A kind of micro-nano anti-collapse plugging agent for drilling fluid and preparation method thereof

A plugging agent and micro-nano technology, which are used in the field of micro-nano anti-slump plugging agents for drilling fluids and their preparation, can solve the limitation of wellbore stability, cannot effectively prevent drilling fluid and its filtrate from eroding, and particles cannot effectively Blocking and other problems, to achieve the effect of good compatibility, good temperature resistance, and rheological adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

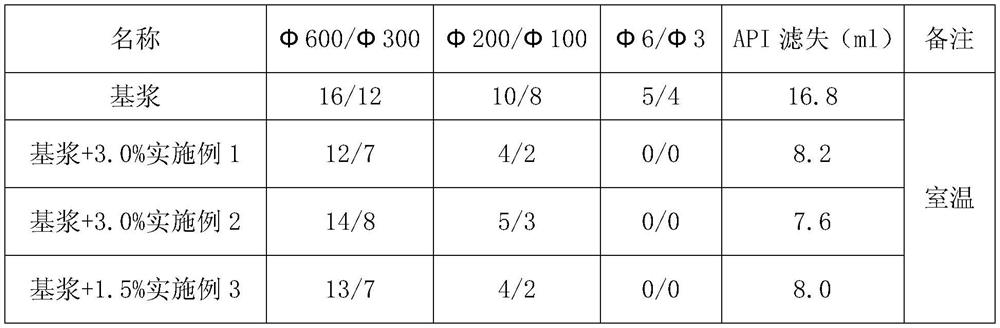

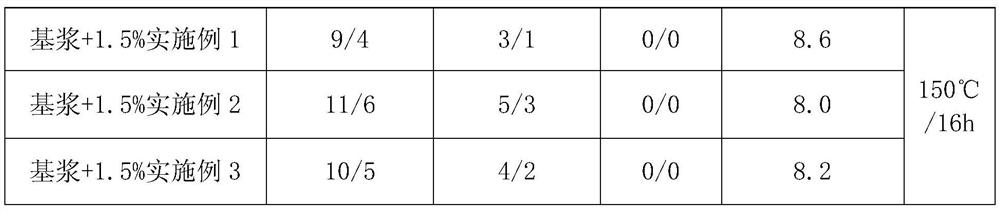

Examples

Embodiment 1

[0023] Preparation:

[0024] Epoxy resin 5kg, itaconic acid 5kg, acrylic acid 18kg, 2-acrylamido-2-methylpropanesulfonic acid 15kg, ammonia water 3kg, octylphenol polyoxyethylene ether 2kg, benzoyl peroxide 0.2kg, n-butyl Alcohol 5kg, water 50kg;

[0025] Processing:

[0026] Step 1) dissolving itaconic acid, acrylic acid, and 2-acrylamido-2-methylpropanesulfonic acid in water, and then adjusting the solution to pH=4 with ammonia water to obtain mixed solution 1;

[0027] Step 2) Weighing epoxy resin and n-butanol and dissolving at 60° C. for 1 hour to obtain feed liquid;

[0028] Step 3) At 80°C, pass nitrogen gas into the feed liquid obtained in step 2) for 30 minutes, then add the mixed solution 1 obtained in step 1) dropwise, and at the same time slowly add benzoyl peroxide and octylphenol polyoxyethylene ether, After the reaction time of 6h, mixed solution 2 was obtained;

[0029] Step 4) Send the mixed solution 2 obtained in step 3) into a high-shear emulsifier, add ...

Embodiment 2

[0031] Preparation:

[0032] Epoxy resin 8kg, itaconic acid 12kg, acrylic acid 10kg, 2-acrylamido-2-methylpropanesulfonic acid 25kg, potassium hydroxide 5kg, polyoxyethylene sorbitan trioleate 3kg, potassium persulfate 0.8 kg, toluene 12kg, water 100kg;

[0033] Processing:

[0034] Step 1) dissolving itaconic acid, acrylic acid, and 2-acrylamido-2-methylpropanesulfonic acid in water, and then adjusting the solution to pH=6 with potassium hydroxide to obtain mixed solution 1;

[0035] Step 2) Weighing epoxy resin and toluene and dissolving at 100° C. for 1 hour to obtain a feed solution;

[0036] Step 3) At 60°C, pass nitrogen gas into the feed solution obtained in step 2) for 30 minutes, then add the mixed solution 1 obtained in step 1) dropwise, and slowly add potassium persulfate and polyoxyethylene sorbitan trioleic acid at the same time ester, after the reaction time of 4h, mixed solution 2 was obtained;

[0037] Step 4) Send the mixed solution 2 obtained in step 3) i...

Embodiment 3

[0039] Preparation:

[0040] Epoxy resin 18kg, itaconic acid 7kg, acrylic acid 30kg, 2-acrylamido-2-methylpropanesulfonic acid 9kg, sodium hydroxide 4kg, mixture of sodium lauryl sulfate and sorbitan oleate 4kg, Azobisisobutyronitrile 0.4kg, mixture of xylene and 1,4-butanediol 10kg, water 70kg;

[0041] Processing:

[0042] Step 1) dissolving itaconic acid, acrylic acid, and 2-acrylamido-2-methylpropanesulfonic acid in water, and then adjusting the solution to pH=3 with sodium hydroxide to obtain mixed solution 1;

[0043] Step 2) Weighing the mixture of epoxy resin, xylene and 1,4-butanediol and dissolving it at 80° C. for 1 hour to obtain a feed solution;

[0044] Step 3) At 70°C, after 30 minutes of passing nitrogen gas into the feed solution obtained in step 2), add the mixed solution 1 obtained in step 1) dropwise, and at the same time slowly add azobisisobutyronitrile, sodium lauryl sulfate and The mixture of sorbitan oleic acid ester, after reaction time 8h, obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com