Patents

Literature

89 results about "Methyl malonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethyl malonate is a diester derivative of malonic acid. It is a common reagent for organic synthesis used, for example, as a precursor for barbituric acid. It is also used in the malonic ester synthesis.

Malonic acid monomethyl derivatives and production process thereof

InactiveUS7109369B2Easy to makeProduct can be usedOrganic compound preparationCarboxylic acid esters preparationHydrogen atomMalonic acid

Owner:DAICEL CHEM IND LTD

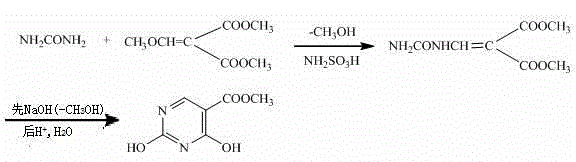

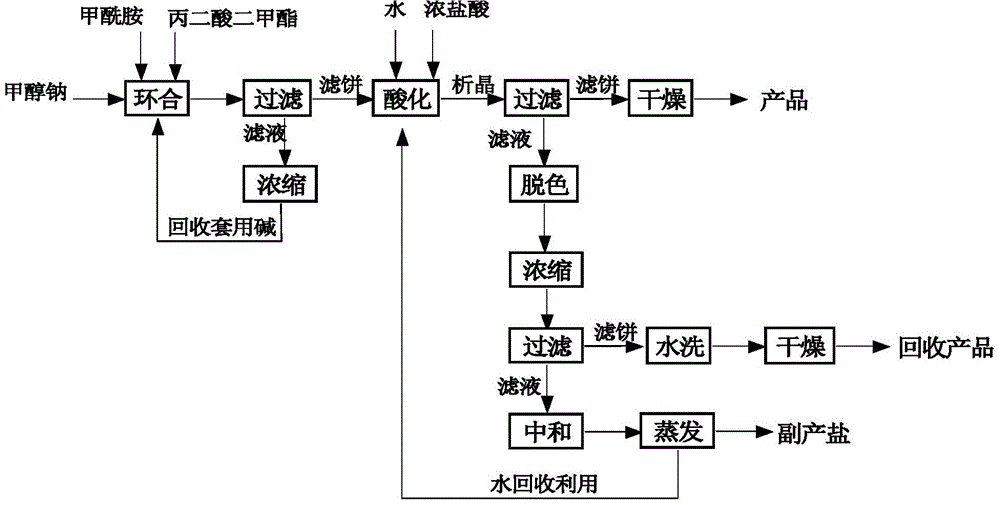

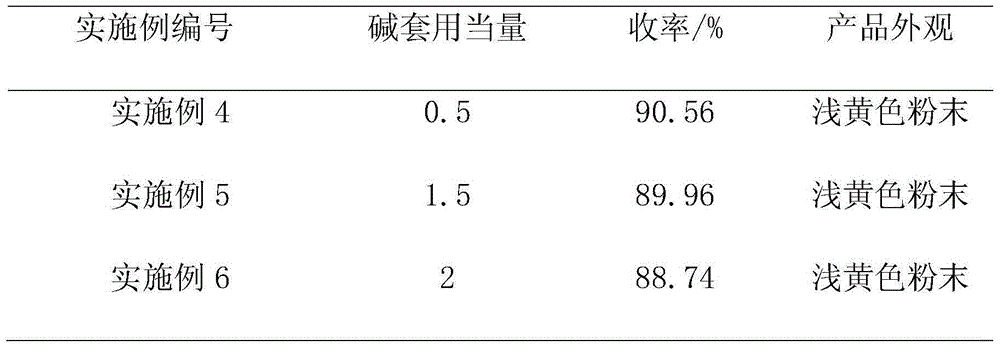

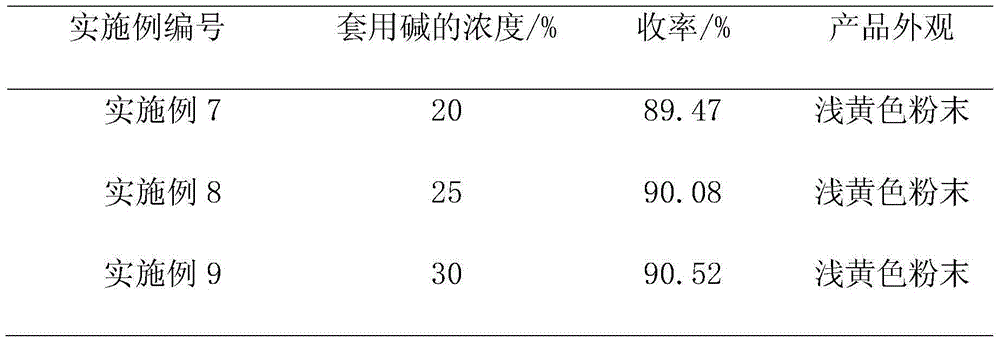

Post-treatment method for 4,6-dihydroxypyrimidine synthesis

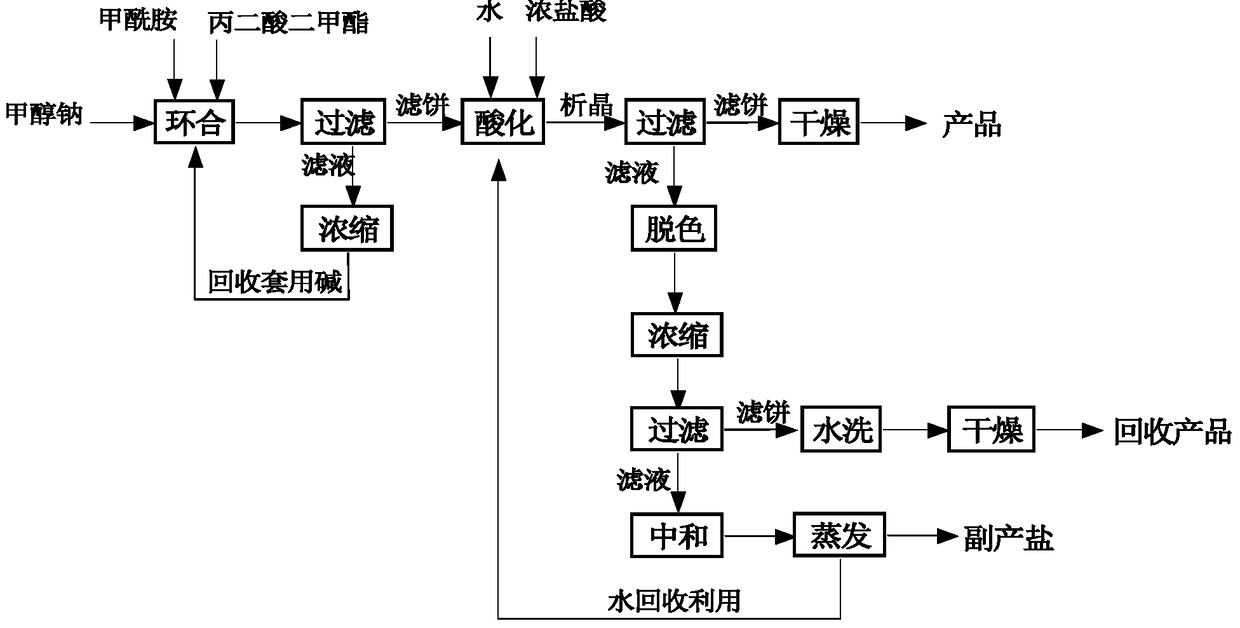

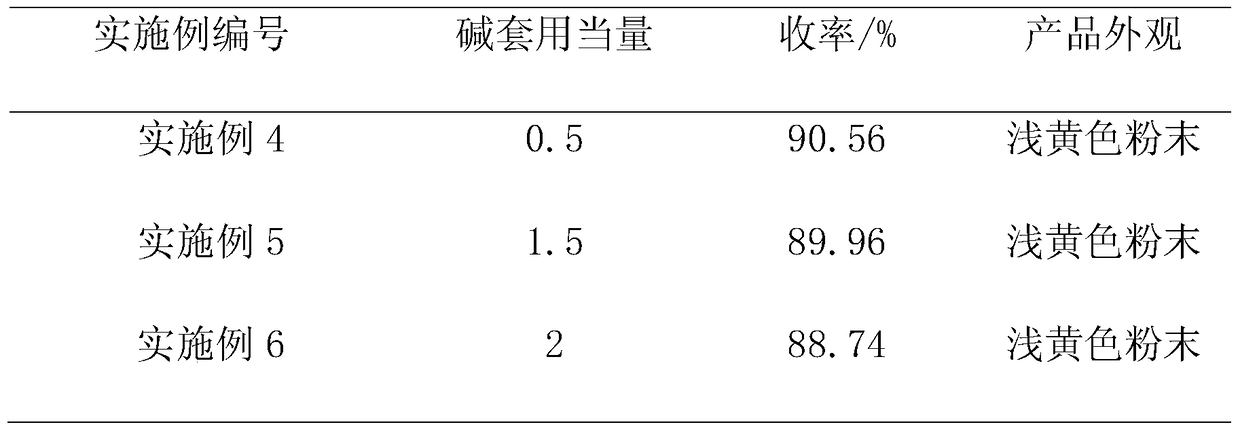

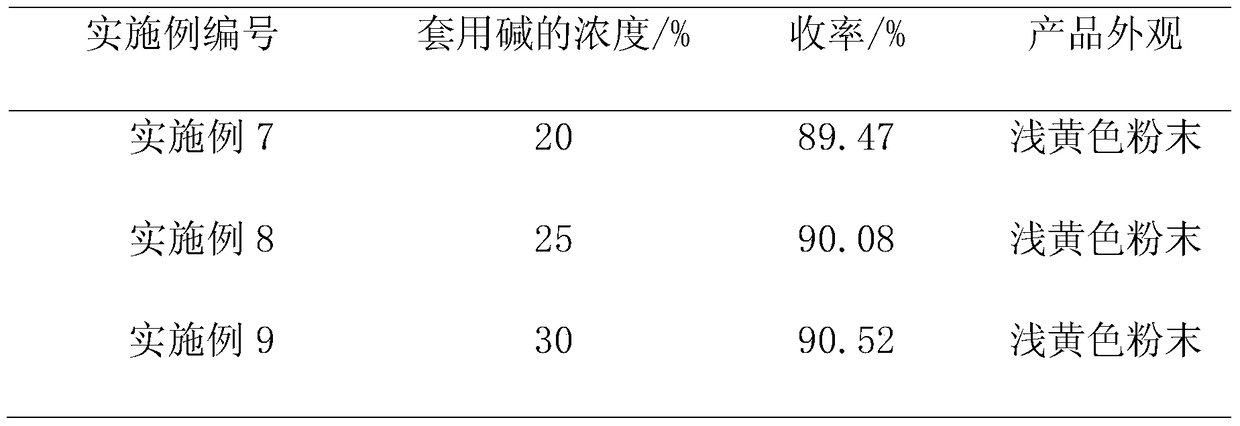

The invention provides a post-treatment method for 4,6-dihydroxypyrimidine synthesis, belongs to the technical field of organic chemical industry, and relates to a method for alkali recovery and application and wastewater recovery and application in a chemical industry product, particularly to a process. According to the process, formamide, dimethyl malonate and sodium methoxide are adopted as starting raw materials and cyclization is performed to prepare 4,6-dihydroxypyrimidine; after the reaction is completed, negative pressure suction filtration is performed, the filtrate is subjected to partial methanol removing, and the alkali is recovered and applied; and after the filter cake is subjected to acidification crystallization, negative pressure suction filtration is performed, the filter cake is dried to obtain the product, the mother liquor is concentrated to recover the 4,6-dihydroxypyrimidine, and the acid water is neutralized so as to be recycled while the by-product salt can be recovered so as to be comprehensively utilized. According to the present invention, after the alkali recovery and application, the acid consumption for the subsequent acidification treatment can be significantly reduced so as to substantially reduce the production cost and the three-waste amount; and the post-treatment method has characteristics of less equipment investment, three-waste treatment cost reducing, easy raw material recovery and application, and the like, and is suitable for industrial production.

Owner:JIANGSU YANGNONG CHEM GROUP +2

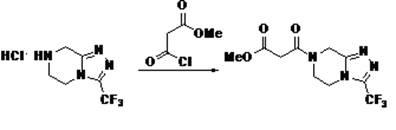

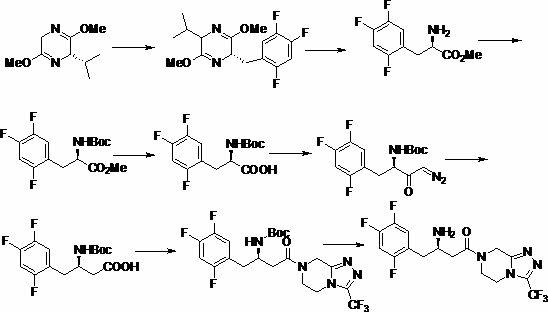

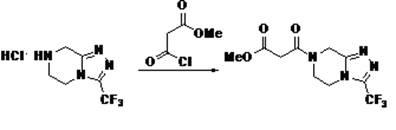

Preparation method of sitagliptin

ActiveCN102627648ALow costHigh yieldOrganic chemistryBulk chemical productionPhenylacetic acidMethyl palmoxirate

The invention provides a preparation method of sitagliptin. The preparation method comprises the following steps of: performing condensation reaction on hydrochloride of 3-trifluoromethyl-[1,2,4] triazol [4,3-a] piperazine serving as a starting raw material and methyl malonyl chloride under a normal temperature condition; reacting an obtained product with 2,4,5-trifluorophenylacetic acid under an alkaline condition and then performing condensation reaction with (S)-phenylglycinamide under normal temperature condition to obtain a product; reducing the obtained product through a reducing agent; removing an ester group through heating reflux; and reacting with a hydrogenation reducing reagent to obtain the sitagliptin. The preparation method has the advantages of low cost, high yield, easiness in operation, all used reagents of conventional reagents, simple post-treatment and convenience for industrial production.

