Patents

Literature

84results about How to "Good anti-collapse effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature resistant circulating micro-foam drilling fluid or completion fluid

ActiveCN101148579AImprove stabilityHigh temperature resistanceDrilling compositionFoaming agentWell drilling

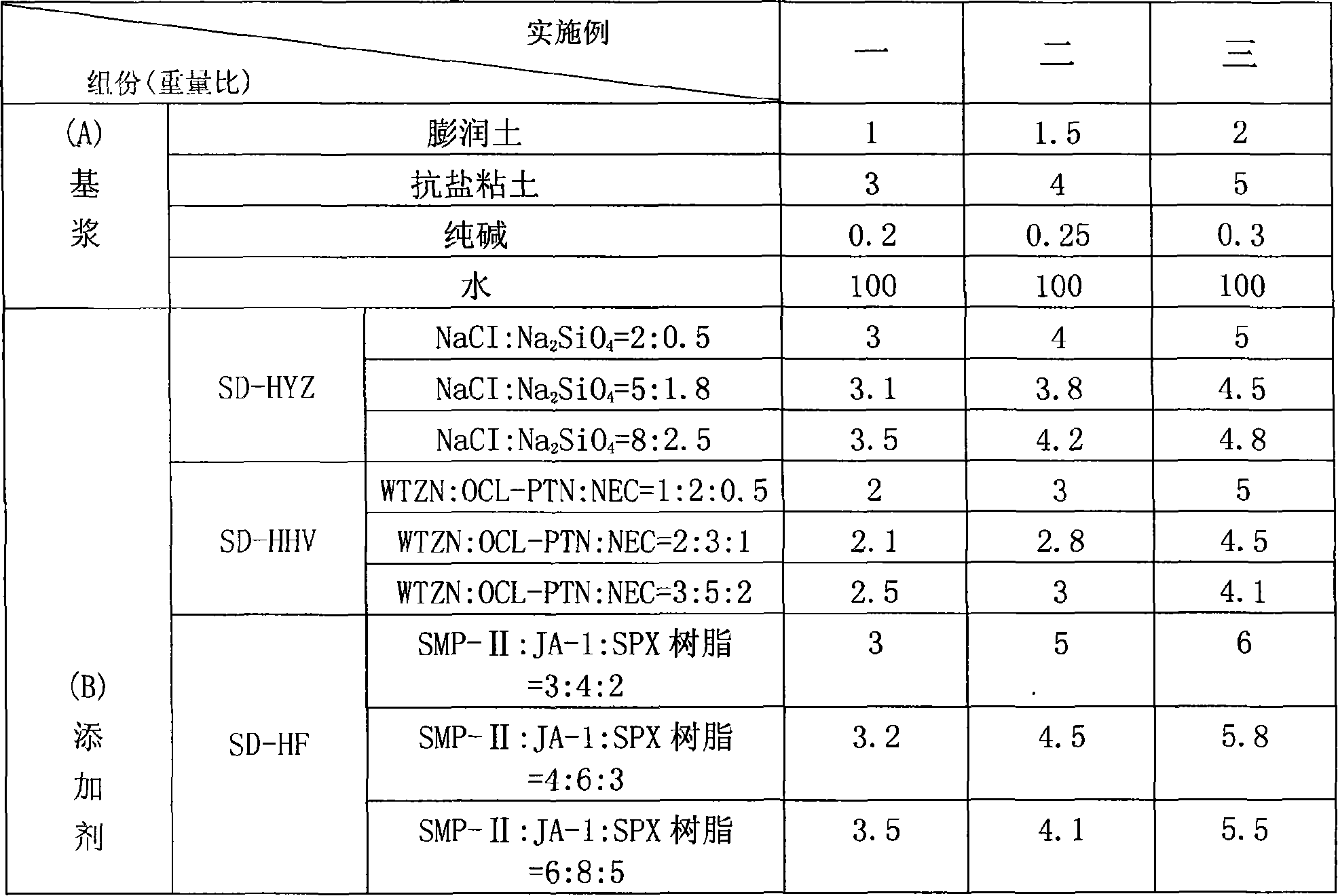

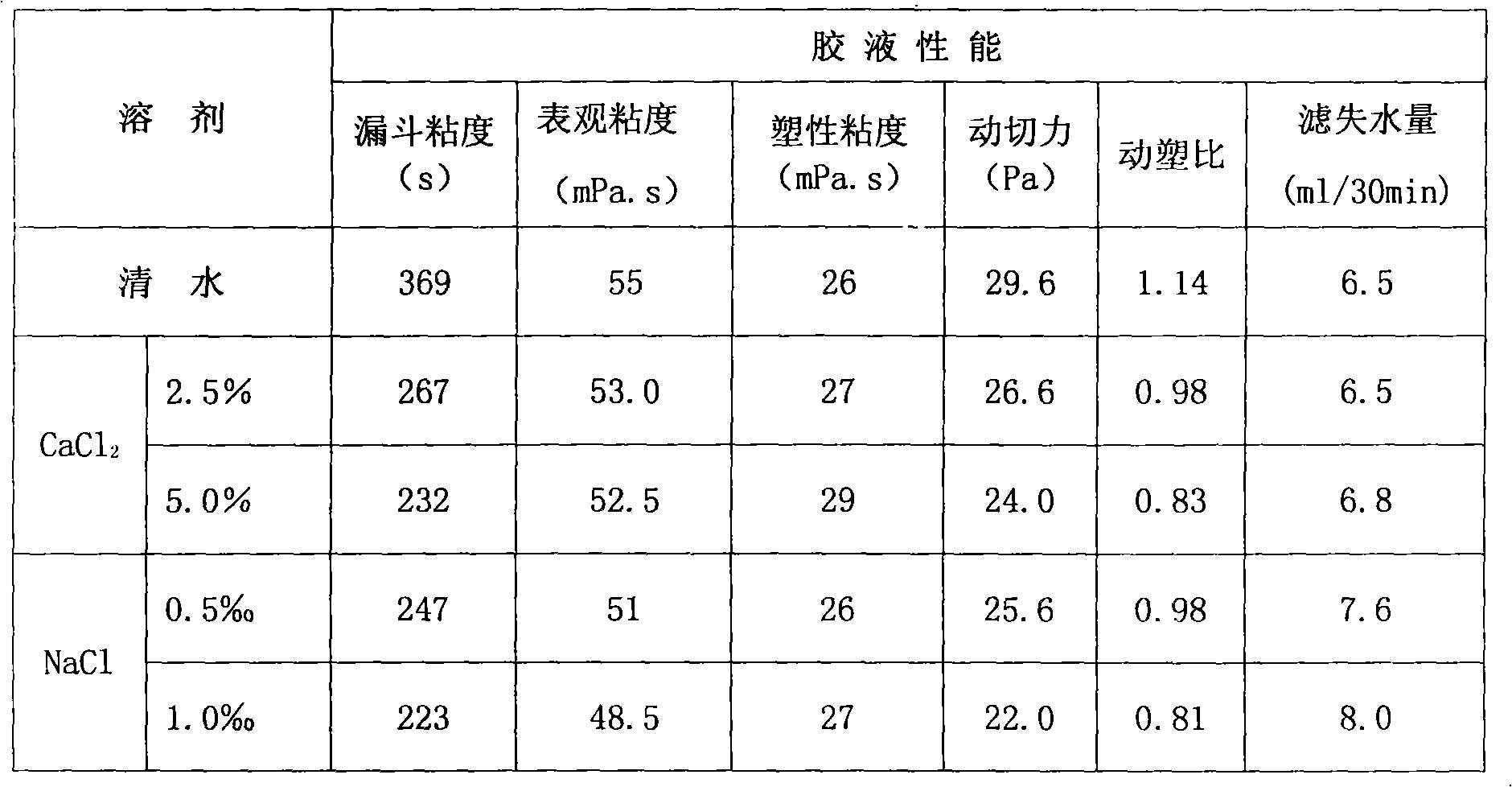

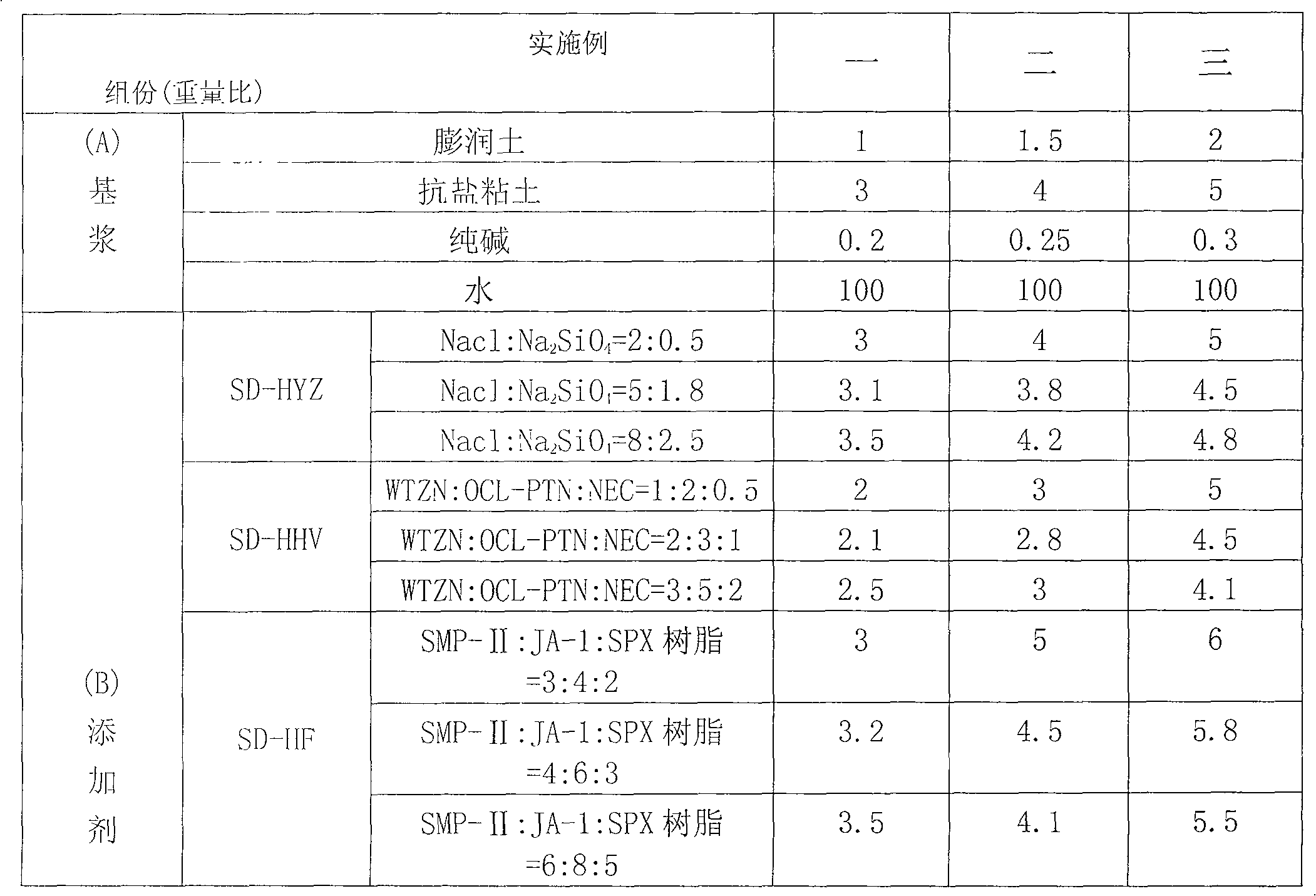

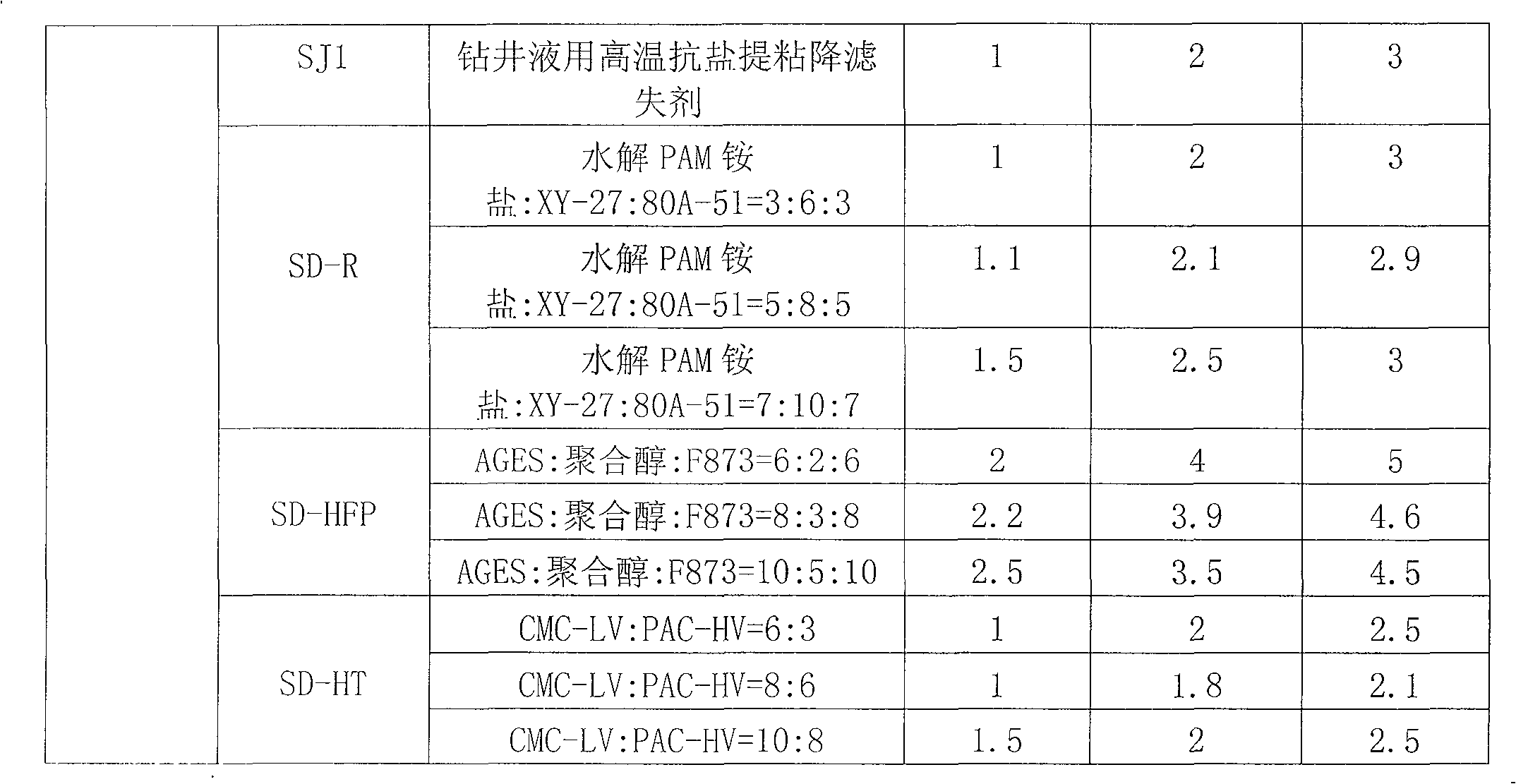

The present invention discloses one kind of high temperature recyclable microbubble drilling and completing fluid, which includes basic slurry comprising bentonite 1-2 (in weight portions, the same below), salt tolerant clay 3-5, sodium carbonate 0.2-0.3 and water 100; and additives comprising high temperature inhibitor 3-5, high temperature tackifier 2-5, high temperature filter loss reducing agent 3-6, high temperature salt resisting filter loss reducing tackifier 1-3, flow form regulator 1-3, high temperature foaming agent 2-5 and high temperature foam stabilizer 1-2.5. The high temperature recyclable microbubble drilling and completing fluid has excellent high temperature performance, high carrying, suspending capacity in low pressure deep well, and functions of inhibiting the hydrating expansion of mudstone and protecting oil and gas reservoir, is suitable for different types of high temperature stratum. It is applied in well drilling and well completing construction for low pressure and low permeation stratum.

