Patents

Literature

325 results about "Do no harm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional high-efficiency thermal insulation insulating mold paint

The invention relates to a multifunctional high-efficiency heat-preservation heat-insulation coating material. The compositions in percentage by weight of the coating material are: 10 to 20 percent of water, 0.1 to 0.2 percent of multifunctional auxiliary agent, 0.1 to 0.2 percent of wetting agent, 0.5 to 0.8 percent of dispersing agent, 0.3 to 0.5 percent of antifoam agent, 1.5 to 3.0 percent of propylene glycol, 16 to 20 percent of rutile-type titanium pigment, 3 to 5 percent of mica powder, 6 to 8 percent of hollow glass microballoon, 3 to 5 percent of infrared powder, 3 to 4 percent of fire retardant, 35 to 40 percent of elastic acrylic acid emulsion, 3 to 5 percent of opaque polymer, 0.5 to 0.8 percent of film-forming auxiliary agent, 0.2 to 0.3 percent of bactericide and preservative and 0.3 to 0.6 percent of thickening agent. The multifunctional high-efficiency heat-preservation heat-insulation coating material is of aqueous monocomponent and does no harm to human body and the environment so as to be an environment-friendly product; meanwhile, the coating material also has excellent waterproof and fire-retardation functions, convenient and quick construction, excellent adhesion strength, outstanding crack resistance, infrequent pollution and service life as long as 15 years; moreover, during practical use, the coating material can effectively reduce solar heat accumulated in a house by approximately 8 to 15 DEG C, and can greatly reduce energy consumption.

Owner:董善刚

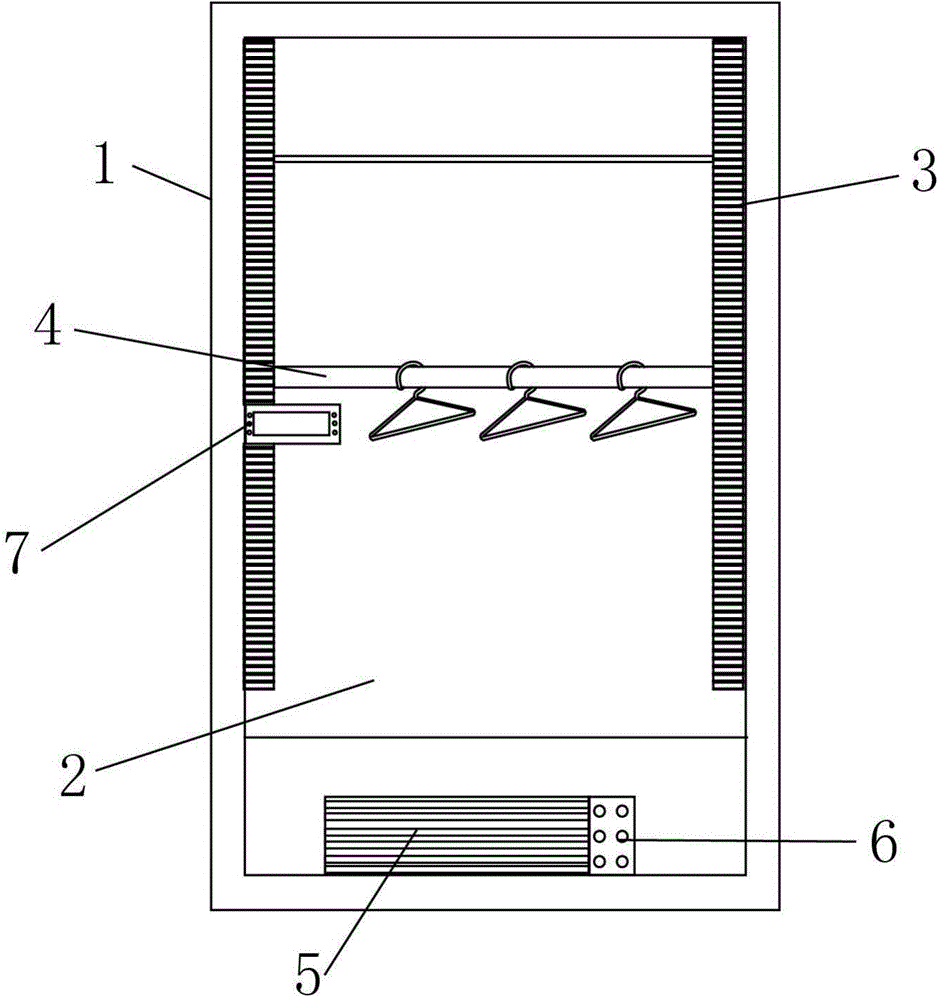

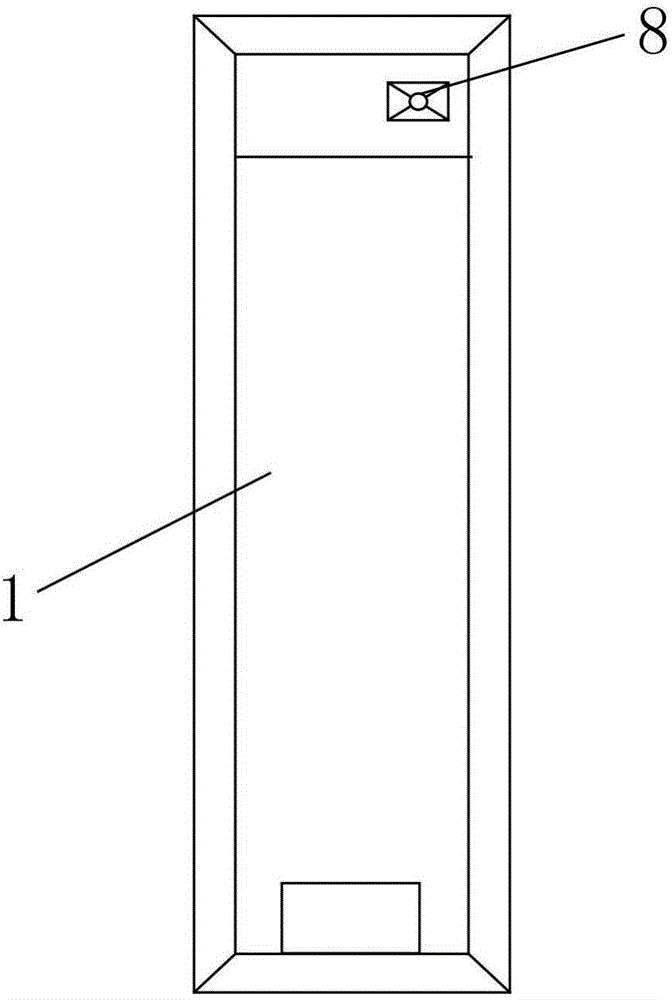

Intelligent dryer

InactiveCN104695187AAvoid harmDisinfect thoroughlyDisinfectionTextiles and paperOzone generatorProcess engineering

The invention provides an intelligent dryer which comprises a cabinet, a door, lifting tracks, a clothes airing bar, a heating component, an ozone generator and a control panel, wherein the door is arranged on the front surface of the cabinet, the lifting tracks are arranged on both the inner walls of the left side and the right side of the cabinet, and the clothes airing bar is arranged between the two lifting tracks and can slide up and down; the heating component and the ozone generator are adjacently arranged at the bottom of the cabinet, and the control panel is arranged on the door and used for controlling the heating temperature and the lifting of the clothes airing bar. The intelligent dryer has the advantages and active effects that the heating component generates heat needed for drying clothes; the height of the clothes airing bar is adjustable, the position of the clothes airing bar can be adjusted according to the clothes with different lengths, and multiple clothes can be simultaneously hung on the clothes airing bar; the ozone generator can disinfect the clothes in the clothes drying process, has no dead angle and does no harm to human body.

Owner:天津市东丽区腾飞静电喷涂厂

Nutrition type composite premix compound for improving pork quality

InactiveCN101380063AReduce incidenceReduce stressAnimal feeding stuffAccessory food factorsAnti stressTrace element

The invention discloses a formulation of a nutritional type compound premix for improving pork quality and a production technique and essentially relates to the field of animal nutrition and feed processing. The formulation contains vitamins, synthetic amino acids, electrolyte, trace elements, magnesium agent and accessories. The production technique, in which all ingredients are prepared into uniform mixture by premixing and blending, is simple and stable. In accordance with safe nutrition strategy, the formulation is completely composed of nutrient substances which do no harm to the health of animals and the human beings at all. The formulation can quickly supplement various nutritional anti-stress substances, thus effectively alleviating or eliminating stress of various causes and greatly improving meat quality. Furthermore, the using method is simple and flexible.

Owner:COFCO BEIJING FEED TECH +2

Process for preparing rubber and clay nano composites by using pre-expanded organic clay

This invention is a method of preparing rubber and clay nanometer compound material with pre-expand organic clay. Pre-expand organic clay is got by quality ratio 1:1 of organic solution and organic clay. Rubber and clay nanometer compound material is got by pre-expand organic clay and rubber and addition agent mixing. The organic solvents are toluene, oleic acid, castor oil or normal butyl alcohol. 3~7 quality portions of pre-expand organic clay is added into 100 portions rubber. The organic solvent dosage is few, and organic solvent that does no harm to human body and environment can be used. The operation method is simple, and easy to industrial generation.

Owner:BEIJING UNIV OF CHEM TECH

Method for treating nuclear waste water and device thereof

InactiveCN101567227AEasy to handleReduce pollutionRadioactive decontaminationWater/sewage treatment by flocculation/precipitationOcean bottomWater discharge

The invention discloses a method for treating nuclear waste water, which comprises the following steps: super absorbent resin with a mass ratio of 1 to 5 percent is directly added to the nuclear waste water concentrated by a chemical precipitation method; the mixture is stirred so as to jellify the nuclear waste water; loose woolen particles and a chemical flocculating agent obtained by filtering the nuclear waste water concentrated by the chemical precipitation method together with the nuclear waste water gel are transferred to an impermeable and radiation-proof cement groove; pressure is applied to deform the gel into the shape of the inner cavity of the cement groove and a layer of cement powder is arranged on the surface of the gel; pressure is applied again to cause part of water in the gel to exude out of the gel and enter the cement power layer to solidify the cement powder; a layer of water-proof, impermeable and leakage-proof coating is painted firstly and then a layer of radiation-proof coating is painted; a cement cover is positioned at the top end of the cement groove to obtain a sealed cement groove; the nuclear waste water is stored in the groove in the form of gel; and finally, the sealed groove is transported and buried in a nuclear waste treatment storehouse established in the underground and thick rock mass or the bottom of a sea which is 4000m in depth, thereby doing no harm to human beings and having little pollution on environment. The method can be applied to treating the nuclear waste water discharged by nuclear power plants.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

