Patents

Literature

2560 results about "Feed processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feed Processing. Processing is the conversion of diverse feed ingredients into a single, homogenized form of feed, such as mash, pellet, and crumbles, among others.

Real time information feed processing

ActiveUS20110029636A1Multiple digital computer combinationsWebsite content managementTime informationSocial graph

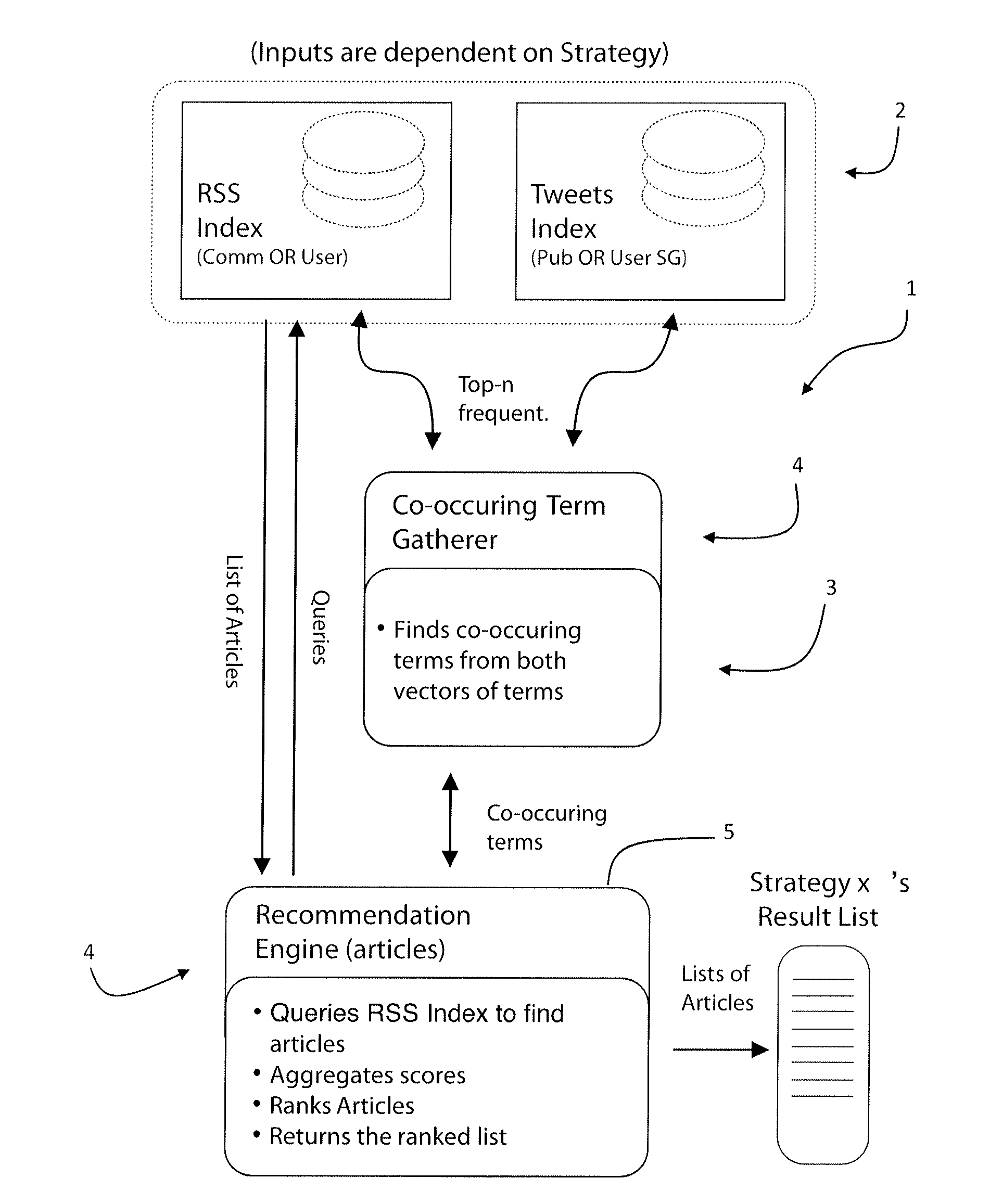

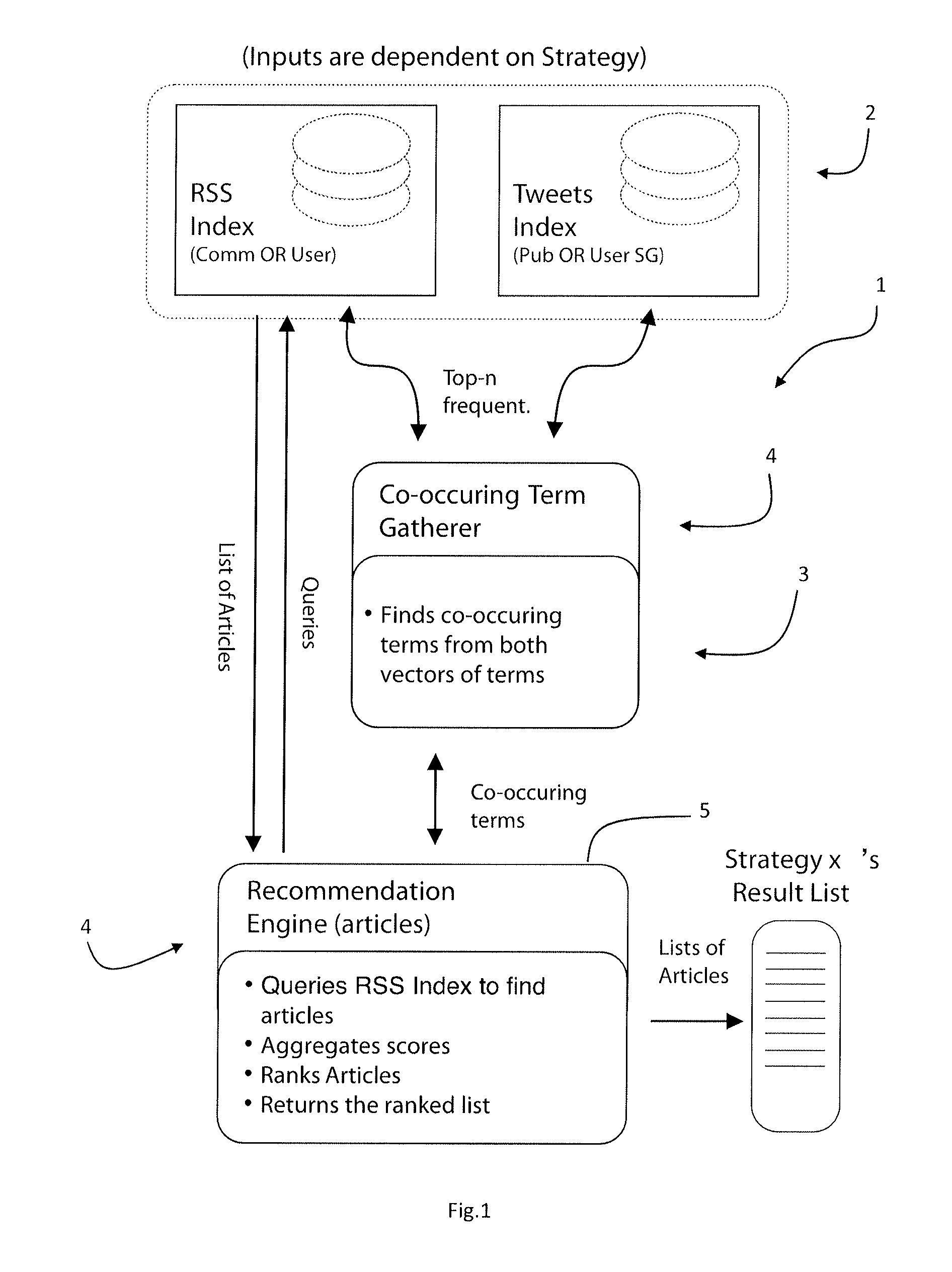

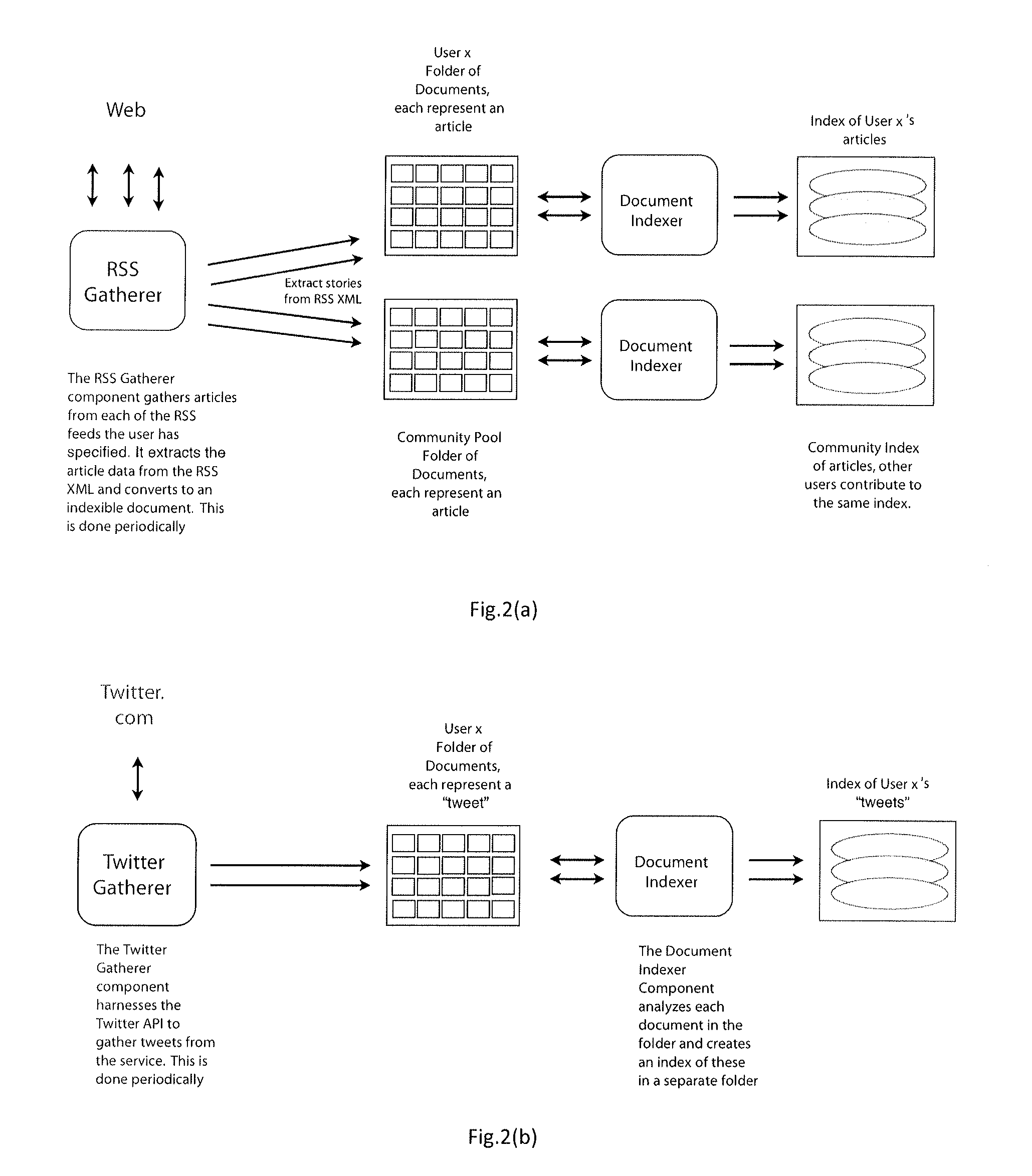

A real time information feed system comprises an interface to receive a real time information feed and a data mining engine for retrieving data concerning a subscriber. A recommendation engine automatically modifies the real time information feed according to the mined data; and a subscriber interface outputs the modified real time information for delivery to the subscriber. The data mining engine is adapted to mine data in a real time communication medium used by the subscriber, such as a micro-blogging service. The data mining engine comprises an indexer for mining and indexing the real time information feed and the subscriber data to provide a plurality of indexes; and to generate vectors representing the separate indexes and to compare the vectors to modify. The data mining engine and the recommendation engine combine recommendation and information retrieval settings from a plurality of online and offline sources to produce a single amalgamated list of results to harness a user's usage patterns and social graph activity on a social network or updating service, that further allows the generation of user profiles as part of a media recommendation system.

Owner:UNIV COLLEGE DUBLIN NAT UNIV OF IRELAND DUBLIN

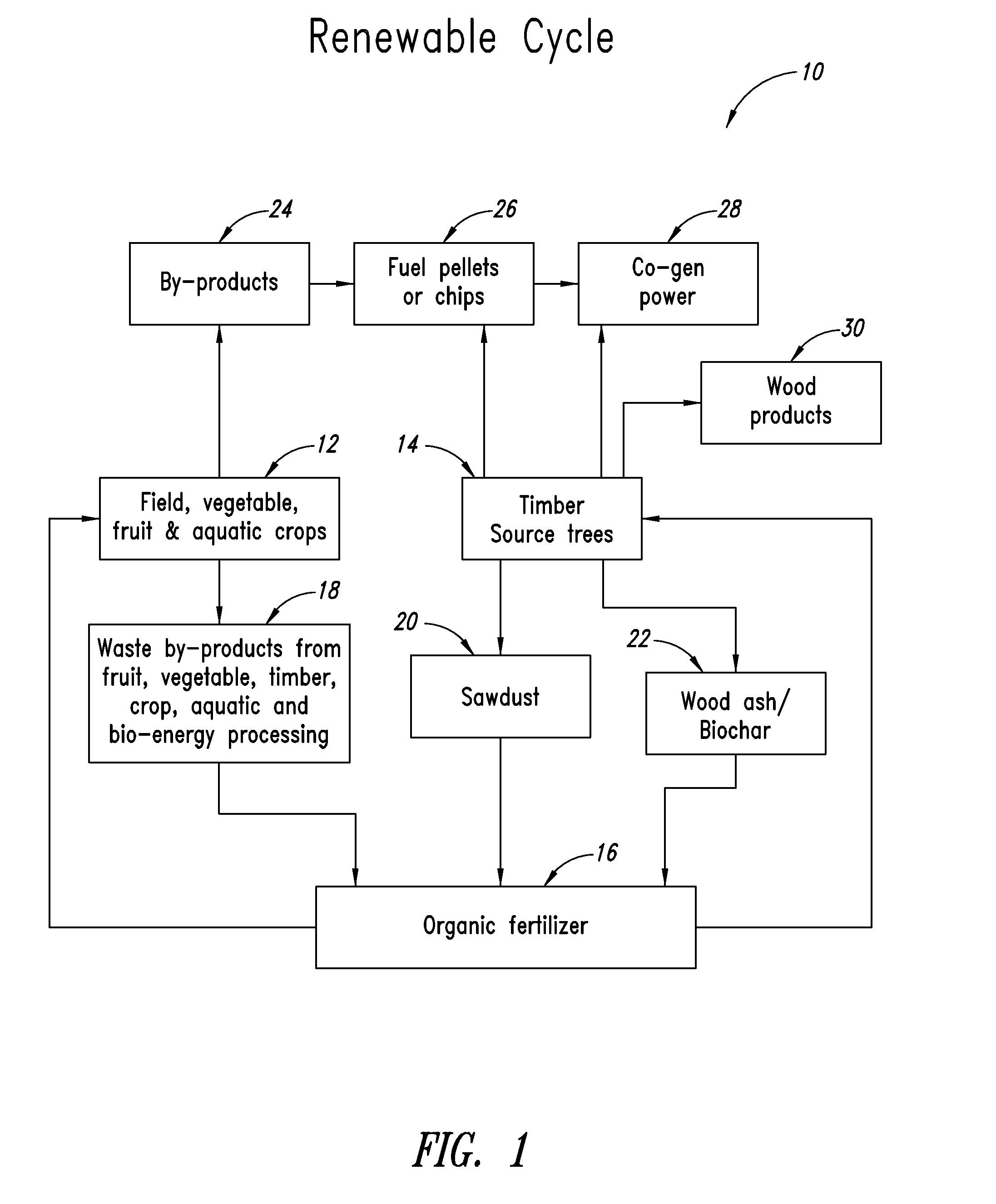

Organic soil treatment compound and method of making and using

InactiveUS20110023566A1Promote plant growthImprove scalabilityClimate change adaptationBioloigcal waste fertilisersParticulatesSoil treatment

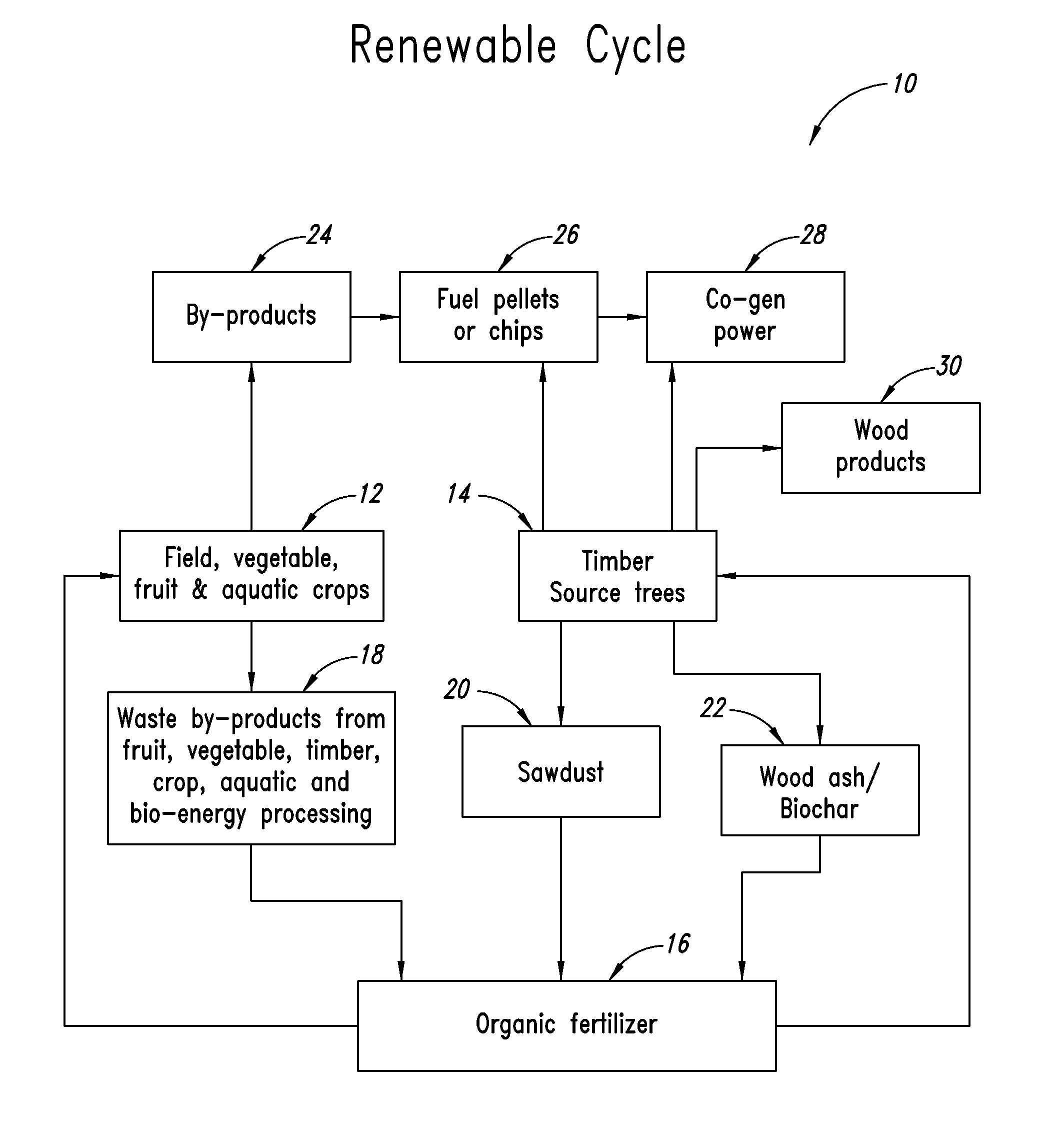

A composition is provided that includes particulates from wood, chaff, hulls, crop compost, biochar, or waste residue, wood or crop ash and biochar, and a nitrogen source from waste residue from gasification processes, food processing waste water or other residual by-products of forest, aquatic, food or feed processing. Ideally, all of the components are environmentally friendly, from natural products, and free of manufactured chemicals.

