Patents

Literature

47results about How to "Increase mutual friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation technique of big-leaf seed tea seed oil

InactiveCN101665742AAvoid the drawbacks of emulsification that is not easy to separateNot easy to blockFatty-oils/fats refiningFatty-oils/fats productionNutritive valuesHusk

The invention discloses a preparation technique of big-leaf seed tea seed oil. The preparation technique comprises the following steps: (1) squeezing the big-leaf seed tea seed oil: removing impurities, drying, husking, separating husks and kernels, softening, rolling embryos, braising, stir-frying and squeezing; and (2) refining the big-leaf seed tea seed oil: degumming raw oil, deacidifying, washing with water, dewatering, decolouring, deodorizing and filtering. The big-leaf seed tea seed oil prepared by the technique has the advantages of high oil output rate, superior oil quality, clear, bright and transparent colour, no bitter taste, pure fragrance and good mouth feel, and the nutritive value of the big-leaf seed tea seed oil is furthest protected. The big-leaf seed tea seed oil is not easy to be oxidized and deteriorate, has stable oil quality, safety, no toxicity, no side effect, and favorable properties of storage resistance and high-temperature resistance, is a better materialfor processing powdered oil, oleomargarin, salad oil and shortening oil and also can be used for cosmetics and medical oil.

Owner:陈军 +2

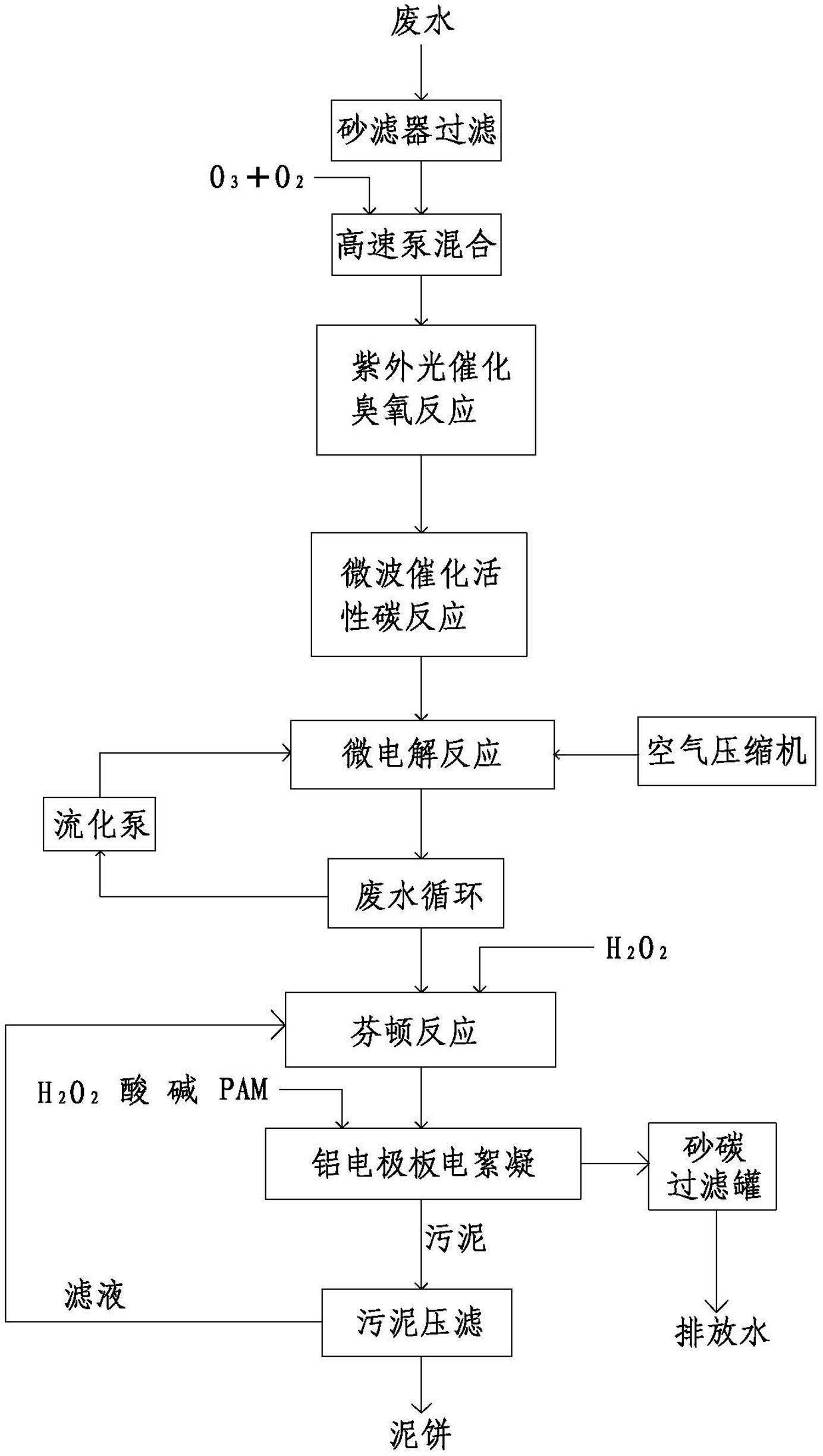

Complex heavy-metal waste water emergency quick treatment method

ActiveCN102603103AIncrease contact areaQuick responseMultistage water/sewage treatmentChemical oxygen demandSludge

The invention relates to a complex heavy-metal waste water emergency quick treatment method, comprising the following steps of: filtering by a sand filter; mixing by a high-speed pump; carrying out an ultraviolet catalyzing ozone reaction; carrying a microwave catalyzing active carbon reaction; carrying micro-electrolytic reaction; circulating waste water; carrying out a Fenton reaction; carryingout electric flocculation on an aluminum electrode plate; and pressing and filtering sludge. Waster water in a circulating slot is pumped into an iron carbon fluidized bed by a fluidizing pump to be circularly treated; an air compressor is connected with the iron carbon fluidized bed and prevents a filler in the iron carbon fluidized bed from blocking; and the microwave active carbon reactor is an active carbon filling tower, and a microwave emitter is arranged outside the body of the active carbon filling tower. The complex heavy-metal waste water emergency quick treatment method disclosed by the invention is used for treating the complex heavy-metal waste water, associated devices are simple, easy, quick, can meet an emergency, and can update and convert, no various chemical raw materials are fed, and various complex heavy-metal waste water with unknown elements can be quickly treated as long as the current magnitude is regulated, and thus the heavy metal in the waste water and chemical oxygen demand can immediately reach the standard and are discharged.

Owner:东莞市珠江海咸水淡化研究所有限公司

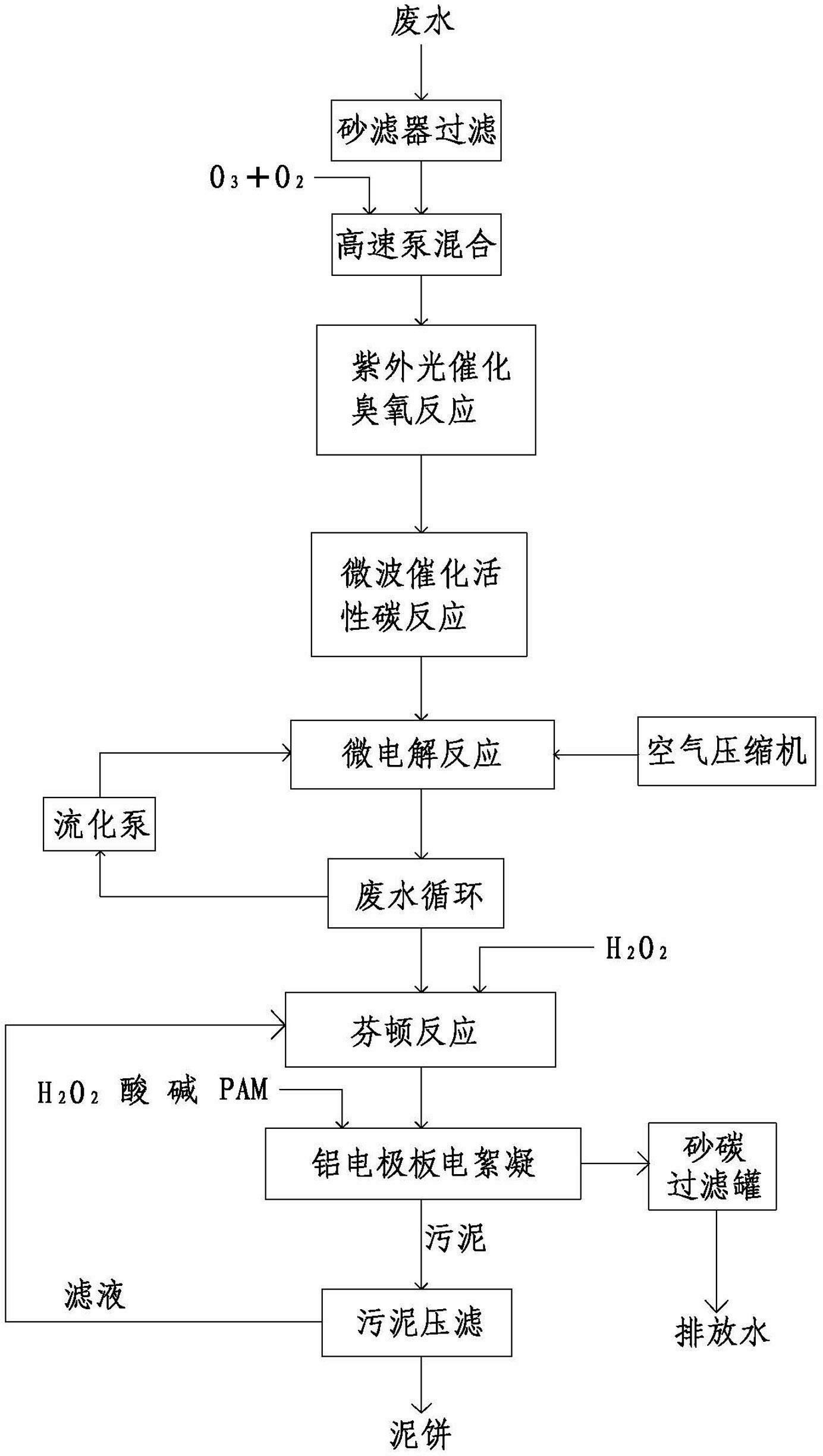

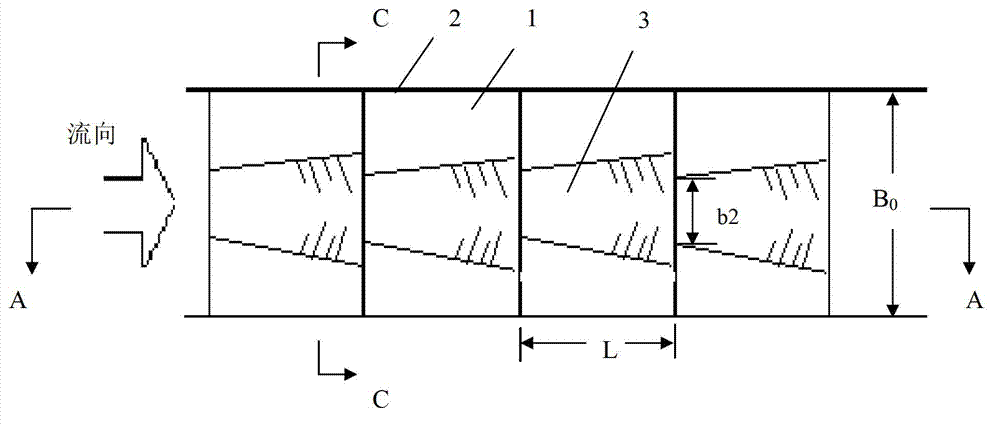

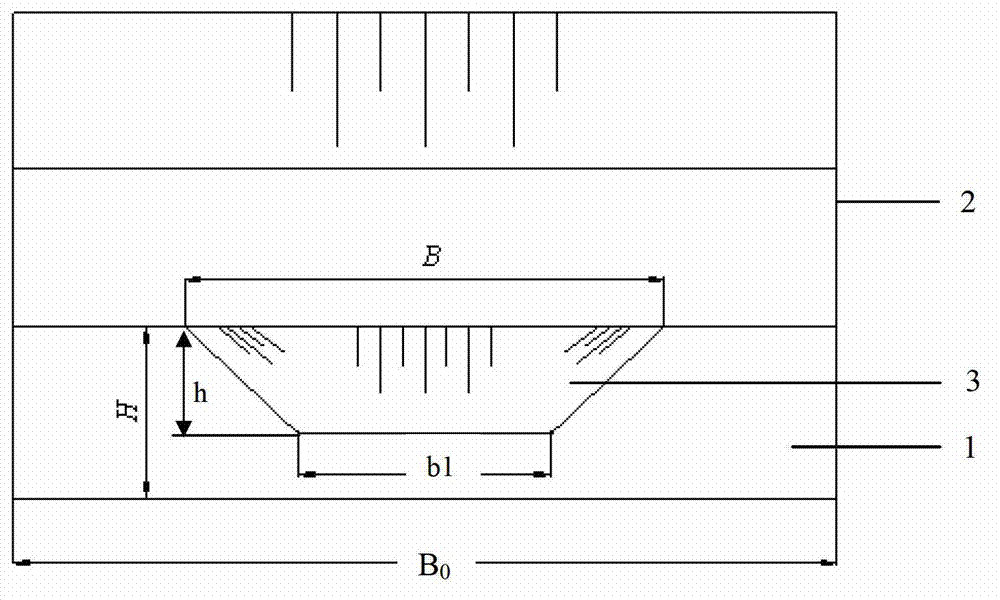

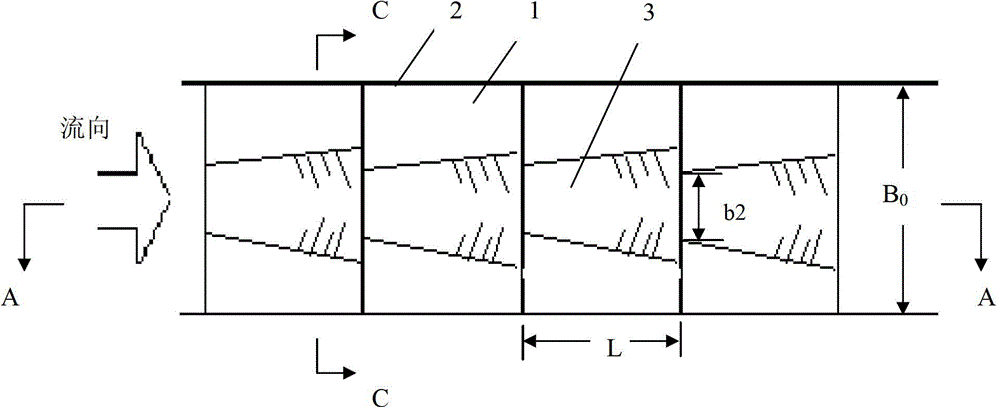

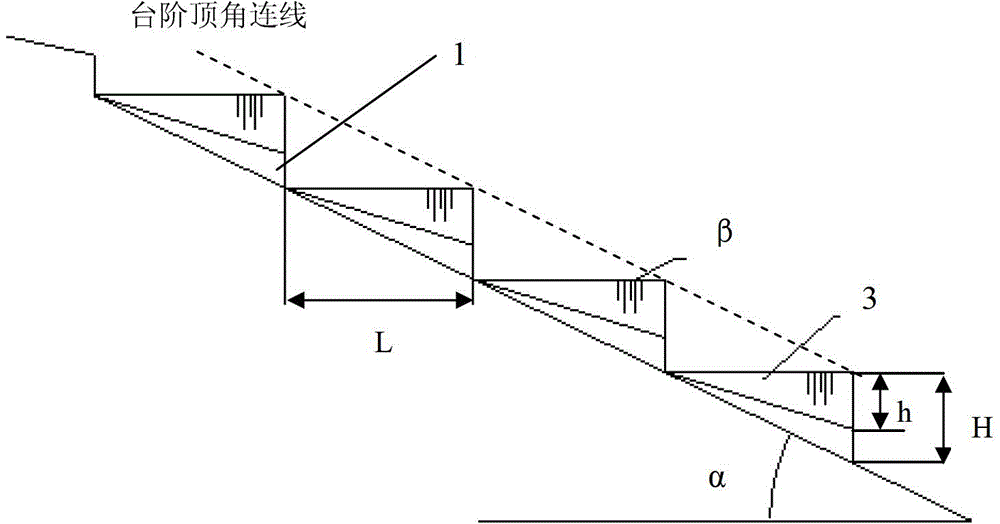

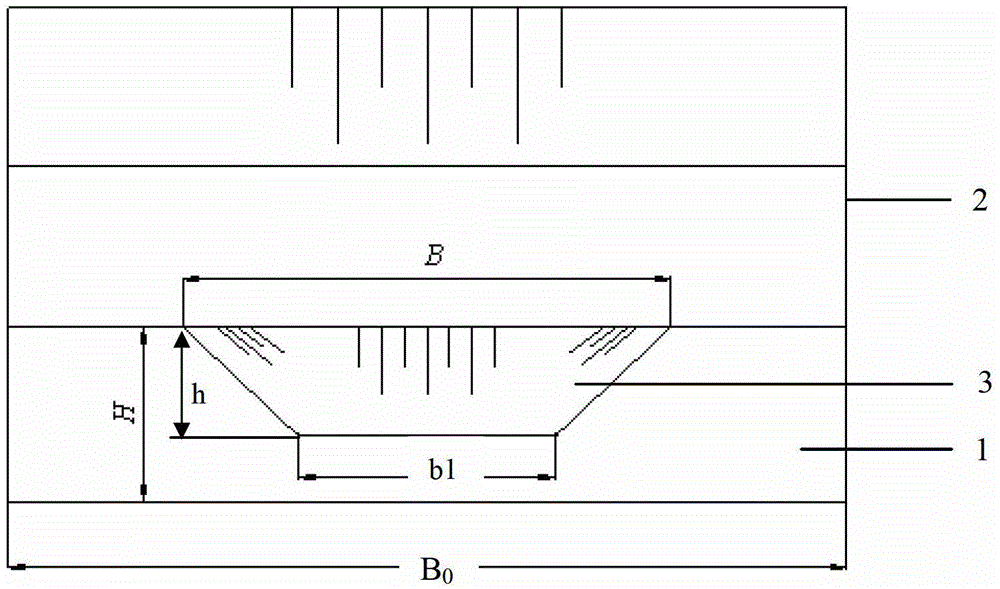

Debris-flow drainage canal with energy dissipation and drainage functions and application thereof

The invention discloses a debris-flow drainage canal with energy dissipation and drainage functions and an application of the debris-flow drainage canal with energy dissipation and drainage functions. The drainage canal comprises a fully-lining drainage canal bottom plate and drainage canal side walls on two sides of the drainage canal bottom plate; the drainage canal bottom plate is in the shape of continuously-connected multiple-stage steps, the steps are provided with grooves; the width of the grooves on the top surfaces of the steps increases gradually along the flow direction of the debris flow, and the width of the grooves on the vertical surfaces of the steps decreases gradually; and the maximum width of the grooves on the top surfaces of the steps coincide with the maximum width B on the vertical surfaces of the steps. Compared wit the prior art, the step shape design is adopted to dissipate the energy of the debris flow all the way and the groove design is adopted to drain the debris flow, so the debris-flow drainage canal disclosed by the invention has high efficiency and good drainage capacity. By adjusting the height and the length of the steps and the size and the shape of grooves, the debris-flow drainagedrainage canal can be used for preventing the debris flow with any gradient and any nature.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

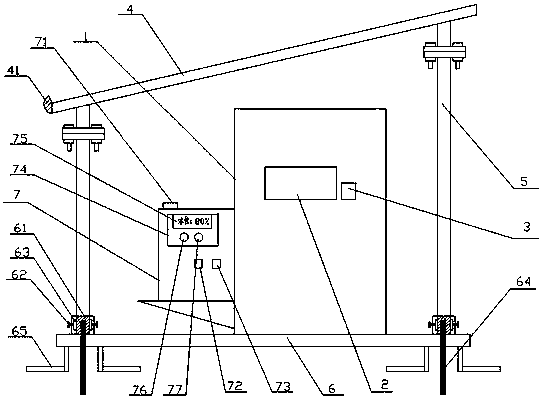

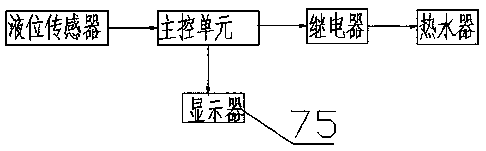

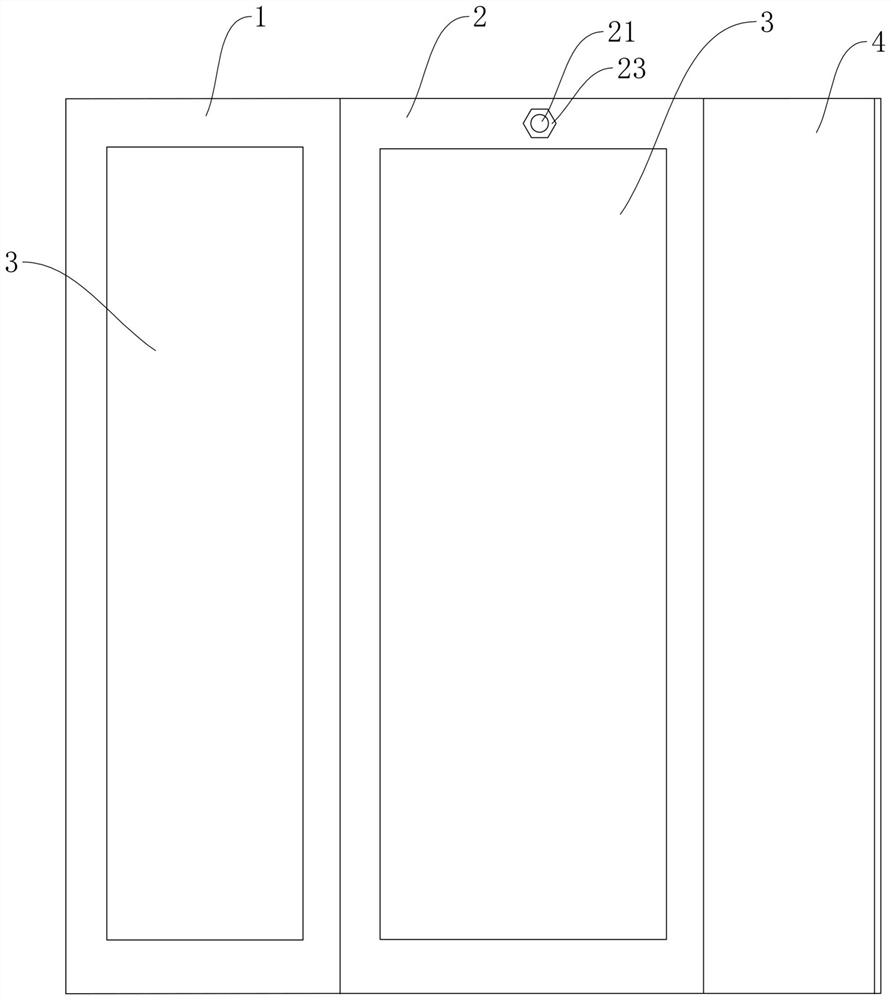

Charging pile

InactiveCN108656996ASolve the service lifeEasy to viewCharging stationsElectric vehicle charging technologyEnvironment effectEngineering

The invention discloses a charging pile. The charging pile comprises a charging pile body; a display control screen is arranged in the middle of the charging pile body, a main control unit is arrangedon the rear side of the display control screen, a wireless connection module is arranged on the right side of the main control unit, and a card swiping sensing area is arranged on the right side of the display control screen; the charging pile further comprises a shielding plate on the upper portion of the charging pile body, supporting rods used for supporting the shielding plate, and a chargingpile base at the bottom of the charging pile body; the bottoms of the supporting rods are connected with the charging pile base, and the tops of the supporting rods are connected with the shielding plate; a drinking water cabinet is arranged on the left side of the charging pile body and internally provided with a water heater and a water tank; and the drinking water cabinet is provided with a water injecting opening, a hot water outlet and a cold water outlet; a sealing cap is arranged on the water injecting opening, the water injecting opening communicates with a water inlet in the water tank through a water pipe, the drinking water cabinet is provided with an observation window, and the output end of the main control unit is connected with a relay used for controlling the water heaterto work. The charging pile is simple in structure and is not affected by rainwater and the severe environment, and the design of the drinking water cabinet is reasonable and humanized.

