Salt-responsive high-temperature-resistant zwitterionic polymer filtrate reducer and preparation method and application thereof

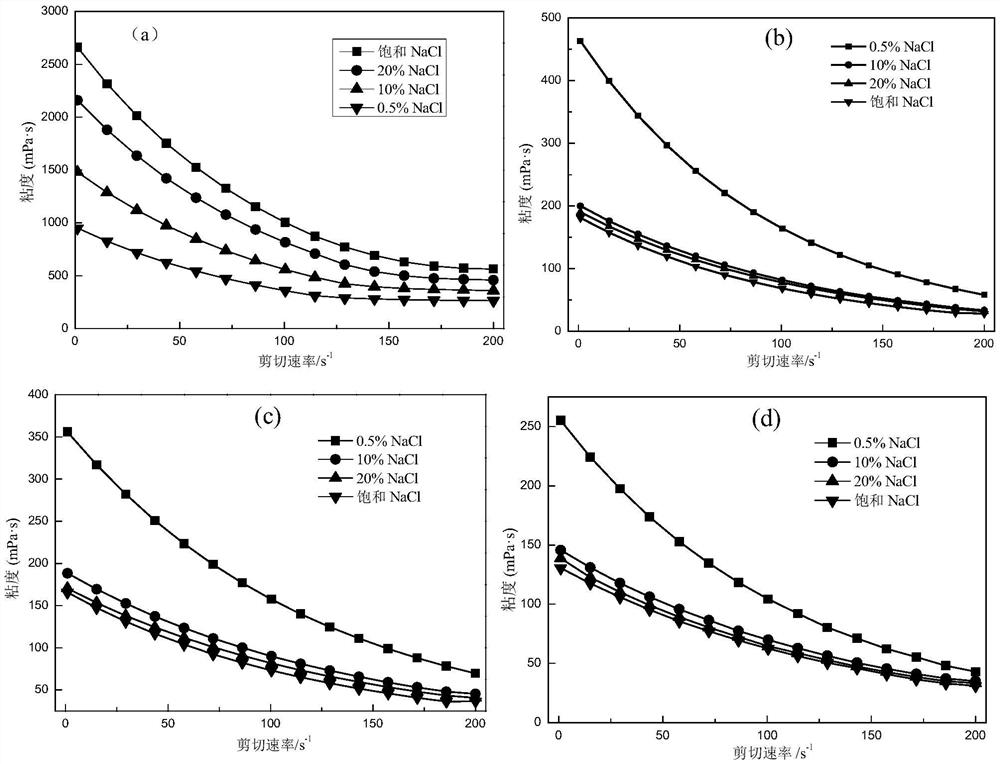

A zwitterionic and fluid loss additive technology, which is applied in the field of drilling fluid fluid loss additives and salt-responsive anti-high temperature zwitterionic polymer fluid loss additives. It can solve the problems of poor salt resistance and fluid loss additives Molecular chain failure, it is difficult for drilling fluid to stabilize the wellbore, balance formation pressure to carry cuttings and lubricate drilling tools, etc., to achieve the effects of avoiding drilling fluid viscosity drop, reducing fluid loss, good viscoelasticity and shear dilution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A salt-responsive anti-high temperature zwitterionic polymer fluid loss reducer, prepared from the following raw materials in parts by mass:

[0048] N,N-dimethylacrylamide 16.4g, methacryloxyethyltrimethylammonium chloride 4.3g, 2-acrylamide-2-methylpropanesulfonic acid 4.3g, nanometer silicon dioxide (average particle size Diameter is 15nm) 6g, silane modifier (vinyl trichlorosilane) 1.2g, initiator ammonium persulfate / sodium bisulfite (mass ratio of ammonium persulfate and sodium bisulfite is 1:1) 0.375g.

[0049] The preparation method of the above-mentioned salt-responsive high temperature resistant zwitterionic polymer fluid loss reducer is as follows:

[0050] (1) Fully disperse 6g of nano-silica in 500mL of ethanol, adjust the pH to 4 with 20% acetic acid aqueous solution; after ultrasonication for 30min, add 1.2g of silane coupling agent, and condense and reflux at a water bath temperature of 70°C 2h; then centrifuge at 10000r / min for 10min, remove the lower l...

Embodiment 2

[0059] A salt-responsive anti-high temperature zwitterionic polymer fluid loss reducer, prepared from the following raw materials in parts by mass:

[0060] N,N-dimethylacrylamide 10.44g, methacryloxyethyltrimethylammonium chloride 7.28g, 2-acrylamide-2-methylpropanesulfonic acid 7.28g, nanometer silicon dioxide (average particle size Diameter is 15nm) 6g, silane modifier (vinyl trichlorosilane) 1.2g, initiator ammonium persulfate / sodium bisulfite (mass ratio of ammonium persulfate and sodium bisulfite is 1:1) 0.375g.

[0061] The preparation method of the above-mentioned salt-responsive high temperature resistant zwitterionic polymer fluid loss reducer is as follows:

[0062](1) Fully disperse 6g of nano-silica in 500mL of ethanol, adjust the pH to 4 with 20% acetic acid aqueous solution; after ultrasonication for 30min, add 1.2g of silane coupling agent, and condense and reflux at a water bath temperature of 70°C 2h; then centrifuge at 10000r / min for 10min, remove the lower...

Embodiment 3

[0065] A salt-responsive anti-high temperature zwitterionic polymer fluid loss reducer, prepared from the following raw materials in parts by mass:

[0066] N,N-dimethylacrylamide 6.06g, methacryloxyethyltrimethylammonium chloride 9.47g, 2-acrylamide-2-methylpropanesulfonic acid 9.47g, nanometer silicon dioxide (average particle size Diameter is 15nm) 6g, silane modifier (vinyl trichlorosilane) 1.2g, initiator ammonium persulfate / sodium bisulfite (mass ratio of ammonium persulfate and sodium bisulfite is 1:1) 0.375g.

[0067] The preparation method of the above-mentioned salt-responsive high temperature resistant zwitterionic polymer fluid loss reducer is as follows:

[0068] (1) Fully disperse 6g of nano-silica in 500mL of ethanol, adjust the pH to 4 with 20% acetic acid aqueous solution; after ultrasonication for 30min, add 1.2g of silane coupling agent, and condense and reflux at a water bath temperature of 70°C 2h; then centrifuge at 10000r / min for 10min, remove the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com