Owner:DONGYING TAIER GASOLINE TECH

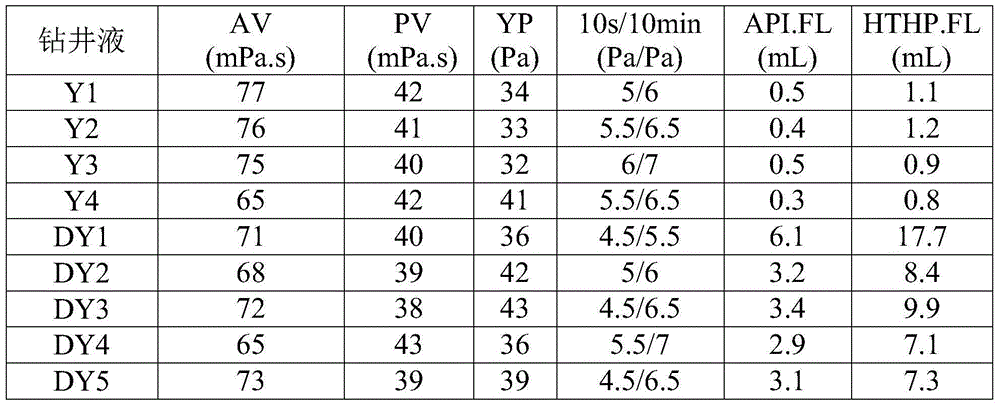

Strong-inhibition drilling fluid system

ActiveCN103013470AEnhanced inhibitory effectImprove stabilityDrilling compositionSlurryHigh pressure

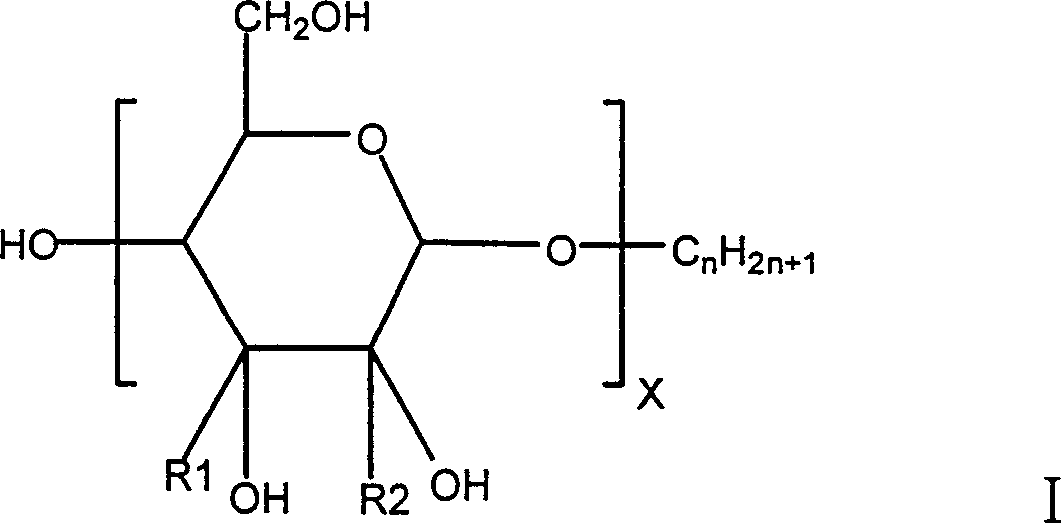

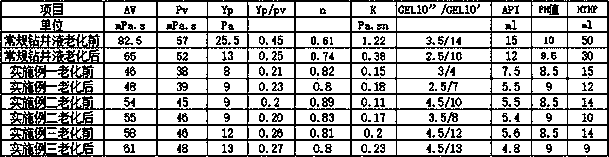

The invention relates to a strong-inhibition drilling fluid system, comprising the following components by mass percent of 2.5-4.5% of bentonite slurry, 0.1-0.3% of alkaline regulator, 0.3-2.0% of shale inhibitor, 0.2-0.4% of metal ion polymer, 2.0-5.0% of walchowite, 2.0-5.0% of sulfomethal phenolaldehy resin, 1.0-3.0% of cation emulsified asphalt, 0.5-3.0% of lubricating agent, 0.2-0.8% of emulsifier, 2.0-8.0% of crude oil, and 1.0-3.0% of calcium carbonate superfine powder according to 100% of water. The compound in a general formula (I) is also provided; R1 is H or CH3; R2 is H, CH3 or C2H5; and X is an integer between 2 and 20 and applied to the shale inhibitor. The compound and the cation emulsified asphalt are applied to the drilling liquid system; the drilling liquid system is strong in shale inhibition; the shale recovery rate can be up to 90.33% and is improved by over 35.02% in comparison with that of water shale; the high temperature resistance can be up to 150 DEG C; the lubricating friction coefficients before and after aging respectively are smaller than 0.1; the strong-inhibition drilling fluid system is strong in capacity of resisting poor soil, salt and calcium contamination, strong in rejection capability, and good in blocking effect; the API (American petroleum institute) water loss of the drilling fluid is smaller than 4.5mL, and the HTHP (high temperature and high pressure) water loss is smaller than 12mL.

Owner:CHINA PETROLEUM & CHEM CORP

Anti-collapse circulative micro-foam drilling fluid or well completion fluid

ActiveCN101182409AReduce complexityIncrease drilling speedDrilling compositionFoaming agentSodium Bentonite

The invention discloses an anti-collapse circulating microfoam drilling fluid or completion fluid, which consists of (A) base slurry: bentonite 2-4.5 or 6-10, soda ash 0.2-0.3 water 100 parts by weight. (B) Additives: ① Anti-slump agent 2-5, ② Cementing agent 3-5, ③ Viscosifier 0.5-3, ④ Fluid loss reducer 1-3, ⑤ Foaming agent 0.5-5, foam stabilizer 0.5- 2.5, flow regulator 0.5-2.5. The invention has strong anti-slump function and strong adaptability, can be used as both drilling fluid and completion fluid, can be applied to low-pressure carbonate formations, and low-pressure, low-permeability mudstone formations and rock formations It is mainly used in drilling and completion of low-pressure, low-permeability and easy-collapse formations.

Owner:DONGYING TAIER GASOLINE TECH

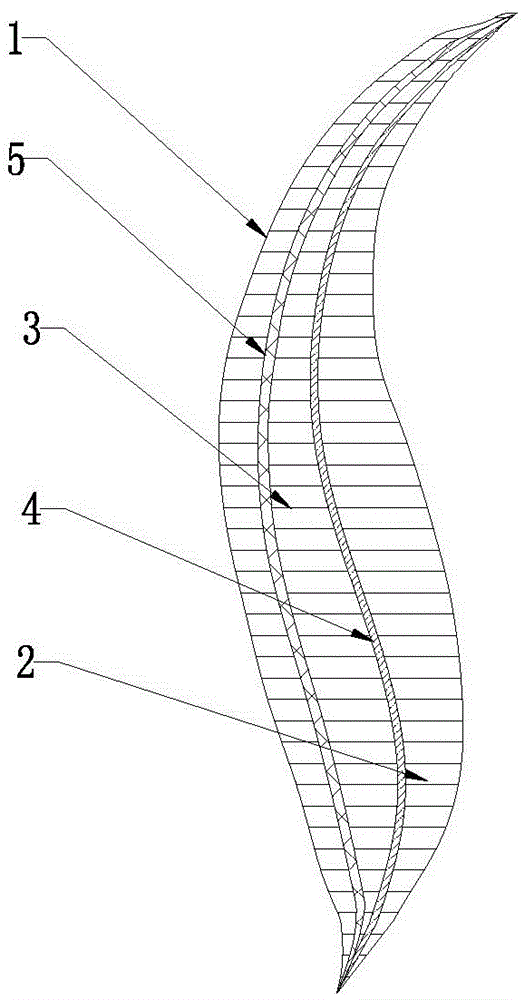

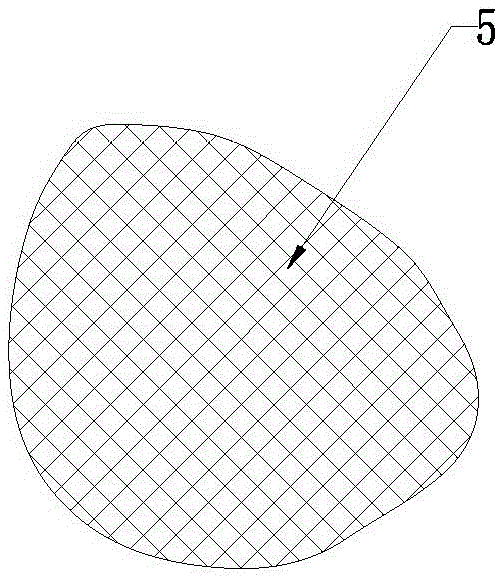

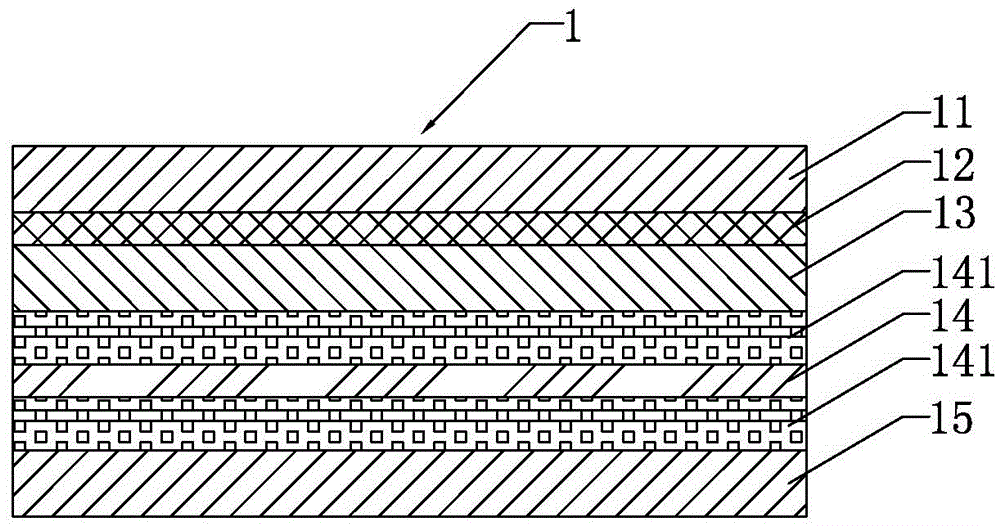

Vertical cotton breathable bra cup pad with silica gel net and preparation method thereof

The invention relates to the technical field of bra cup pad, and specifically relates to a vertical cotton breathable bra cup pad with a silica gel net and a preparation method thereof. The vertical cotton breathable bra cup pad comprises a vertical cotton outer layer and a vertical cotton inner layer; a vertical cotton interlayer is arranged between the vertical cotton outer layer and the vertical cotton inner layer; an adhesive layer is arranged between the vertical cotton interlayer and the vertical cotton inner layer; and a silica gel net layer is arranged between the vertical cotton outer layer and the vertical cotton interlayer. The vertical cotton breathable bra cup pad is prepared by a combined technology of hot pressing and cold pressing. The pad is made of vertical cotton, and is light, comfortable, and breathable. A silica gel layer is arranged between vertical cotton layers, the performance of the pad on resisting water washing is enhanced, the anti-collapse effect is good, three-dimensional effect of the cup pad is long-lasting and stable, and the deformation is difficult to happen.