Owner:河南水天环境工程有限公司

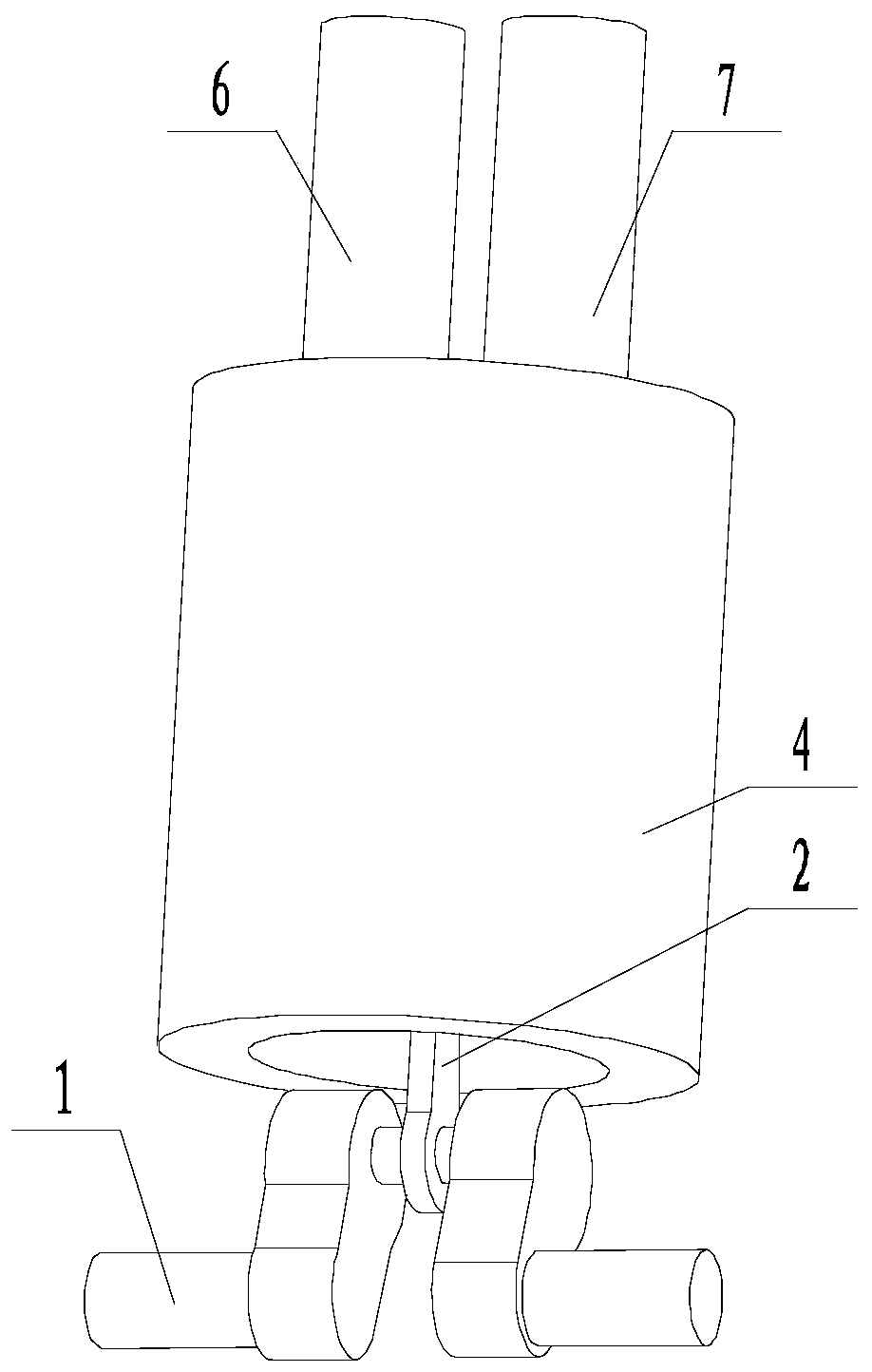

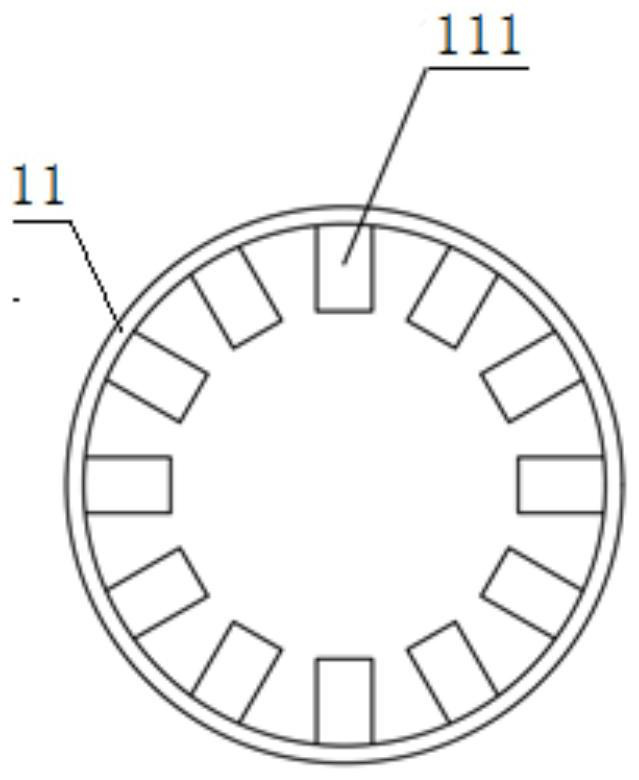

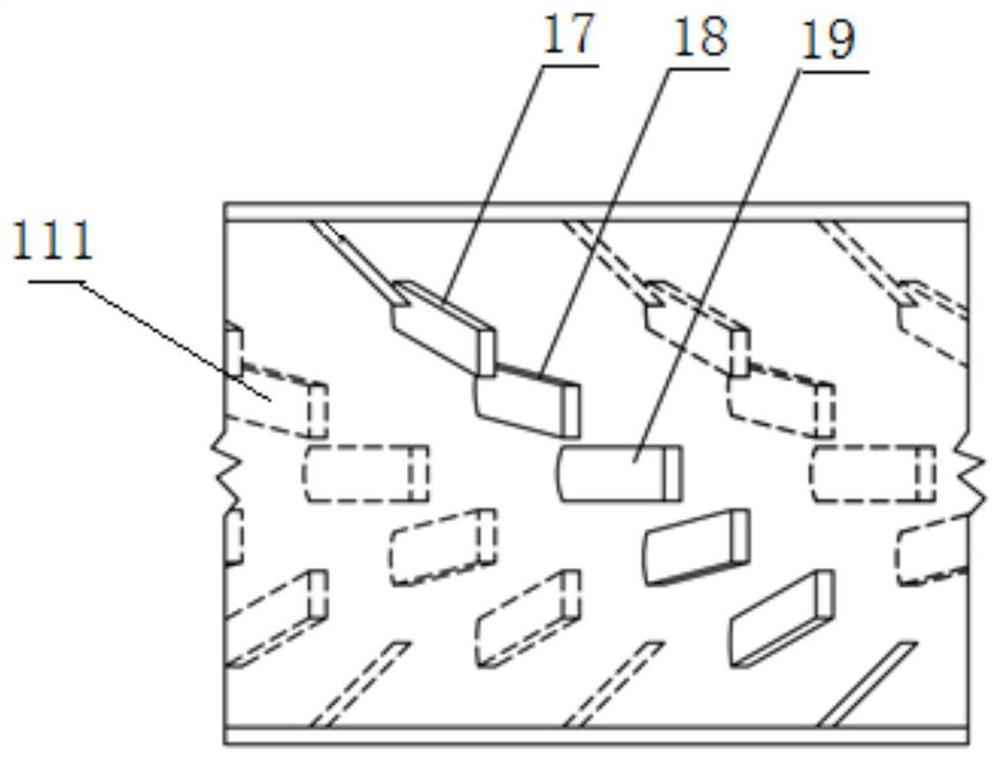

Grinding bar type grinding machine

InactiveCN106269017AImprove whitening efficiencyReduce grain breaking rateGrain huskingGrain polishingPulp and paper industryInvestment cost

The invention discloses a grinding bar type grinding machine. The grinding bar type grinding machine comprises a machine frame and a main shaft, wherein the main shaft is in transmission connection with a motor; a grinding roll is sheathed on the upper part of the main shaft; a screen cylinder is arranged at the periphery of the grinding roll and is matched with the grinding roll; a grinding chamber is formed between the grinding roll and the screen cylinder; the grinding roll comprises a roll body, a plurality of grooves of the roll body are arranged on the outer surface of the roll body along the axial direction, a first grinding bar is fixedly arranged in each groove of the roll body, a convex strip of the roll body is formed between the two grooves of the roll body, and an air ventilating hole is formed in each convex strip of the roll body along the axial direction, and is communicated with the main shaft; the screen cylinder comprises a screen frame body, screen plates and second grinding bars, groove plates are fixedly arranged on the screen frame body, and are provided with grooves, each second grinding bar is fixedly arranged in the corresponding groove, and each screen plate is arranged at the gap between the two groove plates. The grinding bar type grinding machine has the advantages that by adopting the grinding roll and the screen cylinder with the structures, the generation of crushed grains is reduced, and the whitening rate is improved; by utilizing the grinding bars for multiple times, the investment cost of equipment is reduced.

Owner:HUBEI BISHAN MACHINERY CO LTD

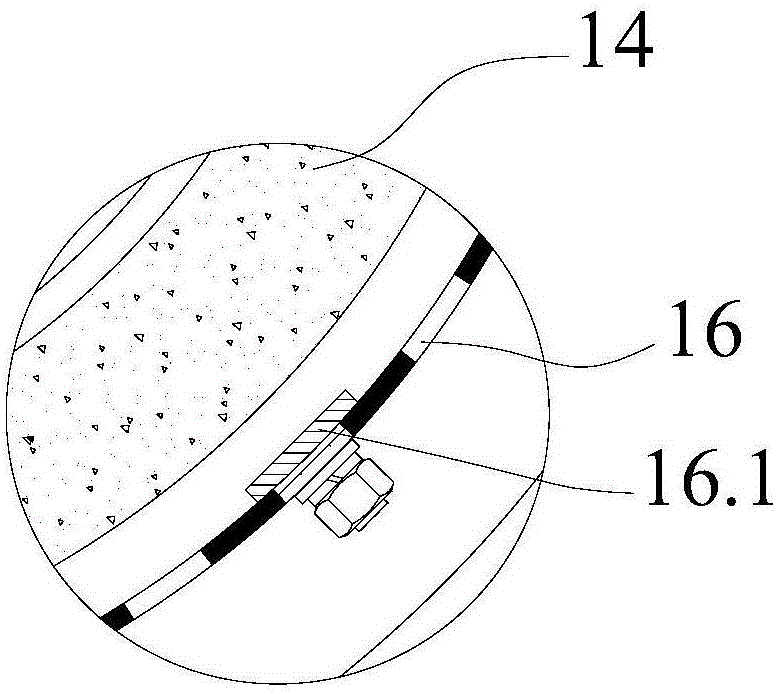

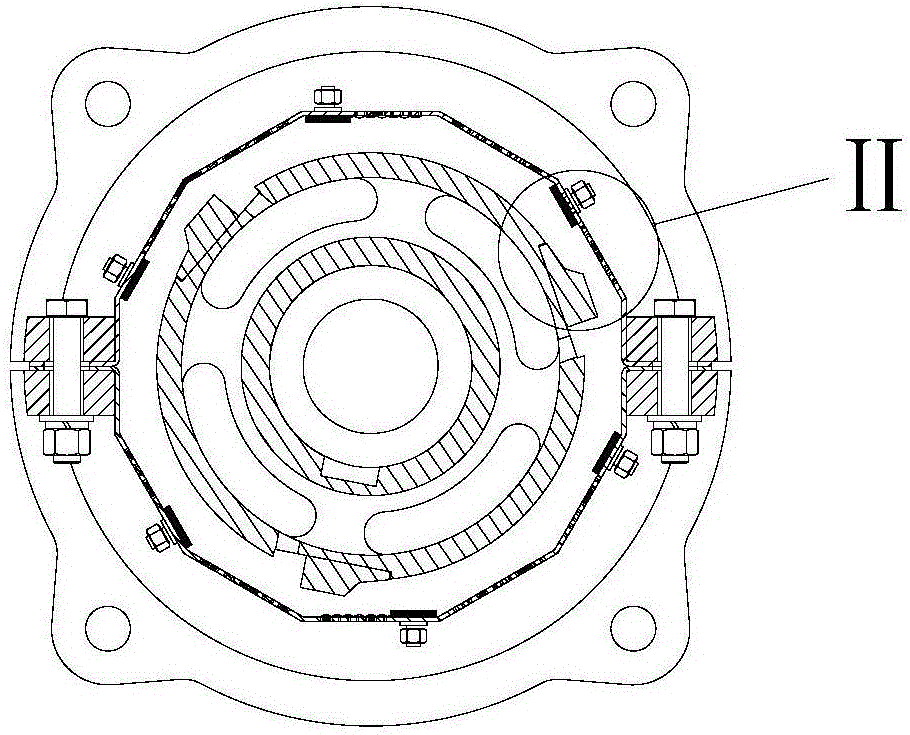

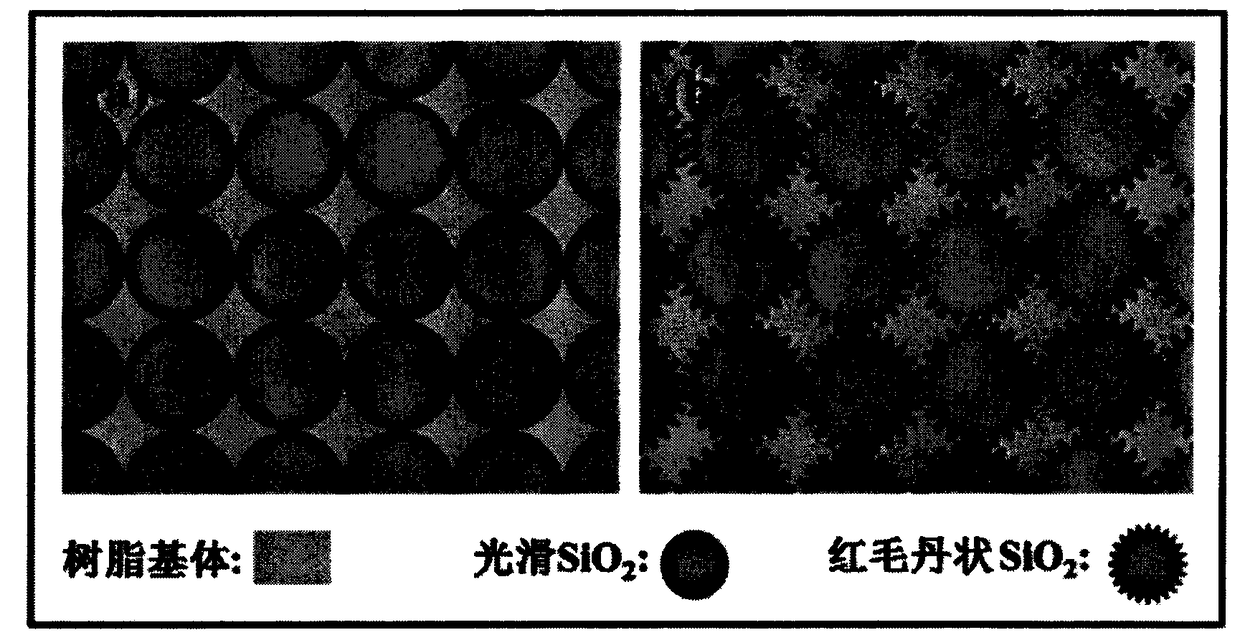

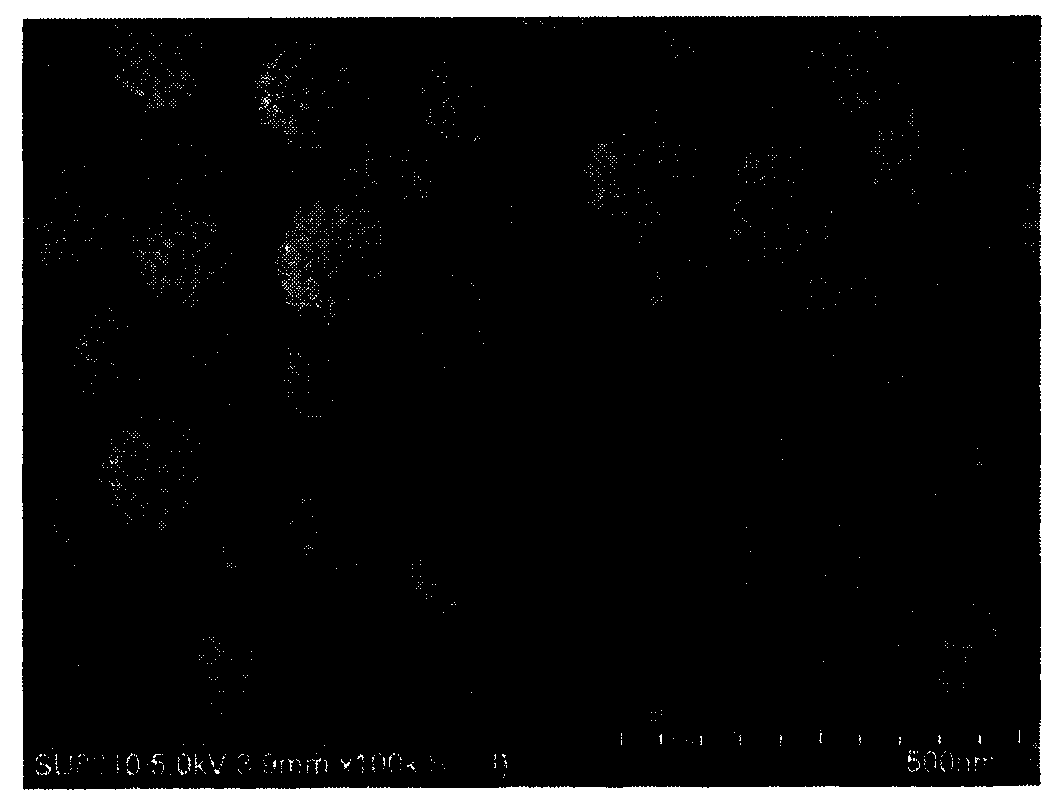

Rambutan-like SiO2-based dental composite resin and preparation method thereof

InactiveCN108852858AIncrease mutual frictionImprove bindingImpression capsDentistry preparationsConvex structureResin matrix

The invention relates to a rambutan-like SiO2-based dental composite resin and a preparation method thereof. The composite resin comprises inorganic filler, a resin matrix and an initiator system, wherein the inorganic filler is rambutan-like SiO2. The preparation method comprises the following steps: mixing the rambutan-like SiO2, the resin matrix and the initiator system to obtain an uncured composite resin paste, and then performing light curing to obtain the dental composite resin. The dental composite resin provided by the invention has simple preparation and excellent performances, and the surface of the rambutan-like SiO2 has a convex structure similar to sawtooth; by the mutual occlusion between the sawtooth, the frictional force between SiO2 particles is improved, and the materialfracture due to relative slippage of particles is reduced; in addition, by utilizing the rough structure of the surface of SiO2, the contact area between the resin matrix and SiO2 is increased, the bonding ability of the organic-inorganic phase interface is improved, and thus the mechanical properties of the composite resin are improved.