Owner:ECOTRAC ORGANICS

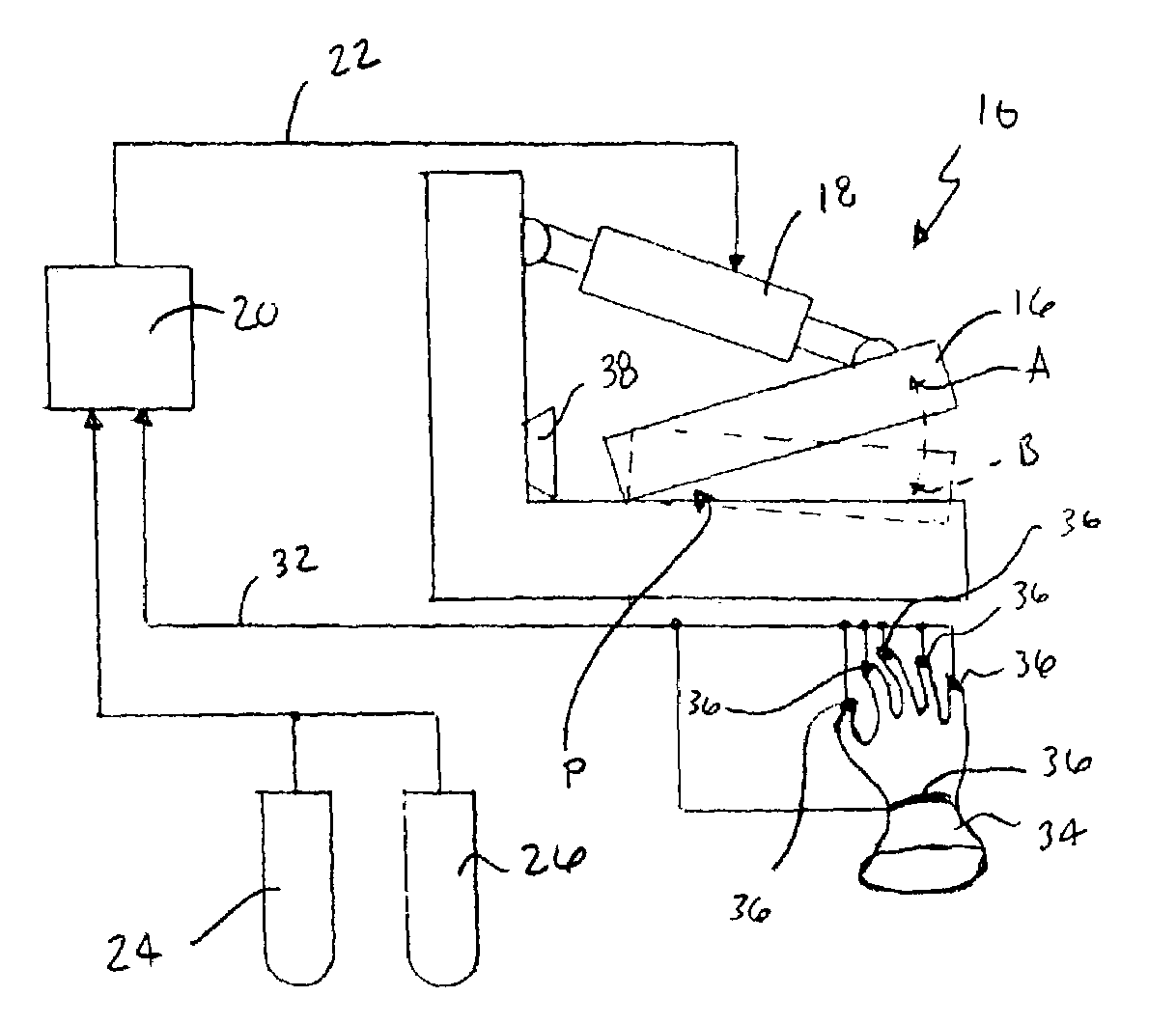

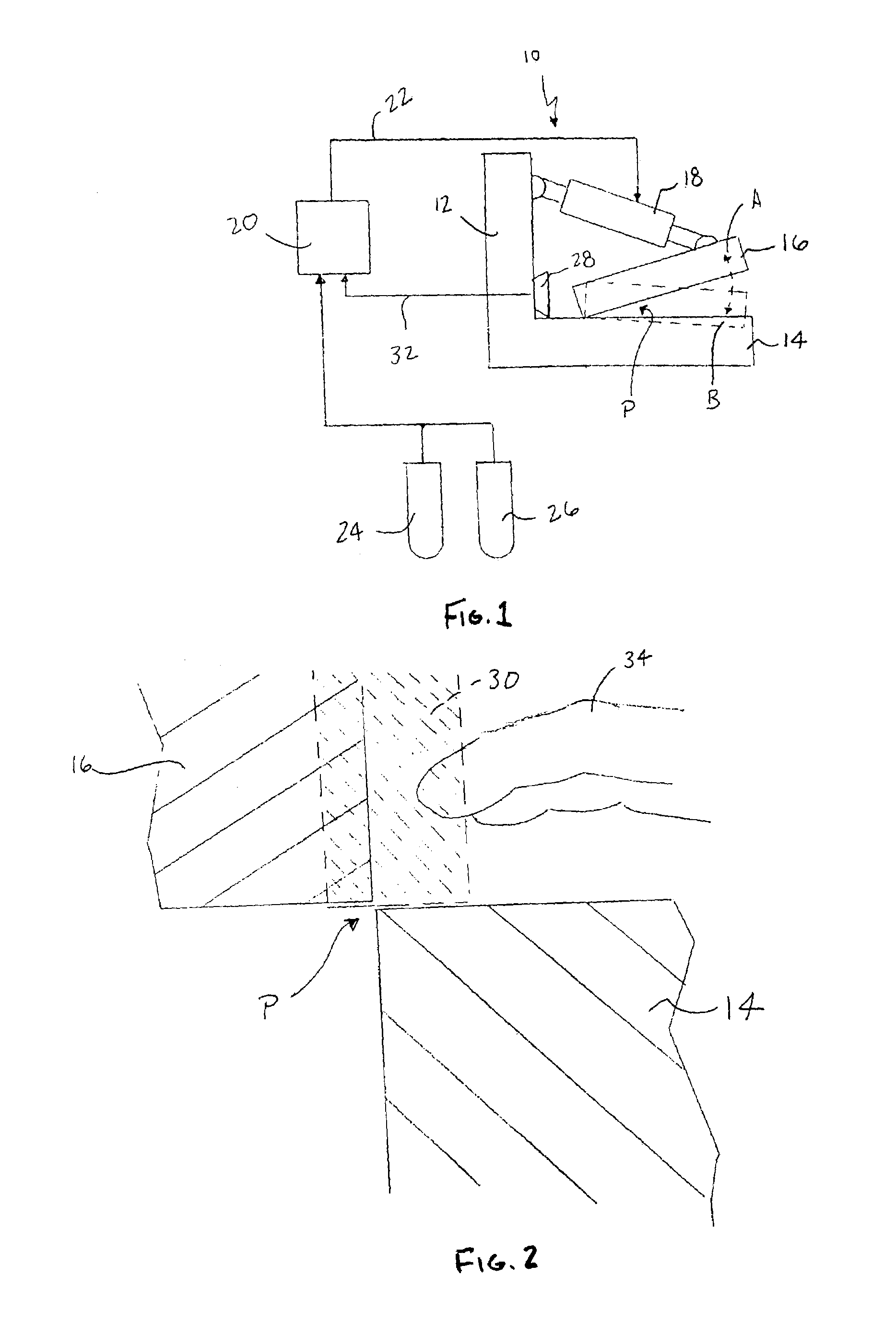

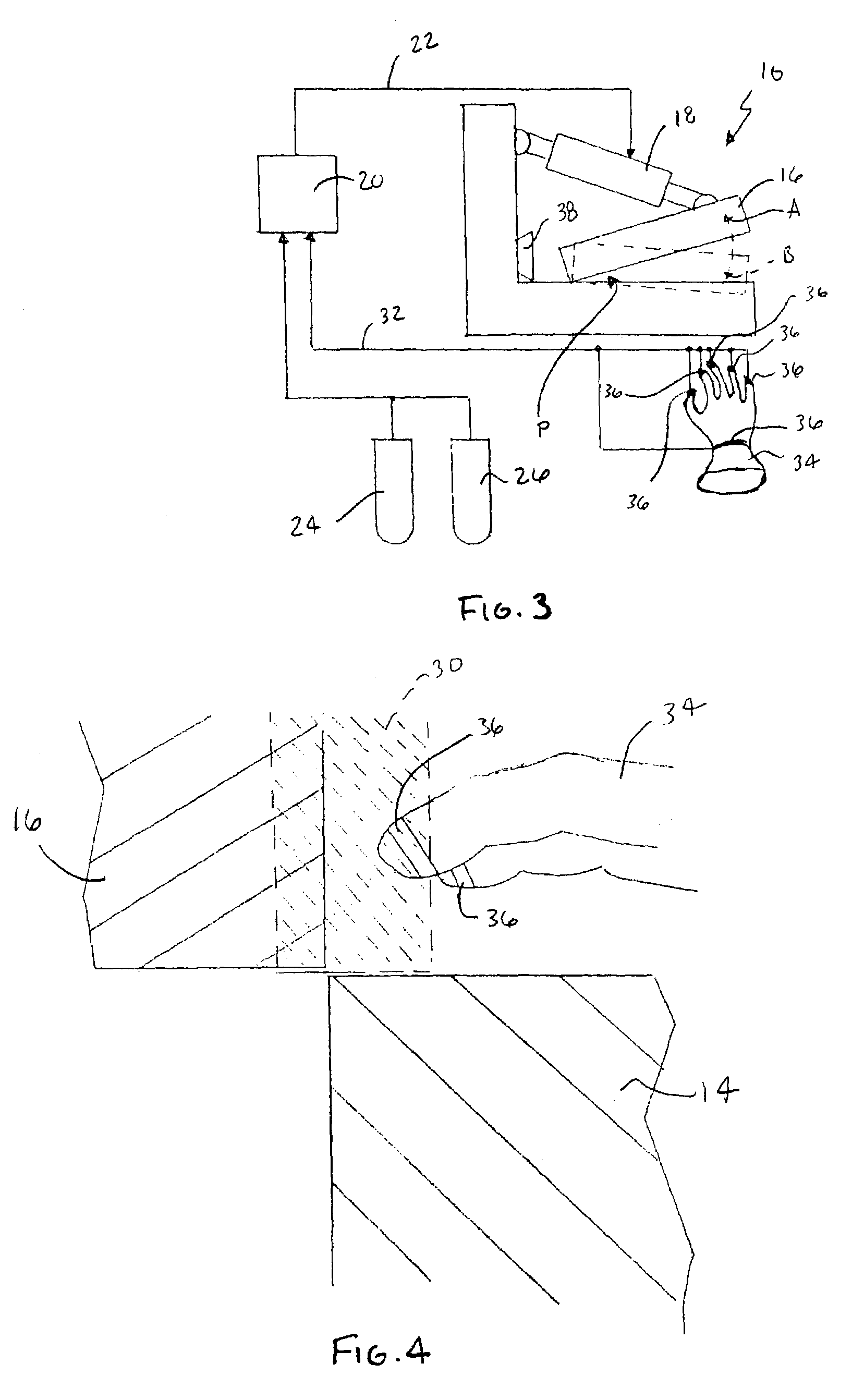

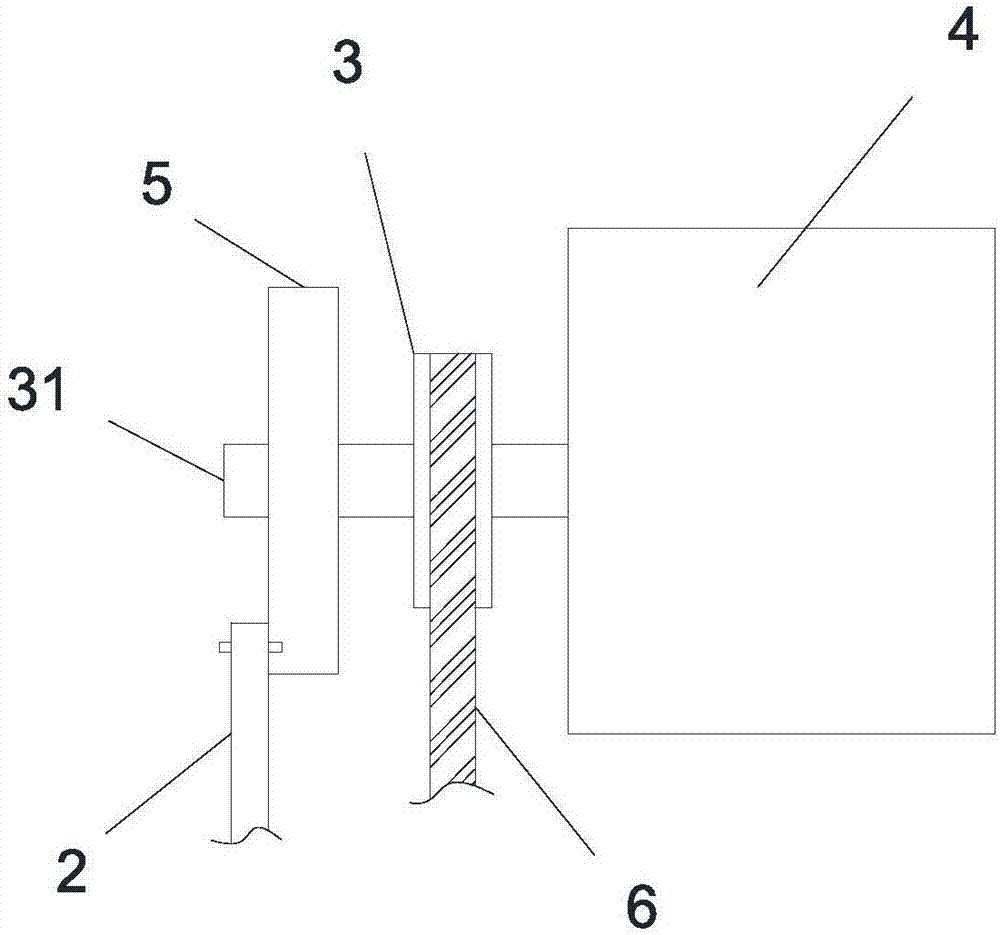

Safety-shutoff device for a manually fed processing machine

InactiveUS6979813B2Operational securityDc network circuit arrangementsMaterial analysis by optical meansComputer scienceFeed processing

An intrusion detection system for altering the operation of an associated machine when an appropriate intrusion is detected, the system comprising: a first detector to detect the presence of a first distinguishing property and to selectively produce an intrusion signal when the first distinguishing property associated with an object is detected within a danger zone approximate a pinch point of a machine, wherein an area approximate the pinch point of the machine does not exhibit the first distinguishing property; and, a controller, operatively coupled to the intrusion detector and the machine, for controlling the operation of the machine, wherein the controller generates a corrective action signal directed toward the machine when intrusion signals are received from the intrusion detector.

Owner:AVRIL JOHN G

Safe efficient environment protection type feedstuff

InactiveCN101380056AImprove digestibilityReflect environmental protectionFood processingAnimal feeding stuffAnimal scienceSide effect

A safe and high-efficient environment-friendly feed comprises the following raw materials in terms of weight percentage: 6 to 20 percent of corn gluten feed, 3 to 25 percent of soybean meals, 1 to 20 percent of powder, 0 to 15 percent of rice bran, 0 to 40 percent of corn, 3.5 to 10 percent of rapeseed dregs, 1 to 5 percent of cotton seed meals, 1 to 5 percent of bone meals, 2 to 6 percent of fish meals, 1 to 6 percent of meat meals, 3 to 15 percent of wheat and right amount of additives. According to the required amounts of all nutritional components of the livestock in different growing stages, the invention combines energy feed, protein feed and various additives in equilibrium according to certain percentages by adopting a scientific method, thus leading various livestock to obtain the largest feed digesting rate and leading the livestock to absorb the feed to the largest degree; the excrement after the digestion of the livestock have no obvious smell and cause no pollution to the surrounded environmental sanitation and the environment protection after the feed being eaten is shown; moreover, no banned substances are added in the process of the feed processing and the feed is processed from natural products, which have no residue side effects on the livestock.

Owner:罗喜华

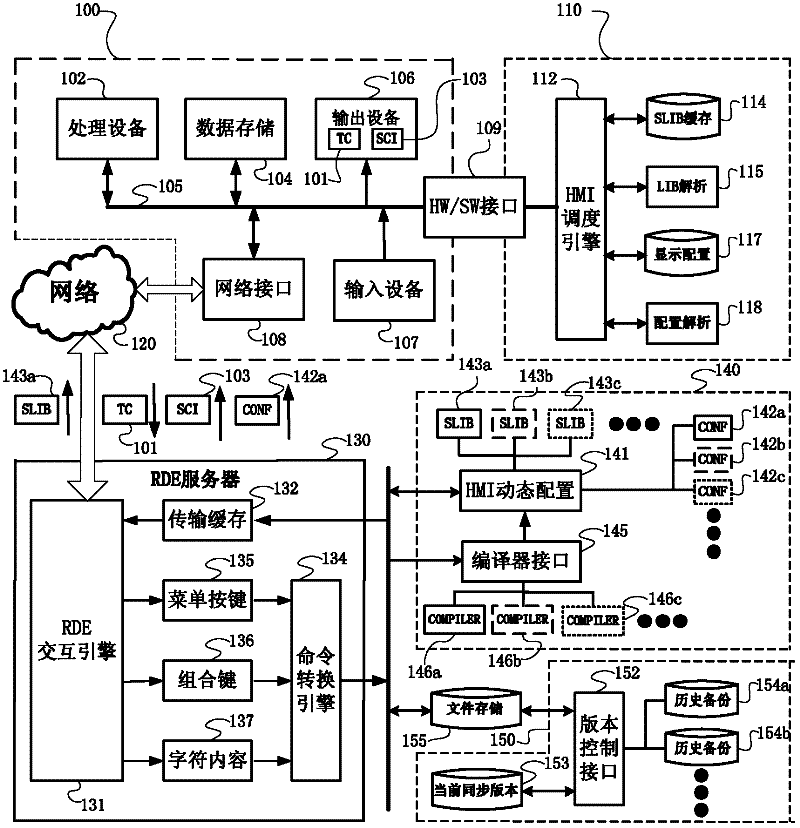

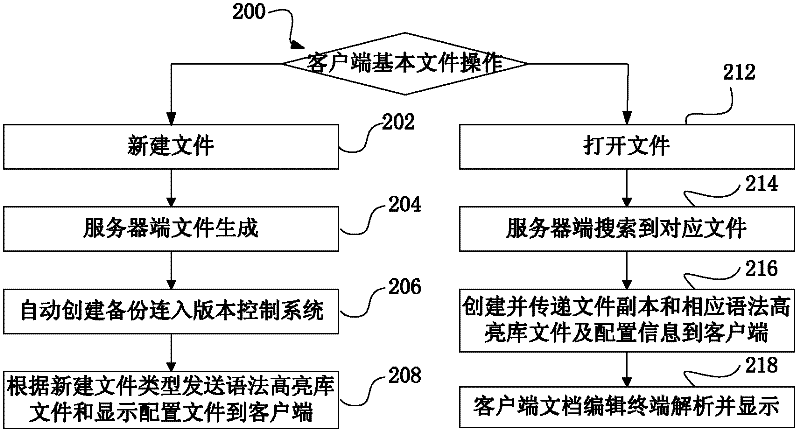

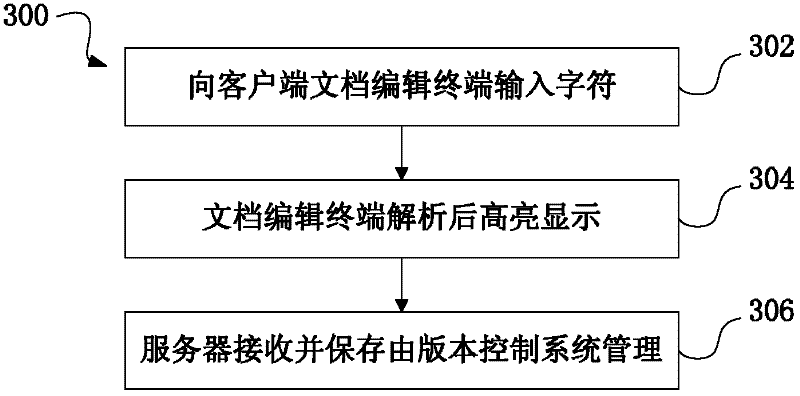

Remote development method and system under coordination environment

InactiveCN102520922AReduce sizeAvoid wastingSpecific program execution arrangementsControl systemComputer terminal

The invention discloses a remote development method and system under a coordination environment. The remote development system comprises a remote development server, a client end display generation system and a file control system, wherein the remote development server is used for interacting with a client end document editing terminal, receiving data of the document editing terminal and sending feedback information to the document editing terminal; the client end display generation system is used for sending a specific grammar library and a display configuration content to a client end through the remote development server according to a request concerning a display change and development command of the document editing terminal or transmitting a development command to a compiler unit for processing and feeding processing result back to the document editing terminal; and the file control system is used for operating a file command on a file copy which is in the course of being edited and carrying out edition control on a development project so as to be convenient for coordination of multiple users. According to the invention, the demand of the client end to the configuration is greatly reduced, the time of building a working platform by the client end is decreased, and the waste to resources is avoided, thus the coordination development efficiency and convenience are greatly improved.