Owner:HONGJI UNDERWEAR CO LTD

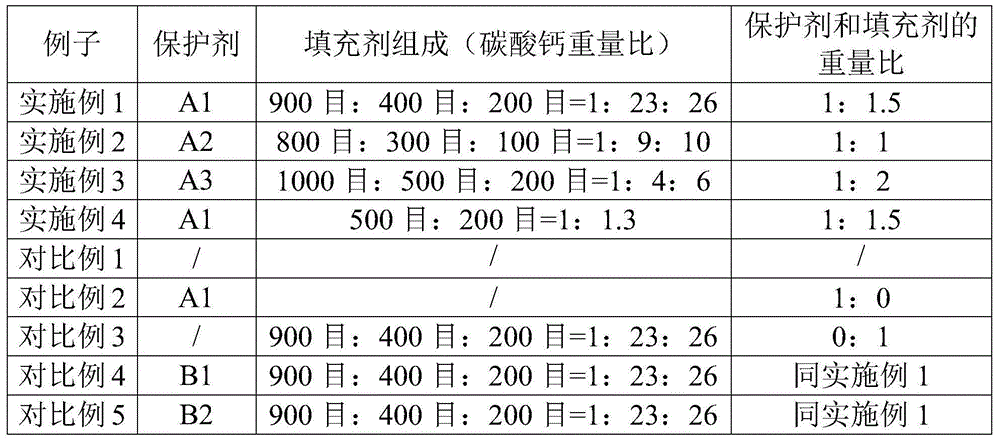

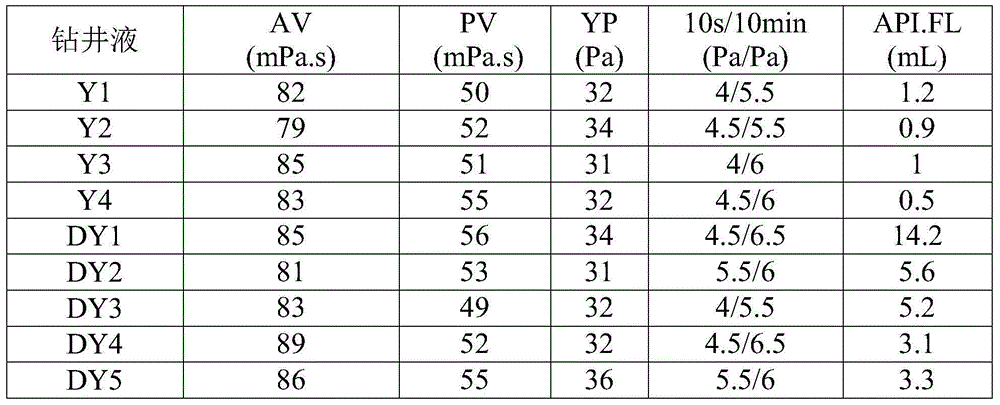

Protective agent composition of hypertonic special-hypertonic reservoir, as well as drilling fluid and applications thereof

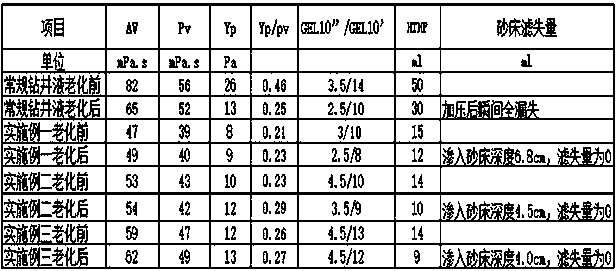

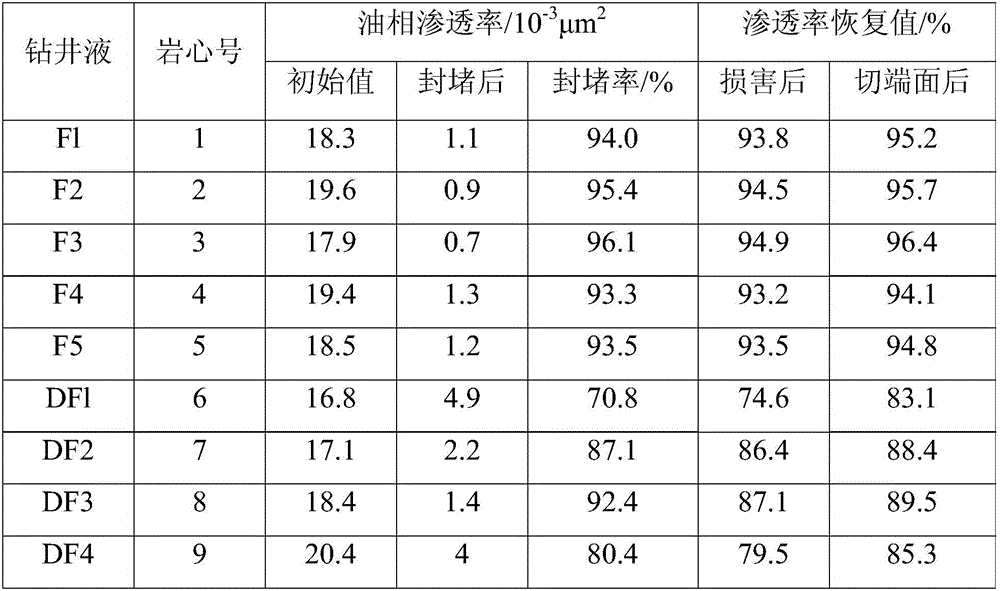

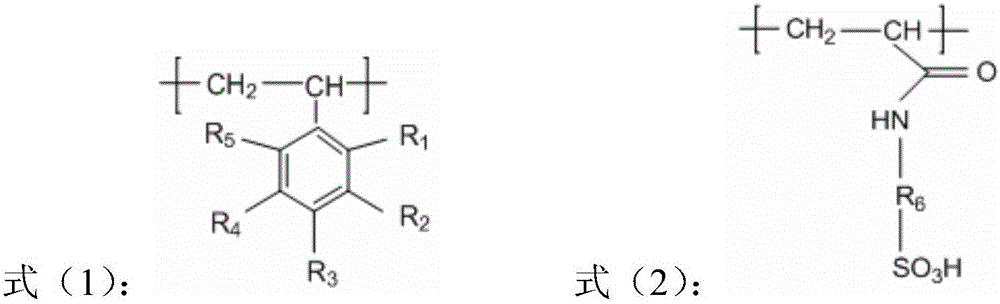

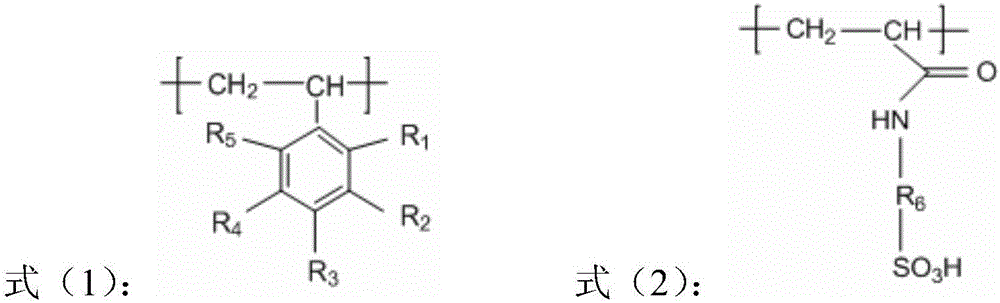

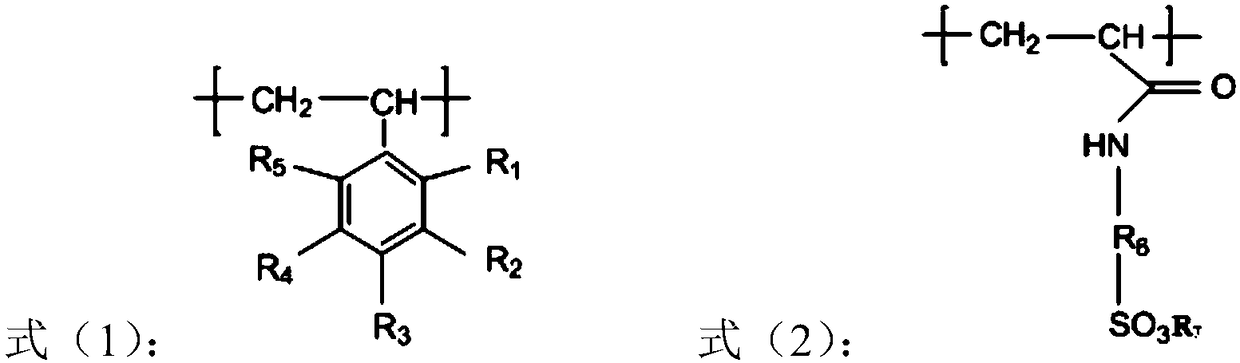

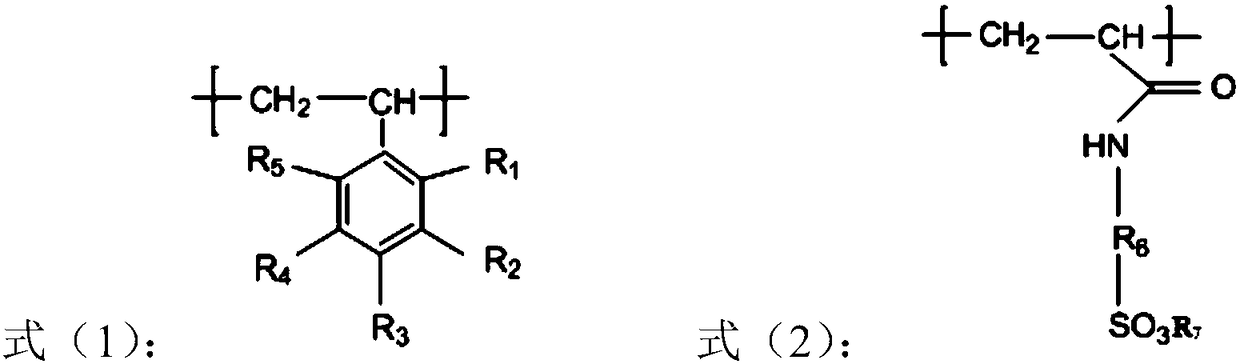

ActiveCN104650823AImprove rheologyImprove temperature resistanceFlushingDrilling compositionEconomic benefitsStructural unit

The invention relates to a protective agent composition of a hypertonic special-hypertonic reservoir. The protective agent composition comprises a protective agent and a filling agent, wherein the filing agent comprises calcium carbonate of 600-1000, 300-590 meshes and 50-200 meshes in the weight ratio of 1:(4-30):(0-40), and the protective agent comprises structure units shown in the formulas (1), (2) and (3). The invention further provides a drilling fluid comprising the composition. The invention further provides applications of the drilling fluid in the drilling of the hypertonic and special-hypertonic reservoir. The drilling fluid has the advantages of being simple to use, good in environment-friendly performance, and excellent in reservoir protection performance, greatly reducing the damage of the drilling fluid to the hypertonic special-hypertonic reservoir, and bringing objective economic benefits.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