Owner:NANTONG SHIMEIKANG PHARMA CHEM

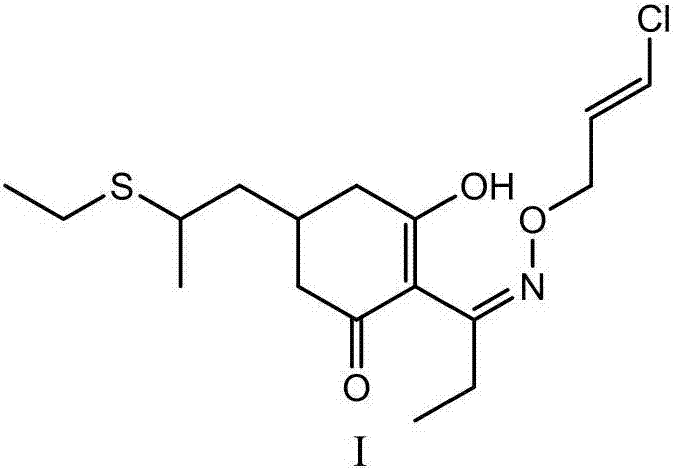

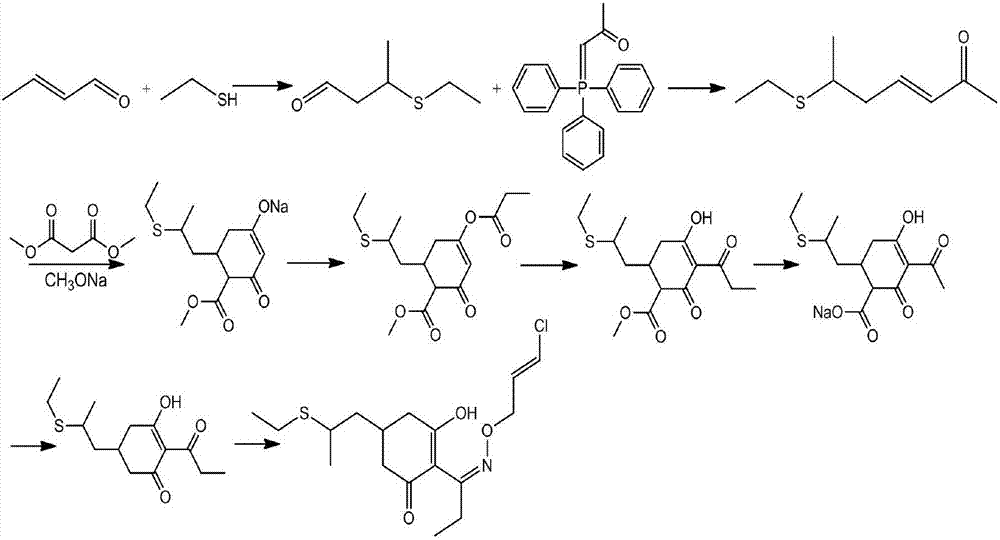

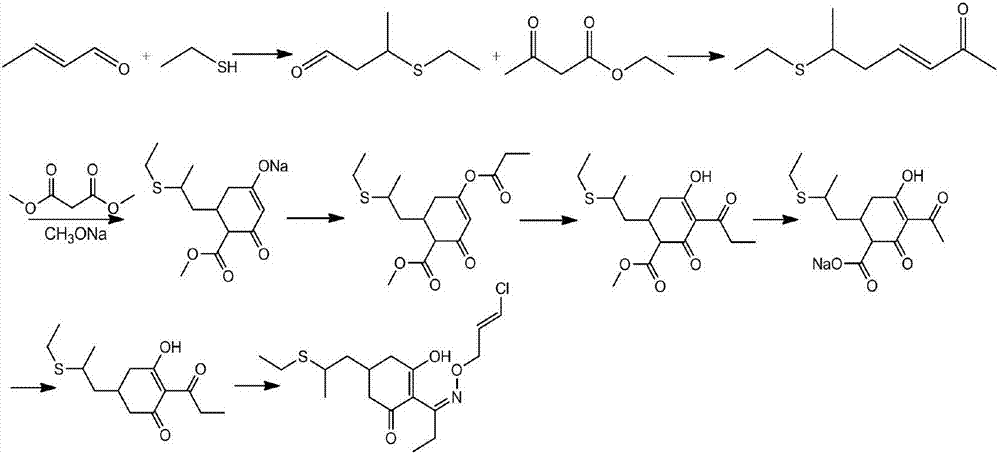

Method for synthesizing clethodim

InactiveCN107162945AHigh yieldImprove product qualitySulfide preparationPropionyl chlorideEthanethiol

The present invention proposes a method for synthesizing clethodim, comprising 3,5-heptadiene-2-one (formula II) and ethanethiol for nucleophilic addition to prepare clethodim intermediate 6-ethylthio ‑3‑heptene‑2‑ketone (formula III); formula III reacts with dimethyl malonate and propionyl chloride to prepare (±)‑3‑[propionyloxy]‑5‑[ 2-(Ethylthio)propyl]-6-[methoxyformyl]cyclohex-2-enone (Formula V); Formula V is then rearranged, hydrolyzed and decarboxylated to obtain (±)-2- [Propionyl]-3-[hydroxyl]-5-[2-(ethylthio) propyl]cyclohex-2-enone (formula VIII); formula VIII reacts with chloroallyloxyamine to obtain alkene Clethodim (formula I), the method for preparing clethodim by using intermediate 3,5-heptadiene-2-one (formula II) in the present invention is proposed for the first time, and the clethodim (formula I) prepared by this method is generally The yield is high, the product quality is good, and the method has low production cost and little environmental pollution, and is suitable for large-scale production.

Owner:江苏威格瑞斯化工有限公司

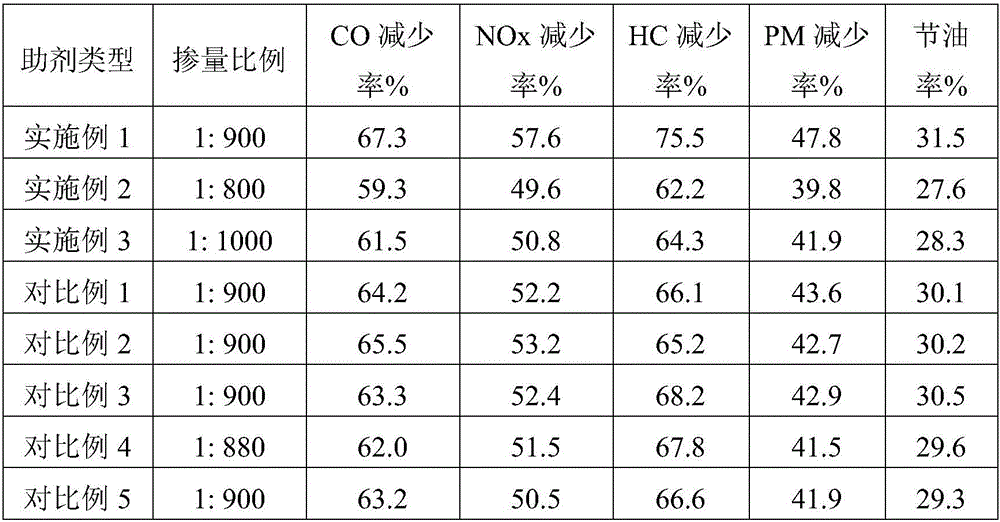

Composite fuel additive

InactiveCN106433819AEmission reductionIncrease surface activation energyLiquid carbonaceous fuelsFuel additivesOctanolEthyl acetate

The invention discloses a composite fuel additive. The composite fuel additive is prepared from the following components in parts by weight: 3 to 5 parts of isopropyl alcohol, 2 to 4 parts of tert butyl alcohol, 1 to 3 parts of octanol, 1 to 3 parts of tertiary amyl methyl ether, 2 to 5 parts of dimethyl malonate, 1 to 4 parts of amyl nitrate, 10 to 15 parts of butyl acetate, 0.6 to 0.8 part of dibutyl phthalate, 1 to 3 parts of strontium peroxide, 0.4 to 0.6 part of ethyl acetate, 2 to 6 parts of fatty alcohol polyoxyethylene ether, 0.2 to 0.6 part of nonylphenol polyoxyethylene ether, 0.3 to 0.7 part of a fluorocarbon surfactant, 0.2 to 0.5 part of sodium carboxymethyl cellulose, 1 to 4 parts of polytetrafluoroethylene, 0.5 to 0.9 part of a catalyst, 0.1 to 0.3 part of attapulgite powder, 1 to 3 parts of nano-ceria and 0.2 to 0.4 part of nanometer magnesium powder.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Preparation method of 6-chloro-1,3-dimethyluracil

The invention provides a preparation method of 6-chloro-1,3-dimethyluracil, which comprises the following steps: carry out reflux reaction on 1,3-dimethylbarbituric acid and a chlorinating agent in a water-insoluble organic solvent to obtain a reaction mixture; and adding water to quench the reaction to obtain the 6-chloro-1,3-dimethyluracil, wherein the chlorinating agent comprises phosphorus oxychloride. The preparation method provided by the invention reduces the consumption of phosphorus oxychloride, and does not need to perform vacuum distillation on the phosphorus oxychloride. Furthermore, additives can be added in the reaction process to enhance the yield of the 6-chloro-1,3-dimethyluracil. The invention also provides a method for synthesizing 1,3-dimethylbarbituric acid, which is implemented by reacting 1,3-dimethylurea, dimethyl malonate and a condensing agent in an organic solvent. The method avoids using abundant malonic acid and acetic anhydride.