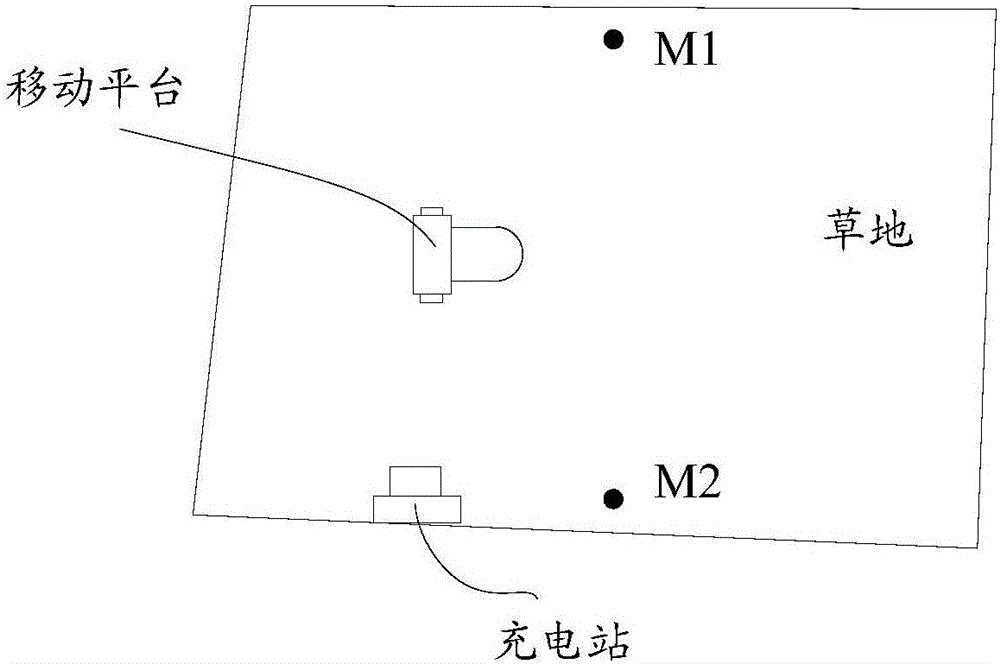

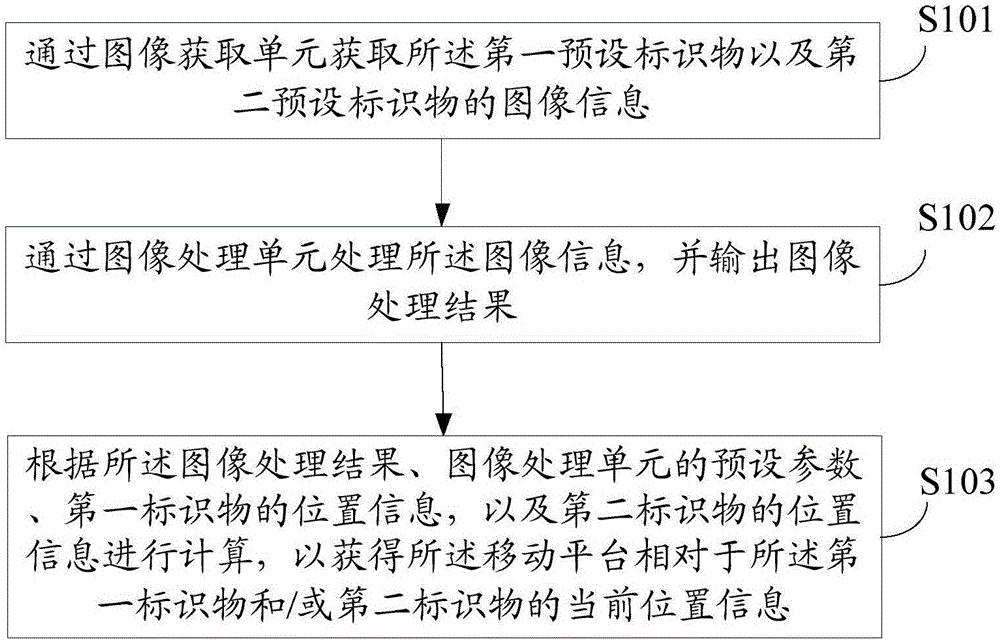

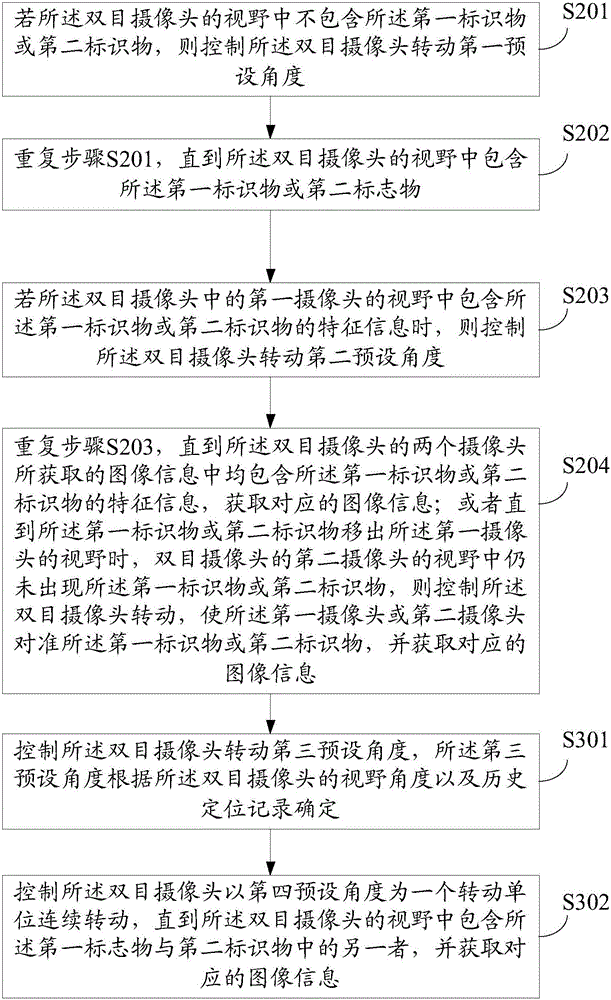

Positioning method, device and system

ActiveCN106851567AAchieve positioningPrecise positioningClosed circuit television systemsLocation information based serviceImaging processingPositioning system

The invention is applicable to the field of mobile robots, and provides a positioning method implemented by a positioning system. The positioning system comprises a mobile platform, and a first marker and a second marker which are preset. The method comprises the following steps: acquiring image information of the first marker and the second marker through an image acquisition unit; processing the image information through an image processing unit, and outputting image processing results; and according to the image processing results, preset parameters of the image processing unit, location information of the first marker and location information of the second marker, carrying out calculation to obtain current location information of the mobile platform relative to the first marker and / or the second marker. The method provided by the invention has the advantages that the mobile platform can be accurately positioned, and the positioning precision is high, so that the mowing efficiency is greatly improved, and the mowing coverage is greatly enlarged; and equipment adopted in the method is low in cost, and does no harm to human bodies, so that high safety is achieved.

Owner:SHENZHEN TOPBAND CO LTD

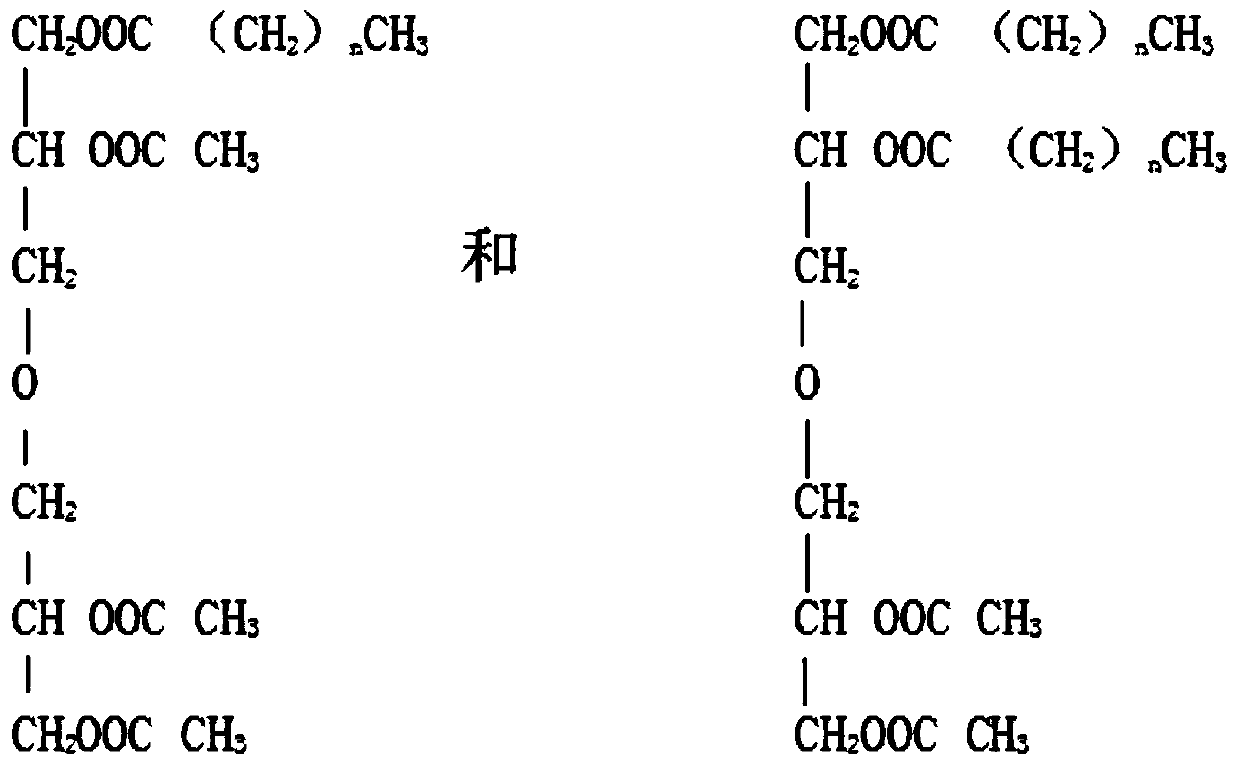

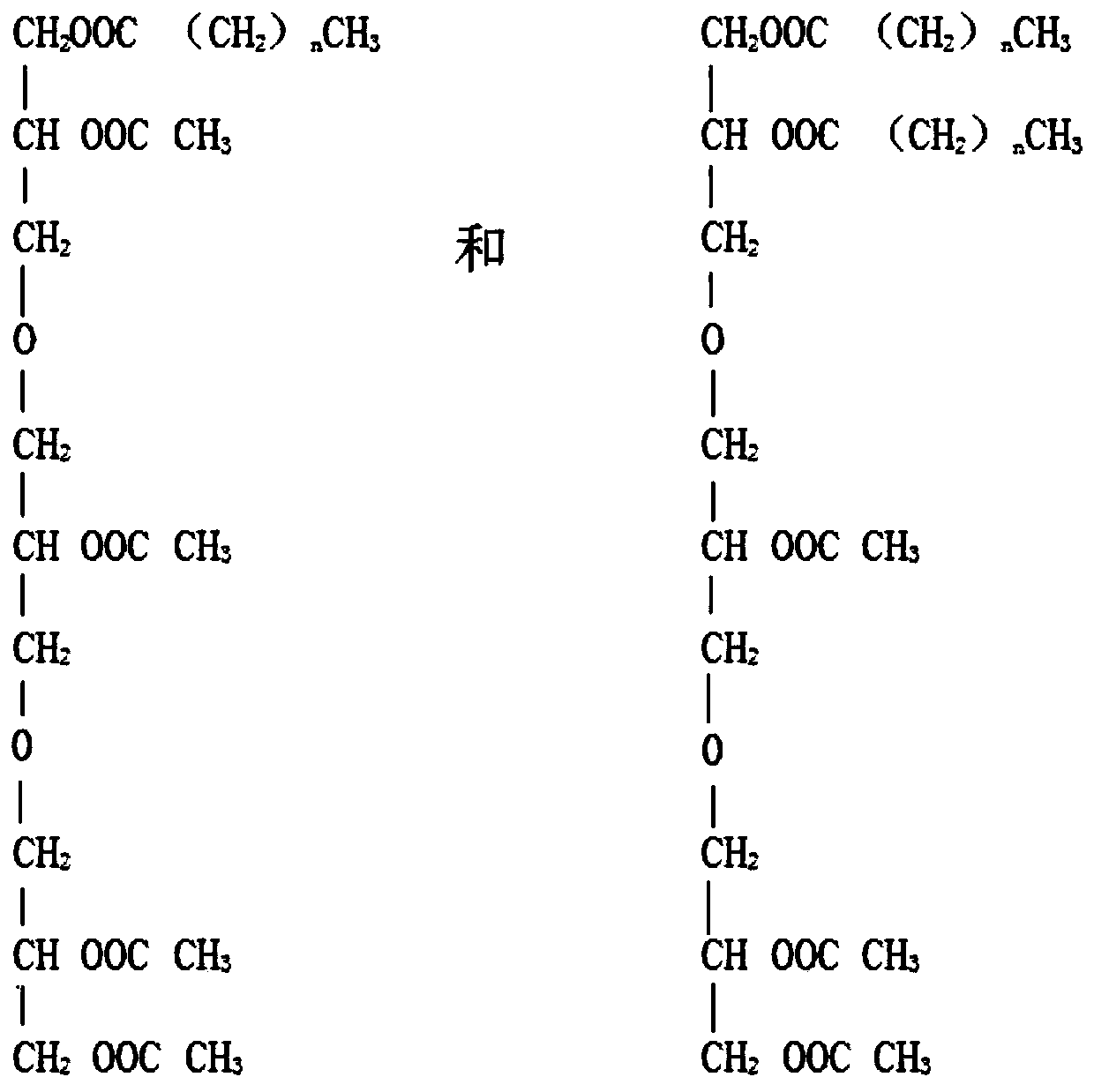

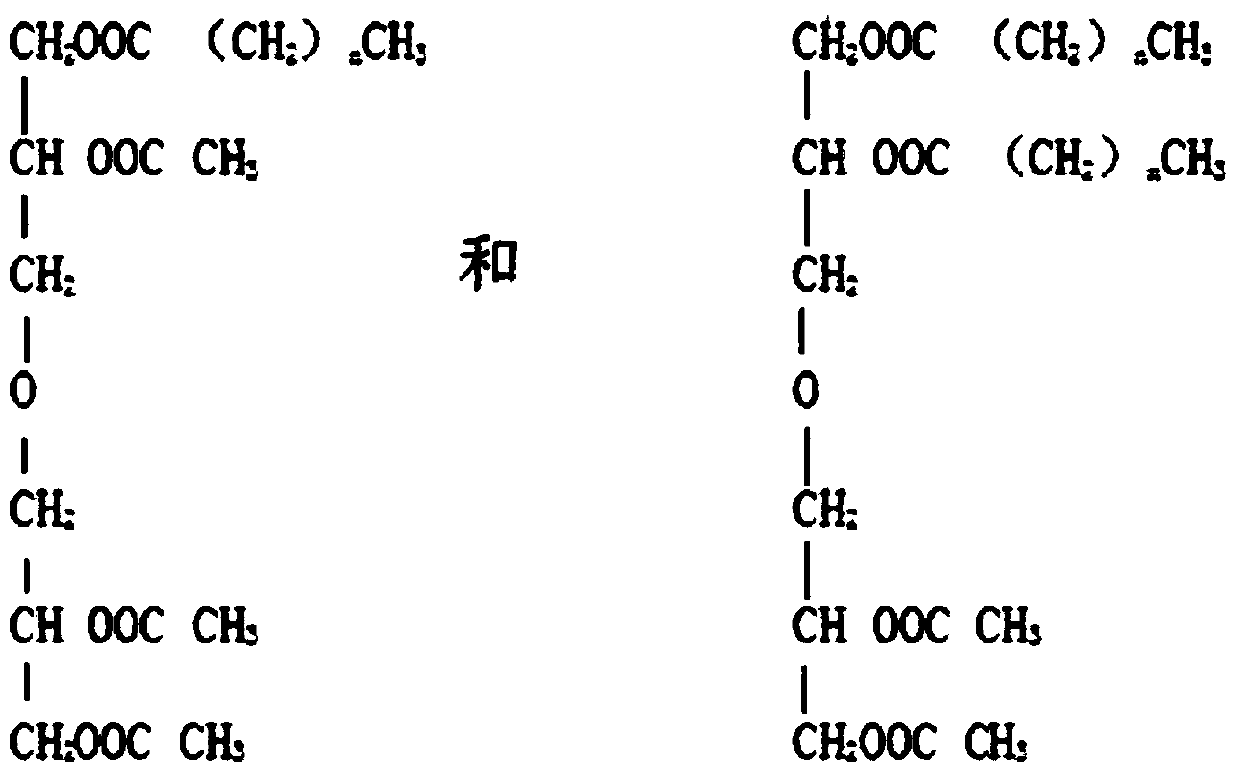

Polyglycerol fatty acid ester plasticizer and preparation method thereof

InactiveCN104177649ALower embrittlement temperatureGood heat and cold resistanceFatty acid esterificationPolymer scienceGlycerol

The invention discloses a polyglycerol ester plasticizer and a preparation method thereof and belongs to the field of plastic additives. According to the invention, an ether bond is intruded, so that a plasticizer molecule not only does not contain a polar ester group but also contains a weak-polarity ether bond, so that polymer glass transition temperature is lowered, and heat resistance and cold resistance are improved. The polyglycerol ester plasticizer takes natural oil as a raw material, does no harm to human body and has high safety as a plasticizer in plastics for food package, medical devices, toys for children and the like; the polyglycerol ester plasticizer also has high biological degradability and high promotional value.