Owner:SHANGHAI JIAO TONG UNIV +1

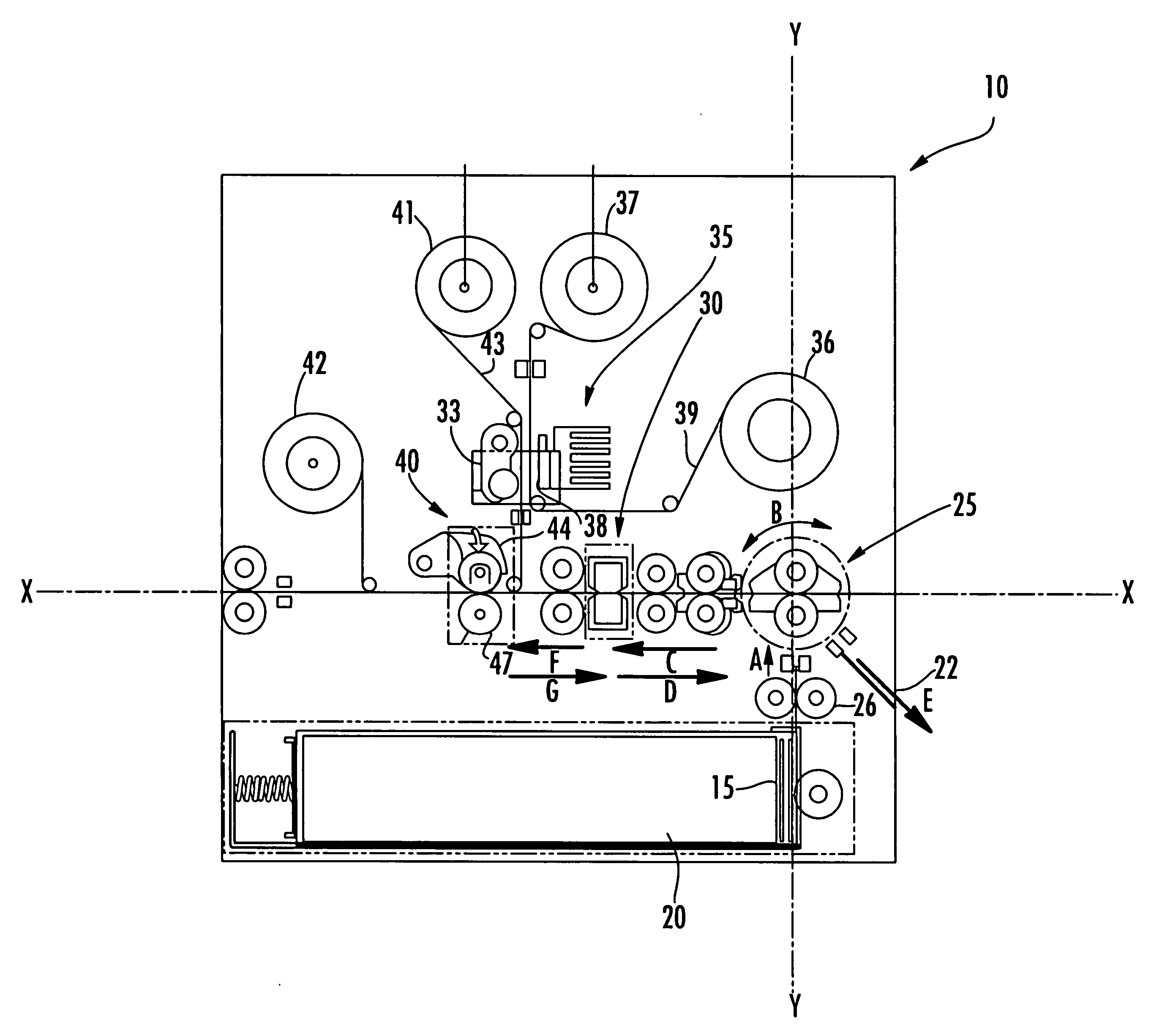

Single-pass double-sided image transfer process and system

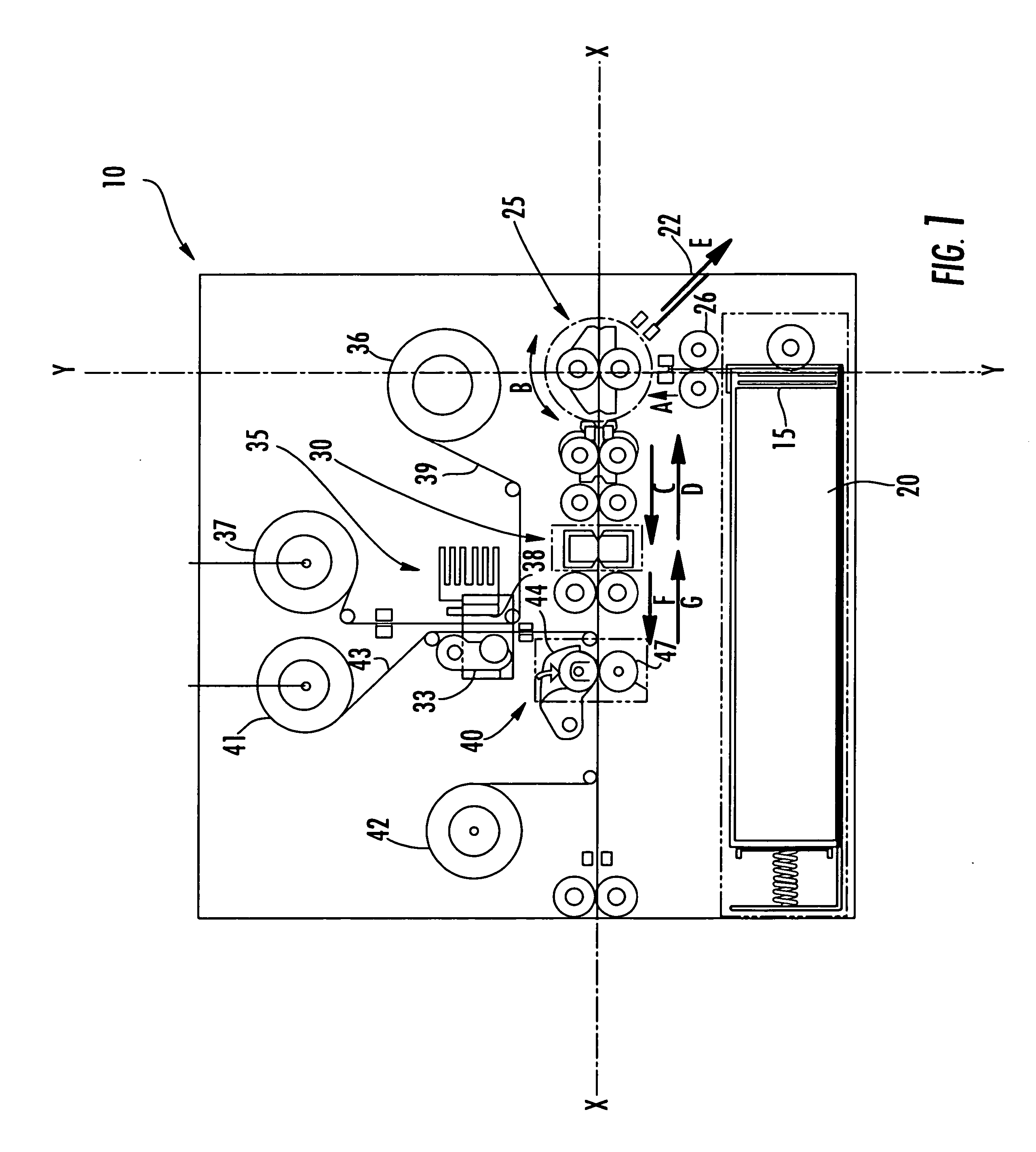

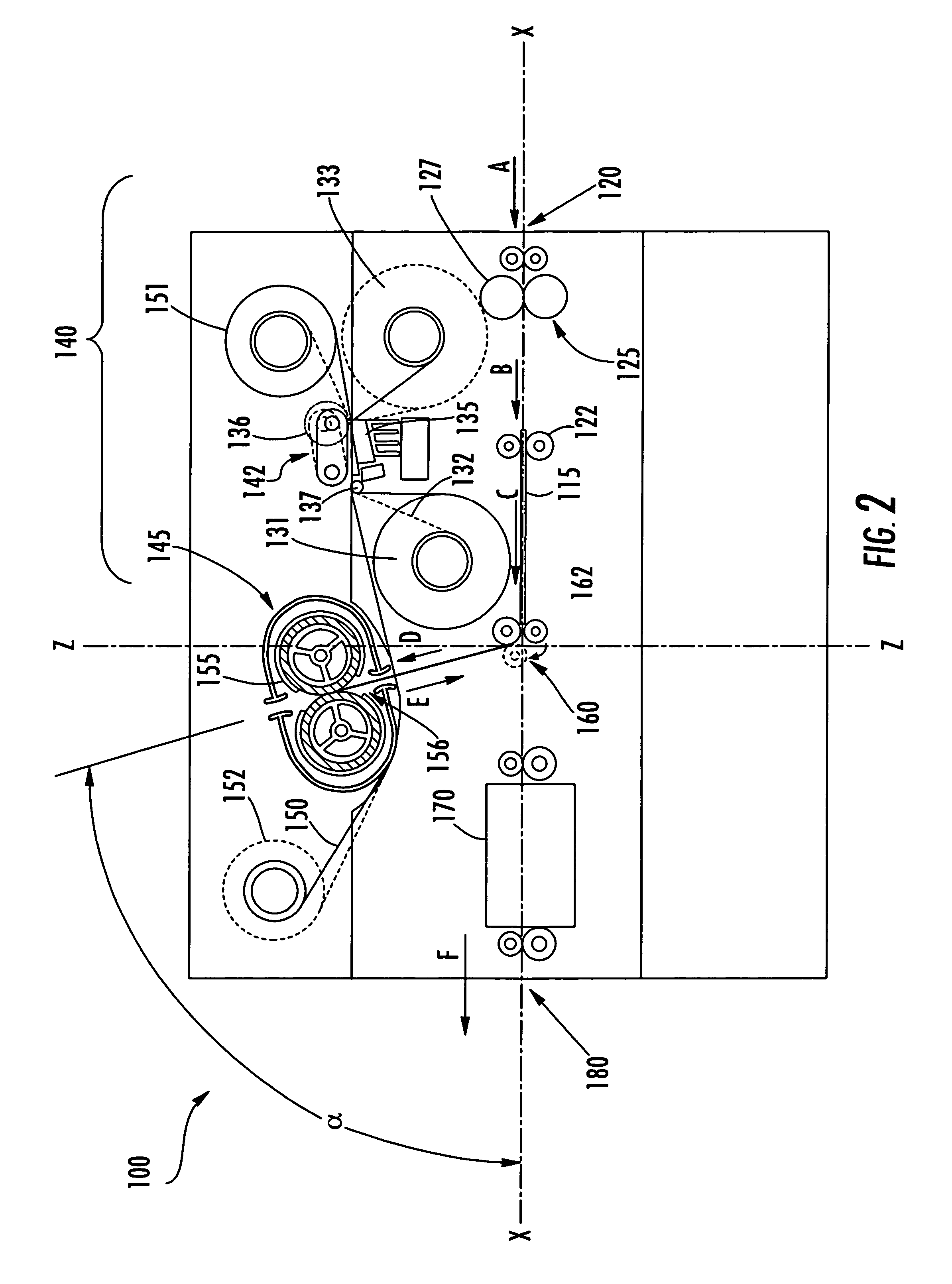

ActiveUS20070099462A1Improve precisionEasy to operateEngagement/disengagement of coupling partsRecord carriersState of artImage transfer

The present disclosure is directed to a printing assembly incorporating an improved double-sided image transfer station. The present disclosure also describes a product processing apparatus including a cross feed processing architecture. The single-pass double-sided image transfer station and cross feed processing architectures described herein provide numerous advantages over prior art product processing devices. In particular, the single-pass double-sided image transfer station provides for reduced print times, less shuttling of the product during printing, and a less complex, therefore, more reliable printing operation overall. The cross feed architecture provides an efficient processing path for the product through the device and facilitates processing modularization.