Owner:SHENGQUAN HEALTANG

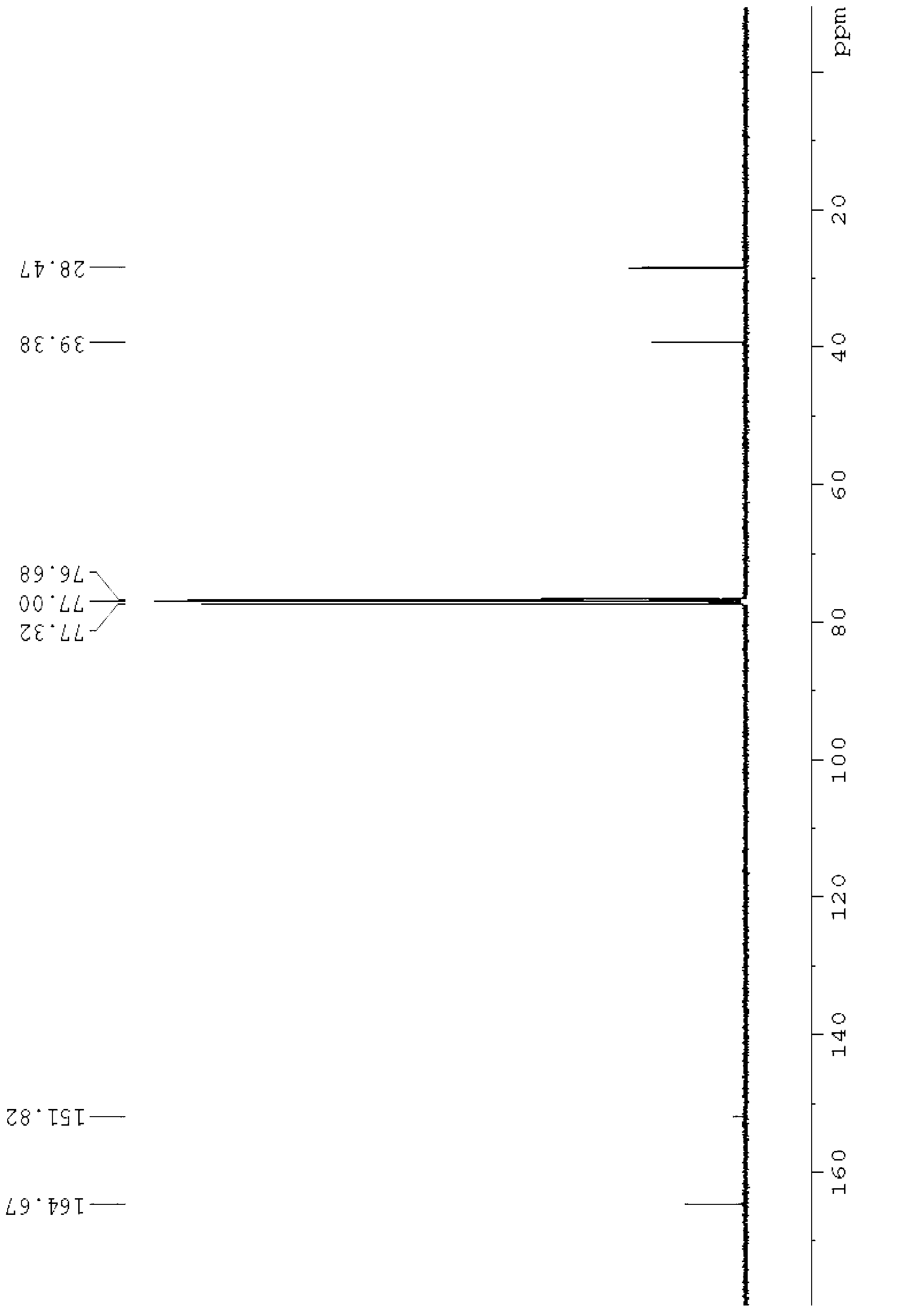

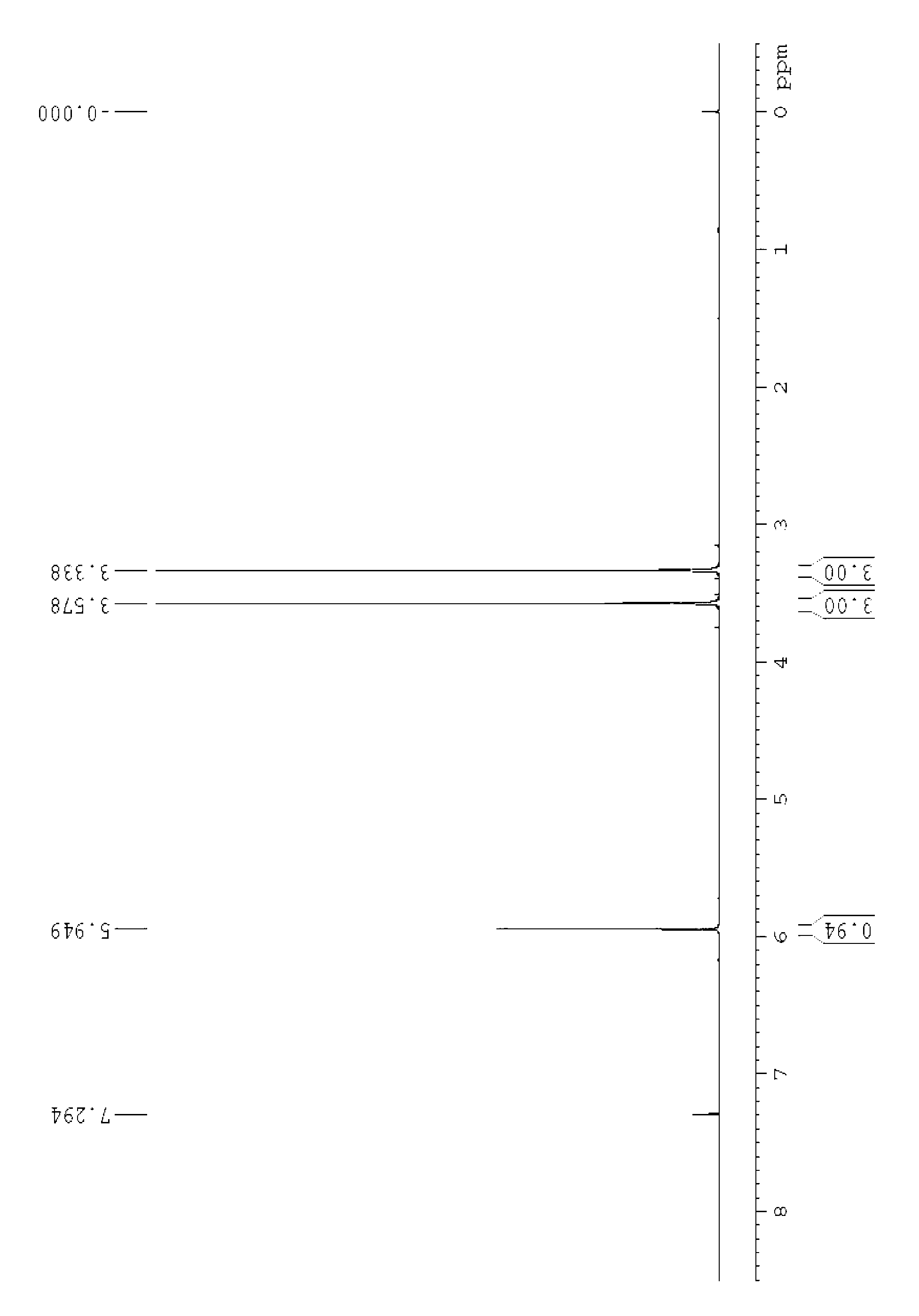

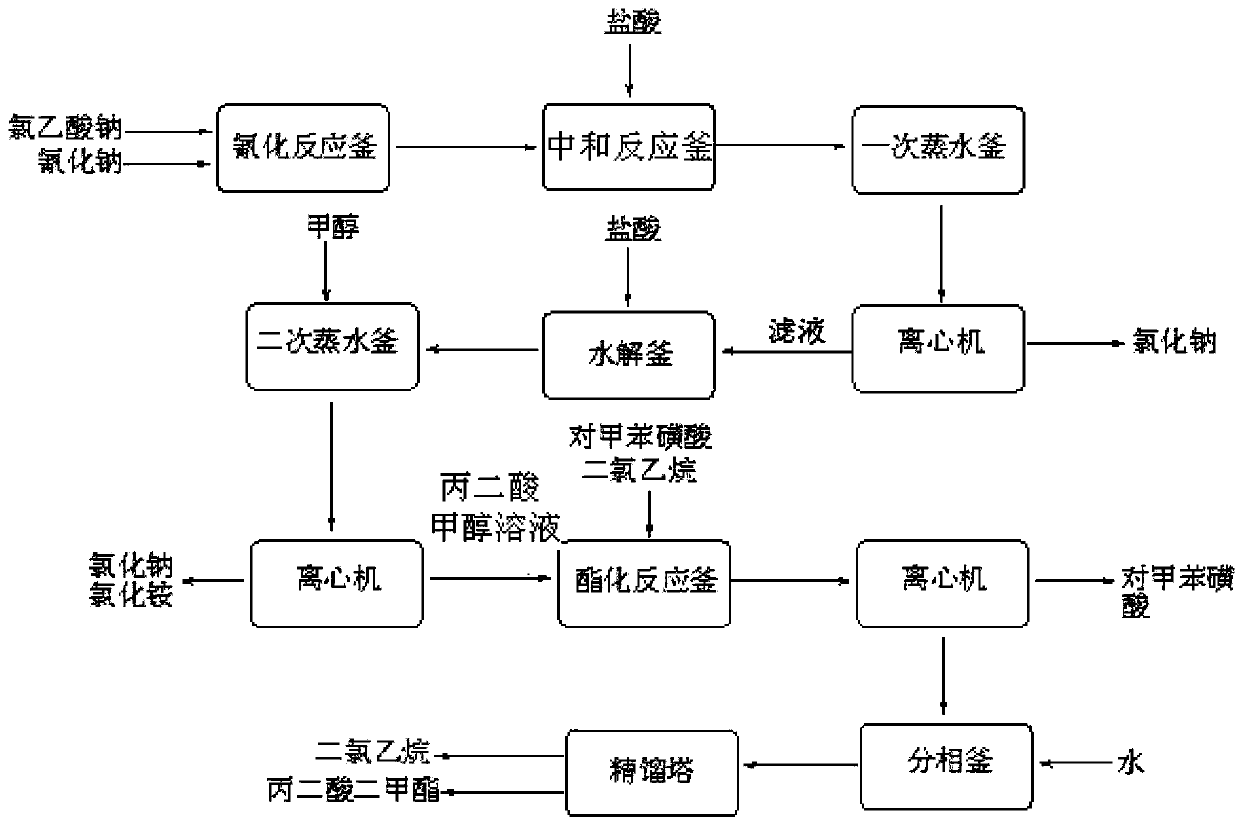

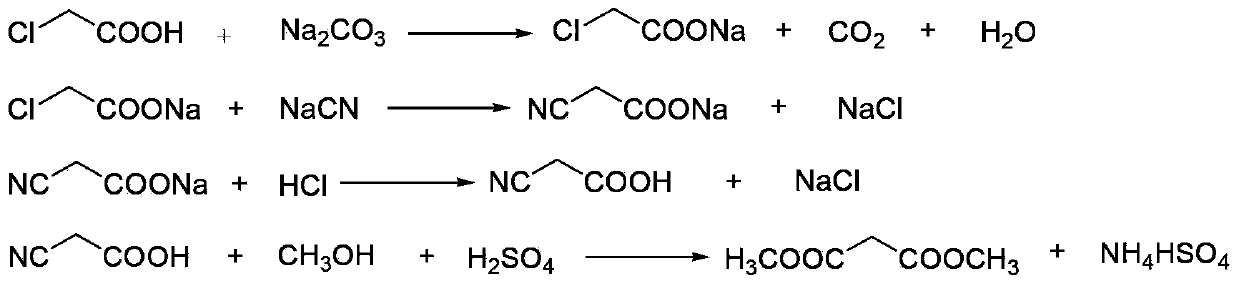

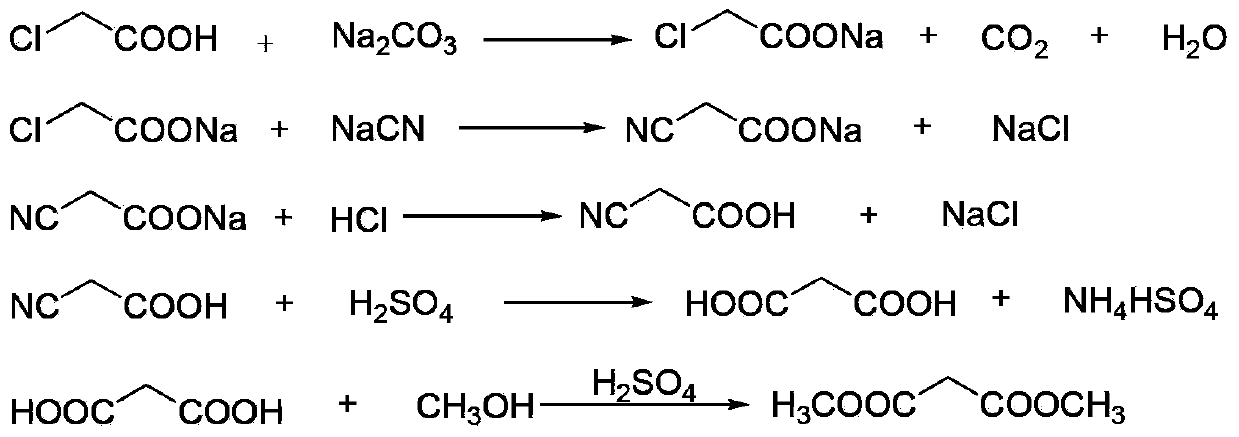

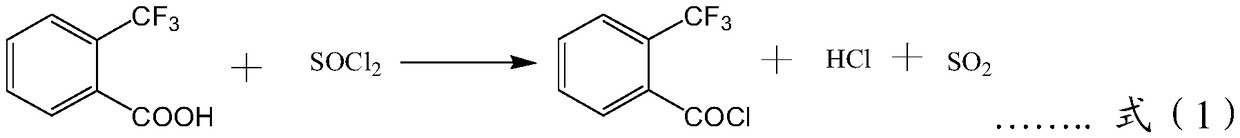

Method for synthesizing p-toluenesulfonic acid-catalyzed dimethyl malonate

ActiveCN103420833AReduce dosageImprove solubilityOrganic compound preparationCarboxylic acid esters preparationPtru catalystChloroacetic acids

The invention discloses a method for synthesizing p-toluenesulfonic acid-catalyzed dimethyl malonate. Chloroacetic acid is taken as a raw material, dimethyl malonate is generated through a neutralization reaction, a cyanation reaction, an acidification reaction, a hydrolysis reaction and an esterification reaction, the esterification reaction is performed under the catalytic effect of p-toluenesulfonic acid, a catalyst is recovered after the reactions, and the recovered catalyst can be recycled, so that the usage amount of the catalyst can be greatly reduced and sulfuric acid-containing wastewater cannot be produced by selecting p-toluenesulfonic acid instead of sulfuric acid in a traditional process as the catalyst in the esterification reaction; meanwhile, dichloroethane is added in the esterification reaction, has a good dissolving property for dimethyl malonate, is easily separated from dimethyl malonate through rectification and forms a ternary azeotropic system along with methanol and water, and the water generated in the reactions is continuously discharged from the system through azeotropy, so that the esterification reaction can be more thoroughly produced.

Owner:CHONGQING UNISPLENDOUR CHEM

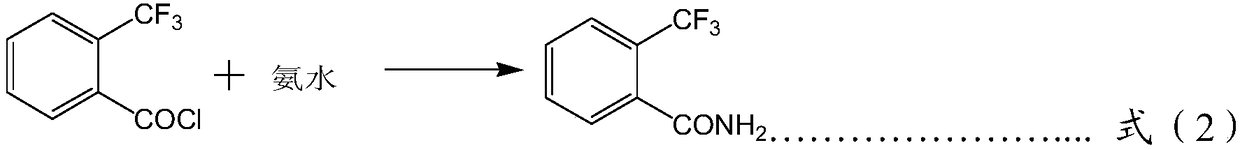

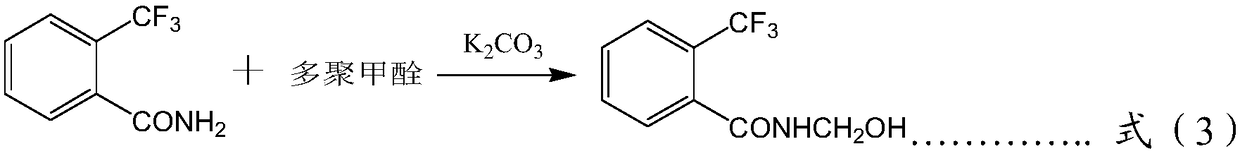

Fluopyram and synthesis method thereof

ActiveCN108822024AThe synthesis method is simpleEasy to operateOrganic chemistryMethyl malonateTrifluoromethyl

The invention discloses fluopyram and a synthesis method thereof. The fluopyram comprises the following raw materials: trifluoromethylbenzoic acid, thionyl chloride, ammonia water, water, potassium carbonate, paraformaldehyde, formamide, acetic anhydride, 5-trifluoromethyl-2-dimethyl malonate--3-chloropyridine, sodium chloride and hydrochloric acid. The content of fluopyram obtained in the invention is 98% or more, and the total yield of fluopyram is 63% or more. The synthesis method of the invention does not use cyano groups with high activity, and the yield of aminolysis can reach 93%; the raw materials are simple to treat and high in utilization rate; waste gas, waste water and industrial residues are not produced; and the synthesis method is simple in process and easy to operate and implement.