Owner:DONGHUA UNIV

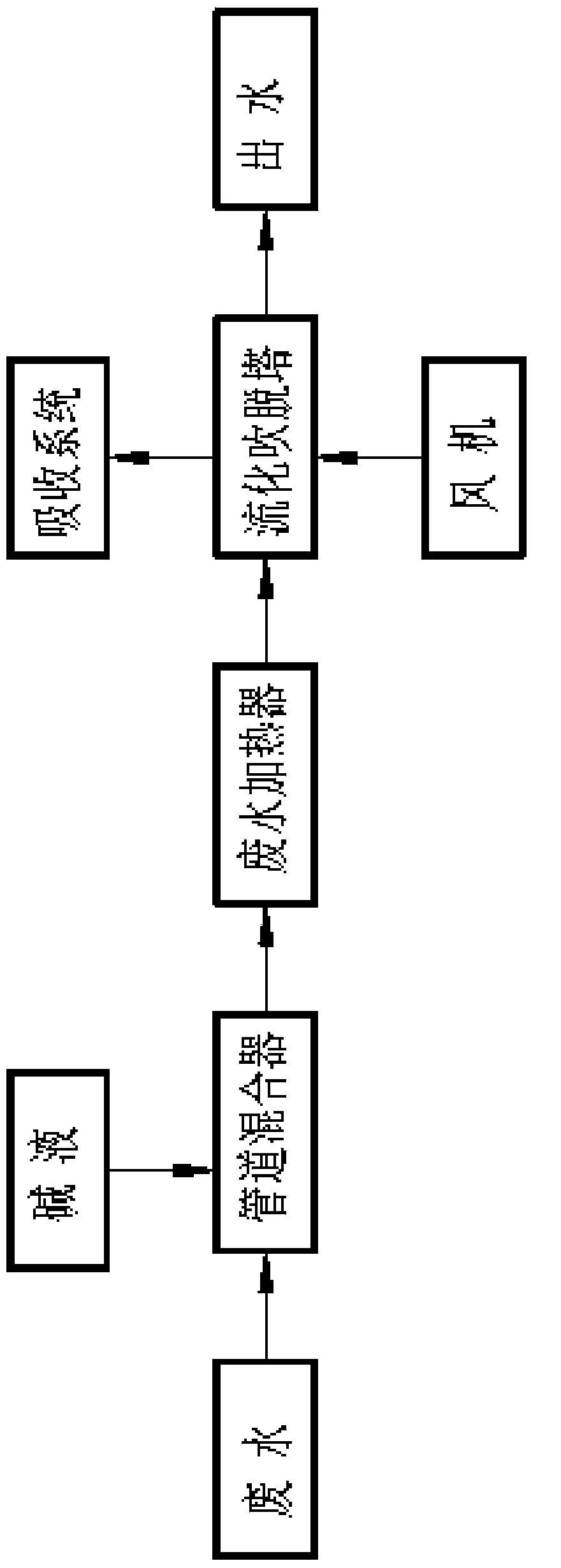

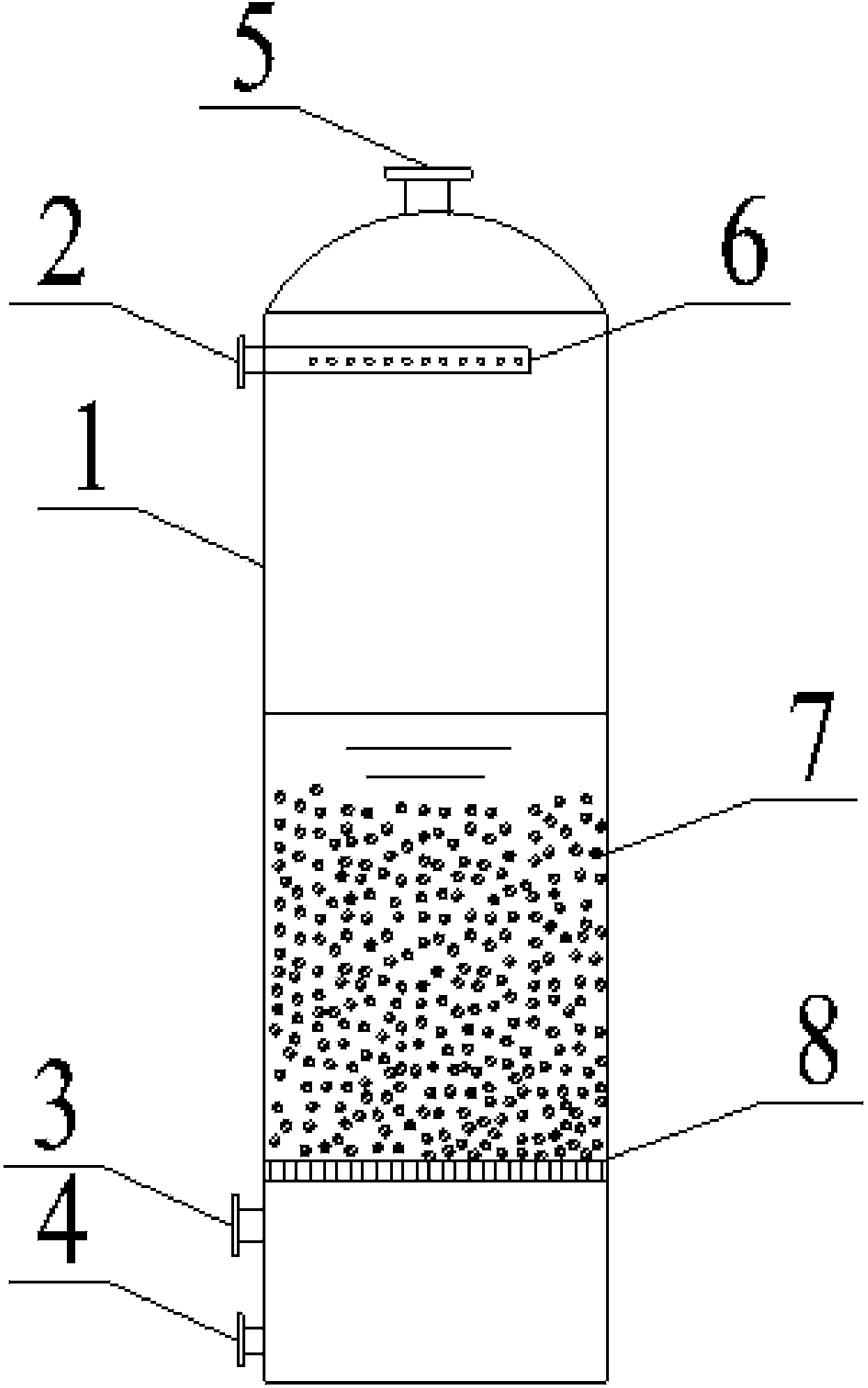

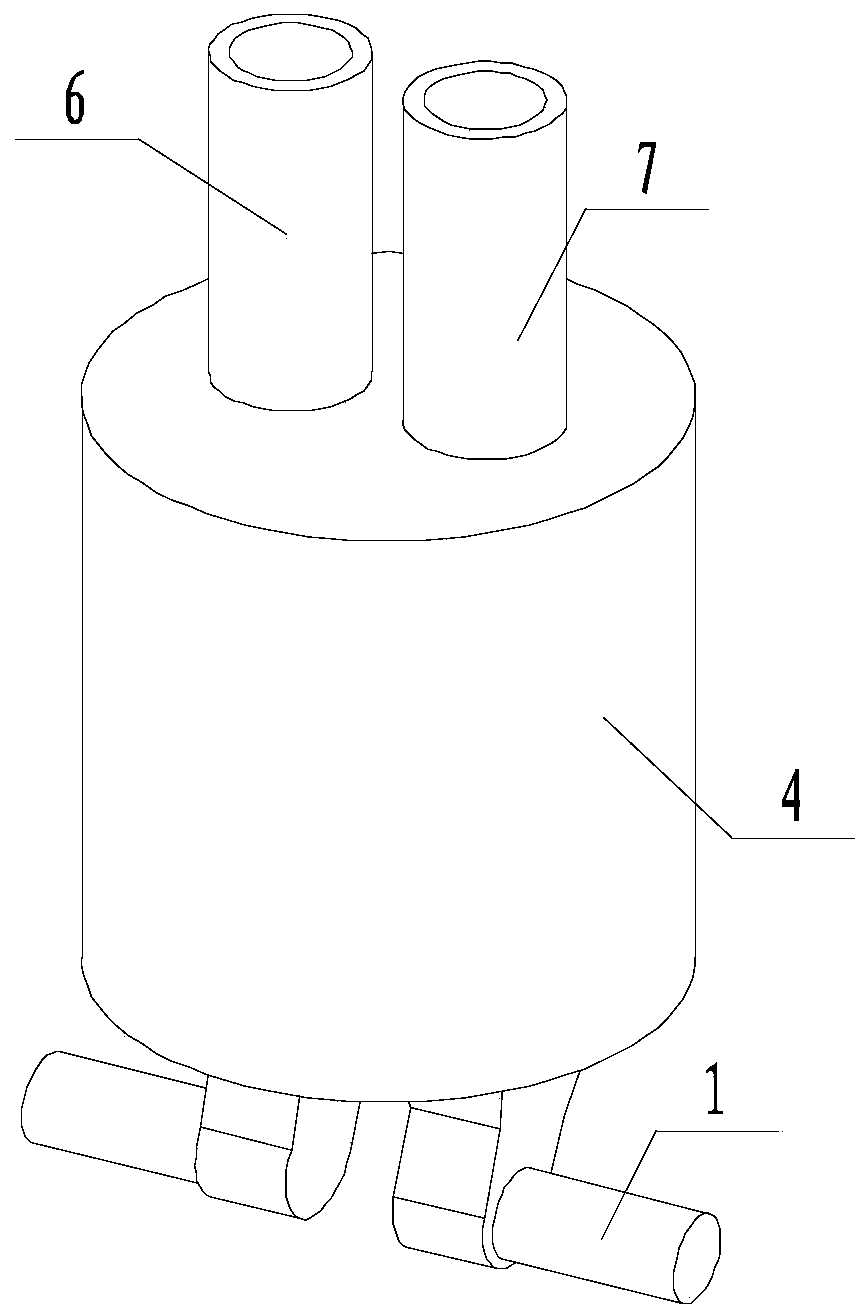

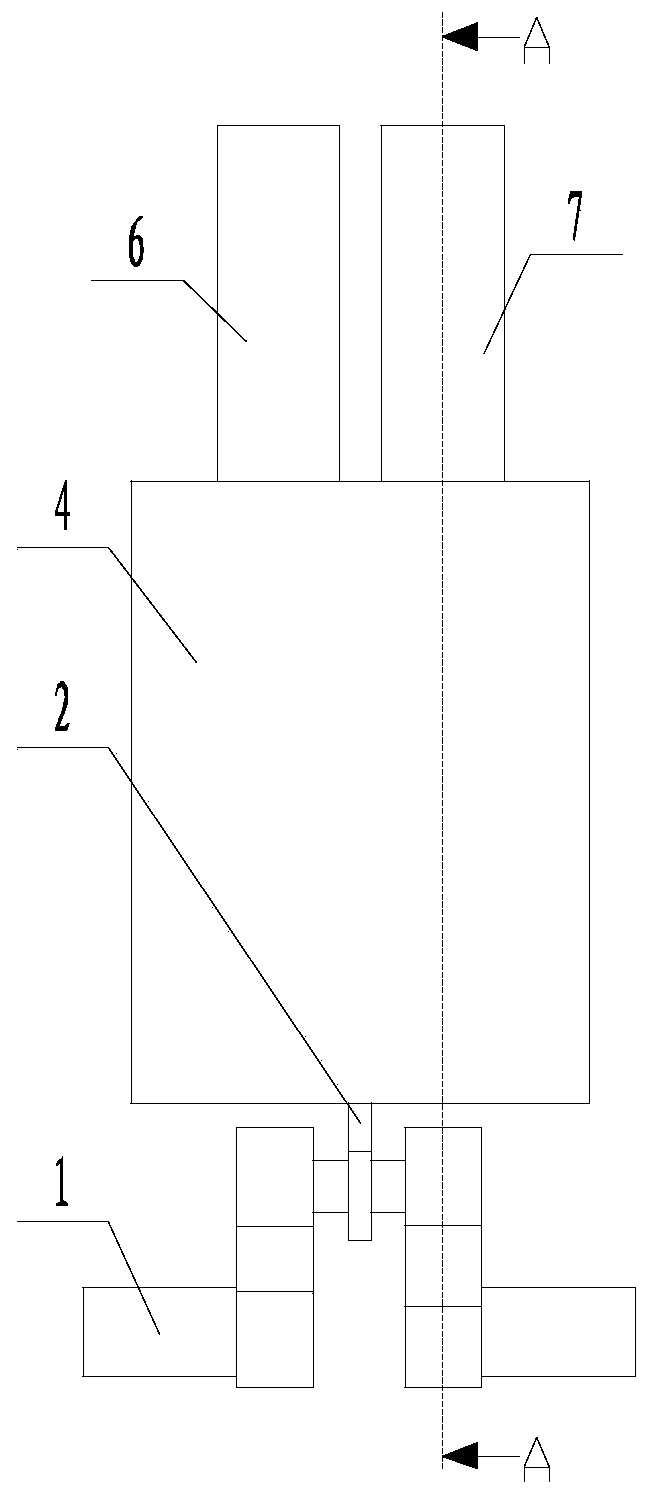

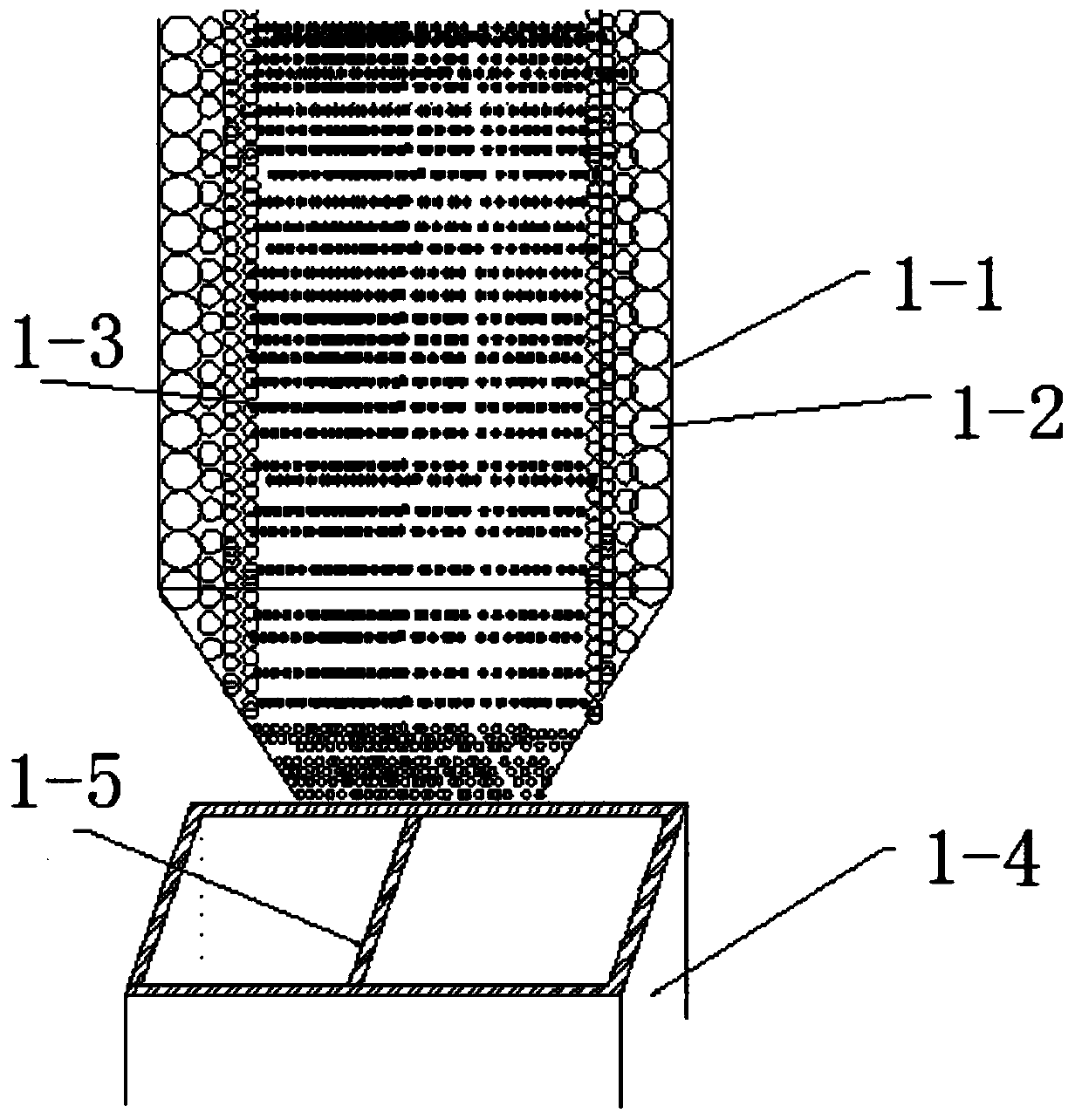

Treatment method and device for fluidizing and stripping high ammonia and nitrogen waste water

InactiveCN103663833AEnhanced mass transferMass transfer is effectiveWater contaminantsMultistage water/sewage treatmentAmmoniacal nitrogenFree form

A treatment method for fluidizing and stripping high ammonia and nitrogen waste water, comprising the following processes of: respectively sending high ammonia and nitrogen waste water and alkali lye into a pipe mixer for mixing, regulating a pH value to be 9-13, and heating until 20-50 DEG C; introducing the heated waste water into a fluidizing and stripping tower to be contacted with air and particle fillers in a fluidization state for mass transfer, discharging the stripped waste water from a waste water outlet on the bottom of the fluidizing and stripping tower, and discharging air containing ammonia in free form from an exhaust gas outlet on the top of the fluidizing and stripping tower. The invention further discloses a device for implementing the method.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

Production process for camellia seed oil

InactiveCN107653054ARetain nutrientsRetention of active substancesFatty-oils/fats productionEdible oils/fatsCamellia oleiferaCell separation

The invention relates to a production process for camellia seed oil. The production process comprises the following steps: 1) raw material cleaning and selecting; 2) hulling treatment; 3) seed-hull separation; 4) camellia seed baking; 5) material steaming and tempering; and 6) cooling, squeezing and oil discharging. The production process provided by the invention adopts physical squeezing, so nutritional components, active substances and camellia fragrance in oil are retained; meanwhile, specific processes like hull-seed separation, camellia seed baking and material steaming and tempering greatly improve the extraction rate of the oil compared with a conventional squeezing process; and the process provided by the invention can produce purely-natural, organic and green camellia seed edibleoil which is comparable to olive oil.

Owner:怀化盛源油脂有限公司

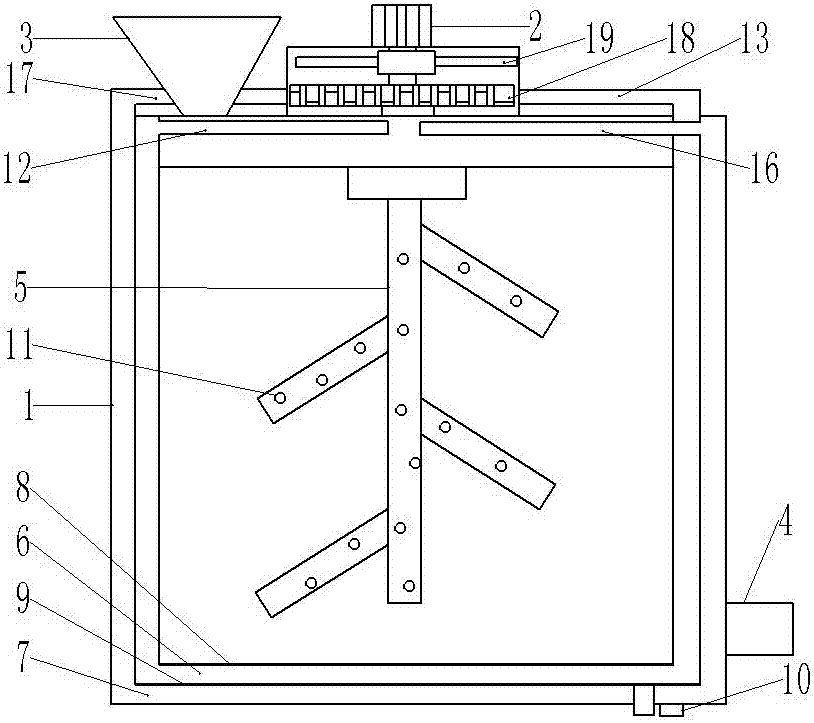

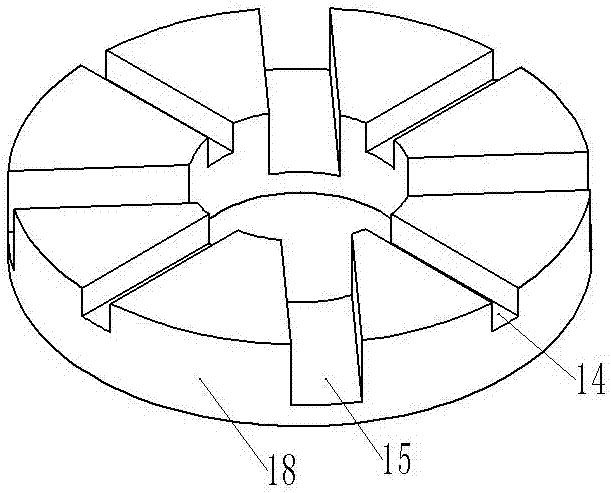

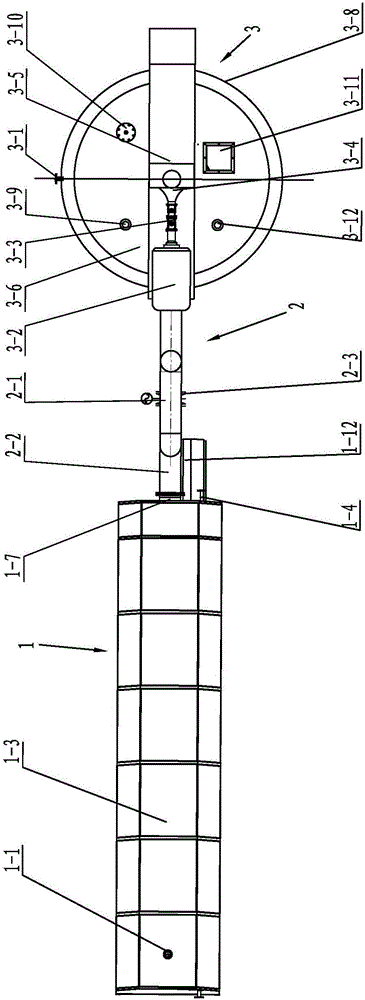

Material mixing device for making bricks by using waste

ActiveCN106902689AReduce air flowIncrease mutual frictionShaking/oscillating/vibrating mixersSolid waste managementCircular discBrick

The invention relates to the technical field of brick-making and material-mixing devices and discloses a material mixing device for making bricks by using waste. The material mixing device comprises a material mixing cylinder, wherein the material mixing cylinder is provided with a motor, a feeding port and a discharging port, a stirring shaft is arranged in the material mixing cylinder, the motor comprises a rotary shaft, the bottom wall of the material mixing cylinder is provided with a hollow layer, the side wall, located inside the material mixing cylinder, of the hollow layer is a first elastic layer, a second elastic layer is arranged in the hollow layer and is divided into a first cavity and a second cavity, the first cavity is provided with a first air inlet and a second air outlet, the second cavity is provided with a second air inlet and a second air outlet, the rotary shaft is fixedly connected with the stirring shaft, the rotary shaft is provided with a disc and a fan, a plurality of air guiding grooves are formed in the disc, second air guiding grooves are formed among the adjacent first air guiding grooves, the depth of the second air guiding grooves is greater than that of the first air guiding grooves, a first air blowing pipe and a second air blowing pipe are arranged on the fan, the first air blowing pipe is communicated with the first air inlet, and the second air blowing pipe is communicated with the second air inlet. Even mixing of brick-making raw materials can be achieved through the material mixing device for making bricks by using waste.

Owner:山东金祥云贸易有限公司

Piston braking system and braking method thereof

PendingCN109826886AReduced reciprocation frequencyAchieve braking effectBrake actuating mechanismsActuatorsReciprocating motionEngineering

The invention discloses a piston braking system and a braking method thereof. The piston braking system comprises transmission rotating shafts located between a starting component and a working component, pistons, and a pressure adjusting mechanism, wherein each piston is connected with the corresponding transmission rotating shaft; when each transmission rotating shaft rotates, the correspondingpiston is driven to be in straight reciprocating motion in a cylinder jacket; a pressure adjusting cavity is formed between each piston and the cylinder jacket; the pressure adjusting mechanism is used for adjusting the pressure in the pressure adjusting cavities, and comprises an inlet pipe and a discharging pipe, wherein the inlet pipe and the discharging pipe separately communicate with the pressure adjusting cavities; one-way valves are respectively arranged in the inlet pipe and the discharging pipe; and an adjusting valve is also arranged in the discharging pipe. Every time the transmission rotating shafts rotate for a circle, the pistons are driven to make a complete reciprocating motion, and in the process, the volume of each of the pressure adjusting cavities is enlarged and reduced. Through the adoption of the piston braking system disclosed by the invention, the problem that a conventional braking manner adopts a manner that kinetic energy is transformed into internal energythrough friction, so that the condition that wear of brake cannot be thoroughly and radically solved to cause invalid slipping is solved, and the purposes of breaking the shackles in the prior art and stopping braking failure caused by damage of friction are realized.