Owner:ZEBRA TECH CORP

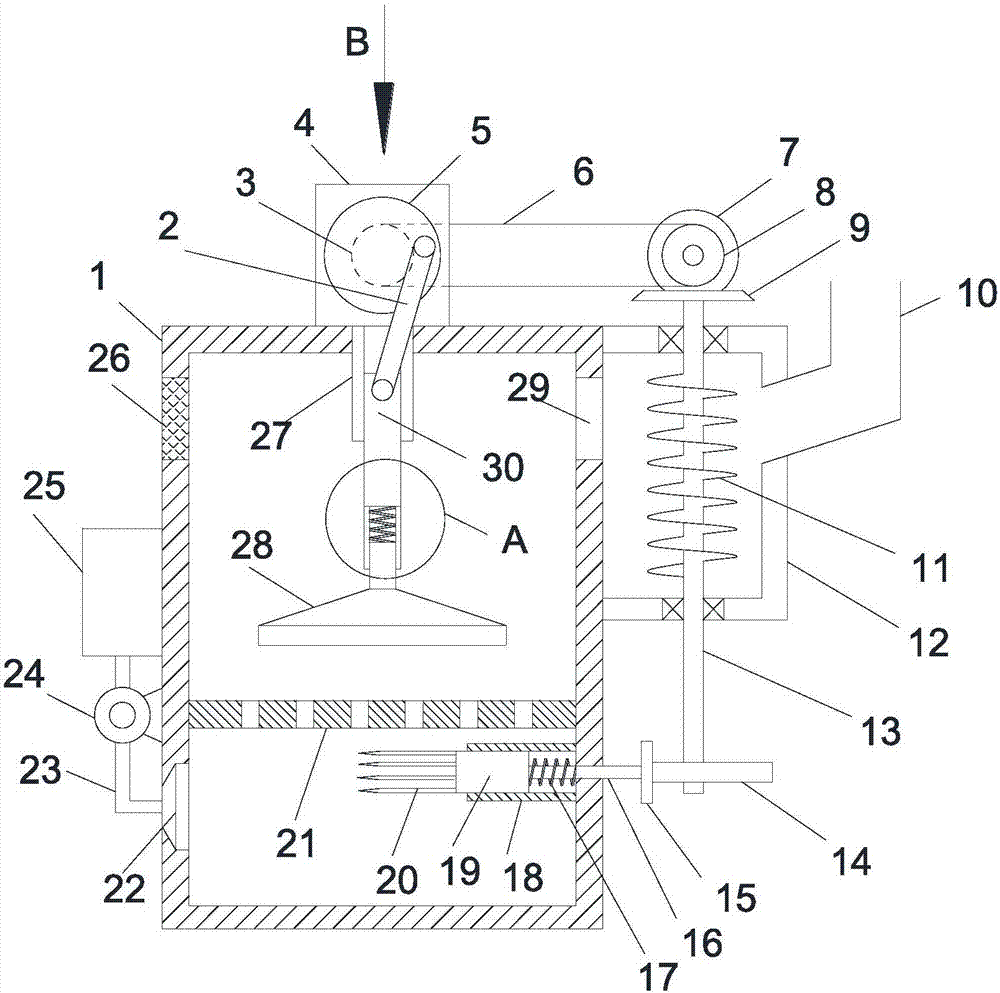

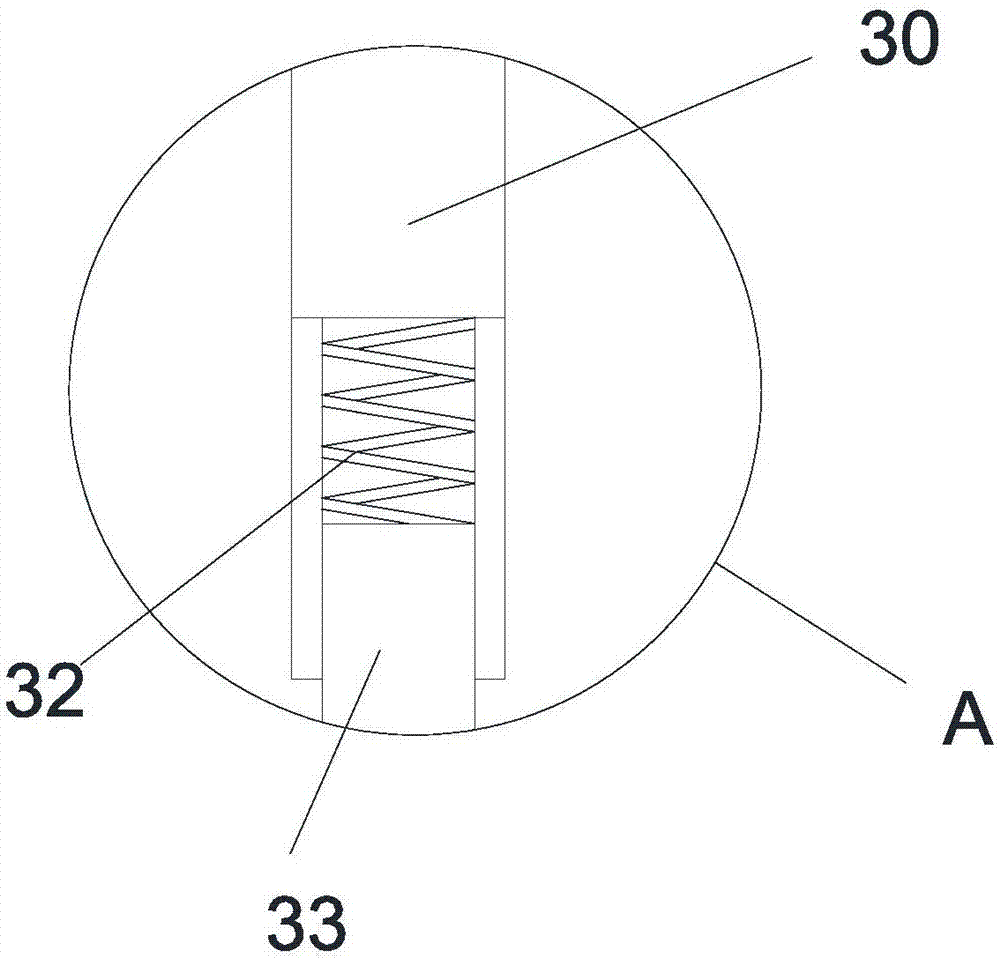

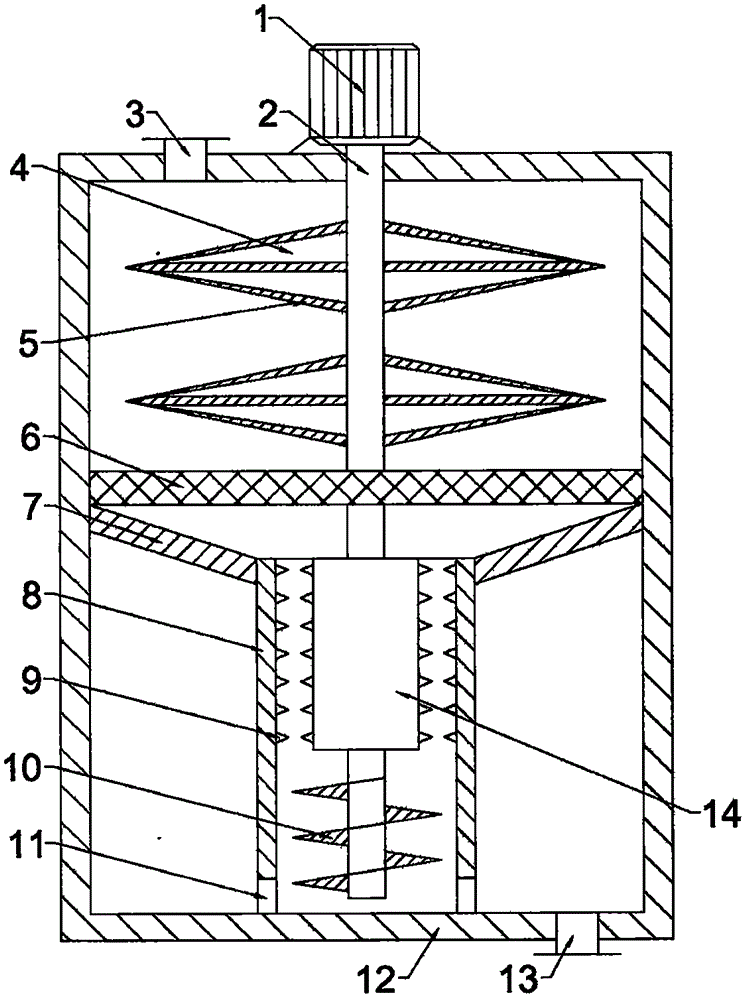

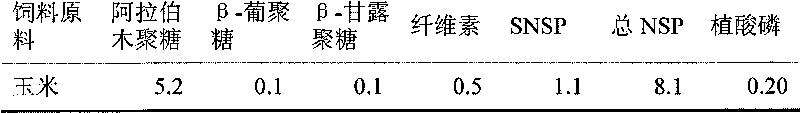

Extruding granulation device for feed processing

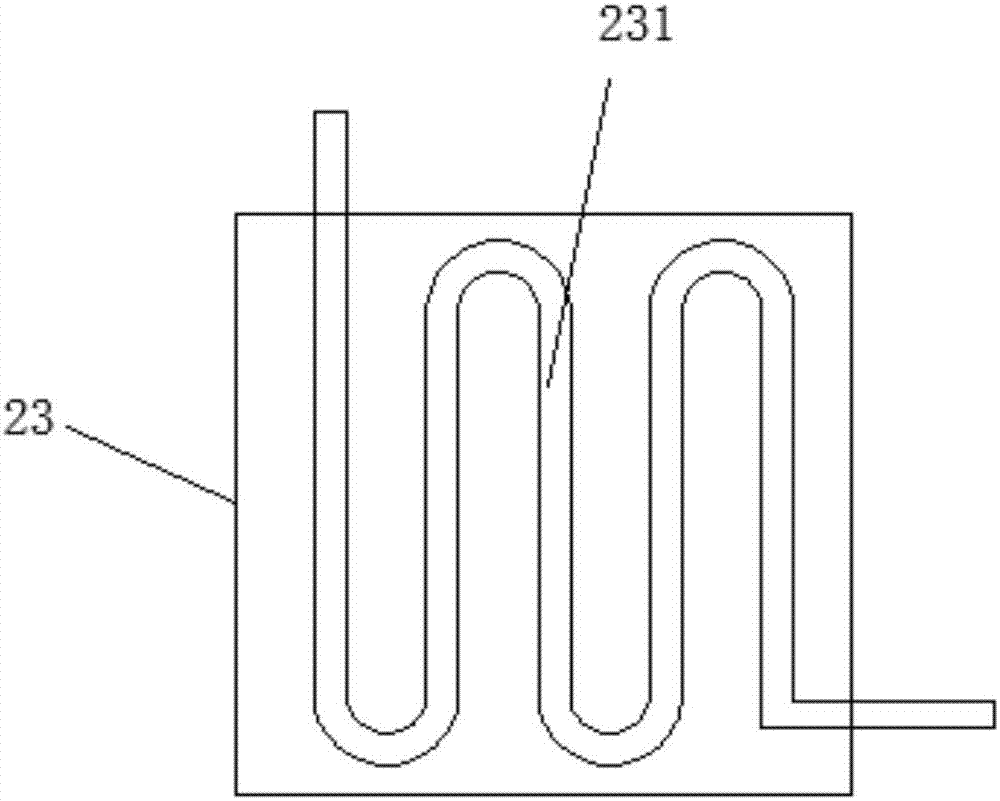

InactiveCN107397052AImprove the efficiency of processing and granulationMix and stirWorking-up animal fodderDrive shaftTransmission belt

The invention discloses an extrusion granulation device for feed processing, which comprises a granulation box, a drive motor is arranged on the top of the granulation box, a transmission shaft is connected to the output shaft of the drive motor, and a coaxial fixed installation is installed on the transmission shaft. The driving pulley and the turntable, the connecting rod is hinged at the side edge of the turntable; the driven pulley is rotated on the granulation box, and the driving belt is wound between the driven pulley and the driving pulley, and the driven pulley is the same The shaft is fixedly installed with a driving bevel gear; the surface of the rotating shaft is provided with a helical blade; the extrusion die is installed horizontally in the granulation box, the horizontal limit sleeve is horizontally installed on the inner wall of the right side of the granulation box, and the left end of the slider is connected with a Several cutting blades are arranged parallel to each other, and the baffle is in contact with the disc cam; the slider drives the cutting blades to cut the feed extruded from the extrusion die, making the feed more refined and uniform, and effectively avoiding feed blockage The extrusion die head greatly improves the efficiency of feed processing and granulation.

Owner:南宁众创空间科技有限公司

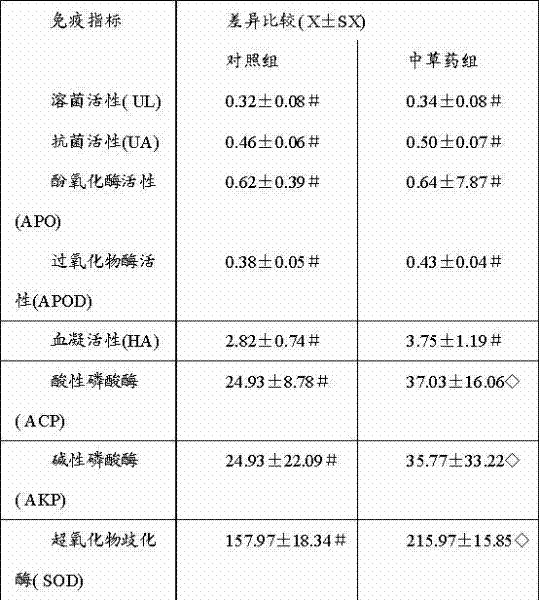

Shrimp feed and preparation method thereof

ActiveCN102450485AGood for growing and breedingImprove submergenceAnimal feeding stuffAnimal scienceAdhesive

The invention discloses a shrimp feed and a preparation method thereof. The feed comprises the following raw materials in percentage: 2.5% of silkworm dropping, 10% of rice bran, 10% of wheat bran, 48% of fish meal, 10% of soybean cake, 2% of beer yeast, 1% of traditional Chinese medicine composition additive, 0.5% of vitamin complex premix, 1% of mineral premix and 15% of feed adhesive. The invention in which Chinese herbal medicines are used for preventing and treating fish and shrimp diseases completely meets the disease control criteria of developing nuisance free aquaculture and producing green marine products, and especially meets the requirements of intensive and large-scale production in the current aquiculture; the Chinese herbal medicines in a certain proportion are prepared into a compound preparation to better play the synergistic effect of the medicines; starch in the feed adhesive is conglutinated at different temperatures by a steaming process, thus increasing the degree of expansion and greatly improving the degree of gelatinization of the starch; and the feed adhesive can completely replace a chemical adhesive on effect in feed processing, improves the sinking property and adhesiveness of the feed, and benefits the shrimp growth and culture, thus creating good economic benefit and social benefit.

Owner:海阳新希望六和饲料有限公司 +1

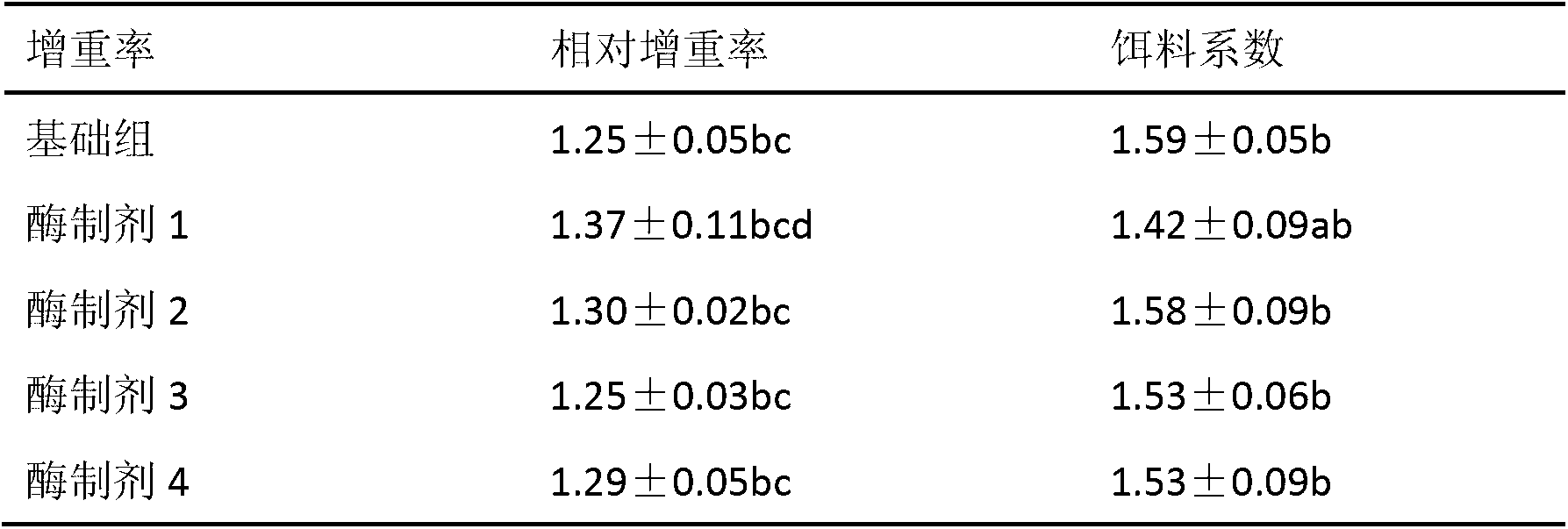

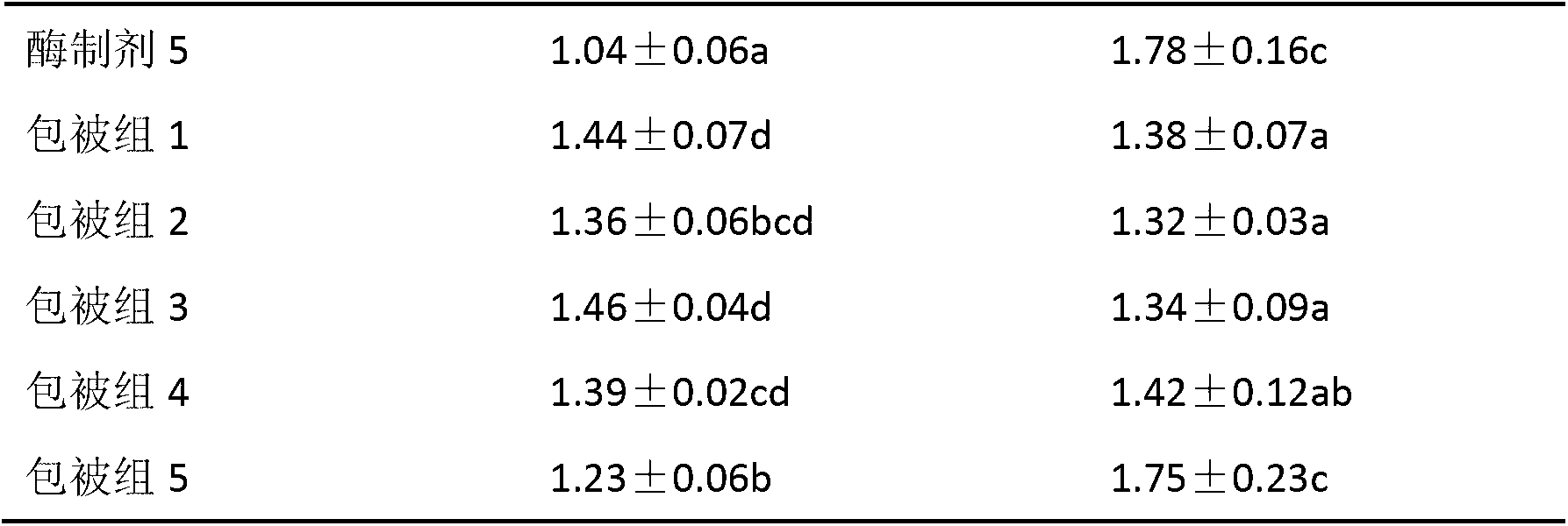

Fermented feed for nursery pig and preparation method thereof

ActiveCN103734542AImprove digestion utilizationGood for healthAnimal feeding stuffBiotechnologySodium butanoate

The invention relates to a fermented feed for nursery pigs and a preparation method thereof. The feed is prepared from the following raw materials in parts by weight through fermenting: 400-700 parts of corns, 50-200 parts of soybean meal, 2-6 pats of lysine hydrochloride, 1-10 parts of calcium formate, 1-10 parts of calcium hydrogen phosphate, 0.2-0.5 part of vitamin premix, 2.5-3.5 parts of organic microelement premix, 1-5 parts of micro-ecologic, 0.2-2 parts of complex enzyme preparation and 0.5-2.0 parts of sodium butyrate. With the consideration of improving the digestion utilization rate of the feed for nursery pigs, together with the physiological characteristics of the nursery pigs, directing to the problems in the existing nursery pig feed processing technology, and through introducing the fermentation technology to prepare the feed and adjusting the structure of daily grains, the plant raw material digestion utilization rate is improved, the feed cost is reduced; in the preparation and production of the feed for the stage, the purposes of reducing energy consumption, reducing cost and improving intestinal health of animals and improving the growth rate are realized.

