAN OIL CO

Pickled hot pepper flouring and its preparing process

InactiveCN1334027AExtended growing seasonEndothelial thicknessFood preparationPreservative freeHot peppers

A pickled hot pepper is prepared from fresh hot pepper as main raw material, ginger, wine, Chinese prickly ash, peanut, table salt, gourmet powder, salad oil and sesame oil through picking and natural fermentation. Its advantages are rich nutrients, smell and hot taste and low cost.

Owner:苏玺州 +1

Method and apparatus for venting a crankcase of an internal combustion engine

ActiveUS20070028903A1Increase volume flowImprove oil qualityNon-fuel substance addition to fuelCombustion enginesExternal combustion engineCentral unit

In a method for venting a crankcase of an internal combustion engine, in which, in a first operating range under part-load, the crankcase is vented via a first venting line, which opens into an intake line of the internal combustion engine downstream of a throttle valve, and in a second operating range under full load engine operation, the crankcase is vented via a second venting line, which opens into the intake line upstream of the throttle valve, the first venting line includes a control valve and a central unit is provided which operates the control valve so as to control the flow of vent gases through the first venting line over a range including a complete flow interruption under engine overrun condition to prevent venting gases from reaching the engine exhaust system when the internal combustion engine is operating in an overrun mode.

Owner:DAIMLER AG

System for producing oil from waste material and catalyst thereof

InactiveUS20130136665A1Quality improvementImprove oil qualityMolecular sieve catalystsSolid waste disposalRefuse-derived fuelCellulose

A system for producing oil from waste material includes a catalytic decomposition reactor providing a stirrer for stirring at least one kind of raw material; the raw material being selected from a group consisting of lingo cellulosic hydrocarbon, biomass like marine plants, waste plastic, waste, waste oil, RDF (Refuse derived fuel) and RPF (Refuse plastic fuel), and a catalyst for decomposing the selected raw materials; the catalytic decomposition reactor serving for decomposing the raw materials and producing vapor and gaseous oil and sludge; a condenser for condensing the gaseous oil generated from the catalytic decomposition reactor; a storing container for storing oil condensed from the condenser; and a distillation tower oil from the storing container by heat from a steam boiler and collecting heavy oil, diesel oil and gasoline through a heavy oil output port, a diesel output port and a gasoline output port in boiling points.

Owner:OIL CITY

Catalytic cracking process of refining biological oil

InactiveCN1432626ANot perishableNot easy to storeLiquid hydrocarbon mixture productionBio-feedstockMolecular sieveReaction temperature

The present invention relates to a catalytic cracking process of refining biological oil. In a cracking reactor, the biological oil produced through cracking various biomass as material oil is catalytically cracked to eliminate excessive oxygen to obtain high quality refined biological oil in the presence of marketed HZSM-5 zeolite molecular sieve as catalyst and at normal pressure and 200-550 deg.c temperature. The yield may reach 50%. The refined biological oil is not easy to deteriorate at normal temperature, easy to store and transport, and good in burning performance. The present invention is favorable to solve the problem of lacking energy source for human to be faced with.

Owner:EAST CHINA UNIV OF SCI & TECH

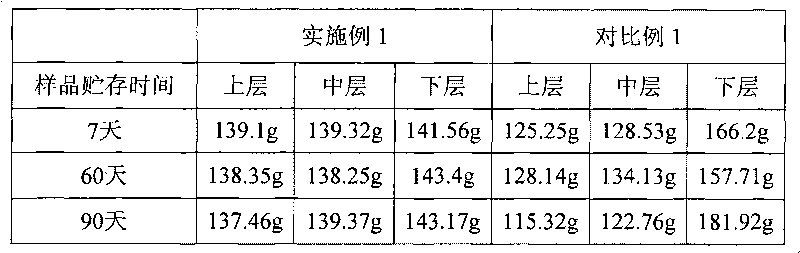

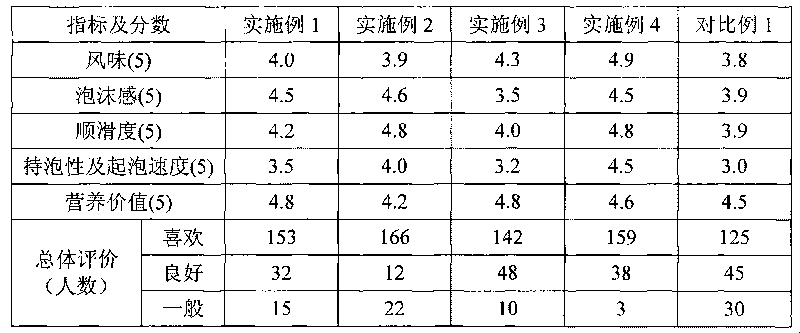

Carbonic acid gas-containing foaming liquid dairy product and method for producing same

The invention provides a carbonic acid gas-containing foaming liquid dairy product and a method for producing the same, wherein the foaming liquid dairy product contains 0.15 to 1 percent of lactoprotein and 1.5 to 3.5 percent of grease substances, and each kilogram of the foaming liquid dairy product contains 0.5 to 1 grams of CO2 gas. The selected raw materials are mixed in a ratio to obtain mixed concentrated solution, and the concentrated solution is sterilized and then mixed with CO2-containing acid liquor to form the carbonic acid gas-containing foaming liquid dairy product, and the product has good foam forming property and persistent foaming property and can be preserved for 6 months.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