Owner:甘泉龙

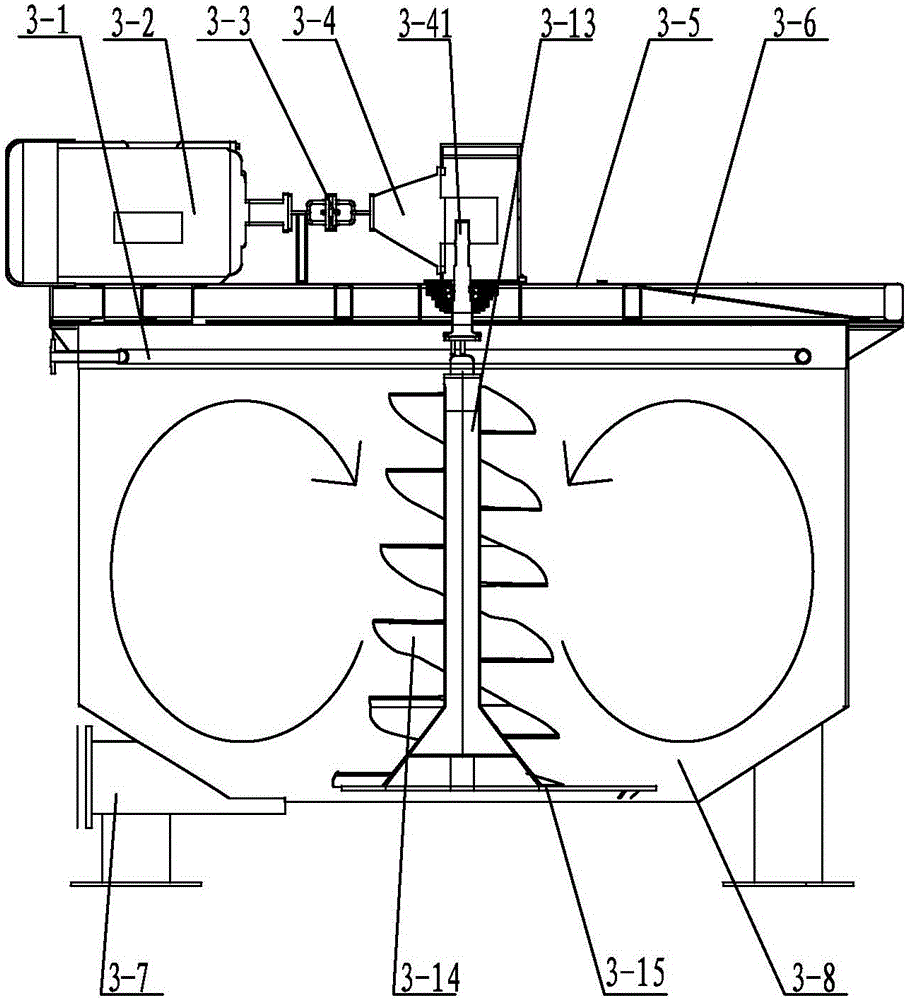

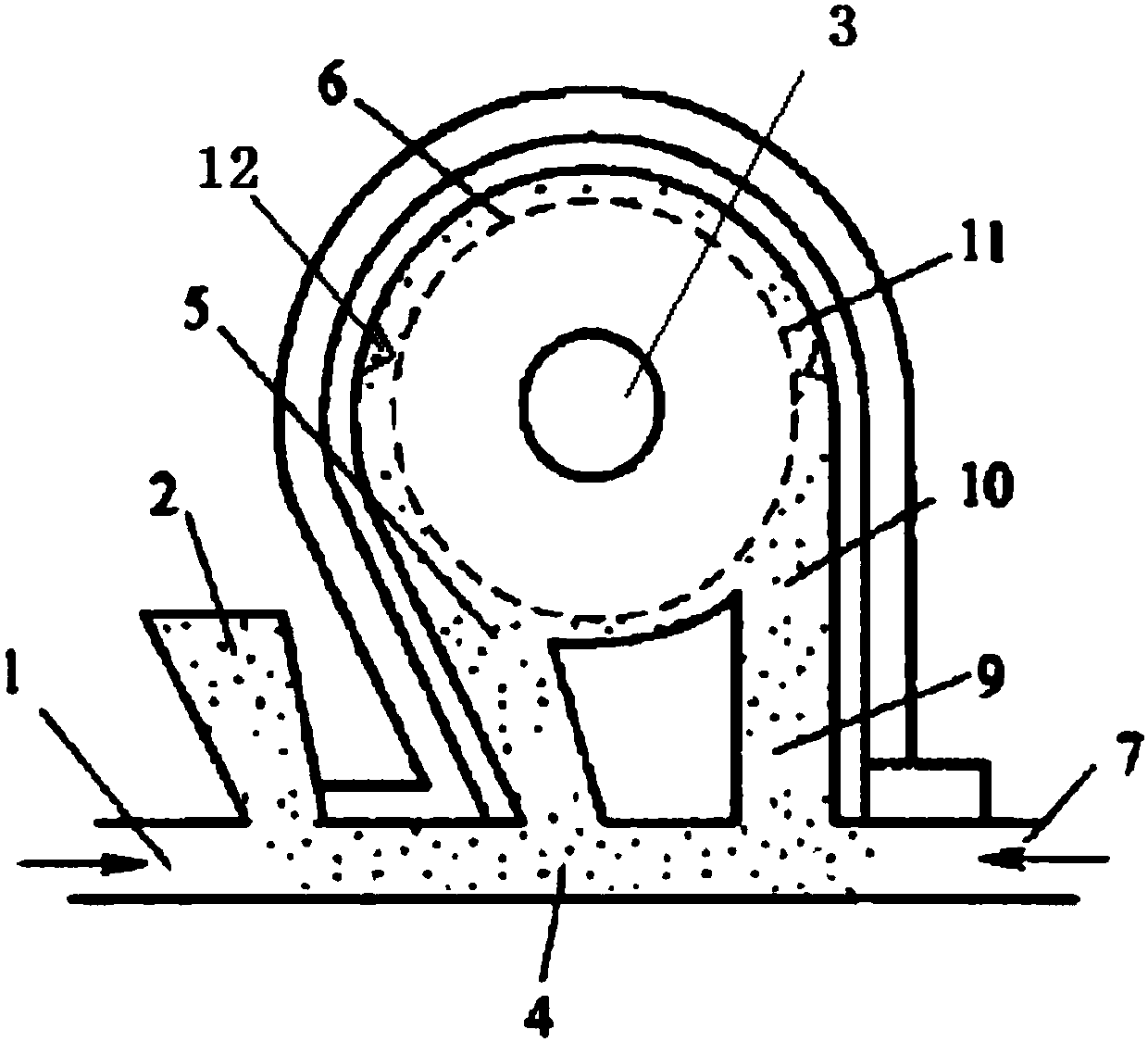

Recycling device for organic matters of solid residues of organic garbage

ActiveCN105689362AIncrease mutual frictionImprove resource utilizationSolid waste disposalSlurry flowOrganic matter

The invention relates to a recycling device for organic matters of solid residues of organic garbage. The recycling device comprises a recycling main body, a recycling auxiliary body and a connecting tube stack connected between the recycling main body and the recycling auxiliary body; a groove of the recycling main body is provided with a stirring mechanism and a cover plate; a discharge port is formed in the lower part of the recycling main body; at least two spiral blades of which diameters are gradually increased from top to bottom are fixed on a stirring shaft of the stirring mechanism; edges of the spiral blades are fillets; during rotation, the spiral blades hydraulically scrub slurry; at least two pushing dead knives of which outer diameters are greater than bottom outer diameters of the spiral blades are arranged at the bottom of the stirring shaft; the pushing dead knives correspond to the discharge port of the lower part of the groove; the recycling auxiliary body comprises the housing and a revolving drum which is inclined upwards in the slurry flowing direction; a feeding opening is formed in the front end of the housing; a residue outlet is formed in the tail of the housing; a liquid collecting tank is arranged at the bottom of the housing; and shaftless spiral blades which are used for pushing the residues are fixed on the inner wall of the revolving drum. The recycling device is simple and reasonable in structure and low in running cost, recycling capability of a system can be improved, and the amount of the solid residues discharged out of the system is reduced.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

Preparation method of crosslinked sodium hyaluronate gel with ultralow crosslinking agent residual quantity and high viscosity

The invention relates to a preparation method of crosslinked sodium hyaluronate gel with ultralow crosslinking agent residual quantity and high viscosity, which comprises the following steps: S1, swelling the gel formed by crosslinking with a buffer solution, and preparing gel particles with proper particle size by using a high-speed dispersion machine; S2, adding dimethyl sulfoxide for washing, so that the unreacted cross-linking agent is eluted from the interior of the gel; S3, removing the dimethyl sulfoxide by adopting ultrafiltration; and S4, collecting a sample, and filling the sample into a filling and sealing injector. The preparation method is simple, the contact area of the gel and the washing filtrate can be effectively increased, and the uncrosslinked crosslinking agent embedded in the gel can be effectively removed by using the dimethyl sulfoxide which is a special organic solvent, so that the residual level of the crosslinking agent is far lower than that of the crosslinking agent prepared by the conventional preparation method.

Owner:CHANGZHOU INST OF MATERIA MEDICA

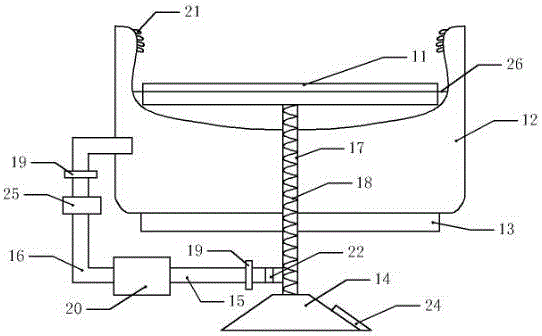

Workbench for clay model manufacturing

ActiveCN106826702AWon't collapseSpeed up heat transferWork benchesCleaning using gasesCircular loopEngineering

The invention belongs to the technical field of clay recycling, and particularly relates to a workbench for clay model manufacturing. The workbench comprises a workbench body and a hollow base. A circular loop of a metal material is arranged on the outer portion of the workbench body in a sleeving manner. A hollow rotary shaft is fixedly mounted on the base. The rotary shaft communicates with the base. A spring is arranged in the rotary shaft in a penetrating manner. Scrap leakage holes are formed in the side wall of the upper end of the rotary shaft. The workbench body is movably mounted at the upper end of the rotary shaft. An air bag and a rotary disc are sequentially arranged on the rotary shaft below the workbench body in a penetrating manner. The air bag and the rotary disc are rotationally connected to the rotary shaft. The upper end, located on the outer side of the workbench body, of the air bag is provided with a plurality of air spray heads. An extraction pipe is connected to the rotary shaft. The end, away from the rotary shaft, of the extraction pipe is connected with an air pump. An exhaust pipe is connected to the air pump. The extraction pipe and the exhaust pipe are provided with one-way valves. An exhaust opening of the exhaust pipe is connected in the air bag. The problem that clay left on the workbench is not prone to being cleaned away is solved.