Owner:HENAN ZHENGTONG CHEM

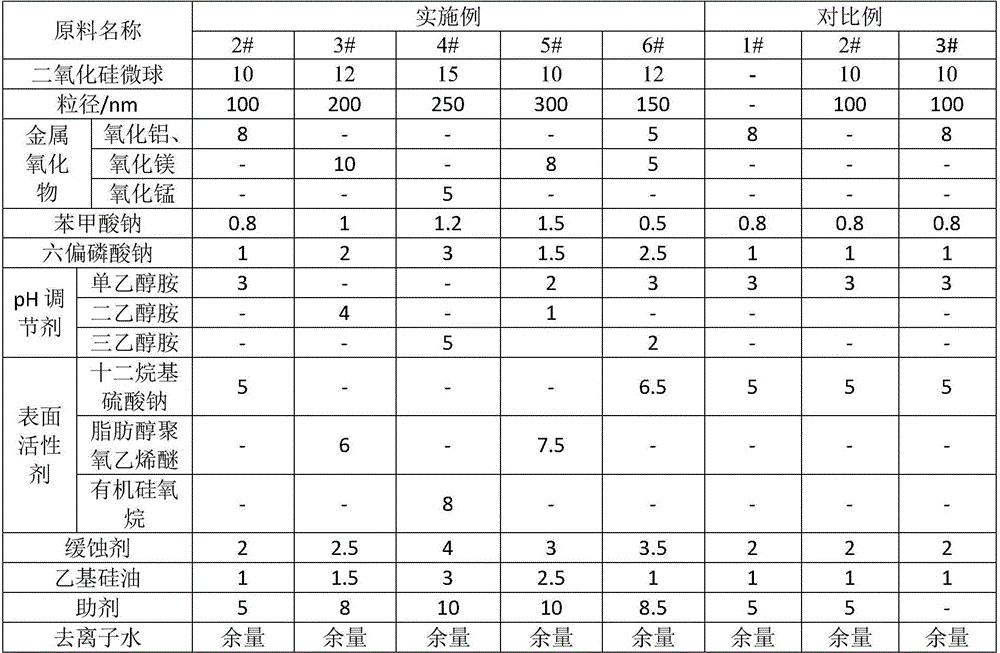

Polishing solution for stainless steel surface machining

InactiveCN106318220AModerate hardnessImprove stress resistancePolishing compositions with abrasivesSurface-active agentsSilicon dioxide

The invention belongs to the technical field of materials, and particularly relates to a polishing solution for stainless steel surface machining. The polishing solution is prepared from, by weight, 10-15 parts of modified silicon dioxide pellets, 5-10 parts of metallic oxide, 0.5-1.5 parts of sodium benzoate, 1-3 parts of sodium hexametaphosphate, 3-5 parts of a pH conditioning agent, 5-8 parts of a surface active agent, 2-4 parts of a corrosion inhibitor, 1-3 parts of ethyl silicon oil, 5-10 parts of auxiliaries and the balance deionized water. The prepared polishing solution is easy to prepare, low in cost, good in polishing effect and high in polishing precision and polishing efficiency, and has the advantages of removing oil stain, resisting rust, being easy to clean and non-toxic, doing no harm to human bodies or environment and being suitable for large-scale production.

Owner:JIANGSU JINYANG STAINLESS PROD

Chinese herbal medicament feedstuff additive for fattening pigs and application thereof

InactiveCN101543267AImprove immunityFormulation ScienceFood processingAnimal feeding stuffDiseaseSide effect

The invention discloses a Chinese herbal medicament feedstuff additive for fattening pigs and application thereof. The additive comprises the following components: atractylodes rhizome, chatoyant, fleece-flower root, unprocessed lumber, hawthorn, medicated leaven, Chinese stractylodes, dried tangerine peel, astragalus, malt and white peony root. Various pertinent components of the additive adopt the strong points of each other and cooperate with each other after compatibility; the obtained additive has the functions of strengthening the stomach and promoting digestion, activating blood circulation and dispersing stasis, ,claming and smoothing the nerves and improving immunity, and effectively promotes the absorption of nutrients to accelerate growth and fattening and enhance pig disease resistance; therefore, the additive can increase the economic benefits of livestock breeding and does not generate side effect and hazardous substance residue, thereby doing no harm to people who eat the pork; moreover, the feedstuff additive has small dosage and does not restrict the growth and the disease resistance of live pigs to ensure that the quality of the pork is obviously better than that of the live pigs fed by the prior feedstuff additive; in addition, the additive increases the average daily gain of the live pigs by 24 to 28 percent as compared with the prior additives, and ensures that the marketing time is reduced by 12 to 16 days, namely fully fattened live pigs can be delivered even less than 100 days.

Owner:邹振可

Process for producing methanesulfonic acid

ActiveCN101219975AEfficient use ofEasy to produceSulfuric acid esters preparationAlkaline earth metalEvaporation

The invention discloses a preparation method for methanesulfonic acid. A water liquor or a solid mixture of a sulfite or a mixture of the sulfite and a bisulfite is reacted with a dimethyl sulfate to generate a methylsulfonate and a sulfate, and the mixture liquor of the reaction directly cools and precipitates a sulfate salt crystallization through concentration by adding a salting-out agent or a concentrated liquor; filtering and removing a dilute-methyl sulfonate liquor of the sulfate; a soluble alkaline earth salt can also be reused as a precipitant for further removing the remained sulfate ion; finally, the purified methylsulfonate liquor is concentrated to pulpiness or dry powder to be acidified by excess concentrated hydrochloric acid or excess hydrogen chloride gas is directly pumped in the purified methylsulfonate liquor to precipitate a sodium chloride crystallization. After filtering, the mixed acid liquor of hydrochloride and methanesulfonic acid can be gotten, which can get the highly-purified methanesulfonic acid after evaporation concentration, vacuum distillation and distillation. The materials of the invention can be gotten easily and the invention has simple techniques and low cost, which does no harm to the environment and is suitable to be used in industry.

Owner:HEBEI YANUO CHEM IND

Pesticide remover

InactiveCN1990850AHigh removal rateNo difference in tasteSoap detergents with organic compounding agentsVitaminBiological materials

The invention relates to a pesticide removing agent. It is characterized in that said pesticide removing agent comprises active calcium oxide 30- 99.99% (by weight), protein 0-50% (by weight) and calcium carbonate 0- 25% (by weight). Said pesticide removing agent takes natural biological material as base, the effective element can absorb pesticide and make the removed pesticide float on the water surface, so the removal rate is as high as more than 80%; the pesticide removing agent does no harm to the vitamin and other nutrient in vegetable and fruits and to the taste, and it has no influence for the storage period of vegetable and fruits.

Owner:谈嘉俊

Environment-protective packaging film and preparation thereof

InactiveCN101298507AExcellent elongation at breakGood flexibilityFlexible coversWrappersCarrageenanTransmittance

An environmental protection packing film of the invention is prepared by konjac glucomannan, carrageenan, glycerine, sucrose fatty acid ester and water; the tensile strength, elongation at break, flexibility and transparency etc. of the invention are superior to like products; and the invention also has advantages of convenient access of materials and low price. The environment protection packing film is non-toxic and does no harm to health even eaten by mistake, thus giving more safety with packing food. Furthermore, transmittance and selectivity are different to different types of gas molecules, selective separation is provided for gases, and oxygen can pass through the film faster than carbon dioxide. The invention is used for packing fruits and vegetables, the proportion of CO2\O2 in the packing bag is gradually increased, which can effectively inhibit respiration of fruits and vegetables and reduce metabolism and senescence.

Owner:FUJIAN AGRI & FORESTRY UNIV

Natural colorful linen

The invention discloses natural color linen, which relates to linen. The linen solves the problems of high production cost, pollution of environment, the residue of the cloth cover boiling bleaching reagent and dye which do harm to the health of users as well as high weight-loss ratio of the fabric. The problems are caused by that the current conventional flax pure cloth, the flax cotton blended cloth and the flax interwoven fabric are dyed with dye so as to obtain needed colors, and boiling bleaching is carried out to obtain good white substrate which is needed when dyeing The natural color linen is made of rescutched tow. The natural color linen is made of 10-90% of rescutched tow and 10-90% color cotton fiber according to the weight percentage. The natural color linen is made of 10-88% of rescutched tow, 10-88 % color cotton fiber and 2-50 % of mucilage glue, tencel yarns or true silk. The invention is not dyed, has low production cost, does no harm to the health of users, has low weight-loss ration, and does not pollute the environment.

Owner:黑龙江圆宝纺织股份有限公司

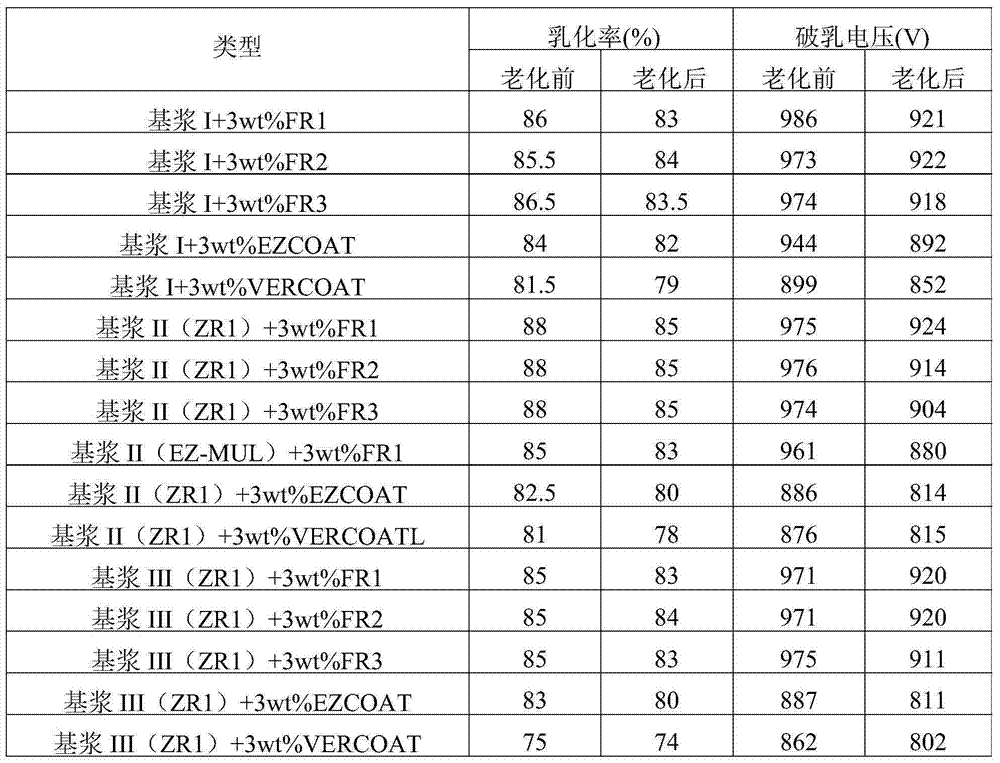

Co-emulsifier and preparation method therefor, emulsifier composition and application thereof, and oil-based drilling fluid

ActiveCN105441039AGood emulsifying effectNo fluorescenceDrilling compositionFluorescenceSystem stability

The present invention relates to the field of drilling fluid, and discloses a co-emulsifier and a preparation method therefor, an emulsifier composition and an application thereof, and oil-based drilling fluid. The co-emulsifier comprises at least two amide groups and at least one hydrocarbon group comprising 7-30 carbon atoms. When the co-emulsifier is used in drilling fluid based slurry, good emulsifying effect and temperature resistance stability are obtained, and the system stability after aging is enhanced. Moreover, synthetic raw materials for the co-emulsifier provided by the present invention are widely available, inexpensive and free of fluorescence, and do no harm to the environment, thereby having a high industrial prospect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