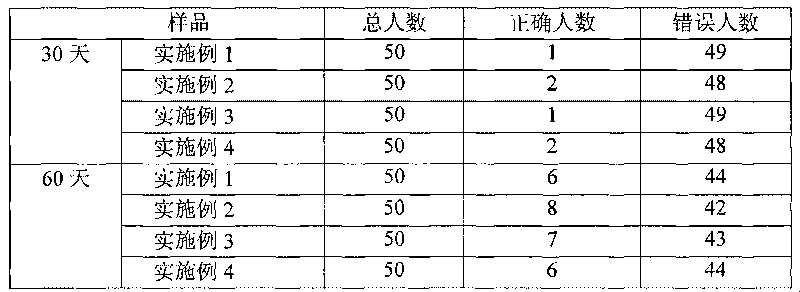

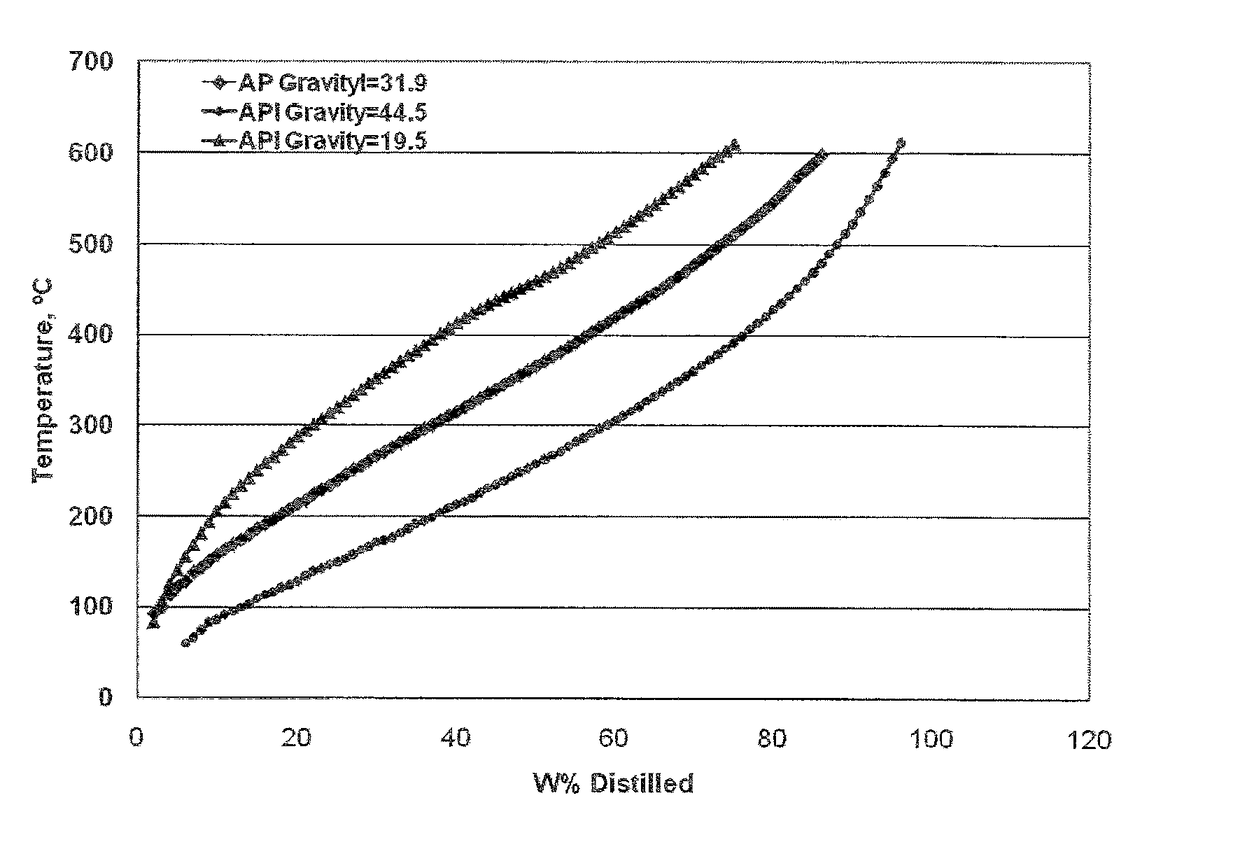

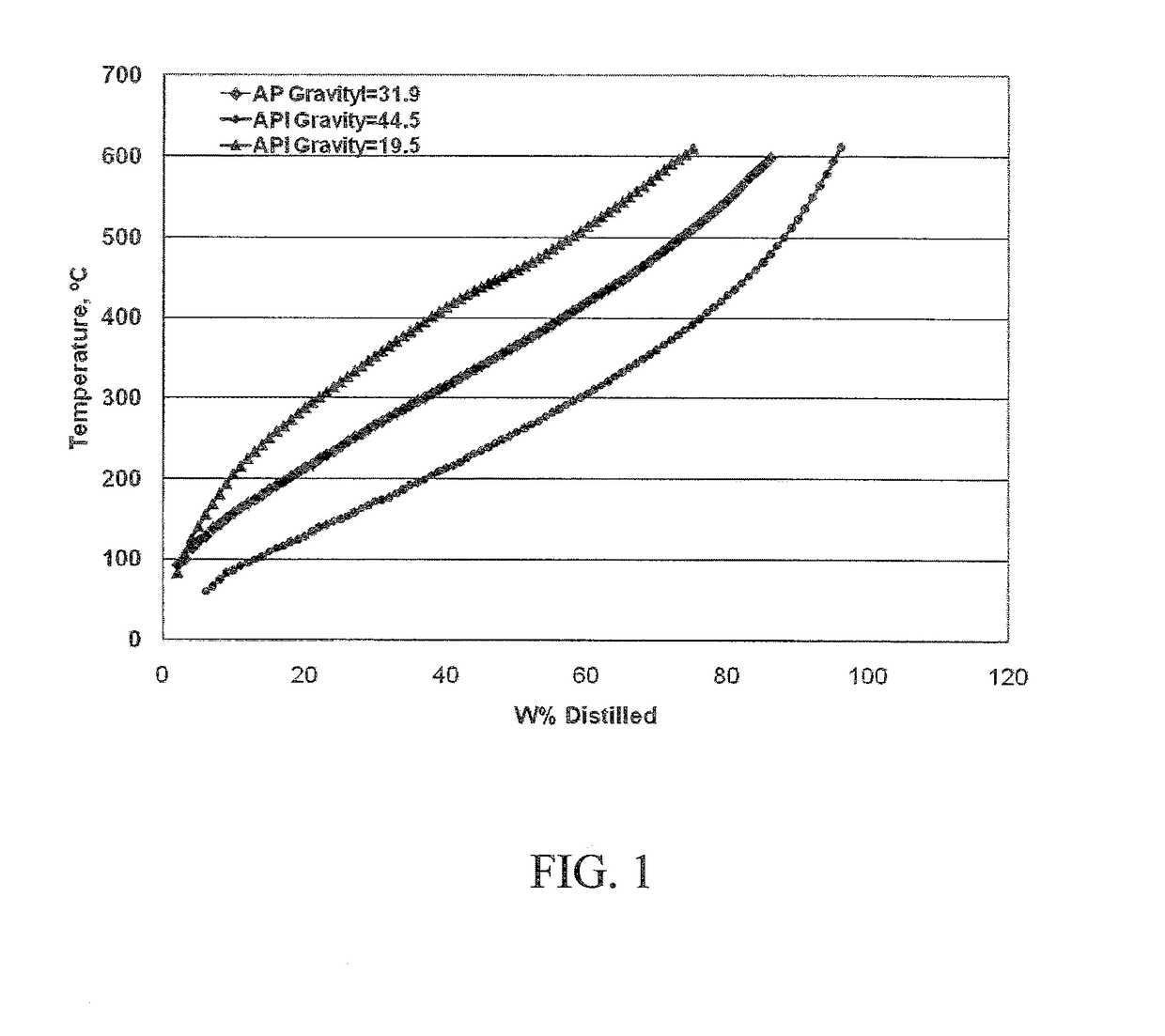

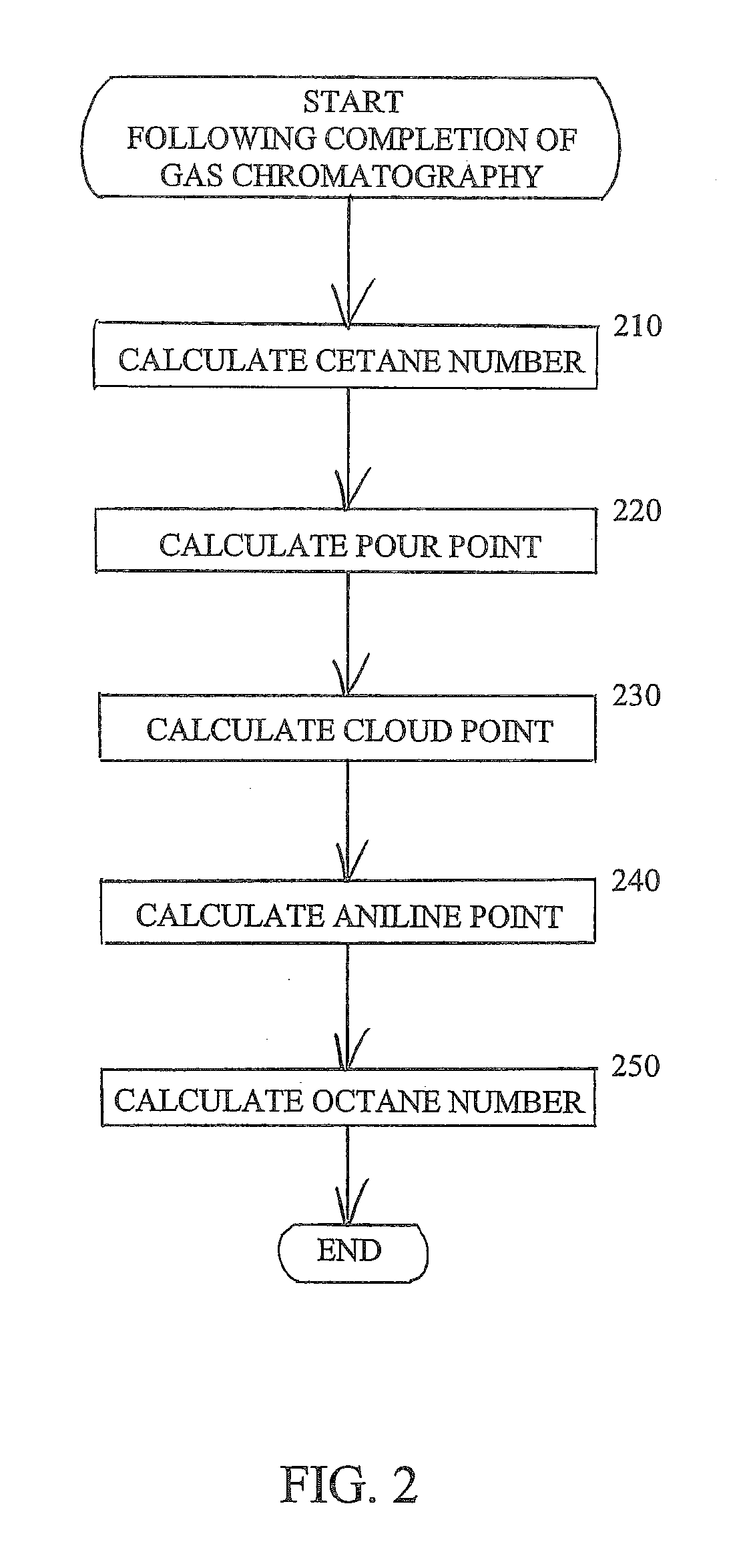

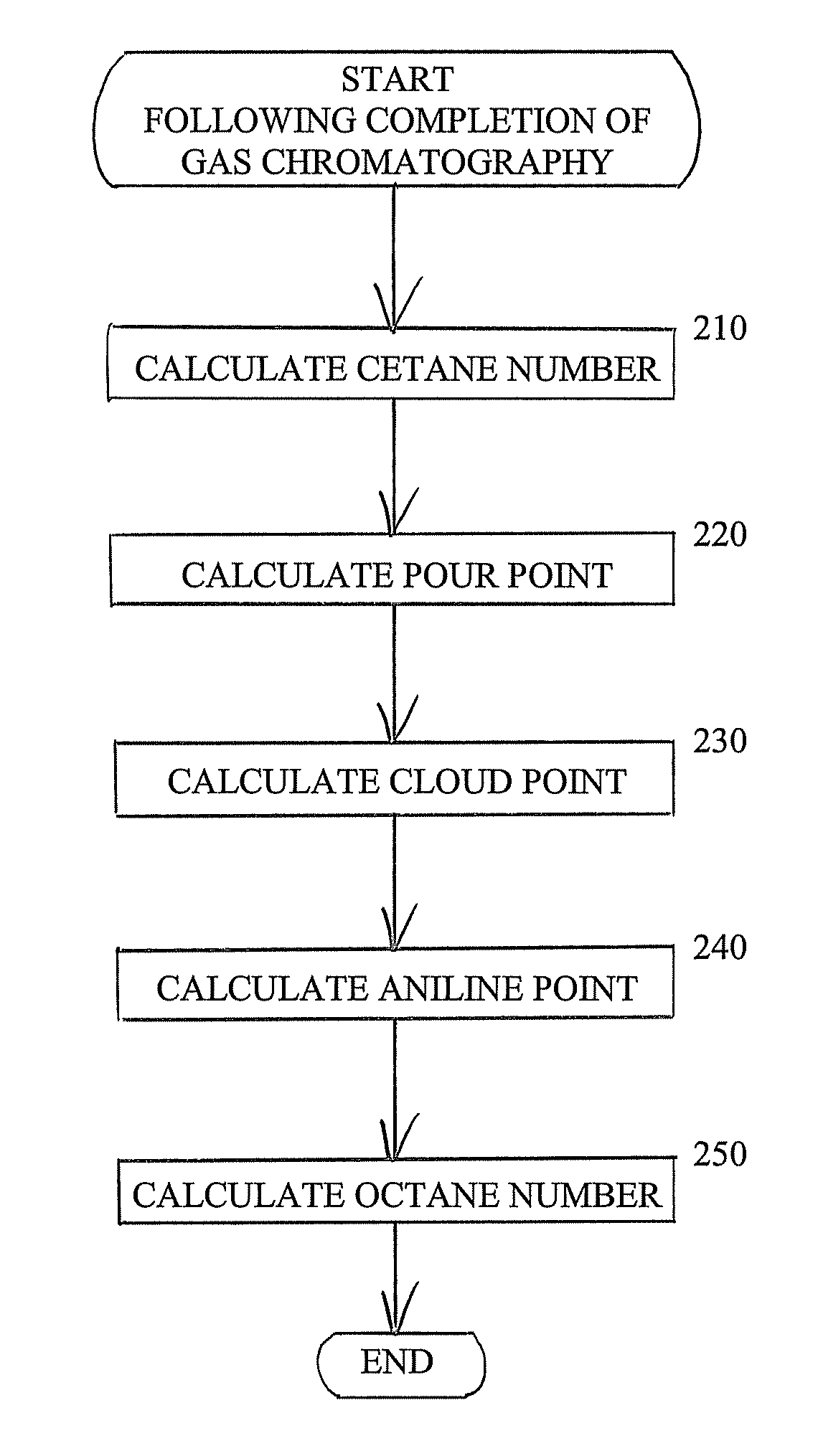

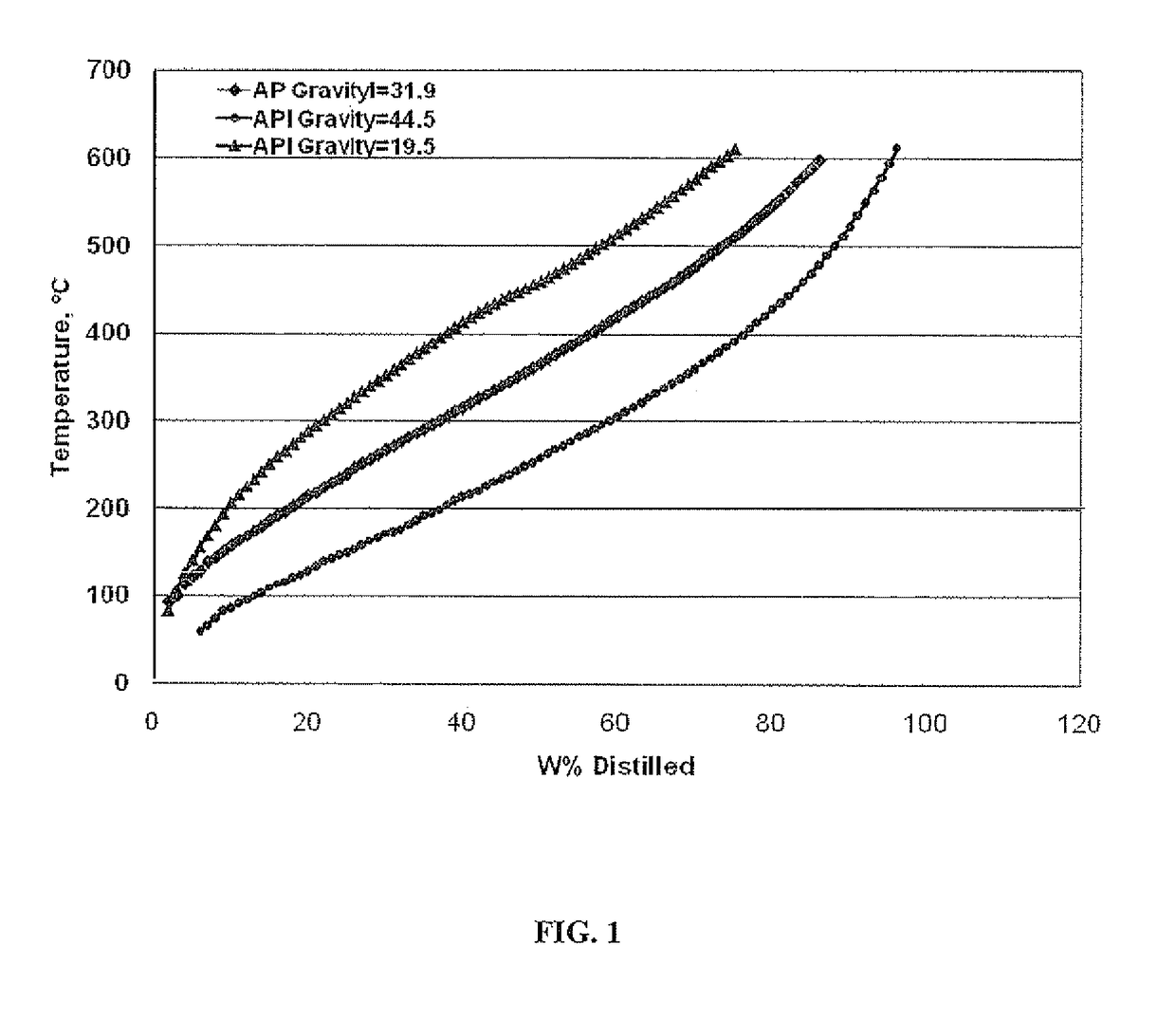

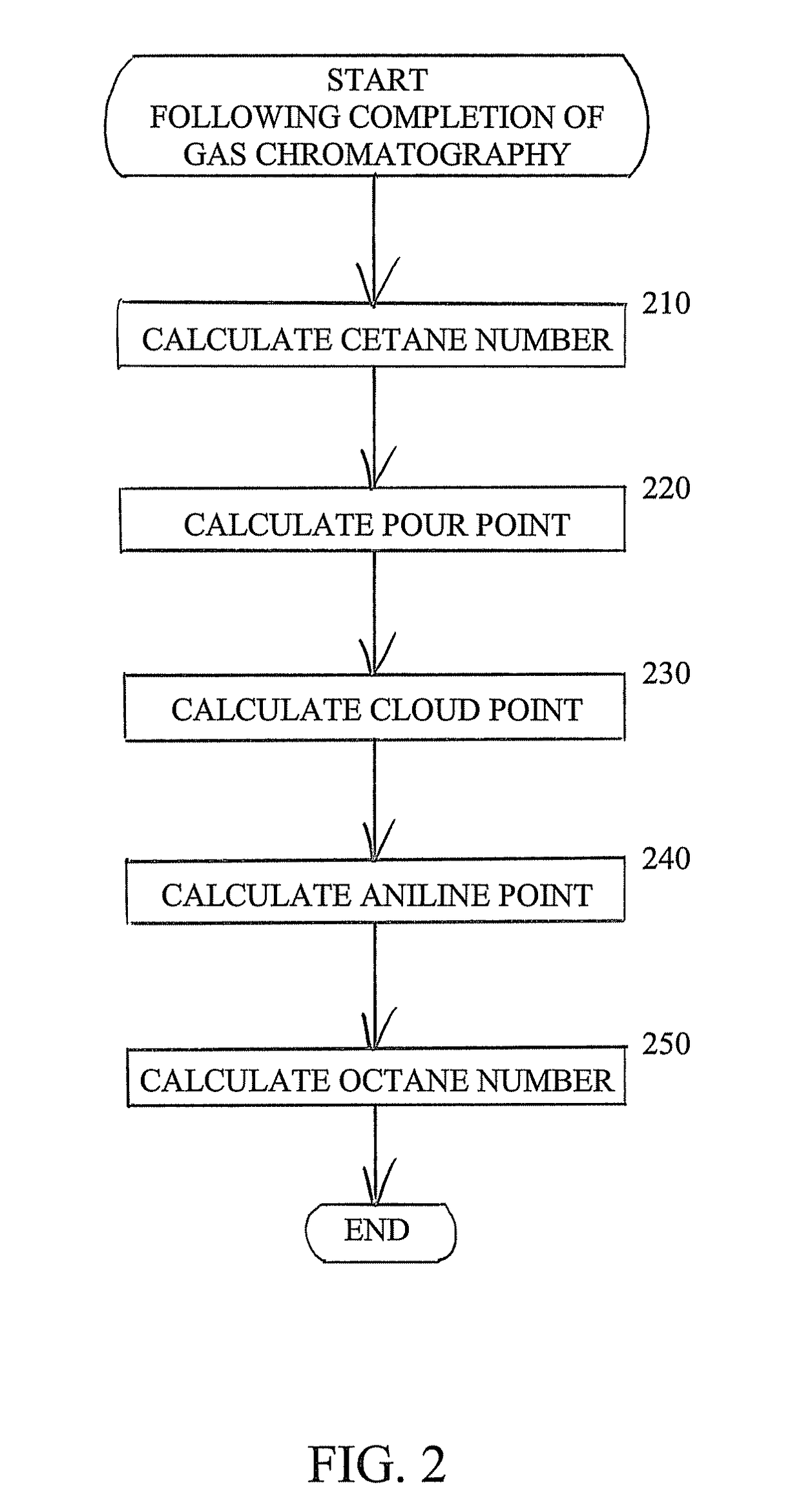

Characterization of crude oil by simulated distillation

ActiveUS20170363591A1Provide informationImprove oil qualityComponent separationColor/spectral properties measurementsAniline pointGas phase

A system and a method is provided for calculating and assigning one or more indicative properties (e.g., cetane number, pour point, cloud point and / or aniline point) of a fractions of a crude oil sample based upon gas chromatographic simulated distillation data.

Owner:SAUDI ARABIAN OIL CO

Characterization of crude oil by simulated distillation

ActiveUS9816919B2Provide informationImprove oil qualityComputation using non-denominational number representationColor/spectral properties measurementsAniline pointDistillation

