Cellulose nanocrystal used as water-based drilling fluid anti-collapse agent and preparation method of cellulose nanocrystal

A water-based drilling fluid and cellulose technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as refractory degradation, difficult recovery, reservoir damage, etc. The effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

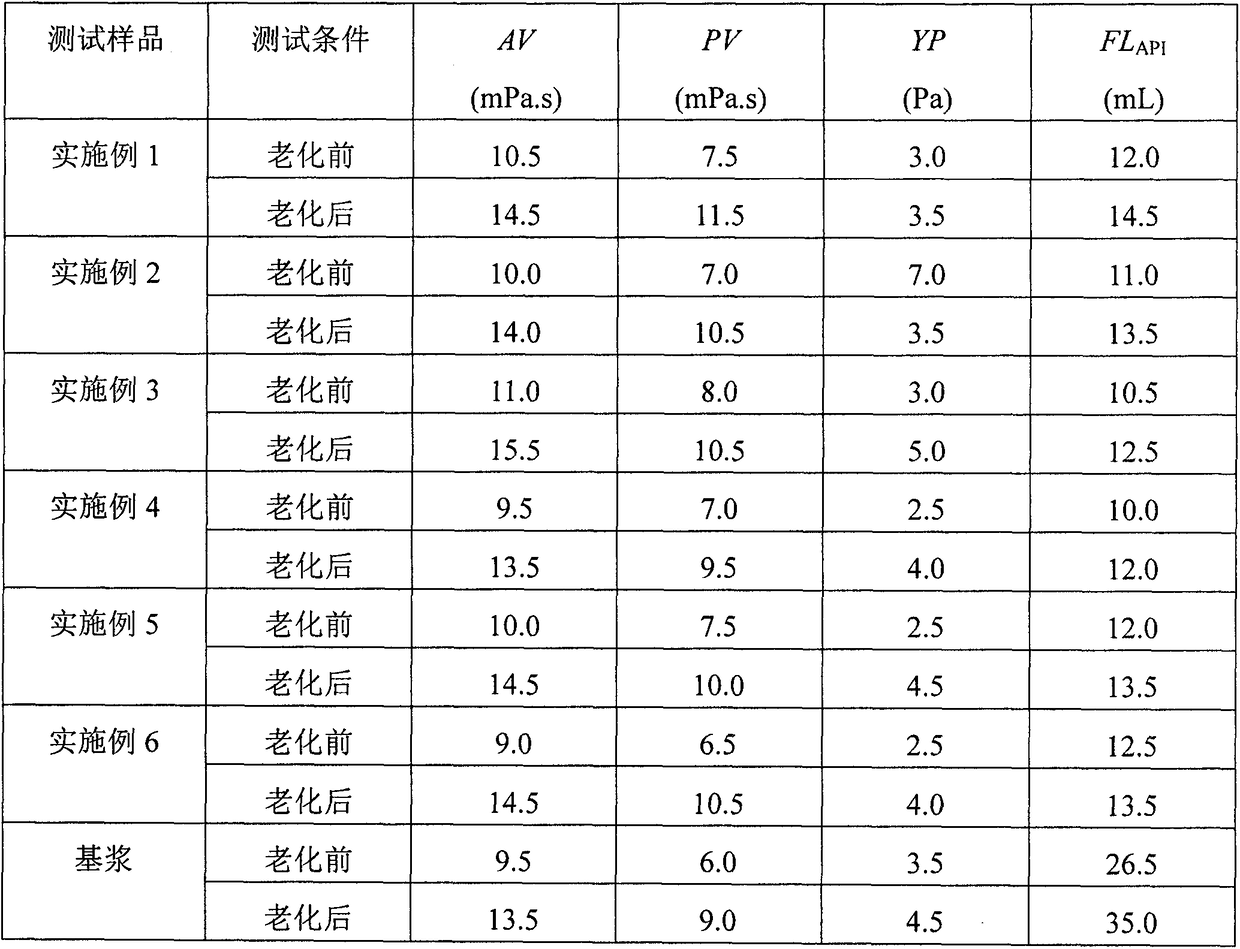

Examples

Embodiment 1

[0025] Add 55g of oxalic acid dihydrate into a three-necked round-bottomed flask with a capacity of 500mL at 20°C, then add 41.7g of distilled water and 0.3g of ferric chloride hexahydrate, stir for 5min, then add 3g of dry bleached poplar For wood pulp, heat up to 100°C with an oil bath, and maintain mechanical stirring at 100°C for 16 hours at a stirring speed of 300r / min. Then, 100 g of distilled water at 90° C. was added to the reaction system, and the reaction solution was directly centrifuged without cooling. The centrifuge speed was set at 6000 r / min, and the running time was 3 min. After centrifugation, transfer the supernatant into a 500mL round-bottomed flask, distill off about 90g of water under reduced pressure, then heat at 100°C for 5min, cool to 20°C, let stand for 0.5h, filter with suction, and filter cake part 2 Water oxalic acid recovery. The precipitate after centrifugation was dispersed with 100mL distilled water, and then centrifuged at a centrifuge speed...

Embodiment 2

[0027] Add 75g of oxalic acid dihydrate into a three-necked round-bottomed flask with a capacity of 500mL at 20°C, then add 21.5g of distilled water and 0.5g of ferric chloride hexahydrate, stir for 5min, then add 3g of dry bleached poplar For wood pulp, heat up to 100°C with an oil bath, and maintain mechanical stirring at 100°C for 10 hours at a stirring speed of 200r / min. Then, 100 g of distilled water at 90° C. was added to the reaction system, and the reaction solution was directly centrifuged without cooling. The centrifuge speed was set at 7000 r / min, and the running time was 3 min. After centrifugation, transfer the supernatant into a 500mL round bottom flask, distill off about 80g of water under reduced pressure, then heat at 100°C for 5min, cool to 20°C, let stand for 0.5h, filter with suction, and filter cake part 2 Water oxalic acid recovery. The precipitate after centrifugation was dispersed with 100mL distilled water, and then centrifuged at a centrifuge speed o...

Embodiment 3

[0029] Add 75g of oxalic acid dihydrate into a three-necked round-bottomed flask with a capacity of 500mL at 20°C, then add 12g of distilled water and 1.0g of ferric chloride hexahydrate, stir for 5min, then add 12g of dry bleached eucalyptus pulp, Raise the temperature to 100°C with an oil bath, and maintain mechanical stirring at 100°C for 7 hours at a stirring speed of 200r / min. Then, 100 g of distilled water at 90° C. was added to the reaction system, and the reaction solution was directly centrifuged without cooling. The centrifuge speed was set at 6000 r / min, and the running time was 3 min. After centrifugation, transfer the supernatant into a 500mL round-bottomed flask, distill off about 75g of water under reduced pressure, then heat at 100°C for 5min, cool to 20°C, let stand for 0.5h, filter with suction, and filter cake part 2 Water oxalic acid recovery. The precipitate after centrifugation is dispersed with 400mL distilled water, and then centrifuged at a centrifuge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com