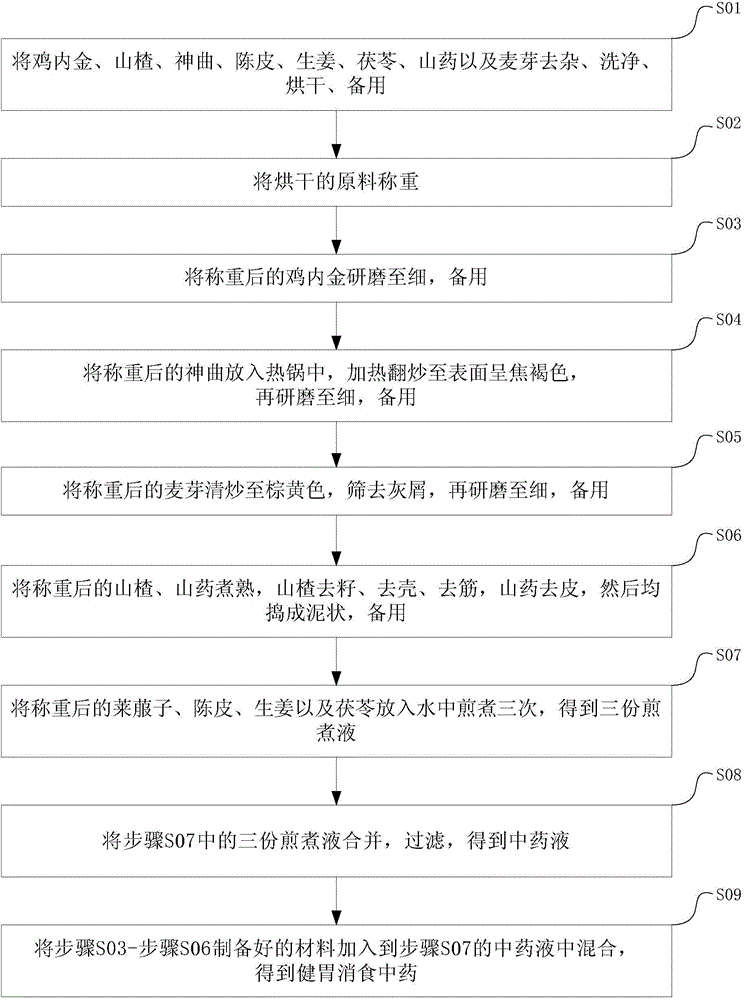

Traditional Chinese medicine with effect of improving digestion and preparation method of traditional Chinese medicine

InactiveCN104857484ASolve problems that damage the bodyDigestive systemBird material medical ingredientsWestern medicineSide effect

The invention provides a traditional Chinese medicine with the effect of improving digestion and a preparation method of the traditional Chinese medicine. The traditional Chinese medicine comprises the following ingredients: endothelium corneum gigeriae galli, semen raphani, hawthorn, medicated leaven, dried tangerine or orange peel, ginger and poria. Semen raphani and medicated leaven in the traditional Chinese medicine have the effects of improving digestion and relieving abdominal distension; endothelium corneum gigeriae galli, hawthorn and dried tangerine or orange peel have the effects of regulating qi and enhancing spleen and stomach digestion; ginger and poria can promote appetite, regulate the middle warmer, strengthen the middle warmer and invigorate stomach. Therefore, the traditional Chinese medicine can solve the symptoms of dyspepsia and food retention, has no toxic or side effects, does no harm to health of a human body, and can further avoid dyspepsia which is caused by adopting western medicine to treat diseases.

Owner:HUNAN UNIV OF CHINESE MEDICINE

Laundry powdered soap with no phosphor and benzene

InactiveCN101003771AImprove washabilityGood foaming performanceSurface-active non-soap compounds and soap mixture detergentsCarcinogenFiller Excipient

This invention discloses phosphorus and benzene-free washing powder, which comprises: sodium fatty acid ethyl ester sulfonate 10-20 parts, soap base 15-25 parts, fatty acid diethanolamide 3-5 parts, fatty alcohol polyoxyethylene ether 3-5 parts, filler 40-60 parts, water 3-10 parts, essence 0.1-0.5 part, preservative 0.01-0.5 part, and bactericide 0.01-0.5 part. The filler comprises sodium sulfate 35-50 parts, and sodium silicate 5-10 parts. The washing powder is neutral, and does no harm to human bodies or environment. The surfactant does not comprise cancerigenic substances, and there are not cancerigenic substances formed during preparation.

Owner:美婷生物科技(常州)有限公司

Technology for dyeing textile by means of plant dyes

The invention belongs to the technical field of printing and dyeing and particularly relates to a technology for dyeing textiles by means of plant dyes. The textiles can be yarn or fabrics and can be made of cotton fiber, bamboo fiber, viscose and chemical fiber modified fiber. The textiles with impurities removed through pretreatment are washed with water and then subjected to normal-temperature dip dyeing and modification, then the plant dyes are used for dip dyeing, and then after-treatment is conducted to obtain dyed textiles. Original plant resources are used for dyeing textile fabrics, so that the fabrics completely get rid of damage of toxic chemical dyes, can be recycled and do no harm to the environment and human beings, the production process is short, and products are stable. Compared with chemical products, cost is low. Compared with other plant dye dyeing technologies, colors are more uniform and dyeing defects are not likely to happen in dyeing application of most plants, color fastness is higher, and accordingly the technology has a very wide prospect in actual application.

Owner:杨江源

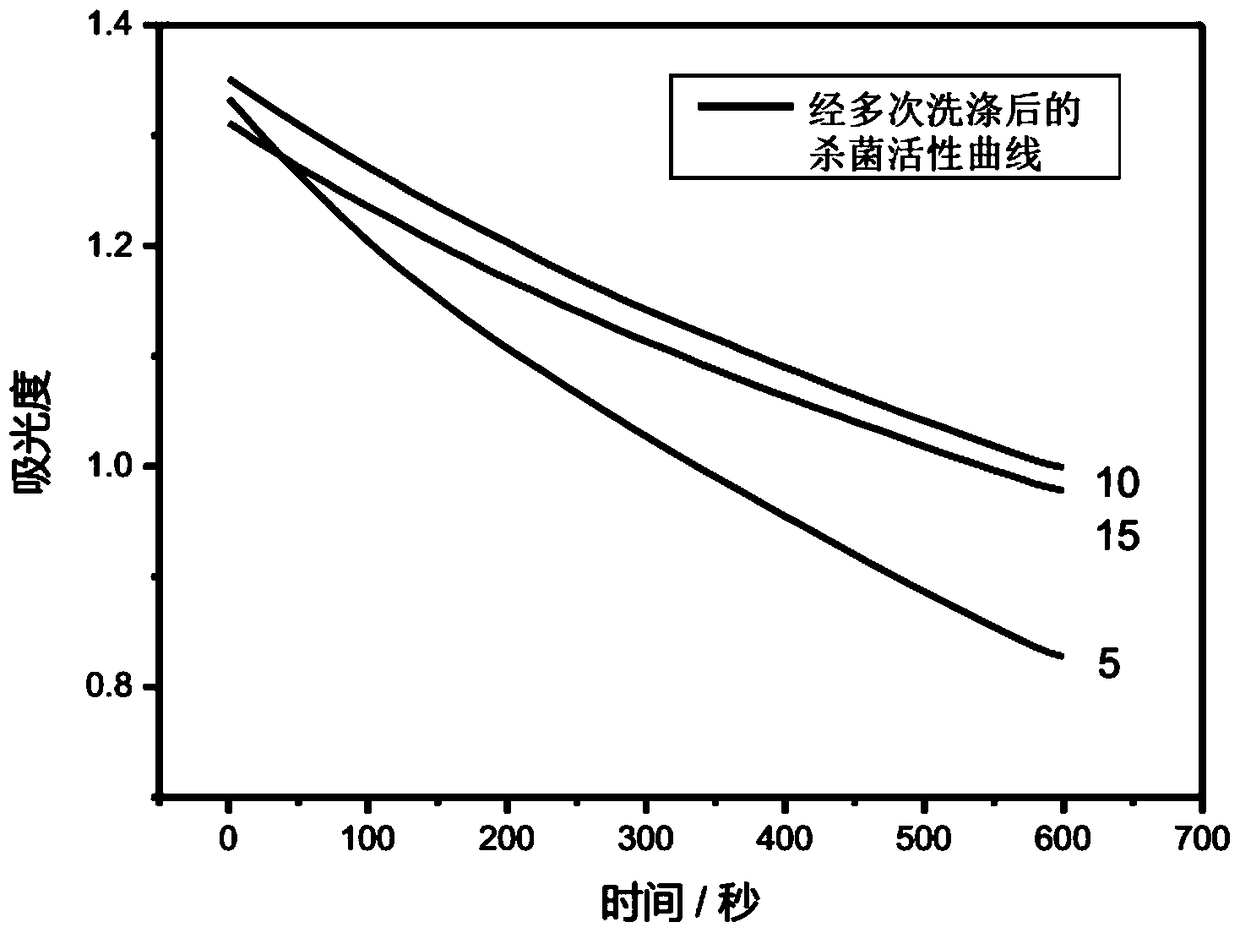

Organosilicone gemini quaternary ammonium salt and synthetic method thereof

InactiveCN101560220AImprove performanceThe synthesis steps are simpleGroup 4/14 element organic compoundsDisinfectantSolvent

The invention relates to organosilicone gemini quaternary ammonium salt and a synthetic method thereof. The synthetic method is as below: mixing and heating (RO)2CH3Si(CH2)3Cl and solvent, dropping (CH3)2NR1N(CH3)2, controlling the reaction conditions, and then obtaining the organosilicone gemini quaternary ammonium salt. The organosilicone gemini quaternary ammonium salt has the advantages of easily obtained raw materials and simple and easily controlled reaction conditions. The obtained compound has high surfaceactivity, therefore, the compound can serve as the cationic surfactant of the organosilicone; in addition, the compound can be used as a disinfectant and an antibacterial. Addition of the organosilicone improves the flexibility and safety of products, and the organosilicone gemini quaternary ammonium salt can serve as a soft antibacterial of textile fabrics and is an antibacterial product doing no harm to human bodies.

Owner:QILU UNIV OF TECH

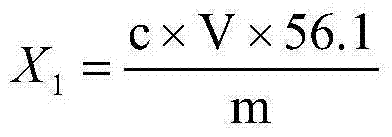

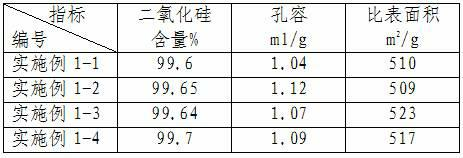

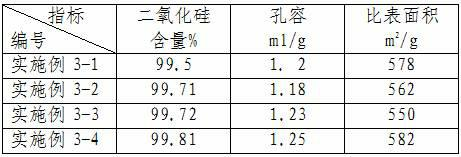

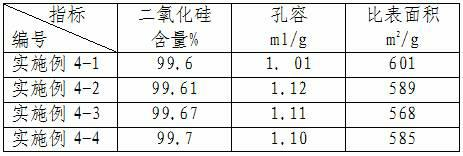

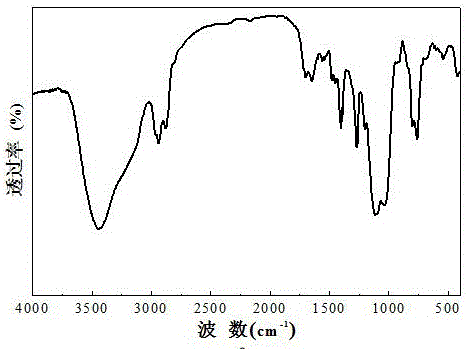

Preparation method of toothpaste abrasive silicon dioxide

The invention relates to a preparation method of toothpaste abrasive silicon dioxide. The preparation method comprises the following steps of: in sodium silicate solution with the concentration of 12-15%, adding 10-30% (weight) sulphuric acid according to weight ratio of pure silicon dioxide to concentrated sulfuric acid of being 1: 0.7, reacting for 2-4 hours at the temperature of 40-50 DEG C to generate silicon dioxide gel; adjusting pH value to be 3-5 with sulphuric acid solution with the concentration of 10-30%; adding polyalcohol accounting for 1-3% of the total weight of silicon dioxide, heating to 60-80 DEG C, insulating for 1-3 hours and carrying out structural control; then filtering, washing, carrying out high pressure beating on filter cakes, curing, and then drying and smashing until average particle size is 8-10Mum. In the invention, the polyalcohol is taken as a structural control agent, the prepared silicon dioxide has appropriate hardness and moderate abrasiveness when being used as toothpaste abrasive, does no harm to gum and has good toothpaste transparency; meanwhile raw materials are available, cost is low, process flow is short, and industrialization is easy to realize.