Owner:CHONGQING BIYANG PROD DESIGN

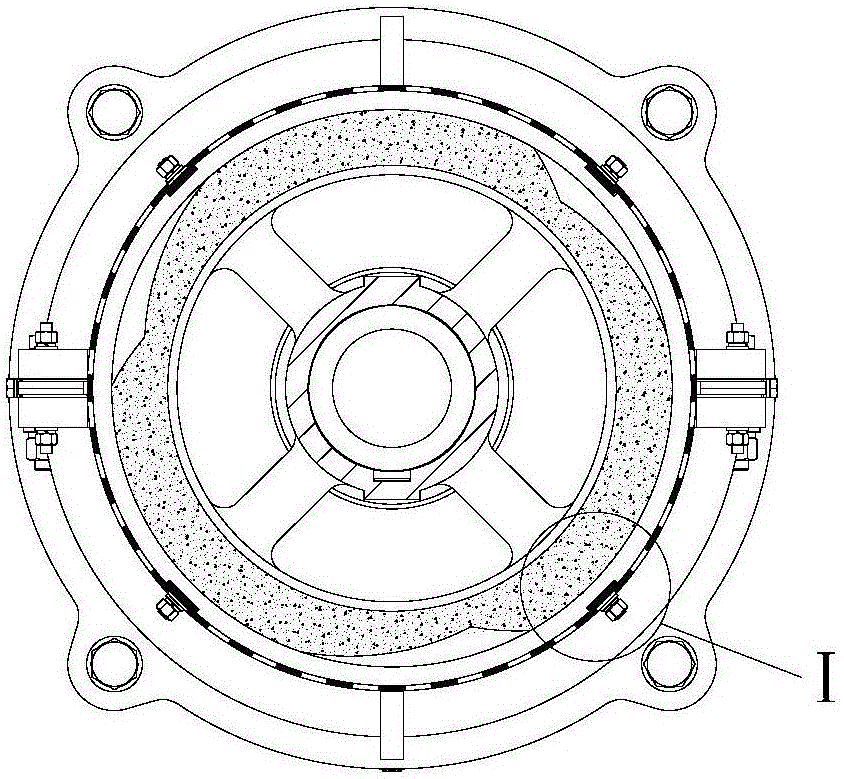

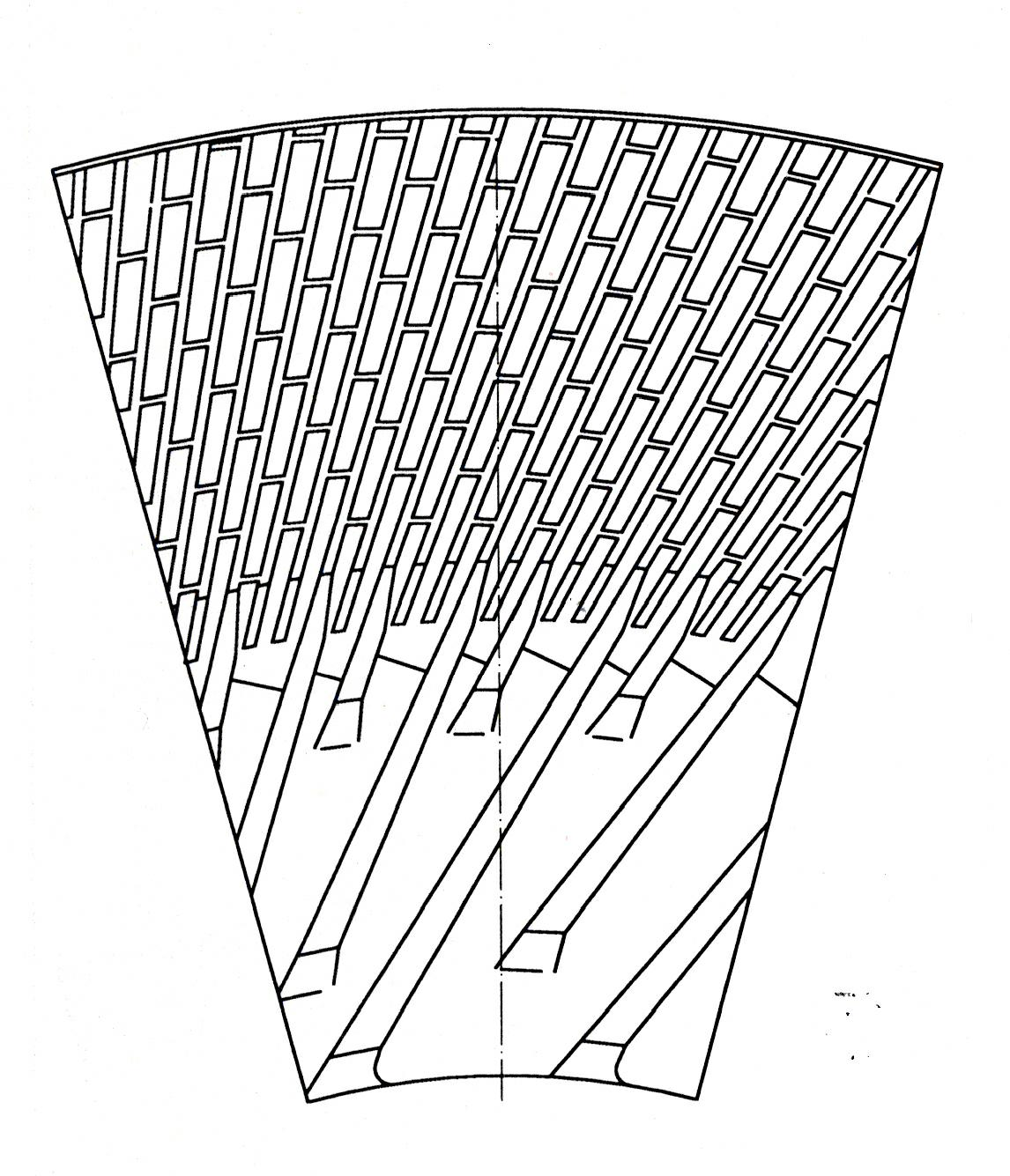

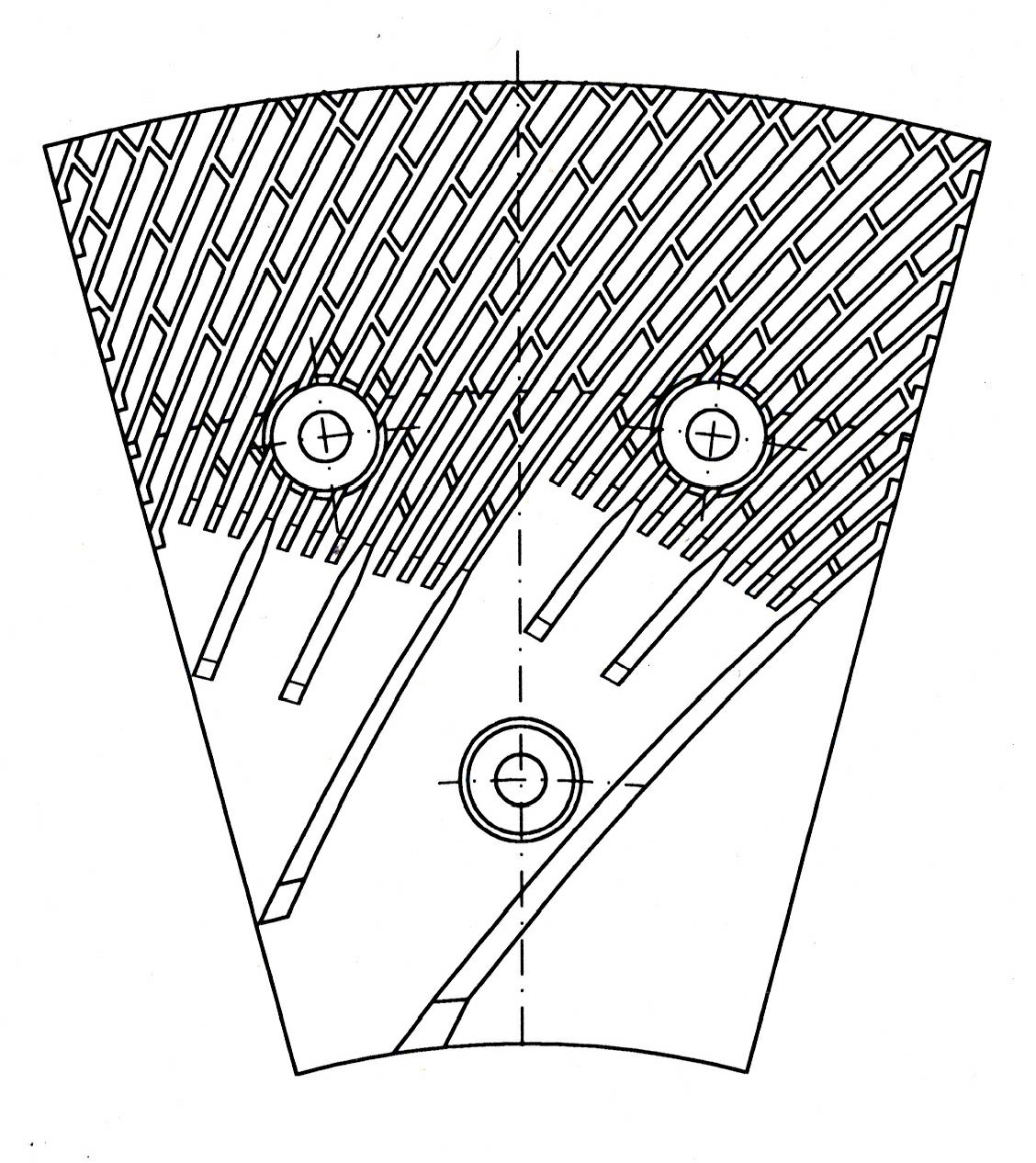

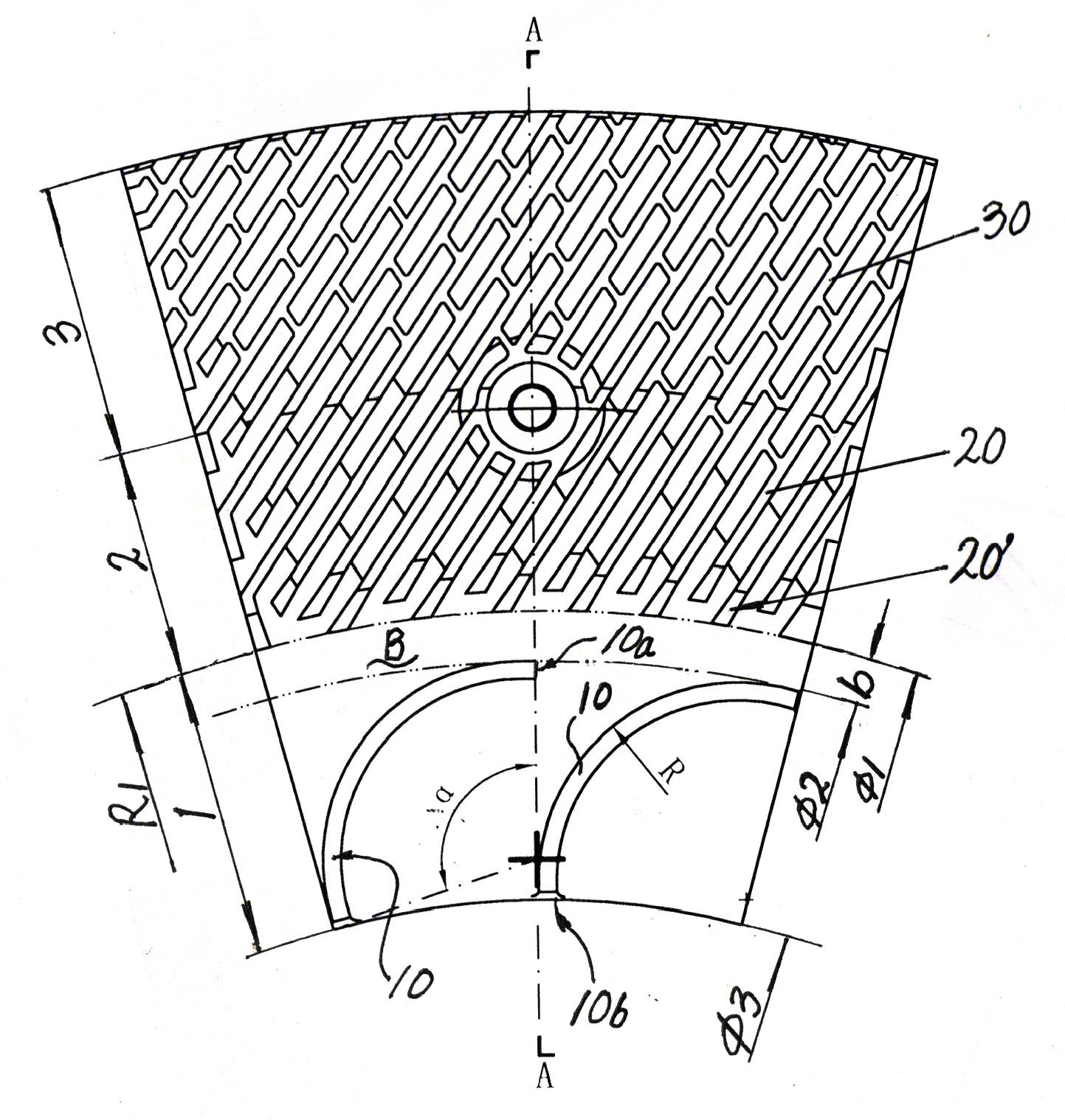

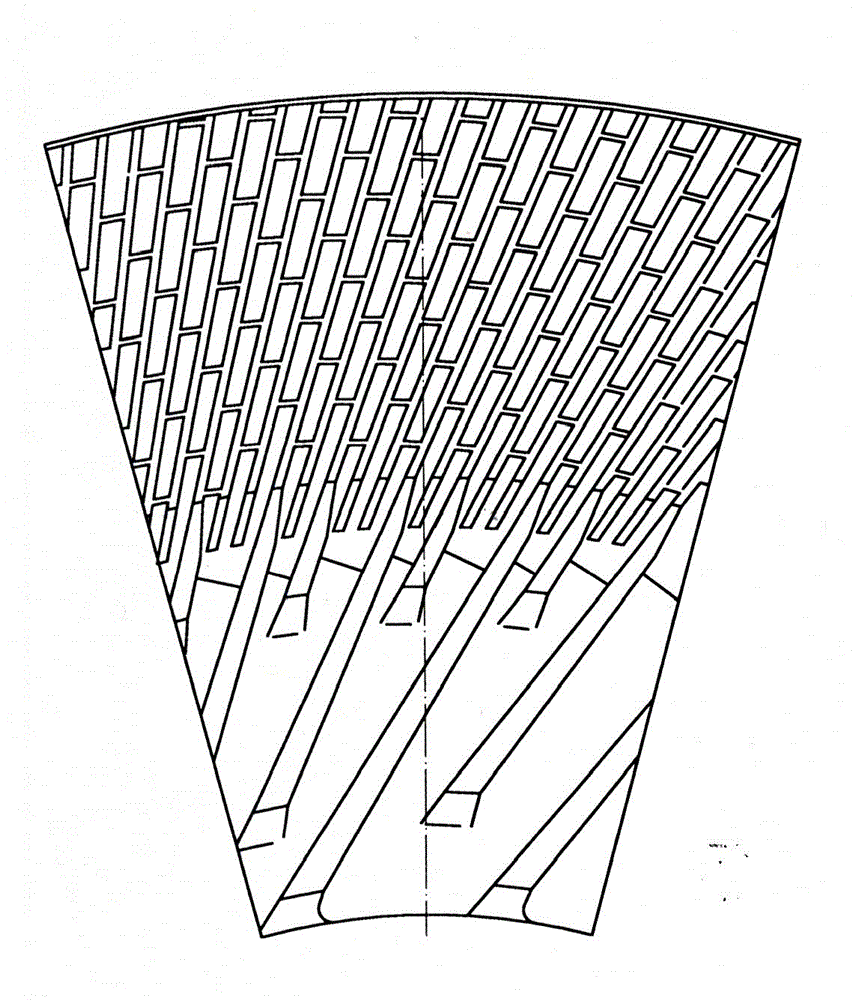

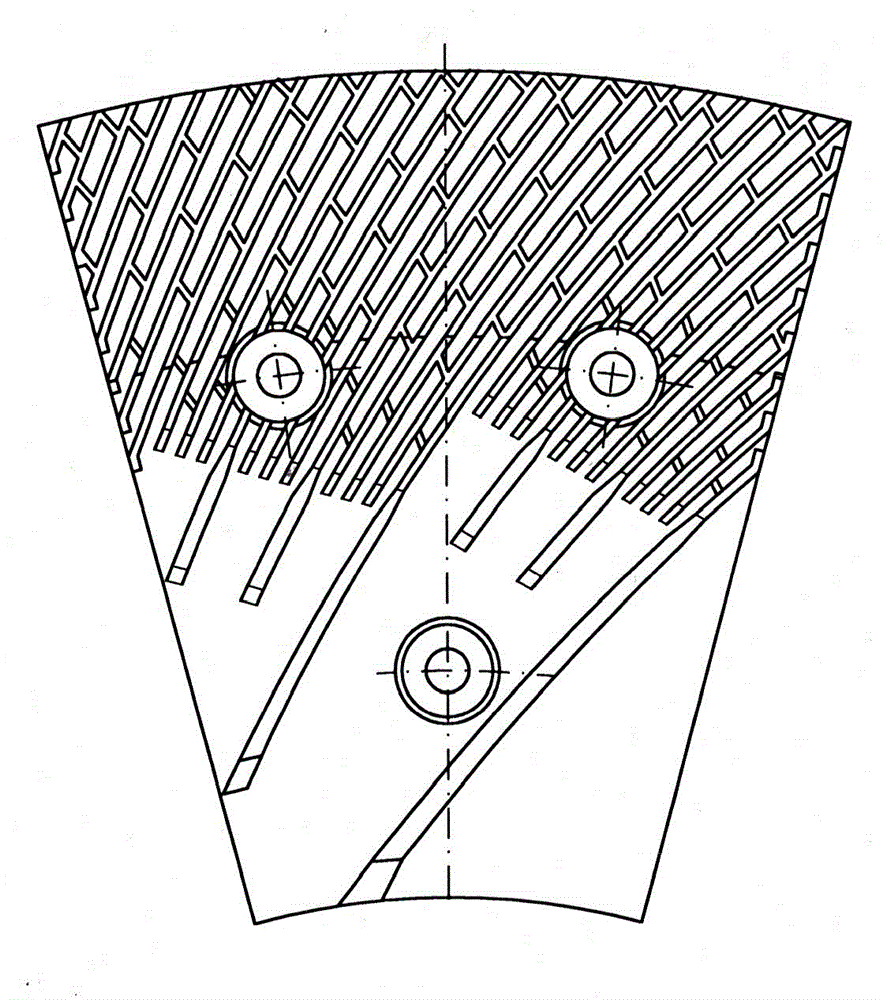

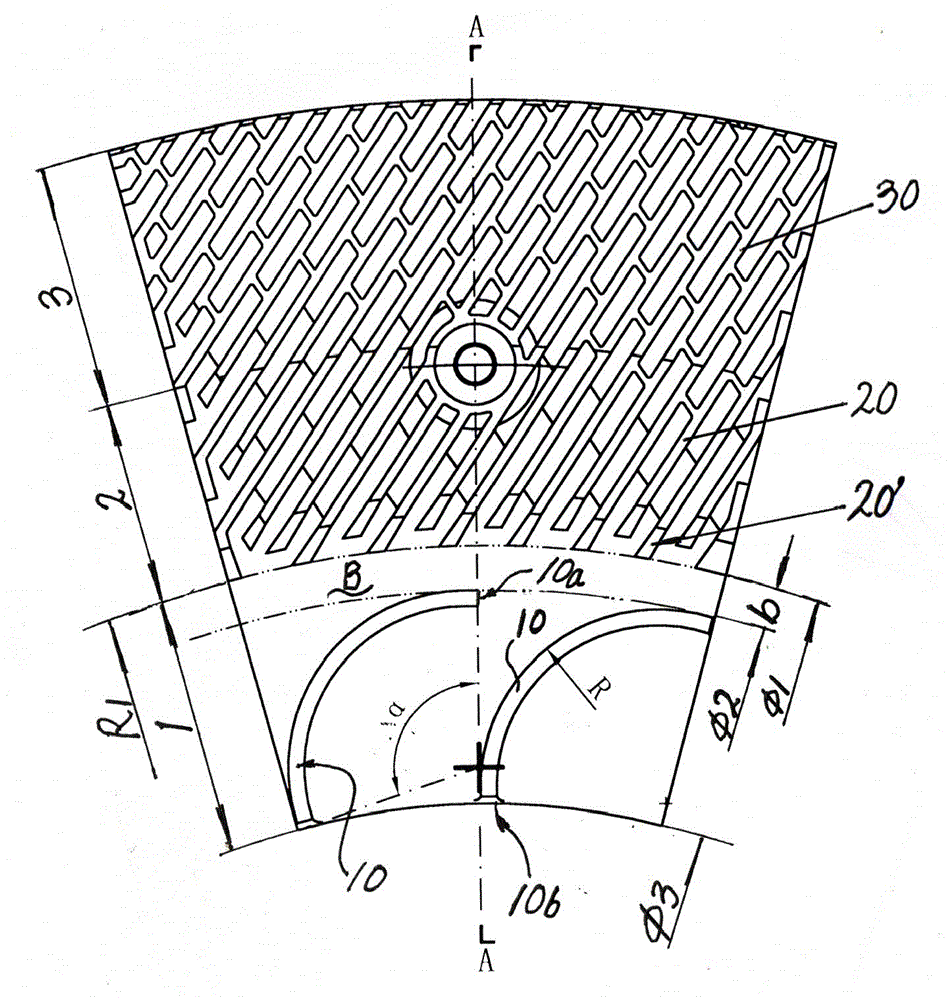

Grinding slice of defibrator

ActiveCN102691220ASmall running resistanceEven by forceFibrous raw materialsDefibratorGrinding teeth

The invention discloses a grinding slice of a defibrator, wherein grinding teeth in a crushing region are separated from those in a coarse grinding region, a ring-shaped buffering deslagging slot is formed between the grinding teeth of the two regions, and the grinding teeth in the crushing region are arc-shaped. According to the grinding slice of the defibrator, the grinding teeth can be effectively prevented from being damaged by hard impurities, the efficiency is improved, the service life of the grinding slice is prolonged, and the power consumption is reduced.

Owner:丹东鸭绿江磨片有限公司

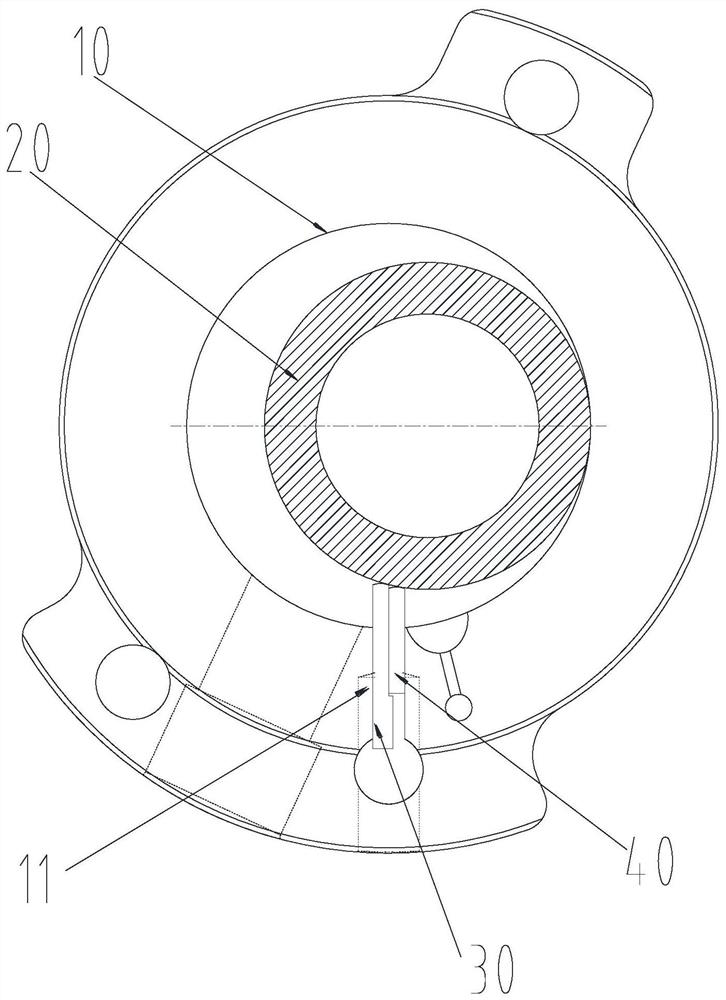

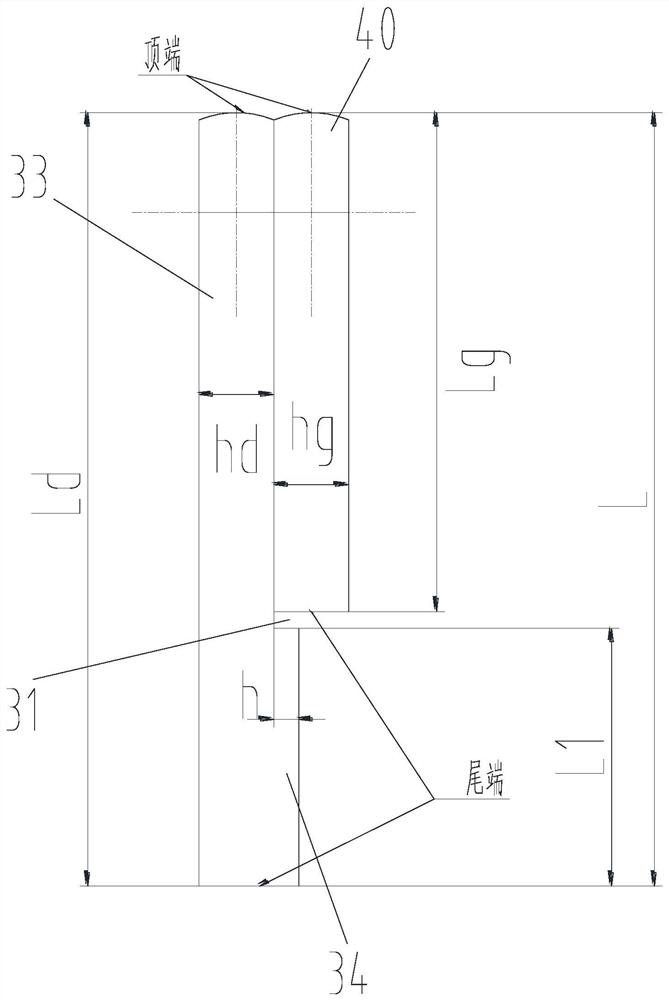

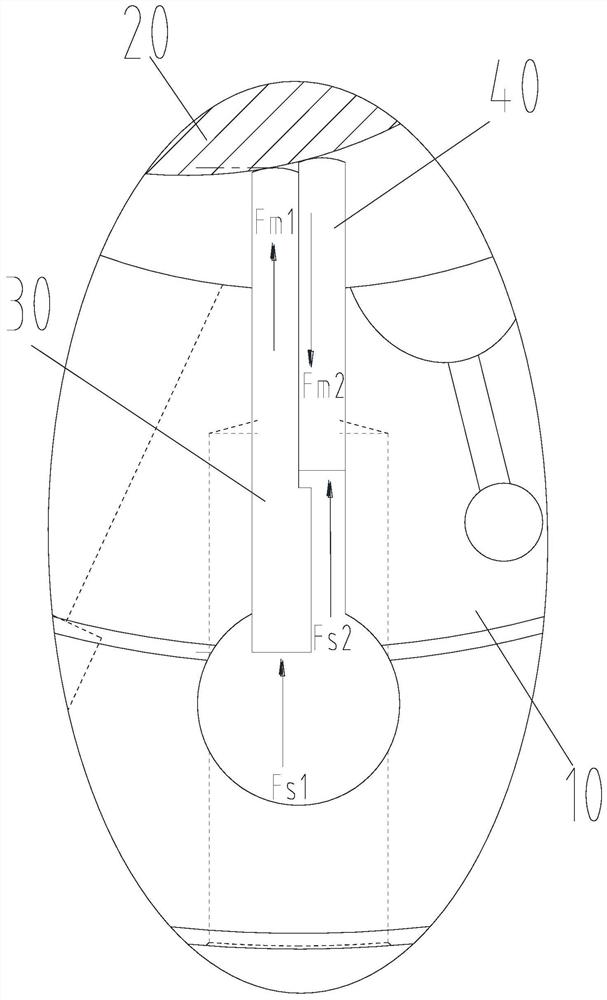

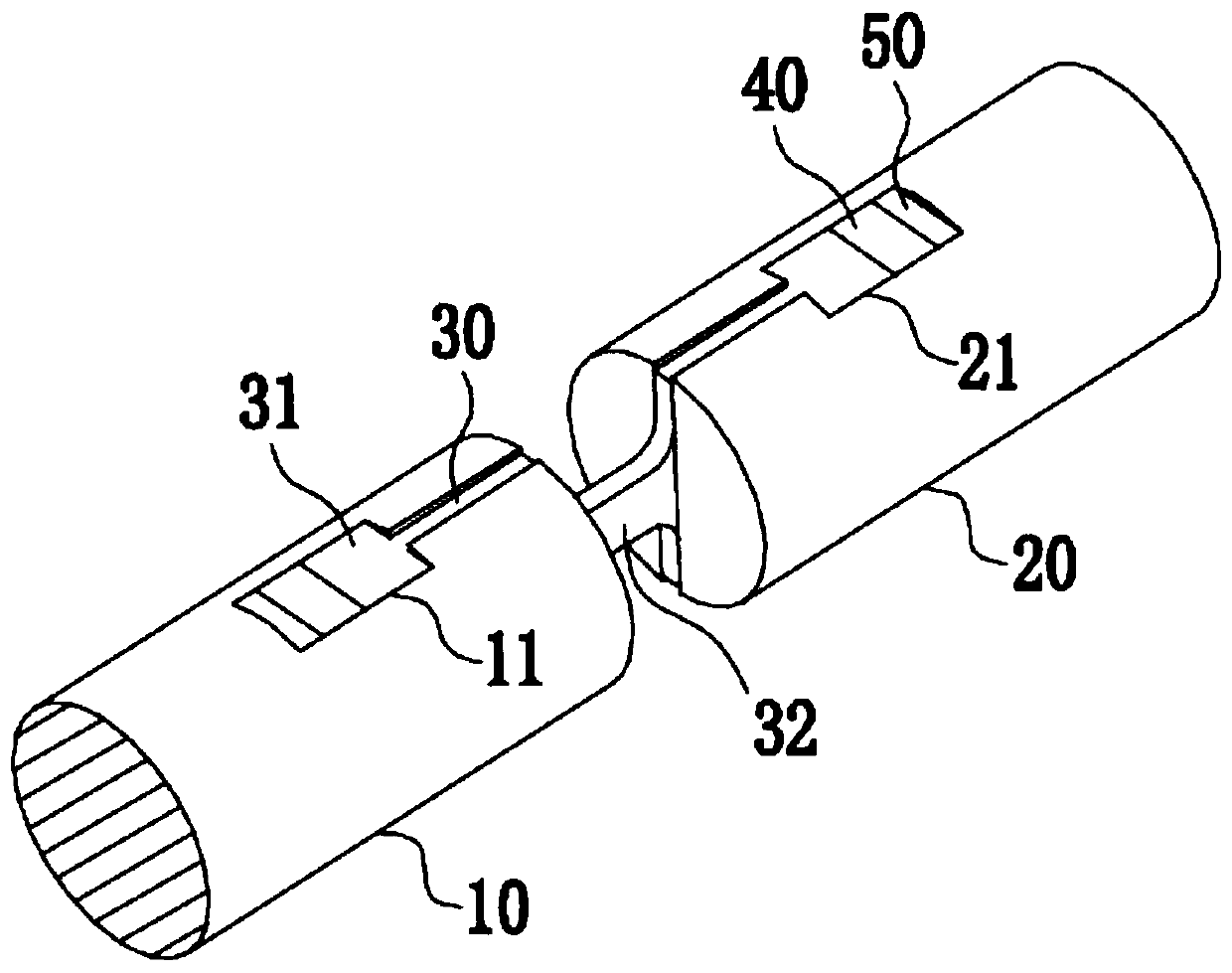

Compressor

ActiveCN112324662AImprove performanceIncrease forceRotary piston pumpsRotary piston liquid enginesMechanical engineeringPhysics

The invention provides a compressor. The compressor comprises an air cylinder, a roller and a sliding piece set, wherein the roller is rotationally arranged in a cavity of the air cylinder; the sliding piece set is arranged in a sliding piece groove of the air cylinder in a sliding manner; the sliding piece set comprises a low-pressure side sliding piece and a high-pressure side sliding piece; anair suction cavity is formed by the area among the low-pressure side sliding piece, the roller and the inner wall of the air cylinder; a compression cavity is formed by the area among the high-pressure side sliding piece, the roller and the inner wall of the air cylinder; the low-pressure side sliding piece is provided with a limiting groove; the limiting groove is provided with a first side wallarranged in the axial direction of the sliding piece groove and a second side wall arranged in the radial direction of the sliding piece groove; and the side wall of the high-pressure side sliding piece is in limiting fit with the first side wall, and the tail end of the high-pressure side sliding piece is in limiting fit with the second side wall. By the adoption of the scheme, the problem of sliding piece disengaging can be solved, leakage is reduced, and the performance of the compressor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

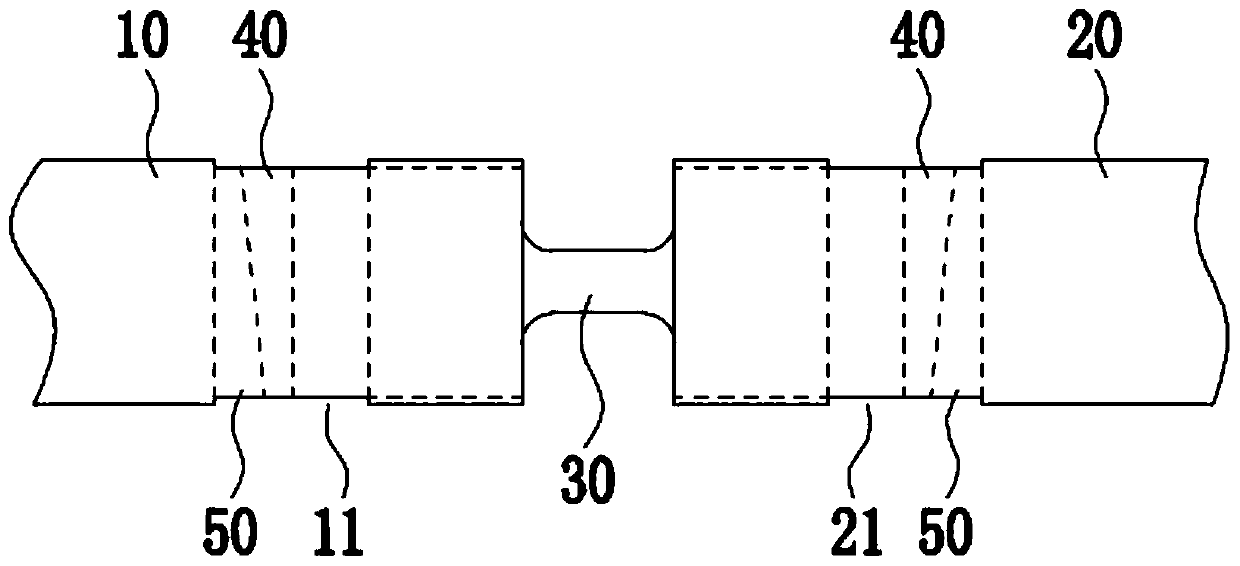

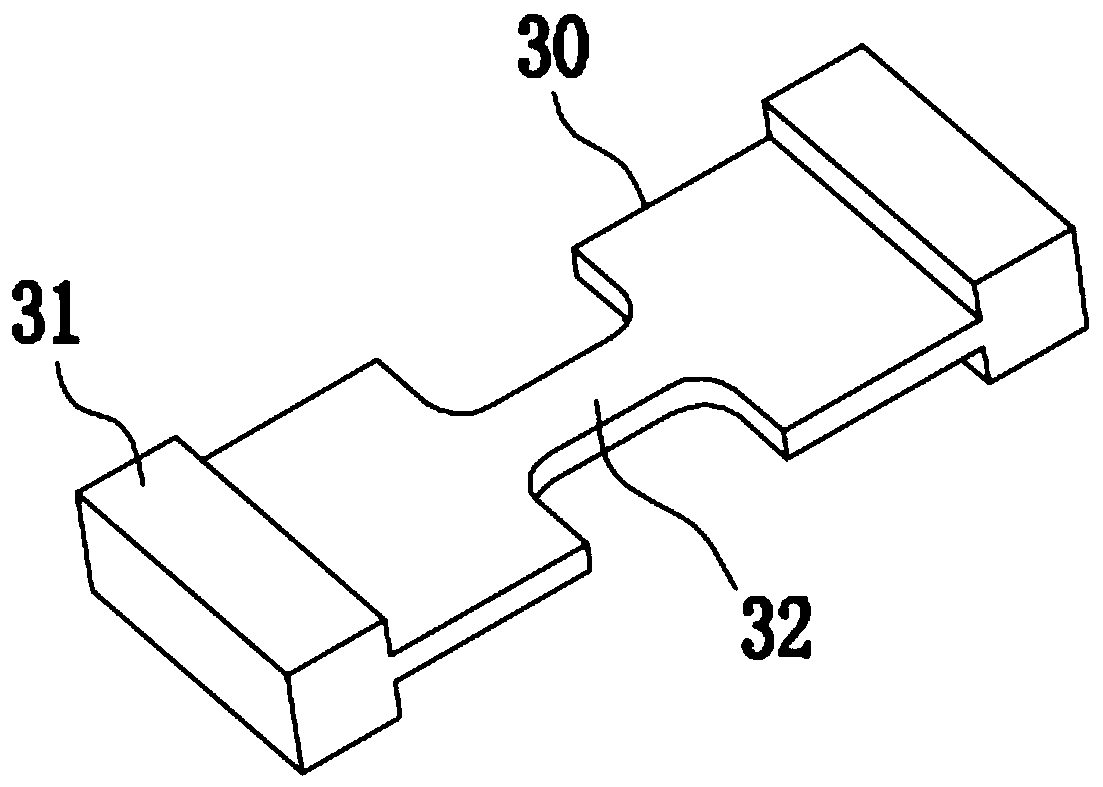

Split-Hopkinson tension bar test piece fixture and mounting method

InactiveCN110082193AImprove accuracyHigh precisionMaterial strength using tensile/compressive forcesTest efficiencyMechanical engineering

The invention discloses a split-Hopkinson tension bar test piece fixture and mounting method, and belongs to the technical field of material dynamic mechanical tests. The fixture comprises an incidentbar, one end of which being provided with a neck I for mounting a test piece; a transmission bar, one end of which being provided with a neck II for mounting the test piece; and wedge blocks A and wedge blocks B, which are fitted to each other and are filled in neck gaps between the two ends of the test piece and the neck I and the neck II; the neck I and the neck II are both "T" shaped through grooves disposed along the radial direction of the bar; the incident bar and the transmission bar are the coaxially disposed; two wedge blocks A and two wedge blocks B are provided; and the wedge blocks A and the wedge blocks B are combined to form a rectangle. When the test piece is mounted, the both ends of the test piece are respectively clamped in the neck I and the neck II at first, and then the wedge blocks A and the wedge blocks B are mounted, so that the test piece is in no clearance fit with the neck I and the neck II. By adopting the split-Hopkinson tension bar test piece fixture disclosed by the invention, fast mounting of the test piece can be achieved, so that the test efficiency is greatly improved, and the test data accuracy is high; and the test piece is easy to process, andthe material is not limited.

