Patents

Literature

42results about How to "Increase surface activation energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-dispersing nanometer silver and high-performance conductive adhesive

InactiveCN102199407AIncrease surface activation energyHigh grafting rateNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyAdhesive

The invention discloses high-dispersing nanometer silver and a high-performance conductive adhesive. A preparation method for the high-performance conductive adhesive comprises the following steps of: mixing an epoxy resin curing agent and an accelerating agent uniformly; mixing the high-dispersing nanometer silver and epoxy resin uniformly; and dripping a mixture of the epoxy resin curing agent and the accelerating agent into a mixed component of the high-dispersing nanometer silver and the epoxy resin, which are being mixed, at the temperature of between 10 and 25 DEG C, and mixing for 3 to 10 hours to obtain the high-performance conductive adhesive. The nanometer silver can be fixed in the epoxy resin and has the excellent dispersibility in the epoxy resin, and the conductive adhesive prepared from the nanometer silver can fix a conductive network in the conductive adhesive, improve electric conductivity and solve the problem of silver migration in the using process of conductive silver. In addition, in epoxy resin of the high-performance conductive adhesive, four epoxy resin combinations with different functions are adopted, so the defects of insufficient bonding strength and shear strength in the current conductive adhesive are overcome.

Owner:中科广化(重庆)新材料研究院有限公司 +3

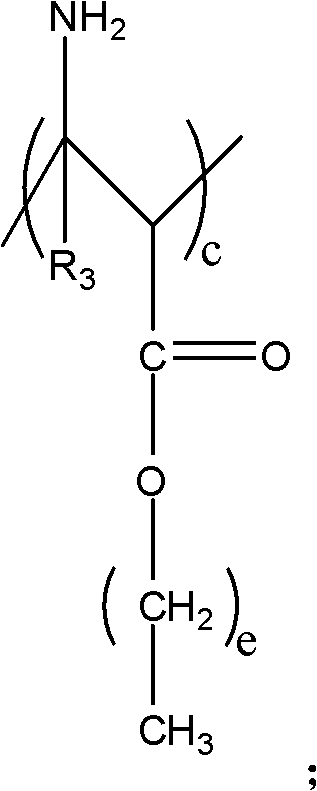

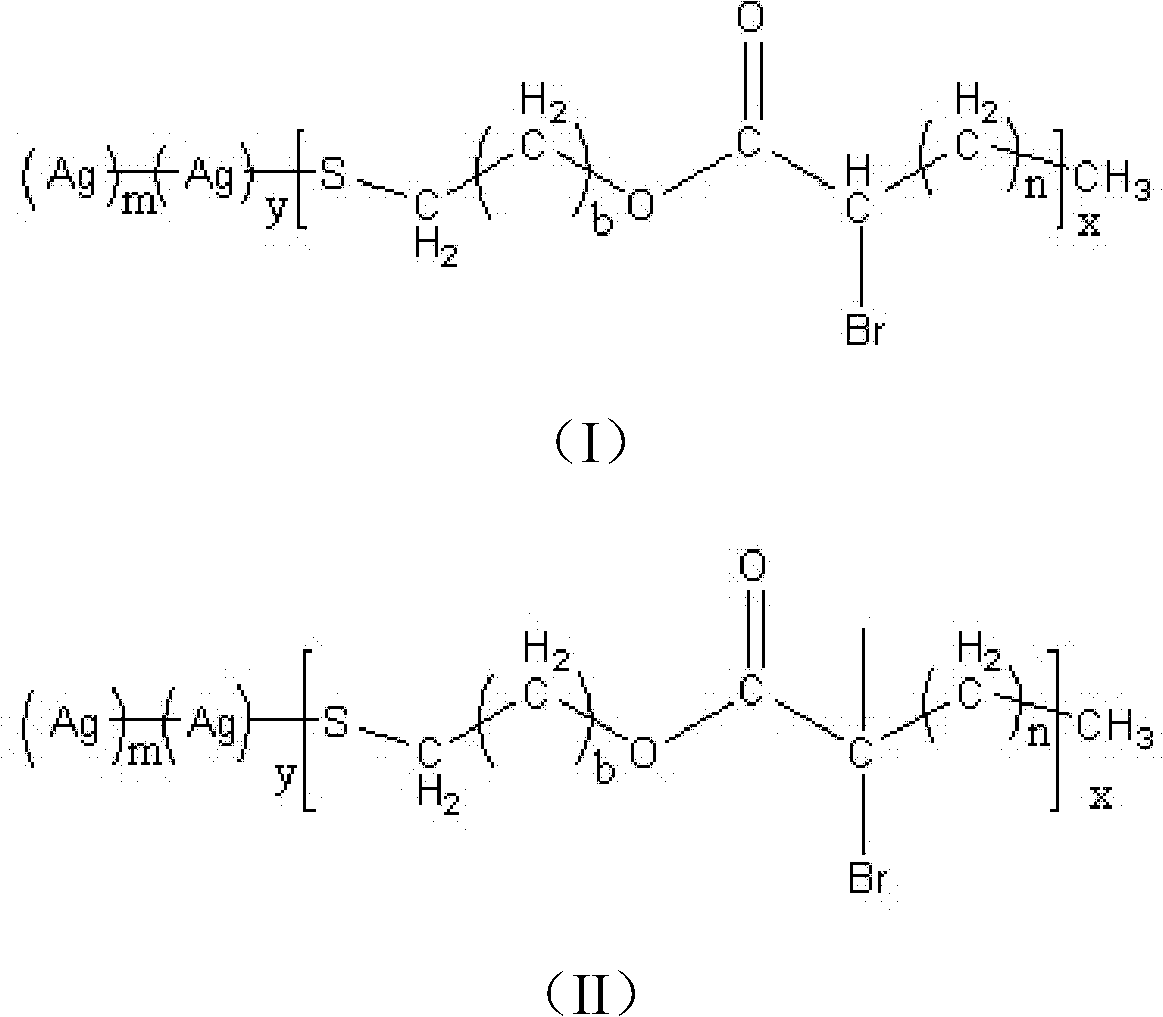

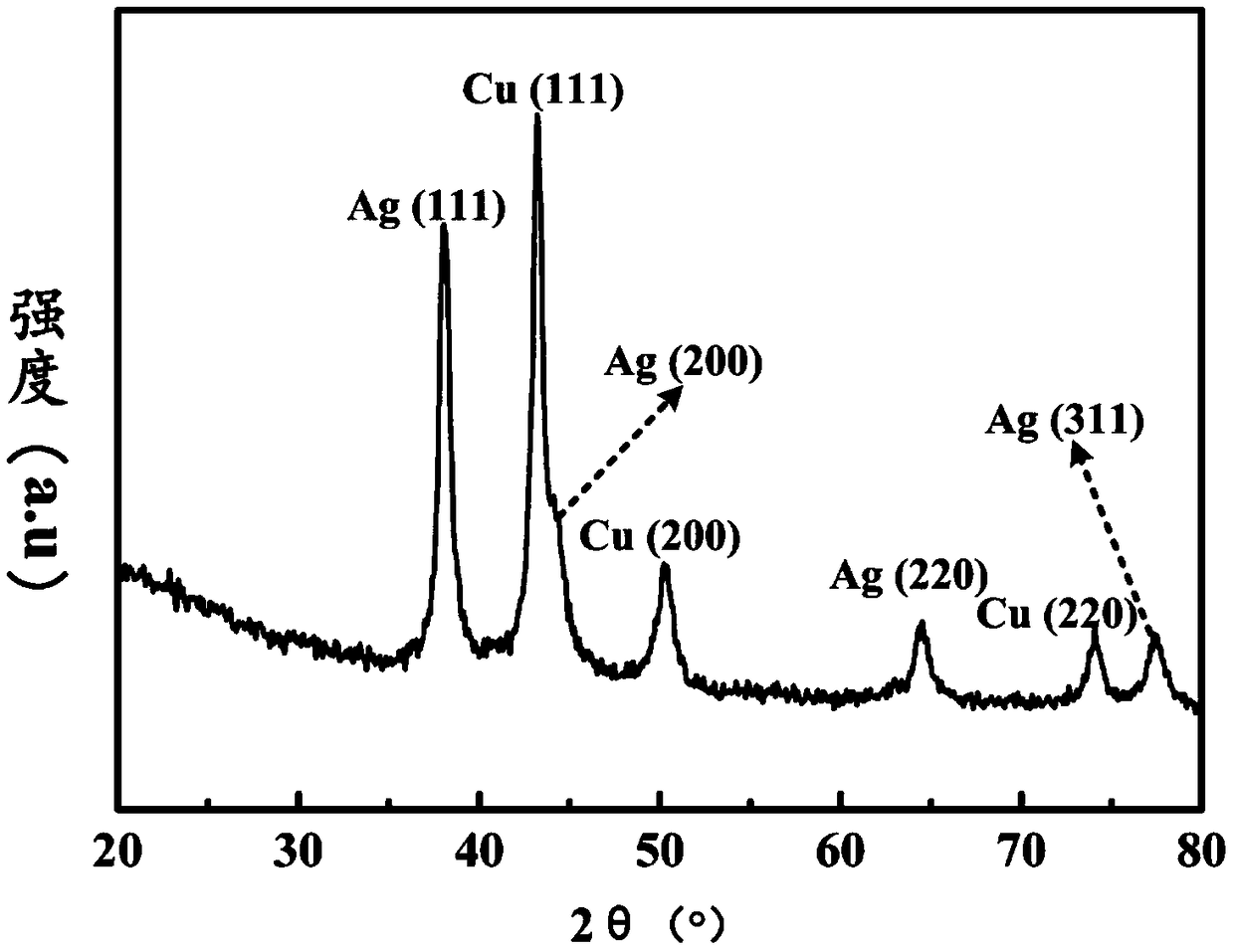

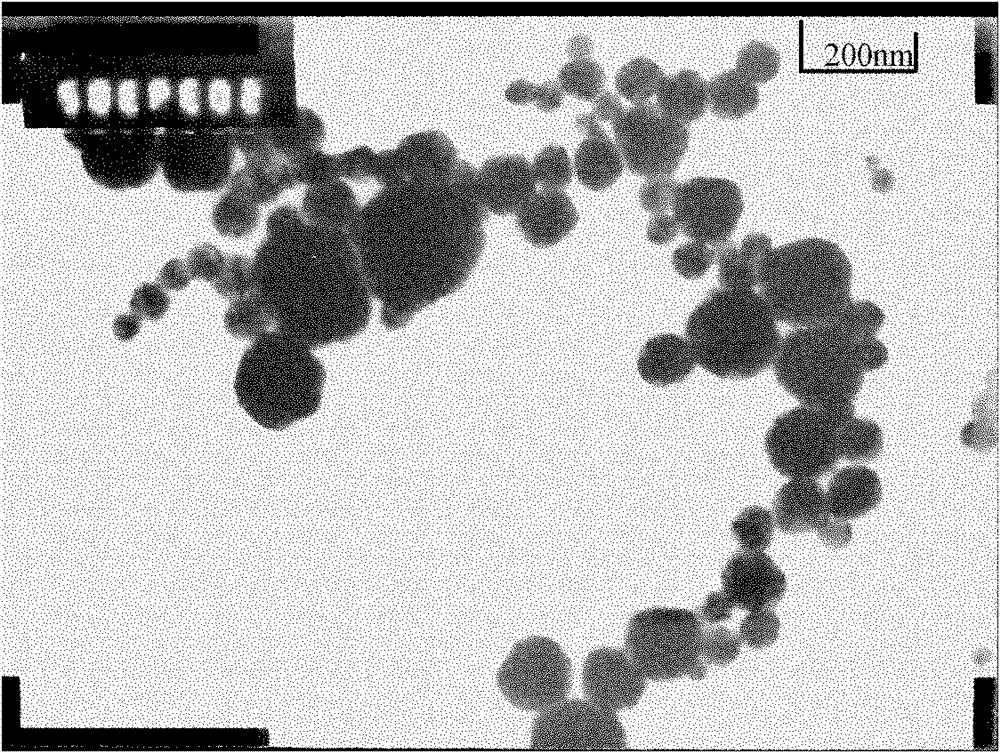

Alloy nanometer particle soldering paste and preparation method thereof

InactiveCN109352206ASimple processProcess parameters are easy to controlWelding/cutting media/materialsSoldering mediaAlloyCleansing Agents

The invention belongs to the field of nanometer technology and microelectronic packaging and discloses alloy nanometer particle soldering paste and a preparation method thereof. The method includes the specific steps that metal salt and a stabilizing agent are completely dissolved in a solvent to prepare a metal salt solution, a reducing agent is added in the metal salt solution and is stirred, and is enabled to perform a full reaction, and an alloy nanometer particle suspension is acquired; the alloy nanometer particle suspension is subjected to solid-liquid separation, precipitate is obtained, the precipitate is washed with a washing agent, and then drying is performed so that alloy nanometer particles can be obtained; and the alloy nanometer particles are added into an organic thickening agent, and after vacuum stirring and bubble removing treating, the alloy nanometer particle soldering paste is made. According to the alloy nanometer particle soldering paste and the preparation method thereof, the alloy nanometer particles are prepared by adopting a liquid phase reducing method, the process is simple, control is easy, and cost is low; and the stabilizing agent is added in whilethe metal salt solution is prepared, agglomeration and oxidization of the particles can be effectively avoided, and the oxidization resistance of the alloy nanometer particles is enhanced.

