Patents

Literature

78results about How to "Reduce high temperature and high pressure filtration loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

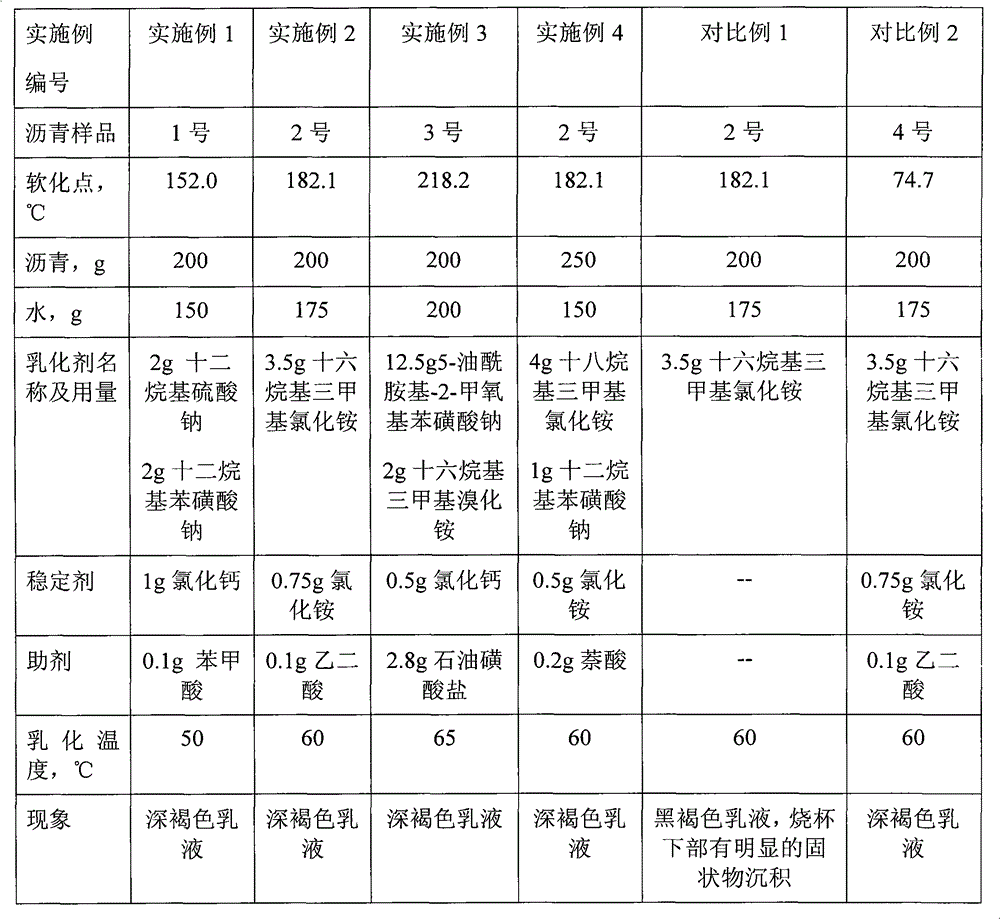

High-softening point emulsified asphalt water-based drilling fluid additive and preparation method thereof

ActiveCN102952526AGood miscibilityMeet high temperature and high pressure requirementsDrilling compositionWater basedPolymer science

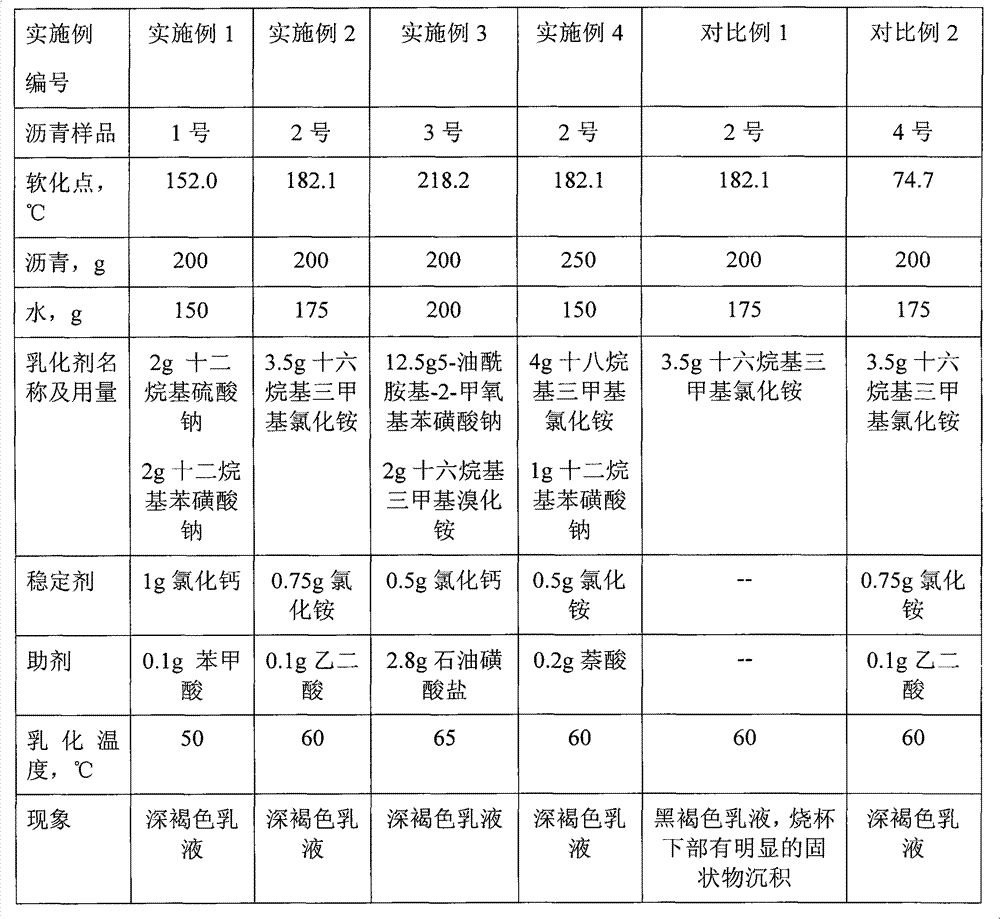

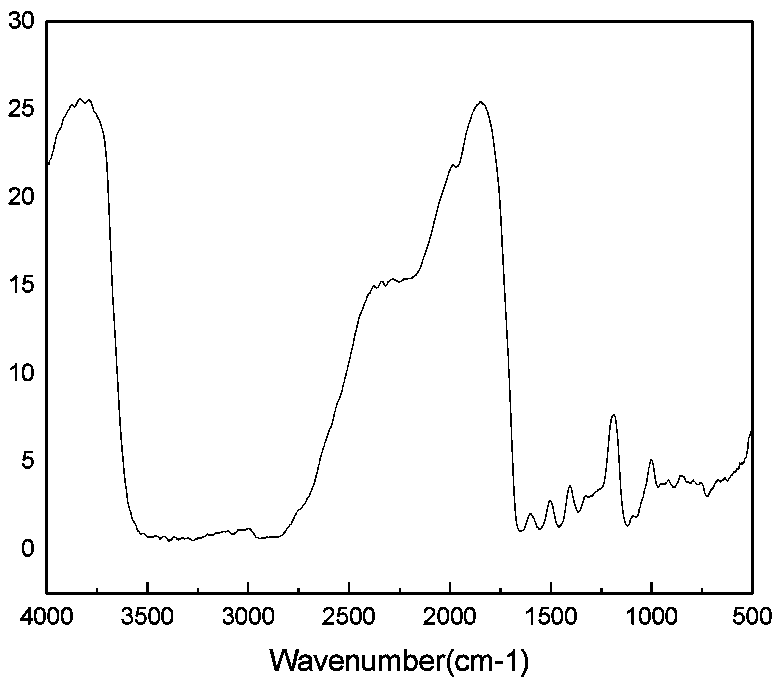

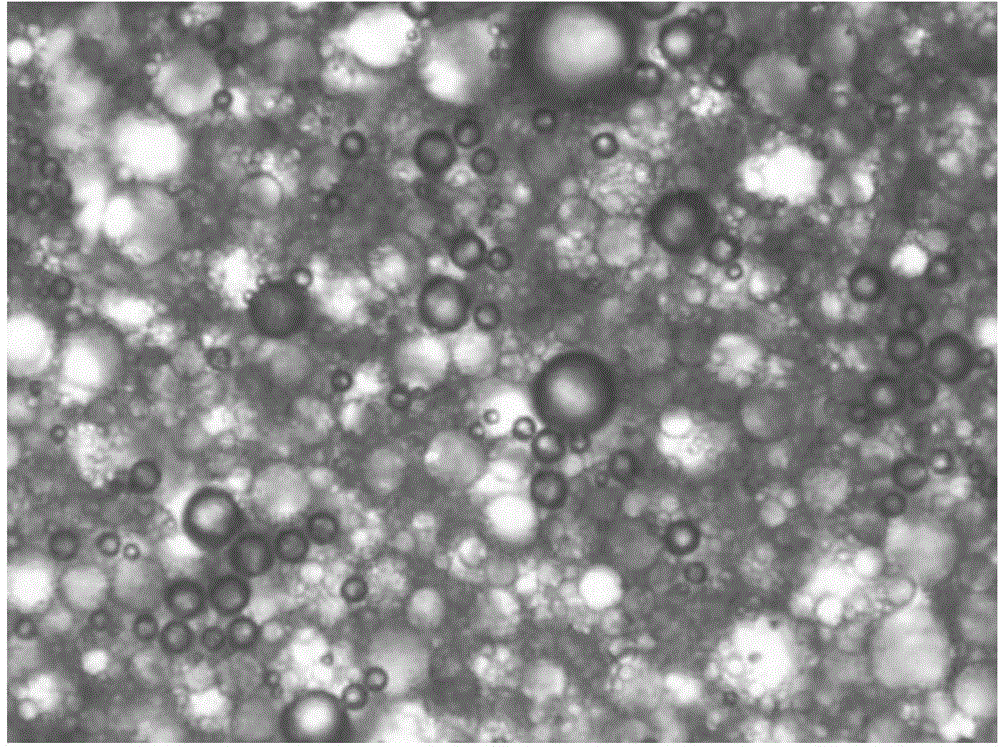

A high-softening point emulsified asphalt water-based drilling fluid additive and a preparation method thereof. The drilling fluid additive comprises 40-70 wt% of asphalt with a softening point of 150 DEG C-240 DEG C, 35-50 wt% of water, 0.02-2 wt% of an auxiliary agent, 0.05-5 wt% of an emulsifier, and 0.01-1 wt% of a stabilizer; the charge of the additive is anion; the storage stability for 1 day is not more than 1%; the storage stability for 5 day is not more than 5%; the high-temperature high-pressure filter loss at 220 DEG C and at 3.45 MPa is not more than 25 ml. The preparation method of the additive comprises the following steps: mixing water, the anion emulsifier, the stabilizer, and the auxiliary agent, then adding the asphalt fine powder with a softening point of 150 DEG C-240 DEG C into the above solution, and stirring. The drilling fluid additive provided by the invention has good high-temperature high-pressure filter loss effect, and is suitable for drilling of high-temperature high-pressure deep wells and extradeep wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

