Patents

Literature

46results about How to "No fluorescence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

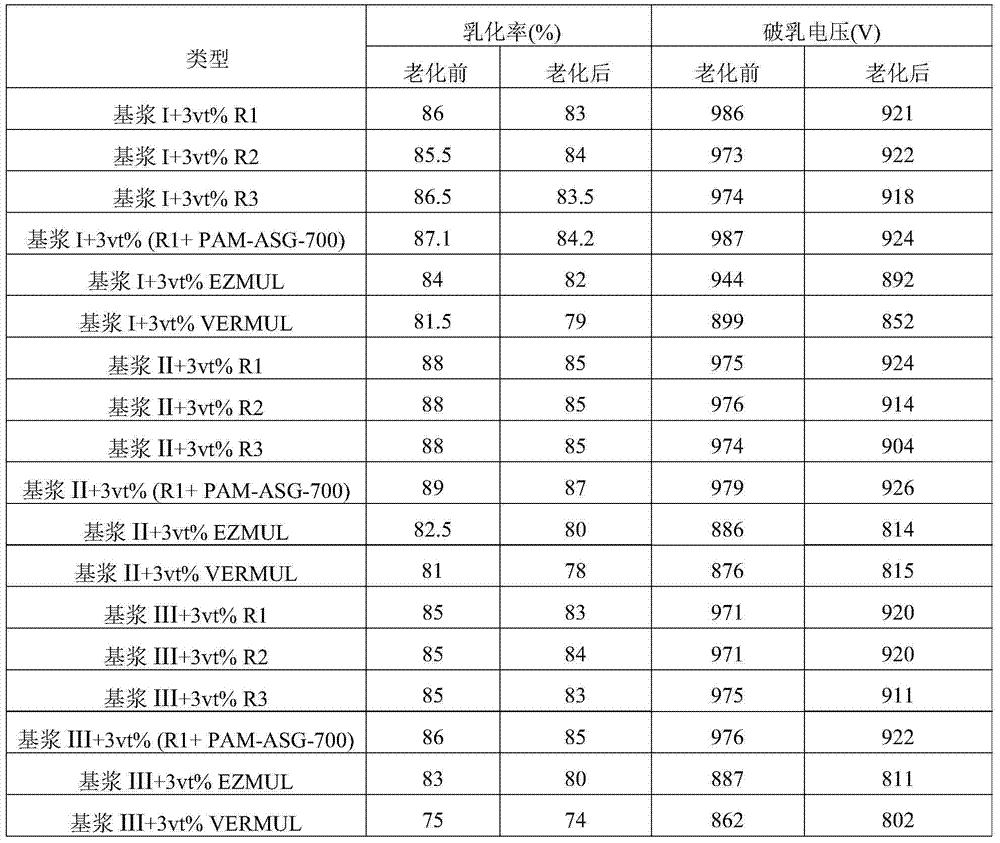

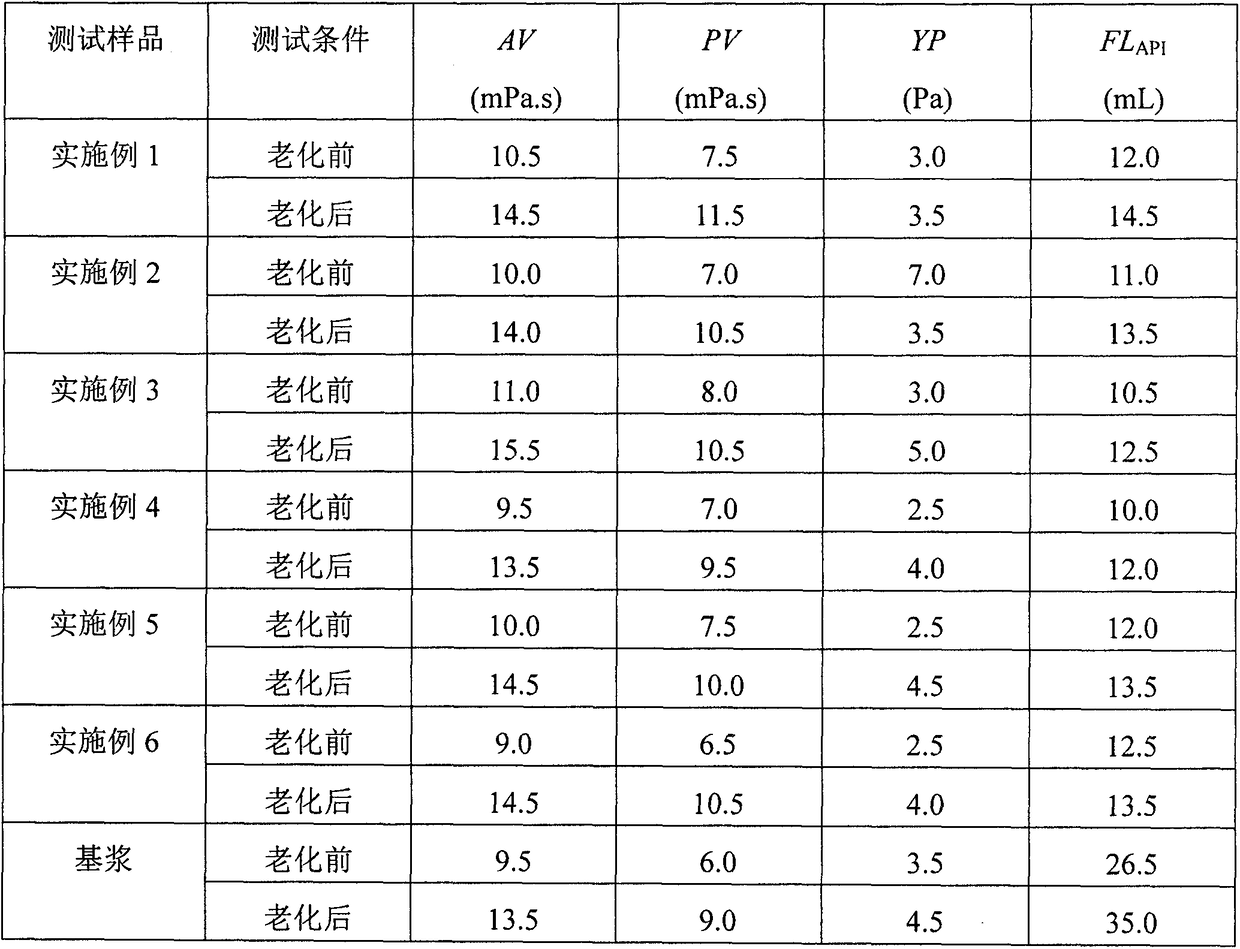

Primary emulsifier and preparation method therefor, emulsifier composition and application thereof, and oil-based drilling fluid

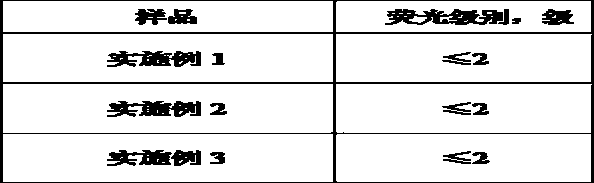

ActiveCN105441038AGood emulsifying effectWidely sourced and cheapDrilling compositionFluorescenceWell drilling

The present invention relates to the field of well drilling, and discloses a primary emulsifier and a preparation method therefor, an emulsifier composition and an application thereof, and oil-based drilling fluid. The primary emulsifier comprises an amide compound and a fatty acid compound; the amide compound comprises at least one amide group, at least one unsaturated double bond, and at least one alkyl containing 14-30 carbon atoms; and the fatty acid compound comprises 20-80 carbon atoms. When the primary emulsifier is used for drilling fluid base mud, the primary emulsifier has a good emulsifying effect and excellent temperature resistance. In addition, the synthetic materials of the primary emulsifier provided by the present invention are widely available and inexpensive, non-fluorescent, and environmentally friendly, and thus the primary emulsifier has great prospects for industrial applications.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

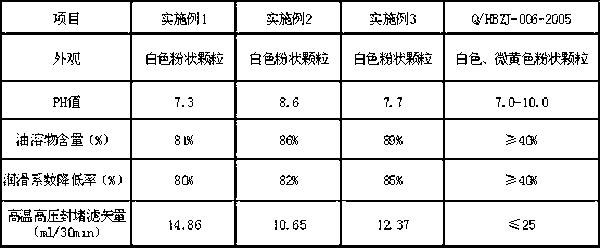

White asphalt for drilling fluid and method for preparing white asphalt for drilling fluid

ActiveCN103013461AGood sealing of cracksEasy to reverseDrilling compositionAlkylphenolPolyacrylamide

The invention discloses white asphalt for drilling fluid and a method for preparing the white asphalt for drilling fluid. The white asphalt is prepared from the following raw materials in parts by weight: 40 parts-50 parts of paraffin, 1 part-2 parts of alkylphenol polyoxyethylene ether, 4 parts-5 parts of polyethylene glycol, 4 parts-5 parts of polyacrylamide, 20 parts-30 parts of stearic acid and 20 parts-30 parts of light calcium carbonate. The method for preparing the white asphalt comprises the following steps: adding the paraffin, alkylphenol polyoxyethylene ether, polyethylene glycol and stearic acid into a reactor proportionally; raising the temperature of the reactor to 70 DEG C-100 DEG C, and then stirring for 20-40 minutes at constant temperature; adding polyacrylamide to be stirred for 30 minutes at constant temperature; and finally, uniformly adding light calcium carbonate to be stirred for 0.5-2 hours at constant temperature and then discharging, and carrying out spray granulation to obtain the white asphalt. The white asphalt does not damage a hydrocarbon reservoir, has good lubricating performance and prevents collapse and blockage, filtration can be effectively reduced, the capacity of oil-gas wells is improved, and the technical problems of easily generated loss, collapse and the like during a drilling process when stratums with complicated conditions are drilled are solved.

Owner:河北华运鸿业化工有限公司

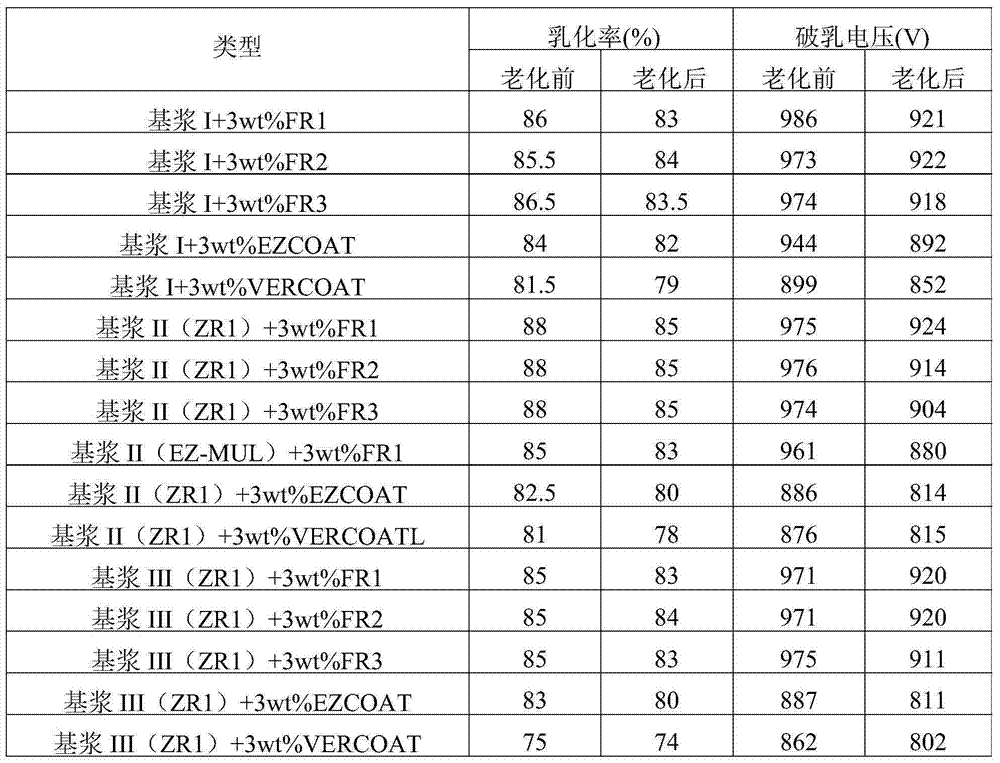

Co-emulsifier and preparation method therefor, emulsifier composition and application thereof, and oil-based drilling fluid

