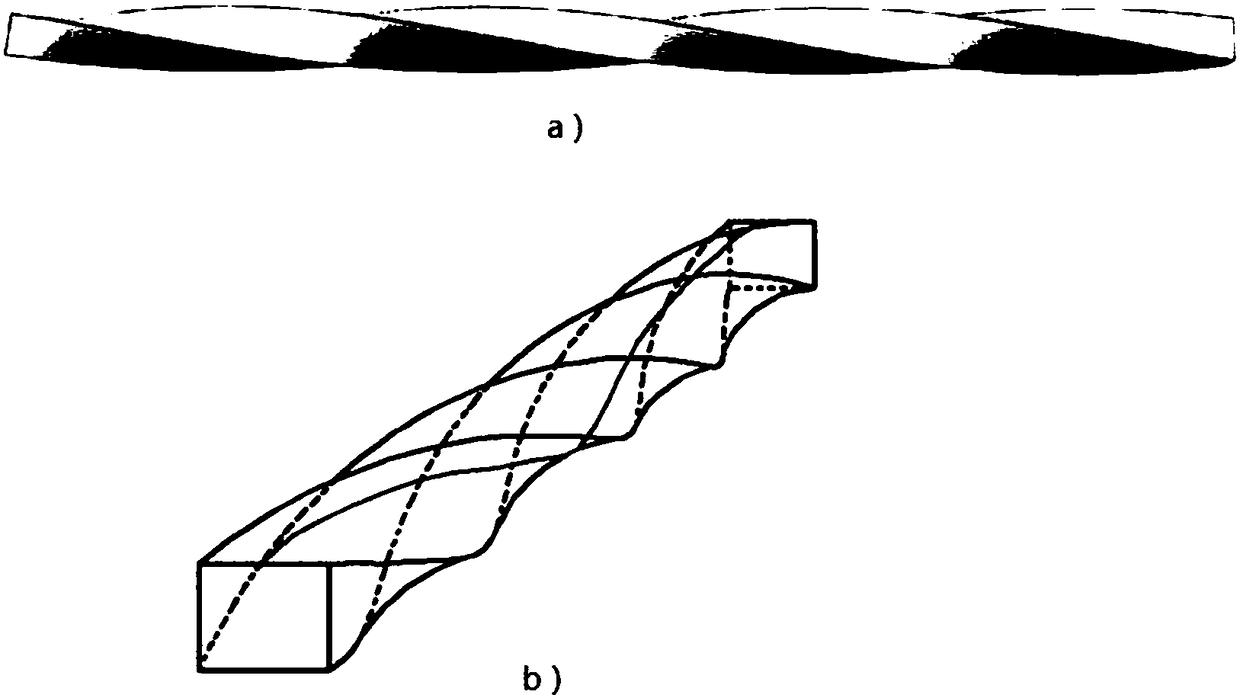

Spiral steel fiber ultra-high-performance concrete and preparation method thereof

An ultra-high performance, spiral steel technology, applied in the field of building materials, can solve the problems of low matrix strength, matrix damage, and difficulty in giving full play to spiral steel fibers, and achieve full drawing curves, strong interfacial bonding properties, and drawing force. The effect of hardening phenomenon is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The spiral steel fiber ultra-high performance concrete material of this embodiment includes cement, silica fume, fine sand, water, quartz powder, high-efficiency water reducer, and steel fiber. A total of 3 groups of concrete materials with different component ratios were designed, numbered 1-1, 1-2, 1-3. The mass of each component in each group of concrete is shown in Table 1 below, given in terms of the mass ratio of each component.

[0034] Table 1 Mixing ratio of spiral steel fiber ultra-high performance concrete materials

[0035]

[0036] In this embodiment, the preparation process of spiral steel fiber concrete is as follows:

[0037] 1) The cement, silica fume, fine sand, water, quartz powder, high-efficiency water reducer, and steel fiber of the mass fractions described in Table 1 are weighed for subsequent use;

[0038] 2) Add the cement, silica fume, fine sand, quartz powder, and high-efficiency water reducer weighed according to the mass fraction descri...