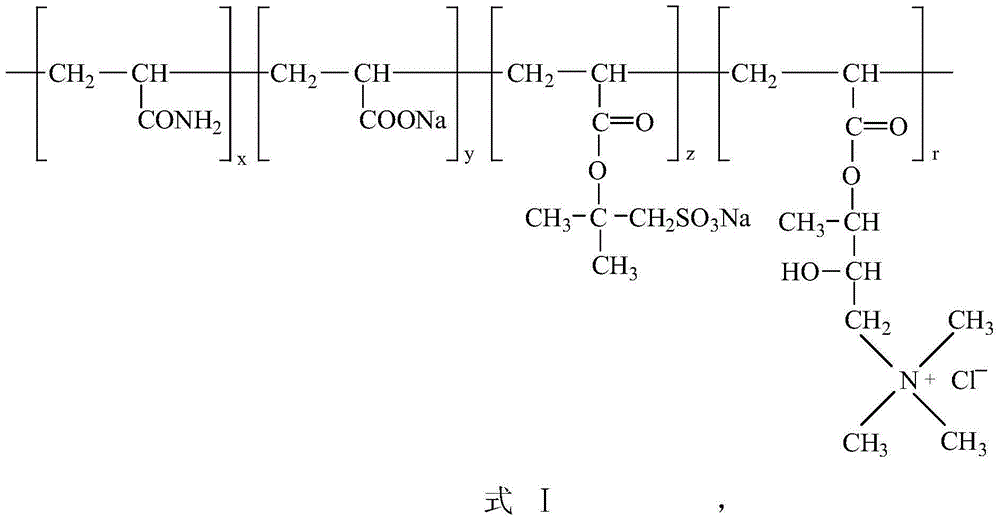

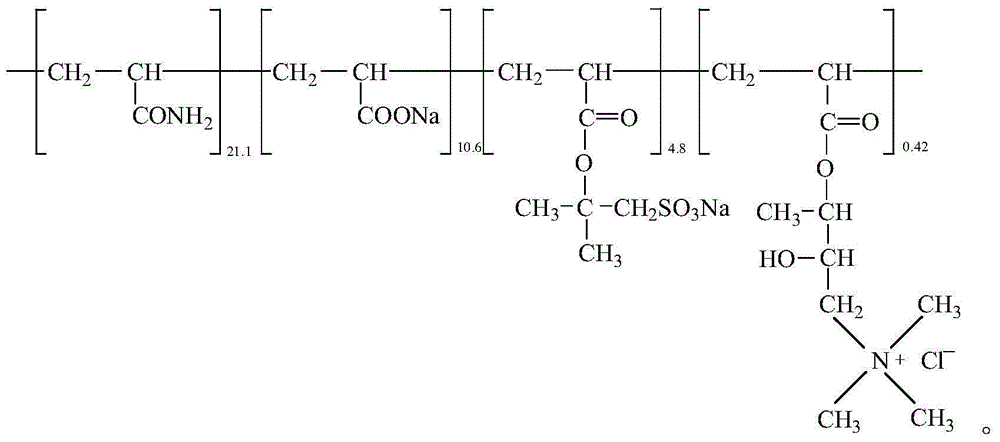

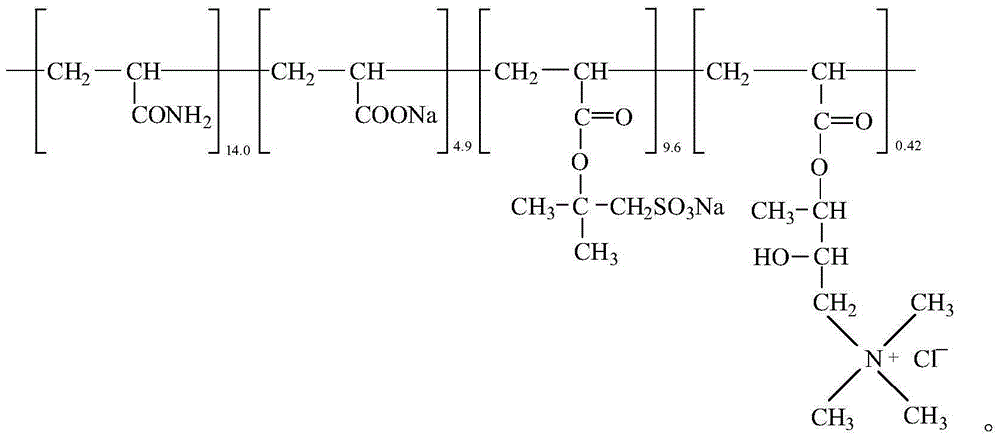

Fluid loss additive for drilling fluid and preparation method thereof

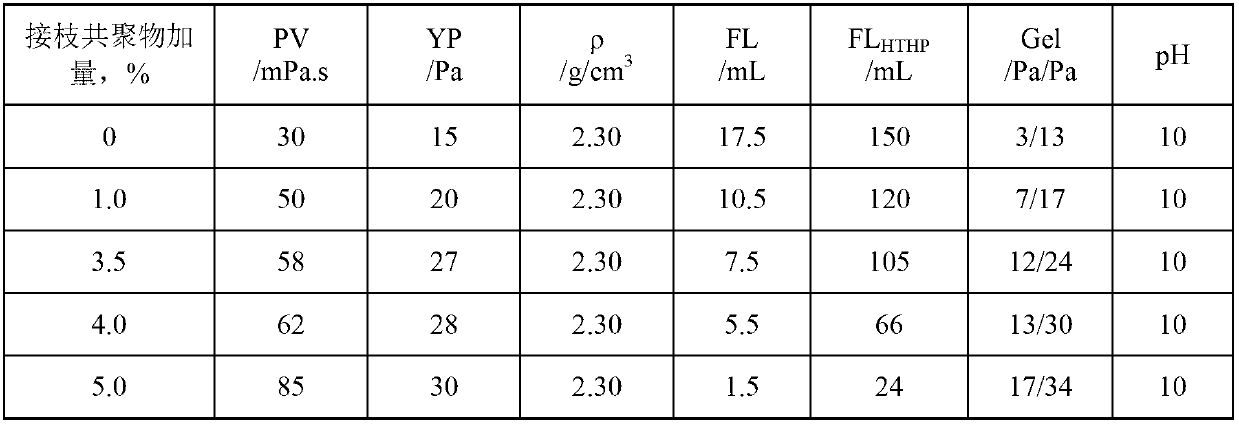

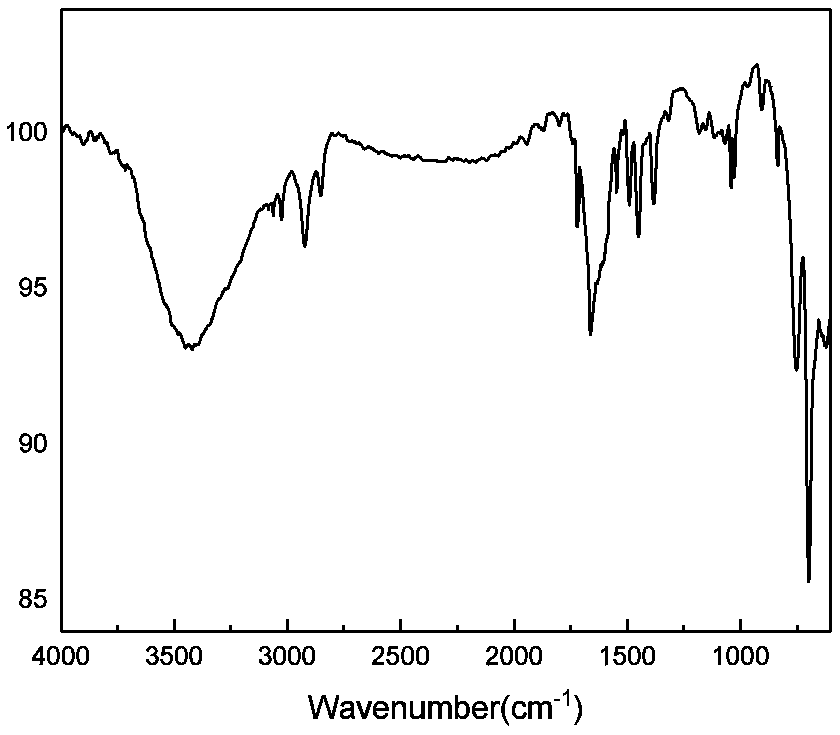

ActiveCN102766240AControl rheologyReduce high temperature and high pressure filtration lossDrilling compositionSide chainWell drilling

The invention discloses a fluid loss additive for drilling fluid and a preparation method thereof, belonging to the technical field of chemical drilling fluid treating agents for oilfields. The method comprises the following steps of: carrying out one-step reaction on phenol, formaldehyde, humate, pyrosulfite and anhydrous sulfite so as to obtain a sulfonated phenolic humic acid resin; in the presence of an initiator, carrying out graft copolymerization on the sulfonated phenolic humic acid resin and a mixture of sodium hydroxide, 2-acrylamide-2-methyl-propyl sulfonate, acrylamide and dodecylacrylamide; and carrying out drying and crushing on the obtained product so as to obtain sulfonated phenolic humic acid resin-alkenyl monomer graft copolymer. The fluid loss additive disclosed by the invention has the functions of controlling the rheological property of drilling fluid and reducing the high-temperature and high-pressure filter loss of drilling fluid, not only enhances the thermal stability of side chains of a chain polymer, but also improves the salt tolerance of a sulfonated phenolic resin, and guarantees that products have good properties under high temperature and high salt conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

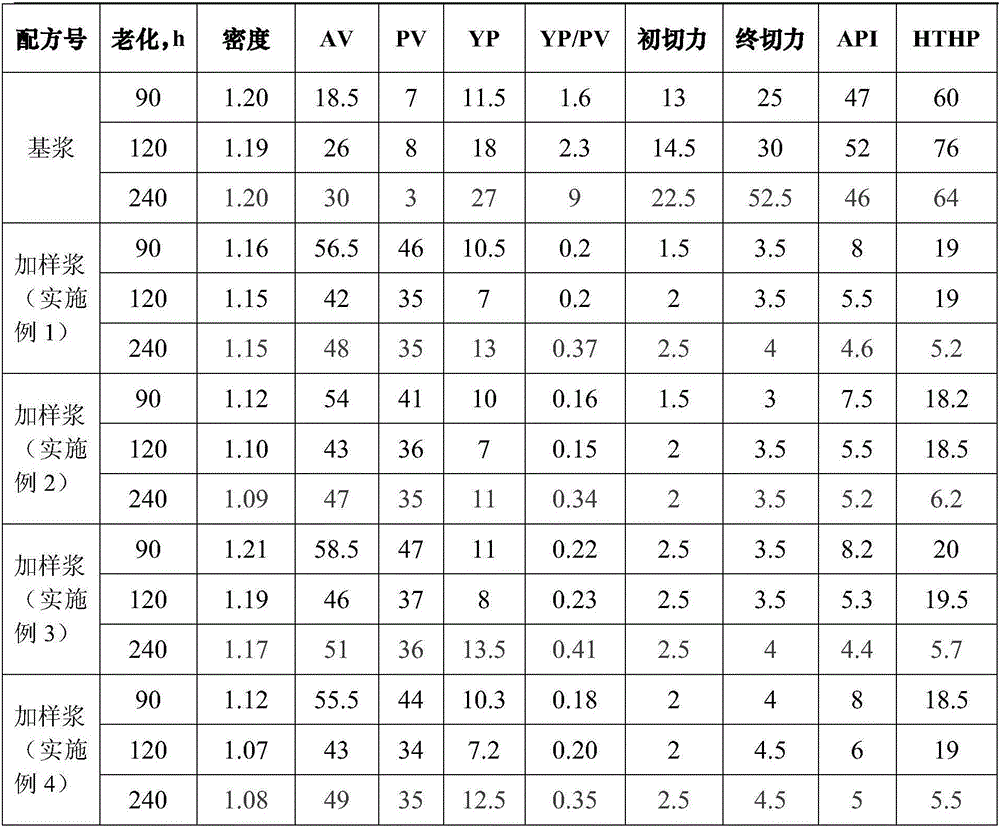

High-temperature-resistant high-density reversible water-in-oil/oil-in-water drilling fluid and preparation method thereof

ActiveCN109097010AGood reversalComparable performanceOrganic compound preparationCarboxylic acid amides preparationOil phasePolyamine

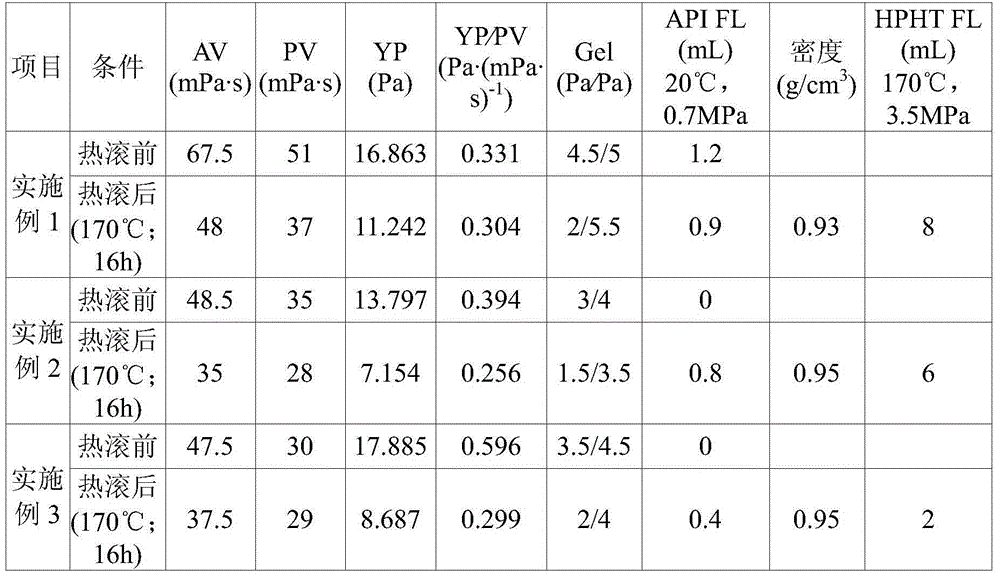

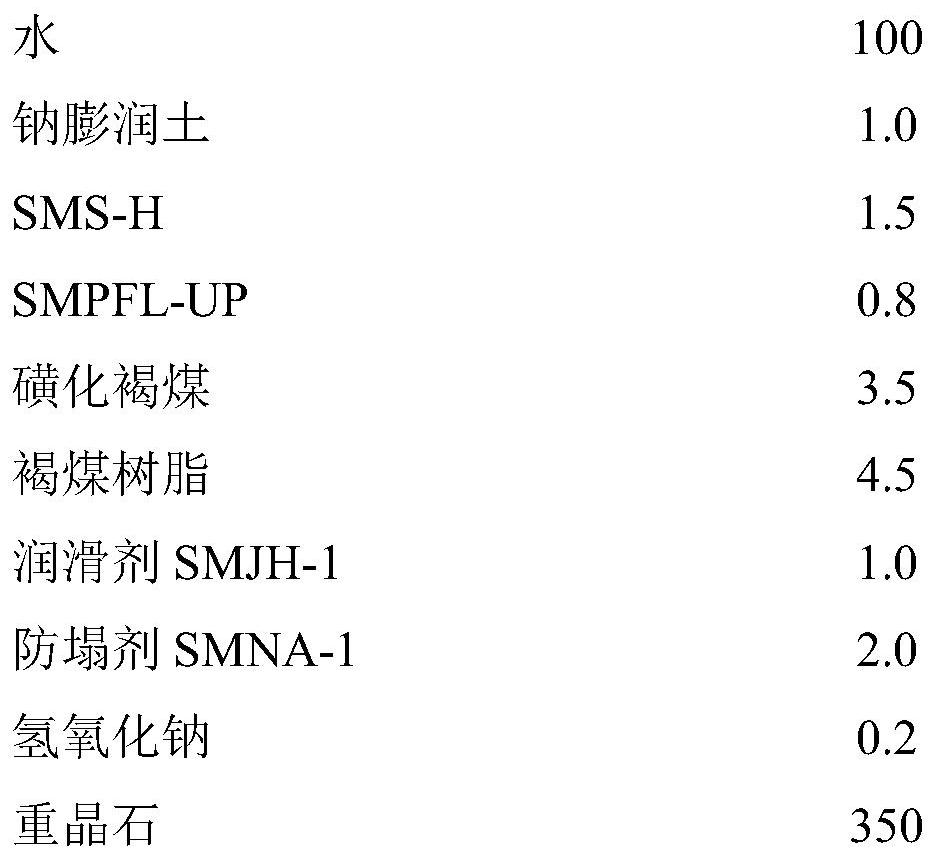

The invention provides high-temperature-resistant high-density reversible water-in-oil / oil-in-water drilling fluid which is composed of the following raw materials in parts by weight: 30-70 parts of an oil phase, 30-70 parts of an aqueous phase, 2-5 parts of a reversible emulsifier, 1-3 parts of an auxiliary emulsifier, 0-2 parts of organic soil, 1-4 parts of a filtrate reducer, 0-1 part of an alkalinity regulator, 0-0.5 part of a wetting agent, 0-2 parts of an enhancer and 0-800 parts of weighting materials. The reversible emulsifier is fatty acyl polyamines and derivatives thereof, and has astructural general formula of R1(CH2)m(CONH)n(C6H4)x(NH)y(NH2)zR2; the filtrate reducer is an amphiphilic filtrate reducer. The amphiphilic filtrate reducer comprises but is not limited to an amphiphilic polymer filtrate reducer, a hydrophilic modified asphalt filtrate reducer and a hydrophobic modified humic acid filtrate reducer. The compounded auxiliary emulsifier is a high HLB (Hydrophile-Lipophile Balance) value surfactant. The drilling fluid disclosed by the invention has directly adjustable density of 0.8-1.8g / cm<3>, and has excellent properties such as rheological property, suspensionstability, filter cake clearance, filter loss control, environment friendliness and stable reversibility of water-in-oil emulsion and oil-in-water emulsion in a range of 100-180 DEG C.