Owner:HUAZHONG UNIV OF SCI & TECH

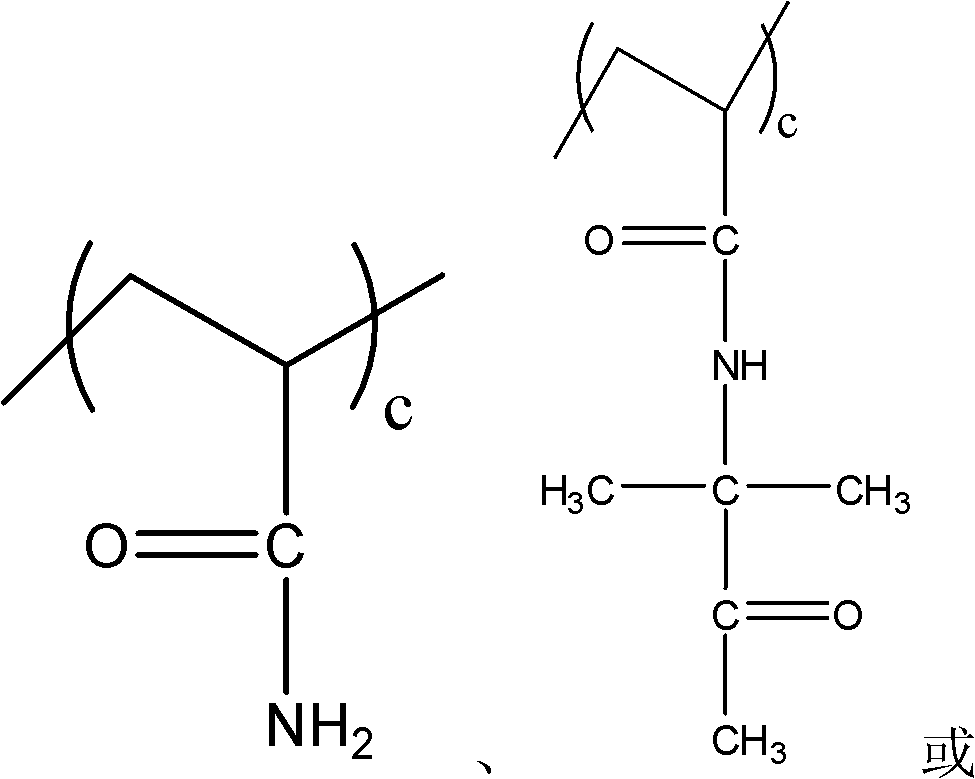

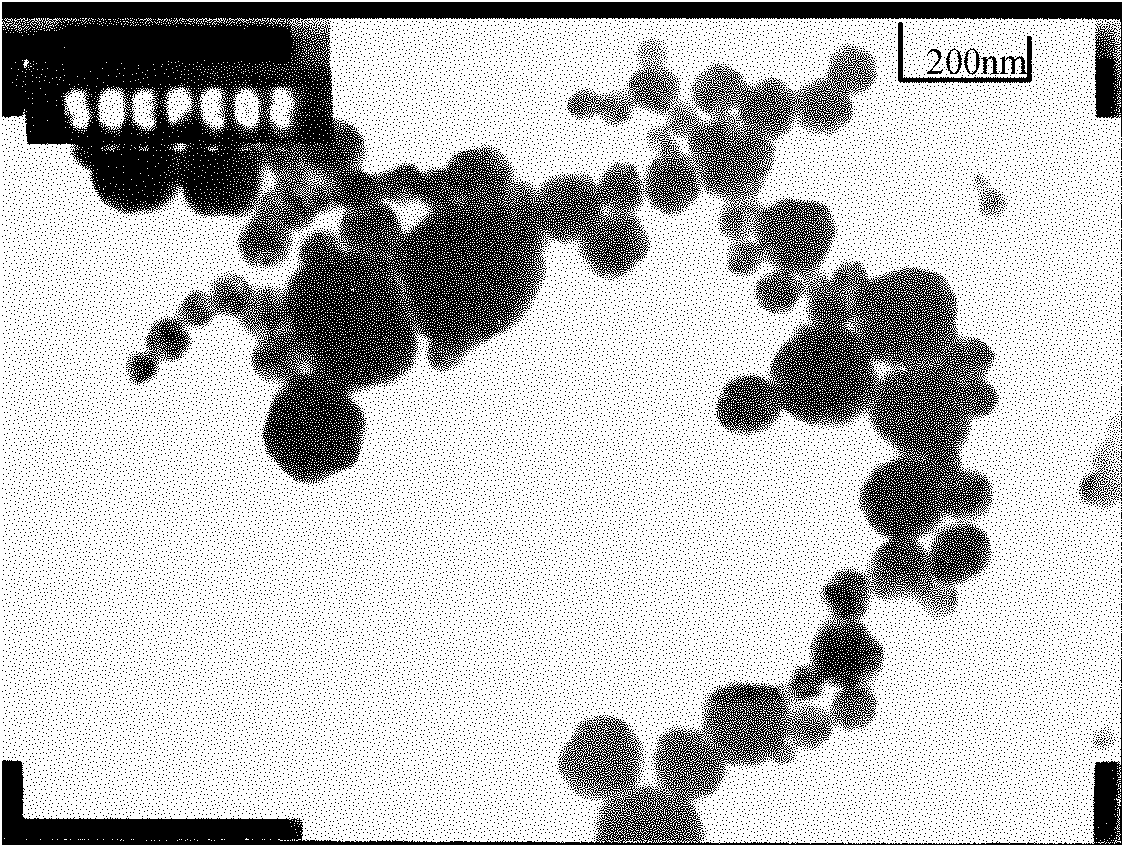

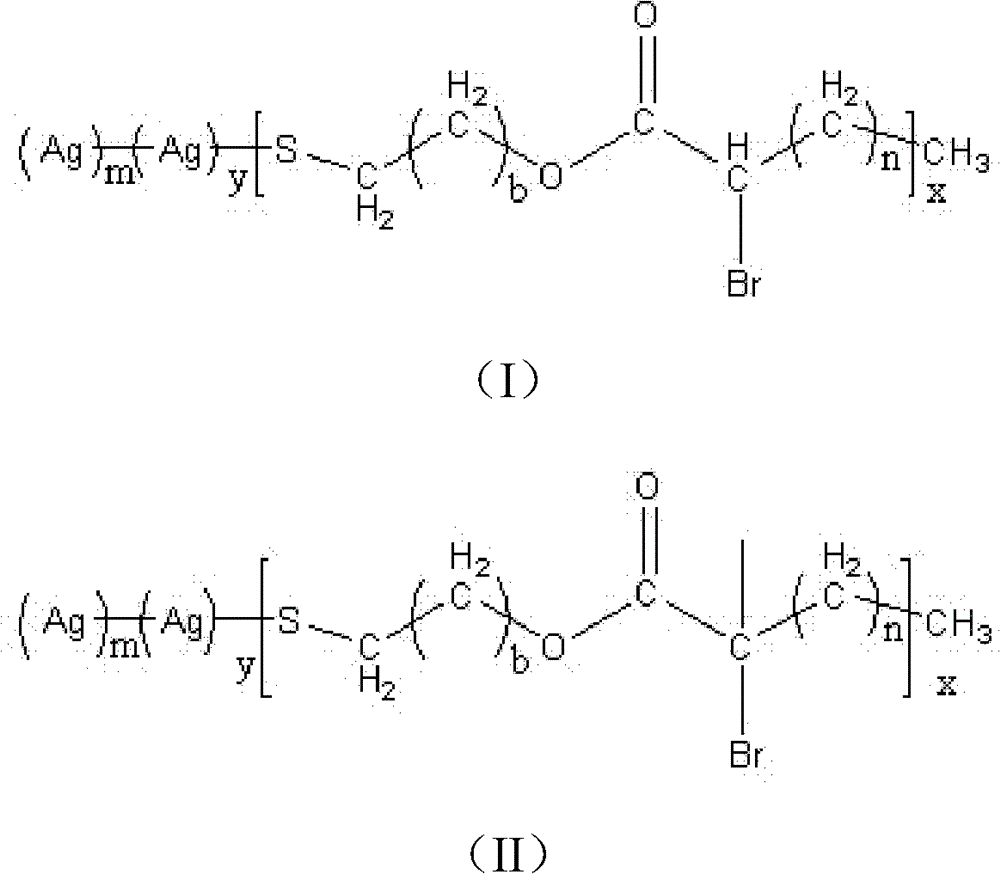

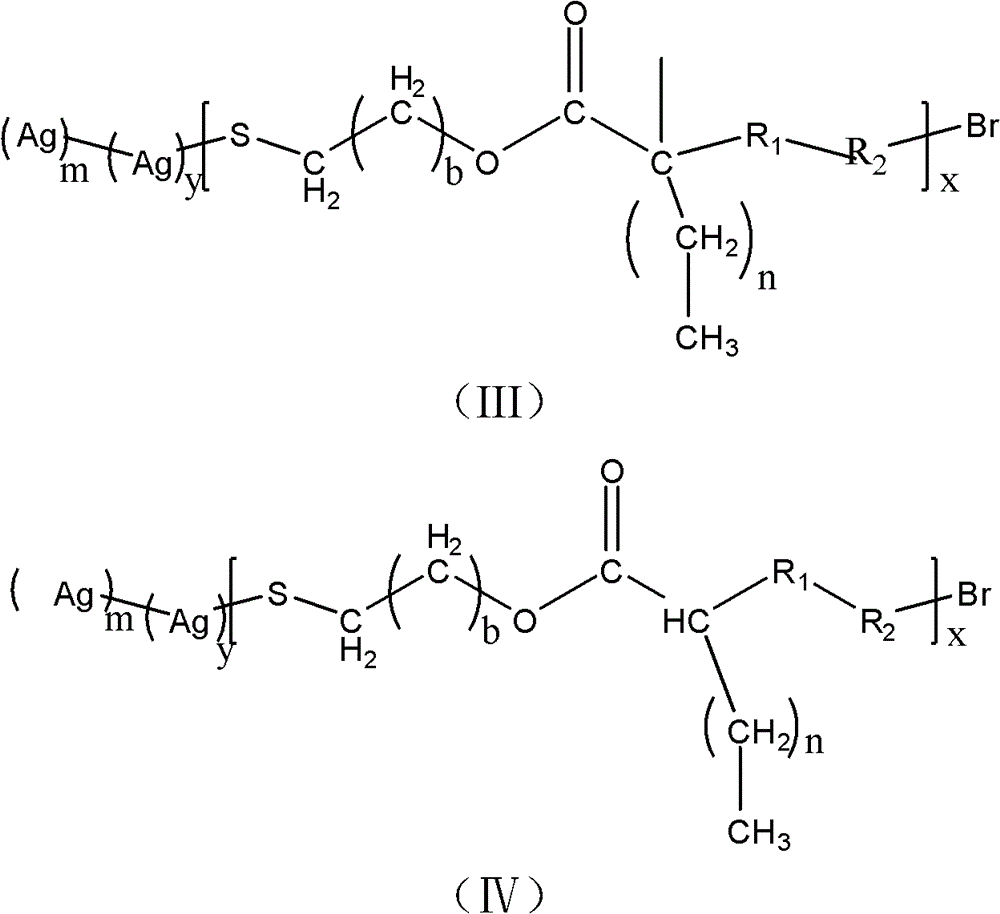

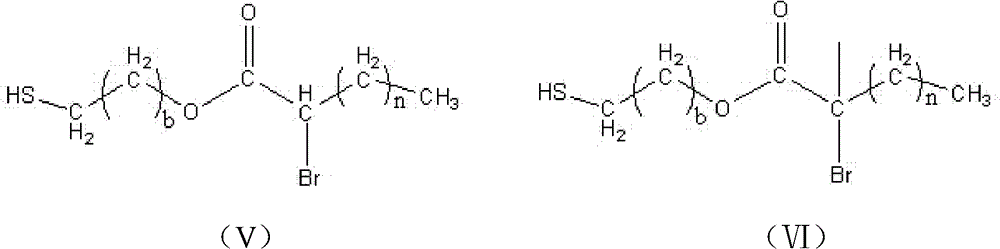

Nano silver capable of being scattered in hydrophobic system and preparation method and application thereof

InactiveCN102059347AIncrease surface activation energyGood modification effectHigh surfaceBiological activation

The invention discloses nano silver capable of being scattered in a hydrophobic system and a preparation method and the application thereof. The preparation method comprises the steps of: adding modifiers during the later period of preparing conventional nano silver so as to obtain the nano silver capable of being scattered in the hydrophobic system. Because the modifiers are added during the later period of preparing the conventional nano silver, the obtained modified nano silver has high surface activation, good scattering performance, and excellent electric conduction performance. The method has broad range of applications, and can be used for modifying various features of nano silver. The nano silver capable of being scattered in the hydrophobic system has strong washing fastness and still keeps good scattering performance after being washed for several times, the preparation method of the nano silver has simple technology, low cost, and broad application range. The invention overcomes a series of defects of the prior art.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

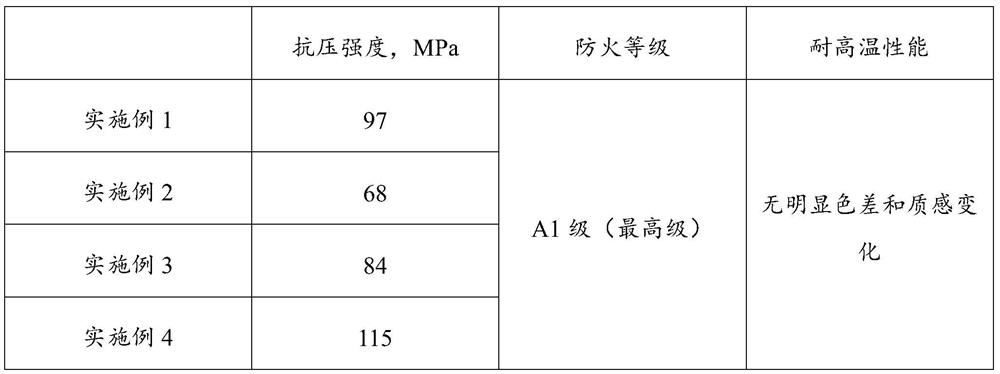

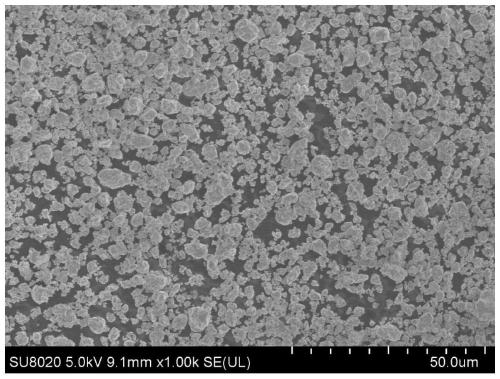

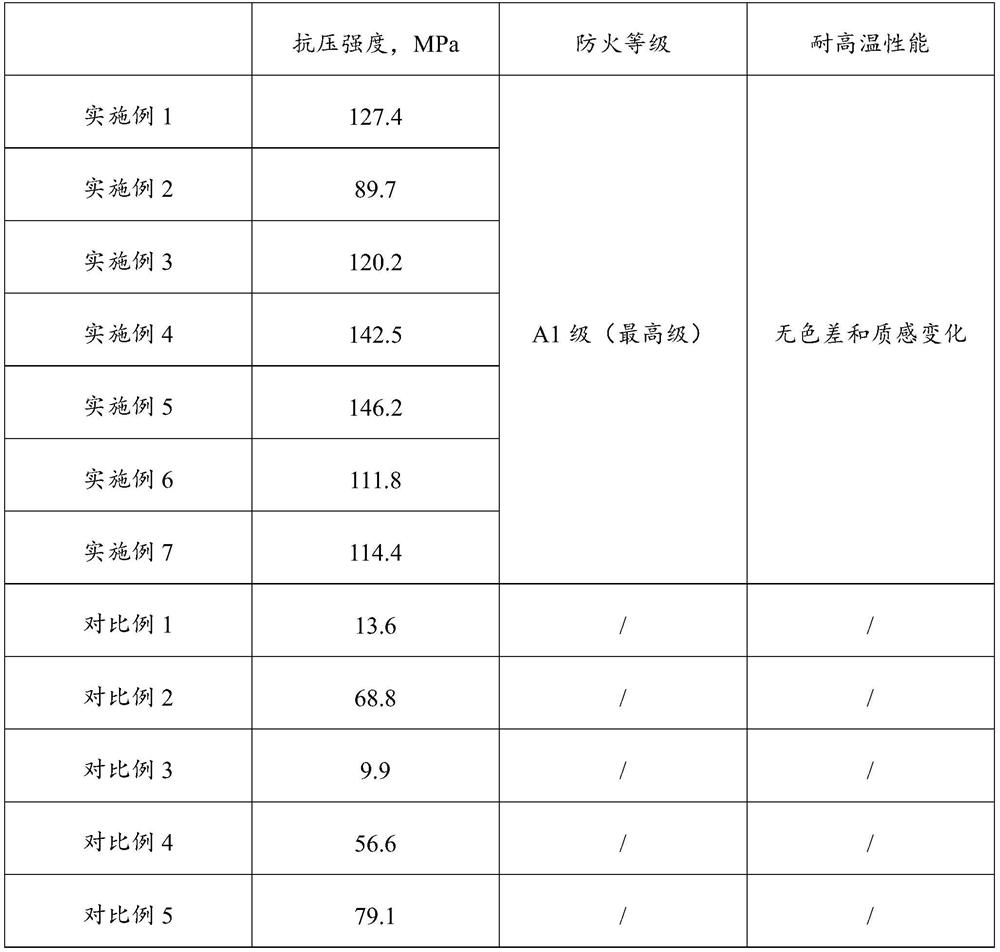

Solid waste-based inorganic artificial stone plate and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to a solid waste-based inorganic artificial stone plate and a preparation method thereof. The solid waste-based inorganic artificial stone plate comprises, by weight, 46-66 parts of a solid waste-based material, 90-165 parts of quartz sand, 4-12 parts of an excitant, 7-16 parts of water, 0-2 parts of a water reducing agent and 0-10 parts of an inorganic pigment. The water consumption is low, generation of pores in the product due to excessive moisture is avoided, and the strength and other mechanical properties of the plate are improved; reinforcing materials such as fibers, resin and polyvinyl alcohol do not need to be additionally added, the chemical activity of solid waste is fully utilized, allthe raw materials are matched and used in proportion, that is, the solid waste-based inorganic artificial stone plate with high polymerization degree, high compactness and high strength can be generated in situ through the coordination effect of all the components, the mechanical property requirement of the artificial stone plate is met, the economic cost is effectively reduced, no free formaldehyde is released, and the solid waste-based inorganic artificial stone plate is more environmentally friendly, better in fireproof and high-temperature-resistant performance and wide in application prospect.