Owner:冷水江三A新材料科技有限公司

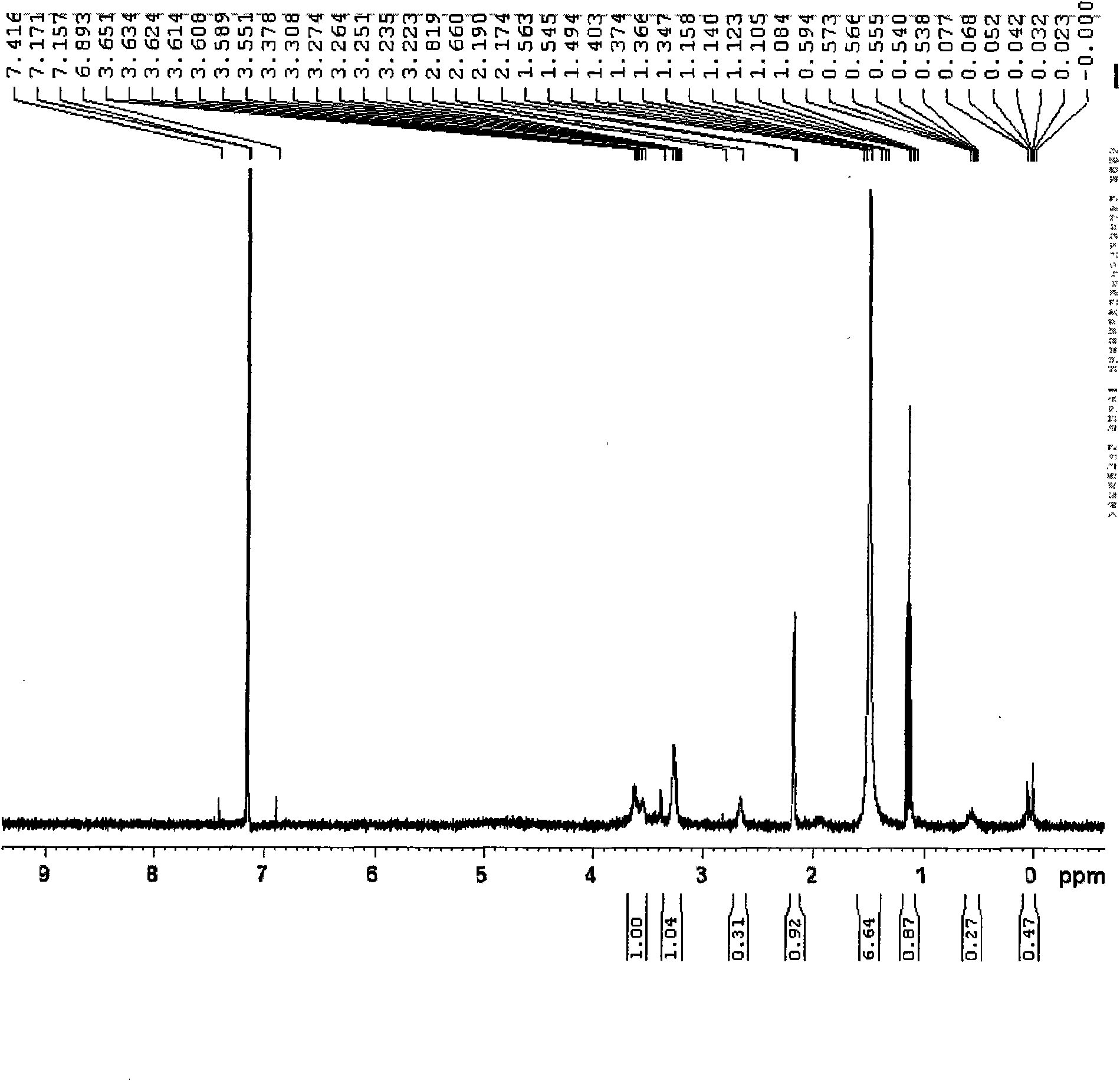

Reaction type polysiloxane flame-retardant coating and preparation method thereof

The invention discloses a reaction type polysiloxane flame-retardant coating and a preparation method thereof, and belongs to the technical field of flame-retardant coatings. The reaction type polysiloxane flame-retardant coating consists of a silane coupling agent, ammonium polyphosphate, a film-forming agent, a polysiloxane flame retardant, a wetting agent and ethanol. The film-forming agent and the silane coupling agent of the reaction type polysiloxane flame-retardant coating have the function of film forming simultaneously, the silane coupling agent and the synthesized polysiloxane flame retardant can be also acted with each other, and the silane coupling agent and the flame retardant can implement microencapsulation on the ammonium polyphosphate, and can be also reacted, so that the reaction type polysiloxane flame-retardant coating of a spatial cross-linked net structure can be prepared, the coating adopts ethanol as a solvent, and the raw materials of the whole system are environmental-friendly reagents which can do no harm to the environment and operators; the coating is a reaction type coating, is high in flame retardancy efficiency, and can be deformed together with a substrate without dropping, the limit oxygen index LOI of polypropylene can be up to 31.3% and can be qualified in UL-94 V0 tests, and the mechanical property of the substrate can be barely affected.

Owner:TAIYUAN UNIV OF TECH

Bone defect repairing material, preparation method and applications thereof

The invention relates to a bone defect repairing material. The bone defect repairing material comprises a bacteria cellulose membrane, a biologic ceramic material and cellulase, wherein the biologic ceramic material is deposited on a microfiber surface of the bacteria cellulose membrane, and the cellulase is dispersed in the bacteria cellulose membrane and can degrade the bacteria cellulose membrane. When the bone defect repairing material is implanted into bone defect positions, as osteoblasts are attached on the microfiber surface of the bacteria cellulose membrane for growing and the ceramic material is deposited on the microfiber surface of the bacteria cellulose membrane, the osteoblasts growing on the ceramic material deposited on the microfiber surface are wrapped easily, and an intact bone organization is formed by the osteoblasts combining with collagen generated from the osteoblasts. The cellulose membrane is degraded gradually by the cellulase embedded, leaving no residues. Glucose as a degraded product does no harm to cells, and the glucose can support osteocyte copying and growing as nutrients. Furthermore, the invention also relates to a preparation method for the bone defect repairing material and applications of the bone defect repairing material.

Owner:SHENZHEN INST OF ADVANCED TECH

Method for synthesizing urea-formaldehyde resin containing micro free formaldehyde for E0-level artificial boards

ActiveCN102604021AReduce generationReduce contentAldehyde/ketone condensation polymer adhesivesThree levelMoisture

The invention provides a method for synthesizing urea-formaldehyde resin containing micro free formaldehyde for E0-level artificial boards and relates to the technical field of urea-formaldehyde resin adhesives. The method has the following advantages: urea and a 37% formaldehyde aqueous solution are used as raw materials and the weak base-weak acid-weak base three-level pH quasi-steady-state control polymerization process is adopted to produce the urea-formaldehyde resin products; the content of free formaldehyde is less than 0.05%; the artificial board products prepared by using the resin have formaldehyde release not more than 0.1mg / L, meet GB / T14732-2006 and do no harm to users; and meanwhile, the resin meets the requirements in moisture content, bonding strength and the like and reaches the E0 level.

Owner:CHANGZHOU UNIV

Organic fertilizer with insect expelling function

InactiveCN104609990ADangerousDo not cause harmBio-organic fraction processingExcrement fertilisersAgricultural residueGleditsia triacanthos

The invention discloses an organic fertilizer with an insect expelling function. The organic fertilizer is prepared from the following raw materials in parts by weight: 5-6 parts of Chinese honey locust, 150-155 parts of fresh sheep manure, 10-15 parts of soybeans, 1-2 parts of garlic, 1-2 parts of clove, 1-2 parts of oil residues, 10-20 parts of waste fruit, melon and vegetable peel, 10-20 parts of fish meal, 5-7 parts of radish peel, 1-2 parts of cassava alcohol residues, 4-6 parts of castor cakes, 5-7 parts of poria cocos, 4-6 parts of astragalus membranaceus, 1-2 parts of pepper leaves, 0.01-0.02 part of trichlorfon, 1-2 parts of red-spotted stonecrop, 2-6 parts of typhonium giganteum, 1-2 parts of radix aconiti agrestis and 0.4-0.5 part of an EM fungicide. The organic fertilizer is prepared through secondary fermentation treatment, is easy in obtaining raw materials, is convenient to use, comprehensive in nutrition, has the functions of yield increase and insect expelling, can do no harm to the soil environment, and is free of pollution or agricultural residues.

Owner:和县宝兰蔬菜种植有限公司

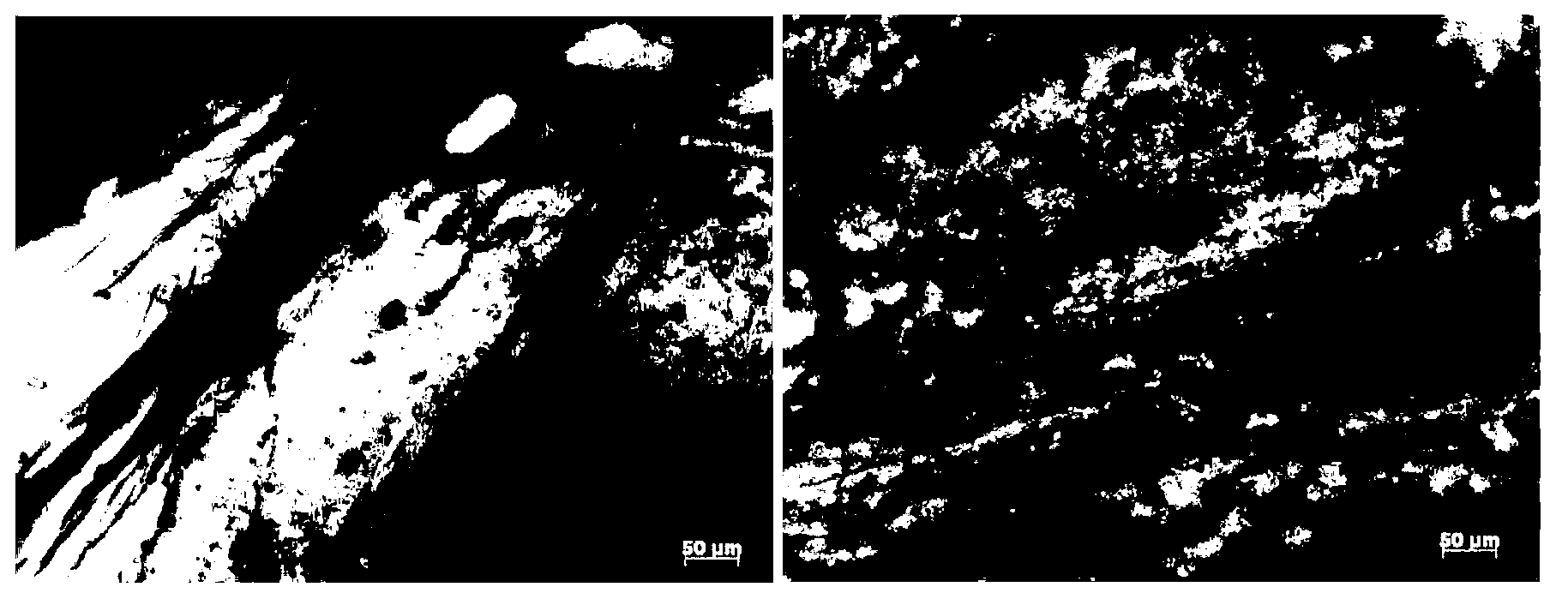

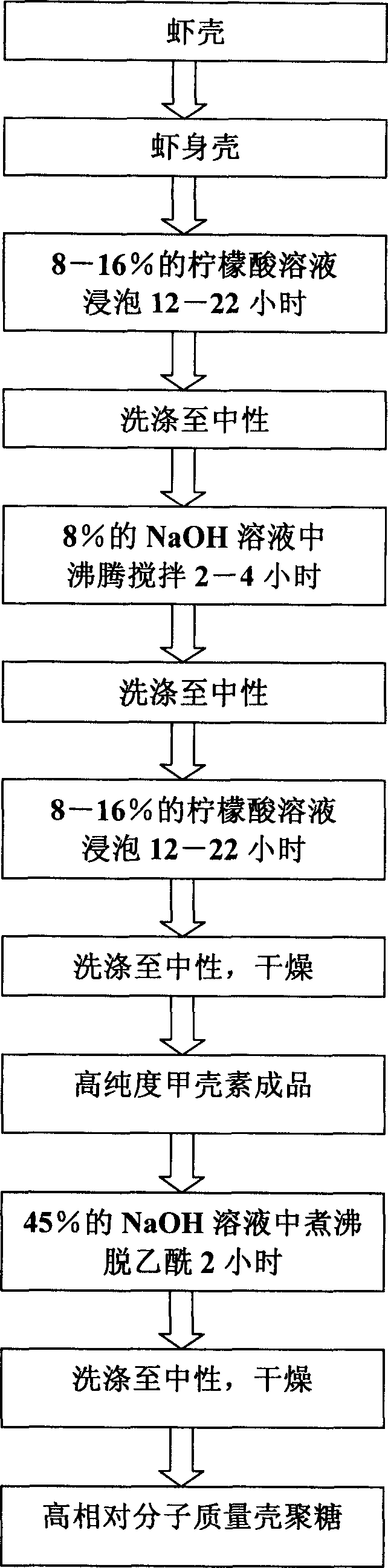

Rtechnique for extracting chitin in high molecular weight

This invention discloses a new technique for extracting high molecular weight chitin. This invention utilizes shrimp shell as the raw material, and adopts citric acid decalcification technique to obtain chitin, which does no harm to the molecular chain of chitin, and can keep the natural state of chitin. Compared with the present HCl and EDTA decalcification techniques, this new technique can obtain high molecular weight (higher than 180000) chitin with a yield increased by more than 12%.