Owner:SOUTHWEST PETROLEUM UNIV

Oil-based polyamide assistant emulsifier for drilling fluids, and preparation method thereof

InactiveCN105907381AStrong emulsifying abilityHigh temperature resistanceDrilling compositionPolymer sciencePolyamide

The invention discloses an oil-based polyamide assistant emulsifier for drilling fluids, and a preparation method thereof. The oil-based polyamide assistant emulsifier is prepared through a dehydration polycondensation reaction of diacid anhydrides, polyalkenepolyamine and aliphatic acid, wherein a molar ratio of the diacid anhydrides to polyalkenepolyamine to aliphatic acid is 1:1:1.4-4. The emulsifier is a macromolecular polymer surfactant, per unit mass of the emulsifier contains more lipophilic and hydrophilic groups, and the emulsifying efficiency is high; hydrophilic groups in the molecular structure is an amido structure, so the emulsifier has good high-temperature resistance; and the emulsifier and a wetting agent have synergism, so the wetting reversal of solid phase surface is facilitated.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

High-temperature resistant water-based drilling fluid and preparation method thereof

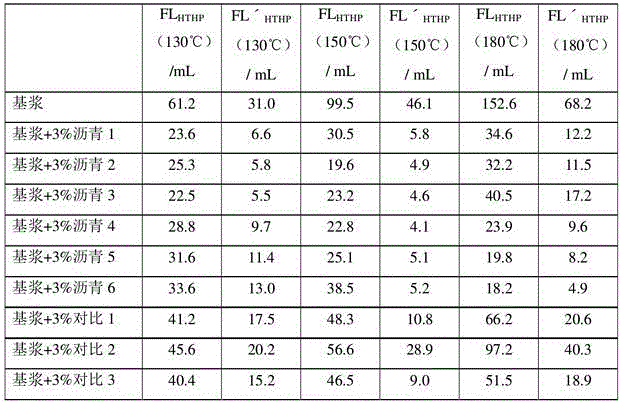

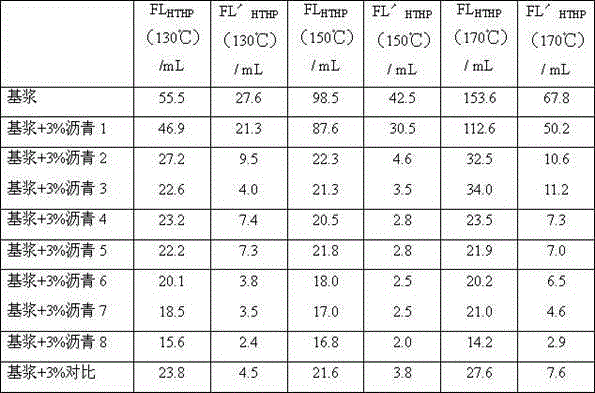

ActiveCN104559968APrevent problems such as stickingEasy to introduceDrilling compositionWater basedFiltration

The invention discloses a high-temperature resistant water-based drilling fluid and a preparation method thereof. The high-temperature resistant water-based drilling fluid comprises the following components in percentage by mass: 85%-97% of basic mud and 3%-15% of asphaltic liquid of a high softening point. The preparation method comprises the following steps: (1), adding asphaltic raw materials of a high softening point into water for performing crushing, adding a stable dispersant, and uniformly mixing the crushed asphaltic raw materials and the stable dispersant so as to obtain the asphaltic liquid of the high softening point; (2),uniformly mixing the asphaltic liquid of the high softening point, a performance modifying agent and the basic mud so as to obtain the high-temperature resistant water-based drilling fluid. In the water-based drilling fluid disclosed by the invention, the dispersion of asphaltic particles of a high softening point is uniform and stable; the water-based drilling liquid is high in high temperature resistance and filtration resistance; the preparation method is simple and convenient, the cost is reduced, and the applied range is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Emulsifier for novel high-temperature water-in-oil drilling fluid

InactiveCN103421473AStrong grid structureImprove rheologyDrilling compositionSURFACTANT BLENDAmmonium

The invention relates to an emulsifier for a novel high-temperature water-in-oil drilling fluid. The emulsifier comprises the following components in percentage by weight: a main emulsifier DQGC and an auxiliary emulsifier DQNS, wherein the main emulsifier DQGC is a Gemini quaternary ammonium salt surfactant; the auxiliary emulsifier DQNS is an amide surfactant; the molecular structures of the main emulsifier DQGC and the auxiliary emulsifier DQNS are as follows: [(R1CONH(CH2)3N(CH3)2CH2CHOHCH2)2NR2]2+.2Cl-R1CONH(CH2)3N(CH3)2, in the formula, R1 is C17H33, C17H31 and C19H29, and R2 is C12H25. According to the emulsifier, better oleophylic and hydrophilic abilities can be obtained, the emulsifying ability is enhanced, and the stability of the water-in-oil drilling fluid is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Water-in-oil based drilling fluid with high temperature resistance and preparation method thereof

ActiveCN105586022AImprove high temperature resistanceImprove bindingDrilling compositionSolubilityHeat stability

The invention provides water-in-oil drilling fluid and a preparation method thereof. The drilling fluid comprises an oil phase, a water phase and an additive; the additive comprises high-softening point asphalt composition particles, a promoter, and an emulsifier. Addition of the high-softening point asphalt composition particles is 1-5% of the total mass of the drilling fluid. Average particle size of the high-softening point asphalt composition particles is less than 60 mesh. The drilling fluid solves the problems of plugging and bad leak-off reduction effect, because good particle state and high temperature deformation capability cannot be kept due to extra high oil solubility, when the high-softening point asphalt is applied to oil base drilling fluid. At the same time, when the water content in the water-in-oil drilling fluid is high, the problems that heat stability and electrical stability become bad are solved by means of synergistic effects of the appropriate main emulsifier, the auxiliary emulsifier and the high-softening point asphalt composition particles; the drilling fluid can be widely applied to the deep oil gas drilling operation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Whole oil-based drilling fluid and preparation method thereof

ActiveCN105586020AEvenly combinedImprove high temperature resistanceDrilling compositionWell drillingBase oil

The invention provides whole oil-based drilling fluid and a preparation method thereof. The drilling fluid comprises base oil and an additive, and the additive comprises a performance modifier. The performance modifier contains modified high-softening point asphalt composition particles, and the asphalt composition particles comprise the following components in parts by weight: 50-80 parts of high-softening point asphalt, and 20-50 parts of rubber powder particles; the high-softening point asphalt covers the rubber powder particles, and the softening point is 120-220 DEG C. Average particle size of the high-softening point asphalt composition particles is less than 60 mesh. The drilling fluid solves the problems of plugging and bad leak-off reduction effect, because good particle state and high temperature deformation capability cannot be kept due to extra high oil solubility, when the high-softening point asphalt is applied to oil base drilling fluid. The drilling fluid can be widely applied to a deep oil gas drilling operation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil-in-water drilling fluid with vegetable oil as internal phase and preparation method of oil-in-water drilling fluid

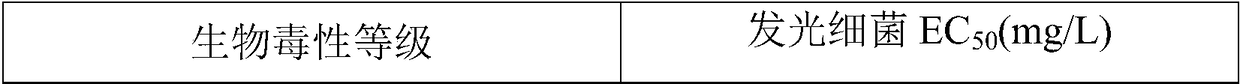

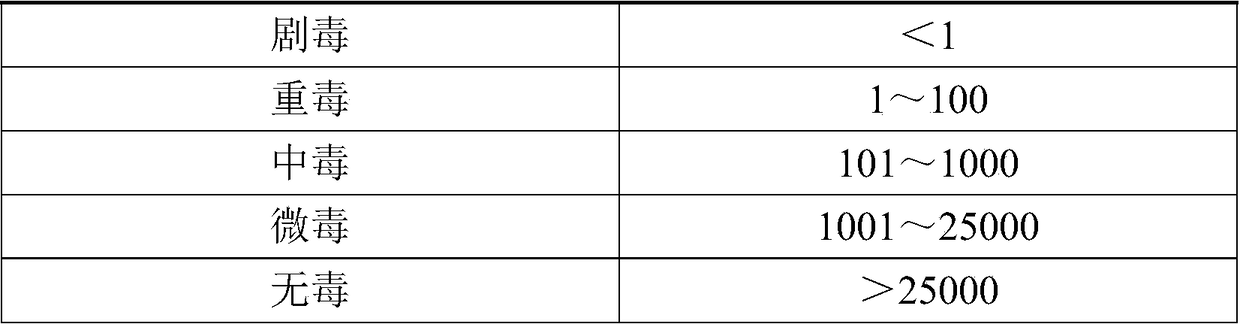

The invention provides an oil-in-water drilling fluid with vegetable oil as an internal phase and a preparation method of the oil-in-water drilling fluid. The drilling fluid is prepared from the vegetable oil, water and a treating agent, wherein the volume ratio of the vegetable oil and water is 40:60 to 60:40; the treating agent comprises a main emulsifier, an auxiliary emulsifier, a filtrate loss reducer I, a thickening agent, NaOH, a thickening and shear strength improving agent, and a filtrate loss reducer II; based on 100 ml of vegetable oil and water, the content of the main emulsifier is 2-3.5 g, the content of the auxiliary emulsifier is 1-2.5 g, the content of the filtrate loss reducer I is 1-3.5 g, the content of the thickening agent is 1-1.5 g, the content of NaOH is 0.25-0.3 g, the content of the thickening and shear strength improving agent is 0.1-0.2 g, and the content of the filtrate loss reducer II is 1.5-4 g. The oil-in-water drilling fluid with the vegetable oil as the internal phase, provided by the invention, is stable in performance, high in drilling cutting resistance and clay pollution capacity, safe and environment-friendly, and can be directly discharged.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Modified asphalt composition particle and preparation method thereof

ActiveCN105524476AImprove high temperature resistanceImprove bindingDrilling compositionBuilding insulationsMolten statePolymer science

The invention discloses modified asphalt composition particle and a preparation method thereof. The modified asphalt composition particle comprises the following components by referring weight part: 50-80 weight part of high softening point asphalt, and 20-50 weight part of rubber powder particle. The preparation method comprises the following steps: high softening point asphalt is heated to a fusion state, and is uniformly sprayed on glue powder particle, and is stood for permeation for a while, the high softening point asphalt is refrigerated, and is vibrated and crushed in a vibrating screen to obtain the asphalt composition particle. The asphalt composition particle has high softening point, good high temperature performance and deformation capability, the preparation method has the advantages of simple process and convenient operation, and the asphalt composition particle has good plugging and de-filtration effect while deep well drilling is carried out.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil-based drilling fluid and its preparation method

InactiveCN103911132AImprove stabilityEnhanced inhibitory effectDrilling compositionOrganoclayOil phase

The invention discloses an oil-based drilling fluid and its preparation method. The waste edible oil oil-based drilling fluid comprises the ingredients of waste edible oil, sulfite, a main emulsifier, an auxiliary emulsifier, organoclay, a filtrate reducer, a wetting agent and a barite; the preparation method of the waste edible oil oil-based drilling fluid comprises the following steps: preparing an oil phase by waste edible oil and sulfite, and then adding the main emulsifier, the auxiliary emulsifier, the organoclay, the filtrate reducer, the wetting agent and barite. The prepared trench oil oil-based drilling fluid takes waste edible oil as a base oil to substitute diesel oil or crude oil, the cost is low, the environment is friendly, the well wall stability is good, the inhibition performance is strong, lubrication performance and rheological performance are excellent, anti-sloughing inhibition performance and high temperature stability are good, construction requirement for the drilling well can be better satisfied, and the oil-based drilling fluid and its preparation method can provide a new approach for using the waste edible oil in the reasonable mode.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