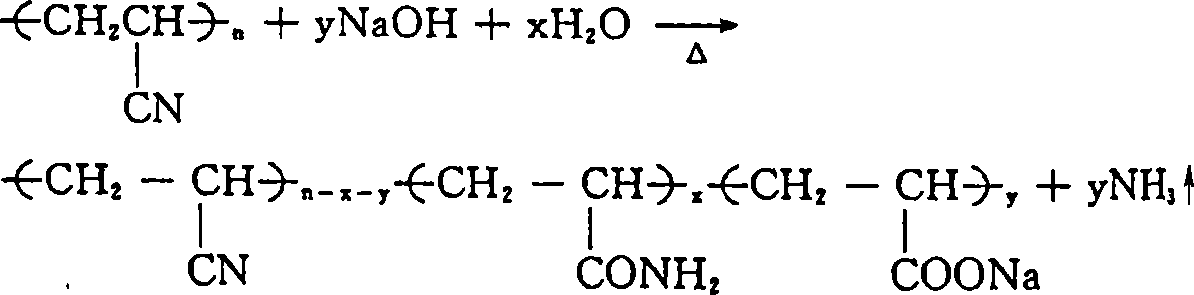

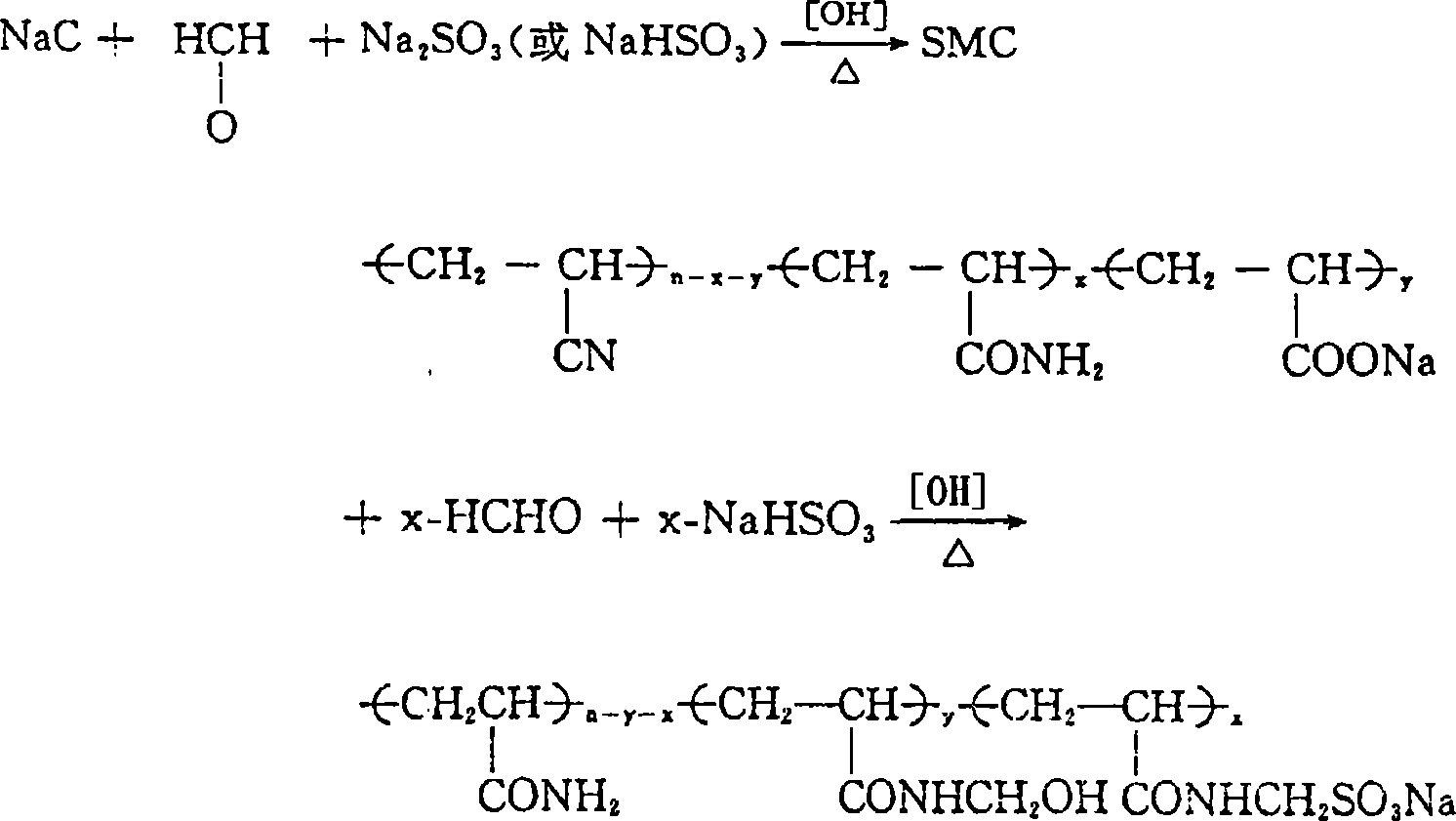

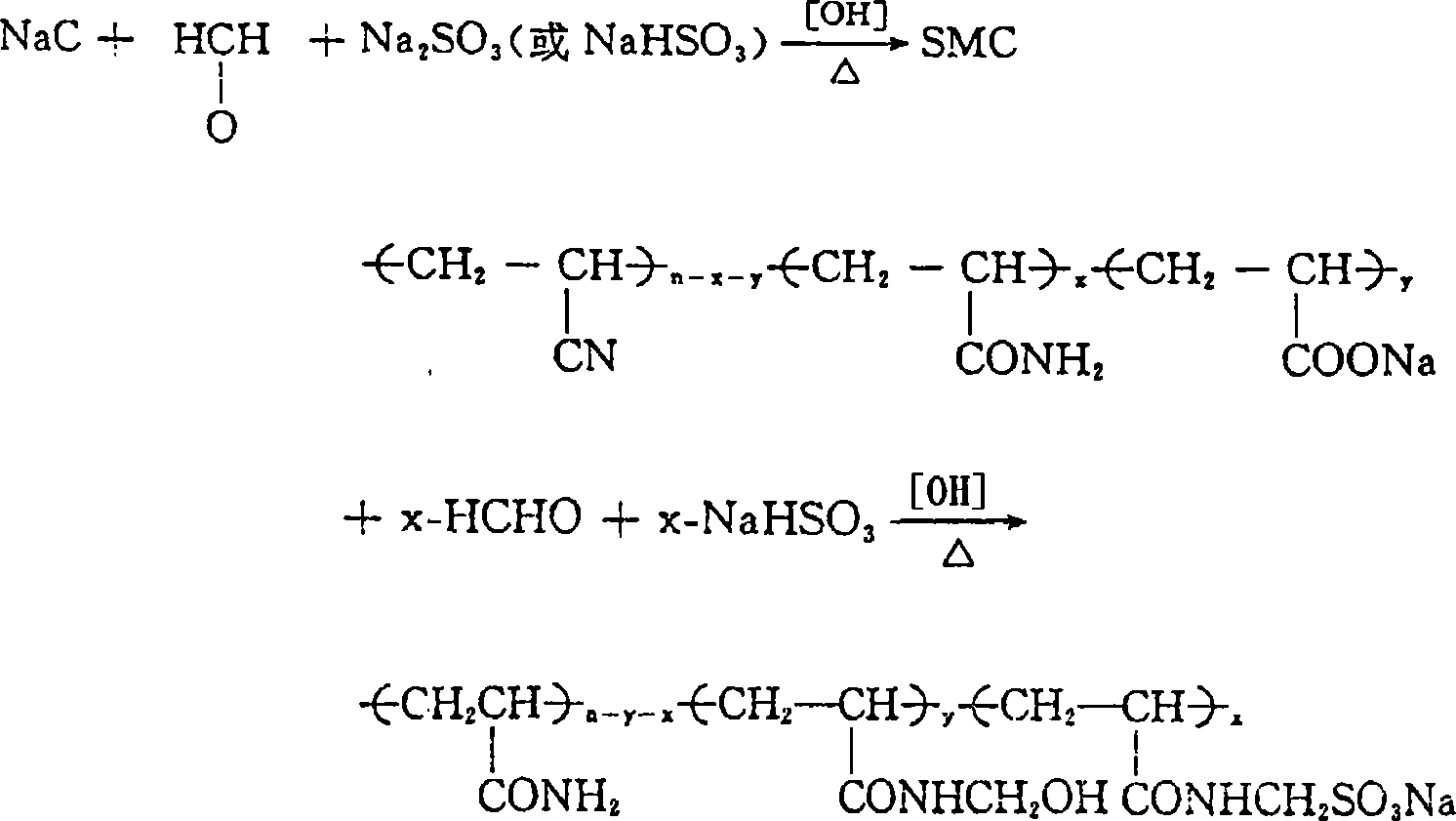

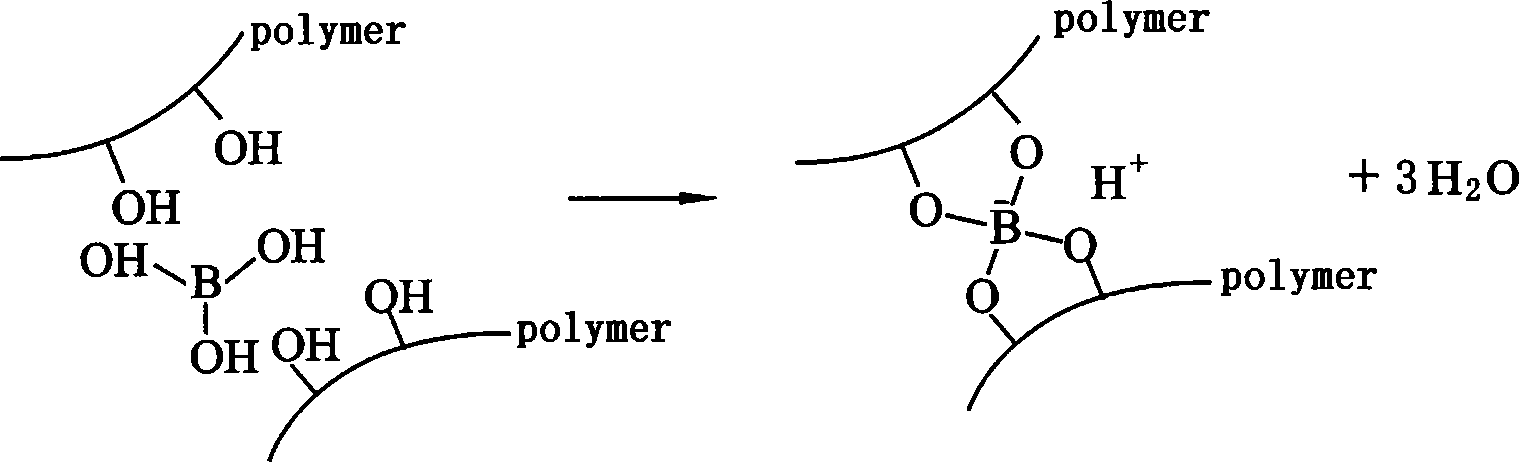

Method for preparation of lignite resin drilling fluid loss additive

InactiveCN101230257AImprove rheologyImprove the lubrication effectDrilling compositionChemical reactionFiltration

The invention provides a preparation method of lignite resin type drilling fluid filtration loss reducing agent, water, lignite, orlon leftovers, polyether polylol, sodium hydroxide, potassium hydroxide, sodium sulfite, sodium bisulfite, laterality sodium sulfite, boric acid, zirconium chloride and formaldehyde are used as materials. The above materials are put into a reactor orderly and are mixed together for reaction; after a series of chemical reactions of alkalization, sulfonation, complexation, graft cross bonding and so on, the lignite resin type drilling fluid filtration loss reducing agent is obtained. When the filtration loss reducing agent provided by the invention is added, the rheology, the unstuousness and the collapse resistance of the drilling fluid can be improved notably. The invention has high temperature resistance, salt resistance, viscidity reducing and collapse preventing performances. The filtration loss reducing agent of the invention has well compatibility with other processing agents in the drilling fluid; can avoid drilling accidents such as that mud wraps the aiguilles and mud cake blocks the drilling machine; and is favorable for stabilizing the well wall and the protecting the oil gas layer.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Composition for anti-collapse drilling fluid capable of reducing collapse pressure, anti-collapse drilling fluid and anti-collapse method

InactiveCN103254879AReduce hydration stressLower hydration collapse pressureDrilling compositionAliphatic amineReducer

The invention provides a composition for an anti-collapse drilling fluid, the anti-collapse drilling fluid, and an anti-collapse method. The composition for the anti-collapse drilling fluid comprises bentonite, a filtrate reducer and a viscosity reducer, wherein the anti-collapse drilling fluid further comprises a reverse wetting agent and a reverse wetting agent auxiliary, the reverse wetting agent is a copolymer of acrylate monomer and styrene, and the reverse wetting agent auxiliary comprises aliphatic amine and asphalt. The anti-collapse drilling fluid provided by the invention is excellent in anti-collapse performance.

Owner:CNPC DRILLING RES INST

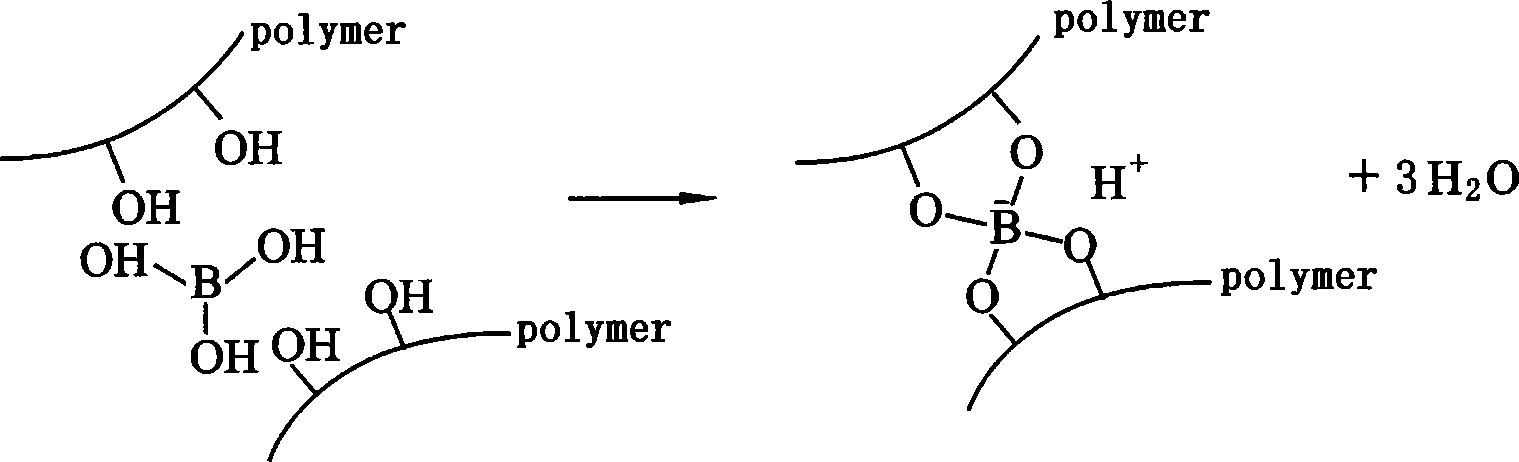

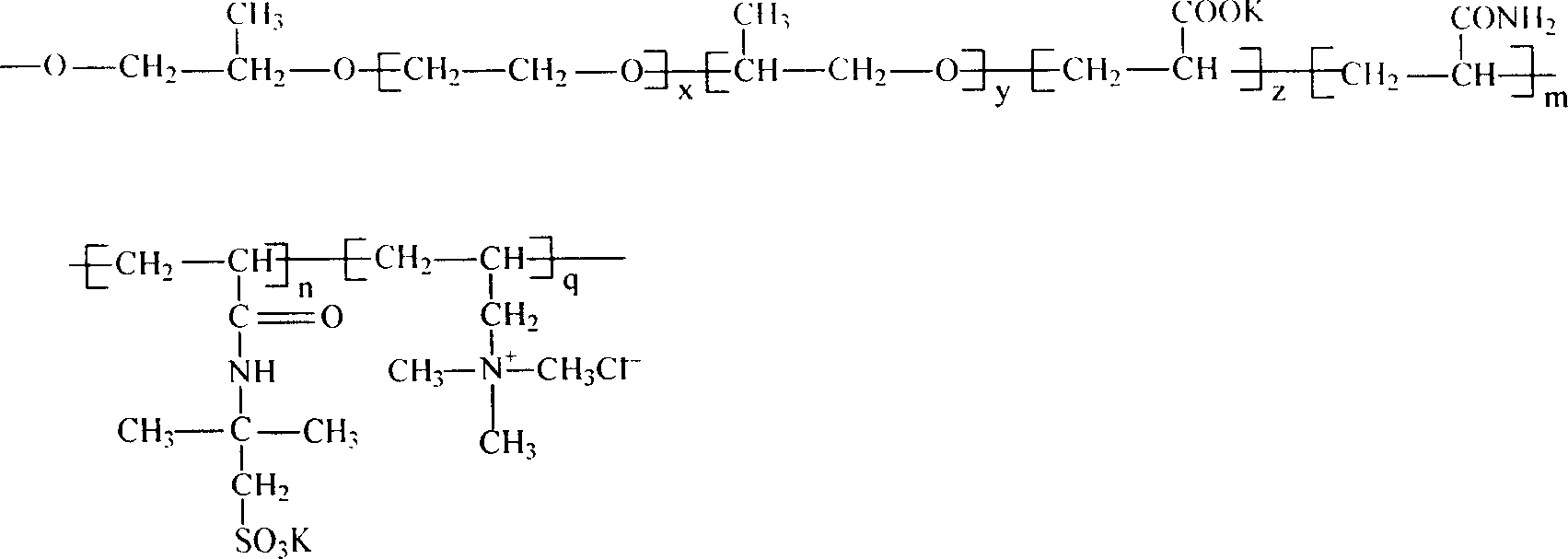

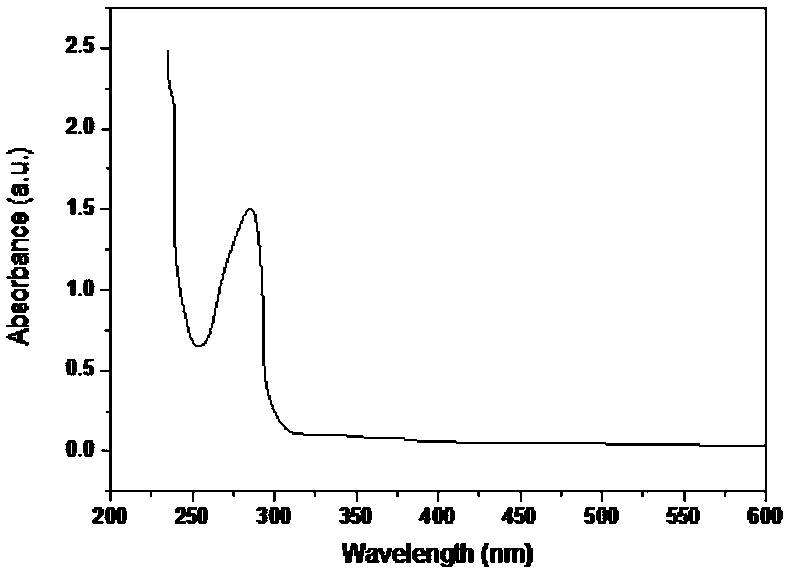

Amphoteric ion polymeric alcohol for drilling fluid and its preparation method

ActiveCN1966605AStrong inhibition of hydrationGood anti-collapse effectDrilling compositionReaction temperaturePotassium hydroxide

The invention relates to a kind of amphion poly-alcohol used in well boring liquid as well as its preparing method which belongs to the domain of accessory ingredient for well boring liquid. The ingredient of the invention includes olefinic acid, alkenyl amide, alkenyl sulfonic acid, alkenyl quaternary ammonium salt, ekibon, epoxypropane, alkenyl metamer. The ratio of alkenyl metamer, ekibon and epoxypropane is 10-30%:15-30%: 20-80%. The preparing procedure includes the following steps: putting the material into the polymerizing reactor and adding the initiator and polymerization catalyst to let them react at 100-150DEG C, 0.1 -2Mpa for 1-5h; neutralizing the polymerized product with carstic potash solution to get the product. The invention has many characteristics such as high temperature proof, salt proof, strong rejection capability, oil gas protection and environment-friendly. It can be used to prevent the collapse, protect the oil gas or be used as the slime stabilizing agent in the proving and exploring of oil and natural gas.

