Method for preparing Guerbet acids by taking malonate as raw material

A technology of malonate and alkyl malonate, which is applied in the field of Guerbet acid preparation technology, can solve the problems that have not been reported in the literature, the reaction is difficult, and the corrosion is large, so as to avoid the reaction difficulty and be easy to operate , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

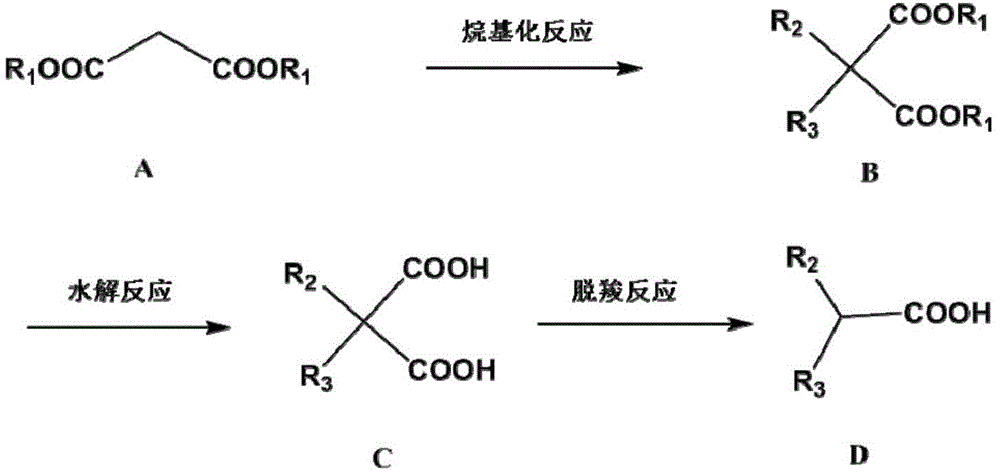

Method used

Image

Examples

Embodiment 1

[0024] Under nitrogen protection, put 100g of diethyl malonate and 300mL of absolute ethanol into a 1000mL three-necked round-bottomed flask, add 40.5g of sodium methoxide at room temperature, then slowly add 102.8g of bromobutane, and heat up after the addition Reflux and react for 3 hours; cool down to room temperature, then add 40.5g of sodium methoxide, then slowly add 102.8g of bromobutane, and heat up and reflux for 3 hours. Cool down to room temperature, remove the solvent, add 1mol / L sulfuric acid aqueous solution to neutralize the system until the pH value is about 7, wash the organic phase with water, and distill under reduced pressure to obtain diethyl dibutylmalonate, 154g (90.6% yield).

[0025] Take 100g diethyl dibutylmalonate, 550mL sodium hydroxide aqueous solution (the concentration of sodium hydroxide is 4mol / L), and 100mL ethanol were added to a 1000mL round bottom flask, heated to reflux for 12h, cooled to room temperature, and added 4mol / L Sulfuric acid w...

Embodiment 2

[0028] Under nitrogen protection, put 100g of diethyl malonate and 300mL of absolute ethanol into a 1000mL three-necked round-bottomed flask, add 40.5g of sodium methoxide at room temperature, then slowly add 102.8g of bromobutane, and heat up after the addition Reflux and react for 3 hours; cool down to room temperature, then add 40.5g of sodium methoxide, then slowly add 91.2g of chloro-n-hexane, heat up and reflux for 3 hours. Cool to room temperature, remove solvent, add 1mol / L sulfuric acid aqueous solution and neutralize system to about pH value 7, organic phase washing, underpressure distillation obtain 2-butyl-2-hexyldiethyl malonate, 167g (productivity 89.1%).

[0029] Take 100g of diethyl 2-butyl-2-hexylmalonate, 500mL of sodium hydroxide aqueous solution (4mol / L), and 100mL of ethanol into a 1000mL round bottom flask, heat to reflux for 12h, cool down to room temperature, and add 4mol / L Sulfuric acid adjusted the pH value to about 1.9, left standing, the upper laye...

Embodiment 3

[0032] Under the protection of nitrogen, put 100g of diethyl malonate and 300mL of absolute ethanol into a 1000mL three-necked round-bottomed flask, add 40.5g of sodium methoxide at room temperature, then slowly add 91.2g of chloro-n-hexane, and then raise the temperature to reflux , reacted for 3h; cooled down to room temperature, then added 40.5g of sodium methoxide, then slowly added 91.2g of chloro-n-hexane, heated to reflux for 3h. Cool down to room temperature, remove the solvent, add 1mol / L sulfuric acid aqueous solution to neutralize the system to a pH value of about 7, wash the organic phase with water, and distill under reduced pressure to obtain diethyl dihexylmalonate, 184g (89.7% yield).

[0033]Take 100g diethyl dihexylmalonate, 450mL aqueous sodium hydroxide solution (4mol / L), and 100mL ethanol into a 1000mL round bottom flask, heat to reflux for 12h, cool down to room temperature, add 4mol / L sulfuric acid to adjust the pH value to 1.9 Left and right, stand stil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com