Owner:UNIV OF JINAN

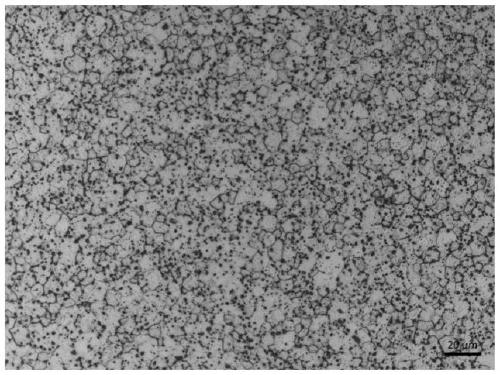

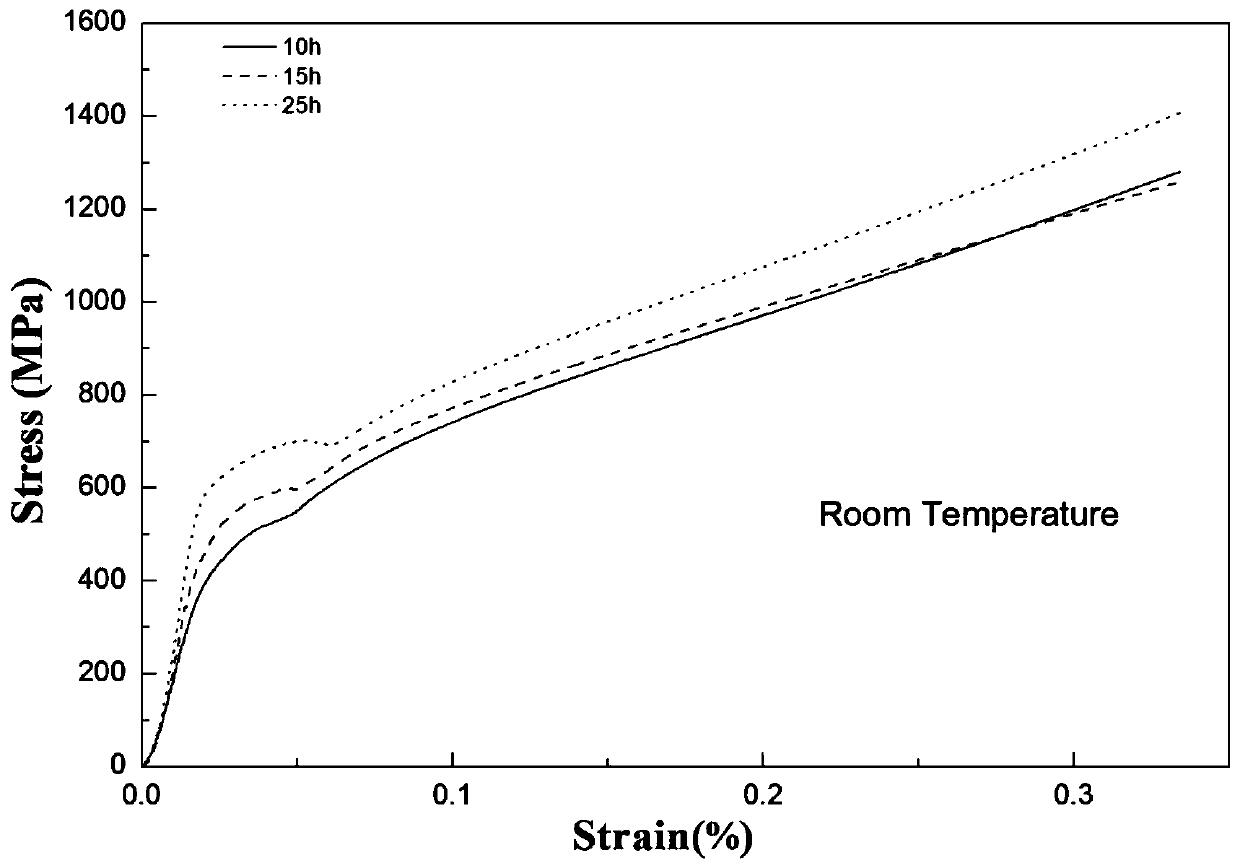

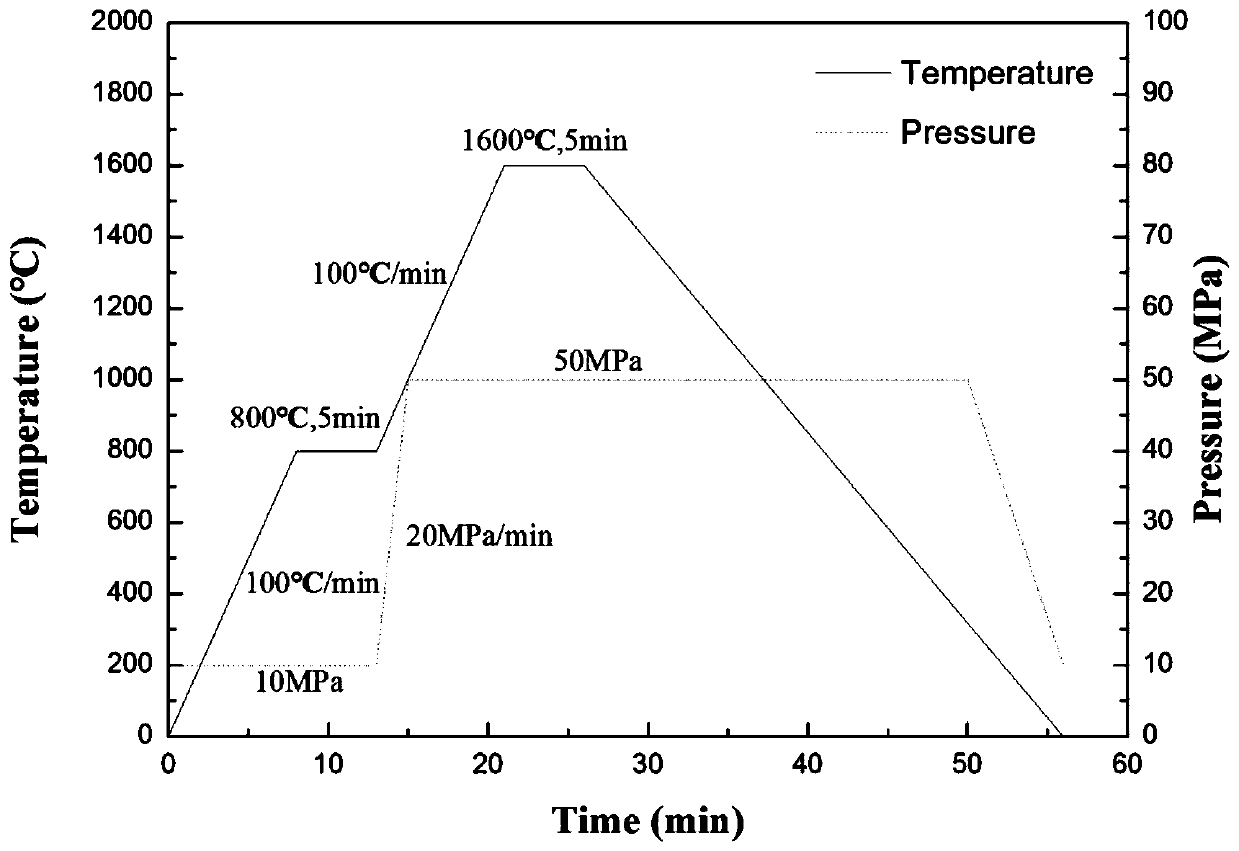

High-strength Mo-Ti-Zr-CNT molybdenum alloy composite material and preparation method thereof

The invention discloses a high-strength Mo-Ti-Zr-CNT molybdenum alloy composite material and a preparation method thereof. Traditional graphite is replaced with a carbon nanotube, and the carbon nanotube serves as a carbon source of a TZM molybdenum alloy, a molybdenum alloy obtained by doping TiH2, ZrH2 and CNT in molybdenum, and the molybdenum alloy is prepared from the components in percentageby mass: 0.5% of Ti, 0.1% of Zr, 0.03% of CNT, and the balance of Mo. According to the high-strength Mo-Ti-Zr-CNT molybdenum alloy composite material and the preparation method thereof, technologies such as ball milling and spark plasma sintering are optimized, and the hardness and the yield strength of the prepared Mo-Ti-Zr-CNT molybdenum alloy composite material are effectively improved.

Owner:HEFEI UNIV OF TECH

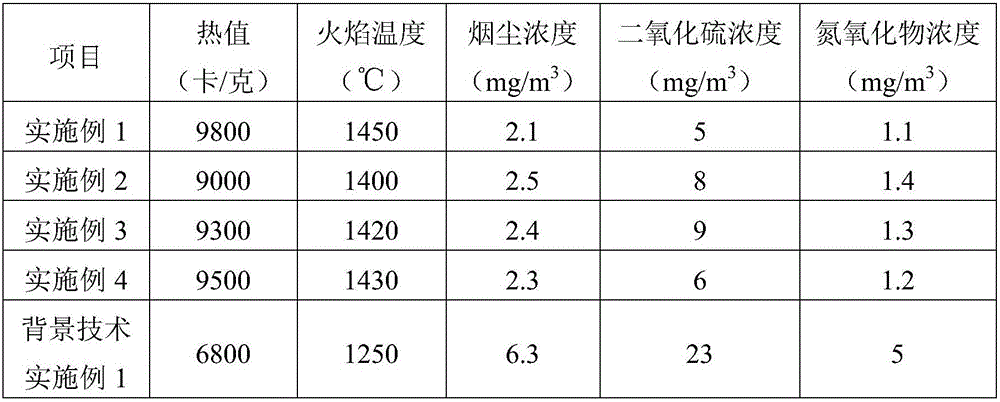

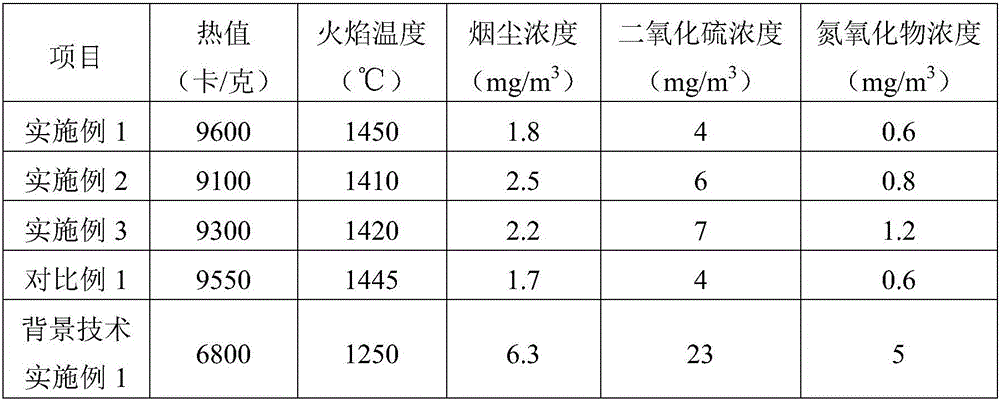

Alcohol-base fuel

InactiveCN106381176AReduce volatilityImprove flammabilityLiquid carbonaceous fuelsFuel additivesIsobutanolGlycerol

The invention discloses an alcohol-base fuel which is prepared from the following components in parts by weight: 70-80 parts of methanol, 2-4 parts of isobutanol, 3-6 parts of tert-butyl alcohol, 2-4 parts of propanediol, 0.6-0.8 part of polyethyleneglycol, 1-3 parts of isopropyl ether, 0.4-0.8 part of tertiary pentyl methyl ether, 3-5 parts of hydrogen peroxide, 0.02-0.05 part of triethylborane, 0.01-0.03 part of triethyl aluminum, 0.3-0.7 part of glycerol, 0.02-0.04 part of ethylene-vinyl acetate copolymer, 0.01-0.03 part of dimethyl silicone oil, 0.3-0.5 part of ethyl acetate, 0.6-0.8 part of nano magnesium powder and 0.4-0.6 part of nano iron oxide. The alcohol-base fuel has the characteristics of favorable combustion performance, especially high heat value, low corrosivity, high stability and the like, and thus, has wide development prospects.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

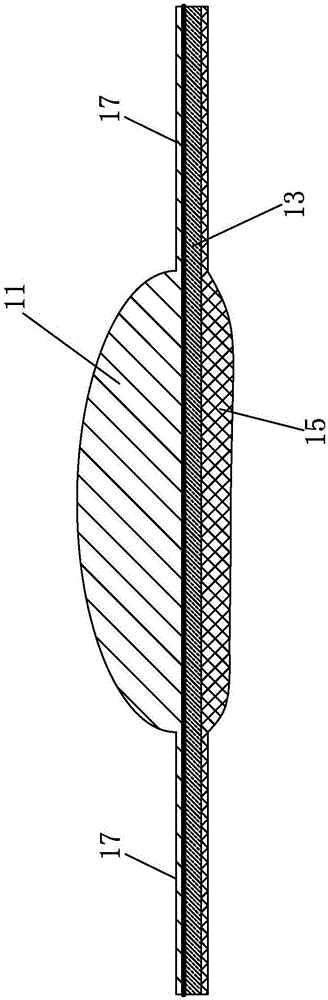

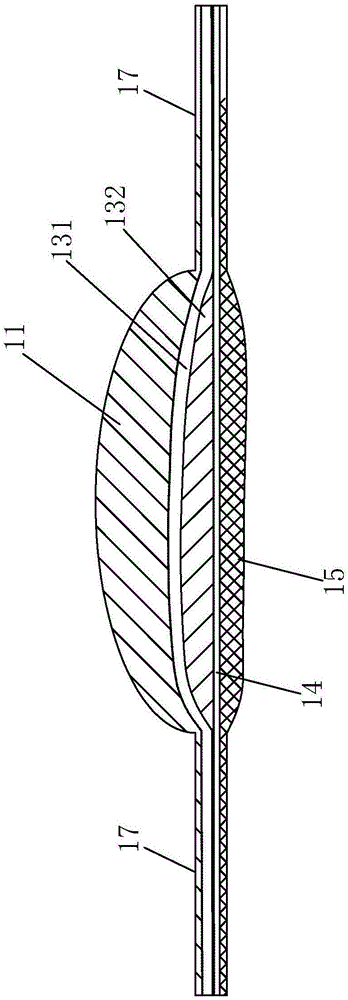

Non-woven fabric coil with printed patterns

ActiveCN106436025ASolve printing problems such as unclearIncrease surface activation energyPersonal careLayered productsEngineeringNonwoven fabric

The invention discloses a non-woven fabric coil with printed patterns. Air permeability of the non-woven fabric coil with the printed patterns is 0-3500L / m<2> / s. The non-woven fabric coil with the printed patterns comprises a top fiber layer, at least one middle printing layer and a bottom fiber layer, which are connected in sequence, wherein fineness of fibers used in the top fiber layer and the bottom fiber layer is larger than 1.0D, fineness of fibers used in the at least one middle printing layer is less than 0.3D, the ink printed patterns of one color or more than one color are printed on the at least one middle printing layer, the fibers used in the top fiber layer, the at least one middle printing layer and the bottom fiber layer are shaped once in heat bonding mode through hot pressing points after the fibers are spread and sprayed to the layers, and the area of a concave area formed by the hot pressing points is 5-70% of the total area. The non-woven fabric coil with the printed patterns can effectively prevent the problems that ink fades, skin sensibility is easily caused and the like.

Owner:XIAMEN HEJIE NON WOVEN FABRICS PROD

Alcohol-based fuel with high calorific value

InactiveCN106350125AReduce volatilityImprove flammabilityLiquid carbonaceous fuelsPolyethylene glycolCarvacryl acetate

The invention discloses an alcohol-based fuel with a high calorific value. The alcohol-based fuel is prepared from the following components in parts by weight: 75 to 85 parts of methanol, 2 to 4 parts of isopropyl alcohol, 1 to 3 parts of isoamyl alcohol, 0.4 to 0.8 part of polyethylene glycol, 1 to 3 parts of petroleum ether, 0.6 to 0.8 part of tert-amyl methyl ether, 1 to 3 parts of cumene hydroperoxide, 0.01 to 0.03 part of ethylene-vinyl acetate copolymer, 0.02 to 0.04 part of calcium stearate, 0.2 to 0.5 part of ethyl acetate, 0.3 to 0.7 part of nanometer magnesium powder and 0.2 to 0.4 part of nanometer iron oxide. The alcohol-based fuel with the high calorific value has the characteristics of good combustion performance, low corrosivity, high stability and the like and has good development prospects, and especially, the calorific value is high.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Heat-conducting low-temperature co-fired ceramic material and preparation method thereof

The invention discloses a heat-conducting low-temperature co-fired ceramic material and a preparation method thereof, wherein the material comprises, by weight, 100 parts of Bi-based glass, 80-150 parts of aluminum oxide ceramic powder and less than or equal to 3 parts of carbide, wherein the particle size of the aluminum oxide ceramic powder is 1-2 [mu]m. The method comprises: mixing bismuth trioxide, boron oxide, silicon oxide, zinc oxide and aluminum oxide, melting, and carrying out water-cooling quenching; carrying out ball milling on obtained Bi-based glass residue into powder, and mixingwith aluminum oxide ceramic powder; sequentially carrying out joint ball milling on the obtained mixed powder, a solvent, a dispersing agent, a binding agent, a plasticizer and a homogenizing agent;and carrying out casting molding on the obtained stable and uniform slurry in a mold, drying, sequentially placing the obtained raw ceramic sheet at 300-600 DEG C to remove organic additives, and carrying out sintering molding at 800-950 DEG C to obtain the target product. According to the invention, the heat-conducting low-temperature co-fired ceramic material has characteristics of significantlyincreased heat-conducting property and significantly improved dielectric property, and is easily, widely and commercially applied to the field of electronic packaging.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

High-dispersing nanometer silver and high-performance conductive adhesive

InactiveCN102199407BIncrease surface activation energyHigh grafting rateNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyAdhesive

The invention discloses high-dispersing nanometer silver and a high-performance conductive adhesive. A preparation method for the high-performance conductive adhesive comprises the following steps of: mixing an epoxy resin curing agent and an accelerating agent uniformly; mixing the high-dispersing nanometer silver and epoxy resin uniformly; and dripping a mixture of the epoxy resin curing agent and the accelerating agent into a mixed component of the high-dispersing nanometer silver and the epoxy resin, which are being mixed, at the temperature of between 10 and 25 DEG C, and mixing for 3 to10 hours to obtain the high-performance conductive adhesive. The nanometer silver can be fixed in the epoxy resin and has the excellent dispersibility in the epoxy resin, and the conductive adhesive prepared from the nanometer silver can fix a conductive network in the conductive adhesive, improve electric conductivity and solve the problem of silver migration in the using process of conductive silver. In addition, in epoxy resin of the high-performance conductive adhesive, four epoxy resin combinations with different functions are adopted, so the defects of insufficient bonding strength and shear strength in the current conductive adhesive are overcome.