Owner:陕西恒润化学工业有限公司

Method for preparing Guerbet acids by taking malonate as raw material

InactiveCN106748724AFlexible Regulatory StructureMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationPotassium hydroxideHigh pressure

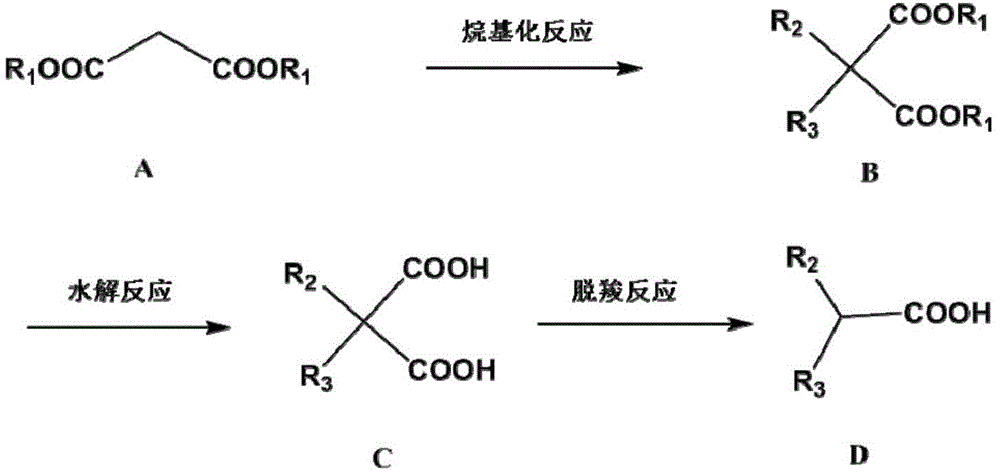

The invention discloses a method for preparing Guerbet acids by taking malonate as a raw material. The method comprises the following steps: using the malonate as the raw material, and carrying out alkylation reaction under the action of alkali to obtain dialkyl malonate; sequentially carrying out hydrolysis reaction and decarboxylic reaction on obtained dialkyl malonate to obtain the Guerbet acid, wherein the malonate is dimethyl malonate or diethyl malonate; the alkali of the alkylation reaction is selected from one or more of potassium carbonate, sodium hydroxide, potassium hydroxide, sodium methylate and sodium ethoxide; an alkylating reagent is haloalkane with 2 to 20 carbons. According to the method disclosed by the invention, the Guerbet acids are prepared by taking the malonate as the raw material for the first time; related three reactions are easily operated, high temperature or high pressure is not needed, and high yield is realized; by means of the alkylation reaction disclosed by the invention, a main chain structure and a branched chain structure of the Guerbet acids can be flexibly regulated and controlled, and further the Guerbet acids with different properties are obtained.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Sewage filter material and preparation method thereof

InactiveCN106563307AHigh degree of recoveryLow costOther chemical processesWater contaminantsTreatment effectSilica gel

The invention discloses a sewage filter material and a preparation method of the sewage filter material. The sewage filter material comprises, by weight, 7-11 parts of styrene sulfonic acid, 20-30 parts of silica gel, 8-20 parts of polyacrylamide, 5-8 parts of dimethyl malonate, 7-14 parts of azodicarbonamide, 10-18 parts of nano-modified activated carbon, 10-15 parts of zeolite, 5-8 parts of straw fibers, 2-6 parts of alum and 0.8-2.0 parts of sepiolite. According to the preparation method of the nanometer modified active carbon, bamboo charcoal and titanium dioxide are mixed for modification, then polyepichlorohydrin and ethyl acetate are added, and the nanometer modified active carbon is obtained after stirring and drying. By the adoption of the sewage filter material and the preparation method, the physicochemical indexes of seriously-contaminated sewage are made to reach the GB18918-2002 standard; and the treatment process is simple, the dosage is small, the treatment effect is good, the performance is stable, the cleaning degree of the contaminated sewage is high, the cost of the treatment agent can be reduced effectively, and the sewage filter material and the preparation method have the very good economic benefits and a wide range of social benefits.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

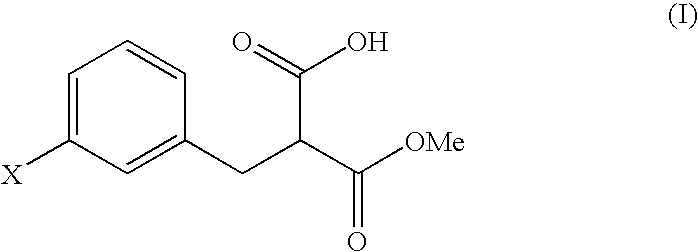

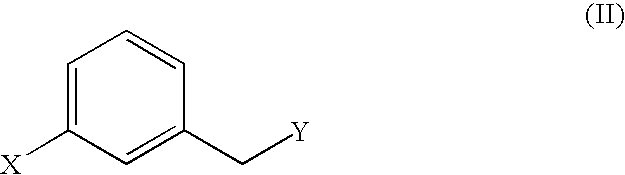

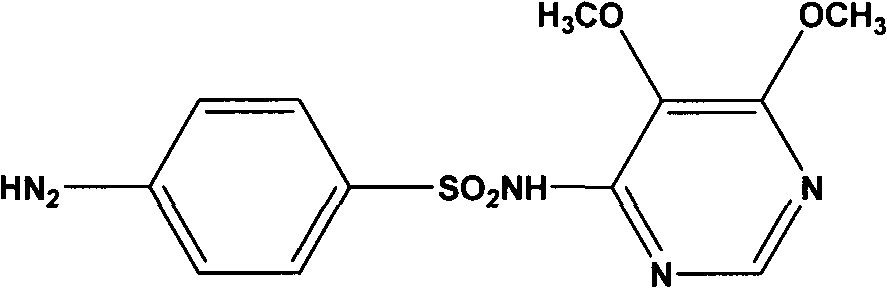

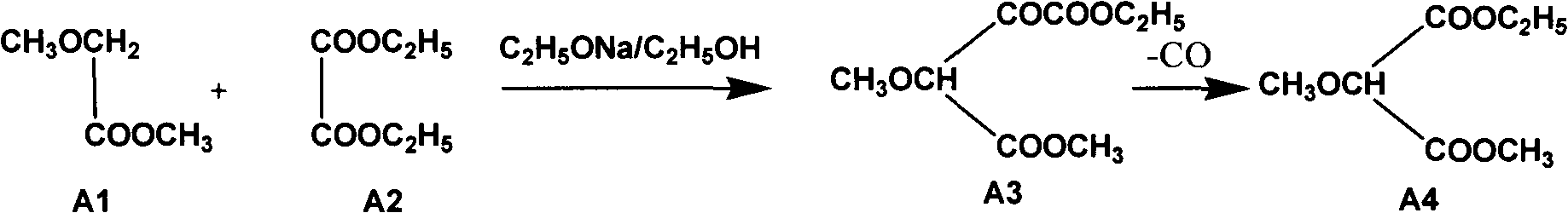

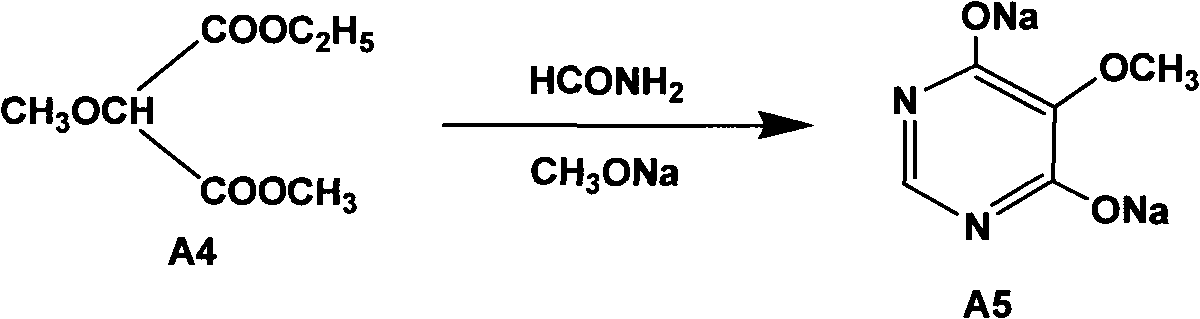

Methods for preparing sulfadoxine and intermediate of sulfadoxine

InactiveCN102432550AQuality improvementImprove qualityOrganic compound preparationCarboxylic acid esters preparationMethyl methoxyacetateDiethyl oxalate

The invention relates to methods for preparing sulfadoxine and an intermediate of the sulfadoxine. The method for preparing the sulfadoxine sequentially comprises the following steps of: (1), in the presence of sodium ethylate, reacting methyl methoxyacetate with excessive diethyl oxalate to generate 3-methoxyl-2-oxo-ethyl methyl succinate, decarbonylating the 3-methoxyl-2-oxo-ethyl methyl succinate to obtain 2-methoxyl-ethyl methyl malonate; (2) reacting the 2-methoxyl-ethyl methyl malonate with formamide to generate a cyclized compound; (3) reacting the cyclized compound with phosphorus oxychloride to generate chloride; (4) performing condensation reaction; and (5) performing methyl oxidation reaction, wherein the purity of the 2-methoxyl-ethyl methyl malonate which is obtained in the step (1) is controlled to be more than or equal to 95 weight percent. By adoption of the methods, the purity of the 2-methoxyl-ethyl methyl malonate is effectively controlled to be more than 95 weight percent, the quality of the cyclized compound for cyclization reaction in next step can be improved, operation is simplified, and production cost is reduced.

Owner:CHANGSHU NANHU INDAL CHEM

A post-processing method for synthesizing 4,6-dihydroxypyrimidine

The invention provides a post-treatment method for 4,6-dihydroxypyrimidine synthesis, belongs to the technical field of organic chemical industry, and relates to a method for alkali recovery and application and wastewater recovery and application in a chemical industry product, particularly to a process. According to the process, formamide, dimethyl malonate and sodium methoxide are adopted as starting raw materials and cyclization is performed to prepare 4,6-dihydroxypyrimidine; after the reaction is completed, negative pressure suction filtration is performed, the filtrate is subjected to partial methanol removing, and the alkali is recovered and applied; and after the filter cake is subjected to acidification crystallization, negative pressure suction filtration is performed, the filter cake is dried to obtain the product, the mother liquor is concentrated to recover the 4,6-dihydroxypyrimidine, and the acid water is neutralized so as to be recycled while the by-product salt can be recovered so as to be comprehensively utilized. According to the present invention, after the alkali recovery and application, the acid consumption for the subsequent acidification treatment can be significantly reduced so as to substantially reduce the production cost and the three-waste amount; and the post-treatment method has characteristics of less equipment investment, three-waste treatment cost reducing, easy raw material recovery and application, and the like, and is suitable for industrial production.

Owner:JIANGSU YANGNONG CHEM GROUP +2

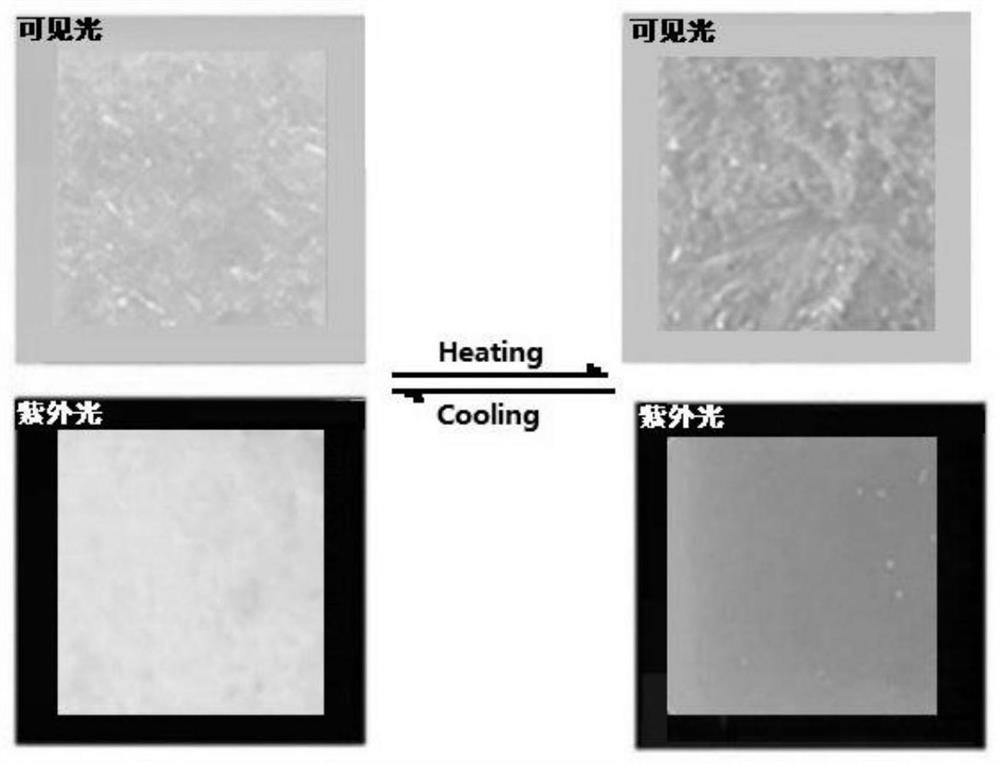

Thermally-stimulated fluorescence/visible light color double-response capsule and synthesis method thereof

ActiveCN112662394AImprove performanceStrong performance and stabilityVegetal fibresLuminescent compositionsChemical synthesisSalicylaldehyde

The invention discloses a thermal-stimulated fluorescence / visible light color double-response capsule and a synthesis method thereof, and belongs to the technical field of chemical synthesis. Through specific molecular structure design, 4-dimethylamino salicylaldehyde and dimethyl malonate are subjected to grafting reaction to prepare chromophoric molecules with a plurality of unsaturated functional groups, the chromophoric molecules are mixed with a phase change material to realize optical double-response reversible output of solvent phase state regulation, and compared with a conventional three-component organic thermal response material, the product only needs two components, namely chromophoric body molecules and a phase change solvent, so that the preparation process is simplified, and the performance stability is high. After microcapsule coating, the material is free from influence of adverse environment, and the performance is stably maintained, so that long-term stable use is realized.