Owner:唐山冀油瑞丰化工有限公司 +1

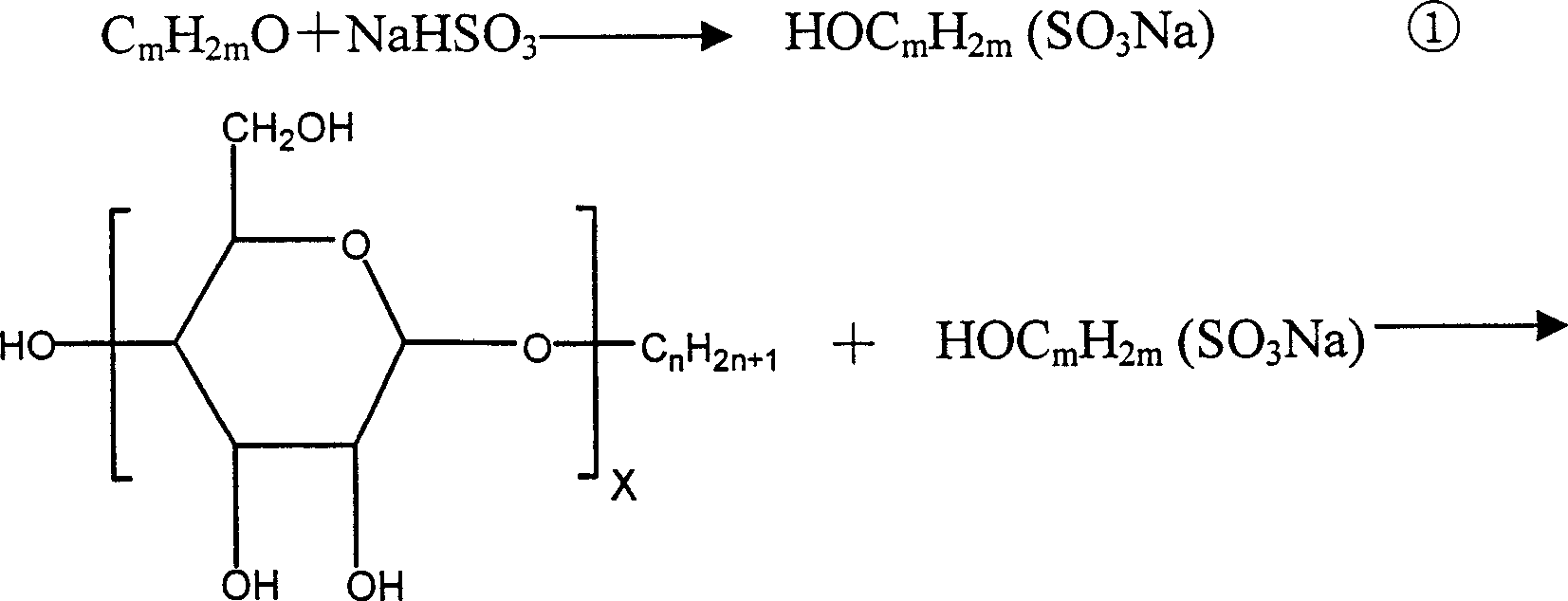

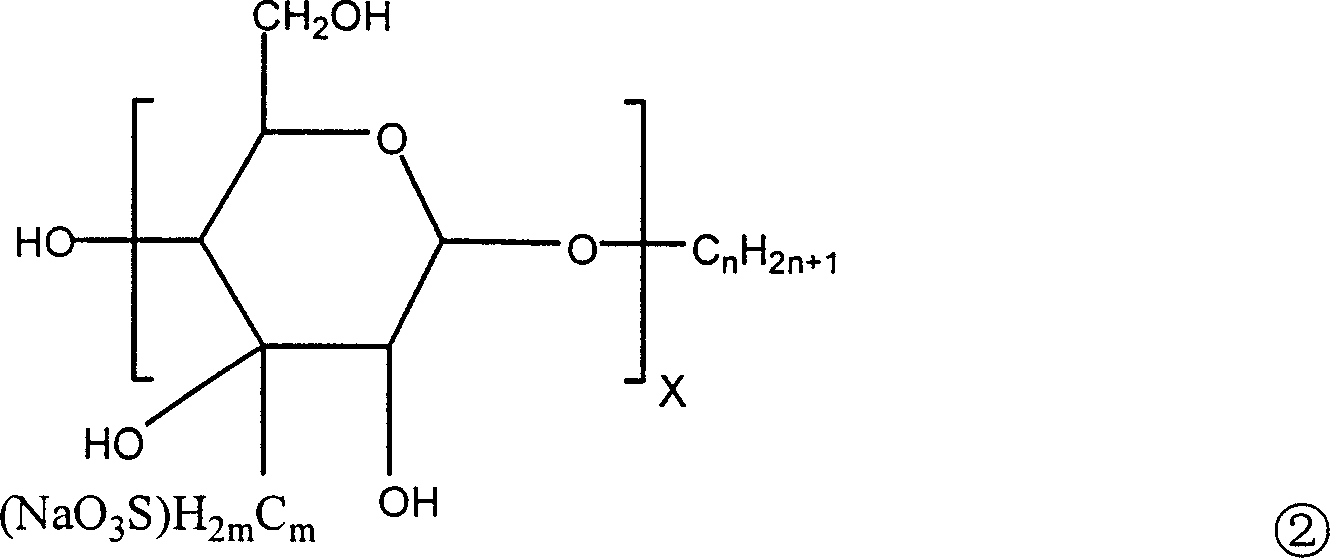

Low foamability drilling fluid and its preparation method

The invention relates to low-foamability drilling fluid as modified auxiliary agent composed of slurry and modified alkyl glycoside, wherein, the volume of modified auxiliary agent is 1-50% of slurry, and prepared by: mixing starch and low-carbon alcohol for glycosidation with catalyst to obtain material contained with low-carbon alkyl glycoside; adding sulphonating agent and aldehyde for further reaction at (50-100)+ / -5Deg to obtain the final product. The product has better adsorption, action ability with bentonite, and viscosity reduction ability, and fits to middle-deep well or ultradeep well.

Owner:CHINA PETROLEUM & CHEM CORP +1

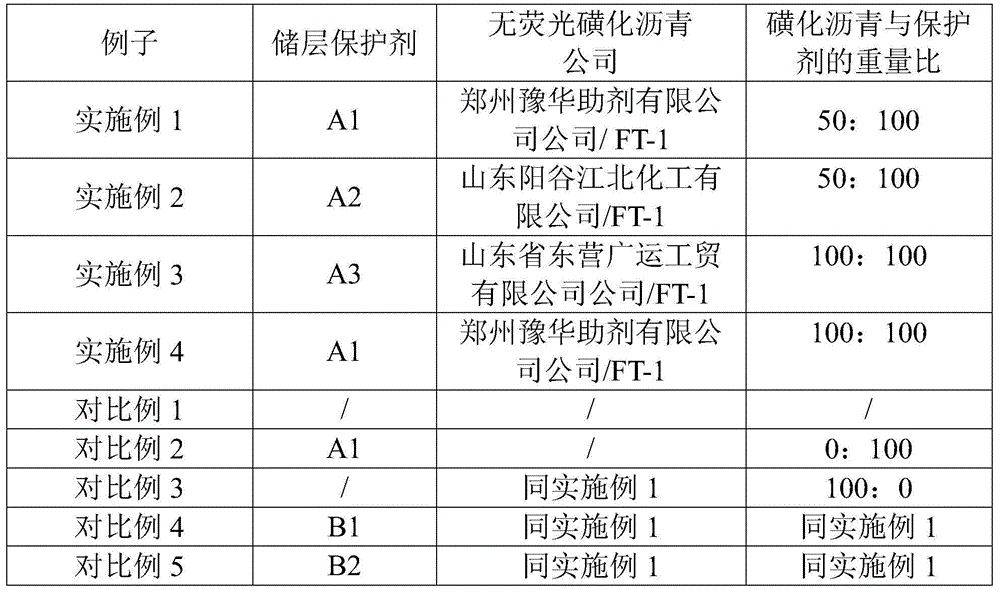

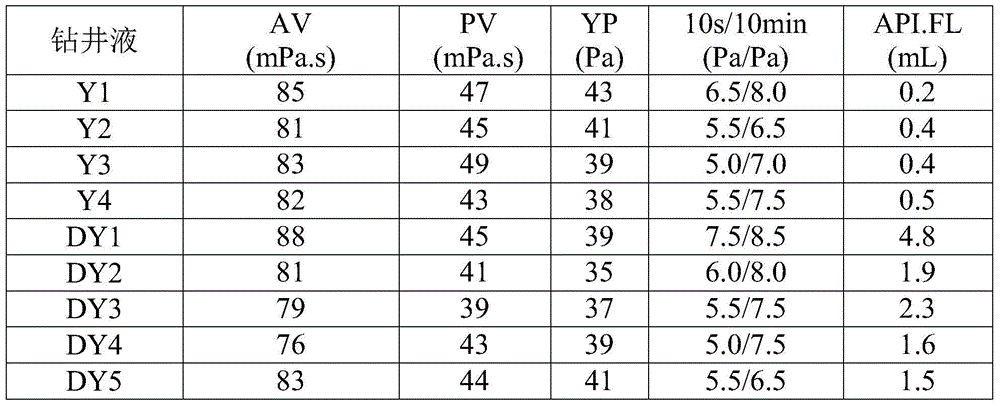

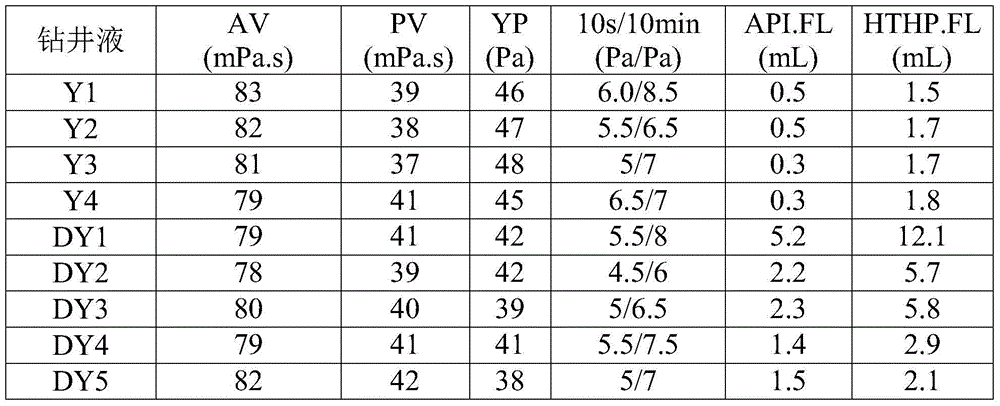

Reservoir protection agent composition and drilling fluid for medium-permeability reservoir and application of drilling fluid

ActiveCN104650829AImprove rheologyImprove temperature resistanceFlushingDrilling compositionSoil scienceFluorescence

The invention discloses a reservoir protection agent composition. The composition is prepared from non-fluorescence sulfonated bitumen and a reservoir protection agent, wherein the reservoir protection agent is formed by structure units shown in formulas (1), (2) and (3) in the specification. The invention further provides a drilling fluid containing the reservoir protection agent composition for a medium-permeability reservoir. The invention further provides an application of the drilling fluid for the medium-permeability reservoir in drilling of the medium-permeability reservoir. The drilling fluid for the medium-permeability reservoir provided by the invention can show relatively good rheological property, heat-resisting property, anti-sag property and protective property.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

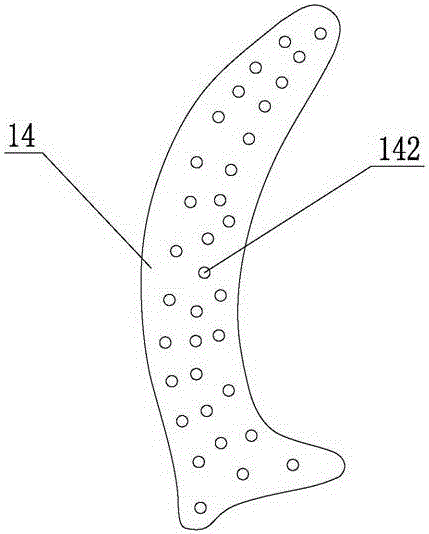

Integrated vertical cotton shaping bra and making method thereof

The invention relates to the technical field of bras, in particular to an integrated vertical cotton shaping bra and a making method thereof. The bra comprises a bra body, the bra body comprises two cups which are each provided with a first vertical cotton layer, an adhesive net layer, a second vertical cotton layer, an adhesive piece and a third vertical cotton layer from outside to inside in sequence, wherein the internal surface and external surface of the adhesive net layer are thermally glued to the external surface of the first vertical cotton layer and the internal surface of the second vertical cotton layer respectively, the internal surface and the external surface of the adhesive piece are thermally glued to the external surface of the second vertical cotton layer and the internal surface of the third vertical cotton layer respectively, the external surface of the adhesive piece is wrapped by coarse cotton cloth, and multiple through holes which are throughout the upper surface and the lower surface of the adhesive piece are formed in the adhesive piece. The integrated vertical cotton shaping bra is good in breathability and light in texture, and wearing is comfortable; the adhesive net layers are added between the vertical cotton layers, in this way, the washing-resistant performance of cup mats is improved, the anti-collapse effect is good, the three-dimensional effect of the cup mats is durable and stable, deformation is not easy, and the shaping effect on breasts is good and durable.