Owner:SAUDI ARABIAN OIL CO

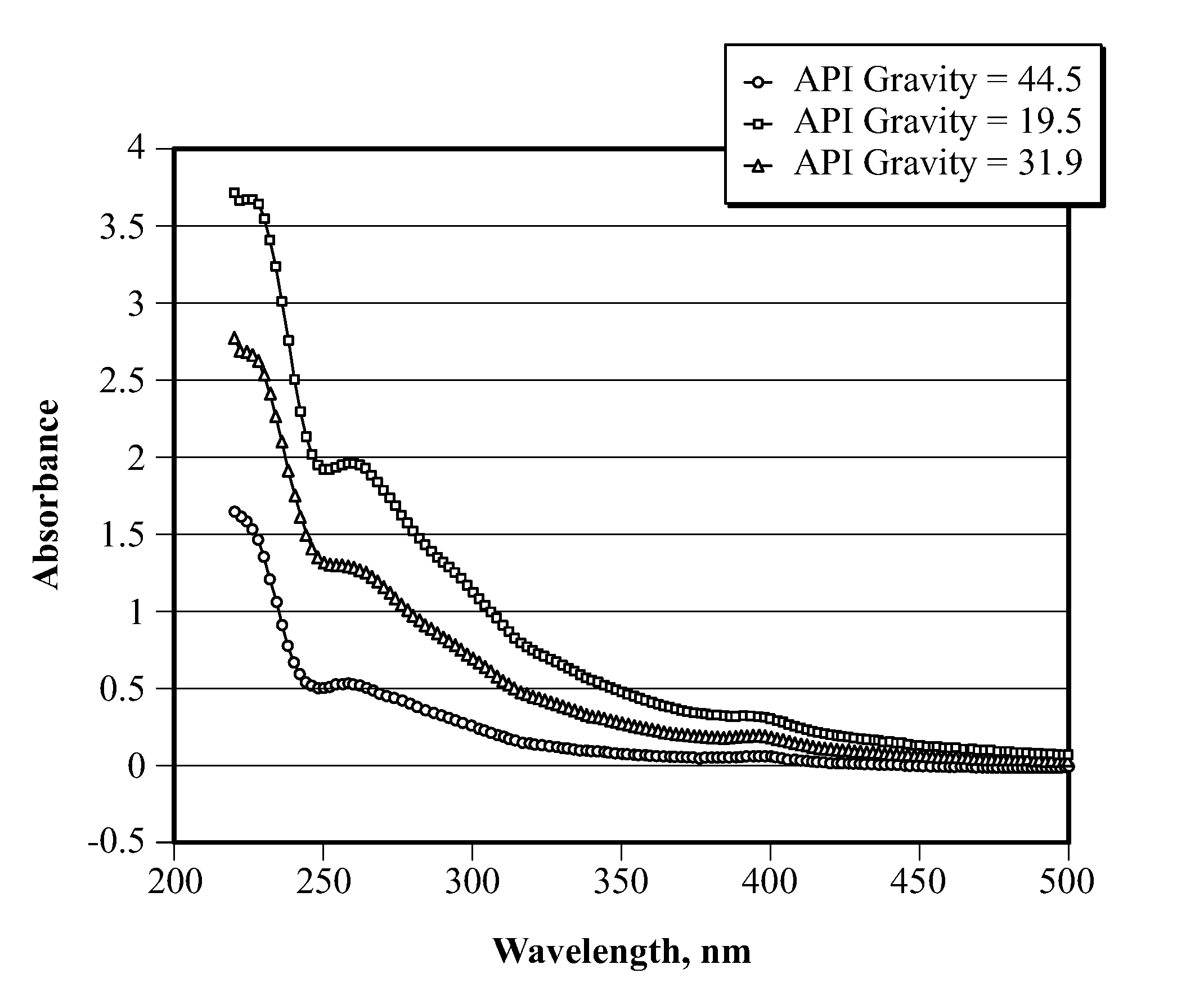

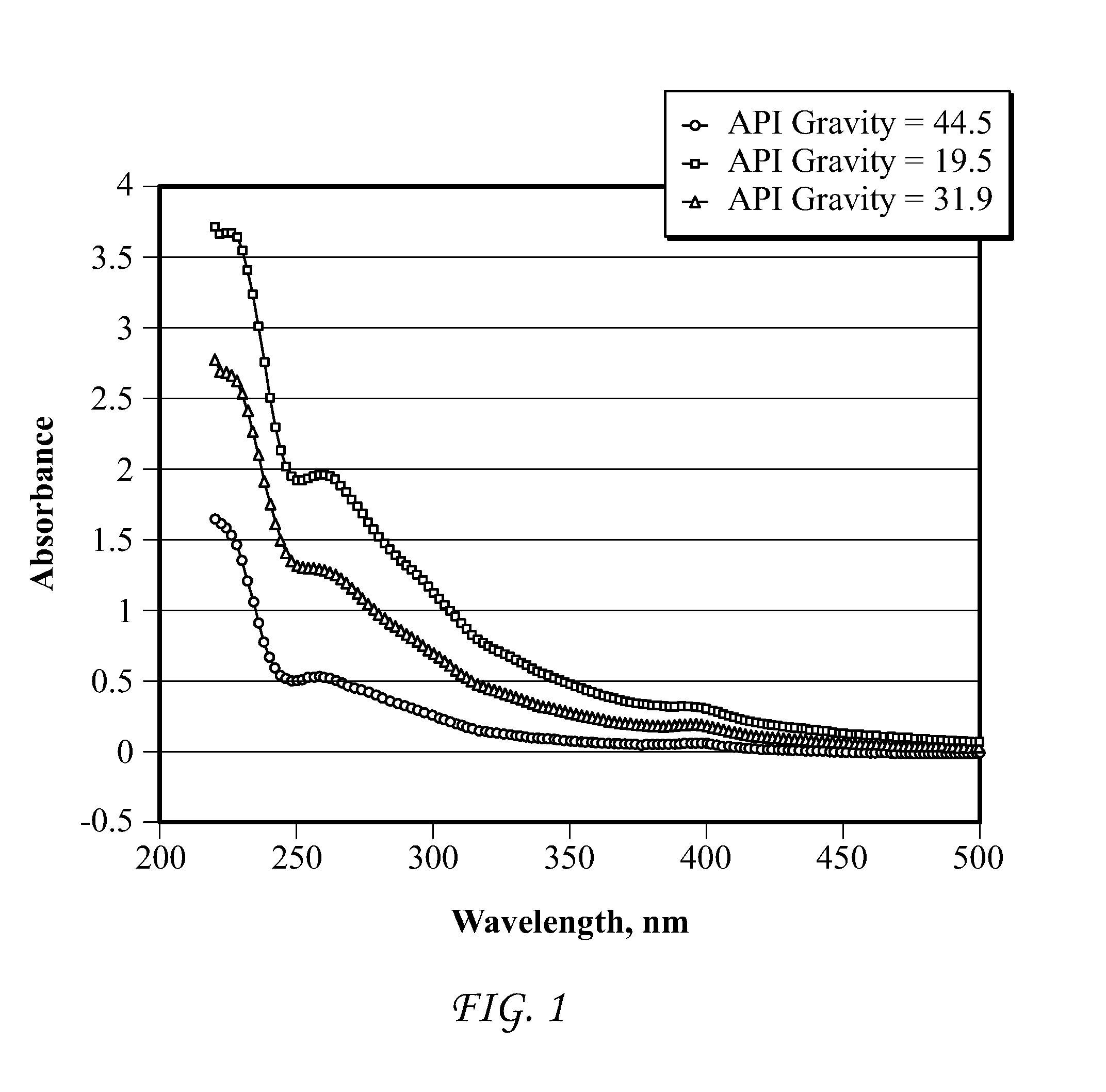

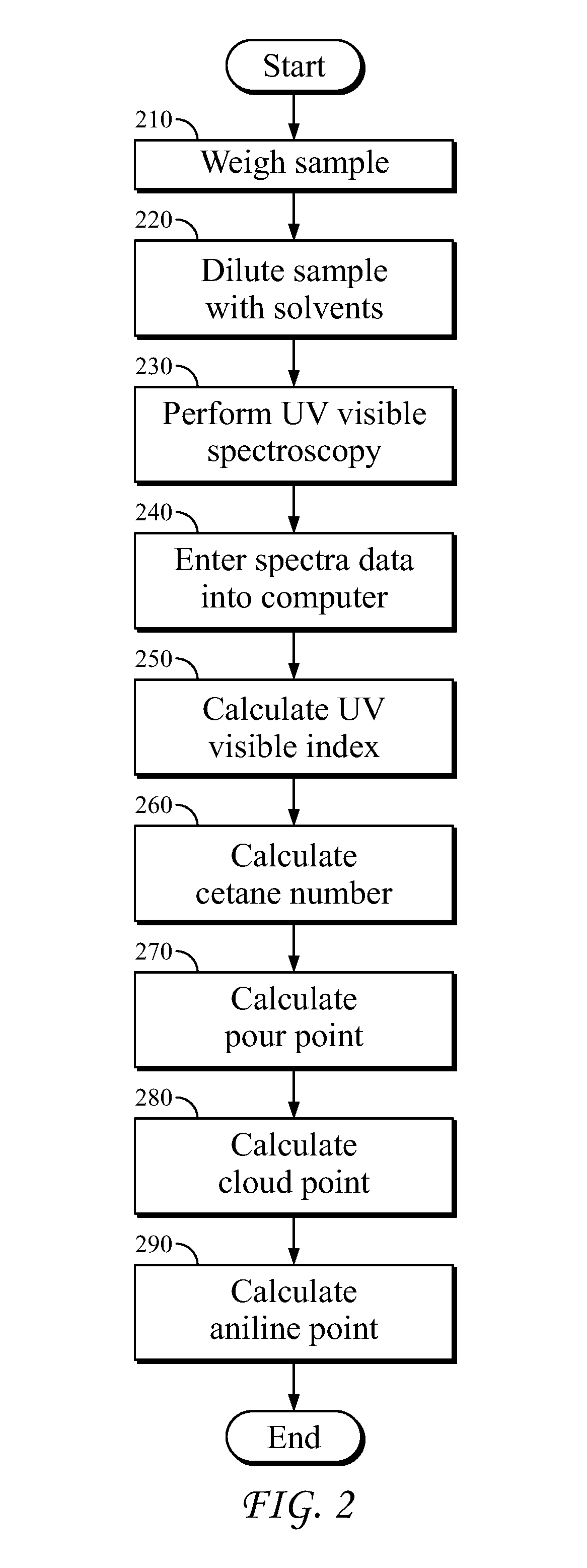

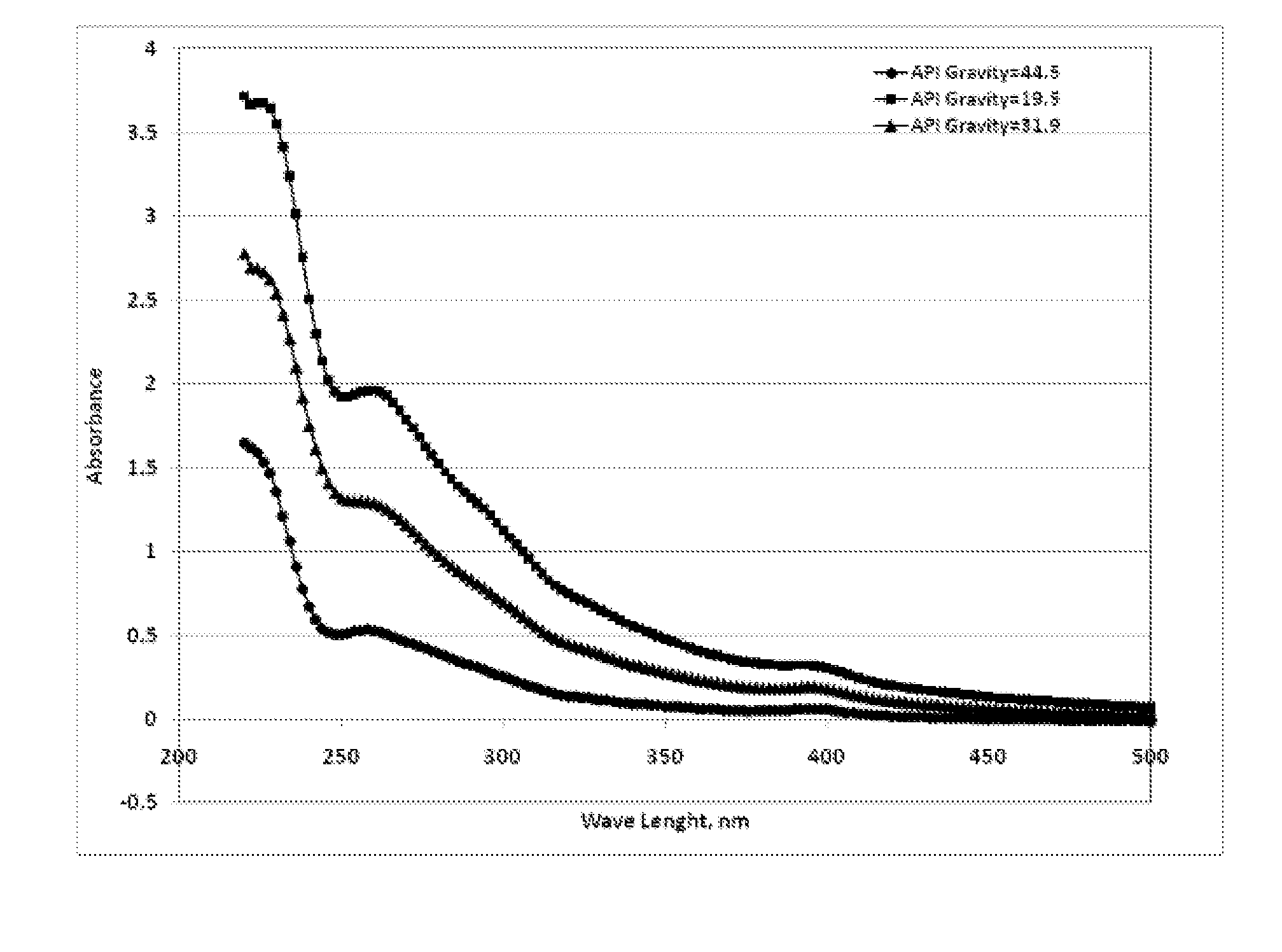

Characterization of crude oil by ultraviolet visible spectroscopy

ActiveUS20160187253A1Provide informationImprove oil qualityColor/spectral properties measurementsMaterial testing goodsAniline pointCloud point

A system and a method for calculating and assigning an indicative value, such as cetane number, pour point, cloud point and aniline point, of a fraction of an oil sample based on an index calculated and assigned from ultraviolet visible spectroscopy data of the oil sample.

Owner:SAUDI ARABIAN OIL CO

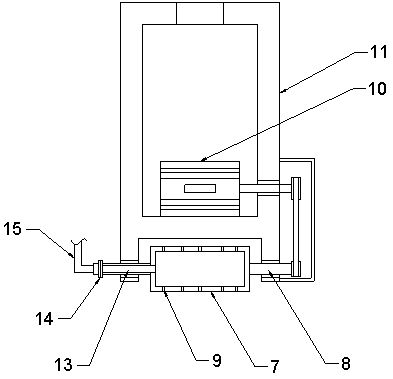

Household hydraulic oil press with integrated drying and squeezing functions

InactiveCN106867654AReduce moistureImprove oil qualityFatty-oils/fats productionPressesFuel tankHydraulic pump

The invention discloses a domestic hydraulic oil press integrated with drying and pressing, which comprises a base and a column frame. The base is provided with an oil tank, the oil tank is provided with a control switch, and the base is provided with a hydraulic pump. The base is provided with a lower hydraulic rod, the column frame is welded on the base, the column frame is provided with an upper hydraulic rod, the column frame is provided with a rotating sleeve, and the column frame is provided with a squeeze chamber. Cylinder, and an oil collecting pan is arranged on the column frame. This kind of drying and pressing integrated household hydraulic oil press, the grain is dried by the heating barrel and poured into the inner cylinder of the pressing chamber, the upper hydraulic rod pushes the briquetting block to squeeze the grain, the oil passes through the filter screen to filter out the oil residue, and flows into the oil collecting pan. It flows into the container from the oil outlet, and the lower hydraulic rod pushes the top block to push the pressed oil cake out of the inner cylinder of the pressing chamber to complete the drying and pressing process. The drying and pressing can be used separately, and the equipment has high efficiency and is easy to operate.

