Modified alkyd resin and preparation method thereof and two-component primer

A kind of alkyd resin, modified technology, applied in the direction of polyester paint, coating, etc., can solve the problem that the higher requirements of paint film anti-collapse cannot be met, and achieve product stability, good compatibility, and good solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The invention provides a kind of preparation method of modified alkyd resin, comprising:

[0078] reacting an alkyd mixture comprising:

[0079] 25 ~ 35 parts by weight of glycidyl tertiary carbonic acid ester;

[0080] 38 ~ 42 parts by weight of glycerin;

[0081] 190 ~ 230 parts by weight of soy oil;

[0082] The ethylene glycol of 25~35 parts by weight;

[0083] 240 ~ 280 parts by weight of phthalic anhydride;

[0084] 30 ~ 38 parts by weight of trimethylolpropane;

[0085] 80~120 parts by weight of pentaerythritol;

[0086] 16 to 40 parts by weight of water-carrying agent;

[0087] The color reducing antioxidant of 1~2 weight part;

[0088] 230 ~ 260 parts by weight of dilute solvent;

[0089] 0.5-1.5 parts by weight of anti-aging agent.

[0090] The present invention reacts the alkyd mixture comprising polyhydric alcohol, organic acid, auxiliary agent and tertiary carbonic acid glycidyl ester as a raw material to generate a modified alkyd resin, and applie...

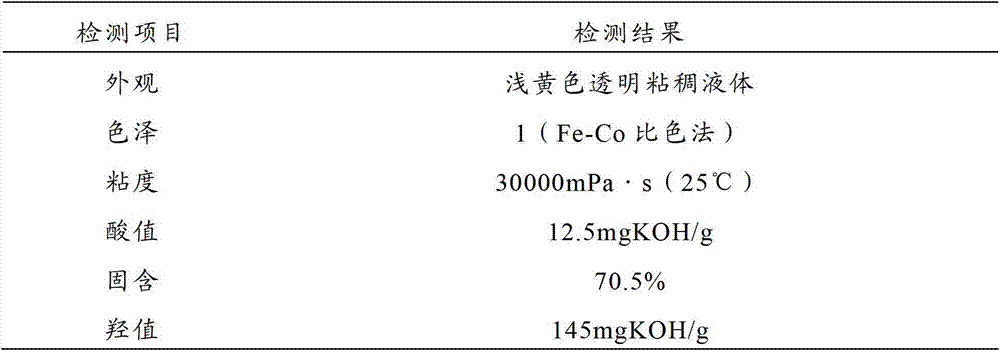

Embodiment 1

[0131] Nitrogen was passed through the empty reactor for 3 minutes in advance, and the nitrogen flow rate was 5m 3 / h;

[0132] To above-mentioned reactor, drop into successively the glycidyl tertiary carbonic acid ester of 25 parts by weight, the glycerin of 38 parts by weight, the soybean oil of 190 parts by weight, the ethylene glycol of 25 parts by weight, the dimethylbenzene of 16 parts by weight and the color reducing agent of 1 part by weight Antioxidant, and 240 parts by weight of phthalic anhydride, 30 parts by weight of trimethylolpropane and 80 parts by weight of pentaerythritol are sequentially put into the above-mentioned reactor from the special feeding port for powder, and the temperature is raised under stirring, and the temperature is raised to 160 ° C, and the temperature is kept Reflux for 2 hours, then heat up to 220°C within 3 hours, keep warm until the acid value is ≤18mgKOH / g, and the viscosity is 23 seconds to 28 seconds / 25°C Grignard tube, cool down un...

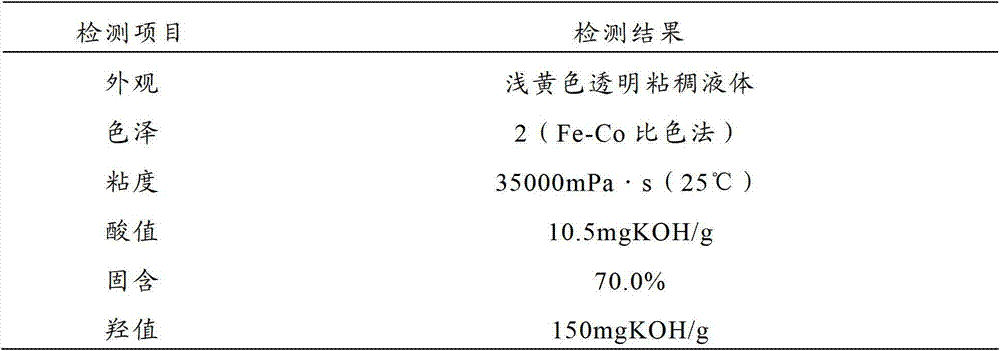

Embodiment 2

[0140] Nitrogen was passed through the empty reactor for 8 minutes in advance, and the nitrogen flow rate was 2m 3 / h;

[0141] To above-mentioned reactor, drop into successively the glycidyl tertiary carbonic acid ester of 35 parts by weight, the glycerin of 42 parts by weight, the soybean oil of 230 parts by weight, the ethylene glycol of 35 parts by weight, the xylene of 40 parts by weight and the color reducing agent of 2 parts by weight Antioxidant, and 280 parts by weight of phthalic anhydride, 38 parts by weight of trimethylolpropane and 120 parts by weight of pentaerythritol are successively put into the above-mentioned reactor from the special feeding port for powder, and the temperature is raised under stirring, and the temperature is raised to 185 ° C, and the temperature is kept Reflux for 1 hour, then heat up to 200°C within 5 hours, keep warm until the acid value is ≤18mgKOH / g, and the viscosity is 23 seconds to 28 seconds / 25°C Grignard tube, then cool down until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com