Owner:JIANGNAN UNIV

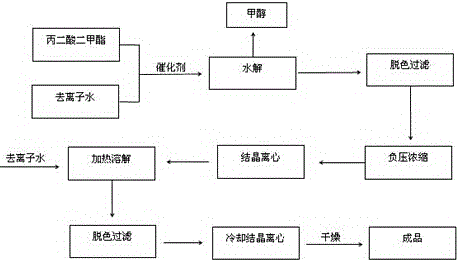

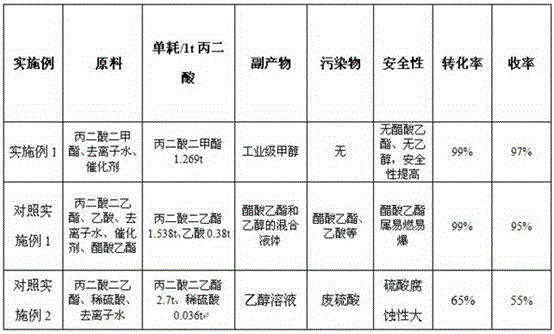

Electronic grade malonic acid

ActiveCN106565455AHigh purityLess impuritiesOxygen-containing compound preparationOrganic compound preparationMalonic acidSulfate

Disclosed is electronic grade malonic acid. The electronic grade malonic acid is obtained by hydrolyzing of dimethyl malonate and deionized water in the existence of a catalyst. The content of the dimethyl malonate and the deionized water is larger than 99.8%, the moisture content is smaller than 50PPM, the chloride content is smaller than 5PPM, the sulfate content is smaller than 5PPM, and the content of heavy metal ions is smaller than 5PPM. The technical problems that the yield of malonic acid in the prior art is low; and the quality on the aspects of purity, impurities, chloride, sulfate and heavy metal cannot meet the using requirement of the electronic industry are effectively solved.

Owner:SUQIAN NANXIANG CHEM MFG CO LTD

Improved cashmere oxidation-reduction bleaching method

InactiveCN105040400AWeakened reduction processing abilityImprove bindingDry-cleaning apparatus for textilesBleaching apparatusBenzaldehydePotassium

The invention discloses an improved cashmere oxidation-reduction bleaching method, which includes the following steps: (a) pre-treating cashmere with 1-3 wt% of a chelating dispersion agent, 0.5-2 wt% of a surfactant, 2-5 wt% of a penetrating agent, 0.1-0.4 wt% of p-tolyl phenylacetate and 0.5-1 wt% of 2,4,5-trimethyl benzaldehyde; (b) performing oxidation bleaching with 40-47 wt% of hydrogen peroxide, 12-15 wt% of sodium pyrophosphate, 0.75-1.2 wt% of sodium pyridine-3-carboxylate, 1.3-1.5 wt% of potassium methyl malonate, 0.05-0.12 wt% of 2,4-dimethyl phenol and 3.5-5 wt% of 5-sulfosalicylic acid; (c) performing neutralizing washing with 35-45 wt% of isopropyl alcohol, and 3.6-7 wt% of s-butyl-diethyl malonate; (d) performing reduction bleaching with 7-10 wt% of sodium hydrosulfite, 3.5-4 wt% of sodium pyrophosphate, 5-7 wt% of acetic acid, 5-6% of softening agent, 0.65-1 wt% of hydroxyethyl acrylate, and 1.1-1.5 wt% of 2-bromo-2'-fluoroacetophenone, and (e) washing the cashmere with deionized water. The method can reduce damage on scale layer on the cashmere during the bleaching process.

Owner:NINGXIA ZHONGYIN CASHMERE

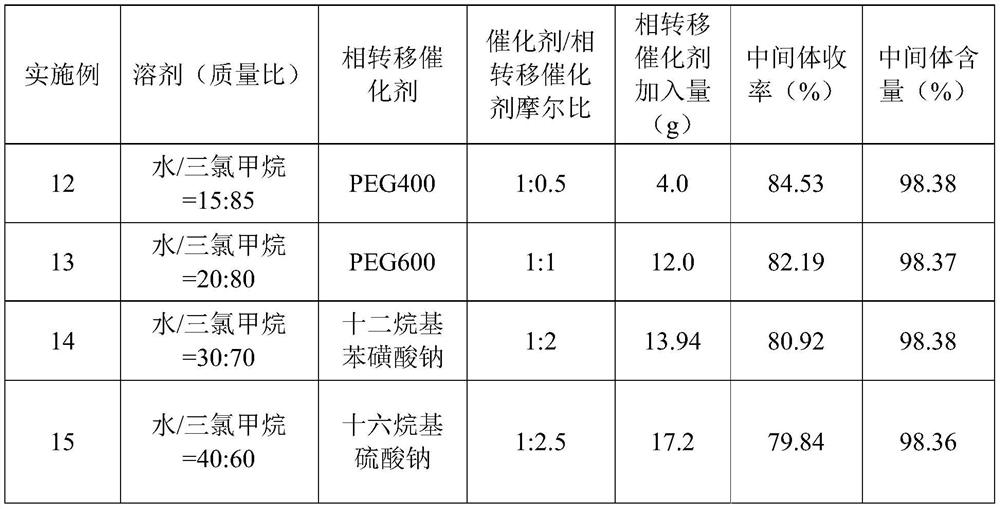

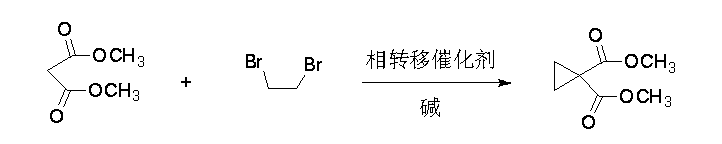

Synthetic process of 1, 1-cyclopropane dicarboxylic acid dimethyl ester

InactiveCN103864618AGuaranteed yieldGuaranteed purityOrganic compound preparationCarboxylic acid esters preparationPtru catalystMalonic acid

The invention relates to a synthetic process of 1, 1-cyclopropane dicarboxylic acid dimethyl ester, and belongs to the technical field of pharmaceutical raw material intermediate synthesis. The synthetic process is characterized in that dimethyl malonate reacts with dibromoethane under the effect of a phase transfer catalyst under an alkaline condition, and thus 1, 1-cyclopropane dicarboxylic acid dimethyl ester is obtained. The preparation method has the advantages that the raw materials are easy to obtain, conditions are mild, technological operation and controllability are strong, the cost is low, and the yield is high.

Owner:ZHANG JIA GANG VINSCE BIO PHARM

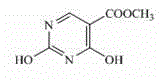

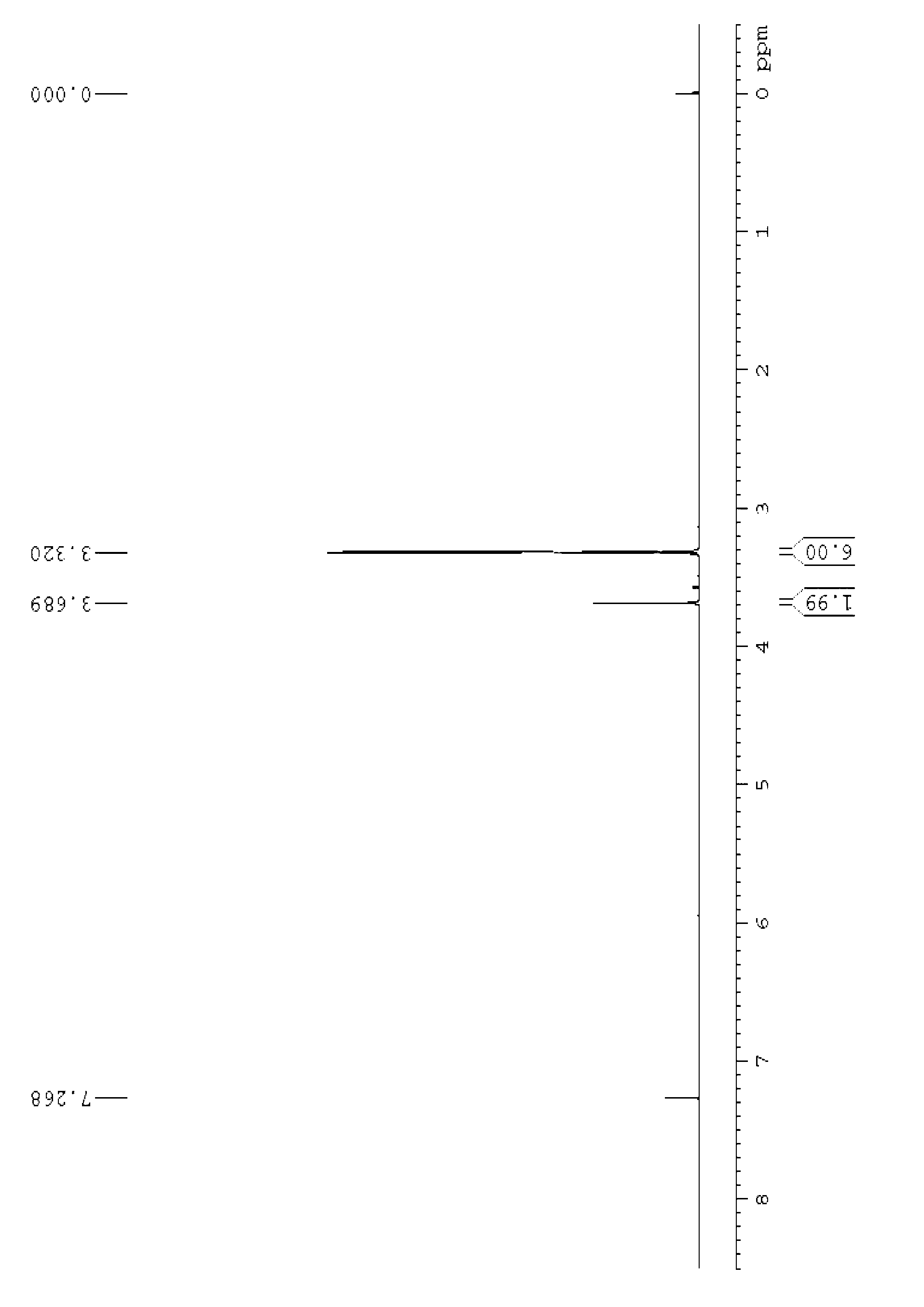

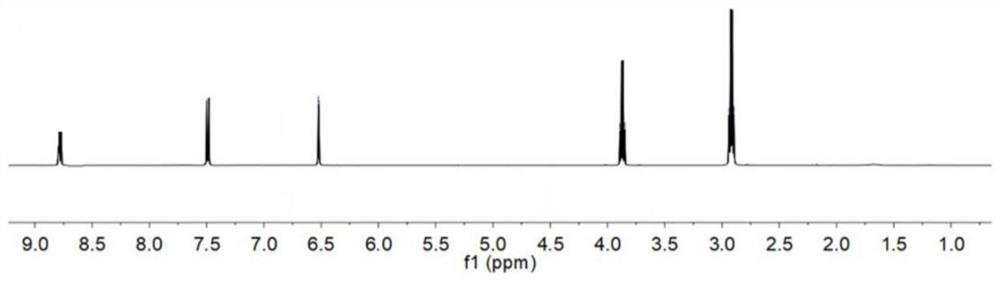

Preparation method of 4-[(4,6-dihydroxyl-2-pyrimidinyl)amino] cyanobenzene

ActiveCN101993420AIncrease productivityHigh reaction yieldOrganic chemistryOrganic compound preparationSodium methoxideAlcohol

The invention relates to a preparation method of 4-[(4,6-dihydroxyl-2-pyrimidinyl)amino] cyanobenzene. The method comprises the following steps: a, using an aqueous solution of para-cyanoaniline and mono cyanamide as a raw material, water or alcohol solvent as the single solvent or a mixed solvent of water and alcohol solvents as the reaction solvent, and hydrochloric acid as a catalyst to react so as to obtain an N-(4-cyanophenyl)guanidine hydrochloride; and b, using the N-(4-cyanophenyl)guanidine hydrochloride as the raw material, methanol as the reaction solvent, and sodium methoxide and dimethyl malonate as the reaction reagents to react so as to obtain the 4-[(4,6-dihydroxyl-2-pyrimidinyl)amino] cyanobenzene. The method is an improvement of the prior art and has the advantages of short reaction process, high production efficiency, high reaction yield, low cost, low impurity content, complete and stable reaction and the like.

Owner:浙江瑞博制药有限公司

Anti-corrosive paint film for mechanical device

InactiveCN104231937AImprove anti-corrosion performanceEasy to useConjugated diene hydrocarbon coatingsAnti-corrosive paintsCarbon monofluorideDiiron Trioxide

The invention discloses an anti-corrosive paint film for a mechanical device. The anti-corrosive paint film is characterized by comprising the following substances in parts by weight: 15-31 parts of tetramethylthiourea, 11-24 parts of carbon monofluoride, 45-60 parts of methyl malonate, 10-18 parts of ferric oxide, 5-20 parts of phosphorus oxide, 3-14 parts of silane coupling agent, 1-5 parts of butadiene styrene rubber, 5-9 parts of nano-powder, 10-14 parts of anion resin, 13-28 parts of mica powder, and 25-31 parts of diatomite. The anti-corrosive paint film disclosed by the invention is good in anti-corrosive effect, convenient to use, and high in finish degree compared with a common paint.

