Solid waste-based inorganic artificial stone plate and preparation method thereof

A technology of artificial slate and artificial stone, applied in the field of building materials, can solve the problems of affecting product strength, increasing economic cost, long delivery time, etc., and achieve the effects of improving mechanical properties, reducing economic costs, and good high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

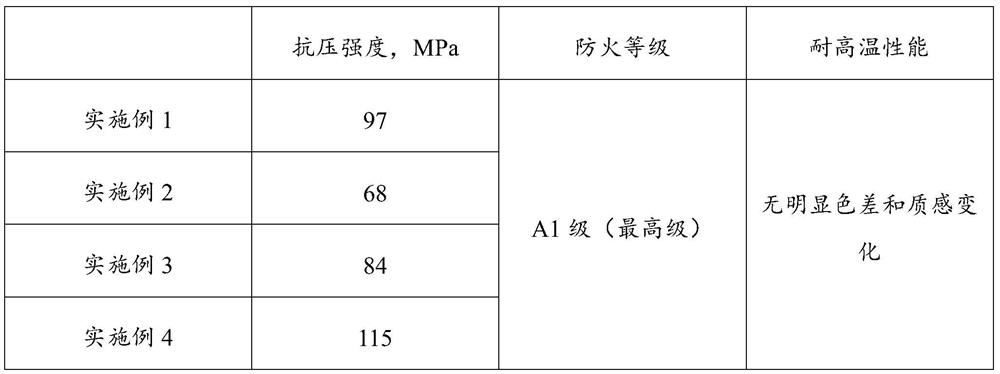

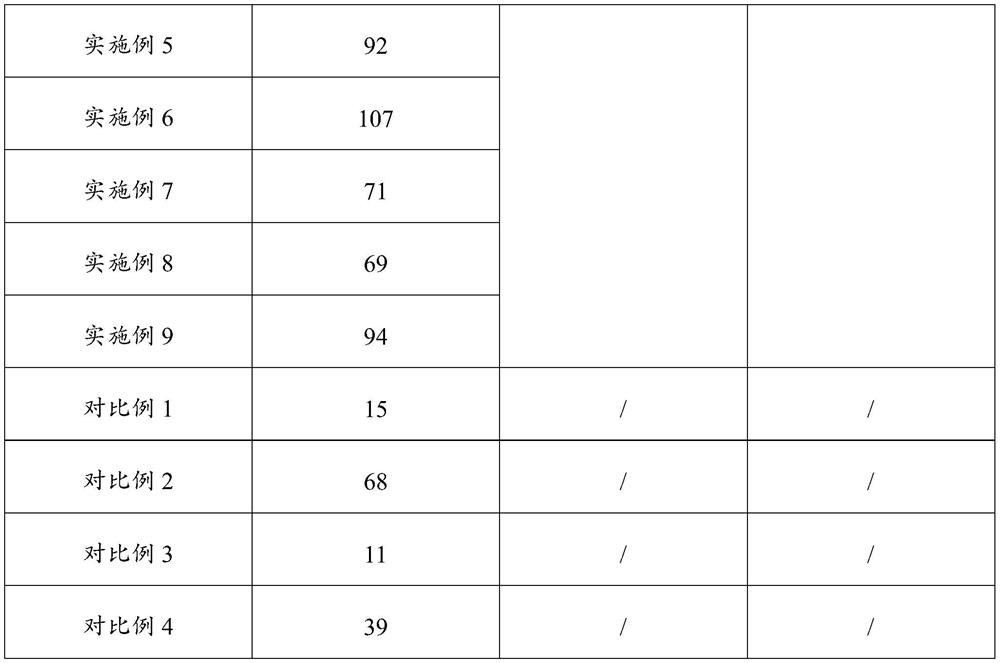

Examples

Embodiment 1

[0056] This embodiment provides a solid waste-based inorganic artificial stone plate, the raw materials are composed of:

[0057] 16kg of blast furnace slag, 34kg of fly ash, 2kg of red mud, 6kg of activator, 8kg of water, 1kg of water reducer, 2kg of inorganic pigment, and 90kg of quartz sand.

[0058] Among them, the activator is mixed with sodium hydroxide and liquid sodium silicate, of which 2.2kg of sodium hydroxide, 3.8kg of liquid sodium silicate, the modulus is between 2.2-2.4, and the solid content is 44.1%; the water reducing agent is Polycarboxylate water reducer; inorganic pigment is copper powder.

[0059] This embodiment also provides a method for preparing a solid waste-based inorganic artificial stone plate, comprising the following steps:

[0060] Step 1: Weigh the activator and water by mass, mix and stir evenly to prepare the activator solution, and cool for 12 hours;

[0061] Step 2: Pour the blast furnace slag, fly ash, red mud and quartz sand into the m...

Embodiment 2

[0070] This embodiment provides a solid waste-based inorganic artificial stone plate, the raw materials are composed of:

[0071] 12kg of blast furnace slag, 38kg of fly ash, 4kg of red mud, 5kg of activator, 12kg of water, 1kg of water reducer, 3kg of inorganic pigment, and 120kg of quartz sand.

[0072] Among them, the activator is mixed with sodium hydroxide and liquid sodium silicate, of which 1.8kg of sodium hydroxide, 3.2kg of liquid sodium silicate, the modulus is between 2.2-2.4, and the solid content is 44.1%; the water reducing agent is Polycarboxylate water reducer; inorganic pigment is copper powder.

[0073] This embodiment also provides a method for preparing a solid waste-based inorganic artificial stone plate, comprising the following steps:

[0074] Step 1: Weigh the activator and water by mass, mix and stir evenly to prepare the activator solution, and cool for 12 hours;

[0075] Step 2: Pour the blast furnace slag, fly ash, red mud and quartz sand into the...

Embodiment 3

[0084] This embodiment provides a solid waste-based inorganic artificial stone plate, the raw materials are composed of:

[0085] 14kg of blast furnace slag, 36kg of fly ash, 2kg of red mud, 5.8kg of activator, 12kg of water, 2kg of water reducing agent, 1kg of inorganic pigment, and 100kg of quartz sand.

[0086] Among them, the activator is mixed with sodium hydroxide and liquid sodium silicate, of which sodium hydroxide is 2kg, liquid sodium silicate is 3.8kg, the modulus is between 2.2-2.4, and the solid content is 44.1%. Carboxylic acid water reducing agent; inorganic pigment is copper powder.

[0087] This embodiment also provides a method for preparing a solid waste-based inorganic artificial stone plate, comprising the following steps:

[0088] Step 1: Weigh the activator and water by mass, mix and stir evenly to prepare the activator solution, and cool for 12 hours;

[0089] Step 2: Pour the blast furnace slag, fly ash, red mud and quartz sand into the mixing tank f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com