Embodiment 2

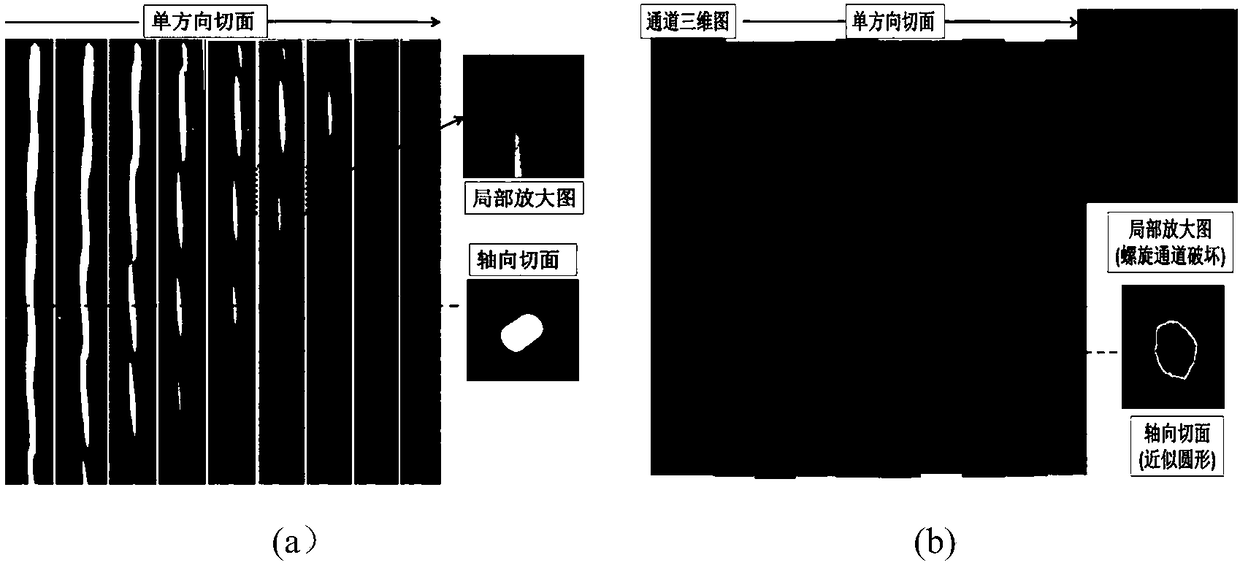

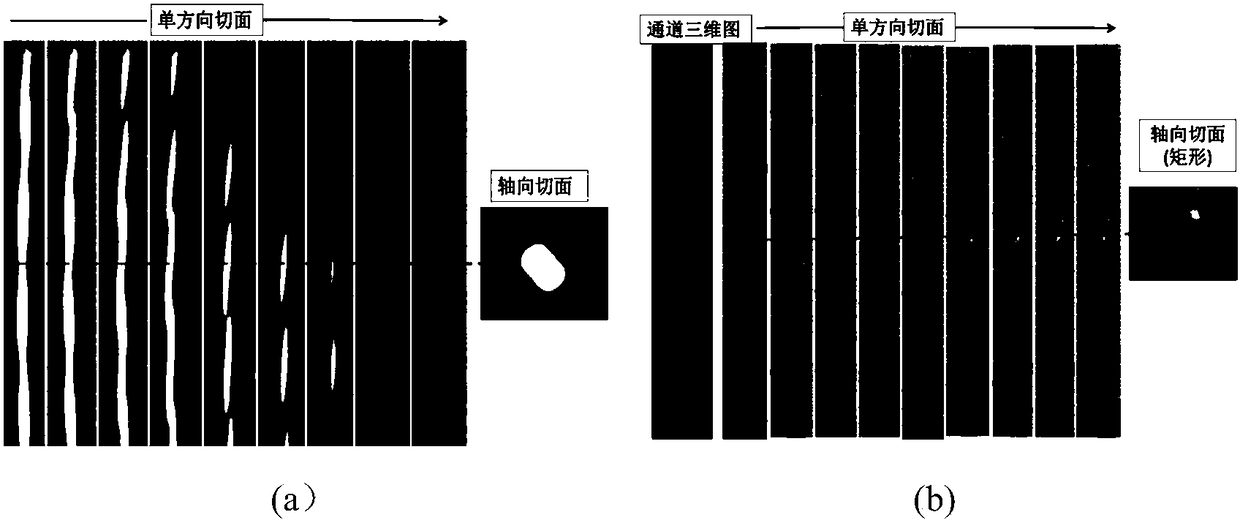

[0043] This embodiment is a pull-out experiment of a single helical steel fiber in its matrix to test the bonding performance between a single helical steel fiber and the matrix. In this embodiment, the experimental method adopted is carried out according to "Steel Fiber Concrete Test Method" (CECS13:89).

[0044] The spiral steel fiber ultra-high performance concrete material matrix in this embodiment includes cement, silica fume, fine sand, water, quartz powder, and high-efficiency water reducer. A total of three sets of tests were set up, and the mass of each component in each set of tests is shown in Table 2 below, given in terms of the mass ratio of each component. The embedding length of a single steel fiber embedded in each specimen in the experiment is also given in Table 2. Each group of products has 6 parallel samples.

[0045] Table 2 The mix ratio of the spiral steel fiber ultra-high performance concrete material matrix

[0046]

[0047] In this embodiment, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com