Owner:QINGDAO JINXIU SHUIYUAN COMMERCE & TRADE

Novel synthesis method of lobaplatin intermediate

ActiveCN113416150ALow priceReduce manufacturing costOrganic compound preparationOrganic chemistry methodsHydrolysisReaction step

The invention relates to the technical field of medicine synthesis, in particular to a novel synthesis method of a lobaplatin intermediate, the method comprises the following steps: taking low-toxicity dimethyl malonate as an initial raw material, carrying out coupling, bromination, cyclization, hydrolysis, amidation and dehydration reaction to synthesize high-purity trans-1, 2-dicyanocyclobutane. In the whole route synthesis, all adopted raw and auxiliary materials are easy to purchase, low in price and low in toxicity, the reaction conditions are not harsh and uncontrollable, the reaction conditions of each step can be suitable for amplified production, although the reaction steps are increased, the yield of the product is greatly improved, so that the cost is greatly reduced, and the purity of the obtained trans-1,2-dicyanocyclobutane is improved and completely meets the subsequent use requirements, and the market competitiveness is greatly improved.

Owner:上海寻科生物医药科技有限公司

Filtering material used for sewage treatment

InactiveCN106621556AHigh degree of recoveryLow costWater/sewage treatmentMembrane filtersPolyethylene glycolMaterials science

The invention discloses a filtering material used for sewage treatment. The filtering material used for sewage treatment comprises the following main raw materials in part by weight: 7-11 parts of sodium allysulfonate, 20-30 parts of silica gel, 8-20 parts of polyethylene glycol, 5-8 parts of dimethyl malonate, 7-14 parts of lead stearate, 10-18 parts of nano modified activated carbon, 10-15 parts of medical stone, 5-8 parts of straw fiber, 2-6 parts of alums, and 0.8-2.0 parts of calcium carbonate. A preparation method of the nano modified activated carbon comprises the following steps of mixing and modifying bamboo charcoal and titanium dioxide, then adding polyepichlorohydrin and ethyl acetate, stirring and drying. Through adoption of the filtering material used for sewage treatment, the physical and chemical indexes of the seriously contaminated sewage reach the standard of GB18918-2002; and the treatment process is simple, the use amount of chemical agents is low, the treatment effect is good, the performance is stable, the recovery level of the contaminated sewage is high, the cost of a treating agent is effectively reduced, and the filtering material has an excellent economic benefit and a wide social benefit.

Owner:ZHENGZHOU BEIDOU COMM TECH

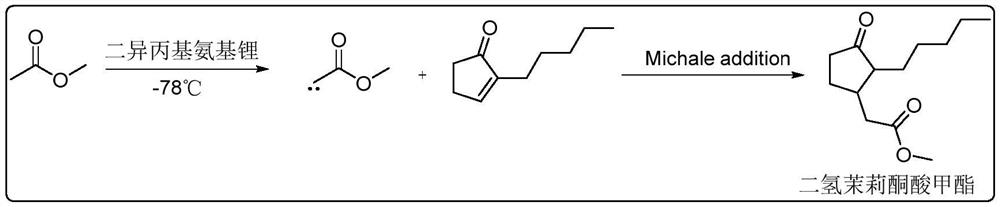

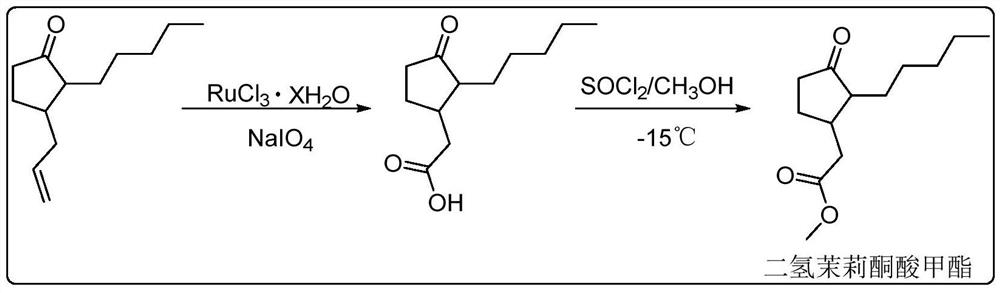

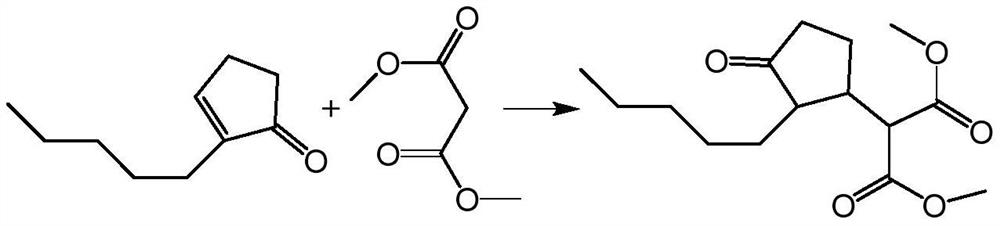

Synthesis method of methyl dihydrojasmonate or intermediate thereof and catalyst used in synthesis method

PendingCN114349640AHigh catalytic activityMild reaction conditionsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystEthylic acid

The invention discloses a synthetic method of methyl dihydrojasmonate or an intermediate thereof, which comprises the following steps: under the action of a supported catalyst, carrying out Michael addition reaction on 2-pentylcyclopentenone and methyl acetate or dimethyl malonate to obtain the methyl dihydrojasmonate or the intermediate thereof, the supported catalyst comprises a carrier and an active component supported on the carrier; the active component is quaternary ammonium base, and the carrier is a modified molecular sieve; the modified molecular sieve is obtained by modifying a molecular sieve with propylene glycol methyl ether acetate. According to the synthesis method, a super-strong base or strong base catalyst which is extremely unstable and has harsh reaction conditions in the prior art is replaced, reaction steps are reduced, the reaction conditions tend to be mild, and the reaction safety is improved. The invention further discloses a catalyst used in the synthesis method.

Owner:SHANDONG NHU PHARMA +1

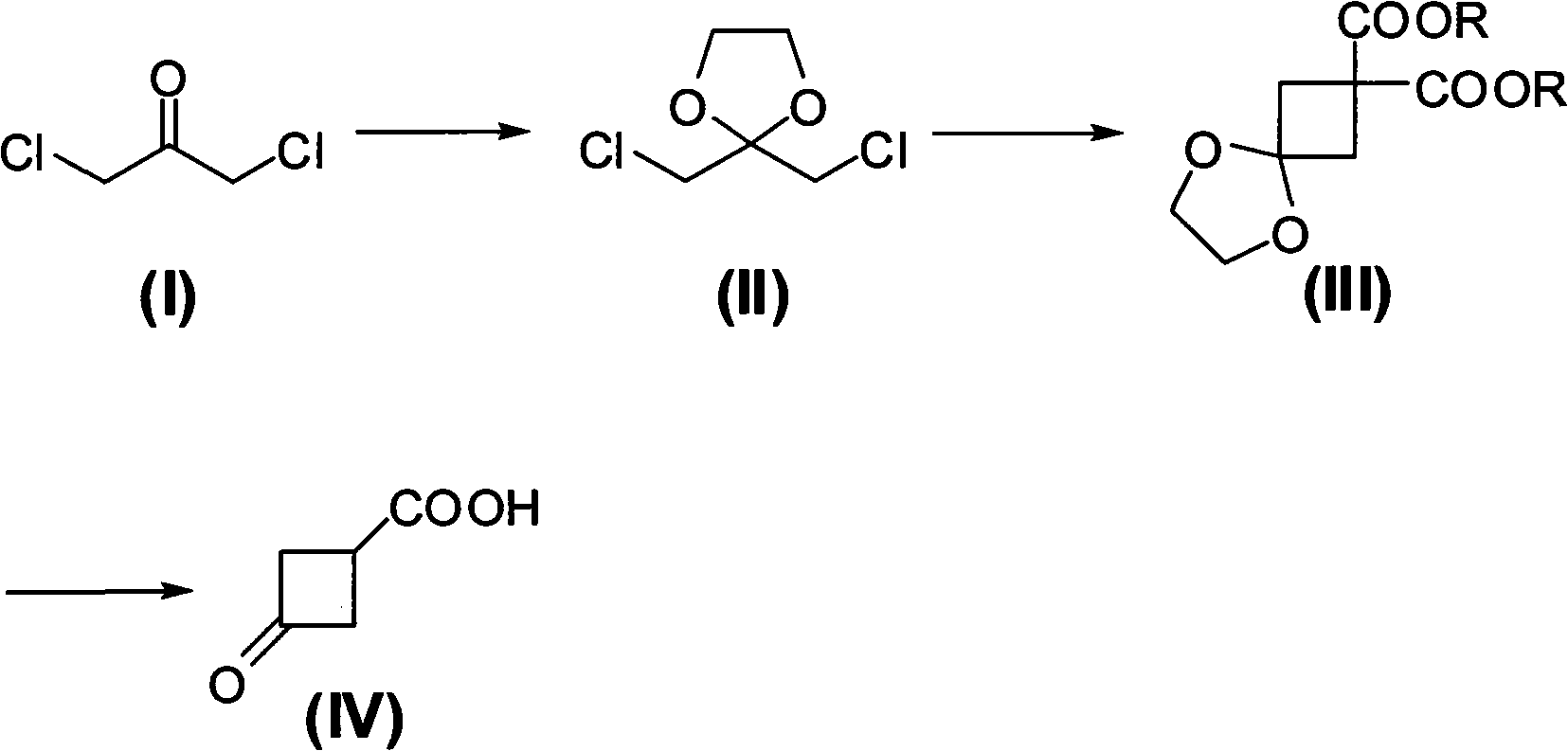

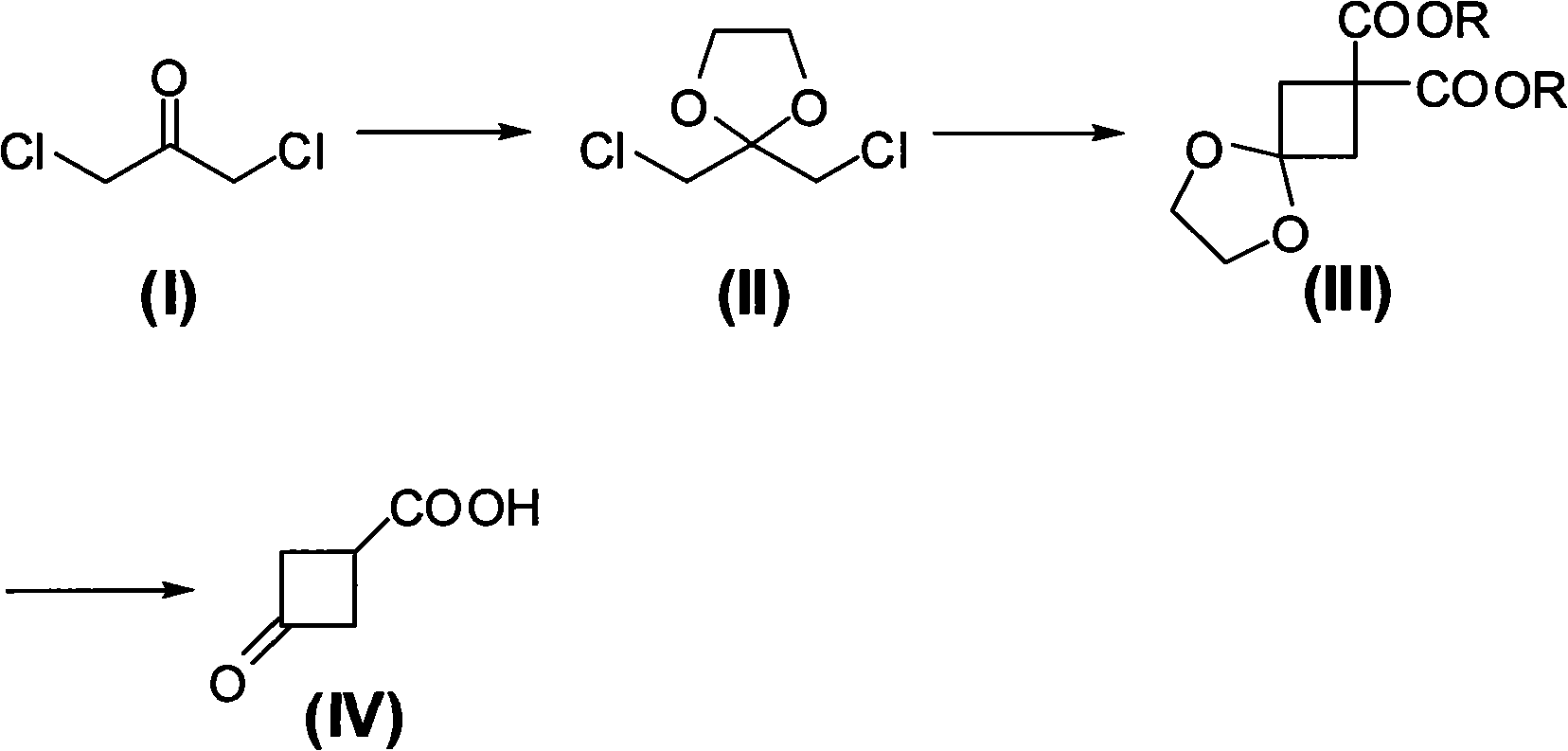

Preparing method of 3-oxo-1-cyclobutane-carboxylic acid

InactiveCN101555205ASufficient supplyLow priceOrganic compound preparationPreparation from carboxylic acid esters/lactonesCyclobutaneStrong acids

The invention discloses a preparing method of 3-oxo-1-cyclobutane-carboxylic acid. The method comprises the following steps: 1, 3-dichloroacetone is adopted as the raw material to generate ketol reaction with ethylene glycol, then generate cyclization reaction with methyl malonate, or ethyl malonate or diisopropyl malonate, and finally generate hydrolysis reaction under strong acid condition to prepare the 3-oxo-1-cyclobutane-carboxylic acid. The method provides a brand new synthetic route, the reaction condition of each step is mild, the process is simple, the reactions in all the steps are normal operations, the raw materials with high cost are effectively avoided, the cost of the product is reduced, and the scale application of the product can be possible.

