Reciprocating shearing type straw rubbing filament and kneading machine

A shearing, straw technology, used in cutting equipment, agricultural machinery and implements, food science, etc., can solve the problems of inability to cut, jam, straw winding, etc., and achieve the effect of improving palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

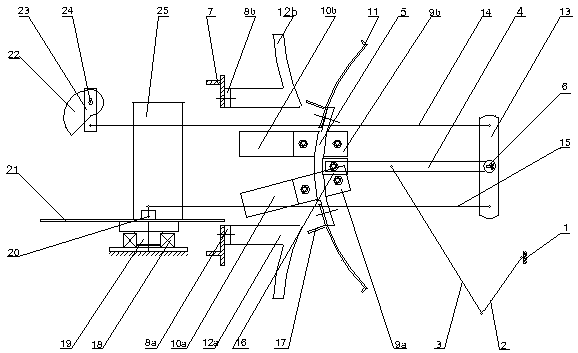

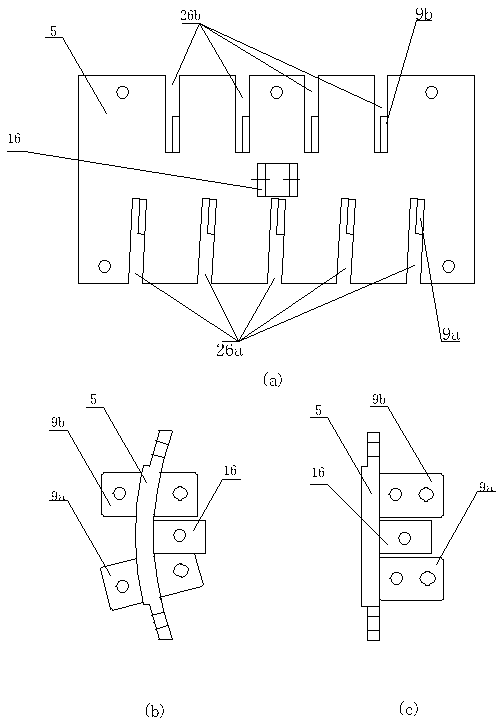

[0035] like figure 1 , figure 2 As shown, the reciprocating shearing straw kneading machine shown in this embodiment includes a machine base 1 and a feeding swing mechanism, a feeding mechanism, a shearing kneading mechanism, and a crank rocker mechanism installed on the machine base.

[0036] Feed swing mechanism

[0037] like figure 1 , figure 2 As shown, the feed swing mechanism includes an offset drive mechanism and a swing trough.

[0038] The offset driving mechanism is composed of the pendulum shaft 6 installed on the bearing, the driving rocker plate 13, and the push-pull rod 15. There is a keyway hole in the center of the driving rocker plate 13, which is sleeved on the shaft end of the pendulum shaft 6, and is fixedly connected with the pendulum shaft 6 through a flat key and an axle nut.

[0039] The swinging chute is composed of a feed chute bottom plate 21, two symmetrical pusher plates 25, a swinging trough shaft 19, a bearing 18, and a connecting sleeve 2...

Embodiment 2

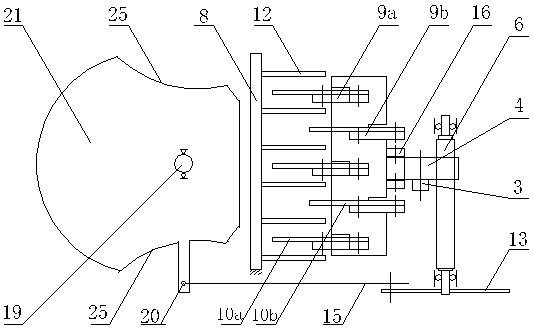

[0062] like Figure 5 As shown, the reciprocating shearing straw kneading machine shown in this embodiment includes a feeding swing mechanism, a shearing kneading mechanism and a crank rocker mechanism installed on the machine base 1 .

[0063] Feed swing mechanism

[0064] Two forms of feeding swing mechanism:

[0065] (1), if Figure 5 As shown, it is made up of a swing shaft 6, a driving rocker plate 13, a push-pull rod 15 and a swing trough. The pendulum chute is made up of feed chute bottom plate 21, left and right pushing plates 25 fixed on both sides of feed chute bottom plate 21, slider 27 and linear slide rail 28 fixed on machine base 1, wherein the top of slider 27 is fixed on The bottom of the feeding trough bottom plate 21 is integrated, the slide block 27 is placed in the slide rail 28, the push-pull rod 15 is respectively hinged with the driving rocker plate 13 and one side of the feeding trough bottom plate 21, and the swinging chute performs reciprocating li...

Embodiment 3

[0076] The reciprocating shearing straw kneading machine shown in this embodiment includes a machine base and a feeding swing mechanism, a shearing kneading mechanism and a crank slider mechanism installed on the machine base.

[0077] Feed swing mechanism

[0078] Two forms of feeding swing mechanism:

[0079] (1) if Figure 7 As shown, it is a rotary feeding swing mechanism. The crank 2, the crank 30, the feed trough bottom plate 21 and the pushing plate 25 form a swing trough, and the swing trough and the connecting rod 31 are connected as one to form a double crank mechanism. The material swinging chute is placed in the outer position of the feeding port 7. When the active crank 2 is working, the swinging chute can rotate without a fixed center, forcing the internal materials to shift.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com