Owner:中科广化(重庆)新材料研究院有限公司 +3

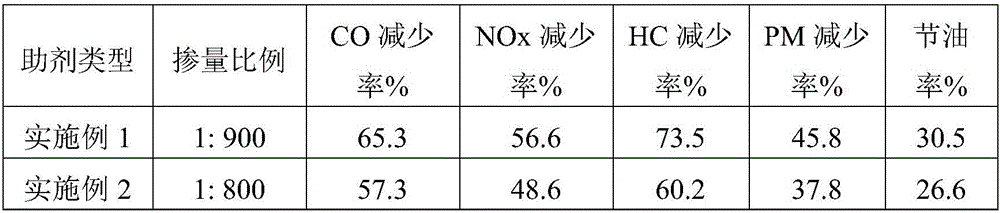

Adjuvant capable of reducing automobile exhaust emission

InactiveCN106350133AEmission reductionIncrease surface activation energyLiquid carbonaceous fuelsAutomotive emissionsCerium oxide

The invention discloses an adjuvant capable of reducing automobile exhaust emission, which is prepared from the following components in parts by weight: 2-5 parts of acetone, 1-3 parts of isoamylol, 2-4 parts of tertiary butanol, 1-3 parts of n-hexanol, 2-4 parts of n-octane, 3-5 parts of vinyl acetate, 4-6 parts of petroleum ether, 1-3 parts of dimethyl ether, 2-5 parts of dimethyl carbonate, 1-4 parts of ethyl nitrate, 10-15 parts of dimethylformamide, 1-3 parts of stearic acid, 0.6-0.8 part of dioctyl phthalate, 1-3 parts of strontium peroxide, 0.2-0.6 part of nonylphenol polyoxyethylene ether, 0.3-0.7 part of fluorocarbon surfactant, 1-4 parts of polytetrafluoroethylene, 0.6-0.9 part of catalyst, 0.3-0.5 part of bentonite powder, 0.2-0.4 part of nano cerium oxide and 0.3-0.6 part of nano magnesium powder.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

High performance composite long fiber reinforced polypropylene material and preparation method thereof

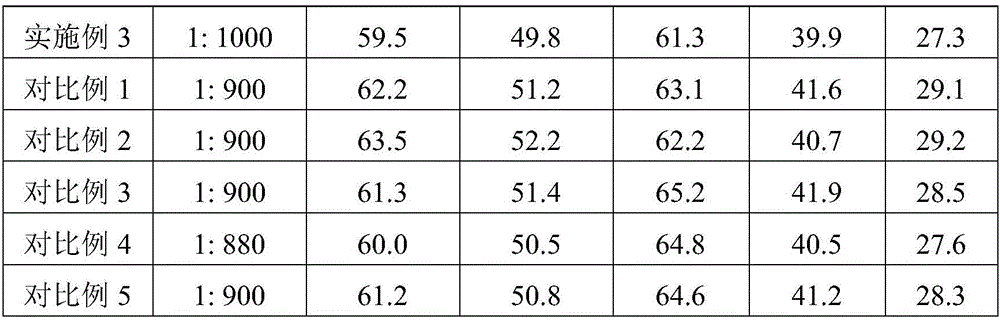

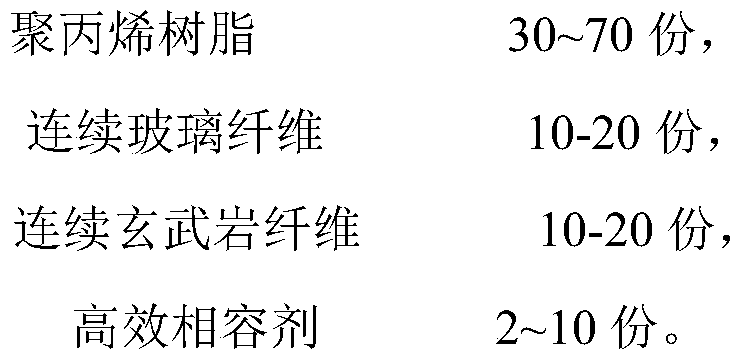

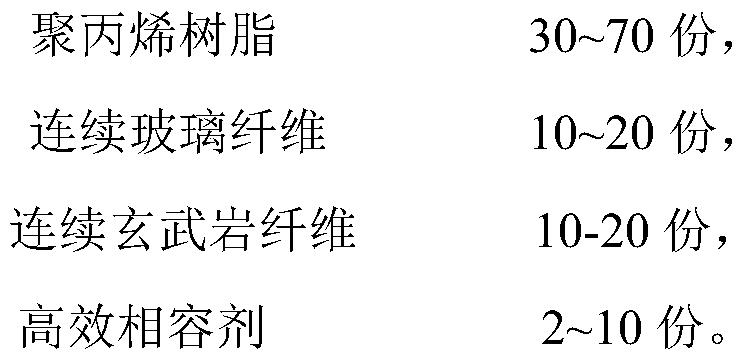

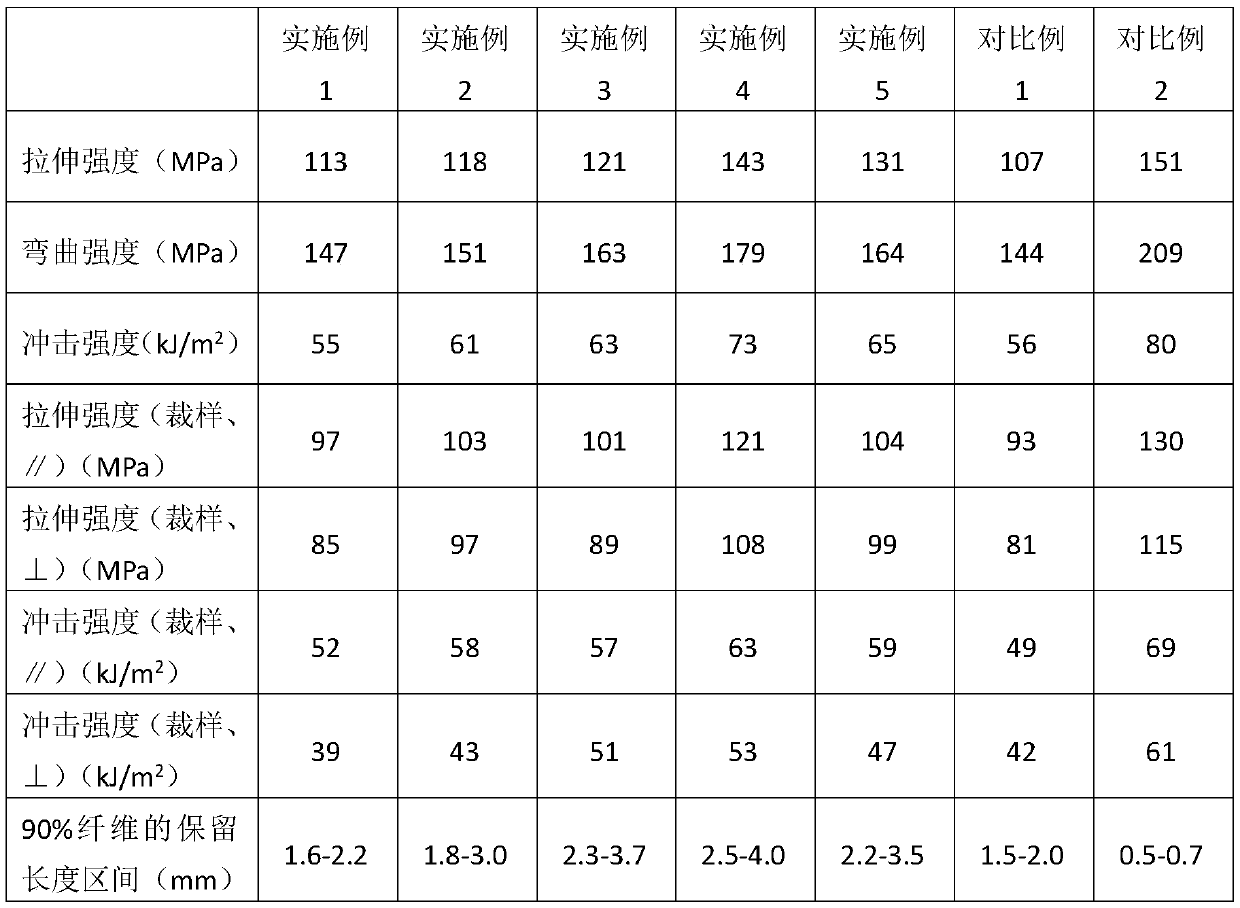

The invention relates to a high performance composite long fiber reinforced polypropylene material and a preparation method thereof. The high performance composite long fiber reinforced polypropylenematerial is specifically composed of the following raw materials by weight: 30-70 parts of polypropylene resin, 10-20 parts of continuous glass fiber, 10-20 parts of continuous basalt fiber, and 2-10parts of a high efficiency compatilizer. The invention has the advantages that: the high-performance and shear resistant novel basalt fiber is introduced as a second fiber reinforcement for compounding, and the long fiber processing way of "melt impregnation, particle long cutting" is employed to maximumly retain the effective retention length of fiber after forming machining of the reinforced polypropylene material. Compared with the 1.5-2mm retention length in conventional long glass fiber reinforced polypropylene material, the composite long fiber reinforced material has significantly higher fiber retention length after forming machining up to 2.5-4mm, and the fiber dispersion is more uniform, the main rigid indexes of the material, like tensile strength and impact strength, are also increased by 30-50% on the same basis, wherein the tensile strength can reach 140MPa or above, and the highest impact strength is 70kJ / m<2>.