Owner:TONGWEI

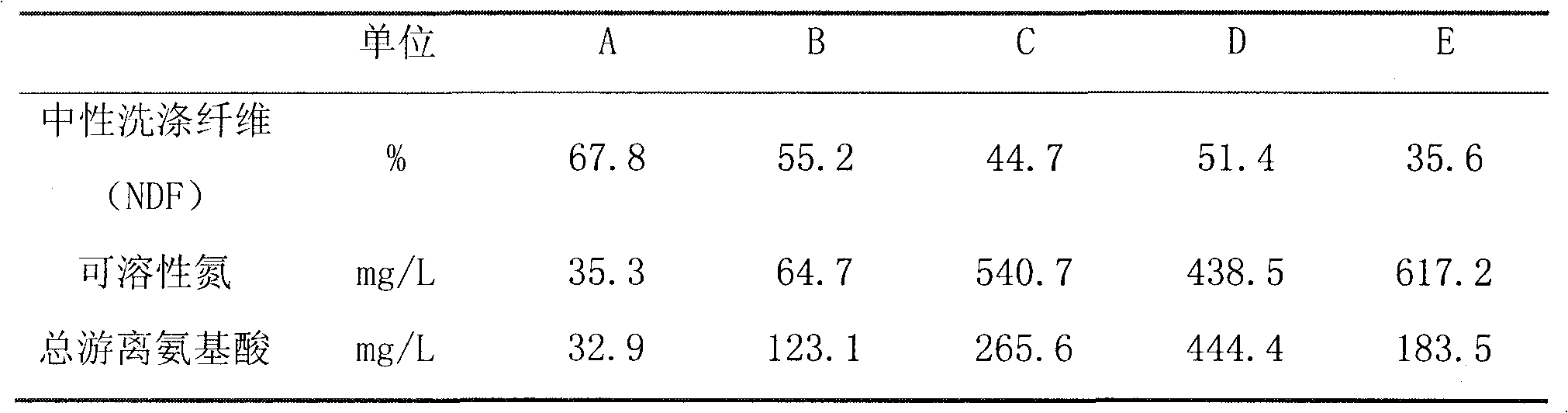

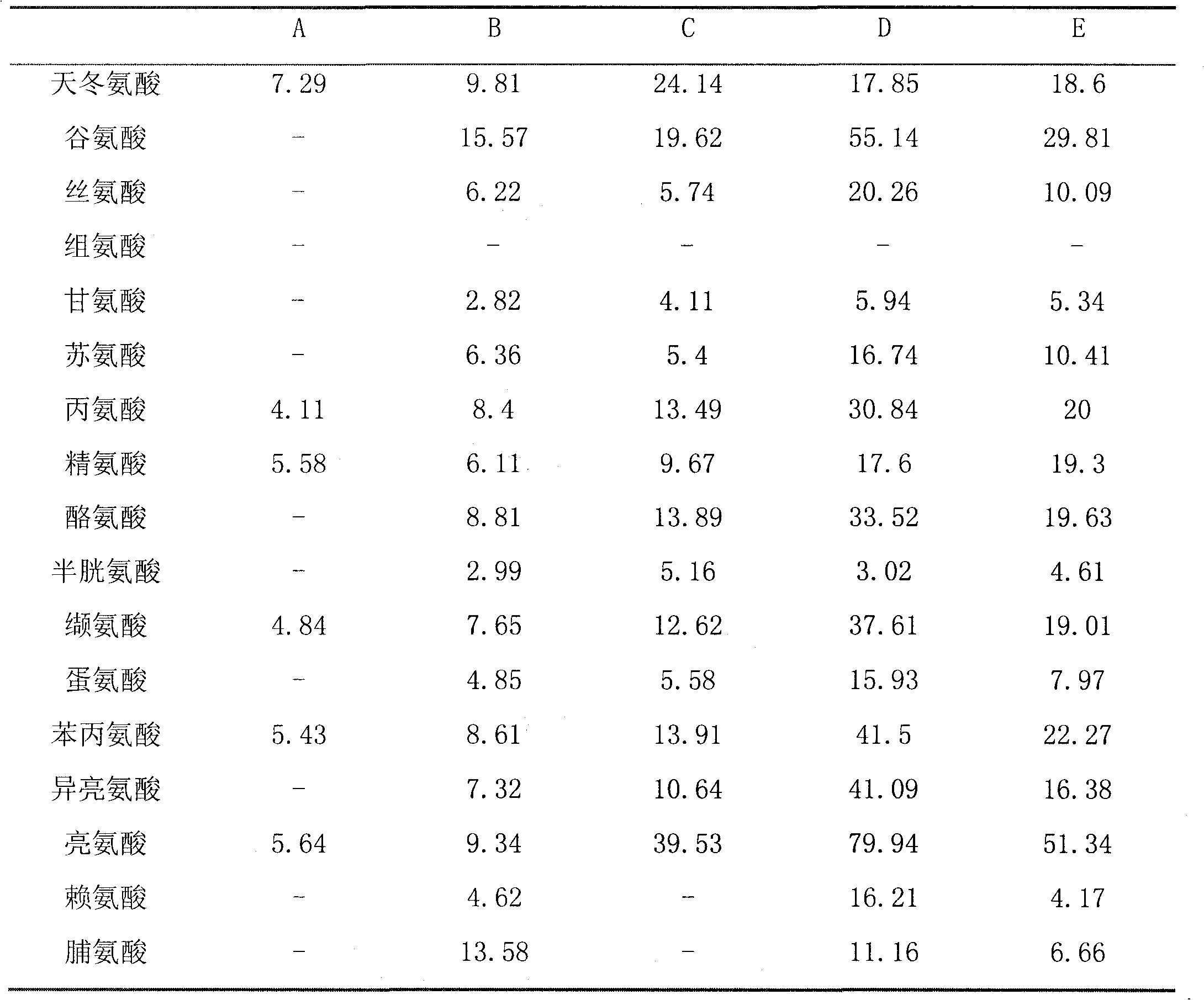

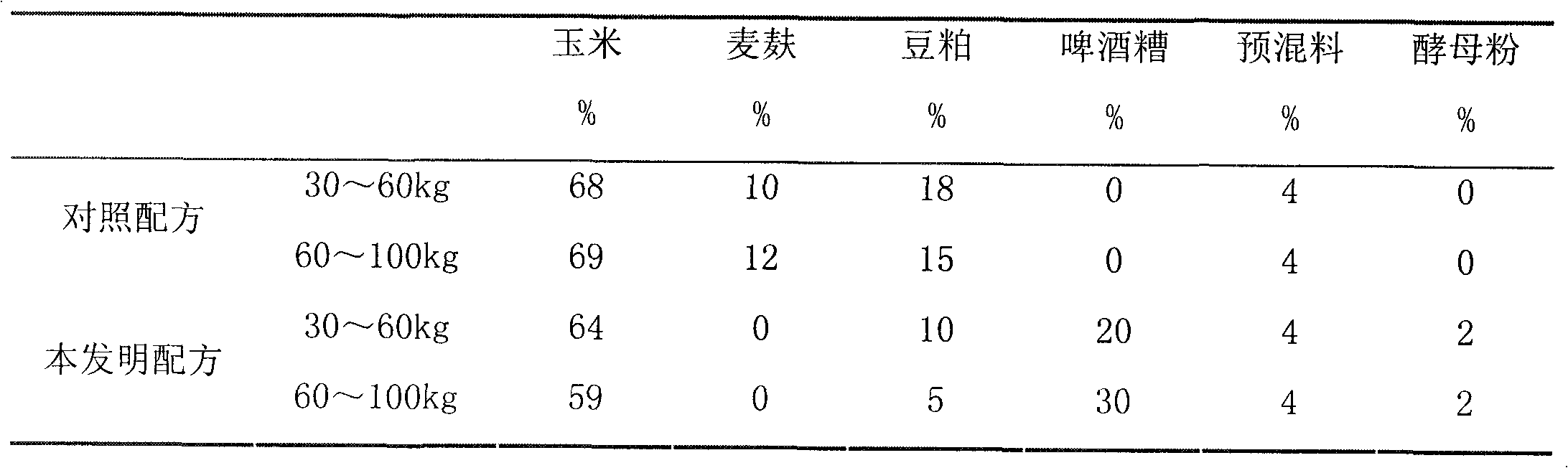

Production method for adding brewer grain fattening pannage

ActiveCN101779749ARich varietyLow costFood processingAnimal feeding stuffAdditive ingredientCorn meal

The invention belongs to a production method for adding brewer grain fattening pannage, which belongs to the technical field of the feed processing. The production method comprises the following steps that: the brewer grain is undertaken the steam explosion pretreatment and is added with mixed bacteria and / or complex enzyme to be undertaken the solid anaerobic fermentation so as to degrade the fiber content in the brewer grain and to improve the soluble nitrogen content of the brewer grain, so the quality is better, and the nutrition is more balanced; then the fermented brewer grain, waste yeast powder, corn meal, soybean meal and pre-mixed material are uniformly mixed to obtain the fattening pannage being added with brewer grain. The source of the brewer grain and the waste yeast is abundant, the nutrition for matching the brewer grain and the waste yeast is balanced, and the cost of the feed can be reduced; and the brewer grain is processed with the steam explosion pre-treatment technology, the enzymolysis technology and the biological fermentation technology, so the fiber content is reduced, the protein quality is improved, and the type of the aminoacid is more abundant; and the production method can reduce the grain ratio, improves the daily gain, reduces the feed compositions, and is free from influencing the feed intake and the growth of the fatty pigs.

Owner:BEIJING YANJING BREWERY

Method for preparing insect feed with organic waste and insect feed

ActiveCN103504151ARealize resource processingValuable protein resourceFood processingAnimal feeding stuffFermentationNutrients substances

The invention relates to the technical field of insect feed processing, in particular to a method for preparing protein insect feed with organic waste and the prepared insect feed. The method comprises the steps of directly crushing the organic waste into powder, mixing with beneficial microorganisms for fermentation, and adding necessary nutrition additives to form the insect feed. The raw material is not required to be sterilized and dried at high temperature; the production cycle is shortened; the production cost is lowered; simultaneously, macromolecular substances of the organic waste are converted to small peptides, organic acid and sugar by physiologic metabolism of the beneficial microorganisms; various nutrient substances such as bio-enzymes and vitamins which have a prebiotic effect on high protein insects and are easier to absorb are produced; and the purpose of recycling is achieved. Fermentation heat energy produced during fermentation of the microorganisms is effectively utilized to kill pathogenic microorganisms possibly existing in the organic waste, and the biosafety of the insect feed is ensured.

Owner:GUANGZHOU UNIQUE BIOTECH CO LTD +1

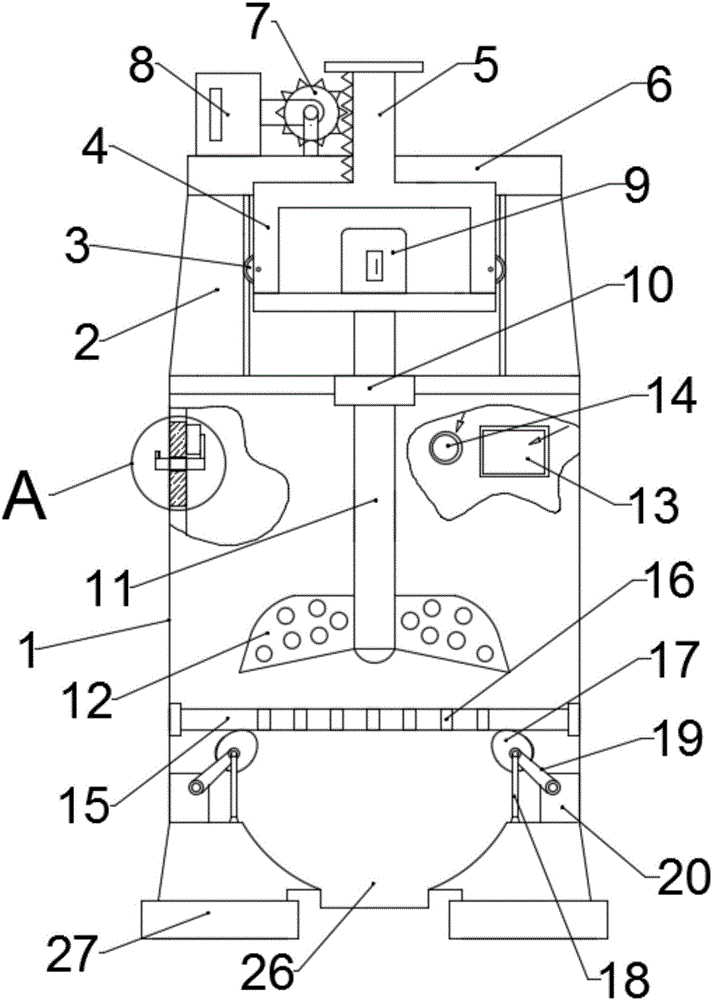

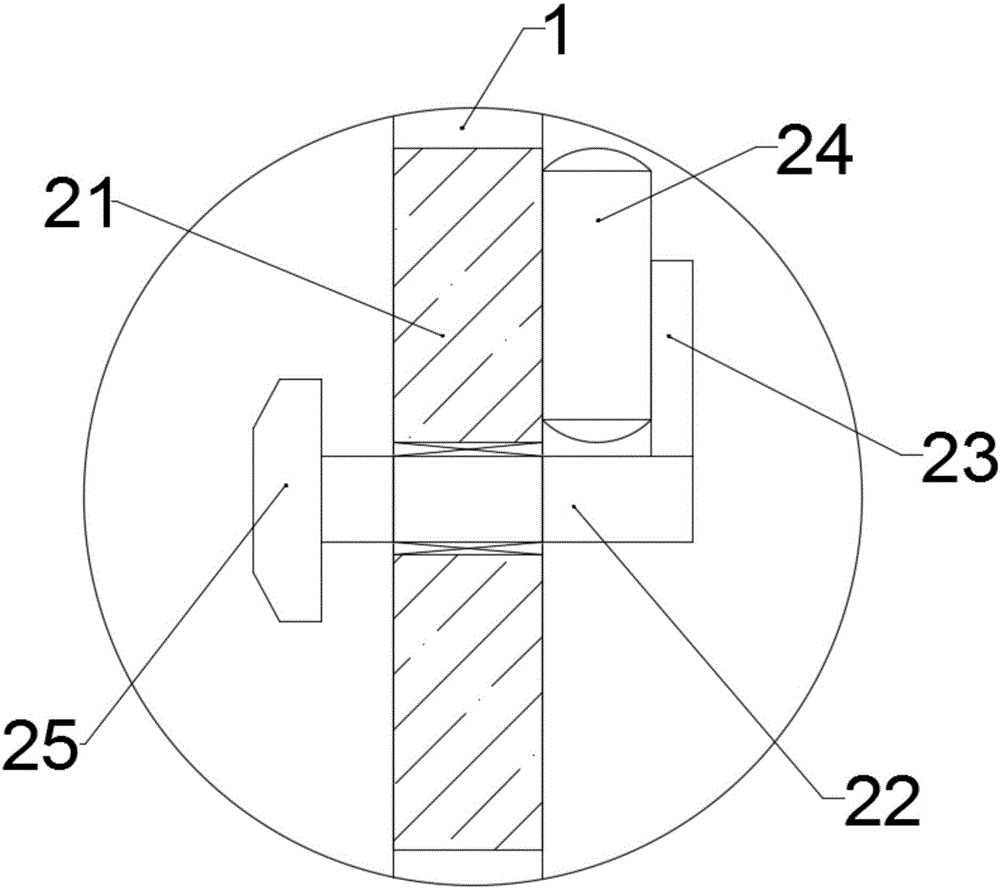

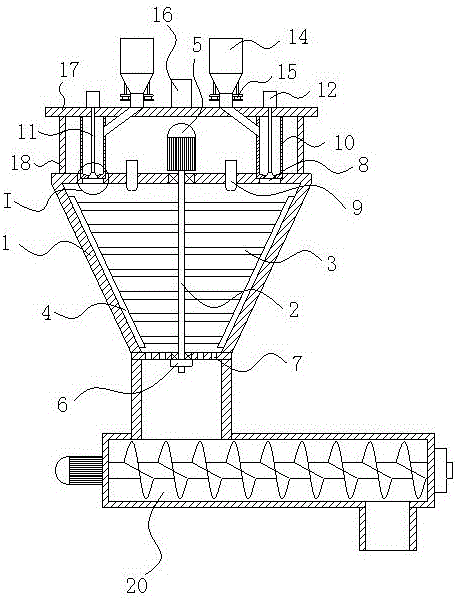

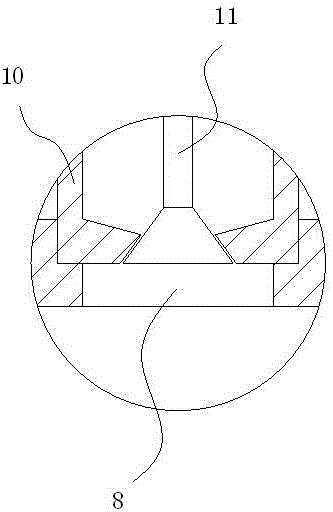

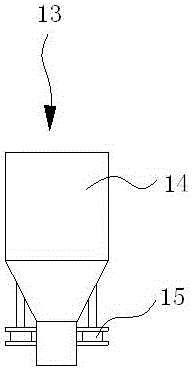

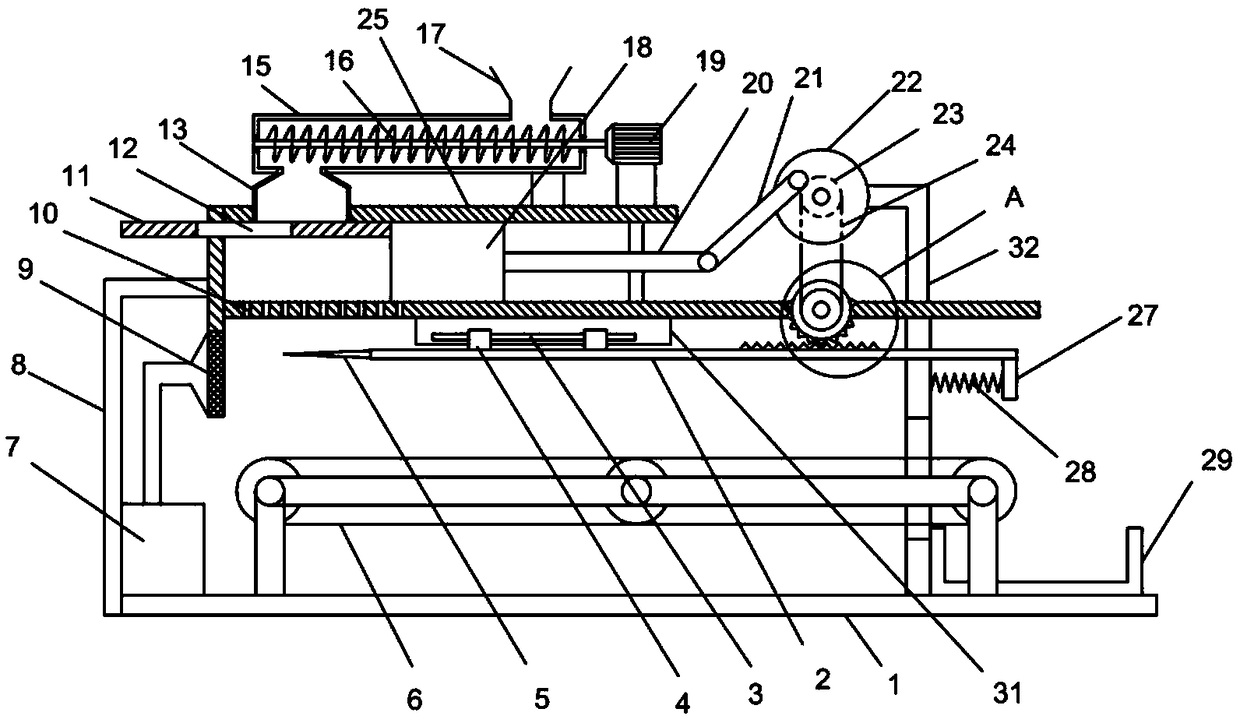

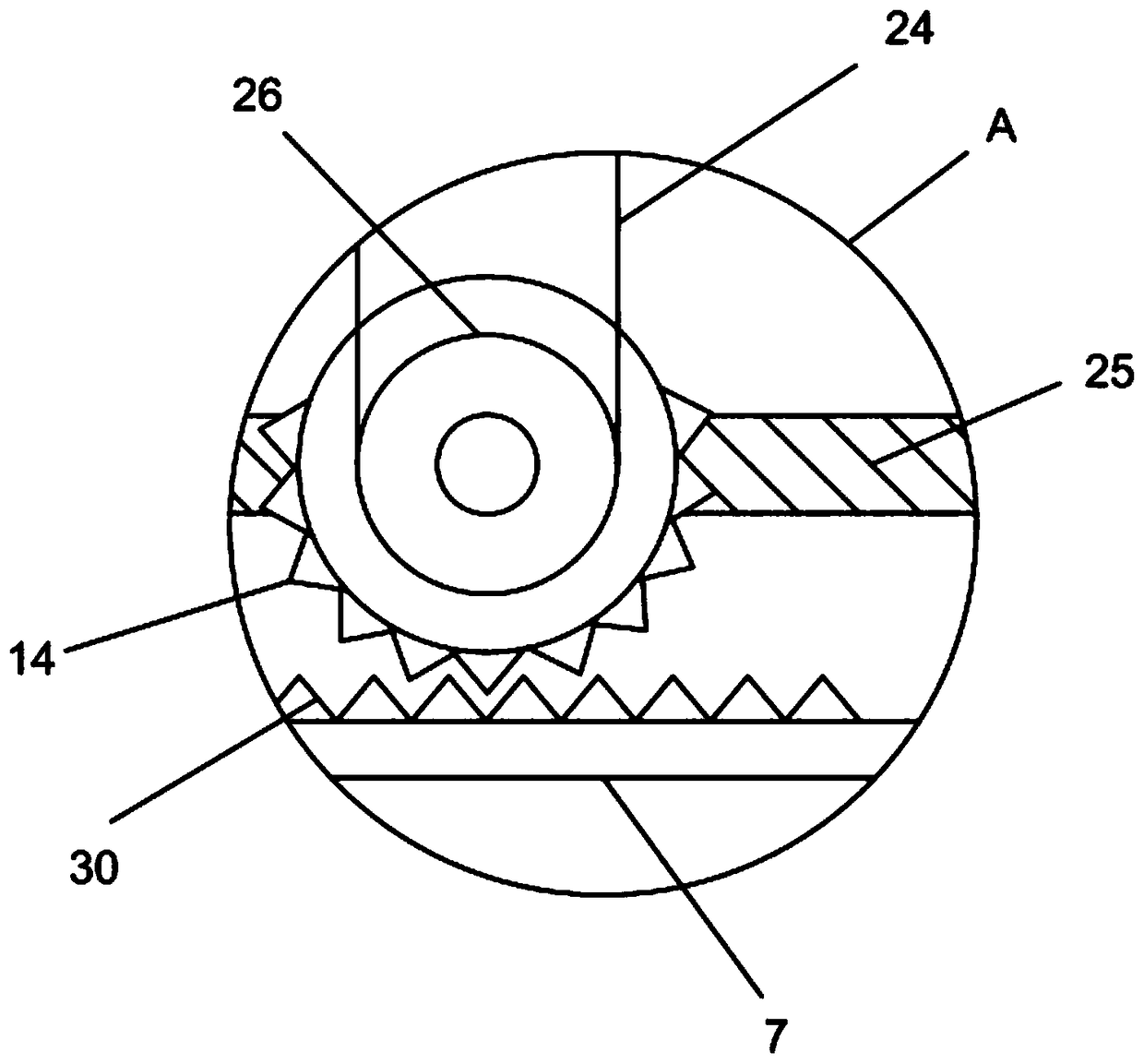

Vertical particle material handling device for agricultural feed processing

InactiveCN106733012AGuaranteed normal processingImprove filtering effectSievingFeeding-stuffEngineeringCam

