M-hydroxy acetophenone preparation method

A technology of m-hydroxyacetophenone and hydroxyacetophenone, which is applied in the field of preparation of m-hydroxyacetophenone, can solve the problems of large waste water discharge, high environmental protection cost, and high cost, and achieve small waste water discharge, avoid pollution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

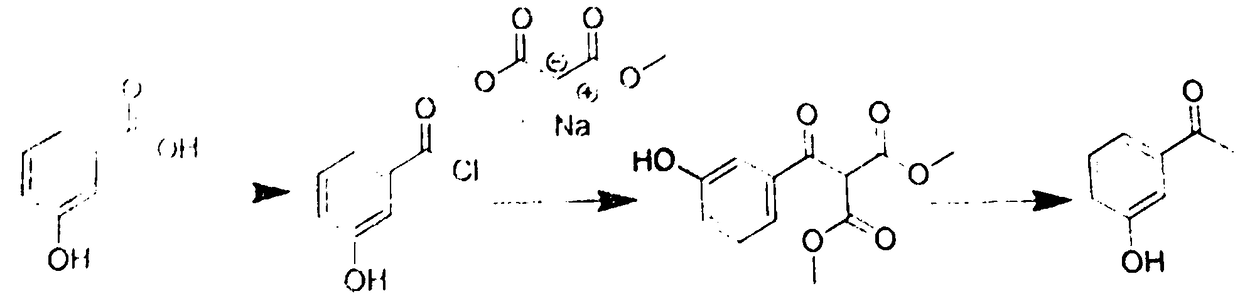

Image

Examples

Embodiment 1

[0031] A preparation method of m-hydroxyacetophenone, which comprises the following steps:

[0032] (1) Chlorination, dissolve meta-hydroxybenzoic acid in toluene, add 4-dimethylaminopyridine as a catalyst, and then add thionyl chloride for chlorination to obtain meta-hydroxybenzoic acid chloride, which is then concentrated and evaporated. Remove thionyl chloride to obtain m-hydroxybenzoic acid chloride-toluene solution;

[0033] (2) Dissolve dimethyl malonate sodium salt in toluene to obtain dimethyl malonate sodium salt-toluene solution, and then add the m-hydroxybenzoic acid chloride-toluene solution obtained in step (1) dropwise to the malonate Dimethyl acid sodium salt-toluene solution, and then react, and reflux reaction is performed at a reaction temperature of 60°C for 4 hours to obtain product A;

[0034] (3) Add the product A obtained in step (2) to a hydrochloric acid solution, and perform a hydrolysis reaction to obtain m-hydroxyacetophenone.

[0035] In the step (1) the ...

Embodiment 2

[0040] A preparation method of m-hydroxyacetophenone, which comprises the following steps:

[0041] (1) Chlorination, dissolve meta-hydroxybenzoic acid in toluene, add 4-dimethylaminopyridine as a catalyst, and then add thionyl chloride for chlorination to obtain meta-hydroxybenzoic acid chloride, which is then concentrated and evaporated. Remove thionyl chloride to obtain m-hydroxybenzoic acid chloride-toluene solution;

[0042] (2) Dissolve dimethyl malonate sodium salt in toluene to obtain dimethyl malonate sodium salt-toluene solution, and then add the m-hydroxybenzoic acid chloride-toluene solution obtained in step (1) dropwise to the malonate In the dimethyl acid sodium salt-toluene solution, the reaction is carried out, and the reflux reaction is carried out at a reaction temperature of 70° C. for 4 hours to obtain product A;

[0043] (3) Add the product A obtained in step (2) to a hydrochloric acid solution, and perform a hydrolysis reaction to obtain m-hydroxyacetophenone. ...

Embodiment 3

[0049] A preparation method of m-hydroxyacetophenone, which comprises the following steps:

[0050] (1) Chlorination, dissolve meta-hydroxybenzoic acid in toluene, add 4-dimethylaminopyridine as a catalyst, and then add thionyl chloride for chlorination to obtain meta-hydroxybenzoic acid chloride, which is then concentrated and evaporated. Remove thionyl chloride to obtain m-hydroxybenzoic acid chloride-toluene solution;

[0051] (2) Dissolve dimethyl malonate sodium salt in toluene to obtain dimethyl malonate sodium salt-toluene solution, and then add the m-hydroxybenzoic acid chloride-toluene solution obtained in step (1) dropwise to the malonate In the dimethyl acid sodium salt-toluene solution, the reaction is carried out, and the reflux reaction is carried out at a reaction temperature of 75°C for 4.2 hours to obtain product A;

[0052] (3) Add the product A obtained in step (2) to a hydrochloric acid solution, and perform a hydrolysis reaction to obtain m-hydroxyacetophenone. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com