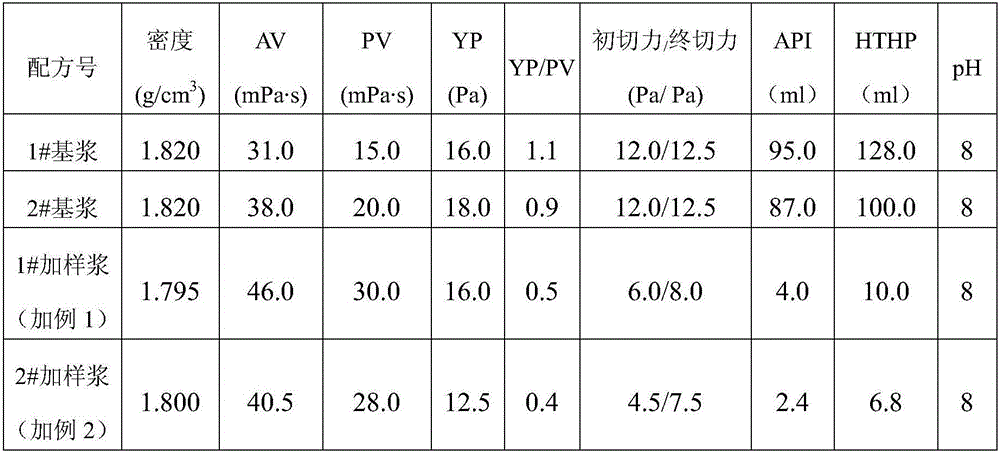

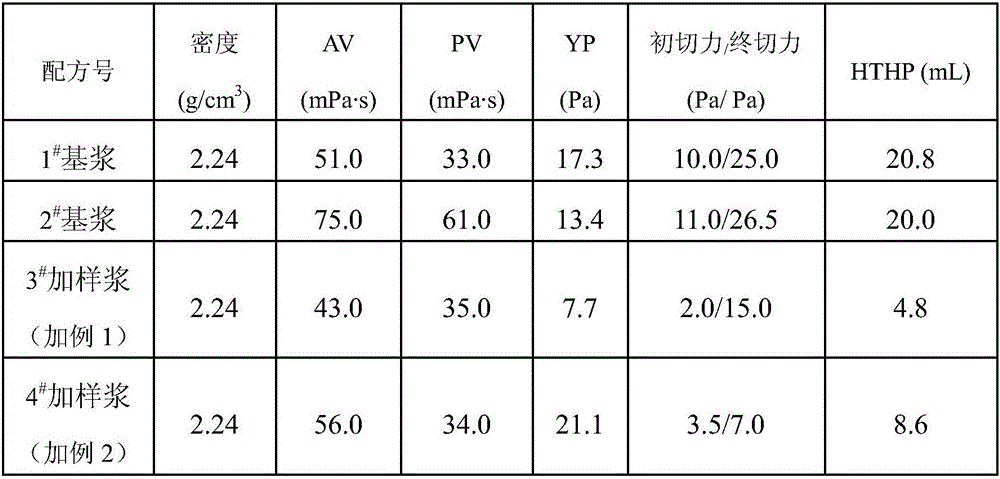

High-density water-based drilling fluid for shale gas horizontal well

ActiveCN105969323AGood sealingEnhanced inhibitory effectDrilling compositionWater basedHorizontal wells

The invention provides high-density water-based drilling fluid for a shale gas horizontal well. The high-density water-based drilling fluid is prepared from, by mass, 3.0%-6.0% of temporary shielding agent, 1.0%-5.0% of inhibitory anti-collapse agent, 2%-5% of solid lubricant, 1.0%-5.0% of balling cleaner, 10%-25% of potassium chloride, 0.1%-0.5% of sodium hydroxide, 1.0%-4.0% of filtrate reducer, 0.2%-0.5% of fluid type modifier, 50%-80% of barite and the balance water. The prepared high-density water-based drilling fluid for the shale gas horizontal well still has excellent blocking and inhibiting performance under the conditions of shale and carbonaceous mudstone, still has good lubricating performance, de-filtration performance and rheological performance under the high-density high-solid-phase condition, can meet the requirements of the shale gas horizontal well, a carbonaceous mudstone horizontal well and construction of other horizontal wells on instable formation for the water-based drilling fluid, and replaces oil-based drilling liquid, and low-cost development of shale gas resources is promoted in the political and economic environment of long-term low oil price.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Water-based drilling fluid for shale gas wells and production method thereof

ActiveCN110628398AEnhanced inhibitory effectImprove the blocking effectDrilling compositionWater basedHorizontal wells

The invention relates to a water-based drilling fluid for shale gas wells and a production method thereof. The method sequentially includes the following steps of: (1) preparing the following raw materials: 1000 parts of water, 45-50 parts of sodium bentonite, 500 parts of a water-soluble inhibition weighting agent II; 100 parts of a water-soluble inhibition weighting agent III; 15-20 parts of aninhibiting and anti-collapse agent non-fluorescence white asphalt, 10-20 parts of solid polymeric alcohol, 10-20 parts of a filtrate reducer, 0.5-1 part of a polyamine inhibitor, 20-30 parts of ultrafine calcium carbonate, 10-25 parts of an extreme pressure lubricant, and 0.5-1 part of a coating inhibitor; (2) mixing the sodium bentonite and water, and performing curing for at least 24h at normaltemperature; and (3) adding the water-soluble inhibition weighting agent II and water-soluble inhibition weighting agent III under stirring, then adding the inhibiting and anti-collapse agent non-fluorescence white asphalt and the solid polymeric alcohol, then adding the filtrate reducer and the polyamine inhibitor, then adding the ultrafine calcium carbonate and the extreme pressure lubricant, finally adding the coating inhibitor, and then adjusting the pH value and density. The drilling fluid has the advantages of high plugging properties, strong inhibition and excellent lubricating properties, and can meet the safe drilling requirements of shale gas horizontal wells.

Owner:SINOPEC EAST CHINA PETROLEUM ENG CO LTD

Asphalt composition particles, and preparation method and application thereof

ActiveCN105623280AHigh affinityGood deformabilityDrilling compositionBuilding insulationsFreeze-dryingFiltration

The invention discloses asphalt composition particles, and a preparation method and application thereof. The asphalt composition particles comprise the following components in parts by weight: 80 to 95 parts of modified asphalt particles with high softening points, and 5 to 20 parts of latex, wherein the modified asphalt particles with high softening points comprise the following components in parts by weight: 50 to 80 parts of asphalt with high softening points and 20 to 50 parts of rubber powder particles; and the modified asphalt particles with high softening points are a combination with different size distribution of two or more than two sizes selected from the group consisting of 60 to 80 meshes, 80 to 120 meshes, 120 to 140 meshes or more than 140 meshes. The preparation method comprises the following contents: uniformly spraying the latex onto the modified asphalt particles with high softening points, carrying out standing permeation for a period of time, and carrying out vacuum freeze drying so as to obtain the asphalt composition particles. The asphalt composition particles provided by the invention have high softening points and good high-temperature performance and deformability, has simple preparation method and convenient operation, and can exert good plugging and filtration-reducing effects during deep drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

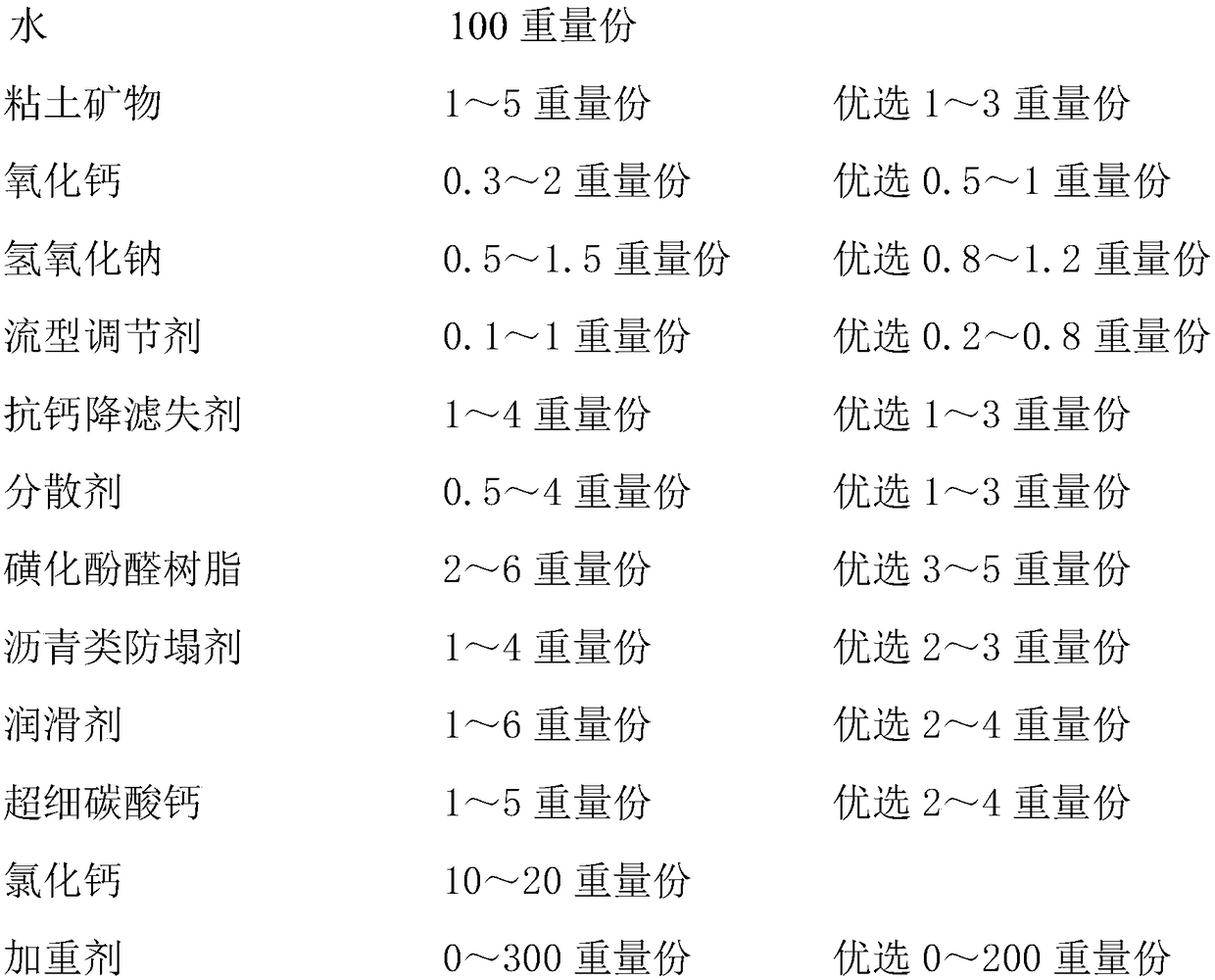

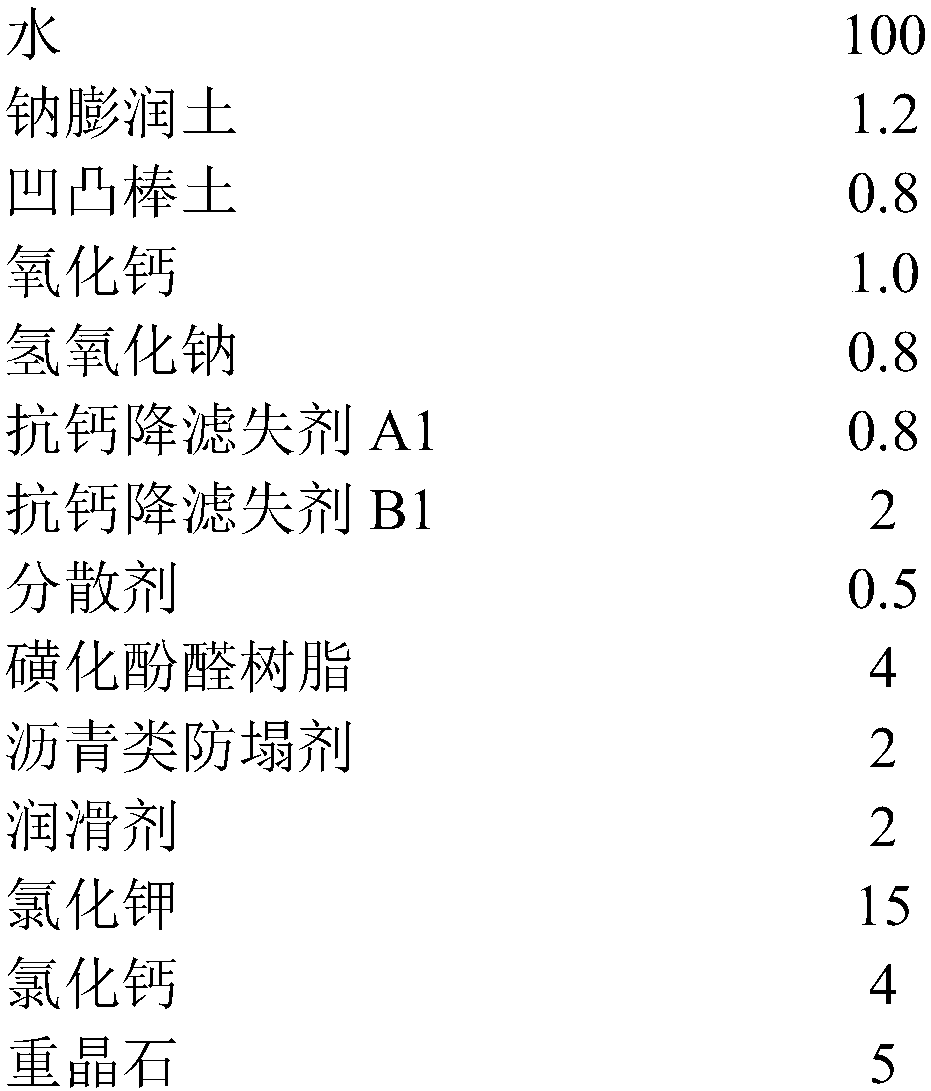

High-calcium-salt drilling fluid and preparation method thereof

ActiveCN108424755AImprove temperature resistanceImprove rheologyDrilling compositionClay mineralsTemperature resistance

The invention discloses a high-calcium-salt drilling fluid and a preparation method thereof. The drilling fluid comprises, by weight, 100 parts of water, 1 to 5 parts of clay minerals, 0.3 to 2 partsof calcium oxide, 0.5 to 1.5 parts of sodium hydroxide, 0.1 to 1 part of a flow pattern regulating agent, 1 to 4 parts of an anti-calcium filtrate reducer, 0.5 to 4 parts of a dispersant, 2 to 6 partsof sulfonated phenolic resin, 1 to 4 parts of an asphalt anti-collapse agent, 1 to 6 parts of a lubricant, 1 to 5 parts of ultrafine calcium carbonate, 10 to 20 parts of calcium chloride and 0 to 300parts of a weighting agent. The high-calcium-salt drilling fluid of the invention has good temperature resistance, calcium salt contamination resistance, anti-sloughing ability, rheological properties and suspension stability, and low filtrate loss at high temperature and high pressure, and is applicable to drilling construction of high-calcium-salt water formations and formations prone to collapse.