The invention discloses a vertical particle material handling device for agricultural feed processing. The vertical particle material handling device comprises a processing shell. Supporting guiding side pillars are fixedly arranged on the left side and the right side of the outer wall of the processing shell. A lifting rack is upwards integrally fixed at the middle position of the top side wall of a rack body of a motor mounting rack. A main stirring motor is arranged on a bottom plate in the inner cavity of the rack body of the motor mounting rack. Crushing cutting blades are arranged on the outer side wall at the bottom end of a shaft body of a rotary crushing rotating shaft. An elastic filter screen is horizontally arranged on the left side wall and the right side wall at the lower part of an inner cavity of the processing shell. The edges of cams cling to the lower surfaces of a left screen body and a right screen body of the elastic filter screen. A transparent observation window is arranged in an observation opening. By means of the vertical particle material handling device, the omnidirectional cutting effect is achieved, the cams on two sides can finely adjusted up and down when the elastic filter screen is used for screening, the screening effects of the mesh bodies is enhanced, and a master worker can more clearly grasp operation of the device.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

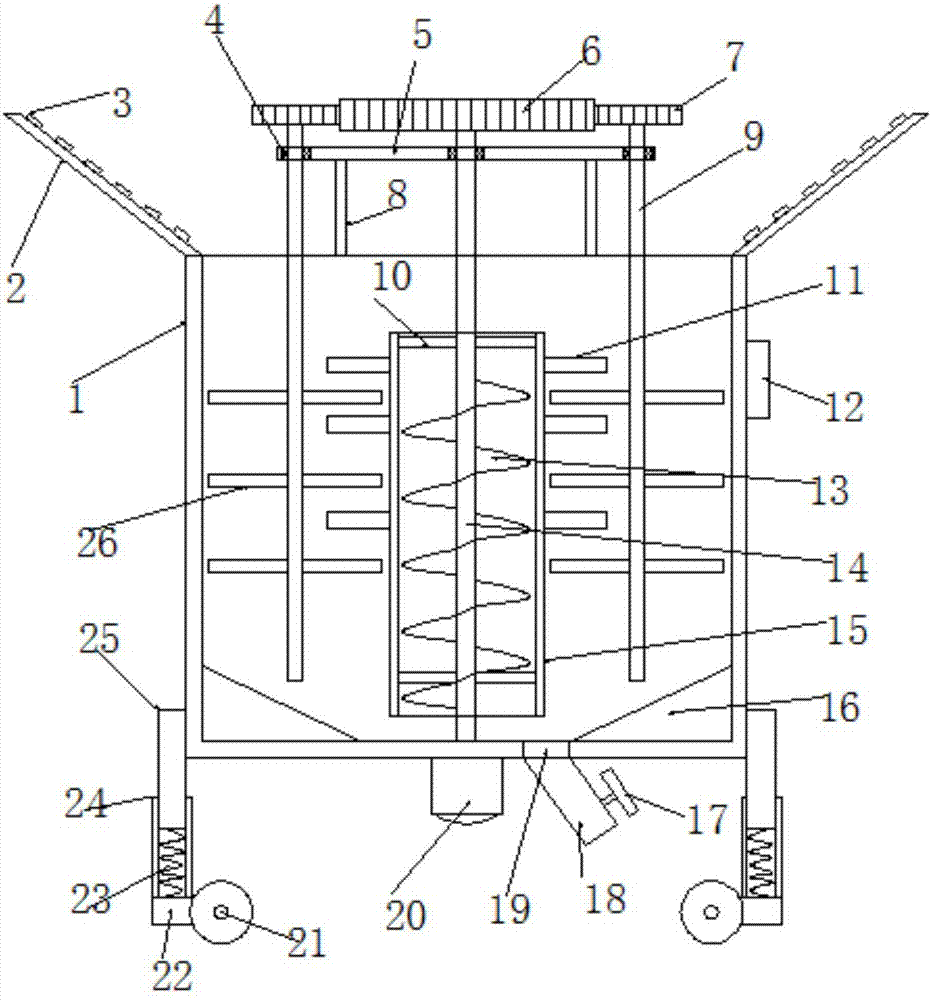

Agitator used for livestock feed processing

PendingCN107321223AImprove the mixing effectQuick mixTransportation and packagingRotary stirring mixersHelical bladeDrive motor

The invention discloses an agitator used for livestock feed processing. The agitator used for livestock feed processing comprises a stirring box; the stirring box is a cylinder with an opening on the upper end; the opening on the upper end of the stirring box is provided with a feed hopper; dispersing blocks are uniformly arranged in the feed hopper; a driving motor is fixedly arranged at the middle part of the lower end of the stirring box; an output terminal of the driving motor is provided with a material pushing shaft; the material pushing shaft in the stirring box is sleeved by a lifting barrel; the upper end and the lower end of the lifting barrel are fixedly connected with the material pushing shaft via fixing rods; a helical blade is arranged on the material pushing shaft in the lifting barrel; No.1 stirring rods are symmetrically arranged on the outside of the lifting barrel; the upper end of the material pushing shaft is fixedly provided with a driving gear. The agitator is simple and reasonable in structure design, is convenient to move, possesses buffer performance, is capable of realizing convection stirring of upper layer material with lower layer material in stirring, realizing reverse stirring of the materials in convection stirring, and improving material stirring effect greatly, is convenient for material rapid mixing, and is high in practicality.

Owner:ZHENGZHOU UNIV

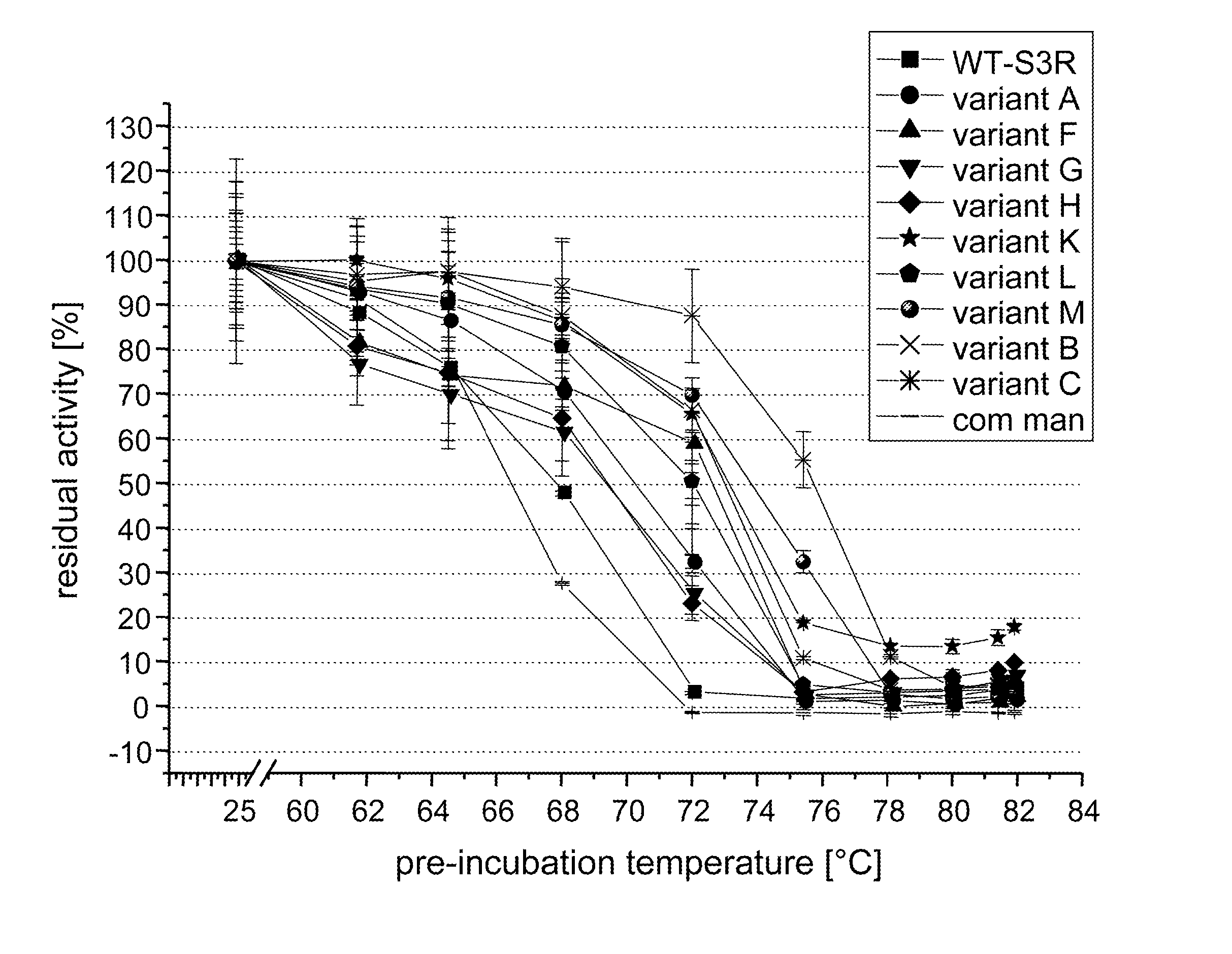

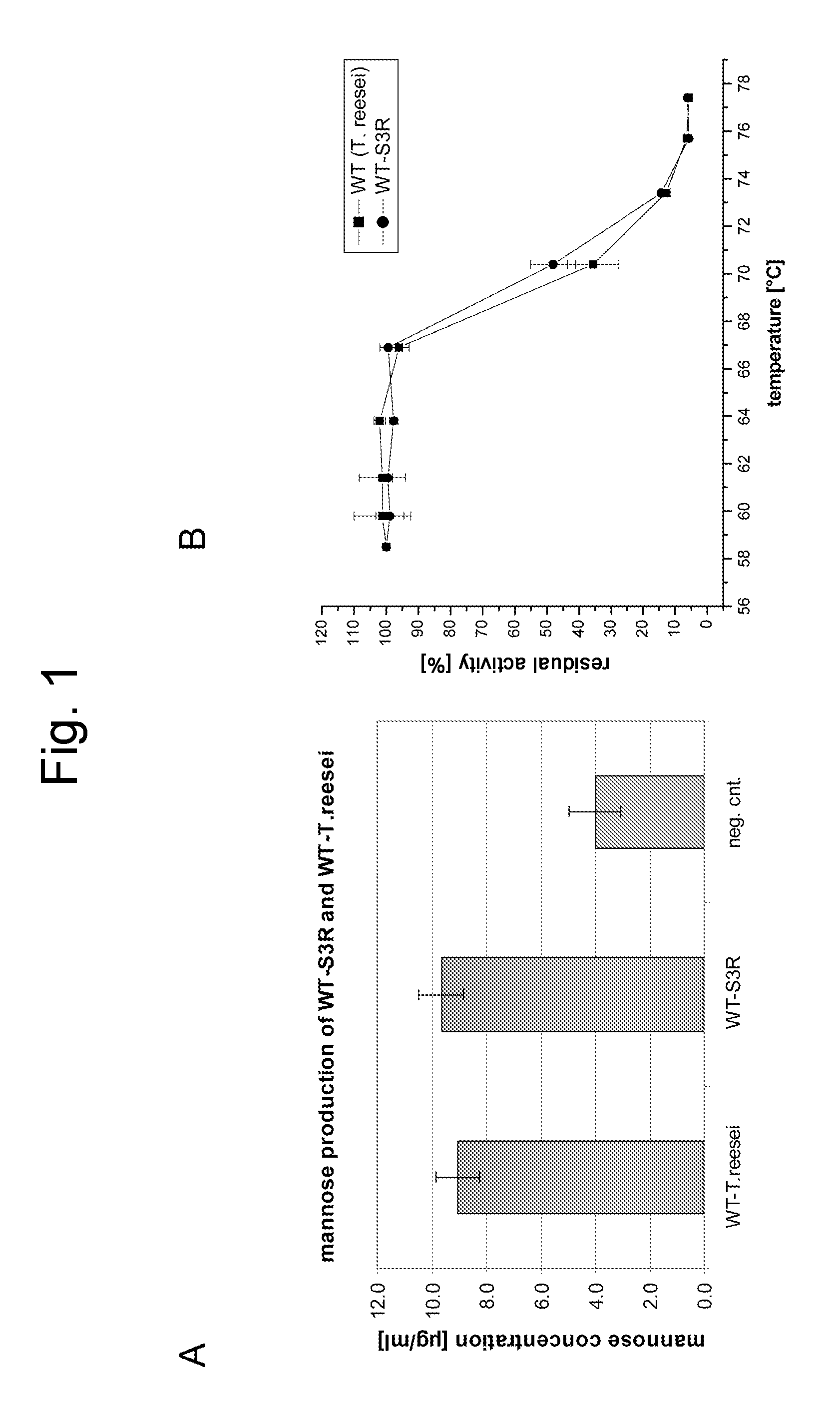

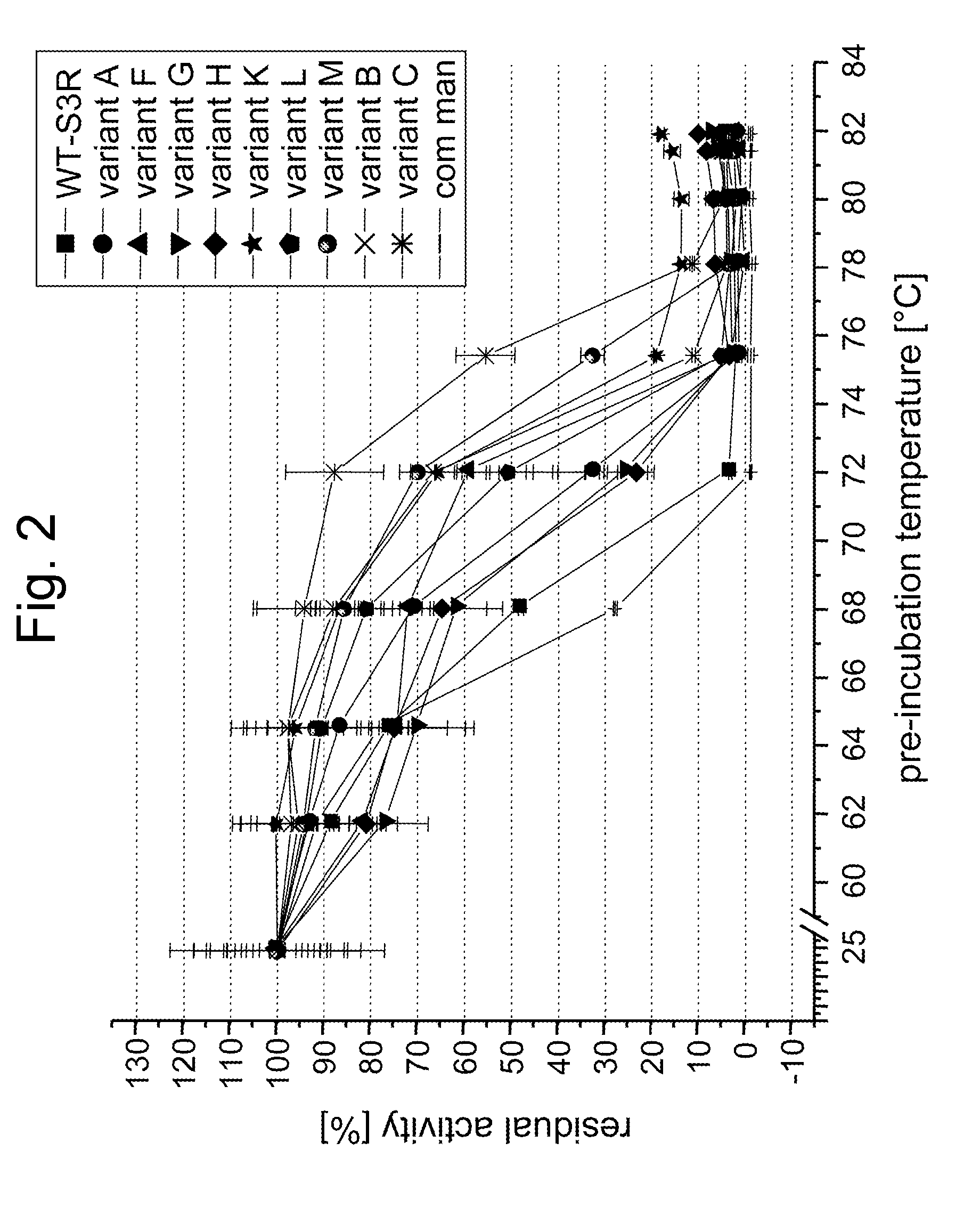

Mannanases

ActiveUS20080064064A1Precise and reproducible enzyme dosagePrevent steppingTissue cultureFlushingBleachWild type

The present invention provides an insertion, deletion and / or substitution mutein of wild-type Trichoderma reesei β-mannanase having enhanced thermostability, proteolytic stability, specific activity and / or stability at low pH, a nucleic acid molecule encoding said mannanase mutein, a composition comprising said mannanase mutein; a method for its preparation, and its use for food and feed processing, for coffee extraction and the processing of coffee waste, as a supplement to food and feed, for enzyme aided bleaching of paper pulps, as bleaching and / or desizing agent in textile industry, for oil and gas well stimulation by hydraulic fracturing, as detergent, for removal of biofilms and in delivery systems, or for the processing of renewable resources intended for the production of biological fuels.

Owner:BASF AG

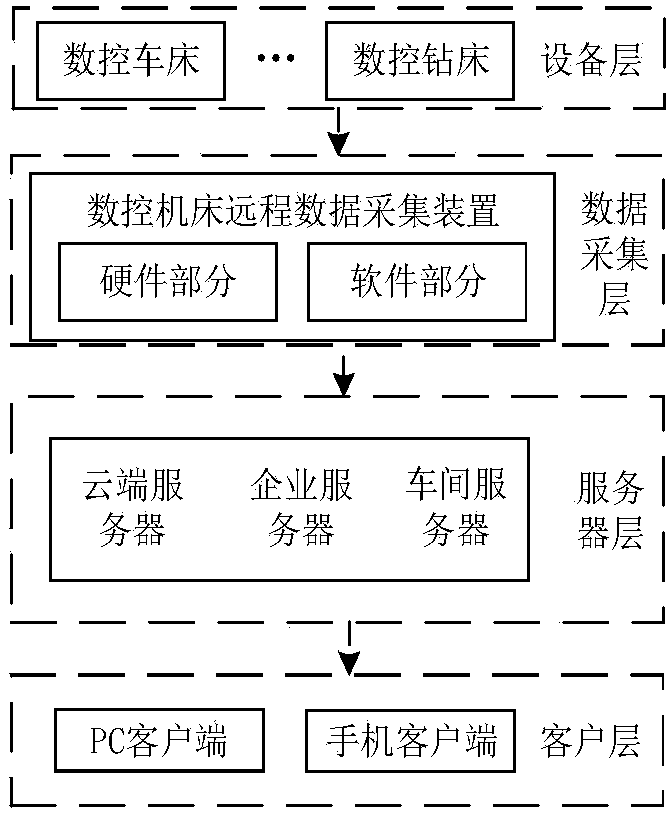

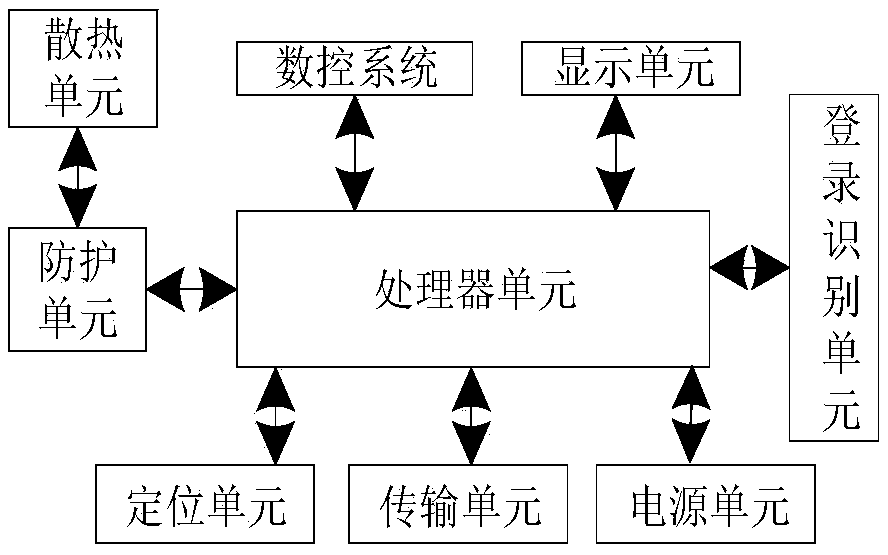

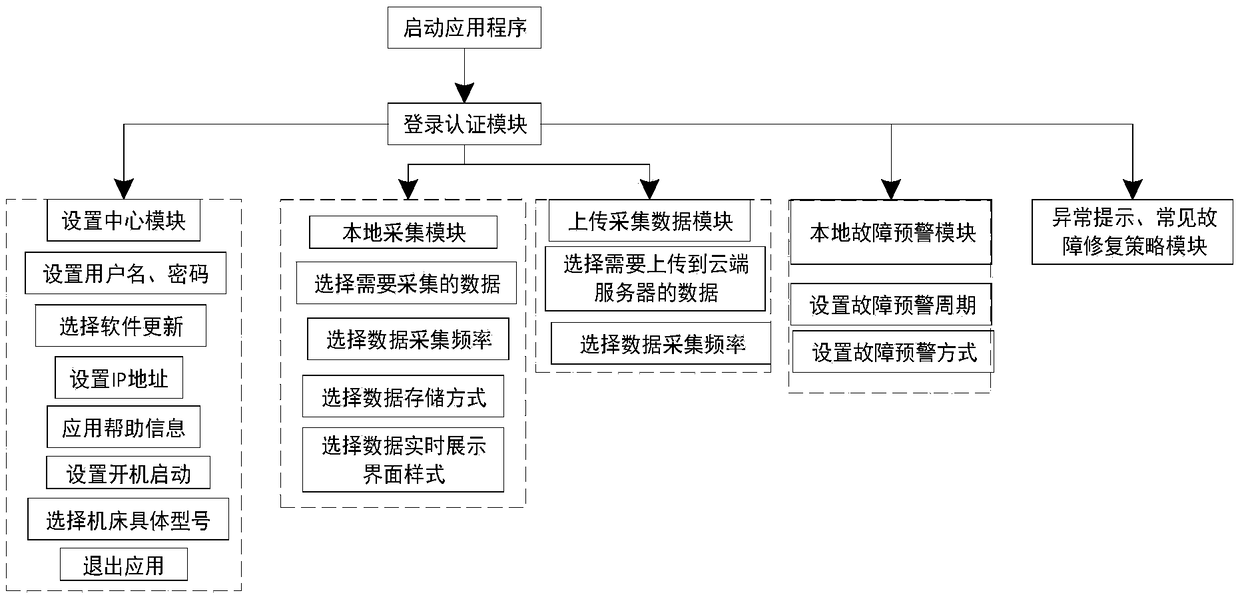

Remote data acquisition and analysis system for numerically-controlled machine tool