Owner:MAANSHAN IRON & STEEL CO LTD

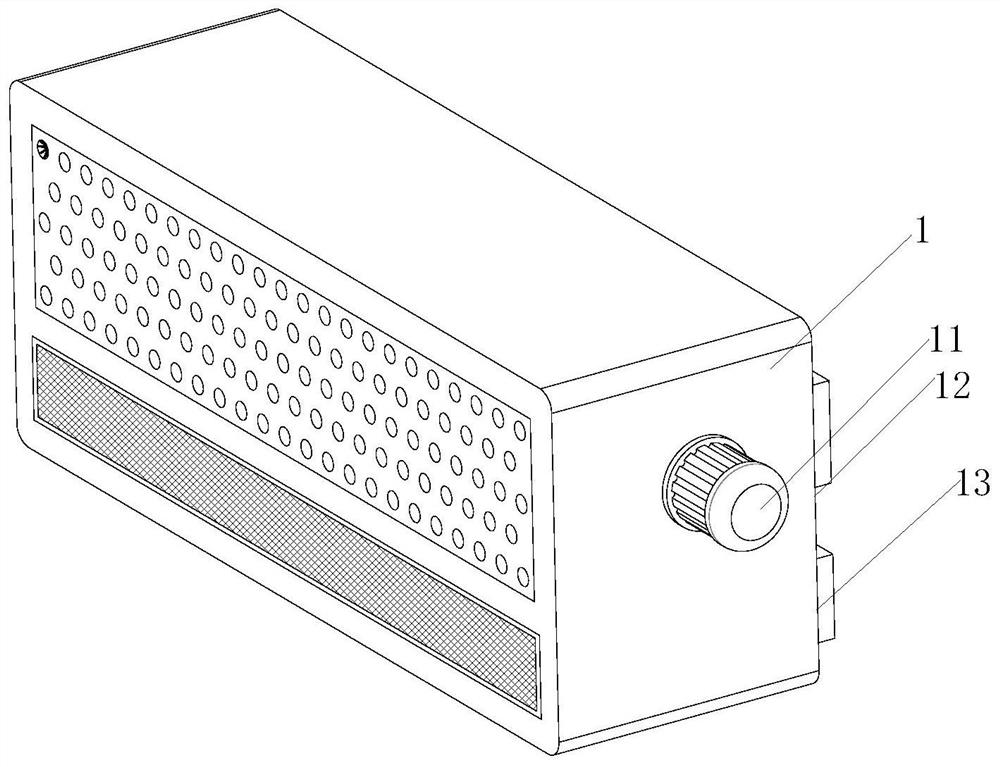

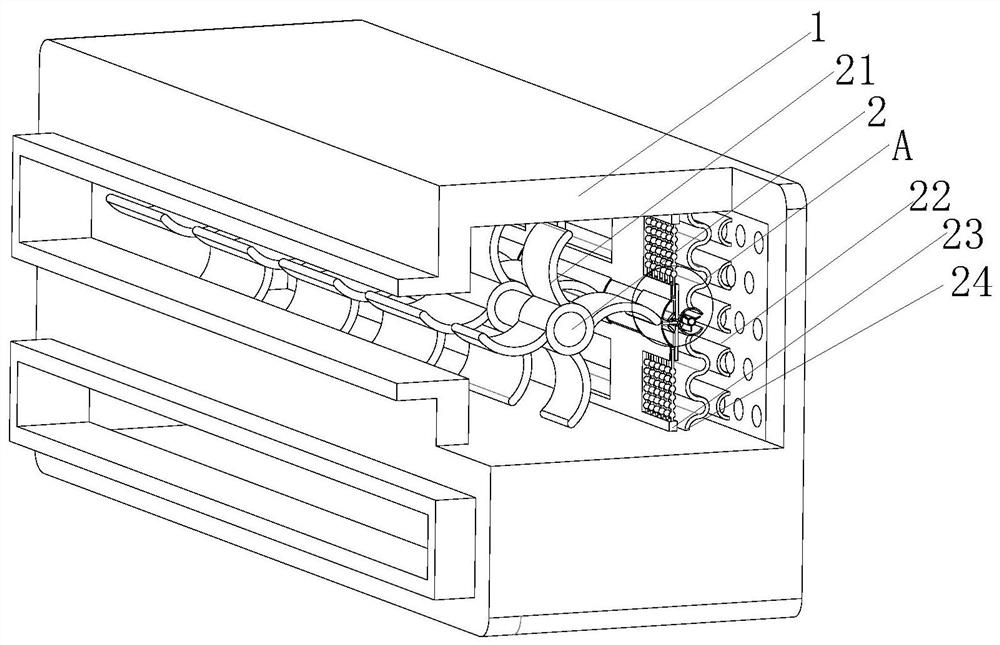

Household energy-saving ventilation equipment

InactiveCN113719940AIncrease the amount of shakingAvoid blockageMechanical apparatusLighting and heating apparatusElectric machineryStructural engineering

The invention discloses household energy-saving ventilation equipment which comprises a ventilation device shell. A driving motor is fixedly installed on the surface of the ventilation device shell, the interior of the ventilation device shell is divided into an air inlet cavity and an air exhaust cavity, ventilation pipelines are fixedly connected to the side walls of the air inlet cavity and the air exhaust cavity correspondingly, a filter screen is fixedly connected onto the inner wall of the other side of the air exhaust cavity, a coarse screening plate is arranged on the surface of the air inlet cavity, multiple anti-blocking mechanisms are arranged in the coarse screening plate, a rotating shaft is rotationally arranged on the inner wall of the air inlet cavity, one end of the rotating shaft is fixedly installed at the output end of the driving motor, and the rotating shaft is fixedly sleeved with multiple fixing tables. Compared with the prior art, according to the household energy-saving ventilation equipment provided by the invention, movable balls can shake under the action of airflow, the shaking amplitude of the movable balls can be enhanced through vibration springs, and most sand grains can be discharged out of screen holes in cooperation with movable shafts, so that the situation that the screen holes are blocked due to long-time operation of the equipment is avoided, and the influence of the sand grains on the operation efficiency of the equipment is reduced.