Owner:CHINA PETROLEUM & CHEM CORP +1

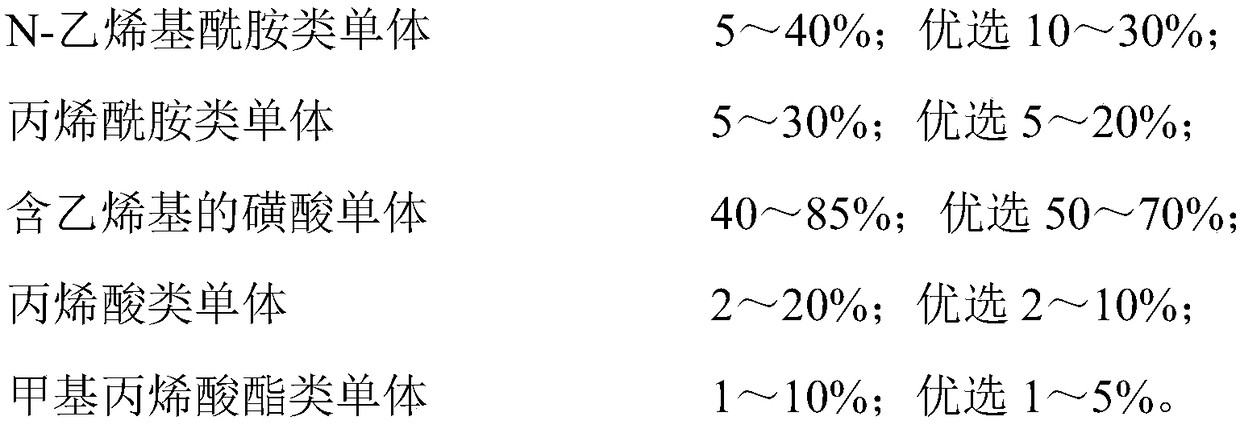

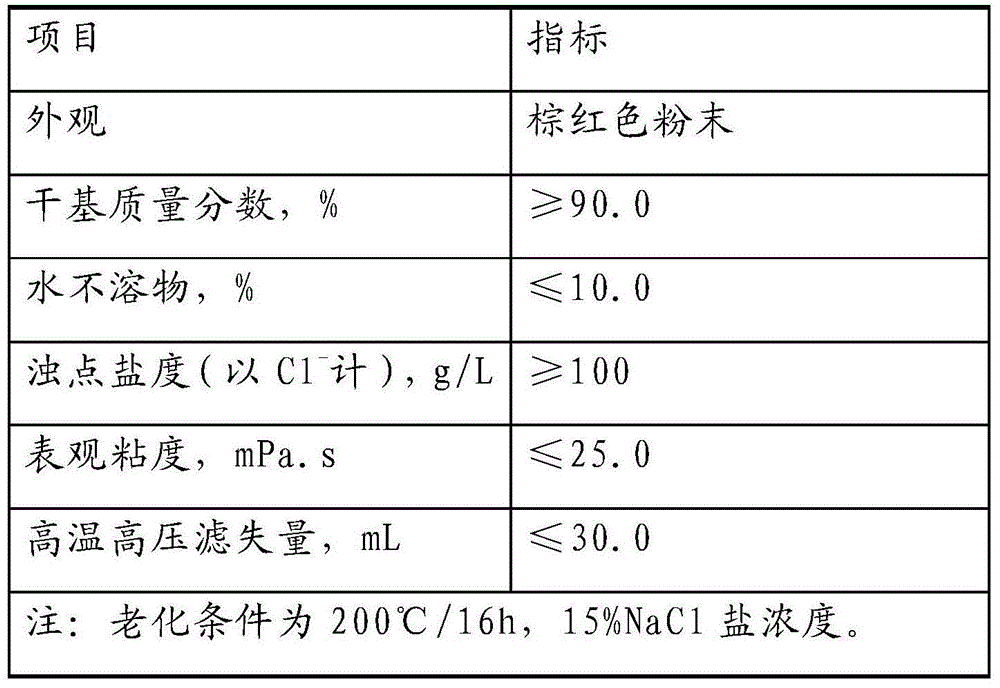

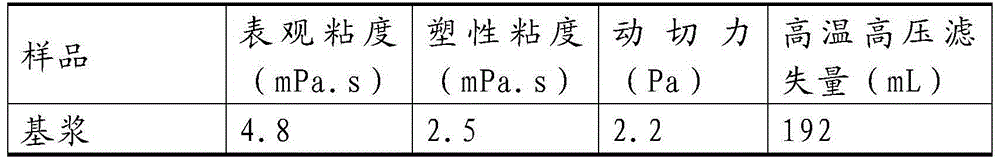

Preparation method of high-temperature-resistant modified sulfonated phenol formaldehyde resin for drilling fluids

ActiveCN104788634AReduce high temperature and high pressure filtration lossImprove performanceDrilling compositionSalt resistanceHigh pressure

The invention discloses a preparation method of a high-temperature-resistant modified sulfonated phenol formaldehyde resin for drilling fluids, which comprises the following steps: 1) adding a phenol reactant, an aldehyde reactant and an acid catalyst into a reaction kettle, mixing, and reacting at 50-110 DEG C for 10-400 minutes; 2) adding an alkali catalyst and an aldehyde reactant into the reaction kettle, keeping the temperature at 50-110 DEG C, adding a sulfonating agent in batches, and reacting for 10-600 minutes; and 3) after the reaction finishes, cooling, discharging, and carrying out spray drying to obtain the product. The temperature resistance of the modified sulfonated phenol formaldehyde resin product can reach 200 DEG C. The high-temperature high-pressure filter loss of the drilling fluid under the aging condition of 200 DEG C can be effectively lowered as compared with the base mud, and the salt resistance can reach the salt concentration of 15% NaCl.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

Silicon fluorine anti-falldown filter agent for drilling fluid

ActiveCN1793278AImproved rheological propertiesReduce high temperature and high pressure filtration lossDrilling compositionChemical reactionFiltration

The invention relates to drilling fluid using silicon fluorine anti-collapse filtration reducing agent. It includes the following steps: reacting methyl tri-fluorine propyl chloride silane with deionized water; expelling the chlorine hydride; moving the resultant into distiller to do vacuum distillation; extracting distilled part at 140-160 centigrade degree methyl tri-fluorine propyl chloride silane known as DFn; using DFn, propylene brighten, acetic acid ethylene as material to react in reactor; hydrolyzing by deionized water; filter pressing; pre-processing; and pneumatic conveying drying. It is new type high efficiency drilling fluid treating compound. And it increases clay xi electric potential and solid phase dispersilbility; it has multi and fine grain, good hydrating, thick salvation film. And the formed cake of press is thin, compact, tenacity, and low permeability.

Owner:宋福如

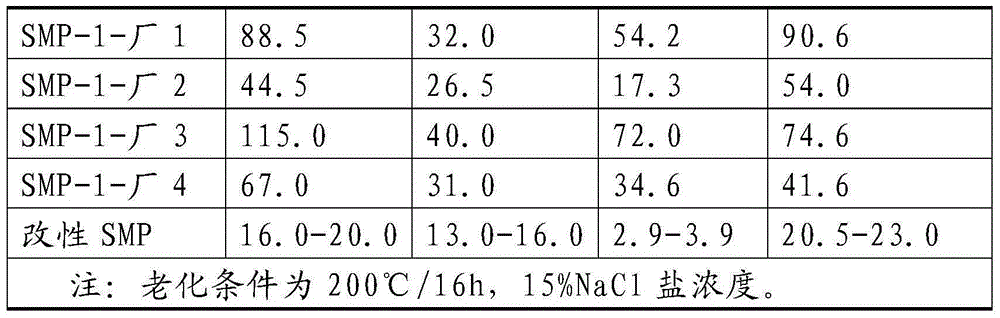

High-calcium-salt drilling fluid with high temperature resistance and preparation method thereof

ActiveCN108424754AImprove suspension stabilityGood anti-collapse effectDrilling compositionClay mineralsPotassium

The invention discloses a high-calcium-salt drilling fluid with high temperature resistance and a preparation method thereof. The drilling fluid comprises, by weight, 100 parts of water, 0.8 to 3 parts of clay minerals, 0.3 to 2 parts of calcium oxide, 0.5 to 1.5 parts of sodium hydroxide, 0.3 to 2 parts of an anti-calcium filtrate reducer A, 1 to 5 parts of an anti-calcium filtrate reducer B, 0.5to 4 parts of a dispersant, 2 to 6 parts of sulfonated phenolic resin, 1 to 4 parts of an asphalt anti-collapse agent, 1 to 5 parts of a lubricant, 0 to 20 parts of potassium chloride, 4 to 15 partsof calcium chloride and 0 to 300 parts of a weighting agent. The high-calcium-salt drilling fluid of the invention has anti-sloughing ability, good rheological properties and suspension stability, andlow filtrate loss at high temperature and high pressure, and is applicable to drilling construction of high-calcium-salt water formations and formations prone to collapse.

Owner:CHINA PETROLEUM & CHEM CORP +1

Drilling fluid for resisting heavy oil pollution

The invention relates to the technical field of drilling fluids used in petroleum drilling engineering, and particularly discloses a drilling fluid for resisting heavy oil pollution. The drilling fluid is prepared by mixing water, sodium bentonite, sodium carbonate, sodium carboxymethyl cellulose, low viscosity polyanionic cellulose, a filtrate loss reducer A, sulfonated phenolic resin, sulfonated lignite, industrial salt, an emulsifier B, an emulsifier C and barite, adjusting the pH value to 10 to 11 and aging at high temperature. The drilling fluid is prepared by reasonably compounding and synergistic effect of the above raw materials, can maintain good rheological properties, also increases significantly the capacity limitation of heavy oil, after the drilling fluid is polluted by 25% heavy oil, the drilling fluid still has good rheology and filtration loss property, the viscosity of the drilling fluid is effectively reduced, and the phenomenon of pasting a vibration sieve can be eliminated.

Owner:中石化石油工程技术服务有限公司 +1

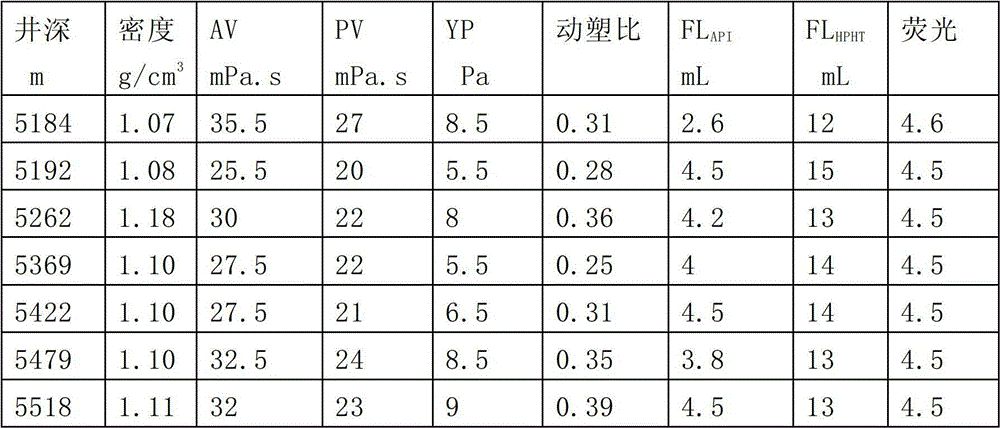

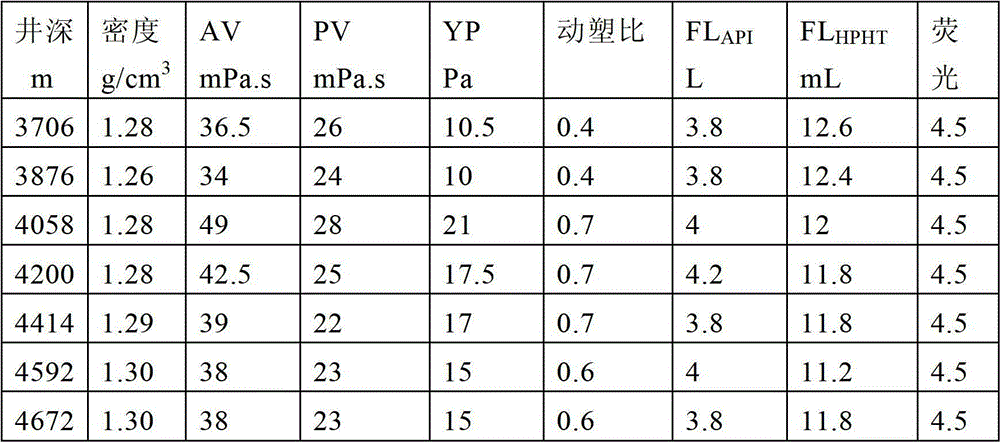

Low-fluorescence high temperature resistant drilling fluid

ActiveCN102676136BReduce high temperature and high pressure filtration lossImprove rheologyDrilling compositionFluorescenceWell drilling

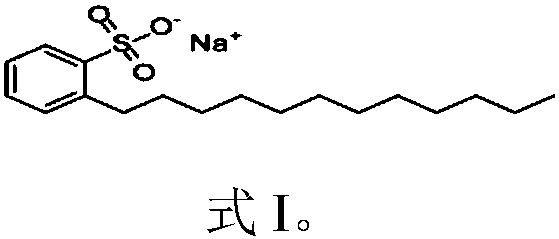

A low-fluorescence high temperature resistant drilling fluid is applied to exploratory well drilling in high-temperature formations of deep wells. The drilling fluid comprises, by weight, 1.0-2.5% of a drilling fluid loss agent PAMS601, 2-4% of sulfonated methypheuo formald-ehyde, 4-8% of sulfonated lignite resin, 0.6-1.0% of di-n-dodecylamine, 0.1-0.5% of fatty alcohol-polyoxyethylene ether, 0.8-1.5% of Na2SO3, 0.1-0.3% of sodium alkyl benzene sulfonate and 30-90% of water. The low-fluorescence high temperature-resistant drilling fluid has the advantages that the fluorescence grade of the drilling fluid system is lower than Grade 5, the temperature resistant ability is above 200 DEG C, and the fluid can restrain formation mud making, improves stability of well walls, controls reservoir clay swelling and improves reservoir protection effects, besides, the fluid has the advantages of being stable at the high temperature, low in fluorescence and particularly applicable to deep well drilling.

