Low-temperature co-fired ceramic material of double-phase ceramic filler, and preparation method thereof

A technology of low-temperature co-fired ceramics and ceramic fillers, which is applied in the field of low-temperature co-fired ceramic materials with dual-phase ceramic fillers and its preparation. and other issues to achieve the effect of low cost, low dielectric constant, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

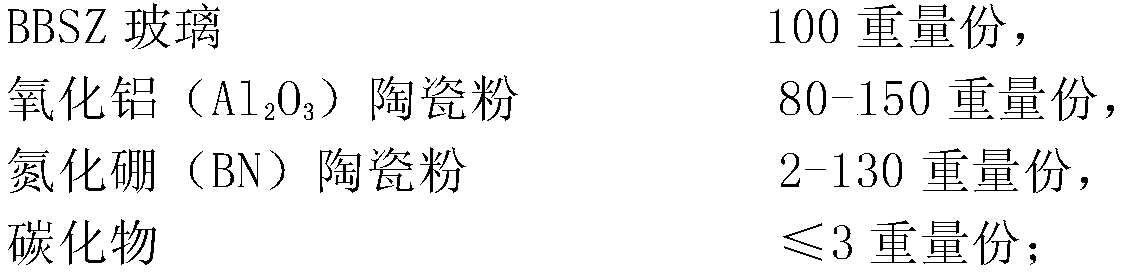

Method used

Image

Examples

Embodiment 1

[0044] The specific steps of preparation are:

[0045] Step 1. First, according to the molar ratio of bismuth trioxide, boron oxide, silicon oxide and zinc oxide of 1:0.1:0.25:0.5, the four are mixed to obtain a mixture. After the mixture was melted at 900°C, it was quenched by water cooling to obtain BBSZ glass slag.

[0046] Step 2: Grind the BBSZ glass slag ball into BBSZ glass powder with a particle size of 360nm. Then according to the weight ratio of BBSZ glass powder, alumina ceramic powder with a particle size of 2 μm and boron nitride ceramic powder with a particle size of 360 nm of 1:0.8:1.3, the three are mixed to obtain a mixed powder.

[0047] Step 3. According to the weight ratio of BBSZ glass powder, solvent and dispersant in the mixed powder of 1:0.1:0.1, the mixed powder, solvent and dispersant are ball milled together for 2h; where the solvent is ethanol and the dispersant It is castor oil to obtain a uniformly dispersed slurry. Then according to the weight ratio ...

Embodiment 2

[0050] Step 1. First, according to the molar ratio of bismuth trioxide, boron oxide, silicon oxide and zinc oxide of 1:0.3:0.2:0.63, the four are mixed to obtain a mixture. After the mixture is melted at 1000°C, it is quenched by water cooling to obtain BBSZ glass slag.

[0051] Step 2: Grind the BBSZ glass slag ball into BBSZ glass powder with a particle size of 370nm. Then according to the weight ratio of BBSZ glass powder, alumina ceramic powder with a particle size of 1.8 μm and boron nitride ceramic powder with a particle size of 370 nm of 1:1:0.98, the three are mixed to obtain a mixed powder.

[0052] Step 3. First, according to the weight ratio of BBSZ glass powder, solvent and dispersant in the mixed powder of 1:0.6:0.078, the mixed powder, solvent and dispersant are ball-milled for 5.25h; where the solvent is ethanol, and the dispersion The agent is castor oil to obtain a uniformly dispersed slurry. Then according to the weight ratio of BBSZ glass powder, binder, plasti...

Embodiment 3

[0055] Step 1. First, according to the molar ratio of bismuth trioxide, boron oxide, silicon oxide and zinc oxide of 1:0.6:0.15:0.75, the four are mixed to obtain a mixture. After the mixture was melted at 1100°C, it was quenched by water cooling to obtain BBSZ glass slag.

[0056] Step 2: Grind the BBSZ glass slag ball into BBSZ glass powder with a particle size of 380nm. Then according to the weight ratio of BBSZ glass powder, alumina ceramic powder with a particle size of 1.5 μm and boron nitride ceramic powder with a particle size of 380 nm of 1:1.2:0.66, the three are mixed to obtain a mixed powder.

[0057] Step 3. First, according to the weight ratio of BBSZ glass powder, solvent and dispersant in the mixed powder of 1:1.05:0.055, the mixed powder, solvent and dispersant are ball-milled for 8.5h; where the solvent is ethanol, and the dispersion The agent is castor oil to obtain a uniformly dispersed slurry. According to the weight ratio of BBSZ glass powder, binder, plasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com