Owner:上海华合复合材料有限公司

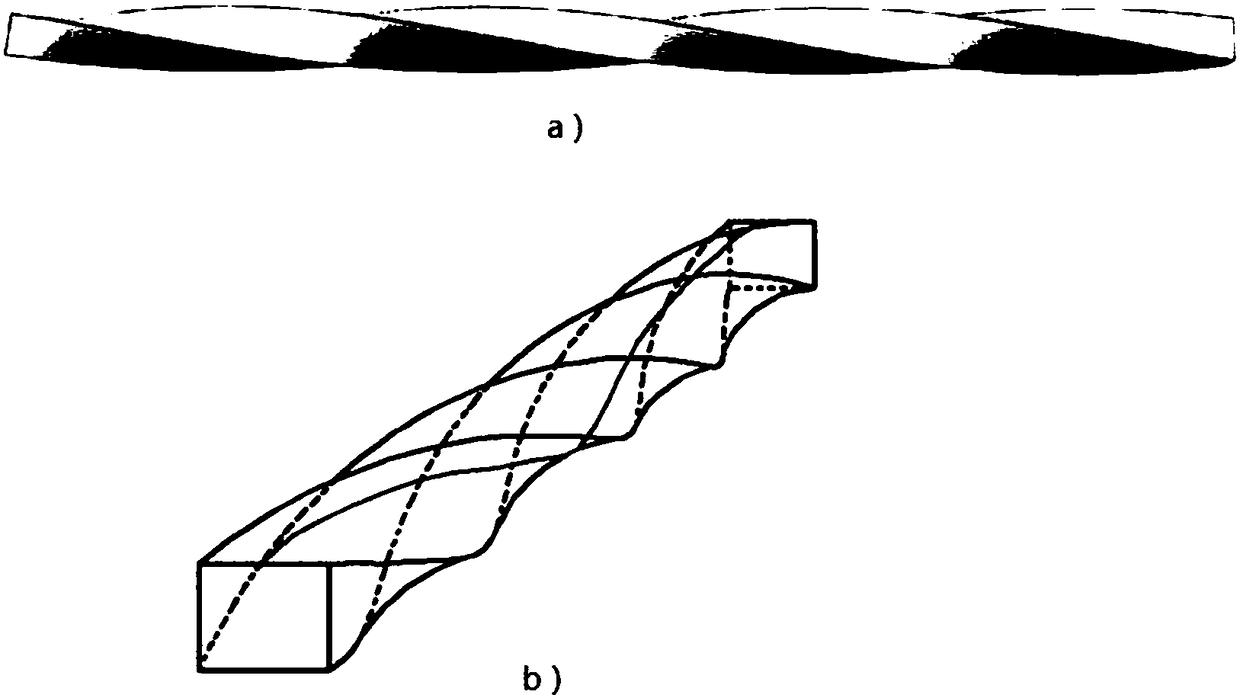

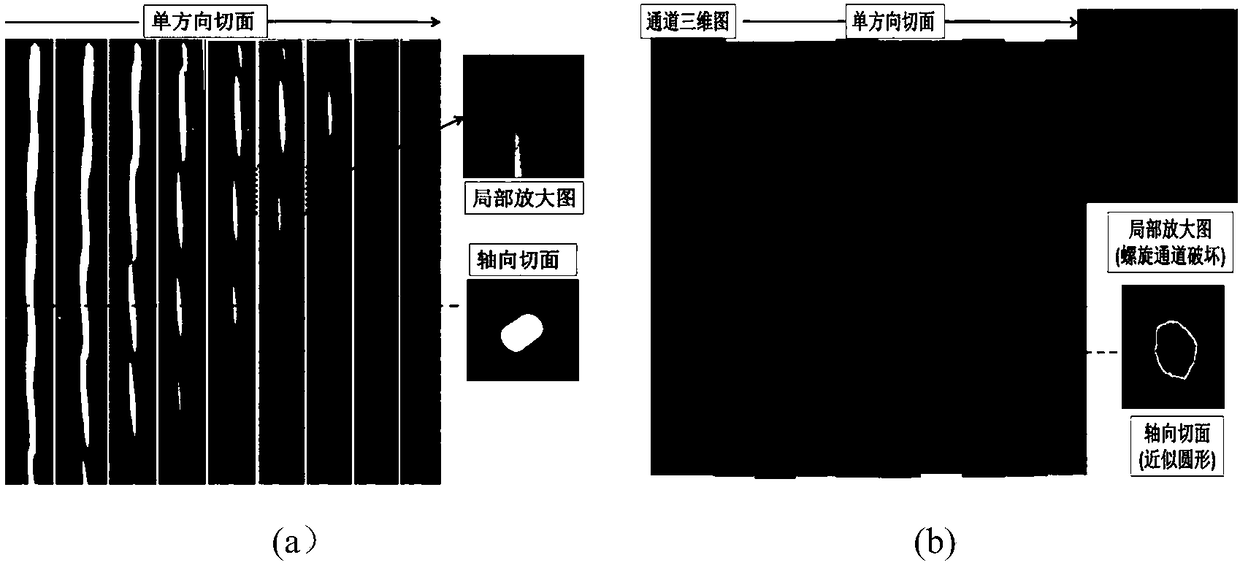

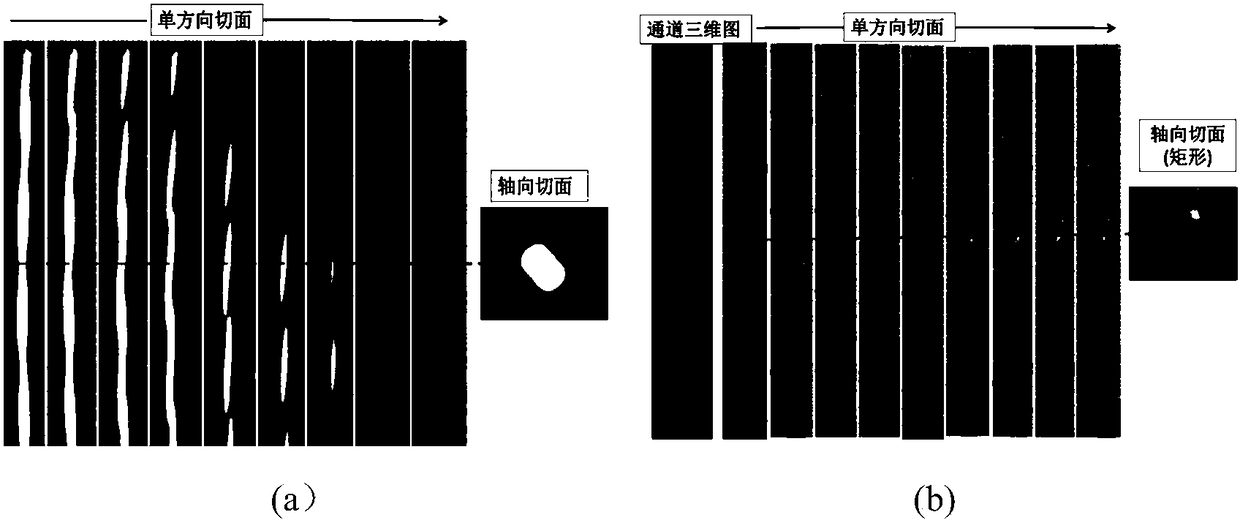

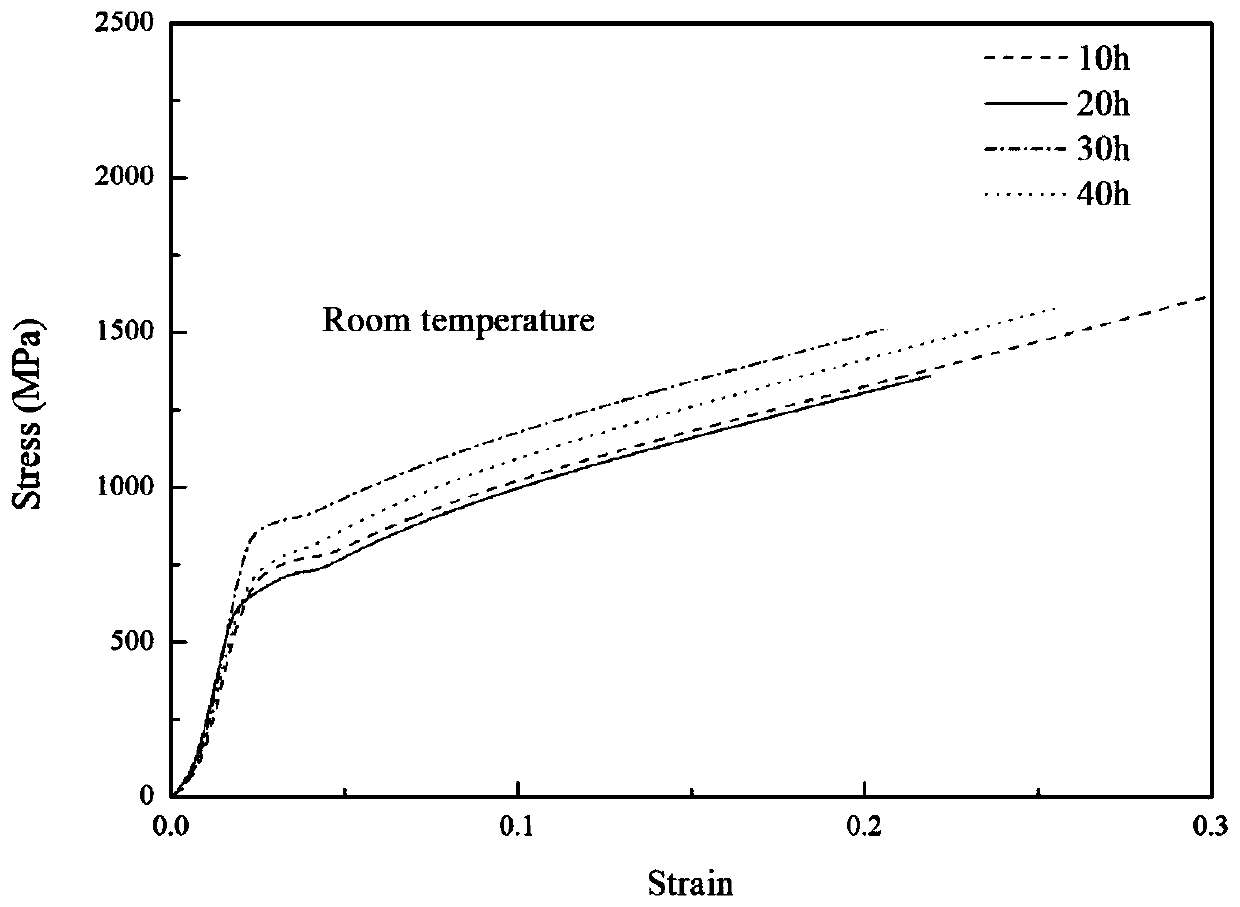

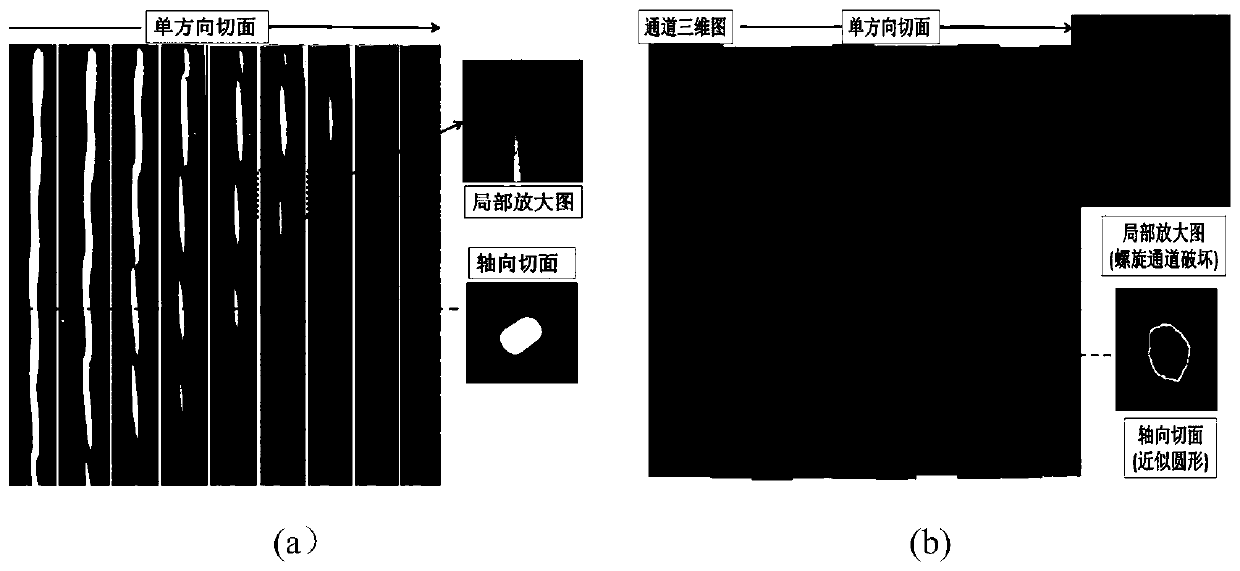

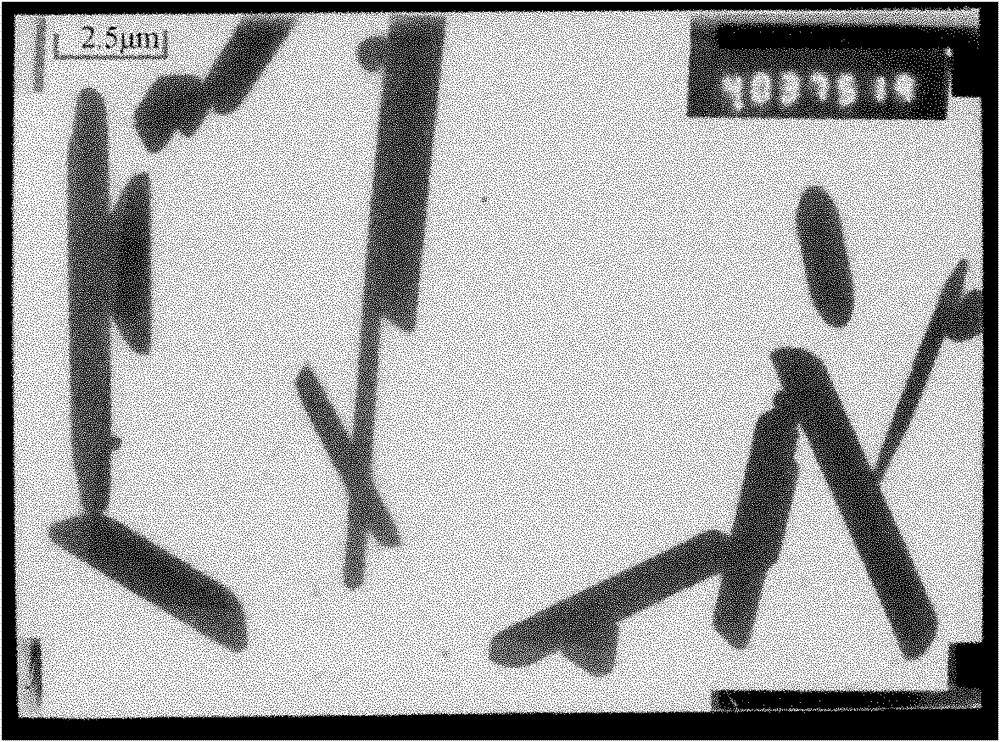

Spiral steel fiber ultra-high-performance concrete and preparation method thereof

The invention provides a spiral steel fiber ultra-high-performance concrete and a preparation method thereof. The concrete material is composed of cement, fine sand, water, quartz powder, high-efficiency water reducing agent and steel fibers, in addition, inorganic mineral admixtures such as fly ash, slag and the like can be selectively added to replace partial cement; and the adopted steel fiberscomprise a linear steel fiber and a spiral steel fiber. The concrete is prepared from, by mass, 1000-1300 parts of the cement, 100-300 parts of silica fume, 900-1200 parts of the fine sand, 100-300 parts of the quartz powder, 30-60 parts of the water reducing agent, 150-400 parts of the water and 50-300 parts of the steel fibers. The obtained spiral steel fiber concrete material has the advantages that compared with the adhesive property between the linear steel fiber and a concrete substrate, the adhesive property between the spiral steel fiber and the concrete substrate can be obviously improved, and the tensile strength of the spiral steel fiber ultra-high-performance concrete is higher than that of conventional steel fiber concrete; since the spiral steel fiber has an 'unspinning' process when being pulled out from the substrate, the deformation ability of the conventional steel fiber concrete can be greatly improved.

Owner:ZHEJIANG UNIV

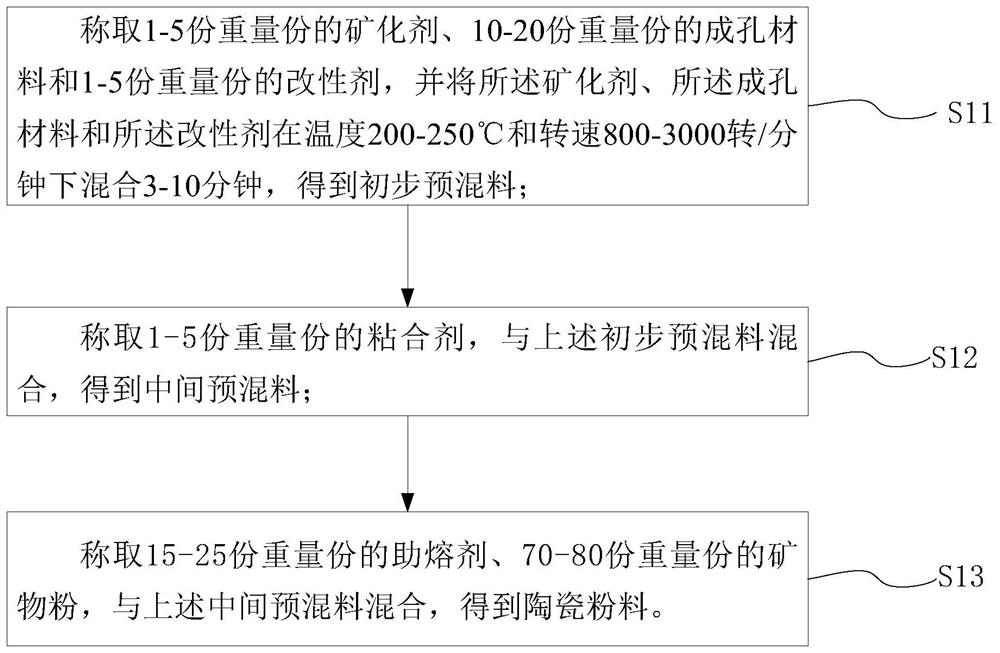

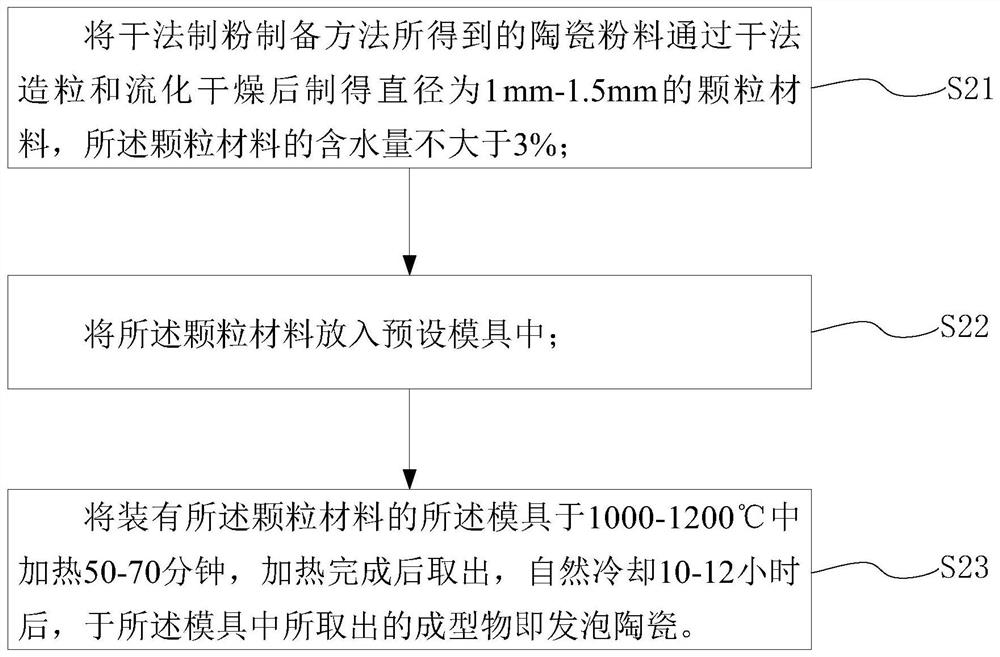

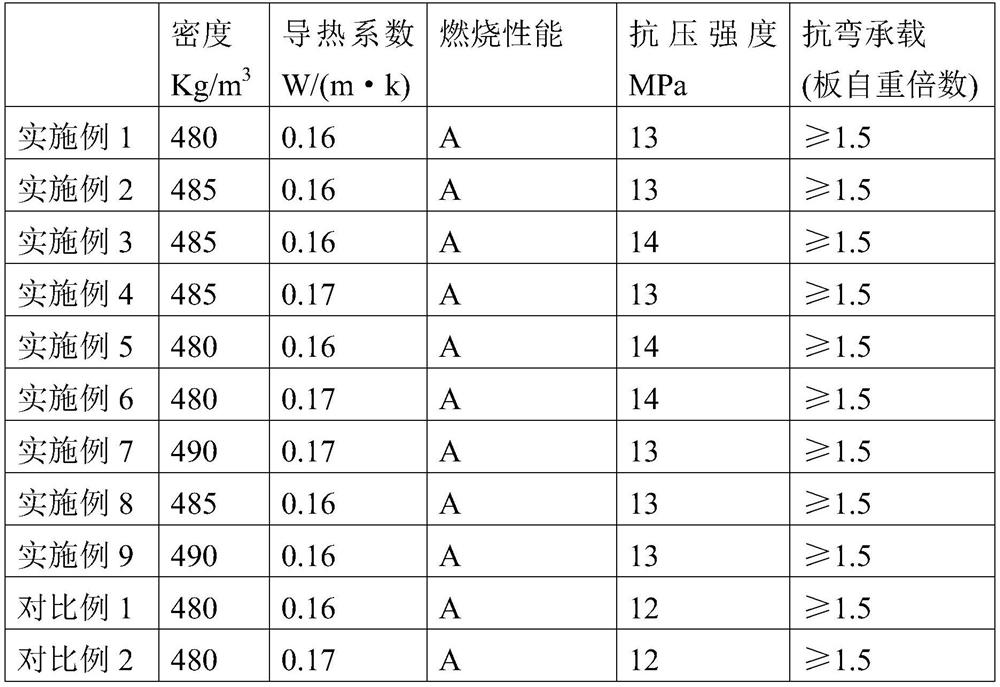

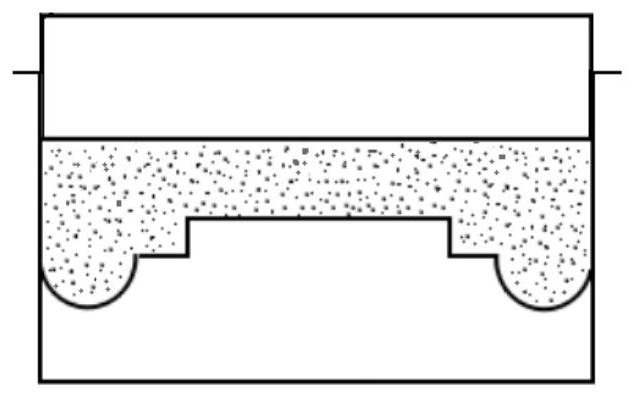

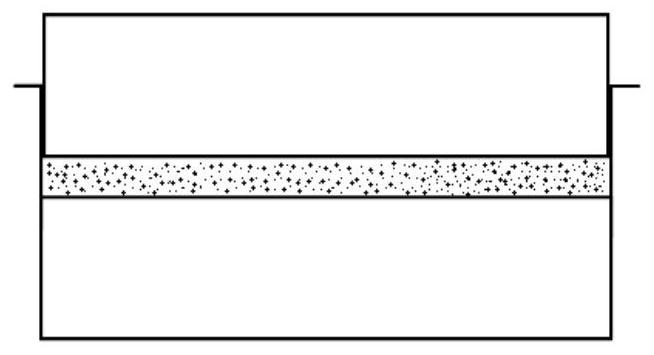

Preparation method of foamed ceramic and dry-method powder preparation method therefor

PendingCN113526977AImprove diffusion abilityImprove uniformityCeramic materials productionCeramicwareAdhesiveCeramic

The invention provides a preparation method of foamed ceramic and a dry-method powder preparation method therefor. The dry powder preparation method of the foamed ceramic comprises the following steps: weighing 1-5 parts by weight of a mineralizer, 10-20 parts by weight of a pore-forming material and 1-5 parts by weight of a modifier, and mixing the mineralizer, the pore-forming material and the modifier for 3-10 minutes at the temperature of 200-250 DEG C and the rotating speed of 800-3000 revolutions per minute to obtain a preliminary premix; weighing 1-5 parts by weight of an adhesive, and mixing the adhesive with the preliminary premix to obtain an intermediate premix; weighing 15-25 parts by weight of a fluxing agent and 70-80 parts by weight of mineral powder, and mixing the fluxing agent and the mineral powder with the intermediate premix to obtain the ceramic powder. The ceramic powder prepared through the dry-method powder preparation method is good in uniformity, the whole material mixing time is short, the time is saved, the material mixing efficiency is improved, and the economic benefits of enterprises are improved.

Owner:中集绿建环保新材料(连云港)有限公司 +3

Geopolymer member and preparation method thereof

ActiveCN111732378AHigh strengthImprove mechanical properties such as strengthCeramic shaping apparatusCement productionFiberPolyvinyl alcohol

The invention belongs to the technical field of building materials, and particularly relates to a geopolymer component and a preparation method thereof. The component is composed of 58-74 parts of a silicon-aluminum raw material, 4-12 parts of an excitant, 3-7 parts of an inorganic curing agent, 0.2-0.5 part of an additive, and 7-20 parts of water. According to the technical scheme, the water consumption is low, generation of pores in the product due to existence of excessive moisture is avoided, and the strength and other mechanical properties of the geopolymer are improved; reinforcing materials such as fibers, resin and polyvinyl alcohol do not need to be additionally added; the chemical activity of the raw materials is fully utilized; especially, an inorganic curing agent is used; allthe raw materials are matched and used in proportion; the geopolymer component with high polymerization degree, high compactness and high strength can be rapidly generated in situ through the coordination effect of all the components, the economic cost is effectively reduced, the delivery time is greatly shortened, no free formaldehyde is released, and the geopolymer component is more environmentally friendly, better in fireproof and high-temperature-resistant performance and wide in application prospect.