Owner:PETROCHINA CO LTD

High-softening point emulsified asphalt water-based drilling fluid additive and preparation method thereof

ActiveCN102952526BGood miscibilityMeet high temperature and high pressure requirementsDrilling compositionWater basedPolymer science

A high-softening point emulsified asphalt water-based drilling fluid additive and a preparation method thereof. The drilling fluid additive comprises 40-70 wt% of asphalt with a softening point of 150 DEG C-240 DEG C, 35-50 wt% of water, 0.02-2 wt% of an auxiliary agent, 0.05-5 wt% of an emulsifier, and 0.01-1 wt% of a stabilizer; the charge of the additive is anion; the storage stability for 1 day is not more than 1%; the storage stability for 5 day is not more than 5%; the high-temperature high-pressure filter loss at 220 DEG C and at 3.45 MPa is not more than 25 ml. The preparation method of the additive comprises the following steps: mixing water, the anion emulsifier, the stabilizer, and the auxiliary agent, then adding the asphalt fine powder with a softening point of 150 DEG C-240 DEG C into the above solution, and stirring. The drilling fluid additive provided by the invention has good high-temperature high-pressure filter loss effect, and is suitable for drilling of high-temperature high-pressure deep wells and extradeep wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

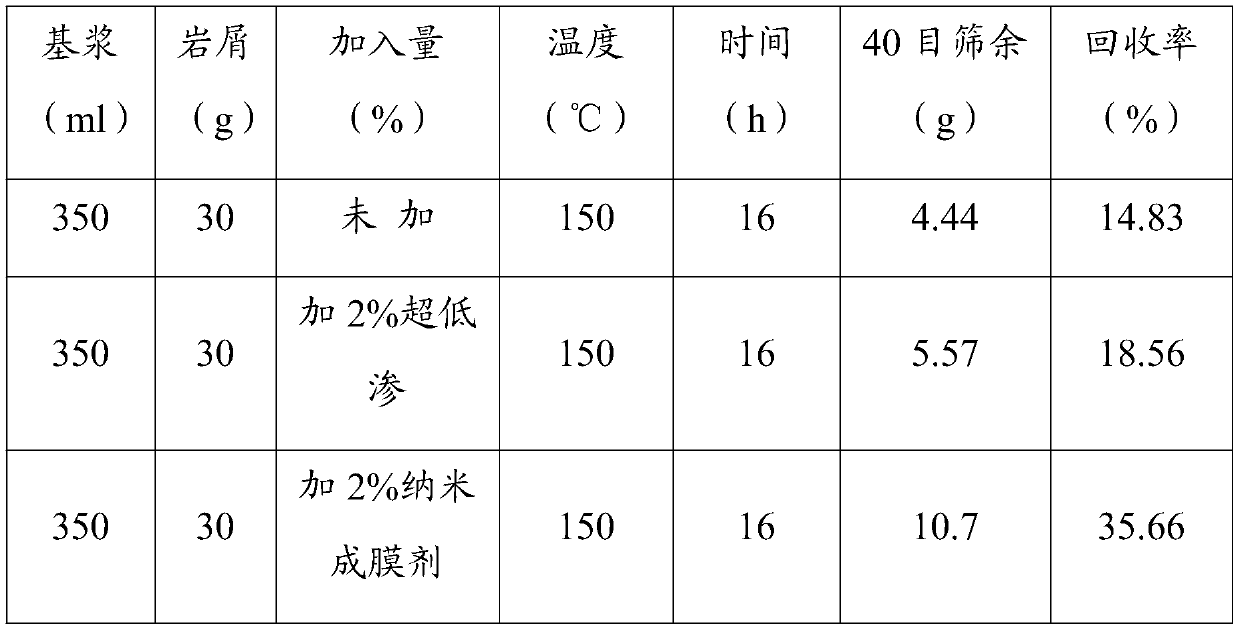

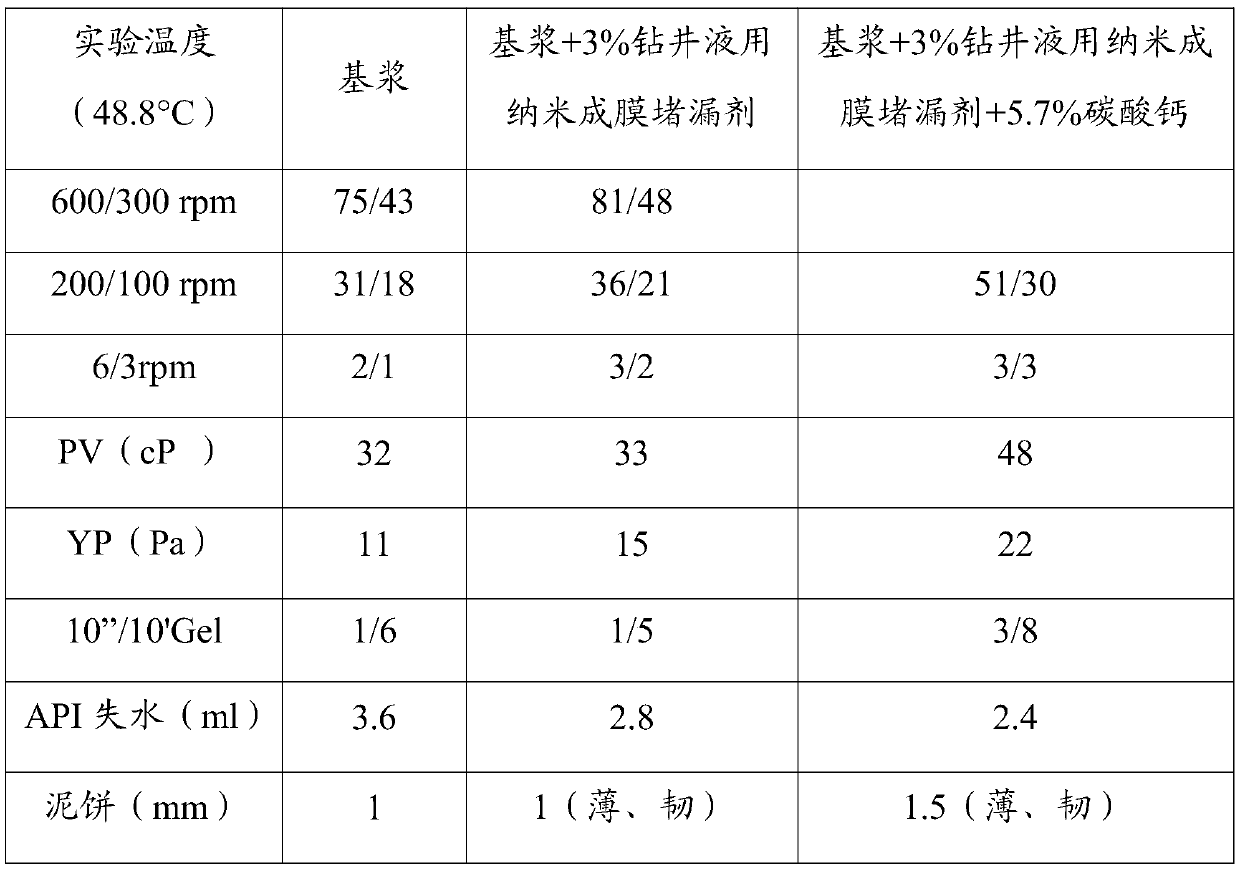

Nano filming plugging agent for drilling fluid and preparation method and application of nano filming plugging agent

InactiveCN110157397AImprove the blocking effectReduce high temperature and high pressure filtration lossDrilling compositionPolymer scienceEngineering

The invention provides a nano filming plugging agent for a drilling fluid. The nano filming plugging agent comprises the following components: silicon oxide, polyurethane granules, a dispersant and analcohol. By controlling proportions and preparation processes of raw materials, the prepared nano filming plugging agent for the drilling fluid is an odorless white liquid, the density is 1.05g / cm<3>, the granularity of solid particles is 50-400nm, the nano filming plugging agent for the drilling fluid is compressed in the surface of a wall well or microcracks of mud shale to form a semi-permeable isolation film, that is, a complete protection layer is formed on the wall well, fluids can be prevented from entering a stratum, effective pressure can be increased, ineffective pressure can be reduced, a wall well stabilizing function can be effectively brought into play, the drilling fluid blocking capability can be improved, the filter loss of the drilling fluid can be reduced, the quality and plugging performance of mud cakes can be improved, the inhibition of the drilling fluid can be improved, a liquid in a shaft can be prevented from entering stratum pores and cracks, the probabilityof differential pressure adhesion and tool jamming can be reduced, and in addition, the nano filming plugging agent is simple, convenient and easy in control of preparation processes, convenient andrapid to use, and high in popularization and application value.

Owner:XINJIANG GRAND OILFIELD TECH

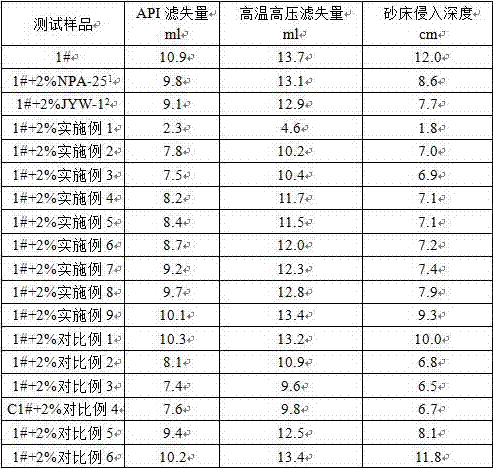

Preparation method of cationic plugging agent for drilling fluid

ActiveCN107501456AEasy accessEffective control of molecular weightDrilling compositionFiltrationEmulsion polymerization

The invention discloses a preparation method of a cationic plugging agent for a drilling fluid. The cationic plugging agent is prepared by emulsion polymerization from raw materials in parts by weight as follows: 30-90 parts of styrene, 5-75 parts of butyl acrylate and 15-75 parts of dimethyl diallyl ammonium chloride. Monomers are initiated by an initiator to be subjected to a polymerization reaction, and the cationic plugging agent with the macromolecular chain is obtained; with addition of a small quantity of the product to the drilling fluid, the filtration loss of the drilling fluid and the invasion depth in the sand bed can be effectively reduced, plugging of underground pore cracks is realized, and drilling safety is guaranteed.

Owner:XUZHOU NORMAL UNIVERSITY

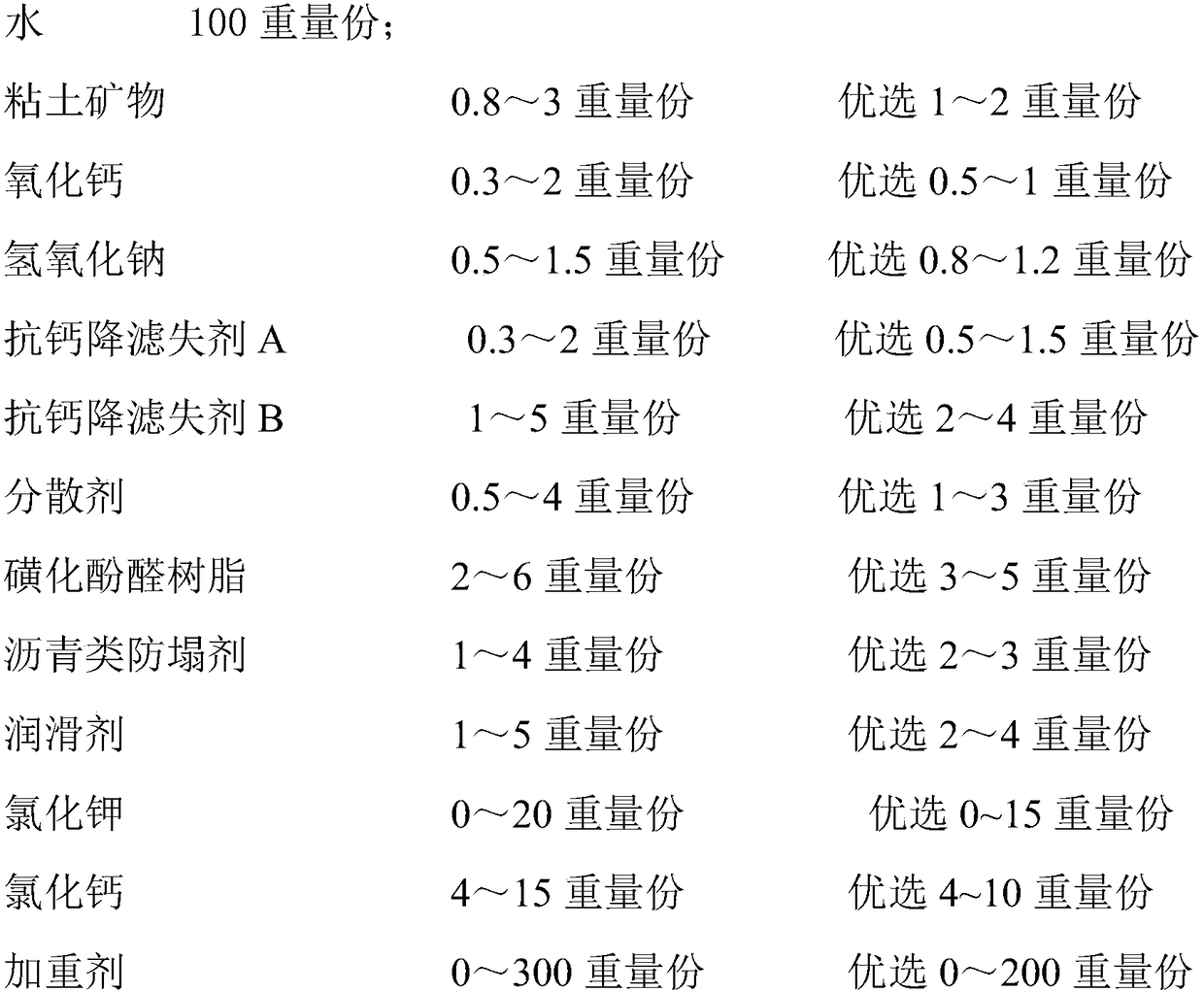

High-temperature-resisting water-based well-drilling fluid filtrate reducer and preparation method thereof