Owner:ZHEJIANG GENEBEST PHARMA

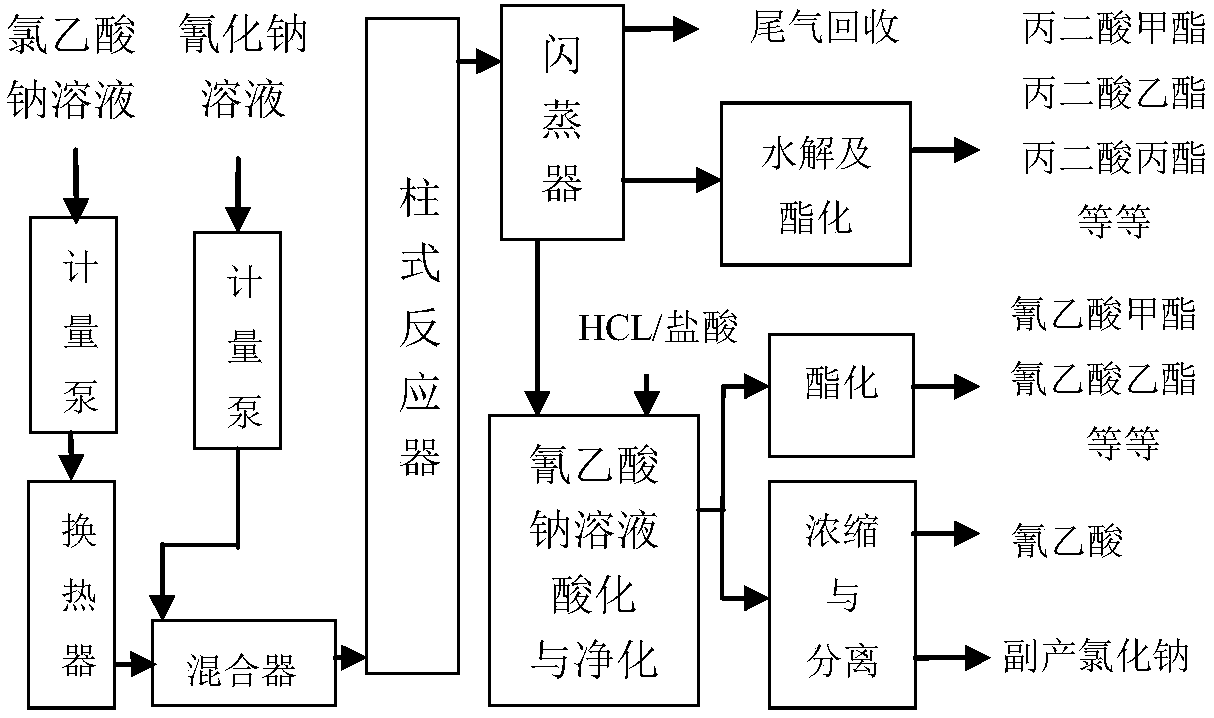

Environment-friendly and clean method for continuous cyaniding synthesis of sodium cyanoacetate and derivatives thereof

InactiveCN107586263ARealize low-carbon environmental protectionAvoid decompositionOrganic compound preparationCarboxylic acid esters preparationMethyl malonateChemistry

The invention provides an environment-friendly and clean method for continuous cyaniding synthesis of sodium cyanoacetate and derivatives thereof. Mainly, a continuous cyaniding reaction device is employed to produce sodium cyanoacetate and derivatives thereof, the cyaniding reaction environment can approach an ideal state and the reaction conversion rate can approach a theoretical value maximumly, thus realizing environment-friendly, clean and safe production. A cyanided material flows out from a column reactor, then directly enters a flash evaporator for flash separation and cooling, thus obtaining a sodium cyanoacetate solution, the sodium cyanoacetate solution can be used for production of derivatives including cyanoacetic acid, methyl cyanoacetate, ethyl cyanoacetate, malonic acid, methyl malonate, ethyl malonate, propyl malonate and the like. And the flash tail gas can be recycled.

Owner:熊知平

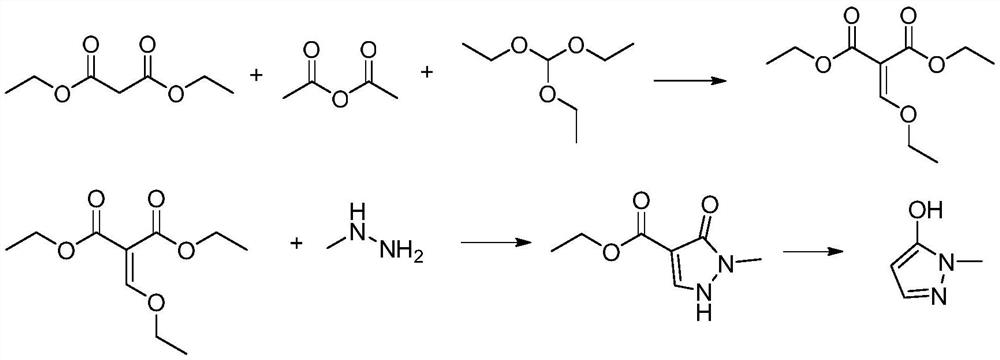

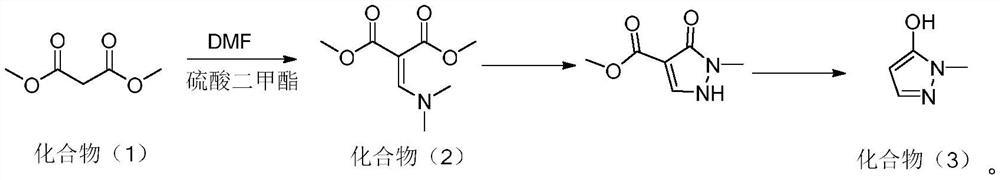

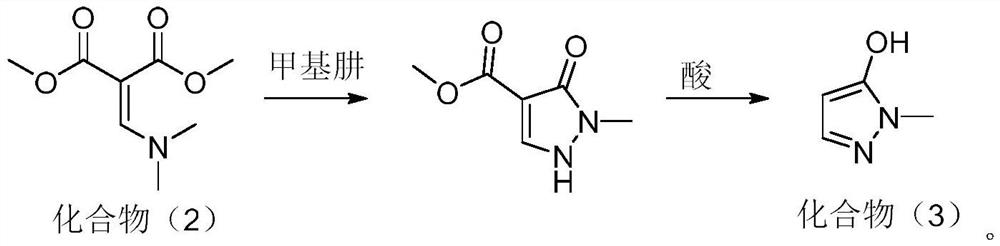

Preparation method of pyrazole type herbicide intermediate 1-methyl-5-hydroxypyrazole

The invention belongs to the technical field of preparation of pyrazole type herbicide intermediates, and particularly relates to a preparation method of a pyrazole type herbicide intermediate 1-methyl-5-hydroxypyrazole. The preparation method of the 1-methyl-5-hydroxypyrazole comprises the following steps: (1) in the presence of alkali, enabling dimethyl malonate of a compound (1) to react with aformamide compound and an alkylation reagent in a solvent to generate a compound (2); and (2) carrying out cyclization reaction on the obtained compound (2) and methylhydrazine / hydrazine hydrate in asolvent, and carrying out hydrolysis and decarboxylation by using an acid to obtain a compound (3). According to the method, DMF, an alkylation reagent and the compound (1) react to obtain the compound (2), the obtained compound (2) is good in selectivity when being subjected to ring-closure reaction with methylhydrazine (or hydrazine hydrate), and a target product compound (3) with higher yieldand purity can be obtained. Moreover, the raw materials used in the synthesis method disclosed by the invention are relatively weak in corrosivity, easy to recover and relatively low in price, so thatindustrial production is facilitated.

Owner:PAPANNA BEIJING TECH

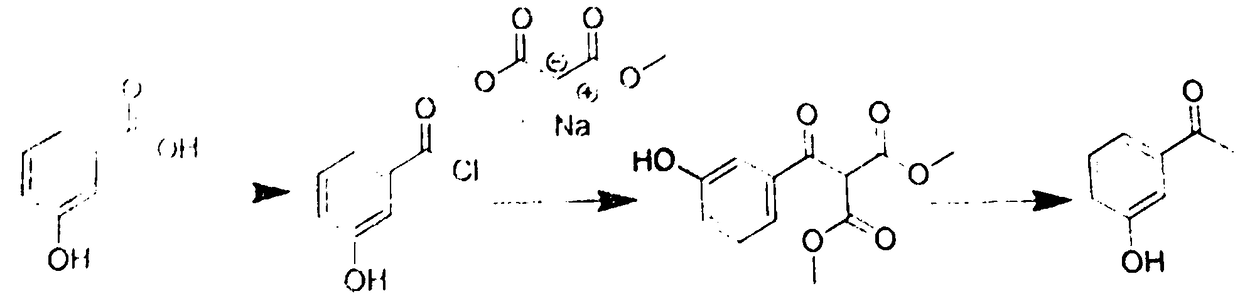

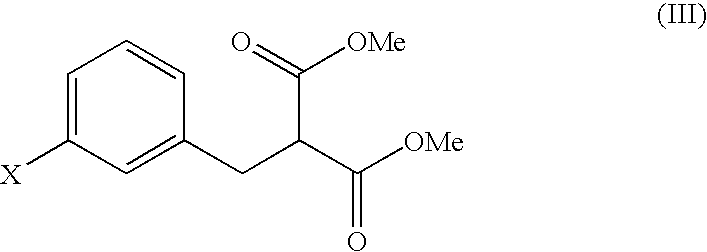

M-hydroxy acetophenone preparation method

InactiveCN108530277AImprove securityPromote environmental protectionOrganic compound preparationCarboxylic acid esters preparationReaction temperatureEvaporation

The invention discloses an m-hydroxy acetophenone preparation method which includes the steps: performing chlorination, dissolving m-hydroxybenzoic acid in methylbenzene, adding 4-dimethylamino pyridine serving as a catalyst, adding acyl thionyl chloride for chlorination to obtain m-hydroxybenzoic acid acyl chloride, and then removing the acyl thionyl chloride by concentration and evaporation to obtain m-hydroxybenzoic acid acyl chloride-methylbenzene solution; dissolving dimethyl malonate sodium salt in methylbenzene to obtain dimethyl malonate sodium salt-methylbenzene solution, dripping them-hydroxybenzoic acid acyl chloride-methylbenzene solution obtained in the step (1) into the dimethyl malonate sodium salt-methylbenzene solution, and then performing reflux reaction for 3-5 hours atthe reaction temperature of 50-80 DEG C to obtain a product A; adding the obtained product A into hydrochloric acid solution, and performing hydrolysis reaction to obtain m-hydroxy acetophenone. Thepreparation method is simple in process, small in wastewater discharge amount, low in cost and high in yield and final product purity.

Owner:JIANGXI YONGTONG TECH

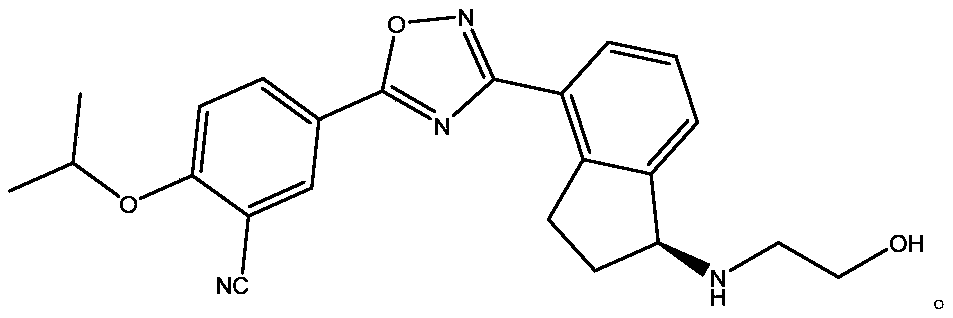

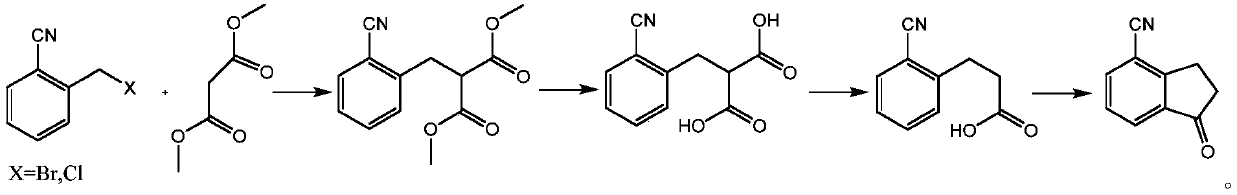

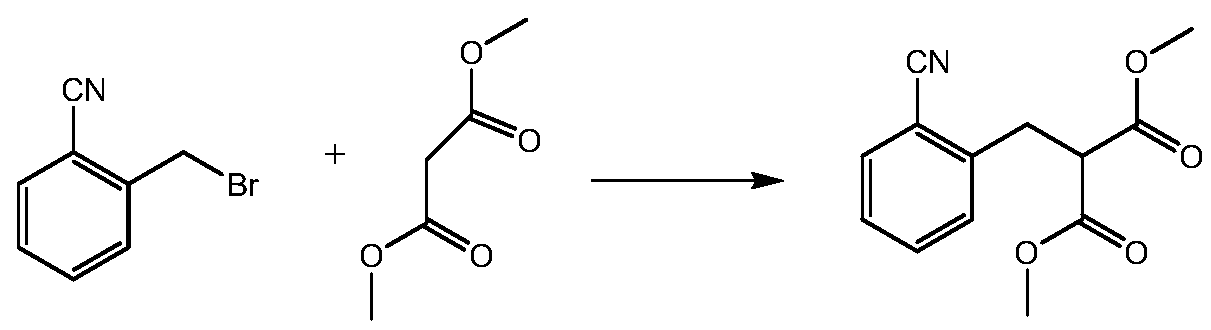

Preparation method of indanone intermediate

InactiveCN110627683ACarboxylic acid nitrile preparationOrganic compound preparationPropanoic acidOrganic solvent

The invention provides a preparation method of an indanone intermediate, and belongs to the field of pharmaceutical chemicals. The prepration method comprises the following steps: carrying out condensation reaction, hydrolysis and decarboxylation of 2-cyanobenzyl bromide or 2-cyanobenzyl chloride and dimethyl malonate in an organic solvent to obtain 2-cyanophenylpropionic acid; and reacting the obtained 2-cyanobenzene propionic acid with aluminum trichloride and an assistant agent to obtain 4-cyano-1-indanone. According to the invention, no highly toxic cyaniding reagent is needed, and the method has the advantages of high product purity, good safety, high yield, simple operation and the like. The method provided by the invention can effectively prepare the indanone intermediate, and provides favorable conditions for further preparation of ozanimod.