Owner:HONGJI UNDERWEAR CO LTD

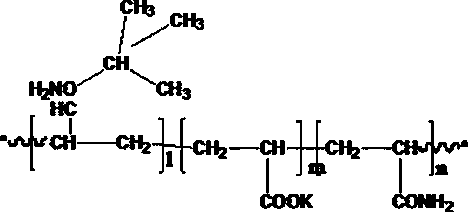

Microemulsion polymerization strong coater for drilling fluid and preparation method of strong coater

The invention discloses a microemulsion polymerization strong coater for a drilling fluid and a preparation method of the strong coater. The key point of the technical scheme disclosed by the invention is as follows: the microemulsion polymerization strong coater for the drilling fluid is a copolymer which is formed from potassium acrylate, acrylamide and 2-acrylamidyl-2-methyl propanesulfonic acid by virtue of free radical polymerization, wherein the molecular weight of the copolymer is 15000 thousand to 24000 thousand. The structure of the copolymer is as shown in the specification, wherein l:m:n is equal to a:b:c, a is greater than or equal to 95 but less than 100, b is greater than 0 but less than or equal to 5 and c is greater than 0 but less than or equal to 5. The invention further discloses the preparation method of the microemulsion polymerization strong coater for the drilling fluid. The strong coater disclosed by the invention is high in polymerization efficiency, and the polymerized product is stable in performance and convenient to apply and is widely applied in the drilling process of an oil field. The strong coater can be used for greatly improving the rejection capability and the coating ability of the drilling fluid so as to form a drilling fluid system with a stable performance.

Owner:XINXIANG FUBANG TECH

Modified alkyd resin and preparation method thereof and two-component primer

The invention provides modified alkyd resin and a preparation method thereof. According to the method, alkyd compounds react to obtain the modified alkyd resin. The alkyd compounds comprise, by weight, 25-35 parts of tertiary carbonate glycidyl ester, 38-42 parts of glycerol, 190-230 parts of soya oil acid, 25-35 parts of ethanediol, 240-280 parts of phthalic anhydride, 30-38 parts of trimethylolpropane, 80-120 parts of pentaerythritol, 16-40 parts of agents with water, 1-2 parts of subtraction colour antioxidants, 230-260 parts of diluted solvent, and 0.5-1.5 parts of antiager. Conventional raw materials of the soya oil acid, the pentaerythritol and the like are adopted to prepare the alkyd resin, and the tertiary carbonate glycidyl ester is adopted to modify the alkyd resin, so a paint film performances well in the aspects of gloss, definition, collapse resistance and the like. The invention further provides two-component primer.

Owner:CARPOLY CHEM GRP

Lubricating collapse-resisting agent for drilling fluid and preparation method thereof

The invention discloses a drill liquid lubricating anti-sloughing agent and preparation method thereof. The lubricating anti-sloughing agent is composed of liquid wax 10 to 30 parts, non-ionic surface activator 1 to 3 parts, polyatomic alcohol 5 to 15 parts, polymer 0.5 to 1 part according to 100 weight parts, and water as residue. The preparation method is: putting liquid wax, non-ionic surface activator, and polyatomic alcohol into reactor, heating the mixture to 60 deg C. to 80 deg C., agitating the mixture for 30min with agitation speed controlled in the ranged of 1000 to 2000 rpm; adding polymer-dissolved polymer into the reactor, agitating the mixture for 60 to 120 min continuously at 60 to 80 deg C. with agitation speed controlled in 1000 to 2000 rpm, cooling it to room temperature, to obtain the product of lubricating anti-sloughing agent. The lubricating anti-sloughing agent of the invention is provided with good stability, with excellent lubricating, anti-sloughing and oil gas layer-protecting effects in drilling liquid, and good environmental protection property without fluorescence, toxic pollution. The adopted materials are easy to obtain. The preparation method is simple, easy to implement with low cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

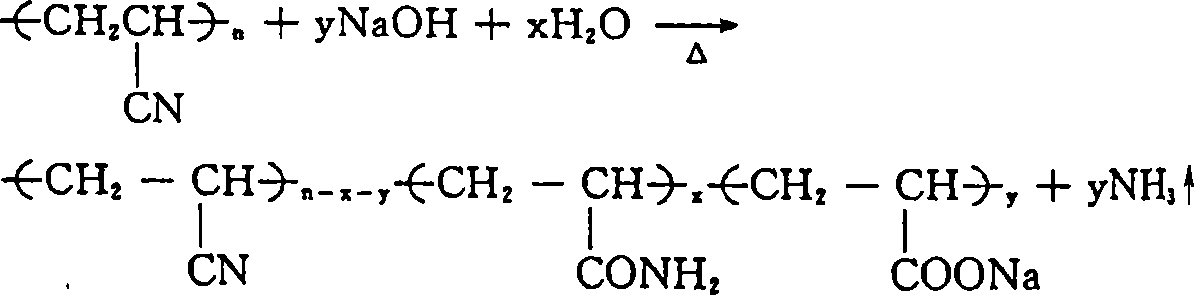

Pure luminescence-free lubricant for petroleum drilling liquid

The invention relates to a pure lubricating agent without fluorescence for bergol drilling fluid, which solves the problem of the existing lubricating agent which is not environmental protection and has fluorescence. The lubricating agent of the invention comprises the following raw materials which are vegetable oil, 15% sodium-hydroxide solution, 10% potassium hydrate solution, slaked lime, 3% carboxymethyl cellulose solution, 12.5-15% ammonium salt solution of partially hydrolyzed polyacrylonitrile, calcium acrylate, sodium acrylate, acrylamide and water. The lubricating agent products of the invention have no pollution to environment, which is easy to be biodegraded, does not corrode metal, does not damage sealing material, when in production, no three wastes are discharged. The lubricating agent belongs to pure products without fluorescence, which does not disturb any geological logging work, and has relative protective function to the productivity of hydrocarbon zones.

Owner:HEFEI BINCHUN CHEM IND TECH

Water-based drilling fluid for shale gas wells and production method thereof

ActiveCN110628398AEnhanced inhibitory effectImprove the blocking effectDrilling compositionWater basedHorizontal wells

The invention relates to a water-based drilling fluid for shale gas wells and a production method thereof. The method sequentially includes the following steps of: (1) preparing the following raw materials: 1000 parts of water, 45-50 parts of sodium bentonite, 500 parts of a water-soluble inhibition weighting agent II; 100 parts of a water-soluble inhibition weighting agent III; 15-20 parts of aninhibiting and anti-collapse agent non-fluorescence white asphalt, 10-20 parts of solid polymeric alcohol, 10-20 parts of a filtrate reducer, 0.5-1 part of a polyamine inhibitor, 20-30 parts of ultrafine calcium carbonate, 10-25 parts of an extreme pressure lubricant, and 0.5-1 part of a coating inhibitor; (2) mixing the sodium bentonite and water, and performing curing for at least 24h at normaltemperature; and (3) adding the water-soluble inhibition weighting agent II and water-soluble inhibition weighting agent III under stirring, then adding the inhibiting and anti-collapse agent non-fluorescence white asphalt and the solid polymeric alcohol, then adding the filtrate reducer and the polyamine inhibitor, then adding the ultrafine calcium carbonate and the extreme pressure lubricant, finally adding the coating inhibitor, and then adjusting the pH value and density. The drilling fluid has the advantages of high plugging properties, strong inhibition and excellent lubricating properties, and can meet the safe drilling requirements of shale gas horizontal wells.

Owner:SINOPEC EAST CHINA PETROLEUM ENG CO LTD

A reservoir protective agent composition, a drilling fluid containing the composition and applications of the drilling fluid in low-permeability reservoir drilling

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Strongly adsorbent solid lubricant for drilling fluid and synthesis method of solid lubricant

ActiveCN105199682AThe synthesis method is simpleTightly boundDrilling compositionOrganic solventSynthesis methods

The invention particularly discloses a strongly adsorbent solid lubricant for drilling fluid. The strongly adsorbent solid lubricant comprises the following components in parts by weight: 100 to 300 parts of reaction carrier, 2 to 15 parts of organic solvent, 15 to 50 parts of monomers, 50 to 200 parts of penetrant, 0.01 to 0.05 part of initiator, 1 to 5 parts of surfactant and 100 to 300 parts of water. The strongly adsorbent solid lubricant for the drilling fluid, which is disclosed by the invention, is easily available in raw materials and simple in synthesis method, has better adsorption performance compared with a common solid lubricant, is not easily removed by solid control equipment, can form a strong adsorption film on a metal surface and a solid particle surface of the drilling fluid, and simultaneously has the capability of improving the filtration reduction performance and blocking to prevent collapse.

Owner:西安长庆化工集团有限公司

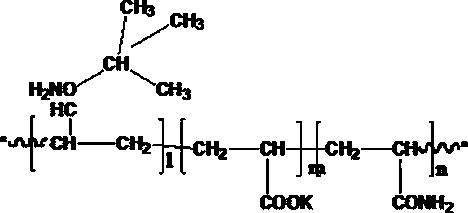

Preparation method for emulsion polymer macro-molecular strong coating agent

InactiveCN102731711ATimely processingImprove adsorption capacityDrilling compositionDispersityActivated carbon filtration

The invention provides a preparation method for an emulsion polymer macro-molecular strong coating agent used for drilling fluid. The method comprises the following steps: mixing potassium hydroxide, acrylic acid and acrylamide with deionized water so as to obtain a first solution; mixing surfactant with an oil-soluble solvent so as to obtain a second solution; and filtering the first solution with active carbon, then adding the first solution into the second solution drop by drop and adding the aqueous solution of an initiator into the second solution for a copolymerization reaction so as to obtain the emulsion macro-molecular strong coating agent. According to the invention, preparation process is simple and easily controllable; a fast polymerization speed is obtained due to usage of an inverse emulsion polymerization method; obtained macro-molecular emulsion is stable and does not undergo delamination when stored for a long time; and the product of the coating agent has good lubrication performance, can be easily dissolved in drilling fluid and has strong capacity in inhibiting dispersity.

Owner:扬州润达油田化学剂有限公司

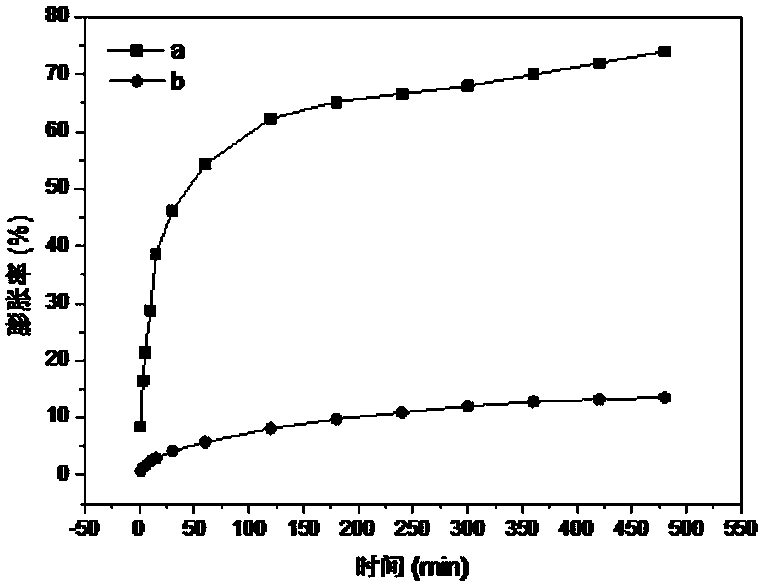

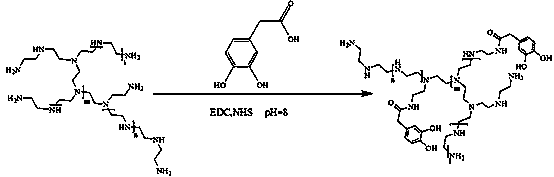

Strong-inhibition and strong-cementation well wall stabilizer and preparation method thereof

InactiveCN108865086AImprove rheologyEnhanced inhibitory effectDrilling compositionWater basedMechanical property

The invention relates to a strong-inhibition and strong-cementation well wall stabilizer and a preparation method thereof. The strong-inhibition and strong-cementation well wall stabilizer is characterized by containing a branched polyethyleneimine structure as a main chain and a catechol group grafted to the main chain. The strong-inhibition and strong-cementation well wall stabilizer has the beneficial effects that the strong-inhibition and strong-cementation well wall stabilizer has better well wall stabilization effect, is convenient in control on preparation process, simple to operate andstable in quality of a product and has better action effect when being used under the condition with the temperature being 150 DEG C, and a water-based drilling fluid system formed by taking strong-inhibition and strong-cementation well wall stabilizer as a key treating agent has relatively good rheological property, rejection capability and anti-sloughing property; and a drilling fluid treatingagent which can strongly inhibit hydration swelling of shales, can block consolidated rocks at the same time, improves the mechanical property of the shales and strengthens the pressure-bearing capacity of the well wall can effectively push a water-based drilling fluid to replace an oil-based drilling fluid, more efficiently keeps the well wall stablity and has an important theoretical and practical significance.

Owner:中石化石油工程技术服务有限公司 +2

Positive-charged polyglycol anti-collapse drilling fluid

InactiveCN105038736AStrong collapse resistanceGood anti-collapse effectDrilling compositionWater basedFluorescence

The invention discloses a positive-charged polyglycol anti-collapse drilling fluid which mainly solves the problems of low anti-collapse capacity and narrow application range in the water-based drilling fluid in the prior art. The positive-charged polyglycol anti-collapse drilling fluid comprises the following components in parts by weight: 2-4 parts of sodium bentonite, 0.1-0.2 part of sodium carbonate, 3-5 parts of positive-charged polyglycol, 2-4 parts of high-molecule inhibitor, 2-4 parts of positive-charged wall protector, 0.5-3 parts of fluid loss additive for drilling fluids, 1-2 parts of plugging agent for drilling fluids, 4-6 parts of low-fluorescence water-based lubricant RY-838, 2-3 parts of low-fluorescence sulfonated asphalt and 100 parts of water. By blending the weighting agent, the density of the drilling fluid reaches 1.30-1.45 g / cm<3>. The positive-charged polyglycol anti-collapse drilling fluid has the advantages of high anti-collapse capacity, longer stability period, high temperature resistance, high solid-phase content, wide application range and the like.

Owner:CHENGDU GAOPU PETROLEUM ENG TECH

Large-membrane thickness PE electrostatic-sprayed paint

InactiveCN104177997ALow resistivityReduce labor intensityPolyester coatingsPolymer scienceElectrostatic coating

The invention discloses large-membrane thickness PE electrostatic-sprayed paint. The large-membrane thickness PE electrostatic-sprayed paint comprises a main agent part A, a cobalt iso-octoate-containing part B and a methylethyl ketone peroxide-containing part C. The main agent part A comprises, by weight, 60-80 parts of unsaturated polyester resin, 0.01-0.03 parts of a polymerization inhibitor, 10-25 parts of an inorganic filling material, 3-5 parts of zinc stearate, 4-8 parts of a solvent, 0.3-0.5 parts of an anti-settling agent, 0.1-0.3 parts of an antifoaming agent, 0.2-0.5 parts of a leveling agent and 0.1-0.5 parts of a conductive agent which is an alkanolamide solution of nonsaturated acidic carboxylate. The alkanolamide solution of nonsaturated acidic carboxylate reduces paint resistance, improves paint conductivity and satisfies electrostatic-coating resistor requirements.