InactiveCN109321216AControl rheologyControl suspension stabilityDrilling compositionCross-linkWater based

The invention discloses a high-temperature-resisting water-based well-drilling fluid filtrate reducer and a preparation method thereof. The high-temperature-resisting water-based well-drilling fluid filtrate reducer is prepared from the following raw materials in parts by mass: 700 parts of sulfomethylated phenol formaldehyde resin, 3-8 parts of formaldehyde, 6-15 parts of melamine, 8-20 parts ofa sulfonate monomer, 40-80 parts of an acrylamide monomer, 0.5-2 parts of a cross-linking agent, 0.3-0.6 part of an initiator, and 60-80 parts of water. The sulfomethylated phenol formaldehyde resin is modified and then subjected to a copolymerization with the multiple monomers, namely the high-temperature-resisting water-based well-drilling fluid filtrate reducer is synthesized by increasing hydration groups of a product and introducing new sulfonic groups and aromatic ring structures, thus the demand of safe well-drilling construction in a downhole high-temperature environment can be met, the rheological property and suspension stability of water-based well-drilling fluid under the high-temperature and high-pressure conditions can be controlled, and the high-temperature and high-pressurefilter loss of the well-drilling fluid is effectively decreased.

Owner:中科宝辰(北京)科技有限公司

High temperature-resisting fluid loss agent for drilling fluid and preparation method thereof

The invention discloses a high temperature-resisting fluid loss agent for drilling fluid. The high temperature-resisting fluid loss agent is characterized by being prepared from the following components and raw materials in percentage by mass: 10 to 15 percent of abietic acid, 8 to 12 percent of glycerol, 30 to 40 percent of sulfonated bitumen, 10 to 12 percent of cationic starch, 10 to 20 percent of temporary plugging agent, 12 to 14 percent of high temperature stabilizer and 0.5 to 1.0 percent of deoxidant, wherein the cationic starch is prepared from starch tert-amino alkyl ether and quaternary ammonium starch ether; the high temperature stabilizer is prepared from sulfonated phenol-formaldehyde resin and sulfonated lignite resin; the temporary plugging agent is prepared from tert-butyl phenolic curing resin, octyl phenolic curing resin and calcium carbonate. The high-temperature resistance is up to 250 DEG C, no blistering exists, the viscosity effect is low, the compatibility is good, a product contains rigid particles and softening film-forming particles in different size grading, the product directly participate in mud cake forming, a high-strength adsorption film is formed on the surface of the mud cake, the permeability rate of the mud cake is reduced, the quality of the mud cake is improved, and the function of reducing high-temperature high-pressure filter loss is achieved.

Owner:成都西油华巍科技有限公司

Fluid loss additive for drilling fluid and preparation method thereof

ActiveCN102766240BControl rheologyReduce high temperature and high pressure filtration lossDrilling compositionSide chainWell drilling

The invention discloses a fluid loss additive for drilling fluid and a preparation method thereof, belonging to the technical field of chemical drilling fluid treating agents for oilfields. The method comprises the following steps of: carrying out one-step reaction on phenol, formaldehyde, humate, pyrosulfite and anhydrous sulfite so as to obtain a sulfonated phenolic humic acid resin; in the presence of an initiator, carrying out graft copolymerization on the sulfonated phenolic humic acid resin and a mixture of sodium hydroxide, 2-acrylamide-2-methyl-propyl sulfonate, acrylamide and dodecylacrylamide; and carrying out drying and crushing on the obtained product so as to obtain sulfonated phenolic humic acid resin-alkenyl monomer graft copolymer. The fluid loss additive disclosed by the invention has the functions of controlling the rheological property of drilling fluid and reducing the high-temperature and high-pressure filter loss of drilling fluid, not only enhances the thermal stability of side chains of a chain polymer, but also improves the salt tolerance of a sulfonated phenolic resin, and guarantees that products have good properties under high temperature and high salt conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

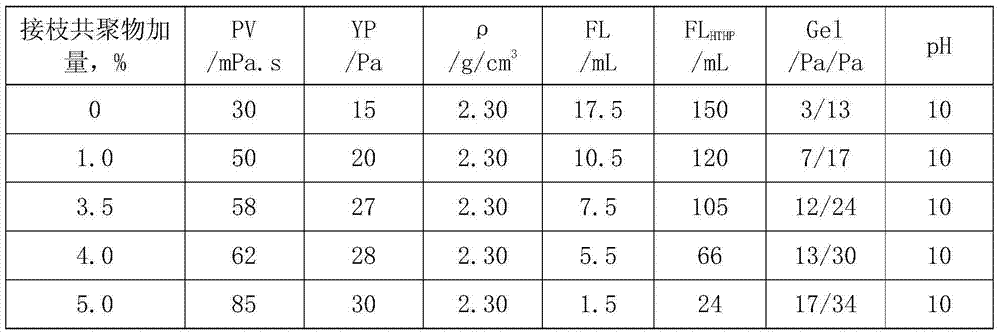

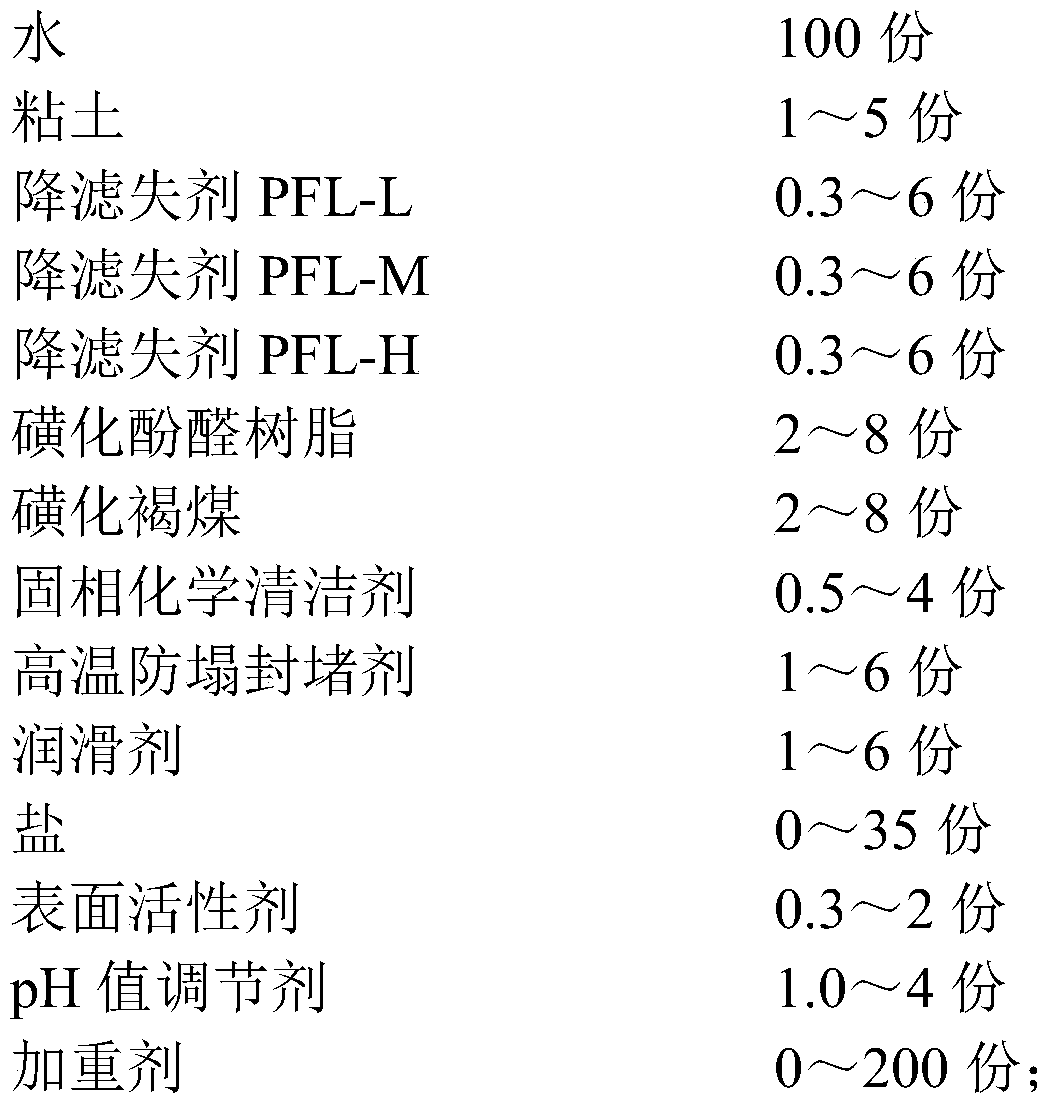

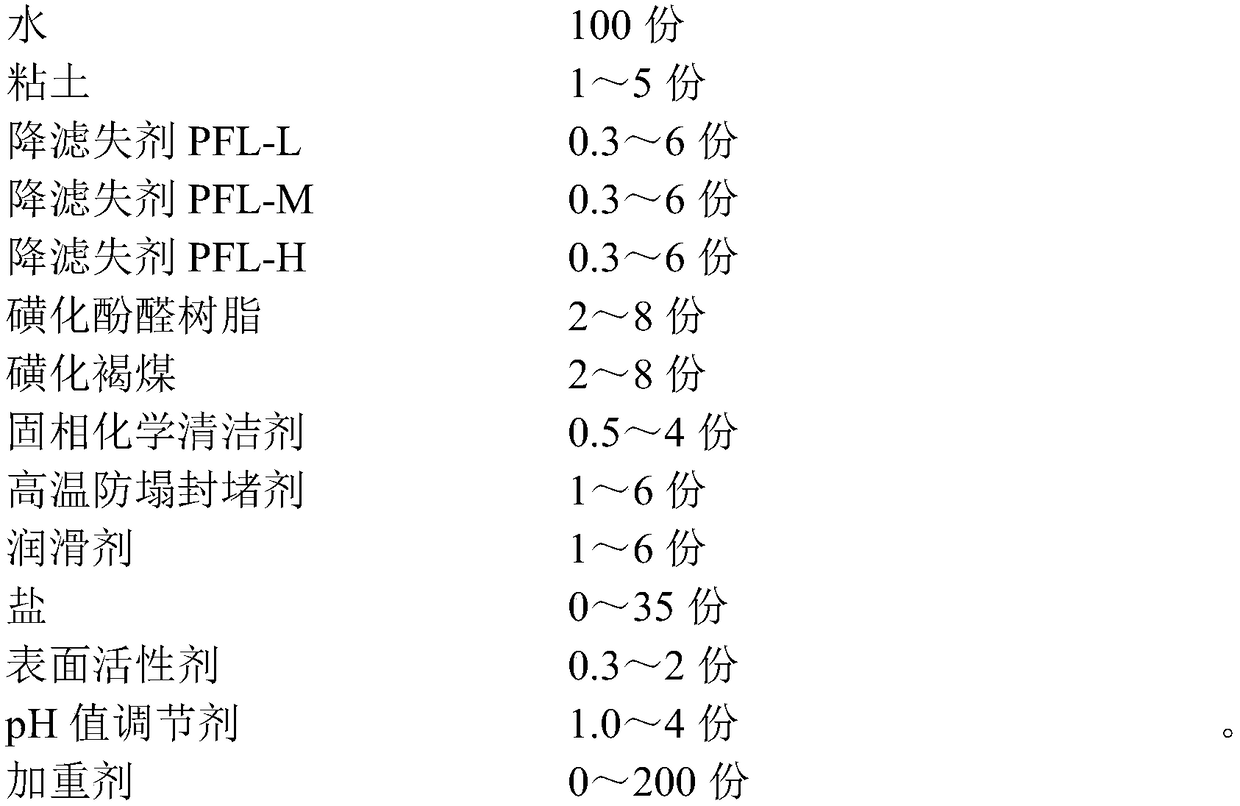

A kind of ultra-high temperature salt-resistant drilling fluid and preparation method thereof

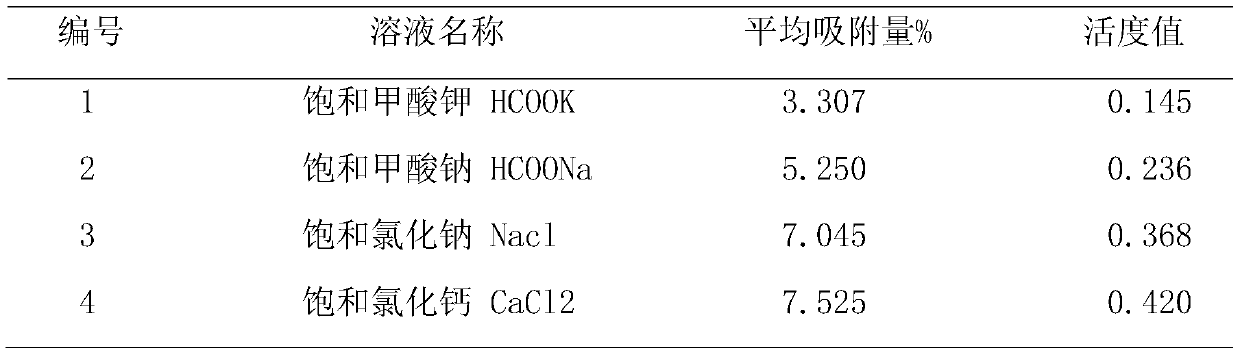

ActiveCN105623627BRheology is easy to controlReduce high temperature and high pressure filtration lossDrilling compositionActive agentWell drilling