ActiveCN105441039AGood emulsifying effectNo fluorescenceDrilling compositionFluorescenceSystem stability

The present invention relates to the field of drilling fluid, and discloses a co-emulsifier and a preparation method therefor, an emulsifier composition and an application thereof, and oil-based drilling fluid. The co-emulsifier comprises at least two amide groups and at least one hydrocarbon group comprising 7-30 carbon atoms. When the co-emulsifier is used in drilling fluid based slurry, good emulsifying effect and temperature resistance stability are obtained, and the system stability after aging is enhanced. Moreover, synthetic raw materials for the co-emulsifier provided by the present invention are widely available, inexpensive and free of fluorescence, and do no harm to the environment, thereby having a high industrial prospect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

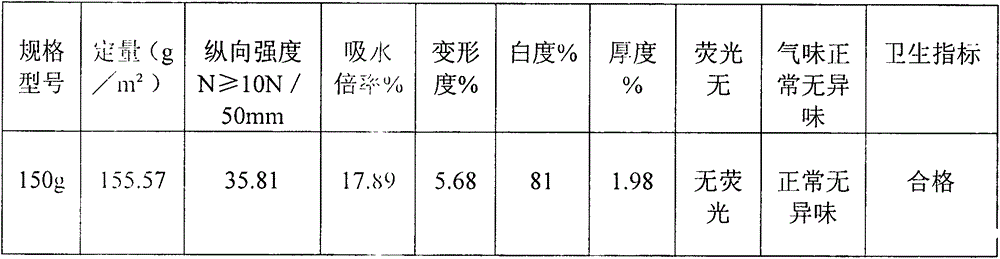

Preparing method of table salt packaging paper

ActiveCN108468248AReduce air permeabilityImprove moisture resistanceNon-fibrous pulp additionPaper coatingBursting strengthSulfate

The invention discloses a preparing method of table salt packaging paper. The method includes the steps of using high-quality bleaching sulfate needle-point leaf pulp and bleaching sulfate broad leafpulp as the raw materials, and conducting pulping and auxiliary material adding, wet page making, squeeze-dewatering, pre-drying, surface sizing, post-drying and the like to prepare the table salt packaging paper large in gram weight, high in opaqueness, tensile strength, bursting strength and tearing strength, small in breathability, high in moisture resistance and free of fluorescent substances.The product quality reaches the performance index of import similar products.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

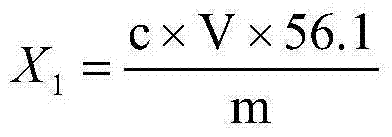

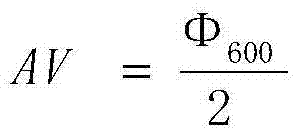

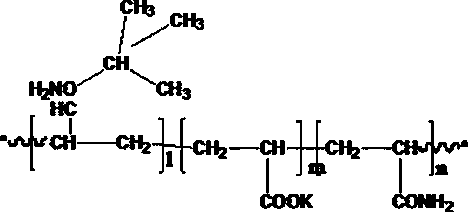

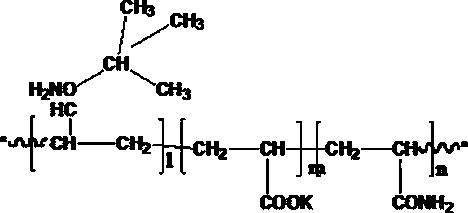

Microemulsion polymerization strong coater for drilling fluid and preparation method of strong coater

The invention discloses a microemulsion polymerization strong coater for a drilling fluid and a preparation method of the strong coater. The key point of the technical scheme disclosed by the invention is as follows: the microemulsion polymerization strong coater for the drilling fluid is a copolymer which is formed from potassium acrylate, acrylamide and 2-acrylamidyl-2-methyl propanesulfonic acid by virtue of free radical polymerization, wherein the molecular weight of the copolymer is 15000 thousand to 24000 thousand. The structure of the copolymer is as shown in the specification, wherein l:m:n is equal to a:b:c, a is greater than or equal to 95 but less than 100, b is greater than 0 but less than or equal to 5 and c is greater than 0 but less than or equal to 5. The invention further discloses the preparation method of the microemulsion polymerization strong coater for the drilling fluid. The strong coater disclosed by the invention is high in polymerization efficiency, and the polymerized product is stable in performance and convenient to apply and is widely applied in the drilling process of an oil field. The strong coater can be used for greatly improving the rejection capability and the coating ability of the drilling fluid so as to form a drilling fluid system with a stable performance.

Owner:XINXIANG FUBANG TECH

Non-fluorescence lubricant for water-base drilling fluid

InactiveCN101787265AGood quality and stabilityDoes not affect discoveryDrilling compositionWater basedFluorescence

The invention discloses a non-fluorescence lubricant for water-base drilling fluid, which relates to the technical field of lubricants for water-base drilling fluid. The lubri cant is prepared from the following raw materials in percentage by weight: 30 to 50 percent of industrial castor oil, rapeseed oil residue and industrial soybean oil, 0.6 to 1.0 percent of sodium pyrosulfite, 2 to 3 percentof nonyl phenol polyoxyethylene ether, 0.02 to 0.04 percent of antioxidant 501, 1.0 to 1.2 percent of caustic soda NaOH, and the balance of water. The lubricant has no adverse effects on geological logging, cannot cause no real cuttings to be got in the logging process, and cannot affect the discovery of new hydrocarbon reservoirs.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

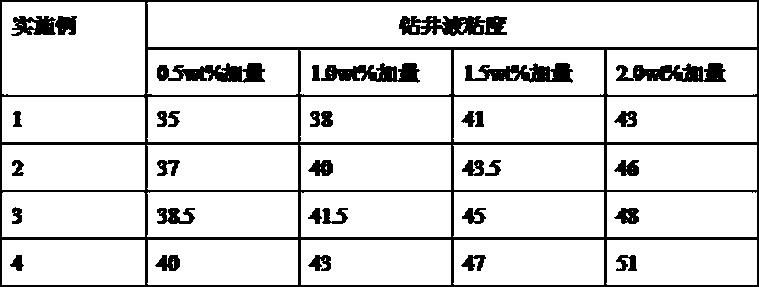

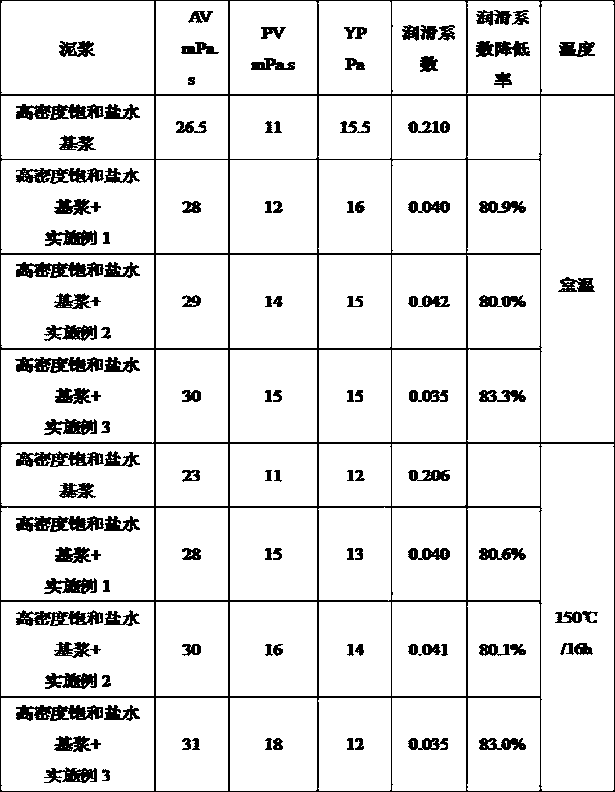

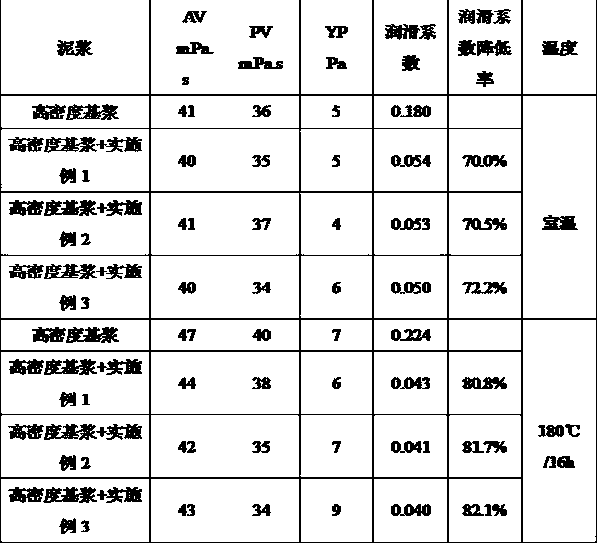

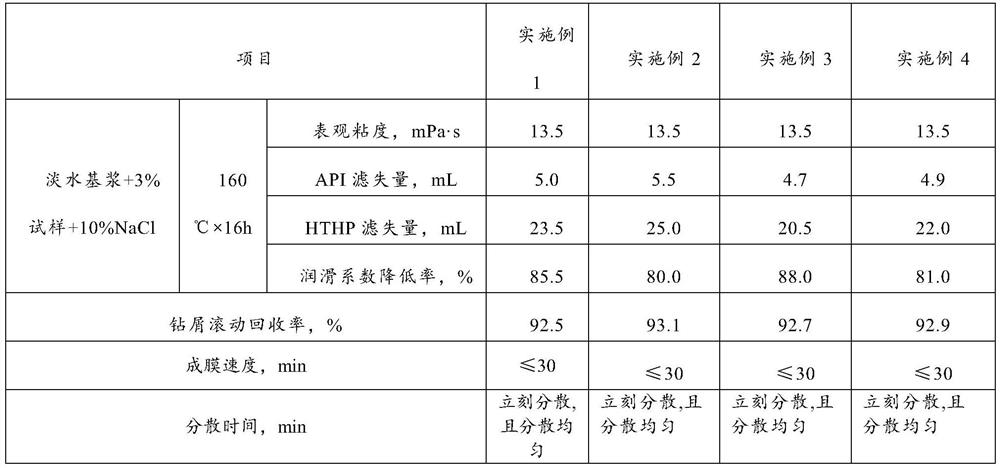

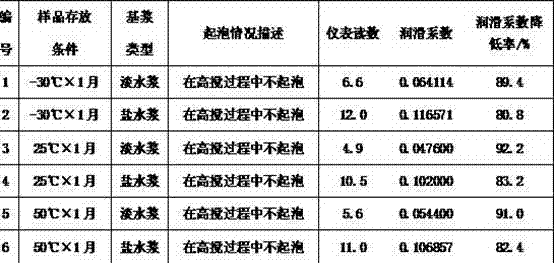

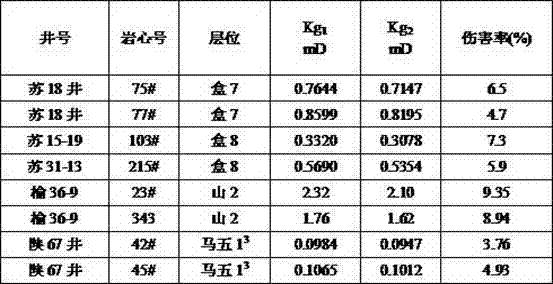

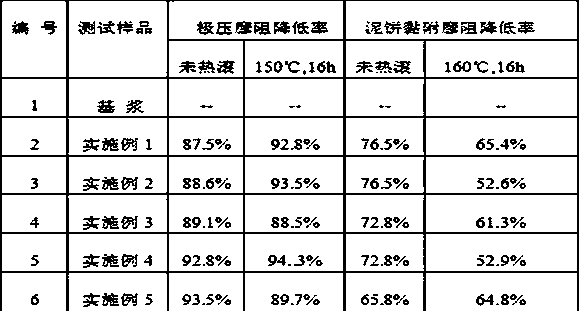

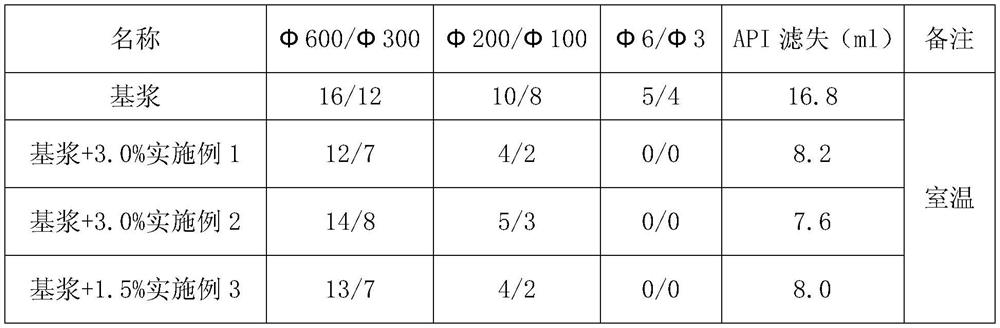

Temperature resistance and salt tolerance extreme pressure lubricant for high density drilling fluid and preparation method thereof