PendingCN108762193ARealize remote monitoringRealize remote operation and maintenanceProgramme controlComputer controlNumerical controlData acquisition

The invention discloses a remote data acquisition and analysis system for a numerically-controlled machine tool. The remote data acquisition and analysis system comprises an equipment layer, a data acquisition layer, a server layer and a client layer, wherein the equipment layer comprises the numerically-controlled machine tool; the data acquisition layer comprises a data acquisition device, and the data acquisition device is used for acquiring data of the numerically-controlled machine tool; the server layer is communicated with the data acquisition layer and is used for receiving and processing data transmitted by the data acquisition layer and storing the processed data in a database; the client layer interacts with the server layer to feed processing results of the server layer back toa user.

Owner:JILIN UNIV

Microbial fermented feed and production process thereof

InactiveCN103156057APromote digestion and absorptionImprove digestion and absorption rateAnimal feeding stuffBiotechnologyMicroorganism

The invention relates to the technical field of feed processing and specifically provides a microbial fermented feed and a production process thereof. The microbial fermented feed is composed of 60% by mass of waste stevia rebaudiana residue, 15% by mass of corn flour, 15% by mass of soybean meal and 10% by mass of liquid strains, wherein the liquid strains comprise lactobacillus fermenti, saccharomyces cerevisiae, bacillus subtilis and clostridium butyricum. According to the invention, a plurality of microbes are utilized and scientifically collocated for fermentation of processing waste of stevia rebaudiana, and the microbial fermented feed with the advantages of low cost, a high nutritional value, fragrant flavor and agreeable taste is produced.

Owner:邝素明

Feed blending system

InactiveCN106582369AQuality improvementAvoid stickingRotary stirring mixersTransportation and packagingProcess engineeringScrew conveyor

The invention relates to the field of feed processing machinery and aims to provide a feed blending system which is high in automation level and having mixing and smashing functions. The feed blending system comprises a mixing bin, radius of an upper-end shell of the mixing bin is greater than that of a lower-end shell, a stirring device is arranged in the mixing bin and comprises a stirring shaft, multiple stirring blades are arranged on the stirring shaft from top to bottom, the ends of the stirring blades are connected with a scraping plate, one end of the stirring shaft is connected with a motor, sieve holes are formed in the lower-end shell of the mixing bin, multiple raw material inlets and an additive inlet are arranged on the upper-end shell, a raw material barrel is arranged above a raw material inlet of the mixing bin and communicated with a raw material bin through a conveying pipeline, and a spiral conveyor is arranged at the lower end of the mixing bin. The feed blending system is high in automation level, has the functions of both mixing and smashing and is high in quality of feed blended by the system.

Owner:云南龙谷生物科技有限公司

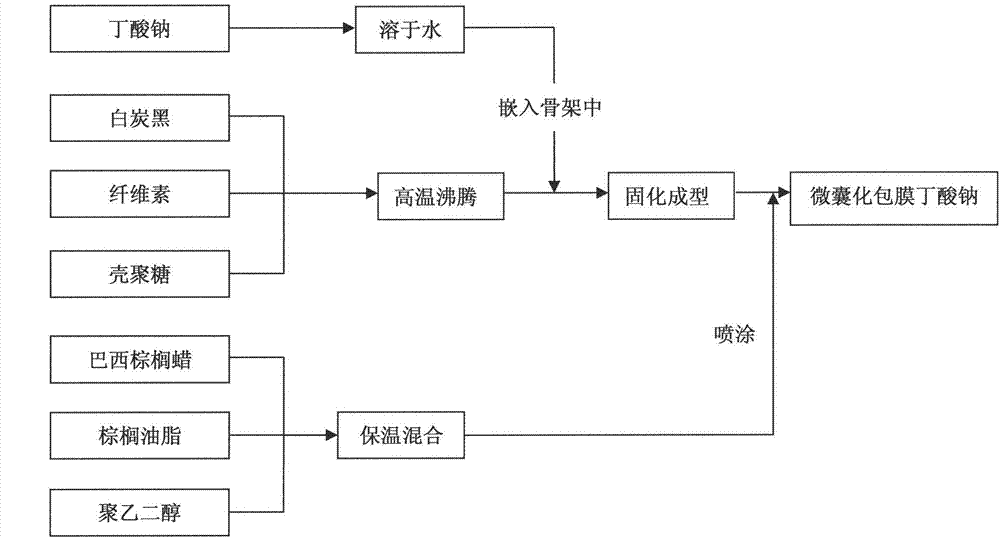

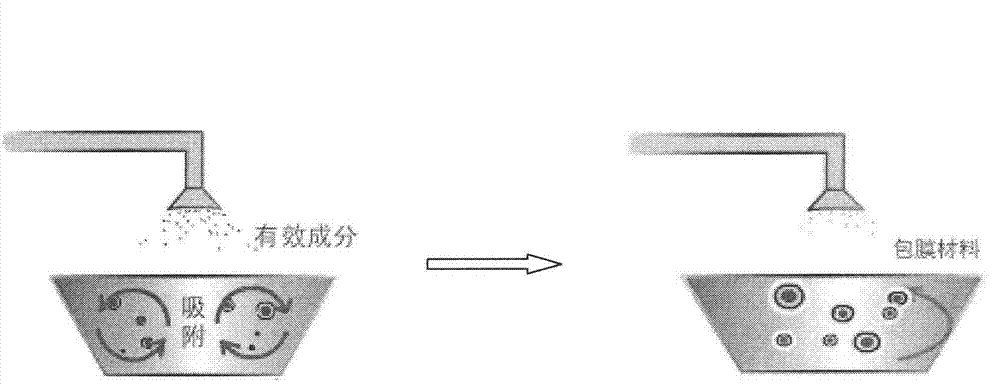

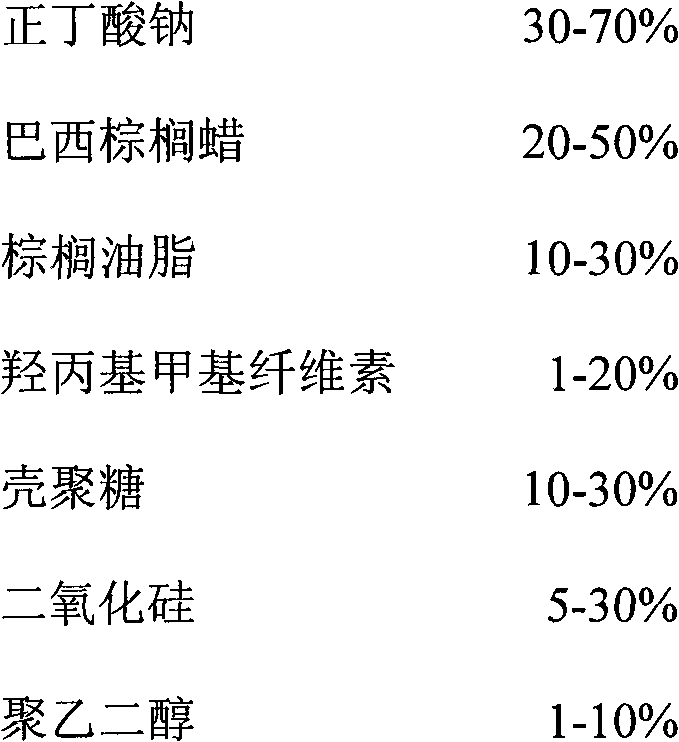

Preparation method of microencapsulation diolame sodium butyrate

ActiveCN103238730ACover up the smellPrevent deliquescenceAnimal feeding stuffLow temperature curingPolyethylene glycol

The invention relates to a preparation method of an animal feed additive microencapsulation diolame sodium butyrate. The method comprises the following steps of: mixing hydroxypropyl methyl cellulose, chitosan and silica, boiling at high temperature of 230DEG C in a fluidized bed; spraying sodium butyrate aqueous solution on a mixture of three materials; drying at a high temperature, solidifying at a low temperature, solidifying and molding sodium butyrate particles; dissolving a coated material Brazil palm wax, palm oil and polyethylene glycol into an organic solvent, carrying out bottom-spraying and coating in a fluidized bed to obtain the evenly-coated sodium butyrate particles of which the mass percent of the sodium butyrate is 30-70%. The microencapsulation process is carried out on feed grade sodium butyrate power to avoid the loss of sodium butyrate in poultry crop and pig stomach, so as to reach the rear section of small intestine and cover the whole intestinal tract, meanwhile, overcomes foul smell, prevents air slaking, and protects sodium butyrate from losing in the process of feed processing.

Owner:HANGZHOU KINGTECHINA FEED CO LTD

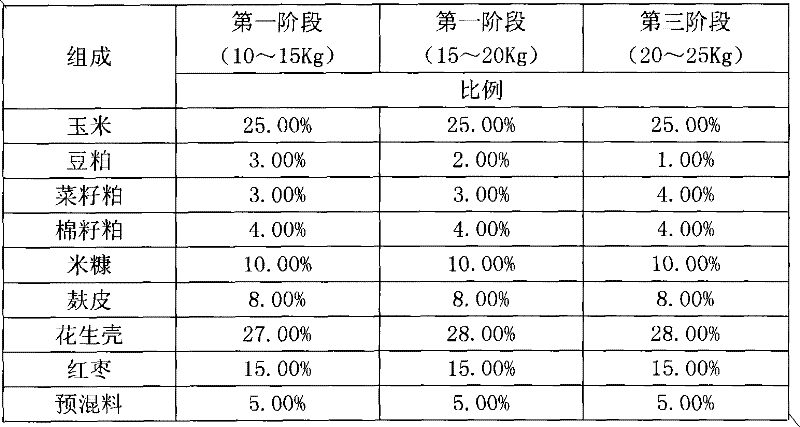

Lamb fattening complete pellet feed

ActiveCN101744107ASimple processing technologyLow costFood processingAnimal feeding stuffAnimal ForagingAnimal science

The invention provides lamb fattening complete pellet feed, which belongs to the field of feed processing in animal husbandry and applies to the intensive complete-barn-feeding production of mutton sheep. According to the nutritional need of lambs in different fattening periods, three types of complete pellet feed are prepared and processed through three formulations in order to satisfy the balanced nutrition supply for weight increase and other aspects except water drinking in a 10 to 15 kg stage, a 15 to 20 kg stage and a 20 to 25 kg stage in a fattening period respectively, so that the factory production of fattening sheep without depending on the conditions of forage grass resources is realized. Due to abundant raw material sources, simple processing technique and low production cost, the pellet feed is beneficial to large-scale commercial production. After application, the pellet feed can ensures that the production of fattening sheep is not restricted to the conditions of natural feed and forage grass resources, and production scale can be adjusted in time according to market demand. Meanwhile, as only one type of pellet geed is used in one fattening stage, more simplified and scientific production process, reliable fattening effect, high production efficiency and low comprehensive cost are ensured.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

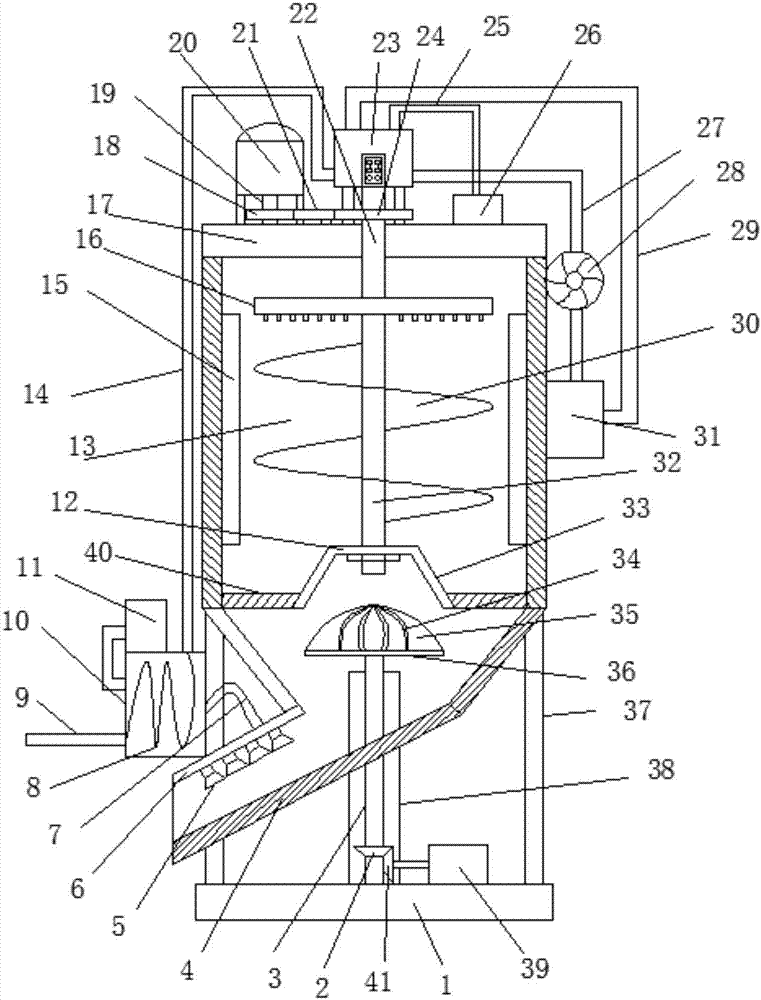

Integrated crushing and drying device for processing pig feed

InactiveCN107319605AHigh efficiency of crushing and dryingDry in timeFeeding-stuffDrying gas arrangementsDrive shaftAgricultural engineering

The invention discloses a crushing and drying integrated equipment for pig feed processing, which comprises a support seat, a support frame is connected to both sides of the upper end of the support seat, a crushing barrel is connected to the upper end of the support frame, and an organic cover is connected to the middle part of the upper end of the crushing barrel. A drive motor is installed on the side, the drive shaft is connected to the lower end of the drive motor, the first pulley is connected to the lower end of the drive shaft, the transmission belt is connected to the right end of the first pulley, the second pulley is connected to the right end of the drive belt, and the middle part of the second pulley is connected to the There is a hollow shaft, the lower end of the hollow shaft is connected with a rotating disc, the middle part of the lower end of the rotating disc is connected with a crushing shaft, the upper middle part of the machine cover is equipped with a condensation box, the lower part of the crushing barrel is connected with a cutting plate, and the middle part of the cutting plate is provided with a fixed sleeve to fix The middle part of the cover is connected with a distribution shaft, and the left end of the left support frame is fixed with a cold air box. The invention realizes the timely drying of the feed after the feed is pulverized, increases the processing efficiency, and satisfies the needs of large-scale feed processing.

Owner:赖高生

Microbial lysozyme microcapsule as well as preparation and application of microbial lysozyme microcapsule

InactiveCN103005168ARetain activityAddressing drug resistanceAnimal feeding stuffFreeze-dryingAquatic animal

The invention relates to the fields of microorganism preparations and aquaculture, and discloses a lysozyme microcapsule. The microbial lysozyme microcapsule is prepared by the following steps of: (1) dropping a mixing solution of sodium alginate and lysozyme into an acetic acid solution containing chitosan and calcium chloride, and stirring; (2) after dropping, curing for 0.5-4hours, and taking and washing a solid to obtain lysozyme / sodium alginate / chitosan beads; and (3) pre-freezing the lysozyme / sodium alginate / chitosan beads, and freeze-drying. The microcapsule disclosed by the invention is used for preparing fish feed, and is capable of reserving comparatively high activity of the microbial lysozyme after being extruded at the high temperature in the feed processing; in the process of conserving at normal temperature, the stability of the microbial lysozyme can be kept for more than half an year; and in feeding and breeding, the microbial lysozyme can bear the strong acid and digesting environment in the stomach of the aquatic animal, release in the intestinal tract and develop an effective growth-promoting healthcare effect.

Owner:SHANGHAI OCEAN UNIV

Preparation method and application of rice hull/straw feed additive

InactiveCN103431174ANutritional supplementsImprove palatabilityFood processingAnimal feeding stuffMaterials preparationAnimal science

The invention discloses a preparation method and an application of a rice hull / straw feed additive and relates to the technical field of feed processing in poultry breeding. The rice hull / straw feed additive is prepared from rice hull / straw, corn, soybean meal, composite enzyme and oily bran. A preparation process of the rice hull / straw feed additive comprises material preparation, pre-treatment on rice hull / straw, ammonification, puffing, treatment by biological enzyme, drying and sterilizing. The rice hull / straw feed additive has the characteristics that the rice hull / straw feed additive can be digested and absorbed by poultry such as chicken and duck and chicken and duck feed prepared by applying the rice hull / straw feed additive is strong in disease resistance, low in feeding cost and complete in nutrition. The prepared rice hull / straw feed additive is feed, can be used for feeding poultry, livestock and herbivorous animals and can be also used for preparing feed for poultry, livestock and herbivorous animals; the prepared rice hull / straw chicken (duck) feed is applicable to feeding middle chickens, big chickens and ducks in a breeding period.

Owner:SHUNKANG ECOLOGICAL AGRI DEV CO LTD

Multiple smashing device for feed processing

InactiveCN105728161AImprove crushing effectReasonable structural designGrain treatmentsPyramidFeed processing

A multiple pulverizing device for feed processing includes a casing, a rotating shaft is vertically arranged in the casing, the top of the rotating shaft is connected with a motor located above the casing, and the upper part of the rotating shaft is provided with a number of pulverizing bodies, the The pulverizing body is in the shape of a triangular pyramid. There are pulverizing blades on the sides of the pulverizing body. A filter screen is arranged below the pulverizing blade. The filter screen is fixedly connected with the inner side wall of the shell. The bottom of the filter screen is provided with a deflector, the deflector is in the shape of a funnel, a sleeve is arranged below the outlet of the deflector, and a rotating roller is arranged on the rotating shaft of the upper half of the sleeve. Several crushing protrusions are evenly arranged on the outer side wall of the rotating roller. The beneficial effect of the invention is that after the material is crushed multiple times, the crushing effect is further improved; the device has a reasonable structure design, simple operation and great popularization and application value.