Owner:展辰新材料集团股份有限公司 +4

Method for manufacturing anti-friction silicon-based collapse prevention well drilling liquid

InactiveCN104962257AStrong collapse resistanceGood anti-collapse effectDrilling compositionWater basedFluorescence

The invention discloses a method for manufacturing anti-friction silicon-based collision prevention well drilling liquid. The method includes heating water until the temperature of the water reaches 80 DEG C, adding sodium bentonite into the water at the rotational speed of 600-800rpm, uniformly mixing the sodium bentonite and the water with each other at the rotational speed of 600-800rpm to obtain first mixtures, adjusting the rotational speed until the rotational speed reaches 3000-4000rpm, adding sodium carbonate into the first mixtures, stirring the sodium carbonate and the first mixtures for 30-60min, then stirring the sodium carbonate and the first mixtures at the stirring speed of 9000-10000rpm for 30-40min to obtain second mixtures, and maintaining the second mixtures; sequentially adding organic silicon stabilizers for well drilling liquid, organic silicon diluents and organic silicon potassium humate into the second mixtures at the stirring speed of 6000-8000rpm and stirring the organic silicon stabilizers for the well drilling liquid, the organic silicon diluents, the organic silicon potassium humate and the second mixtures at the stirring speed of 6000-8000rpm for 30-60min to obtain third mixtures; adding encapsulating agents for the well drilling liquid and filtrate-loss reducers for the well drilling liquid into the third mixtures; adding blocking agents for the well drilling fluid, low-fluorescence water-based lubricants RY-838 and low-fluorescence sulfonated bitumen into the third mixtures and uniformly mixing the blocking agents for the well drilling fluid, the low-fluorescence water-based lubricants RY-838, the low-fluorescence sulfonated bitumen and the third mixtures with one another to obtain fourth mixtures; regulating pH (potential of hydrogen) values of the fourth mixtures; regulating the density of the fourth mixtures. The method has the advantages of high collapse prevention capacity, wide application range, capability of prolonging stability periods and the like.

Owner:CHENGDU GAOPU PETROLEUM ENG TECH

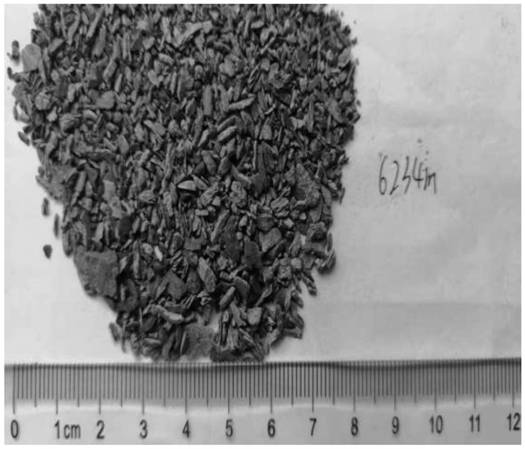

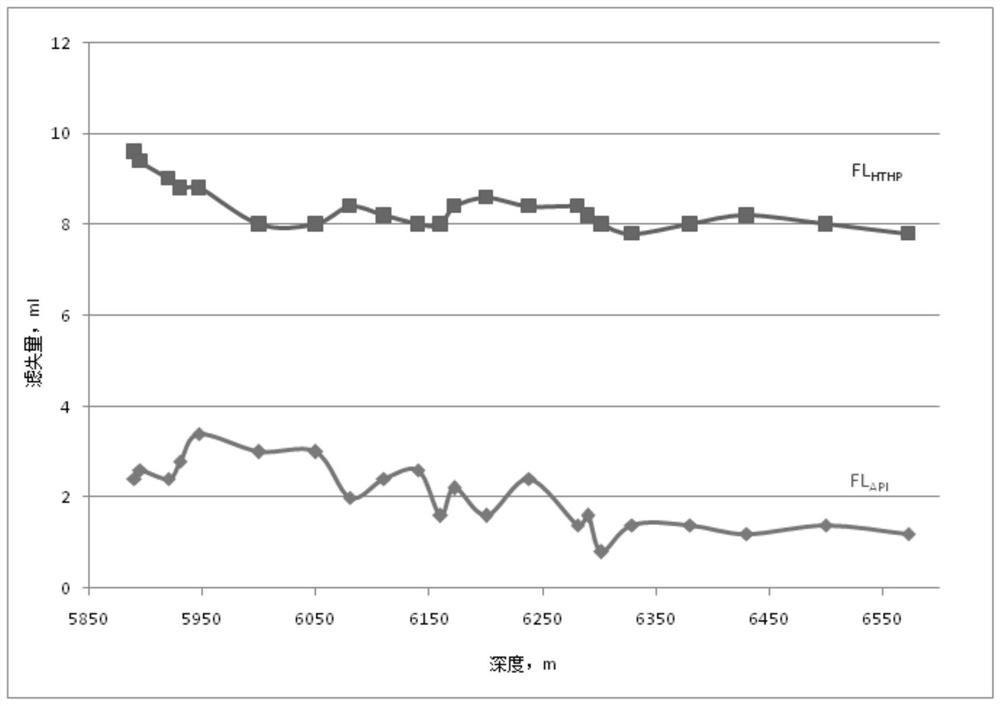

Anti-sloughing drilling fluid as well as preparation method and application thereof

ActiveCN113637464AStrong collapse resistanceRemarkable anti-collapseDrilling compositionWell drillingGraphene

The invention relates to an anti-sloughing drilling fluid for a fractured carbonate rock stratum and a preparation method and application of the anti-sloughing drilling fluid in the field of petroleum drilling. The anti-sloughing drilling fluid can be prepared from the following components in parts by weight: 1000 parts by weight of water, 15 to 40 parts by weight of drilling fluid bentonite, 5 to 35 parts by weight of a micro-nano blocking agent, 20 to 70 parts by weight of a temperature-sensitive blocking anti-collapse agent, 15 to 30 parts by weight of graphene hydrogel and 0 to 1600 parts by weight of an inert weighting agent. The anti-sloughing drilling fluid disclosed by the invention has high anti-sloughing performance, rheological property, temperature resistance and lubricating property, can effectively reduce the well wall instability risk of a fractured carbonate rock stratum, reduce bit bouncing and blocking and ensure underground safe construction, and has a wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

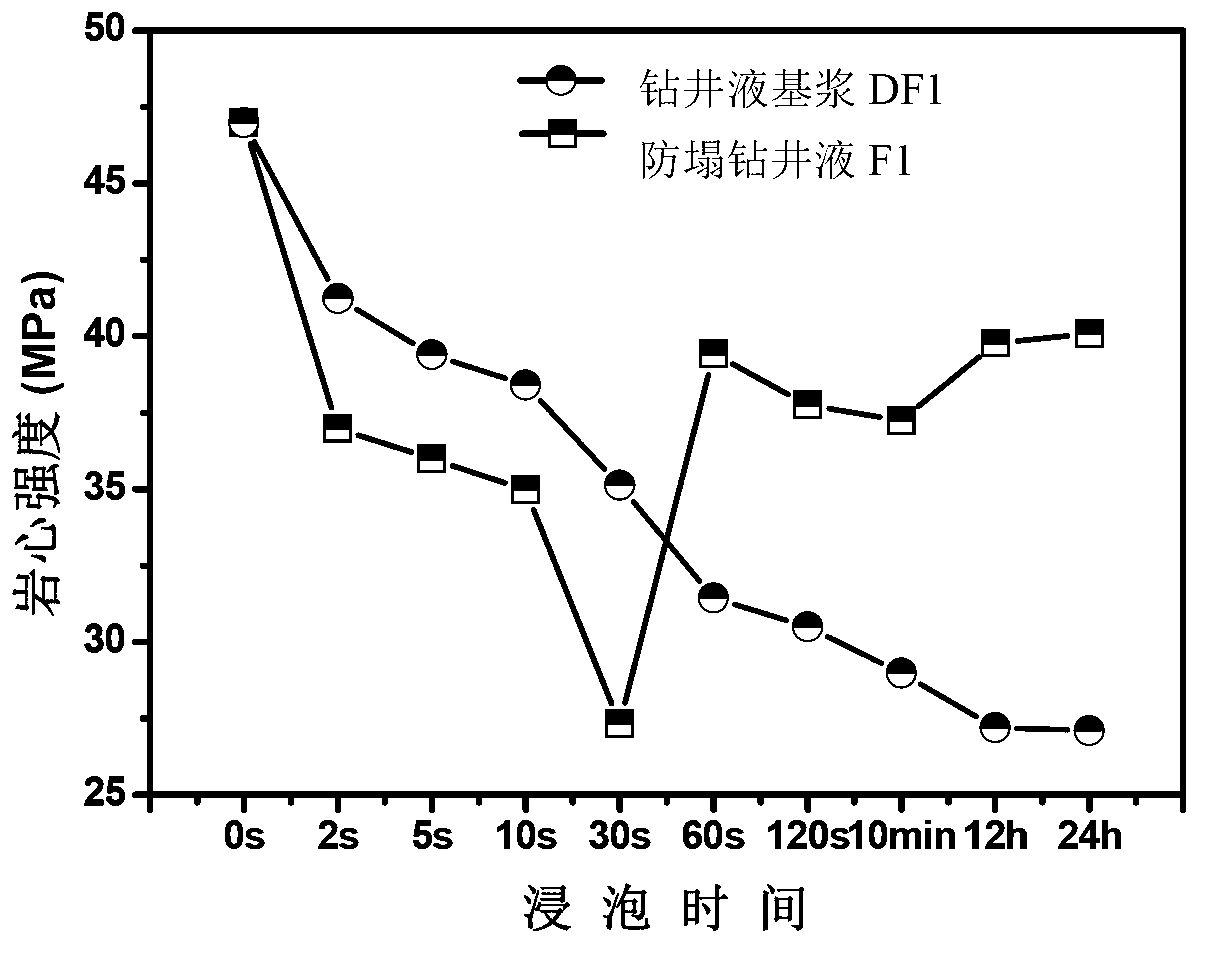

Water-based drilling fluid for stabilizing shale gas stratum borehole wall and application thereof

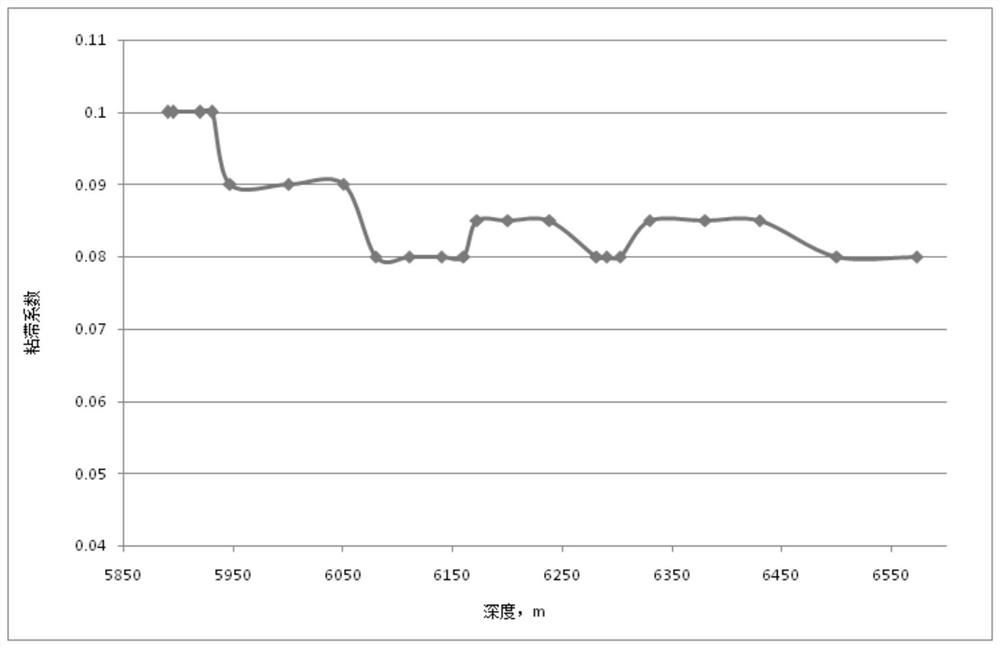

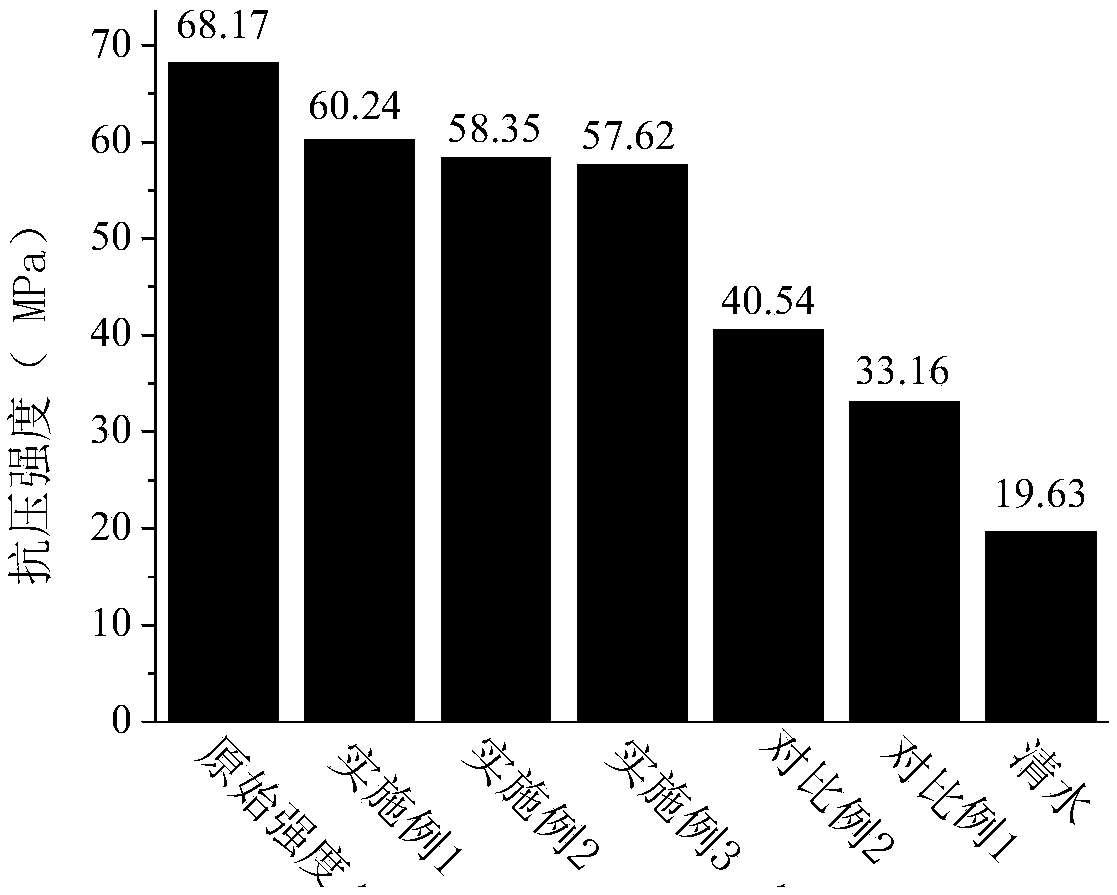

InactiveCN108531147AInhibition of hydrationReduced compressive strengthFlushingDrilling compositionCelluloseWater based