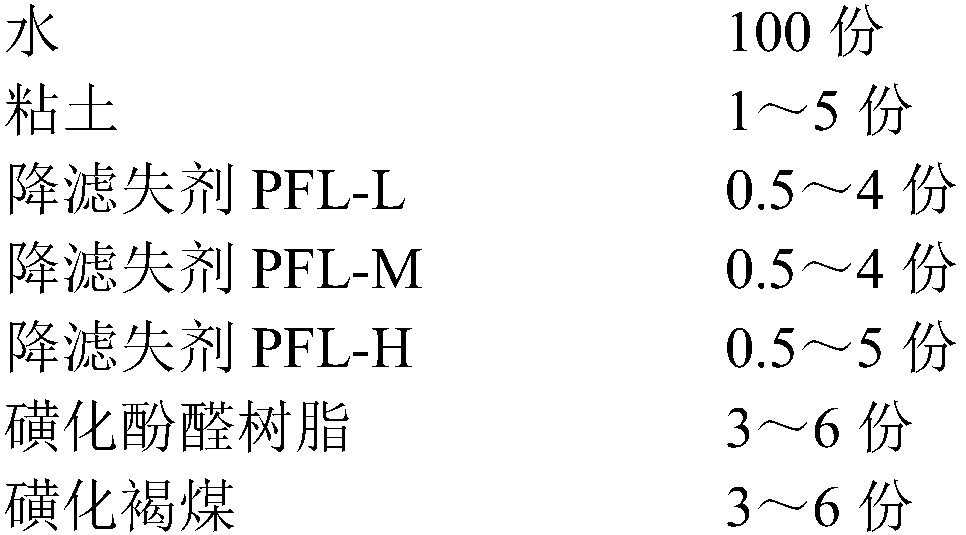

The present invention provides an ultra-high temperature salt-resistant drilling fluid for ultra-deep well and ultra-high temperature stratum drilling, and a preparation method thereof, wherein the ultra-high temperature salt-resistant drilling fluid comprises, by weight, 100 parts of water, 1-5 parts of clay, 0.3-6 parts of a filtrate loss reducer PFL-L, 0.3-6 parts of a filtrate loss reducer PFL-M, 0.3-6 parts of a filtrate loss reducer PFL-H, 2-8 parts of a sulfonated phenol formaldehyde resin, 2-8 parts of sulfonated lignite, 0.5-4 parts of a solid-phase chemical cleaning agent, 1-6 parts of a high temperature anti-collapse blocking agent, 1-6 parts of a lubricant, 0-35 parts of salt, 0.3-2 parts of a surfactant, 1.0-4 parts of a pH value adjusting agent, and 0-200 parts of a weighting agent. According to the present invention, the ultra-high temperature salt-resistant drilling fluid is not thickened at a high temperature of more than or equal to 240 DEG C, has easily-controlled rheology and low high-temperature and high-pressure filtrate loss, can be used for bottom hole drilling construction in the high temperature (more than or equal to 240 DEG C) and high salt (saturated salt) environments, and has the good application effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environmentally-friendly low-fluorescence imitation asphalt plugging agent

ActiveCN109468124AReduce fluorescencePrevents hydration from dispersingDrilling compositionSealing/packingFiltrationFluorescence

The invention discloses an environmentally-friendly low-fluorescence imitation asphalt plugging agent which comprises the following components in percentage by weight: 10-20 percent of polyamide wax powder, 20-25 percent of oxidized polyethylene wax, 5-8 percent of poly-aluminum chloride, 20-25 percent of polyethylene glycol, 2-5 percent of sodium dodecyl benzene sulfonate, 10-15 percent of nanometer calcium carbonate and the balance of water. The plugging agent has low fluorescence, does not contain polycyclic aromatic hydrocarbons and other toxic substances, does not affect geological logging, has good environmental protection performance, has a certain hydration capacity and can prevent the hydration and the dispersion of shale particles when being adsorbed on a shale interface to playa collapse prevention role, and a part that is not soluble in water can fill pore throats and cracks to play a sealing role and can cover the shale interface to improve the quality of a mud cake, so that the high-temperature and high-pressure filtration loss of drilling fluid is reduced, and the plugging capability of the drilling fluid is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Marine high-temperature high-pressure water-based drilling fluid

PendingCN110951468AReduce high temperature and high pressure filtration lossImprove rheologyDrilling compositionCelluloseSlurry

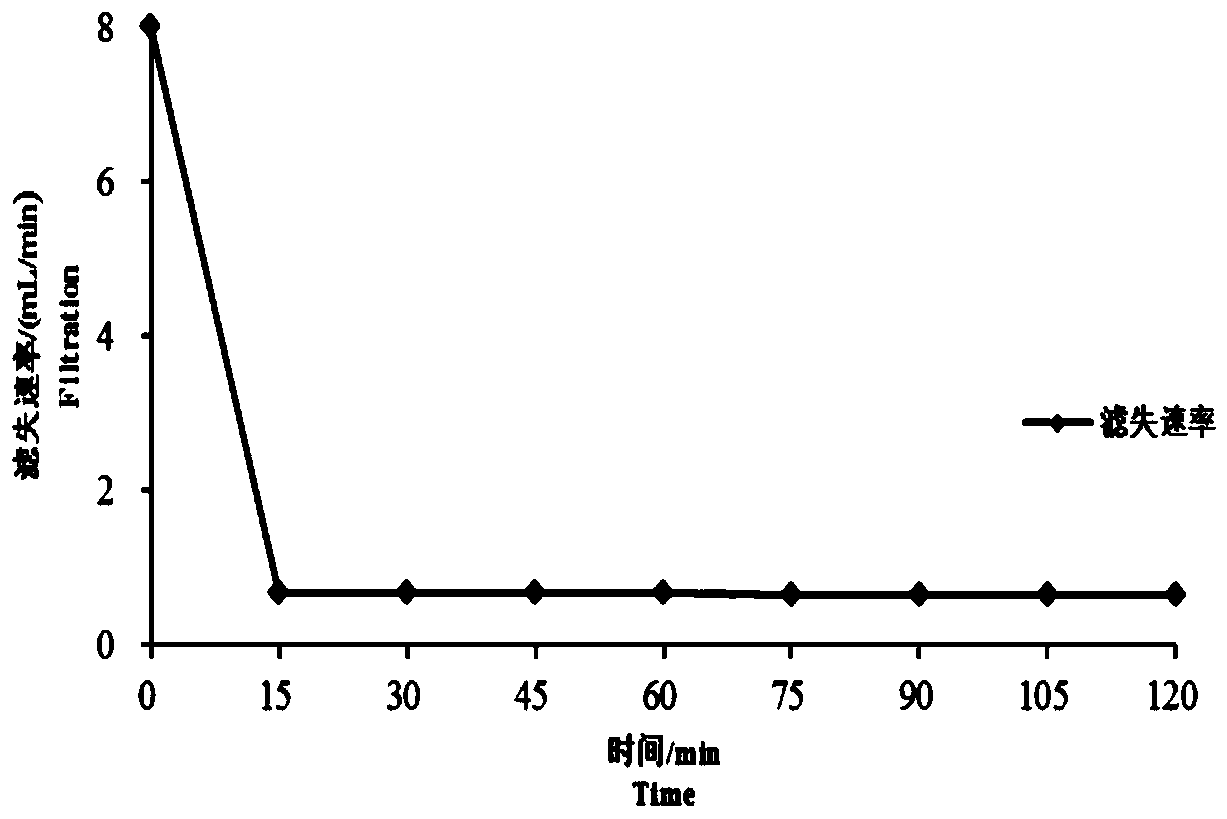

The invention discloses a marine high-temperature high-pressure water-based drilling fluid, which comprises the following components by weight: 2.5% of bentonite slurry, 0.6% of polyanionic cellulose,2% of sulfonated asphalt, 2-3% of a sulfonated resin, 3-4% of sulfonated poly-coal, 2% of a high-temperature-resistant polymer, 1-2% of a high-temperature-resistant diluent, 0.5-0.9% of caustic soda,7.5-8.2% of barite, 10% of potassium formate, 1.5% of a lubricant, and the balance of water, wherein the pH value of the drilling fluid is 10-11, the total filter loss is less than 8 mL / 30 min at a temperature of 150 DEG C under a pressure of 100 MPa, and the filter loss is less than 0.7 mL / min after 15 min. According to the invention, the water-based drilling fluid has low high-temperature and high-pressure filtration loss, the formed filter cake is thin and tough, good in rheological property and good in reservoir protection effect, and the problems of high-temperature and high-pressure drilling and pre-control of downhole accidents can be well solved in the drilling process so as to provide a certain reference significance and popularization value in subsequent similar well operation.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

Ultrahigh-temperature high-density drilling fluid, preparation method and application thereof

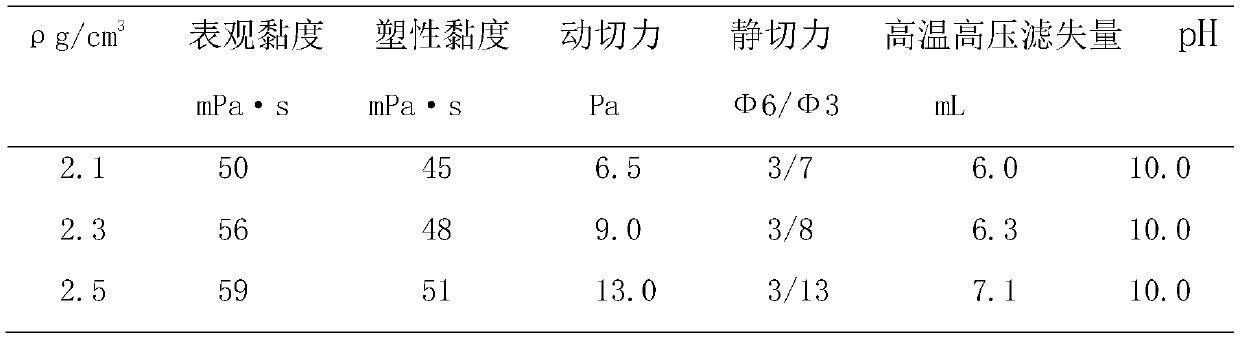

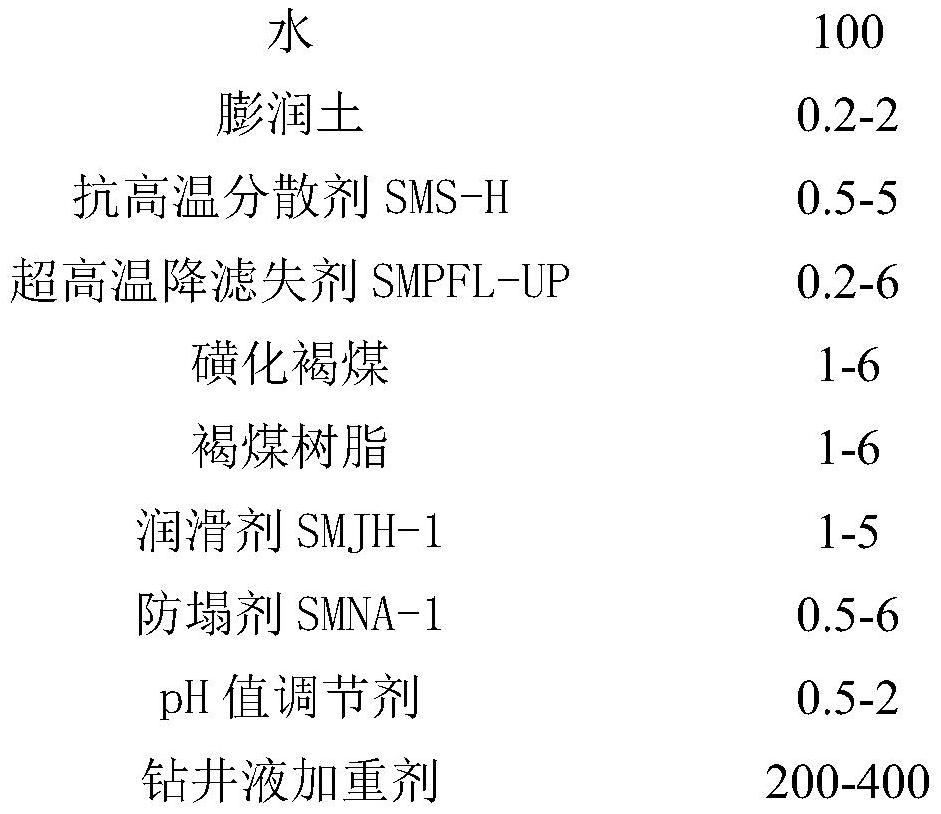

PendingCN112625662AGood rheology at high temperatureReduce high temperature and high pressure filtration lossDrilling compositionThermodynamicsHigh density

The invention relates to an ultrahigh-temperature high-density drilling fluid, which comprises a high-temperature-resistant dispersing agent, an ultrahigh-temperature filtrate reducer, a lubricating agent and an anti-collapse agent. The drilling fluid can resist a temperature of 240DEG C at the density of 2.4g / cm<3>, has good sedimentation stability and rheological property, is low in high-temperature and high-pressure water loss and good in high-temperature stability, and can be used for drilling construction of high-temperature and high-pressure stratums.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com