High-temperature-resistant high-density reversible water-in-oil/oil-in-water drilling fluid and preparation method thereof

An oil-in-water drilling fluid, high-density technology, applied in the field of drilling fluid, can solve the problem of reversible emulsification of drilling fluid without emulsifiers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

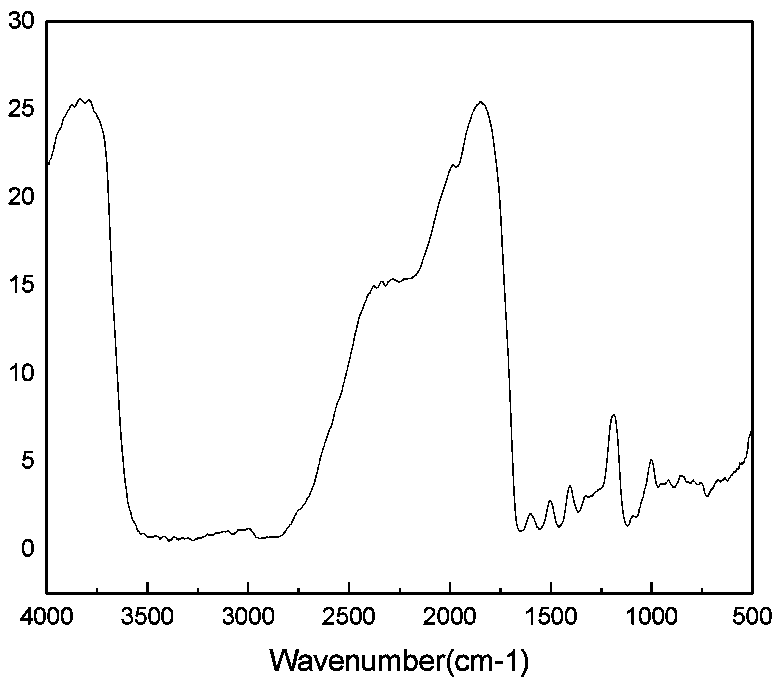

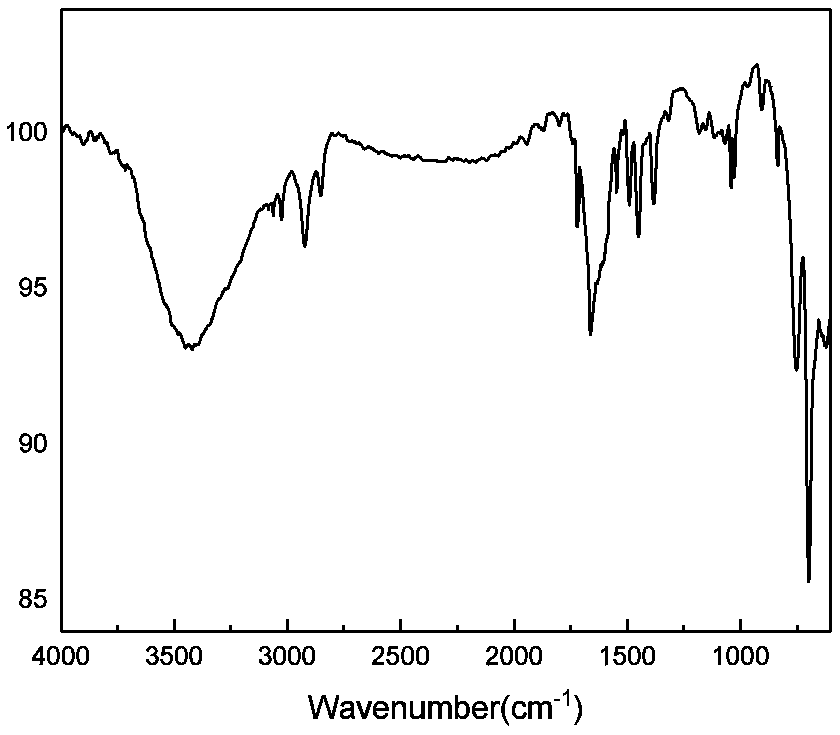

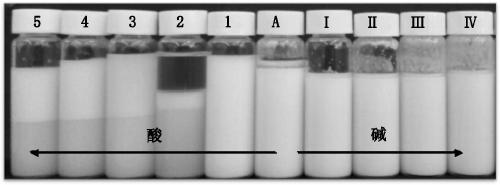

Embodiment 1

[0082] Add 1 mol of lauric acid, 1 mol of diethylenetriamine, and 0.1% catalyst KOH of the total mass of reactants in a four-neck flask equipped with a stirrer, a serpentine reflux condenser, a water separator, and a thermometer. Nitrogen gas was introduced to raise the temperature, and after all the materials were melted, stirring was started, and the water generated by the reaction was distilled off at 180°C. After reacting for 4 hours, add 1 mol of maleic anhydride and 0.5 mol of phenylenediamine, extract twice with ethyl acetate, and recrystallize three times from acetone to obtain a reversible emulsifier based on fatty amides and its derivatives.

Embodiment 2

[0084] In a four-neck flask equipped with a stirrer, a serpentine reflux condenser, a water separator, and a thermometer, add 1 mol of tall oil fatty acid, 1 mol of diethylenetriamine, and add 0.15% of the total mass of the reactant catalyst KOH . Nitrogen gas was introduced to raise the temperature, and after all the materials were melted, stirring was started, and the water generated by the reaction was distilled off at 150°C. After reacting for 4 hours, add 1 mol of maleic anhydride and 0.5 mol of phenylenediamine, extract twice with ethyl acetate, and recrystallize three times from acetone to obtain a reversible emulsifier.

Embodiment 3

[0086] In a four-necked flask equipped with a stirrer, a serpentine reflux condenser, a water separator, and a thermometer, add 1 mol of oleic acid, add 1 mol of N,N-dimethyl-1,3-propanediamine, and add The total mass of reactants is 0.4% catalyst KOH. Nitrogen gas was introduced to raise the temperature, and after all the materials were melted, stirring was started, and the water generated by the reaction was distilled off at 180°C. After reacting for 4 hours, add 1 mol of maleic anhydride and 0.5 mol of ethylenediamine, extract twice with ethyl acetate, and recrystallize three times from acetone to obtain a reversible emulsifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com