Owner:CHONGQING DAYANJIE ADVERTISING CO LTD

Camellia seed storage method

InactiveCN103289814AImprove oil yieldImprove oil qualityFatty-oils/fats productionHorticultureAgricultural engineering

The invention provides a camellia seed storage method which comprises the following process steps: timely harvesting, grading, removing impurities, timely after-ripening, drying under low temperature, shelling, drying again, and reasonably storing. The method is simple in process and convenient to operate, and due to the use of a kelp charcoal mat, the storage period of camellia seeds is greatly prolonged; moreover, by employing the method, the camellia seeds can be stored for 180-200 days under the condition of the temperature of less than 20 DEG C.

Owner:安徽新荣久农业科技有限公司

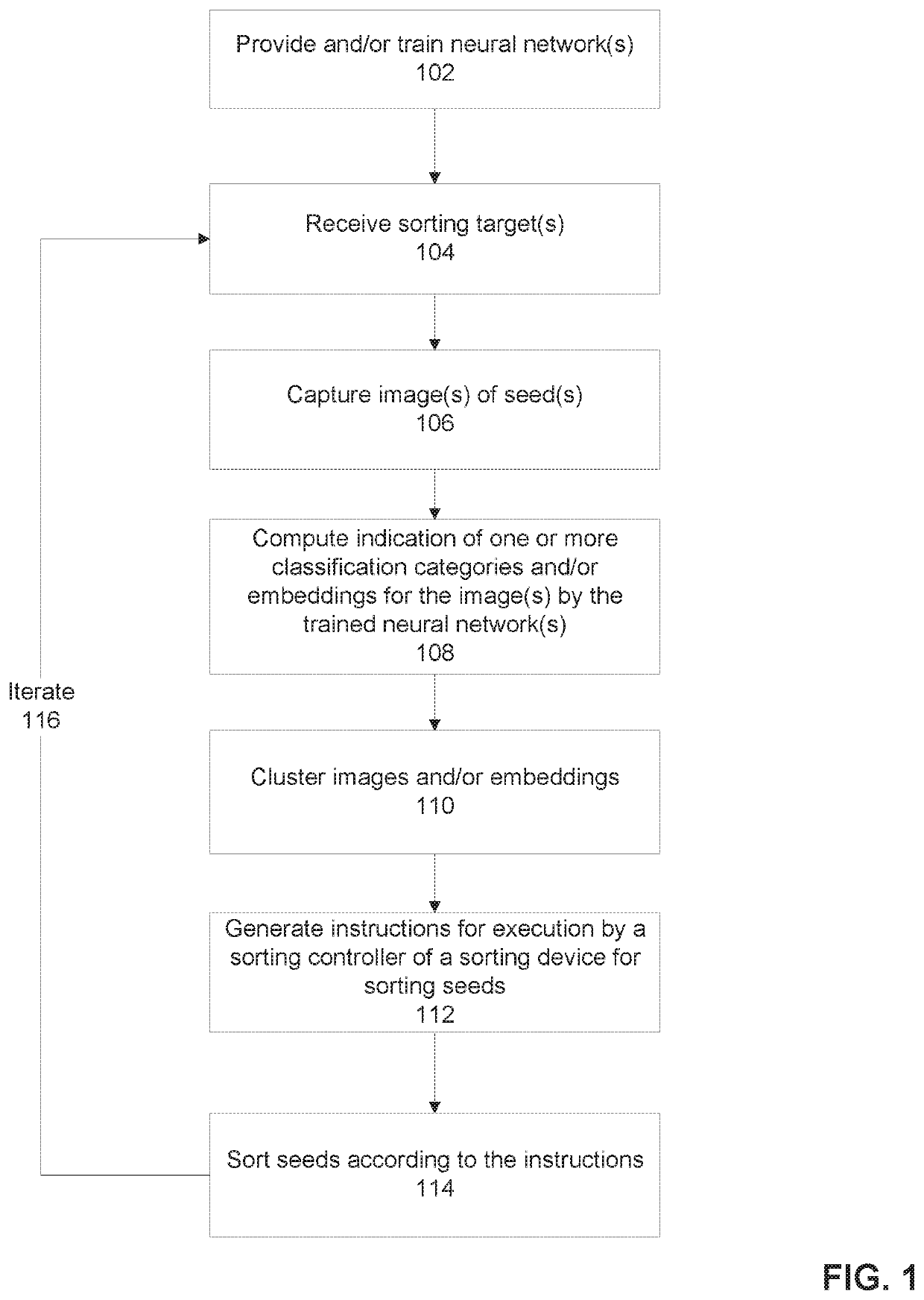

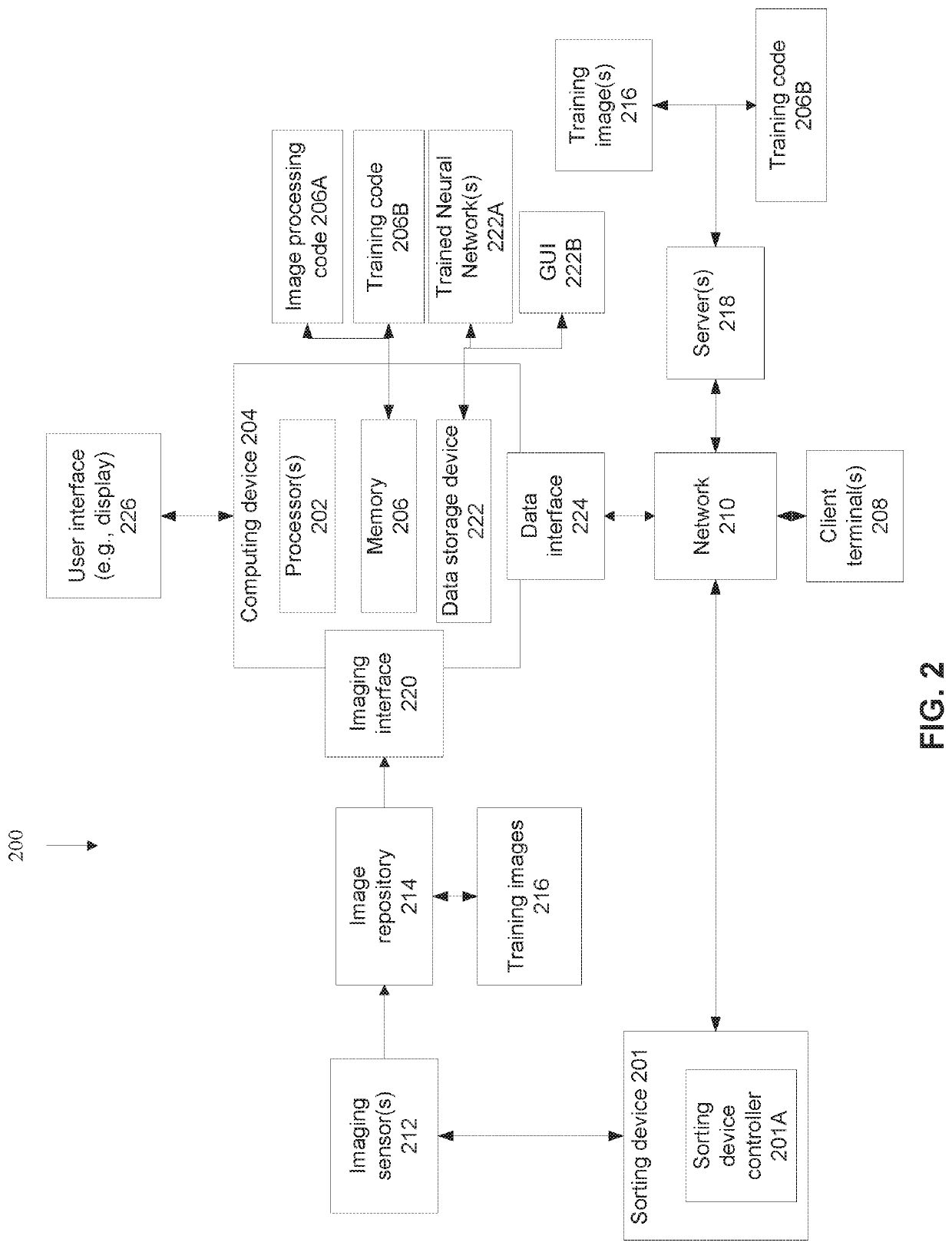

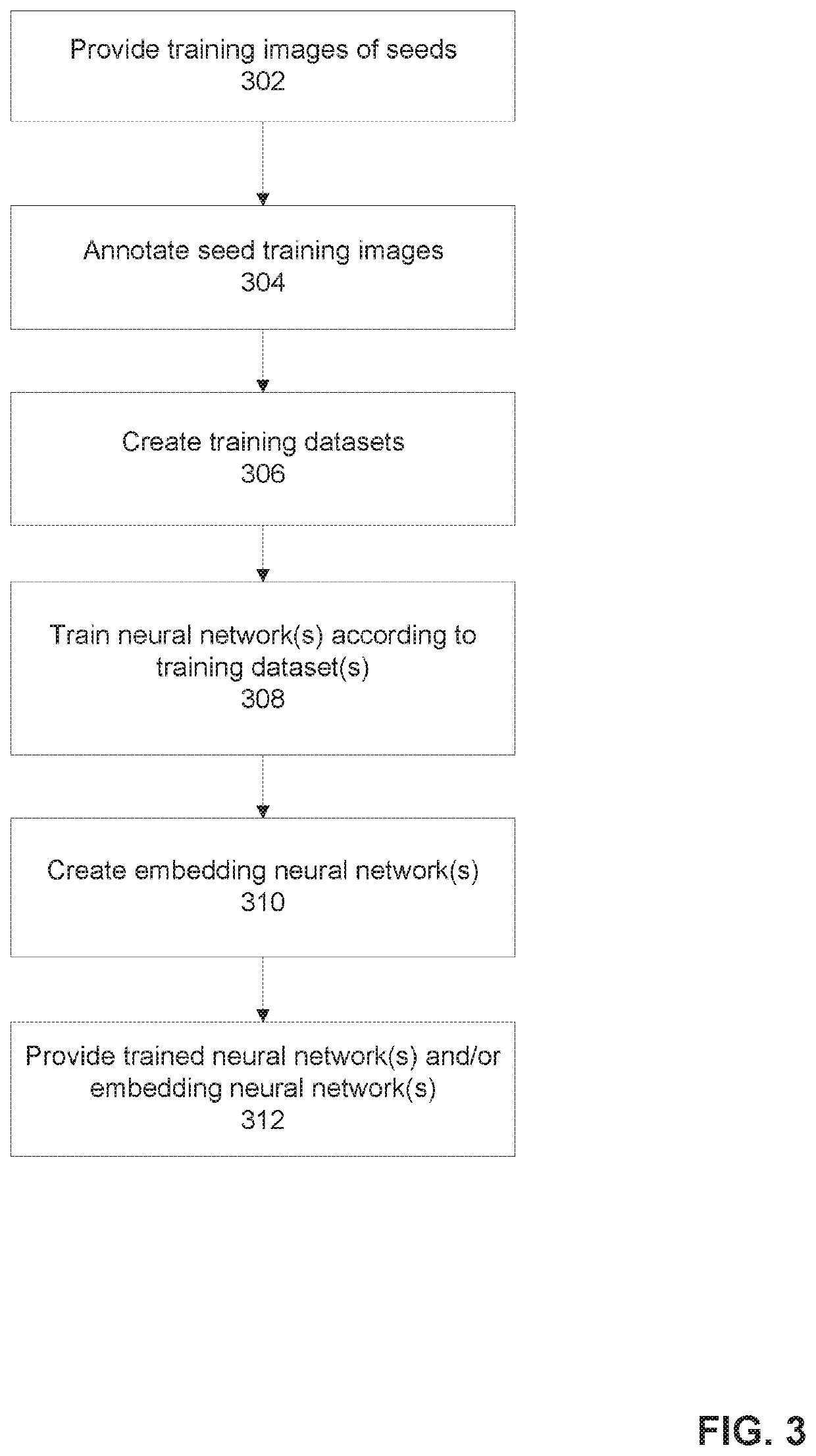

Systems and methods for sorting of seeds

ActiveUS20200338599A1Increase oilIncrease nitrogen use efficiencySeed and root treatmentCharacter and pattern recognitionHorticultureBotany

Owner:SEEDX TECH INC

Method for squeezing edible tea seed oil at normal temperature

ActiveCN102766524AReasonable process routeImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionCamellia oleiferaTea leaf

The invention provides a method for squeezing edible tea seed oil at normal temperature. The method comprises the following steps of: airing tea seeds at the normal temperature, separating seed hulls, extruding for squeezing at the normal temperature, refining crude oil, namely (1) filtering the crude oil to remove impurities; (2) mixing, acidifying, washing and degumming; (3) decolorizing by using a mixed decolorant; (4) standing the crude oil, separating to remove moisture and the impurities from the oil, dehydrating the crude oil from which the impurities are removed at the normal temperature under vacuum; (5) standing the dehydrated crude oil at the temperature of 5 DEG C, crystallizing, growing crystals for 48 hours, precipitating wax and ester in the oil and separating; and (6) performing diaphragm filter pressing on the tea seed oil from which the crystals are removed to obtain the refined tea seed oil. According to the method, a process is performed at the temperature of below 65 DEG C, so the process is simple, low in energy consumption and high in oil yield and belongs to an environment-friendly process; and the squeezed oil tea is high in quality.

Owner:ANHUI HUAYIN CAMELLIA OIL

Characterization of crude oil by ultraviolet visible spectroscopy