Owner:UNIV OF JINAN

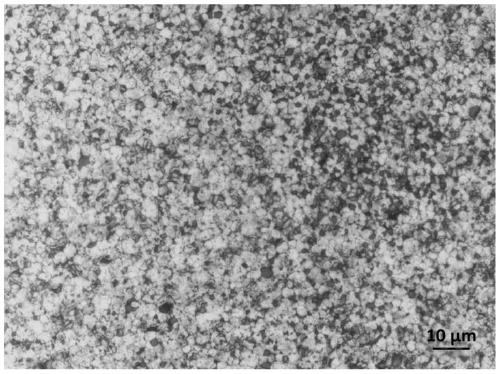

High-strength Mo-Hf-CNT molybdenum-based composite material and a preparation method thereof

The invention discloses a high-strength Mo-Hf-CNT molybdenum-based composite material and a preparation method thereof. The Mo-Hf-CNT molybdenum-based composite material is a molybdenum alloy obtainedby doping HfH2 and CNT into molybdenum, and comprises the following components in percentage by mass: 1.2% of Hf, 0.1% of CNT and the balance Mo. According to the high-strength Mo-Hf-CNT molybdenum-based composite material and the preparation method thereof, carbon nanotubes are adopted to replace graphite to serve as a carbon source of the MHC molybdenum alloy, and the hardness and yield strength of the prepared Mo-Hf-CNT molybdenum-based composite material are effectively improved through optimization of processes such as ball milling and spark plasma sintering.

Owner:HEFEI UNIV OF TECH

Low-temperature co-fired ceramic material of double-phase ceramic filler, and preparation method thereof

The invention discloses a low-temperature co-fired ceramic material of a double-phase ceramic filler, and a preparation method thereof. The material comprises, by weight, 100 parts of BBSZ glass, 80-150 parts of aluminum oxide ceramic powder, 2-130 parts of boron nitride ceramic powder and 3 parts or below of carbide, wherein the particle size of the aluminum oxide ceramic powder is 1-2 [mu]m, andthe particle size of the boron nitride ceramic powder is less than or equal to 400 nm. The method comprises the following steps: mixing bismuth trioxide, boron oxide, silicon oxide and zinc oxide, melting the obtained mixture, carrying out water-cooling quenching, ball-milling the obtained BBSZ glass slag into powder, and mixing the powder with the aluminum oxide ceramic powder and the boron nitride ceramic powder, and then sequentially carrying out joint ball milling on the obtained mixed powder, a solvent, a dispersing agent, a binding agent, a plasticizer and a homogenizing agent, carryingout tape casting on the obtained slurry in a mold, drying the cast slurry, sequentially placing obtained raw ceramic chips at different temperatures to remove organic additives, and carrying out sinter molding to obtain the target product. The material has excellent heat conduction and dielectric properties, and can be easily and widely commercially applied to the field of electronic packaging.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A kind of spiral steel fiber ultra-high performance concrete and its preparation method

The invention provides a spiral steel fiber ultra-high-performance concrete and a preparation method thereof. The concrete material is composed of cement, fine sand, water, quartz powder, high-efficiency water reducing agent and steel fibers, in addition, inorganic mineral admixtures such as fly ash, slag and the like can be selectively added to replace partial cement; and the adopted steel fiberscomprise a linear steel fiber and a spiral steel fiber. The concrete is prepared from, by mass, 1000-1300 parts of the cement, 100-300 parts of silica fume, 900-1200 parts of the fine sand, 100-300 parts of the quartz powder, 30-60 parts of the water reducing agent, 150-400 parts of the water and 50-300 parts of the steel fibers. The obtained spiral steel fiber concrete material has the advantages that compared with the adhesive property between the linear steel fiber and a concrete substrate, the adhesive property between the spiral steel fiber and the concrete substrate can be obviously improved, and the tensile strength of the spiral steel fiber ultra-high-performance concrete is higher than that of conventional steel fiber concrete; since the spiral steel fiber has an 'unspinning' process when being pulled out from the substrate, the deformation ability of the conventional steel fiber concrete can be greatly improved.

Owner:ZHEJIANG UNIV

Preparation method of ultra-pure high-activity battery-grade lithium fluoride

PendingCN112279280AReduce energy consumptionIncrease surface activation energyLithium halidesFluorhydric AcidUltrapure water

The invention discloses a preparation method of ultra-pure high-activity battery-grade lithium fluoride. The preparation method comprises the following steps: 1, blending anhydrous hydrogen fluoride into anhydrous hydrofluoric acid by using ultrapure water, and blending the anhydrous hydrofluoric acid and crude lithium fluoride into lithium fluoride slurry; 2, under continuous stirring, continuously feeding the lithium fluoride slurry into a ball mill for ball milling; 3, adding the ball-milled lithium fluoride slurry into anhydrous hydrogen fluoride, and carrying out filtering to obtain a clear lithium hydrogen fluoride solution; 4, performing cooling and crystallizing to obtain crystal mush; and 5, carrying out vacuum drying after airflow drying to obtain the ultra-pure high-activity battery-grade lithium fluoride crystal. The invention provides a low-energy-consumption short-flow purification process, and a finally obtained lithium fluoride product is applicable to batteries.

Owner:于兴江

Novel alcohol-based fuel

InactiveCN106367137ALow costPromotes full combustionLiquid carbonaceous fuelsFuel additivesBrown iron oxideIsobutyl alcohol

The invention discloses a novel alcohol-based fuel. The novel alcohol-based fuel is prepared from the following components in parts by weight: 60-70 parts of methyl alcohol, 3-6 parts of ethyl alcohol, 2-4 parts of isobutyl alcohol, 1-4 parts of propylene glycol, 1-3 parts of isopropyl ether, 3-5 parts of di-tert-butyl peroxide, 0.4-0.8 part of glycerol, 0.02-0.04 part of polyoxyethylene-polyoxypropylene copolymer, 0.3-0.5 part of triethanolamine, 0.5-0.9 part of nano magnesium powder and 0.3-0.5 part of nano iron oxide. The novel alcohol-based fuel has the characteristic of high combustion performance, particularly high heat value, low corrosion and high stability and has a good development prospect.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