ActiveCN109439294AStrong hydrolytic stabilityStrong salt resistanceDrilling compositionLubricationLong chain fatty acid

The invention discloses a temperature resistance and salt tolerance extreme pressure lubricant for a high density drilling fluid and a preparation method thereof, and belongs to the field of additivesfor oil drilling operation. In order to solve the problem that a lubricant is not ideal in lubrication effect under conditions of high density slurry, high temperature and high salt, the method comprises the following steps: performing stirring reaction on ester base oil and long-chain fatty acid for 30min at 50 to 95 DEG C, then adding an extreme pressure additive and a friction pair surface modifier for performing reaction for 20min at 95 to 100 DEG C, finally adding an emulgator and a defoamer, and cooling down the material to a room temperature while stirring is performed, so as to form the extreme pressure lubricant for high density drilling fluid, with excellent lubrication effect in high-temperature and saturated salt conditions. Compared with the prior art, the method has the advantages that the reduction rate of the extreme pressure lubrication coefficient of the lubricant is greater than 80 percent after the lubricant is aged at 180 DEG C in high density slurry with the density being 2.0g / cm3, and the reduction rate of the extreme pressure lubrication coefficient of the lubricant is greater than 80 percent after the lubricant is aged at 150 DEG C in saturated brine slurry with the density being 2.0g / cm3, and the lubricant has the characteristics of low viscosity increasing and low foaming ratio, and can be applied to drilling operation for deep wells, ultra-deep wells, horizontal wells and highly-deviated wells.

Owner:山东得顺源石油科技有限公司

Lubricating collapse-resisting agent for drilling fluid and preparation method thereof

The invention discloses a drill liquid lubricating anti-sloughing agent and preparation method thereof. The lubricating anti-sloughing agent is composed of liquid wax 10 to 30 parts, non-ionic surface activator 1 to 3 parts, polyatomic alcohol 5 to 15 parts, polymer 0.5 to 1 part according to 100 weight parts, and water as residue. The preparation method is: putting liquid wax, non-ionic surface activator, and polyatomic alcohol into reactor, heating the mixture to 60 deg C. to 80 deg C., agitating the mixture for 30min with agitation speed controlled in the ranged of 1000 to 2000 rpm; adding polymer-dissolved polymer into the reactor, agitating the mixture for 60 to 120 min continuously at 60 to 80 deg C. with agitation speed controlled in 1000 to 2000 rpm, cooling it to room temperature, to obtain the product of lubricating anti-sloughing agent. The lubricating anti-sloughing agent of the invention is provided with good stability, with excellent lubricating, anti-sloughing and oil gas layer-protecting effects in drilling liquid, and good environmental protection property without fluorescence, toxic pollution. The adopted materials are easy to obtain. The preparation method is simple, easy to implement with low cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