ActiveUS9285307B2Provide informationImprove oil qualityColor/spectral properties measurementsMaterial testing goodsAniline pointCloud point

A system and a method for calculating the cetane number, pour point, cloud point and aniline point of a gas oil fraction of crude oil from the density and ultraviolet visible spectroscopy of a sample of the crude oil.

Owner:SAUDI ARABIAN OIL CO

Demulsification method in production processes for extracting tea-seed oil extraction with participation of water phase

InactiveCN103396879AAvoid emulsificationSimple methodFatty-oils/fats refiningFatty-oils/fats productionOil and greaseOil water

The invention discloses a demulsification method in production processes for extracting tea-seed oil extraction with the participation of a water phase, relates to a technology for breaking an oil-water emulsification state during tea-seed oil production, and in particular to a technology for breaking emulsification in production processes for extracting tea-seed oil extraction with the participation of a water phase, such as an aqueous enzymatic method, an aqueous solution method or an aqueous extraction method. The technical scheme is as follows: after tea seeds are moderately crushed, an appropriate amount of water phase is added, and the purpose of breaking an oil-water emulsification phenomenon is achieved by virtue of the comprehensive methods of increasing temperature, regulating pH value and centrifugally separating. The method provided by the invention is simple, feasible and strong in practicability, solves the problem of a low oil yield caused by the fact that oil and water are seriously emulsified and difficult to separate in a water-phase oil extraction process, and is beneficial to actual industrial application and popularization for the water-phase tea-seed oil extraction process technology.

Owner:CHANGSHA HAORUI BIOLOGICAL SCI & TECH

Oil extraction method of oil press

Owner:佛山市南海莉华电子科技有限公司

Characterization of crude oil by fourier transform ion cyclotron resonance mass spectrometry

ActiveUS20170363602A1Provide informationImprove oil qualityChemical property predictionOmegatronsAniline pointCloud point

A system, method and computer program product are provided for calculating one or more indicative properties, e.g., one or more of the cetane number, octane number, pour point, cloud point and aniline point of oil fractions, from the density and Fourier transform ion cyclotron resonance mass spectrometry (FT-ICR MS) of a sample of an oil sample.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com