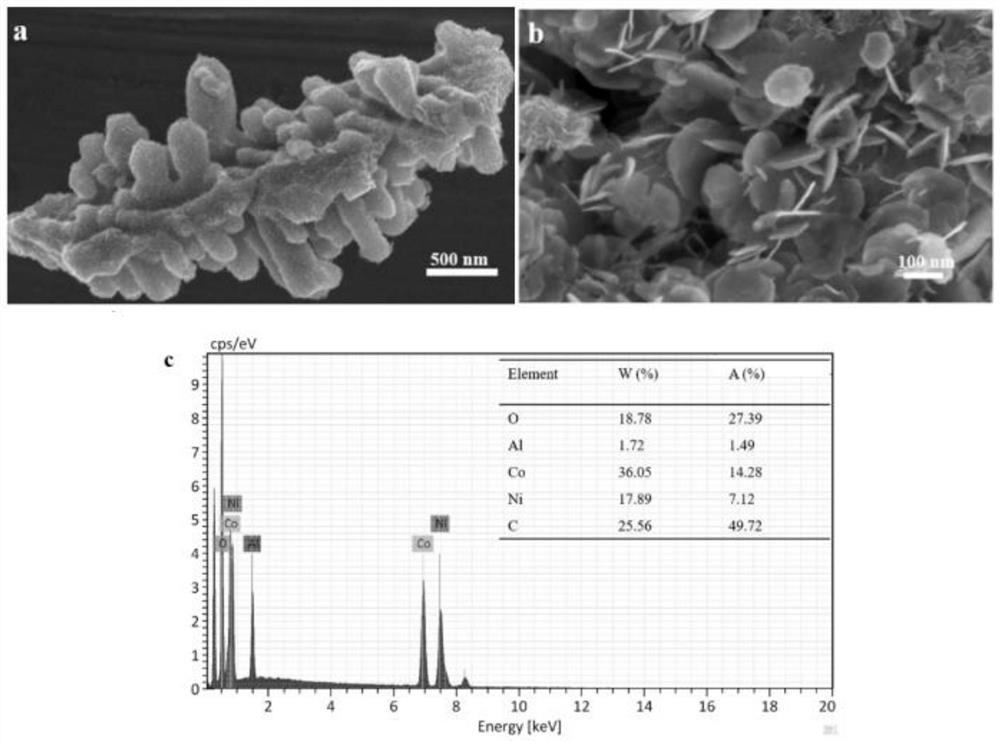

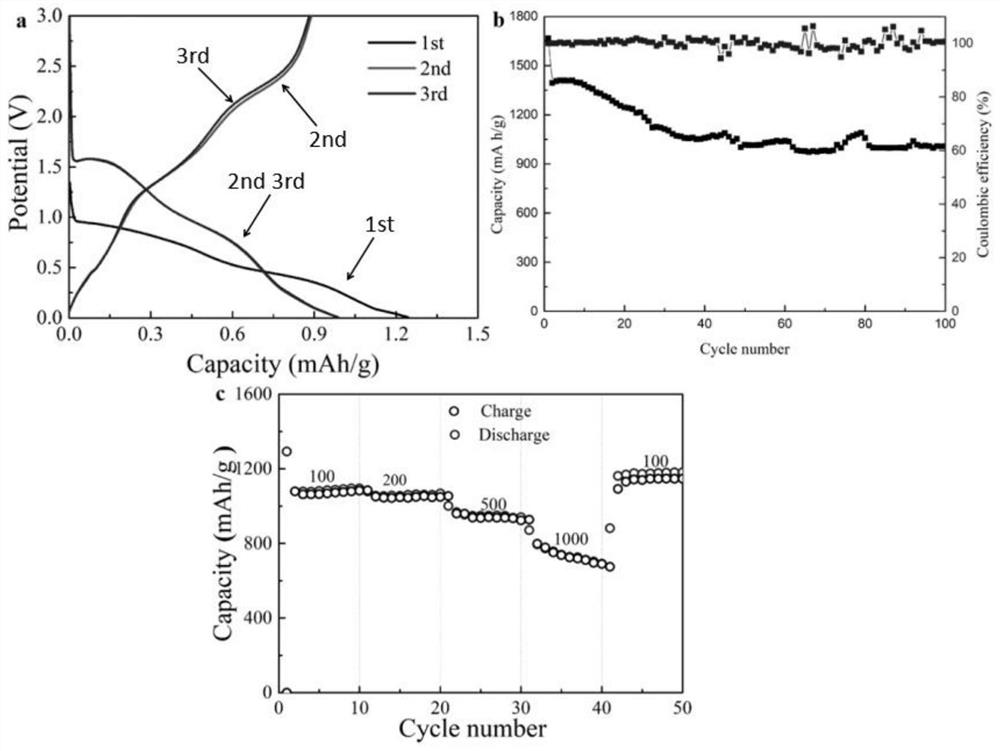

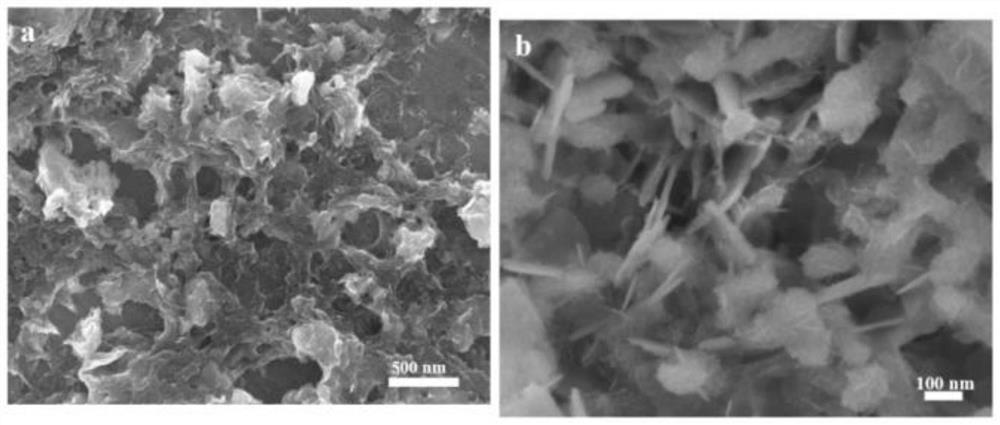

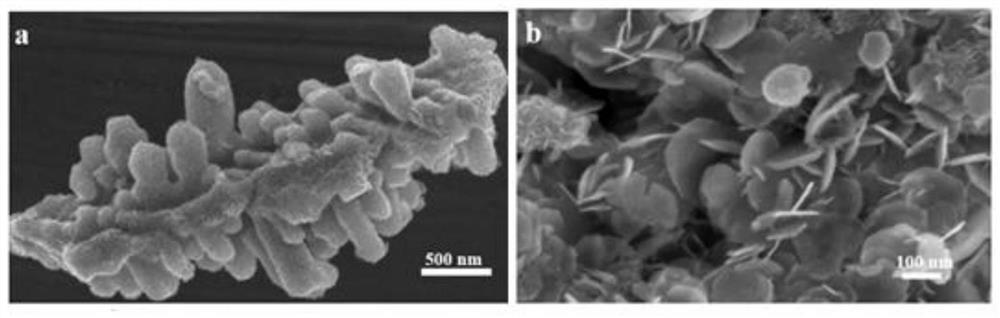

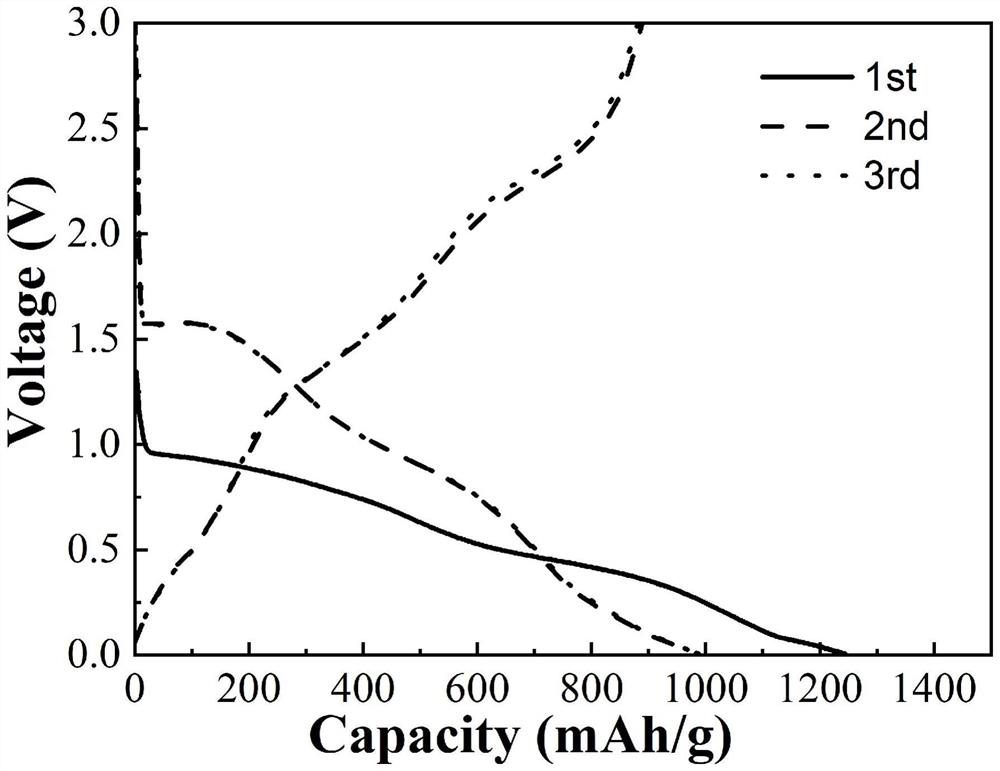

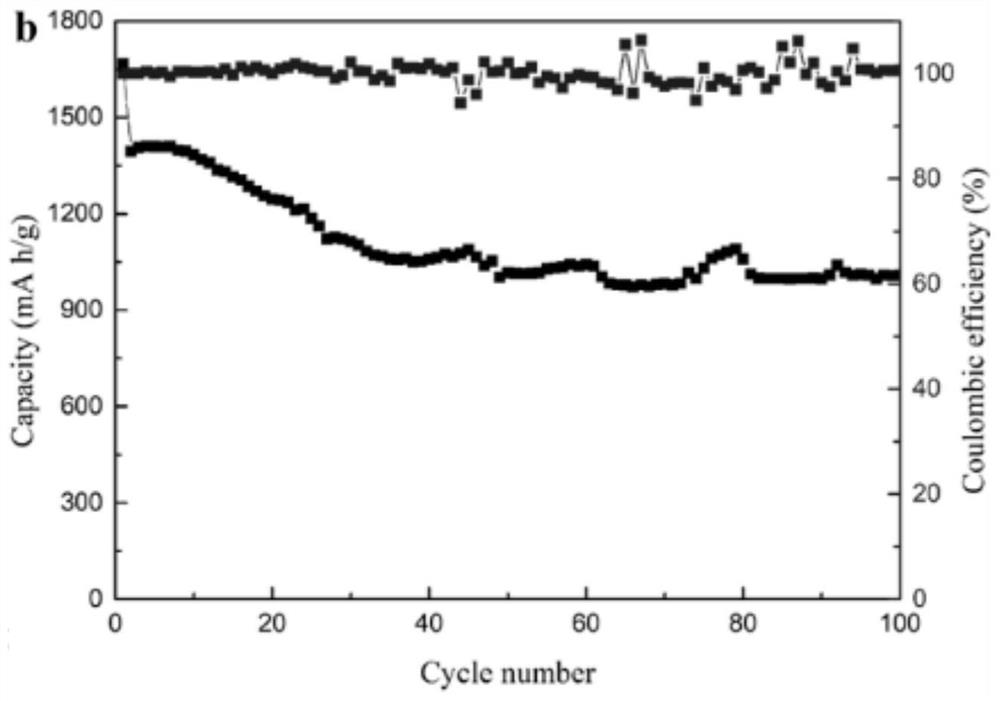

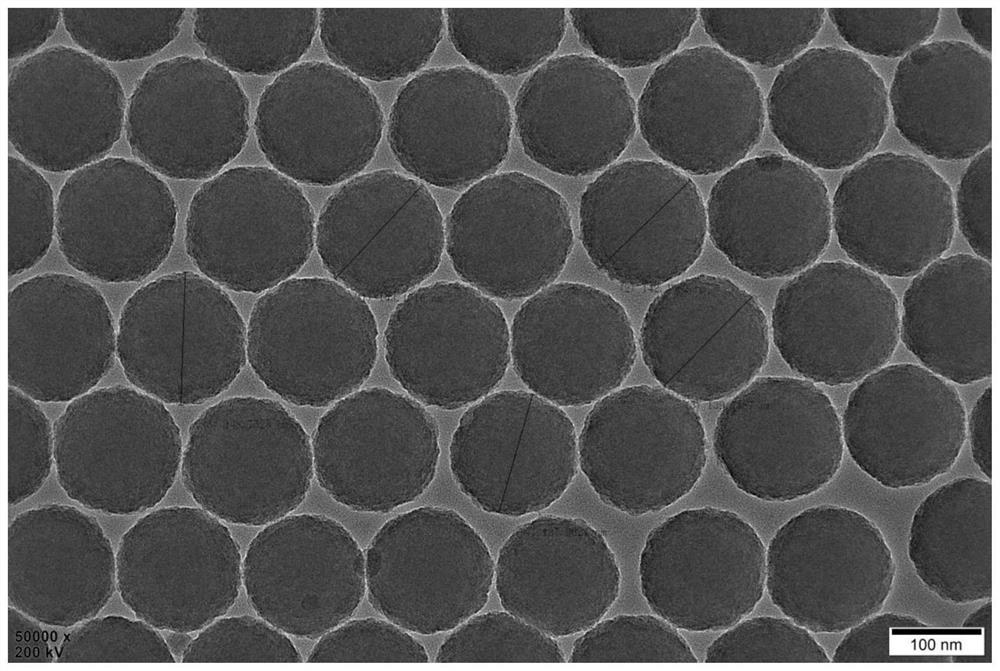

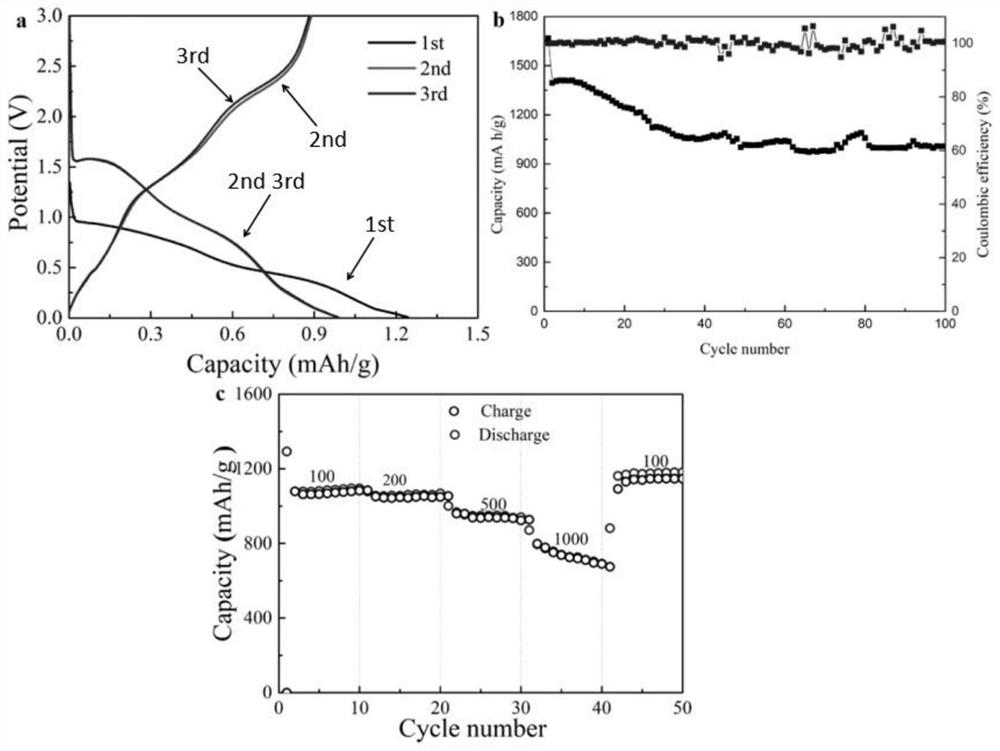

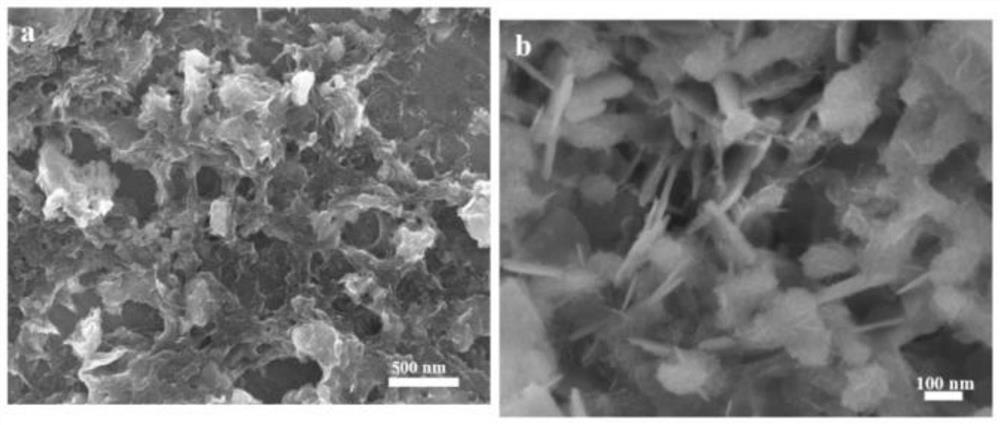

Lithium ion battery material and preparation method thereof by adopting super-assembly and dealloying

ActiveCN113611851AOptimal Control StructureZero lossMaterial nanotechnologyNegative electrodesPhysical chemistryElectrochemistry

The invention belongs to the technical field of lithium battery materials, and provides a lithium ion battery material and a preparation method thereof by adopting super-assembly and dealloying, the preparation method comprises the following steps: placing a ternary alloy containing metals Al, Co and Ni in a hydrogen peroxide solution, adding a strong alkali solution, and carrying out a dealloying reaction; then adding aminopropyl trimethoxy silane, and carrying out ultrasonic treatment for a period of time to obtain a precursor; preparing graphene oxide powder into graphene oxide dispersion liquid, mixing the graphene oxide dispersion liquid with the precursor according to a certain mass ratio, and then adding ammonia water and citric acid to obtain a material intermediate; and finally, heating the material intermediate to a certain temperature in a preset atmosphere, conducting heat preservation for a certain time, then cooling the material intermediate to the room temperature, and obtaining the lithium ion battery material. The material prepared through the method is controllable in component and structure, zero in target material loss and suitable for large-scale production. The compounding of the oxide and the graphene can integrate the advantages of the two components, and the electrochemical performance of a single material is improved.

Owner:FUDAN UNIV

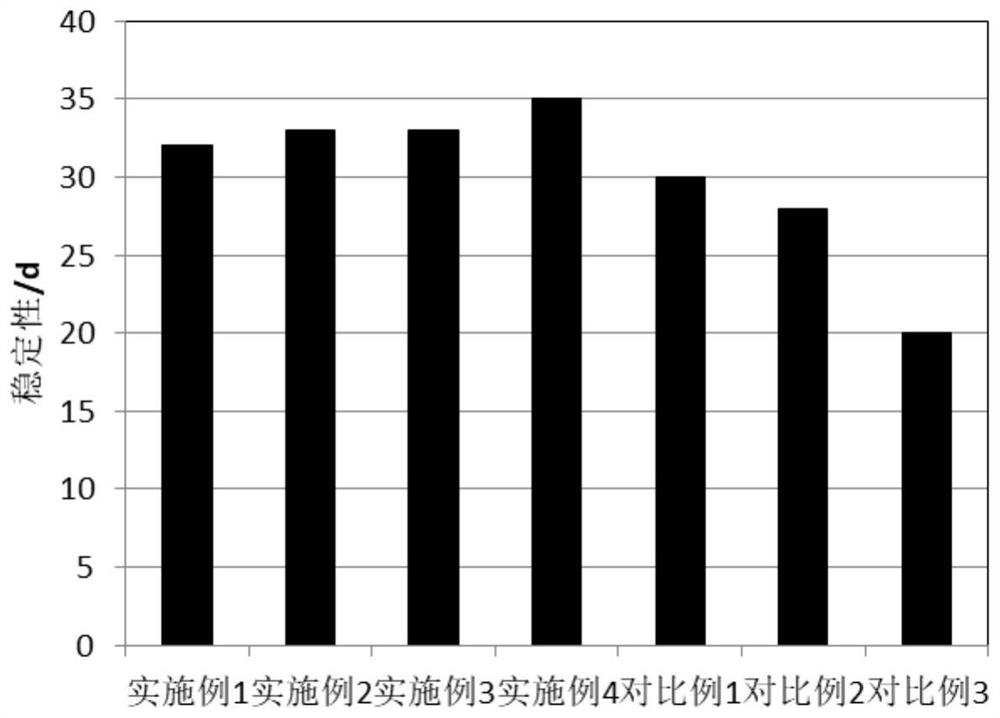

Diesel reverse micelle system, preparation method, application, biodiesel and preparation method

ActiveCN103555381BWide variety of sourcesGood storage stabilityBiofuelsLiquid carbonaceous fuelsBiodieselRhamnolipid

The invention relates to a diesel reverse micelle system, a preparation method, an application, biodiesel and a preparation method thereof. The diesel reverse micelle system is composed of rhamnolipid, diesel oil, a cosurfactant and water, with diesel oil as a solvent, rat The concentration of rhamnolipid is 30-75g / L, the concentration of co-surfactant is 15-60g / L, and the concentration of water is 24-30mg / L. The preparation method is to dissolve rhamnolipid in diesel oil, and then add co-surfactant The active agent and excess water are mixed, left standing, and separated to obtain a diesel reverse micelle system. The biodiesel is composed of a volume ratio of 80-95% diesel reverse micelle system and 5-20% castor oil. The preparation method is to Castor oil is added to the diesel reverse micelles system, heat-preserved and oscillated, centrifuged, and separated to obtain biodiesel. The present invention uses the diesel reverse micelles system to mix castor oil to prepare biodiesel, without changing the chemical structure of castor oil, and there is no secondary process in the preparation process. Pollution, simple process.

Owner:湖南红普创新科技发展有限公司

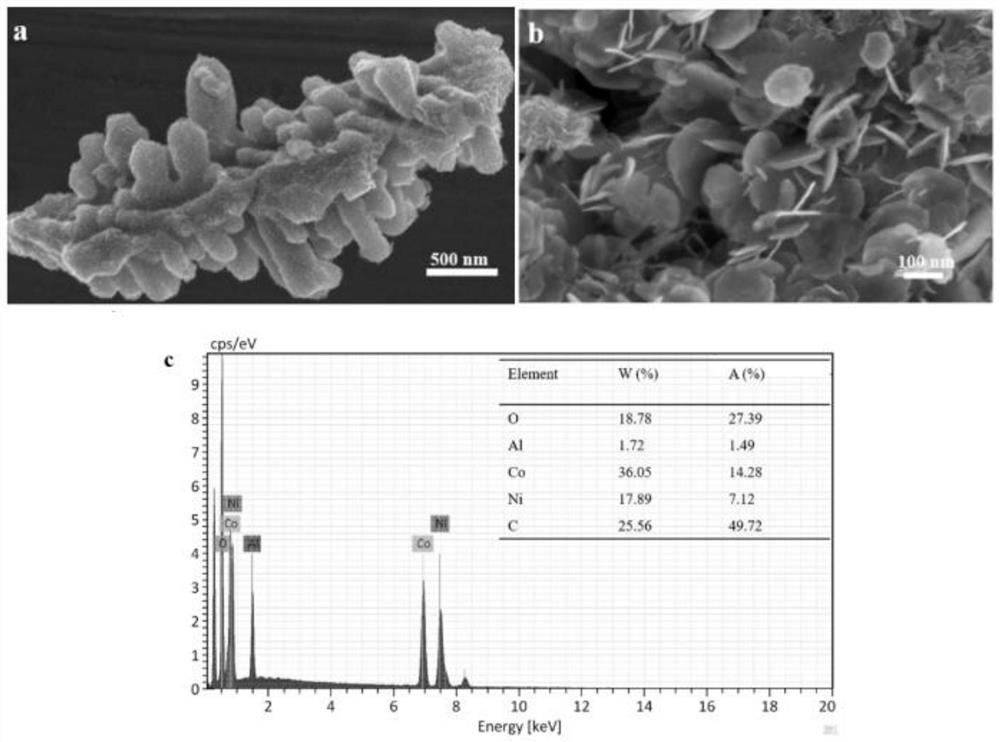

Preparation method of NiCoOx/graphene lithium ion battery negative electrode material

ActiveCN114142000AImprove electrochemical performanceSuitable for mass productionMaterial nanotechnologySecondary cellsBattery cellMaterials science

The invention discloses a preparation method of a NiCoOx / graphene lithium ion battery negative electrode material, and belongs to the technical field of lithium battery electrode materials. The preparation method comprises the following steps: firstly, carrying out dealloying treatment on an Al, Co and Ni ternary alloy, sequentially carrying out ultrasonic treatment on an obtained dealloying material in an alcohol solvent and aminopropyltrimethoxysilane to obtain a precursor, then putting the precursor in a graphene oxide dispersion liquid, adding ammonia water, adding citric acid after the reaction is finished, continuing the reaction to obtain an intermediate, and carrying out vacuum drying on the intermediate to obtain the Al-Co-Ni ternary alloy composite material. And then heating the intermediate and preserving heat to obtain the lithium ion battery negative electrode material. The prepared lithium ion battery negative electrode material is of a micro-nano structure, has rich active sites, is large in specific surface area and high in tap density, shows excellent cycling stability and high specific discharge capacity when being used in a lithium ion battery, and can be widely used as the lithium ion battery negative electrode material.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI +1

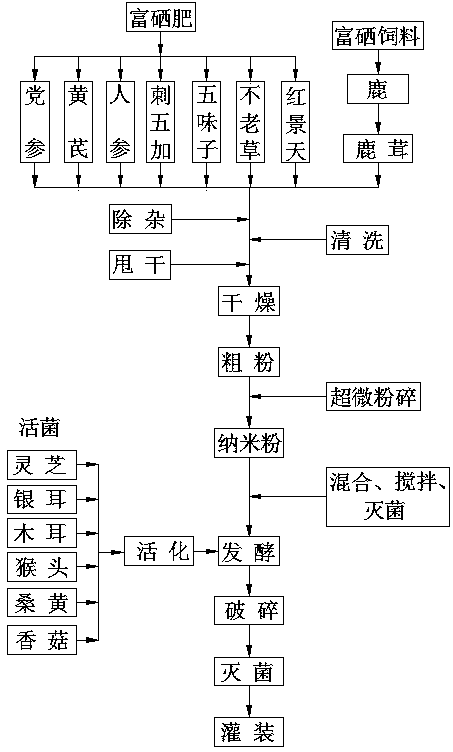

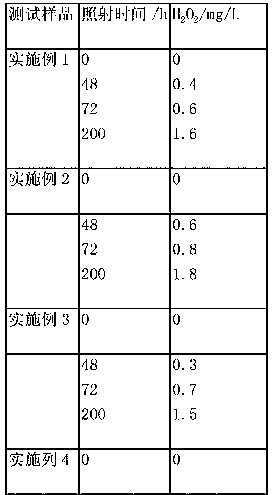

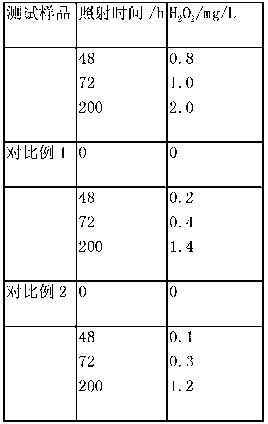

Compound medicinal fungus fermented selenium-enriched nanometer genuine medicinal material oral liquid and preparation method thereof

InactiveCN111346148ALarge specific surface areaReduce dosageDispersion deliveryUnknown materialsChemistryMedicinal herbs

The invention discloses a compound medicinal fungus fermented selenium-enriched nanometer genuine medicinal material oral liquid and a preparation method thereof. The oral liquid comprises medicinal fungi and genuine medicinal materials. First the medicinal fungi are activated with a PDA culture medium, then the genuine medicinal materials are coarsely crushed and nano-crushed, an obtained mixed medicinal material powder is put into a fermentation tank and stirred evenly, cooling is performed, then the fermentation tank is inoculated with the activated medicinal fungi for fermentation, after the fermentation is completed, a fermented material liquid is transferred into a shearing tank for breaking, finally sterilization is performed, a sterilized material liquid is diluted and filled intoan oral liquid bottle, packaging is completed, and one bottle is taken orally every day. The traditional Chinese medicine is subjected to nano-crushing, the surface activation energy is improved, andthen medicinal fungus fermentation and secretase transformation are performed, so that the oral liquid becomes a traditional Chinese medicine fermentation product which is more suitable for the publicto drink, effective ingredients of the drug are fully exerted, absorption of the drug by the human body is also improved, and the efficacy of the drug itself is enhanced.