Relating to the technical field of shale gas drilling, the invention discloses a water-based drilling fluid for stabilizing a shale gas stratum borehole wall and application thereof. The water-based drilling fluid comprises a nanofilm structure plugging agent, a waterproofing agent, a surface hydration inhibitor, polymeric alcohol, bentonite, polyanionic cellulose, a sulfonated lignite resin and water, wherein the waterproofing agent is N-perfluoroalkyl sulfonyl propyl triethoxysilane, and the nanofilm structure plugging agent includes a montmorillonite sheet, a structural unit shown as formula (1) and a structural unit shown as formula (2). The water-based drilling fluid provided by the invention shows good performance of inhibition, rheology and retarding of the shale compressive strength reduction when applied to stabilization of the shale gas stratum borehole wall.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Drilling flushing liquid with excellent anti-collapse performance and preparation method thereof

InactiveCN109796947AIdeal anti-collapse performanceMeet ideal needsDrilling compositionCarboxymethyl celluloseSodium Bentonite

The invention discloses a drilling flushing liquid with excellent anti-collapse performance and a preparation method thereof. Each cubic meter of the drilling flushing liquid is prepared from, by weight, 12.5-50 kg of a matrix, 0.8-1.2 kg of sodium hydroxide, 1.8-2.2 kg of carboxymethyl cellulose, 0.4-0.6 kg of potassium polyacrylate, 5-15 kg of a fluid loss reducer and 1.2-1.8 kg of a liquid lubricant, wherein the matrix is selected from bentonite and / or calcium carbonate. According to the stratum conditions of a Qinghai Muli coal field, the anti-collapse drilling flushing liquid which is more simplified in formula but better in effect is obtained through a new test method and has the advantages that type selection and proportioning are scientific and reasonable, the anti-collapse performance is excellent, the preparation process is simple, and the production cost is low.

Owner:青海煤炭地质一0五勘探队

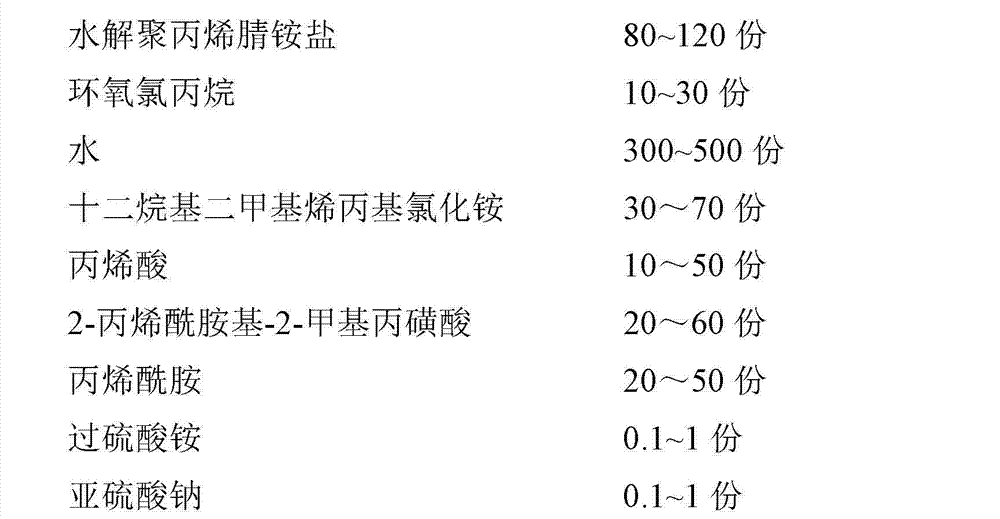

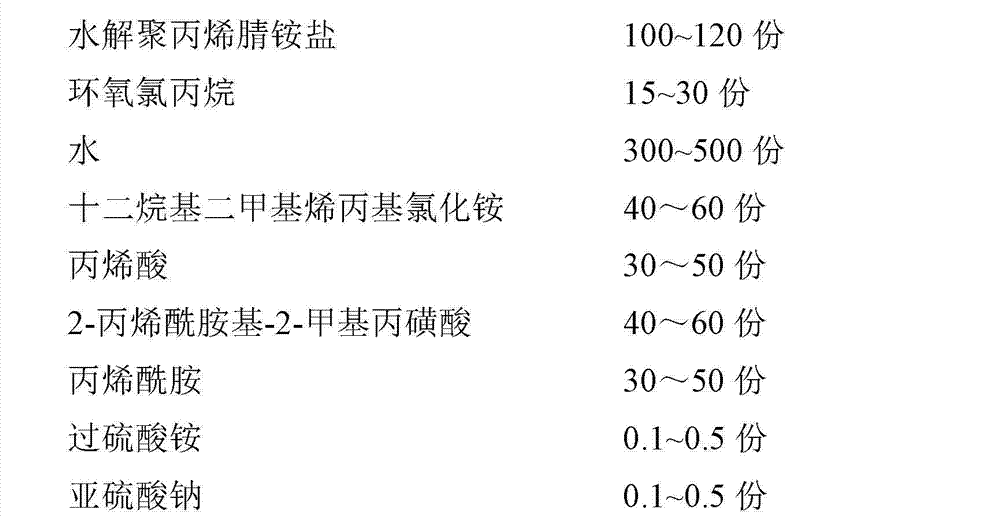

Modified polyanionic ammonium salt for drilling fluid and preparation method of modified polyanion ammonium salt

The invention discloses modified polyanionic ammonium salt for drilling fluid and a preparation method of the modified polyanionic ammonium salt. The ammonium salt is prepared from following materials of hydrolyzed polyacrylonitrile ammonium salt, epoxy chloropropane, water, dodecyl dimethyl allyl ammonium chloride, crylic acid, 2-acrylamide-2-methyl-propanesulfonic acid, acrylamide, ammonium persulfate and sodium sulfite. The preparation method comprises the following steps of: weighing water, hydrolyzed polyacrylonitrile ammonium salt, epoxy chloropropane, dodecyl dimethyl allyl ammonium chloride, ammonium persulfate and sodium sulfite; putting into a reaction kettle, sealing, heating, reacting and cooling; adding the weighed crylic acid, the 2-acrylamide-2-methyl-propanesulfonic acid and acrylamide to the cooled reaction kettle, stirring to completely dissolve, sealing and leading in nitrogen, heating and reacting under protection of the nitrogen; and discharging to obtain a product by vacuulizing and drying. The modified polyanionic ammonium salt can resist super-high temperature of 240 DEG C, resists statured salt water, compound saline water and seawater, can effectively reduce the filter loss of the drilling fluid, does not tackify, and is good in anti-collapse performance.

Owner:河北小钻科技有限公司

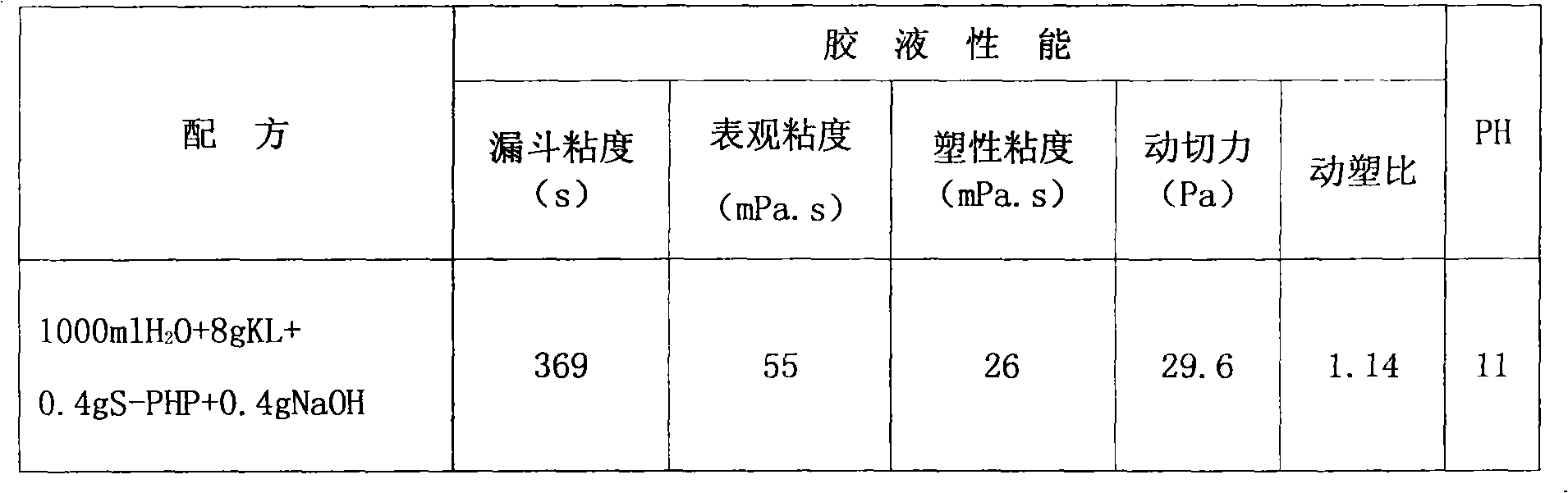

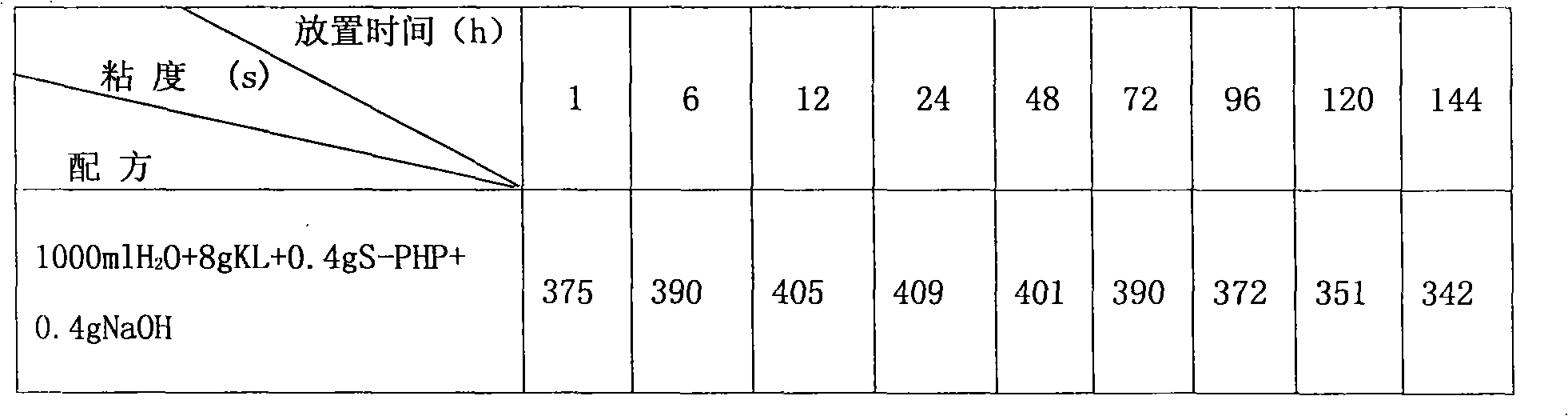

KL bean vegetable gum type environment-protective slurry and preparation thereof

The invention provides a bitter drabanemerosa hebecarpa bean vegetable jelly type environment-friendly slurry, comprising the following components: 6-12g of bitter drabanemerosa hebecarpa bean vegetable jelly, 0.2-0.6g of hydrolyzed polyacrylamide with at least molecular weight of 12 million, 0.2-0.6g of sodium hydroxide and 1,000ml of water. The invention has ready availability of raw materials, stable performance, excellent rheological characteristics, good capability of lubrication, leak stoppage, suspending to remove debris and resisting dilution shearing, simple fabrication operation, low cost and good environment-friendly performance. The invention also provides a method for preparing the bitter drabanemerosa hebecarpa bean vegetable jelly type environment-friendly slurry.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

High temperature resistant circulating micro-foam drilling fluid or completion fluid

ActiveCN100516163CImprove stabilityHigh temperature resistanceDrilling compositionFoaming agentWell drilling

The invention discloses a high-temperature-resistant recyclable micro-foam drilling fluid or well-completion fluid, which is composed of: (A) base slurry: 1-2 bentonite, 3-5 salt-resistant clay, 0.2-0.3 soda ash, and 100 parts by weight ;(B) Additives: ①High temperature inhibitor 3-5, ②High temperature viscosifier 2-5, ③High temperature fluid loss reducer 3-6, ④High temperature salt resistance, viscosity raising fluid loss reducer 1-3, ⑤Flow type Regulator 1-3, ⑥ high temperature foaming agent 2-5, ⑦ high temperature foam stabilizer 1-2.5. The invention has high temperature resistance, good carrying and suspension ability in low pressure deep wells, can be used for deep well exploration and development, has strong adaptability, can be used as drilling fluid and well completion fluid, and can be used in high temperature deep wells and low pressure Carbonate formations can also be used in high-temperature, low-pressure, low-permeability mudstone formations, mudstone shale reservoirs and salt-bearing formations. They have the ability to inhibit hydration expansion of mudstone and have a good effect of protecting oil and gas layers. They are mainly used in low-pressure, low-permeability Formation drilling and well completion construction process.

Owner:DONGYING TAIER GASOLINE TECH

Method for preparation of lignite resin drilling fluid loss additive

InactiveCN101230257BImprove rheologyImprove the lubrication effectDrilling compositionChemical reactionSulfite salt

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com