Owner:杨露萍

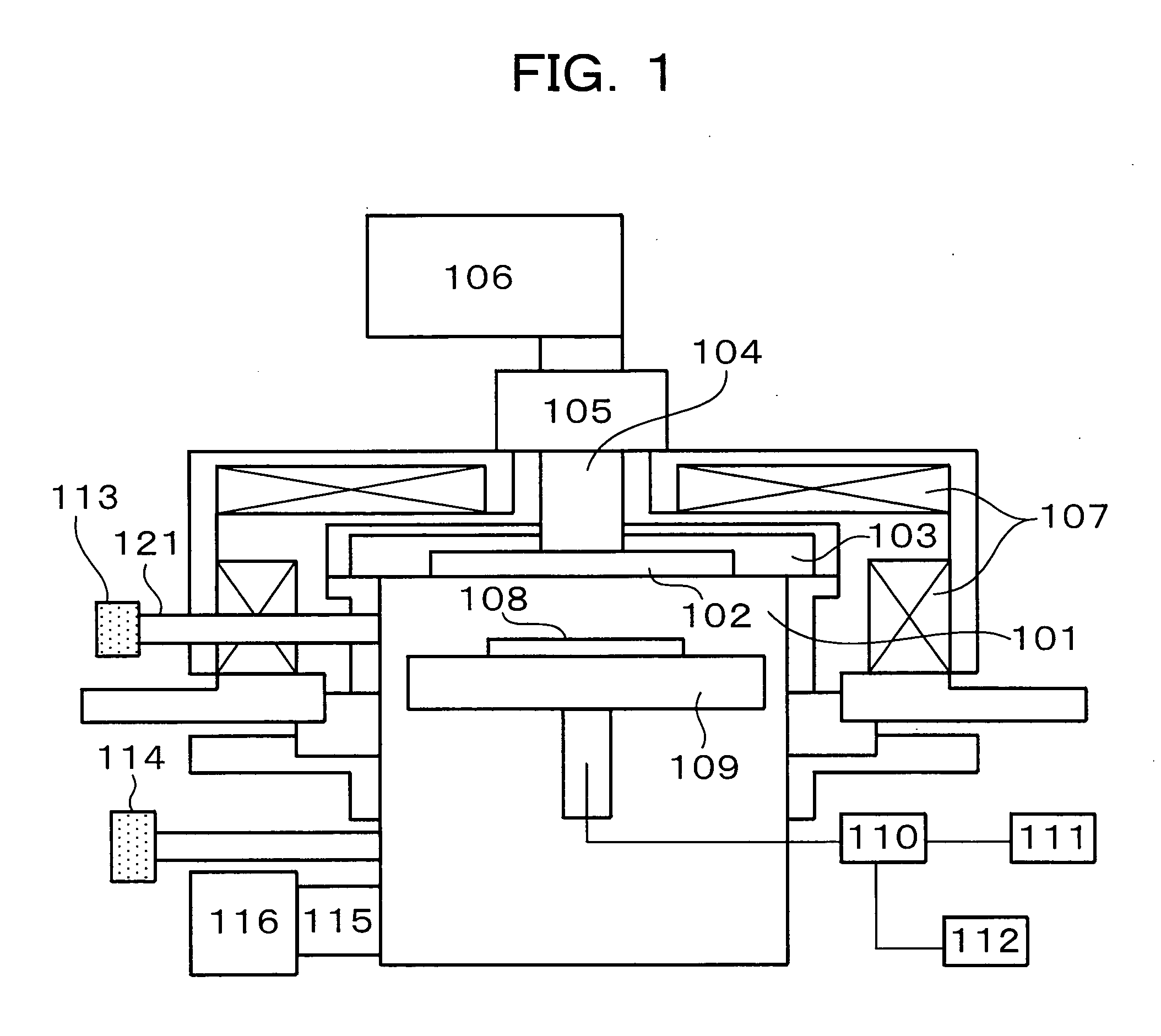

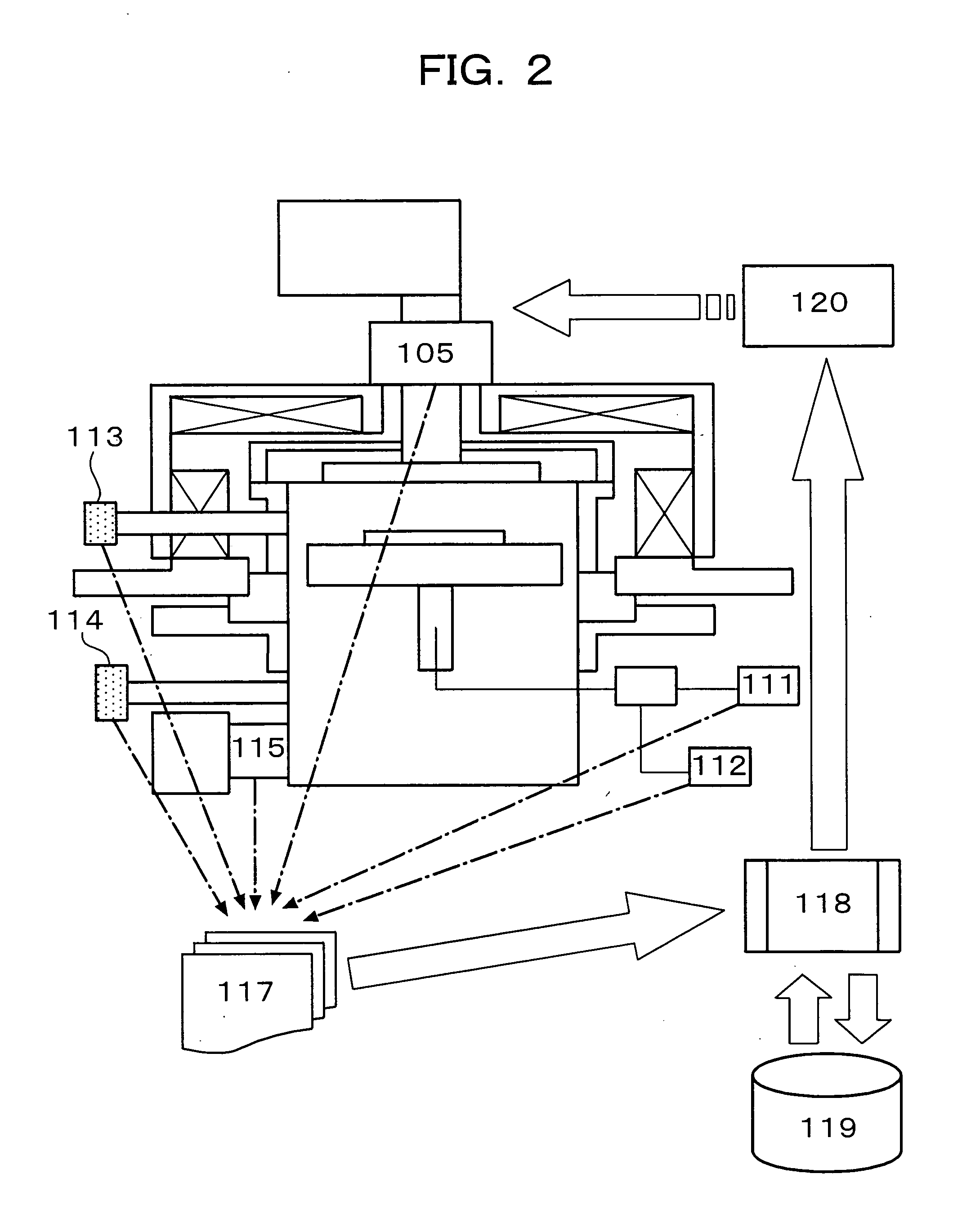

Plasma processing method and apparatus

InactiveUS20070281478A1Improve accuracyElectric discharge tubesVacuum gauge using ionisation effectsInternal pressureEngineering

Plasma processing of plural substrates is performed in a plasma processing apparatus, which is provided with a plasma processing chamber having an antenna electrode and a lower electrode for placing and retaining the plural substrates in turn within the plasma processing chamber, a gas feeder for feeding processing gas into the processing chamber, a vacuum pump for discharging gas from the processing chamber via a vacuum valve, and a solenoid coil for forming a magnetic field within the processing chamber. At least one of the plural substrates is placed on the lower electrode, and the processing gas is fed into the processing chamber. RF power is fed to the antenna electrode via a matching network to produce a plasma within the processing chamber in which a magnetic field has been formed by the solenoid coil. This placing of at least one substrate and this feeding of the processing gas are then repeated until the plasma processing of all of the plural substrates is completed. An end of seasoning is determined when a parameter including an internal pressure of the processing chamber has become stable to a steady value with plasma processing time.

Owner:HITACHI HIGH-TECH CORP

Nutrition type composite premix compound for improving pork quality

InactiveCN101380063AReduce incidenceReduce stressAnimal feeding stuffAccessory food factorsAnti stressTrace element

The invention discloses a formulation of a nutritional type compound premix for improving pork quality and a production technique and essentially relates to the field of animal nutrition and feed processing. The formulation contains vitamins, synthetic amino acids, electrolyte, trace elements, magnesium agent and accessories. The production technique, in which all ingredients are prepared into uniform mixture by premixing and blending, is simple and stable. In accordance with safe nutrition strategy, the formulation is completely composed of nutrient substances which do no harm to the health of animals and the human beings at all. The formulation can quickly supplement various nutritional anti-stress substances, thus effectively alleviating or eliminating stress of various causes and greatly improving meat quality. Furthermore, the using method is simple and flexible.

Owner:COFCO BEIJING FEED TECH +2

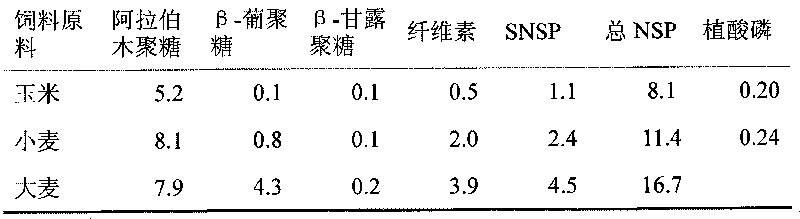

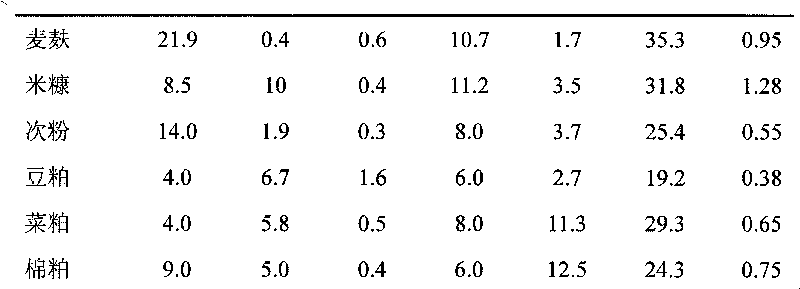

Exogenous composite enzyme preparation special for feed industry and preparation method and application thereof

InactiveCN101735992AWide range of actionEasy to useHydrolasesMicroorganism based processesPhytasePhytic acid

The invention relates to an exogenous composite enzyme preparation special for feed industry and a preparation method and application thereof. The composite enzyme preparation comprises five kinds of water-soluble non-starch polysaccharide enzyme and phytase, namely xylanase, dextranase, mannose, cellulase and pectase. The activity mixture ratio of the contained water-soluble non-starch polysaccharide enzyme to the contained phytase is designed according to the kinds and the contents of the non-starch polysaccharide and the phytase in raw materials of a common feed, the synergistic effect between two kinds of the enzymes can be fully achieved, and the most scientific and economic mixture ratio is provided. The exogenous composite enzyme preparation can improve the degradation efficiency of non-starch polysaccharide anti-nutritional factors and phytic acid in the feed, remove the anti-nutritional effect thereof, improve the absorption and conversion rate of the feed and the utilization rate of phosphorus in the feed, substantially reduce the dosage of inorganic phosphorus and the production cost, bring considerable economic benefit to feed processing enterprises and farmers, greatly reduce the contents of nitrogen and phosphorus in animal excrement so as to reduce environmental pollution, and has remarkable social benefit.

Owner:上海国龙生物科技有限公司

Ecologic turtle feed

InactiveCN103141674AMeet growth requirementsGrow fastAnimal feeding stuffBiotechnologyEffective microorganism

The invention discloses an ecologic turtle feed. The ecologic turtle feed is characterized by selecting fresh wild trash fish, snail and clam, pork liver, earthworm, carrots, bean cake, wheat, astragalus mongholicus, medlar, spirulina powder, multi-vitamin, mineral salt and EM (effective microorganisms) as raw material. A feed processing method is as follows: respectively pulping the fresh trash fish, the snail and clam, the pork liver, the earthworm and the carrots into slurry through a beater, sieving the slurry through a 80-mesh sieve tulle, respectively crushing the bean cake, the wheat, the astragalus mongholicus and the medlar into powder through a crusher, sieving through a 80-mesh sieve tulle, mixing the slurry and the powder with the spirulina powder, the multi-vitamin, the mineral salt and the EM according to a proportion, completely and uniformly stirring to prepare a dough wet feed, and feeding the feed to the turtle. According to the ecologic feed disclosed by the invention, the meat quality of the turtle is improved, the formulation design is scientific, raw material can be easily available, processing and feeding are convenient, the fast growth of the turtle can be promoted and the wild taste of the turtle is kept.

Owner:杨成胜

Edible mushroom residue feed preparation process

InactiveCN104171759AHigh economic valueSolve UtilizationAnimal feeding stuffNutritive valuesSecondary metabolite

The invention discloses edible mushroom residue feed and a preparation method thereof. The edible mushroom residue feed preparation method comprises the following steps: degrading active ingredients of mushroom residue through a complex enzyme and fermenting a mushroom residue enzymolysis product through food-grade microorganisms, further degrading the active ingredients of the mushroom residue and releasing a functional secondary metabolite, and drying or spray-drying a fermentation product to obtain the edible mushroom residue feed which is intense in edible mushroom-featured flavor and easy in nutrient absorption, and has an antioxidant activity and an antibacterial activity. According to the preparation process disclosed by the invention, active ingredients in the mushroom residue raw material are degraded into polysaccharide, oligosaccharide, protein peptide and the like stronger in specific functional characteristics by the complex enzyme through a green biotechnology, and microorganism mixed fermentation is carried out to further generate beneficial secondary metabolite so as to improve antioxidant activity and antibacterial activity of the fermented product, thus improving the additional value of the product. The preparation process disclosed by the invention, breaking through a conventional mushroom residue feed processing technology, overcomes the shortcomings of the mushroom residue feed processing technology (direct material mixing or conventional simple fermentation), such as low mushroom residue utilization rate, low utilization rate of nutritive value and poor functionality, by organically combining biological enzymolysis and biological fermentation, and the economic value of the edible mushroom residue in the field of animal feed is obviously improved.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

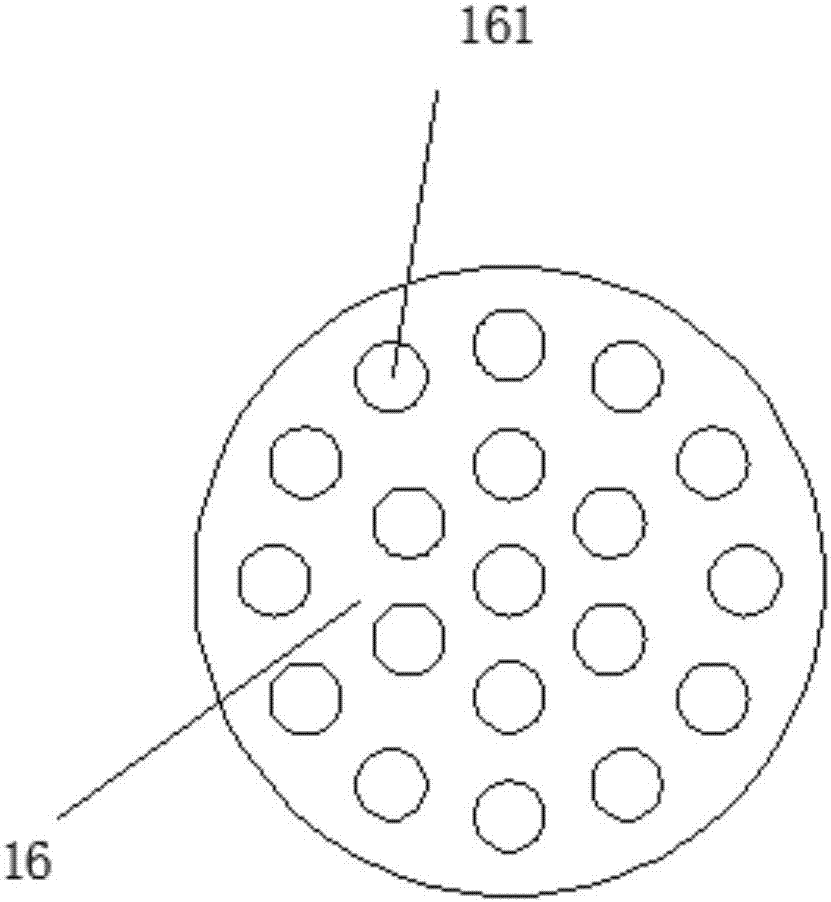

Feed extruding and granulating device for livestock feed processing

InactiveCN108654515AImprove the extrusion effectImprove work efficiencyFeeding-stuffGranulation by material expressionReciprocating motionEngineering

The invention discloses a feed extruding and granulating device for livestock feed processing. The feed extruding and granulating device is characterized in that a support rack is vertically fixedly mounted on a bottom plate, a limit extruding cylinder is fixedly mounted on the support rack, a slider is horizontally slidably arranged in the limit extruding cylinder, a slide plate is horizontally fixedly mounted at the left top end of the slider, the upper surface of the slide plate is abutted against the inner side of the limit extruding cylinder, and a feeding channel is vertically formed inthe slide plate; an air heater is fixedly mounted at the bottom of the bottom plate, and a collecting tank located at the right bottom of a conveying belt is fixedly mounted on the bottom plate. The feed extruding and granulating device has the advantages that feed intermittently enters the limit extruding cylinder is extruded into strip-shaped feed through extruding holes by the leftward and rightward reciprocating movement of the slider, and a good extruding effect and high work efficiency are achieved; the strip-shaped feed is repeated cut by a cutting blade which moves leftwards and rightwards in a reciprocating manner to achieve feed granulation, the feed is fast dried through hot air rightwards discharged by an exhaust mesh cover, feed adhesion is avoided, and the quality of feed granules is increased greatly.

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

Ruminant animal fat powder and preparation process thereof

InactiveCN102948652AIncrease energy concentrationDoes not affect fermentationAnimal feeding stuffBiotechnologyPhospholipid

The invention belongs to the field of feed processing and particularly provides ruminant animal fat powder. The ruminant animal fat powder is prepared by matching hexadecanoic acid, high-melting-point palm oil, soybean concentrated phospholipids and the like as main fat raw materials with a carrier. The ruminant animal fat powder has no influence on normal physiological activity of microflora in ruminant animal rumen, can pass through the rumen, can be converted into an absorbed form under the actions of chemistry and enzyme in abomasums and duodenum of a digestion system and is digested, absorbed and utilized by small intestine. The product prepared by a formula and a processing technique of the invention is favorable in flowing property and can be mixed to the feed by adopting corresponding dosage stirring according to the requirement of animal nutrition; and the product is convenient and practical and is convenient for storage and transportation.

Owner:SHANDONG ZHONGDA ANIMAL HUSBANDRY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com