Owner:白山蜂收蜂制品科技开发有限公司

Nanometer ZnO anti-bacterial and anti-fouling coating and method for preparing same

ActiveCN101701120BIncrease surface activation energyUniversal antibacterialAntifouling/underwater paintsPaints with biocidesPhotosensitizerZno nanoparticles

The invention relates to nanometer ZnO anti-bacterial and anti-fouling coating and a method for preparing the same. The nanometer ZnO anti-bacterial and anti-fouling coating comprises the following components by weight portion: 20-60 portions of nanometer ZnO particles, 0-3 portions of ZnO modified additive, 0.5-3 portions of photosensitizer, 1.5-10 portions of binder, 15-30 portions of high polymer, 2-10 portions of additive, 30-50 portions of solvent and 90-160 portions of cosolvent. The ZnO modified additive is dissolved and stirred in the cosolvent; the nanometer ZnO particles are poured in the mixture; the new mixture is oscillated ultrasonically and then ground and dried to a constant weight to obtain surface-functionalized nanometer ZnO; and the photosensitizer, the binder, the high polymer and the additive are added and stirred to the surface-functionalized nanometer ZnO to obtain the nanometer ZnO anti-bacterial and anti-fouling coating. Compared with the prior art, the nanometer ZnO anti-bacterial and anti-fouling coating has anti-bacterial universality, outstanding anti-fouling ability and excellent weatherability and can be particularly applied to the ship, the transport, the school, the hospital and the construction industry on a large scale.

Owner:南京南大波平电子信息有限公司

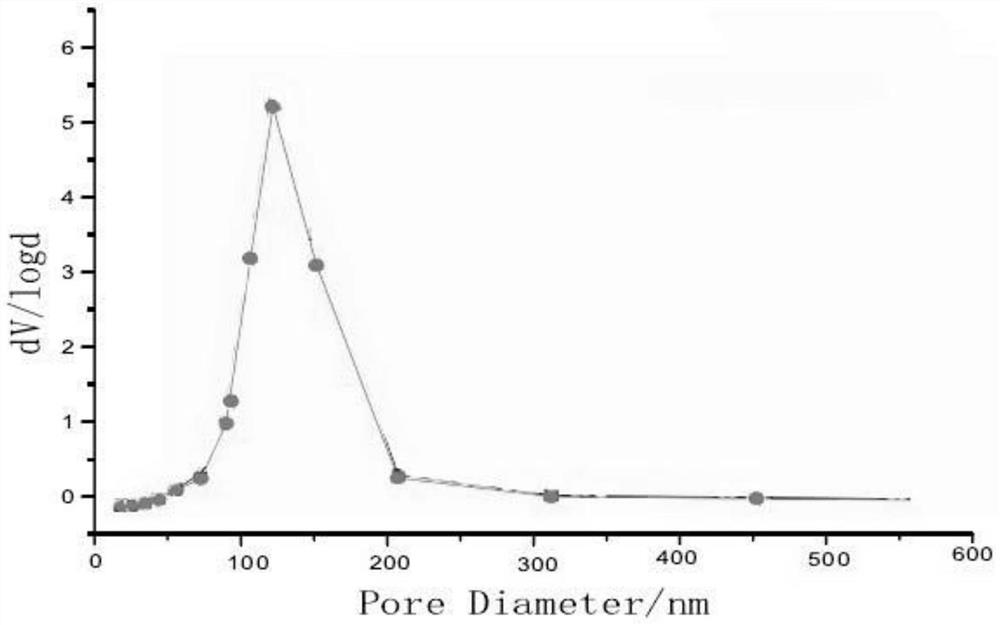

Preparation method and application of silica sol for chemical polishing

PendingCN114477190AReduce the content of metal ionsUniform and stable growthSilicon compoundsPolishing compositions with abrasivesSilicic acidPhysical chemistry

The invention discloses a preparation method and application of silica sol for chemical polishing, and belongs to the technical field of semiconductor chemical polishing materials. According to the invention, silica sol granulation is carried out by adopting a method of combining a traditional silicic acid hydrolysis method and a silica powder hydrolysis method, raw materials are easy to obtain, the preparation process flow can realize mass production, equipment transformation is not needed, and the cost and manual training cost are greatly saved. In the granulation process, silicon powder is introduced as a silicon source, so that the average density of seed particles for granulation is higher, the surface activation energy is favorably increased, and the particles are favorably increased again. The prepared large-particle-size silica sol particles are higher in hardness, show higher surface energy in the terminal application process, and are higher in polishing rate and higher in particle tolerance. The average particle size of the obtained silica sol particles is about 100 nanometers, and the silica sol particles are good in stability, free of agglomeration, high in polishing speed and removal rate and capable of greatly improving the polishing efficiency when applied to chemical polishing.

Owner:山东金亿达新材料有限公司

A lithium ion battery material and its preparation method using superassembly and dealloying

ActiveCN113611851BOptimal Control StructureZero lossMaterial nanotechnologySecondary cellsPhysical chemistryLithium-ion battery

Owner:FUDAN UNIV

Ceramic powder with high covering power and method for preparing ceramic powder

The invention discloses ceramic powder with high covering power. The ceramic powder is characterized in that a method for preparing the ceramic powder with the high covering power includes calcining kaolin micro-powder and pyrophyllite at the high temperatures to obtain calcined powder, smashing the calcined powder by airflow to obtain ultrafine powder, adding the ultrafine powder into water, stirring the ultrafine powder and the water to obtain suspension, adding urea into the suspension, heating the urea and the suspension until the temperatures of the urea and the suspension reach 80-95 DEGC, carrying out stirring reaction for 1-2 h and carrying out primary modification to obtain powder and suspension system; adding titanium dioxide powder and calcium hydroxide into the obtained powderand suspension systems, continuing to carry out stirring reaction at the temperature of 80-95 DEG C for 1-2 h, carrying out suction filtration on obtained reaction mixtures, and drying, scattering and dispersing obtained filter residues to obtain the ceramic powder. The kaolin micro-powder and the pyrophyllite are used as mixed matrix raw materials. The ceramic powder and the method have the advantages that the method includes simple and convenient processes and is convenient to operate, the calcined powder is smashed by the airflow, accordingly, the particle sizes of particles of the calcined powder can be reduced, surface activation energy of the calcined powder can be increased, the ceramic powder prepared by the aid of the method is environmentally friendly and is high in covering powder, excellent technical support can be provided to applying terminal products of the ceramic powder, and the like.

Owner:ZHEJIANG UNIV OF TECH

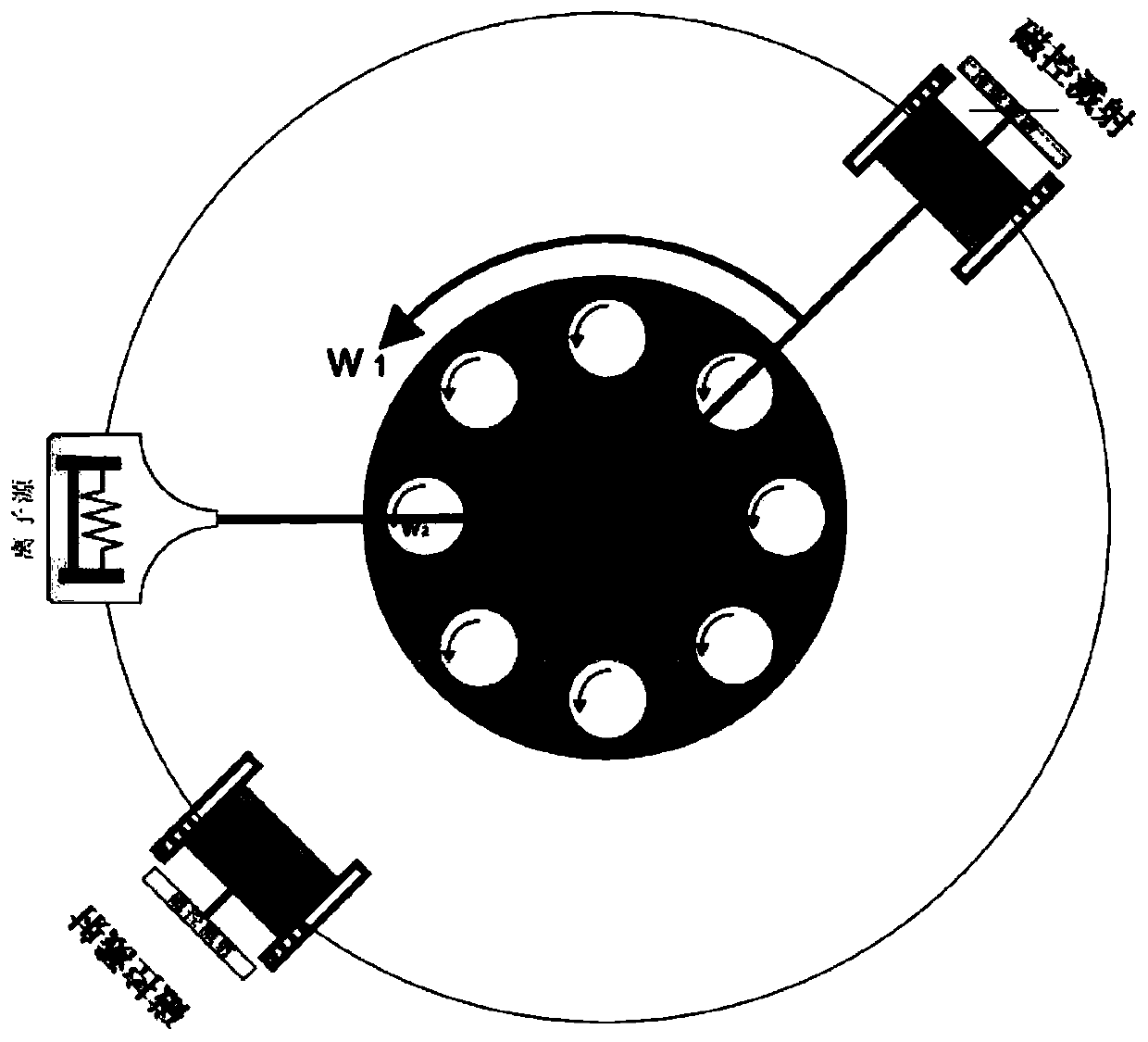

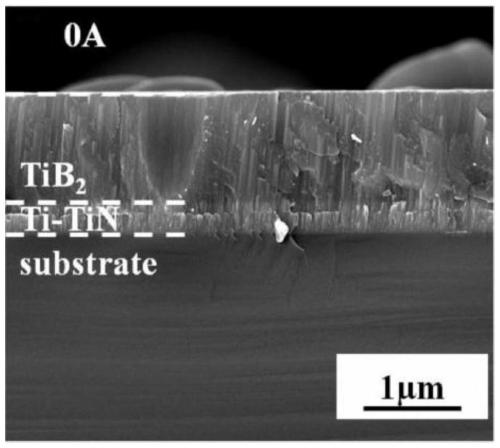

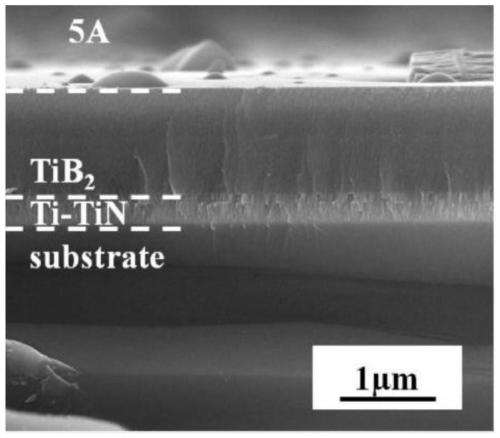

Compact titanium diboride coating, preparation method of compact titanium diboride coating and application of compact titanium diboride coating

ActiveCN110484881ACompact structureImprove surface qualityVacuum evaporation coatingSputtering coatingHardnessWear resistance

The invention belongs to the technical field of surface protection, and discloses a compact titanium diboride coating, a preparation method of the compact titanium diboride coating and application ofthe compact titanium diboride coating. The titanium diboride coating sequentially comprises a Ti transition layer, a Tin overplating layer and a TiB2 layer, wherein titanium diboride existing in the TiB2 layer is in the form of (001) preferentially oriented nano-isometric crystal; the grain diameter of the isometric crystal is 2-5 nm; the titanium diboride coating is prepared by taking a TiB2 target as a raw material and adopting a magnetron sputtering composite ion beam etching method by a coating mechanism; and the coating machine comprises a vacuum chamber, a magnetron sputtering source, anion source and workpiece supports capable of rotating at the same time. The TiB2 coating has excellent toughness and compact structure; and the compact titanium diboride coating and the preparation method have the advantages of being simple in process, high in film forming quality, stable in performance, extremely high in hardness and excellent in friction wear resistance, and widely applicable to protecting the surfaces of products such as machinery and molds.

Owner:GUANGDONG UNIV OF TECH

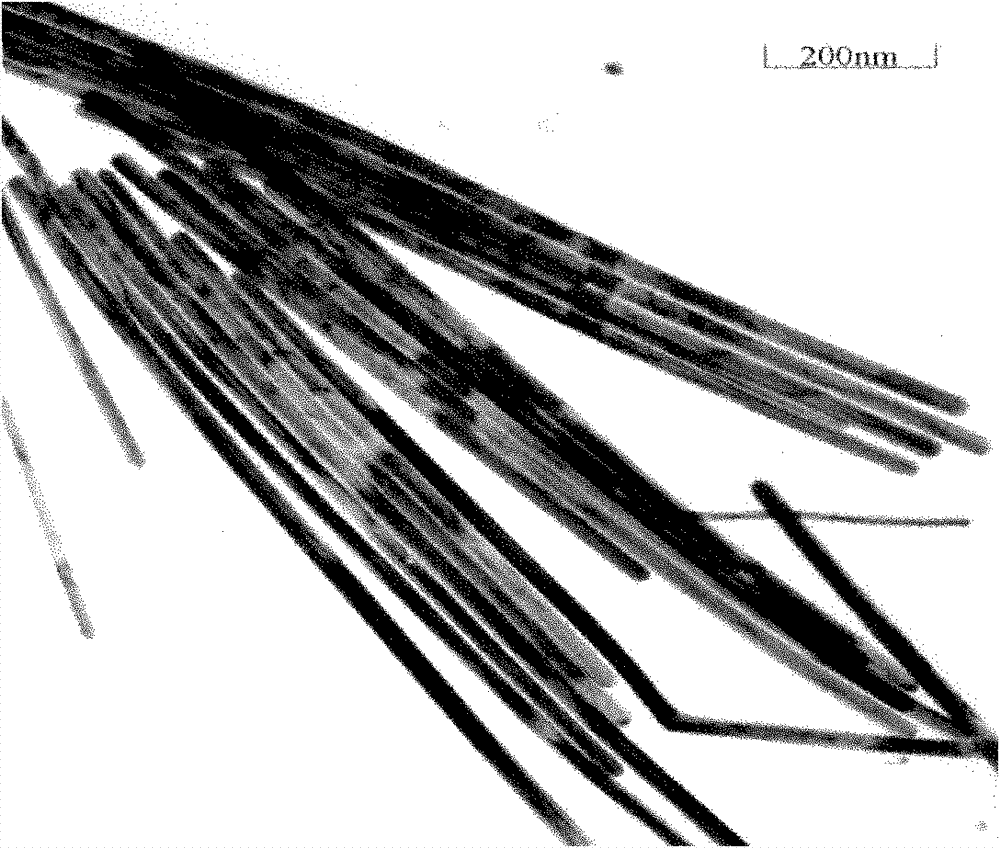

Nano silver capable of being dispersed in hydrophilic system and preparation method thereof

InactiveCN102161092BIncrease surface activation energyHigh grafting rateBiological activationNanotechnology

The invention discloses nano silver capable of being dispersed in a hydrophilic system and a preparation method thereof. The preparation method of the nano silver comprises: the nano silver capable of being dispersed in the hydrophilic system is obtained by adding a modifying agent at the later stage of the synthetic process of the nano silver, at the moment, the surface activation of the nano silver is high, and the dispersion performance of the modified nano silver obtained is good, so that the nano silver can be uniformly dispersed in the hydrophilic system and can exist stably. In the invention, the method and the technique are simple, and the cost is low, so that wide application can be achieved. According to the invention, a series of defects of the prior art are overcome.

Owner:中科广化(重庆)新材料研究院有限公司 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com