Owner:GUANGDONG OCEAN UNIVERSITY

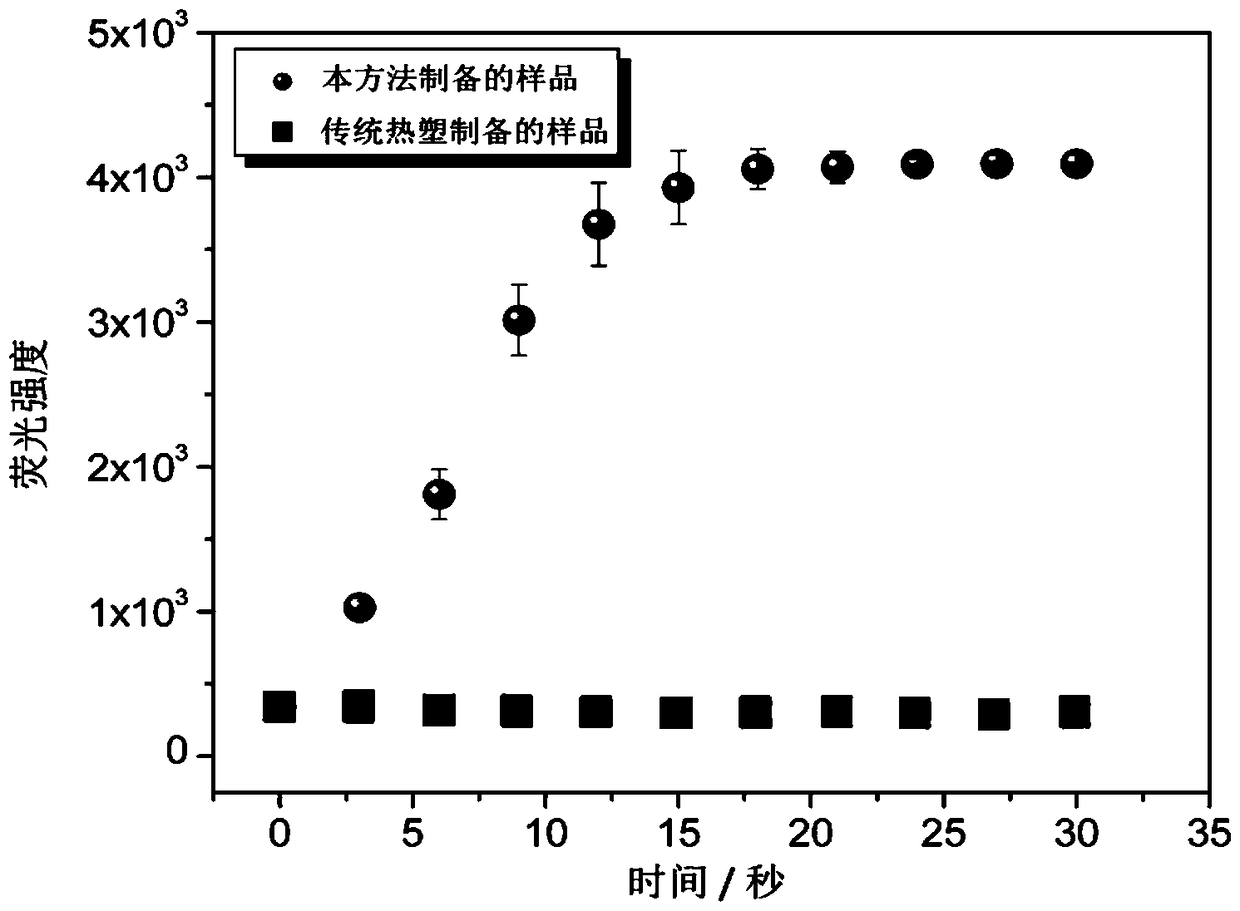

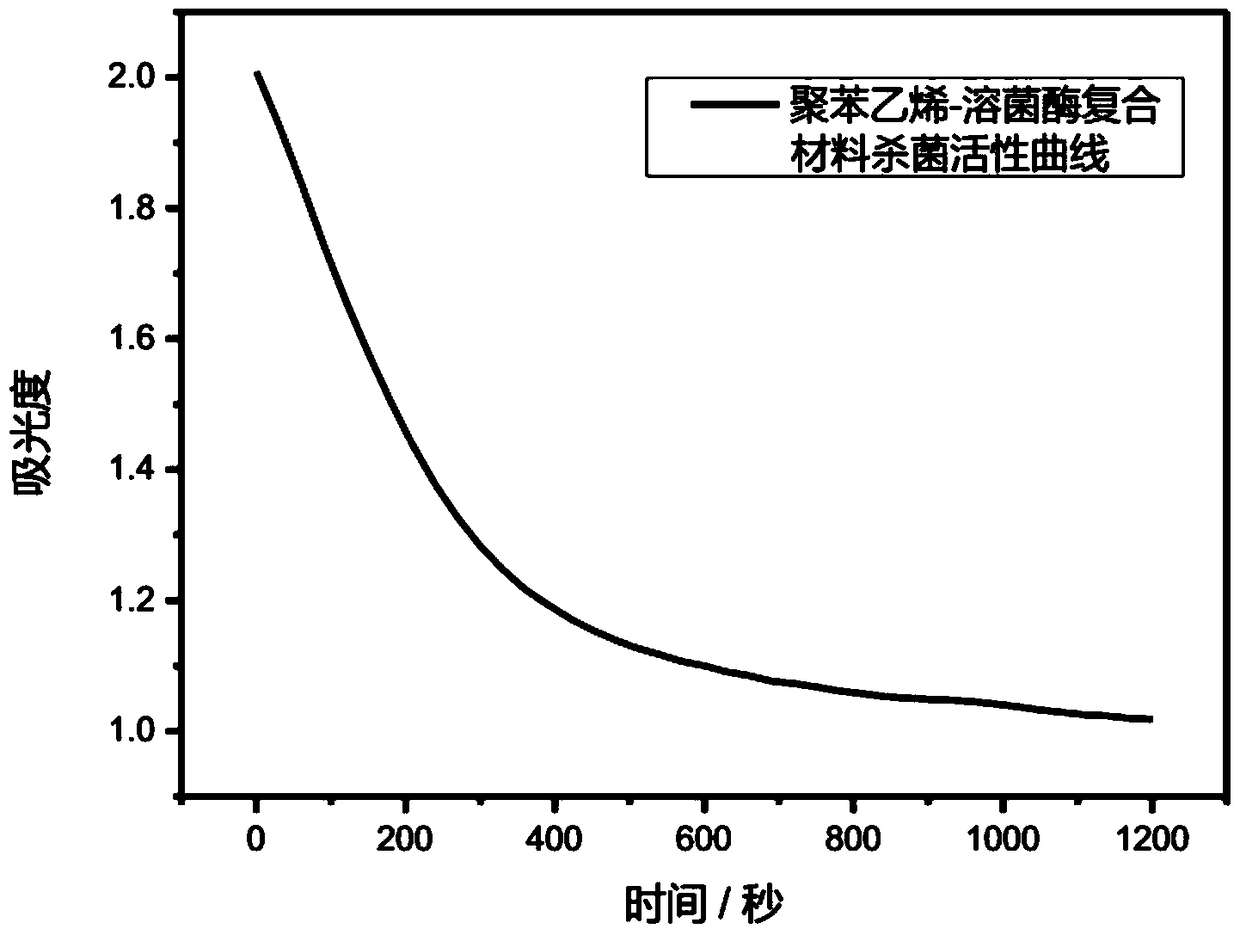

A biocidal plastic

ActiveCN105385056BGood slow-release propertiesNot easy to cause pollutionEnvironmental resistanceRoom temperature