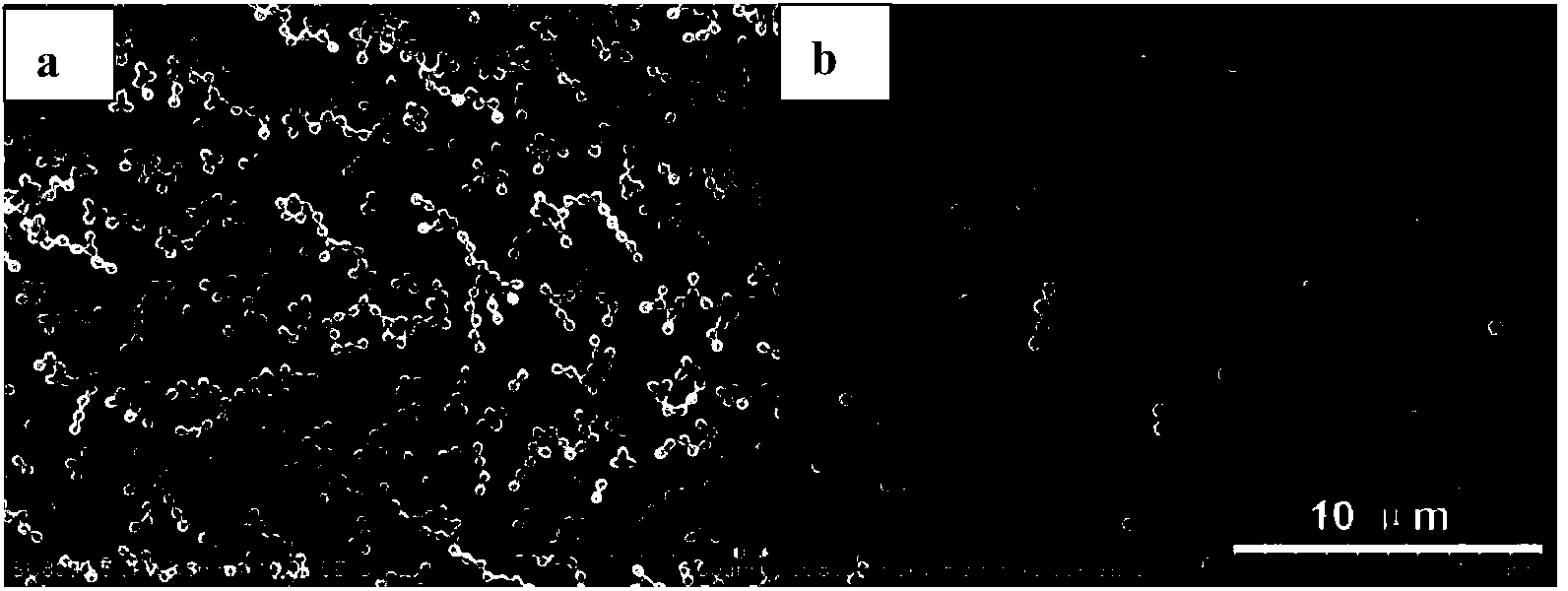

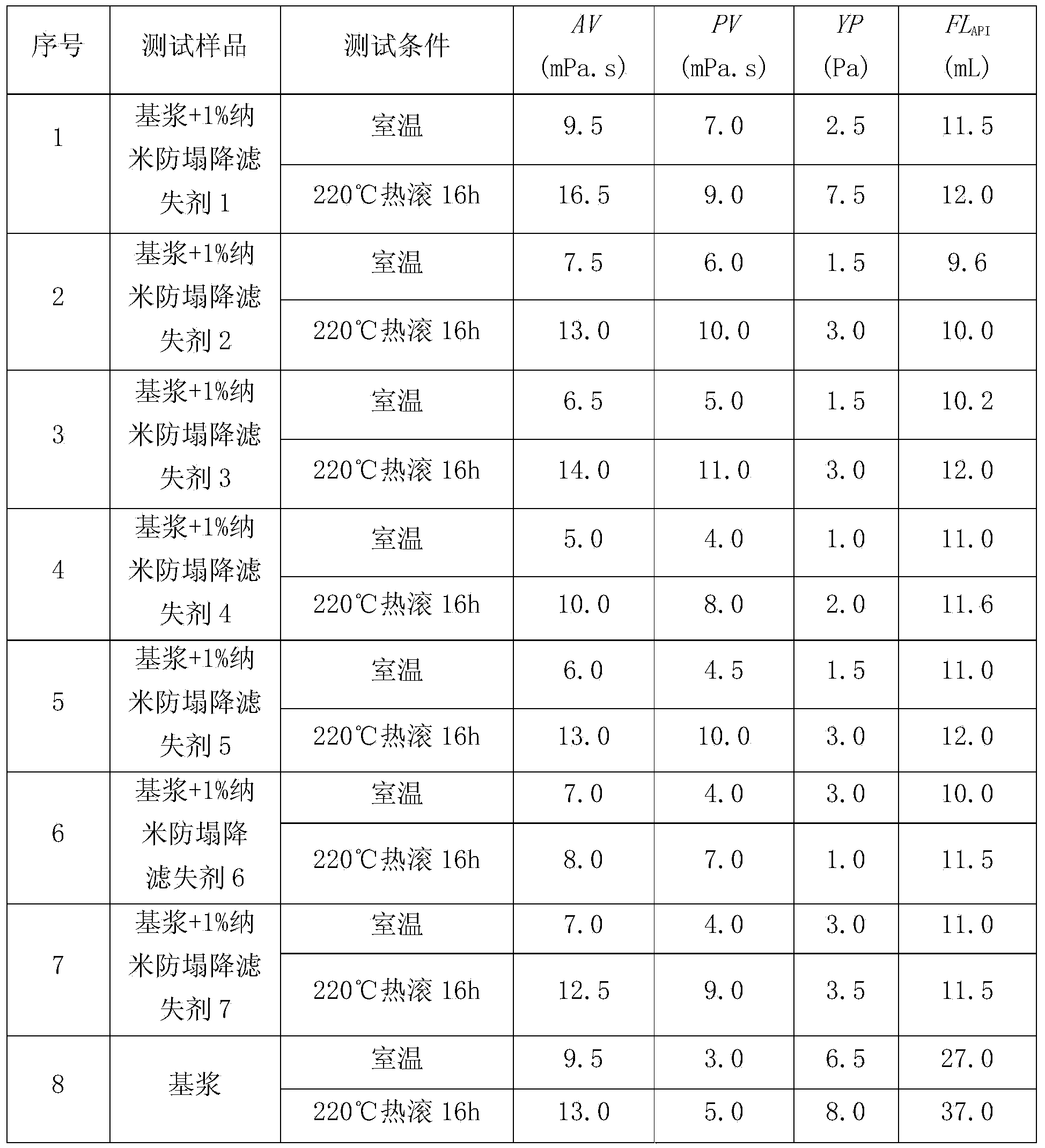

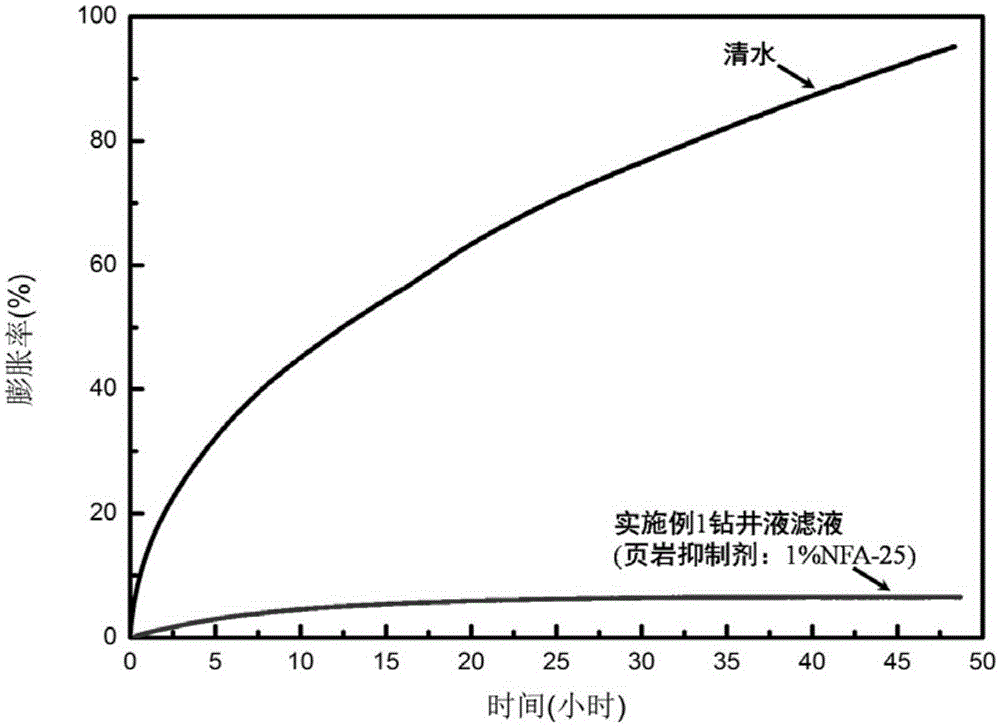

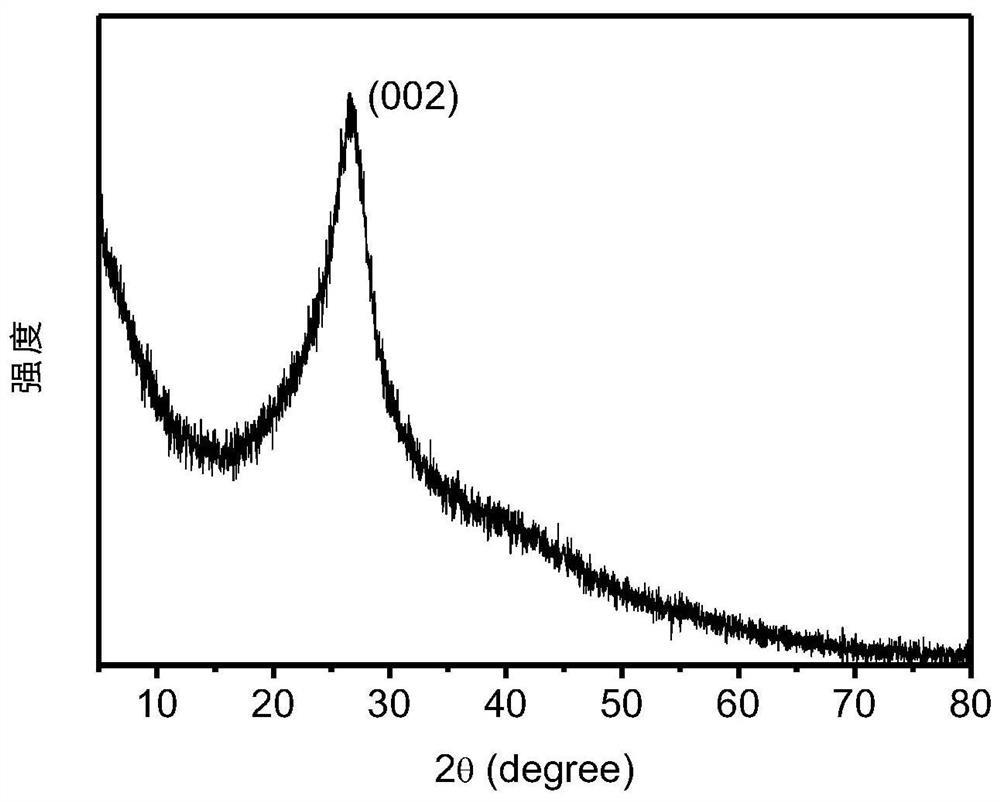

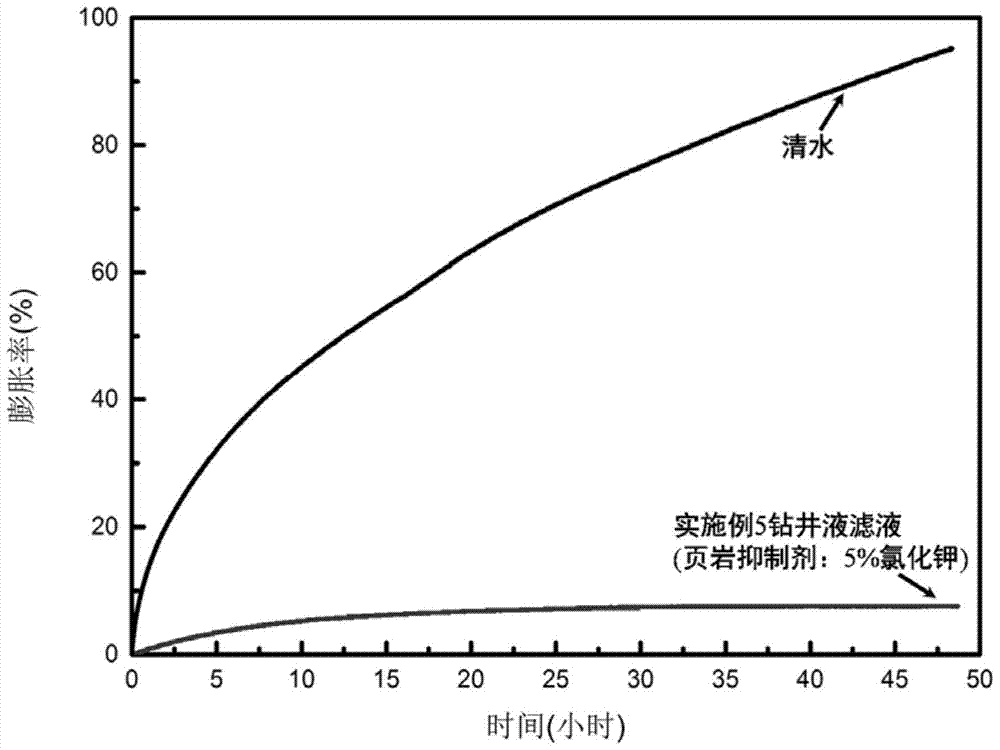

High temperature resistant non-fluorescence anti-sloughing nano-filtrate reducer and preparation method thereof

The invention discloses a high temperature resistant non-fluorescence anti-sloughing nano-filtrate reducer and a preparation method of the high temperature resistant non-fluorescence anti-sloughing nano-filtrate reducer. The anti-sloughing nano-filtrate reducer is synthesized of at least one non-water-soluble monomer and at least one water-soluble monomer with amino or sulfonic acid group by using an emulsion polymerization method in a non-oxygen environment under the condition of stirring. The nanoscale of the anti-sloughing nano-filtrate reducer is 10nm-5,000nm, the surface of the anti-sloughing nano-filtrate reducer contains the amino group with an inhibition function or sulfonic acid base or sulfonic acid group with strong temperature resistance, and the anti-sloughing nano-filtrate reducer has a core-shell structure. The reduction rate of shale swelling inhibition can be more than 70%, the reduction rate of medium pressure filtration can be more than 50%, and the rheological properties of drilling fluid are not significantly affected. After the drilling fluid containing the prepared anti-sloughing filtrate reducer is subjected to hot rolling at 220 DEG C, the performance of the drilling fluid is not significantly changed, so that the anti-sloughing filtrate reducer has a good high temperature resistant effect. The anti-sloughing filtrate reducer has very good application prospect in the term of anti-sloughing inhibition.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Drilling shaft lining stabilizer

InactiveCN101362938AReduce mud cake lubrication coefficientOutstanding lubricity and rebound effectDrilling compositionChemistryEther

The invention discloses a boring well wall stabilizer which is mainly used for solving the technical problem that storage layer is damaged due to unstable well wall and expansion of clay during the boring process; the well wall stabilizer consists of 20-35 parts of diallyldimethylammonium chloride, 2-5 parts of diallyldimethylammonium chloride-acrylamide polymer, 1-5 parts of non-ionic surfactant OP-10, 1-2 parts of fluoride-bearing alkyl ethoxy ether alcohol non-ionic surfactant, 1-3 parts of cellulose, 1-5 parts of KCl and 45-74 parts of water, according to the weight parts. The stabilizer can stabilize the well wall, greatly reduces the expansion rate of the clay at storage layer and eliminates the damages on the storage layer.

