Ultrasonic scrubber for non-metal mine

A non-metallic mineral and ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as poor effect, inability to remove stubborn impurities, and low scrubber efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the present invention clearer, a non-metallic mining ultrasonic scrubbing machine of the present invention will be further described below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention.

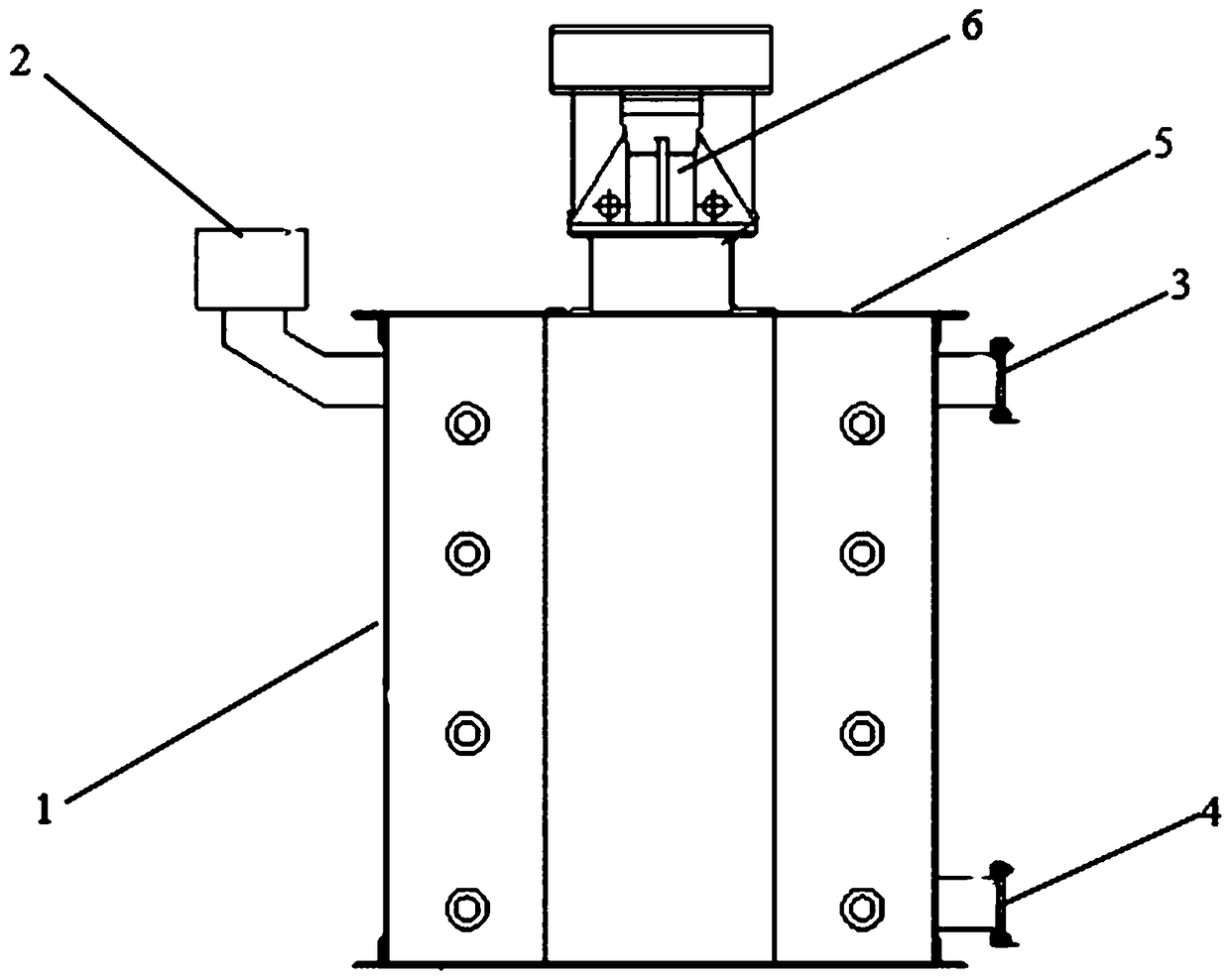

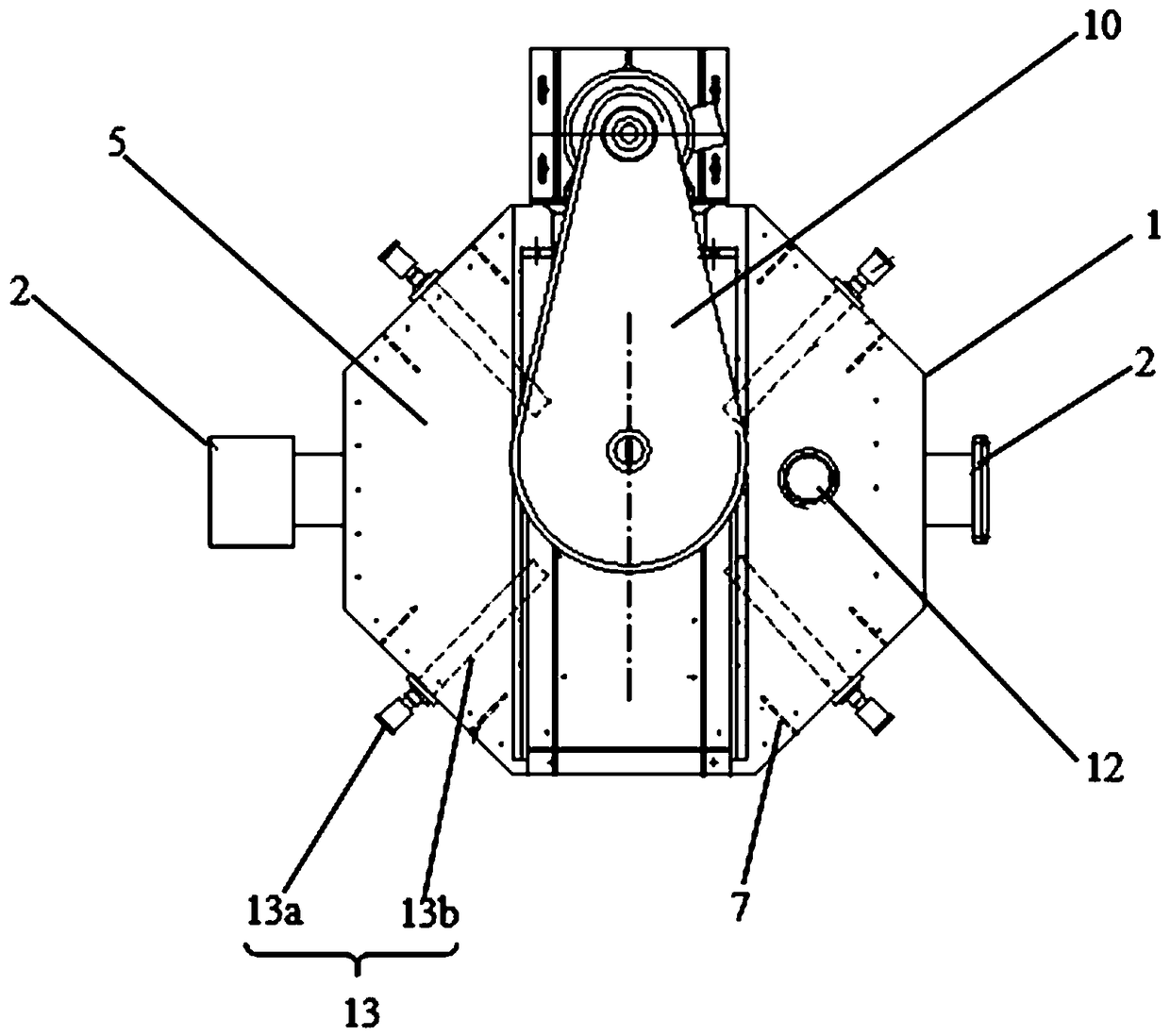

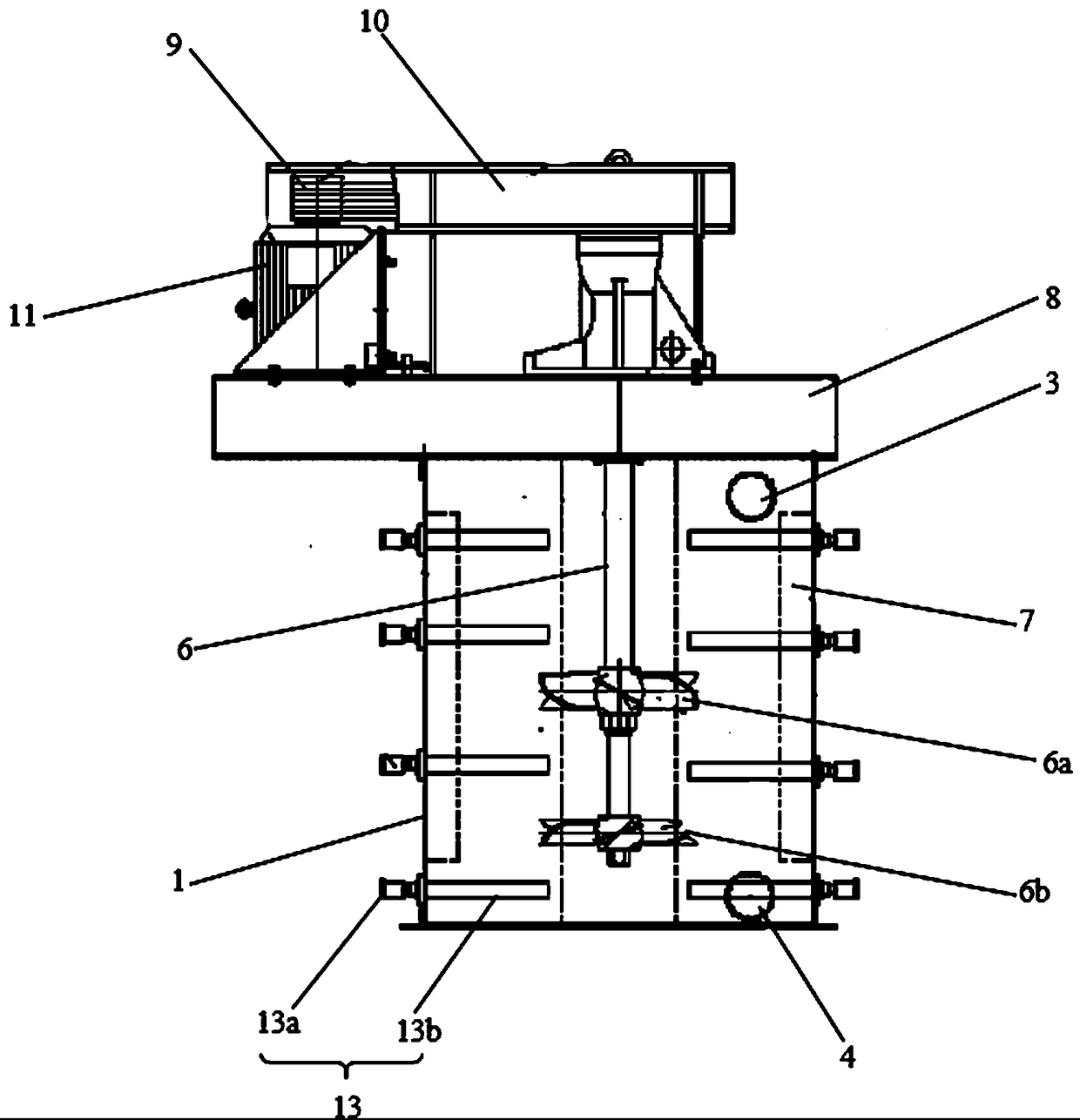

[0017] see figure 1 , figure 2 and image 3 , an ultrasonic scrubbing machine for non-metallic mines, comprising a regular octagonal tank body 1, the two sides of the upper part of the tank body 1 are respectively provided with a feed port 2 and a discharge port 3, and the lower part of the tank body 1 is provided with a sewage outlet 4, There is a cover plate 5 on the top, and a beam 8 is erected above the tank body 1. The stirring shaft 6 passes through the beam 8 and extends into the tank body 1. The upper end of the stirring shaft 6 is connected to the frequency conversion motor 11 through the belt 9, and the lower end is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com