Owner:NANJING UNIV

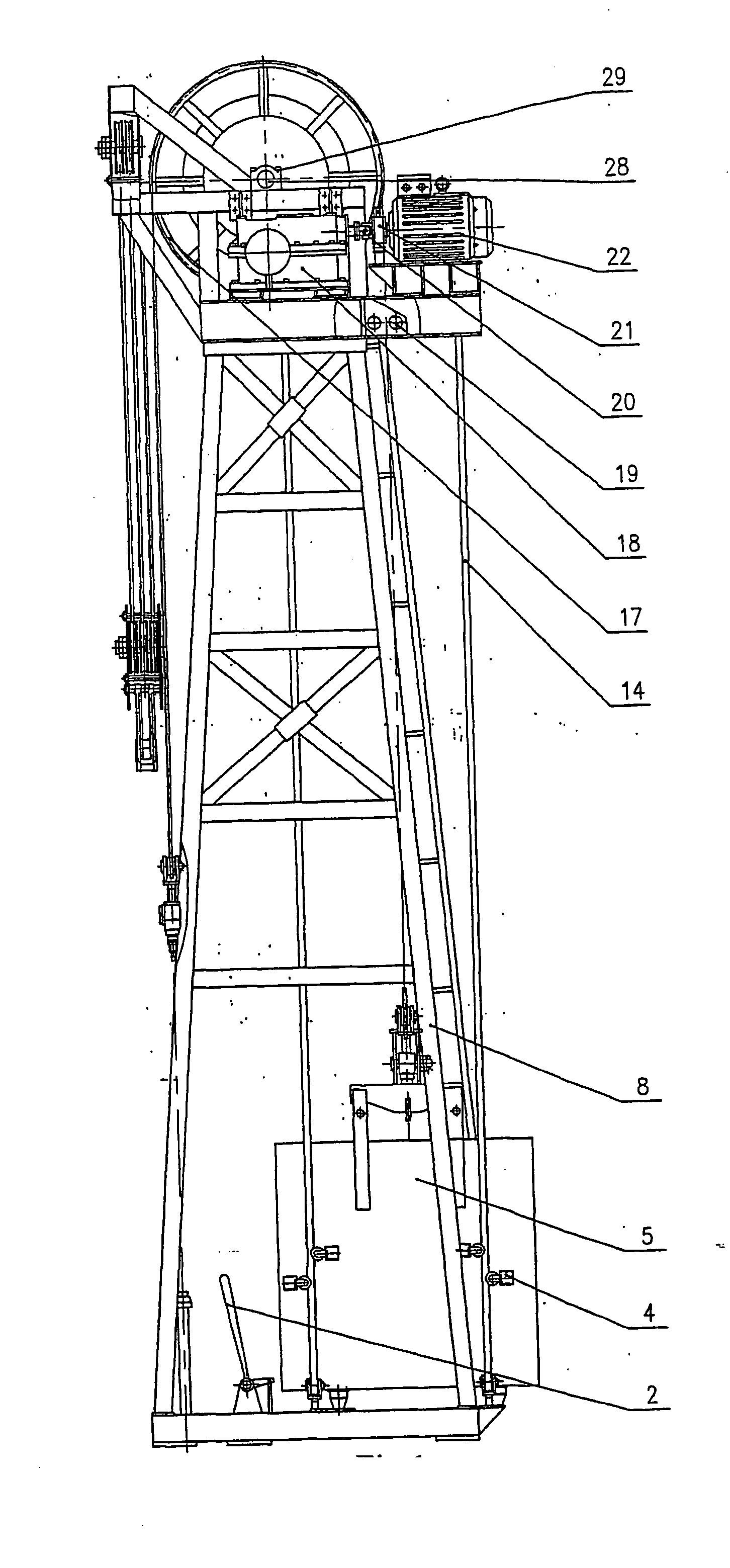

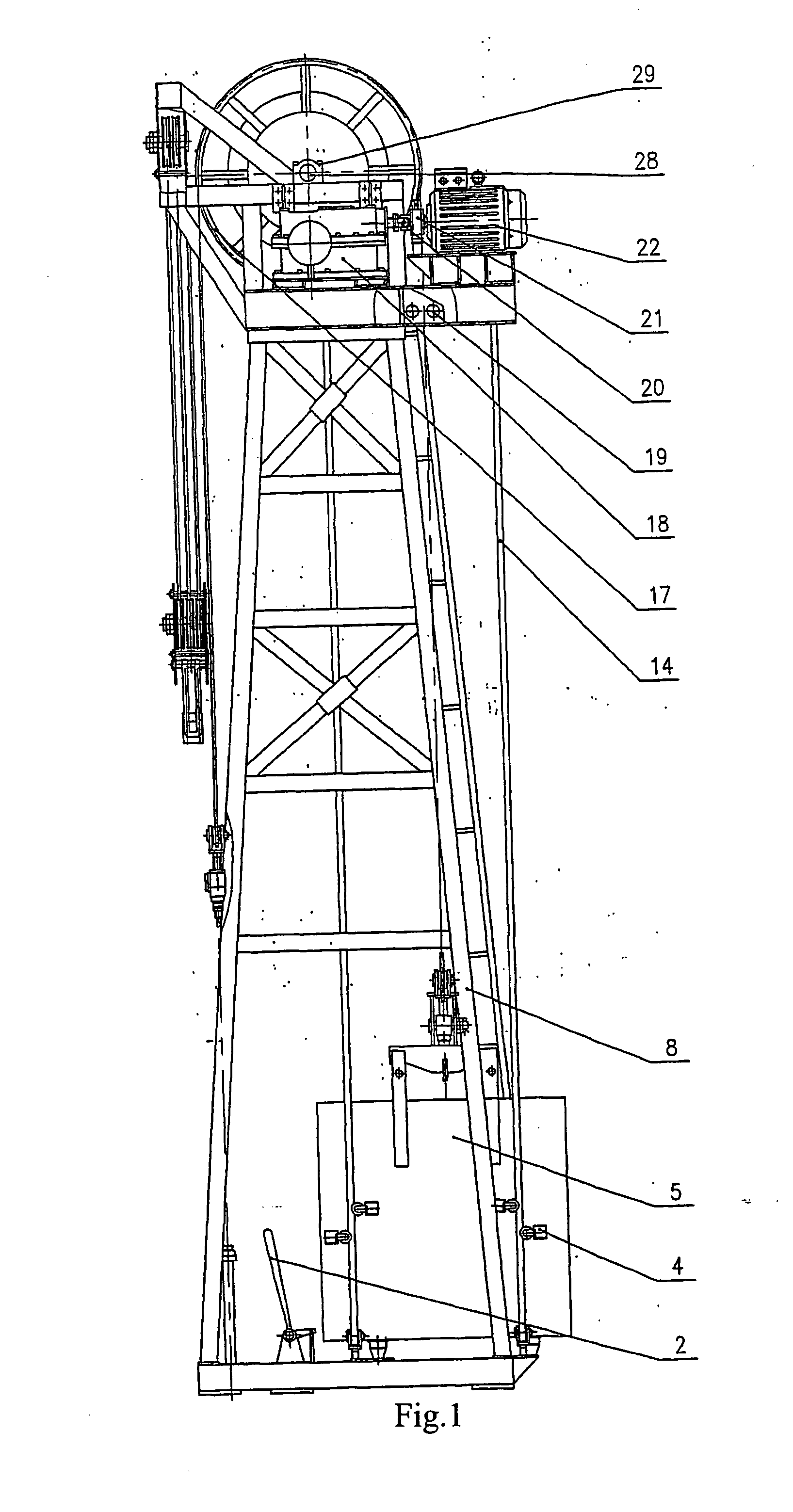

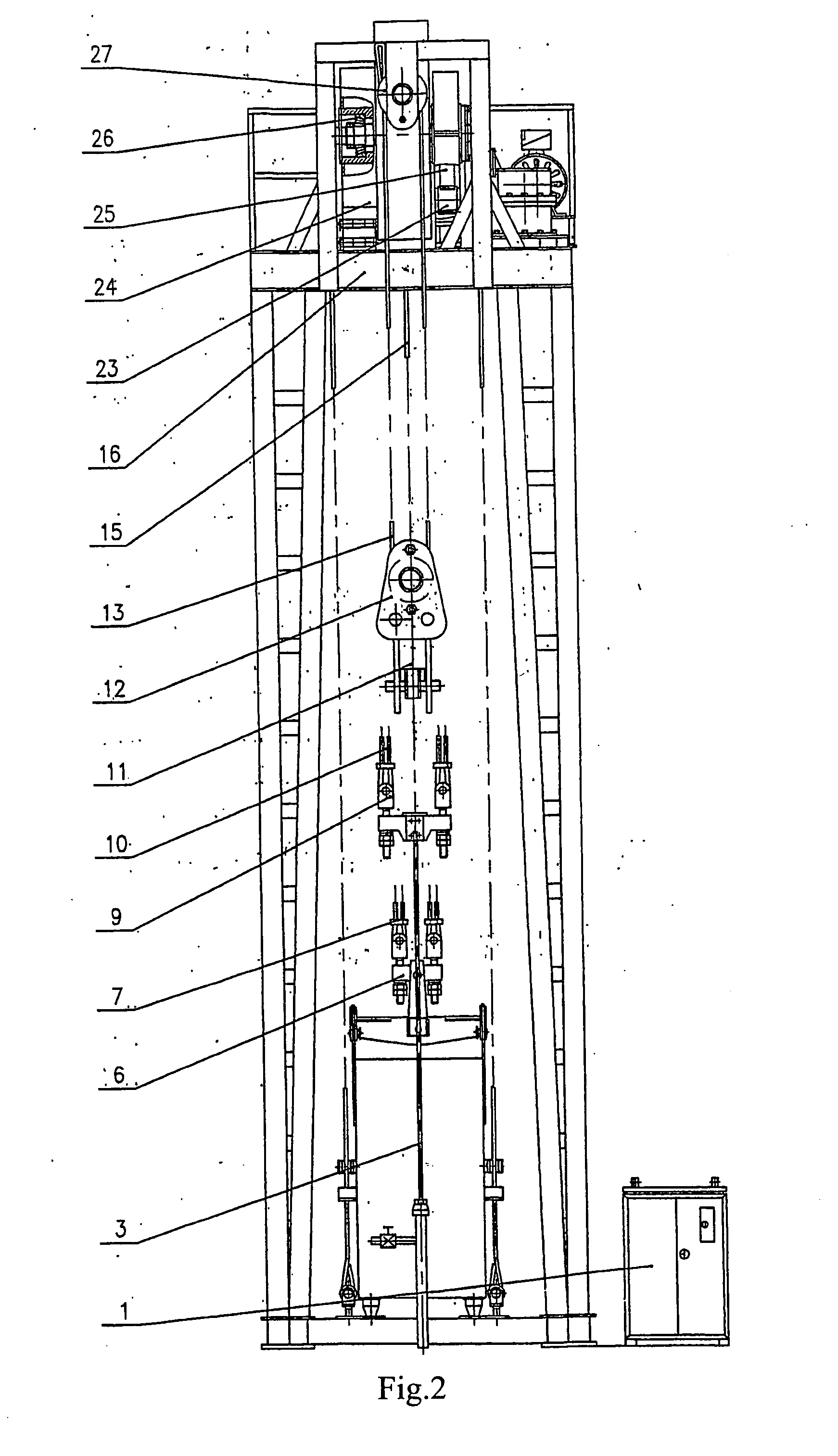

Pumping and Repairing Unit

InactiveUS20080128124A1Improve performanceConvenient in usage and maintenanceDrilling rodsConstructionsCouplingElectrical control

The present invention relates to an oil machinery, and provides a pumping and repairing unit comprising: an electrical control cabinet, a main frame, a supporting platform, a motor, an electrically operated brake, a coupling, a speed reducer, an oil pumping polished rod, a polished rod eye for the oil pumping polished rod, an oil pumping polished rod rope, a balance weight case, a balance weight rope hanging device, a balance weight rope, a protection rope, a protection rope catching device, and a driving device. The oil pumping polished rod rope has an end connected with the oil pumping polished rod and another end fixed to the driving device. Each of the balance weight rope and the protection rope has an end connected with a balance weight rope hanging device, and another end fixed to the driving device. The driving device and a brake wheel disposed at an end of the driving device constitute a driving and braking device. A fixed pulley block is disposed at the supporting platform. A workover rope is fixed to the driving and braking device, and has another end which is fixed to the supporting platform after it has wound around the fixed pulley block and a movable pulley block. An elevator is coupled with a lower end of the movable pulley block. A braking handle is disposed at a bottom of the main frame, and the brake wheel is controlled by the braking handle. The pumping and repairing unit can achieve pumping oil with high efficiency and safe workover. Especially, the pumping and repairing unit has a complete and reliable function of workover, and does no harm to transmission components thereof and does not pollute environment during workover. Entire process of the workover is simple and convenient in operation.

Owner:JIN CHENGQUN

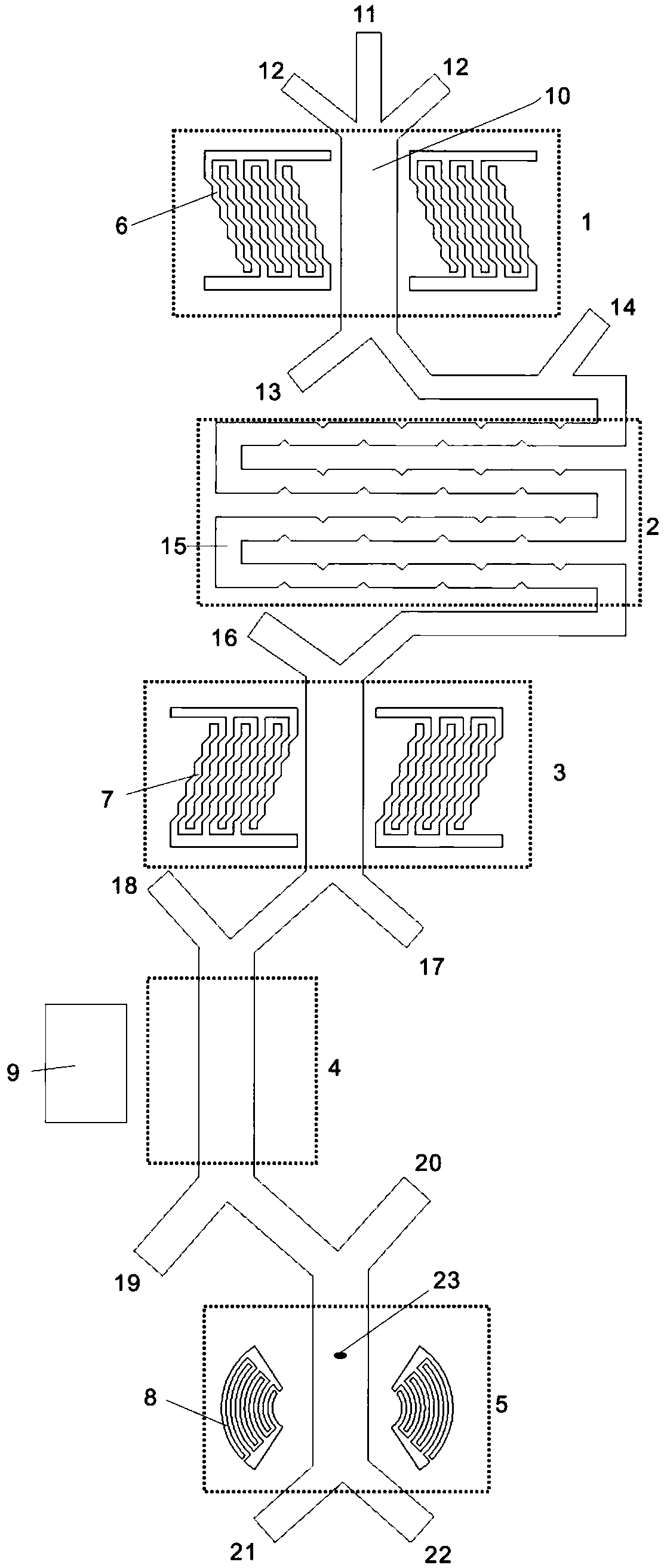

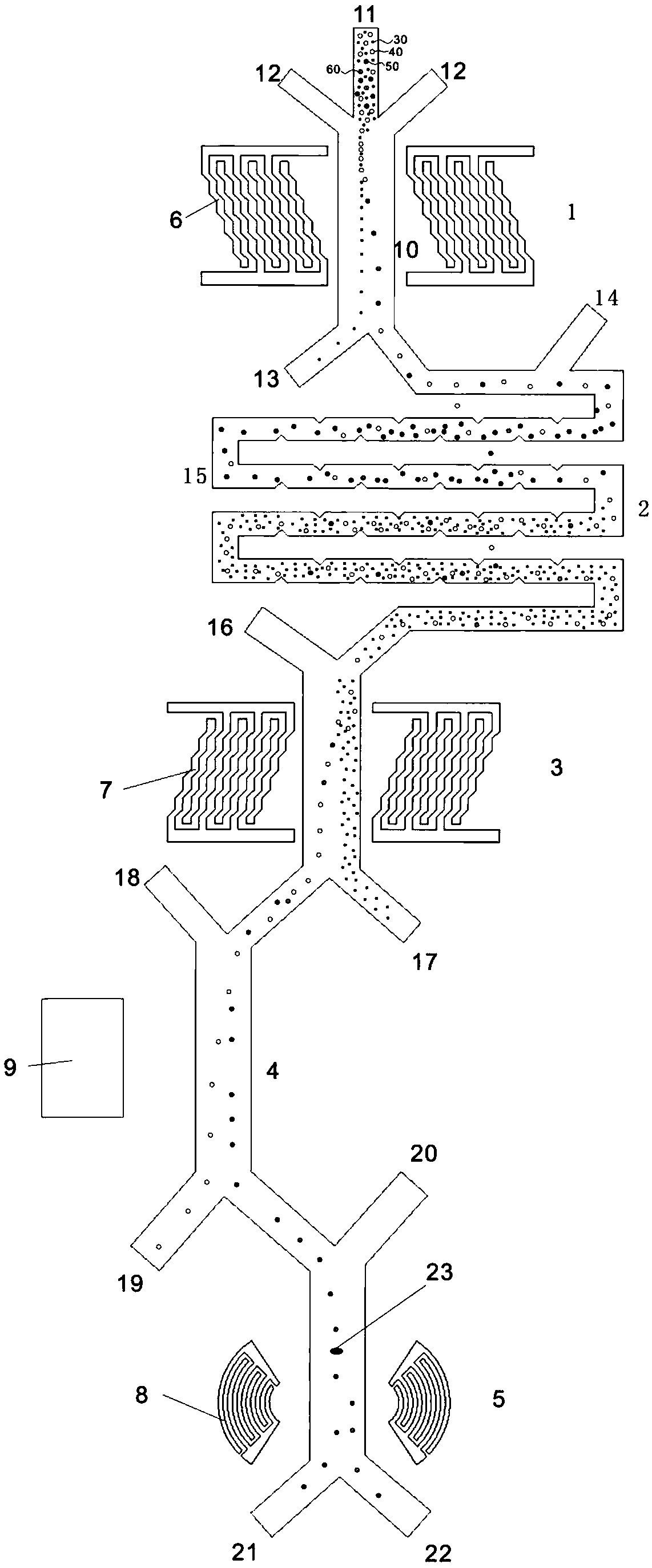

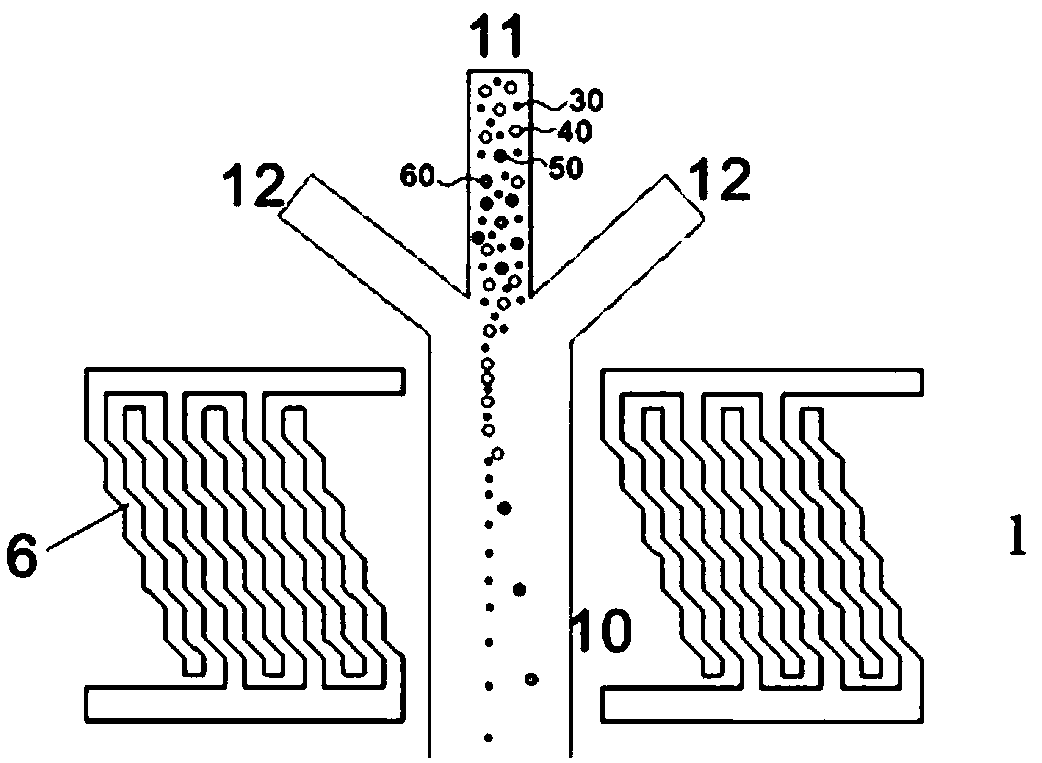

Micro-fluidic chip for screening rare cells in whole blood

PendingCN109439513AHigh purityIncrease capture rateBioreactor/fermenter combinationsBiological substance pretreatmentsRed blood cellMagnetic bead