Owner:康杨超

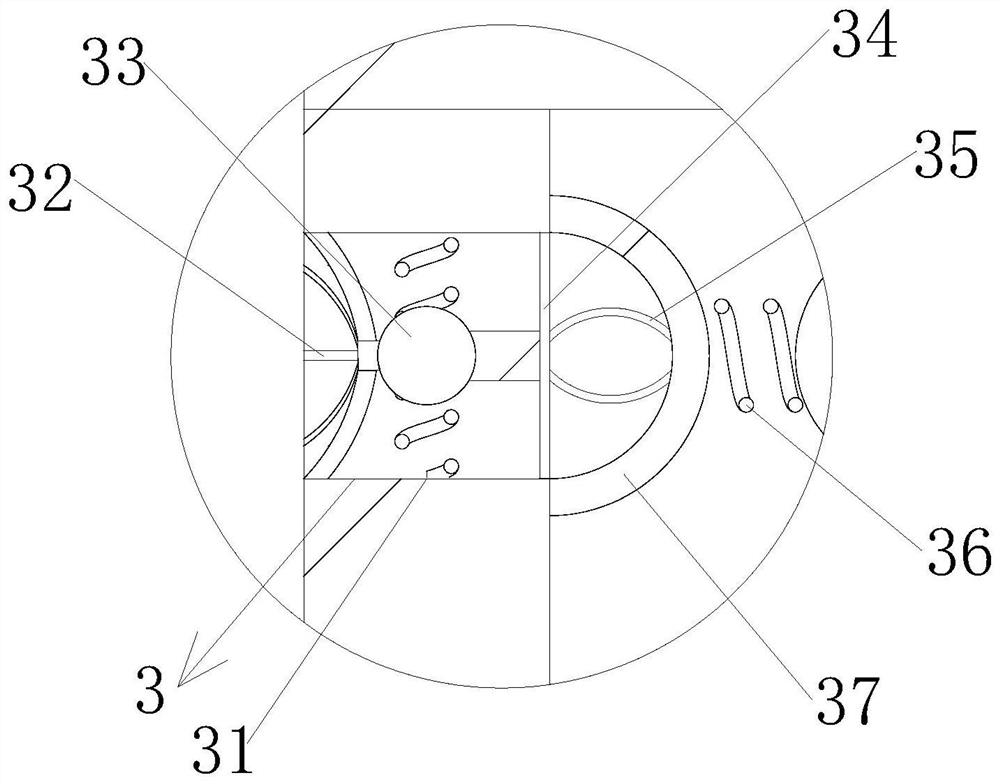

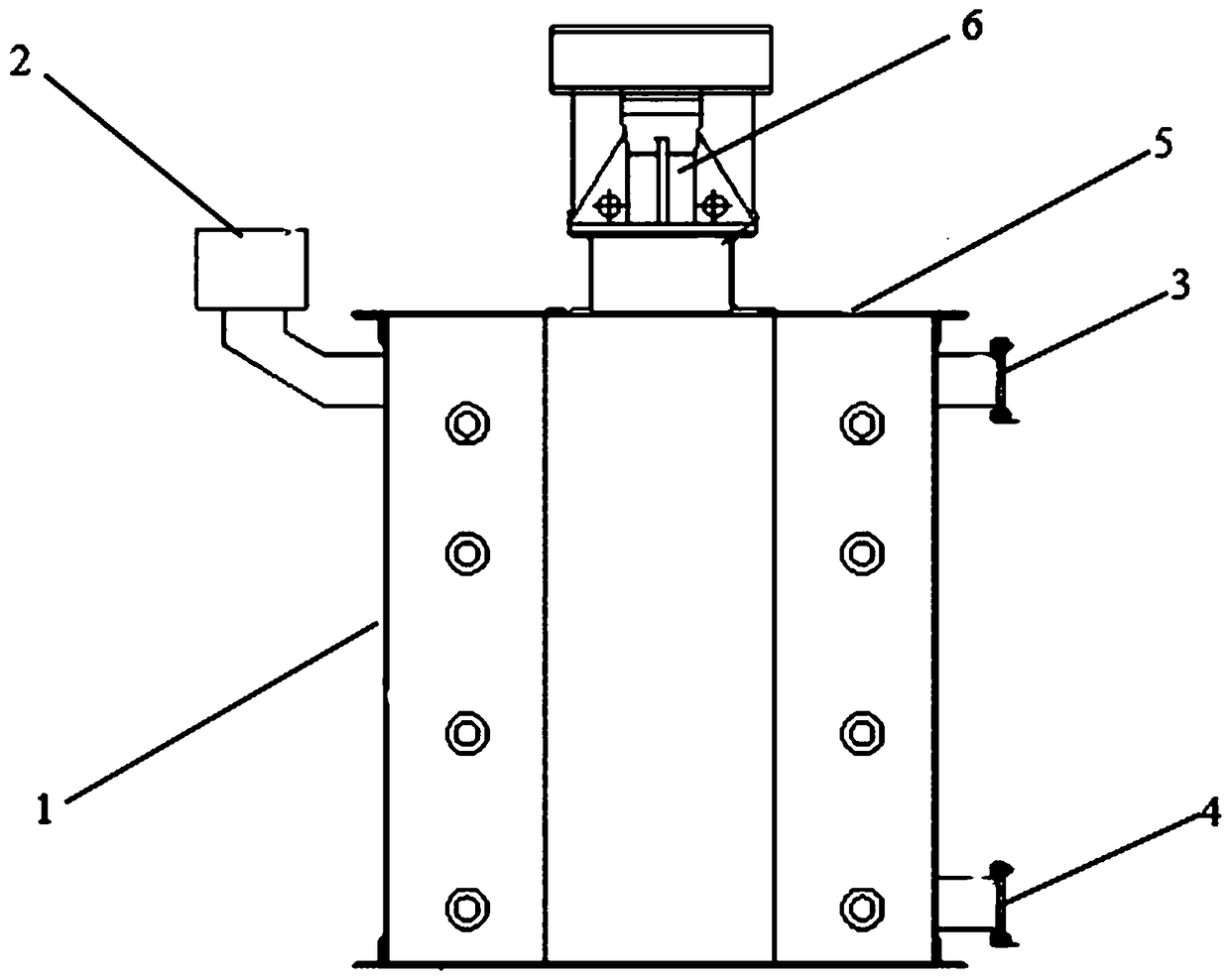

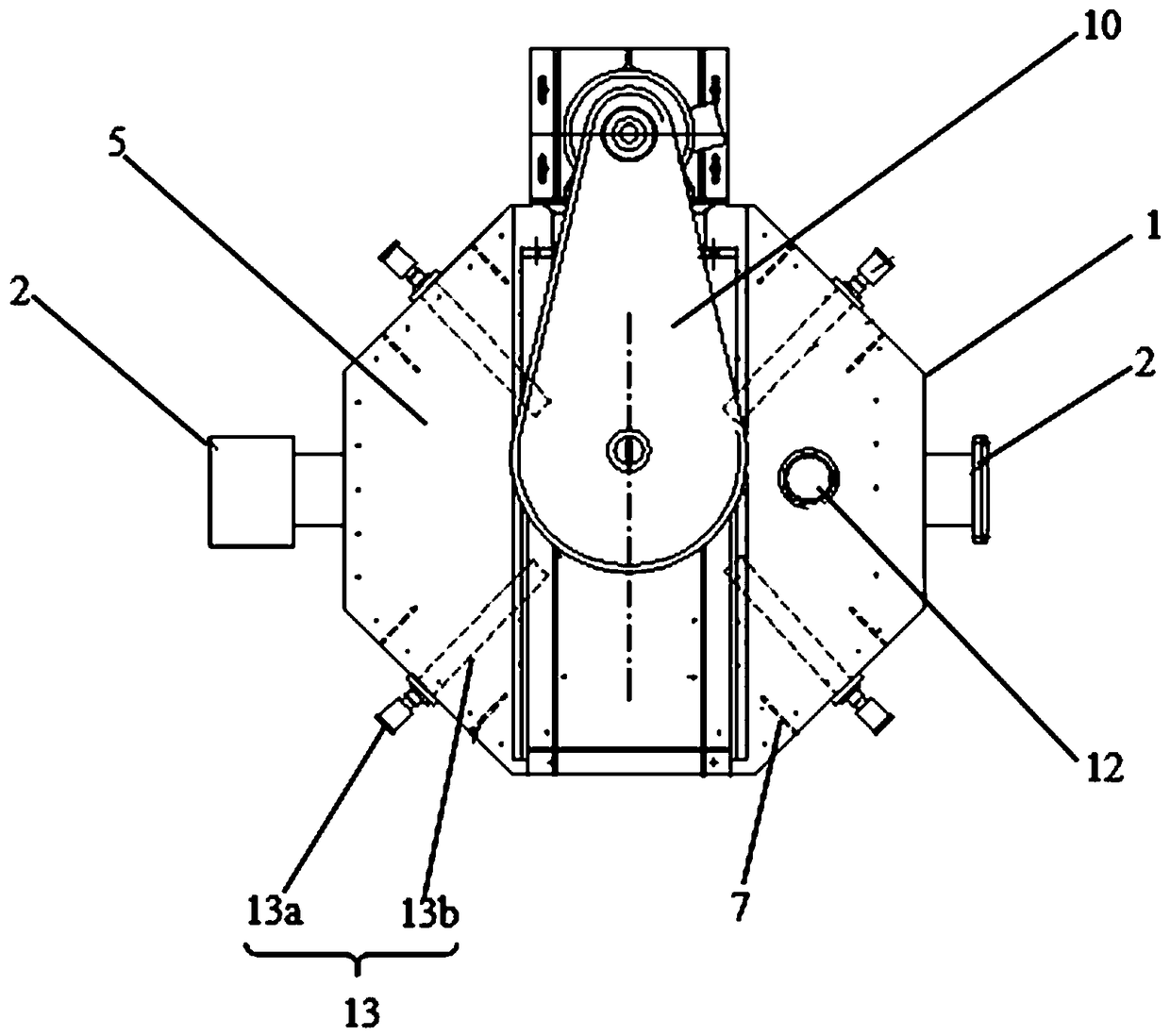

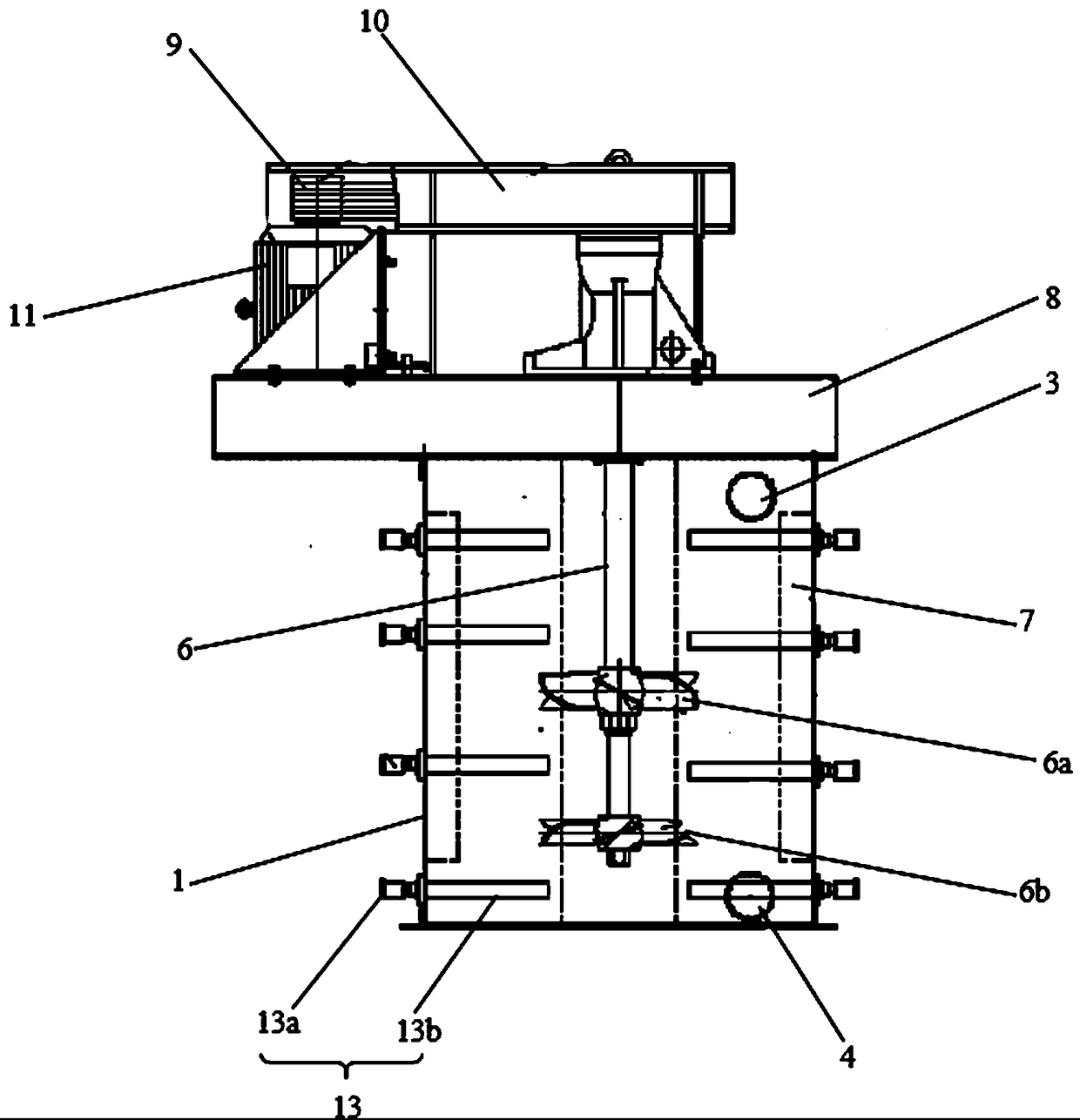

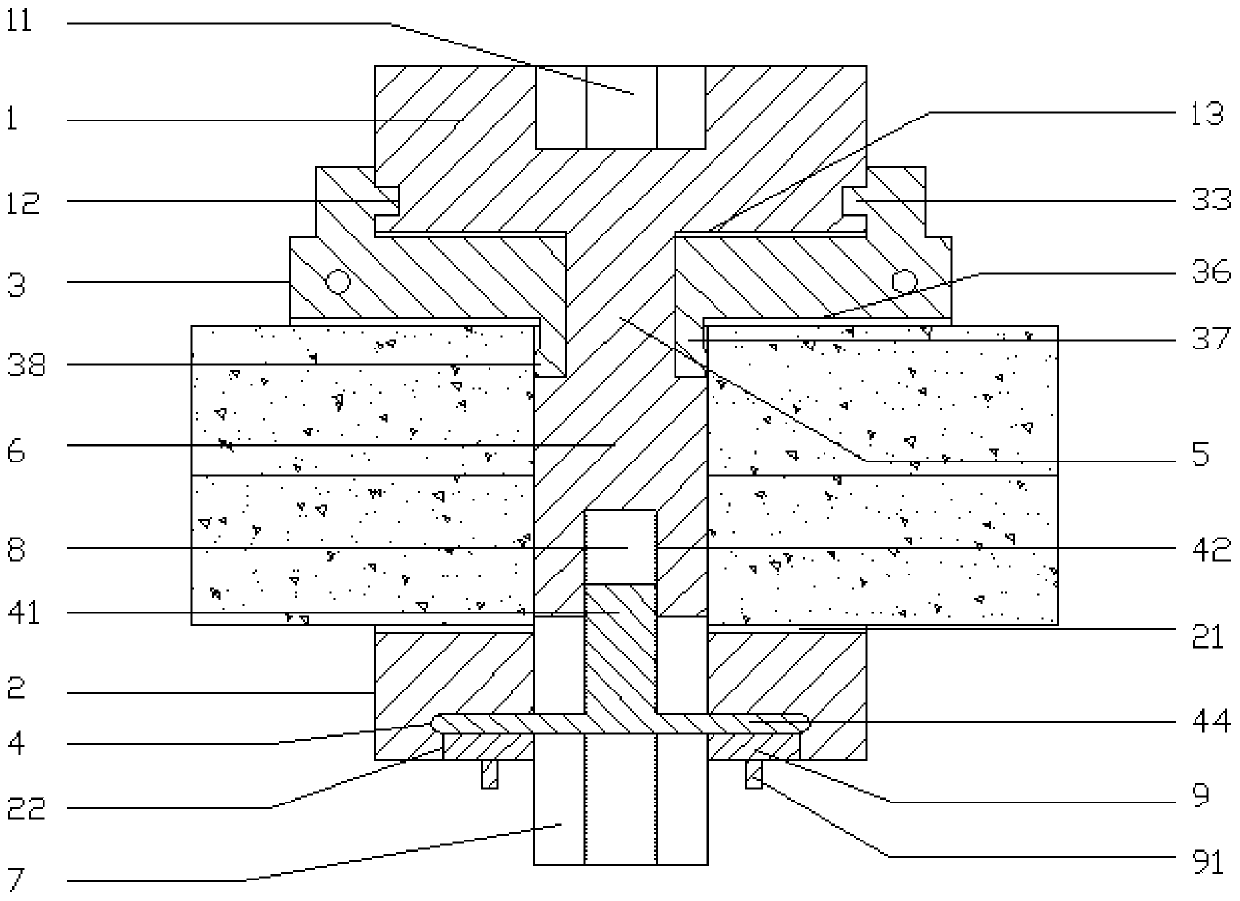

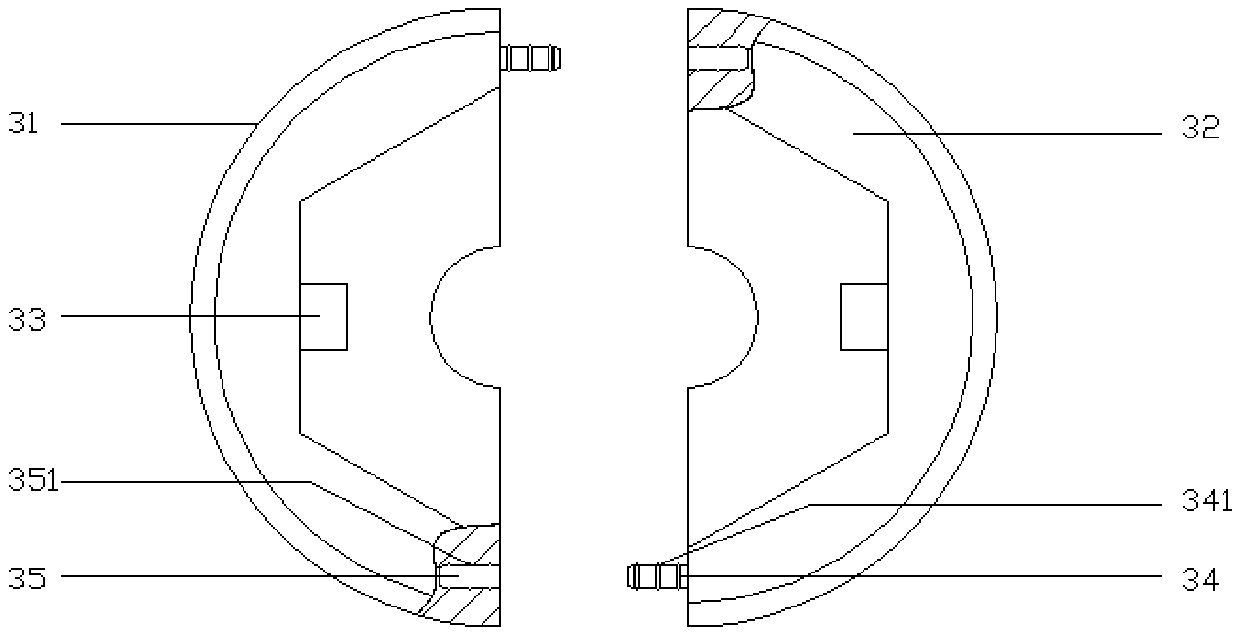

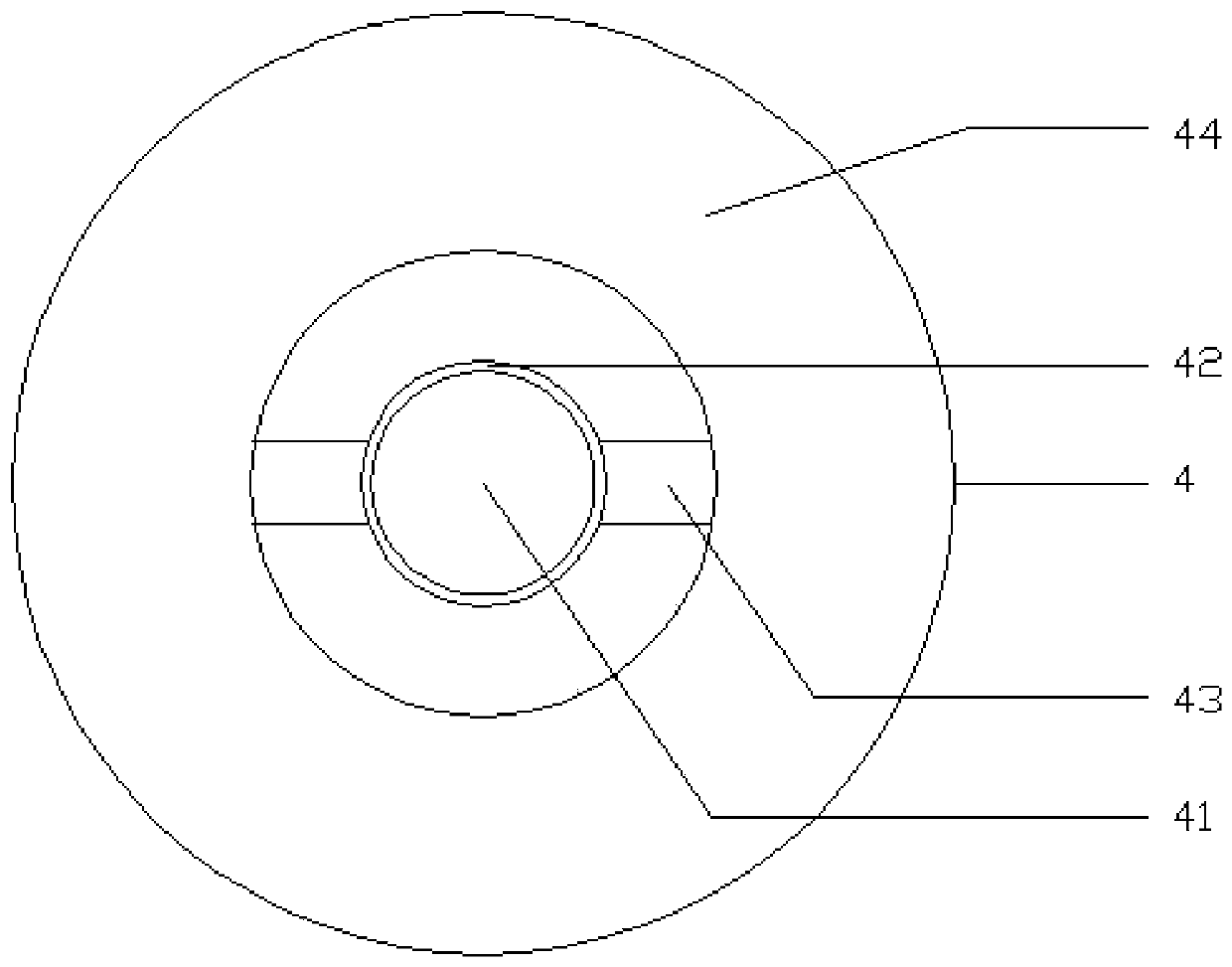

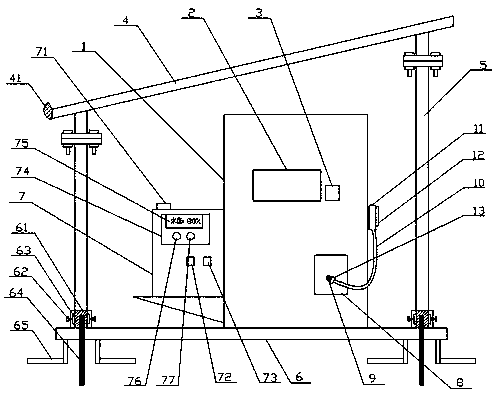

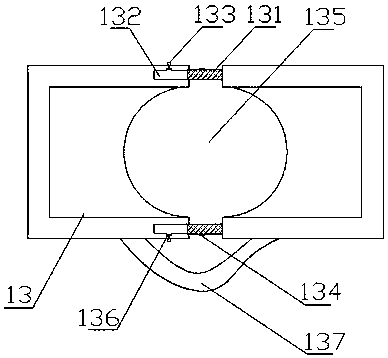

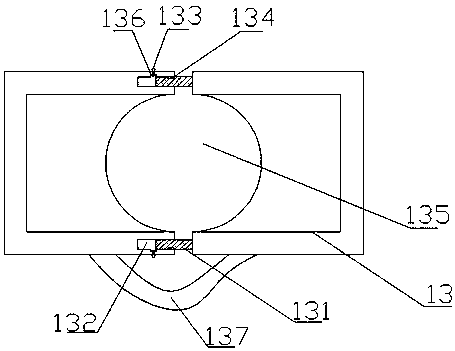

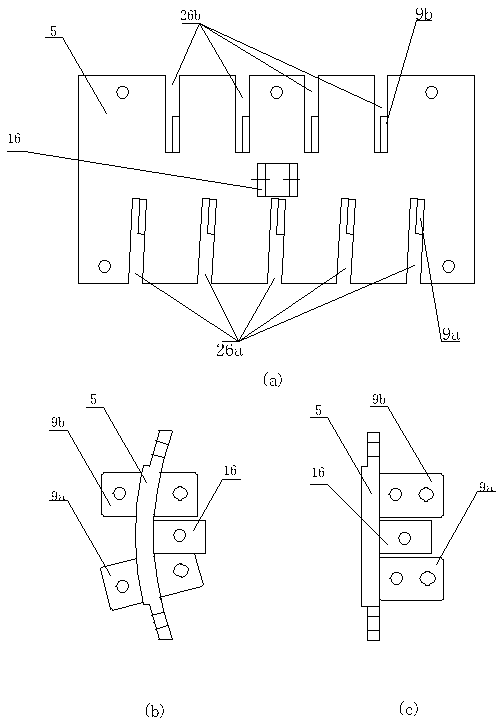

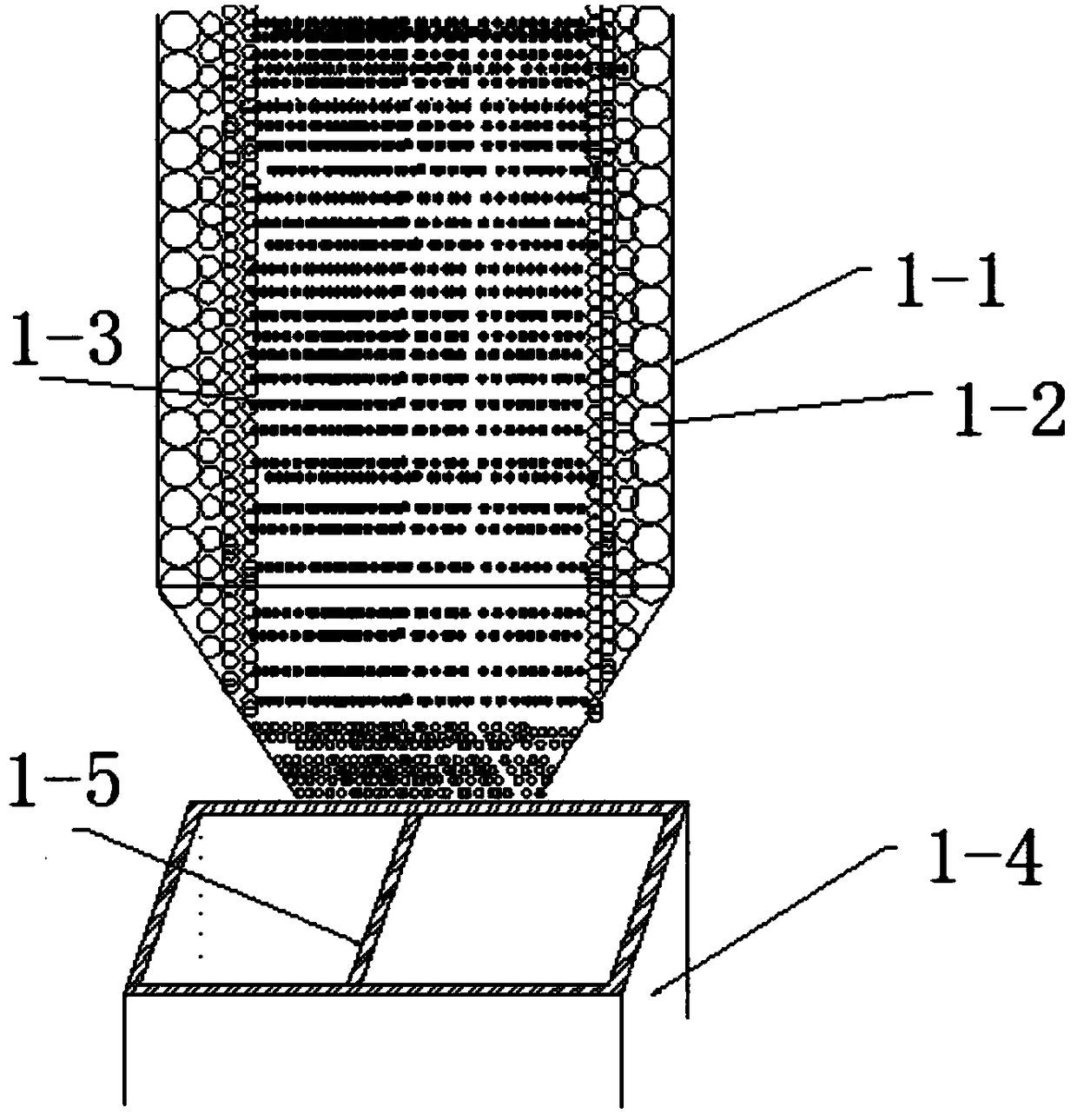

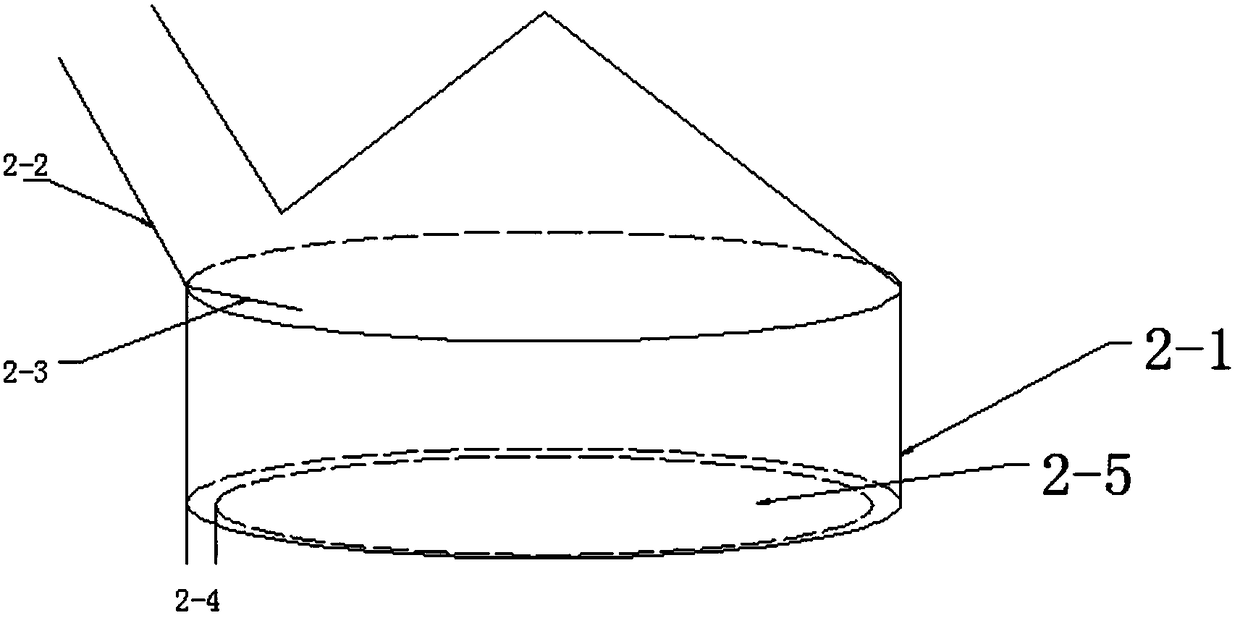

Ultrasonic scrubber for non-metal mine

The invention relates to an ultrasonic scrubber for a non-metal mine, comprising a slot body (1); the two sides of the upper part of the slot body are respectively provided with a feeding port (2) anda discharging port (3), the lower part is provided with a drain outlet (4) and the top is provided with a cover plate (5); a cross beam (8) is erected at the upper part of the slot body (1); a stirring shaft (6) stretches into the interior of the slot body (1) by passing through the cross beam (8); the upper end of the stirring shaft (6) is connected with a variable frequency motor (11) by a belt(9) and the lower end is successively connected with an upper impeller (6a) and a lower impeller (6b); the variable frequency motor (11) is fixed on the cross beam (8); a dosing hole (12) is formed in the cover plate (5); the side of the slot body (1) is uniformly provided with a group of level ultrasonic generators (13) from top to bottom; each ultrasonic generator (13) comprises an ultrasonic energy converter (13a) located outside the slot body (1) and a vibration bar (13b) located in the slot body (1). The ultrasonic scrubber for the non-metal mine provided by the invention has the advantages of removing impurities with great cementing strength or crack in non-metal minerals and improving scrubbing efficiency and product quality.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Check bolt assembly

PendingCN111503121AReduce the likelihood of mutual separationReduce loosenessWashersNutsWasherScrew thread

The invention discloses a check bolt assembly which comprises a bolt, a nut, a first check washer and a second check washer. A step segment, a thread segment and an open groove are sequentially arranged on a stud of the bolt from top to bottom. A nut is arranged on the thread segment. The first check washer is arranged on the step segment. A blind hole extending upwards is formed in the center ofthe open groove. The second check washer is arranged at the bottom of the nut and is fixedly mounted in the blind hole. A non-return assembly is further arranged at the bottom of the second check washer. Compared with the prior art, the check bolt assembly is simple in structure and reasonable in design, stability and reliability of bolt connection can be guaranteed for a long time, the influenceof vibration on bolt connection can be reduced, and the check bolt assembly is worthy of popularization.