Owner:XI'AN PETROLEUM UNIVERSITY

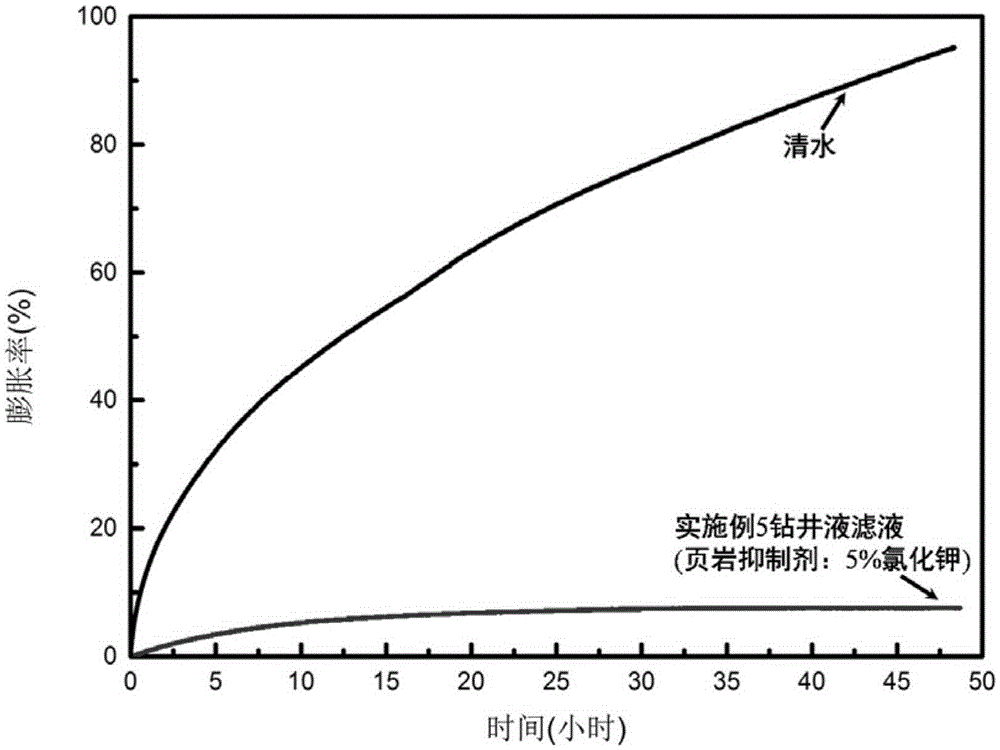

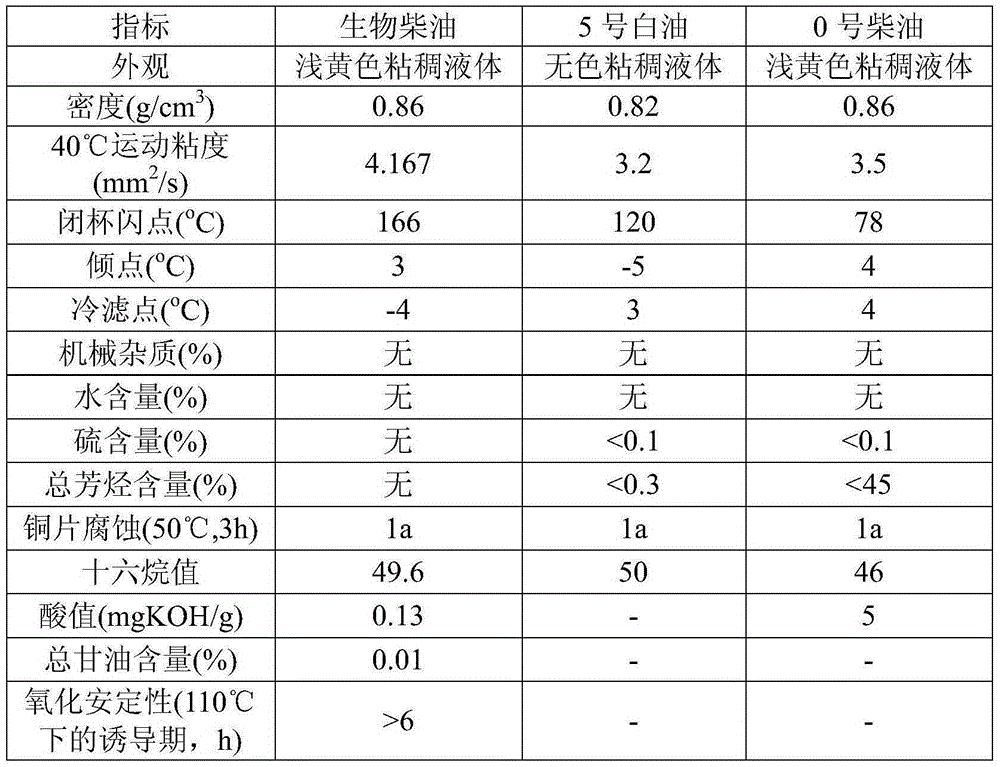

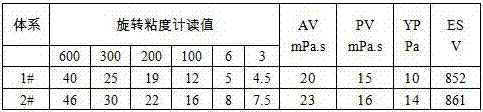

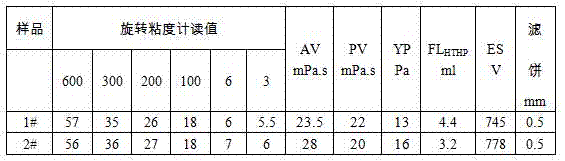

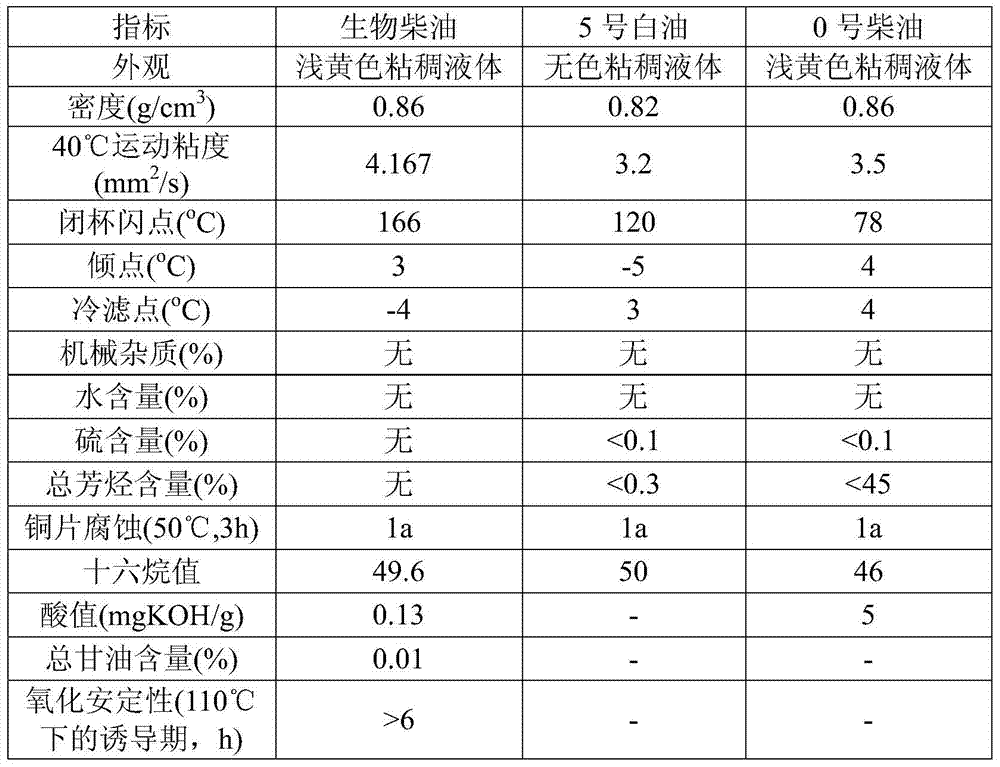

Oil-in-water drilling fluid taking biodiesel as dispersion phase as well as preparation method and application thereof

The invention provides oil-in-water drilling fluid taking biodiesel as a dispersion phase as well as a preparation method and application thereof. The oil-in-water drilling fluid comprises 40-70 parts by volume of water and 30-60 parts by volume of biodiesel, wherein the total volume of water and biodiesel is 100%; the oil-in-water drilling fluid further comprises the following components: bentonite with the mass-to-volume ratio (g / mL) of 1%-6%, sodium carbonate with the mass-to-volume ratio of 0.05%-0.3%, sodium hydroxide with the mass-to-volume ratio of 0.02%-0.05%, a main emulsifier with the mass-to-volume ratio of 2%-5%, an auxiliary emulsifier with the mass-to-volume ratio of 0.2%-1%, a shale inhibitor with the mass-to-volume ratio of 0.5%-5% and a filtrate reducer with the mass-to-volume ratio of 0.5%-5%. The oil-in-water drilling fluid provided by the invention has the characteristics of being low in cost, non-toxic, non-fluorescent, low in density, adjustable, good in rheological property, low in filter loss, excellent in lubricating property and high in upper temperature resistance limit, and further has advantages of being excellent in antifouling property, shale inhibition property, reservoir protection property and environment acceptability.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Cellulose nanocrystal used as water-based drilling fluid anti-collapse agent and preparation method of cellulose nanocrystal

InactiveCN108559463ANo fluorescenceGood anti-collapse effectDrilling compositionWater basedFluorescence

The invention relates to a cellulose nanocrystal used as a water-based drilling fluid anti-collapse agent and a preparation method of the cellulose nanocrystal and belongs to the field of petroleum and natural gas resource exploration and development and natural polymer material preparation. The cellulose nanocrystal used as the water-based drilling fluid anti-collapse agent is prepared from, by weight, 3-12% of cellulose pulp, 54-75% of oxalate dihydrate, 0.25-3.5% of high-priced metal salt and balance water, and made by a reaction at 95-100 DEG C for 7-16 hours under mechanical stirring conditions. The product size is 100-700nm, the cellulose nanocrystal has the advantages of being excellent in anti-collapse capability, free of toxicity and fluorescence, environmentally friendly and thelike and also has good filtrate loss performance, and the temperature resistance is up to 180 DEG C. Since the cellulose nanocrystal is prepared by using natural biomaterials, the cellulose nanocrystal automatically degrades after a period of time to achieve automatic deblocking, and damage to a reservoir is reduced.

Owner:TIANJIN UNIV OF SCI & TECH

Anti-blocking lubricant for drilling fluid and preparing method

InactiveCN102492403AImprove the lubrication effectNo fluorescenceDrilling compositionReduction rateFluorescence

Disclosed are anti-blocking lubricant for drilling fluid and a preparing method. The anti-blocking lubricant for drilling fluid is characterized by including the following components, by weight percentage, 97.5% of No.10 white oil, 2% of oleic acid formic ester and 0.5% of emulsifier (SOP (standard operation procedure)-80). The manufacturing method includes steps of adding 97.5% of the No.10 white oil into a reactor, slowly mixing the same until the temperature rises to 25 DEG C, then adding 2% of the oleic acid formic ester and mixing uniformly slowly as heating in a manner of controlling the temperature to be no higher than 45 DEG C and mixing time to be not less than 30 minutes, finally, adding 0.5% of the emulsifier (SOP-80) and mixing continuously for one hour while heating again and controlling the temperature to be no higher than 50 DEG C. The anti-blocking lubricant for drilling fluid is high in lubricating performance, free of fluorescence and affection on geological logging data, capable of effectively preventing blocking of a drill during drilling and filling the blank of the field in home and abroad and reduction rate of lubrication coefficient is higher than 80%.

Owner:LANGFANG QINGXING CHEM

Novel non-woven fabric material

The invention belongs to the field of manufacturing of non-woven fabric and particularly relates to a novel non-woven fabric material which has the advantages of good ventilation performance, softness and no fluorescence. According to the technical scheme, the novel non-woven fabric comprises, by weight, 5-95% of superabsorbent fibers and 95-5% of cotton fibers.

Owner:NANTONG JIANGCHAO FIBER PRODS

Microcrystalline cellulose used as temporary protective plugging agent for drilling fluid reservoir and preparation method thereof

The invention relates to microcrystalline cellulose used as a temporary protective plugging agent for a drilling fluid reservoir and a preparation method thereof, and belongs to the field of oil and natural gas resource exploration and development and natural polymer material preparation. The microcrystalline cellulose is prepared by mixing 2 wt%-12 wt% of cellulose slurry, 20 wt%-42 wt% of oxalicacid dihydrate, 0.25 wt%-3.5 wt% of high-valence metal salt and the balance water under the temperature of 95 DEG C-100 DEG C and the condition of conducting mechanical stirring for 3h-5h. The dimension of a product is 20 microns-80 microns, the product has the advantages of no toxin, no fluorescence, environmental friendliness, low cost and the like, effective plugging on micro pores and micro cracks of an oil and gas reservoir can be achieved, because the microcrystalline cellulose is prepared from natural biological materials, the product is self-degraded after a period of time, automaticunsealing can be achieved, and the purpose of protecting the reservoir is achieved.

Owner:TIANJIN UNIV OF SCI & TECH

Dual-protection organic lubricant for drilling fluids and preparation method thereof

InactiveCN104164223AImprove the lubrication effectNo pollution in the processDrilling compositionVegetable oilFluorescence

The invention discloses a dual-protection organic lubricant for drilling fluids and a preparation method thereof. The technical scheme is as follows: the dual-protection organic lubricant for drilling fluids is mainly prepared from the following raw materials in parts by weight: 40-70 parts of vegetable oil, 10-20 parts of ethylene glycol, 10-20 parts of triethanolamine, 2-8 parts of concentrated sulfuric acid and 2-8 parts of composite emulsifier. The mass concentration of the concentrated sulfuric acid is 98%; and the composite emulsifier is a mixture of an SP-80 emulsifier and an OP-10 emulsifier. The invention also discloses a preparation method of the dual-protection organic lubricant for drilling fluids. The dual-protection organic lubricant for drilling fluids can greatly enhance the lubricating property of the drilling fluid, has the advantages of extreme pressure resistance, sticking resistance, no environment pollution, no fluorescence and the like, is beneficial to protecting the reservoirs for oil and gas, is suitable for common demands for well drilling, and can satisfy the drilling lubricating requirements for deep wells, high-inclination wells and high and deep horizontal wells.