The invention discloses a micro-fluidic chip for screening rare cells in whole blood. The micro-fluidic chip comprises a microchannel as well as a platelet removing region formed on the microchannel by a first interdigital electrode assembly, a red cell lysis region formed by a lysis pipeline segment on the microchannel, a red cell removing region formed on the microchannel by a second interdigital electrode assembly, a white cell removing region formed on the microchannel by a magnetic field and a target cell extraction region formed on the microchannel through a third interdigital electrodeassembly in sequence. According to the micro-fluidic chip disclosed by the invention, platelets and lysed red cells are removed by using the size difference; white cells are removed by using a specific monoclonal antibody and a magnetic bead mode, and screening purity and capture ratio of target cells are favorably improved; in addition, the micro-fluidic chip can clean samples. The system disclosed by the invention does no harm to cells, can be used for conventional flow cell sorting and screening the rare cells and has important significance for promoting noninvasive prenatal screening and tumor prognosis detection.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

High-property water-based emulsion cutting fluid composite

ActiveCN101613634ALow pour pointModerate viscosityAdditivesBase-materialsWater basedMetalworking fluid

The invention provides a high-property water-based emulsion cutting fluid composite, belonging to the field of metalworking fluid products. The composite is a water soluble product and comprises mineral oil, pentaerythritol fatty acid synthetic esters, a compound acidamide anti-rusting agent, an emulsifier, a corrosion inhibitor, a sulfide aliphatic acid ester extreme pressure lubricant, a bactericide and a defoamer; wherein, the compound acidamide anti-rusting agent is the composite of a component A, namely polycarboxylic acid hydramine acidamide and a component B, namely a mixture of triazole and a cosolvent butyl ether diglycol, thereby obviously improving the anti-rusting property of the product and broadening the anti-rusting applicability of diverse metals. The components of the composite product of the invention are scientific and reasonable in selection and use and balanced and harmonious in proportioning, thus achieving the effects of complementary action and synergy, therefore, the water-based emulsion cutting fluid of the invention not only enjoys high lubricating property, high anti-rusting property, high emulsibility, high antibacterial ability and high stability and has long service life, but also produces no pollution to the environment, does no harm to human bodies and satisfies the requirements of high-difficulty machining on the cutting fluid.

Owner:BOER TECH WUHAN

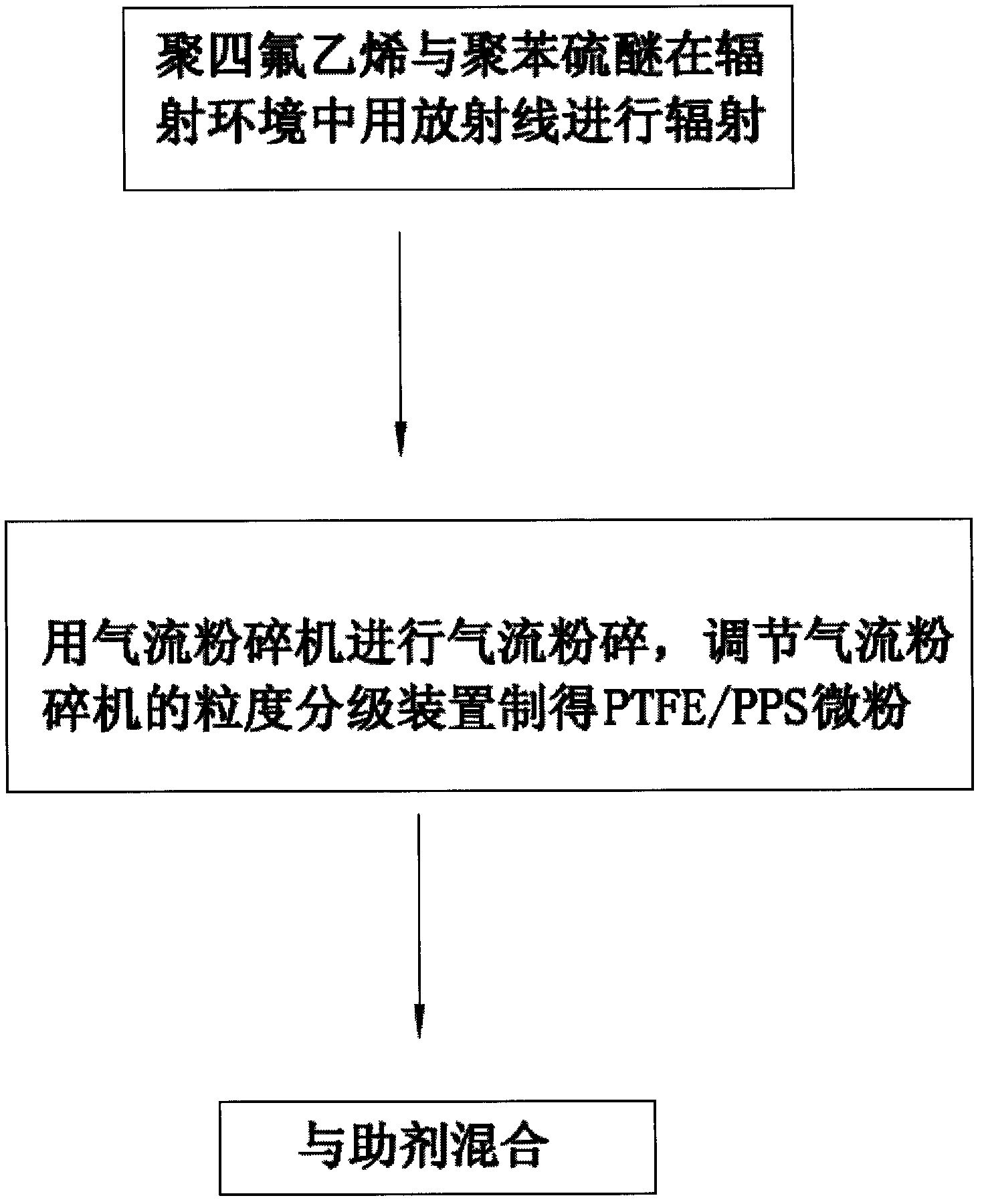

Method for preparing PTFE/PPS micro powder for the coating of the non-stick pan

The invention discloses a method for preparing PTFE (polytetrafluoroethylene) / PPS (polyphenylene sulfite) micro power for the coating of the non-stick pan, including the following steps: a) exposing the raw materials of PTFE and PPS to radioactive rays in radiation environment; b) pulverizing the postirradiation powder by jet mill and adjusting the size grading device of the jet mill to produce PTFE and PPS micro powder; c) mixing PTFE and PPS micro powder with the additive. The PTFE / PPS micro powder for the coating of the non-stick pan produced by the method is non-adhesive and oil-saving and does no harm to the human body and is productive.

Owner:嘉善申嘉科技有限公司

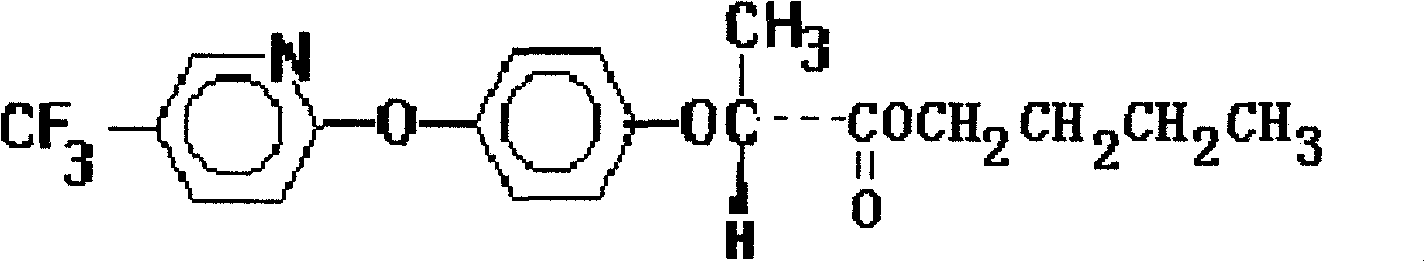

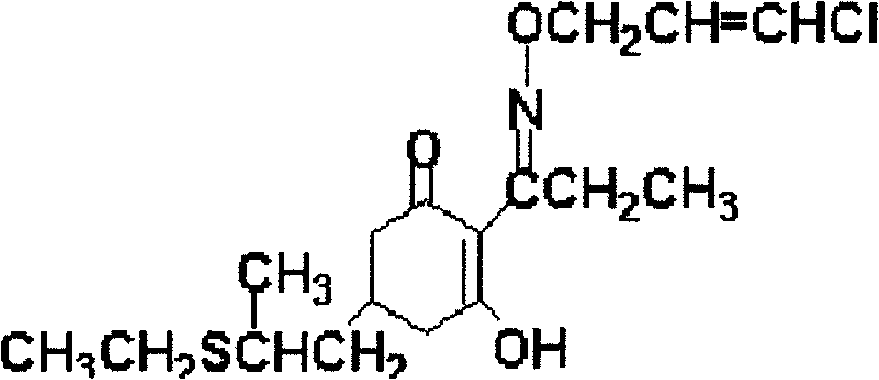

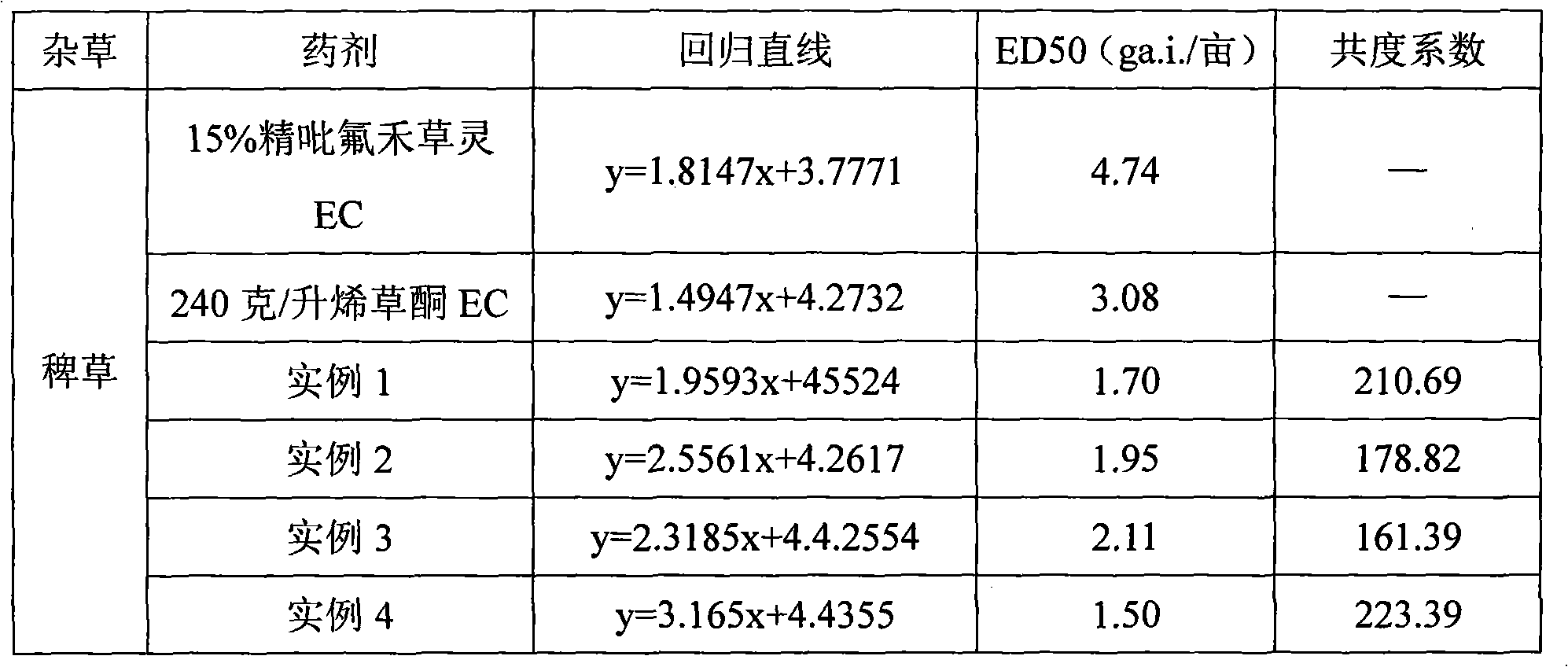

Herbicidal composition containing fluazifop-p-butyl and clethodim and application thereof

ActiveCN102027907AImprove herbicidal activityGood prevention effectBiocideAnimal repellantsChemical compositionBULK ACTIVE INGREDIENT

The invention discloses a herbicidal composition containing fluazifop-p-butyl and clethodim and application thereof. The herbicidal composition takes fluazifop-p-butyl and clethodim as the main active ingredients, wherein the mass ratio of fluazifop-p-butyl to clethodim is (1-70):(1-80) and fluazifop-p-butyl and clethodim account for 5-85% of the herbicidal composition by mass. The herbicidal composition has obvious effect on preparing the herbicides for controlling the postemergence weeds in the soybean fields, especially the herbicides for controlling various grass weeds in the soybean fields. Compared with the single agent, the herbicidal composition delays weed resistance, has wide herbicidal spectrum and long efficacy duration and does no harm to the rapes and the aftercrops on the premise of improving the drug effect.

Owner:NANJING HUAZHOU PHARMA

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com