Owner:HAIYAN GUANGDA STANDARD PARTS CO LTD

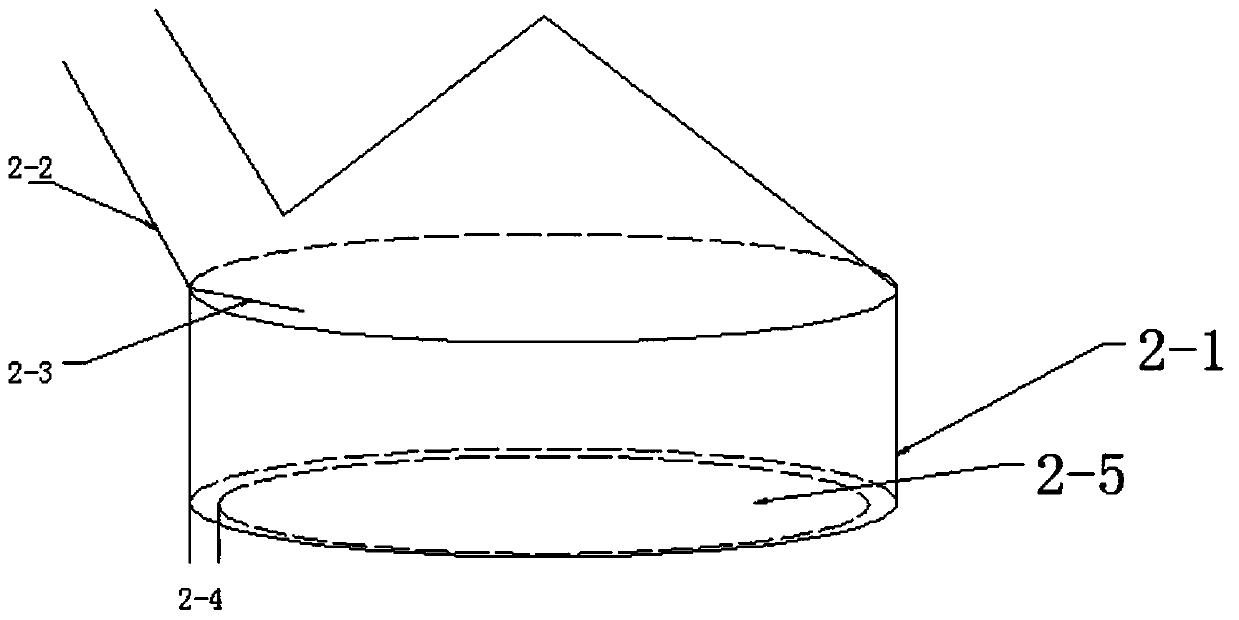

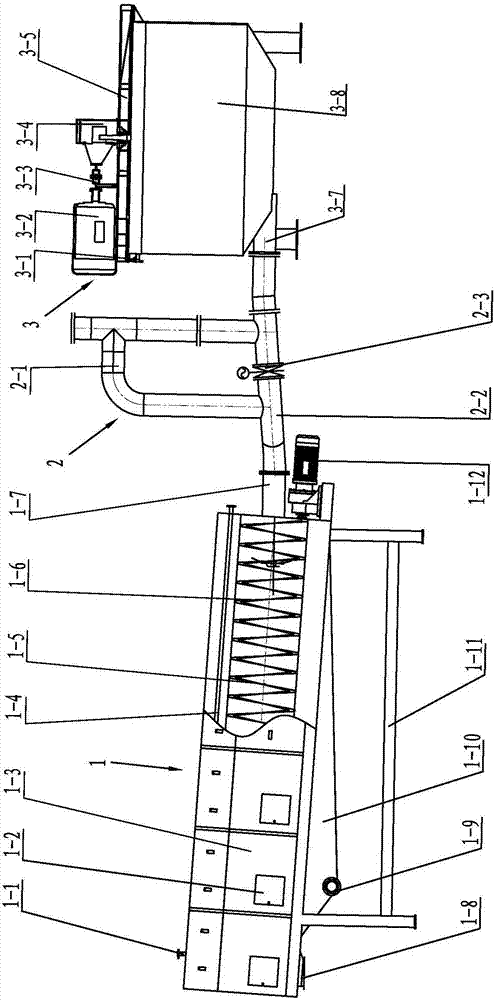

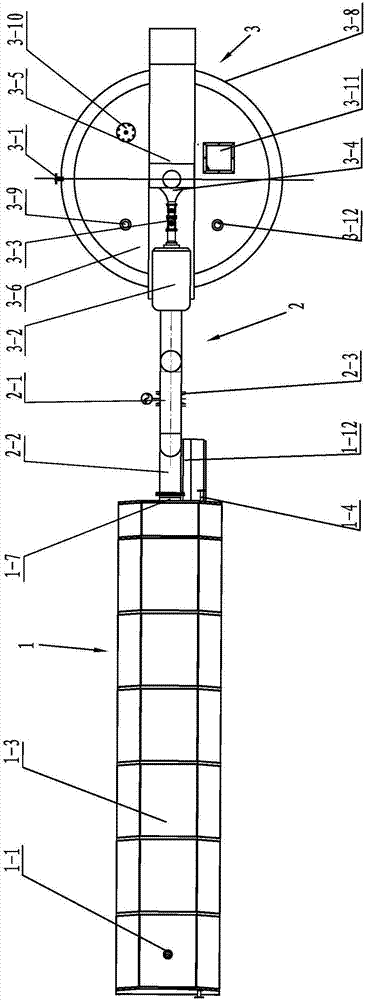

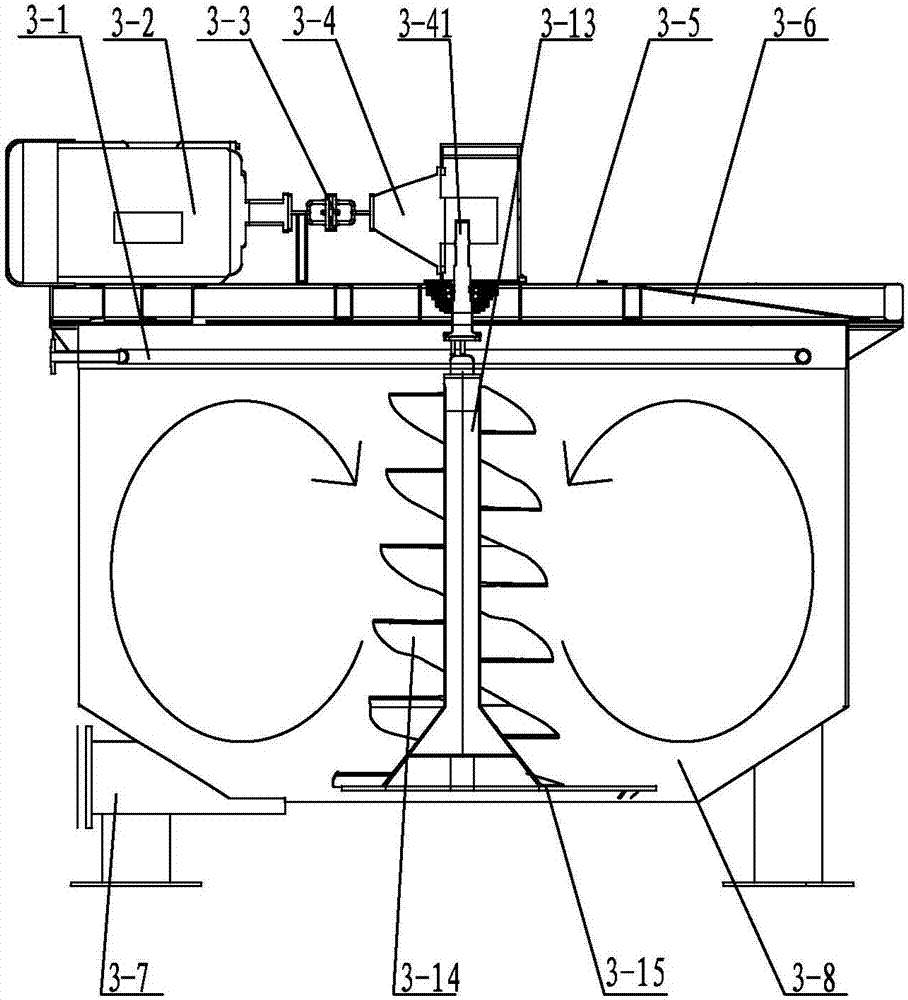

Multi-cylinder type water-free cleaning equipment for waste glass

PendingCN112517547AEquipment is smallIncrease mutual frictionCleaning processes and apparatusPower apparatusWaste recycling

The invention relates to the technical field of solid waste recycling, in particular to multi-cylinder type water-free cleaning equipment for waste glass. The equipment comprises a cleaning and stirring device used for conducting anhydrous cleaning on the waste glass and a power device used for providing power for the cleaning and stirring device. The cleaning and stirring device comprises at least three rollers which are concentrically connected in a sleeved mode, and a plurality of baffle structures which are spirally arranged are distributed on the side walls of the rollers. According to the multi-cylinder type water-free cleaning equipment for the waste glass, through the arrangement, the water-free cleaning of the waste glass is realized; meanwhile, the at least three rollers which are concentrically connected in a sleeving mode are arranged, so that the equipment size is greatly reduced while the material retention time is guaranteed, space utilization of a plant is facilitated,gradient utilization of heat is gradually achieved from an inner layer to an outer layer, and the clean production concept of energy conservation and consumption reduction is better met; and the multiple baffle structures which are spirally arranged are distributed on the side walls of the rollers, so that mutual friction between the waste glass is enhanced, and labels and stains can fall off moreeasily.

Owner:SUN YAT SEN UNIV

Debris-flow drainage canal with energy dissipation and drainage functions and application thereof

ActiveCN102926356BImprove overall efficiencyGood drainage abilityArtificial water canalsMedicineDrainage canal

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

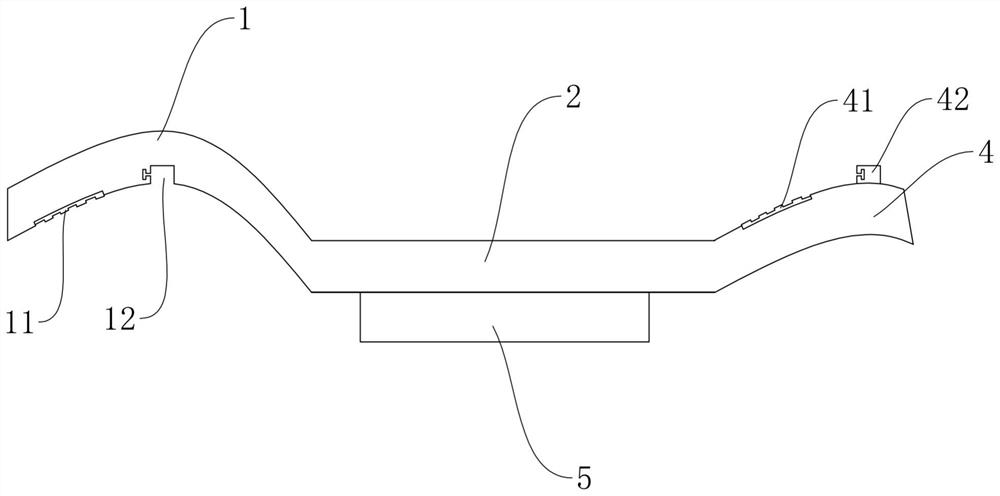

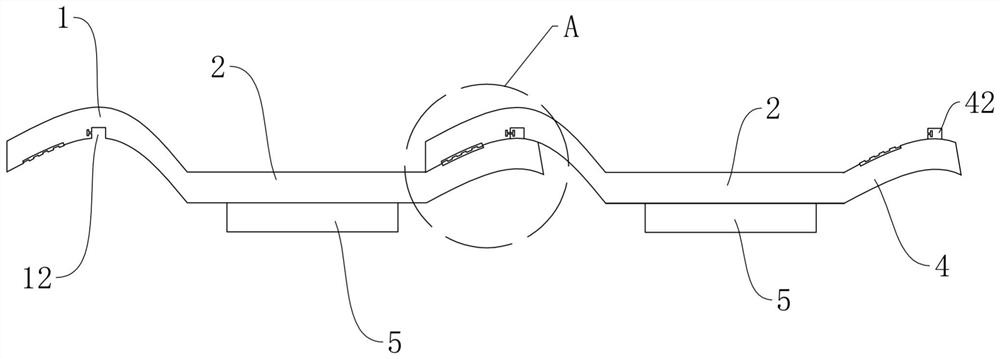

Waterproof photovoltaic tile and photovoltaic building surface

ActiveCN114421863AImprove consistencyImprove the effect of wind and rain protectionPhotovoltaic supportsRoof covering using slabs/sheetsEngineeringStructural engineering

Owner:汉摩尼(江苏)光电科技有限公司

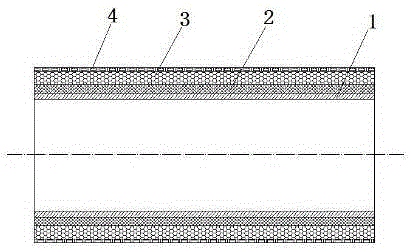

Novel extrusion type large ventilation pipe

InactiveCN106764116AHigh mechanical strengthSmooth mechanical strengthCorrosion preventionFlexible pipesBiochemical engineeringUltimate tensile strength

The invention discloses a novel extrusion type large ventilation pipe. The novel extrusion type large ventilation pipe comprises a fluororubber inner layer, a nylon layer, a foaming layer and an anti-abrasion layer; the nylon layer is arranged outside the rubber inner layer; the foaming layer is arranged outside the nylon layer; and the anti-abrasion layer is arranged outside the foaming layer. The inner diameter of the ventilation pipe is 100-150 mm. By sequentially arranging the fluororubber inner layer, the nylon layer, the foaming layer and the anti-abrasion layer, the heat preserving performance of the ventilation pipe can be enhanced through the foaming layer on the basis of guaranteeing the mechanical strength of the ventilation pipe, and influences of the outside temperature are lowered; and due to the arrangement of the anti-abrasion layer, mutual friction between the ventilation pipe and other automobile parts can be enhanced, and the abrasion probability is lowered. The novel extrusion type large ventilation pipe is simple in structure, convenient to use, high in mechanical strength, safe in use and smooth in ventilation.

Owner:TIANJIN BINHAI ZHONGGUAN RUBBER HOSE

Rainproof charging pile

InactiveCN108454452ASimple structureGood stabilization effectCharging stationsBeverage vesselsEnvironment effectFlange

The invention discloses a rainproof charging pile. The rainproof charging pile comprises a main body of the charging pile, wherein a display control screen is arranged at the middle part of the main body of the charging pile, a main control unit is arranged at the rear side of the display control screen, a wireless connection module is arranged at the right side of the main control unit, and a card sensing area is arranged at the right side of the display control screen. The rainproof charging pile also comprises a baffle plate above the main body of the charging pile, a support rod for supporting the baffle plate and a charging pile base at the bottom of the main body of the charging pile, wherein the bottom of the support rod is connected with the charging pile base, and the top of the support rod is connected with the baffle plate through a flange; a drinking tank is arranged at the left side of the main body of the charging pile, and an observation window is formed in the drinkingtank; and an automatic take-up tank is also arranged on the main body of the charging pile, an automatic take-up device and a charging cable are arranged in the automatic take-up tank, one end of thecharging cable is connected with the main body of the charging pile, and the other end of the charging cable penetrates through a charging cable outlet in the automatic take-up tank and is connected with a charging gun. The rainproof charging pile disclosed by the invention can not be affected by rainwater and severe environments and is more humanized in design and high in practicability.

Owner:河南水天环境工程有限公司

Grinding slice of defibrator

ActiveCN102691220BSmall running resistanceEven by forceFibrous raw materialsDefibratorGrinding teeth

The invention discloses a grinding slice of a defibrator, wherein grinding teeth in a crushing region are separated from those in a coarse grinding region, a ring-shaped buffering deslagging slot is formed between the grinding teeth of the two regions, and the grinding teeth in the crushing region are arc-shaped. According to the grinding slice of the defibrator, the grinding teeth can be effectively prevented from being damaged by hard impurities, the efficiency is improved, the service life of the grinding slice is prolonged, and the power consumption is reduced.

Owner:丹东鸭绿江磨片有限公司

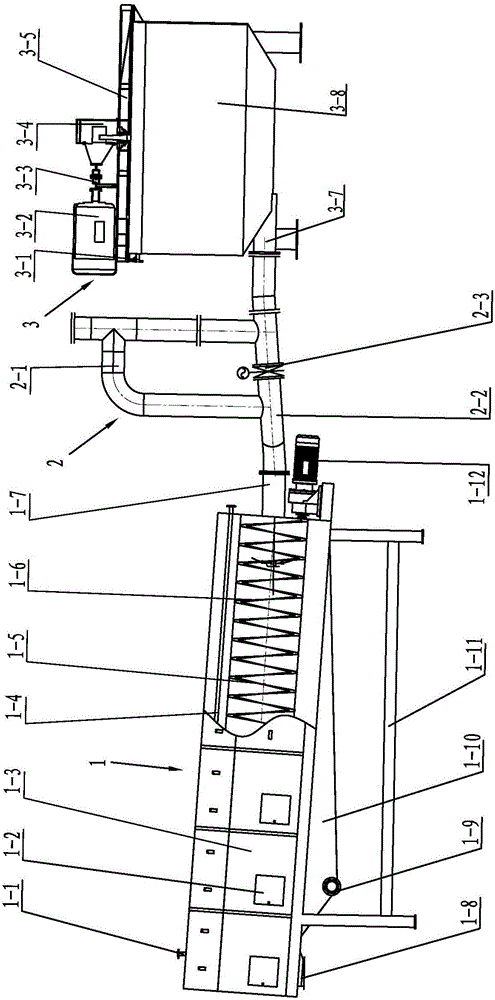

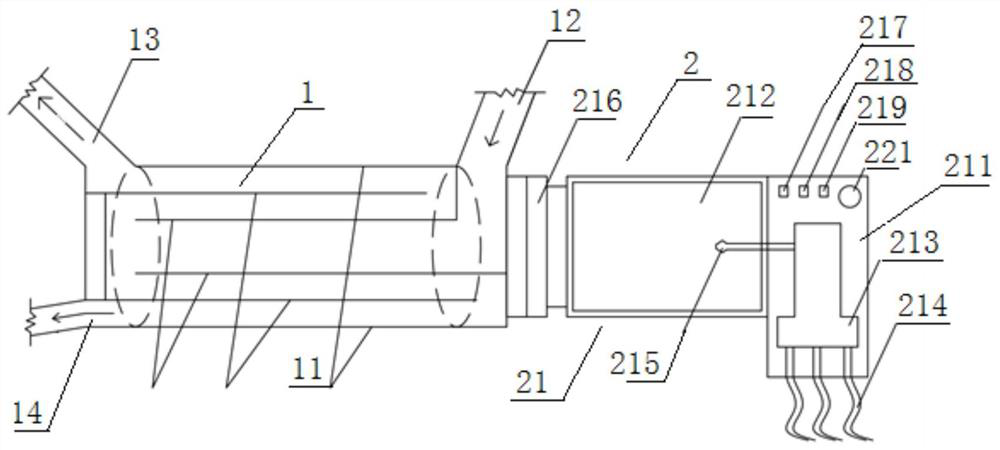

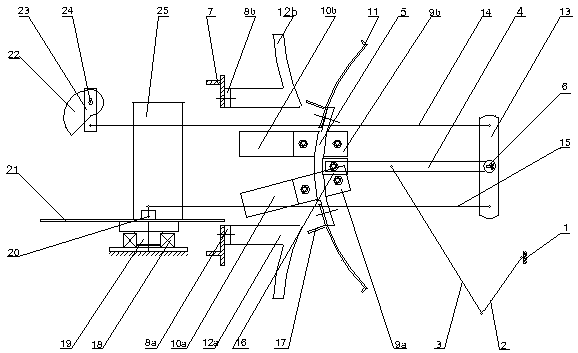

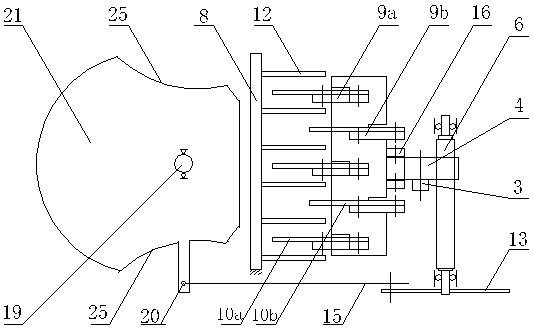

Reciprocating shearing type straw rubbing filament and kneading machine

PendingCN110278785AEnhanced silkinessIncreased chance of longitudinal shearFeeding-stuffCuttersReciprocating motionEngineering

The invention relates to a processing mechanical device for longitudinal shearing, filament and kneading of coarse straight straw such as corn and pennisetum hydridum. The processing mechanical device is a reciprocating shearing type straw rubbing machine and includes a feeding swing mechanism, a shearing rubbing mechanism and a moving cutter driving mechanism. The feeding swing mechanism includes a skewing driving mechanism and a swinging trough, and the skewing driving mechanism drives the swinging trough to move; the shearing rubbing mechanism is composed of a moving cutter component and a fixed cutter component, the moving cutter component is driven by the moving cutter driving mechanism to do reciprocating motion and cooperate with the fixed cutter component and the swinging trough, straw materials are merged in a shearing zone to complete filament and kneading, the processed straw materials can form high-quality soft filaments, and the palatability of livestock straw feed is greatly improved.

Owner:符必成

Ultramicro material grinder

The invention discloses an ultramicro material grinder which comprises a left nozzle and a right nozzle. An impact cavity is arranged between the left nozzle and the right nozzle; a feed inlet is formed between the left nozzle and the impact cavity; the impact cavity communicates with an upper guiding pipe and a lower guiding pipe; the upper guiding pipe and the lower guiding pipe communicate witha classifying cavity; the classifying cavity is in an annular shape; screen holes are formed in the inner side wall; triangular cutters are symmetrically arranged on a cavity wall of the classifyingcavity; the inner diameter of the upper guiding pipe is larger than the inner diameter of the lower guiding pipe; and the length of the upper guiding pipe is smaller than the inner diameter of the lower guiding pipe. The ultramicro material grinder provided by the invention has the advantages that mutual friction and collision between materials are increased, and a grinding effect is good.

Owner:沈阳鑫颖超科技有限公司

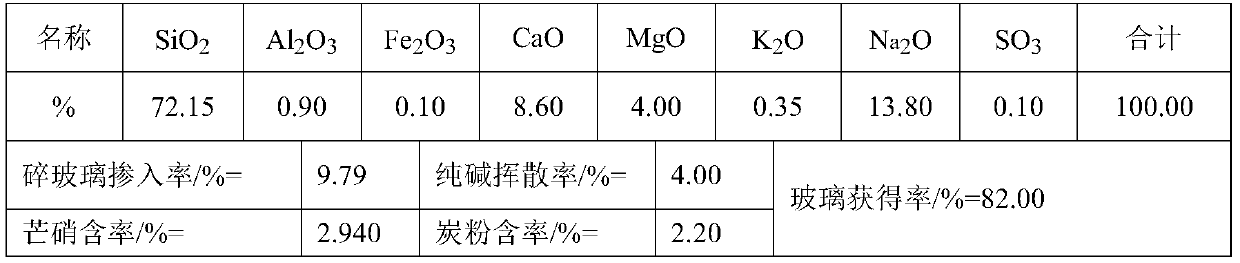

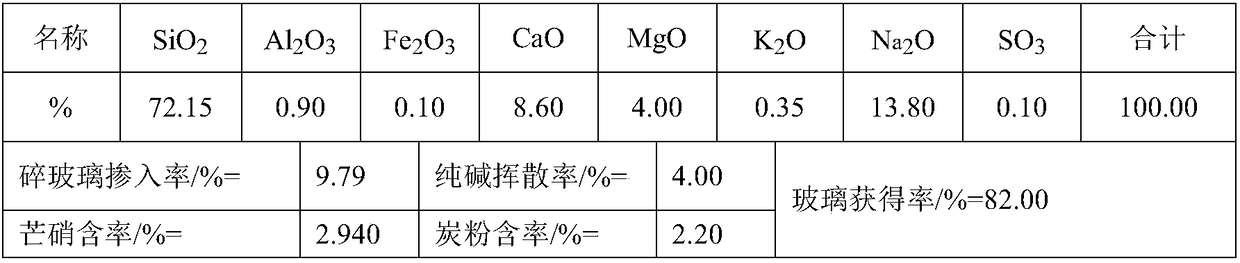

A method based on optimizing the glass frit mixer to improve the mixing efficiency of raw materials

ActiveCN108514847BReduce stratificationIncrease frictionTransportation and packagingMixer accessoriesFritProcess engineering

The invention belongs to the technical field of glass manufacturing, and discloses a method for improving raw material mixing efficiency based on optimizing a glass frit mixer, and in particular relates to the setting of upper and lower baffles of a connecting channel between an intermediate chamber and a mixer. In the present invention, a baffle plate is arranged at the upper end of the connecting channel between the intermediate warehouse and the mixer, on the one hand, it can reduce the batch of adhesive materials in the intermediate warehouse entering into the mixer; The segregation and stratification of different material particles play the role of pre-mixing; the present invention installs a baffle at the lower end of the connecting channel between the intermediate bin and the mixer, so that more materials can enter the mixing area of the mixer, reducing the splashing of materials in the static area, Thereby improving the working efficiency of the mixer.

Owner:HUBEI SANXIA NEW BUILDING MATERIALS CO LTD

Method for improving raw material mixing efficiency by optimizing frit mixing machine

ActiveCN108514847AReduce stratificationIncrease frictionTransportation and packagingMixer accessoriesFritMixing effect

The invention belongs to the technical field of the glassmaking, and discloses a method for improving a raw material mixing efficiency by optimizing a frit mixing machine, and particularly relates toinstallation of upper end and lower end baffles of a connecting channel of an intermediate cabin and a mixing machine. The upper end of the connecting channel of the intermediate cabin and the mixingmachine is provided with the baffle, on the one hand, batch binding materials in the intermediate cabin which enter the mixing machine can be reduced; on the other hand, friction between a dischargedmaterial and the baffles and the channel wall can be increased, separation and hierarchy phenomena between the different material particles are slowed down, and the pre-mixing effect is achieved; thelower end of the connecting channel of the intermediate cabin and the mixing machine is provided with the baffle, the more materials can be enabled to enter a mixing area of the mixing machine, and the material spattering in a static area is reduced, thereby the working efficiency of the mixing machine is improved.

Owner:HUBEI SANXIA NEW BUILDING MATERIALS CO LTD

Organic waste solid residue organic matter recovery device

ActiveCN105689362BIncrease mutual frictionImprove resource utilizationSolid waste disposalSpiral bladeSlag

The invention relates to a recycling device for organic matters of solid residues of organic garbage. The recycling device comprises a recycling main body, a recycling auxiliary body and a connecting tube stack connected between the recycling main body and the recycling auxiliary body; a groove of the recycling main body is provided with a stirring mechanism and a cover plate; a discharge port is formed in the lower part of the recycling main body; at least two spiral blades of which diameters are gradually increased from top to bottom are fixed on a stirring shaft of the stirring mechanism; edges of the spiral blades are fillets; during rotation, the spiral blades hydraulically scrub slurry; at least two pushing dead knives of which outer diameters are greater than bottom outer diameters of the spiral blades are arranged at the bottom of the stirring shaft; the pushing dead knives correspond to the discharge port of the lower part of the groove; the recycling auxiliary body comprises the housing and a revolving drum which is inclined upwards in the slurry flowing direction; a feeding opening is formed in the front end of the housing; a residue outlet is formed in the tail of the housing; a liquid collecting tank is arranged at the bottom of the housing; and shaftless spiral blades which are used for pushing the residues are fixed on the inner wall of the revolving drum. The recycling device is simple and reasonable in structure and low in running cost, recycling capability of a system can be improved, and the amount of the solid residues discharged out of the system is reduced.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com