Owner:XINXIANG FUBANG TECH

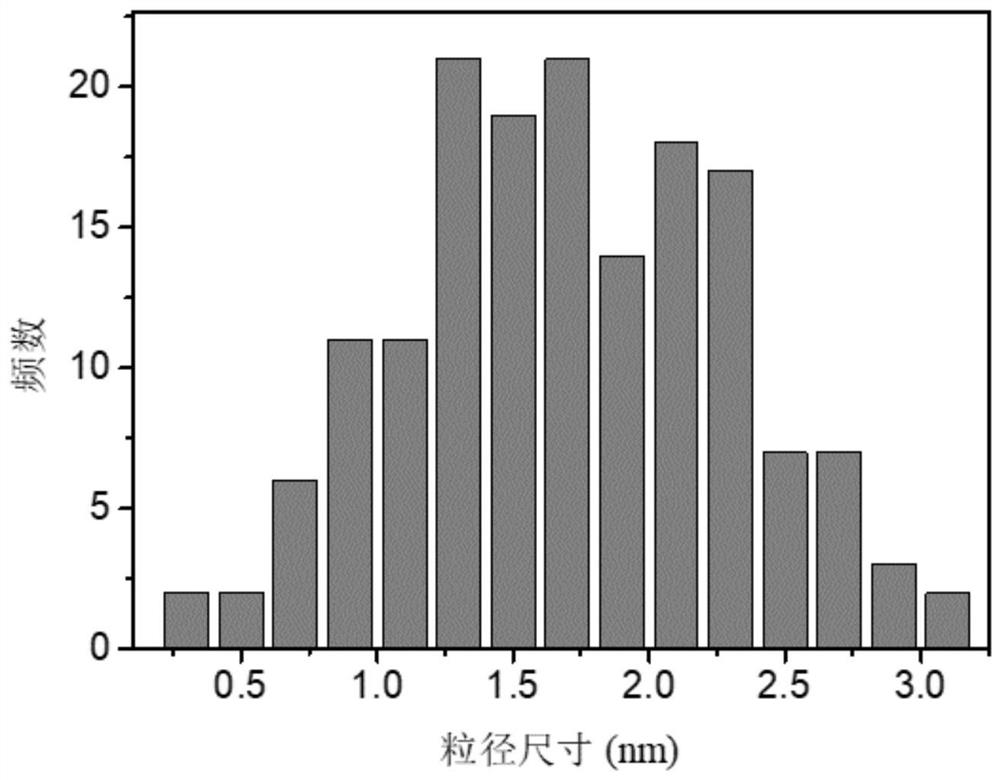

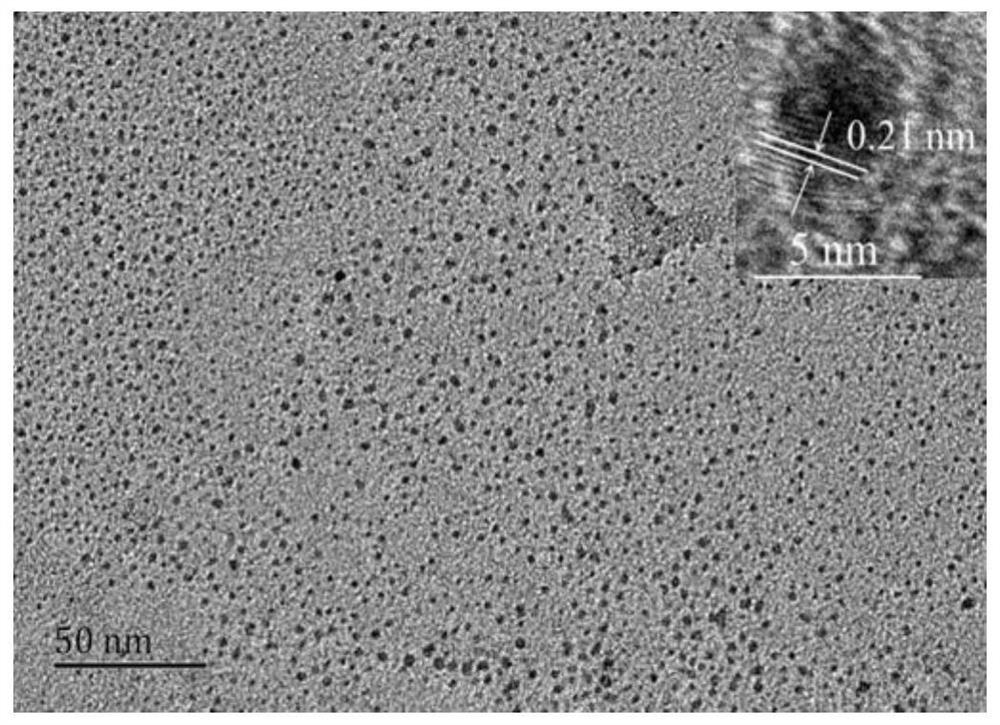

Preparation of phosphate radical-responsive carbon quantum dots and application of phosphate radical-responsive carbon quantum dots in fingerprint fluorescence recognition

ActiveCN112280556ASimple preparation processLow costNanoopticsNano-carbonFreeze-dryingPhosphoric acid

The invention relates to preparation of phosphate radical-responsive carbon quantum dots and application of the phosphate radical-responsive carbon quantum dots in fingerprint fluorescence recognition. The method comprises the following steps of: 1, adding 1, 2, 4-trihydroxybenzene into ultrapure water, and performing stirring to obtain a 1, 2, 4-trihydroxybenzene solution; 2, putting the solutionobtained in the step 1 into a high-pressure reaction kettle lined with polytetrafluoroethylene for reaction; performing centrifuging after finishing the reaction, and taking supernatant for later use; and 3, carrying out rotary evaporation on the supernatant obtained in the step 2, and carrying out vacuum freeze drying to obtain black solid powder which is the carbon quantum dots. The preparationmethod is simple in process, low in cost, and good in stability; and no fluorescence exists in ultrapure water.

Owner:NORTHWEST A & F UNIV

Drilling shaft lining stabilizer

InactiveCN101362938BPlay a stabilizing roleReduce the lubrication coefficientDrilling compositionAlcoholEther

The invention discloses a boring well wall stabilizer which is mainly used for solving the technical problem that storage layer is damaged due to unstable well wall and expansion of clay during the boring process; the well wall stabilizer consists of 20-35 parts of diallyldimethylammonium chloride, 2-5 parts of diallyldimethylammonium chloride-acrylamide polymer, 1-5 parts of non-ionic surfactantOP-10, 1-2 parts of fluoride-bearing alkyl ethoxy ether alcohol non-ionic surfactant, 1-3 parts of cellulose, 1-5 parts of KCl and 45-74 parts of water, according to the weight parts. The stabilizer can stabilize the well wall, greatly reduces the expansion rate of the clay at storage layer and eliminates the damages on the storage layer.

Owner:XI'AN PETROLEUM UNIVERSITY

Environment friendly synthetic base drilling fluid

The invention provides an environment friendly synthetic base drilling fluid including: 65-80 v% of linear paraffin synthetic base oil, 20-35 v% of a calcium chloride water solution being 25 mass%, 2-3 mass% of NHY-1 organic earth, 1-6 mass% of natural fatty acid, natural fatty amine, natural tall oil fatty acid and an alkyl ether emulsifier, 1-4 mass% of calcium oxide, 1-5 mass% of a high-molecular polymer D210 fluid loss additive, and 20-80 mass% of a barite powder weighting agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil-in-water drilling fluid with biodiesel as dispersed phase, preparation method and application thereof

The invention provides oil-in-water drilling fluid taking biodiesel as a dispersion phase as well as a preparation method and application thereof. The oil-in-water drilling fluid comprises 40-70 parts by volume of water and 30-60 parts by volume of biodiesel, wherein the total volume of water and biodiesel is 100%; the oil-in-water drilling fluid further comprises the following components: bentonite with the mass-to-volume ratio (g / mL) of 1%-6%, sodium carbonate with the mass-to-volume ratio of 0.05%-0.3%, sodium hydroxide with the mass-to-volume ratio of 0.02%-0.05%, a main emulsifier with the mass-to-volume ratio of 2%-5%, an auxiliary emulsifier with the mass-to-volume ratio of 0.2%-1%, a shale inhibitor with the mass-to-volume ratio of 0.5%-5% and a filtrate reducer with the mass-to-volume ratio of 0.5%-5%. The oil-in-water drilling fluid provided by the invention has the characteristics of being low in cost, non-toxic, non-fluorescent, low in density, adjustable, good in rheological property, low in filter loss, excellent in lubricating property and high in upper temperature resistance limit, and further has advantages of being excellent in antifouling property, shale inhibition property, reservoir protection property and environment acceptability.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A kind of degradable modified starch-based polymer well wall anti-collapse material and preparation method thereof

ActiveCN108219069BEasy to plug inImprove temperature resistanceDrilling compositionPotassium persulfatePolymer science

The invention discloses a degradable modified starch-based polymer well wall anti-collapse material and a preparation method thereof, which consists of four components: modified starch water-absorbing resin, alkyl glycoside, cross-linking auxiliary agent and defoaming auxiliary agent. The preparation method is to use starch as the skeleton, acrylic acid and acrylamide as the graft comonomer, potassium persulfate as the initiator, N, N'-methylenebisacrylamide as the crosslinking agent, and polymerize in aqueous solution to form a modified Starch water-absorbent resin, mixed with alkyl glucoside, cross-linking aid, and defoaming aid in a weight ratio of 10-14:3-6:2-4:1-2 parts. The degradable modified starch-based polymer well wall anti-slump material synthesized by the present invention is biodegradable and will not cause damage to the stratum; the price is low; the synthesis process is simple; it is not easy to segregate under pressure and has good plugging performance: When the system is added at 3%, the filtration loss reduction rate is 60-80%, and the shale linear expansion inhibition rate is 55-80%; the temperature resistance is 180°C; it is non-toxic and has no fluorescence.

Owner:TIANJIN CHENGJIAN UNIV

Lubricating collapse-resisting agent for drilling fluid and preparation method thereof

The invention discloses a drill liquid lubricating anti-sloughing agent and preparation method thereof. The lubricating anti-sloughing agent is composed of liquid wax 10 to 30 parts, non-ionic surfaceactivator 1 to 3 parts, polyatomic alcohol 5 to 15 parts, polymer 0.5 to 1 part according to 100 weight parts, and water as residue. The preparation method is: putting liquid wax, non-ionic surface activator, and polyatomic alcohol into reactor, heating the mixture to 60 deg C. to 80 deg C., agitating the mixture for 30min with agitation speed controlled in the ranged of 1000 to 2000 rpm; addingpolymer-dissolved polymer into the reactor, agitating the mixture for 60 to 120 min continuously at 60 to 80 deg C. with agitation speed controlled in 1000 to 2000 rpm, cooling it to room temperature,toobtain the product of lubricating anti-sloughing agent. The lubricating anti-sloughing agent of the invention is provided with good stability, with excellent lubricating, anti-sloughing and oil gas l ayer-protecting effects in drilling liquid, and good environmental protection property without fluorescence, toxic pollution. The adopted materials are easy to obtain. The preparation method is simple, easy to implement with low cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