Owner:SUNSHINE LAKE PHARM CO LTD

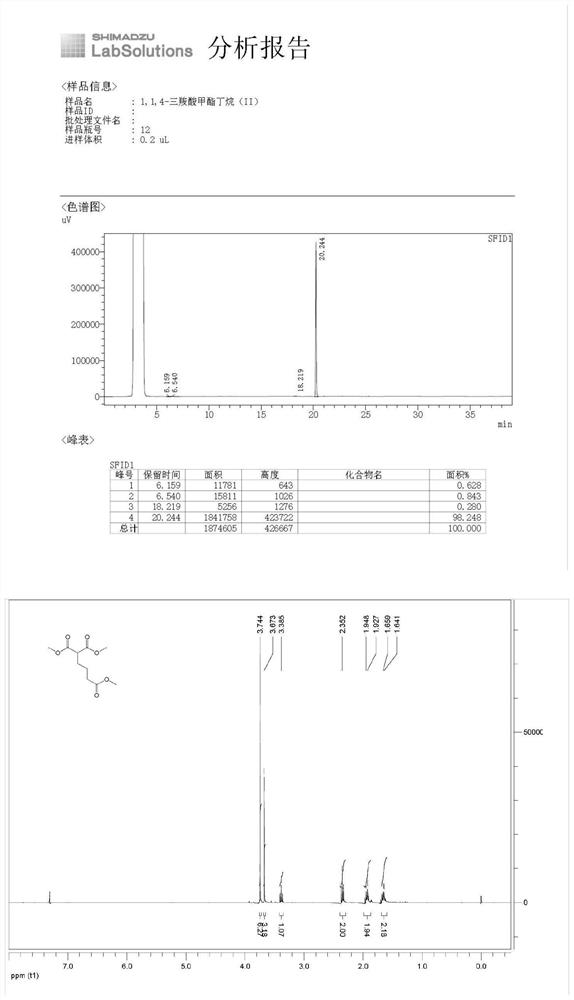

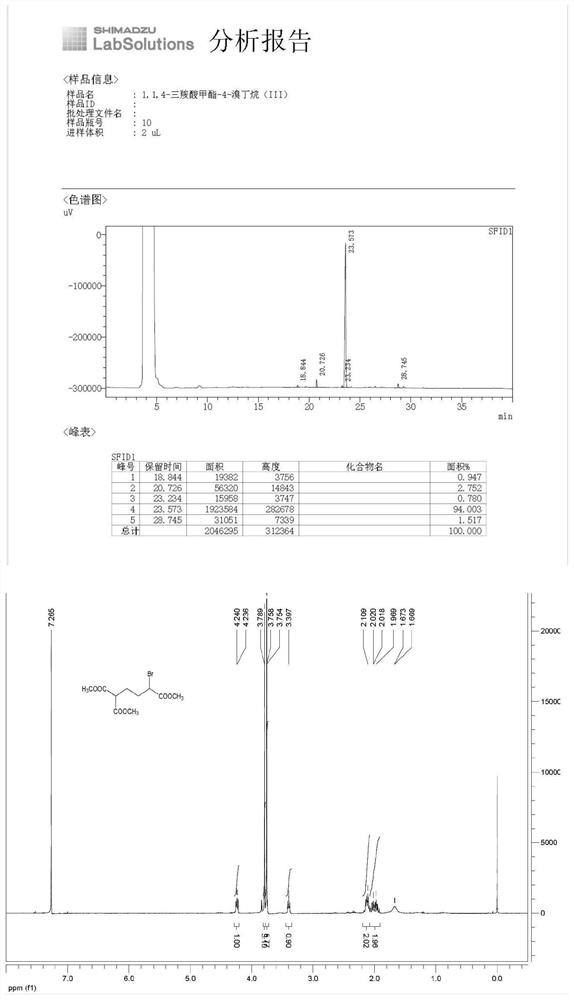

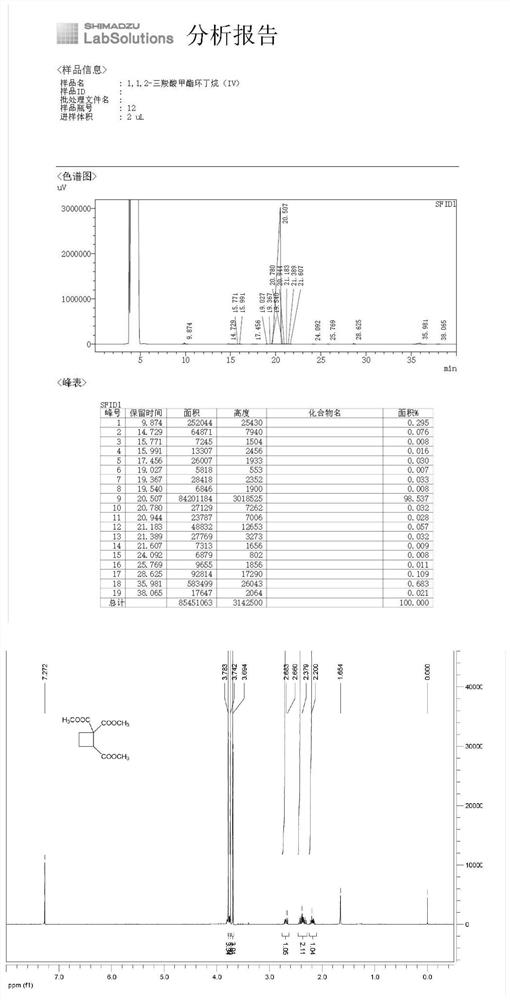

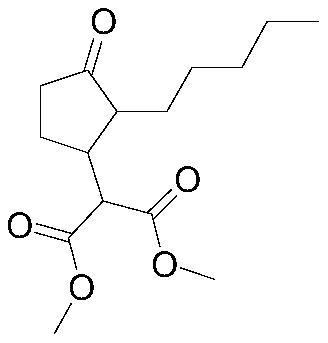

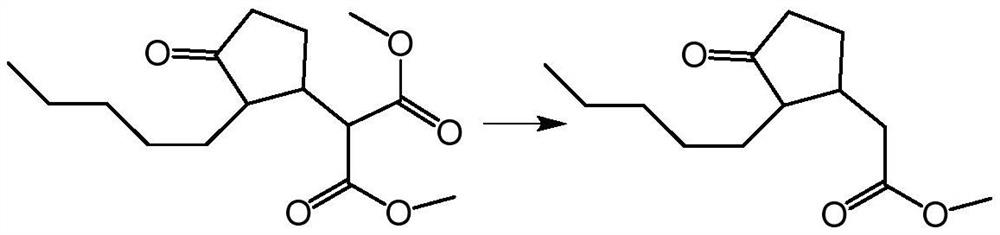

Preparation method of 3-(3-oxo-2-pentyl) cyclopentyl dimethyl malonate

ActiveCN111646899AReduce manufacturing costReduce generationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSodium methoxideMalonic acid

The invention relates to a preparation method of 3-(3-oxo-2-pentyl) cyclopentyl dimethyl malonate. The preparation method of the 3-(3-oxo-2-pentyl) cyclopentyl dimethyl malonate comprises the following step: in the presence of a transition metal complex and a catalytic additive, reacting 2-pentyl-2-cyclopentenone with dimethyl malonate in a reaction solvent to obtain the 3-(3-oxo-2-pentyl) cyclopentyl dimethyl malonate. According to the preparation method provided by the invention, a sodium methoxide strong base catalyst is not needed, the generation of salt-containing wastewater is avoided, the method is environment-friendly and high in yield, and meanwhile, the recycling of the catalyst is realized.

Owner:SHANDONG NHU PHARMA

Efficient glass product cleaning agent

InactiveCN104877786AShort cleaning timeEasy to operateNon-ionic surface-active compoundsDetergent compounding agentsOctanoic AcidsDodecane

The invention discloses an efficient glass product cleaning agent, which is prepared from the following raw materials in parts by weight: 3-5 parts of sodium tripolyphosphate, 1-3 parts of sodium hydroxide, 4-12 parts of isopropyl alcohol, 6-11 parts of dodecyl diphenyl ether sodium disulfonate, 4.5-6.5 parts of sodium silicate, 2.4-4.8 parts of ethanol, 12-24 parts of ammonium polyphosphate, 6-10 parts of acetone, 7-14 parts of stannous octoate, 15-25 parts of methyl malonate, 4-8 parts of a silane coupling agent, 8-14 parts of ferric oxide, 3-7 parts of succinic acid, 4-10 parts of fatty alcohol-polyoxyethylene ether, 3-5 parts of sodium hypochlorite and 2-7 parts of sodium chloride. The efficient glass product cleaning agent has the beneficial effects that the efficient glass product cleaning agent has an efficient cleaning function, and is short in cleaning time and convenient to operate; and the work efficiency is improved.

Owner:QINGDAO DEXITUOCHUANG HIGH TECH CO LTD

Preparation method of 2,4-dyhydroxyl-5-pyrimidinecarboxylic acid

The invention discloses a preparation method of 2,4-dyhydroxyl-5-pyrimidinecarboxylic acid. The method comprises the following steps: with ethyl alcohol as a solvent, and methoxy methylene dimethyl malonate and urea as raw materials, adding sulfamic acid as a catalyst, heating, refluxing and carrying out condensation reaction, and distilling to remove an organic solvent; washing and drying to obtain a condensation product; carrying out a ring-closing reaction on the condensation product and a sodium hydroxide solution; and cooling to a room temperature, neutralizing excessive sodium hydroxide with hydrochloric acid, carrying out acidified hydrolysis, filtering, and washing with ice water for a plurality of times, so as to prepare a product 2,4-dyhydroxyl-5-pyrimidinecarboxylic acid. The preparation method disclosed by the invention has the characteristics of being simple in technological operation, cheap and available in raw material, mild in reaction condition, and simple in post-treatment; and the obtained yield can be accepted by industrialized production.

Owner:QUZHOU UNIV

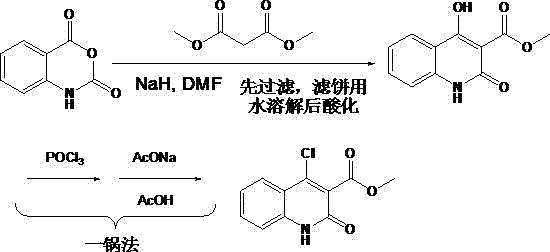

Improved method of synthesizing 4-chlorine-1hydrogen-quinoline-2-ketone-3-carboxylic methyl ester by isatoic anhydride

The invention discloses an improved method of synthesizing 4-chlorine-1hydrogen-quinoline-2-ketone-3-carboxylic methyl ester by isatoic anhydride. The method includes: improving aftertreatment mode of 4-chlorine-1hydrogen-quinoline-2-ketone-3-carboxylic methyl ester and high-yield one-pot process synthesis in the subsequent process. The improved method has the advantages that isatoic anhydride is purified by means of filtering first and acidifying second after reacting with dimethyl malonate in DMF, so that consumption of water and hydrochloric acid is reduced obviously, and generation of wastewater is reduced; compared with treatment modes mentioned in existing reports, an improved treatment mode has the advantages of high yield and zero solvent residue. Synthesis of 4-chlorine-1hydrogen-quinoline-2-ketone-3-carboxylic methyl ester through a 4-chlorine-1hydrogen-quinoline-2-ketone-3-carboxylic methyl ester one-pot process has the advantages of being free of water participation in the process of synthesis, simple to operate, free of organic solvent consumption in the subsequent process and high in yield. Compared with conventional synthesis methods, the method is simple to operate, low in cost and low in wastewater discharge and has important actual application value in the field of chemical industry production.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 4-[(4,6-dihydroxyl-2-pyrimidinyl)amino] cyanobenzene Preparation method of 4-[(4,6-dihydroxyl-2-pyrimidinyl)amino] cyanobenzene](https://images-eureka.patsnap.com/patent_img/03863a37-c69d-4047-b43a-a13380a706f7/B2009101020073D0000011.PNG)

![Preparation method of 4-[(4,6-dihydroxyl-2-pyrimidinyl)amino] cyanobenzene Preparation method of 4-[(4,6-dihydroxyl-2-pyrimidinyl)amino] cyanobenzene](https://images-eureka.patsnap.com/patent_img/03863a37-c69d-4047-b43a-a13380a706f7/B2009101020073D0000012.PNG)

![Preparation method of 4-[(4,6-dihydroxyl-2-pyrimidinyl)amino] cyanobenzene Preparation method of 4-[(4,6-dihydroxyl-2-pyrimidinyl)amino] cyanobenzene](https://images-eureka.patsnap.com/patent_img/03863a37-c69d-4047-b43a-a13380a706f7/B2009101020073D0000021.PNG)