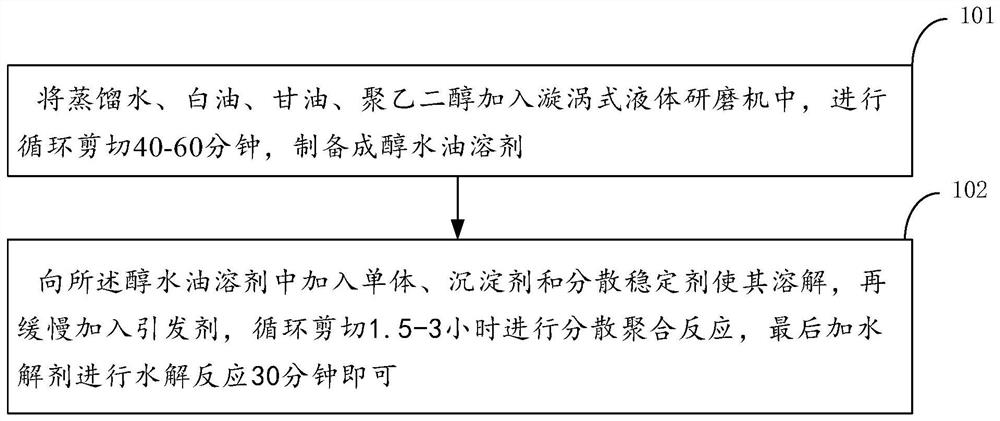

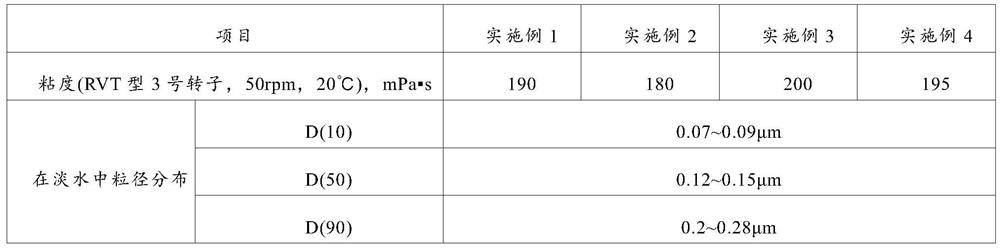

A kind of nano polymer latex, preparation method and application thereof

The present invention provides a kind of nano high molecular polymer latex, preparation method and application thereof, described nano high molecular polymer latex is made of monomer, initiator, precipitating agent, dispersion stabilizer-polyoxyethylene diamine and hydrolyzing agent It is prepared by chemical hydrolysis in an alcohol-water-oil mixed solvent. The mass percentage of each reactant is: monomer 40-60%, initiator 0.5-2%, precipitant 1-5%, dispersion stabilizer-polyoxygen Ethylenediamine 5-10%, hydrolysis agent 5-10%, alcohol-water-oil mixed solvent 15-40%. The invention provides nano-polymer latex and its preparation method, the process is simple and efficient, can resist saturated brine and compound brine, can resist temperature up to 160°C, is non-toxic, has no fluorescence, is suitable for various water-based drilling fluids and is environmentally friendly The drilling environment is demanding, and the prepared nano-polymer latex has multiple uses, not only as the main component of drilling fluid and completion fluid in oil field production, but also as a film in the leather industry and construction industry agent and coating industry as a dispersant.

Owner:安徽中科日升科技有限公司 +1

Illegal cooking oil lubricant and preparation method thereof

The invention discloses an illegal cooking oil lubricant and a preparation method thereof. The illegal cooking oil lubricant comprises the following components in percentage by weight: 40%-60% of illegal cooking oil, 0.5%-1.5% of sodium sulfite, 1%-3% of sorbide oleate, 0.02%-0.04% of antioxidants, 0.2%-0.3% of extreme-pressure antiwear agents, 0.05%-0.1% of formaldehyde, 1.0%-1.2% of sodium hydroxide and the balance of water. Through the illegal cooking oil lubricant disclosed by the invention, the problem that torque and friction resistance are reduced through lubrication in the drilling process of a horizontal well is effectively solved, moreover, a new way is provided for the recycling of the illegal cooking oil, and the preparation cost of the lubricant can be reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Formula and preparation method of paper for children

InactiveCN111996838ANo fluorescenceNo reflectionDefoamers additionSpecial paperSodium carboxymethylcellulosePaper manufacturing

The invention belongs to the technical field of paper manufacturing, and provides a formula and a preparation method of paper for children. The formula of paper for children includes the following components in parts by weight: 500-800 parts of water, 100-200 parts of kaolin, 400-500 parts of ground calcium carbonate, 150-250 parts of light calcium carbonate, 3-4 parts of carboxymethyl cellulose,20-50 parts of starch, 150-250 parts of styrene-butadiene latex, 10-12 parts of a lubricant, 15-20 parts of a water repellent agent, 8-10 parts of titanium dioxide, 1-2 parts of a defoaming agent, 1-5parts of caustic soda and 0.1-0.2 part of a penetrating agent. The paper for children has the beneficial effects that 1, the paper for children is environment-friendly, non-toxic and degradable; 2, the color rendition degree is high, the ink consumption is reduced, and the printing cost is low; 3, eyesight is protected, light source reflection is low, and fluorescence is avoided; and 4, the paperis suitable for OID printing paper.

Owner:深圳市聆听科技传媒有限公司

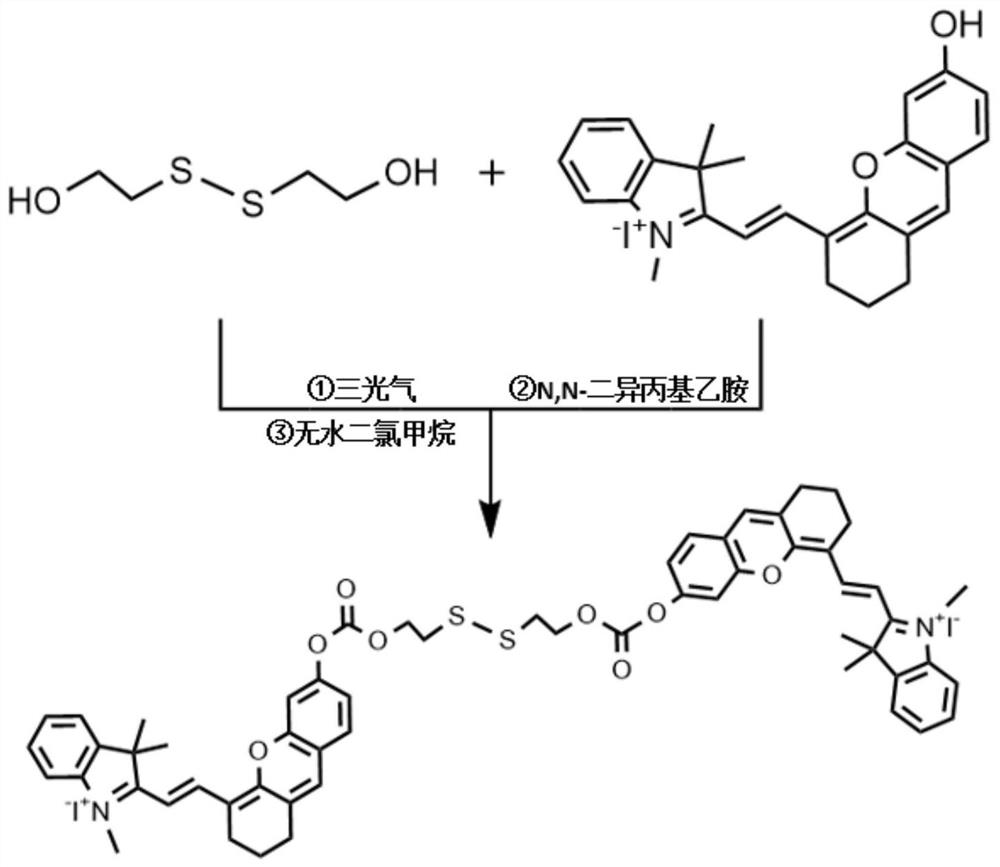

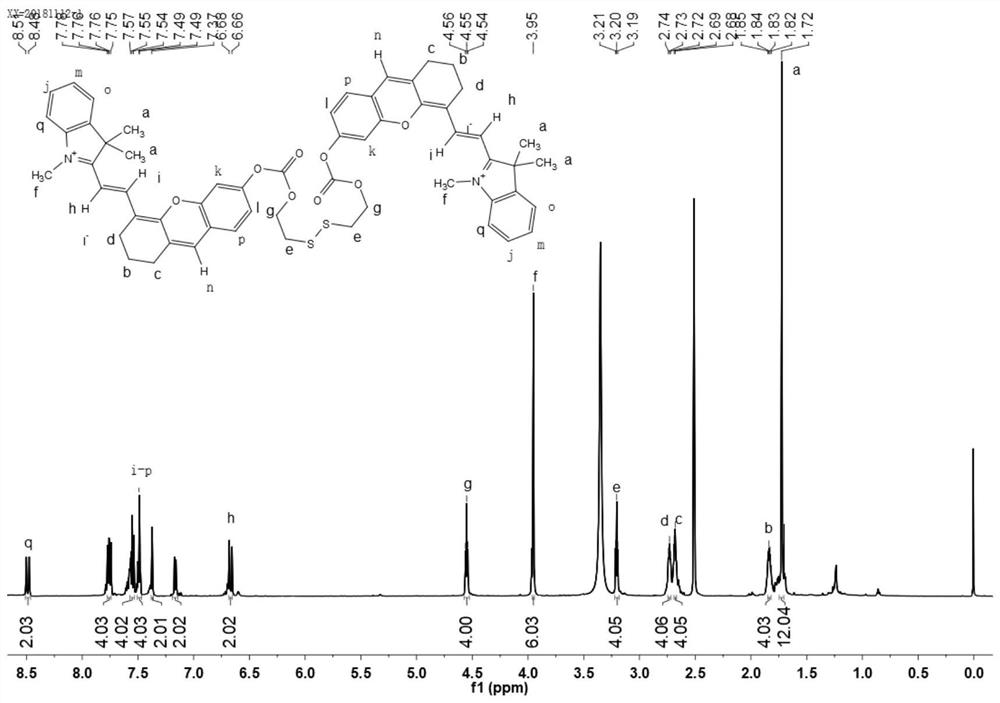

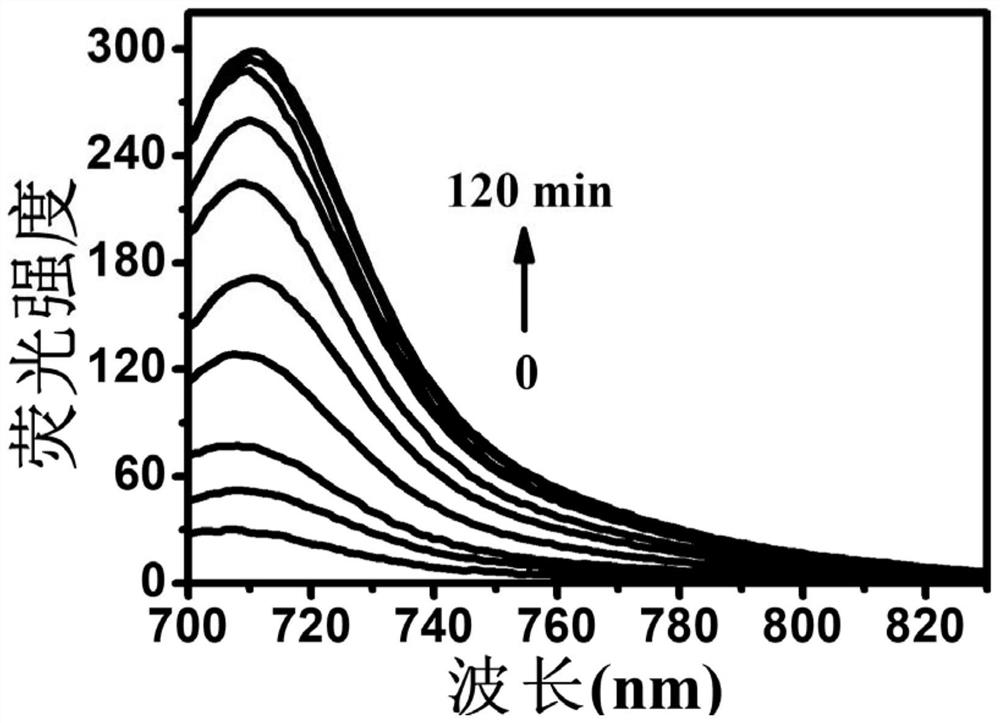

A fluorescent probe for detecting glutathione and its preparation method and application

ActiveCN110078716BNo fluorescenceImprove anti-interference abilityOrganic chemistryFluorescence/phosphorescenceFluoProbesIodide

The invention discloses a fluorescent probe for detecting glutathione, a preparation method and application thereof, and belongs to the technical field of analysis and detection. The fluorescent probe is 2,2'–((1E,1'E)‑(((((dithio(ethane‑2,1‑diyl))bis(oxy))bis(carbonyl))bis (Oxygen))bis(2,3-dihydro-1H-oxanthene-6,4-diyl))bis(ethylene-2,1-diyl))bis(1,3,3-trimethyl Base-3H-indol-1-ium) iodide, the structural formula is as shown in formula (I). Compared with the current fluorescence detection technology, the fluorescent probe of the present invention is easy to synthesize, the detection method is simple and the result is intuitive, and the qualitative and quantitative analysis of glutathione can be carried out through the fluorescence intensity, which has good accuracy and anti-interference It can be applied to the detection of glutathione in the fields of cosmetics and food.

Owner:SOUTH CHINA UNIV OF TECH

A kind of anti-high temperature environment-friendly drilling fluid lubricant and preparation method thereof

ActiveCN107556988BGuarantee authenticityGood water solubilityDrilling compositionThermodynamicsActive agent

The invention relates to a high-temperature-resistant environment-protecting type drilling fluid lubricating agent. The high-temperature-resistant environment-protecting type drilling fluid lubricating agent mainly solves the problems that in the existing drilling process, the lubricating property is not high, high-temperature resistance and high-pressure resistance are low, and the drilling exploitation requirements of a deep well and an extradeep well are difficult to meet. The high-temperature-resistant environment-protecting type drilling fluid lubricating agent is characterized by comprising the following components in percentage by mass: 20 to 35 percent of plant oil, 20 to 40 percent of silicon oil, 5 to 10 percent of an anti-wear agent, 10 to 20 percent of a surfactant and 15 to 30percent of water. The preparation method of the drilling fluid lubricating agent comprises the following steps: (1) adding the silicon oil into the plant oil and performing stirring reaction; (2) mixing the surfactant and the anti-wear agent mixture according to the proportion in advance, performing stirring reaction, and mixing with the base oil in the step (1); (3) adding the water according tothe proportion, continuously performing stirring reaction and filtering to obtain a product. The high-temperature-resistant environment-protecting type drilling fluid lubricating agent can resist 150-DEG C temperature, is simple in synthesis process and convenient for on-site application, meets the environment-protecting requirement and is a high-performance liquid lubricating agent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of micro-nano anti-collapse plugging agent for drilling fluid and preparation method thereof

The invention discloses a micro-nano anti-collapse plugging agent for drilling fluid and a preparation method thereof. The plugging agent is made of the following raw materials in proportions by weight: 5-20 parts of epoxy resin, 5-15 parts of itaconic acid 10-38 parts of acrylic acid, 15-35 parts of 2-acrylamido-2-methylpropanesulfonic acid, 2-10 parts of pH regulator, 1-6 parts of emulsifier, 0.2-1.0 parts of initiator, solvent 5‑15 parts, water 50‑150 parts. Compared with the prior art, the present invention has nano-scale and micron-scale deformable particles, reduces fluid loss, regulates rheology, has good temperature resistance, no fluorescence, and good compatibility; at the same time, the molecular chain of the plugging agent has A variety of adsorption groups can be adsorbed on the surface of clay particles to repair the filter cake formed by the particle filling in the drilling fluid; through the particle size and deformable characteristics, it can enter the pores and bedding of the shale formation and prevent the filtrate from entering The formation plays a role in stabilizing the well wall; the plugging agent has strong dispersion ability and high stability, and is suitable for hard and brittle mudstone with various micro-fractures.

Owner:山东得顺源石油科技有限公司

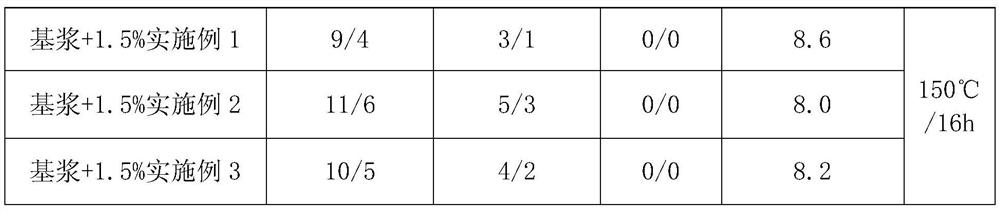

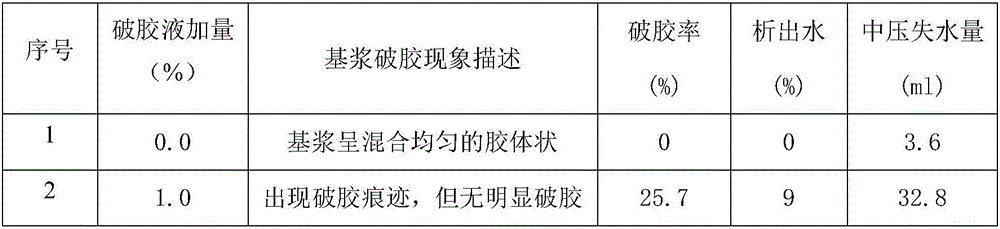

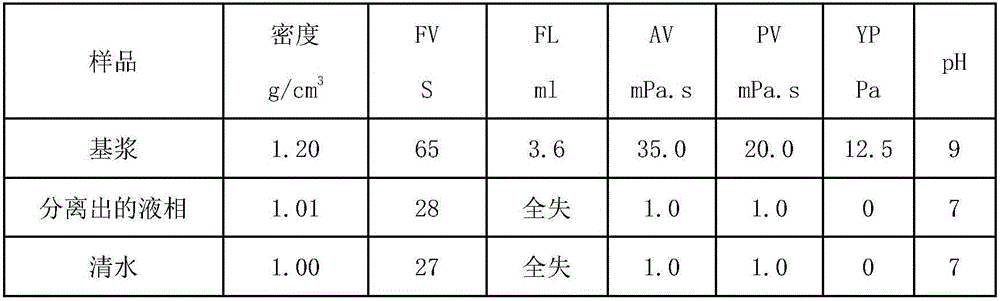

Gel breaking solution and use thereof

The invention provides a gel breaking solution. The gel breaking solution comprises, by weight, 10-30% of a coagulant, 1.0-3.0% of a flocculating agent, 1.0-5.0% of a solid-liquid separating agent and the balance water. The gel breaking solution has no corrosivity, no fluorescence, no chemical toxicity and no biotoxicity, is biodegradable and environmentally friendly, solves the technical problems of gel breaking, solid-liquid separation and recycling of a waste low-solid phase sulphonated polymer mud in a Changqing large-scale well drilling construction process and greatly reduces a well drilling comprehensive cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

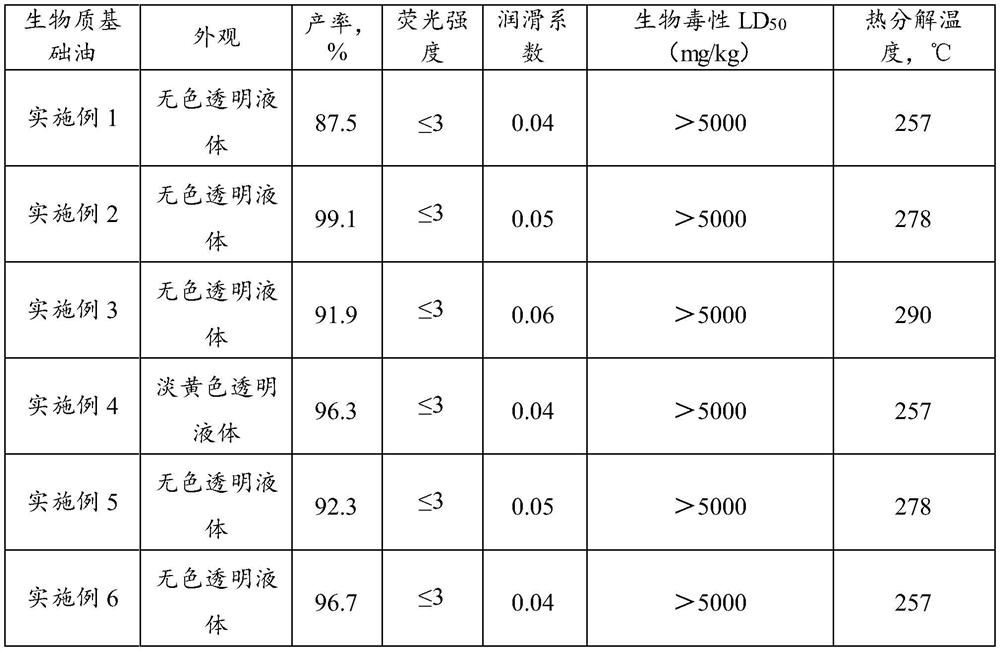

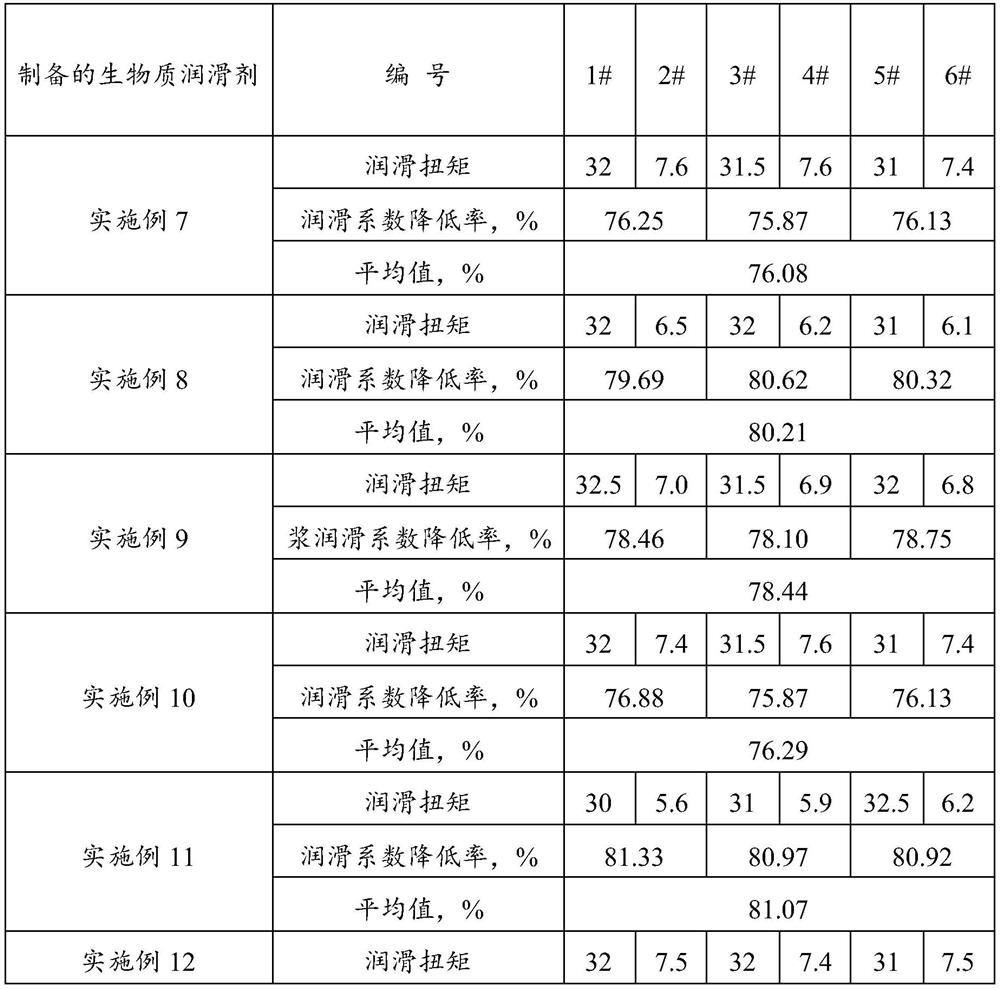

A kind of biomass base oil and preparation method thereof

ActiveCN110699051BNo lubricationImprove the lubrication effectDrilling compositionPtru catalystAliphatic hydrocarbon

Owner:中石化石油工程技术服务有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com